Page 1

Compaq Matrix Printer LA36

User Manual

Compaq Computer Corporation

Page 2

Page 3

Table of Contents

Preface ................................................................................................... v

About This Manual............................................................................................................ v

Printer Models and Options .............................................................................................. v

Organization ...................................................................................................................... vi

The LA36N and LA36W Model Specifications....................................................... vi

Notes, Cautions and Warnings .......................................................................................... vi i

1. Introduction........................................................................................ 1-1

Features .............................................................................................................................. 1-1

Options............................................................................................................................... 1-2

2. Paper Handling .................................................................................. 2-1

Getting to Know the Printer’s Major Parts and the Control Panel.................................... 2-1

Parts of the Printer ..................................................................................................... 2-2

Operations of the Control Panel ............................................................................... 2-4

Selecting Paper .................................................................................................................. 2-7

Overview of Paper Operations........................................................................................... 2-8

Adjusting for Paper Thickness .......................................................................................... 2-10

Using Single Sheets ........................................................................................................... 2-11

Loading a Single Sheet of Paper............................................................................... 2-11

Ejecting Single Sheets .............................................................................................. 2-13

Using Continuous Forms ................................................................................................... 2-14

Positioning the Paper Stack ...................................................................................... 2-15

Loading Continuous Forms (Push Tractor and Rear Feed) ...................................... 2-16

Loading Continuous Forms (Pull Tractor and Bottom Feed) .................................. 2-19

Unloading Continuous Forms (Push-Feed Mode) ................................................... 2-24

Tearing Off Continuous Forms ................................................................................. 2-24

Feeding and Positioning Paper ......................................................................................... 2-26

Print Area Definition ................................................................................................. 2-26

Line Feed/Form Feed ................................................................................................ 2-28

Top-of-Form Adjustment ........................................................................................... 2-28

Switching Paper Types....................................................................................................... 2-29

Switching from Continuous Forms to Single Sheets (Push-Feed Mode)................. 2-30

Switching from Single Sheets to Continuous Forms (Push-Feed Mode)................. 2-30

Switching between Push-Feed and Pull-Feed .......................................................... 2-31

Tips on Paper Handling ..................................................................................................... 2-32

General Tips .............................................................................................................. 2-32

Multipart Forms......................................................................................................... 2-32

Envelopes .................................................................................................................. 2-32

Labels ........................................................................................................................ 2-32

i

Page 4

3. Printing ............................................................................................... 3-1

Selecting Print Features ..................................................................................................... 3-1

Using Commercial Software ..................................................................................... 3-2

Using the Control Panel ............................................................................................ 3-2

Selecting Macro 1 or Macro 2.......................................................................... 3-3

Switching Macros and Selecting Features on the Control Panel .................... 3-4

Selecting a Resident Font ................................................................................ 3-7

Changing the Protocol ...................................................................................... 3-8

Starting or Stopping Printing ............................................................................................ 3-9

Starting Printing ........................................................................................................ 3-9

Stopping and Viewing Printing................................................................................. 3-9

Resuming Printing .................................................................................................... 3-9

Resuming from a Paper-Out ...................................................................................... 3-9

Removing Printed Pages.................................................................................................... 3-10

Removing Single Sheets ........................................................................................... 3-10

Removing Continuous Forms ................................................................................... 3-10

4. Using Set-Up Mode............................................................................ 4-1

What is Set-Up Mode for? ................................................................................................. 4-1

How Set-Up W orks ............................................................................................................. 4-2

Entering the Set-Up Mode................................................................................................. 4-2

Overview of the Set-Up Mode........................................................................................... 4-5

Set-Up Mode Functions ............................................................................................ 4-5

Points to Remember .................................................................................................. 4-11

Printing the Printer Configuration .................................................................................... 4-11

Deciding Which Options to Change ................................................................................. 4-13

Changing Macro 1 and Macro 2 Options ......................................................................... 4-14

Macro 1 and Macro 2 Options List ................................................................................... 4-15

Changing Install Options .................................................................................................. 4-25

Install Options List ............................................................................................................ 4-25

Adjusting T op-of-Form Origin .......................................................................................... 4-29

Changing Menu Access Options....................................................................................... 4-30

Exiting and Saving ............................................................................................................ 4-30

Recalling Factory Settings ................................................................................................ 4-31

Using the Diagnostic Functions ........................................................................................ 4-31

Printing Test .............................................................................................................. 4-31

Hex Dump Mode ....................................................................................................... 4-32

Set-Up Mode Quick Reference.......................................................................................... 4-34

ii

Page 5

5. Maintenance....................................................................................... 5-1

Cleaning............................................................................................................................. 5-1

Cleaning and Vacuuming the Printer........................................................................ 5-1

Cleaning the Platen and Paper Bail Rollers ............................................................. 5-2

Cleaning the Print Head ............................................................................................ 5-3

Replacing the Ribbon Cartridge ....................................................................................... 5-3

Replacing the Print Head................................................................................................... 5-5

6. Trouble-Shooting ............................................................................... 6-1

Solving Problems............................................................................................................... 6-1

Print Quality Problems and Solutions ...................................................................... 6-1

Paper Handling Problems and Solutions .................................................................. 6-4

Operating Problems and Solutions ........................................................................... 6-5

Printer Failures .......................................................................................................... 6-6

Diagnostic Functions ......................................................................................................... 6-6

Checking Vertical Alignment ............................................................................................ 6-7

A. Supplies and Options ....................................................................... A-1

Supplies.............................................................................................................................. A-1

Options............................................................................................................................... A-1

Installing Options .............................................................................................................. A-2

Installing the Color Kit ............................................................................................. A-2

B. Printer and Paper Specifications ..................................................... B-1

Physical Specifications ...................................................................................................... B-1

Functional Specifications ................................................................................................. B-2

Performance Specifications ............................................................................................... B-4

Paper Specifications .......................................................................................................... B-5

Print Area ................................................................................................................... B-5

Paper Thickness......................................................................................................... B-7

C. Command Sets.................................................................................. C-1

DEC PPL2 Quick Reference Guide ................................................................................... C-2

IBM Proprinter X24E and XL24E Quick Reference Guide .............................................. C-22

Epson ESC/P2 Quick Reference Guide............................................................................. C-26

D. Interface Information......................................................................... D-1

Parallel Interface ................................................................................................................ D-1

Serial Interface ................................................................................................................... D-4

Serial Options............................................................................................................ D-5

Cable Wiring ............................................................................................................. D-5

Buffer Control ........................................................................................................... D-5

iii

Page 6

E. Character Sets................................................................................... E-1

DEC PPL2 Protocol ........................................................................................................... E-1

Common to IBM Proprinter X24 and XL24E Protocol and Epson ESC/P2 Protocol ..... E-18

Default Sets ............................................................................................................... E-18

IBM Proprinter X24 and XL24E Protocol......................................................................... E-24

IBM Set 1/2 ............................................................................................................... E-24

Epson ESC/P2 Protocol ..................................................................................................... E-25

National Character Sets............................................................................................. E-25

F. Resident Fonts................................................................................. F-1

Glossary ............................................................................................... GL-1

Index..................................................................................................... IN-1

iv

Page 7

About this Manual

Thank you for buying a Compaq LA36 Companion Printer. You can expect years of

reliable service with very little maintenance. The information provided in this guide

applies both to the Compaq LA36 Companion Printer (80-column printer) and to the

Compaq LA36W Companion printer (136-column printer). However, illustrations are of

LA36N Companion Printer. This guide explains how you can use your printer to full

advantage. It is written for both new and experienced printer users.

This manual consists of two parts: an Installation Guide and a User Manual. The former ,

provided as a hardcopy document with your printer, describes how to install and set up your

printer. This part, describes how to use your printer and printer options, how to keep the

printer in good working condition, and what to do should something go wrong. Detailed

procedures are provided for first-time users. Experienced users can skip some of the details,

using the table of contents and chapter introductions to locate specific information.

This part has several appendixes, a glossary, and an index. Appendix A lists supplies and

options available from your dealer or authorized representative of Compaq Computer

Corporation.

Preface

Printer Models and Options

Model LA36N is an 80-column printer and model LA36W is a 136-column printer. Both

models have a dual interface made up of Bitronics parallel and DEC-423 serial. The

power supply of the printer is either for 100-120 VAC input or for 220-240 VAC input. You

must specify the print line and the power rating when purchasing the printer. Other

options include a color print feature which you can add by yourself after purchasing the

printer. The configuration is:

LA36N/LA36W

Basic specifications

Print line at 10 cpi*: 80 columns for LA36N

136 columns for LA36W

Interfaces: Bitronics parallel and DEC-423 serial

Alternative specification

Power supply: 100–120 VAC or 220–240 VAC

User add-on options

Color Kit

* cpi: characters per inch

v

Page 8

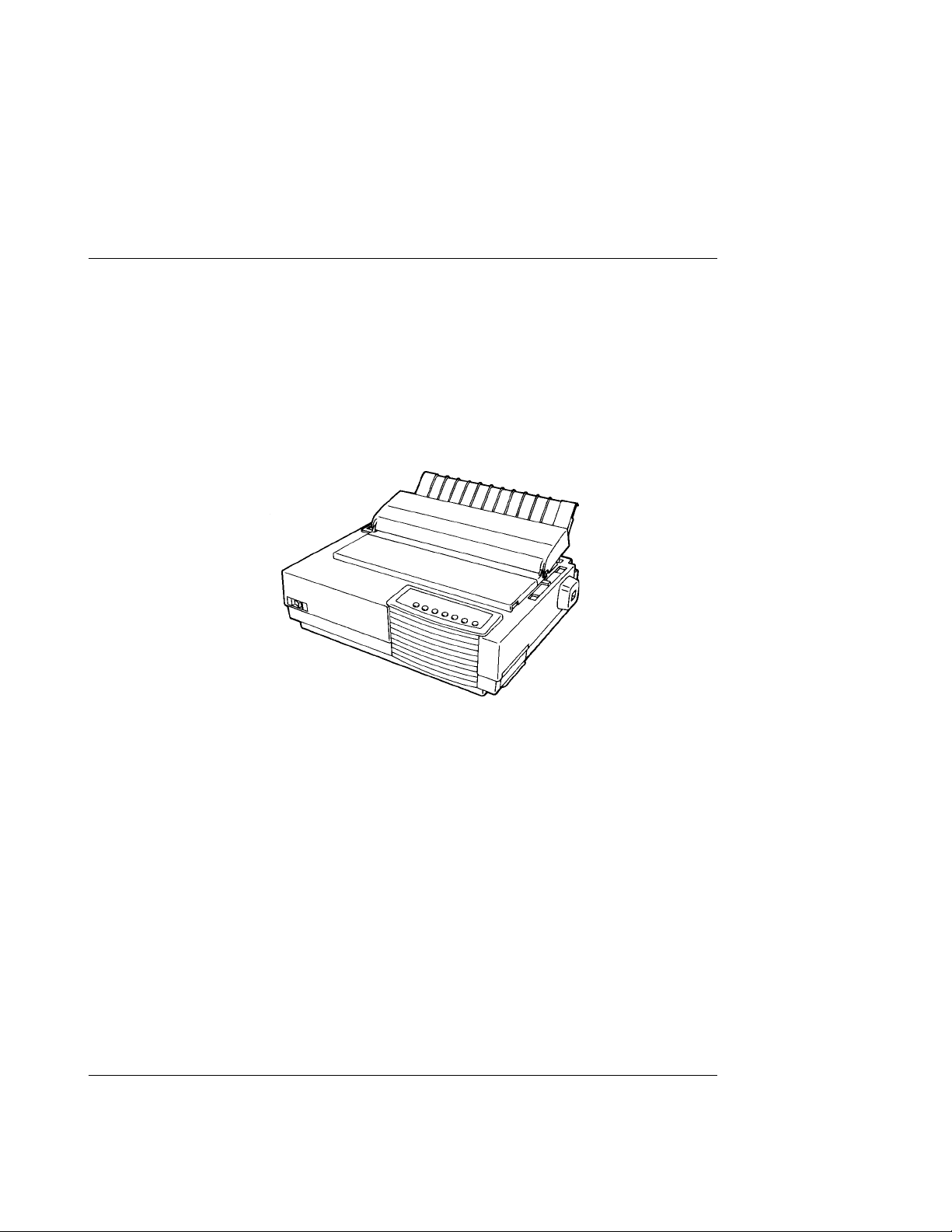

The LA36N and LA36W Model Specifications

The main difference between the LA36N and the LA36W is the “print span”.

The LA36N is an 80-column printer and the LA36W a 136-column printer. As shown in the

following figure, the physical specifications are thus different (size, weight, ...).

Compaq Matrix Printer LA36N Compaq Matrix Printer LA36W

Some minor differences concern mechanical internal parts that do not impact the general uses

of the printer (top cover hinges, bail rollers mechanism, ...). The only visible difference

concerns the accurate location of the notch scale of the paper thickness lever.

Specification differences are clearly identified further in this User Guide.

Organization

The user manual is organized as follows:

1 - Introduction

This chapter introduces the printer and identifies key features and options that enhance the

printer’s capabilities.

2 - Paper Handling

This chapter explains how to load your printer and use paper with it.

3 - Printing

This chapter covers basic printing operations and provides detailed descriptions of

everyday operations from the printer’s control panel, including print feature selection.

vi

Page 9

4 - Using Set-Up Mode

This chapter describes how to change the printer’s optional settings, such as print features,

hardware options, and top-of-form. Most settings only affect print features such as the type

style and page format. Note that certain settings directly affect hardware and software

compatibility. Refer to this chapter as indicated in the part Installation Guide or as

required.

5 - Maintenance

This chapter explains basic maintenance procedures for this printer.

6 - Trouble-Shooting

This chapter describes problem-solving techniques. Before you contact your dealer for

help, check the list of problems and solutions provided in this chapter.

At the end of this guide, you will find several appendices, a glossary, and an index.

Appendix A gives order numbers for printer supplies and options, explaining how to install

them. Other appendices provide additional technical information about the printer.

Notes, Cautions and Warnings

The text contains three different types of annotation which should always be read.

Note: This NOTE annotation provides you with additional information, or indicates

where you can find it.

Caution: This CAUTION annotation should catch your attention, advising you of a

particular situation/problem which may occur/be avoided as a result of a

certain sequence of operations. It may also contain a reminder to execute a

particular operation.

Warning: This WARNING annotation indicates a specific procedure which must be strictly

observed. Failure to comply with the instructions given may result in injury to

the operator and/or damage to the printer.

vii

Page 10

viii

Page 11

Introduction

Introduction

Congratulations on purchasing a Compaq Matrix Printer LA36N/LA36W. This printer is a

compact, versatile printer that offers maximum compatibility with today’s software

packages and personal computers. The 24-wire print head provides crisp, clear printing for

business, office, and home environments. This printer is also easy to install and use.

1

Compaq Matrix Printer LA36N

Features

Key printer features and options are listed in the next two sections.

• Euro Currency Symbol. This Compaq Matrix Printer supports the Euro currency

symbol. This character is contained in the ISO Latin-9 code page for the DEC PPL2

emulation and in the code page 858 and ISO 8859-15 for the IBM and EPSON

emulations. See the Quick Reference Guide, Appendix C, for the emulation you are

using for the escape sequence to select the appropriate code page and see appendix E for

the location of the Euro currency symbol within the code page

• Software compatibility. This printer, which operates with the DEC PPL2 protocol, the

IBM Proprinter X24E (LA36N) or IBM Proprinter XL24E (LA36W) protocol and the

Epson ESC/P2 protocol (for Epson LQ870 or LQ1170 printers or equivalent).

1-1

Page 12

Introduction

• Various character sets. For the DEC PPL2 protocol, 31 character sets (twenty-five 94-

character sets and six 96-character sets) are available. For IBM Proprinter X24E and

XL24E protocol, set 1, set 2, and 30 default sets (code pages and specific character sets)

are available. For Epson ESC/P2 protocol, 15 national character sets and 30 default sets

(code pages and specific character sets) are available.

• Multiple fonts. The printer has nineteen resident fonts: Ten bit-map fonts — Draft,

High-speed (HS) Draft, High-impact (Hi) Draft, Courier 10, Pica 10, Prestige Elite 12,

Compressed 17, Boldface PS, OCR-A 10, and OCR-B 10; nine outline fonts —

Timeless, Courier and Nimbus Sans, each in upright, italic, and bold; three outline fonts

— Courier in upright, italic, and bold (available for the Epson ESC/P2 protocol only);

and nine Barcode fonts — Code 3 of 9, Industrial 2 of 5, Interleaved 2 of 5, Matrix 2 of

5, EAN 8, EAN 13, UPC-A, Codabar, and Postnet.

• High-speed printing. At 10 cpi, print speed ranges from 113 cps for letter quality to

360 cps for high-speed draft quality.

• 128K bytes of input buffer. 128K bytes are available for storing input data and

downloading custom fonts. A minimum download buffer capacity is available

separately.

• Simple switching of paper types. The ability to “park” continuous forms makes it easy

to switch between continuous forms and single sheets.

• Bottom feeding capability. The tractor unit is removable and can be converted to push-

feed or pull-feed. Installing the tractor unit on the platen allows the paper to be fed

through the slot at the bottom of the printer.

• Automatic tear-off advancing. With factory settings of the Set-Up mode, continuous

forms’ perforations are automatically advanced up to the tear bar at the end of each job

so that forms can be torn off. The tear-off feed can be also activated by pressing the

Pause button.

• Auto viewing. Paper (continuous forms or single sheets) is automatically advanced at

the end of each printing so that the last printed line can be read.

• Maintenance-free. The printer only requires periodic cleaning and changing of the

ribbon cartridge.

• Windows printer driver. Printer drivers for Windows 3.x, Windows 98 and Windows

95 are delivered with your printer. The printer driver is a control program to be installed

on your computer for controlling document printing on your printer (for example,

controlling the page size, the paper orientation, and so on). It receives print data from

your application software, converts the data into commands that the printer can execute,

and sends the commands to the printer.

Options

Printer add-on options are listed below. For details, see Appendix A “Supplies and

Options”.

• Color kit. You can turn your monochrome printer into a color printer. Seven-color

printing using a color ribbon is possible if supported by your software.

1-2

Page 13

Paper Handling

This chapter explains how your printer uses paper. Topics covered are:

Getting to know the printers major parts and the control panel

Selecting paper

Overview of paper operations

Adjusting for paper thickness

Using single sheets

Using continuous forms (push-tractor feed and pull-tractor feed)

Feeding and positioning paper

Switching paper types

Paper Handling

2

Tips for paper handling are given at the end of this chapter. Check that section if you are

using multipart forms, envelopes, or labels.

Getting to Know the Printers Major Parts and the Control Panel

This section describes the major parts and controls of the printer and operations of the

control panel. Take a moment to become familiar with the printer.

2-1

Page 14

Paper Handling

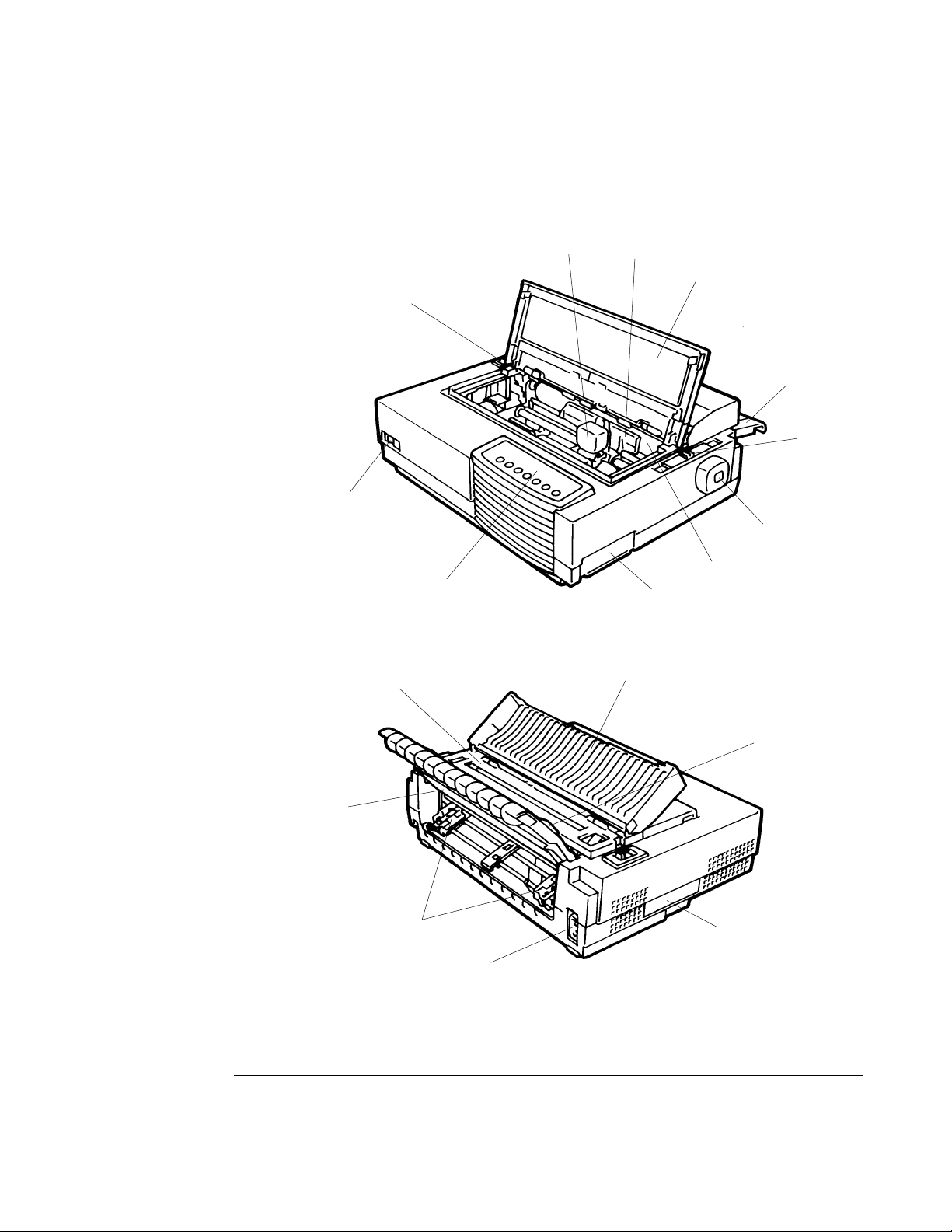

Parts of the Printer

8

9

18

7

10

11

1

2

3

4

5

6

12

2-2

17

16

13

14

15

Front and Rear Views

Page 15

Paper Handling

The figures on the previous page show front and rear views of the printer. The following

parts are indicated:

Front View

1. Front cover (to protect the print head)

2. Cut sheet stand (to hold printing and printed pages)

3. Paper thickness lever (to adjust the print head gap)

4. Platen knob (to manually advance the paper)

5. Platen (to support the paper)

6. Interface connector (to connect the printer to the host system)

7. Control panel (to load and feed paper, select print features, or change the

printers optional settings)

8. Power switch (to switch the printer on/off)

9. Paper select lever (to switch the paper source)

10. Print head (to apply ink to the page)

11. Print guide (to indicate the print line)

Rear View

12. Acoustic cover (to reduce sound noise)

13. Paper guide (to insert single sheets and envelopes)

14. Rating label (to indicate the printer power specifications)

15. Power connector (to connect the printer to the power supply)

16. Forms tractors (to hold and feed continuous forms)

17. Back cover (to protect forms tractors)

18. Top cover (to protect the platen and serve as the tear bar)

2-3

Page 16

Paper Handling

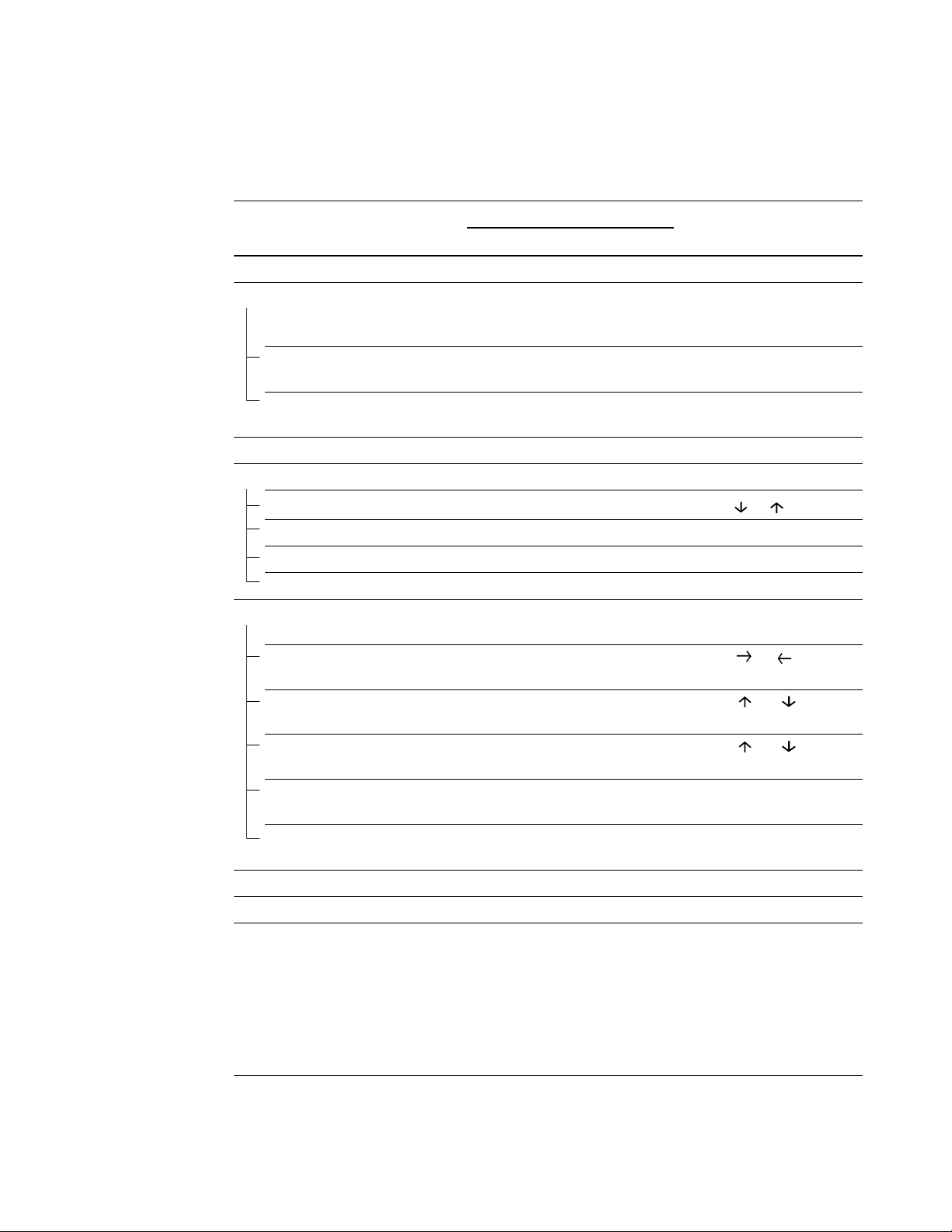

Operations of the Control Panel

This section summarizes status indications and operations of the control panel in Normal

mode. For details on Set-Up mode, see Chapter 4 Using Set-Up Mode.

Normal mode operation includes everyday operations, such as paper handling, font

selection, macro selection, and protocol selection. The first table lists basic states

represented by the Ready and Fault indicators. The second table lists Normal mode

operations and required user response. Operations are listed by functions.

Basic States of the Printer

Indicator Status Printer Status

Ready

On The printer is ready for printing

or

The printer is receiving or printing data.

Blinking The printer is not ready and holds printing data.

Off The printer is not ready and it does not hold printing

data.

Fault On The printer is out of paper.

Blinking slowly The printer has software errors (paper jam, interface

error, carriage error, paper unloading error, etc.).

Blinking fast The printer detected diagnostic errors at power-up.

2-4

Page 17

Paper Handling

Control Panel Operations

: This operation has no connection with this condition.

N/A : The condition does not apply because this operation is executed before powering

on.

*1

Operation Required Conditions

Ready Printing

Load continuous forms paper Not printing On Press FF/Load.

Load single sheet paper Not printing On Press FF/Load if single sheet

Feed paper a page Not printing Off Press FF/Load.

Feed paper a line Not printing Off Press LF.

*2

Required Action

Fault

load is switched from AUTO

to MANUAL in Set-Up mode.

Advance perforation to tear bar Not printing Off

Press

Pause

if the TEAR

option is switched from AUTO

to MANUAL in Set-Up mode,

or

press FF/Load.

Advance paper for viewing Not printing Off

Press

Pause

if the TEAR

option is switched from AUTO

to MANUAL in Set-Up mode.

Return paper to previous position Not printing Off

Press

Pause

if the TEAR

option is switched from AUTO

to MANUAL in Set-Up mode,

or

press FF/Load.

Eject single-sheet paper Not printing Off Press FF/Load or Park or turn

the printer off and on again.

Unload continuous-forms Not printing Off Press Park.

*3

paper

Pause printing On Printing Off Press Pause.

Resume printing Blinking Not printing Off Press Pause.

Resume printing after a fault Off Not printing On Clear error and press Pause.

Resume printing after paper-out Off Not printing On Load paper.

Place printer in Ready state Off Not printing Off Press Pause.

Place printer in pause state On Off Press Pause.

Enter Normal mode N/A N/A N/A Turn power on without

pressing any buttons

Printing test N/A N/A N/A Turn power on while

pressing FF/Load.

2-5

Page 18

Paper Handling

*1

Operation Required Conditions

Ready Printing

*2

Fault

Required Action

Select a resident font Not printing Off Press Font.

Enter Macro selection mode Not printing Off Press Macro. (M1 and M2

will turn blinking

alternately for 3 seconds.)

Select Macro 1

*4

Off Press M1 within 3 seconds

after pressing Macro.

Select Macro 2

*4

Off Press M2 within 3 seconds

after pressing Macro.

Switch the protocol Not printing *4Off Press Protocol.

Enter Top-of-Form Adjustment mode

Not printing Off

Press

Set-Up/Quit

and

Top

Move paper by 1/60 inch Off Off Press or button.

Use the adjustment temporarily Off Off Press Set-Up/Quit.

Use the adjustment permanently

Off Off Press Exit/Save.

Clear the adjustment Off Off Press Top.

Enter Set-Up mode N/A N/A N/A Turn power on while

pressing Set-Up/Quit.

Move cursor to select Off Not printing Off Press or button.

a Set-Up Function or Value

Move cursor to select Off Not printing Off Press or button.

a Set-Up Option

Select a Set-Up Function Off Not printing Off Press or button.

or Value

Select a Set-Up Value and Off Not printing Off Press Exit/Save.

move cursor to SAVE&EXIT

Quit Set-Up mode without

Off Not printing Off Press Set-Up/Quit.

saving values

Clear software-detected errors Blinking Press Pause.

Initialize the printer

Turn power off and on again.

.

*1 In Normal mode operation, all buttons except Pause are inactive in the Busy state in which the printer is

receiving or printing data.

*2 Not printing includes the following situations: the printer is ready and awaiting data, or the Pause button is

pressed and the printer is awaiting data, or the Pause button is pressed during printing.

*3 This operation is available in the rear-feeding push-tractor mode.

*4 Switching is not done if the printer is holding printing data.

2-6

Page 19

Printer Acoustical Feed-Backs

Except for paper handling and when the factory setting for beep is not changed, the printer

beeps in the following ways when you press a control panel button, as follows.

A short beep indicates that the printer accepts your pressing or specification.

A longer beep indicates that your specification is invalid.

In a certain mode, a middle long beep indicates that the specified mode becomes active

and a short beep indicates the end of the mode.

When the Fault indicator lights, the printer also makes a longer beep.

Selecting Paper

The printer can handle either single sheets or continuous forms. Single sheets, also called

cut sheets, include envelopes and noncontinuous, multipart forms. Continuous forms

include labels and multipart forms fed into the printer using the forms tractors.

For best results, use paper that meets the specifications listed in the following table. (See

Appendix B Printer and Paper Specifications for detailed specifications.) If you are

unsure of the suitability of a particular type of paper, try testing the paper or consult your

dealer.

Paper Handling

Paper Specifications

Paper Size

LA36N LA36W

Continuous Width 102 to 267 mm (4 to 10.5 in) 102 to 420 mm (4 to 16.5 in)

forms Length 102 mm (4 in) or greater 102 mm (4 in) or greater

Cut sheets Width 102 to 267 mm (4 to 10.5 in) 102 to 420 mm (4 to 16.5 in)

Length 76 to 364 mm (3 to 14.3 in) 76 to 420 mm (3 to 16.5 in)

Paper Thickness and Number of Copies

Description

Thickness 0.35 mm (0.014 in) maximum total thickness.

Copies 1 to 5 copies, including the original.

For carbon-interleaved paper, the carbon counts as a copy.

2-7

Page 20

Paper Handling

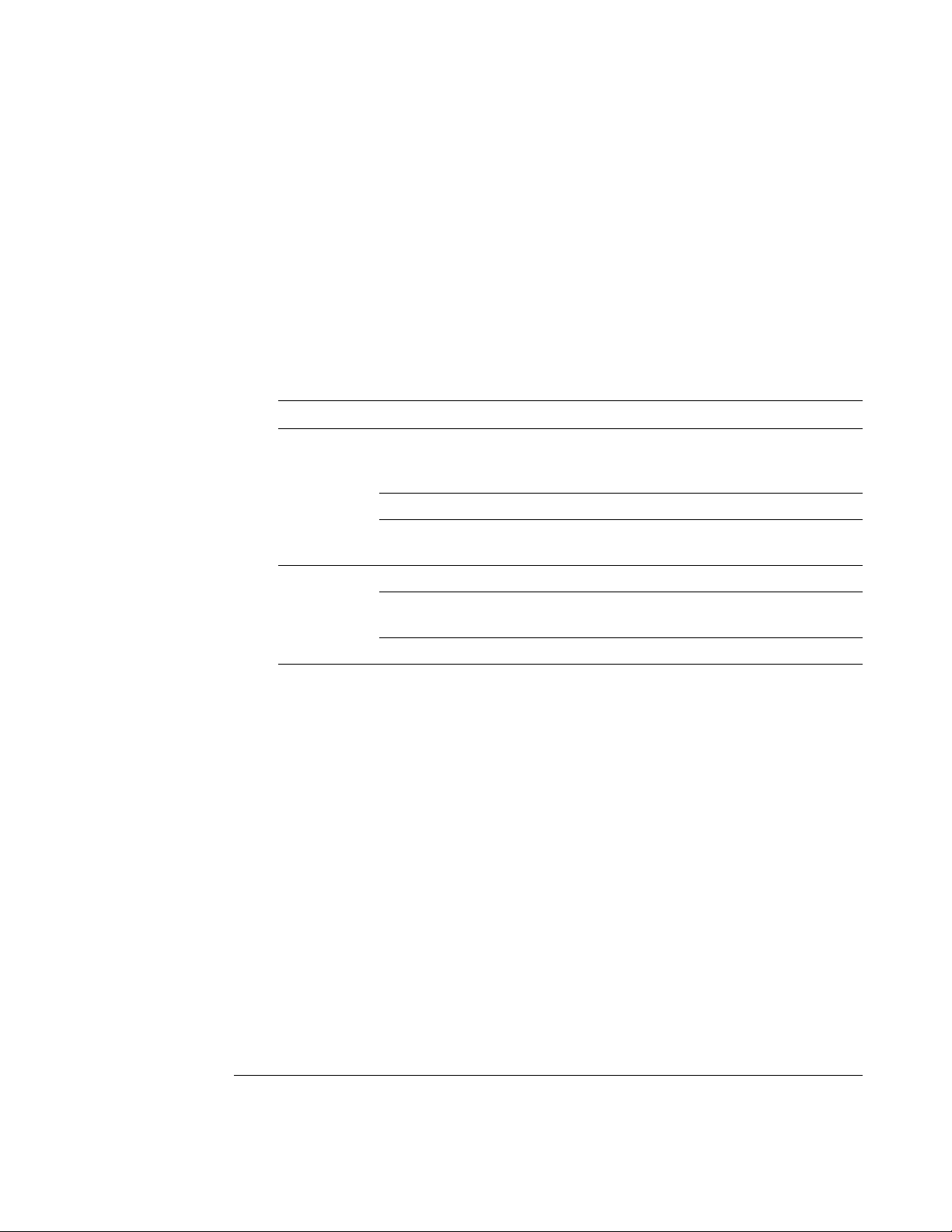

Overview of Paper Operations

The following levers and buttons are used in paper handling:

Paper select lever 1 at the top left corner of the printer

Paper thickness lever 2 at the top right corner of the printer

All buttons 6 on the control panel 3 (Primary and alternative functions are labelled

respectively above and under each button.)

The following figure shows the location of each lever, indicators, and buttons:

1

3

2

Draft

HSDraft

HiDraft

4

Courier 10

Comp. 17

Ready

Set-up/Quit

Nimb. PS

Soft Ctrl.

Top

5

Fault

DEC

EP2

PPX24

M1

M2

M1

M2

Exit/Save

6

Paper select lever 1 Font indicators 4

Paper thickness lever 2 Macro indicators 5

Control panel 3 Buttons 6

Printer Levers and Buttons

The following table summarizes the use of levers and buttons in paper handling. More

detailed information is provided later in this chapter.

Caution: To load or feed paper, the printer must be:

In the Ready state but not receiving or printing data

In the Pause state

2-8

Page 21

Levers and Buttons Used for Paper Handling

Lever/Button Purpose Action

Paper Handling

FF/LOAD

Form feed Press FF/Load to execute a form feed.

Continuous forms are fed forward by one

page. Single sheets are ejected.

Load paper Press FF/Load to feed paper to the top of

form position.

LF Line feed Press LF to feed paper forward by one line.

Park Unload forms Press Park to retract continuous forms to

the park position.

Set-Up/Quit + Top Press Set-Up/Quit and Top at the same time

Press the button to feed paper forward

Exit/Save Save TOF value Press Exit/Save to permanently store the

Enter Top-of-Form

(TOF) Adjustment

mode

Increase TOF value by

1/60 inch

Decrease TOF value by

1/60 inch

to enter TOF Adjustment mode where the

paper loading position can be adjusted.

by 1/60 inch in TOF Adjustment mode.

Press the button to feed paper backward

by 1/60 inch in TOF Adjustment mode.

TOF position adjusted by the button and

the button in TOF Adjustment mode.

Pause Press Pause to advance the forms

Advance forms to the

tear bar when forms are

at the Top-of-Form

(TOF) position..

perforation to the tear bar. Tear off the

forms, then press Pause again to return the

forms to the previous position.

Paper select lever * Select paper path Move the paper select lever forward for

single sheets.

Move the paper select lever backward for

continuous forms.

Paper thickness lever Select the number corresponding to the

Adjust for paper

thickness or number of

copies

number of copies (including the original).

Vary the setting upward or downward

(including A to D) to optimize printing.

Select D when replacing ribbon or clearing

a paper jam.

* The following graphics are engraved on the casing.

Continuous forms

Single sheets

2-9

Page 22

Paper Handling

Adjusting for Paper Thickness

The printer can handle paper with different thicknesses, including multipart forms with up to

five parts (original plus four copies). For details on paper thickness specifications, see

Appendix B Printer and Paper Specifications.

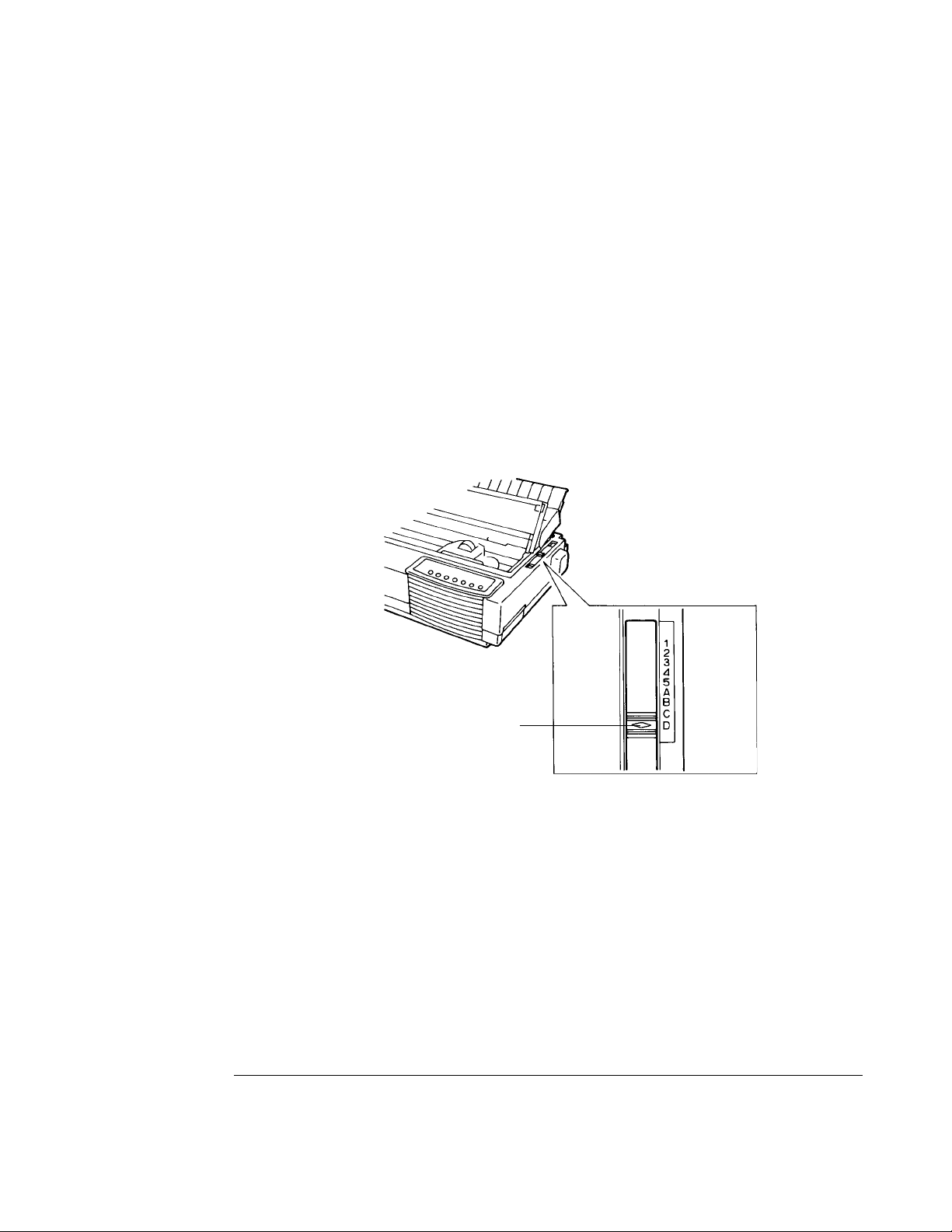

The paper thickness lever, located at the top right corner of the printer, allows you to adjust

for different paper thicknesses. Be sure to adjust the paper thickness lever whenever you

change the number of copies being printed.

The paper thickness lever 1 has nine settings: 1 to 5 and A to D. Use the following table to

determine the appropriate setting for your paper; then, move the paper thickness lever to the

appropriate position.

2-10

1

Adjusting the Paper Thickness Lever

Page 23

Paper Thickness Lever Positions

Paper Handling

Number of Copies Position

(Including the Original)

*1

*

2

1 copy 1

2 copies 2

3 copies 3

4 copies 4

5 copies 5

Ribbon replacement D

*1 For carbon-interleaved paper, the carbon counts as one copy.

*2 Vary the position upward or downward (including A to D) to optimize printing. Select D when replacing a

ribbon or clearing a paper jam. For labels and envelopes, use the trial-and-error approach to determine a

satisfactory position.

Caution: If printing is messy, the ribbon misfeeds, or the paper jams, move the lever one

position higher.

Using Single Sheets

This section describes how to load paper in the cut sheet stand. The cut sheet stand allows

paper to be loaded manually, one sheet at a time.

Loading a Single Sheet of Paper

To load a sheet of paper into the cut sheet stand:

1. Make sure that the printer is turned on. Check that rear-fed continuous forms are

retracted to the park position. (For details, see the section Unloading Continuous

Forms later in this chapter.)

2. If necessary, reset the paper thickness lever. (See the section Adjusting for Paper

Thickness earlier in this chapter.)

3. Move the paper select lever forward. (This lever is at the top left part of the printer.)

4. Raise the cut sheet stand. Position the left paper guide in accordance with the Note

below. Note that the movable range of the paper guide is limited.

2-11

Page 24

Paper Handling

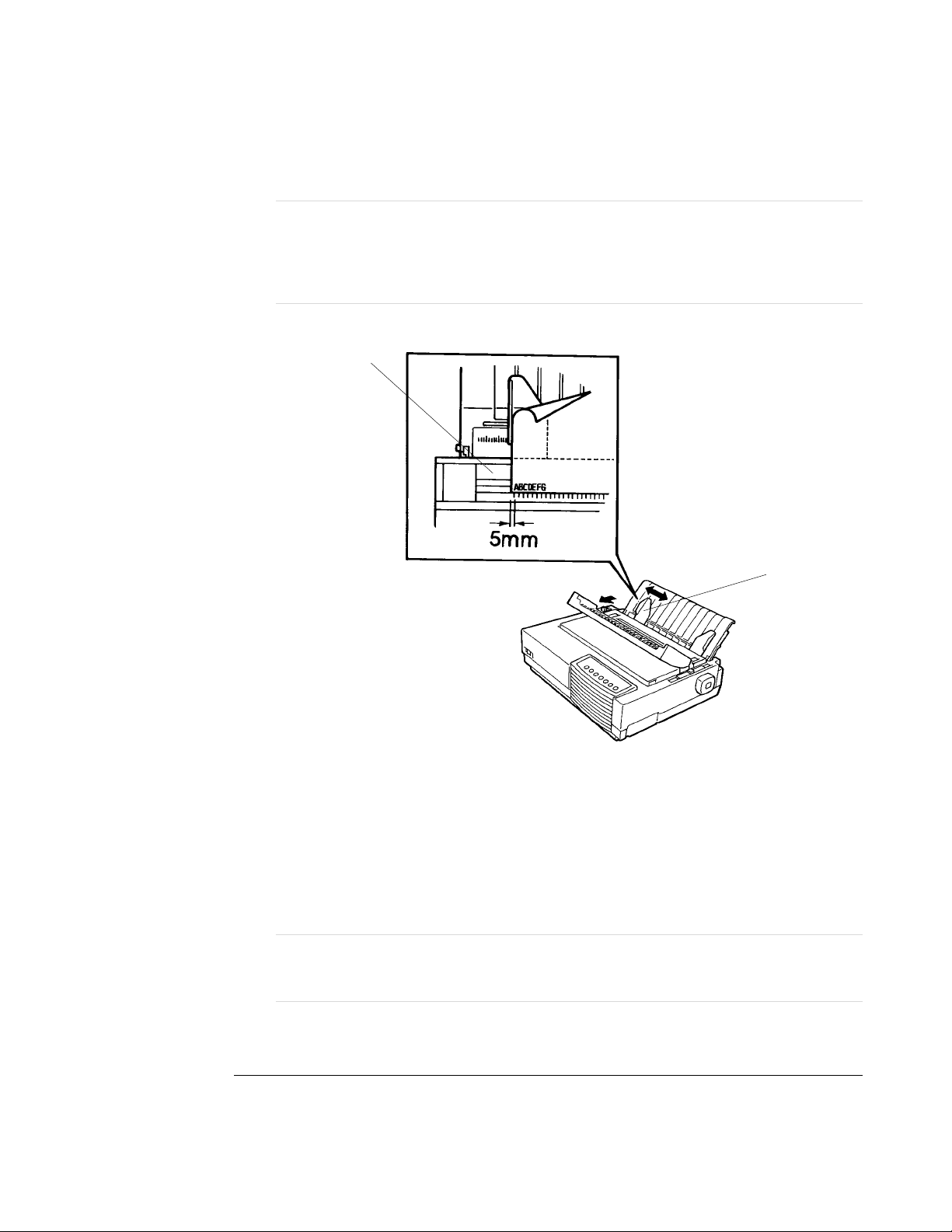

Note: Below the left paper guide 1, the cut sheet stand has a scale graduated in units of

0.1 inch. When the left paper guide is positioned all the way to the right, the left

margin is 5 mm (0.2 inch). To help align paper, also use the inch-based ruler on

the top cover 2 of the printer. The gradations on the ruler are for 10 columns per

inch.

2

1

Setting Paper Select Lever and Left Paper Guide

5. Adjust the right paper guide 3 to the width of paper. Insert the paper into the cut sheet

stand. Make sure that the bottom edge of the paper engages snugly with the platen. The

paper will automatically advance to the top-of-form position if the Single Sheet Load

option of the Set-Up mode is set to Automatic.

Note: The factory setting for the Single Sheet Load option is automatic loading, two

seconds after paper detection. If you set this option to manual, you will have to

press FF/Load to feed the paper.

2-12

Page 25

Paper Handling

3

Loading a Sheet of Paper

6. If you want to slightly adjust the Top-of-Form position, the first line on which printing

can start, adjust the Top-of-Form position of the paper using control panel buttons. Press

the Set-Up/Quit and the Top buttons at the same time. The M1 and M2 indicators flash

alternately with the DEC and PPX24 indicators, indicating Top-of-Form Adjustment

mode. Press the button or the button. The paper will move forward or backward

in 1/60-inch increments. Press the Set-Up/Quit button after adjusting the position. Note

that this adjustment is temporarily saved. It will not be active at next power-up of the

printer. For permanent adjustment, see the section Feeding and Positioning Paper later

in this chapter.

7. Place the printer in the Ready state. Print a sample page and check the page margins.

Make the following adjustments, as necessary:

Horizontal alignment. Readjust the paper guides if required.

Top-of-form setting. Use the printer Set-Up mode (see Chapter 4 Using Set-Up

Mode) or the TOF Adjustment mode (see the section Feeding and Positioning

Paper later in this chapter).

Margin settings. Use your software or the printer Set-Up mode (see Chapter 4

Using Set-Up Mode).

Ejecting Single Sheets

If you print using software, each sheet is ejected automatically upon the completion of the

page printing. To manually eject sheets of paper:

Press the FF/Load button to execute a forward form feed.

Turn the platen knob.

2-13

Page 26

Paper Handling

Using Continuous Forms

Continuous forms paper, fanfolded at the horizontal perforations, is ideal for printing rough

drafts and long files. The paper is fed into the printer using the forms tractor unit. The

forms tractor unit, which is removable, can be used in two different ways. If the forms

tractor unit is mounted at the rear of the printer, it pushes paper from the rear to the platen.

This is called push-tractor feeding. If the forms tractor unit is mounted at the top of the

printer, it pulls paper from the bottom or rear of the printer to the platen. This is called pulltractor feeding.

Caution: When using continuous forms with the cut sheet stand in up position, always

spread the cut sheet stand paper guides to their extreme position before feeding

the paper. This will prevent the paper from jamming against the acoustic cover.

2-14

Page 27

Paper Handling

Positioning the Paper Stack

Place the stack of continuous forms paper directly below the rear of the printer 1 for push,

rear feed or below the bottom slot of the printer 2 for pull, bottom feed.

Caution:

After the paper is installed in the printer, the paper path should look like this:

Good placement

When using paper-stapled multipart forms in push feed, raise the cut sheet stand 3.

1

Push-feed, from rear slot Push-feed, from rear slot

with paper-stapled multipart forms

2

3

Pull-feed, from bottom slot

Bad placement

Placement of Continuous Forms

2-15

Page 28

Paper Handling

Loading Continuous Forms (Push Tractor and Rear Feed)

This section explains how to use continuous forms when the tractor unit is installed at the

rear of the printer. The tractor unit pushes continuous forms. This condition applies when

you first use the printer.

To load continuous forms paper:

1. Make sure that the printer is turned on. Remove any single-sheet paper from the printer.

2. If necessary, readjust the paper thickness lever for continuous forms. (See the section

Adjusting for Paper Thickness earlier in this chapter.)

3. Move the paper select lever 1 to the rear of the printer.

3

4

2

1

Preparing to Load Continuous Forms Paper

4. To access the forms tractors 2, lock the cut sheet stand 3 and the back cover 4 together

and raise them in the up position.

2-16

Page 29

Paper Handling

5. For both forms tractors 2, release the tractor locking levers 5 by pulling them up. Open

the tractor paper holders 6.

6

7

5

12 mm

Positioning the Tractor Using the Tractor Guide

6. Position the right forms tractor (as seen from the rear of the printer) in accordance with

the Note below. Push the right locking lever down to secure the tractor. Center the

middle forms support.

Note: The tractor guide 7 can be found below the right forms tractor, as seen from the

back. This tractor guide is a short inch-based ruler graduated in 10 columns per

inch. Use this ruler to help position the tractor. When the paper edge is

positioned to the leftmost line, the left margin is 12 mm (0.5 inch) including the

perforation area.

7. Once the right forms tractor is positioned, lock it by pushing down its locking lever.

2-17

Page 30

Paper Handling

8. Fit the paper feed holes onto the left and right tractor pins. Adjust the left forms tractor

(as seen from the rear of the printer) to accommodate the width of the form. Close the

paper holders 6.

6

Adjusting Paper Tension

9. Pull the left tractor (as seen from the rear) to extend the paper flat. Do not stretch the

paper taut. Push the left locking lever down to secure the tractor in place. Unlock the

back cover from the cut sheet stand to close it.

10.When using paper-stapled multipart forms, leave the cut sheet stand 3 raised in the up

position. For other continuous forms paper, lower the cut sheet stand to the down

position.

3

Lowering the Cut Sheet Stand

11.Press the FF/Load button to advance the paper to the top-of-form position from which

printing can start. The printer is automatically placed in the Ready state.

2-18

Page 31

Paper Handling

12. Press the ONLINE button to place the printer on line. Print a sample page and check the

page margins. Make the following adjustments, as necessary:

Horizontal alignment. Move the forms tractors as required.

Top-of-form setting. Use the printer Set-Up mode (see Chapter 4 Using Set-Up

Mode) or the Top-of-Form Adjustment mode (see the section Feeding and

Positioning Paper later in this chapter).

Margin settings. Use your software or the printer Set-Up mode (see Chapter 4

Using Set-Up Mode).

Loading Continuous Forms (Pull Tractor and Bottom Feed)

Caution: When manipulating the tractor unit, always be careful not to pull on plastic

parts (below the forms tractors) in order to avoid printing problems (such as

printing on the platen at the end of the paper in push-feed).

Better manipulate the metallic parts of the tractor unit.

This subsection explains how to use continuous forms when the forms tractor unit is

installed at the top of the printer. The forms tractor unit pulls continuous forms. This is

called pull-tractor feed. To use pull-tractor feed, you must remove the forms tractor unit

from the rear of the printer and install it on the top of the printer.

For pull-tractor feed, this printer is equipped with a paper path slot at the bottom of the

printer to allow for continuous forms feed from under the printer. You must use a desk or

rack that has an appropriate paper path slot. For the appropriate paper path, see the section

Positioning the Paper Stack earlier in this section.

Warning: Turn the printer off before reinstalling the forms tractor unit.

To reinstall the forms tractor unit for pull-tractor feed:

1. Set the cut sheet stand and the back cover together to the up position to access the forms

tractor unit.

2-19

Page 32

Paper Handling

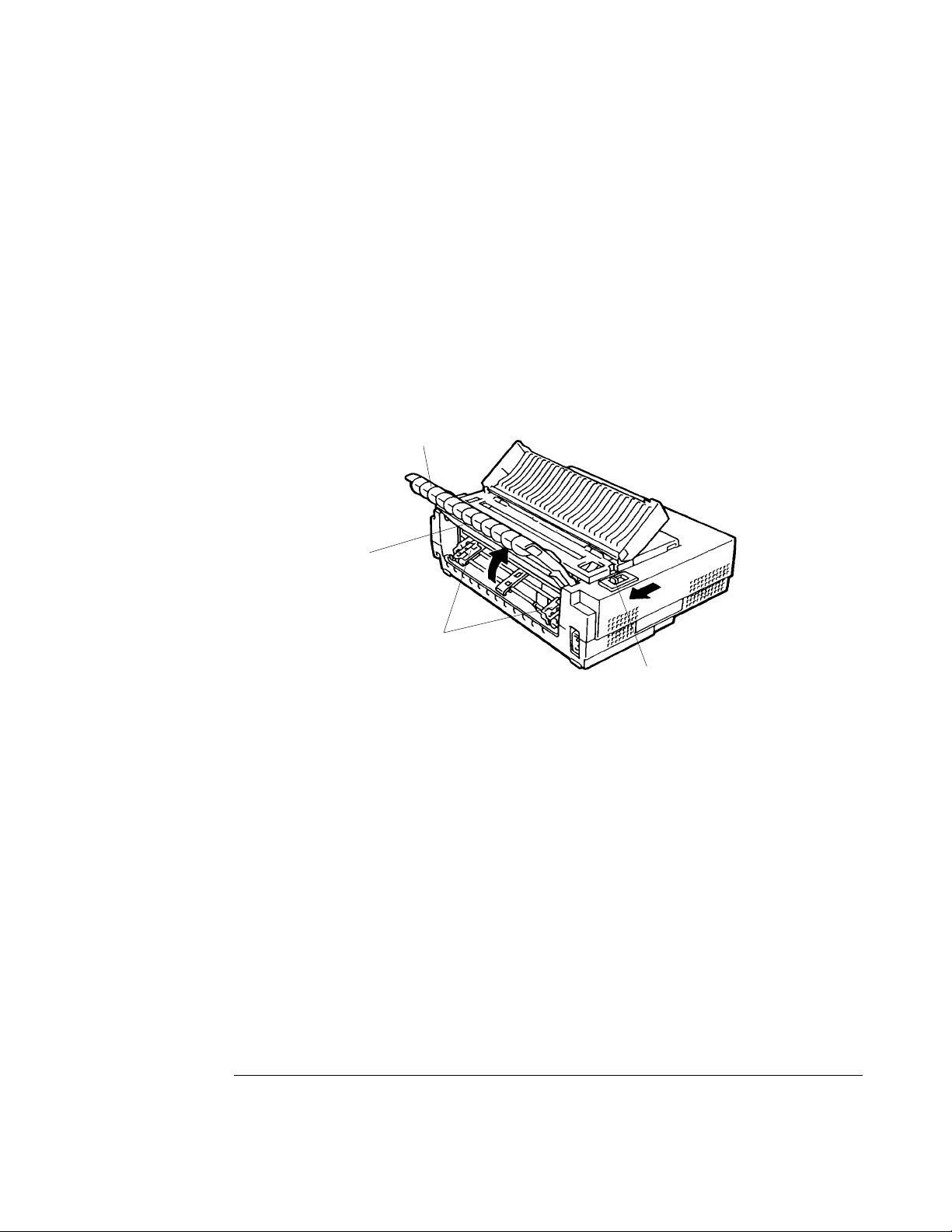

2. Pull up both ends of the tractor unit to detach the catches 1 of the tractor unit from the

support studs 2. Then pull the tractor unit.

1

2

Removing the Tractor Unit

3. Set the cut sheet stand and the back cover to the down position.

2-20

Page 33

Paper Handling

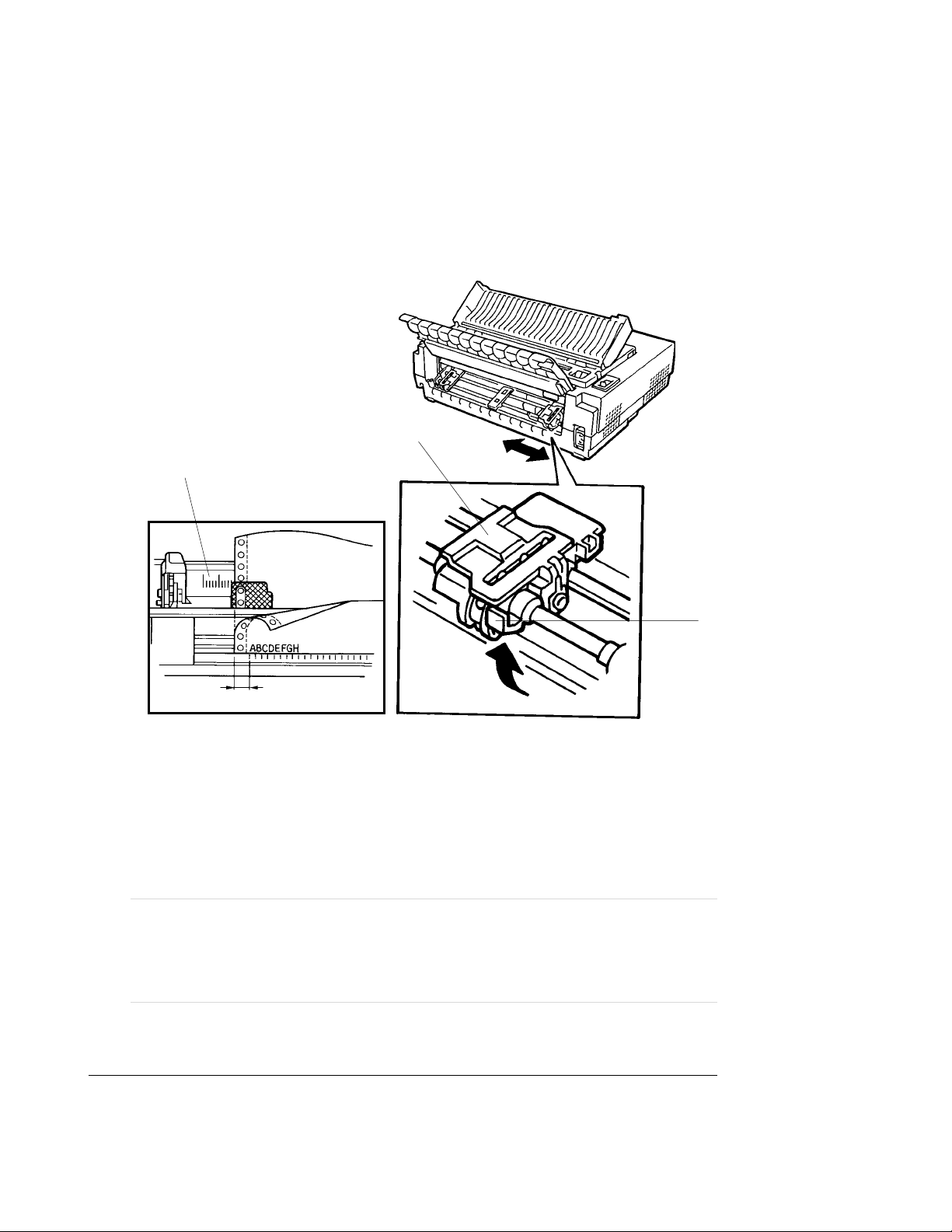

4. Open the acoustic cover and the top cover 3 to access the top of the printer.

5. Position the catches 1 of the tractor unit on the support studs 4 near the platen shaft.

A. Push the forms tractor unit toward the front of the printer.

B. Snap down the tractor unit into place so that the catches click on the rear studs.

1

4

3

Installing the Tractor Unit for Pull-tractor Feed

6. Turn the platen knob to make sure that the tractor gear fully engages the platen shaft

gear. Lean the top cover and the acoustic cover against the tractor unit.

The following are the procedures to take when you want to feed continuous forms paper

from under the printer (bottom feed).

To load continuous forms paper:

1. Turn printer on.

2. Make sure that the bottom slot of the printer is adjusted with the slot of the desk or

printer rack.

3. Set the paper thickness lever to position D (widest gap).

4. Move the paper select lever to the rear (continuous forms).

2-21

Page 34

Paper Handling

4. Open the front cover 1, with taking care of not totally removing it.

5. Place the continuous forms paper below the table and pass the paper through the slot of

the table then through the bottom slot of the printer up to the platen.

1

Passing Continuous Forms Paper From Under the Printer

6. Close the front cover 1 and open the top cover.

7. Open the two holders of the left and right tractors. (Each tractor has a larger main holder

2 and a smaller subholder 3.)

2

3

Opening the Two Holders

8. Set the continuous forms on the tractors and position the tractors to stretch the forms taut

in the same way as described for push-tractor feed.

2-22

Page 35

Paper Handling

9. Turn the platen knob 4 to adjust the print start position and turn the printer on. The

horizontal embossed rib under the red cursor on the print head carriage corresponds to

the base line of the characters to be printed.

4

Setting Continuous Forms Paper on the Tractors

10.Lean the top cover against the tractor unit.

11.Adjust the paper thickness lever to the appropriate position.

12.Press the Pause button to place the printer in the Ready state. Print a sample page and

check the first line and the page margins. Make the following adjustments, as necessary:

Horizontal alignment. Move the forms tractors as required.

Margin settings. Use your software or the printer Set-Up mode (see Chapter 4

Using Set-Up Mode).

Caution: In the pull-feed mode, reverse feeding is allowed up to 1/3 inch and the print

accuracy is lower than the accuracy available with the push-feed mode. Use the

pull-feed mode when printing labels and so on that are affected by curling.

2-23

Page 36

Paper Handling

Unloading Continuous Forms (Push-Feed Mode)

To unload continuous forms:

1. Make sure that the paper select lever is set to the rear position.

2. Press the Park button. The continuous forms paper is retracted to the park position. If

the paper cannot be retracted in one operation, continue to press the Park button until the

paper is parked.

Note: The printer can retract continuous forms paper a maximum of 50.8 cm (20

inches) per operation.

3. To remove the paper, raise the tractor paper holders and lift out the paper.

Note: To unload continuous forms fed by the pull-tractor, set the paper thickness lever

to D, then remove the paper manually.

Recovering from an Unexpected Unloading Operation

If you have accidentally pressed the Park button, you can cancel this operation in two ways,

only if this unexpected operation was unsuccessful (paper not actually parked and Fault

indicator blinking).

Press the Pause button.

The printer switches to the Ready state and the paper moves according to the setting of

the TEAR Set-Up option.

Press the FF/Load button.

The paper moves back to the place it was positioned before you pressed the Park button.

Tearing Off Continuous Forms

Caution: Continuous forms paper that is fed by the pull-tractor cannot be torn off in the

following way.

Automatic-Tear-Off Advancing

Your printer has a special tear bar that allows you to tear off printed pages without

wasting paper. The tear bar is located on the top cover.

Your printer is factory-set for automatic tear-off. When a printing job ends (including a

form feed command), the bottom perforation of the last printed page is automatically

positioned in front of the tear bar. You can change the positioning delay from one to five

seconds, using the Set-Up mode. The printer is placed in the Pause state (Ready indicator

off).

2-24

Page 37

Paper Handling

Note: If the printing job does not include a form feed command, the paper is only

automatically fed so that you can see the last printed line. Press on the FF/Load

button to position the next paper perforation in front of the tear bar.

The paper is automatically retracted when the printer receives the next data. For tearing off

the paper, see the next subsection Manual Tear-Off Advancing.

Manual Tear-Off Advancing

If you have set the TEAR option of the INSTALL function to MANUAL, tear off the paper in

the following way when a printing job ends (including a form feed command).

1. Press the Pause button to position the paper perforation in front of the tear bar.

Note: If the printing job does not include a form feed command, after pressing the

Pause button the paper is only automatically fed so that you can see the last

printed line. Press on the FF/Load button to position the next paper perforation

in front of the tear bar.

Caution: If the paper perforation is not positioned in front of the tear bar, the length of

your paper may not be specified correctly in your software or the Set-Up mode.

Check that the paper length is specified correctly. For information on

specifying page length using the Set-Up mode, see Chapter 4 Using Set-Up

Mode.

2. Tear the paper off at the perforation.

Tearing Off Continuous Forms

3. Press the Pause button again to retract the forms back to the top-of-form position.

2-25

Page 38

Paper Handling

Feeding and Positioning Paper

Print Area Definition

TOF (Top-of-Form):

This value defines the distance between the edge of the paper and the place where you

allow the printing to begin (position of line number 1). You can adjust this distance

according to the condition of your paper (for example, pre-printed forms). When you

load the paper, the printer feeds the paper to this position, waiting for printing

commands.

L (Form Length):

Set the corresponding Set-Up option (FORM LENGH) according to the actual physical

page length (distance between two perforations for continuous forms). This will allow

the printer to know exactly where the print head is and to position it at the same position

when a form feed occurs.

Top line 1:

This is the line where the printing actually starts. To define a top margin, select the

number of this line within Set-Up mode (TOP MRGN option). Example: In the

following picture, TOP MRGN option is set to 3.

Bottom line 2:

This is the line where the printing actually stops. To define a bottom margin, select the

number of this line within Set-Up mode (BOTTOM MRG option). Example: In the

following picture, BOTTOM MRG option is set to 50.

Left column 3:

This is the column where the printing actually starts. To define a left margin, select the

number of this column within Set-Up mode (LEFT MARGN option). Example: In the

following picture, LEFT MARGN option is set to 4.

Print area 4:

Print area defined by the corresponding Set-Up options: Form Length, Top-of-Form,

Top Margin, and Bottom Margin.

Paper perforation 5:

The perforation defines the physical page length.

2-26

Page 39

Paper Handling

3

4

1

2

3

4

5

6

7

8

... ...

48

49

50

51

52

12345

ABCDEFGHIJ ···

ABCDEFGHIJ ···

ABCDEFGHIJ ···

...

6

TOF

1

L

2

5

TOF

1

2

3

4

5

6

...

Print Area Definition

2-27

Page 40

Paper Handling

Line Feed/Form Feed

Use the line feed/form feed function to move paper forward. This function is valid whenever

the printer is not receiving or printing data and has no fault. Pressing the LF button

advances the paper one line. Pressing the FF/Load button feeds one sheet of paper.

Except using the Park button for unloading paper or using the Top-of-Form Adjustment

mode for fine-adjusting the Top-of-Form position, you are not allowed to execute reverse

feed from the control panel. To feed paper backward, manually rotate the platen knob.

Remember that the Top-of-Form will slip from the original setting.

Top-of-Form Adjustment

Note: For Top-of-Form definition, see the previous section Print Area Definition.

The Top-of-Form adjustment is available for single sheets or continuous forms fed by the

push-tractor. The adjustment is reflected to the Top-of-Form setting of Macro 1 or Macro 2

currently selected from the control panel.

Note: This adjustment is not available for continuous forms fed by the pull-tractor.

You can adjust the Top-of-Form value within the range from 0 to 99/60 inches.

Note: The horizontal embossed rib under the red cursor on the print head carriage

corresponds to the base line of the characters to be printed.

1. Position the paper at the current Top-of-Form position:

For continuous forms, park the paper, then press the FF/LOAD button.

For a single sheet, simply insert the sheet in the cut sheet stand.

Paper is automatically fed to the Top-of-Form position, if the Set-Up option

S-SHEET LD (Single Sheet Load) is set to AUTO. Otherwise, press the FF/LOAD

button.

2. Enter the Top-of-Form mode by pressing the Set-Up/Quit and Top buttons at the same

time. The printer beeps and the M1 and M2 indicators flash alternately with the DEC and

PPX24 indicators, indicating the Top-of-Form mode.

3. Adjust the Top-of-Form value:

2-28

Page 41

Paper Handling

To increase the Top-of-Form value of a 1/60 inch, press the button.

The paper moves forward.

To decrease the Top-of-Form value of a 1/60 inch, press the button.

The paper moves backward.

To reset the Top-of-Form value to 0, press the Top button.

The paper moves to the edge of the page (position 0).

Note: If you reach the limit of the permitted range, the printer beeps and the paper

stops moving.

4. Save the Top-of-Form value:

To permanently save the value, press the Exit/Save button.

The printer returns to Normal mode.

To temporarily save the value, press the Set-Up/Quit button.

The printer returns to Normal mode. (The new value is lost at next power-off.)

Note: The use of the and buttons for micro-feeding is available for some cases of

software errors (Fault indicator blinking).

Switching Paper Types

If you have more than one type of job, it is often necessary to switch between continuous

forms and single sheets. This section explains how to switch between paper types. It is not

necessary to remove the continuous forms paper from the printer.

Caution: This function is not available for continuous forms paper that is fed by the pull-

tractor.

Switching from Continuous Forms to Single Sheets (Push-Feed Mode)

2-29

Page 42

Paper Handling

To switch from continuous forms to single sheets:

1. Tear off your printed pages.

2. Retract the forms paper to the park position by pressing the Park button. The Fault

indicator turns on.

Caution: Retracting many pages by using the Park button without tearing off will cause

paper jams. To avoid damage to your printed pages, be sure to tear off the

printed pages before retracting the continuous forms paper.

3. Move the paper select lever forward to the single sheet position.

4. Raise the cut sheet stand to the up position. (For details, see the section Using Single

Sheets earlier in this chapter.) Put a sheet of paper on the cut sheet stand with its

bottom edge aligned with the platen. The paper automatically advance to the top-ofform position if the option S-SHEET LD (Single Sheet Load) is set to AUTO.

Otherwise, press the FF/LOAD button to advance the single sheet paper to the top-ofform position .

You are now ready to print using single sheets.

Switching from Single Sheets to Continuous Forms (Push-Feed Mode)

To switch from single sheets to continuous forms:

1. If a sheet of paper is loaded, remove the paper by turning the platen knob or pressing the

FF/LOAD button.

2. Move the paper select lever to the rear to the continuous forms position.

3. Press the FF/LOAD button. The continuous forms paper advances from the park position

to the top-of-form position.

You are now ready to print using continuous forms paper.

Switching between Push-Feed and Pull-Feed

2-30

Page 43

Paper Handling

Caution: When manipulating the tractor unit, always be careful not to pull on plastic

parts (below the forms tractors) in order to avoid printing problems (such as

printing on the platen at the end of the paper in push-feed).

Better manipulate the metallic parts of the tractor unit.

To allow the printer to properly detect the switching operation, follow the next procedure:

1. Unload the paper.

2. Turn the printer off.

3. Install the tractor unit for the other feed mode.

4. Turn the printer on.

5. Load the paper.

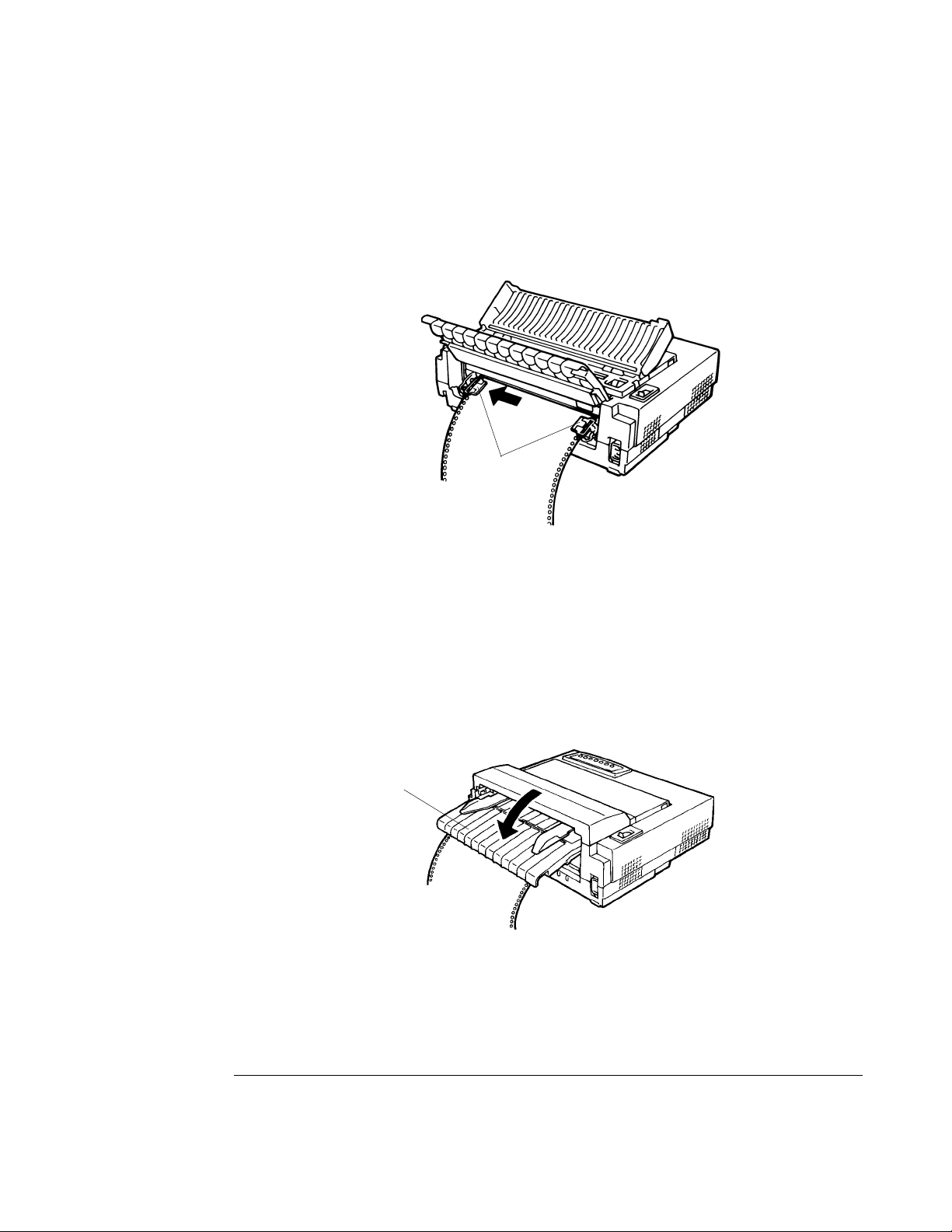

To Reinstall the Tractor Unit for Push-Tractor Feed:

1. Open the acoustic cover and the top cover.

2. Pull up both ends of the tractor unit to detach the catches of the tractor unit from the

support studs. Then pull the tractor unit.

3. Set the cut sheet stand and the back cover to the up position.

4. Keep the tractor unit horizontally (see the horizontal plane in the figure) so that the top

catches 1 of the tractor unit are in front of the inner support studs 2 of the printer.

5. Push the tractor unit toward the front of the printer until the top catches snap into the

inner studs. Then snap down the tractor unit into place.

1

Installing the Tractor Unit for Push-tractor Feed

6. Close the top cover and the acoustic cover.

Tips on Paper Handling

2

2-31

Page 44

Paper Handling

General Tips

Use high-quality paper. Do not use paper that is wrinkled or curled at the edges.

Do not use paper with staples or metal parts.

Do not use paper with unpredictable variations in thickness, such as paper with partial

multilayers, paper with embossed printing, and labels with the backing sheet exposed.

Store paper in a clean, dry environment.

Multipart Forms

Avoid using carbon-interleaved single sheets if possible. Printing tends to become

misaligned on the bottom sheet.

Set the paper thickness lever to best accommodate the multipart form thickness.

To ensure smoother feeding of paper-stapled, multipart forms, raise the cut sheet stand to

support the forms.

Envelopes

When printing envelopes, use the cut sheet stand. Note the following:

Set the paper thickness lever to best accommodate the envelope thickness.

When loading envelopes, make sure that the envelope flaps face forward. Otherwise, the

envelopes may jam in the printer.

Labels

Be careful to check operating conditions when using labels. Labels are sensitive to

temperature and humidity.

Only use labels mounted on continuous forms backing sheets. Do not print labels

mounted on single sheet backing. Labels mounted on single sheet backing tend to slip

and printing becomes crooked.

Do not leave labels loaded in the printer. If labels curl around the platen, jamming may

occur when printing is resumed.

Set the paper thickness lever to best accommodate the label thickness.

Test-print labels before running a job. If jams occur, set the paper thickness lever to a

wider position. If jamming problems continue, try a different type of label.

We recommend you to use the pull-tractor feed mode for printing labels. If using the

push-tractor feed mode:

Use the NO TEAR value of the TEAR option in the Set-Up mode.

Do not unload labels using the Park button. Jamming may occur during backward

feeding.

Do not use the printer tear-off feature when printing labels. If the labels are

retracted, the backing may peel off and the labels may jam in the printer.

2-32

Page 45

Printing

3

Printing

This chapter describes the following everyday printing operations:

Selecting print features

Starting, stopping, or resuming printing and viewing last printed lines

Removing printed pages

The Font button, the Macro, M1, and M2 buttons, the Protocol button, and the Pause button

are used for these operations which are described in detail in this section. For a summary

of the operation of these buttons, see the section Getting to Know the Printers Major Parts

and the Control Panel in Chapter 2 Paper Handling.

Instructions for loading and handling paper are also given in Chapter 2 Paper Handling.

Selecting Print Features

The print features you select determine how your printer interprets commands from the

computer and how your printed pages will look. For example, print features include the

following:

Protocol

Font

Pitch (characters per horizontal inch)

Line spacing (lines per vertical inch)

Page length and margins

To select print features, you can use either commercial software or the printer control panel.

The method you use depends on the capabilities of your software. If your software has most

of the features you require, you may rarely if ever have to use the control panel. In fact,

your software often overrides the printer settings.

If your software has limited values, you can use the printer control panel to select print

features. Sometimes, the control panel enables you to select features not available through

your software. For example, you can change the top-of-form position or select a character

set for printing your document.

3-1

Page 46

Printing

Using Commercial Software

Many commercial software packages offer a wide variety of print features, including some

features that are not supported by this printer. For example, software often provides a wider

range of font sizes than the printer can accommodate. Software also allows you to specify

multiple fonts on a single page and multicolor printing. To determine which features your

software supports and how to select them, refer to your software documentation.

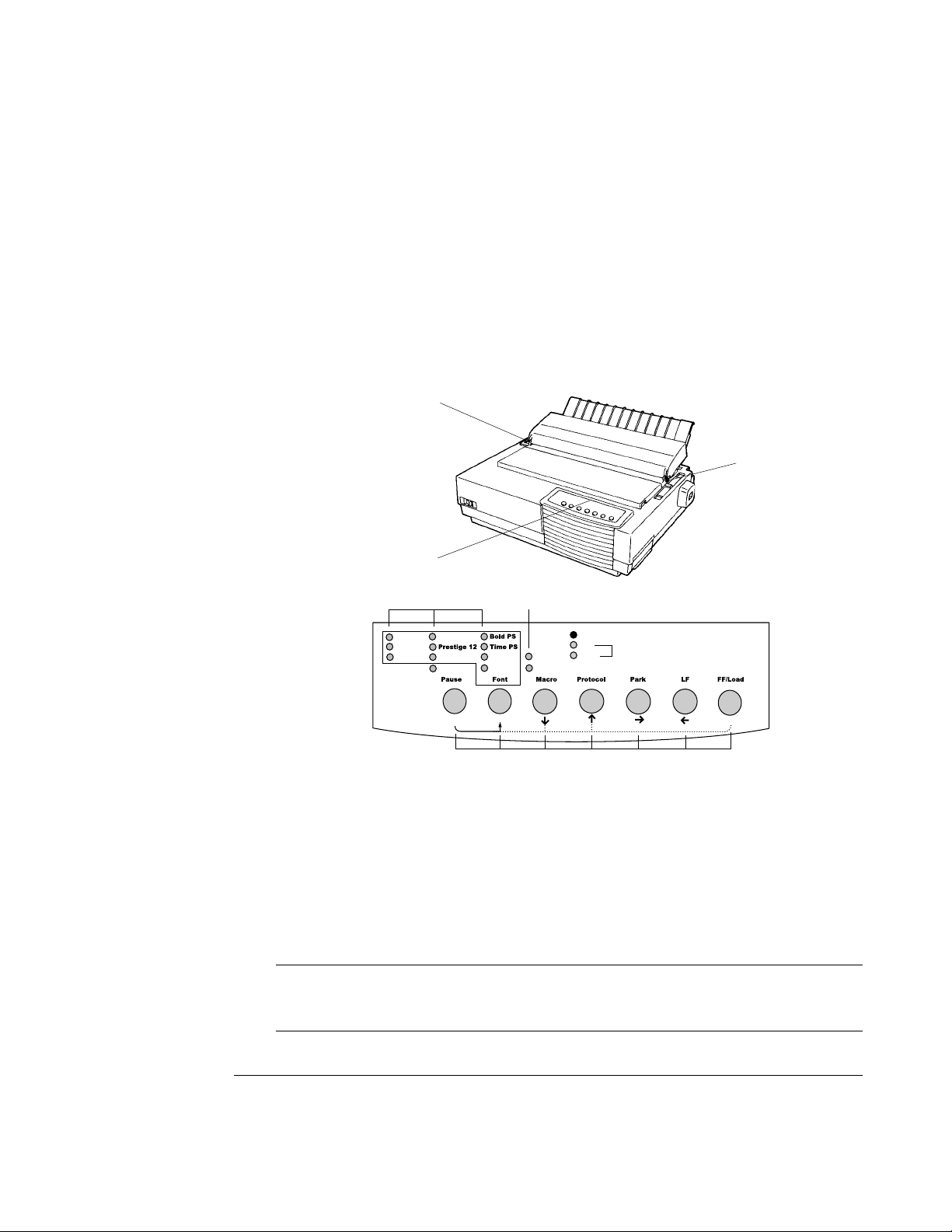

Using the Control Panel

This printer can directly select some print features from the control panel. These features,

listed on the control panel, are two predetermined sets (macros) of print features, nine

resident fonts, and three protocols. Use the Macro, Font, and Protocol buttons as follows:

Macro to select one of the two sets of print features, Macro 1 (M1) and Macro 2 (M2)

Font to select one of nine resident fonts (You can access three other fonts in Set-Up

mode)

Protocol to select one of the three protocols

Draft

HSDraft

HiDraft

Courier 10

Comp. 17

Ready

Set-up/Quit

Nimb. PS

Soft Ctrl.

Top

M1

M2

Printer Control Panel

Fault

DEC

PPX24

EP2

M2M1

Exit/Save

The Macro button specifies Macro 1 or Macro 2, either of which allows you to specify

different sets of values in advance. Some of the print features include protocol, font,

character pitch, and line spacing. The following table lists the default values of options in

Macro 1 and Macro 2. This chapter does not explain how to assign values to options in the

macro. If you havent already assigned values to Macro 1 and Macro 2, see Chapter 4

Using Set-Up Mode now.

3-2

Page 47

Printing

The Font button specifies one of the nine resident fonts defined by font names and pitches

on the control panel. The selectable resident fonts are Draft, High-speed (HS) Draft, and

High-impact (Hi) Draft, Courier 10, Prestige 12, Compressed 17, Boldface PS, Timeless PS,

Nimbus Sans PS. Even if you select a font (excepting Soft Control), the printer will monitor

font commands from the computer, but continue to use the font specified by the control

panel until another selection is made or the printer is turned off. If you select Soft Crtl, (Soft

Control) the printer will use the font specified by commands from the computer.

The Protocol button allows you either to choose one of the three resident protocols or to

allow the printer to automatically switch to one of the three protocols, according to Set-Up

settings. The resident protocols are DEC PPL2, IBM Proprinter X24E, and Epson ESC/P2

protocols.

When you first turn the printer on, the M1 indicator is lit with the DEC and PPX24

indicators flashing alternately, the Soft Ctrl. indicator is lit, and the Ready indicator is lit (the

Fault indicator will be lit if no paper is loaded). That is, all of the print features assigned to

Macro 1 are enabled; fonts used depend on font commands from the computer but the Draft

font is used if no font command is received (because the FONT option is set to DRAFT in

Set-Up mode for Macro 1); and the printer assigns the DEC PPL2 protocol to the serial

interface port, and the Epson protocol to the parallel interface port. However, you can

easily switch to other settings before printing as described below:

Selecting Macro 1 or Macro 2

When you first turn the printer on, Macro 1 is selected. To change to Macro 2 or back to

Macro 1, proceed as follows:

1. Press the Macro button 1 to place the printer in the macro changeable state. The M1 and

M2 indicators blink alternately.

2. Within three seconds, press the M1 or M2 button 2. The lighted indicator (M1 or M2)

shows the macro selected. This selection is permanently retained in the printer.

Draft

HSDraft

HiDraft

Courier 10

Comp. 17

Ready

Set-up/Quit

Nimb. PS

Soft Ctrl.

Top

M1

M2

1

Control Panel

Fault

DEC

PPX24

M1

EP2

M2

Exit/Save

2

3-3

Page 48

Printing

3. To change to a resident font, see the next section. Otherwise, press the Pause button to

return the printer to the Ready state. You are ready to print using the selected macro.

Note: The active Macro at power-off remains active at next power-up.

Switching Macros and Selecting Features on the Control Panel

When you switch from a macro to another, each modification you made using the control

panel for the Top-of-Form option or the Protocol option is lost, and the values of these

options stored in the new macro become active.

This behavior does not apply to the Font selection. If you have changed a font using the

control panel before changing the macro, this font will still remain active, overriding the

font set in the new macro.

For example, assume that Macro 1 is set to Draft and Macro 2 to Courier. You switch the

Font selection of Macro 1 from Draft to Prestige using the Font button. When you switch

the Macro selection from Macro 1 to Macro 2, Prestige will remain active, overriding the

Courier set in Macro 2.

The following tables list default values of options for print features. The former is for

options in Macro 1 and Macro 2 and the latter is for options independent of Macro selection.

Macro 1 and Macro 2 Settings

Print Feature Factory Settings

Macro 1 Macro 2

Protocol Port dependent Port dependent

Protocol serial DEC DEC

Protocol parallel EPSON IBM

Font Draft Draft

Horizontal pitch 10 cpi 10 cpi

Vertical pitch 6 lpi 6 lpi

Form length 11 inches (A) 11 inches (A)

Left margin 1 column 1 column

Top of Form

Top margin 1 line 1 line

Bottom margin 66 lines 66 lines

Line mode LF = LF, CR = CR LF = LF, CR = CR

Paper source

Print direction Soft control Soft control

*1

*2

0/60 inch 0/60 inch

Tractor Tractor

3-4

Page 49

Printing

Print Feature Factory Settings

Macro 1 Macro 2

DEC mode

DEC printer ID PPL2 PPL2

Auto wrap Wrap Wrap

EOT disconnect No disconnect on EOT No disconnect on EOT

Initial report No No

Auto answerback No No

Answerback on ENQ No No

DEC G0 character set US ASCII US ASCII

DEC user preference character set DEC Supplemental DEC Supplemental

IBM&Epson mode

Default Character set CP 437 CP 437

IBM mode

IBM set 1 or 2 IBM set 1 IBM set 1

IBM double height No No

IBM AGM No No

Epson mode

Epson national character set USA USA

*1 When you change the Macro selection and the new Top-of-Form value is different from

the former, paper is automatically fed to the next page, using the new Top-of-Form

value.

*2 When you change the Macro selection and the paper source selection is different, the

printer automatically parks the continuous forms (in Push-Feed mode only) or ejects the

cut sheet. The Fault indicator blinks, indicating you should change the position of the

paper select lever.

Note: You cannot attempt to change the Macro selection when the printer is printing,

even if you switch to the Pause state.

3-5

Page 50

Printing

Installation Settings

Print Feature Factory Settings

Language English

Tear Auto, 1 second

Single sheet loading Auto, 2 second

Error beep One

Buffer 64K bytes

Interface type Automatic sense

Auto interface switch time 2 seconds

Baud rate 9600 bps

Bits and parity 8 bits and none

Buffer control XON/XOFF

Disconnected on fault No

Adjustments Settings

Print Feature Factory Settings

Fanfold adjust (continuous forms) 0/60 inch

Manual adjust (single sheets) 0/60 inch

Reserved 1 0/60 inch

Reserved 2 0/60 inch

Menu Access Settings

Print Feature Factory Settings

Menu access All functions allowed

3-6

Page 51

Printing

Selecting a Resident Font

You can use the control panel to select a resident font other than the font specified in the

selected macro or by commands from the computer.

To select a resident font:

1. Switch the printer to the Pause state if you are currently printing.

2. Repeatedly press the Font button 1. The lighted indicator 2 shows the font selected.

2

w

Draft

HSDraft

HiDraft

Courier 10

Comp. 17

Ready

Set-up/Quit

Nimb. PS

Soft Ctrl.

Top

M1

M2

Fault

DEC

PPX24

M1

EP2

M2

Exit/Save

1

Control Panel

Draft: Draft font at any pitch (last active pitch or software pitch)

HSDraft: High-speed draft font at any pitch (last active pitch or software pitch)

HiDraft *: High-impact draft font at any pitch (last active pitch or software pitch)

Courier 10: Courier font at 10 cpi

Prestige 12: Prestige Elite font at 12 cpi

Compress 17: Compressed font at 17 cpi

Bold PS: Boldface font proportionally spaced

Time PS: Timeless font proportionally spaced

Nimb. PS: Nimbus Sans font proportionally spaced

Soft Ctrl: Font selected by commands from the computer

* The HiDraft font optimizes print quality for multipart forms.