Page 1

INSTALLATION

& OPERATION

MANUAL

TRICORE® NARROWSTIKTM

TORUSTM NARROWSTIKTM

Contents:

IMPORTANT:

Introduction (with

Unpacking & Pre-installation ................................................2

Installation ............................................................................2

Wiring Instruction ...............................................................3-5

Product Specications .......................................................... 5

Maintenance-Parts List ......................................................... 6

Trouble Shooting Guide ........................................................ 6

Notes ....................................................................................7

Warranty ...............................................................................8

Read all instructions and warnings before installing and using.

INSTALLER: This manual must be delivered to the end user of this equipment.

warnings

) ...............................................2

Page 2

Introduction

The TriCore® and Torus™ NarrowStik™ are trafc directing devices that will mount in many locations including the back of a light bar or

rear panel of a truck. The NarrowStik Product is a series of lights that point trafc away from the scene of an accident or work site.

The use of this or any warning device does not ensure that all drivers can or will observe or react to an

emergency warning signal. Never take the right-of-way for granted. It is your responsibility to be sure

you can proceed safely before entering an intersection, driving against trafc, responding at a high rate of

speed, or walking on or around trafc lanes.

The effectiveness of this warning device is highly dependent upon correct mounting and wiring. Read and

follow the manufacturer’s instructions before installing or using this device. The vehicle operator should

insure daily that all features of the device operate correctly. In use, the vehicle operator should insure the

projection of the warning signal is not blocked by vehicle components (i.e.: open trunks or compartment

doors), people, vehicles, or other obstructions.

This equipment is intended for use by authorized personnel only. It is the user’s responsibility to

understand and obey all laws regarding emergency warning devices. The user should check all

applicable city, state and federal laws and regulations.

WARNING!

Code 3, Inc., assumes no liability for any loss resulting from the use of this warning device.

Proper installation is vital to the performance of this warning device and the safe operation of the

emergency vehicle. It is important to recognize that the operator of the emergency vehicle is under

psychological and physiological stress caused by the emergency situation. The warning device should

be installed in such a manner as to: A) Not reduce the output performance of the system, B) Place the

controls within convenient reach of the operator so that he can operate the system without losing eye

contact with the roadway.

Emergency warning devices often require high electrical voltages and/or currents. Properly protect and

use caution around live electrical connections. Grounding or shorting of electrical connections can cause

high current arcing, which can cause personal injury and/or severe vehicle damage, including re.

PROPER INSTALLATION COMBINED WITH OPERATOR TRAINING IN THE PROPER USE OF

EMERGENCY WARNING DEVICES IS ESSENTIAL TO INSURE THE SAFETY OF EMERGENCY

PERSONNEL AND THE PUBLIC.

Unpacking & Pre-installation

After unpacking the items, carefully inspect the unit and its associated parts for any damage that may have been caused in transit.

Report any damage to the carrier immediately.

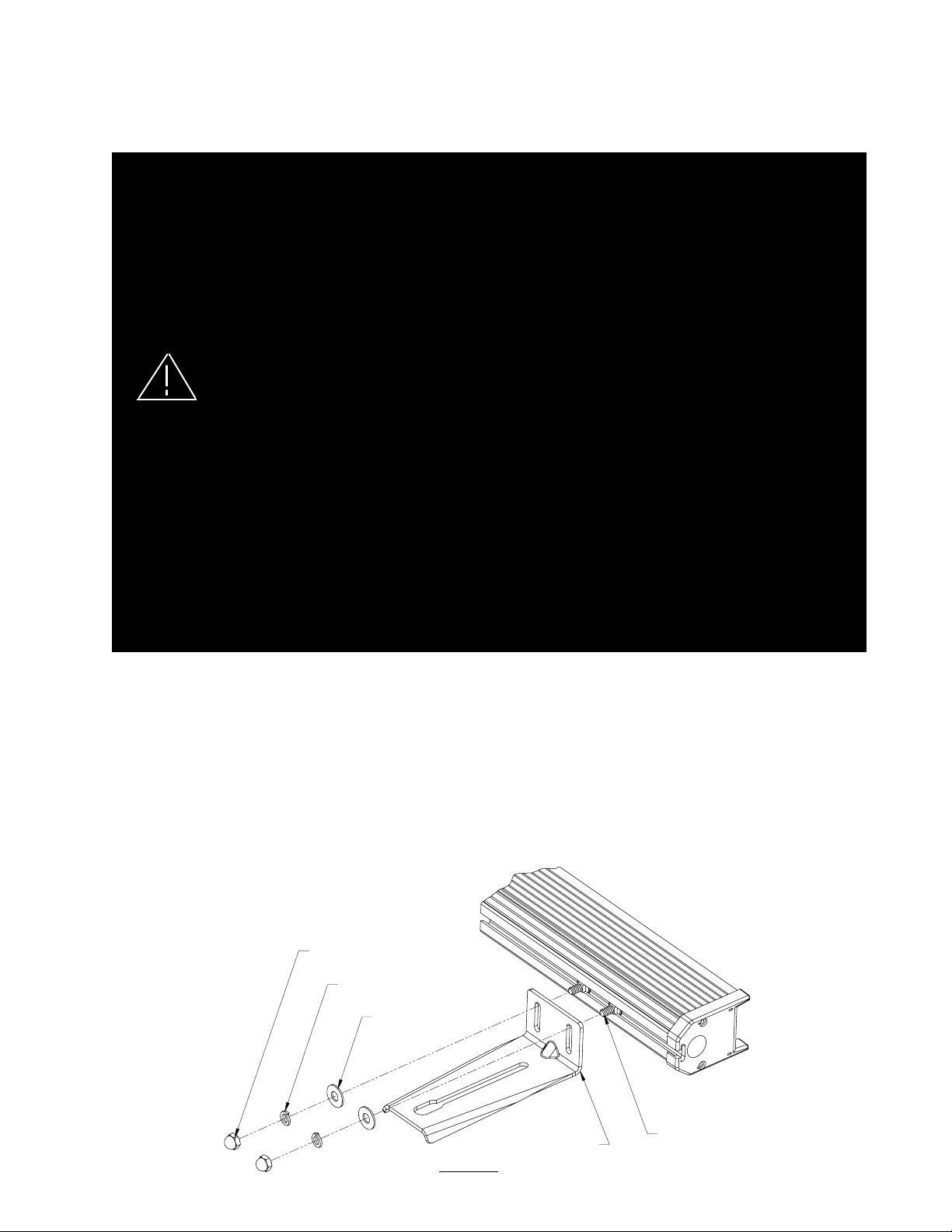

Installation & Mounting

The TriCore® and Torus™ NarrowStik™ were designed with a exible mounting system to allow its use with as many light bars as pos-

sible. Figure-1 below shows the mounting bracket assembly that allows the NarrowStik to be attached to most light bar systems. Ques-

tions about a specic application should be directed to the Technical Hot Line number given on the last page of this manual.

Permanent Mounting

Prior to mounting, consideration must be given to cable location. The cable should exit the end cap on the

Driver's side unless otherwise specied.

1/4"-20 ACORN NUT

1/4" SPLIT WASHER

1/4" FLAT WASHER

FIGURE 1

2

MOUNTING BRACKET

1/4"-20 X 1/2" LG

CARRIAGE BOLT

Page 3

Larger wires and tight connections will provide longer service life for components. For high current wires it

is highly recommended that terminal blocks or soldered connections be used with shrink tubing to protect

the connections. Do not use insulation displacement connectors (e.g. 3M® Scotchlock type connectors).

Route wiring using grommets and sealant when passing through compartment walls. Minimize the number

of splices to reduce voltage drop. High ambient temperatures (e.g. underhood) will signicantly reduce the

current carrying capacity of wires, fuses, and circuit breakers. Use "SXL" type wire in engine compartment.

All wiring should conform to the minimum wire size and other recommendations of the manufacturer and

be protected from moving parts and hot surfaces. Looms, grommets, cable ties, and similar installation

hardware should be used to anchor and protect all wiring. Fuses or circuit breakers should be located

WARNING!

as close to the power takeoff points as possible and properly sized to protect the wiring and devices.

Particular attention should be paid to the location and method of making electrical connections and splices

to protect these points from corrosion and loss of conductivity. Ground terminations should only be made

to substantial chassis components, preferably directly to the vehicle battery. The user should install a

fuse sized to approximately 125% of the maximum Amp capacity in the supply line to protect against

short circuits. For example, a 30 Amp fuse should carry a maximum of 24 Amps. DO NOT USE 1/4"

DIAMETER GLASS FUSES AS THEY ARE NOT SUITABLE FOR CONTINUOUS DUTY IN SIZES ABOVE

15 AMPS. Circuit breakers are very sensitive to high temperatures and will "false trip" when mounted in hot

environments or operated close to their capacity.

Wiring Instructions

Refer to the manual packaged with the 8 Output NarrowStik™ Controller for detailed control head wiring, installation and operation instructions.

Step-1. After installing the Narrowstik, route the cable into the vehicle to where the NarrowStik Control Head will be mounted.

Step-2. Cut the cable to length and strip back the cable insulation.

Step-3. Using a minimum 16 gauge user supplied wire, connect a power wire through a user supplied 15 amp fuse or breaker

from the positive (+12V) side of the battery and route the wire to the NarrowStik Control Head.

Step-4. Using a minimum 16 gauge user supplied black wire, Route a wire from the battery negative (ground) (earth) and using

the 1/4" insulated quick slide located in the NarrowStik Control Head Parts Bag, connect the black 16 gauge wire to the terminal

in the back of the NarrowStik Control Head.

Step-5. Remove the 14 Position Terminal Plug from the back of the Narrowstik Control Head. Connect the user supplied power

wire from Step-3 above and the 10 wires from the TriCore NarrowStik Cable to the 14 Position Terminal Plug as shown in

Figure-2 on page 4. See the Installation Manual for the Narrowstik Control Head for auxiliary wire functions.

Note: The Standard NarrowStik is set up as a Front or Rear Facing System with the cable exiting the Drivers Side. When

installing the Narrowstik with the cable exiting from the Passenger side, the Control Wires will need to be in reverse

order from the Standard. See Figure-3 on page 4 for details.

Step-6. Check all connections for frayed or shorted wires. Insert the plug back into the Narrowstik control head.

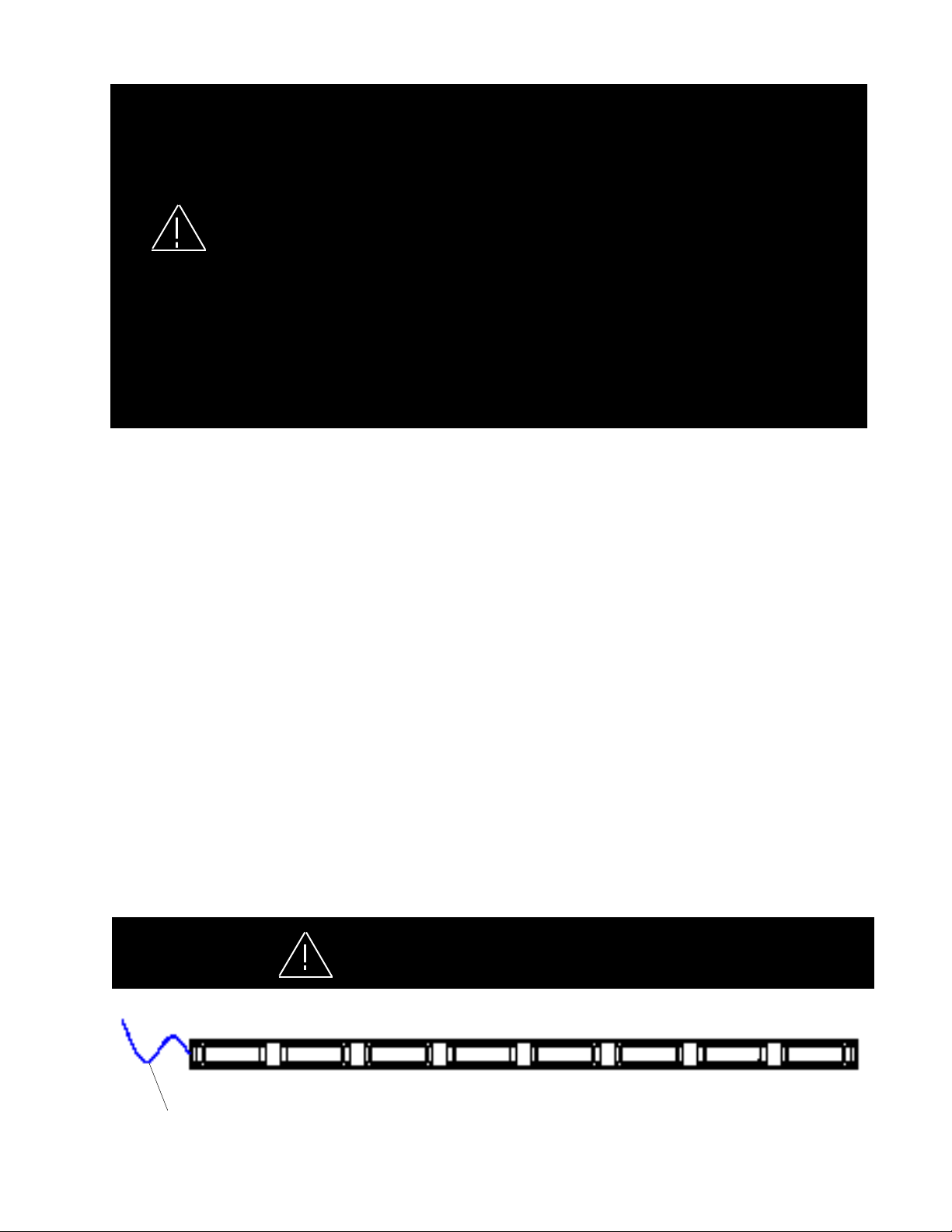

WARNING!

This Product contains high intensity TriCore devices. To prevent eye damage,

DO NOT stare into light beam at close range.

Blue

DRIVER SIDE PASSENGER SIDE

Input Cable

Yellow

Grey Green TanViolet Orange Brown

STANDARD TRICORE & TORUS NARROWSTIK WIRE COLORS - LIGHT HEAD

3

Page 4

TriCore® and Torus™ NarrowStik™ Wire Designations

CABLE ON DRIVERS SIDE

BLUE

YELLOW

GRAY

GREEN

VIOLET

TAN

ORANGE

BROWN

USER SUPPLIED POWER WIRE

RED FROM NARROWSTIK 10 WIRE CABLE

RED/WHT FROM NARROWSTIK 10 WIRE CABLE

STANDARD SYSTEM WITH

BLUE

USER SUPPLIED POWER WIRE

RED FROM NARROWSTIK 10 WIRE CABLE

RED/WHT FROM NARROWSTIK 10 WIRE CABLE

Figure 2

BROWN

ORANGE

TAN

VIOLET

GREEN

GRAY

YELLOW

SYSTEM WITH CABLE

ON PASSENGER SIDE

Figure 3

4

Page 5

Connecting TriCore® or Torus™ NarrowStik™ Cable

to a 5 Output Control Head or RLS System

It may be necessary to t the Narrowstik to a 5 output control system. The required connections are shown below, in Fig. 4, to connect

a 5 output control head or a 5 output RLS. Refer to the 5 output control head user manual, or RLS manual, for control head

operation.

NASLDC, 5 Output Control Head Connections RLS 5 Output Connections

As shown, the Orange and Tan, Violet and Green, and the Grey and Yellow wires will need to be paired into each single output

as indicated. Note that the each wire shown with two color designations is actually representing two individual wires into a

single output.

Figure 4

Dimming

All TriCore and Torus Narrowstik models come equipped with a DIM, low power, mode as standard that allows the user to reduce

the light intensity if desired. The current consumption is also signicantly reduced in this mode (approximately 60%). See the Control

Head manual for details.

The Dim setting reduces the light output of emergency warning lights reducing the effectiveness of

them especially in brightly lit areas. Failure to use adequate light for the circumstances can cause

motorists to fail to see the emergency vehicle and lead to serious personal injury or death. Never

WARNING!

use the DIM setting in a brightly lit area. Use of the DIM setting may cause emergency lights to not

comply with applicable emergency warning light standards. Use caution when using the DIM setting to

assure that motorists can clearly see the emergency vehicle.

Specications

Size: Varies" L X 2-7/8" W X 2" H

Operating Voltage : 10 - 16VDC

Current Draw : 8 Head 6 Head 5 Head

Average : 4 A 3 A 2.5 A

Maximum : 8 A 6 A 5 A

Note: Current consumption is reduced by approximately 60% when in DIM mode.

5

Page 6

Maintenance

The TriCore® and Torus™ NarrowStik™ require minimal routine maintenance. Occasional cleaning of the Light Head Lens is all that is

required to sustain maximum light output. Water or Code 3® lens polish and a very soft cloth is needed for cleaning. The plastic scratches

easily, so cleaning is recommended only when necessary.

Parts List

Name Type Part Number

TriCore Light Heads TriCore Narrowstik Contact Code 3 for Replacements

Chassis Extrusion 30" T09585

40" T07964

47" T07965

Cable 22' TriCore Narrowstik T15222

End Cap T09502

Follow the guide below for information on repair and troubleshooting.

TROUBLESHOOTING GUIDE

Note: TriCore Modules must be replaced as a module. There are no user serviceable parts.

PROBLEM

Light head not

operating when

powered.

WARNING!

QUESTIONS POSSIBLE CAUSE

N/A

Any disassembly of any of the TriCore light heads will result in loss of warranty coverage on the

equipment.

a. Bad power/ground

connection.

b. Defective module.

a. Fix connection.

b. Replace module

SOLUTION

6

Page 7

NOTES

7

Page 8

WARRANTY

This product with TriCore® Technology or Torus technology was tested and found to be operational at

the time of manufacture. Provided this product is installed and operated in accordance with the manufacturer's

recommendations, Code 3®, Inc. warrants all parts and components (with the exception of all incandescent

and halogen bulbs) of the product to be free of defects in material and workmanship for a period of one (1) year

and TriCore light heads for a period of ve (5) years from the date of purchase. This Warranty excludes normal

wear & tear. Units demonstrated to be defective within the warranty period will be repaired or replaced at the

factory service center at no cost. Code 3, Inc. will return the repaired product with transportation cost prepaid.

Code 3, Inc. assumes no liability for expenses incurred in the packaging, handling, and shipping of the product

to the Factory Technical Service Department for repair. For in-warranty product return authorization, questions

regarding product warranty coverage or questions regarding out-of-warranty repair quotes, contact the Factory

Technical Service Department.

The TriCore and Torus light heads are sealed as part of the quality control process. This Warranty is void

if, in the judgment of Code 3, Inc. (1) an attempt has been made to break the light head seal or repair the light

head, and/or (2) the product has been used with inappropriate or inadequate wiring or circuit protection, and/or

(3) the product has failed as a result of abuse or unusual use and/or accidents.

CODE 3, INC. SHALL IN NO WAY BE LIABLE FOR ANY OTHER DAMAGES RELATING TO THE

PRODUCT INCLUDING BUT NOT LIMITED TO CONSEQUENTIAL, INCIDENTAL, INDIRECT OR SPECIAL DAMAGES OR LOST PROFITS OR REVENUE; NOR ANY EXPENSES INCURRED IN THE REMOVAL AND/OR RE-INSTALLATION OF PRODUCTS REQUIRING SERVICE AND/OR REPAIR.

EXCEPT AS SET FORTH ABOVE, CODE 3, INC. MAKES NO OTHER EXPRESS OR IMPLIED

WARRANTIES WHATSOEVER, INCLUDING, WITHOUT LIMITATION, WARRANTIES OF FITNESS FOR A

PARTICULAR PURPOSE OR MERCHANTABILITY, WITH RESPECT TO THIS PRODUCT.

NEED HELP? Call our Technical Assistance HOTLINE - (314) 996-2800

PRODUCT RETURNS

If a product must be returned for repair or replacement*, please contact our factory to obtain a Return

Goods Authorization Number (RGA number) before you ship the product to Code 3, Inc. Write the RGA number

clearly on the package near the mailing label. Be sure you use sufcient packing materials to avoid damage to

the product being returned while in transit.

*Code 3, Inc. reserves the right to repair or replace at its discretion. Code 3, Inc. assumes no responsibility or liability for expenses incurred for the removal and /or

reinstallation of products requiring service and/or repair.; nor for the packaging, handling, and shipping: nor for the handling of products returned to sender after the service has been

rendered.

Code 3 and TriCore are registered trademarks of Code 3, Inc. a subsidiary of Public Safety Equipment, Inc.

Code 3®, Inc.

St. Louis, Missouri 63114-2029—USA

Ph. (314) 426-2700 Fax (314) 426-1337

Revision 1, 01/2013- Instruction Book Part No.T15231

10986 N. Warson Road

www.code3pse.com

©2013, Code 3, Inc. Printed in USA

Loading...

Loading...