Page 1

INSTALLATION

& OPERATION

MANUAL

TM

MODEL 430

Model 430

SWITCH CONTROL

Contents:

Introduction ...................................................... 2

Safety First..................................................................3

Unpacking & Pre-Installation........................... 3

Installation......................................................... 4

Wiring...............................................................5

Parts List ........................................................... 6

Warranty............................................................ 8

TM

IMPORTANT:

Read all instructions and warnings before installing and using.

INSTALLER: This manual must be delivered to the end user of this equipment.

Page 2

Introduction

The Switch Box switch control panel is designed to accommodate six rocker type switches, which are used to

control various vehicle mounted devices. Six legend inserts are installed above the switches as shown in figure

1 and 2. Six additional legend inserts are included as part of the accessory kit packed with the switch module.

A thermal lock out type circuit breaker, rated at 40 amps, protects the rotating light circuit (#1). The circuit of

one load current is rated at 40 amps. The other circuits (2 through 6) are protected by automotive blade type

fuses rated at 20 amperes.

The switch module is designed to be installed in a vehicle mounting surface to mate with other devices of the

same width.

It can be installed on top of TSD style panels, trunion mount, and many other types of the same width. It may

be used with various models of electronic sirens with the hardware included in the accessory kit, and secured to

the mounting surface with the bracket included with the electronic siren.

Sizes, ratings and switches: the switches are a rugged unit and rated at 20 amperes @ 12 VDC. The panel's

dimensions are 2 3/16" x 6 1/16" x 5 7/8" (including fuses). Overall weight of the unit is 2 pounds.

FIGURE 1

!

WARNING!

The use of this or any warning device does not insure that all drivers can or will observe or

react to an emergency warning signal. Never take the right-of-way for granted. It is your

responsibility to be sure you can proceed safely before entering an intersection, driving

against traffic, responding at a high rate of speed, or walking on or around traffic lanes.

The effectiveness of this warning device is highly dependent upon correct mounting and

wiring. Read and follow the manufacturer’s instructions before installing or using this

device. The vehicle operator should insure daily that all features of the device operate

correctly. In use, the vehicle operator should insure the projection of the warning signal is

not blocked by vehicle components (i.e.: open trunks or compartment doors), people,

vehicles, or other obstructions.

This equipment is intended for use by authorized personnel only. It is the user’s responsibility to understand and obey all laws regarding emergency warning devices. The user

should check all applicable city, state and federal laws and regulations.

Public Safety Equipment, Inc., assumes no liability for any loss resulting from the use of

this warning device.

Proper installation is vital to the performance of this warning device and the safe operation

of the emergency vehicle. It is important to recognize that the operator of the emergency

vehicle is under psychological and physiological stress caused by the emergency situation.

The warning device should be installed in such a manner as to: A) Not reduce the output

performance of the system, B) Place the controls within convenient reach of the operator

so that he can operate the system without losing eye contact with the roadway.

Emergency warning devices often require high electrical voltages and/or currents. Properly

protect and use caution around live electrical connections. Grounding or shorting of

electrical connections can cause high current arcing, which can cause personal injury and/

or severe vehicle damage, including fire. Incandescent lamps are extremely hot, allow to

cool completely before attempting to remove.

Any electronic device may create or be affected by electromagnetic interference. After

installation of any electronic device operate all equipment simultaneously to insure that

operation is free of interference. Never power emergency warning equipment from the

same circuit or share the same grounding circuit with radio communication equipment.

PROPER INSTALLATION COMBINED WITH OPERATOR TRAINING IN THE PROPER

USE OF EMERGENCY WARNING DEVICES IS ESSENTIAL TO INSURE THE SAFETY

OF EMERGENCY PERSONNEL AND THE PUBLIC.

2

Page 3

Safety First

Installers should keep in mind the importance of safe installation to protect the lives of those who may depend

upon this equipment. Please read all instructions supplied with this equipment. Listed below are some other

important safety instructions to follow:

To properly install the equipment described in this instruction sheet: you must have a good

understanding of automotive electrical procedures and systems, along with proficiency in the

installation and use of safety warning equipment.

Locate the switch module so the vehicle and controls can be operated safely under all driving

conditions.

When drilling into a vehicle structure, be sure that both sides of the surface are clear of anything

that could be damaged.

Keep these instructions in a safe place and refer to them when maintaining and/or reinstalling the

product.

Failure to follow all safety precautions and instructions may result in property damage, serious injury, or death

to you or others.

Unpacking & Pre-installation

Carefully remove the Switch Control from the shipping carton and place on a flat surface, taking care not to

damage the wire cable coming out of the back of control box. Examine the unit for transit damage, dented

cover, ect.. If convenient, you may wish to bench test the unit before installing. Before applying voltage to the

bar, be sure you have read and understand the wiring instructions on page 5.

FIGURE 2

3

Page 4

Installation

All devices should be mounted in accordance with the manufacturer's instructions and

securely fasten to vehicle elements of sufficient strength to withstand the forces applied to

!

WARNING!

WARNING!

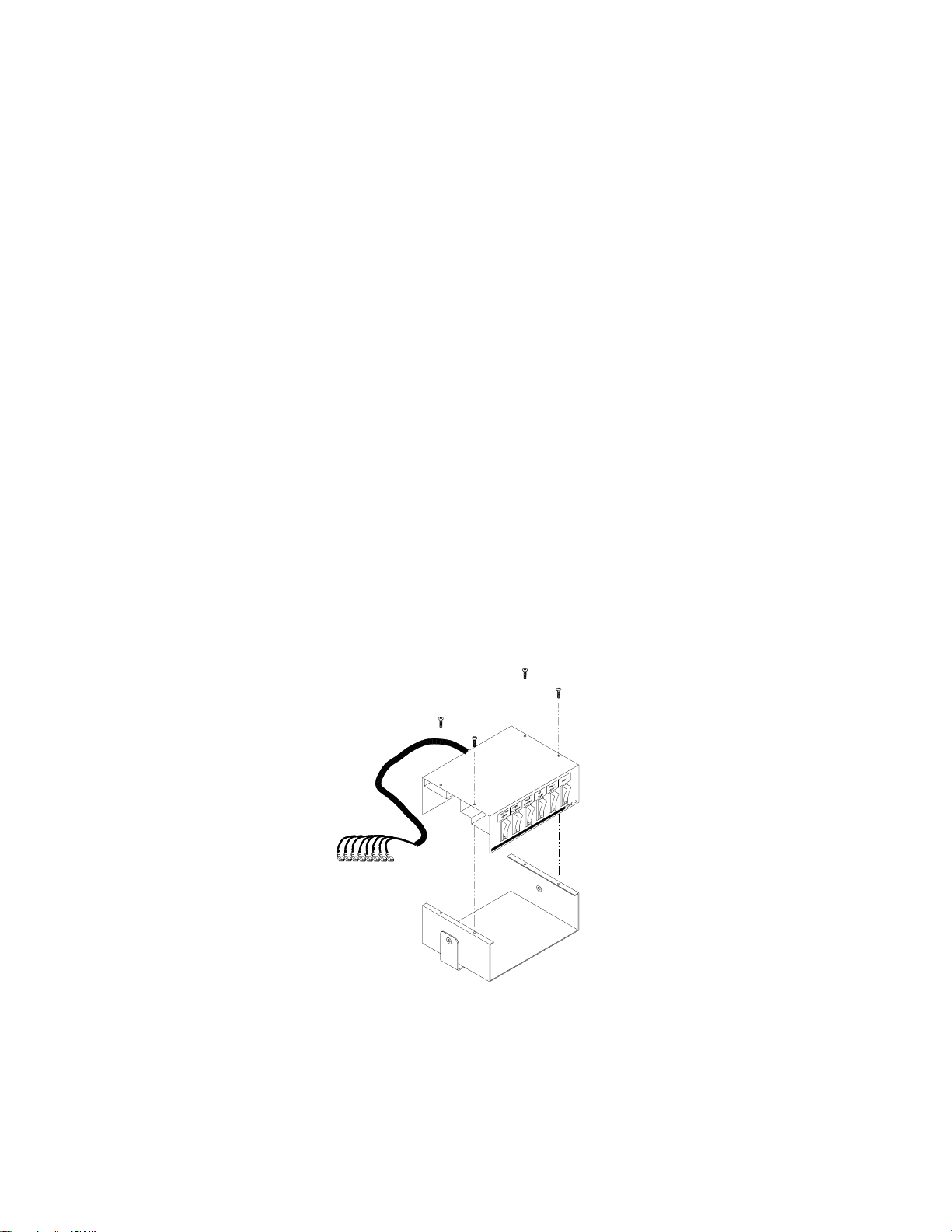

To install the Switch Box follow the installation instructions. There are several ways you may install this unit,

but if it is installed with the TSD trunion mounting bracket, you will need to follow the instructions provided for

the "CO" series brackets.

If you choose to mount this unit by a bail bracket (not provided), then follow the instructions that come with our

bail brackets.

The Switch Box may be mounted on top of or below a siren system. If this is your choice, then follow

the instructions below:

the device. Driver and/or passenger air bags (SRS) will affect the way equipment should

be mounted. This device should be mounted by permanent installation and within the

zones specified by the vehicle manufacturer, if any. Any device mounted in the deployment area of an air bag will damage or reduce the effectiveness of the air bag and may

damage or dislodge the device. Installer must be sure that this device, its mounting

hardware and electrical supply wiring does not interfere with the air bag or the SRS wiring

or sensors. Front or rear grille/bumper placement must avoid interference with SRS

sensors. Mounting the unit inside the vehicle by a method other than the permanent

installation is not recommended as unit may become dislodged during swerving, sudden

braking, or collision. Failure to follow instructions can result in personal injury.

1) Select a mounting location which allows the vehicle and all controls to be

operated safely under all driving conditions.

2) Choose an adequately ventilated area. Never install near heat ducts or totally

enclosed areas.

3) Arrange the bottom of the switch control unit so that it is even with the siren face

module. Fasten the two units together with trunion mounts or brackets (not provided)

from both sides. You may need to remove the switch control for the housing. If this is

the case, it will require the removal of four phillips head screws located on top of the

switch control housing.

4) Secure the case with 1/4" - 20 x 5/8" hex head screws and 1/4" split lockwasher

(provided in kit). Do not tighten securely until a proper angle is positioned for safe

operator visibility.

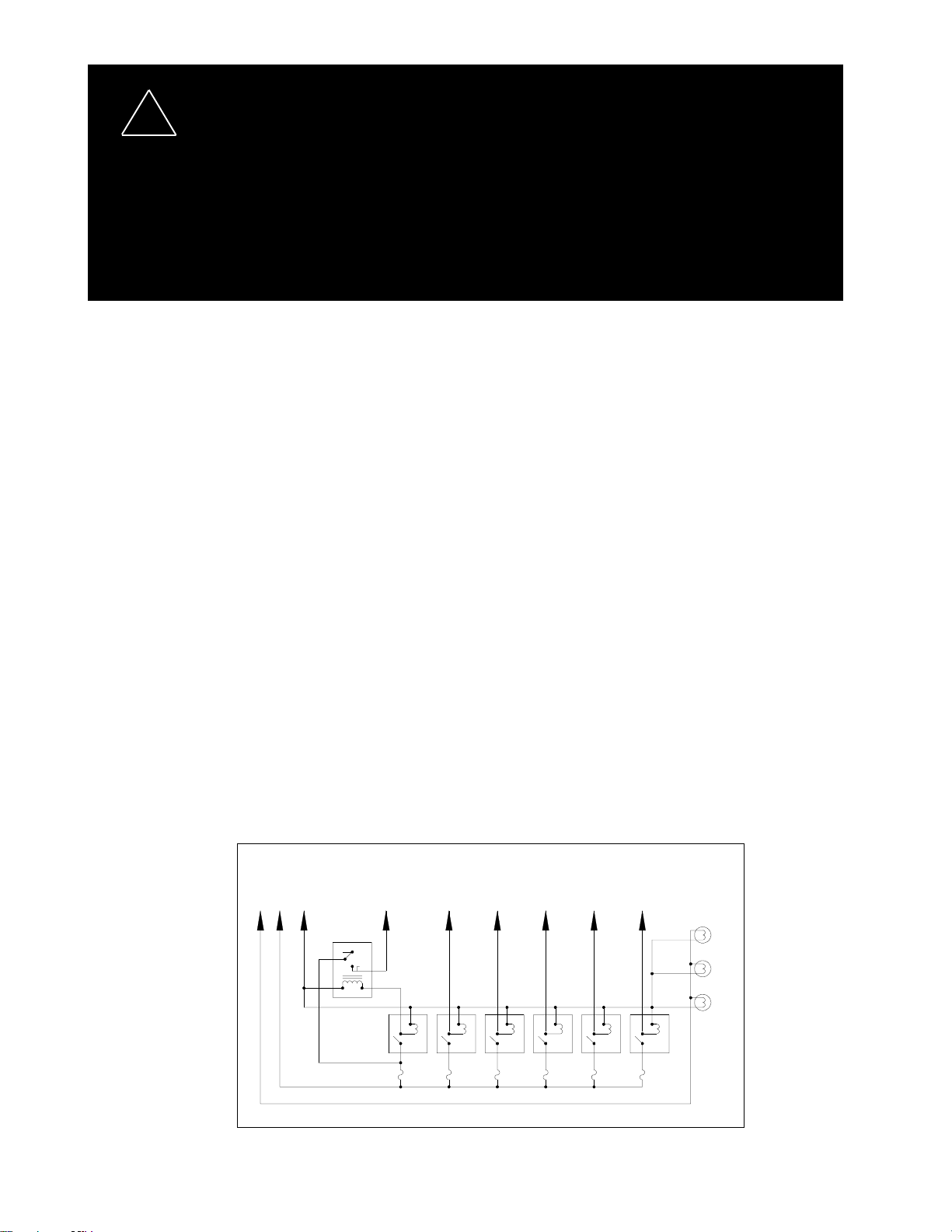

B H G 1 2 3 4 5 6 PANEL

+ + GND LIGHTS

BATT.

F1 F2 F3 F4 F5 F6

+ BATTERY 40A 20A 20A 20A 20A 20A

BACK LIGHTING

WIRING DIAGRAM

FIGURE 3

4

Page 5

WARNING!

Wiring

!

WARNING!

5) Tilt the unit to the desired position and tighten the 1/4" - 20 x 3/8" hex head

screws.

6) Use the mounting bracket as a templet and position for two hole by marking the

position with a scribe. Drill holes for positioning the mounting bracket.

CAUTION: When drilling holes in any part of the vehicle, make sure that both sides

of the surface are clear of parts that could be damaged; such as brake lines,

electrical wiring, fuel lines, or other vital parts of the vehicle.

7) Drill two 1/4" diameter holes at the position marked.

8) Secure the mounting bracket in place. Make sure all positions are tight and

screws secured in place.

NOTE: Many other locations may be of better choice for your operation. If other

locations are selected, use every precautionary measure to safely install to prevent

damage to the vehicle.

Larger wires and tight connections will provide longer service life for components. For high

current wires it is highly recommended that terminal blocks or soldered connections be used

with shrink tubing to protect the connections. Do not use insulation displacement

connectors (e.g. 3M® Scotchlock type connectors). Route wiring using grommets and

sealant when passing through compartment walls. Minimize the number of splices to

reduce voltage drop. High ambient temperatures (e.g. underhood) will significantly reduce

the current carrying capacity of wires, fuses, and circuit breakers. Use "SXL" type wire in

engine compartment. All wiring should conform to the minimum wire size and other

recommendations of the manufacturer and be protected from moving parts and hot

surfaces. Looms, grommets, cable ties, and similar installation hardware should be used to

anchor and protect all wiring.

Fuses or circuit breakers should be located as close to the power takeoff points as possible

and properly sized to protect the wiring and devices.

Particular attention should be paid to the location and method of making electrical

connections and splices to protect these points from corrosion and loss of conductivity.

Ground terminations should only be made to substantial chassis components, preferably

directly to the vehicle battery.

The user should install a fuse sized to approximately 125% of the maximum Amp capacity

in the supply line to protect against short circuits. For example, a 30 Amp fuse should

carry a maximum of 24 Amps. DO NOT USE 1/4" DIAMETER GLASS FUSES AS THEY

ARE NOT SUITABLE FOR CONTINUOUS DUTY IN SIZES ABOVE 15 AMPS. Circuit

breakers are very sensitive to high temperatures and will "false trip" when mounted in hot

environments or operated close to their capacity.

Figure 2 illustrates the correlation of tagged wires to a corresponding operation. Example: Switch one (starting

from left to right) controls the electronic operation of the wire tagged as #1.

Insulated male terminals, which mate with the female terminals on the switch module wiring harness, have

been included in the accessory kit to facilitate installation. These terminals should be installed on the end of

the lead wire which will mate with the wiring harness lead wire. Use yellow terminals for 10-12 AWG wire and

pink terminals for 18-22 AWG wire.

NOTE: When using the insulated terminals, insure that all crimps are secure and that the male/female

terminals slip into each other and not over each other.

5

Page 6

To properly wire the switch module, see the wiring diagram shown in figure 3 and perform the following

procedures:

1) Use 12 AWG wire and connect leads "1" through "6" to the applicable accessory

load. Remember: lead "1" corresponds to switch "1", lead "2" to switch "2", and so

on.

2) Use 18 AWG wire and connect the ground (earth) lead "G" to a reliable ground

(earth). Each switched device must be grounded with a separate ground (earth) wire.

3) Use 18 AWG wire and connect the backlighting circuit lead "B" to the accessory

terminal of the ignition switch or the vehicle instrument light circuit.

4) Power for the switch module may be obtained from a vehicle power distribution

center (TSD part number D1X1F-PD90) or by a 60, 80, or 100 amp master circuit

breaker (call TSD for part number required). We recommend that all circuits be

protected by fuses or circuit breakers. Installation of a power distribution center or

master circuit breaker should be placed near the battery. Use 8 AWG wire and

connect the power distribution center. If power is obtained in the engine

compartment, a hole will probably have to be drilled into the vehicle firewall. Place a

grommet or similar device in the hole to protect the wire (S) against damage from

rough edges.

CAUTION: When drilling holes in any part of any of the vehicle, ensure that both sides of the surface are clear

of parts that could be damaged: such as brake lines, electrical wiring, fuel lines, or any other vital part of the

vehicle.

Parts List

Description Qty.

1/4" - 20 x 5/8" bolts 2

1/4" lock washer 2

wire ties 2

insulated 1/4" male terminals (yellow) 7

insulated 1/4" male terminals (pink) 2

legend inserts, (TAKE DOWN, GRILLE LIGHTS, DECK LIGHTS, 8

STROBE,AUX., WIGWAG, FRT/REAR FLASHER, (CENTER &

SWEEPS))

6

Page 7

NOTES

7

Page 8

WARRANTY

This product was tested and found to be operational at the time of manufacture. Provided this product is

installed and operated in accordance with the manufacturer's recommendations, Public Safety Equipment

guarantees all parts and components except the lamps for a period of 1 year from the date of purchase or

delivery, whichever is later. Units demonstrated to be defective within the warranty period will be repaired or

replaced at the factory service center at no cost.

Use of a lamp or other electrical load of a wattage higher than installed or recommended by the factory,

or use of inappropriate or inadequate wiring or circuit protection causes this warranty to become void. Failure

or destruction of the product resulting from abuse or unusual use and/or accidents is not covered by this

warranty.

PSE shall in no way be liable for other damages including consequential, indirect or special damages

whether loss is due to negligence or breach of warranty.

PSE MAKES NO OTHER EXPRESS OR IMPLIED WARRANTY INCLUDING, WITHOUT LIMITATION, WARRANTIES OF FITNESS OR MERCHANTABILITY, WITH RESPECT TO THIS PRODUCT.

PRODUCT RETURNS

If a product must be returned for repair or replacement*, please contact our factory to obtain

a Return Goods Authorization Number (RGA number) before you ship the product to Code 3, Inc.

Write the RGA number clearly on the package near the mailing label. Be sure you use sufficient

packing materials to avoid damage to the product being returned while in transit.

*Code 3, Inc. reserves the right to repair or replace at its discretion. Code 3, Inc. assumes no responsibility or liability for expenses incurred for the

removal and /or reinstallation of products requiring service and/or repair.; nor for the packaging, handling, and shipping: nor for the handling of products return to

sender after the service has been rendered.

Public Safety Equipment, Inc.

St. Louis, Missouri 63114-2029USA

Ph. (314) 426-2700 Fax (314) 426-1337

10986 N. Warson Road

www.code3pse.com

Code 3 is a registered trademarks of

Public Safety Equipment, Inc.

Revision 3, 10/01 - Instruction Book Part No. T04922

©2001 Public Safety Equipment, Inc. Printed in USA

Page 9

Wiring

&

Installation

Guide

415 Series

Rocker Switch

Control Panels

Contents:

DESCRIPTION PAGE

GENERAL INSTRUCTIONS 2

MODEL 415F 2

MODEL 415PO 2

MODEL 415PR 2

MODEL 415PS 3

MODEL 415T 3

STINGRAY HOOK-UP 3

PARTS AND SWITCHES 5

WIRE REQUIREMENTS 5

MOUNTING WITH SIREN 6

PTO HOOK-UP 6

Page 10

The Code 3 RockerPak Series Lighting Control is a reliable and versatile

unit with options that allow customized switch packages. The variety of final

products is too great to be shown here in its entirety, but factory wiring

makes the installation similar to the following examples in most cases.

R

The Code 3 RockerPak Series Lighting Control

is a reliable and versatile

General Instructions

1. Determine whether your control unit should be wired from the vehicle's

battery or ignition circuitry, depending on the need for security and/or total

access.

2. See the hook-up details for your model(s) as shown below. If you have a

non-standard model, use the hook-up for the model having the same switch

in the position illustrated.

3. Use #10 A.W.G. wire feed +(POS)12-volt supply to circuit breaker or

fuse, then to switch unit. Circuit protection should be rated at 125% of the

total load. Units with factory installed circuit breakers or fuse stacks may be

straight wired without additional protection.

4. Units with Legend Backlighting may be hooked up as provided if you

choose to operate the system from the ignition circuit. If you plan to operate

with the switches always live, carefully cut the single red feed line to the

backlighting light bulbs and use a butt-splice connector to provide power

from the ignition circuit to prevent battery discharge. Remove the cut off end

to prevent short circuits.

5. IMPORTANT: You will save time and protect the switches from damage

by carefully aligning the male and female spade connectors before inserting.

Use free hand on the rocker switch face to oppose insertion force.

6. Connect from vehicle chassis to switch unit ground (black wire) using #18

A.W.G. wire.

7. Connect each switch to the appropriate device using recommended wire

sizes from the table on page 5, with fuses rated at 125% of each individual

wire load. Do not fuse higher than the switch rating.

Models 415F, 415PR and 415PO

Use for any control with DPST switch (40 amps) in this position

2

Page 11

Models 415PS

Use this hook-up for any control having StringRay switching circuits.

GROUND

ddddd

TM

IMPORTANT NOTE:

The STINGRAY and ROTATE switches are

wired together to provide the unique operational

features of the StingRay oscillating signal. These

switches may be activated at the same time; however

ROTATE overrides STINGRAY R (Rear only). STINGRAY F (Front only) overrides

ROTATE and does not operate unless ROTATE is also activated. The ROTATE

switch will be lighted whenever the warning lights are lit.

Model 415T and all models with Circuit Breakers

Use this hook-up (as shown on right) for any control furnished with circuit

breakers. See page 6 for PTO bracket installation.

1

3

Page 12

Individual Switches Wiring & Hook-up

Rear view of switches- -top is up.

Lighted SPST

P/N T02811

Lighted Progressive

P/N T02824

Lighted SPDT

P/N T02812

Non-Lighted SPST

Momentary

P/N T02813

Lighted DPST

P/N T02821

Non-Lighted SPDT

Momentary

P/N T02815

Non-Lighted DPDT

Radio Rebroadcast

P/N T02823

4

Fuse Stack

P/N S38033

Fuse Stack

P/N S38033

Page 13

RECOMMENDED MINIMUM WIRE SIZES

AMP DRAW MIN. WIRE SIZE

Below 5 #18 AWG

5-8 #16 AWG

9-13 #14 AWG

14-21 #12 AWG

22-36 #10 AWG

NOTE: Larger wires and tight connections will provide longer service life for

switches and improve lighting performance. High ambient temperatures

(e.g. under hood) will significantly reduce the current carrying capacity of wires,

BASED ON 15-FOOT WIRE RUN

fuses and circuit breakers.

PARTS AND SWITCHES

SPST Single Pole, Single Throw switch; controls a single circuit.

SPDT Single Pole, Double Throw switch; controls either one or two circuits.

DPST Double Pole, Single Throw switch; high amperage single circuit.

DPDT Double Pole, Double Throw switch; for radio rebroadcast.

Radio Rebroadcast Transfers radio messages to siren speaker.

Momentary Remains active only while held, springs back to OFF.

Progressive Turns two functions on or off in a set sequence.

NUMBER TYPE APPLICATION POSITIONS LIGHTED RATING

T02811 SPST Single circuit OFF-ON YES 20 amp

T02812 SPDT Alternate circ. ON-OFF-ON YES 20 amp

T02813 SPST Momentary OFF-MomON NO 8 amp

T02814 Blank Fills hole NO

T02815 SPDT Moment/Moment ON-OFF-ON NO 8 amp

T02820 - Red Indicator Light YES T02821 DPST High Amperage OFF-ON YES 40 amp

T02822 SPDT StringRay switch ON-OFF-0N NO 20 amp

T02823 DPDT Radio Rebroadcast ON-ON NO 8 amp

T02824 PROG Progressive OFF-ON-ON YES 20 amp

T02838 Auto Reset Circuit Breaker - 40 amp

T02871 Push Button Switch (415T only) OFF-ON NO 1 amp

T02872 Actuator Disk (PTO unit only)

S38033 Fuse Stack (Factory Upgradecannot be field installed)

S38046 Backlighting Assembly (Bulbs with wires only)

S38049 Backlighting Assembly (Complete)

S38093 Floor-mounting Bracket, PTO Control

S25013 RockerPak Mounting Bracket (2 required)

Parts not listed should be purchased locally

5

Page 14

Suggested Mounting with V-Con Siren

R

PTO Mounting Bracket Hook-up

PTO KNOB

PTO CABLE

6

Page 15

N

NOTES

7

Page 16

Code 3, Inc.s emergency devices are tested and found to be operational at the time of manufacture.

Provided they are installed and operated in accordance with manufacturers recommendations, Code 3, Inc.

guarantees all parts and components except the lamps to a period of 1 year (unless otherwise expressed) from the

date of purchase or delivery, whichever is later. Units demonstrated to be defective within the warranty period will

be repaired or replaced at the factory service center at no cost.

Use of lamp or other electrical load of a wattage higher than installed or recommended by the factory, or use

of inappropriate or inadequate wiring or circuit protection causes this warranty to become void. Failure or destruction

of the product resulting from abuse or unusual use and/or accidents is not covered by this warranty. Code 3, Inc. shall

in no way be liable for other damages including consequential, indirect or special damages whether loss is due to

negligence or breach of warranty.

CODE 3, INC. MAKES NO OTHER EXPRESS OR IMPLIED WARRANTY INCLUDING,

WITHOUT LIMITATION, WARRANTIES OF FITNESS OR MERCHANTABILITY, WITH

RESPECT TO THIS PRODUCT.

PRODUCT RETURNS

If a product must be returned for repair or replacement*, please contact our factory to

obtain a Return Goods Authorization Number (RGA number) before you ship the product

to Code 3, Inc. Write the RGA number clearly on the package near the mailing label. Be

sure you use sufficient packing materials to avoid damage to the product being returned

while in transit.

*Code 3, Inc. reserves the right to repair or replace at its discretion. Code 3, Inc. assumes no responsibility or liability for expenses incurred for the removal

and /or reinstallation of products requiring service and/or repair.; nor for the packaging, handling, and shipping: nor for the handling of products return to sender after the service

has been rendered.

WARRANTY

8

Public Safety Equipment, Inc.

St. Louis, Missouri 63114-2029USA

Ph. (314) 426-2700 Fax (314) 426-1337

Revision C, 11/00 - Instruction Book Part No.T02887

©2000 Public Safety Equipment, Inc. Printed in USA

10986 N. Warson Road

Code 3,® Inc., a subsidiary of

Public Safety Equipment, Inc.

Page 17

INSTALLATION

& OPERATION

MANUAL

Introduction

The 416 Switchbox is a 6 switch control center

without circuit breakers. The model 426 is the same

6 switch control center protected by 3 circuit breakers.

The 426 also offers backlighting as standard

equipment. Backlighting is optional on the 416.

Procedure

Wiring Instructions:

1) The installer needs to first determine the

current load in amps of each of the devices

to be switched by the Switchbox.

2) Connect the devices to the desired switch,

noting the current limitations of each switch

and group of switches.

3) An 8 gauge wire should be run from the

Red 8 gauge Switchbox input wire to a

user supplied fuse, then to the (+) side of

the battery, the alternator, or the stud on

the battery side of the solenoid. The user

supplied fuse should be located as close

to the battery as possible and sized to

125% of the total load carried by the

Switchbox (i.e.: if the total load carried is

40 amps; 40 amps x 125% = 50 amp fuse).

A circuit breaker is not recommended

here, they are very sensitive to high

ambient temperatures and will false trip

416 Switchbox

4) Connect the black wire to vehicle chassis

Larger wires and tight connections (crimp

!

WARNING!

Customer supplied

fuse (sized to 125%)

40 amp

breaker

MODEL 416/ 426

SWITCHBOX

when mounted in hot environments or

operated close to their capacity. Do not use

1/4" dia. glass fuses as they are not suitable

for continuous duty in sizes above 15 amps.

(earth).

connectors perform poorly over time) will

provide longer service life for components. It

is highly recommended that terminal blocks

or soldered connections be used with shrink

tubing to protect the connections. Do not use

insulation displacement connectors (e.g. 3M®

Scotchlock type connectors). Route wiring

using grommets and sealant when passing

through compartment walls. Minimize the

number of splices to reduce voltage drop.

High ambient temperatures (e.g. under hood)

will significantly reduce the current carrying

capacity of wires, fuses, and circuit breakers.

Use "SXL" type wire in engine compartments.

426 Switchbox

Battery

(+) 12 Volt ignition circuit

white/ black wire

Vehicle chassis (earth)

18 ga. black wire

8 ga red input

20 amp

breaker

Panel backlighting

20 amp

breaker

Customer supplied

fuse (sized to 125%)

8 ga red

input

32 amps 16 amps 16 amps 10 amps 10 amps 10 amps

32 amps 16 amps 16 amps

Battery

10 ga.

red/ black

55 amps max load for entire Switchbox

14 ga.

white

2

IMPORTANT:

16 ga.

yellow/

black

6

16 ga.

orange

14 ga.

purple

3

16 ga.

16 ga.

yellow/

blue

45

black

Vehicle chassis (earth)

18 ga. black wire

16 ga.

orange

61

10 ga.

red/ black

1

32 amps 16 amps 16 amps 10 amps 10 amps 10 amps

32 amps

55 amps max load for entire Switchbox

14 ga.

white

2

16 amps 16 amps

14 ga.

purple

3

16 ga.

blue

4

5

Read all instructions and warnings before installing and using.

INSTALLER: This manual must be delivered to the end user of this equipment.

Page 18

!

WARNING!

The use of this or any warning device does not insure that all drivers can or will observe or

react to an emergency warning signal. Never take the right-of-way for granted. It is your

responsibility to be sure you can proceed safely before entering an intersection, driving

against traffic, responding at a high rate of speed, or walking on or around traffic lanes.

The effectiveness of this warning device is highly dependent upon correct mounting and

wiring. Read and follow the manufacturers instructions before installing or using this device.

The vehicle operator should insure daily that all features of the device operate correctly. In

use, the vehicle operator should insure the projection of the warning signal is not blocked by

vehicle components (i.e.: open trunks or compartment doors), people, vehicles, or other

obstructions.

This equipment is intended for use by authorized personnel only. It is the users responsibility to understand and obey all laws regarding emergency warning devices. The user should

check all applicable city, state and federal laws and regulations.

Public Safety Equipment, Inc., assumes no liability for any loss resulting from the use of

this warning device.

2

Page 19

NOTES

3

Page 20

WARRANTY

This product was tested and found to be operational at the time of manufacture. Provided this product

is installed and operated in accordance with the manufacturer's recommendations, Public Safety Equipment

guarantees all parts and components except the lamps for a period of 1 year from the date of purchase or

delivery, whichever is later. Units demonstrated to be defective within the warranty period will be repaired or

replaced by the factory or at a factory authorized service center at no cost.

Use of a lamp or other electrical load of a wattage higher than installed or recommended by the factory

causes this warranty to become void. Failure or destruction of the product resulting from abuse or unusual

use and/or accidents is not covered by this warranty.

PSE shall in no way be liable for other damages including consequential, indirect or special damages

whether loss is due to negligence or breach of warranty.

PSE MAKES NO OTHER EXPRESS OR IMPLIED WARRANTY INCLUDING, WITHOUT LIMITATION,

WARRANTIES OF FITNESS OR MERCHANTABILITY, WITH RESPECT TO THIS PRODUCT.

PRODUCT RETURNS

In order to provide you with faster service, if you are going to return a product for repair or replacement*, please contact our factory to obtain a Return Goods Authorization Number (RGA number) before you

ship the product to PSE. Write the RGA number clearly on the package near the mailing label. Be sure you

use sufficient packing materials to avoid damage to the product being returned while in transit.

*PSE reserves the right to repair or replace product at its discretion. PSE assumes no responsibility or liability for

expenses incurred for the removal and/or reinstallation of products requiring service and/or repair.

Code 3 is a registered trademark of Public Safety Equipment, Inc.

3M is a registered trademark of 3M Company, Inc.

Public Safety Equipment, Inc.

St. Louis, Missouri 63114-2029USA

Ph. (314) 426-2700 Fax (314) 426-1337

Revision 4, 5/02 - Instruction Book Part N0 T06581

©2002 Public Safety Equipment, Inc. Printed in USA

10986 N. Warson Road

www.code3pse.com

Loading...

Loading...