Page 1

INSTALLATION

& OPERATION

MANUAL

ASL1060H

ASLSP10H

ASLC1060H

LARGE LED

NARROWSTIK™

Contents:

Introduction (with

Models................................................................................2

Unpacking & Pre-installation............................................... 2

Installation & Mounting ........................................................2

Assembly Diagrams............................................................3

Wiring Instructions .......................................................... 4-10

Specifications.................................................................... 10

Maintenance......................................................................10

Troubleshooting ................................................................ 11

Notes.................................................................................11

Warranty ............................................................................ 12

warnings

)..............................................2

IMPORTANT:

Read all instructions and warnings before installing and using.

INSTALLER: This manual must be delivered to the end user of this equipment.

1

Page 2

Introduction

The Large LED Narrowstik® is a traffic directing device that will mount in many locations. The Large LED Narrowstik is a series of

lights that point traffic away from the scene of an accident or work site and utilizes state-of-the-art High-Flux L.E.D. lightheads. These

lightheads last longer and use much less current than standard incandescent lamps.

The use of this or any warning device does not insure that all drivers can or will observe or react

to an emergency warning signal. Never take the right-of-way for granted. It is your responsibility

to be sure you can proceed safely before entering an intersection, driving against traffic,

responding at a high rate of speed, or walking on or around traffic lanes.

The effectiveness of this warning device is highly dependent upon correct mounting and wiring.

Read and follow the manufacturer’s instructions before installing or using this device. The

vehicle operator should insure daily that all features of the device operate correctly. In use, the

vehicle operator should insure the projection of the warning signal is not blocked by vehicle

components (i.e.: open trunks or compartment doors), people, vehicles, or other obstructions.

This equipment is intended for use by authorized personnel only. It is the user’s responsibility

to understand and obey all laws regarding emergency warning devices. The user should check

all applicable city, state and federal laws and regulations.

!

WARNING!

Public Safety Equipment, Inc., assumes no liability for any loss resulting from the use of this

warning device.

Proper installation is vital to the performance of this warning device and the safe operation of

the emergency vehicle. It is important to recognize that the operator of the emergency vehicle

is under psychological and physiological stress caused by the emergency situation. The

warning device should be installed in such a manner as to: A) Not reduce the output performance

of the system, B) Place the controls within convenient reach of the operator so that he can

operate the system without losing eye contact with the roadway.

Emergency warning devices often require high electrical voltages and/or currents. Properly

protect and use caution around live electrical connections. Grounding or shorting of electrical

connections can cause high current arcing, which can cause personal injury and/or severe

vehicle damage, including fire.

PROPER INSTALLATION COMBINED WITH OPERATOR TRAINING IN THE PROPER USE

OF EMERGENCY WARNING DEVICES IS ESSENTIAL TO INSURE THE SAFETY OF

EMERGENCY PERSONNEL AND THE PUBLIC.

Models:

1: ASL1060H: Standard LED 10-position Amber 60" Narrowstik

2: ASLSP10H: Split LED 10-position Amber 33" (each) Narrowstik

3: ASLC1060H: Standard LED 10-position Amber 60" LC-Stik

Unpacking & Pre-installation

After unpacking the items, carefully inspect the unit and its associated parts for any damage that may have

been caused in transit. Report any damage to the carrier immediately.

Installation & Mounting

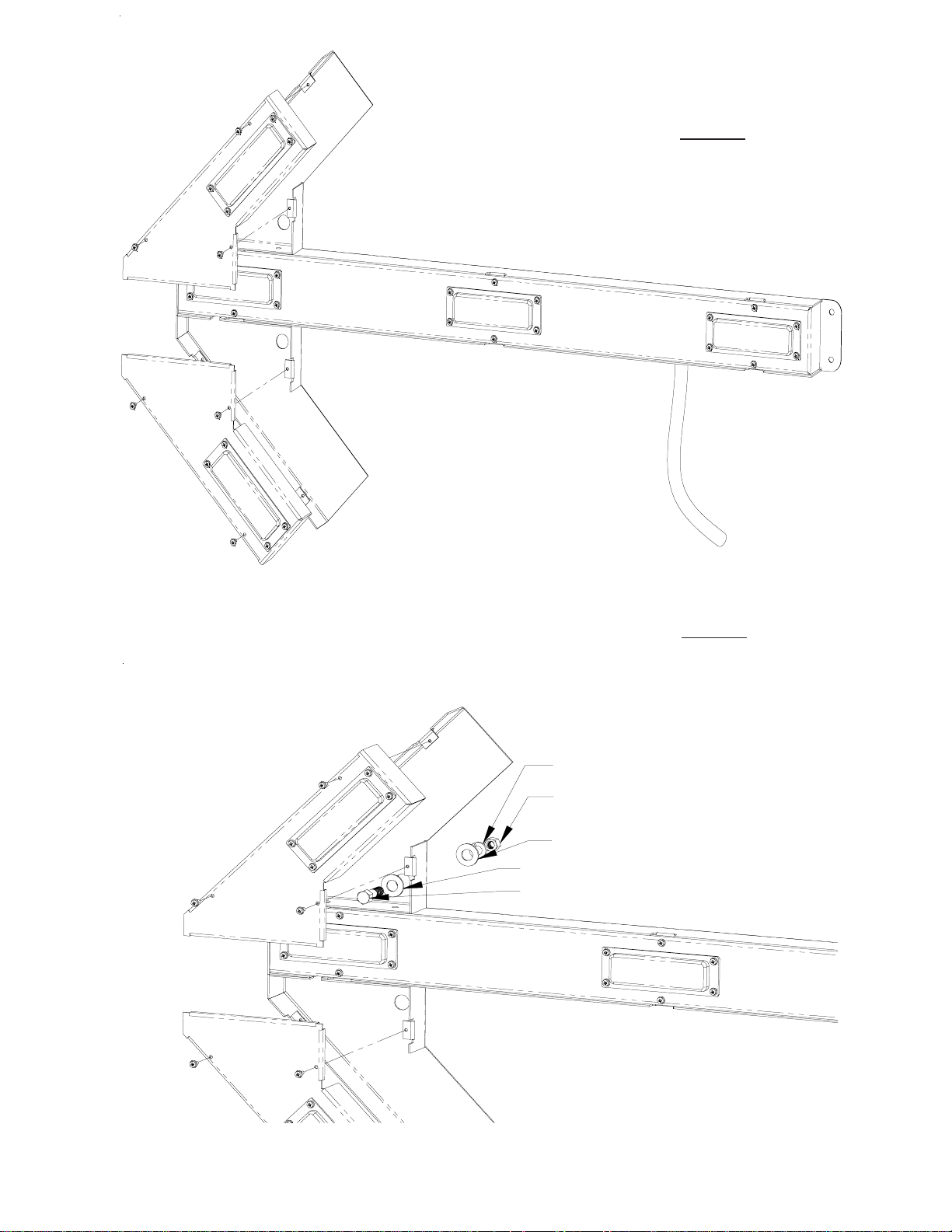

The Large LED Narrowstik was designed for mounting with a minimum four fasteners. The outer covers at each arrow wing must be

removed since they conceal the prepunched mounting holes for a more aesthetically pleasing appearance. Three #6 x .5" sheet metal

screws attach the covers and may be removed with a T-15 Torx screwdriver. (See Figure 1) The system is designed to use 3/8"-16

fasteners (included in the parts bag, see Figure 2 for details) for attaching the Narrowstik frame to the customer’s mounting surface. The

Split Narrowstik assembly is mounted in a similar fashion but uses two ¼”-20 fasteners (included in the parts bag) to attach each end flange

and complete the mounting. Attachment holes may be drilled anywhere along the main horizontal frame to attach the Narrowstik assembly

for a variety of mounting applications. Care should be taken to first remove the outer cover and be certain that no wiring is damaged during

the drilling and mounting process. The plastic caps (included in the parts bag) may be installed in the prepunched mounting holes if not

used to install the Narrowstik.

2

Page 3

Figure 1

Figure 2

3/8" LOCK WASHER

3/8"-16 HEX NUT

3/8" FLAT WASHER

3/8" FLAT WASHER

3/8"-16 X 1-1/4" HEX BOLT

3

Page 4

Wiring Instructions

Refer to the manual packaged with the 8 Output LED Narrowstik® Controller for detailed

control head wiring, installation and operation instructions.

Larger wires and tight connections will provide longer service life for components. For high current wires it is highly

recommended that terminal blocks or soldered connections be used with shrink tubing to protect the connections. Do

not use insulation displacement connectors (e.g. 3M® Scotchlock type connectors). Route wiring using grommets and

sealant when passing through compartment walls. Minimize the number of splices to reduce voltage drop. High ambient

temperatures (e.g. underhood) will significantly reduce the current carrying capacity of wires, fuses, and circuit breakers.

Use "SXL" type wire in engine compartment. All wiring should conform to the minimum wire size and other

recommendations of the manufacturer and be protected from moving parts and hot surfaces. Looms, grommets, cable

ties, and similar installation hardware should be used to anchor and protect all wiring.

!

WARNING!

Fuses or circuit breakers should be located as close to the power takeoff points as possible and properly sized to protect

the wiring and devices.

Particular attention should be paid to the location and method of making electrical connections and splices to protect these

points from corrosion and loss of conductivity.

Ground terminations should only be made to substantial chassis components, preferably directly to the vehicle battery.

The user should install a fuse sized to approximately 125% of the maximum Amp capacity in the supply line to protect

against short circuits. For example, a 30 Amp fuse should carry a maximum of 24 Amps.

DO NOT USE 1/4" DIAMETER GLASS FUSES AS THEY ARE NOT SUITABLE FOR CONTINUOUS DUTY IN

SIZES ABOVE 15 AMPS.

Circuitbreakers are very sensitive to high temperatures and will "false trip" when mounted in hot environments or

operated close to their capacity.

1. After installing the Large LED Narrowstik , route the 11-wire cable into the vehicle to where the control head will be mounted.

2. Cut the cable to length and strip back the cable insulation on the 11- wire cable.

3. Connect the red and red/white wires in, the 11- wire cable, to the positive (+12V) side of the battery through a user supplied

15 amp fuse or breakering an 16 gauge minimum wire or larger.

4. Route a minimum 16 gauge black wire to the battery negative ( ground) (earth). Use the 1/4" insulated quickslide located in

control head parts bag and connect the black 16 gauge wire control head.

5. Remove the 14- position terminal plug from the back of the control head. Connect the the remaining wires, in the 11-wire

cable, to the plug as shown in Figure 5, page 5. Connect power to the control head. See control head manual for auxillary

wire functions.

Note: When installing the Large LED Narrowstik as a Front Facing system, or if it is desired to have the cable exit from

the Passenger side, the LED module control wires will be reversed. See Figure 6, page 6, for details.

6. Check all connections for frayed or shorted wires. Insert the plug back into the Narrowstik control head.

WARNING!

!

This Product contains high intensity LED devices. To prevent eye damage, DO NOT

stare into light beam at close range.

4

Page 5

Blue

Yellow Grey Green TanViolet Orange

Blue

DRIVER SIDE

11-Wire Cable Wire Designations-Standard Rear Facing Mounting

Input Cable

STANDARD REAR FACING MOUNTING

RED, RED/WHITE Large L.E.D. Narrowstik® (+12V) wires

WHITE DIM Control wire

BROWN

ORANGE

TAN INDIVIDUAL

VIOLET L.E.D. MODULE CONTROL WIRES

GREEN (SEE FIGURE 5)

GREY

YELLOW

BLUE

Brown

Brown

PASSENGER SIDE

BLUE

YELLOW

GREY

GREEN

VIOLET

TAN

ORANGE

BROWN

WHITE

CONT HD PWR (+12V)

Rear Facing System Wiring

Figure 5

Large LED Narrowstik wire designations for standard rear facing mounting

5

Page 6

Blue

Blue

PASSENGER SIDE

OPTIONAL FRONT FACING MOUNTING

Yellow Grey Green TanViolet Orange

Input Cable

Brown

Brown

DRIVER SIDE

BROWN

ORANGE

TAN

VIOLET

GREEN

GREY

YELLOW

BLUE

WHITE

CONT HD PWR (+12V)

Front Facing System Wiring

Figure 6

Large LED Narrowstik wire designations for optional front facing mounting

Large Split LED Narrowstik®

1. After installing the Large Split LED Narrowstik, route the two (2) 11-wire cables into the vehicle to where the control head

will be mounted.

2. Cut the cables to length and strip back the cable insulation on the 11- wire cables.

3. Connect the red and red/white wires in both 11- wire cables, to the positive (+12V) side of the battery through a user

supplied 15 amp fuse or breakering an 16 gauge minimum wire or larger.

4. Route a minimum 16 gauge black wire to the battery negative ( ground) (earth). Use the 1/4" insulated quickslide located in

control head parts bag and connect the black 16 gauge wire control head.

5. Remove the 14 position terminal plug from the back of the control head. Connect the the remaining wires, in the 11-wire

cables, to the plug as shown in Figure 7, page 7. Connect power to the control head. See control head manual for auxillary

wire functions.

Note: When installing the Large Split L.E.D. Narowstik as a Front Facing system, or if it is desired to have the cable exit

from the Passenger side, the L.E.D. module control wires will be reversed. See Figure 8, page 8, for details.

6. Check all connections for frayed or shorted wires. Insert the plug back into the Narrowstik control head.

6

Page 7

Blue

Brown

DRIVER SIDE

Yellow

Grey

Green

Violet

Tan

Orange

Input Cables

Blue

STANDARD REAR FACING MOUNTING

11-Wire Cable Wire Designations- Standard Rear Facing Mounting

RED, RED/WHITE Large Split Narrowstik® (+12V) wires (Both Input Cables)

WHITE DIM Control wire (Both Input Cables)

BROWN

ORANGE Passenger Side

TAN Input Cable

VIOLET

GREEN No Connection

GREY No Connection

YELLOW No Connection INDIVIDUAL

BLUE No Connection LED MODULE CONTROL WIRES

BLUE (SEE FIGURE 7)

YELLOW Driver Side

GREY Input Cable

GREEN

VIOLET No Connection

TAN No Connection

ORANGE No Connection

BRO WN No Connection

PASSENGER SIDE

Brown

BLUE

YELLOW

GREY

GREEN

VIOLET

TAN

ORANGE

BROWN

WHITE(2 REQ'D)

CONT HD PWR (+12V)

Rear Facing System Wiring

Figure 7

Large Split LED Narrowstik wire designations for standard rear facing mounting

7

Page 8

Brown

Blue

OPTIONAL FRONT FACING MOUNTING

Yellow Grey Green TanViolet Orange

Input Cables

Blue

DRIVER SIDEPASSENGER SIDE

11-Wire Cable Wire Designations- Optional Rear Facing Mounting

RED, RED/WHITE Large Split Narrowstik® (+12V) wires (Both Input Cables)

WHITE DIM Control wire (Both Input Cables)

BROWN

ORANGE Driver Side

TAN Input Cable

VIOLET

GREEN No Connection

GREY No Connection

YELLOW No Connection INDIVIDUAL

BLUE No Connection LED MODULE CONTROL WIRES

BLUE (SEE FIGURE 8)

YELLOW Passenger Side

GREY Input Cable

GREEN

VIOLET No Connection

TAN No Connection

ORANGE No Connection

BRO WN No Connection

Brown

BROWN

ORANGE

TAN

VIOLET

GREEN

GREY

YELLOW

BLUE

WHITE(2 REQ'D)

CONT HD PWR (+12V)

Front Facing System Wiring

Figure 8

Large Split LED Narrowstik wire designations for optional front facing mounting

8

Page 9

Connecting An 1 1-wire LED Narrowstik cable

to a 5 Outptut Control Head or RLS System

It may be necessary to retrofit the new 1 1-wire cable to a 5 output control system. The required connections are shown below, in Fig. 9, to

connect a 5 output control head or a 5 output RLS. Stand alone LED Narrowstiks and internal Lightbar LED Narrowstiks will follow the same

wire designations. Refer to the 5 output control head user manual, or RLS manual, for control head operation.

New Standard 11-Wire Cabler Designations

RED, RED/WHITE Power (+12V) wires

WHITE LED DIM Control wire

BROWN

ORANGE

TAN Individual

VIOLET LED Control Wires

GREEN

GREY

YELLOW

BLUE

Existing 7-Wire Cable Designations

RED, RED/WHITE Power (+12V) wires

BROWN

ORANGE Individual LED Control

VIOLET Wires

YELLOW

BLUE

RLS 5 Output Connections

NASLDC, 5 Output Control Head Connections

As shown, the Orange and T an, Violet and Green, and the Grey and Y ellow wires will need to be paired into each single output as

indicated. Note that the each wire shown with two color designations is actually representing two individual wires into a

single output.

Figure 9

9

Page 10

Wiring for Narrowstik® models with outboard positions flashing:

When independently flashing modules are selected to replace the standard modules in the outboard positions the BLUE and the Brown

wires will be used to activate these modules and will not be connected to the Blue / Brown outputs on the control head as usual. Instead

the Blue* ( positive) wire can be connected to +12V and the Brown* ( negative ) wire can be connected to the AUX output on the

control head. When the AUX button is activated the flashing modules will be enabled. Refer to the control head manual for further details on

use of the AUX function.

Alternaively the Blue ( positive ) wire can be connected through a switch to +12V and the Brown ( negative ) wire can connected to

ground. When the switch is closed the Flashing modules will be enabled.

Dimming

All Narrowstik models come equipped with a DIM, low power, mode as standard that allows the user to reduce the L.E.D.

intensity, if desired. The current consumption is also significantly reduced in this mode ( approximately 60% ). Dim mode

is controlled by the White wire in the 11-wire cable, see figure 5, page 5. When +12V is applied to this white wire the

modules will DIM until removed. The Narrowstik control head has an output dedicated to provide this +12V, see the

Control Head manual for details.

Note: This feature is not available on LC-Stik models.

The Dim setting reduces the light output of emergency warning lights reducing the effectiveness of them

especially in brightly lit areas. Failure to use adequate light for the circumstances can cause motorists to

!

WARNING!

fail to see the emergency vehicle and lead to serious personal injury or death. Never use the DIM

setting in a brightly lit area. Use of the DIM setting may cause emergency lights to not comply with

applicable emergency warning light standards. Use caution when using the DIM setting to assure that

motorists can clearly see the emergency vehicle.

Specifications

ASL-1060H Size: 60" L, 2" D, 20" H Operating Voltage : 10 - 16VDC

Weight : 6.2 lb Current Draw : 10 Head Split 10 Head Std 10 Head LC

ASL-SP10H Size: 33" L, 2" D, 20" H Average : 5A 5A 1.25A

Weight : 9.8 lb

Maximum : 10A 10A 2.5A

ASLC-1060H Size: 60" L, 2" D, 20" H

Weight : 6.2 lb

Current Draw is reduced by approximately 60% in Dim mode.

Maintenance

The Large LED Narrowstik® requires minimal routine maintenance. Occasional cleaning of the lens is all that is required to sustain

maximum light output. Water or Code 3® lens polish and a very soft cloth is needed for cleaning. The plastic scratches easily, so cleaning

is recommended only when necessary.

10

Page 11

Parts List

Name Type Part Number

LED Lightheads Red Contact Code3 for Replacements

Blue

Amber

T roubleshooting

Verify that all connections for the Large LED Narrowstik are correct as detailed in this manual. Each head can be checked

by placing POWER on the red and red/white wires while grounding each individual LED control wire

( see figure 5, page 5).If any heads do not light replace with a new LED module or return the entire unit for service. If all

heads are functioning refer to the control head manual for troubleshooting details related to the control head.

NOTES

11

Page 12

WARRANTY

Code 3® , Inc.'s L.E.D. emergency devices are tested and found to be operational at the time of manufacture.

Provided they are installed and operated in accordance with manufacturer's recommendations, Code 3® , Inc. guarantees

all parts and components to a period of 5 years (unless otherwise expressed) from the date of purchase or delivery,

whichever is later. Units demonstrated to be defective within the warranty period will be repaired or replaced at the

factory service center at no cost.

Use of inappropriate or inadequate wiring or circuit protection causes this warranty to become void. Failure

or destruction of the product resulting from abuse or unusual use and/or accidents is not covered by this warranty.

Code 3®, Inc. shall in no way be liable for other damages including consequential, indirect or special damages whether

loss is due to negligence or breach of warranty.

CODE 3® , INC. MAKES NO OTHER EXPRESS OR IMPLIED WARRANTY INCLUDING, WITHOUT

LIMITATION, WARRANTIES OF FITNESS OR MERCHANTABILITY, WITH RESPECT TO THIS PRODUCT.

PRODUCT RETURNS

In order to provide you with faster service, if you are going to return a product for repair or

replacement*, please contact our factory to obtain a Return Goods Authorization Number (RGA number)

before you ship the product to Code 3® , Inc.. Write the RGA number clearly on the package near the

mailing label. Be sure you use sufficient packing materials to avoid damage to the product being

returned while in transit.

*Code 3® , Inc. reserves the right to repair or replace at its discretion. Code 3® , Inc. assumes no responsibility or

liability for expenses incurred for the removal and/or reinstallation of products requiring service and/or repair.; nor for

the packaging, handling, and shipping: nor for the handling of products returned to sender after the service has been

rendered.

Problems or Questions? Call The Technical Assistance HOTLINE - (314) 996-2800

Code 3®, Inc.

St. Louis, Missouri 63114-2029—USA

Ph. (314) 426-2700 Fax (314) 426-1337

10986 N. Warson Road

www.code3pse.com

Code 3® and NarrowStik® are registered trademarks of Public Safety Equipment, Inc.

3M is a registered trademark of 3M Company, Inc.

12

Revision 5, 8/06 - Instruction Book Part No. T09544

©2003, Public Safety Equipment, Inc. Printed in USA

Loading...

Loading...