Page 1

INSTALLATION

& OPERATION

MANUAL

EXTERIOR LED

MODULES

LXEX1

LXEX2

LXEX125P

LED-EX SINGLE OR

DUAL EXTERIOR LED

Contents:

IMPORTANT:

LXEX64P

LXEX73P

MODULE

Introduction........................................................3

Features and Specifications............................3-4

Installation.......................................................5-6

Wiring.............................................................7-8

Programming..................................................8-9

Maintenance......................................................9

Warranty..........................................................12

Read all instructions and warnings before installing and using.

INSTALLER:

This manual must be delivered to the

end user of this equipment.

Page 2

WARNING!

The use of this or any warning device does not insure that all drivers can

or will observe or react to an emergency warning signal. Never take the

right-of-way for granted. It is your responsibility to be sure you can proceed

safely before entering an intersection, driving against traffic, responding at

a high rate of speed, or walking on or around traffic lanes.

The effectiveness of this warning device is highly dependent upon correct

mounting and wiring. Read and follow the manufacturer’s instructions before

!

WARNING!

installing or using this device. The vehicle operator should insure daily that

all features of the device operate correctly. In use, the vehicle operator

should insure the projection of the warning signal is not blocked by vehicle

components (i.e.: open trunks or compartment doors), people, vehicles, or

other obstructions. This equipment is intended for use by authorized

personnel only. It is the user’s responsibility to understand and obey all laws

regarding emergency warning devices. The user should check all

applicable city, state and federal laws and regulations.

Code 3 , Inc., assumes no liability for any loss resulting from the use of this

warning device. Proper installation is vital to the performance of this warning

device and the safe operation of the emergency vehicle. It is important to

recognize that the operator of the emergency vehicle is under psychological

and physiological stress caused by the emergency situation. The warning

device should be installed in such a manner as to: A) Not reduce the output

performance of the system, B) Place the controls within convenient reach

of the operator so that he can operate the system without losing eye contact

with the roadway.

Emergency warning devices often require high electrical voltages and/or

currents. Properly protect and use caution around live electrical connections. Grounding or shorting of electrical connections can cause high current

arcing, which can cause personal injury and/or severe vehicle damage,

including fire.

PROPER INSTALLATION COMBINED WITH OPERATOR TRAINING IN

THE PROPER USE OF EMERGENCY WARNING DEVICES IS ESSENTIAL TO INSURE THE SAFETY OF EMERGENCY PERSONNEL AND

THE PUBLIC.

This Product contains high intensity LED

!

devices. To prevent eye damage, DO NOT

stare into light beam at close range.

2

Page 3

Introduction:

The Exterior LED modules are weatherproof LED based warning light modules that contain

state-of-the-art high intensity LEDs. These products provide eight different operation modes

including a steady-burn mode. These products may be adapted to a variety of exterior

applications such as motorcycle applications, OEM fire truck, grill light and back-deck

applications. The exterior LED is available in either a +12V or a +24V version.

Features and Specifications:

Operating Voltage: 10-16Vdc (+12V version), 22-30Vdc (+24V version), Reverse

Polarity Protection. 50% Duty Cycle unless otherwise stated.

Flash Rate: 70 fpm minimum

Flash Modes (Flashing version only):

1. Cycle-Flash: Cycles through Triple, Quad, Double, and Fast

Single modes at approximately 109 fpm.

2. Triple-Flash: Three consecutive pulses per flash at

approxmately 83 fpm.

3. Quad-Flash: Four consecutive pulses per flash at

approximately 77 fpm.

4. Double-Flash: Two consecutive pulses per flash at

approximately 78 fpm.

5. Single-Flash: Single flash pattern at 75 fpm.

6. Quad-Flash 70% Duty Cycle: Can be used for NFPA.

7. Steady-burn: Continuous ON-state operation.

Flashing Current Draw: Red/Amber:

Single - .25A Avg.

Dual - .5A Avg.

Blue:

Single - .4A Avg.

Dual - .8A Avg.

Steady Burn Current Draw:Red/Amber:

Single - .5A A vg.

Dual - 1.0A Avg.

Blue:

Single - .8A A vg.

Dual - 1.6A Avg.

Available colors - Red, Amber or Blue or any combination for dual modules.

Available configurations - Single or dual light heads, Amber , Red, or Blue.

3

Page 4

Options:

The LED-EX is available in five basic models:

· LXEX1F- A single head unit. The housing is available in black or brushed

aluminum finish. The sealed cover lens is available in clear or colored to

match the LED light output.

· LXEX2F- A dual head (over under) unit. The housing is available in black or

brushed aluminum finish. The sealed cover lens is available in clear or

colored to match the LED light output. Each head is individually controlled.

· LXEX125P-A single head unit. The housing is available in highly polished

aluminum (chrome-like appearance).

· LXEX73P- A dual head (side by side) unit. The housing is available in highly

polished aluminum (chrome-like appearance). For retrofit purposes, the

mounting hole pattern matches the mounting hole pattern of a series 40 (7x3)

perimeter light.

· LXEX64P-A dual head (over under) unit. The housing is available in highly

polished aluminum (chrome-like appearance). For retrofit purposes, the

mounting hole pattern matches the mounting hole pattern of a series 60 (4x6)

perimeter light, and the periphery of the unit matches the periphery of an

OsciLaserTM lens.

In addition to the flashing models, The LED-EX1 is also available in two special function

versions:

The STT (Stop-Turn-Tail) version:

This version can be used as an Auxiliary stop-turn-tail light. When only the power (red)

and ground (black) wire are connected, the light will come on in a reduced intensity steady

burn tail-light mode. Grounding the white wire will result in a bright steady burn mode (stoplight) mode.

The steady-burning (non-flashing) version:

This version can be used as a stand-alone steady-burning light or be flashed with an LED

flasher such as Code 3 PSELED12. This model has only two wires, a power (red) wire

and a ground (black) wire.

4

Page 5

Installation:

Single Exterior LED Module (LXEX1, LXEX125P):

This unit can be mounted to metal surfaces using two #8 x 1/2 pan head sheet metal screws

(included). This unit can also be mounted to plastic surfaces using two #8 x 1/2 pan head

machine screws (included). An additional 0.25" minimum diameter mounting hole is needed to

mount the single exterior LED module. The cable routing hole can be drilled (Refer to Figure

as shown below). An optional mounting rubber gasket, included with the unit, may be used to

prevent oxidization and galvanization of the mounting surface due to metal-on-metal contact.

Figure 1 LXEX1

Figure 2 LXEX125

5

Page 6

Dual Exterior LED Module (LXEX2, LXEX73P, LXEX64P):

This unit can be mounted to metal surfaces using #8 x 1/2 pan head sheet metal screws

(included). This unit can also be mounted to plastic surfaces using #8 x 1/2 pan head

machine screws (included). Two additional 0.25" minimum diameter , or (1) .500" minimum

diameter mounting holes are drilled as shown in Figure below. An optional mounting rubber

gasket, included with the unit, may be used to prevent oxidization and galvanization of the

mounting surface due to metal-on-metal contact.

Figure 3 LXEX2F

Figure 4 LXEX73P

Figure 5 LXEX64P

6

Page 7

!

WARNING!

If the product is to be used inside the vehicle, it may cause severe personal

injury if not properly mounted and secured. Objects used in vehicle may

become airborne during a collision or other sudden changes in vehicle

speed or direction, such as braking, acceleration or turns.

Wiring:

Flashing Models:

Both single and dual LED-EX modules are equipped with a 8" long 3-wire cable harness

(two for dual modules). The user is required to furnish terminals to attach wires to meet

specific requirement.

Connect wires as follows:

1. Red wire: Power wire, connect to +12V (+24V for 24 volt version) voltage

line.

2. Black wire: GND wire, connect to ground terminal.

3. White wire: Control wire, may be left unconnected. It can also be connected to

GND through a momentary push-button switch, and be used for

programming the operation mode.

Note: The white wire should NOT be connected to a positive voltage

under any circumstances.

Note: It is possible to tie the red wires from both modules, and the black wires

from both modules when wiring the dual modules, provided that a properly

sized wire is used for the common connection. The white wires should not

be wired together if independent programming of the two heads is desired.

Note: The +24V versions will have a 24 volt label designating the unit for

operation on a +24 volt electrical system. The label will typically be

located on the back of the unit.

7

Page 8

STT (Stop-Turn-Tail) Models:

These models are equipped with a 8" long 3-wire cable harness. The user is required to

furnish terminals according to his or her preference. Connect the wires as follows:

1. Red wire: Power wire, connect to +12V voltage line.

2. Black wire: GND wire, connect to a ground terminal.

3. White wire: Stop-Light trigger input, grounding this wire will result in high-intensity

operation. This wire may be connected to an active low brake-light trigger

output if available.

Steady-Burning (Non-Flashing) Models:

These models are supplied with only two wires. Red power wire and black GND wire. The

third (white) wire is not available on these models.

Connect the wires as follows:

1. Red wire: Power wire, connect to +12V voltage line.

2. Black wire: GND wire, connect to Ground terminal.

Programming:

Programming the desired flash pattern (or operation mode ) is done with the white control

wire. Y ou can scroll through the eight available flash patterns, by momentarily grounding the

white control wire until you arrive at the desired operation mode. Momentary grounding of

the white wire can be accomplished either by momentarily touching the wire to GND, or

through a momentary push-button switch.

The unit will come on in the default Cycle-flash mode at the time of first power-up, until the

desired flash pattern is programmed. The default flash pattern can then be changed by

programming the desired pattern into the unit, the unit will continue to operate in the same

mode every time the unit is turned off and turned back on. The default flash pattern can be

changed at will for any number of times.

The unit can be reset back to the default flash pattern ( cycle-flash ) by grounding the control

wire for about 8-10 seconds and then releasing it. This can be done while operating in any

of the flash modes.

8

Page 9

Note: It is possible to program the two heads on the dual module individually as

shown on page 7. This should be done when a different flash pattern is

desired for each head. The two heads can also be programmed

simultaneously into the same flash pattern by tying the two white control

wires together then programming as shown on page 7.

Maintenance:

The Exterior LED Modules are completely sealed units designed to be trouble and

maintenance free. Refer to the guide below for help with troubleshooting. Should the unit be

diagnosed as malfunctioning, remove unit and replace with a new module.

LED module housings may become hot with

WARNING!

!

extended use. Allow modules to cool completely

before attempting to remove.

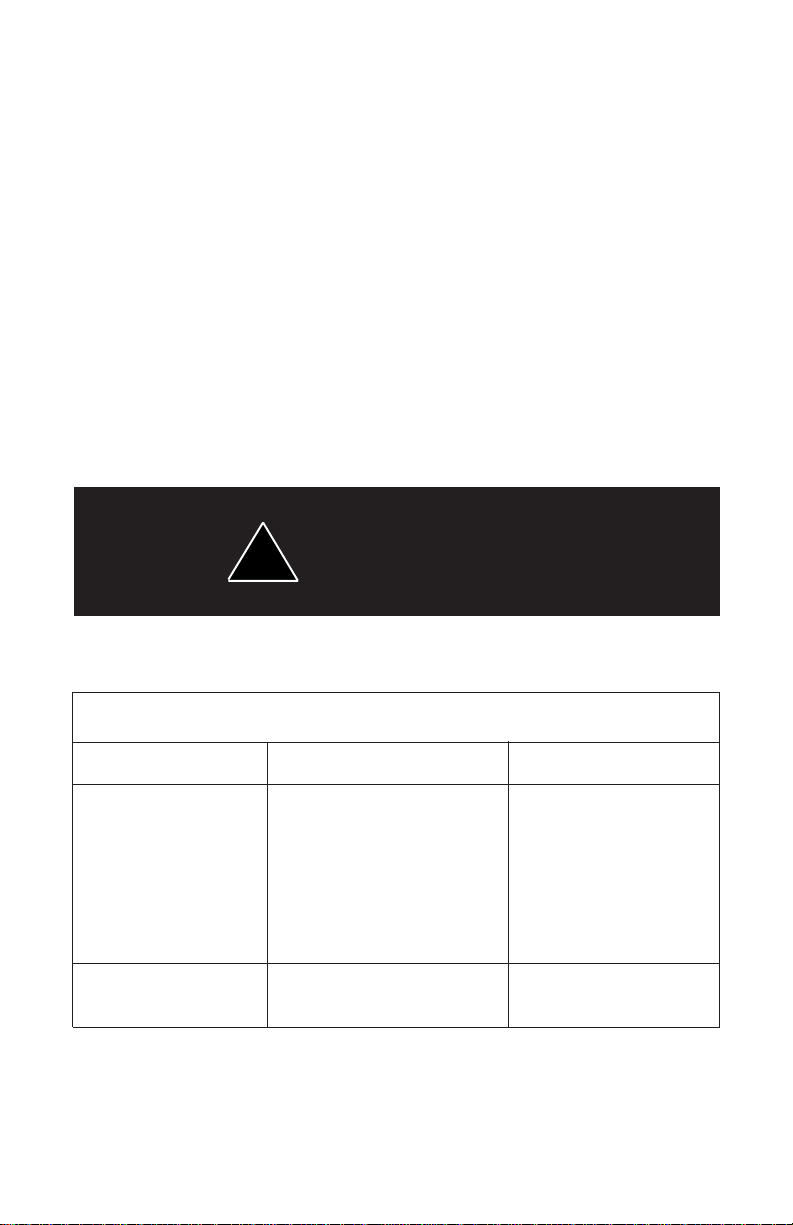

TROUBLESHOOTING

Problem Probable Cause Remedy

Lighthead does not

activate

Lighthead is constantly

ON

a. No Power to unit

b. Power input wire reversed

c. Damaged or shorted

cabling

d. Defective Lighthead

e. Control wire permanently

grounded or shorted to

GND

a. Control wire permanently

grounded or shorted to

GND

9

a. Check wiring for loose

connection

b. Reverse Power wires

c. Check cables for

damage

d. Replace lighthead module

e. Avoid permanent

grounding of control wire

a. Avoid permanent

grounding of control

wire

Page 10

Notes

10

Page 11

Notes

11

Page 12

WARRANTY

Code 3,®Inc.'s L.E.D. emergency devices are tested and found to be operational

at the time of manufacture. Provided they are installed and operated in accordance with

manufacturer's recommendations, Code 3, Inc. guarantees all parts and components

to a period of 5 years (unless otherwise expressed) from the date of purchase or

delivery, whichever is later. Units demonstrated to be defective within the warranty

period will be repaired or replaced at the factory service center at no cost.

Use of inappropriate or inadequate wiring or circuit protection causes this

warranty to become void. Failure or destruction of the product resulting from abuse or

unusual use and/or accidents is not covered by this warranty. Code 3, Inc. shall in no

way be liable for other damages including consequential, indirect or special damages

whether loss is due to negligence or breach of warranty.

CODE 3, INC. MAKES NO OTHER EXPRESS OR IMPLIED WAR-

RANTY INCLUDING, WITHOUT LIMITATION, WARRANTIES OF FITNESS

OR MERCHANTABILITY, WITH RESPECT TO THIS PRODUCT.

PRODUCT RETURNS

If a product must be returned for repair or replacement*, please contact our factory

to obtain a Return Goods Authorization Number (RGA number) before you ship the

product to Code 3, Inc. Write the RGA number clearly on the package near the mailing

label. Be sure you use sufficient packing materials to avoid damage to the product being

returned while in transit.

*Code 3, Inc. reserves the right to repair or replace at its discretion. Code 3, Inc. assumes no responsibility or liability for

expenses incurred for the removal and /or reinstallation of products requiring service and/or repair.; nor for the packaging,

handling, and shipping: nor for the handling of products return to sender after the service has been rendered.

For Technical Support / Service, please call 314-996-2800.

10986 N. Warson Road

www.code3pse.com

©2002 Code 3, Inc. Printed in USA

Code 3, Inc., a subsidiary of

Public Safety Equipment, Inc.

Code 3 is a registered trademark of Code

3, Inc.

St. Louis, Missouri 63114-2029—USA

Ph. (314) 426-2700 Fax (314) 426-1337

Revision 8, 11/05 - Instruction Book Part No. T05793

12

Code 3,®Inc.

Loading...

Loading...