Page 1

INSTALLATION

& OPERATION

MANUAL

79SCBZ

IMPORTANT:

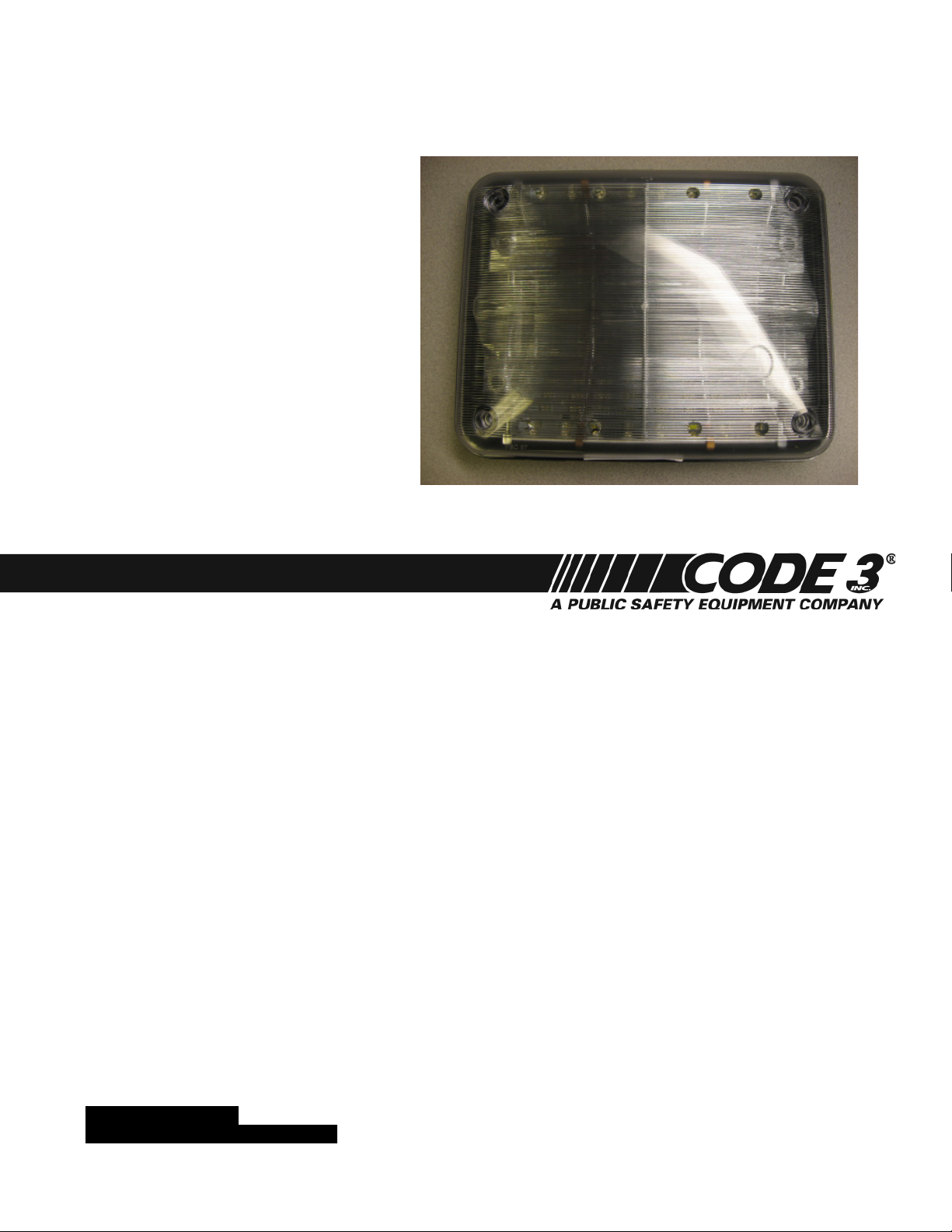

79SCBZ

7 x 9 Scene Light

Contents:

General Description....................................................2

Installation & Mounting.................................................2

Electrical Connections..................................................3

Maintenance...............................................................3

Warranty.....................................................................4

Read all instruction and warnings before installing and using.

INSTALLER: This manual must be delivered to the end user of this equipment.

1

Page 2

The use of this or any warning device does not ensure that all drivers can or will observe or react to an emergency warning signal. Never

take the right-of-way for granted. It is your responsibility to be sure you can proceed safely before entering an intersection, driving against

traffi c, responding at a high rate of speed, or walking on or around traffi c lanes.

!

WARNING

The effectiveness of this warning device is highly dependent upon correct mounting and wiring. Read and follow the manufacturer’s instructions before installing or using this device. The vehicle operator should insure daily that all features of the device operate correctly. In use,

the vehicle operator should insure the projection of the warning signal is not blocked by vehicle components (i.e. open trunks or compartment

doors), people, vehicles, or other obstructions.

This equipment is intended for use by authorized personnel only. It is the user’s responsibility to understand and obey all laws regarding

emergency warning devices. The user should check all applicable city, state and federal laws and regulations.

Code 3, Inc., assumes no liability for any loss resulting from the use of this warning device.

Proper installation is vital to the performance of this warning device and the safe operation of the emergency vehicle. It is important to recognize that the operator of the emergency vehicle is under psychological and physiological stress caused by the emergency situation. The

warning device should be installed in such a manner as to: A) Not reduce the output performance of the system; B) Place the controls within

convenient reach of the operator so that he can operate the system without losing eye contact with the roadway.

Emergency warning devices often require high electrical voltages and/or currents. Properly protect and use caution around live electrical

connections. Grounding or shorting of electrical connections can cause high current arcing, which can cause personal injury and/or severe

vehicle damage, including fi re. Wait 10 minutes after turning off the power from system before touching any internal components. Always

wear hand and eye protection when handling electrical components.

PROPER INSTALLATION COMBINED WITH OPERATOR TRAINING IN THE PROPER USE OF EMERGENCY WARNING DEVICES IS

ESSENTIAL TO INSURE THE SAFETY OF EMERGENCY PERSONNEL AND THE PUBLIC.

GENERAL DESCRIPTION

The 79SCBZ is a self-contained, high intensity LED light designed for mounting to the exterior of a vehicle. This product is designed for operation on

12VDC.

After unpacking the light, inspect it for damage that may have occurred in transit. The unit can be checked electrically by following the instructions in

the Electrical Connections section of this manual. If the unit has been damaged, do not attempt to install or operate it. File a claim immediately with

the carrier, stating the extent of damage. Carefully check all envelopes, shipping labels, and tags before removing or destroying them.

INSTALLATION & MOUNTING

Make certain that the drain hole in each bezel casting is orientated on the bottom prior to mounting.

Before proceeding with installation, determine the approximate location of the light assembly and plan all cable/wire routing.

1. Position the Scene Light assembly on the desired mounting surface. Ensure that the unit is level side to side. Four mounting holes will

need to be drilled (1/4” diameter), as well as one wire routing hole (1” diameter). The center to center horizontal dimension (for the mounting

holes) is 7.250”. The vertical center to center distance is 5.250”. The wire routing hole is at the center of these holes. Scribe the four mounting

hole locations and a wire routing hole location on the mounting surface.

Before drilling holes in ANY part of a vehicle, be sure that both sides of the mounting surface are clear of parts that could be damaged; such as brake

lines, fuel lines, electrical wiring or other vital parts.

2. Drill the four mounting holes and wire routing hole.

All drilled holes should be free of burrs and sharp edges. All wire routing holes should be grommeted (user supplied) and/or sealed to avoid wire and/

or vehicle damage.

3. Complete the electrical connections for each respective Triple Stack light as described in Electrical Connections.

4. Insert the screw grommets into the mounting holes.

5. Align the mounting gasket and Triple Stack warning light assembly over the previously drilled holes. Carefully place any wire or connectors

into the recessed area in the back of the aluminum bezel. Secure the assembly in position with the provided #10 x 3/4” screws.

2

Page 3

ELECTRICAL CONNECTIONS

The Scene Light is designed to operate on 12VDC.

Two 12-inch long lead wires are supplied for making electrical connections to the Scene Light.

Using 18-gauge (minimum) wire, connect the red (+) lead to the positive power source terminal and the black (–) lead to the negative power source

terminal.

MAINTENANCE

Crazing (cracking) of lenses will cause reduced effectiveness of the light. Do not use cleaning agents (which will cause crazing)

such as strong detergents, solvents, or petroleum products. If crazing of lenses does occur, reliability of light for emergency

signalling purposes may be reduced until lenses are replaced.

Ordinary cleaning of the plastic lenses can be accomplished by using mild soap and a soft cloth. Should fi ne scratches or a haze appear on a lens,

they can ordinarily be removed with a non-abrasive, high quality, one-step, automotive paste cleaner/wax and a soft cloth.

Larger wires and tight connections will provide longer service life for components. Do not use insulation displacement connectors

(e.g. 3M® Scotchlock type connectors). Route wiring using grommets and sealant when passing through compartment walls.

Minimize the number of splices to reduce voltage drop. High ambient temperatures (e.g. under-hood) will signifi cantly reduce

!

WARNING

the current carrying capacity of wires, fuses, and circuit breakers. Use “SXL” type wire in engine compartment. All wiring should

conform to the minimum wire size and other recommendations of the manufacturer and be protected from moving parts and hot

surfaces. Looms, grommets, cable ties, and similar installation hardware should be used to anchor and protect all wiring.

Particular attention should be paid to the location and method of making electrical connections and splices to protect these

points from corrosion and loss of conductivity. Ground terminations should only be made to substantial chassis components,

preferably directly to the vehicle battery.

The user should install a fuse sized to approximately 125% of the maximum Amp capacity in the supply line and each switched

circuit to protect against short circuits. For example, a 30 Amp fuse should carry a maximum of 24 Amps. DO NOT USE 1/4”

DIAMETER GLASS FUSES AS THEY ARE NOT SUITABLE FOR CONTINUOUS DUTY IN SIZES ABOVE 15 AMPS. Circuit

breakers are very sensitive to high temperatures and will “false trip” when mounted in hot environments or operated close to

their capacity. Fuses or circuit breakers should be located as close to the power takeoff points as possible and properly sized

to protect the wiring and devices.

WARNING

Any electronic device may create or be affected by electromagnetic interference. After installation of any electronic

!

device, operate all equipment simultaneously to insure that operation is free of interference.

3

Page 4

WARRANTY

Code 3®, Inc.’s emergency devices are tested and found to be operational at the time of manufacture. Provided they are installed and

operated in accordance with manufacturer’s recommendations, Code 3®, Inc. guarantees all parts and components except the lamps to a period

of 1 year, LED Lighthead modules to a period of 5 years (unless otherwise expressed) from the date of purchase or delivery, whichever is later.

Units demonstrated to be defective within the warranty period will be repaired or replaced at the factory service center at no cost.

Use of lamp or other electrical load of a wattage higher than installed or recommended by the factory, or use of inappropriate or

inadequate wiring or circuit protection causes this warranty to become void. Failure or destruction of the product resulting from abuse or unusual

use and/or accidents is not covered by this warranty. Code 3®, Inc. shall in no way be liable for other damages including consequential, indirect

or special damages whether loss is due to negligence or breach of warranty.

CODE 3®, INC. MAKES NO OTHER EXPRESS OR IMPLIED WARRANTY INCLUDING, WITHOUT LIMITATION, WARRANTIES OF

FITNESS OR MERCHANTABILITY, WITH RESPECT TO THIS PRODUCT.

PRODUCT RETURNS

If a product must be returned for repair or replacement*, please contact our factory to obtain a Return Goods Authorization

Number (RGA number) before you ship the product to Code 3®, Inc. Write the RGA number clearly on the package near

the mailing label. Be sure you use suffi cient packing materials to avoid damage to the product being returned while in

transit.

*Code 3®, Inc. reserves the right to repair or replace at its discretion. Code 3®, Inc. assumes no responsibility or liability for expenses incurred for the removal and /or reinstallation of products requiring service and/or repair; nor for the

packaging, handling, and shipping: nor for the handling of products returned to sender after the service has been rendered.

Problems or Questions? Call The Technical Assistance HOTLINE - (314) 996-2800

Code 3, Inc.

www.code3pse.com

Code 3 is a registered trademark of

Code 3, Inc.

St. Louis, Missouri 63114-2029—USA

Ph. (314) 426-2700 Fax (314) 426-1337

Revision 0, 1/2011 - Instruction Book Part No. T16489

©2011 Public Safety Equipment, Inc. Printed in USA

10986 N. Warson Road

Code 3,® Inc., a subsidiary of

Public Safety Equipment, Inc.

4

Loading...

Loading...