Page 1

INSTALLATION &

OPERATION

MANUAL

LED PERIMETER,

STOP/TURN/TAIL

SERIES 45, 65, 85

SERIES 45, 65, 85

LED PERIMETER,

STOP/TURN/TAIL

Contents:

Introduction .......................................................... 2

Unpacking & Pre-Installation ............................... 2

Mounting Options ................................................. 3

Installation & Wiring ..........................................3-6

Flash Pattern Selection ........................................ 7

Power Requirements ........................................ 7-8

Parts & Exploded View ........................................ 8

Maintenance ......................................................... 9

Options ................................................................. 9

Warranty ............................................................. 12

IMPORTANT:

Read all instructions and warnings before installing and using.

INSTALLER:

This manual must be delivered to the end user of this equipment.

Page 2

Introduction

!

The 45/65/85 Series LED Perimeter Light Heads are designed for the emergency vehicle market. The light

heads are to be connected directly to +12 or +24 VDC systems for independent flashing or through electromechanical or solid state flasher units. These light heads with their unique optics are designed for full,

optimized signals at all angles.

Models 45STR and 65STR (Red Stop-Turn-Tail); 45STA and 65STA (Amber Turn) meet the requirements for

Stop-Turn-Tail lamps of Federal Motor Vehicle Safety Standard No. 108 and SAE specifications J2040, J2261

and J593. These units are to be installed only on the rear of the vehicle. The units are to be connected to the

stop/tail, turn signal, and reverse light circuitry of the vehicle.

Consisting of an LED base unit, lens, o-ring, gasket, optional bezel and mounting screws, these units are

easy to install.

The use of this or any warning device does not insure that all drivers can or will observe or react

to an emergency warning signal. Never take the right-of-way for granted. It is your

responsibility to be sure you can proceed safely before entering an intersection, driving against

traffic, responding at a high rate of speed, or walking on or around traffic lanes.

The effectiveness of this warning device is highly dependent upon correct mounting and wiring.

Read and follow the manufacturer’s instructions before installing or using this device. The

vehicle operator should insure daily that all features of the device operate correctly. In use,

WARNING!

the vehicle operator should insure the projection of the warning signal is not blocked by vehicle

components (i.e.: open trunks or compartment doors), people, vehicles, or other obstructions.

This equipment is intended for use by authorized personnel only. It is the user’s responsibility

to understand and obey all laws regarding emergency warning devices. The user should

check all applicable city, state and federal laws and regulations.

Public Safety Equipment, Inc., assumes no liability for any loss resulting from the use of this

warning device.

Proper installation is vital to the performance of this warning device and the safe operation of

the emergency vehicle. It is important to recognize that the operator of the emergency vehicle

is under psychological and physiological stress caused by the emergency situation. The

warning device should be installed in such a manner as to: A) Not reduce the output

performance of the system, B) Place the controls within convenient reach of the operator so

that he can operate the system without losing eye contact with the roadway.

Emergency warning devices often require high electrical voltages and/or currents. Properly

protect and use caution around live electrical connections. Grounding or shorting of electrical

connections can cause high current arcing, which can cause personal injury and/or severe

vehicle damage, including fire. Wait 10 minutes after turning off the power from system before

touching any internal components. Always wear hand and eye protection when handling

electrical components.

PROPER INSTALLATION COMBINED WITH OPERATOR TRAINING IN THE PROPER USE

OF EMERGENCY WARNING DEVICES IS ESSENTIAL TO INSURE THE SAFETY OF

EMERGENCY PERSONNEL AND THE PUBLIC.

Unpacking and Pre-Installation

Carefully remove the light head from its protective packaging. Inspect the unit for transit damage. Report any

damage to the carrier and keep the shipping carton. Verify the contents of the package (refer to Figures 4 & 5

on page 8).

2

Page 3

Mounting Options

There are three mounting options for the LED base unit:

1. Attaching the LED base unit with high strength double-sided foam tape (customer supplied). This option

minimizes the piercing of the vehicle by requiring only a center wire hole.

2. Attaching the LED base unit with four #10 x ¾” sheet metal screws.

3. Attaching the LED base unit and lens together using four #6 x 1-½” sheet metal screws.

Options 1 and 2 allow removal of the outer lens without removing the base from the vehicle. Option 3 allows

removal of the entire unit from the vehicle with the removal of only four screws.

Installation

1. Determine the mounting options to be used. Select the desired mounting location for the light head

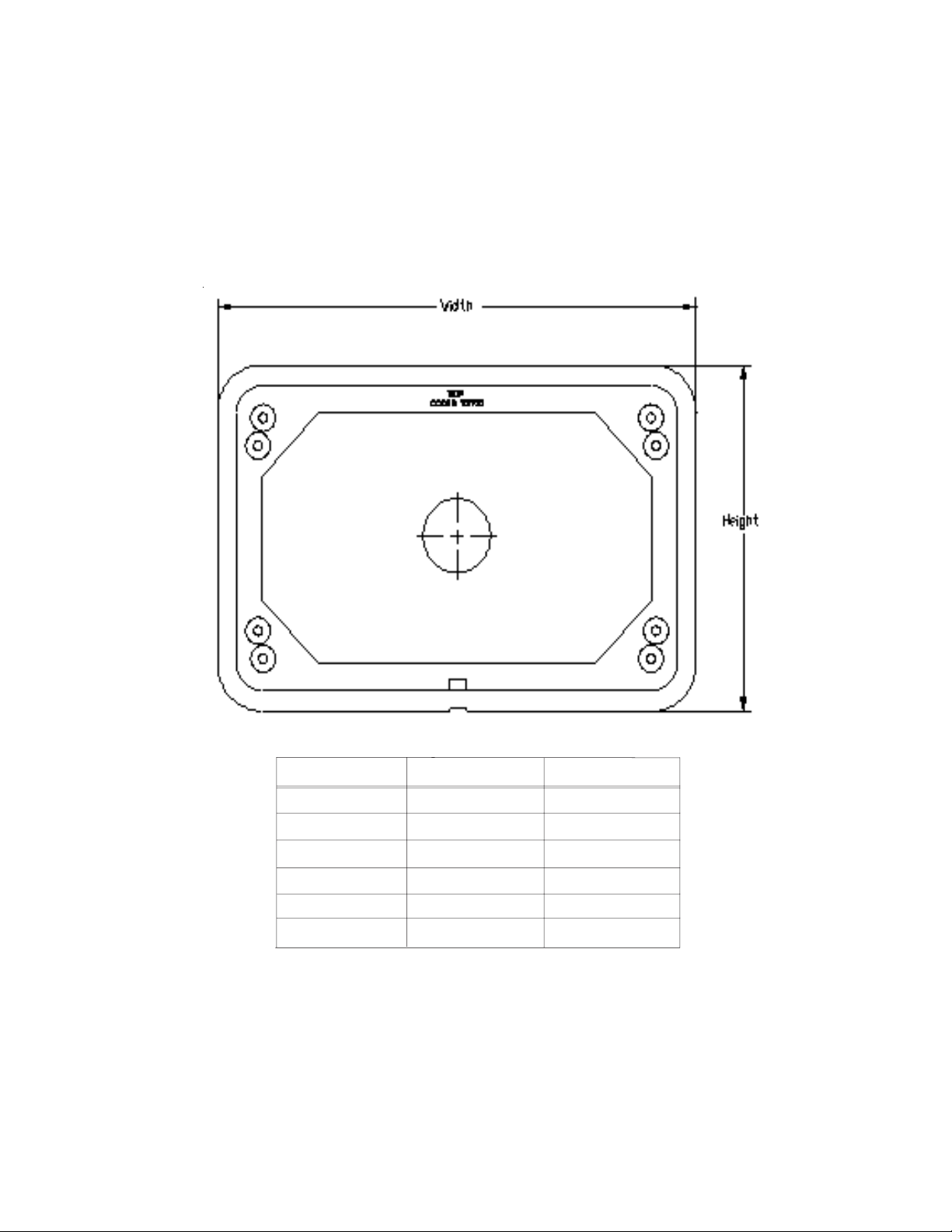

assembly. The installation must accomodate the base gaskets. Refer to Figure 1 for gasket dimensions.

2. Verify free clearance behind the mounting surface for wiring and fasteners.

3. Using the appropriate template (Figures 2-4) cut the center opening for the wiring and install a

grommet (customer supplied). Use a drill bit sized for the appropriate thickness of the mounting

surface and a #10 sheet metal screw for drilling the screw holes. For example: for aluminum alloy

sheet metal .125" thick, a #23 (.154") drill size is recommended.

with very high bond tape instead of screws then the screw holes need not be drilled. Clean the

mounting surfaces of the vehicle and the light head with isopropyl alcohol and dry thoroughly prior to

attaching tape.

4. Route the vehicle power wires and allow a minimum of 3 inches of slack to protrude from the center

opening at each light head location. Use 18 AWG for wires up to 40 feet length, 16 AWG for wires up

to 70 feet length.

5. Place the light head gasket (and bezel if used) over the light head location and run the vehicle power

wire slack through the center opening of the gasket. Refer to Figures 5 & 6.

6. For Perimeter Lights refer to the section Flash Pattern Selection prior to finalizing the electrical

connections. Prepare the vehicle power wires and the light head’s wires with terminations of the

customer’s choice (not supplied). Waterproof connectors are recommended. Refer to the following

table for appropriate wiring connections.

Note: The gaskets are flexible. Do not use them for drill templates.

Note: If the unit is to be attached

Code 3 LED Perimeter Light Models

Models 45, 65, 85 - Perimeter Configurations +12 or +24 Program

45STR & 65STR - LED STT, Red Stop or Turn Tail Ground

45STA & 65STA - LED STT, Amber Turn none

Connect the light head’s black and red wires to the vehicle system’s ground and positive (+12 or +24

VDC), respectively.

protected from contact with the system ground to prevent inadvertent changes to the flash

pattern. This can be accomplished by sealing or capping the end of the wire.

7. At the power source end of the cable determine if the cable length is acceptable. If a shorter length is

required, coil the cable and tie with an electrical tie.

8. Verify proper light head operation by supplying electrical power to the system wires at the power

source end of the cable.

9. Verify that the O-ring is properly seated onto the LED base unit.

10. Push the assembled electrical connectors through the center opening and into the vehicle.

11. Push the LED base unit (and bezel if used) into the gasket. The LED base unit is symmetric and does

not have a preferred top or bottom. Verify that the gasket (and bezel if used) is properly oriented.

These parts are labeled with “TOP” and their part numbers at the top and have a drain slot at the

bottom.

Note: For Perimeter Lights the white flash pattern selection wire must be

Wire Function

Red White Black

3

Page 4

12. Mount the LED base unit and gasket (and bezel if used) using four #10 x ¾” screws. Optionally the unit

may be mounted with very high bond tape (customer supplied). If tape is used it should be attached to the

base unit and the vehicle. Do not use tape to secure the gasket to either the LED base unit or the vehicle

chassis. Follow the tape manufacturer’s instructions to ensure proper adhesion.

13. Verify the “TOP” lens marking is on the top and install the lens using four screws. Two screw options are

supplied: four #10 x ¾” screws or four #6 x 1-½” screws. The #10 screws attach the lens to the LED base

unit. The optional longer #6 screws go through the LED base unit and tap into the vehicle body. If the longer

#6 screws are used then first drill an appropriate pilot hole into the vehicle body.

MODEL WIDTH HEIGHT

45 7.84 3.67

65 7.00 4.6

85 9.77 7.78

45BZ 9.18 5

65BZ 8.00 5.6

85BZ 11.1 9.11

FIGURE 1

Gasket Dimensions

(For Layout Purposes Only. Do Not Scale.)

4

Page 5

!

"

"

This is a full size template.

Do not use a facsimile or

copied reproduction. Do

not use this template if the

"

WARN-

largest dimension in each

direction is not within +/-.010".

ING!

"

"

9x7 (Model 85)

FIGURE 2

5

Page 6

WARN-

!

!

ING!

This is a full size template.

Do not use a facsimile or

copied reproduction. Do

not use this template if the

largest dimension in each

direction is not within +/-.010".

"

"

"

"

"

7x3 (Model 45)

FIGURE 3

------------------------

"

"

"

"

"

WARNING!

This is a full size template.

Do not use a facsimile or

copied reproduction. Do

not use this template if the

largest dimension in each

direction is not within +/-.010".

6x4 (Model 65)

FIGURE 4

6

Page 7

Flash Pattern Selection

The LED Perimeter Lights are equipped with one steady burn and twenty flashing patterns

alternating patterns, an exclusive feature of the Code 3 LED Perimeter Light.

75 flashes per minute (FPM) or 150 FPM.

To select a different flash pattern, apply +12 or +24 VDC to the red wire and connect the black wire to the

power supply ground. The unit will flash in whatever pattern was last set. Change the pattern by momentarily

touching the white wire to the power supply ground. The flash pattern will change to the next pattern according to the following list:

All flash patterns are either

including ten

Pattern

Number

- Steady Burn

1 75 FPM Single

2 75 FPM, Alternating Sides

3 150 FPM Single

4 150 FPM Single, Alternating Sides

5 75 FPM Double

6 75 FPM Double, Alternating Sides

7 75 FPM Triple

8 75 FPM Triple, Alternating Sides

9 75 FPM Quad

10 75 FPM Quad, Alternating Sides

11 150 FPM Quad

12 150 FPM Quad, Alternating Sides

13 75 FPM Hi-Low-Low-Hi

14 75 FPM Hi-Low-Low-Hi, Alternating Sides

15 150 FPM Double

16 150 FPM Double, Alternating Sides

17 150 FPM Triple

18 150 FPM Triple, Alternating Sides

19 75 FPM Hi-Low-Hi

20 75 FPM Hi-Low-Hi, Alternating Sides

Description

Continue to cycle through the various patterns until the desired pattern is selected. The unit will retain this

pattern even when power is removed.

must be protected from contact with the system ground to prevent inadvertent changes to the flash

pattern. This can be accomplished by sealing or capping the end of the wire.

For units that are flashed with an external control system such as a multiplexer or a flasher unit, the heads

should be set to steady burn. Note: Regardless of the location in the program in the flash pattern list, the unit

can be forced to steady burn by permanently electrically tying the white wire to the black wire.

It is recommended that all heads be set to the desired pattern at a workbench prior to installation.

Note: For Perimeter Lights the white flash pattern selection wire

Power Requirements

The Code3 LED Perimeter Lights are designed to be long life, full signal, light weight and low current draw.

The following table lists the number of LED's in each model and the average current draw for various conditions.

7

Page 8

Standard Unit, Figure 4 B ezeled Unit, Figure 5 1 2 3 4 * 5 * 6 * 7

Code 3 Model N um ber - Description Code 3 Model N um ber - Description

Base Lens Lens O-

Ring

G asket Bezel Bezel

Gas ket

Bag of

Screws

45R - LED Perim, 7x3, Red 45BZR - LED Perim , 7x3, Red, Bezel -- T07891

45A - LED Perim, 7x3, Am ber 45BZA - LED Perim, 7x3, Amber, Bezel -- T07892

45B - LED Perim, 7x3, Blue 45BZB - LED Perim, 7x3, Blue, Bezel -- T07893

45W - LED Perim, 7x3, White 45BZW - LED Perim , 7x3, White, Bezel -- T07894

45RB - LED Perim, 7x3, Red-Blue 45BZ RB - LED Perim, 7x3, Red-Blue -- T07894

45RA - LED Perim, 7x3, Red-Amber 45BZ R AW - LED Perim , 7x3, Red-Amber -- T 07894

45RW - LED Perim , 7x3, Red-White 45BZRW - LED Perim, 7x3, Red-White -- T07894

45AW - LED Perim, 7x3, White-Amber 45BZAW - LED Perim, 7x3, White-Amber -- T07894

45STR - LED ST T, 7x3, Red 45STBZ R - LED STT, 7x3, Red -- T07895

45STA - LED Turn, 7x3, Amber 45STBZ A - LED T urn, 7x3, Am ber -- T07896

65R - LED Perim, 6x4, Red 65BZR - LED Perim , 6x4, Red, Bezel -- T07901

65A - LED Perim, 6x4, Am ber 65BZA - LED Perim, 6x4, Amber, Bezel -- T07902

65B - LED Perim, 6x4, Blue 65BZB - LED Perim, 6x4, Blue, Bezel -- T07903

65W - LED Perim, 6x4, White 65BZW - LED Perim , 6x4, White, Bezel -- T07904

65RB - LED Perim, 6x4, Red-Blue 65BZ RB - LED Perim, 6x4, Red-Blue -- T07904

65RA - LED Perim, 6x4, Red-Amber 65BZ R AW - LED Perim , 6x4, Red-Amber -- T 07904

65RW - LED Perim , 6x4, Red-White 65BZRW - LED Perim, 6x4, Red-White -- T07904

65AW - LED Perim, 6x4, Am ber-White 65BZAW - LED Perim, 6x4, Am ber-White -- T07904

65STR - LED ST T, 6x4, Red 65STBZ R - LED STT, 6x4, Red, Bezel -- T07905

65STA - LED Turn, 6x4, Amber 65STBZ A - LED T urn, 6x4, Am ber, Bezel -- T07906

85R - LED Perim, 9x7, Red 85BZR - LED Perim , 9x7, Red, Bezel -- T07911

85A - LED Perim, 9x7, Am ber 85BZA - LED Perim, 9x7, Amber, Bezel -- T07912

85B - LED Perim, 9x7, Blue 85BZB - LED Perim, 9x7, Blue, Bezel -- T07913

85W - LED Perim, 9x7, White 85BZW - LED Perim , 9x7, White, Bezel -- T07914

T07928

T07926 T07920 T07917 T07923

T07927 T07921 T07918 T07924

T07925 T07919 T07916 T07922

Average Current Draw, Amps

Code 3 LED Perimeter Light Models

Number

of LED's

Model 45,45STA&45STR 7x3 Perimeter 62 1.0 0.5 0.5 0.3

Model 65, 6x4 Perimeter 76 1.0 0.5 0.5 0.3

Model 85, 9x7 Perimeter 124 1.5 0.8 0.8 0.4

65STR - 6x4, Red (Stop or Turn Config.) 54 0.7 0.4 0.4 0.2

65STR - 6x4, Red (Tail Configuration) 0.05 n/a 0.04 n/a

65STA - 6x4, Amber Turn 54 0.7 0.4 0.4 0.2

Steady

Burn

13.8VDC

Flashing

13.8VDC

Steady

Burn

24.0VDC

Parts & Exploded

Views

Note: All of the components illustrated are for the 45 series. They are shown for reference only. The

procedures outlined within are generic procedures and are for use in the 65 & 85 series as well.

Flashing

24VDC

* Gasket, item 4, only used for Standard Units.

Bezel, item 5, and Bezel Gasket, item 6, only used for Bezeled Units.

Turn Arrow Insert T04580 only used with 65STA.

8

Page 9

Maintenance

The lens is field removable for cleaning or replacement. Remove the lens by unscrewing the four mounting

screws. Use mild detergent, warm water and a soft cloth to clean both surfaces of the lens. Use of any other

chemicals may void product warranty. Thoroughly dry before reinstalling.

Because plastic scratches easily, cleaning is only recommended when necessary. Do not subject the lenses

to car washes that use brushes as these will scratch the lenses. Do not use a pressure washer.

FIGURE 4 FIGURE 5

Case Products

Cases of ten units, all the same. Add suffix letter K to the model number. For example, 45BZRK is a

case of ten LED perimeter lights, 7 X 3, Red, Bezel.

65F 4x6 LED for Headlamp Housing (See figure 6 below)

1.Slip (4) tinnerman clips onto the four corners of the lower mtg brkt #S89856

2.Attach the lens, gasket, and LED, to the mounting plate part #S95273.

3.Attach assembled LED assy to the lower mtg bracket with screws through the tinnerman clips.

-----------HEADLAMP

HOUSING

---------------#S89856 LOWER MTG BRKT

------------#S95273 MOUNTING PLATE

------------LED ASSEMBLY

FIGURE 6

9

Page 10

MOUNTING DIMENSIONSFOR

65STK3 4X6 LED PERIMETER

TRIPLE STACK HOUSING

MOUNTING DIMENSIONS FOR

45STK3 3X7 LED PERIMETER

TRIPLE STACK HOUSING

MOUNTING DIMENSIONS FOR

65STK4 4X6 LED PERIMETER

QUAD STACK HOUSING

10

Page 11

NOTES:

11

Page 12

WARRANTY

Code 3, Inc. L.E.D. emergency warning devices are designed to exceed all industry

standards and are tested and found to be operational at the time of manufacture. Provided they

are installed and operated in accordance with manufacturer's recommendations, Code 3, Inc.

guarantees all parts and components to a period of 1 year and the LED base unit for 5 years from

the date of purchase or delivery, whichever is later. LED emergency warning devices which do

not meet industry standards, within the warranty period, will be repaired or replaced, at Code 3

Inc.'s option, at the factory service center.

Use of inappropriate or inadequate wiring or circuit protection causes this warranty to

become void. Failure or destruction of the product resulting from abuse or unusual use and/or

accidents is not covered by this warranty. Code 3, Inc. shall in no way be liable for other damages

including consequential, indirect or special damages whether loss is due to negligence or breach

of warranty.

CODE 3, INC. MAKES NO OTHER EXPRESS OR IMPLIED WARRANTY INCLUDING,

WITHOUT LIMITATION, WARRANTIES OF FITNESS OR MERCHANTABILITY, WITH

RESPECT TO THIS PRODUCT.

PRODUCT RETURNS

If a product must be returned for repair or replacement*, please contact our factory to

obtain a Return Goods Authorization Number (RGA number) before you ship the product to

Code 3, Inc. Write the RGA number clearly on the package near the mailing label. Be sure you

use sufficient packing materials to avoid damage to the product being returned while in transit.

*Code 3, Inc. reserves the right to repair or replace at its discretion. Code 3, Inc. assumes no responsibility or liability for expenses incurred for

the removal and /or reinstallation of products requiring service and/or repair.; nor for the packaging, handling, and shipping: nor for the handling of

products return to sender after the service has been rendered.

PROBLEMS OR QUESTIONS? CALL OUR TECHNICAL ASSISTANCE HOTLINE (314) 996-2800

St. Louis, Missouri 63114-2029—USA

10986 N. Warson Road

www.code3pse.com

Code 3, Inc.

Ph. (314) 426-2700

Fax (314) 426-1337

Code 3 is a registered trademark of Code3, Inc a subsidiary of Public Safety Equipment, Inc.

Revision 8, 11/2005 - Instruction Book Part No. T07929

©2005 Code 3, Inc. Printed in USA

Loading...

Loading...