Page 1

INSTALLATION GUIDE

1

DEUCE

DUAL HEAD W600

TECHNICAL SPECIFICATIONS

INPUT VOLTAGE ........................10 to 30 Volts DC.

INPUT CURRENT .......................0.5A @ 12.8V, 0.45A @ 25.6V

LIGHT OUTPUT ...........................AMBER: 160+ LUMENS

BLUE: 155+ LUMENS

RED: 123+ LUMENS

WHITE: 660+ LUMENS

CABLE LENGTH ..........................7 FT. (HEAD A), 4FT. (HEAD B)

LED ELEMENTS ..........................4 (EACH HEAD)

FLASH PATTERNS ......................16 (8 Standard, 8 optional cycle)

MAX NUMBER OF SYNC’D HEADS ... 64

WARRANTY PERIOD ..................5 YEARS

DIMENSIONS

1.28"

0.875"

1.50"

4.89"

LED HEAD

HEAD A

HEAD B

"59.0

0.150"

0.980"

1.50"

0.59"

833 W. Diamond St Boise, Idaho 83705

TEL: 888-844-6682 www.strobe.com

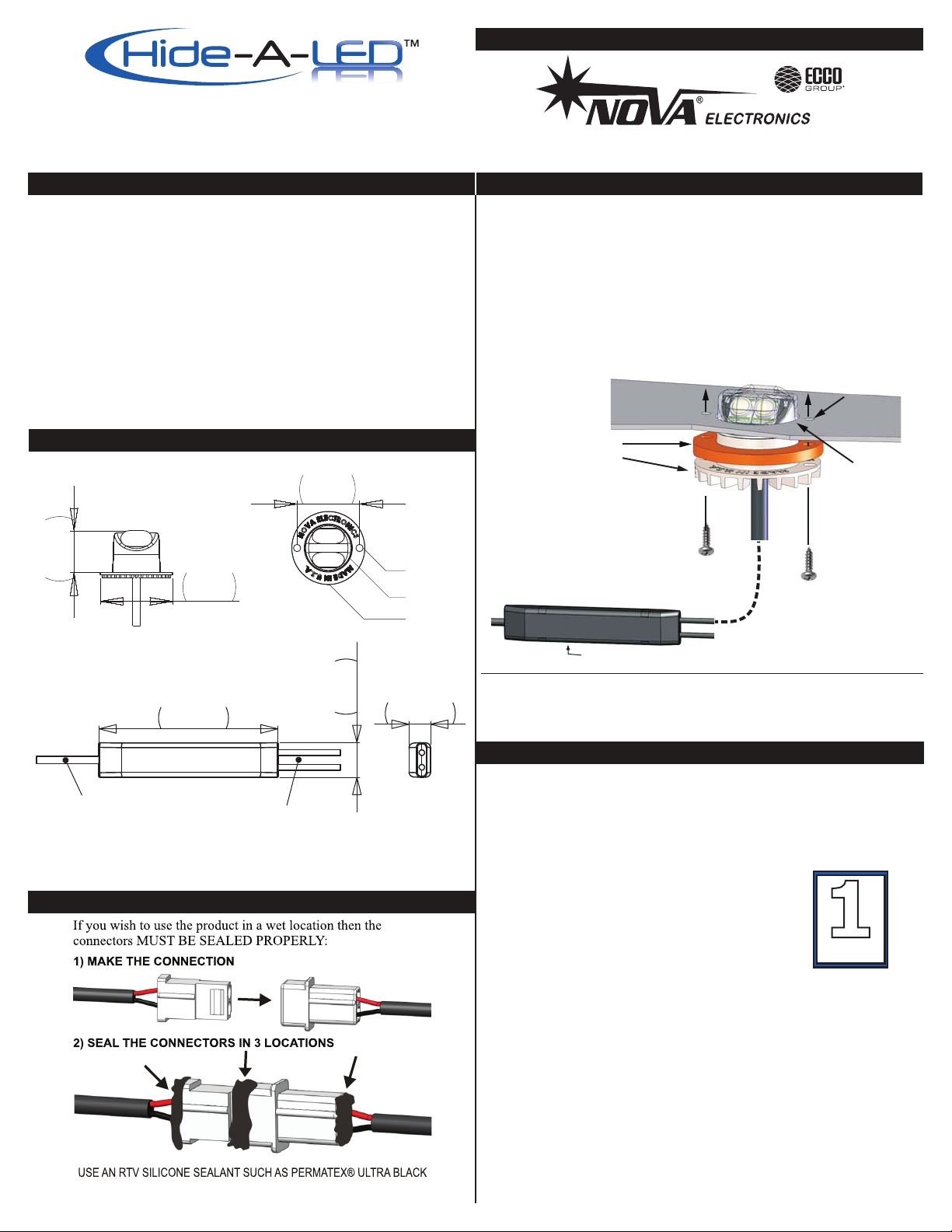

MOUNTING

Drill a 1” diameter hole in the reector of the lens assembly.

A 1” hole saw is typically used. The HIDE-A-LED™ may be used as a

template to mark the location of the two screw holes. The W600 may

be mounted in either the back surface, bottom or sides of a reector.

Drill pilot holes with a 7/64” drill bit. Install the HIDE-A-LED™ into the

lens assembly using the supplied gasket and screws. If the mounting surface is curved additional sealing may be necessary. Use RTV

Silicone sealant if needed.

LOCATE LED HEAD AT LEAST 1” AWAY

FROM ANY FACTORY BULB!

REFLECTOR

GASKET

! HOT !

THE HEATSINK WILL BE HOT AFTER RUNNING

FOR AN EXTENDED PERIOD. DO NOT TOUCH.

IT WILL NOT MELT ANY OF THE PLASTIC

PARTS OF THE LENS ASSEMBLY.

STRAP THE WATERPROOF

POWER MODULE TO THE BODY

OF THE VEHICLE AWAY FROM

ANY HIGH HEAT SOURCES.

DO NOT DRILL HOLES THROUGH THE POWER MODULE!

FOR DUAL WALL REFLECTORS: FIRST USE A 1.5” HOLE SAW TO DRILL THROUGH OUTER

LAYER ONLY. THEN USE 1” HOLE SAW TO DRILL THROUGH INNER LAYER USING SAME

PILOT DRILL HOLE. INSTALL THE LED HEAD THROUGH THE 1.5” HOLE AND SEAL THE GAP

WITH RTV SILICONE.

7/64” PILOT

HOLES

1” HOLE

SCREWS

TIP: APPLY RTV SILICONE

TO THE SCREWS TO SEAL

THE THREADS.

ELECTRICAL CONNECTIONS

The wiring diagram on page 2 shows a typical install.

INPUT MABLE: 4FT

LED HEAD

CABLES:

4FT, 7FT

POWER MODULE

CONNECTOR SEALING

RED: +V

Connect to +V through an ON/OFF switch.

The use of a fuse located close to the voltage source is recommended.

Size the fuse according to the number of heads used in the system.

18AWG or larger wire is recommended.

BLACK: - GROUND

Connect to - GROUND vehicle chassis.

18AWG or larger wire is recommended.

BLUE: Flash pattern SYNC and SELECTION wire.

If you wish to have all the LED heads synchronize

their ash timings and patterns with each other then all the BLUE wires

must be connected together(64 Heads Maximum).

The BLUE wire is also used to select the ash pattern.

Touch the BLUE wire to +V to select the next pattern in the FLASH

PATTERN LIST. The BLUE wire can also be run to a momentary

push-button located on the dashboard to allow the ash pattern to be

changed when desired.

Note: Do not connect the BLUE wire to - Ground.

It will disrupt the ash pattern sync signal.

SYNC

TM

PAGE 1920-9121-00 REV. C

Page 2

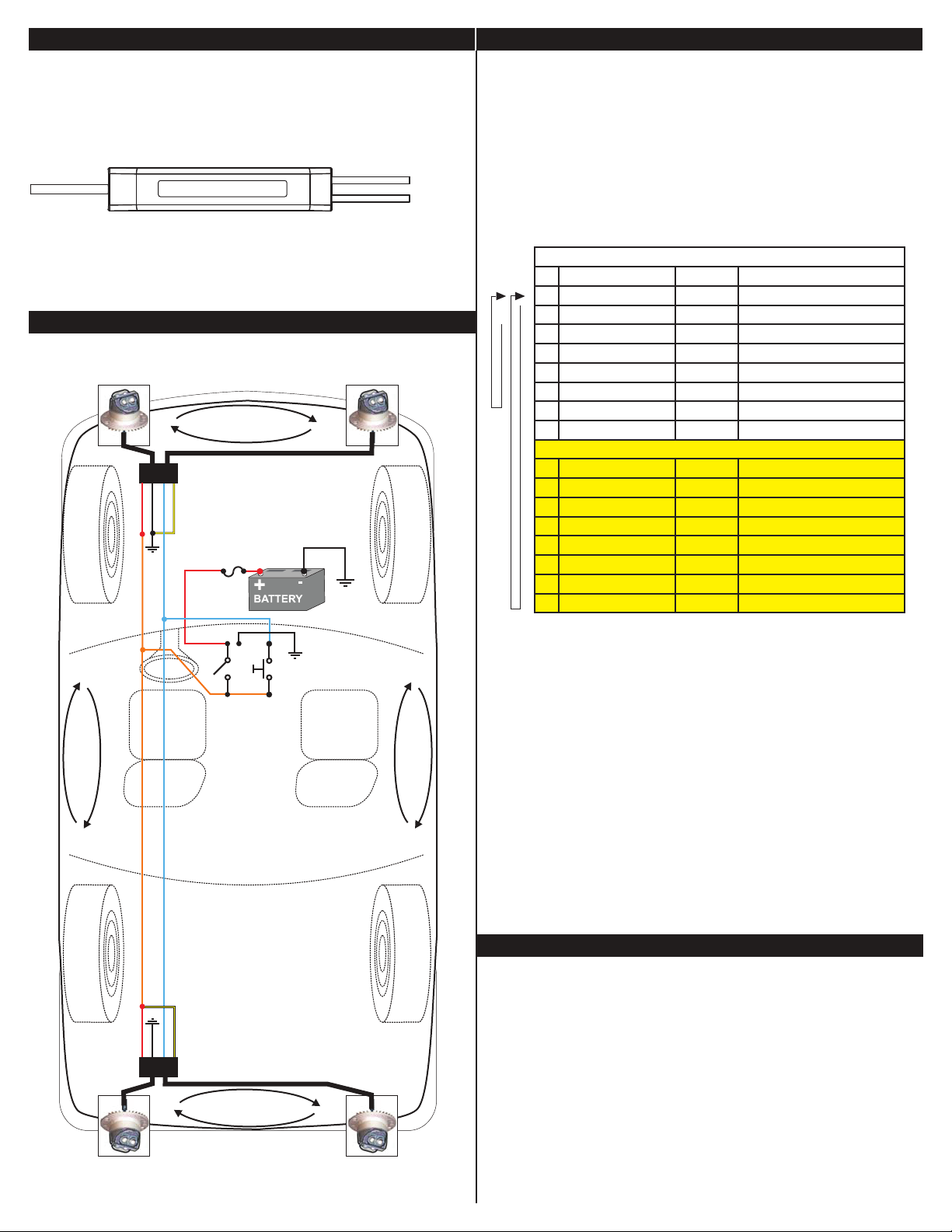

ELECTRICAL CONNECTIONS FLASH PATTERNS

YELLOW: Swap Alternating heads.

Connect to either +V or GROUND (GND).

When using more than one HIDE-A-LED™ Deuce, this wire will swap

the order of the two LED heads so HEAD A will re with HEAD B on

the other unit. Tie to GND if not used.

HEAD A

HEAD B

POWER-UP RESET:

After installing the system it is best to do a POWER-UP RESET the

rst time to ensure that all heads are in sync.

Touch BLUE wire to +V while applying power for 1 second.

Release BLUE wire. All heads will reset to Pattern #2.

If you have installed a pattern select push-button, press and hold pattern select while turning power switch ON. Release pattern select after

1 second. To select a ash pattern, touch BLUE to +V or press pattern

select switch to increment the ash pattern. The heads will remember

the selected pattern even if power is removed.

The HIDE-A-LED™ DEUCE will also synchronize with any BULL

LED™ or SD24 LED head . The wiring colors and functions are

identical.

WIRING DIAGRAM

INSTALLATION OF 2 HIDE-A-LED™ DEUCE USING PATTERN SELECT SWITCH PANEL (OPTIONAL) ON DASHBOARD.

ALTERNATE FLASHING

KCALB

EULB

DER

WOLLEY

YELLOW TO - GND

RED

BLUE

FUSE

FFO/NO

NRETTAP

EGNARO

GNIHSALFETANRETLA

TCELES

BLACK

CHASSIS

GROUND

ANRETLA GNIHSALFET

STANDARD PATTERNS

# Pattern: Frequency: Description:

1 Quad Flash 1.25 Hz 75 Quad Flashes Per Minute

2 Double Flash 1.25 Hz 75 Double Flashes Per Minute

3 Triple Flash 1.53 Hz 92.3 Triple Flashes Per Minute

4 DeciBlast 1.42 Hz 85.5 Deci Flashes Per Minute

5 Single Flash 1.25 Hz 75 Single Flashes Per Minute

6 Mega Flash 1.90 Hz 114 Single Flashes Per Minute

STANDARD ONLY

7 Triple+Burst 1.37 Hz 82.5 Triple+Burst Flashes Per Minute

8 Steady On Steady on. Split Color = Fast Mega

CYCLE PATTERNS

9 Cycle All Cycle through patterns 1 to 7

STANDARD + CYCLE

10 Double-Triple+Burst 2 Double, 2 Triple+Burst cycle

11 Cycle Classic 1 Double, 1 Quad, 2 Mega cycle

12 Quad-Mega 3 Quad, 4 Mega cycle

13 Single-Quad 2 Single, 2 Quad cycle

14 DeciBlast-Quad 2 DeciBlast, 2 Quad cycle

15 Single-Triple-DeciBlast 2 Single, 2 Triple, 2 DeciBlast cycle

16 Mega-Triple+Burst 1 Mega, 1 Triple+Burst cycle

STANDARD PATTERNS:

In order to maintain compatibility with the BULL LED™ product, the HIDE-A-

LED™ ships with only the standard patterns enabled (1 through 8).

CYCLE PATTERNS:

You may add patterns 9 through 16 by following this procedure:

1) Touch BLUE wires to +V (RED wire) while applying power.

If you have installed a pattern select push-button, press and hold pattern select

while turning power switch ON.

2) Hold BLUE wires on +V for 5 SECONDS (heads will not be ashing during

this time). After 5 SECONDS the heads will ash once or twice to indicate the

ash pattern list that has been selected:

ONE FLASH = Standard Patterns only.

TWO FLASHES = Standard + Cycle Patterns.

3) Remove the BLUE wires from +V (or release push-button).

You may switch the pattern set at any time as many times as you wish. All

heads will remember the pattern set that was selected even when power is

removed.

© 2009

TROUBLESHOOTING

HEAD NOT FLASHING:

Check the RED and BLACK wires for a reversed connection. (Reverse connection will

not damage the unit). Check RED and BLACK wires for either a bad splice or a corroded

ground connection.

WOLLEY

KCALB

EULB

DER

YELLOW TO +V

ALTERNATE FLASHING

HEADS NOT SYNCHRONIZING:

Check for a short circuit on the BLUE wire to either +V or GROUND.

Saltwater on the wire connections will short circuit the sync signal on the BLUE wire. Check

for non-functional heads in the system. If any one of the heads has a bad GROUND connection it can cause the sync signal to become corrupted. If any one of the heads has it’s

RED and BLACK wires reverse connected it will corrupt the sync signal.

FLASH PATTERN CHANGING:

If the ash pattern changes on it’s own there may be an intermittent short between the

BLUE wire and +V. Check for water in the wiring connections. If any one of the heads in

the system has an intermittent GROUND connection it can also cause the ash pattern to

change.

PAGE 2920-9121-00 REV. C

Loading...

Loading...