Page 1

8113936 00 10/04 page 1 of 4

16 Bit PCB & Metal Arm Temporary

Instructions - 1800/1850 Balancer

COATS, Inc. • Hennessy Industries • 1601 J.P. Hennessy Drive, LaVergne, TN 37086-3565

(800) 688-6359 • (615) 641-7533 • (615) 641-5104 FAX • www.ammcoats.com

Instructions

1. The Plastic Diameter Arm on the end of the distance rod has been replaced with a more robust Metal

Diameter Arm. The plastic roller step is placed under

the bead seat area of the rim for all normal measurements (clip-on weights and Rim Runout) and the large

diameter is placed at the point of application for tape-aweights.

2. On startup, the software recognizes whether the

machine is 1800 or 1850 and the appropriate menus

appear.

3. Important: It is necessary to perform a NOVRAM

reset on startup.

4. Power up machine and check for function of all

operations. Make any necessary adjustments:

• Ensure that Distance and Diameter Pots are set

between 2500 & 3500 on Machine Self-Test (Green

Screen).

• If Arm Calibrations are required:

Press the key and select the SERVICE

ADJUSTMENTS option . At the PASSWORD

prompt enter 1-3-5-7.

Toggle the DISTANCE/DIAMETER ARM TYPE

option to METAL.

In the following order, select the DISTANCE ARM

CALIBRATION option , WIDTH SONAR CALIBRATION option , and DIAMETER ARM CALIBRATION option

,

following the on-screen

instructions for each calibration. Note: At the end of

the Diameter Arm Calibration, hold the NEXT button down until 281 degrees flashes on-screen; then

return the arm to its home position.

Important: Once the Arm is calibrated, there is little need to calibrate it again.

5. If the machine is an 1850 model or upgrade, a

Printer selection will appear in the GENERAL SETUP

menu (press the key, then select option ). At

the PRINTER menu select option to verify that the

printer option is toggled ON. For all other options the

default is ON.

An LED on the face of the printer will blink every sec-

ond to verify that the printer is powered.

6. To Calibrate with the 4-ounce weight, press the

key, then select SPECIAL FUNCTIONS option

and choose MACHINE SELF-CALIBRATION selec-

tion

.

Follow the instructions on-screen.

Important: The dimensions entered must match the

“calibration wheel”. A dimension cannot be zero.

7. If not already done, you may want to enter the

Owner Name and Address for the screen saver. The

OWNER ADDRESS selection is found under the SPECIAL FUNCTIONS menu.

8. The Board is factory set with the following menu

settings:

General Set-up

Printer = ON

Runout Unloaded " = SONAR (lateral)

Runout Unloaded # = SONAR (radial)

B

alancing Set-up

Runout Diagnostic = ON

Runout Limits

Max. True Limit = .050"

Rim Runout Limit = .010"

Correction Runout Limit = .030"

Special Functions

Static Unbalance Displayed = ON

Stop On Top = OFF

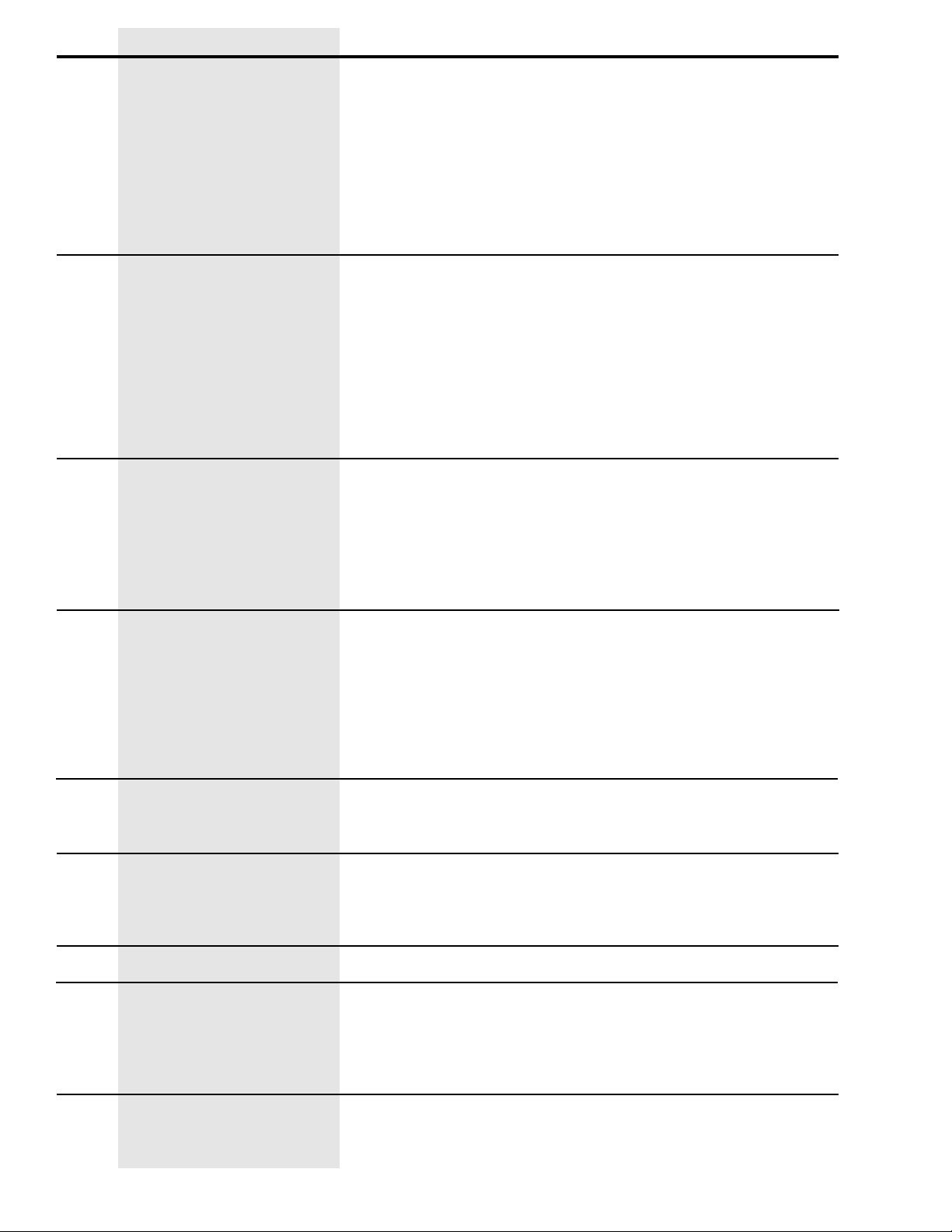

9. Refer to figure 1 showing the proper placement of

the metal arm roller on the rim.

Figure 1 - Placing The Metal Arm Roller On The Rim

10. See the new error code listing on the following

pages.

6

7

MENU

5

5

MENU

3

2

1

5

4

MENU

Page 2

Error

No

Video

Err. 1

Err. 2

Err. 3

Err. 4

Err. 5

Err. 6

Err. 7 /

Err. 8

Err. 9

Symptom

The balancer does not turn on.

Rotation signal missing.

Wheel spins too fast & no brake.

Balancer does not start.

Motor turns but no rotation.

Too low speed when taking the

measurement.

During rotation to measure the

unbalance value, the wheel

speed has gone below 42 r.p.m.

Calculation Error.

Incorrect Machine SelfCalibration.

Counterclockwise rotation.

After pushing START the wheel

turns in the opposite direction.

Wheel guard hood open or the

START button has been pushed

without closing the wheel guard

hood.

Ram Error or defect.

Reading error of NOVRAM parameters.

Access error in NOVRAM parameters writing.

Check

1. Check for proper connection to the power supply.

2. Check and replace fuses on the power PCB if necessary.

3. Check the monitor function - press monitor menu button. (see trouble

shooting tips)

4. Check control transformer output.

5. Check FS1 & FS2 fuses on power PCB.

6. Check power cable to main PCB & output at power PCB.

7. Replace power PCB.

8. Replace the main PCB.

1. Check the belt tightness.

2. Encoder disconnected, bad or damaged wiring, failed optical unit - no

reset signal.

3. Check hood switch operation.

4. Replace the encoder unit.

5. Motor disconnected or bad wiring - check for motor voltage at power

PCB - check circuit breaker - check machine power.

6. If motor hums - remove belt and check for motor rotation at pulley - if

rotation, replace capacitor.

7. Check for faulty power PCB or main PCB.

1. Very light / small wheel mounted on balancer - not enough inertia to

keep wheel rotating.

2. Check belt tightening.

3. Check the operation and adjustment of the encoder and in particular, the

reset signal. (in MACHINE SELF-TEST “green screen”, Pos counts from

0 to 255 and then 0 again). UP = cw, DOWN = ccw.

4. Replace the main PCB.

1. Check the wheel dimensions setting.

2. Check the piezo pick-ups connections - electrical & mechanical. (in

MACHINE SELF-TEST “green screen”, push on spindle shaft and verify

that both piezo outputs change.

3. Execute the 4-ounce weight (Machine Self-Calibration).

4. Mount a wheel having a known unbalance (lower than 4.00 ounces or

100 grams) and check the balancer reading.

5. Replace the PC board.

1. In MACHINE SELF-TEST “green screen” - check the operation of

UP/DOWN - RESET signals of the encoder.

2. Check the connection of the motor for correct rotation.

1. Reset the error by pushing button 7 = EXIT

2. Close the wheel guard hood and press START button.

3. Check operation of the wheel guard micro-switch.

4. Press the START button.

1. Reset NOVRAM & check operation or Replace PCB.

1. Repeat the entire balancer calibration.

2. Switch the balancer OFF.

3. Wait a minimum time of 1 minute (approx).

4. Switch the balancer ON and check the proper operation.

5. Replace the PCB board.

1. Replace the PCB board.

8113936 00 10/04 page 2 of 4

Page 3

Error

Err. 11

Err. 12

Err.13

Err.14

Err.17

Err.18

Err.15 /

Err.16 /

Err.19

Err.20

Err. 21

Err. 22

Err. 23

Err. 25

Err. 30

Err.40,41

42, 43

Err.45,

46, 47,

48

Err.50,

51, 52,

53

Symptom

High speed error.

During rotation to measure the

unbalance value, the wheel

speed has gone over 270 r.p.m.

Error in the unbalance measuring

cycle.

Error in the unbalance measurement.

Over ranging - too much unbalance

Wheel stopped before it was

positioned or before taking

runout reading.

Weight dispenser time out.

Error in calculating impulses

referred to the weight to cut

(impulses = 0). (weight dispenser)

STOP button pushed during the

weight dispenser operation.

Number of impulses referred to

the correction weight lower than

number of anticipated impulses.

(weight dispenser)

Clock error

Error in creating the runout graph.

Error in the reading of the values

which are used to create the

runout graph.

Error in the writing procedure of

the cursor for the current value of

the runout graph.

Check

1. Check for possible damage or dirt on the encoder disc - clean dirt with a

soft cloth - blow air across the optical units.

2. Check the operation and adjustment of the encoder and in particular, of

the reset signal. (in MACHINE SELF-TEST “green screen”, Pos counts

from 0 to 255 and then 0 again). UP = cw. DOWN = ccw.

3. Replace the main PCB.

1. Press EXIT and respin. Check PHASE in MACHINE SELF-TEST”green

screen”, if 180 deg diff., recalibrate & check piezos.

2. Check encoder adjustment and operation. (clearance .020” to .035”)

3. Check motor operation.

4. Check belt tightness.

5. Check hub nut tightness.

6. Replace the main PCB.

1. Press EXIT and respin. Check PHASE, VCO (dynamic), VCI (static) in

MACHINE SELF-TEST “green screen”.

2. Check the piezo pick-ups connection. (electrical & mechanical)

3. Check the balancer spindle connections.

4. Mount a wheel having a known unbalance (lower than 4 oz or 100

grams) and check the balancer readings.

5. Replace the PC board.

A.) Follow screen instructions for “heavy side” down balancing to bring

wheel unbalance into range and then balance normally.

B.) Follow instructions 1 thru 5 above.

1. Wheel too light - not enough inertia. Use heavier wheel.

2. Check positioning of sonar unit behind wheel.

1. Press MENU and 5 - turn OFF weight dispenser function.

1. Press MENU and 5 - turn OFF weight dispenser function.

1. Press MENU and 5 - turn OFF weight dispenser function.

1. Press MENU and 5 - turn OFF weight dispenser function.

1. Replace the PC board

Execute a new Runout measurement.

1. Execute a new runout measurement.

1. Execute a new runout measurement.

8113936 00 10/04 page 3 of 4

Page 4

Error

Err.54

Err.55

Err.56

Err.57

Err.58

Err 59

Err.65

Symptom

Error in the Sonar reading.

Sonar did not read any value.

Error in the Radial Sonar reading.

The values taken by the Sonar are

insufficient for a correct Radial

Runout measurement.

Error in the Lateral Sonar reading.

Sonar did not read any value.

Error in the Lateral Sonar reading.

The values taken by the Sonar are

insufficient for a correct Lateral

Runout measurement.

Error in the Radial & Lateral Sonar

reading. No value was read by

the Radial and Lateral Sonars.

Error in the Radial and Lateral

Sonar reading. The values taken

by the Radial and Lateral Sonars

are insufficient for a correct

Runout measurement.

Printer Not Connected.

Check

1. Before taking the measurement, make sure that the RADIAL RUNOUT

SONAR is properly positioned.

2. Check the RADIAL RUNOUT SONAR connection. Unplug and replug at

power PCB.

3. Check the power supplies on the power board.

4. Replace the RADIAL RUNOUT SONAR.

5. Check that the wheel doesn’t stop before making at least 3 complete

turns after the first braking impulse.

6. Check the belt tightening.

7. Replace the PC board

1. Before taking the measurement, make sure that the RADIAL RUNOUT

SONAR is properly positioned.

2. Check that the wheel doesn’t stop before making at least 3 complete

turns after the first breaking impulse.

3. Check the belt tightening.

4. Fit a medium-sized wheel (14” x 5-3/4”) and execute a Radial Runout

measurement. If error 55 doesn’t take place anymore, it means that the

inertia of the wheel that gave the problem is the cause of the wheel

stopping before the acquisition of the minimum number of values necessary for a reliable Runout measurement.

1. Before taking the measurement make sure that the LATERAL RUNOUT

SONAR is properly positioned.

2. Check the Lateral Runout Sonar connection. Unplug and Replug at

power PCB.

3. Check the power supplies on the power board.

4. Replace the LATERAL RUNOUT SONAR.

5. Check that the wheel doesn’t stop before making at least 3 complete

turns after the first braking impulse.

6. Check the belt tightening.

7 Replace the PC board.

1. Before taking the measurement, make sure that the LATERAL RUNOUT

SONAR is properly positioned.

2. Check that the wheel doesn’t stop before making at least 3 complete

turns after the first braking impulse.

3. Check the belt tightening.

4. Fit a medium-sized wheel (14”x5-3/4") and execute a Lateral Runout

measurement. If error 57 doesn’t take place anymore, it means that the

inertia of the wheel that gave the problem is the cause of the wheel

stopping before the acquisition of the minimum number of values necessary for a reliable Runout measurement.

1. Check actions in Error 54.

2. Check actions in Error 56.

1. Check actions in Error 55.

2. Check actions in Error 57.

1. Check serial connector at computer PCB.

2. Check serial connections inside cabinet at wire tray.

8113936 00 10/04 page 4 of 4

© COPYRIGHT 2004 HENNESSY INDUSTRIES AND COATS ALL RIGHTS RESERVED PRINTED IN U.S.A.

Loading...

Loading...