Page 1

Models 1100,

1150-2D

Wheel Balancers

Model 1150-2D

See

ÌBalancing Your

First Tire

on page 4.

Safety Instructions

Shown

Set-up Instructions

Operation Instructions

Maintenance Instructions

READ these instructions before placing unit in

service. KEEP these and other materials delivered

with the unit in a binder near the machine for ease

of reference by supervisors and operators.

1601 J. P. Hennessy Drive, LaVergne, TN USA 37086 615/641-7533 800/688/6359 www.ammcoats.com Manual Part No.: 85609415 01

HENNESSY INDUSTRIES INC. Manufacturer of AMMCO

®

, COATS® and BADA® Automotive Service Equipment and Tools. Revision: 5/14

Page 2

IMPORTANT SAFETY INSTRUCTIONS

READ ALL INSTRUCTIONS

1. Eye and face protection recommendations:

“Protective eye and face equipment is required to

be used where there is a reasonable probability

of injury that can be prevented by the use of

such equipment.” O.S.H.A. 1910.133(a) Protective

goggles, safety glasses, or a face shield must be

provided by the owner and worn by the operator

of the equipment. Care should be taken to see

that all eye and face safety precautions are followed by the operator. ALWAYS WEAR SAFETY

GLASSES. Everyday glasses only have impact

resistant lenses, they are not safety glasses.

2. Do not disable hood safety interlock system, or in

any way shortcut safety controls and operations.

3. Be sure that wheels are mounted properly, the

hub nut engages the arbor for not less than four

(4) turns, and the hub nut is firmly tightened

before spinning the wheel.

4. Read and understand this manual before operating. Abuse and misuse will shorten the functional

life.

5. Be sure the balancer is properly connected to the

power supply and electrically grounded.

6. Do not operate equipment with a damaged cord

or if the equipment has been dropped or damaged – until it has been examined and repaired by

a qualified serviceman.

7. Do not let cord hang over edge of table, bench, or

counter or come in contact with hot manifolds or

moving fan blades.

8. If an extension cord is necessary, a cord with a

current rating equal to or more than that of the

equipment should be used. Cords rated for less

current than the equipment may overheat. Care

should be taken to arrange the cord so that it will

not be tripped over or pulled.

10. Wear proper clothing. Safety toe, non-slip footwear and protective hair covering to contain hair

is recommended. Do not wear jewelry, loose

clothing, neckties, or gloves when operating the

balancer.

11. Keep work area clean and well lighted. Cluttered

and/or dark areas invite accidents.

12. Avoid dangerous environments. Do not use power

tools or electrical equipment in damp or wet locations, or expose them to rain.

13. Avoid unintentional starting. Be sure the balancer

is turned off and power disconnected before

servicing.

14. Disconnect the balancer before servicing.

15. Use only manufacturer’s recommended accessories. Improper accessories may result in personal

injury or property damage.

16. Repair or replace any part that is damaged or worn

and that may cause unsafe balancer operation. Do

not operate damaged equipment until it has been

examined by a qualified service technician.

17. Never overload or stand on the weight tray or any

part of the balancer.

18. Do not allow untrained persons to operate machinery.

19. To reduce the risk of fire, do not operate equipment in the vicinity of open containers or flammable liquids (gasoline).

20. Adequate ventilation should be provided when

working on or operating internal combustion

engines.

21. Keep hair, loose clothing, fingers, and all parts of

body away from moving parts.

22. Use equipment only as described in this manual.

9. Keep guards and safety features in place and in

working order.

23. Use only manufacturer’s recommended attachments and accessories.

SAVE THESE INSTRUCTIONS

ii • Important: Always read and follow instructions.

Page 3

Owner’s Responsibility

To maintain machine and user safety, the responsibility

of the owner is to read and follow these instructions:

Definitions of Hazard Levels

Identify the hazard levels used in this manual with the

following definitions and signal words:

• Follow all installation instructions.

• Make sure installation conforms to all applicable

Local, State, and Federal Codes, Rules, and Regulations; such as State and Federal OSHA Regulations

and Electrical Codes.

• Carefully check the unit for correct initial function.

• Read and follow the safety instructions. Keep them

readily available for machine operators.

• Make certain all operators are properly trained,

know how to safely and correctly operate the unit,

and are properly supervised.

• Allow unit operation only with all parts in place and

operating safely.

• Carefully inspect the unit on a regular basis and

perform all maintenance as required.

• Service and maintain the unit only with authorized

or approved replacement parts.

• Keep all instructions permanently with the unit

and all decals/labels/notices on the unit clean and

visible.

• Do not override safety features.

Operator Protective Equipment

Personal protective equipment helps make tire servicing safer. However, equipment does not take the

place of safe operating practices. Always wear durable

work clothing during tire service activity. Loose fitting

clothing should be avoided. Tight fitting leather gloves

are recommended to protect operator’s hands when

handling worn tires and wheels. Sturdy leather work

shoes with steel toes and oil resistant soles should be

used by tire service personnel to help prevent injury

in typical shop activities. Eye protection is essential

during tire service activity. Safety glasses with side

shields, goggles, or face shields are acceptable. Back

belts provide support during lifting activities and are also

helpful in providing operator protection. Consideration

should also be given to the use of hearing protection if

tire service activity is performed in an enclosed area, or

if noise levels are high.

DANGER

Watch for this symbol:

DANGER

It Means: Immediate hazards, which will result in

severe personal injury or death.

WARNING

Watch for this symbol:

It Means: Hazards or unsafe practices, which could

result in severe personal injury or death.

CAUTION

Watch for this symbol:

CAUTION

It Means: Hazards or unsafe practices, which may

result in minor personal injury or product or property

damage.

Watch for this symbol! It means BE ALERT! Your

safety, or the safety of others, is involved!

Important: Always read and follow instructions. • iii

Page 4

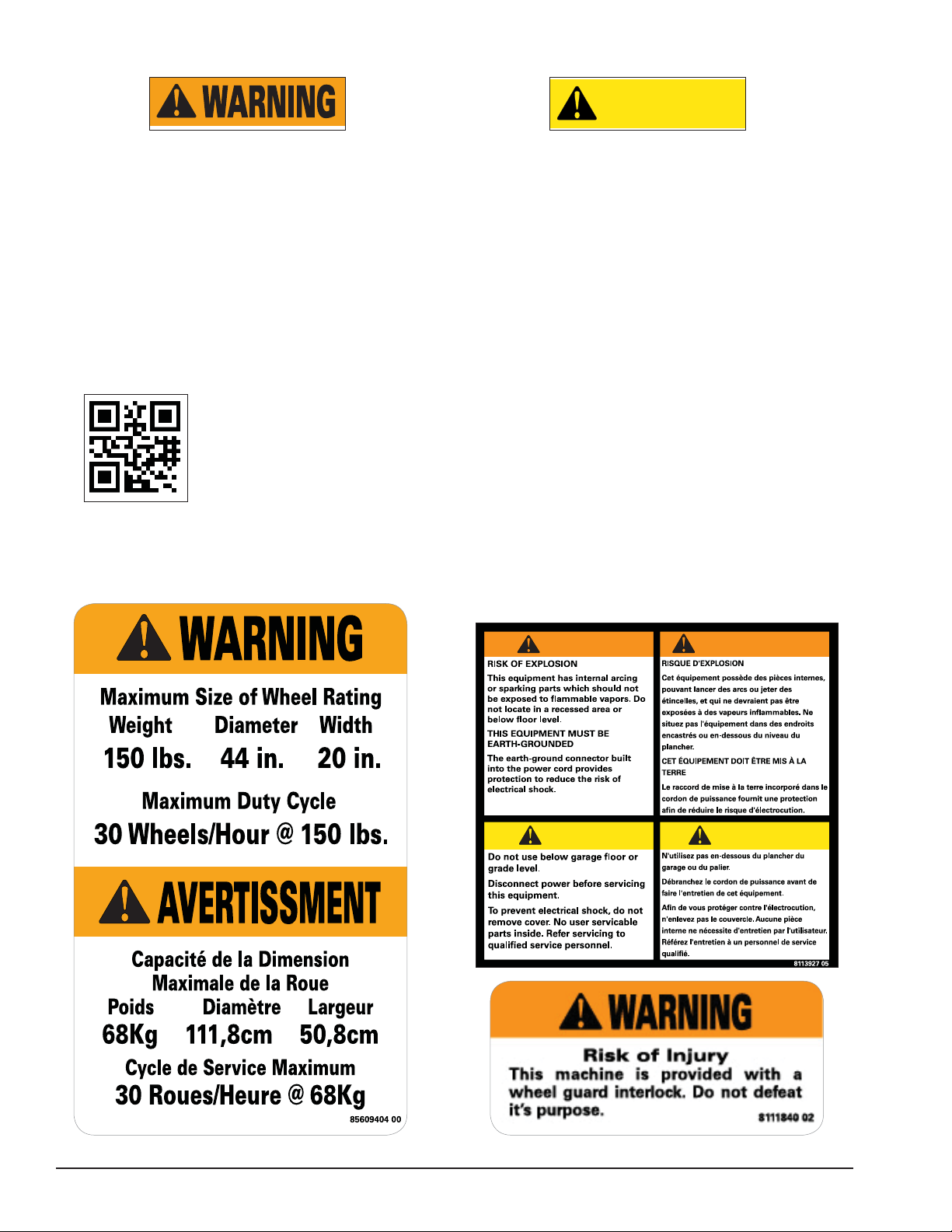

Safety Notices and Decals

Standard Safety Devices

CAUTION

Failure to follow danger, warning, and caution

instructions may lead to serious personal

injury or death to operator or bystander or

damage to property. Do not operate this

machine until you read and understand all

the dangers, warnings and cautions in this

manual. For additional copies of either, or

further information, contact:

Hennessy Industries, Inc.

1601 JP Hennessy Drive

LaVergne, TN 37086

(615) 641-7533 or (800) 688-6359

www.ammcoats.com

Never raise up the wheel guard before the

wheel has come to a stop. Keep hair, loose

clothing, fingers and all parts of body away

from moving parts.

• STOP key for stopping the wheel under emergency

conditions.

• A hood guard of high impact plastic that is designed

to prevent the counterweights from flying out in any

direction except towards the floor.

• A hood switch interlock system that prevents the

machine from starting if the guard is not lowered

and stops the wheel whenever the guard is raised.

WARNING

CAUTION

AVERTISSEMENT

ATTENTION

iv • Important: Always read and follow instructions.

Page 5

Table of Contents

Owner’s Responsibility............................................ iii

Operator Protective Equipment .............................. iii

Definitions of Hazard Levels ...................................iii

Safety Notices and Decals ......................................iv

Standard Safety Devices .........................................iv

Set Up Instructions .................................................. 2

Receiving ................................................................. 2

Electrical Requirements .......................................... 2

Machine Set Up ...................................................... 2

Floor and Space Requirements ............................... 2

Connect to Power ................................................... 2

Specifications ............................................................ 3

Features ..................................................................... 3

Accessory Options.................................................... 3

Basic Accessory Kit 85009974 ................................ 3

★Balancing Your First Tire ........................................ 4

Principle Operating Parts ......................................... 5

Know Your Unit ........................................................ 5

Power Switch .......................................................... 6

Using The Offset Arm .............................................. 6

Control Panel Layout ............................................... 8

Control Panel Function and Review ........................ 8

Mounting Wheel On Balancer Shaft ......................10

Standard Back Cone Mounting ..............................10

Standard Front Cone Mounting ..............................11

Alternate Mounting ................................................11

Direct Select™ Weight Location ........................... 12

Setting Wheel Dimensions (DIM) .......................... 12

Definition of Dimensions (DIM) ............................ 12

Basic Wheel Data Entry ........................................ 13

Entering Wheel Dimensions Manually .................. 13

Balancing A Wheel .................................................. 14

Dynamic Balancing ................................................ 14

Static Balancing ..................................................... 14

Behind Spoke Mode (1150-2D only) ...................... 15

Corrective Weight Placement ................................ 15

Match Balance (Optimization) .............................. 16

Match Balance Mode ............................................ 16

Calibration Program ............................................... 17

Machine Calibration ................................................17

Arm Calibration ...................................................... 18

Maintenance Instructions ...................................... 19

Diagnostic Procedures ........................................... 20

After Balance Vibration Problems .......................... 20

Troubleshooting ..................................................... 20

Glossary ................................................................... 22

NOTICE

Read entire manual before assembling,

installing, operating, or servicing this

equipment.

Important: Always read and follow instructions. • 1

Page 6

Set Up Instructions

Receiving

The shipment should be thoroughly inspected as soon

as it is received. The signed bill of lading is acknowledgement, for the carrier, of receipt in good condition

of the shipment covered by our invoice.

If any of the goods called for on this bill of lading are

shorted or damaged, do not accept them until the carrier makes a notation of the shorted or damaged goods

on the freight bill. Do this for your own protection.

NOTIFY THE CARRIER AT ONCE if any hidden loss or

damage is discovered after receipt and request him to

make an inspection. If the carrier will not do so, prepare

an affidavit to the effect that you have so notified the

carrier (on a certain date) and that he has failed to

comply with your request.

IT IS DIFFICULT TO COLLECT FOR LOSS OR DAMAGE AFTER YOU HAVE GIVEN THE CARRIER A CLEAR

RECEIPT.

File your claim with the carrier promptly. Support

your claim with copies of the bill of lading, freight bill,

invoice, and photographs, if possible.

Although COATS responsibility ceases upon delivery

of the shipment to the carrier, we will gladly assist

in tracing lost shipments. Our willingness to assist in

every possible manner does not make COATS responsible for collection of claims, or replacement of lost or

damaged materials.

Electrical Requirements

See serial tag for the appropriate power requirements

of your machine.

Always have a qualified electrician install the proper

receptacles in accordance with state and local codes.

Machine Set Up

CAUTION

Do not use the control panel, control panel

base, accessory storage, faceplate, hood or

shaft to lift the balancer.

CAUTION

Do not attempt to install and set up the unit

yourself. Contact COATS as noted below.

A factory trained COATS Service Technician must

perform the install, set up, and initial test procedures on

your wheel balancer. Do not attempt to install and set

up the unit yourself. Accurate and reliable operation of

your unit depends on proper installation. Please contact

COATS directly at 86-512-62620469 for the Certified

Service Partner nearest you.

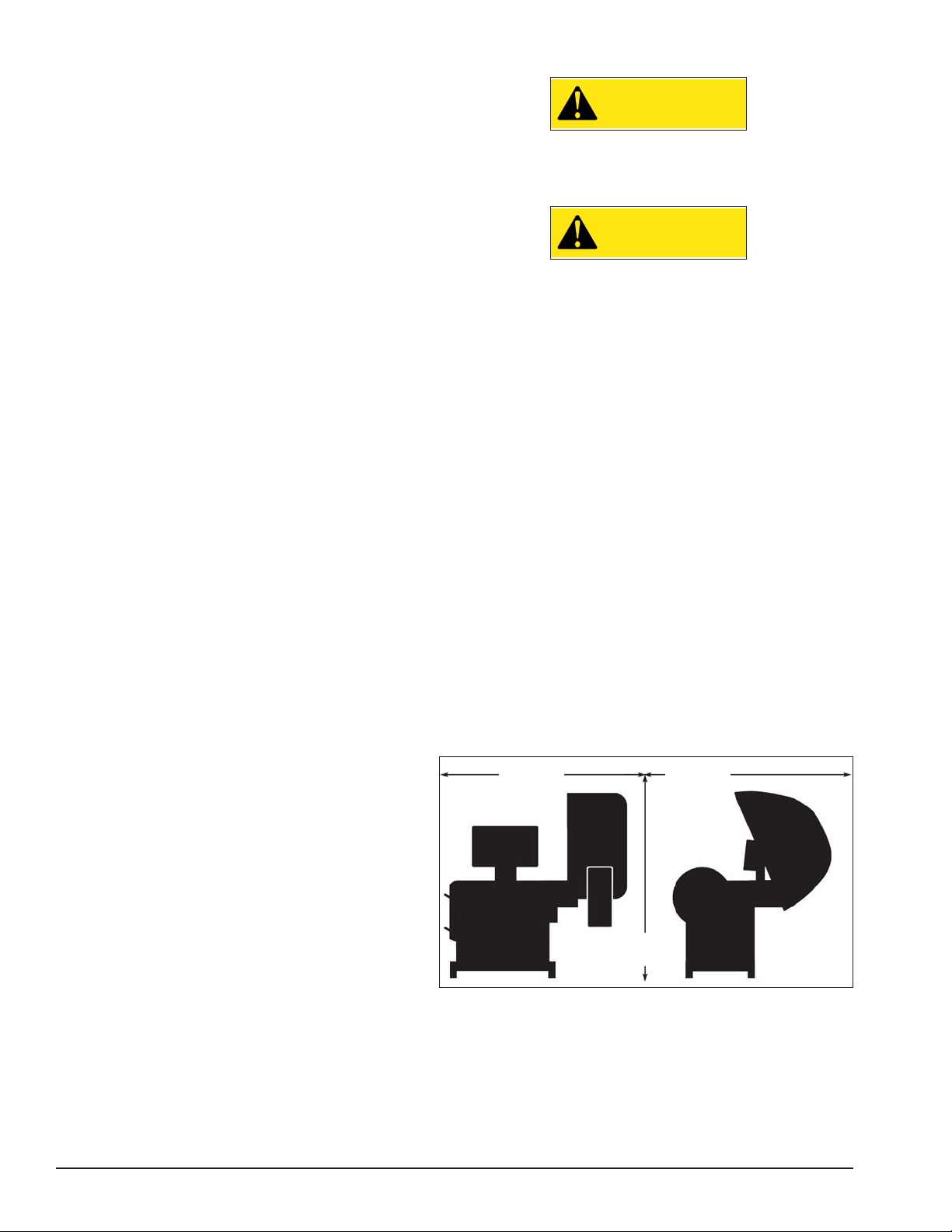

Floor and Space Requirements

The balancer must be located on a flat floor of solid

construction, preferably concrete. The balancer must

sit solidly on its three feet. If the balancer is not level,

does not sit solidly on its three feet, or is placed on an

unstable floor, the balancer will not function properly

and may produce inaccurate balance readings.

Do not operate the balancer while it is on the pallet.

Select a location for the balancer that provides a level,

solid floor, and adequate clearance around and above

the balancer. Make sure the location selected has

enough room above and behind the unit so the hood

can be raised completely. The location must also provide working room for mounting and removing wheels.

Make sure the area has adequate lighting.

5-ft.

(1529mm)

5-ft.

(1529mm)

6.5-ft.

(1981mm)

Figure 1 - Space Requirements

Connect to Power

Your factory trained COATS® Service Technician should

do the final check to verify the power installation before

connecting the balancer to a power supply. Failure due

to improper power connection may void the warranty

2 • Important: Always read and follow instructions.

Page 7

Specifi cations

Features

Wheel Diameter Range

8 - 30 inches (203 - 762 mm)

Wheel Width Range

2 - 20 inches (51 - 508 mm)

Maximum Outside Tire Diameter

Up to 44 inches (1016 mm)

Maximum Tire/Wheel Weight

150 pounds (68 Kg)

Mounting Shaft Diameter

40 mm

Resolution (Round Off Mode)

0.25 ounce, position 1.40 degrees

Resolution (Non-Round Off Mode)

0.01 ounce, position 1.40 degrees

Balancing Display Increments

0.25 or 0.01 ounces

Electrical Requirements

220V, 1 PH, 60 Hz, 20A

NEMA L6-20R

220V, 3 PH, 60 Hz, 20A

NEMA L15-20R

(use grounding type plug)

Footprint

Depth: 60 inches (1524 mm)

Width: 60 inches (1524 mm)

Shipping Weight

680 pounds (308 Kg)

(with accessories)

• Automatic Data Entry for Offset and Diameter - Manual Entry Backup on all Parameters (1150-2D only)

• Static-on-Screen™

• Direct Select™ Weight Placement Location

Dynamic (Standard): Clip-on Weights

Alloy: User Defined

Static

• Behind the Spoke Weight Placement (1150-2D only)

• Automatic Start When Hood is Lowered

• Single Spin Balancing - Dynamic and Static

• Easy-To-Read Position Indicators

• Hood Safety Interlock System

• Extended Mounting Faceplate for Deeper Wheels

• Removable Center Shaft for Closed Center Wheels

• Match Balance (Optimization)

• Operator Memory for Two Different Users

• User Friendly Weight and Position Calibration

• No Bolt-down Installation

• Solid State Motor Control

Accessory Options

Basic Accessory Kit 85009974

• Small Cone

• Medium Cone

• Large Cone

• Light Truck Cone

• Rim Width Calipers

• Wheel Weight Pliers

• Hubnut Handle

• Small Pressure Cup & Rubber Lip

• Cone Spring

• Scraper

• Cone Peg Brackets

Important: Always read and follow instructions. • 3

Page 8

★Balancing Your First Tire

1. Turn the machine OFF then ON

(resets machine).

The machine wakes up using

standard clip-on wheel weight

locations (Clip 1 & Clip 2) and

wheel dimensions.

2. Mount a tire/wheel onto

balancer that will use standard

clip-on wheel weights.

Use the most appropriate mounting method.

3. Always remove any weights

already attached to the wheel.

4. Enter A & D wheel dimensions

using offset arm.

For Automatic Measurement — pull offset arm

out to the wheel, hold it still at clip-on weight

position against wheel flange, and wait for

BEEP. Return arm to home position.

Clip-on Weight Location — viewed on a cut-

away rim for clarification.

7. Raise hood after tire stops

rotating.

Note: Wait for wheel to stop before raising the

wheel guard.

8. Rotate wheel until Inboard

weight position bar blinks.

Note: If an inboard corrective weight is not

required then go to step 10.

9. Attach inboard corrective

weight.

Attach specified weight amount at top-dead-

center on inside flange of wheel (clip 1).

10. Rotate wheel until Outboard

weight position bar blinks.

11. Attach outboard corrective

weight.

Attach specified weight amount at top-dead-

center on outside flange of wheel.

12. Lower the hood to respin the

tire/wheel and check balance.

Figure 2 - Clip-On Weight Location

Note the value entry of A & D dimension.

5. Enter Width wheel dimension.

For Manual Entry — Use plastic calipers to

measure wheel width. Press W key. Press Up

or Down arrow to enter Width value (between

2.0 and 14.0 inches).

6. Lower Wheel Guard; wheel spins

and unbalances are measured

and displayed.

The corrective weight amount appears in the

weight display window for inboard and outboard weight locations.

The weight readings should now be 0.00.

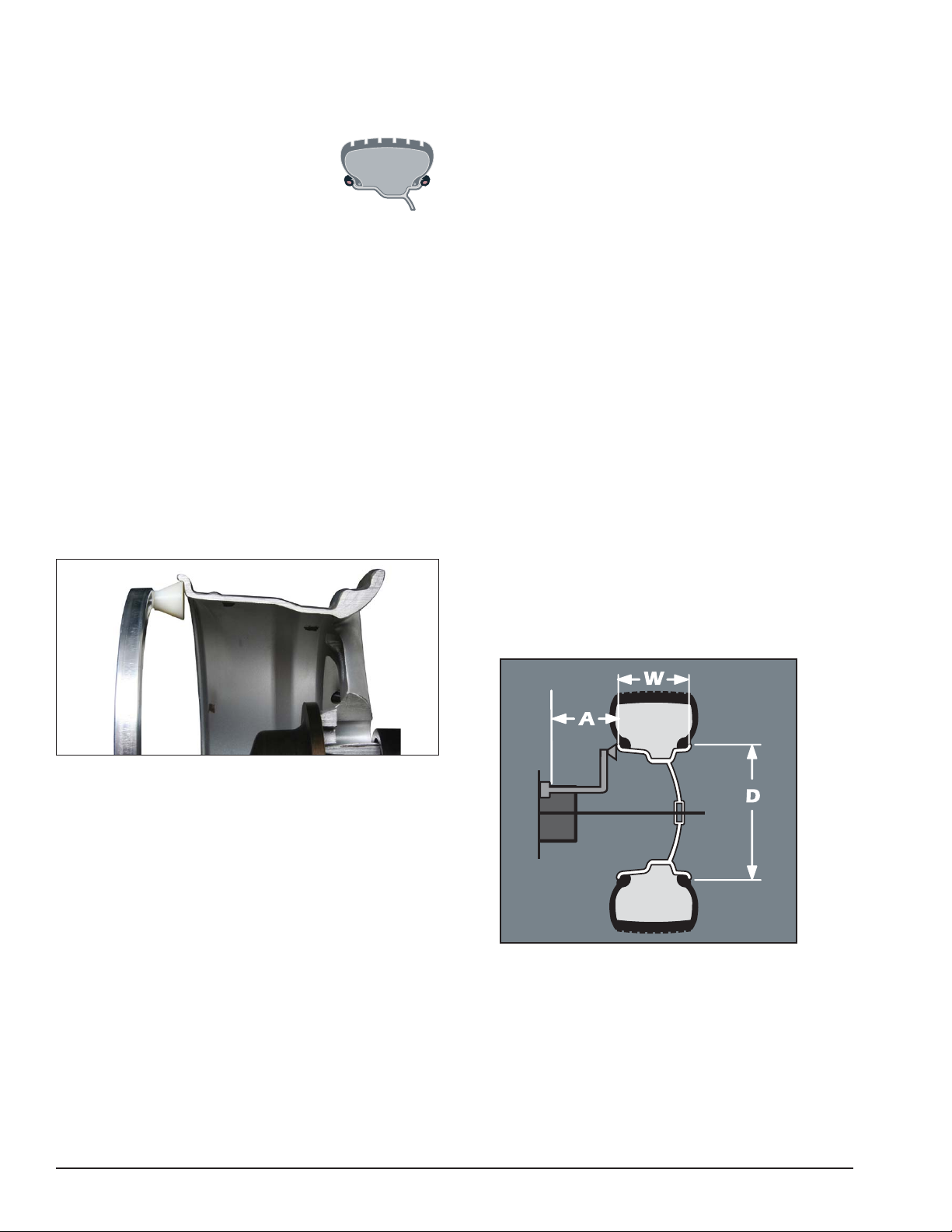

Note: Throughout this manual tire dimensions

are referred to as A, W, and D, see figure 3.

Figure 3 - A, W, and D Tire Dimensions

4 • Important: Always read and follow instructions.

Page 9

Principle Operating Parts

A

B

C

D

E

G

H

A

C

B

D

G

E

H

A - Control Panel

Know Your Unit

Compare this illustration with the unit before placing

it into service. Maximum performance and safety will

be obtained only when all persons using the unit are

fully trained in its parts and operation. Each user should

learn the function and location, of all controls.

Prevent accidents and injuries by ensuring the unit is

properly installed, operated and maintained.

B - ON/OFF Switch (back of machine)

C - Plug (back of machine)

D - Weight Tray with Pockets for Weights

E - Offset Arm, Measures A & D of Tire/Wheel

(Shown In Home Position)

G - 40 mm Shaft

H - Hood Guard

D

C

B

A

E

G

H

Important: Always read and follow instructions. • 5

Page 10

Note: Throughout this manual, wheel weights are

referred to as Clip-on or Tape-A-Weight®. Figure 4

shows an example of each weight.

Using The Offset Arm

When not in use or when prompted by the balancer

instructions, store the offset arm in the home position

as shown in figure 6.

Clip-on Weight Tape-A-Weight

Figure 4 - Corrective Weight Examples. For Best Results, use

BADA® Brand Wheel Weights.

®

Power Switch

The ON/OFF switch location (figure 5) is at the back

of the balancer; below the weight tray.

Offset Arm

In Home

Position

Figure 6 - Location of Offset Arm (Stored In Home Position)

When prompted by balancer instructions, use the

offset arm (figure 6) to enter A & D measurements

automatically. Pull the arm out and up against the wheel

flange; hold it still at the clip-on weight location (figure

7), against the wheel flange, and wait for the BEEP.

ON/OFF

Power

Switch

Figure 7- Automatic A & D Measurement At Clip-on Weight

Location

Figure 5 - On/Off Switch

6 • Important: Always read and follow instructions.

Page 11

Be sure to place the offset arm on the wheel flange at

the clip-on weight location as shown, figure 8.

Important: The A2 measurement must be at least 2

inches greater than the A1 measurement.

Figure 8 - Clip-on Weight Location Viewed on a Cut-Away Rim

for Clarification

Note: Use the offset arm to automatically measure

the A & D dimension for all balancing modes.

Note: Refer to page 13 to measure the A dimension

manually using the offset arm.

Note: The T2 Tape Direct™ Select Weight position is

the only mode that requires the A2 & D2 dimension

measurements.

A1 A2

At least

2-inch

minimum

difference

Figure 10 - T2 Tape (Hidden Tape-A-Weight®) Keep At Least

2-inches Between A1 and A2 Measurement

If the T2 Tape (hidden Tape-A-Weight®) location is

selected, use the offset arm to enter A2 & D2 measurements, automatically. After the A & D measurement is

entered, move the arm from the clip-on weight location

to the inner area of the wheel; up against the rim at the

Outboard weight placement location (see figures 9 &

10). Wait for the BEEP.

Figure 9 - Hidden Weight Location Viewed on a Cut-Away Rim

for Clarification

Figure 11 - T2 Tape (Hidden Tape-A-Weight

gram

®

) Data Entry Dia-

Important: Always read and follow instructions. • 7

Page 12

Control Panel Layout

7

4

6

5

3

2

2

1

1

2

3

4

2

3

1

2

4

5

7

6

Figure 12 - Control Panel Feature Reference (Model 1150 Shown)

Control Panel Function and Review

1 Weight Display Windows

Two weight display windows, one Inboard and one Outboard, are positioned above the Wheel Cross-section

Diagram. After a wheel measurement cycle, the balancer calculates the corrective weight amount and indicates

it in the appropriate display window. All weight readings are shown in Ounces or Grams. Also displays A, W,

and D values, functions, and instructions for the operator. Error messages will also be shown in this display.

The Total Static window indicates the value of the total static unbalance. See MATCH BALANCE (Optimization)

on page 16 for further details.

2 Weight Position Bars

Located on either side of the wheel cross-section diagram are the weight position bars, one Inboard and one

Outboard. After a measurement cycle, rotate wheel until the center weight position bar blinks, indicating the

correct weight placement position is at top-dead-center.

Key Group If you press/select ... Then indicator illuminates/displays...

3 Direct Select™ Weight Keys & Wheel Cross-section Diagram

Clip 1, or T1 Tape

, or

T2 Tape, T3 Tape or Clip 2

, or

the activated Inboard weight location

on the wheel cross-section diagram.

the activated Outboard weight location

on the wheel cross-section diagram.

4 Wheel Dimensions (DIM) Keys & Measurement Diagram

, , or

A, D, or W

A2+Function or D2+Function

+ or +

the activated wheel measurement

location. The default is Clip 1 and Clip 2.

Enter wheel data manually using either

the Up or Down arrow key.

8 • Important: Always read and follow instructions.

Page 13

Key Group If you press/select ... Then indicator illuminates/displays...

5

6

7

5 Balance Mode Keys

+

6 Balance Option Keys

Match

Spoke (1150-2D only)

Calibration

Function+Calibration that Arm Calibration mode is activated.

Dynamic or Static

A or B

Ounce or Gram

Car or Light Truck

Round Off

that Match Balance (Optimization)

mode is activated.

that Behind Spoke mode is activated

Toggle to activate / select location 1 or

location 2 for adhesive weights.

that Machine Calibration mode is

activated.

the Balance mode that is activated.

Scroll to select Dynamic (default),

Dynamic/Total Static or Static.

the Operator Memory option that is

activated. Toggle between two operator

memories A (default) or B.

the weight measurement option that is

activated. Toggle to select either Ounce

(default) or Gram.

the weight increment option that

is activated. Toggle to select either

0.25-ounce passenger car (default) or

0.50-ounce RV-Lt Truck (heavy wheels).

the weight increment option

0.25-ounce (default) is activated. Toggle

off to select 0.01-ounce (fine).

7 Navigation Keys

Down Arrow or Up Arrow

or

Function

EXIT that the function or error is deactivated.

START / STOP

the data entry values. Scroll to select

desired value.

the activated function. Usually used in

combination with another key.

that measurement cycle is either

begun (hood lowered) or is halted.

Important: Always read and follow instructions. • 9

Page 14

Mounting Wheel On Balancer

Shaft

CAUTION

Avoid back injury, seek assistance when

lifting heavy tire/rim assemblies onto the

balancer shaft.

CAUTION

Failure to tighten the hub nut properly may

result in the wheel dismounting, causing

personal injury and property damage.

Select the most appropriate mounting method for

the wheel you are balancing. Using the proper method

ensures secure mounting and safe balancer operation,

and prevents damage to the wheel.

On most wheels, the inner side of the wheel hub usually has the most uniform surface for wheel balancing.

Always center the wheel by the most uniform shaped

side of the hub to achieve the most accurate balance.

Regardless of mounting type, on standard units,

always make sure that the wheel is forced firmly against

the shaft faceplate and that the hub nut engages the

threaded shaft for at least four complete turns. To assist

in centering the wheel properly, rotate the wheel and

the shaft while tightening the hub nut.

Standard Back Cone Mounting

Most original equipment and steel wheels can be

mounted properly using this method. The wheel is

centered on a cone from the inner side of the hub.

Faceplate

Cone

Spring

Figure 13 - Standard Back Cone Mounting

1. Place the cone spring onto the balancer shaft with

the large end towards the faceplate.

2. Select the cone that best fits the center hole in the

wheel. Slide the cone onto the shaft with the large end

towards the cone spring.

3. Lift wheel onto the shaft and center it on the cone.

4. Attach pressure cup to hub nut. Install the hub nut

assembly onto the shaft and tighten it securely against

the wheel. The wheel must be forced firmly against the

faceplate. The hub nut must engage the threads for at

least four full turns

Note: Use a nylon spacer (protective ring) to protect

custom wheel finishes.

Shaft

Cone

Protective

Ring

Pressure Cup and

Quick Lock Hub Nut

Note: If the hub nut will not tighten completely, use

the front cone mounting method.

10 • Important: Always read and follow instructions.

Page 15

Standard Front Cone Mounting

A wheel should be centered by the outer side of the

hub only when the inner surface will not provide an

accurate surface to center on.

Alternate Mounting

If the wheel has a protruding outer hub which will not

permit the use of the pressure cup, or the cup will not

permit the hub nut to engage at least four turns of the

shaft, this alternate method should be used.

Faceplate

Figure 14 - Front Cone Mounting

Shaft

Cone

Quick Lock

Hub Nut

1. Select the cone that best fits the center hole in

the wheel.

2. Lift the wheel onto the balancer shaft and slide it

back against the faceplate.

3. Slide the cone onto the shaft and into the center

hole of the wheel. You will need to lift the tire to seat

the cone in the center hole.

4. Install the hub nut (without pressure cup) onto the

shaft. Tighten it securely against the cone. The hub nut

must engage the threads for at least four full turns.

Note: If the hub nut will not tighten completely

because of a lack of threads, use an additional cone as

a spacer between the mounting cone and the hub nut.

The wheel must be forced firmly against the faceplate.

Faceplate

Cone

Spring

Figure 15 - Alternate Mounting

Shaft

Cone

No-Mar

Ring

Quick Lock

Hub Nut

1. Place the cone spring onto the balancer shaft with

the large end towards the faceplate.

2. Select the cone that best fits the center hole in the

wheel. Slide the cone onto the shaft with the large end

towards the faceplate.

3. Lift wheel onto the shaft and center it on the cone.

4. Use the small nylon spacer (no-mar ring) or a

centering cone to press against the outer wheel hub.

5. Install the hub nut (without the pressure cup) onto

the shaft. Tighten securely.

Important: Always read and follow instructions. • 11

Page 16

Direct Select™ Weight Location

Setting Wheel Dimensions (DIM)

Before spinning the wheel, use direct select to indicate

weight placement locations on the wheel as follows:

Figure 16 - Direct Select™ Weight Keys & Wheel Crosssection Diagram

Note: When the machine is turned ON, the balancer

defaults to a 2-plane dynamic mode using standard

clip-on wheel weight locations (Clip 1 and Clip 2) and

wheel dimensions.

Clip 1 (default) - select this location to place a stan-

dard clip weight on the Inboard rim flange.

Before a wheel can be balanced, wheel dimensions

must be entered into the computer.

Definition of Dimensions (DIM)

A = Offset

The distance measured from the balancer (“0” on offset arm) to inner plane of the rim (inner weight location).

W = Width

The width of the wheel at the rim flanges, measured

with the calipers as shown in figure 19.

Note: Only use calipers provided by the wheel bal-

ancer manufacturer because others may not be the

same.

D = Diameter

The diameter of the wheel as indicated on the tire.

Note: A thick flange, on some aluminum wheels, can

effect the measured diameter. For example, a 16-inch

rim can have a measured diameter of 15.5-inches.

T1 Tape - select this location to place an adhesive

weight on the Inboard side of the wheel that is the

horizontal plane at the outer edge.

T2 Tape - select this location to place an adhesive (hid-

den) weight on the Outboard side of the wheel that is

the horizontal plane in the inner area.

T3 Tape - select this location to place an adhesive

weight on the Outboard side of the wheel that is the

horizontal plane at the outer edge.

Clip 2 (default) - select this location to place a stan-

dard clip weight on the Outboard rim flange.

Figure 17 - W, D, and A Tire Dimensions

A2 = Offset

The distance measured from the balancer (“0” on

offset arm) to outer plane of the rim (outer weight location). Used only for adhesive weight location.

D2 = Diameter

The diameter as measured at the A2 weight location.

Used only for adhesive weight location.

Figure 18 - A2 and D2 Tire Dimensions

12 • Important: Always read and follow instructions.

Page 17

Basic Wheel Data Entry

1. Direct Select™ an Inboard weight location (Clip 1,

or T1 Tape) and an Outboard weight location (T2 Tape,

T3 Tape or Clip 2).

2. Position offset arm at clip weight location; wait for

BEEP (A & D enters automatically).

If the T2 Tape location is selected, then move the

offset arm from the clip weight location to the inner

area of the wheel; up against the rim at the outboard

weight placement location; wait for BEEP (A2 & D2

enters automatically).

Entering Wheel Dimensions Manually

Information entered into the balancer software for A,

W, and D can be changed anytime during a balancing

procedure by entering the measurements manually. The

balancer will recalculate weights and positions based on

the new measurements.

Wheel Offset - A

1. Press the A (wheel offset) key.

2. Position offset arm at weight location on wheel and

read the number on the offset arm gauge, at the cabinet

(this is the correct offset A DIM).

3. Return offset arm to the home position.

4. Use caliper and measurement rim width.

5. Use UP / DOWN arrows to adjust the W (Width

DIM) to match measured caliper width of mounted rim.

6. Lower hood and spin wheel.

3. Use UP / DOWN arrow to adjust the measurement.

Wheel Diameter - D

1. Press the D (wheel diameter) key.

2. Inspect mounted tire sidewall to determine the

exact diameter this is printed on the tire.

3. Use the UP / DOWN arrow to adjust the D (Diam-

eter DIM) to match the tire sidewall size.

Note: Auto entry is the preferred method for entering A2 and D2. However, to manually enter A2, press

Function+A and hold. And to enter D2, press Function+D

and hold.

Wheel Width - W

1. Press the W (wheel width) key.

2. Use the plastic calipers provided with the wheel

balancer to measure the wheel width.

Figure 19 - Caliper Placement On Wheel

3. Use UP / DOWN arrows to adjust the W (Width

DIM) to match measured caliper width of mounted rim.

Important: Always read and follow instructions. • 13

Page 18

Balancing A Wheel

A variety of wheel configurations can be balanced

using this wheel balancer. Read through this section,

it will help in determining which balancing mode and

options are best suited for certain wheel assemblies.

Remember: As with any balancing procedure, first

remove any weights attached to the wheel, inspect the

tire and wheel, and use the most appropriate balancer

mounting method before beginning.

Dynamic Balancing

Choose a dynamic balance to balance a wheel using

two planes for correction. Select the weight option that

best fits the available weight locations on the rim.

Clip-on Weights - The standard default; used for most

passenger tire/wheel assemblies using the most common location for corrective weights. Clip-on weights

are placed on the inner (inboard) and outer (outboard)

rim flanges.

ALUS (Aluminum Wheels) - To balance aluminium

wheels you usually use a self-adhesive weight location

that is positioned differently from the clip-on weight

position(s) used in standard balancing. Be sure to use

the appropriate wheel data entry method since the

balancer calculates out of balance values based on the

wheel dimension measurements (DIM) entered for the

tire/wheel assembly.

Static Balancing

Choose a static balance to balance a wheel using one

plane for correction. Place the single corrective weight

at top-dead-center (12 o’clock) on either flange, at the

center of the rim channel, placed inward either side, or

split on either sides.

Figure 21 - Static Balance Weight Locations

Note: When in static mode, you only need to input the

DIAMETER wheel measurement.

Important: If you decide to use the rim channel for

corrective weight placement, remember you may need

to adjust the DIAMETER measurement input. Typically

you would make it 2 or 3 inches less than the actual tire/

wheel diameter.

Figure 20 - Dynamic Balance Weight Locations

Note: When the machine is switched on, a standard

dynamic balance using clip-on weight locations is the

default setting.

14 • Important: Always read and follow instructions.

Page 19

Behind Spoke Mode (1150-2D only)

“Splitting” the T2 Tape corrective weight amount is

used to hide the adhesive weight behind two rim

spokes.

1. When the unbalance is displayed, rotate wheel

until Inboard center bar blinks. Attach Inboard corrective

weight at top-dead-center.

2. Next, rotate wheel until the outboard center bar

blinks.

3. Select the Behind Spoke mode option. “SP1” will

display in the static display window.

4. Rotate the wheel toward front until the first spoke

is at top-dead-center.; press Spoke and 1 illuminates.

“SP2” will display in the static display window.

5. Rotate the wheel toward rear until the second

spoke is at top-dead-center; press Spoke and 2 illuminates. Now at the Spoke 2 location, the Outboard

center bar stops blinking.

Corrective Weight Placement

After the wheel spins and out of balances are measured and displayed, the corrective weight amount

appears on the weight display window for Inboard and

Outboard weight locations. Bars appear on either side

of the wheel cross-section diagram to aid in positioning

the wheel for corrective weight at the application point.

After a measurement cycle, rotate wheel until the

center weight position bar blinks, indicating the correct weight placement position is at top-dead-center.

If the out-of-balance is less than the chosen threshold

value, 000 appears instead of an out-of-balance value

to indicate that, on that particular side, the wheel is in

tolerance.

Figure 22 - Spoke 1 and Spoke 2 Locations On Either Side Of

Original Outboard Weight Location

6. Attach the Spoke 2 Outboard corrective weight at

top-dead-center behind spoke 2.

7. Next, rotate the wheel toward the Spoke 1 location

until the outboard center bar is blinking.

8. Attach the Spoke 1 Outboard corrective weight at

top-dead-center behind spoke 1.

9. Respin tire/wheel to check balance.

Important: Always read and follow instructions. • 15

Page 20

Match Balance (Optimization)

Match Balance involves the loosening of

tire beads and the inflation of a tire. Training

is necessary in tire changer operation and

understanding the dangers involved during bead seating and tire inflation before

attempting this stage of the Match Balance

procedure. Read the operators manual supplied with the tire changer and consult a

supervisor.

Use the Match Balance (Tire/Rim Weight Optimization)

program to determine the best mating of tire and rim

that will result in the least amount of total unbalance of

the assembly. It requires two spins and two rotations

of the tire on the rim. Match Balance may be needed

when:

• The customer complains of ride problems.

• The balancer calculates a high out of balance.

• The balancer calls for Total Static weights in excess

of 3 ounces (85 grams) on passenger car tires.

Match Balance Mode

If you choose to use Match Balance to correct for a

condition, such as a large static unbalance, then follow

the machine prompts and instructions for the MATCH

BALANCE procedure as outlined in the following steps.

Note: Use this procedure only after the wheel has

spun and the corrective weight amount is displayed.

Note: Use the Total Static display option. See Balance

Options, page 14, for further details.

1. Press Match to select the Match Balance mode. A

“1” will appear in the Outboard weight display.

2. Raise the hood and rotate the wheel until the valve

stem is at top-dead-center. Mark the tire sidewall at the

valve stem.

3. Press Function on the control panel; a “2” will

appear in the Outboard weight display.

4. Remove the wheel assembly from the balancer.

5. Using a tire changer, rotate the tire 180 degrees

on the rim.

6. Remount wheel assembly on the balancer. Press

Function on the control panel; a “3” will appear in the

Outboard weight display.

Important: A high unbalance may indicate the

improper mounting of the assembly on the balancer, or

a rim that is out of round or misformed, or a tire with a

bubble or other problem. If the unbalance is excessive,

it may be prudent to replace the rim, the tire, or both. If

either is replaced, do not continue with Match Balance.

Balance the new tire and rim and evaluate the readings.

7. Lower the hood. The wheel spins; a “4” will appear

in the Outboard weight display.

8. When the wheel stops spinning, raise the hood

and rotate the wheel until the valve stem is at top-deadcenter.

9. Press Function on the control panel. Weight

amounts appear on the control panel.

The amount in the Inboard weight display is the weight

imbalance for the rim. The amount in the Outboard

weight display is the weight imbalance for the tire. Use

these weight amounts to determine the suitability of

the rim or tire.

Note: If either the rim or the tire weight amount is

close to zero or zero then using Match Balance will not

affect the total unbalance of the assembly.

10. Rotate the wheel until the Outboard weight posi-

tion bar flashes. Mark the tire at top-dead-center.

11. Remove wheel assembly from balancer.

12. Using a tire changer, rotate the tire until the mark

is aligned with the valve stem.

13. Remount the wheel assembly on the balancer.

14. Press Function to exit Match Balance. Select a

balancing mode and balance the wheel assembly.

16 • Important: Always read and follow instructions.

Page 21

Calibration Program

Important: Be sure to use the correct calibration

weight amount: a 4-ounce calibration weight with the

ounce option or a 100-gram calibration weight with the

gram option activated. Be sure to deactivate the Round

Off option.

Machine Calibration

For machine calibration, proceed as follows:

1. Mount a 14, 15, or 16-inch steel tire/wheel assem-

bly on the balancer. A balanced tire/wheel is required.

Note: Position wheel so that no weights are on either

flange at the top-dead-center location. Turn the machine

OFF then ON.

2. Press and hold Calibration key for three (3) seconds

to select Machine Calibration mode.

3. Press “D” key to enter the D (diameter) dimension.

Press the Up and/or Down arrow key to adjust numbers.

A valid data entry is either “14”, “15”, or “16”.

4. Press the Function key.

5. Lower the hood and press the START key to begin

the measurement cycle.

6. After the tire/wheel stops spinning, raise the hood.

Important: It is critical that the inner weight be placed

accurately to achieve proper calibration. If the calibration

weight is not moved from the outside flange directly

across to the inside flange, an inner weight placement

error will occur and the calibration will be “failed”.

Figure 25 - Calibration Weight On Inboard Flange At Top-DeadCenter

11. Lower the hood and press the START key to

begin the measurement cycle.

12. After the tire/wheel stops spinning, machine dis-

plays “100, END CAL”.. Machine Calibration is complete.

13. Press FUNCTION to exit.

7. Rotate wheel until the Outboard center bar blinks.

Attach calibration weight (either 4-ounce or 100 gram) to

the outboard flange at top-dead-center.

Figure 24 - Calibration Weight On Outboard Flange At TopDead-Center

8. Lower the hood and press the START key to begin

the measurement cycle.

9. After the tire/wheel stops spinning, raise the hood.

10. Rotate wheel until the Inboard center bar blinks.

Move and attach the 100-gram calibration weight to the

inside flange at top-dead-center.

Important: Always read and follow instructions. • 17

Page 22

Arm Calibration

Important: Always perform the Arm Calibration imme-

diately after Machine Calibration. The balancer software

will not permit it otherwise. During Machine Calibration,

the balancer software calculates both the A (offset) and

W (width) dimensions. The Arm Calibration gives the

balancer software a reference point to the edge of the

faceplate and home position. When the user enters the

A dimension from the arm rod, it calculates the difference from the Machine Calibration A and uses that as a

factor for the manual A entry. Arm Calibration also gives

the D dimension a reference point from home position.

1. Complete the Machine Calibration procedure (see

page 17).

2. Press and hold the Function key and Calibration

key for three (3) seconds to select the Arm Calibration

mode.

3. Bring the tip edge of the arm precisely to the outer

edge of the faceplate and hold it there while pressing

the Function key. If necessary to reach the faceplate

accurately, loosen the calibration wheel temporarily.

4. With the arm still at the edge of the faceplate,

press A key and use UP / DOWN arrow to adjust A

dimension value as shown on arm gauge. Display will

show at static position of LED. Press Function key.

8. Return arm to home position.

9. When machine displays “END”, the Arm Calibration

is complete. Press FUNCTION to exit.

Important: To redo the Arm Calibration procedure,

press and hold FUNCTION and press “Clip 1” for 3

seconds to enter CDE mode, then press “T1 Tape” then

press “W” to bypass the Machine Calibration requirement. Always use the same wheel assembly that was

used during the Machine Calibration or else the calibration will not be correct.

Hold Arm

Tip Edge

At Edge Of

Faceplate

Enter A

Value

Shown On

Arm Gauge

Figure 26 - While holding Arm At Faceplate Edge, Enter A

5. Move the arm to its home position and press the

Function key.

6. Move the arm to the clip-on weight location on the

rim flange and hold it there; press D key and use UP /

DOWN arrows to adjust the D dimension value. Display

will show at static position of LED. Press Function key.

7. While still holding the arm at the clip-on weight

position on the wheel, press A key and use UP / DOWN

arrows to adjust the A dimension value as read off the

arm gauge. Press Function key.

18 • Important: Always read and follow instructions.

Page 23

Maintenance Instructions

Use common sense, this is an electrical

device. Exposing the balancer to water,

either by hose or bucket, or by exposure

to rain or snow, may cause risk of shock

or electrocution to operator or bystanders.

Place, store, and operate the balancer only

in a dry, sheltered location.

CAUTION

Do not hose down with water or bucket

wash the balancer. Extensive damage to

the balancer will result. Sensitive electronic

components, wiring harnesses, and other

devices housed in the balancer are not

intended to be exposed to water.

The balancer requires only minor maintenance to keep

the unit operating properly.

1. Keep the display clean and clear. Use a damp cloth.

Do not use cleaners or solvents which leave oily or filmy

residues behind.

2. Keep the adapters, cones, faceplate, threaded

shaft, pressure cup, and hub nut clean. Grease and dirt

buildup will cause inaccurate balancing and premature

wear. Clean these items at least once a day with a

vaporizing solvent.

3. Clean weight tray and any accessory posts, pegs,

or storage shelves with a vaporizing solvent. Weights

stored in a dirty tray may pick up grease and dirt which

may keep them from securely attaching to the wheel.

4. Keep the area around and under the balancer

clear. Remove any tools or other items that are leaning

against the balancer. Remove any items that may cause

the balancer to not sit level. Be particularly cautious of

new or used wheel weights on the floor, as they may

cause personal injury due to falls.

5. Use only COATS® accessories. Accessories from

other manufacturers may not fit or function properly,

and may damage the balancer.

Important: Always be sure to remove the wheel

assembly from the pneumatic shaft before disconnecting the air supply from the machine.

Important: Always read and follow instructions. • 19

Page 24

Diagnostic Procedures

After Balance Vibration Problems

If vibration is still present after balancing the wheels

and driving the vehicle on smooth pavement, remove

the wheels and recheck the balance. If a wheel is out

of balance the cause maybe:

• Wheel was not mounted/centered correctly on the

balancer.

• A weight has come off the wheel (possibly the

wrong clip style). Remove the other weights from

the wheel and rebalance.

• Foreign material inside the tire. Remove the tire

from the wheel, remove the foreign material, and

remount. Remove wheel weights and rebalance the

wheel.

Troubleshooting

A COATS® Service Technician may ask for information to help diagnose service concerns (please contact

COATS directly at 1-800-688-9240 for the Certified

Service Partner nearest you). Conveying this information to your service technician prior to servicing can help

to expedite service to your equipment. Although much

of the diagnostic information aids your COATS Service

Technician, several remedies for balancer misfunctions

are available to the operator.

Error Messages - One of the following error messages, shown in the display windows, may appear

indicating a problem with the balancer.

Note: Always exit the error message by pressing the

Up arrow+Function key; then repeat the procedure to

see if the error is eliminated.

• Stones or other foreign objects caught in the tire

tread or rim. Remove the objects. Check and rebalance if needed.

If the balancer still indicates the wheels are balanced

to within 0.05 ounces (1.42 grams) on both Inboard and

Outboard displays, the problem is not in the balance of

the wheels. Check the following possible sources of

vibration:

• Tire pressure. Bring all tires up to the recommended

PSI.

• Radial or lateral runout in the tire or wheel. Replace

the damaged part.

• Unbalance in wheel covers or trim rings. Remove

the wheel covers or trim rings and test drive. If

the vibration is gone, remove the shaft and use

an appropriate adapter to mount the wheel to the

balancer. Balance the wheel with the wheel cover

or trim ring attached to the wheel.

• Incorrectly mounted tire and wheel. Remount correctly.

• Damaged wheel bolt holes. Replace wheel.

• Worn universal joints. Replace as required.

• Drive shaft unbalance or damaged. Balance, repair,

or replace.

• Unbalance in brake rotor(s) or drum(s).

• Suspension out of alignment. Align the vehicle and

replace any damaged or worn parts.

Error Description

Spin up is too slow - Verify power supply

E1

to balancer and motor connection

Spin up time too long - Check Wheel DIA

E2

and power supply - press STOP - EXIT

No rotation signal - Check motor &

E3

encoder function & wiring -press STOP EXIT

Wheel rotation direction is reversed -

E4

Disconnect power and correct wiring

Stop time too long - Verify power supply

E5

and motor connection - press STOP - EXIT

Encoder is not connected or has failed -

E6

Disconnect power supply and repair

Wheel coast speed is too slow

E9

User cancelled the operation

E11

Arm scale is out of range

E20

Lower hood to spin

E24

Loose hub nut. Tighten hub nut and respin

E25

CAL ERROR

E26

Err Hod

Err Hub

Err Ad

Hood switch is not closed when machine

cycle is started - Lower hood to spin Verify hood switch

No load condition detected - Verify wheel

mounted properly on the shaft - Check

repeatability

No dimension input

20 • Important: Always read and follow instructions.

Page 25

Error Description

100, N01, CAL

100, N02, CAL

100, N03, CAL

Overload Protection - The balancer’s motor is over-

load protected per UL requirements. After 4 to 5 minutes the machine automatically resets itself; activating

the fan motor. If this happens, notify your Certified

Service Partner immediately.

Important: Allow the fan to cool the motor for at least

30 minutes before using the balancer so the overload

protection is not tripped again.

Exceeded 5 degree range

between placement of calibration

weight from outside flange to

inside flange.

Calibration wheel is more than

1-ounce out of balance. Calibration

is rejected.

Calibration wheel is more than

0.25-ounce but less than 1-ounce

out of balance. Calibration is

stored, but with warning.

Important: Always read and follow instructions. • 21

Page 26

Glossary

ALUS -Alloy wheel mode that typically requires the

use of one or two adhesive weights for correction.

Balancer Flange – Disk that mates with the disk of

the wheel mounted to the balancer. The flange also

serves to keep the wheel perfectly perpendicular to its

axis of rotation.

Balancing Cycle – Sequence of operations performed

by the user and the machine, beginning from the start

of the wheel spin to the time that the wheel is braked to

a standstill after the out of balance signals are acquired

and the relative values calculated.

Centering – Procedure for positioning the wheel on

the spindle shaft with the aim of ensuring that the

rotational axis of the wheel is aligned with the center

of the shaft.

Centering Flange (accessory) – Device serving to

support and center the wheel. Also keeps the wheel

perfectly perpendicular to its axis of rotation. The centering flange is mounted to the balancer shaft by means

of its center hole.

Cone – Conical components with center hole. When

inserted on the spin shaft, serves to center wheels with

centre holes whose diameter is between maximum and

minimum values.

Spin – Procedure starting from the action that causes

the wheel to rotate and the successive free rotation of

the wheel.

Quick Nut – Device for clamping the wheel to the bal-

ancer. The hubnut features elements for engaging to the

threaded hub and lateral pins that are used to tighten it.

Static Balancing – In static balancing only the static

component of out of balance is corrected. This is

achieved by fitting a single weight, usually at the

center of the rim channel. The accuracy of this system

increases as the width of the wheel decreases.

Threaded Hub – Threaded part of the shaft that is

engaged with the hubnut to clamp the wheel. This

component is supplied disassembled from the machine.

Out of balance – Non-uniform distribution of the

wheel mass that results in the generation of centrifugal

force during rotation.

Dynamic Balancing – Operation in which out of bal-

ance is corrected by the application of two weights, one

on each side of the wheel.

Self-calibration – A procedure whereby suitable cor-

rection coefficients are calculated by starting from

known operating conditions. Self-calibration improves

the measurement precision of the machine by correcting, within limits, calculation errors that may arise due

to alteration of the machine’s characteristic over the

course of time.

22 • Important: Always read and follow instructions.

Page 27

Important: Always read and follow instructions. • 23

Page 28

85609415 01 5/2014 © Copyright 2014 Hennessy Industries and COATS®. All Rights Reserved

Loading...

Loading...