Page 1

P.O. Box 3002, 1601 J. P. Hennessy Drive, LaVergne, TN USA 37086 615/641-7533 800/688-6359 Manual Part No.: 8143259

HENNESSY INDUSTRIES INC. Manufacturer of AMMCO

®

, COATS®and BADA®Automotive Service Equipment and Tools. Revision: 01/01 rev. 2

1001 Computer

Wheel Balancer

®

Installation Instructions

Operating Instructions

Safety Instructions

Maintenance Instructions

READ these instructions before placing unit in

service KEEP these and other materials delivered

with the unit in a binder near the machine for

ease of reference by supervisors and operators.

Page 2

ii • COATS 1001 Wheel Balancer

Direct Drive

Page 3

COATS 1001 Wheel Balancer • iii

Table of Contents

Operator Protective Equipment . . . . . . . . . .iv

Owner’s Responsibility . . . . . . . . . . . . . . . . .v

Definitions of Hazard Levels . . . . . . . . . . . . .v

Important Safety Instructions . . . . . . . . . . .vi

Specifications . . . . . . . . . . . . . . . . . . . . . . . . .1

Power Requirements . . . . . . . . . . . . . . . . . . .1

Standard Package . . . . . . . . . . . . . . . . . . . . .1

Installation and Setup . . . . . . . . . . . . . . . . . .2

Floor and Space Requirements . . . . . . . . . . . . . . .2

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 3

Hood and Pod Set-up . . . . . . . . . . . . . . . . . . . . . .3

Electrical Power . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Initial Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

New Features of (C) 1985 Microprocessor . . . . . .5

Balancing Procedure

Display Board Layout . . . . . . . . . . . . . . . . . . . . . . .6

1. Mount Wheel . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2. Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3. Rim Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

4. Rim Diameter . . . . . . . . . . . . . . . . . . . . . . . . . .9

5. Spin Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

6. Take Readings . . . . . . . . . . . . . . . . . . . . . . . . .10

7. Attach Weight . . . . . . . . . . . . . . . . . . . . . . . . . .10

Balancing Special MAG Wheels (Adhesive

Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

1. Two Adhesive Weights

(Outside Weight Visible) . . . . . . . . . . . . . . . . . . . .11

2. Standard Clip Weight - One Adhesive Weight

(Hidden Method) . . . . . . . . . . . . . . . . . . . . . . . . .12

3. Two Adhesive Weights

(Hidden Method) . . . . . . . . . . . . . . . . . . . . . . . . .12

Static Balancing (Adhesive Weight) . . . . . . . . . . .13

Wheel Mounting Options

Back Cone Mounting . . . . . . . . . . . . . . . . . . . . . .14

Light Truck Cone . . . . . . . . . . . . . . . . . . . . . . . . .14

Special Problems . . . . . . . . . . . . . . . . . . . . .15

Calibration

Calibration Check Procedure . . . . . . . . . . . . . . . .15

Calibration Adjustment Procedure . . . . . . . . . . . .16

Optional Combi Adaptor . . . . . . . . . . . .16 -17

Preventive Maintenance . . . . . . . . . . . . . . .17

Contents

Page 4

Important Information

Rubber Manufacturers Association

1400 K Street N. W.

Washington, DC 20005

(202) 682-4800

Tire Guides, Inc.

The Tire Information Center

1101-6 South Rogers Circle

Boca Raton, FL 33487-2795

(561) 997-9229

www.tireguides.com

Failure to follow danger, warning, and caution

instructions may lead to serious personal injury or

death to operator or bystander or damage to property. Do not operate this machine until you read

and understand all the dangers, warnings and cautions in this manual. For additional copies of either,

or further information, contact:

Hennessy Industries, Inc.

P.O. Box 3002, 1601 J.P. Hennessy Drive

LaVergne, TN 37086-1982

(615) 641-7533 or (800) 688-6359

www.Hennessy-Ind.com

Operator Protective

Equipment

Personal protective equipment helps make tire servicing safer. However, equipment does not take the

place of safe operating practices. Always wear durable

work clothing during tire service activity. Loose fitting

clothing should be avoided. Tight fitting leather gloves

are recommended to protect operator’s hands when

handling worn tires and wheels. Sturdy leather work

shoes with steel toes and oil resistant soles should be

used by tire service personnel to help prevent injury in

typical shop activities. Eye protection is essential during tire service activity. Safety glasses with side

shields, goggles, or face shields are acceptable. Back

belts provide support during lifting activities and are

also helpful in providing operator protection.

Consideration should also be given to the use of hearing protection if tire service activity is performed in an

enclosed area, or if noise levels are high.

Read entire manual

before assembling,

installing, operating,

or servicing this

equipment.

iv • COATS 1001 Wheel Balancer

Safety

WARNING

WARNING

Page 5

COATS 1001 Wheel Balancer • v

Owner’s Responsibility

To maintain machine and user safety, the responsibility of the owner is to read and follow these instructions:

• Follow all installation instructions.

• Make sure installation conforms to all applicable

Local, State, and Federal Codes, Rules, and

Regulations; such as State and Federal OSHA

Regulations and Electrical Codes.

• Carefully check the unit for correct initial function.

• Read and follow the safety instructions. Keep

them readily available for machine operators.

• Make certain all operators are properly trained,

know how to safely and correctly operate the unit,

and are properly supervised.

• Allow unit operation only with all parts in place

and operating safely.

• Carefully inspect the unit on a regular basis and

perform all maintenance as required.

• Service and maintain the unit only with authorized

or approved replacement parts.

• Keep all instructions permanently with the unit

and all decals/labels/notices on the unit clean and

visible.

• Do not override safety features.

• If ownership of the unit is transferred, provide

new owner all information, manuals, and provide

COATS new ownership information.

Definitions of Hazard

Levels

Identify the hazard levels used in this manual with

the following definitions and signal words:

DANGER

Watch for this symbol:

It Means: Immediate hazards, which will result in

severe personal injury or death.

WARNING

Watch for this symbol:

It Means: Hazards or unsafe practices, which could

result in severe personal injury or death.

CAUTION

Watch for this symbol:

It Means: Hazards or unsafe practices, which may

result in minor personal injury or product or property

damage.

Watch for this symbol! It means BE ALERT! Your

safety, or the safety of others, is involved!

Safety

DANGER

WARNING

CAUTION

Page 6

vi • COATS 1001 Wheel Balancer

Safety

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

READ ALL INSTRUCTIONS

1. Eye and face protection recommendations:

“Protective eye and face equipment is required to

be used where there is a reasonable probability of

injury that can be prevented by the use of such

equipment.” O.S.H.A. 1910.133(a) Protective goggles, safety glasses, or a face shield must be provided by the owner and worn by the operator of

the equipment. Care should be taken to see that

all eye and face safety precautions are followed by

the operator. ALWAYS WEAR SAFETY GLASSES.

Everyday glasses only have impact resistant

lenses, they are not safety glasses.

2. Do not disable hood safety interlock system, or in

any way shortcut safety controls and operations.

3. Be sure that wheels are mounted properly, the

hub nut engages the arbor for not less than four

(4) turns, and the hub nut is firmly tightened

before spinning the wheel.

4. Read and understand this manual before operating. Abuse and misuse will shorten the functional

life.

5. Be sure the balancer is properly connected to the

power supply and electrically grounded.

6. Do not operate equipment with a damaged cord

or if the equipment has been dropped or damaged

– until it has been examined by a qualified serviceman.

7. Do not let cord hang over edge of table, bench, or

counter or come in contact with hot manifolds or

moving fan blades.

8. If an extension cord is necessary, a cord with a

current rating equal to or more than that of the

equipment should be used. Cords rated for less

current than the equipment may overheat. Care

should be taken to arrange the cord so that it will

not be tripped over or pulled.

9. Keep guards and safety features in place and in

working order.

10. Wear proper clothing. Safety toe, non-slip

footwear and protective hair covering to contain

hair is recommended. Do not wear jewelry, loose

clothing, neckties, or gloves when operating the

balancer.

11. Keep work area clean and well lighted. Cluttered

and/or dark areas invite accidents.

12. Avoid dangerous environments. Do not use power

tools or electrical equipment in damp or wet locations, or expose them to rain.

13. Avoid unintentional starting. Be sure the balancer

is turned off before servicing.

14. Disconnect the balancer before servicing.

15. Use only manufacturer’s recommended accessories. Improper accessories may result in personal injury or property damage.

16. Repair or replace any part that is damaged or worn

and that may cause unsafe balancer operation. Do

not operate damaged equipment until it has been

examined by a qualified service technician.

17. Never overload or stand on the balancer.

18. Do not allow untrained persons to operate

machinery.

19. To reduce the risk of fire, do not operate equipment in the vicinity of open containers or flammable liquids (gasoline).

20. Adequate ventilation should be provided when

working on operating internal combustion

engines.

21. Keep hair, loose clothing, fingers, and all parts of

body away from moving parts.

22. Use equipment only as described in this manual.

23. Use only manufacturer’s recommended attachments.

Page 7

COATS 1001 Wheel Balancer • 1

Direct Drive

Specifications

• 5/16 Allen Wrench

• Single spin dynamic/static, twin plane.

• Vertical wheel mounting.

• Backcone and light truck cone mounting systems

standard.

• Accuracy ± 0.1 ounce (or ± 3 gram).

• Exclusive direct drive system (no belt - no pulleys).

• Forced air cooling.

• Cycle time - 4 1/2 seconds (standard tire).

• Rim diameter 10-17 inches.

• Fully interlocked guard hood (safety feature).

• Maximum tire diameter 42 inches.

• Shipping Weight 650 lbs.

• Fewest moving parts of any balancer.

• Large dials for data entry.

• “No bolt down” installation.

• Static/mag feature.

• Large readout in 1/4 ounce or 1/10 ounce or gram

increments.

• Greater distance from shaft to machine (better for

front wheel drive application).

• 1 1/2 H.P. modified torque motor:

Large housing for heat dissipation.

Motor insulation - heavy duty for high tem-

perature application.

Motor rated for 900 RPM use.

• Oversized weight bins.

• Standard adapters fit.

• ABS hood.

• Removable shaft for closed-center wheels.

• Control panel positioned for best visibility.

• Easy to read position lights.

• Scratch resistance surface.

• On-Off switch.

• Electronics isolated from motor heat.

• Simple calibration.

• Automatic rim gauge return.

• Strategically numbered dials for easy reading.

• 6-12-24 month guarantee.

Power Requirements

Standard: Optional: (Factory Installed)

220 VAC 115 VAC 220 VAC

20 AMPS 20 AMPS 20 AMPS

60 Hz 60 Hz 60 Hz

3 Phase 1 Phase 1 Phase

Standard Package

Includes balancer with built-in 17 bin weight tray,

interlocked guard hood, passenger car backcone

mounting system and light truck cone, 6 accessory

pegs, instruction manual, wheel weight tool and

calipers.

Page 8

2 • COATS 1001 Wheel Balancer

Direct Drive

Installation and Setup

A factory trained COATS®Service Technician must

perform the install, setup, and initial test procedures

on your 6401 balancer. Do not attempt to install and

setup the unit yourself. Accurate and reliable operation

of your unit depends on proper installation. Please

contact COATS®directly at 1-800-688-9240 for the

Certified Service Partner nearest you.

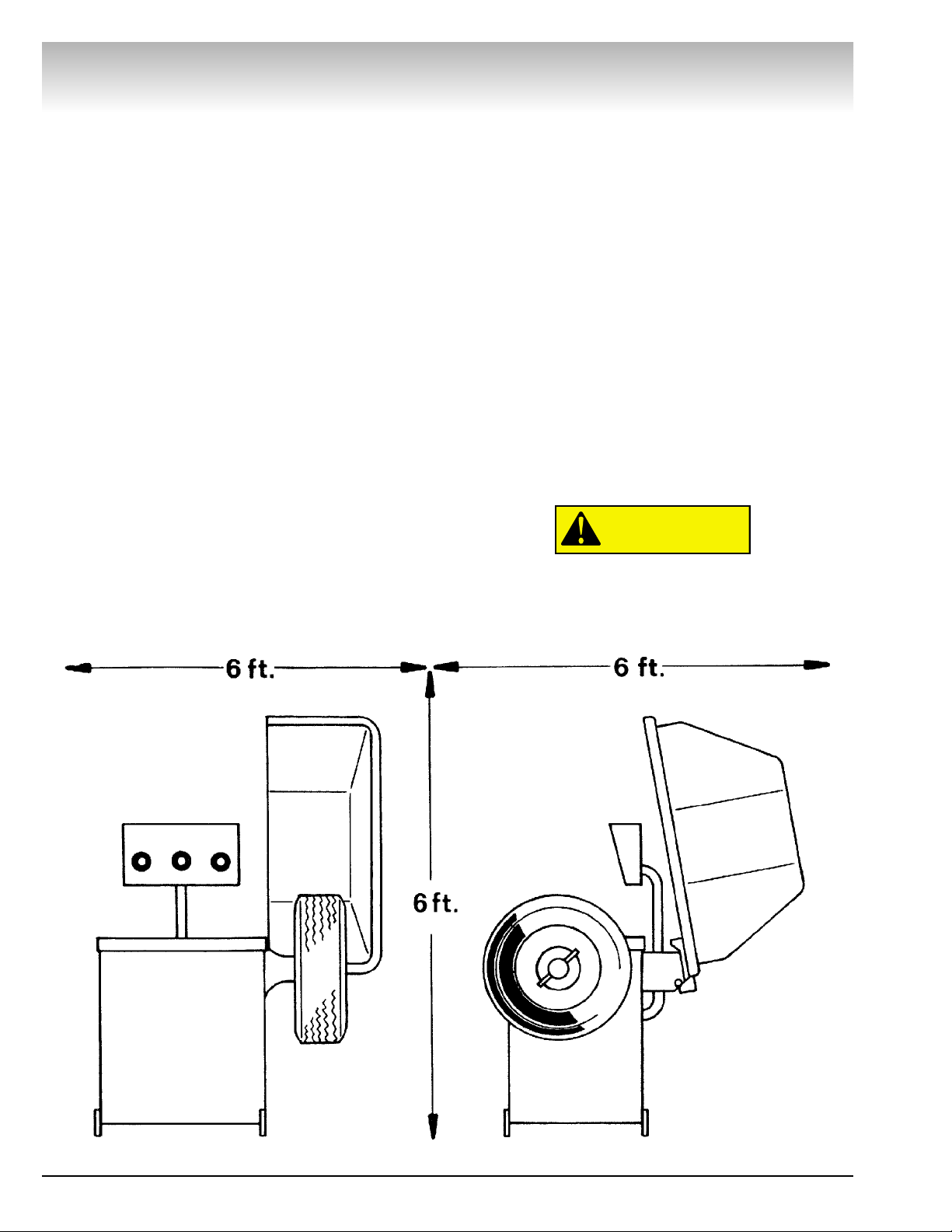

Floor and Space Requirements

The balancer must be located on a flat floor of solid

construction, preferably concrete. The balancer must

sit solidly on its three feet. If the balancer is not level,

does not sit solidly on its three feet, or is placed on an

unstable floor, the balancer will not function properly

and will produce inaccurate balance readings.

Do not operate the balancer when it is still bolted

down or while it is on the pallet.

Select a location for the balancer that provides a

level, solid floor, and adequate clearance around and

above the balancer. Make sure the location selected

has enough room above and behind the unit so the

hood can be raised completely. The location must also

provide working room for mounting and removing

wheels.

Unpacking

Check carton and pallet for crushed corners, broken

slats, gouges, and punctures which may indicate hidden damage. Make a note of all external damage on

the receiving waybill. Freight damage is the responsibility of the delivering carrier.

Initial testing and training are provided by our

COATS®distributor.

Remove outer carton from pallet. Remove strapping

holding hood in shipping position. Locate and remove

accessories. Notify manufacturers representative of

any missing accessories that were ordered.

Perform HOOD AND POD SET-UP.

Remove the single lag bolt and loosen the two (2)

anchor bolts holding the balancer to the pallet. Locate

and install the top two (2) accessory pegs. Carefully

slide the balancer off the pallet and move to final location.

Do not use the control pod, control pod

arm, faceplate, hood or stub shaft to lift the

balancer.

CAUTION

Page 9

COATS 1001 Wheel Balancer • 3

Install and tighten the four (4) remaining accessory pegs and

hang the accessories.

Note: Balancer will not operate properly on pallet.

Hood and Pod Set-up

To set up hood: Locate hood stop in accessory box and install

as shown. Install hood spring as shown. Do not install hood

spring until Control Pod has been set up.

Control Pod Setup: Carefully hold control Pod and Post while

removing 4 retaining screws. Swing Pod upright as shown

above and tightly reinstall the 4 screws. Now attach hood spring

from hood bar pin to base.

Note: Certain models will have the control pod already in its

operating position when received.

DO NOT drop Control Pod when removing the 4

screws.

Direct Drive

CAUTION

Page 10

Electrical Power

Consult a licensed electrical contractor for proper installation

to local electrical codes. Power outlets must be enclosed in a

floor raceway or overhead drop if predestrian or equipment traffic can damage existing power cord.

Operation with a defective ground circuit will create

a shock hazard for the operator and could damage

the balancers electronics. Operation with a defective

ground circuit may void warranty.

Precautions

Check voltage requirements on balancer ID plate. Balancer

requires nominal 220VAC, 60 Hz, three-phase power with a 20ampere fuse or circuit breaker. Mating outlet (not furnished) is

Hubbel 2420 or Bryant 71520, connected as shown below. A

factory installed option is available allowing operation from 115

VAC, single-phase power. A 20 ampere fuse or circuit breaker

and a standard three-pin safety outlet wired as shown below is

required. Electric outlets must have a solid connection (less

than one ohm between ground and pin and building ground).

Voltage Reading Between: 220V Type

X - Y 200 - 250

X - Z 200 - 250

X - Z 200 - 250

Voltage Reading Between: 220V Type

A - B 105 - 130

Power and ground requirements must be verified by installer

or inspector before connecting balancer. Failure to observe this

precaution may void warranty.

If balancer is bolted down, a licensed electrical contractor

must be consulted. Most electrical codes require “hard” wiring

when balancer Is bolted down.

Consult a licensed electrical contractor for proper installation

to local electrical codes. Power outlets must be enclosed in a

floor raceway or overhead drop if pedestrian or equipment traffic can damage existing power cord.

Direct Drive

4 • COATS 1001 Wheel Balancer

White

Black

Red

Green

Ground

To Outlet

X

Y

Z

White

Black

Green

To Outlet

Ground

CAUTION

Page 11

Initial Testing

Initial testing and training are provided by your COATS distributor. Complete instructions for unpacking and installIng your balancer are contained in the INSTALLATION AND SETUP section

of this manual.

Precautions: Initial testing should be performed by instructor.

Power requirements must be verified by installer or instructor

before connecting balancer. Failure to observe this precaution

may void warranty.

Power: Plug power cable into power outlet receptacle. Set circuit breaker in building breaker panel ON. Set ON-OFF switch

ON. Leave power on during working day.

Cooling Air: Check to verily cooling air blower is running. Do

not operate Unit unless cooling air flow is present.

Spin: (Standard 220 VAC 3-phase units.) Press START button

with hood down. Faceplate should rotate clockwise. If initial

direction of faceplate rotation is incorrect, set ON-OFF switch

OFF. Set building circuit breaker OFF. Interchange X-Y wires in

outlet plug. Set building circuit breaker ON, set ON-OFF switch

ON. Press START button. Faceplate initial rotation should be

clockwise when facing faceplate.

Spin: (Alternate 115 VAC single-phase Units.) Press START button with hood down. Faceplate should rotate clockwise for an

Interval and then stop.

If the above conditions cannot be obtained during initial test,

call the distributor for service advice.

New Features of (C) 1985 Microprocessor

1. “HUB” error message if wheel comes loose or no wheel.

2. “rr” error message if wheel goes up to speed in reverse

direction.

3. Display dims after 3 minutes if wheel is stationary.

4. “HI-ACC” active only when button held down. Initiated by

static and mag or by pushing start button 3 times.

5. Duty cycle display more accurate.

For all 1001 boards with S/N greater than 506625.

Direct Drive

COATS 1001 Wheel Balancer • 5

Page 12

6 • COATS 1001 Wheel Balancer

Direct Drive

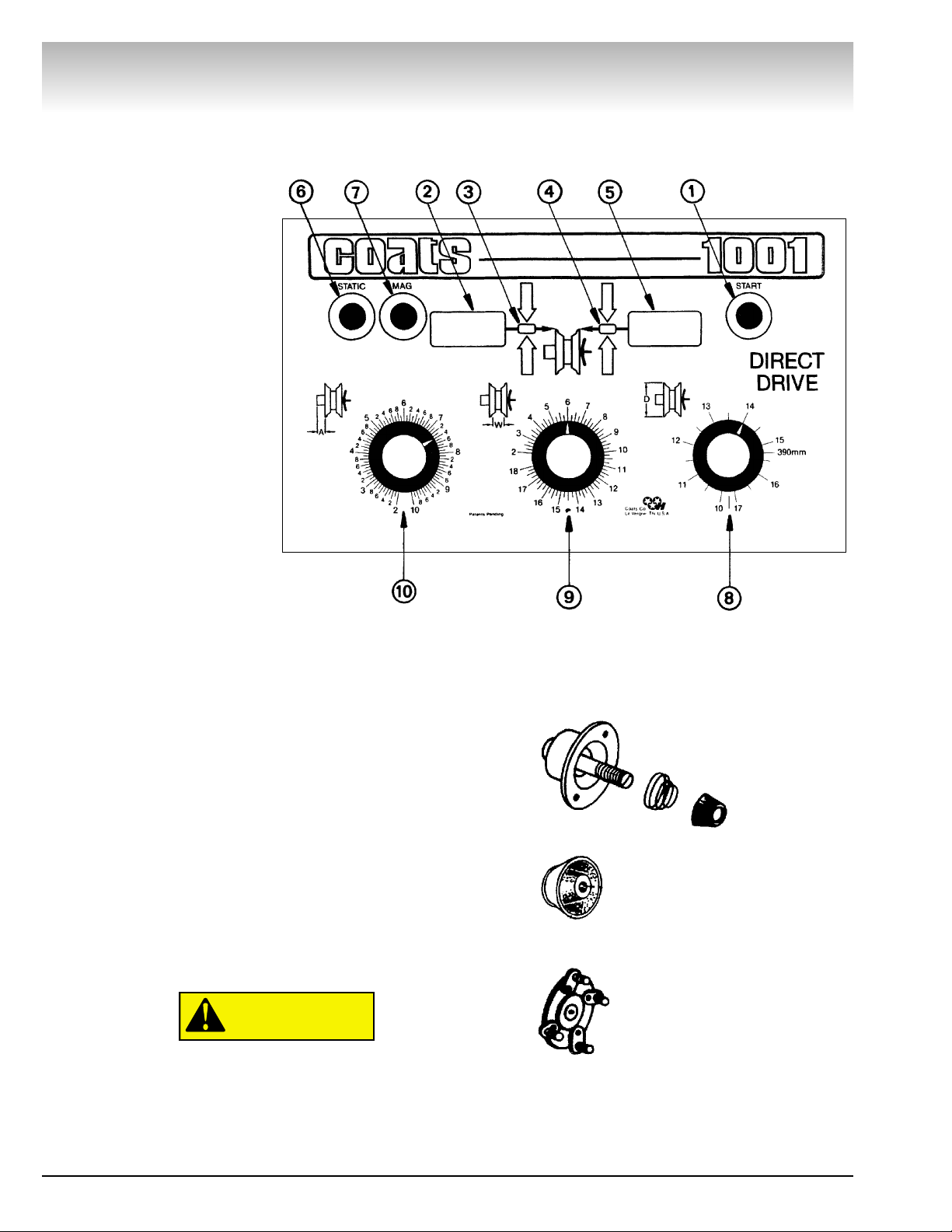

1. Start button

2. INNER weight display.

3. INNER position display.

4. OUTER position display.

5. OUTER weight display.

6. STATIC balance button.

7. “MAG” balance button.

8. Wheel diameter (D) knob.

9. Wheel width (W) knob.

10. Wheel offset (A) knob.

Balancing Procedure

Display Board Layout

Leave balancer power on all day.

Static power use is approximately 70 watts.

1. Mount Wheel

Select proper adapter. Adapter selected should center wheel

the same as the wheel is centered on the vehicle.

Almost all wheels, including aftermarket or “mag” wheels,

can be mounted using the standard back-cone mounting kit.

Light truck wheels can be mounted using The standard light

truck cone. Aftermarket wheels with larger than OE center

holes can be mounted using lug adapters.

Wheels that center off the lug pattern, i.e., 68 and older VW,

Peugeot, etc., can be mounted using the optional lug adapter.

The hubnut or lug nut threads must engage four full

turns. Rotate wheel while tightening to ensure centering. Failure to tighten hubnut securely may result

in serious personal injury.

CAUTION

Page 13

COATS 1001 Wheel Balancer • 7

Direct Drive

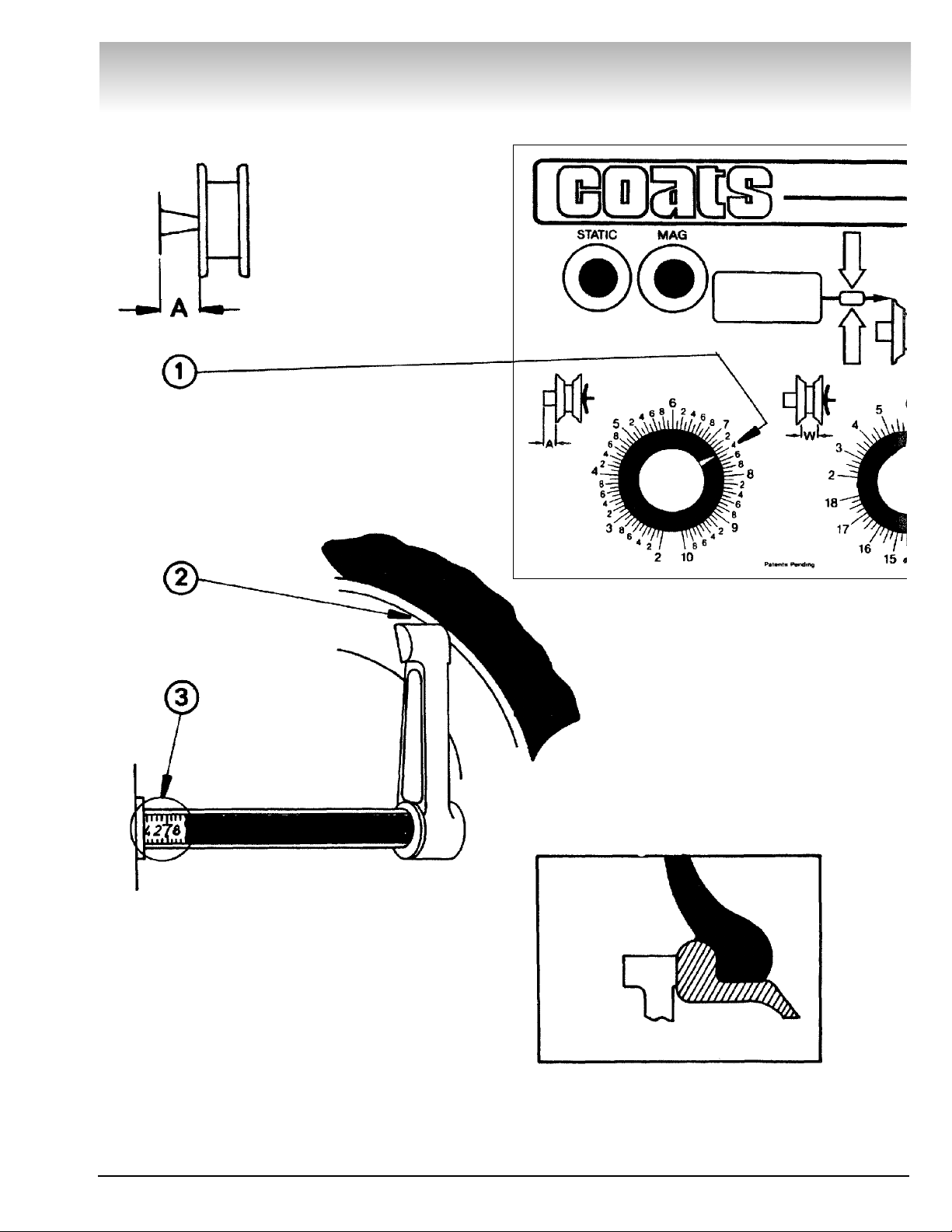

2. Offset

Enter offset distance with this knob.

Move distance gauge to

touch edge of wheel.

Setup for hidden weights on “mag”

is the same as for standard wheels.

Enter this distance

measurement with offset (A) knob. (Shown

in Fig. 1).

MAG Wheels

Page 14

8 • COATS 1001 Wheel Balancer

Direct Drive

3. Rim Width

Enter wheel width information

with this knob.

Use rim width calipers to

measure wheel at points

shown.

MAG Wheels

Setup for hidden weights on “mag” wheels

is the same as for standard wheels.

Enter this width reading

with the width (W) knob.

(Shown in Fig. 1).

Page 15

COATS 1001 Wheel Balancer • 9

Direct Drive

4. Rim Diameter

Enter rim diameter size as

read from tire sidewall.

Setup for hidden weights on

“mag” wheels is the same as

for standard wheels.

Enter this diameter reading

with the diameter (D) knob.

(Shown in Fig. 1).

Page 16

10 • COATS 1001 Wheel Balancer

Direct Drive

5. Spin Mode

Lower Guard Hood Before Starting Spin.

Press start button to obtain normal readings. Balancer will spin

and stop automatically.

6.Take Readings

Weight and position readings will appear on displays as balancer is braking tire.

FINE BALANCE (for unbalance of 0.2 ounce or less): hold

button down during spin cycle. Position readings will always

appear. (Not needed in normal use.)

7. Attach Weight

1. Rotate wheel until right (OUTER) twin lights blink alter-

nately.

2. Attach a weight equal to outer weight reading to outer rim

at top dead center. (See #2)

3. Rotate wheel until left (INNER) twin lights blink alternately.

4. Attach a weight equal to inner weight reading to inner rim at

top dead center. (See #4)

Note: The more accurate you are in

selecting the exact weight and position,

the more often you will balance in one

spin. Respin after applying weights to

obtain 0.00 reading.

CAUTION

Page 17

COATS 1001 Wheel Balancer • 11

Direct Drive

Balancing Special MAG

Wheels (Adhesive

Weights)

If standard clip weights are to be used, balance as a

“standard” wheel. The mag button is used when some

specialty wheels are to be balanced or when adhesive

weights are required (i.e., hidden weight method).

Note: Some specialty wheels do not require the hidden weight method of balancing. See example 2. If

adhesive weights must be used, follow these instructions.

See examples 1, 2 and 3 and select how weights will

be applied.

Set distance gauge, wheel width, and wheel diameter

as indicated in the proper example.

Lower hood and push appropriate button.

Read weight amount and locate position as with a

“standard” wheel.

Raise hood. Apply required weights.

Lower hood. Push appropriate button and check

weight application.

Note: Since hiding adhesive weights involves approx-

imations to actual wheel width and wheel diameter,

additional spins may be required. Simply respin and

apply weights as called for.

Be sure wheel surfaces are clean as per

adhesive weight manufacturer’s recommendations. Apply weight securely, failure to do

so may cause weights to come loose resulting in serious personal injury.

START

Note: The mag button is

not used for this method

of balancing.

Since rim diameter is slightly

smaller than tire size “D”, enter

one inch smaller than tire size.

Move distance gauge arm to

here, and enter distance

gauge reading.

Measure rim width “W” with

rim width calipers and enter

this measurement.

OUTER adhesive

weight will be

applied here.

Read OUTER weight amount

and locate position for outer

plane. Install weights as

described above.

Read INNER weight amount

and locate position for Inner

plane. Install weights as

described above.

INNER adhesive

weight will be

applied here.

Note: Be sure adhesive weights will clear disc brake calipers.

1. Two Adhesive Weights

(Outside Weight Visible)

WARNING

Page 18

Direct Drive

12 • COATS 1001 Wheel Balancer

MAG

Use Mag Button.

Enter rim diameter as read

from the sidewall.

Move distance gauge arm to

touch inner edge of wheel.

Enter distance gauge reading.

Read INNER weight amount

and locate position for inner

plane. Standard clip weight

will be placed here.

OUTER adhesive weight

will be applied here.

Read OUTER weight amount and

locate position for outer plane, Install

weight as described on page above.

Measure rim width “W”

with rim width calipers and

enter this measurement.

Note: Be sure adhesive weights will clear disc brake calipers.

MAG

Use Mag Button.

Enter rim diameter as read

from the sidewall.

OUTER adhesive

weight will be

applied here.

INNER adhesive

weight will be

applied here.

Note: Be sure adhesive weights will clear disc brake calipers.

3. Two Adhesive Weights

(Hidden Method)

2. Standard Clip Weight One Adhesive Weight

(Hidden Method)

Move distance gauge arm

to here and enter distance

gauge readings.

Read INNER weight amount

and locate position for inner

plane. Install weight as

described on page above.

Measure rim width “W”

with rim width calipers and

enter this measurement.

Read OUTER weight amount

and locate position for outer

plane. Install weight as

described on above.

Page 19

Direct Drive

COATS 1001 Wheel Balancer • 13

Note: This method should only be used when the customer requests no visible

weights (outer plane) and there is a caliper clearance problem on the inner plane.

Since rim diameter is slightly

smaller than tire size “D” enter

one inch smaller than tire size.

Note: Since Static balancing is not as

good as twin-plane (Dynamic/Static)

balancing, the offset (A) and width

(W) knobs do not have to be set.

Adhesive weight will be

applied here.

Read INNER weight amount

and locate position for static

imbalance. Install weight as

described on above.

Note: Be sure adhesive weights will clear disc brake calipers.

Static Balancing

(Adhesive Weight)

STATIC

Use Static Button.

Page 20

Wheel Mounting Options

Back Cone Mounting

1. Place spring over threaded stud with the large end

inside of the faceplate.

2. Select a cone that best fits into wheel center hole.

3. Slide selected cone onto threaded shaft with the

large end against the spring.

4. Lift wheel onto shaft and center on cone.

Cone centers wheel—Cone must be centered in wheel center hole before tightening.

The wheel must be forced firmly against the

faceplate. Thread hubnut on and tighten by

rotating wheel and striking both arms of

hubnut with palm of hand. Hubnut must

engage threads for at least four full turns.

Failure to tighten hubnut securely may result

in serious personal injury.

Light Truck Cone

Cone must be centered in wheel center hole

before tightening. Thread hubnut on and

tighten by rotating wheel and striking both

arms of hubnut with palm of hand.

Hubnut must engage threads for at least

four full turns. Reverse hubnut when necessary. Hubnut and cone must force wheel

firmly against faceplate. Failure to tighten

hubnut securely may result in serious personal injury.

Direct Drive

14 • COATS 1001 Wheel Balancer

CAUTION

CAUTION

CAUTION

CAUTION

Page 21

COATS 1001 Wheel Balancer • 15

Special Problems

Customers will occasionally complain of vibration on

the car after balancing. Some possible causes are

listed below:

1. Beads improperly seated. Check bead seating and

inflation pressure before balancing spin.

2. Stiffness variations in radial belts.

3. Tire out of round; wheel out of round, bent, or not

running true. Visually check runout of wheel and tire

during balance spin. Re-check mounting. Replace

wheel or tire if necessary.

4. Suspension wear, misalignment, or loose vehicle

components.

5. Wheels not correctly centered due to damaged

hub, damaged or worn center hole, worn bolt circle

holes, or imprecise original design. Check wheel run

out before balance spin and on the vehicle after mounting.

6. Sensitive suspensions. Use FINE BALANCE (See

page 10).

Complaint: Balancer uses too many weights or several spins to balance.

Remedy: Recheck rim dimensions entered. Position

the weights exactly top dead center when green position lights are on.

Complaint: Weight or position readings fluctuate.

Remedy: Check cone/hubnut for slippage. Check that

the balancer is resting firmly on three mounting points,

floor is flat and stable, and that no tools or weights are

between balancer and floor.

Calibration

Calibration Check Procedure

The calibration check procedure can be performed by

the operator to ensure that the balancer is operating

correctly and is properly calibrated. The only purpose of

calibration is to trim the balancer to yield single-spin

balancing.

Note: If the balancer is set up to display weights in

grams instead of ounces, then observe the parenthesis (0.00 gram) values in the CALIBRATION CHECK

PROCEDURE and the CALIBRATION ADJUSTMENT

MODE.

Throughout the calibration, check procedure, keep

the start button depressed during each cycle. This is

the FINE BALANCE mode which allows the balancer to

read in .01 ounce (1 gram) increments.

1. Mount a standard domestic 14" x 6" wheel with an

F78-14 or 206/75-14 tire using the proper back cone.

Ensure that the wheel is not bent or misaligned and

that the center hole is free of nicks and burrs.

2. Program the distance, rim width, and rim diame-

ter information into the balancer by setting the knobs

on the front panel.

3. Balance the wheel using FINE BALANCE until

0.00 weight readings appear on INNER and OUTER

displays while holding down the start button during the

entire cycle.

4. After getting 0.00 to appear while holding the

start button, change the Rim Diameter adjustment to

read 10.5. If any weight reading appears, repeat step 3.

5. Return the Rim Diameter adjustment to 14.

6. Install a 4 ounce (113 gram) test weight on the

outer rim.

7. Spin. The new weight reading should be 3.80 to

4.20 ounce (108 gram to 119 gram). Rotate the wheel

so that the central position lights on the outer position

indicator come on. The test weight should be directly

across (at 6 o’clock).

Weight readings on the inner display should be 0.20

ounce (6 gram) or less. (This results from interference

between the two balancing planes.)

8. Repeat steps 6 and 7 with the 4 ounce (113 gram)

test weight on the inner rim.

9. If the balancer fails to yield the results required by

this procedure, perform the CALIBRATION ADJUSTMENT PROCEDURE.

Direct Drive

Page 22

16 • COATS 1001 Wheel Balancer

Direct Drive

Calibration Adjustment Procedure

Note: Do not preform Calibration Adjustment when

motor is excessively hot.

1. Perform the calibration check procedure steps

one (1) through seven (7) (See Page 15).

2. Remove the four (4) screws holding the control

panel shroud and lift the shroud off.

3. Place an 8 ounce (226 gram) test weight on outer

rim of wheel.

4. Set service switch to upper position (test mode).

Press the START button. The display will now read

“TEST”. The outer and inner position lights will now act

as bar graphs. First adjust the gain trimpot until the

minimum number of lights are on or flashing.

Alternately adjust the gain and phase trimpots until all

the lights are off.

5. Set service switch to bottom position (NORM).

Remove the test weight and then balance the wheel.

A maximum imbalance of .07 ounce (2 gram) on the

inner and outer weight displays is allowed.

6. Place a 4 ounce (113 gram) test weight on the

outer rim.

7. Set the service switch to center position (non-

stop). Press the START button. Wheel will come up to

speed, but not go into braking mode. Now adjust the

outer weight trimpot (affects outer magnitude). After

each adjustment of the trimpot, press and hold the

START button until a new reading appears on the display. Continue this procedure until the outer weight

display reads 4 ounce (113 gram). The inner weight

reading should be .21 ounce (6 gram) or less. Set the

service, switch to the bottom position so that the

wheel will brake to a stop.

8. Place the 4 ounce (113 gram) test weight on the

inner rim. Set service switch to center position. Press

the START button.

9. Adjust the inner weight trimpot (affects inner

magnitude) until display reads 4 ounce (113 gram). Use

the same procedure as in Step 7. The outer weight

reading should be .21 ounce (6 gram) or less. Set the

service switch to the bottom position (NORM).

10. Calibration is now complete. To return the bal-

ancer to the normal operating mode: Switch off the

power and then turn it on again (On/Off switch located

on rear of machine). This clears the high accuracy

mode and the balancer is ready to use.

Optional Combi Adaptor

Combi adapter may be used for 3, 4, 5, 6, 8, or 10Lug wheels by installing swivel plates in Combi plate

hole pattern. Set up adapter as follows:

Install a swivel plate in combi plate “common” hole.

Line up number gear to match “345” mark with index

mark on swivel plate. Insert swivel plate bolt through

back of combi plate and run up. DO NOT TIGHTEN.

Note: This swivel plate is used for all bolt circle patterns.

Install proper number of swivel plates in combi plate

holes marked “3”, “4”, or “5” as required. Insert swivel

plate bolts through back of combi plate and run up, DO

NOT TIGHTEN. Ensure that index marks on all swivel

plates line up with the appropriate “3”, “4”, or “5” mark

on the number gear.

Install combi adapter on wheel Run up lug nuts by

hand. Tighten lug nuts with adapter wrench, using a

star or criss-cross pattern.

Lug nuts must be centered and threaded at

least four full turns Reverse lug nuts as

required. Use only adapter wrench furnished with adapter Do not use air tools or

impact wrenches.

Tighten swivel plate bolts with alien wrench.

Attach wheel and adapter to faceplate with two

faceplate nuts.

Faceplate nuts must be hand tightened.

Rotate wheel while tightening to ensure

centering.

Adapter should remain on faceplate for additional

wheels with same bolt circle.

High Accuracy Mode For Calibration

CAUTION

CAUTION

Page 23

COATS 1001 Wheel Balancer • 17

Optional Combi Adapter

Direct Drive

Preventative

Maintenance

DO NOT use a solvent which leaves an oil

residue.

NEVER use compressed air or a water hose

to clean any part of your balancer.

Daily: Clean shaft and faceplate with a vaporizing sol-

vent. Cones, hubnut and other mounting hardware

should be checked/cleaned at this time.

Monthly: Clean entire machine. Remove all used

weights, tools and parts which may be under, or leaning against balancer. Perform Calibration Check

Procedure. Make adjustments only if required.

Yearly: Have your COATS authorized service person-

nel perform the following: Clean Optical Sensor, Clean

Fan Motor Air Inlet.

CAUTION

CAUTION

Page 24

8143259 01/01 rev. 2 © Copyright 1993, 2001 Hennessy Industries and COATS All Rights Reserved Printed in USA

Loading...

Loading...