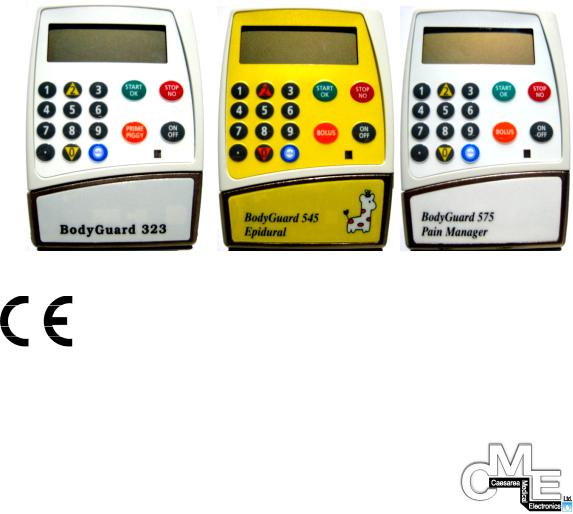

CME BodyGuard 323, BodyGuard 545, BodyGuard 575 Service manual

Service Manual

for

BodyGuard 323, 545, & 575

Infusion pumps

0344

Manufacturer: |

|

Caesarea Medical Electronics Ltd. |

|

International Toll Free: +800-323-575-00 |

|

European address: |

|

Staufenburgstr. 23 Lichtenstein |

|

P.o.b. 1248 Lichtenstein 72805 Germany |

|

E-mail: sales@cme-infusion.com |

|

www.cme-infusion.com |

PN 100-091X ver. 191009 |

|

Table of Contents |

|

Introduction ........................................................................................... |

3 |

Warnings and Cautions......................................................................... |

4 |

Service Process Diagram ....................................................................... |

7 |

Tools and Test Equipment................................................................... |

10 |

Adjustable Operating Parameters and Options................................. |

12 |

Operational Checklist and Performance Acceptance Test................ |

19 |

Calibration ........................................................................................... |

22 |

Troubleshooting................................................................................... |

29 |

Service actions...................................................................................... |

34 |

Service Center Recommended Parts................................................... |

48 |

Cleaning and Storage........................................................................... |

48 |

APPENDIX A....................................................................................... |

49 |

2 of 50

Introduction

This manual provides instructions for the service of BodyGuard infusion pump models 323, 545, and 575 and their software, and mechanical service for pole mount chargers. Sets are single use and are not serviceable.

The following requirements and conditions apply when performing service on BodyGuard products, failure to follow these instructions will invalidate warranty and creates unacceptable risk:

•Service of BodyGuard pumps, chargers and accessories may only be performed by CME authorized service personnel. Service can only be performed with the recommended equipment and CME approved parts.

•This manual is intended to support CME authorized service technicians performing service.

•Clinical personnel, patients, and other users are advised to return pumps to an authorized service center for service.

•Refer to operation manual for pump operation instructions, cautions and warnings.

•Refer to BodyComm operations manual for BodyComm operation instructions.

•Document service performed in accordance with service provider’s prevailing procedures.

3 of 50

Warnings and Cautions

Warning: Warnings advise you of circumstances that could result in injury or death to the patient or operator. Read and understand this manual and the Operation’s Manual taking note of all warnings before operating or performing service on the BodyGuard Infusion System. Caution: Cautions advise you of circumstances that could result in damage to the device. Read and understand this manual and the Operation’s Manual taking note of all cautions before operating or performing service on the BodyGuard Infusion System.

Note: Indicates that the information that follows is additional important information or a tip that will help you when operating or performing service on the BodyGuard Infusion System.

Warnings

To avoid possible personal injury or loss of life, observe the following:

Read the entire Operation’s Manual before using the pump, since the text includes important precautions.

The maximum volume that may be infused under SINGLE FAULT CONDITION is 0.1 ml.

Voltage present on internal components may cause severe shock or death upon contact. Disconnect the charger from AC power prior to opening the casing. Only authorized service personnel should open the pump cover.

Blown fuses could cause a fire hazard. Replace blown fuses on the charger only with fuses of the same type and rating (see fuse values on the charger PCB).

The equipment is not suitable for use in the presence of flammable anesthetic-air/oxygen/nitrous oxide mixture. Do not use the system in the presence of these gases.

Make sure the pump is attached securely to the charger, which is connected snugly to an IV pole.

A kinked or occluded IV line may impair the operation of the pump and the accuracy of the infusion. Before operation, verify that the IV line is not kinked or occluded.

The BodyGuard should be operated only with BodyGuard tubing sets. Use of administration sets other than manufacturer-produced BodyGuard tubing set may impair the operation of the pump and the accuracy of an infusion.

4 of 50

Drugs must not be administered to the epidural space unless the drugs are indicated for this purpose and are administered in accordance with the indications included in the manufacturer’s package insert accompanying the drugs.

Epidural administration of drugs other than those indicated for epidural use could result in serious injury to the patient.

Any adjustments, maintenance, or repair of the uncovered pump may impair the operation of the BodyGuard Infusion System and/or the accuracy of the infusion. Only CME authorized technicians should perform any adjustments, maintenance, or repair of the uncovered pump. Any adjustments, maintenance, or repair of the uncovered pump while connected to the power should be avoided.

The BodyGuard Infusion System should be operated within a temperature range of 15°C (50°F) to 45°C (115°F) and at up to 85% humidity. Operating the pump at temperatures and/or humidity other than within this range may affect accuracy.

Unsafe operation may result from using improper accessories. Use only accessories and options designed for this system and supplied by manufacturer.

The BodyGuard tubing sets should not be use for blood, blood products or nitroglycerin administration.

Battery charging is enabled as long as the charger cord is connected to AC power and the pump is in the charger. Switching the pump off does not disconnect it from AC power. To disconnect from AC power, remove the charger cord from AC power. To disconnect pump from AC power, remove it from the charger.

Dropping the BodyGuard Infusion System could cause damage to components. If the pump is dropped, return the pump for inspection by qualified service personnel.

Use aseptic technique. Patient infection may result from the use of nonsterile components. Maintain sterility of all disposable components and do not re-use single use IV sets.

When operating the pump in PCA mode with a rate of 0.0 ml/hr there is a hazard of blood clot formation. Connect saline infusion in parallel to avoid this problem.

Do not operate the pump near high-energy radio-frequency emitting equipment, such as electro-surgical cauterizing equipment. False alarm signals may occur.

Watch your fingers / nails when opening and closing the pump door.

5 of 50

Cautions

To avoid possible damage to the equipment, observe the following:

Leaving the battery in a discharged state for a long period of time may damage the battery. Connect the pump to the AC power via the charger whenever possible to recharge the battery.

Do not store the pump with the battery fully depleted.

Xylene, acetone or similar solvents could cause damage to components. Do not clean the pump with these chemicals. Clean solution spills on the pump immediately. Use a damp cloth or sponge. A mild detergent may be used. Wipe thoroughly with a dry cloth.

Immersing the BodyGuard Infusion pump into liquid could cause damage to components. Do not immerse the pump into any type of liquid. Battery damage could occur if left in a temperature warmer than 500C.

6 of 50

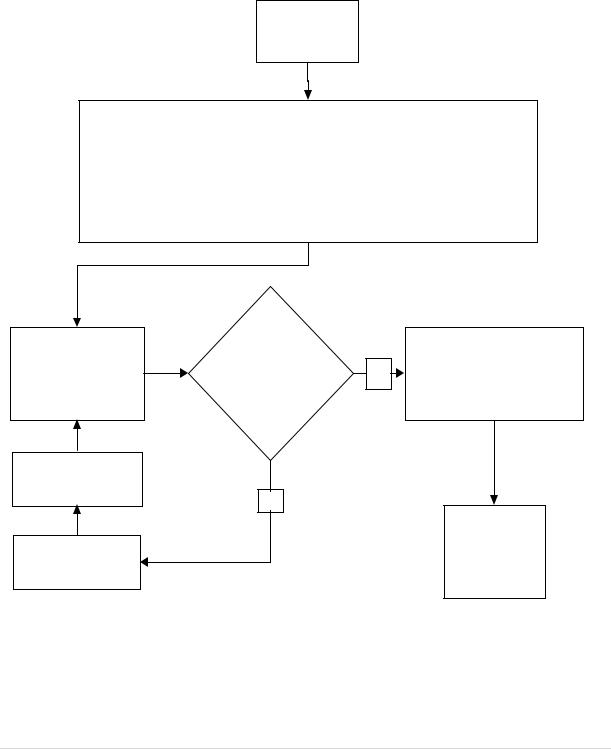

Service Process Diagram

The service operation is diagrammed below:

7 of 50

Customer and Device Information &Pre-

Service Checklist

Before performing any service procedure:

1.Authorized service personnel

Service of BodyGuard pumps may only be performed by authorized service personnel. Service can only be performed with the recommended equipment and CME approved parts.

2.Confirm Customer Information

Confirm proper document record has been completed for, Log receipt, pump serial number & physical appearance (i.e. damage, signs of tampering).

3.Disinfect the pump according to cleaning instructions as described in the user manual.

4.Open a service file to include all required documentation.

5.Download or View the Event Log - The event log records program and calibration settings, and notes the frequency and nature of any alarms/alerts that may be associated with past pump performance or a complaint.

Download the Event Log

a.Use the BodyComm Software and Communication charger.

b.Refer to the BodyComm Operations Manual:

i.Connect BodyGuard to a PC using BodyComm.

ii.Download and Record the Event Log

iii.Download and Record Pump Settings.

iv.Once done Power down the pump.

Manual View the Event Log and History

BodyGuard 323

a.Start pump normal operation mode

b.Enter Change Set up Mode by pressing INFO key until options are displayed.

8 of 50

c.Select Change Set Up, Press START/OK key

d.Scroll down to option “More”, Press START/OK

e.For BodyGuard 323 Enter Change Set Up Code

f.Scroll to option History, Press START/OK key.

g.Using arrow key scroll through events, Press INFO key for more detail.

h.Exit by pressing start/OK key

BodyGuard 545, & 575

a.Start pump normal operation mode

b.Enter Level 1 code, Press START/OK to enter Main Menu

c.Scroll down to Event Log, Press START/OK

d.Using arrow keys scroll through events, Press INFO key for more detail.

e.Exit by pressing START/OK key

Manual Review of Pump settings

a.Enter the Technician Menu (power up the pump while holding down the INFO & POWER keys simultaneously until the Technician Code prompt appears).

b.Enter Technician Code.

c.Scroll to ‘Manual Calibration’ and record all pump calibration settings (volume and pressure calibration) by pressing START/OK continuously to review each setting.

d.Scroll to and perform ‘Main Self-Test’ and record any failures or issues identified during the test.

6.Review Customer supplied Service Request Information

a.Has the user operated the pump correctly? Cross reference their report with the Operation’s Manual to ensure the steps they took prior to the incident did not cause, or result in, an alarm state or error code.

7.When the Pre-Service checklist has been completed, begin Service by performing the Operational Checklist.

a.If a charger was returned as a complaint item, test the charger with the associated pump cited in the complaint. If no pump was returned with the charger, process the charger as usual.

9 of 50

Tools and Test Equipment

The following tools and test equipment are required to perform the procedures contained in this manual. Since all fasteners on this device are metric, ensure that all tools used are for metric fasteners.

Test Equipment

•Digital voltmeter (Fluke 115 or equivalent)

•BodyGuard Operations Manual

•PC with a RS232 9way Serial port

•BodyComm Communication Software*

•BodyComm Operations Manual*

•BodyComm Communications Charger (150-318X)*

•BodyGuard Charger may be required (pulse oximeter charger for 545, and 575)

•RS 232 cable (197-000X)**

•ESD work station Mat and Wrist Strap

•BodyGuard tubing set with proximal Y-Site**

•Infusion Bag (sterile water for injection)

•Scale (.01g resolution)

•Pressure Gauge, maximum pressure 30psi, .01 psi resolution

•Timer (seconds resolution)

•Burning Station PN 100-405X* (for software updates)

•5 pin male to male connection wire*

•Prog08sz software*

Tools

•Phillips screwdriver, M3

•Flat screwdriver, M3

•Allen key 2.5 mm

•Forceps

•2mm Push shaft

•Air Sensor ‘Go No-Go’ gauge/or gauge pins (GO, 2.2 mm, No-GO, 2.3 mm)

•Sharp knife

•3 ml Syringe with graduated markings

•DC Cable BG (196-000X)*

10 of 50

*Available only from CME ** Optional Equipment

Note: CME prefers the download of the pump settings, event log and/or history review be performed with BodyComm Software available from CME. However, when the software is not available the review and/or download can be performed manually.

11 of 50

Adjustable Operating Parameters and Options

BodyGuard 323

The BodyGuard 323 pump has adjustable operating parameters. These operating parameters and options may be viewed and adjusted to modify the operation of the pump. The operating parameters and options available for the BodyGuard 323 are described below in the Techncian Menu, Change Set Up Menu, Program Lock, and Keypad Lock sections. If access to a specific mode of operation is required (i.e.

Continuous, Intermitent, PCA, TPN, or 25 steps), refer to the operation manual for instructions.

Technician Menu

To access the Technician Menu, press and hold the INFO key during the power on operation until ‘Technician Code’ prompt appears. The display will show the software version for 2 seconds before the access code prompt. Enter Technician Code to access the Technical Menu.

The pump will display all the parameters that can be set, calibrated or tested. The technician can scroll through all parameters using the ARROW keys (2 & 0 keys on the pump).

Item |

Parameter |

Description |

1 |

Restart Pump |

Exit Technician Mode. |

2 |

Serial Number |

Displays serial number & production date. |

3 |

Manual Calibration |

Summary of volume & pressure calibrations and ability to check/re- |

|

|

enter software default calibrations after service. |

4 |

Main Self-Test |

Performs keypad, display, alarm sound, door sensor, air sensor, |

|

|

temperature, motor & encoder, and pressure sensor tests. |

5 |

Manual Test |

Same as Main Self-Test but with a menu so technician can focus on |

|

|

individual tests. |

6 |

Pressure Calibration |

Allows manual calibration of pressure settings. |

7 |

Volume Calibration |

Allows manual calibration of pumping mechanism. |

8Software default Caution: pressing START/OK will restore software defaults and

Setting |

delete all pre-set protocols and set-up changes. |

9Reset Calibrations Caution: pressing START/OK restores default settings. Pump must

be re-calibrated after reseting calibrations.

10 Operating time/ Hours from last service – reset to zero by pressing STOP/NO key. hours counter

12 of 50

Change Set Up Menu

To access Change Set Up Menu:

1.Turn the pump on in the normal operation mode.

2.To access the Change Set Up Menu, press the INFO key multiple times until the “Change Set Up” option is displayed,(it is always displayed as the 4th option).

3.Select “Change Set Up”, press OK.

4.Scroll down to the option “More”, press OK.

5.Enter access “Change Set Up” Code, press OK.

The Change Set Up Menu is intended for use by clinical personnel and authorized service technicians.

Item |

Parameter |

Description |

|

|

|

1 |

restart pump |

Allows clinical personnel to return pump to normal operation mode. |

2 |

pressure default |

Allows clinical personnel to set the default occlusion alarm pressure. |

|

|

The pump will default to this pressure setting each time the pump is |

|

|

started. |

3 |

select program |

Allows clinical personnel to select program from list (Continuous, |

|

|

Intermitent, PCA, TPN, or 25 steps). |

4 |

priming rate |

Allows clinical personnel to set priming rate. |

5 |

max bolus volume |

Allows clinical personnel to set maximum bolus volume (0-100 ml). |

6 |

titration bolus |

Allows clinical personnel to set titration bolus (On/ Off). |

7 |

bolus rate |

Allows clinical personnel to set bolus rate (0-1200 ml/h). |

8 |

maximal rate |

Allows clinical personnel to set maximal rate (0.1-1200 ml/h). |

9 |

KVO rate |

Allows clinical personnel to set KVO rate (0.0-5.0 ml/h). |

10 |

flow control |

Allows clinical personnel to set flow control (0 - 20 drops/ml). |

11 |

set loading test |

Allows clinical personnel to activate set loading test (On/Off). |

12 |

air bubble size |

Allows clinical personnel to set air bubble size (0.1 - 2.0 ml). |

13 |

store last program |

Allows clinical personnel to store last program (On/Off). |

14 |

operation LED |

Allows clinical personnel to set operational indicator LED (On/Off) |

15 |

time option |

Allows clinical personnel to set time option (On/Off). |

16 |

delay before start |

Allows clinical personnel to set delay before start (On/Off). |

17 |

language |

Allows clinical personnel to choose language (English, Spanish). |

18 |

set time and date |

Allows clinical personnel to date and time (dd, mm, yy, hh, mm). |

19 |

history |

Allows clinical personnel to review event history settings and alarms |

|

|

(for last 500 events) |

13 of 50

Program Lock

To access Program Lock:

1.Turn the pump on in the normal operation mode.

2.To access the Change Set Up Menu, press the INFO key multiple times until the “Change Set Up” option is displayed,( it is always displayed as the 4th option).

3.Select “Change Set Up”, press OK.

4.Scroll down to the option “More”, press OK.

5.Enter Program Lock Code, press OK.

6.Select ON to activate lock (Off/On).

The Program Lock is intended for use by clinical personnel and authorized service techncians.

Item |

Parameter |

Description |

|

|

|

1 |

Locks ability to |

Enables clinical personnel to lock out the pump so that programs can |

|

change programs |

only be started or stopped. |

Keypad Lock

To access Keypad Lock:

1.With the pump operating in normal operation mode, to activate the Keypad Lock: Press and Hold the INFO Key until the bar graph is filled.

2.Repeat step 1 to deactivate.

The Keypad Lock is intended for use by clinical personnel and authorized service technicians.

Item |

Parameter |

Description |

|

|

|

1 |

Locks all keypad |

Enables clinical personnel to lock all buttons but the INFO, |

|

buttons except the |

START/OK and STOP keys to prevent tampering with the pump |

|

INFO START/OK |

during normal operation. |

|

and STOP keys |

|

14 of 50

BodyGuard 545 and BodyGuard 575

The BodyGuard 545 and 575 pumps have adjustable operating parameters. These operating parameters and options may be viewed and adjusted to modify the operation of the pump. The operating parameters and options available for the BodyGuard 545, and 575 are described in the Technician Menu, Level 1 Menu and Keypad Lock.

Technician Menu

To access the Technician Menu, press and hold the INFO key during the power on operation until ‘Technician Code’ prompt appears. The display will show the software version for 2 seconds before the access code prompt. Enter Technician Code to access the menu.

The pump will display all the parameters that can be set, calibrated or tested. The technician can scroll through all parameters using the ARROW keys (2 & 0 keys on the pump).

Item |

Parameter |

Description |

|

|

|

1 |

Restart Pump |

Exit Technician Mode. |

2 |

Serial Number |

Displays serial number & production date. |

|

|

|

3 |

Manual Calibration |

Summary of volume & pressure calibrations and ability to check/re- |

|

|

enter software default calibrations after service. |

4 |

Main Self-Test |

Performs keypad, display, alarm sound, door sensor, air sensor, |

|

|

temperature, motor & encoder, and pressure sensor tests. |

5 |

Volume Test |

Program rate & volume to be delivered during flow rate test. |

6 |

Manual Test |

Same as Main Self-Test but with a menu so technician can focus on |

|

|

individual tests. |

7 |

Pressure Calibration |

Allows manual calibration of pressure settings. |

8 |

Volume Calibration |

Allows manual calibration of pumping mechanism. |

9Software default Caution: pressing START/OK will restore software default defaults

|

Setting |

and delete all pre-set protocols and set-up changes. |

10 |

Reset Calibrations |

Caution: pressing START/OK restores default settings. Pump must |

|

|

be re-calibrated after reseting calibrations. |

11 |

Operating hours |

Hours from last service – reset to zero by pressing STOP/NO key. |

12 |

Access Codes |

Displays current access codes and allows change. |

15 of 50

Loading...

Loading...