CMA Dishmachines EST44 Operation Manual

www.cmadishmachines.com

Table of Contents

EST-44

1. |

SPECIFICATIONS................................................................................................. |

2 |

|

1.1. |

EST44........................................................................................................................................... |

2 |

|

2. |

GETTING STARTED............................................................................................ |

3 |

|

2.1. |

Introduction to EST -44.................................................................................................................. |

3 |

|

2.2. |

Receiving and Installation .............................................................................................................. |

4 |

|

2.2.1. |

Electrical ................................................................................................................................ |

5 |

|

2.2.2. |

Plumbing*............................................................................................................................... |

5 |

|

2.2.3. |

Installation Notes.................................................................................................................... |

5 |

|

2.2.4. Optional Table Limit Switch................................................................................................... |

7 |

||

2.2.5. Scrap Tray Assembly Installation........................................................................................... |

8 |

||

2.2.6. |

Pump Impeller Note................................................................................................................ |

9 |

|

2.2.7. Optional Hood Adapter (Set of Two).................................................................................... |

10 |

||

2.2.8. |

Field Installed Accessories ................................................................................................... |

11 |

|

|

2.2.8.1. |

Chemical Dispensers .................................................................................................... |

11 |

|

2.2.8.2. |

Hood Fan Motor ........................................................................................................... |

11 |

2.2.9. |

EST-44 Heaters..................................................................................................................... |

11 |

|

2.3. Safety Tips for the EST-44........................................................................................................... |

13 |

||

3. |

OPERATION ........................................................................................................ |

14 |

|

3.1. |

Initial Setup .................................................................................................................................. |

14 |

|

3.1.1. |

Rinse Pressure Regulator ..................................................................................................... |

14 |

|

3.1.2. Wash and Rinse Temperatures ............................................................................................. |

14 |

||

3.2. |

Beginning Operation..................................................................................................................... |

15 |

|

3.2.1. |

Chemical Dispensing............................................................................................................ |

16 |

|

|

3.2.1.1. |

Low Temperature Applications .................................................................................... |

17 |

3.3. Regular Service and Maintenance Checklist ................................................................................ |

17 |

||

3.4. |

Trouble Shooting .......................................................................................................................... |

19 |

|

4. EST-44 CUSTOMER NOTICE.............................................................................. |

20 |

||

5. ELECTRICAL DIAGRAM FOR 230V EST-44................................................ |

22 |

||

6. ELECTRICAL DIAGRAM FOR E-TEMP HEATER ONLY......................... |

23 |

||

7. ELECTRICAL DIAGRAM FOR 480V EST-44................................................ |

24 |

||

www.cmadishmachines.com

1. Specifications

1.1. EST44 |

EST-44 |

EST-44 |

|

|

|

|

H.T. |

WATER CONSUMPTION |

L.T. |

||

|

|

|

|

PER RACK (FINAL RINSE) |

.49 GAL. |

.49GAL. |

|

PER HOUR (FINAL RINSE) |

119 GAL. |

119 GAL. |

|

CONVEYOR SPEED |

|

|

|

FEET PER MINUTE |

6.75 |

|

6.75 |

OPERATING CAPACITY |

|

|

|

RACKS PER HOUR (NSF rated) |

243 |

OPERATING TEMPERATURE |

|

WASH RECOMMENDED |

140° - 150° F |

PUMPED RINSE RECOMMENDED |

140° - 150° F |

FINAL RINSE RECOMMENDED |

140° - 150° F |

WATER REQUIREMENTS |

|

243

150° - 160° F 150° - 160° F 180° - 195° F

INLET TEMPERATURE (MIN) |

140° F |

180° F |

||||

WATER INLET SIZE |

|

|

1/2” |

|

|

|

FINAL RINSE SIZE |

|

|

1/2” |

|

|

|

DRAIN SIZE |

|

|

2” |

|

|

|

FINAL RINSE PRESSURE |

|

|

20 PSI |

|

|

|

HEATERS |

|

|

|

|

|

|

WASH HEATER |

12.75 KW/240V, 10KW/208V |

|||||

RINSE HEATER |

|

|

3KW |

|

|

|

MOTORS |

|

|

|

|

|

|

WASH PUMP |

|

|

1 HP |

|

|

|

RINSE PUMP |

|

|

1/3 HP |

|

|

|

CONVEYOR |

|

|

1/3 HP |

|

|

|

DIMENSIONS |

|

|

|

|

|

|

DEPTH |

|

|

25-1/8” |

|

|

|

WIDTH |

|

|

44” |

|

|

|

HEIGHT |

|

55 -1/2”-56-1/2” |

||||

STANDARD TABLE HEIGHT |

32 ½” adjusts to 34” |

|||||

MAX CLEARANCE FOR DISHES |

|

|

19” |

|

|

|

STRANDARD RACKS |

|

19 ¾” x 19 ¾” |

||||

ELECTRICAL RATING |

VOLTS |

|

PHASE |

|

AMPS |

|

|

208 |

1 |

69 |

|||

|

240 |

1 |

76 |

|||

|

208 |

3 |

46 |

|||

|

240 |

3 |

51 |

|||

|

480 |

3 |

24 |

|||

SHIPPING WEIGHT |

662# |

|

|

(300kg) |

||

MODEL EST-44 Installation and Operation Manual Rev. 2 .01A |

Page 2 |

Getting Started

2. Getting Started

2.1.Introduction to EST -44

The EST is designed to give maximum cleaning in 44 inches. It represents the cleaning power of machines twice its length. The curtains incorporated in the machine minimize transfer from tank to tank during the wash and sanitizing procedures.

Energy costs for running the EST-44 have been greatly reduced by the introduction of stage washing. EST (energy star) models lower gal/rack ratings are related to new washing stages being introduced: wash/recirculating rinse/final rinse. EST models have one tank for wash water and one tank for pumped rinse water, followed by a final rinse sanitizing rinse.

The supply water to the EST-44L must be a minimum of 140°F, while the EST-44H requires two supply lines; one at a minimum water temperature of 180°F (for RINSE), and the other at a minimum temperature of 140° F (for FILL).

The EST-44 features a scrap tray that may be emptied on a periodic basis without interruption of the flow of work and the manner in which the tank is filled ensures that the dishes are always rinsed with fresh water instead of re-circulated water. The EST machine is designed to deliver 0.49 gallons of fresh rinse water for each rack. This water flows from the rinse and pre-rinse tank into the wash tank and then overflows into the scrap tray carrying debris with it, thereby providing a much cleaner environment for the wash and rinse cycles.

There are also enhancements that can be chosen when desired such as optional Vent Hood Adaptors and other machine accessories such as stainless steel dish tables.

MODEL EST-44 Installation and Operation Manual Rev. 2 .01A |

Page 3 |

Getting Started

2.2.Receiving and Installation

When you receive your new EST-44, complete the assembly by installing the scrap tray assembly with its overflow chute, the two wrapper shields and the curtain rods, which are shipped inside the machine. After the box has been removed from the machine, remove the left and right stainless steel wrapper shields and bolt them in place with the nuts and bolts provided. The wrapper shield with the extra curtain clamps mounts onto the dirty end of the machine. Next, mount the scrap tray assembly and overflow chute into position (see section 2.2.5 Scrap Tray Assembly ).

All of the spray arms should be inserted and in place over the wash tank compartments.

There are a total of three curtains used in the EST-44; two are longnarrow, one is shortwide. The two long-narrow curtains have shorter rods than the other two curtains. The short rods hold the curtains at the entrance and exit of the machine.

The sketch below lists curtain positions 1 through 3.

LONG-NARROW CURTAIN

EST-44

2

1

SHORT- |

WIDE |

CURTAINS |

DISH FLOW |

3

LONG-NARROW CURTAIN

DISHMACHINE FRONT VIEW

MODEL EST-44 Installation and Operation Manual Rev. 2 .01A |

Page 4 |

Getting Started

2.2.1. Electrical*

A 3-phase 208-240 volt AC, 60 Hz dedicated circuit should be used to supply electrical energy to the EST-44 dishwasher (see specification sheet page 2). Connect the wire that has the highest voltage (stinger lead) to the main contactor’s power terminal L2. Power lead wires (L1, L2 and L3) used for the EST-44 at installation must comply with all local and State electrical codes.

2.2.2. Plumbing*

The water supply connection is made with a ½” hot water line to the water supply inlet on the top of the machine. The water supplied to the machine must be a minimum of 140° F for the EST44L and a minimum of 180° F for the EST-44H.

NOTES:

1.The Low Temp machine (EST-44L) can be supplied with single point water inlet kit with braided hose included for fill and final rinse inlets connection.

2.The High Temp machine (EST-44H) comes with two water supply line connections. One for the final rinse at 180° F and the second line is to fill the wash tank with 140° F —the water will be heated to the appropriate temperature by the wash tank heater. (See specification sheet on page 2).

There are two 2” drain connections to be made. One connection is made at either end of the horizontal drainpipe coming from the wash tank and the other connection is made at the scrap tray drain. (Instructions for installing the scrap tray assembly are provided in section 2.2.5 Scrap Tray Assembly .) One of the ends of the horizontal drainpipe has a cap on it – simply move the cap to the other end if it’s currently on the end needed for the drain connection.

2.2.3.Installation Notes

1.Tables must slant into the machine for proper drainage (for each 28" of table length a drop of at least ¾” in table height is recommended). See Figure 2.2.3a.

|

FRESH WATER |

|

|

TABLE SLANT |

|

WASH |

PRE-RINSE/RINSE |

|

TO SCRAP |

||

|

||

ACCUMULATOR |

|

|

|

DISH FLOW |

Figure 2.2.3a

See also installation instructions on EST-44 conveyor (Section 4. Customer Notice)

2.The scrap tray assembly is placed inside the machine for shipping. Follow the instructions provided in section 2.2.5 Scrap Tray Assembly to properly attach the scrap tray assembly to the dishmachine.

3.Figure 2.2.3b shows the different settings available on the conveyor cam.

*Electrical and plumbing connections must be made by a qualified person who will comply with all available Federal, State, and Local Health, Electrical, Plumbing and Safety codes

MODEL EST-44 Installation and Operation Manual Rev. 2 .01A |

Page 5 |

Getting Started

P/N 13505.14

205 RACKS/HOUR

243 RACKS/HOUR

Figure 2.2.3b

4.On a 3-phase machine the water pump motors are also 3-phase and, depending on which terminal each phase is connected to, the motor can rotate in either direction. Check the direction of rotation by removing the dust cap on the back of the motor.

The motors must turn clockwise looking at the shaft from the back of each motor. To change the direction of rotation, switch any two power lead wires at the motor.

5.The machine must be running to set the pressure regulator. While the machine is in the FINAL RINSE CYCLE, adjust the pressure regulator to 20 PSI. See section

3.1.1 Rinse Pressure Regulator for detailed instructions.

MODEL EST-44 Installation and Operation Manual Rev. 2 .01A |

Page 6 |

Getting Started

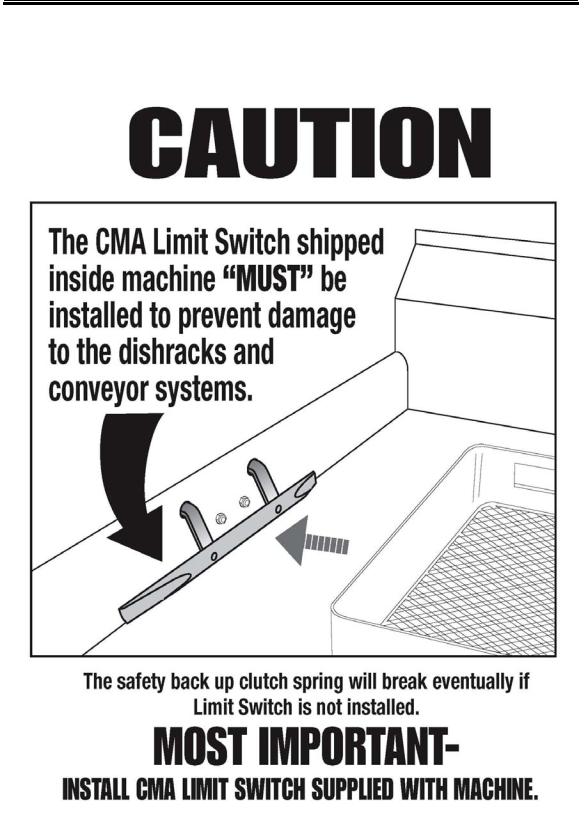

2.2.4. Optional Table Limit Switch

(Please see section 5 for Installation Instructions)

MODEL EST-44 Installation and Operation Manual Rev. 2 .01A |

Page 7 |

Loading...

Loading...