Page 1

MODEL CWS

SERVICE & PARTS MANUAL

Rev 1.00

CMA DISHMACHINES

12700 KNOTT AVENUE

GARDEN GROVE, CALIFORNIA 92841

800-854-6417

FAX 714-895-2141

www.cmadishmachines.com

Page 2

TABLE OF CONTENTS

Model CWS

1. SPECIFICATIONS.........................................................................................2

1.1 CWS ............................................................................................................................................... 2

2. GETTING STARTED .....................................................................................3

2.1. INTRODUCTION TO THE CWS .......................................................................................................... 3

2.2. RECEIVING AND INSTALLATION ...................................................................................................... 4

2.2.1. Electrical ................................................................................................................................4

2.2.2. Plumbing................................................................................................................................. 4

2.2.3. Connecting the Scrap Accumulator and Drain....................................................................... 5

3. OPERATION..................................................................................................6

3.1. INITIAL SETUP................................................................................................................................. 6

3.2. STARTUP PROCEDURES ................................................................................................................... 7

4. PARTS MANUAL ..........................................................................................8

4.1. INITIAL PARTS KIT (P/N)................................................................................................................. 8

4.2. OPTIONAL SANI ALARM .................................................................................................................. 9

4.3. EXPLODED VIEW DRAWINGS......................................................................................................... 10

4.3.1. Cabinet Assembly ................................................................................................................. 10

4.3.2. Three Compartment Sink...................................................................................................... 11

4.3.3. Control Box Assembly .......................................................................................................... 12

4.3.4. Door Actuator Assembly....................................................................................................... 13

4.3.5. Pump Assembly..................................................................................................................... 14

4.3.6. Plumbing System Assembly................................................................................................... 15

4.3.7. Spray System Assembly......................................................................................................... 16

4.3.8. Power Drain Assembly......................................................................................................... 17

4.3.9. Power Drain Retrofit Kit ...................................................................................................... 18

4.3.10. Peristaltic Pump Assembly................................................................................................... 19

4.3.11. Booster Heater Assembly...................................................................................................... 20

5. ELECTRICAL DIAGRAM ............................................................................21

www.cmadishmachines.com

Page 3

y

1. Specifications

Electrical and plumbing connections must be made by a qualified service person who will

compl

with all available Federal, State, and Local Health, Electrical, Plumbing and Safety

1.1 CWS

METRIC USA

WATER CONSUMPTION

PER RACK 1.7 GAL. (6.4 L)

PER HOUR 51 GPH. (193 LPH)

OPERATING CYCLE

WASH TIME-SEC. 57 57

RINSE TIME-SEC. 48 48

DWELL TIME-SEC. 15 15

TOTAL CYCLE 120 SEC. 120 SEC.

OPERATING CAPACITY

RACKS PER HOUR 30 30

WASH TANK CAPACITY 1.7 GAL. (6.4 L)

PUMP CAPACITY 68 GPM (257 LPM)

WATER REQUIREMENTS

REQUIRED MINIMUM TEMP. 120°F (49°C)

RECOMMENDED TEMP. 140°F (60°C)

WATER INLET 3/4” —

DRAIN -MACHINE 2” —

DRAIN-SINKS 1-1/2” —

DIMENSIONS

DEPTH 31” (78.7 cm)

WIDTH CWS 102” (259 cm)

WIDTH CWS W/DRAIN BOARD 120-1/4” (305 cm)

HEIGHT 68” (172 cm)

MAX CLEARANCE FOR DISHES 27” (68 cm)

STRANDARD RACKS 19 ¾” x 19 ¾” (50 x 50 cm)

ELECTRICAL RATING

SINGLE PHASE

SINGLE PHASE

THREE PHASE

THREE PHASE

WASH PUMP MOTOR 2 HP

VOLTS

(60-Hz)

208

240

208

240

AMPS

57

62

38

40

SHIPPING WEIGHT

APPROXIMATE 708# (321 kg)

MODEL CWS SERVICE & PARTS MANUAL Rev. 1.00 Page

2

Page 4

Getting Started

2. Getting Started

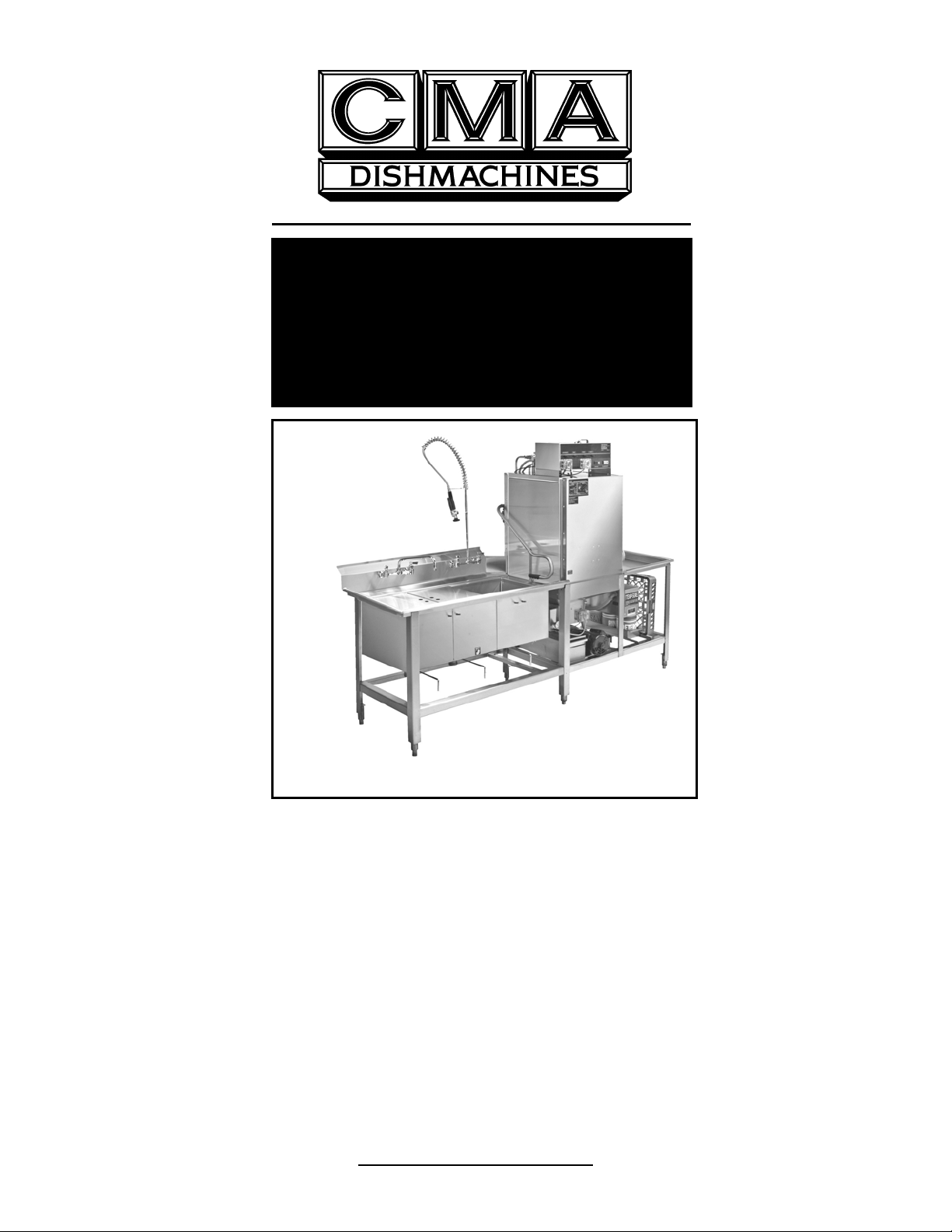

2.1. Introduction to the CWS

The CWS Dishmachine is safe and easy to operate with its “Auto Start/Stop” and it’s economical

to operate—using only 1.7gallons of water per cycle. The CWS Dishmachine’s top mounted

controls include built-in chemical pumps and a de-liming system that assures prop er chemical

usage. Its integrated scrap tray prevents food soil from entering the drain system. The CWS can

be run at a rate of 30 racks / 120 covers per hour and its heavy duty stainless steel construction

assures long life and years of trouble free operation.

The supply water to the dishmachine should be 140°F. The pipe supplying the water must be ¾”

minimum. The supply water connects to the gate valve located at the back of the machine (¾”

female pipe thread connection). Temp Sure Hot Water Assurance System guarantees hot water

every cycle. The drain is 2" and comes off of the scrap accumulator for easy attachment of your

drain line. See section

The CWS conceals a three-compartment sink within the soiled dishtable that complies with local

health code requirements.

This manual is structured to provide a complete reference guide to the CWS Dishmachine. It is

presented in a manner that all users will be able to comprehend and use as an effective tool in

supporting the operation and maintenance of the dishmachine. The first section explains how the

machine is packaged and what to look for when receiving the machine.

After unpacking the machine, this manual explains how to install and set up the machine for use.

Requirements are given for plumbing, wiring, and space considerations. These attributes of the

machine are always taken into consideration by our well-trained sales representatives prior to the

order being placed. In the manual, guidance is also given for installation to ensure that the

machine will be able to run at optimum conditions.

The Operation section of the manual may be used for instruction and procedures when required.

We make this portion of the manual easy to understand so that all levels of operators may be

able to read and comprehend the operation of the machine. The function of the machine itself is

mostly automatic and takes little training to put into full operation.

A wiring diagram for the machine is located at the end of the manual.

CMA warranties the workmanship of the machine.

We are committed to providing the best machines and customer service in the food industry and

your feedback is welcome.

2.2.3 Connecting the Scrap Accumulator and Drain

MODEL CWS SERVICE & PARTS MANUAL Rev. 1.00 Page

3

Page 5

Getting Started

2.2. Receiving and Installation

The dishwasher is shipped from the factory in a corrugated box on a wooden pallet. The

installation guidelines give a systematic procedure for setting up the machine.

Start by removing the dishmachine from the box. Remove the packaging, unwrap the machine

and check for the following components:

Scrap Accumulator complete with lid and scrap tray.

Inside the wash tank is a box with one control box key, 4 legs, thermometer, spray

arms, machine manual and a cam timer wrench.

Tube Stiffeners: The tube stiffeners must be used to prevent the feed tubes from

curling up inside the chemical pail allowing the tip to rise out of the chemical.

Remove the tie-wraps securing the tube stiffeners to the dishmachine to free them up

for use. Be careful not to remove any of the tie-wraps securing the tube bundle. Red

is for detergent, white for sanitizer, and blue for rinse aid.

2.2.1. Electrical1

The CWS Dishmachine must be hard wired directly to a dedicated 240 VAC, 60Hz, 3 Phase.

circuit equipped with proper circuit protection.

2.2.2. Plumbing2

The water supply connection is made with a ¾” hot water line to the water supply inlet on the top

of the machine. The water supplied to the machine is recommended to be 140° F (120° F

minimum).

Caution: Do not connect galvanized pipe water supply to dishmachine. This will create

electrolysis, causing corrosion.

The CWS Dishmachine has a 2” drain. The following section explains how to connect the drain.

1

All electrical connections must be made by a qualified electrician

2

All plumbing connections must comply with all plumbing and safety codes

MODEL CWS SERVICE & PARTS MANUAL Rev. 1.00 Page

4

Page 6

Getting Started

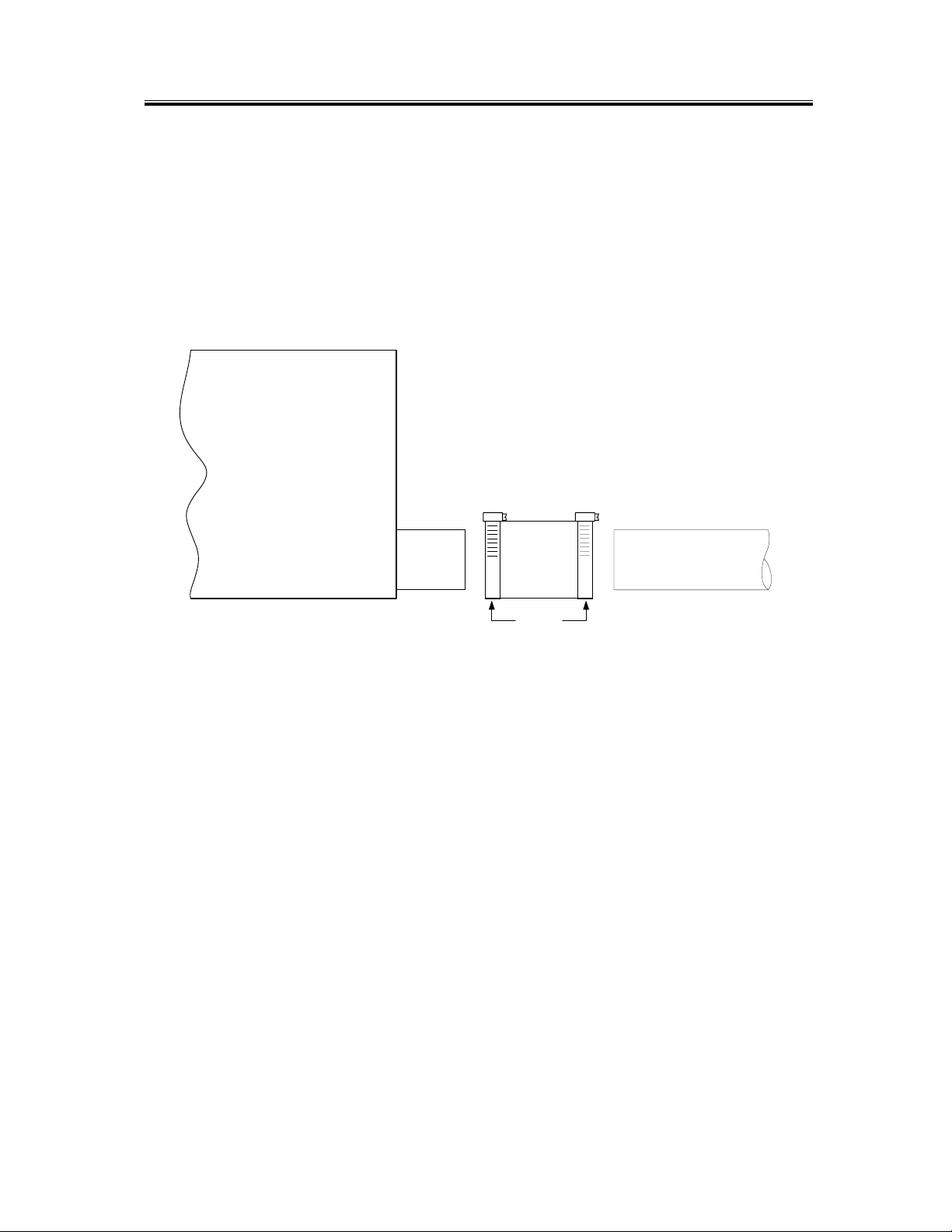

2.2.3. Connecting the Scrap Accumulator and Drain

The scrap accumulator is designed to perform two basic functions:

1. It allows a method to discharge all the heavy solids out of the machine with each

wash cycle.

2. It provides accumulation capacity to allow draining the contents of one cycle

regardless of the discharge rate of the existing drain.

The drainpipe is connected to the scrap accumulator drain using a 2” no-hu b connector as shown

Figure 2.2.3 below.

in

SCRAP ACCUMULATOR

2" DRAIN

SLEEVE

Figure

2.2.3

2"

NO-HUB

HOSE

CLAMPS

2" DRAINPIPE

MODEL CWS SERVICE & PARTS MANUAL Rev. 1.00 Page

5

Page 7

Operation

3. Operation

3.1. Initial Setup

All machines are equipped with switches to prime the peristaltic pumps at anytime the master

switch is "ON".

Following completion of the installation, always fill the machine with water before starting the

machine.

1. With the power “ON” hold the fill button until the water level overflows into the scrap

accumulator.

2. Check the chemical lines to the chemical containers.

a. Red: detergent line.

b. Blue: rinse agent line.

c. Clear/White: sanitizers destainer line.

3. Activate the prime switches for the three chemical pumps until product is

discharging into the machine.

4. To start the machine, close the doors - this will automatically start the machine. The

machine will run through its cycle.

5. Operate the machine one cycle and watch to ensure that the chemicals are

delivered and stop during the cycle. Remember: red tube - detergent: blue tube rinse: and clear/white tube - sanitizer. Check temperature at the end of the cycle for

140°F, 60°C.

The amount of product delivered by each cam is controlled by adjusting the cam’s

opening. When the micro switch rides down into the cam the peristaltic pump motor

begins to rotate. It will continue to rotate until it rides up out of the groove.

Therefore, to extend the amount of product delivered to the machine, open the

grove; to reduce the amount of product delivered to the machine, close the groove.

The cams are slip fit and a cam adjustment wrench is provided.

CAUTION: The motors on the new peristaltic pumps may be stalled by excessive tightening of

the cover plate screws. If a peristaltic pump does not turn when the micro switch is activated,

loosen the screws on the cover plate.

Technical personnel are available during normal business hours at CMA He adquarters should

you, as an installer, have any questions please call 800-854-6417.

MODEL CWS SERVICE & PARTS MANUAL Rev. 1.00 Page

6

Page 8

Operation

3.2. Startup Procedures

Please follow the instructions given here before each shift to assure trouble free operation.

1. Drain the water if it is cold by activating the drain switch until all the water is

out of the machine.

2. Check the drain screen and, if needed, remove it from the machine and clean

it out. After cleaning, replace it properly into the sump housing.

3. Check the wash arm spray tips. If they are clogged, clean them with a

toothpick and rinse them at the sink. Replace the wash arms.

4. Press and hold the fill switch until the water overflows into the scrap

accumulator.

5. Once a proper water level is established, check the temperature of the water

(it should be approximately 140°F, 60°C).

6. Insert the tray of dishes into the machine and close the doors. The machine

will automatically start when the doors are closed.

7. After the machine stops, raise the doors, remove the tray of dishes and allow

to dry before stacking.

If the doors are lifted during a cycle, the machine will automatically stop running.

The CWS will run through the wash and rinse cycles automatically feeding the proper chemica ls

and then turn itself off.

MODEL CWS SERVICE & PARTS MANUAL Rev. 1.00 Page

7

Page 9

4. Parts Manual

4.1. Initial Parts Kit (P/N)

P/N DESCRIPTION Qty

00104.86 50 RPM Drain Motor, 220 V 50 HZ 1

00115.85 Drain Sump Screen 1

00121.60 Drain Diaphragm 1

00105.81 Drain Spring 1

00200.14 Pump Assembly CWS 1

00205.00 Pump Gasket 1

00206.00 Pump Seal kit 1

00304.06 Spray Arm A&C 1

00308.50 Spray Arm End Plug SS 1

00341.00 Spray Arm Bearing 1

00363.00 Spray Base Lock Pin 1

00404.80 Contactor 220 V 20 Amp 1

00411.00 Micro Switch 1

00415.20 Peristaltic Pump Assembly 220 V/60Hz 1

00418.00 Peristaltic Pump Cover 1

00421.35 Lighted Rocker Switch 220 V (Amber) 1

00421.87 CMA-44 Rocker Switch (White) 1

00433.00 Master Switch (30 Amp) 1

00435.00 Squeeze Tube 8” Silicone 1

00501.10 Timer Motor Assembly 2Min 220/60Hz 1

00562.00 Roller Door Switch 1

00631.05 Ice Cube Relay 220 V 1

00706.00 3/4” Water Solenoid Repair Kit JE 1

00715.00 1/2” Boll Check Valve 1

00735.00 3/4” Vac. Breaker Repair Kit Watts 1

13003.50 Contactor 60 Amp 3 Pole 1

13003.50 Contactor 30 Amp 1

13415.00 EGO Thermostat Retrofit Kit 1

17523.51 Hi Limit Switch 250 Deg. 1

Parts Manual

MODEL CWS SERVICE & PARTS MANUAL Rev. 1.00 Page

8

Page 10

4.2. Optional Sani Alarm

Parts Manual

Part Number 12508.05

Exploded View

ITEM

NO.

NO.

REQ’D

1 3 00400.00 Conduit, 3/8” Sealtite 8 5 00931.00 Wire Tie, Small

2 1 00401.00 S.T. 3/8” Straight Connector 9 1 12510.00 Sanitizer Alarm Box Assembly

3 1 00402.00 S.T. 90 Degree 3/8” Connector 10 1 12511.00 Sanitizer Low Level Vacuum Switch

4 1 00406.05 Control Box Light, .5” Diameter, Red 11 1 12512.05 Sanitizer Alarm Buzzer, 220 Volts

5 1 00435.00 Squeeze Tube, 8” 12 4 40126.10 #10 x 3/4" Sheet metal Screw

6 1 00521.00 Wire, 18 Gauge, Orange, 6 ft. 13 4 40127.00 Wall Anchors

7 1 00531.00 Wire, 18 Gauge, White, 6 ft.

P/N DESCRIPTION

MODEL CWS SERVICE & PARTS MANUAL Rev. 1.00 Page

ITEM

NO.

NO.

REQ’D

14 1 00426.00 Y Hose Connector, 3/16”

DESCRIPTION

P/N

9

Page 11

4.3. Exploded View Drawings

4.3.1. Cabinet Assembly

Parts Manual

ITEM

NO.

NO.

REQ’D

1 1 01500.21 Wrapper 10B 1 16920.00 CWS Pan /Stand Left Sink

2 2 01505.32 Tray Track Inline (AH) 11 1 00120.50 Power Drain Cover CWS/N-EVA

3 2 01506.20 Door (Scullary & CWS) 12 1 01573.50 Sani Mount Drain Lid-CWS

4 1 01577.10 Molded Scrap Trap Body (New) 13 24 00924.00 ¼”ss Washer

5 1 01577.20 Molded Scrap Trap Drawer (New) 14 24 00912.00 ¼”-20 Nylon Lock Nut

6 4 01310.00 Bullet Foot 15 20 00905.00 ¼”-20x1/2” Truss Head Bolt

7 4 00636.30 EZ Glide Plastic Dr 31 ¾” 16 4 00914.10 ¼”-20x5/8” Hex Head Bolt

8 1 16904.00 CWS Chemical Tray 17 4 00911.00 8-32x1/2 » Pan Head Screw

9 4 01554.50 EZ Glide Door Guide ss.33”

10 1 16920.50 CWS Pan /Stand Right Sink 19 1 00115.85 Drain Screen VA

MODEL CWS SERVICE & PARTS MANUAL Rev. 1.00 Page

P/N DESCRIPTION

ITEM

NO.

NO.

REQ’D

18 1 01577.40 Scrap Trap Lid

DESCRIPTION

P/N

10

Page 12

Parts Manual

4.3.2. Three Compartment Sink

ITEM

NO.

NO.

REQ’D

1 1 16922.00 CWS 3 Comp Sink Left 9 1 20472.00 Bumper Spray

1A 1 16922.50 CWS 3 Comp Sink Right 10 1 20475.00 Spray Valve

2 1 16906.00 CWS Sink Scrap Basket 11 1 20450.00 Pre Rinse Hose Handle

3 2 16905.00 CWS Sink Covers 12 1 20416.00 Pre Rinse Check Valve

4 3 20500.00 CWS Rotary Waste Valve 13 1 20451.00 Pre Rinse Hose

4A 3 20500.10 Waste Valve Screen Gasket 14 1 20417.00 Pre Rinse Spring

4B 4 20500.20 Waste Valve Screen 15 1 20419.00 Pre Rinse Hook

5 2 01310.00 Bullet foot 16 1 20420.00 Pre Rinse Hose Pipe Adapter

6 1 20505.00 CWS ½” Faucet

7 1 20411.00 Pre Rinse Unit 18 1 20418.00 Pre Rinse Riser Pipe

8 1 20414.00 Pre Rinse Brush 19 1 20413.00 Add On Faucet

P/N DESCRIPTION

ITEM

NO.

NO.

REQ’D

17 1 20415.00 Pre Rinse Wall Bracket

DESCRIPTION

P/N

MODEL CWS SERVICE & PARTS MANUAL Rev. 1.00 Page

11

Page 13

Parts Manual

4.3.3. Control Box Assembly

ITEM

NO.

NO.

REQ’D

1 3 00416.20 Peristaltic Pump Motor 220 V 17 3 00911.50 8-32 X 3/8” Pan Head Screw

2 3 00417.00 Peristaltic Pump Block 18 3 00927.00 8-32 Nylon Lock Nut

3 3 00418.00 Peristaltic Pump Cover 19 1 00631.05 Ice Cube relay 220 V

4 3 00419.00 Peristaltic Pump Rotor 20 1 00433.10 Master Switch (20Amp)

5 6 00919.00 10-32 X 1 ½” Panhead Bolt 21 1 13404.20 Socket Terminal Block

6 12 00911.00 8-32 X ½” Panhead screw 22 2 13825.00 8-32 X 1” Pan Head Screw

7 3 00918.00 10-32 X 1 ½” Filister Bolt 23 6 00907.00 6-32 X 1/2” Pan Head Screw

8 1 00449.00 Lock and Key 24 1 00535.00 Control Box Lid Handle

8A 1 00450.00 Key Only 25 1 01504.14 Control Box Lid

9 1 00562.00 Roller Switch 26 3 03470.00 Primer Switch (Momentary)

10 1 00562.60 Roller Switch Connector 27 1 00475.30 Delimer Switch (DPDT 15Amp)

11 5FT 00546.00 Switch Cord 28 1 00421.35 Illuminated Rocker Switch (Amber)

12 1 00404.80 Motor Contactor 20 Amp

13 1 13003.17 Main Contactor 60 Amp 30 1 03408.55 Counter (Panel Mount) 220 V

14 1 00408.40 Timer 120 Sec 8 Cam 220V/60Hz 31 1 16903.00 Control Box Body

15 1 01514.00 Timer Support Bar 32 5 00470.10 Toggle Switch Rubber Boot

16 8 00411.00 Microswitch

P/N DESCRIPTION

MODEL CWS SERVICE & PARTS MANUAL Rev. 1.00 Page

ITEM

NO.

NO.

REQ’D

29 1 00421.87 Illuminated Rocker Switch (White)

DESCRIPTION

P/N

12

Page 14

Parts Manual

4.3.4. Door Actuator Assembly

ITEM

NO.

NO.

REQ’D

1 1 00613.65 Door Handle For CWS 11 4 00906.00 1/4-20 x 1/2" Hex Head Screw

2 1 01556.50 Door Handle Support, 1” (Right) 12 6 00924.00 1/4" SS Washer

3 2 00603.63 Door Spring Extension Rod 13 8 00912.00 1/4-20 Nylon Locknut

4 2 00602.00 Door Spring 14 4 00610.00 Door Handle Spacer, Small

5 2 01552.00 Door Stop 15 4 00611.00 Door Handle Spacer, Large

6 2 01553.20 Door Handle Link 16 2 00904.00 1/4-20 x 2” Hex Screw

7 2 00606.00 5/16-18 x 7” Eyebolt 17 1 01555.50 Door Handle Support, 1” (Left)

8 2 00913.00 5/16-18 Nut 18 2 00903.00 1/4-20 x 1-3/4” Hex Head Screw

9 2 00926.00 5/16” SS Washer 19 2 00607.04 Door Handle Cap, 1”

10 2 00900.00 Cotter Pin

P/N DESCRIPTION

MODEL CWS SERVICE & PARTS MANUAL Rev. 1.00 Page

ITEM

NO.

NO.

REQ’D

P/N

DESCRIPTION

13

Page 15

Parts Manual

4.3.5. Pump Assembly

ITEM

NO.

NO.

REQ’D

1 1 00206.00 Pump Seal Kit 9 1 03108.61 Intake Hose

2 1 00201.30 Pump Motor 2HP 230/115 V 10 2 03108.00 Hose Clamp

3 1 00203.05 Impeller (close) 4-1/2” 11 2 00238.00 3/8” Male Plug

4 1 00202.00 Pump Base Large 12 2 00914.10 1/4 “ - 20 X 5/8 “ Hex Head Bolt

5 1 00205.00 Pump Gasket 13 2 00912.00 1/4 “ - 20 Nylon Lock Nut

6 1 00204.00 Pump Cover 14 8 00921.00 3/8 “ –16 X 3/4” Hex Head Bolt

7 1 50302.40 1-1/4” MIP X 1” Barb Fitting 15 4 00926.00 5/16” SS Washer

8 1 50302.06 1” MPT X 1” Barb Fitting

P/N DESCRIPTION

ITEM

NO.

NO.

REQ’D

16 1 00200.14 CWS Pump Motor Assembly

DESCRIPTION

P/N

MODEL CWS SERVICE & PARTS MANUAL Rev. 1.00 Page

14

Page 16

Parts Manual

4.3.6. Plumbing System Assembly

ITEM

NO.

NO.

REQ’D

1 1 00700.00 3/4" Gate Valve 7 1 00747.10 Nipple Brass 1/2” X 5”

2 2 00704.00 3/4" Street Elbow 8 2 00748.00 1/2” Sprinkler Head

3 1 00705.05 3/4" Water Solenoid Valve JE 220 V 9 2 00760.00 5/8 “ Comp X 1/2” MIP Adapter

3A 1 00706.00 Solenoid Valve Repair Kit ¾” 10 2 00761.00 5/8 “ Comp X 3/4” MIP Adapter

3B 1 00705.20 Solenoid Valve Bonnet 11 1 00797.00 CWS Booster Heater Water Line

3C 1 00786.00 Solenoid Valve Plunger w/Spring 12 4 00797.10 CWS Booster Heater Water Line

3D 1 00738.15 Solenoid Valve Coil 220 V 13 1 01525.06 Plumbing Support Bracket

4 1 00710.50 3/4” Vacuum Breaker, Watts 14 1 13633.20 Booster Heater ¾”’ In/Out Adapter

4A 1 00735.00 3/4” Vacuum Breaker Repair Kit

4B 1 00735.60 Vacuum Breaker Bonnet, Brass 16 2 00745.00 1/2” 90 Deg. Street Elbow

4C 2 00970.40 6-32 X 1/4” Self Threading Screw 17 1 00795.60 Flush Tube CWS

5 1 00716.00 1/2 “ X 1/2” X 3/4” Tee F X F X F 18 1 00912.00 1/4”-20 Nylon Lock Nut

6 2 00721.00 1/2 “ Jamb Nut Thin Pattern 19 1 00922.00 1/4” Lock Nut

P/N DESCRIPTION

MODEL CWS SERVICE & PARTS MANUAL Rev. 1.00 Page

ITEM

NO.

NO.

REQ’D

15 2 13639.00 Nipple S/S 3/4” Close

DESCRIPTION

P/N

15

Page 17

Parts Manual

4.3.7. Spray System Assembly

ITEM

NO.

NO.

REQ’D

1 4 00914.00 1/4-20 x 3/4" Hex Head Bolt 10 1 03108.24 Discharge Hose CWS 7”

2 9 00924.00 1/4" SS Washer 11 2 03101.00 Hose Clamp

3 4 00912.00 1/4-20 Nylon Lock Nut 12 1 00905.82 1/4-20 x 3/8” Truss Head Bolt

4 1 00966.10 10-32 x 1/4" Hex Head SS Bolt 13 1 00360.05 CWS Lower Spray Base

5 2 00341.00 Spray Arm Bearing 14 4 00363.00 Spray Base Lock Pin

6 2 00304.06 Spray Arm 14A 4 00363.10 Lock Pin Spring

7 4 00308.50 Spray Arm End Plug 15 1 50302.06 1" MPT X 1" Barb Fitting

8 1 00305.65 CWS Manifold

9 1 04306.00 Square Manifold Gasket

P/N DESCRIPTION

MODEL CWS SERVICE & PARTS MANUAL Rev. 1.00 Page

ITEM

NO.

NO.

REQ’D

16 1 00302.84 Spray Base 0-Ring

DESCRIPTION

P/N

16

Page 18

Parts Manual

4.3.8. Power Drain Assembly

ITEM

NO.

NO.

REQ’D

1 2 00938.82 1/2" Drain Bushing, Brass (V) 8A 2 00109.50 10-32 x 1” Stud

2 4 03801.00 10-32 Lock Nut 9 1 01511.84 Drain Motor Bracket – 3rd Generation

3 1 00906.82 1/4-20 x 5/8” Socket Head Screw 10 2 00941.00 10-32 x 5/8” Pan Head Screw

4 1 00105.81 Drain Spring (V) 11 1 01520.82 Diaphragm Support Disk, 1-1/8”

5 1 00108.82 Drain Actuator Arm 12 1 00121.60 Drain Diaphragm

6 1 00109.82 Drain Actuator Shaft (V) 13 1 00912.00 1/4-20 Nylon Lock Nut

7 1 00104.86 50 RPM Drain Motor, 220V 60Hz 14 1 01521.82 Diaphragm Support Disk, 2”

8 2 00109.40 Shoulder Nut, SS

P/N DESCRIPTION

ITEM

NO.

NO.

REQ’D

15 2 04806.00 #10 Brass Washer

DESCRIPTION

P/N

MODEL CWS SERVICE & PARTS MANUAL Rev. 1.00 Page

17

Page 19

Parts Manual

4.3.9. Power Drain Retrofit Kit

MODEL CWS SERVICE & PARTS MANUAL Rev. 1.00 Page

18

Page 20

Parts Manual

4.3.10. Peristaltic Pump Assembly

ITEM

NO.

NO.

REQ’D

1 1 00416.00 Peristaltic Pump Motor E 2 00423.00 Rotor Bearing

2 1 00417.00 Peristaltic Pump Block F 2 00422.00 Rotor Bearing Pin

3 2 00919.00 10-32 x 1-1/2” Pan Head Screw G 1 00424.00 Rotor Bearing Carriage

4 1 00918.00 10-32 x 1-1/2” Fillister Head Screw H 1 00935.00 1/4-20 x 1/4" Allen Screw

5 1 00418.00 Peristaltic Pump Block Cover 10 2 00448.00 Barrel Connector, Male

6 1 03415.50 Flex-Tight Fitting 11 1 00425.51 Chemical Tubing, Blue

7 4 00911.00 8-32 x 1/2" Pan Head Screw 00425.53 Chemical Tubing, Red

8 1 00435.00 Squeeze Tube

9 1 00419.00 2-Bearing Rotor Assembly

13 2 03426.00 Sight Glass 90 Deg Elbow 14 2 00435.11 Squeeze Tube 3”

15 4 00932.00 Twist tye

P/N DESCRIPTION

ITEM

NO.

NO.

REQ’D

12 1 00443.00 Tube Stiffener

DESCRIPTION

P/N

00425.54 Chemical Tubing, White

MODEL CWS SERVICE & PARTS MANUAL Rev. 1.00 Page

19

Page 21

Parts Manual

4.3.11. Booster Heater Assembly

ITEM

NO.

NO.

REQ’D

1 1 00214.30 1/4” Comp X 3/8” MIP Fitting 12 1 01594.30 3 Sided Heater Tank Shield w/o Hole

2 1 00743.10 1/2 “ Tee FXFXF Brass 13 1 01595.20 Heater Tank For Temp Sure

3 2 00760.00 5/8 “ Comp X 1/2 ” MIP Adapter 14 1 13003.17 Contactor 60 Amp 3 Pole

4 2 00911.50 8-32” X 3/8 “ Pan Head Screw 15 1 13417.47 CMA 180 Booster Heater Gasket

5 2 00911.60 Screw Phillips M4X6 16 1 13417.67 Immersion Heater 12 Kw 3ph/1ph

6 14 00912.00 1/4”-20 Nylon Lock Nut 17 1 13417.89 Thermostat For 12 Kw Heater (EGO)

7 8 00914.10 1/4”-20 X 5/8 Hex Head Bolt 18 1 13426.50 Ground Block

8 6 00924.00 1/4” S/S Washer 19 1 13642.00 1/2” Male Plug Brass

9 2 00941.00 10-32” X 5/8 “ Pan Head Screw

10 2 00971.10 4-40 Nylon Lock Nut 21 1 41030.10 ½” 90 Deg. Ell. FXF Brass

11 1 01594.10 Booster Tank Access Cover

P/N DESCRIPTION

MODEL CWS SERVICE & PARTS MANUAL Rev. 1.00 Page

ITEM

NO.

NO.

REQ’D

20 1 17523.51 Hi Limit Switch 250 Deg.

DESCRIPTION

P/N

20

Page 22

5. Electrical Diagram

R

P

O

M

T

U

O

P

M

R

P

O

M

T

U

P

H

S

A

W

1

L

C

A

T

N

O

C

1

T

Electrical Diagram

R

O

R

E

T

E

H

C

T

T

A

A

T

O

E

N

T

H

O

C

N

I

A

T

E

D

I

N

A

S

8

7

1

2

3

7

2

3

R

D

T

R

A

H

T

C

S

T

I

W

S

L

L

I

F

R

H

E

C

T

T

I

A

W

E

S

H

E

S

N

I

R

D

I

E

N

O

I

V

N

A

L

E

R

A

L

D

V

O

S

D

I

R

E

O

E

V

N

T

L

E

A

A

L

V

W

O

S

R

E

T

N

U

O

C

Y

R

T

E

O

F

O

A

R

O

R

E

T

E

H

C

T

T

A

A

T

O

E

N

T

H

O

C

D

S

R

E

IM

T

M

A

C

8

H

C

T

I

W

S

8

7

6

5

4

3

2

H

C

T

I

W

S

E

S

N

I

R

H

C

T

I

W

S

I

N

A

S

H

C

T

I

W

S

T

E

D

1

3

2

T1T

T

C

M

O

N

A

I

N

T

A

C

T

O

R

1

3

L

L2L

4

C

N

1

H

R

C

F

N

O

R

K

E

3

2

L

L

C

1

O

W

L

L

O

B

P

E

F

T

I

W

O

O

W

P

S

1

1

O

T

Y

S

/

O

N

5

A

L

C

T

E

R

R

A

3

9

T

1

S

P

4

2

8

L

E

A

M

M

I

R

L

O

E

N

D

MODEL CWS SERVICE & PARTS MANUAL Rev. 1.00 Page

21

Loading...

Loading...