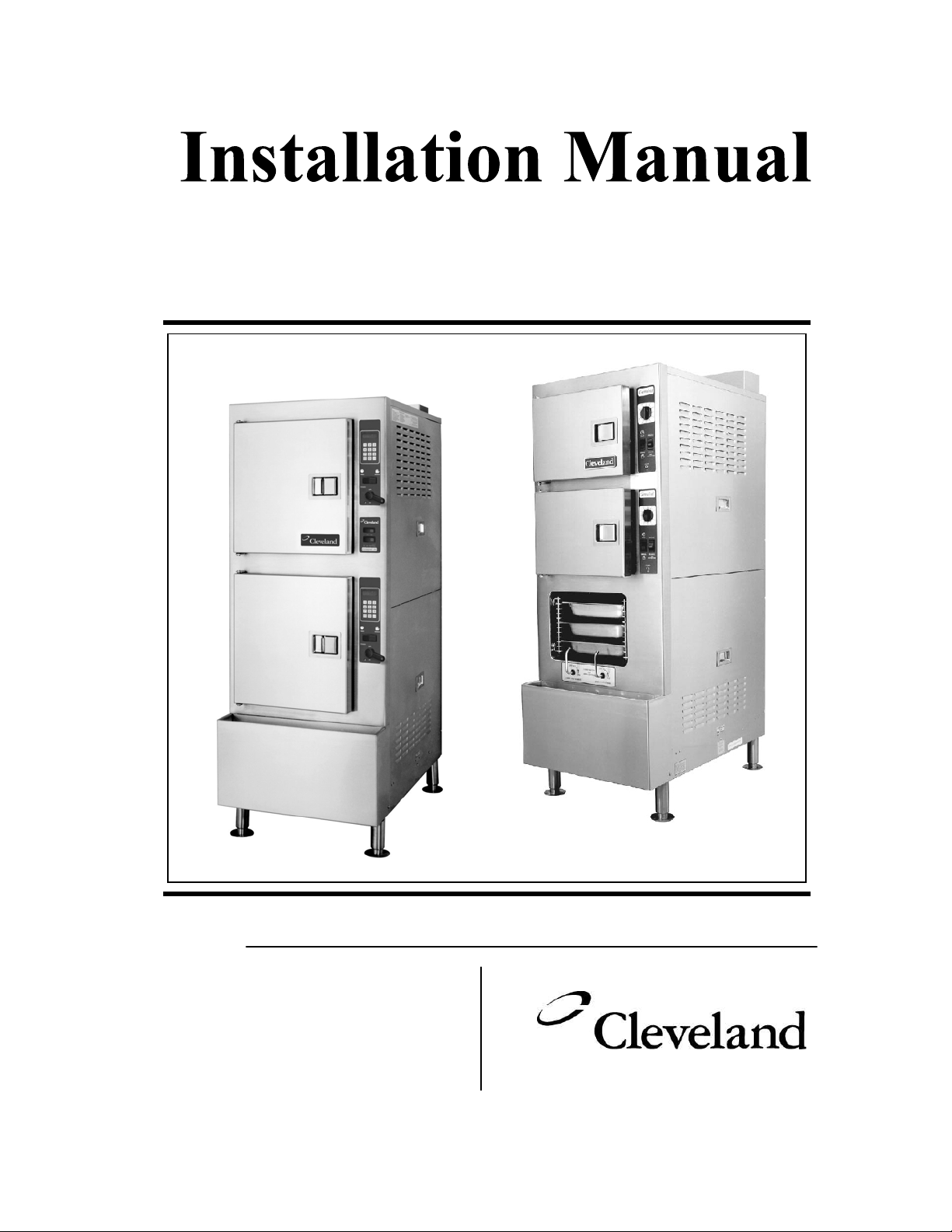

Cleveland 24CGA10.2 Installation Manual

Installation and Maintenance Instructions

Dual Gas Steam Generator & Convection Steamer

24CGA10.2

24CGA6.2

Series: Gemini Model Nos. 24CGA6.2, 24CGA10.2

1333 East 179th Street

Cleveland, Ohio 44110

Phone: (216) 481-4900

Fax: (216) 481 3782

Part No. GEMINI-INM B 7/02

r

r

r

FOR THE INSTALLER

FOR YOUR SAFETY

Do not store or use gasoline o

other flammable vapors o

liquids in the vicinity of this o

any other appliance.

Disconnect power before servicing

WARNING

Improper installation, adjustment, alterations,

service or maintenance can cause property

damage, injury or death. Read the

installation, operating and maintenance

instructions thoroughly before installing or

servicing this equipment.

IMPORTANT

IT IS IMPORTANT TO POST INSTRUCTIONS WHICH ARE TO BE FOLLOWED

IN THE EVENT THE USER SMELLS GAS. THESE INSTRUCTIONS SHOULD

BE LOCATED IN A PROMINENT LOCATION, AND BE FULLY UNDERSTOOD

BY ALL USERS OF THIS EQUIPMENT. THIS INFORMATION SHOULD BE

OBTAINED FROM YOUR LOCAL GAS SUPPLIER.

ALL SERVICE MUST BE PERFORMED BY A QUALIFIED CLEVELAND

RANGE AUTHORIZED TECHNICIAN.

The wiring diagram is located on the back of the lower front panel.

RETAIN THIS MANUAL FOR YOUR REFERENCE

WARNING

INSTALLATION AND MAINTENANCE

Gemini Dual Gas Steam Generator and Convection Steamer

Table of Contents

Chapter Page

CHAPTER 1 PRODUCT IDENTIFICATION ________________________________________ 1

A. MODEL NUMBER ________________________________________________________ 1

B. SERIAL NUMBER ________________________________________________________ 1

C. PRODUCT INFORMATION PLATE __________________________________________ 1

D. 24CGA6.2 PRODUCT VIEW _______________________________________________ 2

E. 24CGA10.2 PRODUCT VIEW _______________________________________________ 3

CHAPTER 2 INSTALLATION INSTRUCTIONS _____________________________________ 4

A. GENERAL ______________________________________________________________ 4

B. INSTALLATION OF THE STEAMER _________________________________________ 4

1. Locating the Steamer __________________________________________________ 5

a. Location and Clearance Requirements of the Steamer _____________________ 5

b. Exhaust Hood Requirements _________________________________________ 8

c. Positioning and Leveling the Steamer __________________________________ 8

2. Install Slide Racks _____________________________________________________ 8

3. Install the Free Air Vented Drain Lines _____________________________________ 9

4. Install Gas Supply Lines ________________________________________________ 10

a. Gas Supply Requirements ___________________________________________ 10

b. Install Gas Supply Lines ____________________________________________ 10

c. Testing Gas Supply Lines ___________________________________________ 11

5. Install Electric Power Lines _____________________________________________ 11

6. Water Supply Requirements and Installation ________________________________ 12

a. Water Supply Requirements _________________________________________ 12

b. Setting the Descale Required Light ____________________________________ 13

c. Install Water Supply Lines ___________________________________________ 15

d. Testing Water Supply Lines __________________________________________ 16

C. STARTUP AND CHECKOUT _______________________________________________ 16

1. Installation Checkout __________________________________________________ 17

2. Burner Ignition Test (Lighting and Shutdown Instructions) ______________________ 18

a. Lighting Instructions ________________________________________________ 18

b. Shutdown Instructions ______________________________________________ 19

3. Start Up Test Procedure Gas Gemini ______________________________________ 19

a. Startup Procedure __________________________________________________ 20

b. Blowdown Inspection _______________________________________________ 20

c. Operating Tests and Final Checkout Procedure __________________________ 21

CHAPTER 3 PREVENTATIVE MAINTENANCE AND TROUBLESHOOTING ____________ 23

A. MAINTENANCE _________________________________________________________ 23

1. Maintenance Records __________________________________________________ 23

2. Yearly Maintenance ___________________________________________________ 24

B. TROUBLESHOOTING GUIDE ______________________________________________ 24

CHAPTER 1 PRODUCT IDENTIFICATION

Cleveland Range, Inc. assigns two product identification numbers to each steamer: a model number and a

serial number. The model number identifies the product characteristics. The serial number identifies the

individual unit.

A. MODEL NUMBER

This manual covers the Gemini Model No. 24CGA6.2 and 24CGA10.2 Dual Steam Generator and

Convection Steamer.

Each character of this model number identifies a characteristic of the steamer. The Gemini Model No.

24CGA10.2 is 24 inches wide, a Convection steamer, Gas powered, and an Atmospheric steam generator

with a capacity for 10 cooking pans, this model has the extra suffix “.2” to differentiate it from our standard

10 pan model that does not have two separate generators. This manual covers all standard features and

options available on Gemini gas steamers.

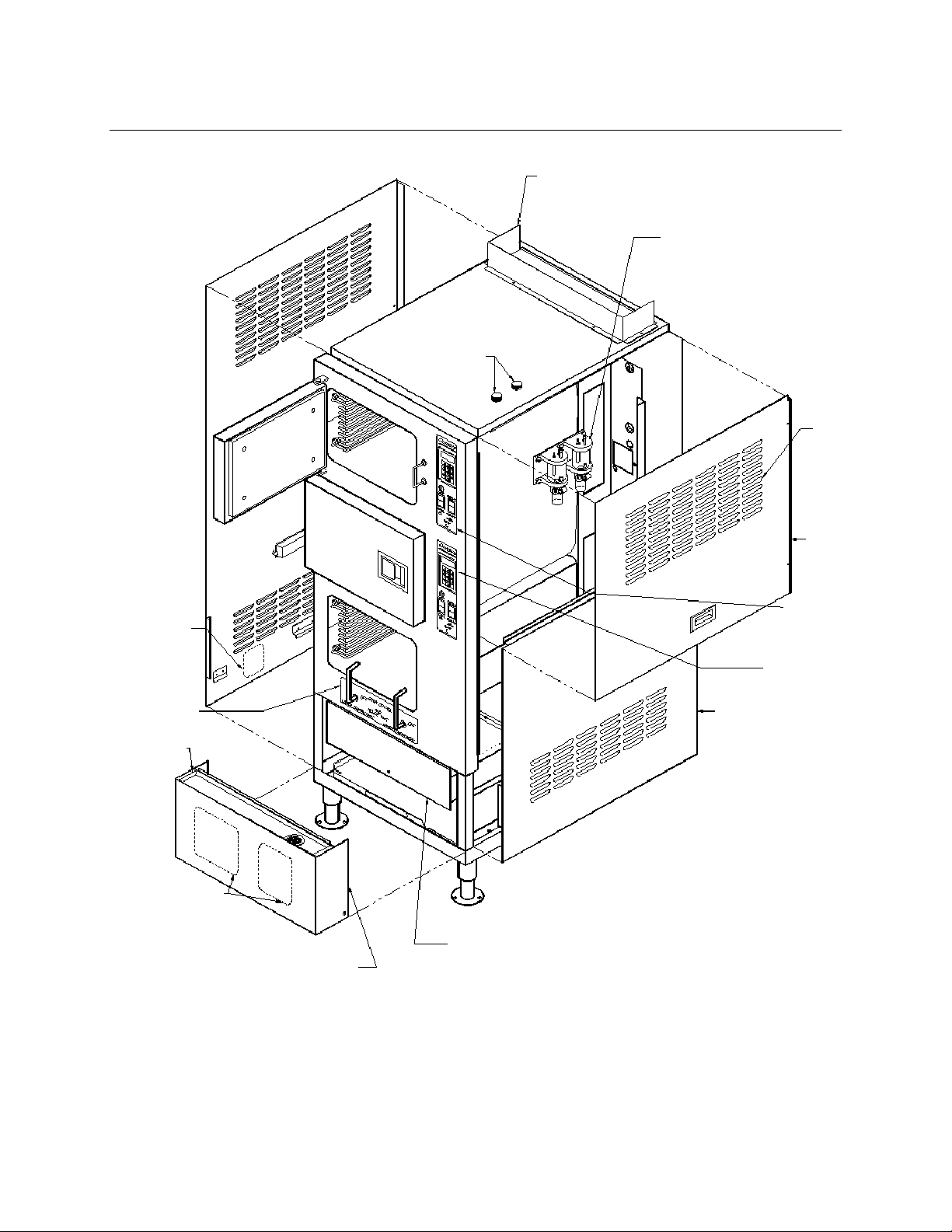

Other than selection of options, there are presently no significant design, parts, or operating differences

among steamers with this model number. Figures 1-2 and 1-3 illustrate the two Gemini designs of gas fired

steamers and identifies their major components.

B. SERIAL NUMBER

During manufacture, Gemini Steamers are assigned individual serial numbers. Whenever any inquiry is

made with Cleveland Range regarding a steamer the serial number should be referenced.

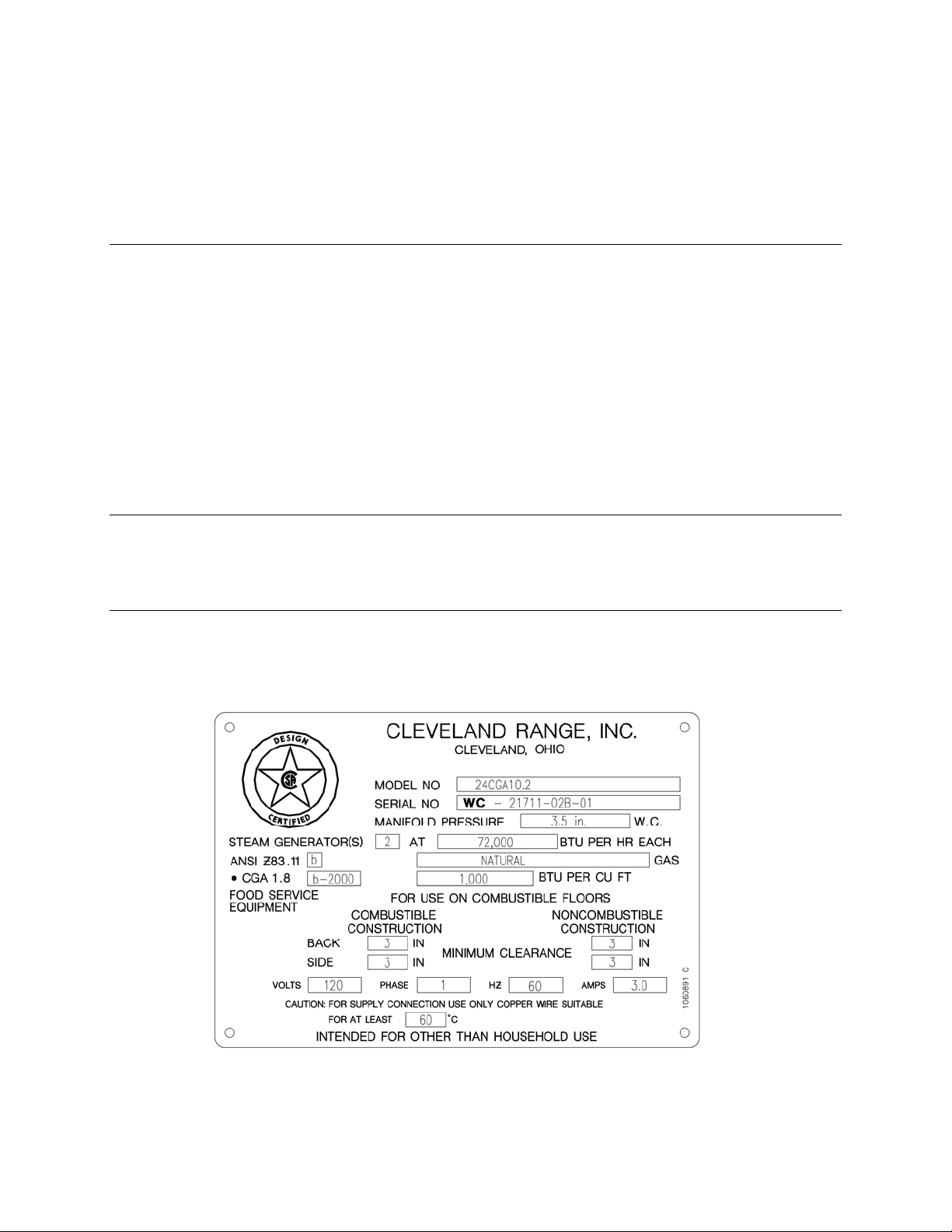

C. PRODUCT INFORMATION PLATE

The Product Information Plate on the left side of the unit lists the model and serial number of the steamer.

Refer to Figures 1-2 and 1-3 for the location of the plate. Figure 1-1 illustrates a typical Gemini Product

Information Plate. The rating plate also lists power and wiring requirements.

Figure 1-1 Gemini Product Information Plates

1

Y

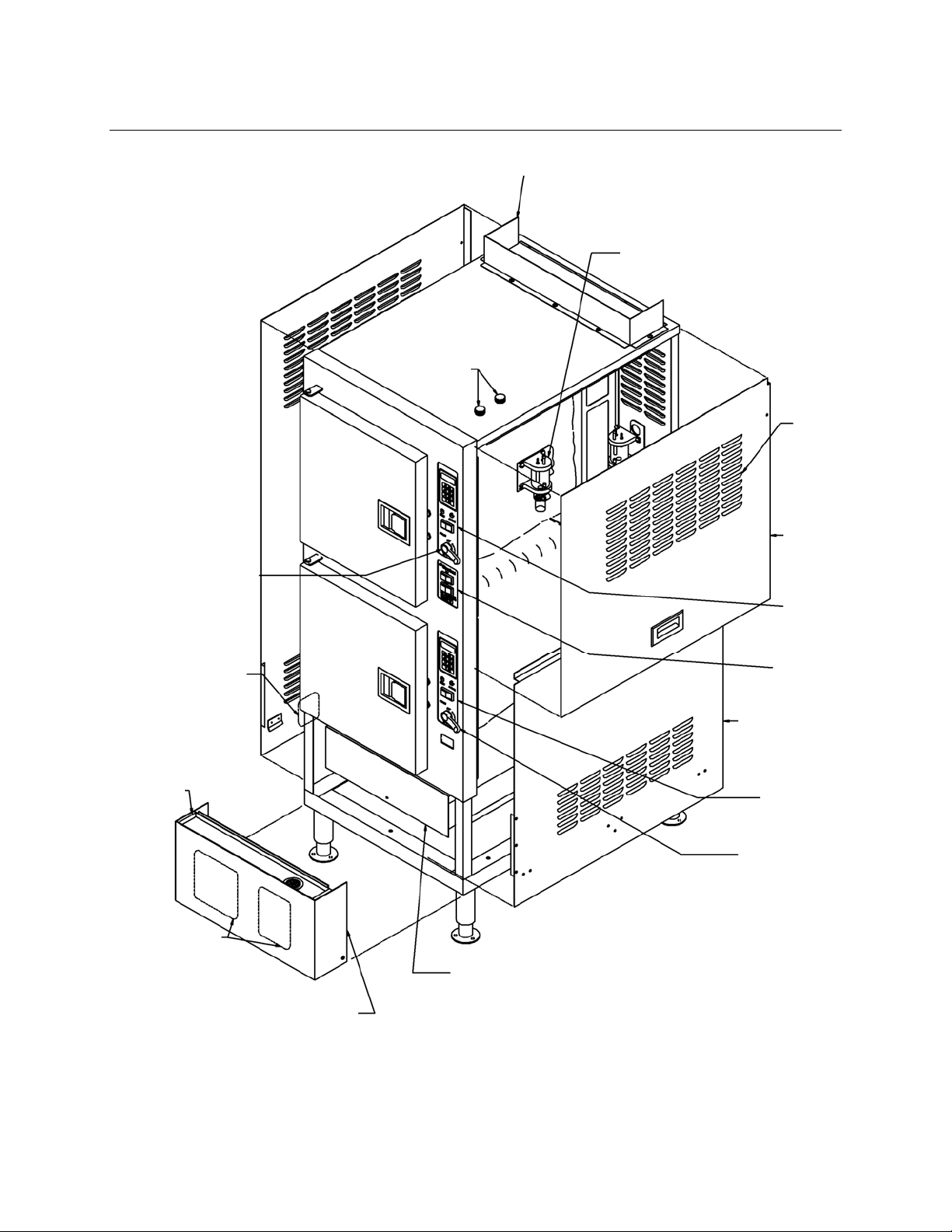

D. 24CGA6.2 PRODUCT VIEW

PRODUCT INFO.

PLATE ON LEFT

ACCESS PANEL

POWER ON/OFF

CONTROLS

DRIP TRA

WIRING DIAGRAMS ARE

LOCATED ON THE BACK OF

FRONT ACCESS PANEL

FRONT ACCESS PANEL

Figure 1-2. Gemini 6-Pan Dual Atmospheric Steam Generator

FLUE OUTLET

DESCALING

PORTS

MAIN

CONTROL

DRAWER

and Convection Steamer

WATER LEVEL PROBE HOUSINGS

LEFT- LOWER COMPARTMENT

RIGHT- UPPER COMPARTMENT

CONTROL PANEL

(LOWER)

RIGHT SIDE

SERVICE PANEL

AIR VENTS

RIGHT SIDE

SERVICE

PANEL

CONTROL PANEL

(UPPER)

NOTE: NOT ALL DETAILS ARE SHOWN

2

Y

T

E. 24CGA10.2 PRODUCT VIEW

POWER ON/OFF

CONTROLS

(UPPER)

PRODUCT INFO

PLATE ON LEF

ACCESS PANEL

DRIP TRA

WIRING DIAGRAMS ARE

LOCATED ON THE BACK OF

FRONT ACCESS PANEL

FRONT ACCESS PANEL

DESCALING

PORTS

MAIN

CONTROL

DRAWER

FLUE OUTLET

WATER LEVEL PROBE HOUSINGS

LEFT- LOWER COMPARTMENT

RIGHT- UPPER COMPARTMENT

RIGHT SIDE

SERVICE PANEL

POWER ON/OFF

CONTROL

(LOWER)

AIR VENTS

RIGHT SIDE

SERVICE

PANEL

CONTROL PANEL

(UPPER)

DESCALE INDICATOR

SWITCH PANEL

CONTROL PANEL

(LOWER)

NOTE: NOT ALL DETAILS ARE SHOWN

Figure 1-3. Gemini 10-Pan Dual Atmospheric Steam Generator

and Convection Steamer

3

CHAPTER 2 INSTALLATION INSTRUCTIONS

A. GENERAL

This equipment should only be installed by qualified, professional plumbers, pipe fitters, and electricians.

·

The installation of this steamer must conform with the Basic Plumbing Code of the Building Officials and

Code Administrators International, Inc. (BOCA), the National Fuel Gas Code, ANSI Z223.1-(latest

edition) or the Natural Gas Installation Code CAN/CGA-B149.1 or the Propane Installation Code

CAN/CGA-B149.2 as applicable, The National Electrical Code, ANSI/NFPA No. 70-(latest edition) or the

Canadian Electrical Code, CSA C22.2 as applicable, the Food Service Sanitation Manual of the Food

and Drug Administration (FDA) and all applicable state and local codes and regulations.

·

The installation instructions must be read in their entirety before starting the installation of this steamer.

WARNING

DEATH, INJURY, AND EQUIPMENT DAMAGE could result from the

improper installation, adjustment, alteration, service or maintenance

of a steamer or installation of a unit damaged during shipment or

storage. Any of these conditions could also void the equipment

warranty.

DO NOT INSTALL a Gemini steamer that has been damaged.

Install the Gemini steamer according to the policies and procedures

·

To install this steamer, the following requirements must be considered when selecting a location.

a. A suitable drain must be available within 12 ft. of the steamer.

b. An electrical supply matching the power requirements found on the rating plate must be available.

c. A gas supply matching the fuel requirements found on the rating plate must be available.

d. The location must have sufficient space to meet the clearance requirements of the steamer as

outlined in Chapter 2, Section B, Part 1, “Locating the Steamer”.

e. A water supply meeting the requirements outlined in Chapter 2, Section B, Part 6 “Water Supply

Requirements and Installation” must be available.

B. INSTALLATION OF THE STEAMER

After selecting the steamer’s operating location the steamer can be positioned, and installed. After Final

Setup and Checkout, the Gemini steamer should provide years of reliable operation.

outlined in this manual.

4

1. Locating the Steamer

a. Location and Clearance Requirements of the Steamer

For safe and efficient operation, observe the following criteria when selecting an operating location

for the Gemini steamer.

1) The unit should be installed in an area that is free and clear of combustible materials.

2) Do not locate the steamer directly over a floor drain.

3) A proper air supply for combustion and ventilation is critical to safe, efficient operation of Gemini

gas steamers.

4) Do not install any heat producing equipment near the air vents of the equipment. Do not block

the air vents of the unit. Do not store articles on top of the unit.

.

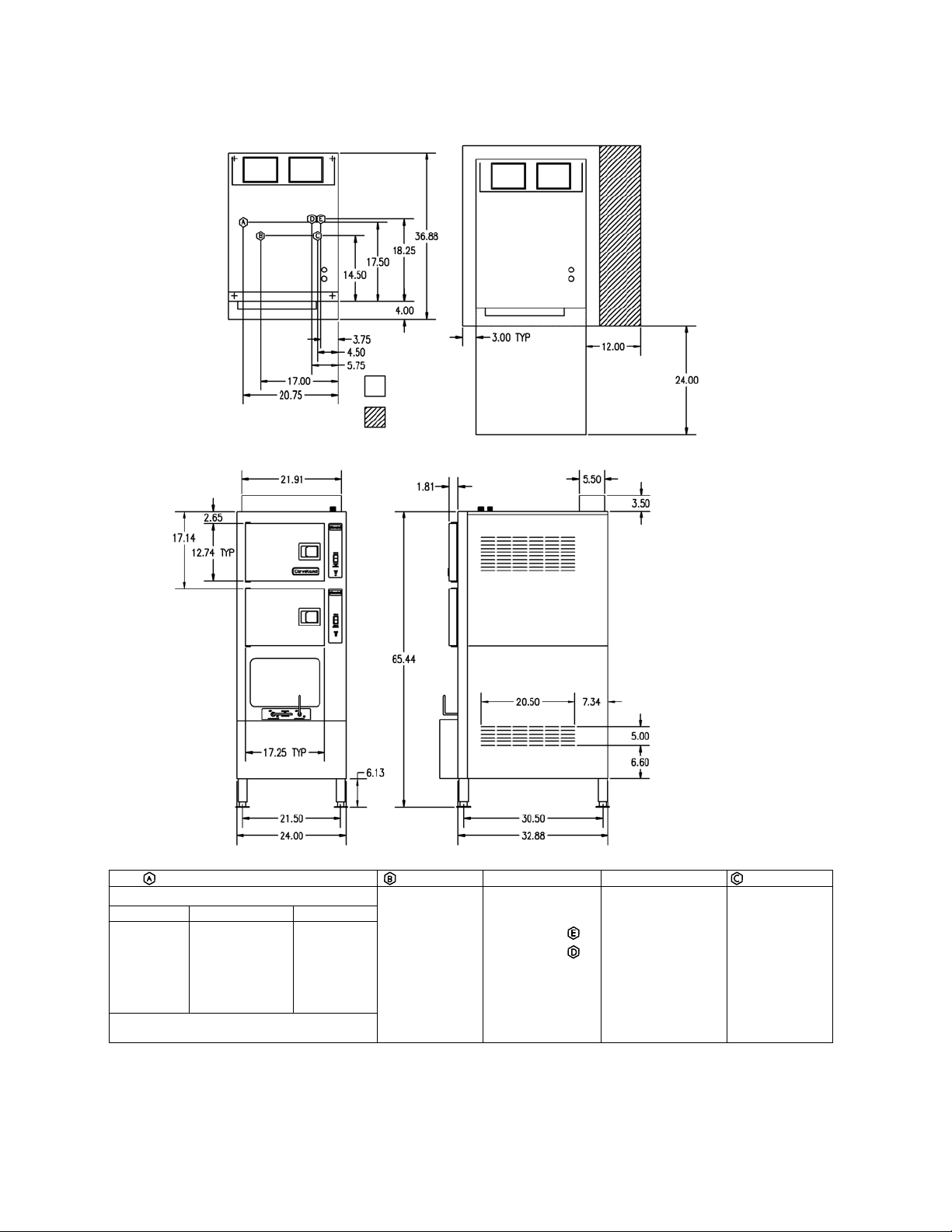

5) Figure 2-1 and 2-2 illustrate the dimensions and clearances required for these steamers.

Maintain the following minimum dimensions around the unit for safe and efficient operation,

maintenance and service.

·

·

·

6) The steamer must be level both front to back and side to side. Select an operating surface

that is level enough to allow leveling the unit without extreme adjustment of the legs.

7) The location selected must be capable of supporting 650 lbs. for a Gemini steamer. This

includes the weight of the water and the food.

Malfunctions and equipment damage may result from improper

mounting. Malfunctions and/or damage resulting from improper

mounting are not covered by the equipment warranty.

The steamer MUST BE LEVEL BOTH FRONT TO BACK AND

SIDE TO SIDE in all mounting arrangements.

Catastrophic damage will result from shifting the steamer more than

o

10

out of level with power supplied to the unit.

All clearance requirements above, below, and

around the unit are the same for non-combustible

locations as for combustible locations.

Maintain a 3-inch operating clearance at the sides of the unit, and at least a 3-inch

clearance at the back.

A 12 in clearance is recommended on the right side for servicing the steamer.

Approximately 24 inches of clearance is recommended in front of the unit for opening the

door and standard pan clearance.

CAUTION

WARNING

5

OPERATING

CLEARANCE

SECONDARY

CLEARANCE

GAS ELECTRIC COLD WATER CLEARANCE DRAINAGE

1-1/4" IPS line size, 3/4" connection

NATURAL PROPANE BTU 2 Fans & controls 60 psi maximum SIDES = 3.00” Do not connect other

Piping 3/4" N.P.T Piping 3/4" N.P.T. 50,000

Supply pressure Supply pressure Generator (1) 3/8" dia. IPS for FRONT = 24.00”

4.50" W.C. Min.

14.00” W.C. Max.

Manufacturer must be notified if unit will

be used above 2,000 feet

11.00" W.C. Min.

14.00” W.C. Max.

Do not use PVC pipe

each

100,000 total

120V-1Phase, 60 Hz. 35 PSI minimum RIGHT = 12.00" for service 1-1/2" dia.

150 watts each (1) 3/8" dia. IPS for

Generator

Condenser

REAR = 3.00” units to this drain

Drain must be vented

Figure 2-1 Gemini 24CGA6.2 Dimensions and Clearances

6

Loading...

Loading...