Clarke BEXT 100, BEXT 300HV, BEXT 120V, BEXT 100H, BEXT 150H User Manual

Operator's Manual |

®-100, 100H, |

|

150H, 300HV |

||

Manual del Operador |

||

Manuel de l'operateur |

120V |

|

|

Extractor's

READ THIS

This book has important information for the use and safe operation of this machine. Failure to read this book prior to operating or attempting any service or maintenance procedure to your Clarke machine could result in injury to you or to other personnel; damage to the machine or to other property could occur as well. You must have training in the operation of this machine before using it. If your operator(s) cannot read English, have this manual explained fully before attempting to operate this machine.

Si Ud. o sus operadores no pueden leer el Inglés, se hagan explicar este manual completamente antes de tratar el manejo o servicio de esta máquina.

All directions given in this book are as seen from the operator’s position at the rear of the machine.

For new books write to: Clarke® , 2100 Highway 265, Springdale, Arkansas 72764.

Form No. 70416A 7/06 |

Clarke® |

Printed in the U.S.A. |

CONTENTS OF THIS BOOK |

|

Operator Safety Instructions .................................................................................. |

5 |

Introduction and Machine Specifications .................................................................. |

6 |

Controls and Machine Features ............................................................................... |

12 |

How to Prepare the Machine for Operation .............................................................. |

14 |

Set-Up ........................................................................................................ |

14 |

BEXT®-100ControlPanel ............................................................................. |

16 |

BEXT®-100HControlPanel ........................................................................... |

16 |

BEXT®-150HControlPanel ........................................................................... |

18 |

BEXT®-300HVControlPanel ........................................................................ |

18 |

Instructions for Connection to the Power Supply - 120V |

|

Extension Cords - 120V ............................................................................. |

20 |

Machine Operating Instructions ............................................................................... |

22 |

How to Clean an Area of Carpet .................................................................. |

22 |

How To clean a Larger Area of Carpet......................................................... |

22 |

Maintenance ........................................................................................................... |

24 |

After Each Use of the Machine ................................................................... |

24 |

How to Prevent Damage from Freezing Temperatures ................................. |

26 |

The Pump and Vacuum Motor ................................................................... |

26 |

How To Check The Commutator and The Carbon Brushes .......................... |

28 |

How to Correct Problems in the Machine ................................................................. |

30 |

BEXT®-100 Assembly Drawing ................................................................................. |

34 |

Parts List ................................................................................................ |

35 |

BEXT®-100H Assembly Drawing............................................................................... |

36 |

Parts List ................................................................................................ |

37 |

BEXT®-150H Assembly Drawing............................................................................... |

38 |

Parts List ................................................................................................ |

39 |

BEXT®-300HV Assembly Drawing ............................................................................ |

40 |

Parts List ................................................................................................ |

41 |

BEXT®-100 Accessories ............................................................................................ |

42 |

BEXT®-100HAccessories ......................................................................................... |

43 |

BEXT®-150HAccessories ......................................................................................... |

44 |

BEXT®-300HV Accessories ....................................................................................... |

45 |

Control Panel Wiring Diagram ................................................................................. |

46 |

Electrical Schematic 120V ...................................................................................... |

47 |

Page 2 |

Clarke® BEXT® -100, 100H 150H, 300HV Operator's Manual |

OPERATORSAFETYINSTRUCTIONS |

|

|

WARNING |

AVERTISSEMENT |

ADVERTENCIA |

For the safe operation of this machine, read and understand all warnings and cautions.

|

DANGER means: |

Severe bodily injury or death can occur to you or other personnel if |

|

|

|

the DANGER statements found on your machine or in your Owner's |

|

|

|

Manual are ignored or are not adhered to. Read and observe all |

|

|

|

DANGER statements found in your Owner's Manual and on your |

|

|

|

machine. |

|

|

WARNING means : |

Injury can occur to you or to other personnel if the WARNING |

|

|

|

statements found on your machine or in your Owner's Manual are |

|

|

|

ignored or are not adhered to. Read and observe all WARNING |

|

|

|

statements found in your Owner's Manual and on your machine. |

|

|

CAUTIONmeans: |

Damage can occur to the machine or to other property if the |

|

|

|

CAUTION statements found on your machine or in your Owner's |

|

|

|

Manual are ignored or not adhered to. Read and observe all |

|

|

|

CAUTION statements found in your Owner's Manual and on |

|

|

|

your machine. |

|

DANGER: Machinescancauseanexplosionwhenoperatednearflammablematerialsandvapors. Donot

use this machine with or near fuels, grain dust, solvents, thinners, or other flammable materials.

DANGER: Do not immerse. To reduce the risk of an electric shock, use only on a carpet that has been moistened by a cleaning process. Protect the machine from rain. Keep the machine in a dry building. Always clean the machine with a clean dry cloth.

WARNING: You must have training in the operation of this machine before using it. READ THE

INSTRUCTION BOOK FIRST.

WARNING: Always use a three-wire electrical system connected to the electrical ground. For maximum protection against electric shock, use a circuit that is protected by a ground fault circuit interrupter. Consult your electrical contractor.

WARNING: To prevent electric shock, always remove the electrical plug from the electrical outlet before doing any repairs or maintenance to this machine.

WARNING: Do not use this machine as a step or furniture. Injury could occur to the operator.

WARNING: To avoid serious injury, use proper lifting procedures when lifting the machine.

WARNING: Maintenance and repairs must be done by authorized personnel only.

WARNING: Keep all fasteners tight. Keep the adjustments according to specifications.

WARNING: Make sure that all the labels, decals, warnings, cautions and instructions are fastened to the machine. Replace them when necessary by ordering them from Clarke.

WARNING: Do not use water that is hotter than 120°F (40°C).

WARNING: If foam/liquid comes out, stop extracting immediately. Allow vacuum('s) to run until exhaust air is dry.

Clarke® BEXT®-100, 100H 150H, 300HV Operator's Manual |

Page 5 |

OPERATORSAFETYINSTRUCTIONS(CONT.)

WARNING: Improper discharge of waste water may damage the environment and be illegal. The United States Environmental Protection Agency has established certain regulations regarding discharge of waste water. Also, city and state regulation regarding this discharge may be in effect in your area. Understand and follow the regulations in your area. Be aware of the environmental hazards of chemicals that you dispose.

CAUTION: To prevent damage to the power cord, do not move this machine over the power cord, instead, lift the power cord over the machine. If the cord supplied is damaged, it must be replaced by the manufacturer, its service agent or a similarly qualifed person in order to avoid the hazard.

CAUTION: To prevent damage to the power cord and hoses, do not use the power cord or hoses to pull the machine.

CAUTION: To prevent damage to the machine avoid extreme temperatures.

CAUTION: To prevent damage to the machine avoid extreme temperatures.

CAUTION: To prevent damage to the machine do not let pump run dry.

CAUTION: To prevent damage to the machine do not let pump run dry.

INSPECTION: Carfefully unpack and inspect your new Extractor for shipping damage. Each unit is tested and inspected before shipment. Any damage incurred is the responsibility of the carrier, who should be notified immediately.

CLEANING SOLUTIONS: We recommend liquid cleaning chemicals. A pH of 7-9 is strongly recommended to avoid premature pump wear, which would voide the warranty.

INTRODUCTION andMACHINE SPECIFICATIONS

•The Model BEXT®-100, 100H, 150H or 300HV is an extractor for cleaning carpet. When used with a floor tool, the machine applies cleaning solution to the carpet and removes the dirty solution and soil from the carpet.

•The extractor has controls to start the pump for the solution and the motor for the vacuum. The floor tools have controls to release the solution.

•The extractor has a bypass pump. The pump runs when switched on, bypassing solution internally to keep pressure even.The extractor starts when the solution lever on the floor tool is activated.

SPECIFICATIONS |

Bext 100 |

|

Bext 100H |

|

Bext 150H |

|

Bext 300H |

|

|

|

Bext 100H Detailer |

|

Bext 150H Detailer |

|

|

Part Number |

04156A |

|

04157A / 04158A |

|

04147A / 04152A |

|

04148A |

Solution Tank |

9 gallon rotationally molded |

|

13 gallon rotationally molded |

||||

Solutin Pump |

100 psi demand pump |

|

150 psi demand pump |

|

300 psi demand pump |

||

Vacuum Motor |

|

5.7", 3 stage |

|

(2) - 5.7" 2-stage |

|

7.2" 3-stage |

|

Waterlift |

|

140" |

|

150" |

|

140" |

|

Easy Circuit Locator |

N/A |

|

Standard |

|

Standard |

|

Standard |

|

|

|

|

|

|

|

|

On-board Heater |

N/A |

|

Standard |

|

Standard |

|

Standard |

Wand |

|

|

Double bend twin nozzle polished stainless steel |

|

|||

Power Cable |

25 ft. 12-3 hosp. |

|

(2) 25 ft. 12-3 hosp. grade plug |

|

|||

|

grade plug |

|

|

|

|

|

|

Wheels |

(2) 8" non-marking & (2) 3" casters |

|

(2) 10" non-marking & (2) 2" casters |

||||

Hose |

|

15 ft. crushproof vacuum and high pressure solution line |

|

||||

Low Moisture System |

|

|

Standard |

|

|||

Float Shut-Off |

|

|

Standard |

|

|||

Weight |

69 lbs. |

|

75 lbs. |

|

90 lbs. |

|

119 lbs. |

Warranty |

Product Lifetime (10 years) on tank and mainframe; 1 year Parts and labor |

||||||

|

|

|

|

|

|

|

|

NOTE: When using the extractor to clean carpets, follow this procedure:

1.Do not walk on freshly cleaned carpets for at least four hours or until the carpet is dry to touch.

2.Do not remove aluminum or plastic pieces that have been placed under the legs of furniture until the carpet is dry.

3.Do not allow children or pets to crawl or walk around on the damp carpet.

4.Vacuum right after the carpet is dry and then vacuum the carpet once a week as needed.

Page 6 |

Clarke® BEXT® -100, 100H 150H, 300HV Operator's Manual |

1H |

1B |

1A |

1C |

|

|

|

1D

1G

1F

1E

Figure 1

1I

1J

Figure 1

Figure 2

CONTROLS and MACHINE FEATURES

The Vacuum Motor Switches See Figure 1-A

The vacuum motor switches are located on the top of the machine.

The Switch To Activate The Pump See Figure 1-B The switch to start/stop the pump motor is on the top of the machine. Press the lever on the floor tool to start the solution flow. Release the lever on the floor tool to stop the solution flow.

NOTE: While the BEXT-150 machine is in operation, the pump will shut-off automatically when it reaches full pressure. The pump will automatically turn on when the pressure decreases.

The Float Shut-Off -See Figure 1C

The float shut-off is in the recovery tank. When the liquid raises the float, the air stops moving through the machine.

NOTE: To avoid vacuum motor damage, always inspect the float filter and ball. Verify ball travels easily prior to use of unit. See Figure 2

The Vacuum Hose Connector See figure 1D

The vacuum hose connector is on the front of the unit.

The Solution Hose Connector See Figure 1E

The solution hose connector is on the lower part of the extractor, below the vacuum hose connector.

The Recovery Tank See Figure 1F

The recovery tank is in the top of the machine.

The Solution Tank See Figure 1G

The solution tank is in the top of the machine next to the recovery tank.

Electric Circuit Locator See Figure 1H

This unique, patented "smart system", operated by a solid state circuit, will inform the operator when the two cords are plugged into separate circuits by illuminating the "Locator" indicator light. This helps prevent tripping circuit breakers.

NOTE: Ground plug on the cord is required to allow circuit locator to operate correctly. The system will not function without proper ground.

The Machine Power Cord (Red "H") See Figure 1I

This cord powers all machine functions exceptthe heater.

The Heater Power Cord See Figure 1J

This cord powers heater only.

Page 12 |

Clarke® BEXT® -100, 100H 150H, 300HV Operator's Manual |

Figure 3A

Figure 3B

HOW TO PREPARE THE MACHINE FOR OPERATION

To prepare the machine for operation, follow this procedure:

1.Connect the vacuum hose to the hose connector on the extractor and to the end of the vacuum tube on the floor tool. See Figure 1 D, E

2.Connect the solution hose to the extractor and the floor tool. To fasten the quick disconnect fitting, slide the knurled collar on the female coupling away from the opening. Push the male coupling into the female coupling. See figure 3 A & B

WARNING: |

Do not use water that is hotter than |

|

120°F (48°C). |

3.Before moving the extractor onto the carpet, put clean hot water into the solution tank.

4.Add a cleaning chemical, such as Clarkare® Ex-

tractor Concentrate, to the hot water. For the correct amount, follow the directions shown on the container.

Set-Up

WARNING: We recommend that you use liquid cleaningchemicals. Powdercandamage machine. Powders can cause build-up in the lines, heater, pump, quick disconnects, etc., all of which would void the warranty on those items. A pH of 7-9 is strongly recommended to avoid damage and premature wear to the pump, which would void the warranty.

Fill the holding tank with clear water and the detergent of your choice. Mix well. Although this machine is designed to supply instant hot water, the addition of warm or hot water to the holding tank is beneficial and will reduce pre-heat times.

A.Plug in cord #1 (vac and pump), identified by the red "H" on the end of the cord. Attach the priming hose to the machine (on 300 HV only). Turn the pump on and set the switch to the upholstery setting. Run until the pump is fully primed, then turn off the pump. Remove the priming hose and attach the cleaning hoses and tool.

B.Turn on the pump and spray through the cleaning tool for a few seconds to fill the lines with solution.

BEXT® 100H, 150H & 300HV

C.Plug in cord #2. The "Locator" light will illuminate when the cords are plugged into separate circuits. Turn the "Heat" switch on; wait two minutes for the heat exchanger to reach operating temperature. You may now begin cleaning. It will take about 10 seconds for the initial heat to reach the wand. The "Mode" light will turn on when the heat exchanger is actively heating. (See Figures 5, 6 and 7)

NOTE: If the "Locator" indicator light does not illuminate when cord #2 is plugged in, then both cords are on the same line. Try other outlets until the light comes on.

CAUTION: If both cords are plugged into the same circuit breaker, the breaker may blow when operating with the heater on.

Page 14 |

Clarke® BEXT® -100, 100H 150H, 300HV Operator's Manual |

5.If the extractor removes an excess amount of foam from the carpet, add a de-foamer such as Clarkare® De-foamer Concentrate to the recovery tank. The amount needed will vary according to the amount of detergent already in the carpet.

CAUTION: |

To prevent damage, use a water-based de- |

CAUTION: |

foamer ratherthananoil-basedde-foamer. |

Donot leavetheextractororothercleaning |

|

|

machines or tools on the carpet when not |

|

in use. Cleaning solution in the machines |

|

and tools can leak onto the carpet and |

|

cause light spots or stains. |

NOTE: To order Clarkare® Extractor Concentrate, order part no. 398421. To order Clarkare® Defoamer, order part no. 398420.

For instructions for preparation and operation of your floor tool, read the instruction sheet given with your floor tool.

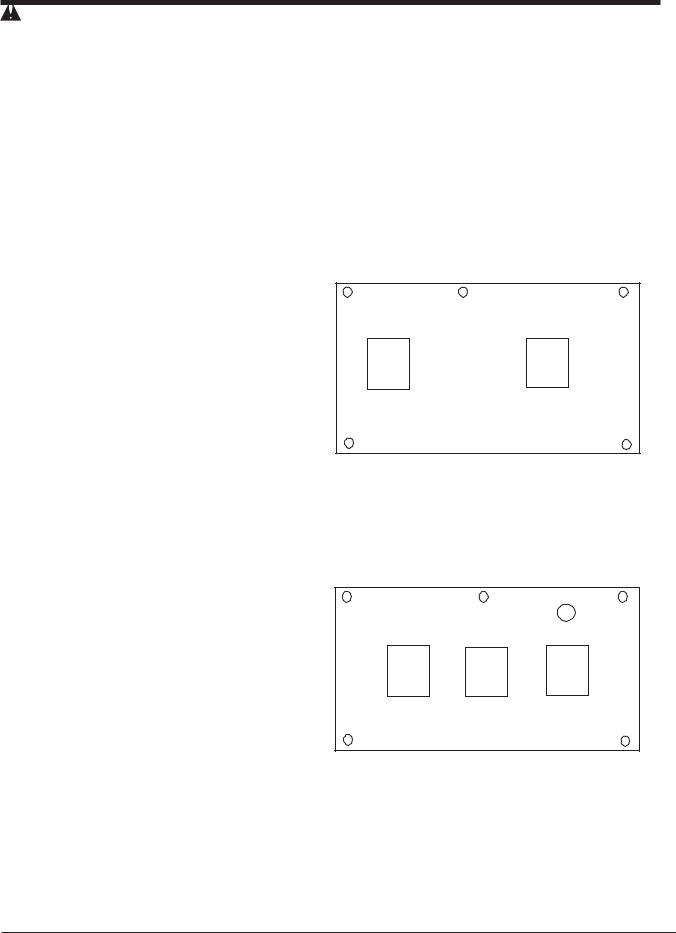

BEXT®-100 Control Panel

1 |

2 |

VAC |

PUMP |

Figure 4

VACUUM SWITCH (1 ): The vac switches illuminate when turned on.

PUMP SWITCH (2): This switch will illuminate when the pump is on.

BEXT®-100H Control Panel

|

|

1 |

|

|

LOCATOR |

2 |

3 |

4 |

VAC |

PUMP |

HEAT |

Figure 5

CIRCUIT LOCATOR (1):When this light is on, it indicates that cord #2 is on a separate line from cord #1. Cord #2 supplies voltage to the heater allowing it to heat to the proper temperature range.

VACUUM SWITCH (2): The vacuum switch will illuminate when the vacuum motor is turned on.

PUMP SWITCH (3): This switch will illuminate when the pump is on.

HEAT SWITCH (4): The heat switch will illuminate when it is activated and will turn the heater on.

Page 16 |

Clarke® BEXT® -100, 100H 150H, 300HV Operator's Manual |

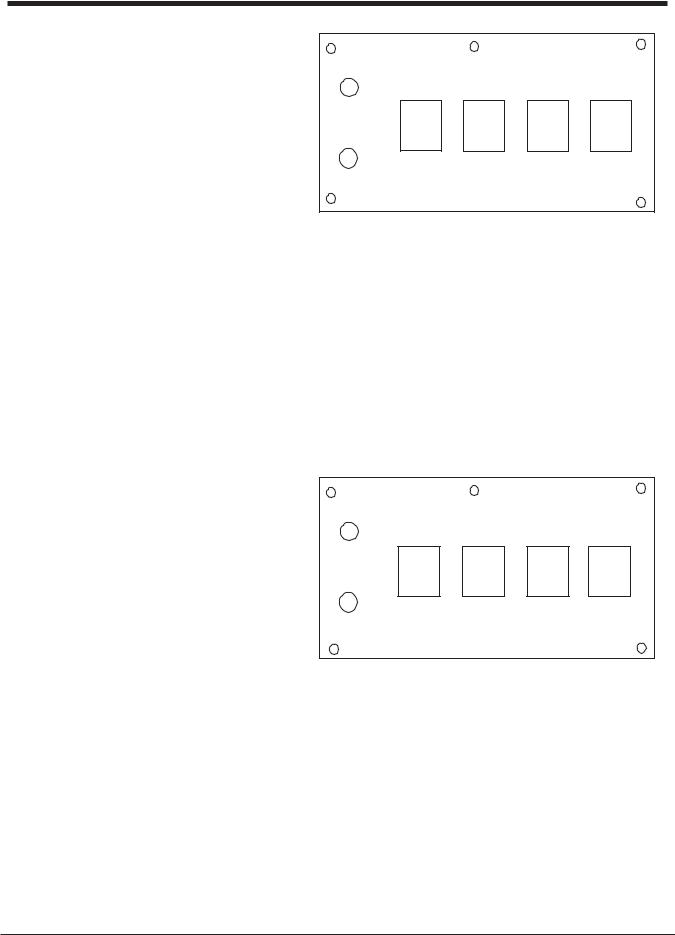

BEXT®-150 H Control Panel

1

LOCATOR |

3 |

4 |

5 |

6 |

|

||||

2 |

VAC 1 |

VAC 2 |

PUMP |

HEAT |

MODE |

Figure 6

CIRCUIT LOCATOR ( 1 ): When this light is on, it indicates that cord #2 is on a separate line from cord #1. Cord #2 supplies voltage to the heater allowing it to heat to the proper temperature range.

HEAT MODE LIGHT ( 2 ): This light will only illuminate when the heater is heating and will turn off when it reaches operating temperature.

VACUUM SWITCH ( 3 & 4): Each switch turns on one vac motor. turn both switches on for maximum lift. The vac switches illuminate when turned on.

PUMP SWITCH ( 5 ): This switch will illuminate when the pump is on.

HEAT SWITCH ( 6 ) : The heat switch will illuminate when it is activated and will turn the heater on.

BEXT®-300 HV Control Panel

5 |

|

|

Upholstery |

|

|

LOCATOR |

1 |

2 |

3 |

4 |

|

|

|||||

6 |

VAC |

PUMP |

CARPET |

HEAT |

|

MODE |

|||||

|

|

|

|

Figure 7

VAC ( 1 ) & PUMP ( 2 ) SWITCHES: These switches are powered by cord #1 (4" red band). Switches are on when illuminated.

CARPET / UPHOLSTERY SWITCH ( 3 ): This switch is also powered by cord #1. The carpet setting (down position) is high pressure (approximately 300 psi). The upholstery setting (up position) is low pressure (approximately 75 psi). NOTE: Switch does not illuminate.

HEAT SWITCH ( 4): Turning on this switch (switch illuminates when on) turns the heater on.

GREEN CIRCUIT LOCATOR LIGHT ( 5 ): When this light is illuminated, it confirms that the machine is on two separate circuits. See previous page for additional information on the circuit locator.

HEAT LIGHT MODE ( 6 ) : The light will only illuminate when the heater uis heating and will turn off when it reaches operating

temperature.

Page 18 |

Clarke® BEXT® -100, 100H 150H, 300HV Operator's Manual |

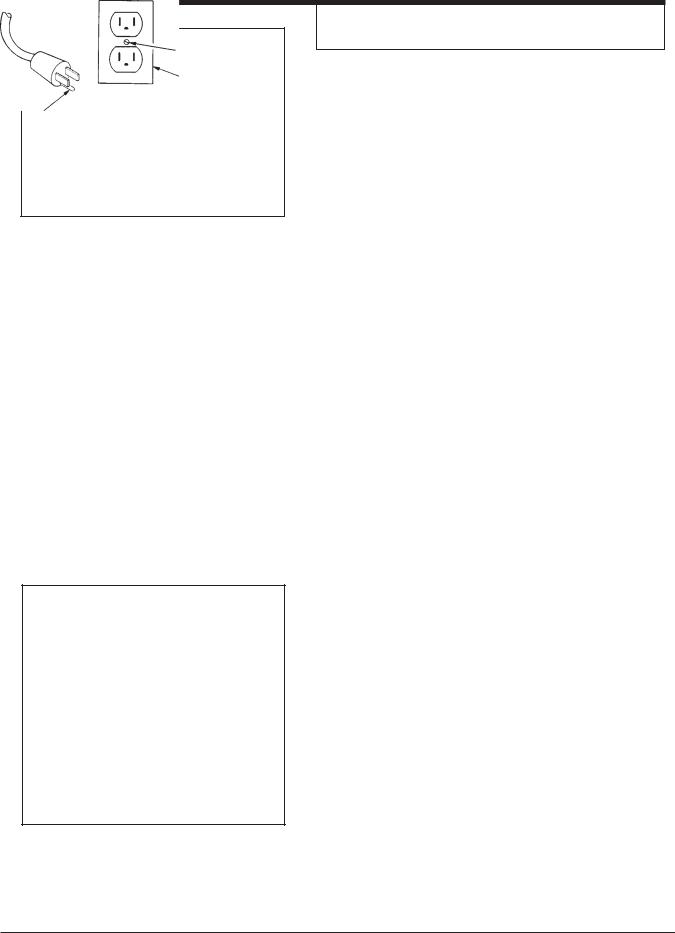

Plate

Screw

Outlet must be connected to

Ground Pin the electrical ground

Figure 7

|

|

Tornillo |

|

|

|

de la |

|

|

|

placa |

|

|

|

||

|

|

|

|

|

tomacorriente |

||

Terminal de |

debe estar |

||

conectado al |

|||

tierra |

|||

borne de puesta |

|||

|

|||

|

a tierra |

||

|

|

|

|

|

Figura 7 |

||

Borne mâle de la prise

réceptacle

être

Fiche de terre connecté à la masse

Figure 7

INSTRUCTIONS FOR CONNECTION TO THE

POWER SUPPLY AND ELECTRICAL GROUND - 120 V

CAUTION: This machine will operate only on an AC frequency and on the specified electrical voltage shown on the nameplate. Make sure you have the correct frequency and voltage before connecting the power cord to an outlet.

This machine must be connected to an electrically grounded circuit in order to protect the operator from electric shock. This machine has an approved power cord with three conductors as well as a plug with three terminals. Connect the plug to a three holed receptacle. For maximum protection against electric shock, use a circuit that is protected by a ground fault circuit interrupter.

This machine uses a 120 volt AC 50/60 cycle electrical circuit. Make sure you have the correct frequency and voltage before connecting the power cord to an outlet. The machine has a plug as shown in Figure 7. If a receptacle connected to the electrical ground as shown in Figure 7 is not available, contact an electrical contractor. Do not use an adapter.

WARNING: To prevent possible electric shock, protect the machine from rain. Keep the machine in a dry building.

WARNING: To prevent possible electric shock, always use a 3-wire electrical system connected to the electrical ground. For maximum protection against electrical shock, use a circuit that is protected by a ground fault circuit interrupter. Consult your electrical contractor.

WARNING: Do not cut, remove, or break the ground pin. If the outlet does not fit the plug, consult your electrical contractor.

WARNING: If the cords or plugs are worn or damaged in any way, have them replaced by an authorized service person.

Extension Cords

Use only an approved extension cord with three conductors, a plug with three terminals and a three-holed connector body. This machine has a power cord with a wire size of 12 AWG. (AWG stands for American Wire Gauge).

CAUTION: If you use an extension cord, use one that has a minimum wire size of 12 AWG. Be sure your extension cord is no longer than 50 ft. Do not join two extension cords.

Page 20 |

Clarke® BEXT® -100, 100H 150H, 300HV Operator's Manual |

Loading...

Loading...