Page 1

XERION 3300

Technical

Systems

Hydraulic System

Page 2

410

Page 3

Content

1 Overall hydraulic system

Overall circuit diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Circuit diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Overall circuit diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Key to diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

PFC pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Compensating valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Initial position (engine OFF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Low-pressure standby . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Pump starts pumping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Constant volume flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Downstroking the PFC pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Maximum pressure limitation (pressure relie f valve function), maximum standby pressure . 24

2 Steering hydraulics

System concept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Fully hydraulic steering (Emergency steering) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Circuit diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Key to diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Orbitrol axle = Floating axle (1), the rigid axle (2) is tracked by electro-hydraulic means . . . 37

Circuit diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Key to diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Orbitrol axle = Rigid axle (2), the floating axle (1) is tracked by electro-hydraulic means . . . 43

Circuit diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Key to diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

The floating axle (1) and the rigid axle (2) are steered electro-hydraulically – the Orbitrol

steering circuit is closed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Circuit diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Key to diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Steering valve VI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Graphics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Key to diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Content

410

3 Working hydraulics

Working hydraulics circuit diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Circuit diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Key to diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Main valve block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Graphics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Key to diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

000 293 646 0 - SYS-H XERION 3300 - 04/05 3

Page 4

Content

410

4 000 293 646 0 - SYS-H XERION 3300 - 04/05

Page 5

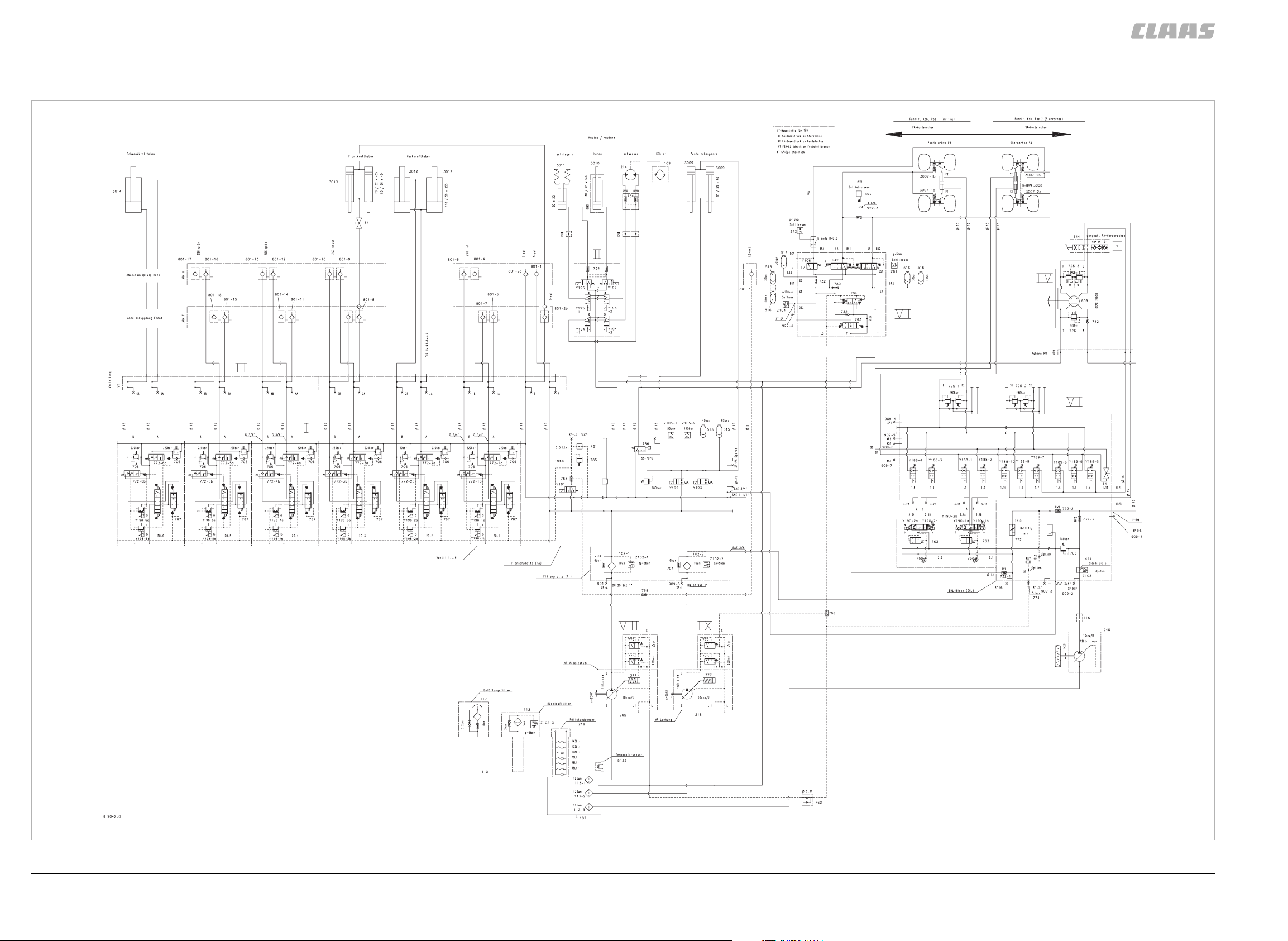

1 Overall hydraulic system

Overall circuit diagram

1 Overall hydraulic system

Overall circuit diagram

387

000 293 646 0 - SYS-H XERION 3300 - 04/05 5

Page 6

1 Overall hydraulic system

Overall circuit diagram

Circuit diagram

387

323-1 323-2

408

400996

6 000 293 646 0 - SYS-H XERION 3300 - 04/05

Page 7

1 Overall hydraulic system

Overall circuit dia gram

Key to diagram

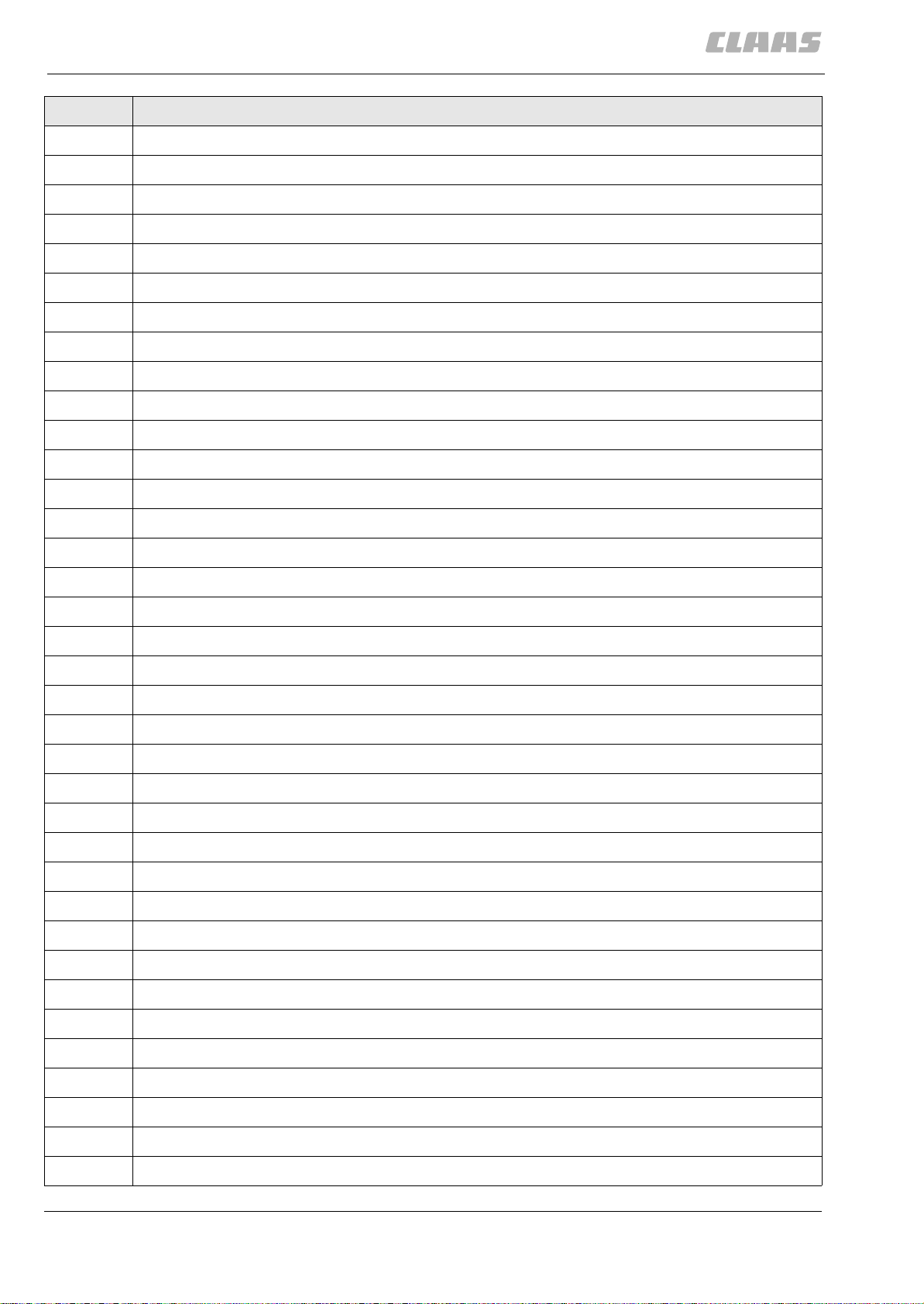

Item Component

I Main valve block

II Cab valve block

III Distributor block

IV Orbitrol steering valve

V Steering sense valve

VI EHL valve block – Electro-hydraulic steering

VII Main brake valve

VIII Working hydraulics variable-displacement pump

IX Steering hydraulics variable-displacement pump

1 Overall hydraulic system

Overall circuit diagram

391

-102-1 Working hydraulics pressure filter

102-2 Steering hydraulics pressure filter

107 Oil drain

109 Hydraulic system oil cooler

110 Oil tank

112 Return filter

113-1 Working hydraulics suction filter

113-2 Steering hydraulics suction filter

113-3 Emergency steering suction filter

116 Resonance tube (Silencer)

117 Fresh air filter element

-205 Working hydraulics pump

214 Hydraulic motor

218 Steering hydraul ics pump

245 Emergency steering pump

-323-1 Floating axle steering hydraulic cylinder

323-2 Rigid axle steering hydraulic cylinder

377 Variable-displacement pump hydraulic cylinder

3007-1a Service brake hydraulic cylinder

3007-1b Service brake hydraulic cylinder

3007-2a Service brake hydraulic cylinder

000 293 646 0 - SYS-H XERION 3300 - 04/05 7

Page 8

1 Overall hydraulic system

Overall circuit diagram

Item Component

3007-2b Service brake hydraulic cylinder

3008 Parking brake hydraulic cylinder

3009 Floating axle lock hy dr au lic cylind e r

3010 Cab raise/lo we r hy dr a ulic cylin de r

3011 Unlock cab hydraulic cylinder

3012 Rear power lift hydraulic cylinder

3013 Front power lift hydraul ic cylinder

3014 Swing lower link hy dr aulic cylin de r

-406 Orifice plate F (Ø 0. 8 mm)

414 Orifice plate F (Ø 3. 5 mm)

421 Restrictor

391

-515 Pressure accumula to r

516 Service brake pressur e ac cu m ulato r

519 Parking brake pr essure accumulator

-609 Orbitrol steering system rotary valve

641 Shut-off valve

642 Service brake valve

644 Steering sense valve

-704 Bypass valve (non-return valve)

706 Pressure relief valve

725-1 Floating axle steering double shock valve

725-2 Fixed axle steering double shock valve

725-3 Orbitrol steering double shock valve

726 Steering pressure relief valve

732 Non-return valve

734 Lock-up valve unit (non-return valve)

742 Steering safety valve

760 One-way restri ctor valve, one-sided

763 Input pressure balance

768 LS signal shuttle valve

772 Volume flow contr oller

772-1a Volume flow controller (red A)

8 000 293 646 0 - SYS-H XERION 3300 - 04/05

Page 9

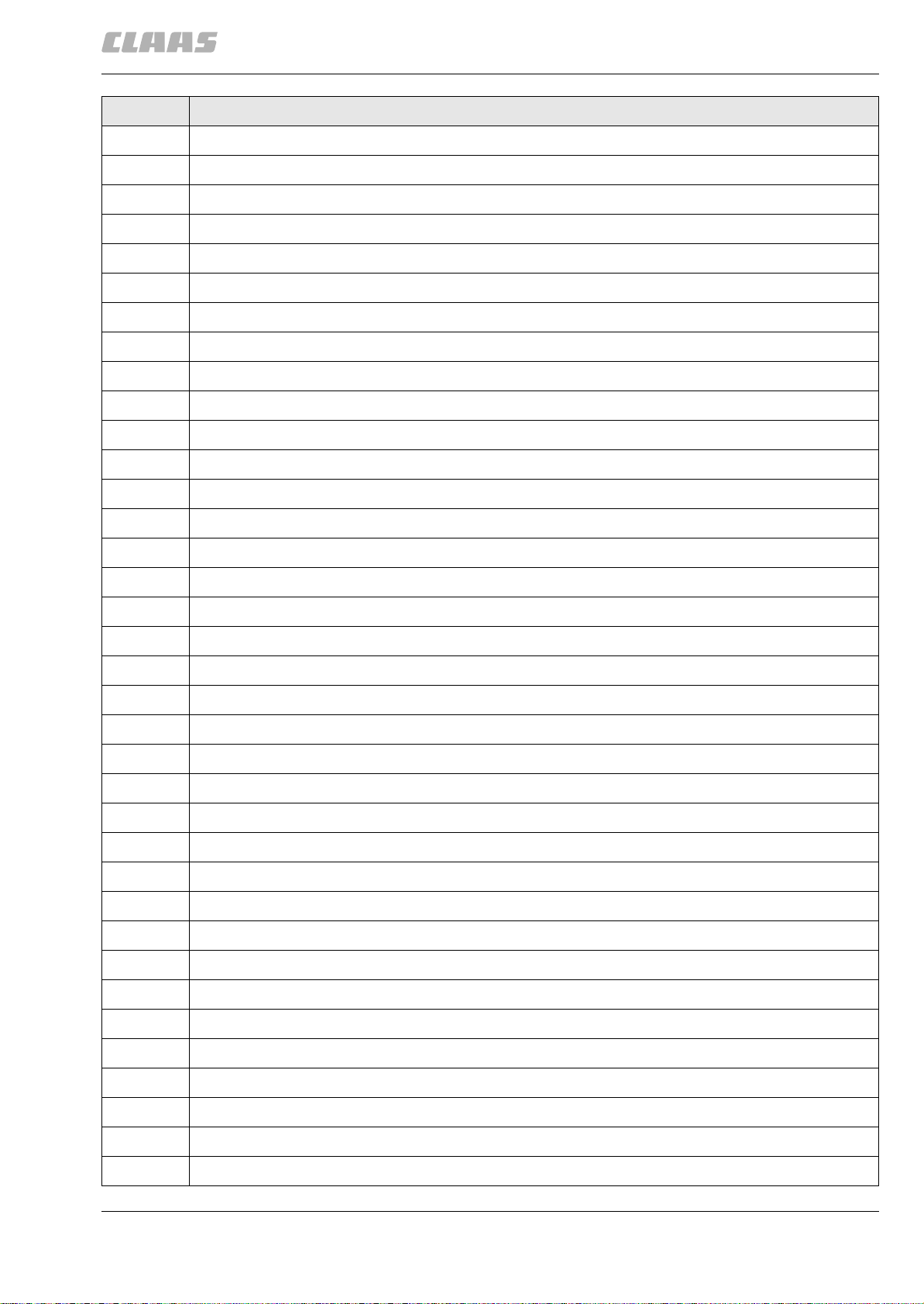

Item Component

772-1b Volume flow controller (red B)

772-2a Volume flow controller (EHR A)

772-2b Volume flow controller (EHR B)

772-3a Volume flow controller (white A)

772-3b Volume flow controller (white B)

772-4a Volume flow controller (yellow A)

772-4b Volume flow controller (yellow B)

772-5a Volume flow controller (green A)

772-5b Volume flow controller (green B)

772-6a Volume flow controller (swing lower link A)

772-6b Volume flow controller (swing lower link B)

773 Pressure controller

1 Overall hydraulic system

Overall circuit diagram

391

774 Pressurizing valve

780 Shuttle valve

783 Trailer brake valve

784 Accumulator charge valve

785 LS pressure relief valve

786 Thermostat valve

787 Pressure balance

-801-1 Quick-release coupling (P power beyond)

801-2a Quick-release coupling (T power beyond rear)

801-2b Quic k- re le as e co up lin g (T fro n t)

801-3 Quick-release coupling (LS power beyond)

801-4 Quick- rel e as e co up lin g (r ed A rea r)

801-5 Quick- rel e as e co up lin g (r ed A fro nt )

801-6 Quick- rel e as e co up lin g (r ed B rea r)

801-7 Quick- rel e as e co up lin g (r ed B fro nt )

801-8 Quick-re le as e coup lin g (white A front)

801-9 Quick-re le as e coup lin g (white A rear)

801-10 Quic k- rele ase coupling (white B rear)

801-11 Quick- re le as e co up lin g (y ello w A fro nt)

801-12 Quick- re le as e co up lin g (y ello w A rear )

801-13 Quick- re le as e co up lin g (y ello w B rear )

801-14 Quick- re le as e co up lin g (y ello w B fro nt)

801-15 Quick-release coupling (green A front)

000 293 646 0 - SYS-H XERION 3300 - 04/05 9

Page 10

1 Overall hydraulic system

Overall circuit diagram

Item Component

801-16 Quick-release coupli ng (green A rear)

801-17 Quick-release coupli ng (green B rear)

801-18 Quick-release coupli ng (green B front)

-B123 Hydraulic oil temperature

-Y106 Parking brake solenoid valve

Y188-1 Steering logics shut-off valve solenoid valve

Y188-2 Steering logics shut-off valve solenoid valve

Y188-3 Steering logics shut-off valve solenoid valve

Y188-4 Steering logics shut-off valve solenoid valve

Y189-5 Steering logics definition valve solenoid v alve

391

Y189-6 Steering logics definition valve solenoid v alve

Y189-7 Steering logics definition valve solenoid v alve

Y189-8 Steering logics definition valve solenoid v alve

Y189-9 Steering logics definition valve solenoid v alve

Y189-10 Steering logics definition valve solenoid valve

Y190-1a Automatic steering solenoid valve

Y190-1b Automatic steering solenoid valve

Y190-2a Automatic steering solenoid valve

Y190-2b Automatic steering solenoid valve

Y191 Constant-pressure s ystem solenoid valve

Y192 Floating axle locking sole no id valve

Y193 Floating axle unlock ing sole n oid valv e

Y194-1 Cab rotation solenoid valve ?

Y194-2 Cab rotation solenoid valve ?

Y195-1 Unlock cab solenoid valve

Y195-2 Unlock cab solenoid valve (not used)

Y196 Cab raise solenoid valve

Y197 Cab lower solenoid valve

Y198-1a Pilot valve solenoid valve (red A)

Y198-1b Pilot valve solenoid valve (red B)

Y198-2a Pilot valve solenoid valve (EHR A)

Y198-2b Pilot valve solenoid valve (EHR B)

Y198-3a Pilot valve solenoid valve (white A)

Y198-3b Pilot valve solenoid valve (white B)

10 000 293 646 0 - SYS-H XERION 3300 - 04/05

Page 11

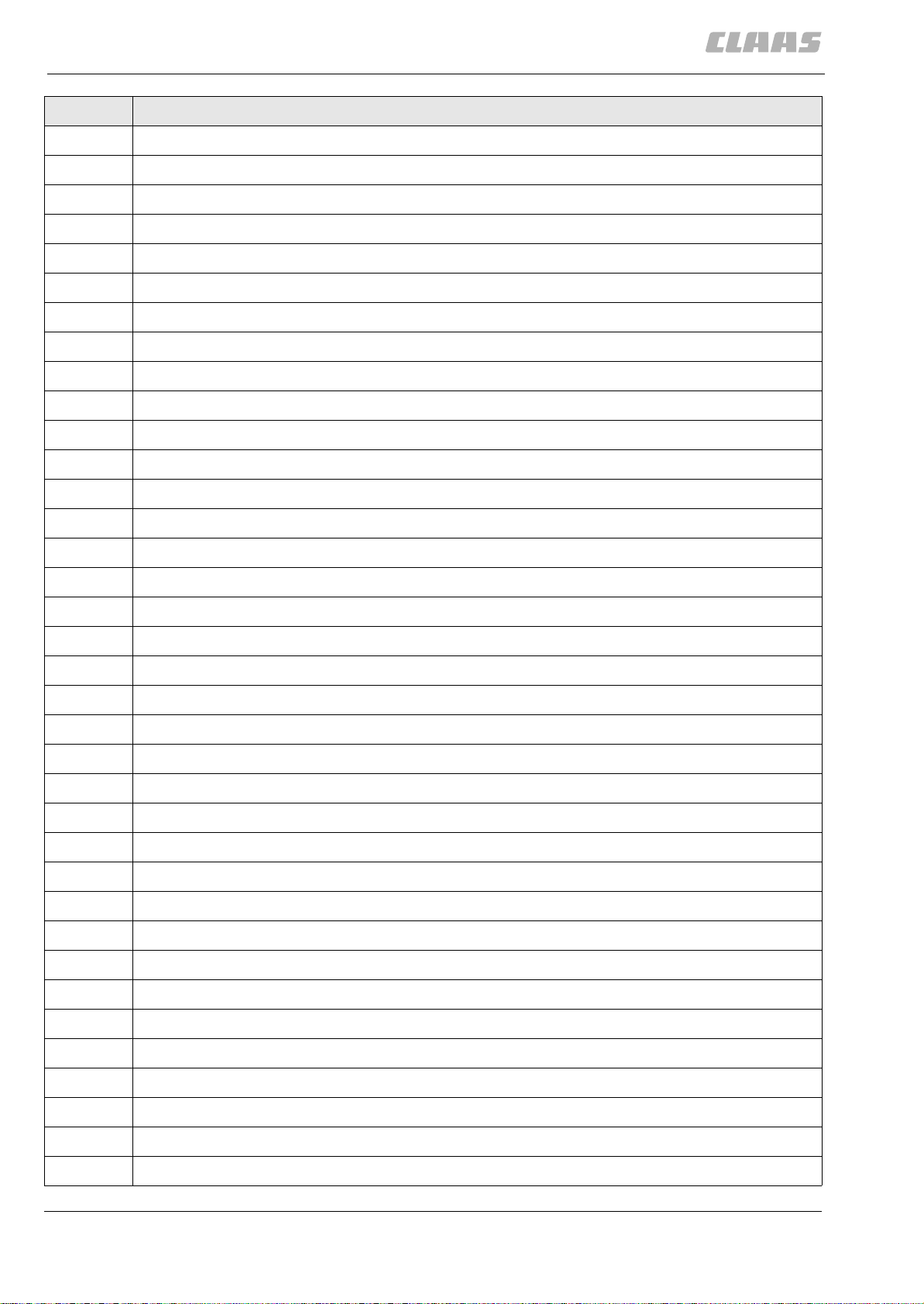

Item Component

Y198-4a Pilot valve solenoid valve (yello w A)

Y198-4b Pilot valve solenoid valve (yello w B)

Y198-5a Pilot valve solenoid valve (g ree n A)

Y198-5b Pilot valve solenoid valve (g ree n B)

Y198-6a Pilot valve solenoid valve (swi ng low er link A)

Y198-6b Pilot valve solenoid valve (swi ng low er link B)

-Z12 Parking brake actual value switch

Z19 Hydraulic oil level (min.) actual value switch

Z81 Service brake pressure actual value switch

Z102-1 Working hydraulics filter bypass actual value switch (bypass open)

Z102-2 Steering hydraulics filter bypass actual value switch (bypass open)

1 Overall hydraulic system

Overall circuit diagram

391

Z102-3 Return line filter bypass actual value switch (bypass open)

Z103 Pump function actual value switch

Z104 Brake accumulator pressure actual value switch

Z105-1 Floating axle lock 55 bar pressure

Z105-2 Floating axle lock 115 bar pressure

Z12 Parking brake actual value switch

Z19 Hydraulic oil level (min.) actual value switch

Z81 Service brake pressure actual value switch

Z102-1 Working hydraulics filter bypass actual value switch (bypass open)

Z102-2 Steering hydraulics filter bypass actual value switch (bypass open)

Z102-3 Return line filter bypass actual value switch (bypass open)

Z103 Pump function actual value switch (emergency steering pump)

000 293 646 0 - SYS-H XERION 3300 - 04/05 11

Page 12

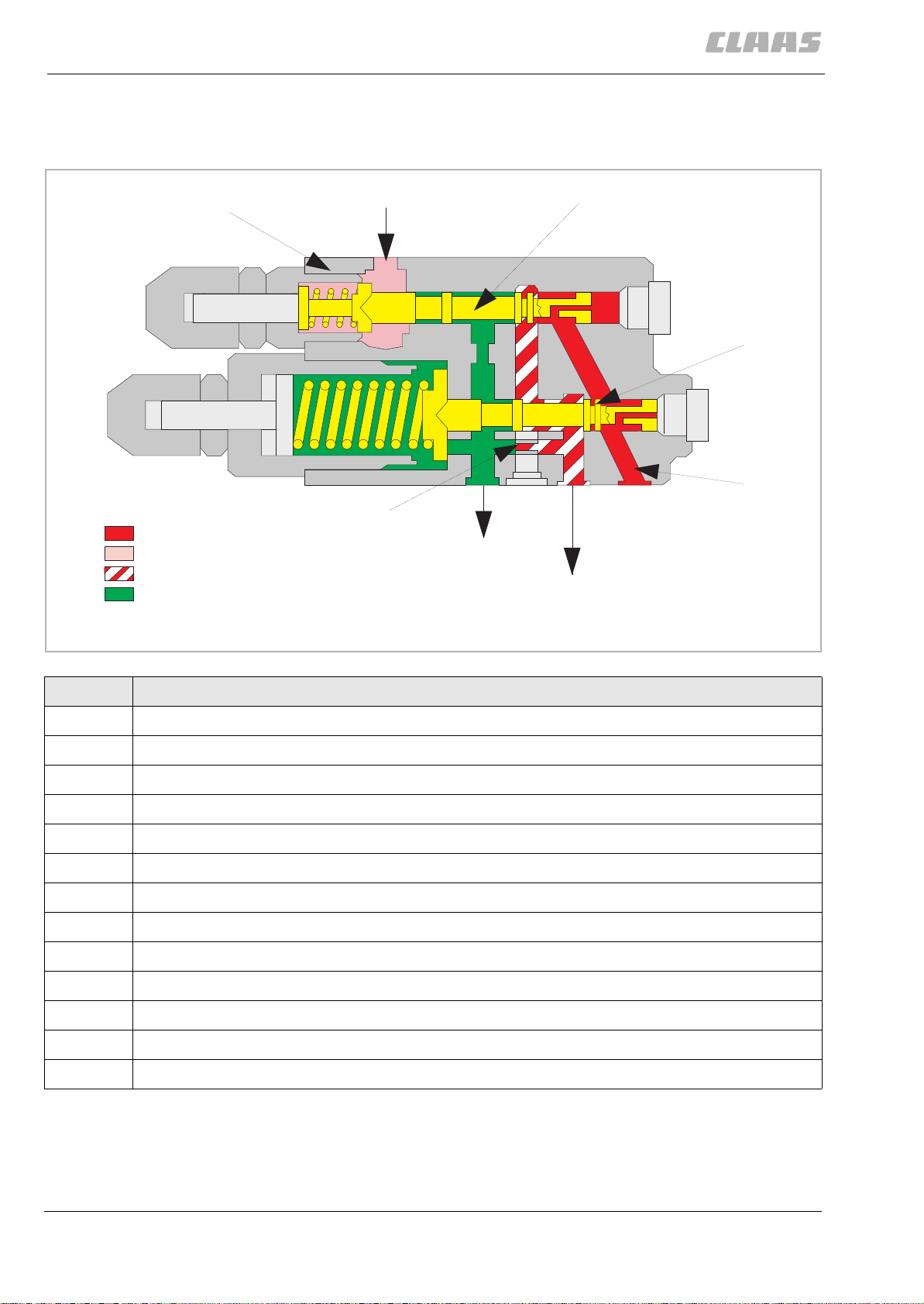

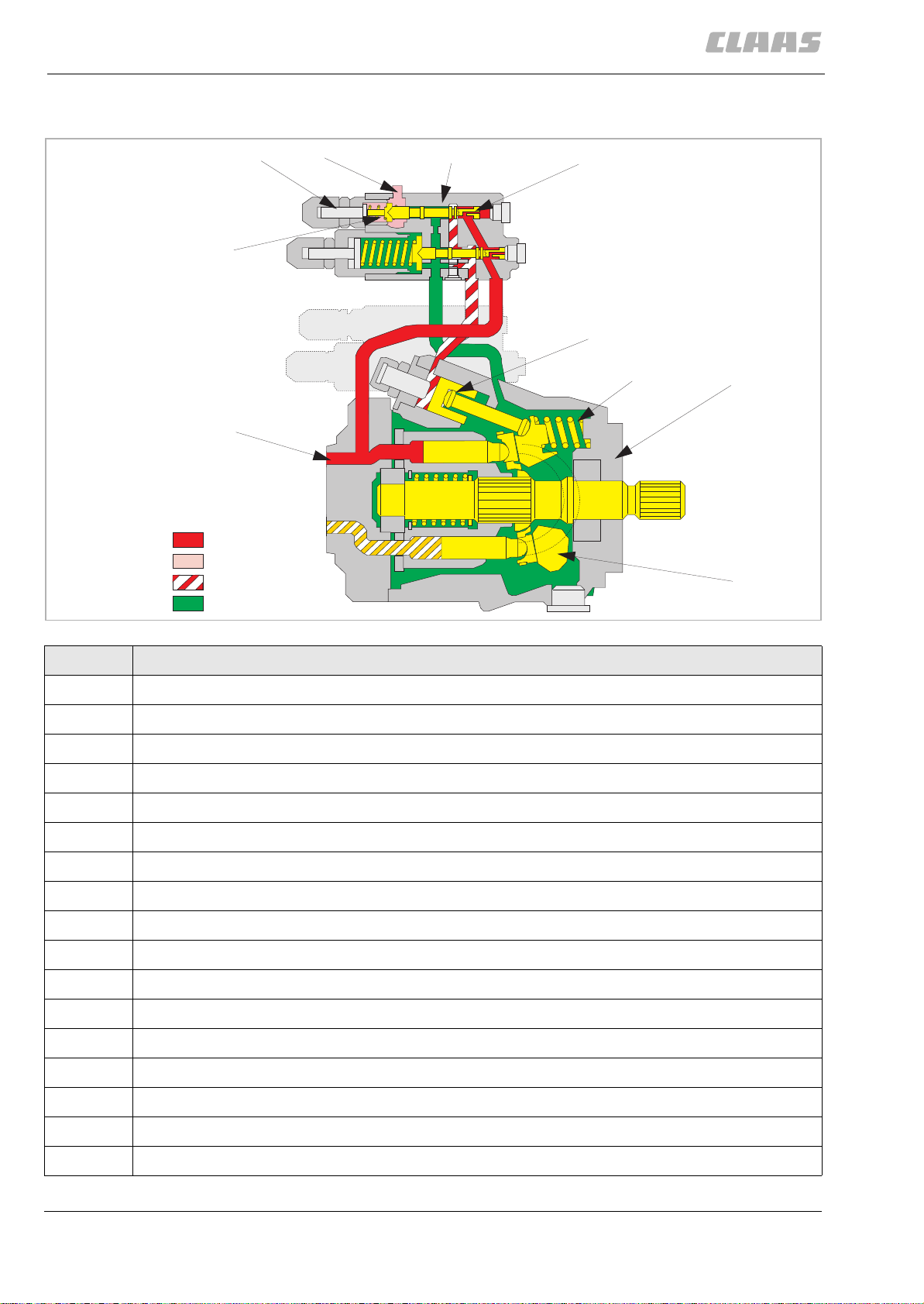

1 Overall hydraulic system

PFC pump

PFC pump

Compensating valve

6

391

772

7

773

AA

13

DD

BB

LL

401482

Item Component

6 Compensating valve

7 Input (load pressure from signal network)

10 Working hydraulics pump port

11 Port of control piston of working hydraulics pump

12 Tank port

13 Restrictor

772 Volume flow controller

773 Pressure controller

10

12

11

-AA Oil supply

BB Pressure-reduced oil

DD Control oil

LL Tank (pressureless)

12 000 293 646 0 - SYS-H XERION 3300 - 04/05

Page 13

1 Overall hydraulic system

PFC pump

Description of function The PFC pump (2) is an axial piston pump.

PFC means:

– P (Pressure)

– F (Flow)

– C (Controlled)

PFC pump The compression spring of the volume flow controller (772) is designed so that

the pump pressure acting on the face end is always 20 bar above the load

pressure acting via port (7). This pressure of 20 bar is ref erred to as "Margin

pressure". The pressure controller (773) limit s the pressure in the working

hydraulics circuit to 200±5 bar (Pressure relief valve function).

391

000 293 646 0 - SYS-H XERION 3300 - 04/05 13

Page 14

1 Overall hydraulic system

PFC pump

Initial position (engine OFF)

391

401483

LL

21

20

19

18

7

6

772

377

15

2

16

17

Item Component

2(PFC) Pump

6 Compensating valve

7 Input (load pressure from signal network)

14 Control piston

15 Control spring

16 Pump drive

17 Swash plate

18 Ram

19 Pump inlet

20 Pump outlet

21 Compression spring (margin pressure)

377 Hydraulic cylinder variable-displacement pump

772 Volume flow controller

14 000 293 646 0 - SYS-H XERION 3300 - 04/05

Page 15

1 Overall hydraulic system

PFC pump

Initial position Since the engine has been shut down, there is no pressure in the hydraulic

system. The compression spring (21) has pushed the vol u me flow controller

(772) to the right. In this po sition , the top side of the varia ble-di splaceme nt pump

hydraulic cylinder (37 7) i s conn ec te d wit h th e tank via the volume flow contr oll er

(772). The control spri ng (15) has swi vell ed the swash plat e (17) to its maximum

position.

391

000 293 646 0 - SYS-H XERION 3300 - 04/05 15

Page 16

1 Overall hydraulic system

PFC pump

Low-pressure standby

391

401484

21

20

AA

DD

BB

LL

7

772

377

15

2

17

Item Component

2(PFC) Pump

6 Compensating valve

7 Input (load pressure from signal network)

14 Control piston

15 Control spring

17 Swash plate

20 Pump outlet

21 Compression spring (margin pressure)

25 Control edge

377 Hydraulic cylinder variable-displacement pump

772 Volume flow controller

-AA Oil supply

BB Pressure-reduced oil

DD Control oil

LL Tank (pressureless)

16 000 293 646 0 - SYS-H XERION 3300 - 04/05

Page 17

1 Overall hydraulic system

PFC pump

391

Description of function All control units are i n their neutral posi tion. At t he beginnin g of this exa mple, the

swash plate (17) is in its maximum end position (see also Engine OFF).

When the engine is started, the pump feeds the maximum volume flow via the

pump output (20) up to the spools of all control units.

Since the spools block the flow completely, the pr essure rises and is applied to

the right face end of the volume flow controller (772) which is moved to the left

against the compression spring (margin pressure) (21). In this process, the

control edge (25) is opened so that the pressure gains ac cess to the top side of

the variable-displacement pump hydraulic cylinder (377). Now the swash plate

(17) is moved to the "Minimum vo lume flow" position against the control spring

(15). This process takes only 10 milliseconds.

In this pump position, the following happens: Volume flow is generated only to

such an extent that lea kage losses are compensated. The pressure required for

initial actuation of a consum er is ma in tained.

When all control units are set to their neutral positions, the load pres sure input

(7) is pressureless. To move the volume flow controller (772), the pum p pressure

must overcome the compres sion spring (margin pressu re) (21) and the LS

residual pressure. The pressure required for this is 20 + X bar and is referred to

as "Low-pressure standby". The "Low-pressure standby" is slightly higher than

the "Margin pressure" of 20 bar. As a function of the setting of the volume flow

controller (772) and of the pump leakage, "Low-pressure standby" and "Margin

pressure" may be almost i dentical. However, the "Margin pr essure" c an never be

higher. The low-pressure standby cannot be adjusted and may therefore vary

from machine to machine. It changes as the leakage rate i n the pump or in the

system rises. The pump remains in the "Low-pressure standby" position until a

control unit is actuated. In this operating position, the pump only requires little

drive energy.

000 293 646 0 - SYS-H XERION 3300 - 04/05 17

Page 18

1 Overall hydraulic system

PFC pump

Pump starts pu mping

391

401485

21

20

AA

DD

BB

LL

7

6

772

377

15

2

17

Item Component

2 (PFC) pump

6 Compensating valve

7 Input (load pressure from signal network)

14 Control piston

15 Control spring

17 Swash plate

20 Pump outlet

21 Compression spring (margin pressure)

25 Control edge

377 Variable-displacement pump hydraulic cylinder

772 Volume flow controller

-AA Oil supply

BB Pressure-reduced oil

DD Control oil

LL Tank (pressureless)

18 000 293 646 0 - SYS-H XERION 3300 - 04/05

Page 19

1 Overall hydraulic system

PFC pump

391

Description of function When a control unit is actuated, a load pressure builds up in the LS line. In this

process, the following conditions result at the volume flow controller (772):

– the pump pressure acts on the right face end

– the load pressure and the spring force of the compression spring (margin

pressure) (21) act in the spring space.

– Since the load pressure + the spring force of the compression spring

(margin pressure) (21) is higher than the pump pressure on the right face

end, the volume flow controller is moved to the right .

This :

– shuts off the passage of the pump pressure to the variable-displacement

pump hydraulic cylinder (377);

– connects the variable-displacement pump h ydraulic cylinder (377) wi th the

tank (no pressure on top side of ram)

– makes the control spring (15) swing out the swash plate (17).

The pump now feeds a higher volume flow. This process is referred to as

"Upstroking". The volume flow of the pump is determined by the restrictor effect

of the open spool cross-section or by the setting of a control unit.

Lower volume flow requirement: When the spool cross-section is reduced (the volume flow is to be reduced), the

load pressure at the input (7) drops. This changes the force ratio at the volume

flow controller (772), actuating the volume flow controller to the left according to

the pressure drop, against the compression spring. The variable-displ acement

pump hydraulic cylinder (377) is subject to pressure and the swash plate (17) is

set to a flatter position, and the pump performs a downstroke until the volume

flow requirement is met.

Higher volume flow requirement.

An example: A control unit h as been ac t uat ed. Th e l oa d pr essu re i s 140 ba r, the

pump pressure now goes to (160 bar).(Load pressure 140 bar + 20 bar margin

pressure). When another co nt ro l uni t wi th a l oa d pr ess ure of 100 ba r is actu at ed

now, the pump pressure drops slightly.

This also decreases the pressure on the top face of th e variable-displacement

pump hydraulic cylinder (377) accordingly, the swash plate (17) is moved to a

steeper position, increasing the volume flow until the additional volume flow

requirement of the second circuit has been met and the pump pressure of 160

bar has been re-established. The load pressure on the controller remai ns stable

at 140 bar.

000 293 646 0 - SYS-H XERION 3300 - 04/05 19

Page 20

1 Overall hydraulic system

PFC pump

Constant volume flow

391

401486

21

20

AA

DD

BB

LL

22

7

6

772

377

15

2

17

Item Component

2(PFC) Pump

6 Compensating valve

7 Input (load pressure from signal network)

14 Control piston

15 Control spring

17 Swash plate

20 Pump outlet

21 Compression spring (margin pressure)

22 Setscrew

25 Control edge

377 Variable-displacement pump hydraulic cylinder

772 Volume flow controller

-AA Oil supply

BB Pressure-reduced oil

DD Control oil

LL Tank (pressureless)

20 000 293 646 0 - SYS-H XERION 3300 - 04/05

Page 21

1 Overall hydraulic system

PFC pump

Description of function When operating a consumer with a constant load (e.g. a hydraulic motor), the

volume flow controller (772) is actuated to a stable position. This keeps both the

pressure on the top face of the variable-displacement pump hydraulic cylinder

(377) and the posit ion of the swash plat e (17) co nstant. As long as the positi on of

the swash plate (17) remains unchanged, the pump pumps a constant volume

flow.

The following pressure s now result on the volume flow controller (772):

– Load pressure (signal) + s pring force of the compression spring (margin

pressure) (21) on the left side.

– ·Pump pressure on the right side.

The differential pressure is the margin pressure corresponding to the spring

force of the compression sp ring (21). The margin pressur e is to be 20 bar and

may be adjusted using set screw (22).

391

000 293 646 0 - SYS-H XERION 3300 - 04/05 21

Page 22

1 Overall hydraulic system

PFC pump

Downstroking the PFC pump

391

401487

21

20

AA

DD

BB

LL

7

6

772

377

15

2

17

Item Component

2(PFC) Pump

6 Compensating valve

7 Input (load pressure from signal network)

14 Control piston

15 Control spring

17 Swash plate

20 Pump outlet

21 Compression spring (margin pressure)

22 Setscrew

25 Control edge

377 Variable-displacement pump hydraulic cylinder

772 Volume flow controller

-AA Oil supply

BB Pressure-reduced oil

DD Control oil

LL Tank (pressureless)

22 000 293 646 0 - SYS-H XERION 3300 - 04/05

Page 23

1 Overall hydraulic system

PFC pump

Description of function Downstroking of the PFC pump is performed under the following conditions:

– ·a control unit is actuated to neutral position, no volume flow is required.

– ·an additional contro l unit is actu ated into the fi ne control range, a very sm all

volume flow is required.

– ·in parallel operation, a control unit is actuated to the neutral position or to

the fine control range. A smaller volume flow is required.

The pump must perform a downstroke whenever a smaller volume flow is

needed. The downstroking process is started when the pressure on the right

face end of the volume flow co nt roll e r (7 72) is hi g her tha n on t he le ft face (in the

spring space). In this case, the volume flow controller (772) is moved to the left

against the compressio n spring (21), in this process opening the control edge

(25). This results in a rising pressure on the top face of the variable-displ ace

ment pump hydraulic cylinder (377) that sets the swash plate (17) to a flatter

position against the control spring (15) – the volume flow is reduced.When a

control unit is actuated in the fine control range (a very small volume flow is to

flow to the consumer), the load pressure at input (7) drops. This changes the

force ratio at the volume flow controller (772) so that it is actuated to the left

according to the pressure drop, against the compression spring. The control

edge (25) is opened, thus subjecting the variable-displacement pump hydraulic

cylinder (377) to pressure. The swash plate (17) is se t to a flatter position and

the pump performs a downstroke until the volume flow requirement is met.

391

-

Parallel operation of t wo cont rol

units

When operating two cont rol units in paral lel, the load pressure values are 140

bar and 100 bar. In this process, the pu mp pressure adjusts to 170 bar. (Load

pressure 140 bar + 20 bar margin pressure). Both the volume flow controller

(772) and the swash plate ( 17) are in a co nstant po sition. The pump provid es the

volume flow required for both consumers.When the second control unit (load

pressure 100 bar) is now actuated in the neutral position, the volume flow must

decrease since only the first hydraulic circuit remains to be supplied. This is

achieved by increasing the pump pressure for a short ti me following the shutdown of a hydraulic circuit, since the high volume flow flows to the first control

unit only. The volume flow c ontro l ler ( 772 ) i s n ow a ctuat ed to the left, the control

edge (25) opens and the pressure on the top face of the control ram rises. The

swash plate (17) is set to a flatter position, thus reducing the volume flow.

000 293 646 0 - SYS-H XERION 3300 - 04/05 23

Page 24

1 Overall hydraulic system

PFC pump

Maximum pressure limitation (pressure relief valve function), maximum standby pressure

391

401488

21

23

24

20

AA

DD

BB

LL

7

6

772

773

337

15

2

17

Item Component

2(PFC) Pump

6 Compensating valve

7 Input (load pressure from signal network)

15 Control spring

17 Swash plate

20 Pump outlet

21 Compression spring (margin pressure)

22 Setscrew

26 Control edge

377 Variable-displacement pump hydraulic cylinder

772 Volume flow controller

773 Pressure controller

-AA Oil supply

BB Pressure-reduced oil

DD Control oil

LL Tank (pressureless)

24 000 293 646 0 - SYS-H XERION 3300 - 04/05

Page 25

1 Overall hydraulic system

PFC pump

391

Description of function The pressure in the hydraul ic syst em is li mite d to 200 ± 5 bar in order to pre vent

component damage. This function is ensured by pressure controller (773).During

normal operation (working pressure < max. pressure), the pressure controller

(773) is pushed to the right by compression spring (24). Under such pressure

conditions:

– ·the volume flow controller (772) is pushed to the right by compression

spring (21).

– ·the pressure controller (773) is pushed to the left against compression

spring (24).

This movement occurs at a press ure of 200 ± 5 bar. The control edge (26) is now

opened, enabling the pump pressure to act upon the top face of the variabledisplacement pump hydraulic cylinder (377). The swash plate (17) is now

actuated towards "Min. pump capacity" against the control spring (15). This

takes 8 – 10 milliseconds. The PFC pump now pumps the smallest volume flow

against the maximum pressure of 200 ± 5 bar. The max. pressure can be set

using the set screw (23). The hydraulic system remains at the max. pressure

level until the control unit is actuated in neutral position or until the load on the

LS line is relieved at input (7).

000 293 646 0 - SYS-H XERION 3300 - 04/05 25

Page 26

1 Overall hydraulic system

PFC pump

391

26 000 293 646 0 - SYS-H XERION 3300 - 04/05

Page 27

2 Steering hydraulics

System concept

Description

The vehicle is equipped with an EHL steering system.

EHL is the German abbreviation of "Electro-hydraulic steering".

The electro-hydraulic steering system EHL is an electro-hydraulically controlled,

intelligent automatic steering system for the rigid axle (2).The floating axle (1)

located at the front in direction of travel is steered manually by the steering

wheel as usual. When Autopi lot steering is activated, sensors ensure the

automatic steering of the floating axle (1) along the crop edge. The rigid axle (2)

located at the rear in direction of travel is steered automatically as a function of

the current steering a ngle of the front axle and of the s elected steering strategy.

If required, the "Ground speed control lever" steering strategy also enables

manual steering of the rigid axle (2) independently of the front axle. Both axles

may be steered in order to incre as e ve hic le m an o eu vr a bilit y.

There is a differentiation between the emergenc y steering and Orbitrol steering

of rigid axle (2) or floating axle (1) operating modes. When using the Orbitrol

steering, the floati ng axle (1) is steered entirely by hydraulic means. This ax le is

steered by electro-hydraulic means, but cannot be influenced. At high vehicle

speeds (road travel) the rigid axle (2) is tracked in the straight ahead position .

2 Steering hydraulics

System concept

413

000 293 646 0 - SYS-H XERION 3300 - 04/05 27

Page 28

2 Steering hydraulics

System concept

Definition of axles The floating axle (1) is always located below the engine, regardless of the cab

position.

1 = Floating axle 2 = Rigid axle

413

Fully automatic steering operation. Special steering programs

Emergency steering safety

concept

1 = Floating axle 2 = Rigid axle

In the special steering progr am s (e.g . Au to pilo t, cra b stee r mo d e) , th e fr on t an d

the rear axle are steered by electro-hydraulic means. These special steering

programs are available only for fieldwork. Transmission of the steering

commands is fully electronic.

In case of disturbances, the steered axles are brought to a "safe condition". A

"safe condition" is defined as both axles being steered simultaneously and by

purely hydraulic means, using the Orbitrol (steering wheel). To achieve this, the

steering cylinders of the floating axle and of the r igid axle are connected in

series, using the definition valves. The oil supply is ensured by the wheel-driven

emergency steering pump (245). The steering angles of the floating axle and of

the rigid axle are identical, but have their senses reversed.

28 000 293 646 0 - SYS-H XERION 3300 - 04/05

Page 29

Adjusting the straight-l ine

stability of the rigid axle (2).

2 Steering hydraulics

System concept

413

When "Emergency steering operation" is started, the current wheel position of

the rigid axle (2) is adopted . Straight-line stability may no t be pr ov ide d .

In this case:

– Open the shut-off valve (641)

– Set the rigid axle (2) to straight-line travel, using the steering wheel

– Close the shut-off valve (641) again.

000 293 646 0 - SYS-H XERION 3300 - 04/05 29

Page 30

2 Steering hydraulics

System concept

413

30 000 293 646 0 - SYS-H XERION 3300 - 04/05

Page 31

2 Steering hydraulics

Fully hydraulic steering (Emergency steering)

2 Steering hydraulics

Fully hydraulic steering (Emergency steering)

417

000 293 646 0 - SYS-H XERION 3300 - 04/05 31

Page 32

2 Steering hydraulics

Fully hydraulic steering (Emergency steering)

Circuit diagram

30bar

30bar

40bar

40bar

30bar

30bar

408

30bar

30bar

40bar

40bar

417

786

3,5mm

32 000 293 646 0 - SYS-H XERION 3300 - 04/05

Page 33

2 Steering hydraulicsFully hydraulic steering (Emergency steering)

Key to diagram

Item Component

I Main valve block

IX Steering / brake hydraulics pump

-102 Pressure filter

107 Oil drain

112 Return filter

113 Suction filter

116 Resonance tube (Silencer)

117 Fresh air filter element

-218 Steering hydraulics pump

2 Steering hydraulics

Fully hydraulic steering (Emergency steering)

395

245 Emergency steering pump

-323-1 Floating axle steering hydraulic cylinder

323-2 Rigid axle steering hydraulic cylinder

377 Variable-displacement pump hydraulic cylinder

-408 Orifice plate Ø 0.8 m m

-516 Service brake pressure accumulator

-609 Orbitrol steering system rotary valve

641 Shut-off valve

642 Service brake valve

644 Steering sense valve

-704 Bypass valve (non-return valve)

706 Pressure relief valve

725 Steering double shock valve

726 Steering pressure relief valve

732 Non-return valve

742 Steering safety valve

763 Input pressure balance

772 Volume flow controller

000 293 646 0 - SYS-H XERION 3300 - 04/05 33

Page 34

2 Steering hydraulics

Fully hydraulic steering (Emergency steering)

Item Component

772 Volume flow controller

773 Pressure controller

773 Pressure controller

774 Pressurizing valve

780 Shuttle valve

783 Trailer brake valve

786 LS signal shuttle valve

-909-1 Steering hydraulics Orbitrol measuring point

909-2 Steering hydraulics emergency steering pump measur ing point

909-4 Steering hydraulics steering cylinder XS1 measuring point

909-5 Steering hydraulics steering cylinder XS2 measuring point

395

909-6 Steering hydraulics steering cylinder XP2 measuring point

909-7 Steering hydraulics steering cylinder XP1 measuring point

922 Measuring point

-3007 Service brake hydraulic cylinder

3008 Parking brake hydraulic cylinder

-B123 Hydraulic oil temperature sensor

-Y106 Parking brake solenoid coil

Y188-1 Steering logics shut-off valve solenoid coil

Y188-2 Steering logics shut-off valve solenoid coil

Y188-3 Steering logics shut-off valve solenoid coil

Y188-4 Steering logics shut-off valve solenoid coil

Y189-10 Steering logics definition valve solenoid coil

Y189-5 Steering logics definition valve solenoid c oil

Y189-6 Steering logics definition valve solenoid c oil

Y189-7 Steering logics definition valve solenoid c oil

Y189-8 Steering logics definition valve solenoid c oil

Y189-9 Steering logics definition valve solenoid c oil

Y190-1a Automatic steering solenoid coil

Y190-1b Automatic steering solenoid coil

Y190-2a Automatic steering solenoid coil

Y190-2b Automatic steering solenoid coil

34 000 293 646 0 - SYS-H XERION 3300 - 04/05

Page 35

Item Component

Z19 Hydraulic oil level (min.)

Z81 Service brake pressure actual value switch

Z102 Filter bypass actual value switch (bypass open)

Z103 Pump function actual value switch

Z104 Brake accumulator pressure actual value switch

2 Steering hydraulics

Fully hydraulic steering (Emergency steering)

395

000 293 646 0 - SYS-H XERION 3300 - 04/05 35

Page 36

2 Steering hydraulics

Fully hydraulic steering (Emergency steering)

395

36 000 293 646 0 - SYS-H XERION 3300 - 04/05

Page 37

2 Steering hydraulics

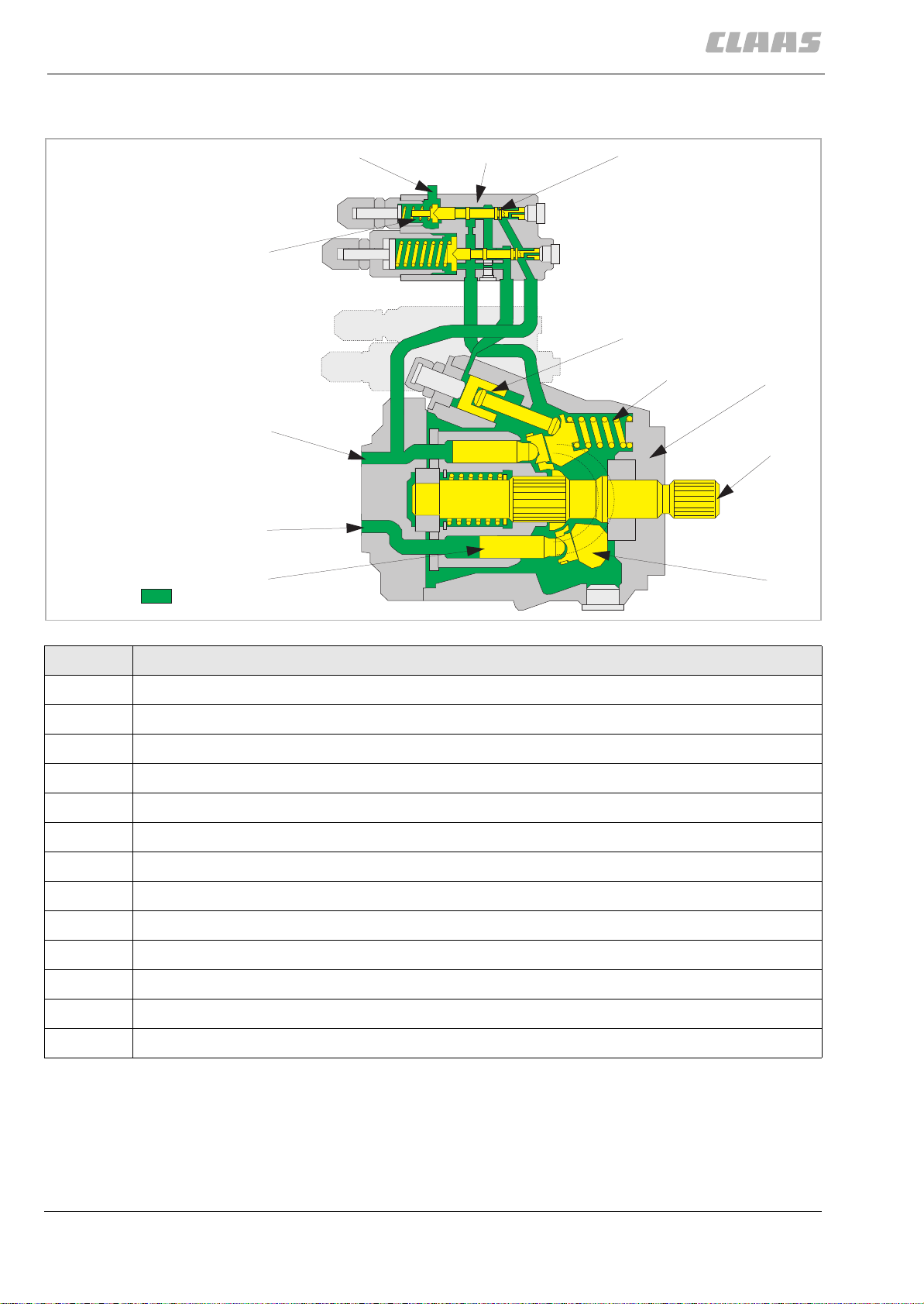

Orbitrol axle = Floating axle (1), the rigid axle (2) is tracked by electro-hydraulic means

2 Steering hydraulics

Orbitrol axle = Floating axle (1), the rigid axle (2) is tracked by electro-hydraulic means

397

000 293 646 0 - SYS-H XERION 3300 - 04/05 37

Page 38

2 Steering hydraulics

Orbitrol axle = Floating axle (1), the rigid axle (2) is tracked by electro-hydraulic means

Circuit diagram

408

30bar

397

30bar

40bar

30bar

40bar

786

3,5mm

Xer-h-02a-2

38 000 293 646 0 - SYS-H XERION 3300 - 04/05

Page 39

2 Steering hydraulics

Orbitrol axle = Floatin g axle (1), the rigid axle (2) is tr acked by electro-hydraulic means

2 Steering hydraulics

Orbitrol axle = Floating axle (1), the rigid axle (2) is tracked by electro-hydraulic means

Key to diagram

Item Component

I Main valve block

IX Steering / brake hydraulics pump

-102 Pressure filter

107 Oil drain

112 Return filter

113 Suction filter

116 Resonance tube (Silencer)

117 Fresh air filter element

398

-218 Steering hydraulics pump

245 Emergency steering pump

323-1 Floating axle steering hydraulic cylinder

323-2 Rigid axle steering hydraulic cylinder

377 Variable-displacement pump hydraulic cylinder

-406 Orifice plate

-516 Service brake pressure accumulator

-609 Orbitrol steering system rotary valve

641 Shut-off valve

642 Service brake valve

644 Steering sense valve

-704 Bypass valve (non-return valve)

706 Pressure relief valve

725 Steering double shock valve

726 Steering pressure relief valve

732 Non-return valve

742 Steering safety valve

763 Input pressure balance

772 Volume flow controller

000 293 646 0 - SYS-H XERION 3300 - 04/05 39

Page 40

2 Steering hydraulics

Orbitrol axle = Floating axle (1), the rigid axle (2) is tracked by electro-hydraulic means

Item Component

772 Volume flow controller

773 Pressure controller

773 Pressure controller

774 Pressurizing valve

780 Shuttle valve

783 Trailer brake valve

786 LS signal shuttle valve

-909-1 Steering hydraulics Orbitrol measuring point

909-2 Steering hydraulics emergency steering pump measur ing point

909-4 Steering hydraulics steering cylinder XS1 measuring point

909-5 Steering hydraulics steering cylinder XS2 measuring point

398

909-6 Steering hydraulics steering cylinder XP2 measuring point

909-7 Steering hydraulics steering cylinder XP1 measuring point

-3007 Service brake hydraulic cylinder

3008 Parking brake hydraulic cylinder

-B123 Hydraulic oil temperature sensor

-Y106 Parking brake solenoid coil

Y188-1 Steering logics shut-off valve solenoid coil

Y188-2 Steering logics shut-off valve solenoid coil

Y188-3 Steering logics shut-off valve solenoid coil

Y188-4 Steering logics shut-off valve solenoid coil

Y189-10 Steering logics definition valve solenoid coil

Y189-5 Steering logics definition valve solenoid c oil

Y189-6 Steering logics definition valve solenoid c oil

Y189-7 Steering logics definition valve solenoid c oil

Y189-8 Steering logics definition valve solenoid c oil

Y189-9 Steering logics definition valve solenoid c oil

Y190-1a Automatic steering solenoid coil

Y190-1b Automatic steering solenoid coil

Y190-2a Automatic steering solenoid coil

Y190-2b Automatic steering solenoid coil

Z19 Hydraulic oil level (min.)

40 000 293 646 0 - SYS-H XERION 3300 - 04/05

Page 41

Orbitrol axle = Floatin g axle (1), the rigid axle (2) is tr acked by electro-hydraulic means

Item Component

Z81 Service brake pressure actual value switch

Z102 Filter bypass actual value switch (bypass open)

Z103 Pump function actual value switch

Z104 Brake accumulator pressure actual value switch

2 Steering hydraulics

398

000 293 646 0 - SYS-H XERION 3300 - 04/05 41

Page 42

2 Steering hydraulics

Orbitrol axle = Floating axle (1), the rigid axle (2) is tracked by electro-hydraulic means

398

42 000 293 646 0 - SYS-H XERION 3300 - 04/05

Page 43

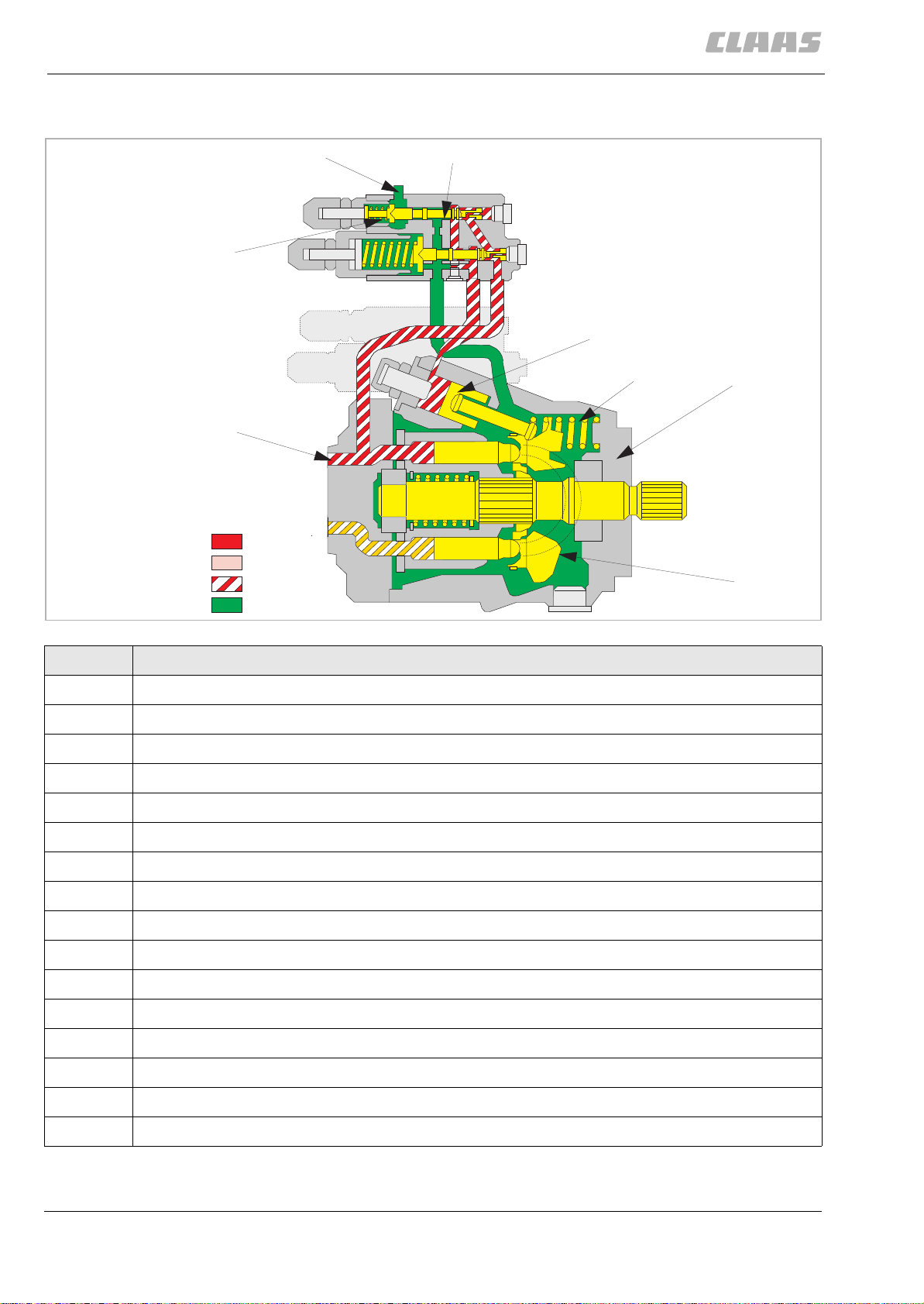

2 Steering hydraulics

Orbitrol axle = Rigid axle (2), the floating axle (1) is tracked by electro-hydraulic means

2 Steering hydraulics

Orbitrol axle = Rigid axle (2), the floating axle (1) is tracked by electro-hydraulic means

399

000 293 646 0 - SYS-H XERION 3300 - 04/05 43

Page 44

2 Steering hydraulics

Orbitrol axle = Rigid axle (2), the floating axle (1) is tracked by electro-hydraulic means

Circuit diagram

408

30bar

399

30bar

40bar

30bar

40bar

3,5mm

xer-h-02a-3

44 000 293 646 0 - SYS-H XERION 3300 - 04/05

Page 45

Orbitrol axle = Rigid axle (2), the floating axle (1) is tracked by electro-hydraulic means

2 Steering hydraulicsOrbitrol axle = Rigid axle (2), the floating axle (1) is tracked by electro-hydraulic means

Key to diagram

Item Component

I Main valve block

IX Steering / brake hydraulics pump

-102 Pressure filter

107 Oil drain

112 Return filter

113 Suction filter

116 Resonance tube (Silencer)

117 Fresh air filter element

-218 Steering hydraulics pump

2 Steering hydraulics

400

245 Emergency steering pump

-323-1 Floating axle steering hydraulic cylinder

323-2 Rigid axle steering hydraulic cylinder

377 Variable-displacement pump hydraulic cylinder

-408 Orifice plate Ø 0.8 m m

-516 Service brake pressure accumulator

-609 Orbitrol steering system rotary valve

641 Shut-off valve

642 Service brake valve

644 Steering sense valve

-704 Bypass valve (non-return valve)

706 Pressure relief valve

725 Steering double shock valve

726 Steering pressure relief valve

732 Non-return valve

742 Steering safety valve

763 Input pressure balance

772 Volume flow controller

000 293 646 0 - SYS-H XERION 3300 - 04/05 45

Page 46

2 Steering hydraulics

Orbitrol axle = Rigid axle (2), the floating axle (1) is tracked by electro-hydraulic means

Item Component

772 Volume flow controller

773 Pressure controller

773 Pressure controller

774 Pressurizing valve

780 Shuttle valve

783 Trailer brake valve

786 LS signal shuttle valve

-909-1 Steering hydraulics Orbitrol measuring point

909-2 Steering hydraulics emergency steering pump measur ing point

909-4 Steering hydraulics steering cylinder XS1 measuring point

909-5 Steering hydraulics steering cylinder XS2 measuring point

400

909-6 Steering hydraulics steering cylinder XP2 measuring point

909-7 Steering hydraulics steering cylinder XP1 measuring point

922 Measuring point

-3007 Service brake hydraulic cylinder

3008 Parking brake hydraulic cylinder

-B123 Hydraulic oil temperature sensor

-Y106 Parking brake solenoid coil

Y188-1 Steering logics shut-off valve solenoid coil

Y188-2 Steering logics shut-off valve solenoid coil

Y188-3 Steering logics shut-off valve solenoid coil

Y188-4 Steering logics shut-off valve solenoid coil

Y189-10 Steering logics definition valve solenoid coil

Y189-5 Steering logics definition valve solenoid c oil

Y189-6 Steering logics definition valve solenoid c oil

Y189-7 Steering logics definition valve solenoid c oil

Y189-8 Steering logics definition valve solenoid c oil

Y189-9 Steering logics definition valve solenoid c oil

Y190-1a Automatic steering solenoid coil

Y190-1b Automatic steering solenoid coil

Y190-2a Automatic steering solenoid coil

Y190-2b Automatic steering solenoid coil

46 000 293 646 0 - SYS-H XERION 3300 - 04/05

Page 47

Orbitrol axle = Rigid axle (2), the floating axle (1) is tracked by electro-hydraulic means

Item Component

Z19 Hydraulic oil level (min.)

Z81 Service brake pressure actual value switch

Z102 Filter bypass actual value switch (bypass open)

Z103 Pump function actual value switch

Z104 Brake accumulator pressure actual value switch

2 Steering hydraulics

400

000 293 646 0 - SYS-H XERION 3300 - 04/05 47

Page 48

2 Steering hydraulics

Orbitrol axle = Rigid axle (2), the floating axle (1) is tracked by electro-hydraulic means

400

48 000 293 646 0 - SYS-H XERION 3300 - 04/05

Page 49

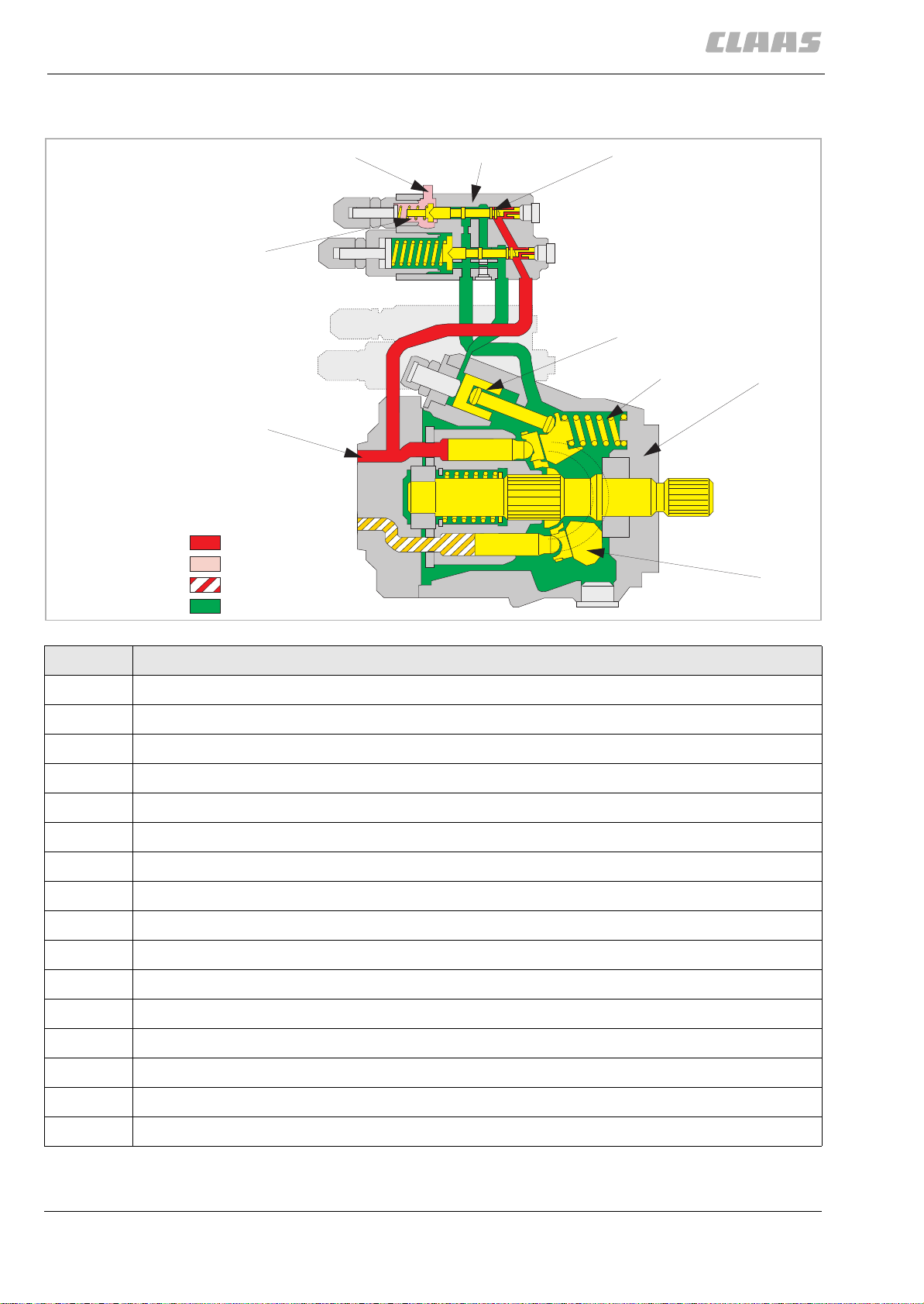

2 Steering hydraulics

The floating axle (1) and the rigid axle (2) are steered electrohydraulically – the Orbitrol steering circuit is closed.

2 Steering hydraulics

The floating axle (1) and the rigid axle (2) are steered electro-hydraulically – the Orbitrol steering circ uit is closed.

401

000 293 646 0 - SYS-H XERION 3300 - 04/05 49

Page 50

2 Steering hydraulics

The floating axle (1) and the rigid axle (2) are steered el ectro-hydraulically – the Orbitrol steering circuit is closed.

Circuit diagram

408

30bar

401

30bar

40bar

30bar

40bar

786

3,5mm

xer-h-02a-4

50 000 293 646 0 - SYS-H XERION 3300 - 04/05

Page 51

2 Steering hydraulics

The floating axle (1) and t he rigid axle (2) are steered electro-hydraulically – t he Orbitrol steering circuit is closed.

2 Steering hydraulicsThe floating axle (1) and the rigid axle (2) are steered electro-hydraulica lly – the Orbitrol steering circuit is closed.

Key to diagram

Item Component

I Main valve block

IX Steering / brake hydraulics pump

-102 Pressure filter

107 Oil drain

112 Return filter

113 Suction filter

116 Resonance tube (Silencer)

117 Fresh air filter element

-218 Steering hydraulics pump

402

245 Emergency steering pump

-323-1 Floating axle steering hydraulic cylinder

323-2 Rigid axle steering hydraulic cylinder

377 Variable-displacement pump hydraulic cylinder

-408 Orifice plate Ø 0.8 m m

-516 Service brake pressure accumulator

-609 Orbitrol steering system rotary valve

641 Shut-off valve

642 Service brake valve

644 Steering sense valve

-704 Bypass valve (non-return valve)

706 Pressure relief valve

725 Steering double shock valve

726 Steering pressure relief valve

732 Non-return valve

742 Steering safety valve

763 Input pressure balance

772 Volume flow controller

000 293 646 0 - SYS-H XERION 3300 - 04/05 51

Page 52

2 Steering hydraulics

The floating axle (1) and the rigid axle (2) are steered el ectro-hydraulically – the Orbitrol steering circuit is closed.

Item Component

772 Volume flow controller

773 Pressure controller

773 Pressure controller

774 Pressurizing valve

780 Shuttle valve

783 Trailer brake valve

786 LS signal shuttle valve

-909-1 Steering hydraulics Orbitrol measuring point

909-2 Steering hydraulics emergency steering pump measur ing point

909-4 Steering hydraulics steering cylinder XS1 measuring point

909-5 Steering hydraulics steering cylinder XS2 measuring point

402

909-6 Steering hydraulics steering cylinder XP2 measuring point

909-7 Steering hydraulics steering cylinder XP1 measuring point

922 Measuring point

-3007 Service brake hydraulic cylinder

3008 Parking brake hydraulic cylinder

-B123 Hydraulic oil temperature sensor

-Y106 Parking brake solenoid coil

Y188-1 Steering logics shut-off valve solenoid coil

Y188-2 Steering logics shut-off valve solenoid coil

Y188-3 Steering logics shut-off valve solenoid coil

Y188-4 Steering logics shut-off valve solenoid coil

Y189-10 Steering logics definition valve solenoid coil

Y189-5 Steering logics definition valve solenoid c oil

Y189-6 Steering logics definition valve solenoid c oil

Y189-7 Steering logics definition valve solenoid c oil

Y189-8 Steering logics definition valve solenoid c oil

Y189-9 Steering logics definition valve solenoid c oil

Y190-1a Automatic steering solenoid coil

Y190-1b Automatic steering solenoid coil

Y190-2a Automatic steering solenoid coil

Y190-2b Automatic steering solenoid coil

52 000 293 646 0 - SYS-H XERION 3300 - 04/05

Page 53

2 Steering hydraulics

The floating axle (1) and t he rigid axle (2) are steered electro-hydraulically – t he Orbitrol steering circuit is closed.

402

Item Component

Z19 Hydraulic oil level (min.)

Z81 Service brake pressure actual value switch

Z102 Filter bypass actual value switch (bypass open)

Z103 Pump function actual value switch

Z104 Brake accumulator pressure actual value switch

000 293 646 0 - SYS-H XERION 3300 - 04/05 53

Page 54

2 Steering hydraulics

The floating axle (1) and the rigid axle (2) are steered el ectro-hydraulically – the Orbitrol steering circuit is closed.

402

54 000 293 646 0 - SYS-H XERION 3300 - 04/05

Page 55

2 Steering hydraulics

Steering valve VI

2 Steering hydraulics

Steering valve VI

403

000 293 646 0 - SYS-H XERION 3300 - 04/05 55

Page 56

2 Steering hydraulics

Steering valve VI

Graphics

403

Y190-1a

Y190-2a

3.1A

3.1B

3.1

VI

909-2(XP-NLP)

909-1(XP-Orb)

3.2A

Y190-1b

Y190-2b

772

3.2B

P-Orb

706

LS

AR/R

3.2A 3.1A

BL/L

Y188-10(DV10)

Y188-8(DV8)

641(1.11)

909-7(P1)

3.2B

3.1B

909-6(P2)

3.1A

3.2A

Y188-2(DV2)

Y188-3(DV3)

Y188-9(DV9)

909-3(XP-BR)

400995

NLP

VP

BR

XP-ZLP

ZLP

T

725-2

Z103

Y189-7(DV7)

19.0

Y189-6(DV6)

725-1

S2

S1

Y189-5(DV5)

909-5(S2)

P2

909-4(XP1)

P1

Y188-4(DV4)

Y188-1(DV1)

3,5mm

56 000 293 646 0 - SYS-H XERION 3300 - 04/05

Page 57

2 Steering hydraulicsSteering valve VI

Key to diagram

Item Component

VI Steering valve

-116 Resonance tube (Silencer)

-245 Emergency steering pump

-641 Shut-off valve

-706 Pressure relief valve

725 Steering double shock valve

726 Steering pressure relief valve

2 Steering hydraulics

Steering valve VI

404

732 Non-return valve

763 Input pressure balance

768 LS signal shuttle valve

772 Volume flow controller

774 Pressurizing valve

-909-1 Steering hydraulics Orbitrol measuring point

909-2 Steering hydraulics emergency steering pump measuri ng point

909-3 Steering hydraulics system pressure (steering/brake) measuring point

909-4 Steering hydraulics steering cylinder XS1 measuring point

909-5 Steering hydraulics steering cylinder XS2 measuring point

909-6 Steering hydraulics steering cylinder XP2 measuring point

909-7 Steering hydraulics steering cylinder XP1 measuring point

-Y188-1 Steering logics shut-off valve solenoid coil

Y188-2 Steering logics shut-off valve solenoid coil

Y188-3 Steering logics shut-off valve solenoid coil

Y188-4 Steering logics shut-off valve solenoid coil

Y189-5 Steering logics definit ion valve solenoid coil

Y189-6 Steering logics definit ion valve solenoid coil

Y189-7 Steering logics definit ion valve solenoid coil

Y189-8 Steering logics definit ion valve solenoid coil

Y189-9 Steering logics definit ion valve solenoid coil

000 293 646 0 - SYS-H XERION 3300 - 04/05 57

Page 58

2 Steering hydraulics

Steering valve VI

Item Component

Y189-10 Steering logics definition valve solenoid coil

Y190-1a Automatic steering solenoid coil

Y190-1b Automatic steering solenoid coil

Y190-2a Automatic steering solenoid coil

Y190-2b Automatic steering solenoid coil

404

58 000 293 646 0 - SYS-H XERION 3300 - 04/05

Page 59

3 Working hydraulics

Working hydraulics circuit diagram

3 Working hydraulics

Working hydraulics circuit diagram

405

000 293 646 0 - SYS-H XERION 3300 - 04/05 59

Page 60

3 Working hydraulics

Working hydraulics circuit diagram

Circuit diagram

405

50bar

100bar

XP-PA

60 000 293 646 0 - SYS-H XERION 3300 - 04/05

Page 61

3 Working hydraulicsWorking hydraulics circuit diagram

Key to diagram

Item Component

I Main valve block

-102-1 Working hydraulics pressure filter

-515 Pressure accumulator

-704 Bypass valve (non-return valve)

706 Pressure relief valve

768 LS signal shuttle valve

772-1a Volume flow controller (red A)

772-1b Volume flow controller (red B)

3 Working hydraulics

Working hydraulics circuit diagram

406

772-2a Volume flow controller (EHR A)

772-2b Volume flow controller (EHR B)

772-3a Volume flow controller (white A)

772-3b Volume flow controller (white B)

772-4a Volume flow controller (yellow A)

772-4b Volume flow controller (yellow B)

772-5a Volume flow controller (green A)

772-5b Volume flow controller (green B)

772-6a Volume flow controller (swing lower link A)

772-6b Volume flow controller (swing lower link B)

787 Pressure balance

-901 Working hydraulics measuring point

-Y121 Shifting aid, reverse

Y192 Floating axle locking solenoid valve

Y193 Floating axle unlocking solenoid valve

Y198-1a Pilot valve (red A)

Y198-1b Pilot valve (red B)

Y198-2a Pilot valve (EHR A)

Y198-2b Pilot valve (EHR B)

Y198-3a Pilot valve (white A)

Y198-3b Pilot valve (white B)

000 293 646 0 - SYS-H XERION 3300 - 04/05 61

Page 62

3 Working hydraulics

Working hydraulics circuit diagram

Item Component

Y198-4a Pilot valve (yellow A)

Y198-4b Pilot valve (yellow B)

Y198-5a Pilot valve (green A)

Y198-5b Pilot valve (green B)

Y198-6a Pilot valve (blue A)

Y198-6b Pilot valve (blue B)

-Z102-1 Working hydraulics filter bypass actual value switch (bypass open)

Z105-1 Floating axle lock 55 bar pres sure

Z105-2 Floating axle lock 115 bar pressure

406

62 000 293 646 0 - SYS-H XERION 3300 - 04/05

Page 63

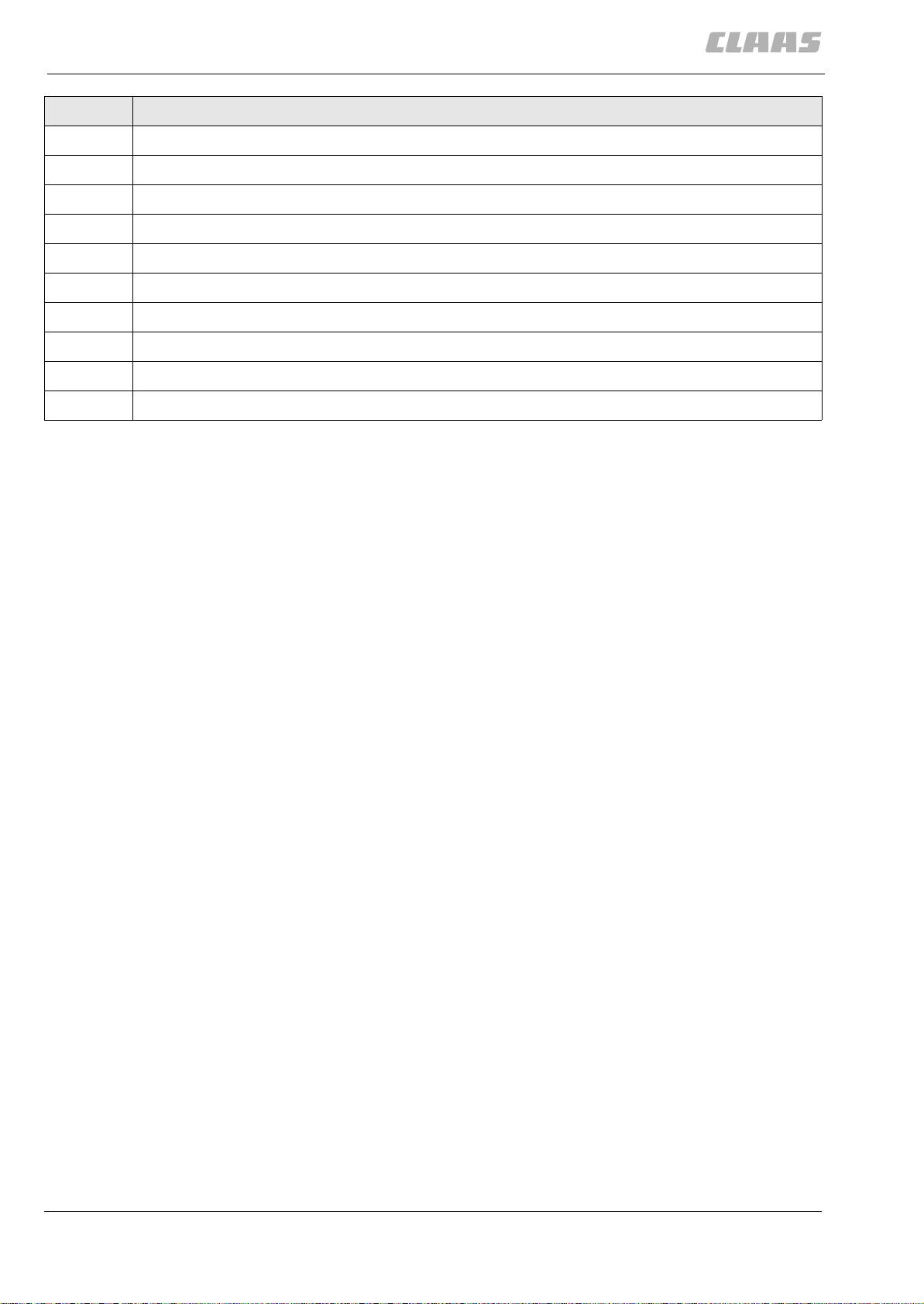

3 Working hydraulics

Main valve block

3 Working hydraulics

Main valve block

407

000 293 646 0 - SYS-H XERION 3300 - 04/05 63

Page 64

3 Working hydraulics

Main valve block

Graphics

XP-L

Z102-2

XP-A

515 (40 bar)

515 (80 bar)

515 (40 bar)

515 (40 bar)

515 (80 bar)

901

(XP-A)

Z102-1 Z102-2

909-3

(XP-L)

LS

407

XP-T-Orb

Z102-1

Y192 Y121 Y193

Z105-1 Z105-2

706

XP-PA

20.1

20.2

20.3

20.4

20.5

102-1

924

(XP-LS)

924

(XP-T)

102-2

785 421

20.6 20.5 20.4 20.3 20.2 20.1

401003

64 000 293 646 0 - SYS-H XERION 3300 - 04/05

Page 65

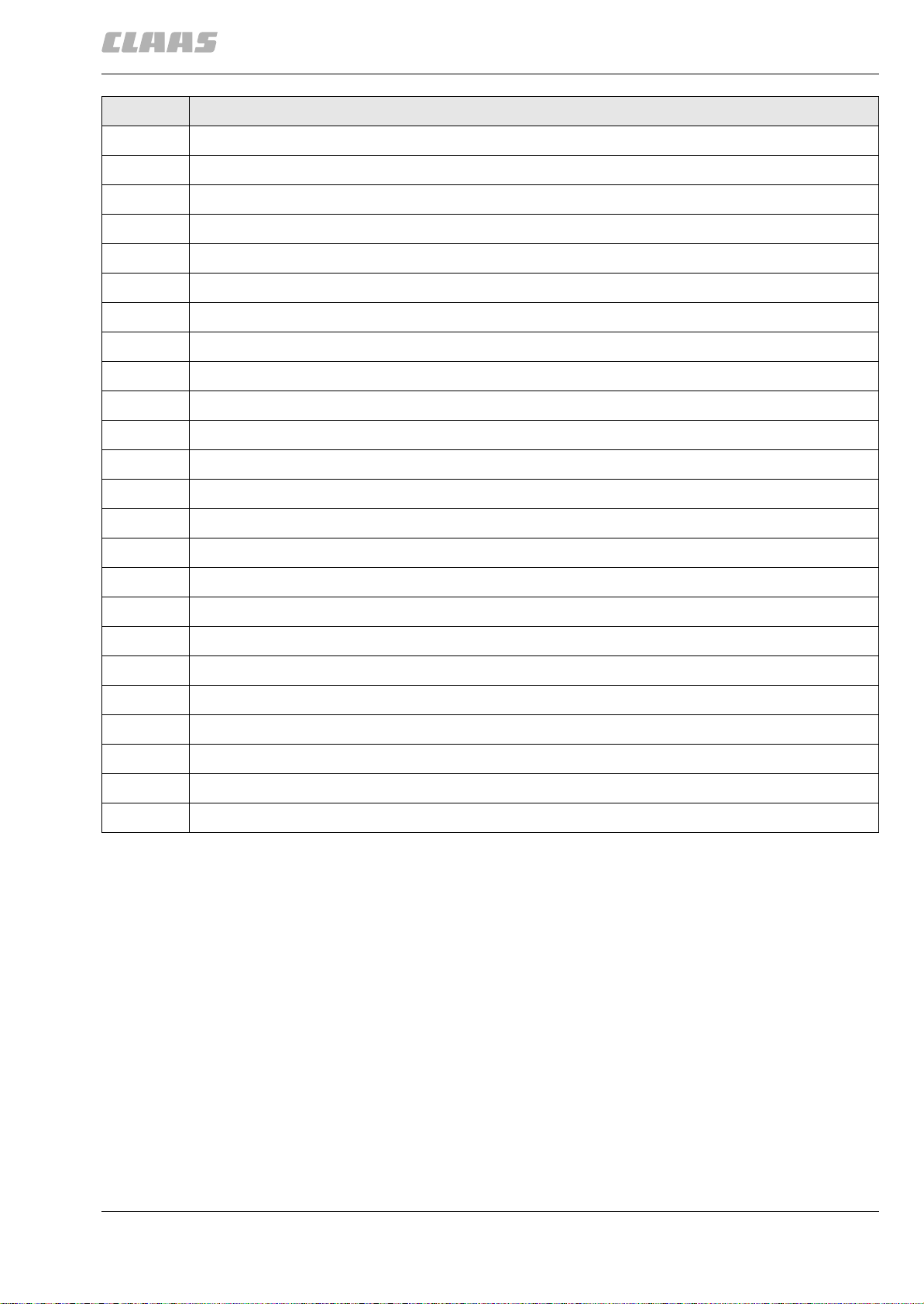

3 Working hydraulicsMain valve block

Key to diagram

Item Component

I Main valve block

-102-1 Working hydraulics pressure filter

-515 Pressure accumulator

-704 Bypass valve (non-return valve)

706 Pressure relief valve

768 LS signal shuttle valve

772-1a Volume flow controller (red A)

772-1b Volume flow controller (red B)

3 Working hydraulics

Main valve block

408

772-2a Volume flow controller (EHR A)

772-2b Volume flow controller (EHR B)

772-3a Volume flow controller (white A)

772-3b Volume flow controller (white B)

772-4a Volume flow controller (yellow A)

772-4b Volume flow controller (yellow B)

772-5a Volume flow controller (green A)

772-5b Volume flow controller (green B)

772-6a Volume flow controller (swing lower link A)

772-6b Volume flow controller (swing lower link B)

787 Pressure balance

-901 Working hydraulics measuring point

924 LS pressure measuring point

-Y121 Shifting aid, reverse

Y192 Floating axle locking solenoid valve

Y193 Floating axle unlocking solenoid valve

Y198-1a Pilot valve (red A)

Y198-1b Pilot valve (red B)

Y198-2a Pilot valve (EHR A)

Y198-2b Pilot valve (EHR B)

Y198-3a Pilot valve (white A)

000 293 646 0 - SYS-H XERION 3300 - 04/05 65

Page 66

3 Working hydraulics

Main valve block

Item Component

Y198-3b Pilot valve (white B)

Y198-4a Pilot valve (yellow A)

Y198-4b Pilot valve (yellow B)

Y198-5a Pilot valve (green A)

Y198-5b Pilot valve (green B)

Y198-6a Pilot valve (blue A)

Y198-6b Pilot valve (blue B)

-Z102-1 Working hydraulics filter bypass actual value switch (bypass open)

Z105-1 Floating axle lock 55 bar pres sure

Z105-2 Floating axle lock 115 bar pressure

408

66 000 293 646 0 - SYS-H XERION 3300 - 04/05

Page 67

Following the policy of CLAAS KGaA mbH to improve

their products as technical developments continue,

CLAAS reserve the right to make alterations which

must not necessarily corr es po n d to tex t an d illus tr a

tions contained in this publication, and without

incurring obligation to alter any machines previously

delivered.Technical data, dimensions and weights are

given as an indication only. Responsibility for errors

and omissions not accepted. Reproduction or transla

tion of this publication, in whole or in part, is not

permitted without the wri tt en c onsen t of CL AAS KGaA

mbH.All rights under th e provisi on of the Copyrig ht Act

are reserved. CLAAS KGaA mbH33426

HARSEWINKEL Germany

411

-

Our contribution to the environment:CLAAS

have printed this manual on 100% chlorine

free paper.

Page 68

CLAAS KGaA mbH

Postfach 1163

33426 Harsewinkel

Tel. +49 (0)5247 12-0

www.claas.com

000 293 646 0

SYS-H XERION 3300

EN - 04/05

Printed in Germany

Loading...

Loading...