Page 1

Combine harvesters

TUCANO

450 440 430 420 340 320

Page 2

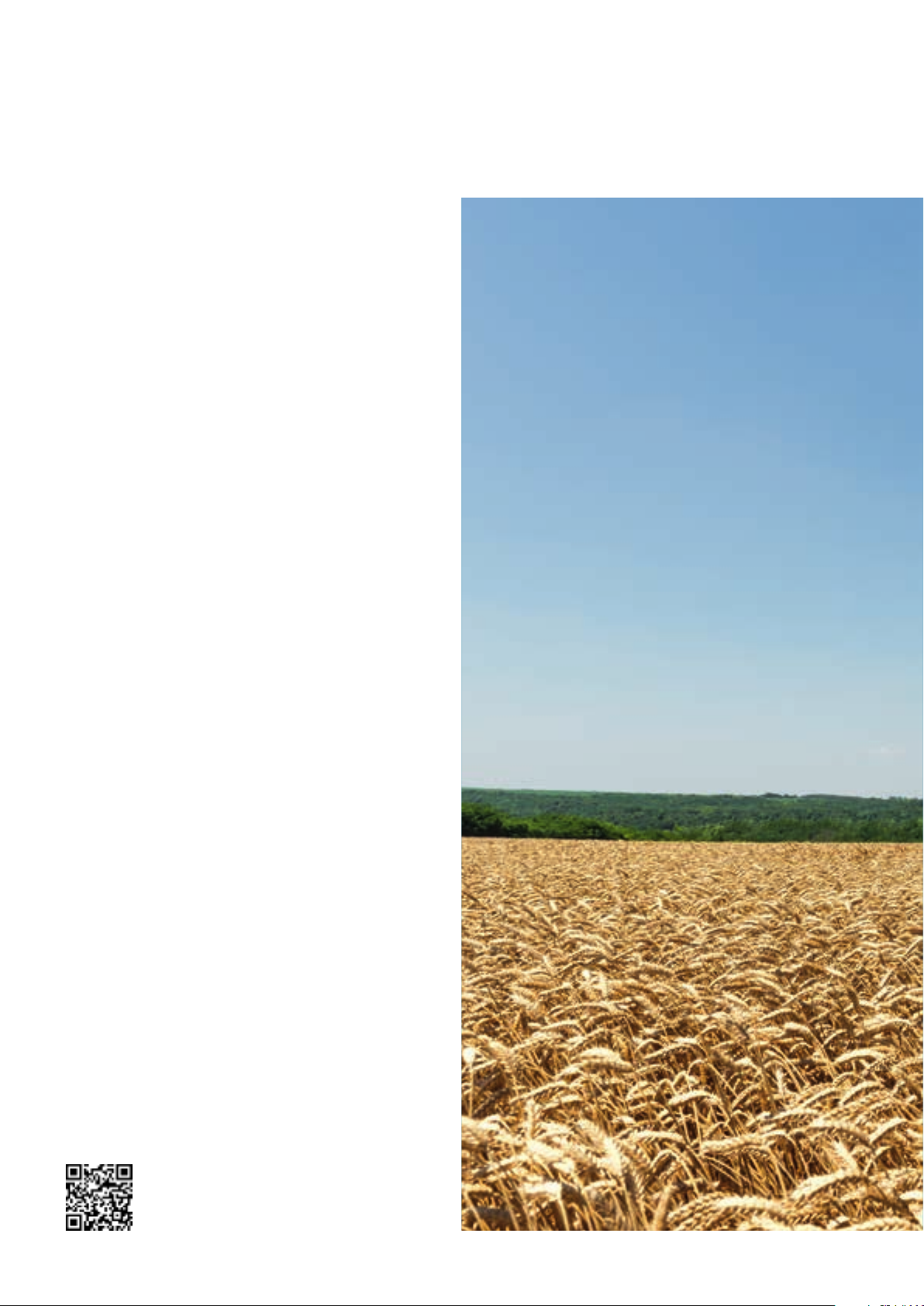

Time to grow.

The new TUCANO.

Healthy growth is the basis of every successful harvest. It was

with this principle in mind that we developed the new

TUCANO. As well as growing to incorporate the intelligence

and comfort of the large combine segment, it has a design

which immediately announces a new dimension of excellence

and gives you the capacity you need for the future:

Time to grow.

tucano400-300.claas.com

2

Page 3

TUCANO

3

Page 4

TUCANO 450 / 440 / 430 / 420 / 340 / 320.

4

Page 5

Contents

Cab 6

EASY 11

CEBIS 12

CEBIS, multifunction control lever,

CMOTION 14

TELEMATICS 16

Yield mapping, job management 18

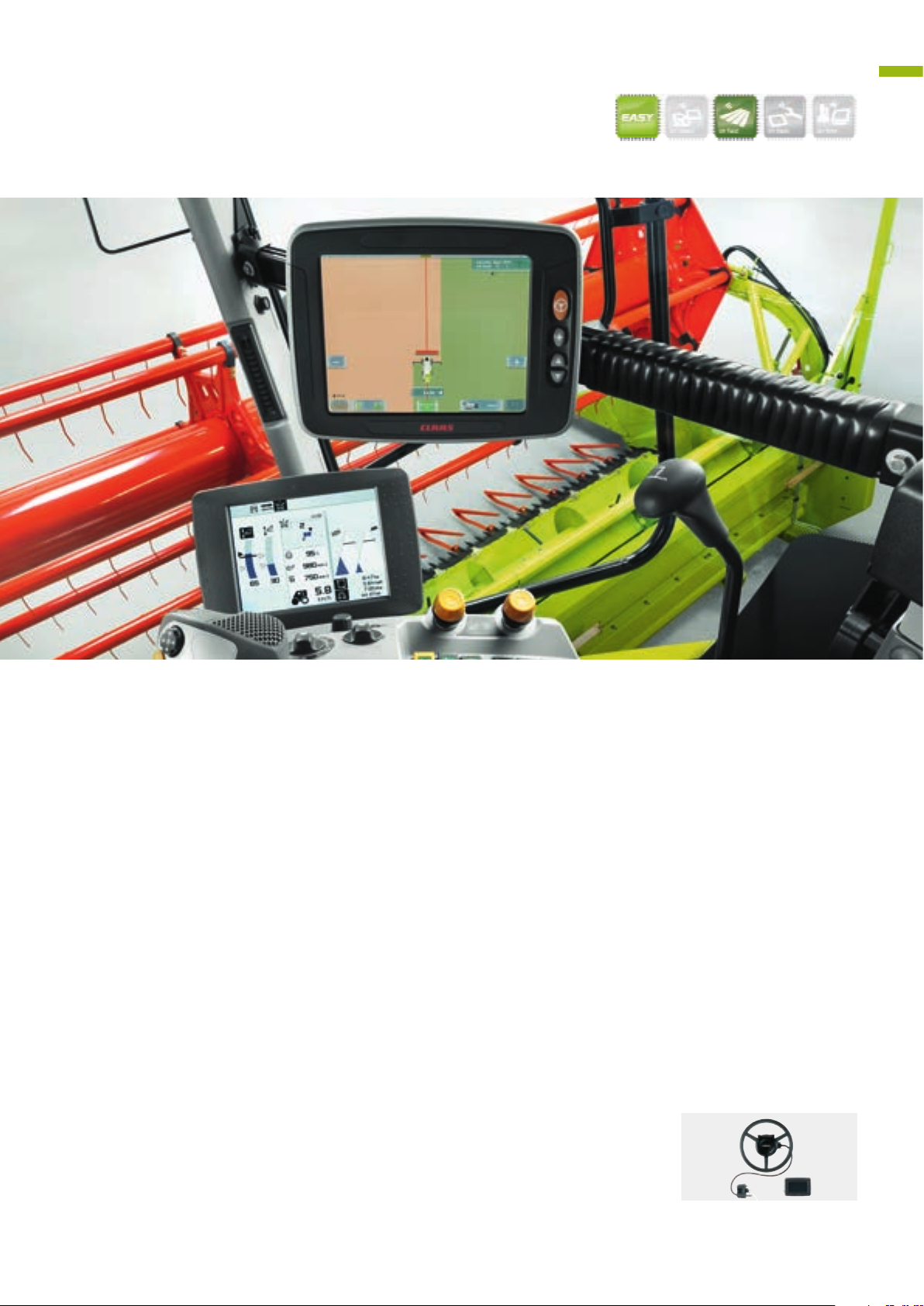

Automatic guidance systems 20

Front attachments 22

Cutterbar 25

VARIO cutterbar, rapeseed cutterbar 26

VARIO 930 / 770, CERIO cutterbars 28

CONSPEED, CONSPEED LINEAR 30

SUNSPEED, SWATH UP 32

Rice cutterbar, FLEX 34

Automated cutterbar control 36

Threshing system 38

APS threshing system 40

CLAAS threshing system 42

Straw walker technology 44

Crop cleaning 46

Grain tank, QUANTIMETER,

PROFI CAM 48

Straw management 50

CLAAS POWER SYSTEMS 52

Engine, drive train 54

All-wheel drive,

central lubrication system 56

Tyres, maintenance 58

First CLAAS Service 60

Technology in detail 62

Benefits 66

Technical data 67

5

Page 6

Well-being at work.

Deluxe comfort in your working environment.

At CLAAS, comfort and convenience mean that

everything is designed to enable you to work with

optimal efficiency. From the flawless 360° view to the

smallest action.

6

Page 7

Cab

7

Page 8

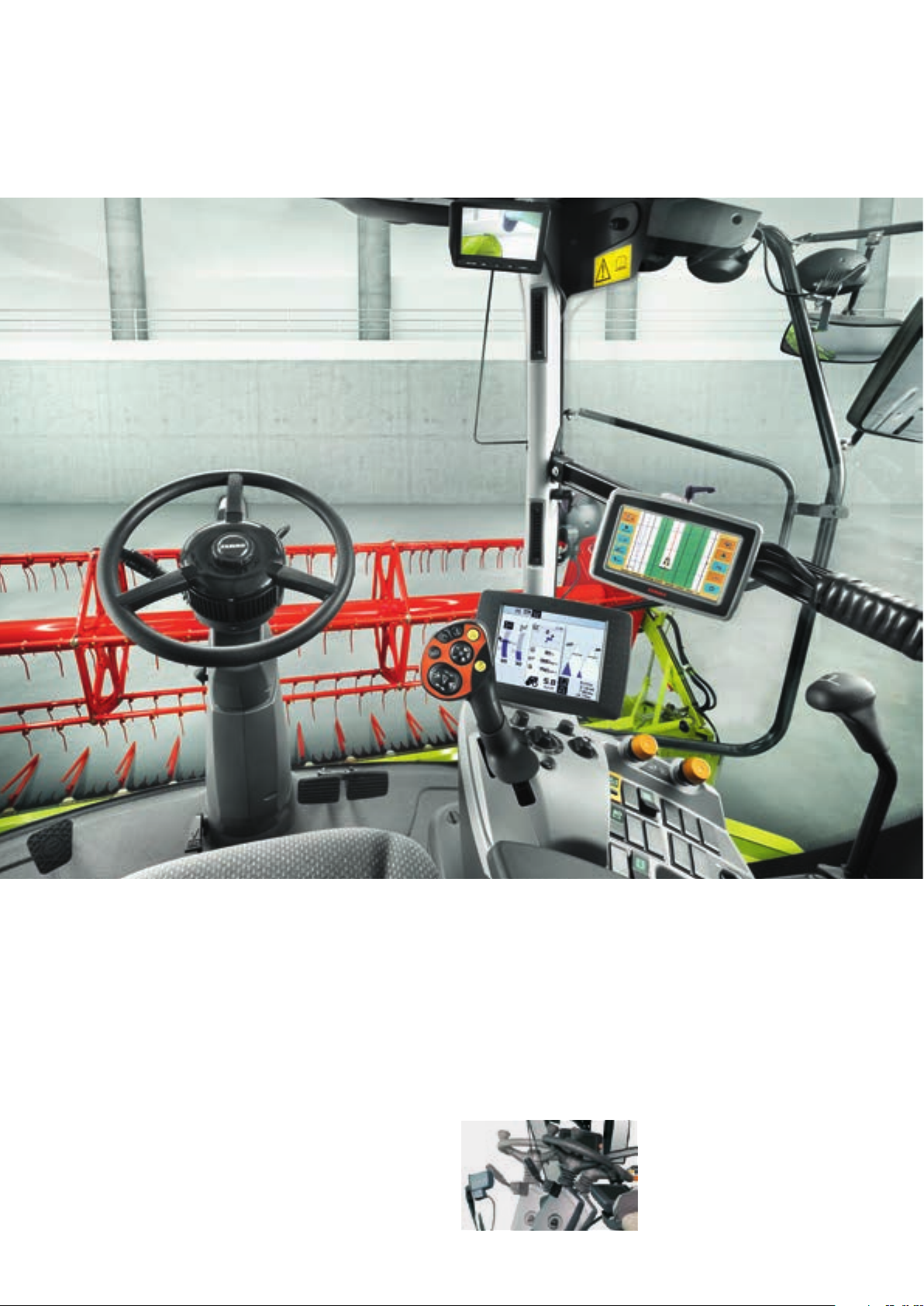

More space. More comfort.

A more productive workplace.

For optimal working conditions.

The TUCANO gives the operator freedom of movement, a

clear control layout and excellent visibility on all sides. The air

conditioning maintains a consistent, comfortable atmosphere,

which together with superb soundproofing and a three-

position adjustable steering column provides first-class

working conditions.

8

The steering column is adjustable

three ways.

Page 9

Cab

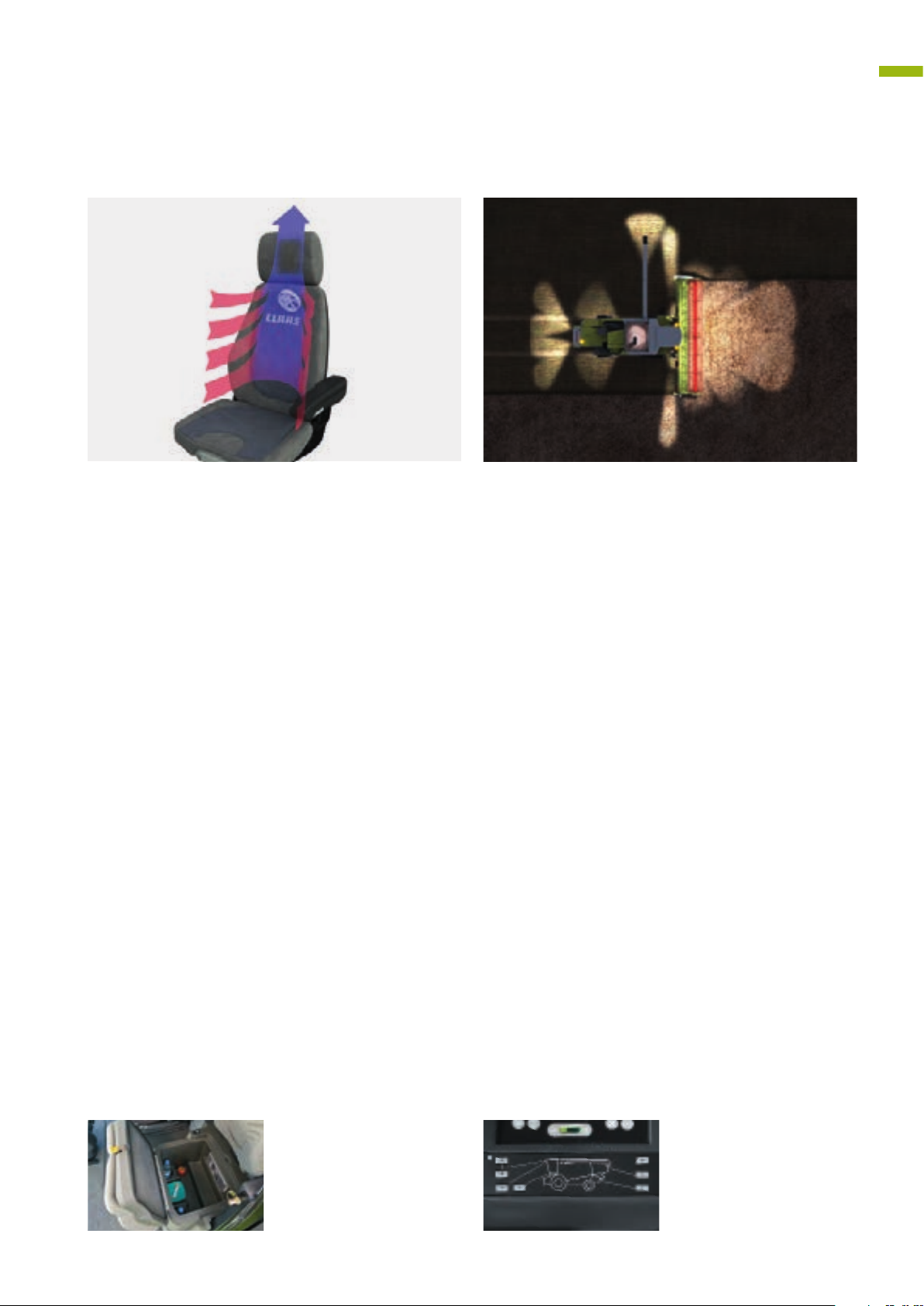

Cushions, supports, ventilates and keeps you

warm: the deluxe operator’s seat.

Full support for dynamic, active work while seated. Active

comfort control ensures optimal ventilation and sweat removal

without subjecting the operator to unhealthy draughts. The air

suspension seat with automatic height control adjusts

automatically to the operator’s weight and effectively

attenuates vibrations by up to 40%. A pneumatic, two-part

lumbar support keeps your back in shape while the automatic

thermostat for the seat’s heating keeps you warm and

comfortable.

Fully featured: trainee's seat with

integrated cooler.

− Integrated armrest at left on door

− Foldable backrest as a table

− Large in-cab refrigerator,with capacity

of 43 litres and a bottle holder

− Many other stowage compartments

Turns night into day at the flick of a switch.

The lighting systems ensure the best visibility for the entire

work area and machine parts even at night. Intelligent

features, such as the afterlight function, make for a complete

package. Powerful H9 and xenon lights turn night into day.

− Up to ten work lights

− Lighting for folding front attachments

− Side lights, stubble lights, steering axle lights

− Automatic lighting of the discharge auger tube

− Automatic reversing lights

− Lighting for the cleaning system, grain tank and returns

− Service lights below the side panels

− Mobile work light

Refrigerator box integrated in

trainee's seat

The operating panel gives a good

overview and enables simple control

of the working lights. The light

settings can be adjusted easily in

CEBIS.

9

Page 10

EASY. Simply more.

10

Page 11

EASY – Efficient Agriculture Systems by CLAAS

The name says it all.

All the electronics expertise of CLAAS

can be summarised in a word: EASY.

That stands for Efficient Agriculture

Systems, and it lives up to the name.

Equipment settings, guidance systems,

software solutions and more: EASY

makes it all simple. Your systems can

be matched perfectly with each other,

enabling you to get the best

performance from your combines and

top results for your operation.

Go on. Go easy.

The EASY concept is made up of four

components, each providing specialist

competence and together forming a

strong team.

− on board – Control and performance

optimisation of the combine from

the cab

− on field – Increased productivity

directly in the field

− on track – Equipment monitoring and

remote diagnostics

− on farm – Software solutions for your

operation

11

Page 12

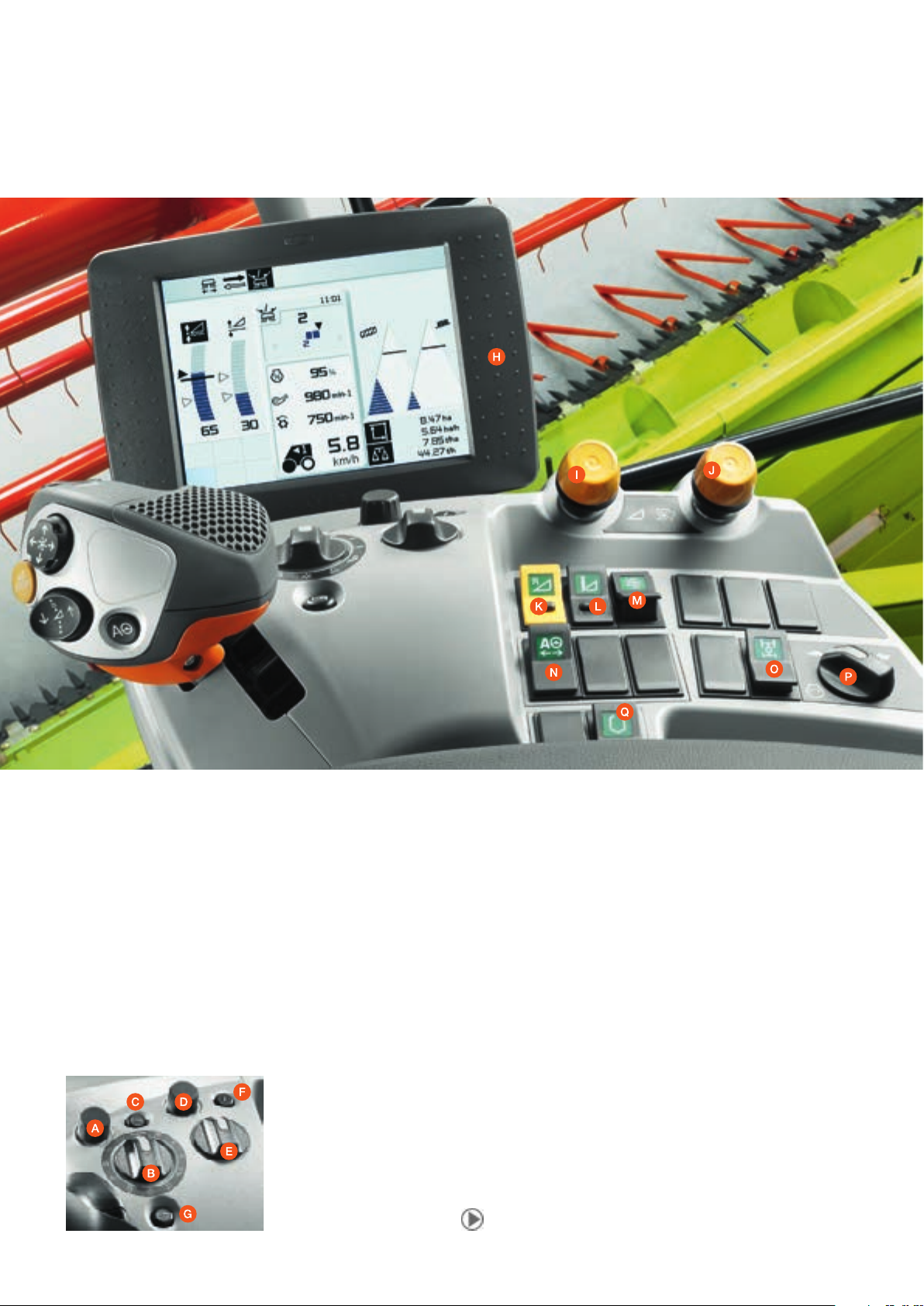

More informed, more monitoring.

All’s clear on the operating panel!

Integrated with the operator's seat, its flexible functions can

be adapted as needed. Function switches include:

A Menu selection rotary/push switch

B CEBIS direct menu rotary switch

C Escape button

D HOTKEY rotary/push switch

E HOTKEY direct menu rotary switch

F Information button

CEBIS controls and HOTKEY

G DIRECT ACCESS button

H CEBIS screen

I Front attachment on/off

J Threshing unit on/off

K Front attachment reverser

L Rapeseed knife, left, on/off

M Lateral adjustment of cutterbar / changes to values in

HOTKEY menu / longitudinal position of VARIO cutterbar

table

N LASER PILOT left/right preselection

O All-wheel drive

P Diesel engine speed (three steps)

Q Grain tank cover open

For more information, please visit: tucano400-300.claas.com

12

Page 13

CEBIS

Keeping the operator in the picture at all times.

Information, registration, control and monitoring are the tasks

of the CEBIS electronic on-board information system. It is

distinguished by its clear, logical organisation of functions in

the menu structure.

A brief glance at the CEBIS display gives an overview of the

current processes and conditions: all the relevant information

for driving or harvesting is summarised clearly on the screen.

Warning messages are given audibly as a buzz tone and

visually as icons and text.

An eye-catching 21 cm screen.

The 8.4" colour CEBIS screen offers an ideal view thanks to

its ball coupling mount which enables the monitor to be

adjusted as required by the operator. It can be adjusted for

angle as well as horizontally and vertically.

Clear, simple and fast operation.

− The basic machine settings in working mode are made

via the CEBIS rotary switch (B)

− An additional HOTKEY rotary switch allows fast access

to other functions (E)

− The position of the rotary switch is shown on the

CEBIS display (H)

− The CEBIS and HOTKEY rotary/push switches (A / D) are

used for menu navigation and making changes to settings

− A Compact Flash Card makes data exchange particularly

easy

− The DIRECT ACCESS button provides direct access to

the last menu setting. It also offers fast access to the

image from the camera

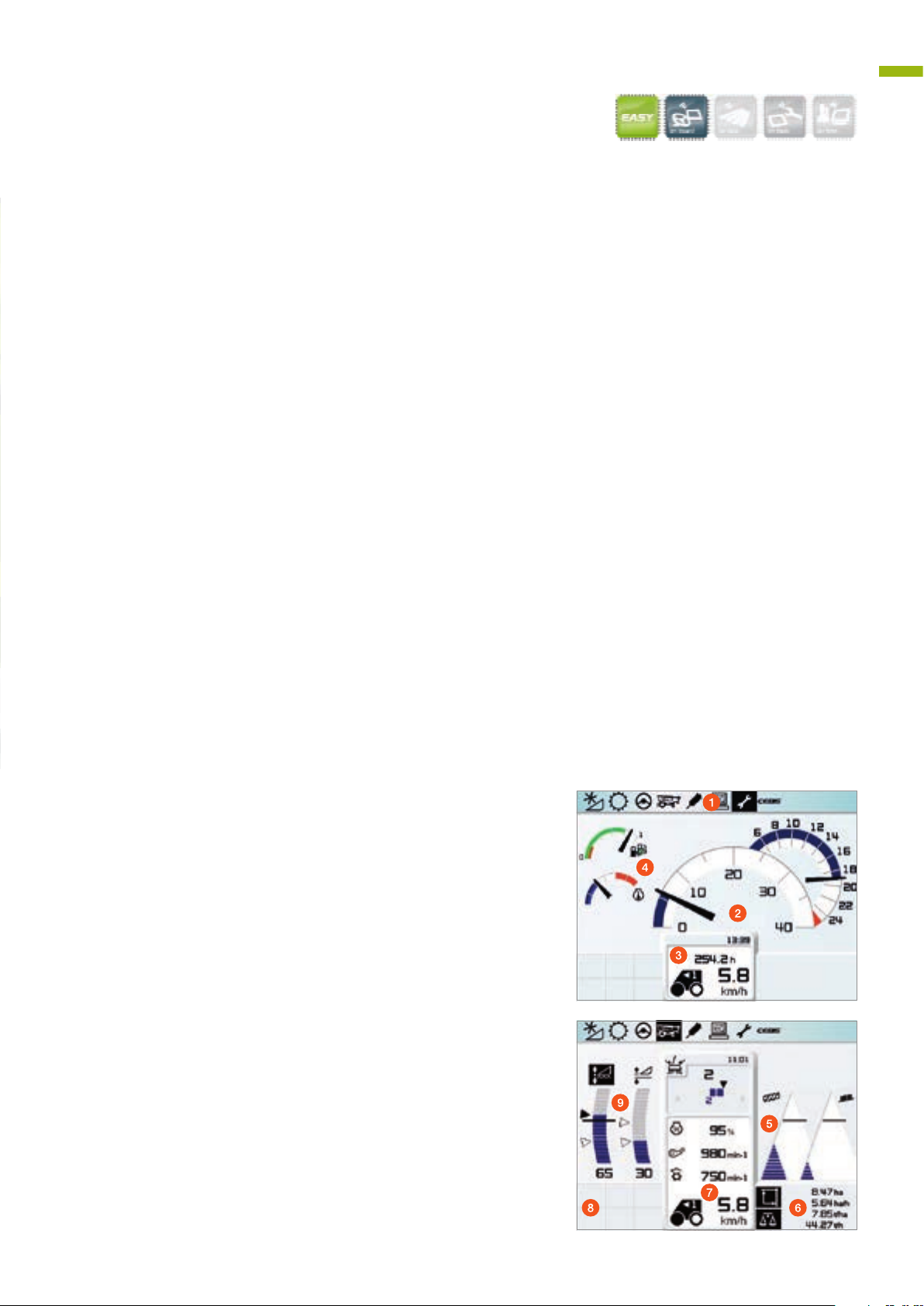

CEBIS on the road.

1 Menu bar

2 Travel speed and rpm

3 Operating hours

4 Fuel level and temperature display as well as AdBlue level

CEBIS in the field.

5 Throughput monitoring

6 Area scaling and yield metering

7 Driving information (up to 40 displays freely selectable)

8 Message window (for alarms and information)

9 Front attachment position (AUTO CONTOUR/

cutting height)

13

Page 14

NEW

More functions at your fingertips.

CMOTION. Greater comfort.

The multifunction control lever, which is integrated in the right

armrest of the operator's seat, plays a key role in making the

TUCANO so user-friendly and comfortable for the operator.

The CMOTION has been specially developed for ergonomic

operation by the right hand. The innovative, three-finger

control concept allows several functions to be controlled

intuitively without having to reposition one's hand.

1 Extend grain tank discharge auger

2 Retract grain tank discharge auger

3 Grain tank offloading on / off

4 Cutterbar stop

5 Reel operation

6 Front attachment height control

7 AUTO PILOT, LASER PILOT, GPS PILOT

Another toggle switch (8) is situated on the back of the

multifunction control lever. With three functions assigned to it,

this switch enables manual lateral control of the cutterbar,

changes to values in the HOTKEY menu or manual adjustment

of the VARIO cutterbar table.

14

The choice is yours: multifunction control

lever or CMOTION

Three-function

toggle switch (8)

Page 15

CEBIS | Multifunction control lever | CMOTION

Comprehensive information.

CEBIS is simple to use, allowing a wealth of equipment

information to be displayed and printed in addition to

performing full control and monitoring.

− Automatic crop setting

− GPS PILOT, LASER PILOT, AUTO PILOT –

automatic guidance

− Automated cutterbar control

− QUANTIMETER – yield determination / moisture

measurement

− Area counter

− Fuel consumption measurement

− Yield mapping – crop log

− Performance display – remaining diesel running time /

range / grain tank fill level

− Job management

− Maintenance interval display and tasks

− On-board diagnostics, alarm lists and alarm history

− Speed monitoring, slippage display (for the threshing

drum, for example)

NEW: Automatic machine setup.

Factory-programmed settings for over 35 crop types are

available. In addition, users' own settings based on

experience (especially relating to specific varieties) can be

stored and called up whenever required. Furthermore,

favourite settings can be stored and recalled quickly by means

of the hotkey rotary switch. The following machine parameters

are set:

− Threshing drum speed

− Concave gap

− Fan speed

− Upper and lower sieve opening

− Sieve throughput monitoring sensitivity

− Residual grain separation throughput monitoring sensitivity

− Specific crop weight (bulk density)

− Crop-specific calibration factor

15

Page 16

TELEMATICS.

Makes good operators even better.

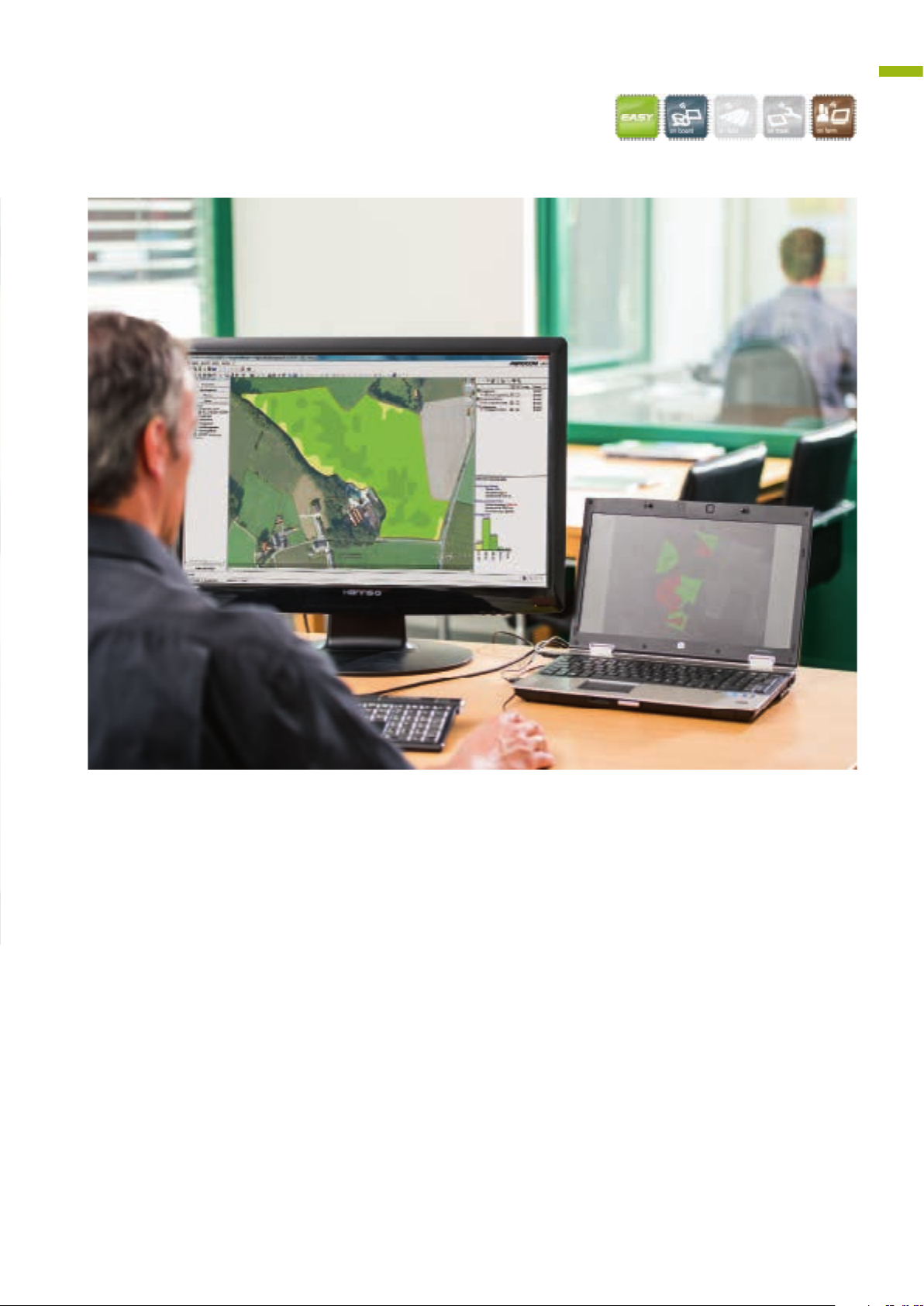

A full overview with just a click of the mouse.

The CLAAS TELEMATICS feature enables you to access all

the important data for your combine any time, anywhere via

the internet. Enjoy the benefits of TELEMATICS.

Optimise your settings.

Use your personal access to the TELEMATICS web server to

quickly compare the performance and harvesting data for your

machines so that you can fine tune the settings for the best

results under all conditions every day.

Improve work processes.

A report with the operating time analysis and other important

evaluations of the machine is sent to you by e-mail each day.

This enables you to review the specific data from the previous

day and determine when and how efficiently the combine

operated before you start work again. In addition, the working

tracks of the machine can be viewed together with the event

log in order to optimise the transport logistics. TELEMATICS

enables planned fleet management and helps avoid

unprofitable idle time.

A range of packages to meet your

requirements.

TELEMATICS is available in three different packages: basic,

advanced and professional.

16

Page 17

TELEMATICS

Simplify documentation.

Use TELEMATICS to export the relevant data to your field

catalogue and save valuable time. Transfer data on area-

specific yields, for example.

Faster service with CLAAS remote diagnostics.

With your consent, TELEMATICS can transmit maintenance

and repair data to your CLAAS sales partner. This enables

your CLAAS partner to carry out an initial analysis via

CDS Remote - when required - to find the causes of faults

more quickly and to make optimum preparations to assist

you on site as quickly as possible.

Automatic documentation.

This function automatically documents and processes all

process data. As an extension to TELEMATICS, automatic

documentation transfers (without any intervention by the

machine operator) the work data relating to the specific field

deployment to the server, where they are interpreted and

processed. Data interpretation and processing are based on

the field boundaries previously uploaded from your system.

Further processing is straightforward, as all machine-relevant

data can be exported in IsoXML format.

17

Page 18

More potential when you need it.

Fast data processing.

With its extremely fast on-board network, the TUCANO is

already prepared to meet the far-reaching challenges of the

future.

18

A wealth of information can

be printed whenever

required.

The working tracks picked up

by GPS can also be displayed

in CEBIS.

Page 19

Yield mapping | Job management

Yield mapping.

Building on the foundation of the job management functions,

you can use your TUCANO to perform yield mapping. Sensors

in the TUCANO measure the yield and grain moisture while

CEBIS adds geographic coordinates using GPS satellite data.

All measurements are stored on portable chip cards to

facilitate transfer. AGROCOM MAP START software is

included to enable you to produce informative yield maps to

use as a basis for your future production strategy.

Job management.

You can manage your jobs with CEBIS. Moreover, with

AGROCOM MAP START software from CLAAS you can

prepare customer and parcel data to be run and processed

with CEBIS.

− All data is backed up when a specific task is completed or

the working day comes to an end

− The data can be printed out on the combine or transferred

with a data card

− All data can be viewed and processed further on a PC

− Daily counts, crop counts and total counts can also be

displayed and printed in CEBIS

19

Page 20

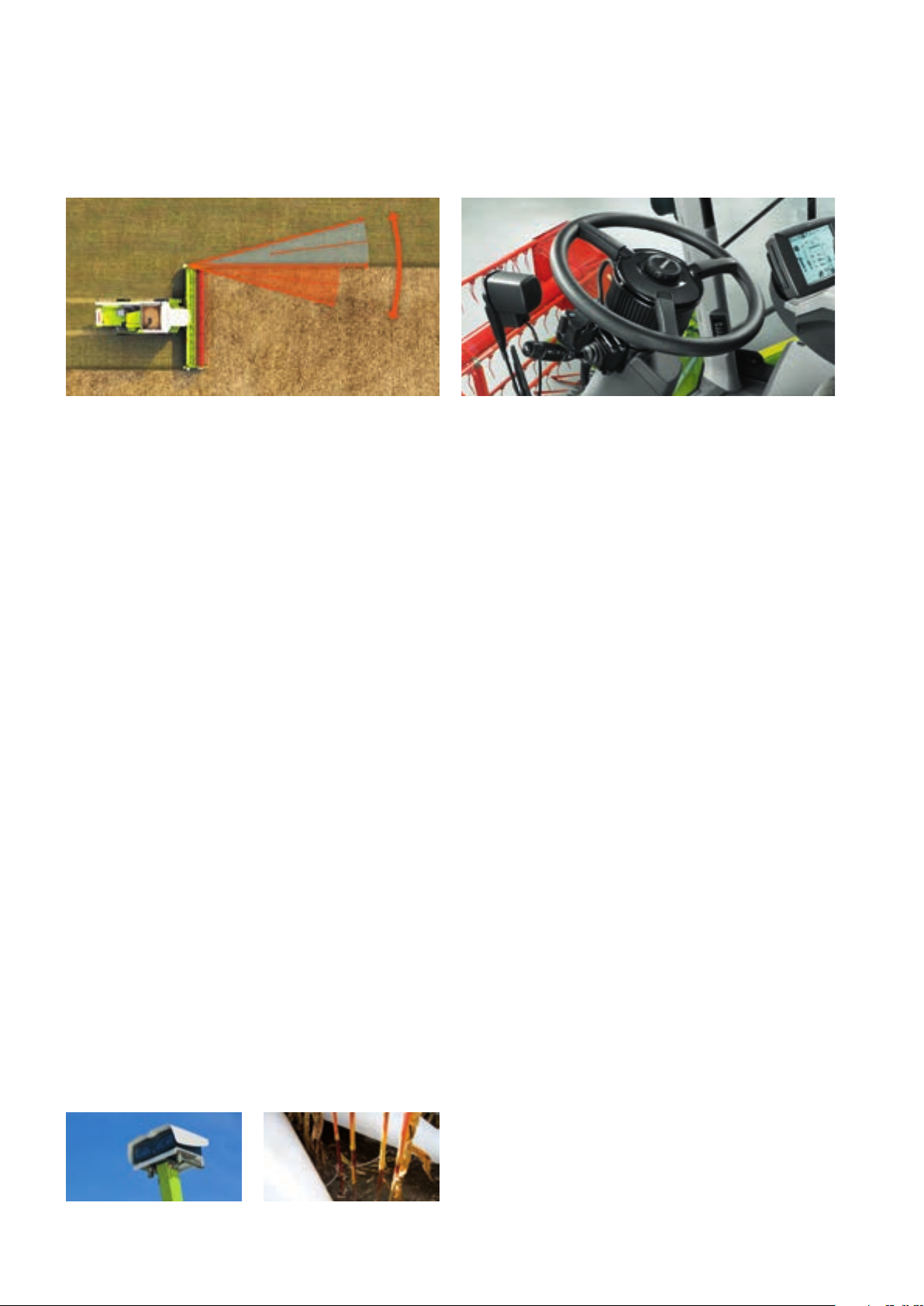

More precise guidance.

LASER PILOT.

The electro-optical sensors of the LASER PILOT use pulses

of light to scan between the crop and stubble and guide the

TUCANO automatically along the edge.

The LASER PILOT can be folded away for transport and is

available for both the left and right side of the cutterbar. Its

optimal positioning on the cutterbar side close to the crop

edge enables a good viewing angle and ensures high

functional reliability even with laid crops and slopes.

AUTO PILOT.

Two digital sensors, incorporated in one of the picker units,

record the position of the TUCANO and automatically guide it

on the best path through the rows of maize in all field

conditions. In this way, AUTO PILOT contributes to greater

performance and efficiency.

Choose from three automatic guidance

systems.

All the TUCANO models can be factory-fitted with three

automatic guidance systems which can be selected as

needed according to application.

− GPS PILOT – the satellite-supported guidance system

− LASER PILOT – the electro-optical guidance system

− AUTO PILOT – the electro-mechanical guidance system

The way you want it.

Portable displays from CLAASoffer a flexible control option for

ISOBUS and guidance systems. The terminal can also be

moved from one tractor or self-propelled harvester to another,

depending on the season or job in hand. Fit your TUCANO

with the equipment you need, straight from the factory or as

a retrofit option:

LASER PILOT AUTO PILOT

20

− S10: high-resolution 10.4" touchscreen terminal with

guidance and ISOBUS functions: up to four cameras

can be viewed

− S7: high-resolution 7" touchscreen terminal with

guidance functions

Page 21

Automatic guidance systems

Automatic steering at the headland.

The AUTO TURN function takes care of turning manoeuvres at

the headland.The direction of the turn and the next track to

be worked are pre-selected on the terminal. The steering

system does the rest.

How you benefit.

− High functional reliability and safety regardless

of visibility conditions

− Optimal use of the full width of the cutterbar

− Greater precision for mapping areas and yields

− Reduced fuel consumption

− Reduced turning times

− Increased seasonal performance

− Significant reduction in workload for the operator,

enabling greater concentration on threshing

GPS PILOT FLEX.

The GPS PILOT can be used not only with hydraulically

actuated steering, but also with the GPS PILOT FLEX

automatic steering wheel. This steering wheel allows you to

operate the machine with a high degree of accuracy. The

great advantage of the GPS PILOT FLEX is its versatility.

− No need to touch the hydraulics

− Guidance system can quickly be moved between

different machines

The electric steering wheel transfers steering commands from

the terminal and navigation controller to the steering axle in

order to steer the machine

GPS PILOT FLEX steering wheel

21

Page 22

A real all-rounder.

Top performance with all crops.

The TUCANO can handle whatever

work you've got planned.

22

Page 23

Front attachments

VARIO cutterbarVARIO cutterbar with rapeseed equipment

CONSPEED ⁄ CONSPEED LINEARFLEX soybean cutterbar:

Folding cutterbarCERIO ⁄ standard cutterbar

SUNSPEEDSWATH UP

23

Page 24

It’s all about higher throughput.

The leader in versatility and flexibility.

The TUCANO was developed to unite a wide variety of

features at the highest level. Offering optimal throughput

performance and long-term reliability combined with great

versatility and minimal setup time, the TUCANO is simply

unbeatable. Our top combine harvesters were the prototypes

for this model. Take advantage of a unique combination of

sophisticated performance features and equipment.

The V channel.

With the flexible positioning of the cutterbar mount, the V

channel facilitates fast, easy adjustment of the cutting angle.

This ensures optimal adaptation to all field conditions and

different types of tyres.

MultiCoupler.

The central coupling for all hydraulic and electrical cutterbar

functions.

− You gain valuable time due to shorter attachment and

removal procedures

− No danger of confusion thanks to the integrated design

− Easy to connect, even under pressure

− Environmentally friendly with no oil leakage

24

That familiar comfort

and convenience

Page 25

Central locking system.

A single lever on the left side of the cutterbar operates all

locks simultaneously.

− Safe, fast locking mechanism

− Fast, easy cutterbar attachment and removal

Replacement knife bar and crop lifters.

All CLAAS cutterbars are factory-equipped with a replacement

knife bar. The knife sections are made of hardened material

and are therefore extremely durable.

Cutterbar

The use of crop lifters enables loss-free pickup of laid crops in

particular while reducing the intake of stones. Crop lifter

replacements can be carried conveniently on the rear side

of the cutterbar.

Hydrostatic reel drive.

A variable displacement pump on the basic machine supplies

a maximum torque of 1000 Nm at the reel. The reel speed is

automatically adjusted independently of the ground speed.

− Plenty of pulling power thanks to high torque

− Greater efficiency than gear pumps

− A closed hydraulic circuit ensures better reel rotation

− Fast adjustment of the reel speed

The trailer for road transport.

Everything to save you time: The trailer provides compact,

convenient and safe storage for the cutterbar. It is locked in

seconds with two bolts.

Made-to-measure compartments are provided to transport

the accessories you need for the rapeseed equipment. The

rubber-coated floor ensures non-slip, protective, theft-proof

storage.

Adjustable stripper rails.

The spacing between the stripper rails and the intake auger

can be conveniently set externally on the V 930, V 770,

CERIO 930, CERIO 770, C 490, C 430 and C 370 cutterbars.

Hydraulic reversing

on the feeder housing Adjusting the stripper rails

25

Page 26

The TUCANO is extremely versatile.

Rapeseed and grain.

A first-class combination for a unique

competitive edge.

The TUCANO is the first combine harvester to unite a machine

of the mid-sized class with the VARIO high-performance

cutterbar. This is a unique combination from which you will

reap the benefits every time you use it:

− Highest throughput due to particularly even crop intake

− The VARIO is available in five different cutting widths:

V 540, V 600, V 660, V 770 and V 930

− The hydrostatic reel drive comes equipped with

automatic speed adjustment

− Reliable and rugged: the multifinger intake auger

Consistent crop flow to enhance performance.

The VARIO high-performance cutterbar feeds the crop

uniformly to the threshing unit. This is the only way to increase

performance and to utilise the full design capacity.

Furthermore, it reduces fuel consumption and supports the

operator in significantly increasing productivity.

26

− Automatic reel speed

− Automatic reel height

− Automatic reel levelling

− Automatic table positioning

Page 27

VARIO cutterbar | Rapeseed cutterbar

–10 cm

Standard

+20 cm

+50 cm

You also benefit from the following additional

advantages:

− High RPM stability in the engine, threshing and separation

units and during the cleaning process

− Extremely consistent performance

− No load peaks in the threshing equipment

− Protection of the drives

− Enhanced reel design with optimised reel tine carriers a

nd bearings for significantly reduced risk of wrapping

− Hydraulic pump for rapeseed knives that can be switched

on and off to reduce the power required and so

reduce wear

− Overload protection features protect against damage

Rapeseed requires particular attention.

Ripe rapeseed pods need careful handling during threshing

because they often burst, causing grains to scatter in all

directions. This is why the rapeseed deflector and extension

are indispensable parts of the rapeseed equipment on VARIO

cutterbars: they serve to keep losses to a minimum. The

rapeseed equipment is stored in a lockable box on the trailer

for road transport, thus saving a great deal of weight on the

cutterbar.

The right cut.

For grain harvesting, the cutterbar table can be extended by

up to 20 cm or shortened by as much as 10 cm to keep the

crop flow even and ensure efficient, trouble-free working.

For rapeseed, the cutterbar table can be moved forward by

50 cm. Once the rapeseed plates are inserted, the rapeseed

table is ready for immediate use.

Hydraulically driven side cutters on the right and on the left

(the latter can be switched on and off at will) can be fitted

quickly and easily without additional tools.

The knife bar comes with an integrated hydraulic drive.

Knife position

–10 cm

Knife position

+20 cm

Knife position

+ 50 cm

incl. rapeseed

plates

27

Page 28

NEW

The new generation of

CLAAS VARIO and CERIO cutterbars.

–10 cm

Standard

VARIO 930 / 770 –

The success story continues.

With its two new models, the V930 and V770, CLAAS

has made systematic enhancements to its proven VARIO

cutterbars in order to provide increased throughput, a better

crop flow, high reliability, a reduced maintenance requirement,

greater flexibility and more comfort/convenience.

+ 60 cm

The highlights at a glance.

− Integrated rapeseed plates allow infinite adjustment within

a range of 70 cm

− Diameter of intake auger increased to 660 mm

− Intake auger and knife bar mechanically driven via gearbox

and drive shaft

− Reel with optimised reel tine carriers, wear-resistant tine

tube bearings and a new design to reduce stalk take-up

− Quick-release mounting system allows dividers and

rapeseed knives to be fitted/removed without the need

for tools

− Hydraulic pump for rapeseed knives switches off

automatically

− LASERPILOT can be folded and adjusted without the

need for tools

− Stripper bars adjustable from the outside

− Automatic parking position at the touch of a button

− Angled cross-tube for a better view of the cutterbar table

from the cab

28

Page 29

VARIO 930 / 770 | CERIO cutterbars

Ready for rapeseed harvesting with just a few

adjustments.

Converting the

V 930 and V 770 cutterbars to harvest rapeseed takes only a

matter of minutes. The process involves nothing more than

replacing the dividers with the rapeseed knives – a task which

can be carried out without the need for tools thanks to the

two quick-release mounts. Inserting the rapeseed knives

automatically activates the hydraulic pump which drives the

side knives. The connection is made simply by means of two

flat-seal connectors. An additional cover is fitted on the right-

hand side to keep the losses in rapeseed to a minimum.

The end positions of the table and reel are also transmitted

automatically from the cutterbar to the combine. Even with the

rapeseed equipment fitted, the table can be extended or

retracted by 20 cm. The rapeseed knives are carried in a box

on the transport trailer and are therefore available for use at

any time.

NEW: CERIO 930 and CERIO 770.

Based on the new VARIO cutterbars, the CERIO model series

is an alternative for grain harvesting. The table of the CERIO

cutterbars can be adjusted manually from –10 to +10 cm in

order to optimise the crop flow. The adjustment is made by

loosening ten bolts in order to allow the table to slide in or out.

The entire frame, the intake auger, the drives and the reel of

the CERIO cutterbars are identical to those of the VARIO

model series. Similarly, the CERIO cutterbars are equipped

with the automatic reel parking function.

The dividers and rapeseed knives can be secured

without the need for tools

Fitting the rapeseed knives Adjusting the table length of the

CERIO 930 and 770

29

Page 30

More picking power.

Committed to higher picking performance:

CONSPEED and CONSPEED LINEAR.

Picking at a high rate while handling the ears of maize gently

has a critical influence on the combine’s throughput. The

CONSPEED and CONSPEED LINEAR maize pickers meet

these requirements and are optimally adapted to the

performance of the TUCANO. The display of the snapping

plate spacing in CEBIS is also ideal.

30

Make the most of the maximum efficiency of the CONSPEED:

− Snapping rollers with tungsten carbide coated knives

− Electrohydraulic snapping plate adjustment

− Horizontal chopper

− Reliable drives using only shafts and gears

− Durable, non-corroding plastic covers

− Automatic machine guidance via AUTO PILOT

− Simple rpm adjustment

− Can be adapted to all field conditions

Page 31

CONSPEED | CONSPEED LINEAR

The CONSPEED principle:

conical snapping rollers.

Each picker unit has a compact, integrated gearbox for the

snapping rollers, intake chains and the chopper. Each drive

unit is individually protected against overload. The picker

speed can be adjusted continuously using a front attachment

variator. The conical snapping rollers are a particular feature of

the CONSPEED. They first pull the maize plants down slowly

so the ears contact the snapping plate slowly. The rest of the

plant is then drawn down quickly. This design ensures a high

picking rate with careful handling of the ears and low grain

loss.

Convenient transport to the field and back.

The individual picking units of the hinged 6 and 8-row

CONSPEED and CONSPEED LINEAR fold in hydraulically

to a transport width of only three metres. This operation is

performed from the cab.

The CONSPEED LINEAR principle:

linear snapping rollers.

The CONSPEED LINEAR maize picker is driven by spur

gears which provide six different picker speeds simply by

exchanging two gearwheels. The straight, linear snapping

rollers are set forward and are thus particularly rugged.

CONSPEED LINEAR sunflower kit.

The CONSPEED LINEAR maize picker can be converted for

sunflower harvesting with a kit. This involves mounting knives

over the snapping rollers as well as adding lateral cover

extensions and an attachment on the back of the

CONSPEED. The chain is turned and the guide changed.

A horizontal rotating knife under each

snapping unit chops stalks finely so they

will decompose quickly.

31

Page 32

More flexibility.

The effective SUNSPEED principle.

The SUNSPEED sunflower cutterbar was developed with the

goal of achieving maximum output per unit area with the

lowest losses. Particular attention was paid to keeping set-up

times as short as possible and making the system extremely

easy to operate.

The sunflower stems are first captured by the shuttles. An

adjustable guide plate ensures that the sunflower heads are

pushed to the front. At the same time, the snapping roller

under the knife bar pushes the stalks down. It is impossible

for them to be cut too early as this only takes place once the

special reel has captured the sunflower heads. The precisely

cut heads are then passed to the intake auger and feeder

housing. The entire process is conducted on a row-

independent basis in the most diverse harvesting conditions

and ensures a high level of grain cleanness and low wear.

1 Adjustable guide plate

2 Reel

3 Knife bar

4 Snapping roller

32

Snapping roller

Page 33

SUNSPEED | SWATH UP

SUNSPEED adapts.

− Reel height and speed can be adjusted hydraulically

− Adjustable guide plates keep the stalks securely positioned

so only the sunflower seed heads are harvested

− The gap between the shuttles can be adapted to the

relative stalk diameter via adjustable rails – nothing gets

jammed and harvesting runs like clockwork

− The angle of the shuttles is also adjustable, so they can

be adapted to the most diverse harvesting conditions

The specialist: SWATH UP.

In areas which are unsuited to direct threshing the TUCANO

once again proves its reliability under all imaginable conditions.

The SWATH UP enables nearly all windrowed crops to be

picked up. This is an extraordinarily efficient concept,

particularly for crops such as rapeseed and grass seed.

Perfect pick-up at high speeds.

Two consecutive conveyors pick up the crop. The first belt

equipped with plastic tines ensures a clean pick-up; the

second belt then conveys the crop flow to the intake auger.

Thanks to the large overlap between the two belts, the crop

reaches the feeder housing without any losses.

The straightforward design ensures long operating times

and a low maintenance requirement.

Adjustable shuttles

33

Page 34

More expertise for rice and soybeans.

Dual blade knife bar.

Rice stalks are extremely tough. To achieve clean, top quality

cutting results at a high rate in this hard, unforgiving crop, all

the rice cutterbars are equipped with a dual blade knife bar.

The specially hardened knife blades are particularly durable.

A rice harvesting system is available as a retrofit kit for the

new VARIO and CERIO 930 and 770 cutterbars.

Hardened intake auger

Hardened intake auger.

The intensive irrigation of rice fields leads to high levels of

dirt particles on the plants, which is particularly tough on

combines during harvesting operations. To protect against

wear, the edges of the hardened intake auger are sintered.

Special deflectors on its sides reliably prevent wrapping.

Altogether, these features ensure smooth crop flow and

high throughput.

The two new VARIO 930 and 770 cutterbars are also available

as HD versions.

34

Page 35

Rice cutterbar | FLEX

FLEX: down-to-earth quality.

Legumes such as soybeans grow in pods close to the ground.

Thus to prevent substantial losses during harvesting, the

crops must be cut as close as possible to the ground to

ensure that every last pod gets picked up by the machine.

FLEX cutterbars from CLAAS are equipped with a flexible knife

bar which compensates automatically for the slightest ground

contours. The knife bar can flex up to 100 mm. Together with

the V channel, it enables intake losses to be avoided under all

field conditions.

These cutterbars are also suited for peas and other

specialised crops such as clover.

Special crop dividers.

The FLEX cutterbars are equipped with special crop dividers

which can be deflected vertically, thereby avoiding damage

and preventing interruptions to the harvesting process.

A versatile operator.

The FLEX cutterbars also offer outstanding flexibility thanks to

the knife bar which can be set to rigid mode manually, thus

allowing it to be used for other crops, such as grains.

35

Page 36

More intelligence for the cutterbar.

CLAAS CONTOUR ensures excellent

adaptation to ground contours.

The cutterbar with CLAAS CONTOUR adjusts automatically to

ground irregularities along the direction of travel. You select a

contact pressure and CONTOUR ensures that it will be

uniformly maintained. Every time the cutterbar is lowered, the

preselected cutting height ensures that the specified cutting

height is always found automatically.

AUTO CONTOUR:

faster and more accurate than ever.

AUTO CONTOUR goes a step further by compensating all

ground irregularities, including those which are transverse to

the direction of travel. Sensor bands below the cutterbar

provide early detection of undulations and trigger the

corresponding cutterbarrams on the feeder housing.

− Electronic sensors detect the hydraulic pressure in the

system and react quickly

− Valve-controlled, nitrogen-filled accumulators ensure

optimal shock absorption with front attachments of

different weights

With fully automated comparison of the current status and the

setpoint, the AUTO CONTOUR adapts the cutterbar position

optimally to the terrain. This greatly simplifies the work of

harvesting, particularly with large cutting widths, at night, with

laid crops, on side slopes and rocky ground. AUTO CONTOUR

helps to increase performance and to make the use of the

TUCANO pay even greater dividends.

Automatic reel control.

The RPM of the reel and thus its speed adjust automatically

and proportionally to the ground speed. The operator can

select and save various settings for the ratio of ground speed

to reel speed. The reel speed can be adjusted continuously

between forward, synchronous and after-running. A digital

RPM sensor ensures absolutely exact adjustment of the

rotation speed.

Different working heights of the reel can be saved and recalled

for various cutting heights. But the reel height can always be

adjusted directly.

36

2-way cutterbar rams

control the ground pressure

precisely.

The automatic cutterbar control is activated simply

by pressing the button for height adjustment on the

multifunction control lever.

Page 37

Automated cutterbar control

VARIO automation.

The VARIO cutterbar with automated reel control enables the

reel levelling and table position to be saved and recalled by

activating the automatic cutterbar control. Manual

adjustments can also be made.

Parking position for the V 930 and V 770.

A touch of a button is all it takes for these two VARIO

cutterbars to move into the parking position for mounting on

the road transport trailer or, after coupling, to move straight

into the working position. The threshing system must be

switched off before this function can be used.

Sensor bands detect the position of the front

attachment.

Automated cutterbar control.

− CONTOUR / AUTO CONTOUR

− Automatic reel speed

− Automatic reel height

− Automatic reel levelling (VARIO only)

− Automatic table position (VARIO only)

− Automatic parking position (V 930 and V 770 only)

37

Page 38

APS System. Threshing technology from CLAAS.

A combination of impressive advantages unique in its

class. CLAAS has redefined high performance.

38

Page 39

Threshing system

39

Page 40

NEW

APS gets good results fast.

TUCANO 450 / 440 / 430 / 420.

1 Accelerator

2 Threshing drum

3 Impeller

Unique APS threshing system.

The distinct competitive edge of CLAAS appears well before

the threshing drum. The dramatic acceleration of the crop flow

from 3 m/s to 20 m/s triggers a chain of extremely efficient

processes:

40

− The pre-accelerator separates the crop more thoroughly

− The crop flow is particularly even and up to 33% faster

− Higher centrifugal forces sort considerably more grain

− Up to 30% of all grains are already sorted in the pre-

separation concave directly below the accelerator,

significantly reducing the load on the main concave

Thus there is a net performance increase of up to 20% with

no rise in fuel consumption. APS really pays.

Page 41

Versatile pre-separation concave.

The pre-separation concave is designed as a MULTICROP

concave so it can handle all types of crops. The three

concave segments can be changed rapidly, minimising

changeover times between crops and maximising efficiency

and profitability.

NEW: Hydraulic concave adjustment.

The concave is adjusted hydraulically from the operator's seat.

This allows immediate and extremely convenient adaptation to

changing harvesting conditions in the course of the day. The

parallel concave control ensures that optimum threshing

quality is maintained.

NEW: Overload protection increases daily

output.

Integrated hydraulic overload protection reliably prevents

damage from foreign bodies and allows the machine to be

used at full capacity without risk. The concaves are pre-

tensioned hydraulically and open when pressure peaks arise.

The concaves then return automatically to the set working

position.

APS threshing system

Optimal grain quality is purely a matter of the

right settings.

The APS system is equipped with multistage adapters for

optimal deawning. With the intensive threshing component

and the deawning plates, which can be engaged in just

seconds via a lever on the feeder housing, APS ensures

outstanding grain quality.

Synchronised function.

The accelerator and threshing drum are driven by a central

variator. Each change in drum speed causes a corresponding

adjustment of the speed of the accelerator.

The result:

Long threshing channel with a large grain

separation area.

In the CLAAS APS threshing unit, we've succeeded in

wrapping the main concave much farther around the threshing

drum than in conventional machines. No other threshing unit

offers an angle of wrap of 151°. You benefit from gentle yet

thorough threshing with a large concave clearance and low

drum speed with reduced fuel consumption.

− Continuous protective crop handling with uniform crop flow

− No broken grains

Changing the MULTICROP

pre-separation concaves

Stone trap

41

Page 42

NEW

CLAAS threshing system.

The champion in all fields.

A high-quality threshing unit must remove and separate grains

reliably in all harvest conditions. The classic CLAAS threshing

mechanism provides impressive proof of its abilities time and

again. Regardless of the harvesting challenges you face, it has

the versatility to take them in its stride with the full threshing

drum width of 1.58 m (TUCANO 340) as well as with the

smaller 1.32 m version (TUCANO 320).

− The threshing unit can be easily accessed from the front via

the feed rake and from both sides through large openings

− The extremely robust design of all the drives, and of the

threshing drum drive in particular, ensures top reliability

during the harvest.

From field beans to clover seeds: the

MULTICROP concave can handle anything.

The concave below the threshing drum is designed as a

MULTICROP concave with individual segments that can be

changed easily. You can switch the concave quickly for a wide

assortment of crops, different varieties or various stages of

ripeness - always ensuring the right combination of clean

threshing, protective handling of the crop and a high

separation rate.

42

Page 43

CLAAS threshing system

NEW: Hydraulic concave adjustment and

overload protection.

In the TUCANO 340 and 320 models, the concave gap is

also set in CEBIS.

The hydraulic overload protection also protects the

conventional threshing system from damage by foreign

bodies and blockages.

NEW: Hydraulic adjustment

of the concave outlet.

In order to adjust the machine for different crop types, the

concave outlet can be set to two different positions: wide for

crops such as maize and beans, narrow for grain. The

adjustment is made by actuating a valve near the cab door.

Changing the MULTICROP

pre-separation concaves

43

Page 44

The straw walker gets out the last 10% for you.

View of straw walkers from the rear

44

Page 45

Straw walker technology

Cleanly separated over 4.40 metres length.

Grains this way, straw that way. The even flow of the straw on

the 4.40 metre long, open-bottomed straw walker ensures

that practically all the grain is separated from the straw. A

separate returns pan sends the grains on their way to the

preparation floor. Even large volumes of straw are moved with

ease by the system.

Resistance is futile!

The CLAAS intensive separation system.

There are two guide-controlled agitator tines mounted above

every straw walker, which actively loosen the straw from the

top to ensure that it flows quickly in a thin layer. As a result,

the remaining grains fall easily out of the straw, through the

walker floor and onto the returns pan.

Work safely at the capacity limit with the

throughput monitor.

It's easy to keep an eye on the separation and cleaning from

the cab, as if through a "rear view mirror", with the CLAAS

throughput monitor. It works with high-precision adjustments

to adapt automatically to crops of different weights and

display the results accurately.

How you benefit:

− In parallel viewing mode, you can fine-tune the combine

faster by optimising the balance of the cleaning and residual

grain separation functions

− The throughput monitor indicates whether you are threshing

at the best forward speed

− You run safely at the performance limit of the combine

45

Page 46

Clean work pays better.

Electric sieve adjustment

Divided preparation floor that can be

pulled out towards the front

Rotary fan or turbine blowers.

− Depending on the model, there are six or four turbines or a

rotary fan to ensure a consistent, uniformly distributed air

flow pressure, even with variations in the sieve loading

− Forced air flow control prevents crop mat formation

− Reliable air flow even at low air speeds

− Continuously adjustable from the cab

Preparation floor.

Pre-sorting of the grains (bottom) and chaff and broken straw

(top) takes place on the preparation floor. The resulting

reduction in the load on the upper sieve increases the

cleaning capacity. The 400 series models have a plastic

preparation floor that can be pulled out towards the front.

Single or double steps.

− These significantly reduce the load on the upper sieve

− Result in increased performance, especially in the case

of dry and brittle straw

Electric sieve adjustment.

Developed by CLAAS, copied by the competition.

Electronic sieve adjustment from the cab:

− Easy and convenient

− No need to exit the cab

− Immediate result monitoring

46

Page 47

With 3D

Without 3D

Crop cleaning

The 3D-cleaning system.

− Dynamic side slope levelling – active control of the

upper sieve

− Completely consistent performance on side slopes

with an inclination of up to 20%

− No wear - completely maintenance free

− Fast, simple retrofitting

− Together with the AUTO CONTOUR, it is the ideal

"hillside package"

3D-cleaning system

hydraulic control unit

47

Page 48

NEW

Faster offloading.

NEW: Faster discharging.

The new TUCANO model series is equipped with the new

turret auger and has a discharge rate of 105 l/s or 90l/s. With

a capacity of up to 9000 l, the grain tank is emptied in less

than two minutes. Furthermore, the new TUCANO has a

greater discharge height and reach. As a result, even large

transport vehicles can be filled without difficulty.

A corresponding range of grain tank discharge augers for

cutterbar widths up to 9.22 m is available.

NEW: Electric grain tank cover.

The grain tank cover can be opened by means of a switch on

the armrest. It is no longer necessary for the operator to leave

the cab.

Well-designed overall concept.

Many more well-thought-out details complete the overall grain

tank design concept:

− Easy grain sampling

− High overhead discharge height

− Ideal weight distribution

− Good view into grain tank

− Fast, direct offloading at up to 105 litres per second

− Smooth surfaces in the grain tank facilitate complete

emptying

Innovative: visual inspection of returns from

the operator's seat.

− The illuminated inspection window for monitoring the

returns

− Users quickly identify the combine settings which work best

for them

− This facilitates optimal utilisation of the performance

potential

The QUANTIMETER measures and checks.

The primary functions of the QUANTIMETER include

throughput measurement, moisture content measurement and

data display in CEBIS.

The throughput measurement is grain-specific. The moisture

content of the crop is monitored continuously and displayed

upon request.

Wide grain tank window Smooth surfaces in the grain tank

48

During the volume measurement in the grain elevator, a photo

cell records the filling of the individual paddles. Using

appropriate correction factors, including the lateral and

transverse tilt of the machine, the QUANTIMETER

automatically determines the precise quantity harvested.

Page 49

Grain tank | QUANTIMETER | PROFI CAM

PROFI CAM – everything in view.

All TUCANO models can be equipped with a PROFI CAM at

the end of the grain tank discharge auger tube. This camera

position has been chosen precisely to allow up to three

processes to be monitored simultaneously from the comfort of

the cab on an additional colour display or on the S10 terminal:

− Grain tank discharge auger tube deployed: transfer process

− Grain tank discharge auger tube retracted: distribution of

chopped material

− Grain tank discharge auger tube retracted: rear of machine

during reversing or on-road operation

Up to four cameras can be connected to the system and

simultaneously feed their images to the colour monitor or the

S10 terminal in the cab.

CEBIS rear camera.

The image from the rear camera fitted on the rear hood is fed

straight to the CEBIS screen. As soon as the TUCANO moves

backwards, the image from the camera is displayed

automatically.

CEBIS rear camera Image from rear camera in CEBIS

Image from PROFI CAM on

additional screen

49

Page 50

Chopped short and spread wide:

your field is clear for the next harvest.

1 Adjustable cross-cutter

2 Rotor shaft

3 Knives

4 Bolt-on rasp bar

5 Adjustable stationary knife

Short chop, even distribution.

As it leaves the straw walkers, the straw is finely chopped and

spread evenly across the full working width. The debris from

the sieve pan is fed to the heavy duty chaff spreader, which

then distributes it evenly over the field. The spreading distance

can be adjusted easily.

SPECIAL CUT.

The SPECIAL CUT straw chopper is available for all TUCANO

models as an alternative to the STANDARD CUT model.

The chopper is switched on and off by a sensor-controlled

electrohydraulic system as soon as the straw guide plate is

operated. The SPECIAL CUT has 30% more knives: 68 for

five-walker models (430 / 420 / 320) and 80 for those with six

straw walkers (450 / 440 / 340). The streamlined housing

ensures even feeding of the straw to keep power consumption

low and spreading reliable.

50

Page 51

Spread across the full working width:

ACTIVE SPREADER (TUCANO 450 / 440 / 340).

The larger the volume of straw and the cutting width, the more

precisely and evenly the straw must be spread. The ACTIVE

SPREADER by CLAAS offers you the right solution.

The mixture of chopped material and chaff is grabbed while in

motion by two counter-rotating spreading rotors, accelerated

again and distributed over a total width of more than 9.3

metres. The direction of spreading can be conveniently

controlled from the cab.

Straw management

Thus, the TUCANO ensures efficient straw spreading with

minimal effort. Both the ACTIVE SPREADER and the

SPECIAL CUT are unique in this performance class and put

the TUCANO at the very top of the upper middle segment.

The TUCANO handles straw very gently.

Take long straw, for example. Thanks to the protective

threshing and separation process, the straw retains its full

original structure, which is ideal for high-quality bedding straw.

When the chopper is switched off, the swath is layered

loosely, allowing it to dry quickly and be compacted easily into

firm bales.

If you need a chaff spreader,

you'll want the HD.

There are many advantages:

− Suitable for corn and grain – no changeover necessary

− HD components for a longer service life

− Outstanding spreading width

− Consistent crop feed in all conditions

− No influence on the cleaning air flow

− Optimal ease of access to the sieve pan with folding

chaff spreader

Swath former on the deflector

Swath former on the ACTIVE

SPREADER

Electrohydraulic actuation of the

straw chopper

51

Page 52

CLAAS POWER SYSTEMS.

Optimal drive for maximum performance:

CPS.

At CLAAS, machine development means an ongoing

effort to achieve even greater efficiency and reliability

as well as greater profitability in the field.

Of course, this applies to all aspects of a CLAAS

combine harvester. The drive system is of decisive

importance – and requires much more than just a

powerful engine.

In CLAAS POWER SYSTEMS, we have brought

together the best components to create a drive system

in a class of its own. One that always delivers the

greatest power when needed. Ideally matched to the

work systems and with fuel-saving technology that

quickly pays for itself.

It goes without saying that the TUCANO also

embodies this development philosophy: the experience

gained through 75 years of combine development has

resulted in the best ever CLAAS drive system that

delivers the best working results.

More technological landmarks and engineering

refinements: for maximum reliability even under

extreme conditions. The TUCANO is ready.

52

Page 53

CLAAS POWER SYSTEMS

53

Page 54

Increased engine output with high efficiency.

54

Fuel tank with capacity

of up to 650 l.

Three batteries for the

TUCANO:

two are wired in series

for the 24-volt engine

electronics, one

supplies power to the

12-volt on-board

electronics.

Page 55

Engine | Drive

No compromises on power or endurance.

The 7.7-litre high-performance engine in the TUCANO

complies with the Tier 4 emissions standard thanks to an

exhaust aftertreatment system and cooled exhaust gas

recirculation (EGR). In addition, the engine output of all

TUCANO models has been increased.

Conversion of nitrogen oxides by

SCR and EGR.

The Mercedes-Benz engine in the TUCANO complies with the

standard thanks to a selective catalytic reduction (SCR)

exhaust aftertreatment system. This process converts the

nitrogen oxides in the exhaust flow into pure nitrogen and

water. The urea solution necessary for this is carried in a

57-litre tank. A further reduction in nitrogen oxides is achieved

by cooled exhaust gas recirculation (EGR).

Larger cooling system with automatic dust

extraction.

The TUCANO works with an extremely efficient common

cooling system for the engine, the hydraulic system and the

climate control system. The radiator frame has been enlarged

to deliver a significant increase in cooling power.

The automatic dust extraction facilitates continuous cleaning

of the hydraulically rotating radiator frame and thus enables

optimal cooling performance. Soiling of the cooling ribs is

significantly reduced.

NEW: Air intake and air filter.

Fresh air for the engine of the new TUCANO is first drawn in

by the rotating radiator screen. Thanks to the active pre-

separation process, few particles reach the two air filters, the

size of which has been increased considerably for the new

engine. These important improvements allow maintenance

intervals to be extended significantly and downtime to be

reduced drastically.

For more information, please visit: tucano400-300.claas.com

55

Page 56

NEW

More power under all conditions.

NEW: 4-TRAC all-wheel drive.

You can control the hydrostatic ground drive of the TUCANO

– without operating a clutch or having to change gear – very

easily and conveniently with the multifunction lever. Such

operating comfort and convenience directly enhances

performance with faster turns and precise adjustment of the

travel speed to changing field conditions. Your choice for

added power: all-wheel drive. A simple touch of a button

switches to a hydraulically driven power system which keeps

you moving forward even in the most adverse terrain. The all-

wheel drive is reliable and maintenance-free.

NEW: 30% more traction from the all-wheeldrive axle.

The new all-wheel-drive axle has two central hydrostatic

motors which are integrated in the axle and are characterised

by significantly greater efficiency. The integrated design means

that there are far fewer external hydraulic lines. Less dirt can

be deposited in wet conditions and the risk of damage to the

drive is reduced to a minimum.

NEW: Larger tyres for the all-wheel-drive axle.

For even greater traction in difficult conditions and reduced

ground pressure, 600/65 R 28 or VF 620/70 R 26 tyres are

available (TUCANO 450 and 440). These two tyre options can

be combined with certain tyres with a width of 800 mm.

56

Page 57

All-wheel drive | Central lubrication system

NEW: Central lubrication system.

The central lubrication system supplies grease to practically all

lubrication service points as required. Lubrication points and

intervals only need to be programmed once. This system

differs from individual manual lubrication in that the grease is

distributed to the lubrication service points from a central

reservoir.

How you benefit:

− Reliable and controlled lubrication of all points while

machine is running

− Service life of pins and bearings is extended

− Cost savings through reduced grease consumption

and reduced wear

− Reduced maintenance work and costs

57

Page 58

All the traction you need.

Tyre technology for long-term ground

protection.

Intensive joint efforts between CLAAS and renowned tyre

manufacturers have led to the development of this tyre

technology.

Reduced transport

width with increased

contact area

58

How you benefit:

The tyres improve mobility on the road. Their greater contact

area provides more traction, less slippage and lower fuel

consumption for travel, while the lower tyre pressure reduces

ground compaction and so makes a long-term contribution to

improving soil structure.

Page 59

Tyres | Maintenance

Standard tyres

2

5857 cm

800/70 R 32 / 9000 kg IF 800/70 R 32 / 9000 kg

2.4 bar 1.6 bar

7314 cm

2

CerexBib

Tyre size Standard tyres MICHELIN CerexBib

680/85 R 32 bar 2.9 1.8

800/70 R 32 bar 2.4 1.6

Tyre size Standard tyres SVT CHO Continental

800/70 R 32 bar 2.4 1.6

Facts and figures:

− Tyre pressure can be reduced by between 0.6 and 1.1 bar

with full load capacity compared to standard tyres of the

same size – this represents a reduction of 35%

− The tyres have the contact area of standard tyres two sizes

larger, providing 22% more ground contact with the same

transport width

− Tyres on drive axle: 800/70 R 32 and 680/85 R 32, tyres

on steering axle: 620/70 R 26 and 520/80 R 26

Maintenance. Could you do with less of it?

− Pivoting radiator frame for fast manual cleaning

− Large, continuous side doors for unimpeded access

− Easy access to the engine compartment and other

maintenance areas with a mobile, foldable ladder

− Fully folding rear hood

− Compressed air system

− Lubrication banks

− Storage box for hand tools, for example

− Long service intervals

Accessibility,

right side

Accessibility,

left side

59

Page 60

More service from us.

More success for you.

In the best hands.

CLAAS dealers are among the most efficient agricultural

technology companies in the world. Our service teams are

ideally qualified and equipped with the all-important special

tools and diagnostic systems. CLAAS Service stands for high-

quality work which meets all your expectations with regard to

expertise and reliability.

CLAAS ORIGINAL.

Long live your machine.

Members of the First CLAAS Service teams from CLAAS sales

partners worldwide are available round the clock to provide a

full spare parts supply and reliable service. They are on hand

to assist you at any time, with expert knowledge, experience

and a genuine commitment to you and your machine, and can

also supply CLAAS ORIGINAL parts, characterised by top

quality, superb function and a long service life, within very

short timeframes.

We're there for you wherever you need us.

Our central parts warehouse in Hamm (Germany) delivers all

CLAAS ORIGINAL parts quickly and reliably all over the world.

The dense network of CLAAS dealers around the world

ensures that parts reach their destination as quickly as

possible – wherever you happen to be.

Invest in the best.

Invest in success!

Increasing cost pressure and narrow timeframes during the

harvesting season call for measures with which you can

ensure the availability of your machine – far beyond the first

twelve months covered by the statutory warranty. With this in

mind, CLAAS offers individual service products with easily

predictable costs which ensure that you can count on a high

degree of reliability and efficiency. With the CLAAS post-

harvest check, maintenance contract and MAXI CARE

(warranty extension) service products we can tailor a service

package to meet your specific requirements. This allows you

to work on the basis of predictable costs while minimising the

risk of a machine breakdown.

TELEMATICS.

Thanks to TELEMATICS, our service staff have access to all

the performance and electronic data of your CLAAS machine

via GPRS and the internet. This means that problems can

often be resolved remotely, thus reducing annoying downtime.

60

Page 61

First CLAAS Service

61

Page 62

The TUCANO 400 at a glance.

62

Page 63

Technology in detail

1 GPS PILOT S7 or S10, GPS PILOT FLEX

2 Comfort cab

3 CEBIS with automatic crop setting

4 Turret auger delivering up to 105 l/s

5 LASERPILOT

6 VARIO cutterbars / NEW: VARIO 930 and 770

with integrated rapeseed plates

7 AUTO CONTOUR

8 MultiCoupler

9 V channel

10 APS threshing system

11 Hydraulic concave adjustment for all models

12 Hydraulic concave overload protection

13 Turbine fan

14 Intensive separation system

15 HD chaff spreader

16 SPECIAL CUT chopper

17 ACTIVE SPREADER

18 PROFI CAM

19 Mercedes-Benz engines with Tier 4 emissions

standard

20 All-wheel-drive axle with new drive concept

63

Page 64

The TUCANO 300 at a glance.

64

Page 65

Technology in detail

1 GPS PILOT S7 or S10, GPS PILOT FLEX

2 Comfort cab

3 CEBIS with automatic crop setting

4 Turret auger delivering 90 l/s

5 LASERPILOT

6 VARIO cutterbars / NEW: VARIO 930 and 770

with integrated rapeseed plates

7 AUTO CONTOUR

8 MultiCoupler

9 V channel

10 CLAAS threshing system

11 Hydraulic concave adjustment for all models

12 Hydraulic concave overload protection

13 Radial blower

14 Intensive separation system

15 HD chaff spreader

16 SPECIAL CUT chopper

17 Straw spreader

18 PROFI CAM

19 Mercedes-Benz engines with Tier 4 emissions

standard

20 All-wheel-drive axle with new drive concept

65

Page 66

The power of persuasion.

A wealth of impressive features.

Cab.

− The sound-insulated, spacious VISTA CAB provides an

exceptionally quiet environment which allows you to focus

on your work

− Visual returns checked from the operator's seat through the

lit inspection window

− CMOTION, the multifunction lever, CEBIS, TELEMATICS,

yield mapping and GPS PILOT ensure innovative and

convenient control and performance monitoring

Cutterbars.

− VARIO cutterbars in widths up to 9.22 m give up to 10%

better performance by optimising the crop flow

− AUTO CONTOUR is an intelligently controlled cutterbar

which automatically compensates for undulations in the

direction of travel as well as those in the transverse

direction

− Especially versatile thanks to the standard and VARIO

cutterbars, CONSPEED, SUNSPEED, RAKE UP, folding

cutterbar and FLEX cutterbar

− New VARIO V 930 and V 770 cutterbars with an adjustment

range of 700 mm thanks to integrated rapeseed plates

Threshing technology.

− Up to 20% more throughput with the APS threshing system

− 7/18 concave for maximum separation, optimised grain

quality and reduced returns

− APS. A threshing technology unique in its class

− 3D-cleaning system for slopes up to 20%

− The grain tank capacity of up to 9000 litres reduces

offloading frequency in the field while the high offloading

rate reduces the time to empty the tank. Together, these

features considerably increase your daily output

− ACTIVE SPREADER for precise, even straw distribution

over the entire working width

CPS – CLAAS POWER SYSTEMS.

− Mercedes-Benz OM 936 offers reliable reserves of power

for the most demanding field conditions

− Tyre technology for optimal ground protection with a limited

transport width

− New all-wheel drive axle with 30% more traction

− Easy and convenient access to maintenance points

− First CLAAS Service around the clock

66

Page 67

TUCANO 450 440 430 420 340 320

Threshing system

APS acceleration and pre-separation ● ● ● ● – –

Accelerator rpm 80% of the threshing drum – –

MULTICROP ● ● ● ● ● ●

Drum width mm 1580 1580 1320 1320 1580 1320

Drum diameter mm 450 450 450 450 450 450

Drum speed rpm 650–1500 650–1500 650–1500 650–1500 650–1500 650–1500

with reduction gear rpm 280–1500 280–1500 280–1500 280–1500 280–1500 280–1500

7/18 concave ○ ○ ○ ○ – –

Pre-separation wrap angle degrees 60 60 60 60 – –

Concave wrap angle degrees 151 151 151 151 121 121

Externally folding deawner plates ● ● ● ● – –

Hydraulic concave adjustment ● ● ● ● ● ●

Large stone trap ● ● ● ● ● ●

Residual grain separation

Straw walkers number 6 6 5 5 6 5

Straw walker steps number 4 4 4 4 4 4

Straw walker length m 4.4 4.4 4.4 4.4 4.4 4.4

2

Straw walker area m

Separation area m

7 7 5.8 5.8 7 5.8

2

8.75 8.75 7.26 7.26 8.17 6.78

2 intensive separation systems ● ● ● ● ● ○

Crop cleaning

Removable preparation floor ● ● ● ● ● ●

Fan 6-turbine 6-turbine 4-turbine 4-turbine 6-turbine Radial blower

Fan adjustment, electric ● ● ● ● ● ●

Dual ventilated step ● ● ● ● – –

Divided, counterdirectional sieve pan ● ● ● ● ● ●

3D-cleaning system ○ ○ ○ ○ ○ ○

2

Total sieve area m

5.65 5.65 4.70 4.70 5.10 4.25

Sieve adjustment, electric ○ ○ ○ ○ ○ ○

Returns feed to accelerator ● ● ● ● ● ●

Returns visible from the cab on the go ● ● ● ● ● ●

Grain tank

Capacity l 9000 8500 8000 7500 7500 6500

Unloading auger swivel angle degrees 99 99 99 99 99 99

Discharge rate l/s 105 105 90 90 90 90

QUANTIMETER yield meter ○ ○ ○ ○ ○ ○

Chopper

SPECIAL CUT 80-blade straw chopper ○ ○ – – ○ –

SPECIAL CUT 68-blade straw chopper – – ○ ○ – ○

STANDARD CUT 60-blade straw chopper ○ ○ – – ○ –

STANDARD CUT 52-blade straw chopper – – ○ ○ – ○

HD chaff spreader ○ ○ ○ ○ ○ ○

Straw spreader ○ ○ ○ ○ ○ ○

ACTIVE SPREADER ○ ○ – – ○ –

Running gear

4-TRAC ○ ○ ○ ○ ○ ○

EASY

CEBIS ● ● ● ● ● ●

TELEMATICS ○ ○ ○ ○ ○ ○

Job management ○ ○ ○ ○ ○ ○

Yield mapping ○ ○ ○ ○ ○ ○

GPS PILOT, LASER PILOT, AUTO PILOT ○ ○ ○ ○ ○ ○

TUCANO 450 440 430 420 340 320

Engine

Manufacturer Mercedes-Benz Mercedes-Benz Mercedes-Benz Mercedes-Benz Mercedes-Benz Mercedes-Benz

Emissions standard Stage IV (Tier 4)

Model OM 936 LA OM 936 LA OM 936 LA OM 936 LA OM 936 LA OM 936 LA

Cylinders / displacement no./l S 6/7.7 S 6/7.7 S 6/7.7 S 6/7.7 S 6/7.7 S 6/7.7

Maximum output (ECE R 120) kW/hp 230/313 210/286 210/286 180/245 210/286 180/245

Exhaust aftertreatment SCR + EGR ● ● ● ● ● ●

Urea tank, 57 l ● ● ● ● ● ●

Air compressor ○ ○ ○ ○ ○ ○

Engine control electronic electronic electronic electronic electronic electronic

Fuel tank capacity, 500 l – ● ● ● ● ●

Fuel tank capacity, 650 l ● ○ ○ ○ ○ ○

Weights

(can vary depending on equipment) without cutterbar,

kg 12,750 12,750 12,150 12,150 12,050 11,050

chopper and chaff spreader

TUCANO 450 440 430 420 340 320

Tyres on the drive axle

Tyre size External width

800/65 R 32 MI m 3.75 3.75 3.49 3.49 3.75 3.49

IF800/70 R 32 MI m 3.73 3.73 3.47 3.47 – 3.47

800/70 R 32 m 3.73 3.73 3.47 3.47 – 3.47

800/65 R 32 m 3.83 3.83 3.47 3.57 3.83 3.56

30.5 LR 32 m – – 3,49 3,49 – 3,49

710/75 R 34 m 3.62 3.62 3.36 3.36 3.62 3.36

IF 680/85 R 32 CFO m 3.48 3.48 3.21 3.21 3.48 3.21

680/85 R 32 m 3.48 3.48 3.21 3.21 3.48 3.21

650/75 R 32 m 3.47 3.47 3.21 3.21 3.47 3.21

620/75 R 30 F16 m – – 2.99 2.99 – 2.99

620/75 R 30 F20 m – – – – – 3.23

650/75 R 32 + dual 18.4 R 38 m 4.88 4.88 – – – –

Steel half track for rice 900 mm m 4.17 4.17 – – – –

TUCANO 450 440 430 420 340 320

Tyres on the steering axle

Tyre size External width

14.5/75-20 IMP m – – 2.95 2.95 – 2.95

16.5/85-24 IMP m 3.26 3.26 3.11 3.11 3.26 3.11

440/80 R 24 MI m 3.26 3.26 3.11 3.11 3.26 3.11

500/70 R 24 IMP m 3.32/ 3.46

1

3.32/ 3.4613.17/ 3.2613.17/ 3.2613.32/ 3.4613.17/ 3.26

1

500/70 R 24 MI m 3.32 3.32 3.17 3.17 3.32 3.17

1

500/85 R 24 IMP m 3.34/ 3.48

3.34/ 3.4813.19/ 3.2813.19/ 3.2813.34/ 3.4813.19/ 3.28

VF 520/80 R 26 m 3.34/ 3.4813.34/ 3.4813.19/ 3.2813.19/ 3.2813.34/ 3.4813.19/ 3.28

600/55-26.5 IMP m 3.61/ 3.7

600/65 R 28 IMP m 3.7

VF620/70 R 26 MI m 3.7

1 All-wheel-drive axle – 4-TRAC

1

1

5945 mm (short)

1

6836 mm (long)

7315 mm (extra long)

7333 mm (XL)

7900 mm (XXL)

3.61/ 3.7

1

3.7

1

3.7

1

– – – –

– – – –

– – – –

1

1

CLAAS continually develops its products to meet customers' requirements, so all products are subject to change without notice. All descriptions and specifications in this brochure should be considered

approximate and may include optional equipment that is not part of the standard specifications. This brochure is designed for worldwide use. Please consult your nearest CLAAS dealer and their price

list for local specification details. Some protective panels may have been removed for photographic purposes in order to present the function clearly. To avoid hazards, never remove these protective

panels yourself. Please refer to the relevant instructions in the operator's manual in this regard.

All technical specifications relating to engines are based on the European emission regulation standards: Stage. Any reference to the Tier standards in this document is intended solely for information

purposes and ease of understanding. It does not imply approval for regions in which emissions are regulated by Tier.

4583 mm

4440 mm

4435 mm

4314 mm

4089 mm

VARIO 540

VARIO 600

VARIO 660

VARIO 770

● Standard ○ Option □ Available – Not available● Standard ○ Option □ Available – Not available

VARIO 930

Page 68

Cutterbars

Front attachments

VARIO cutterbars V 930, V 770, V 660, V 600, V 540

CERIO cutterbars CERIO 930, CERIO 770

Standard cutterbars C 660, C 600, C 540, C 490, C 430, C 370

Rapeseed attachments For all standard and VARIO cutterbars, not available for CERIO cutterbars

Folding cutterbars C 540, C 450

Maize picker rows 8 (TUCANO 450 440), 6

SUNSPEED rows 12 and 8

FLEX cutterbars S 900, S 750, S 600, S 510, S 450

MAXFLO 1050, 900

Standard rice cutterbars R 660, R 600, R 540, R 490, R 430

VARIO rice cutterbars V 930 and V 770 available as HD versions with rice harvesting accessory pack, V 660, V 600, V

540

CERIO rice cutterbars CERIO 930 and 770 available as HD versions with rice harvesting accessory pack

SWATH UP SWATH UP 450

Standard cutterbars

Effective cutting widths C 660 (6.68 m), C 600 (6.07 m), C 540 (5.46),

CERIO 930 (9.22 m), CERIO 770 (7.70 m)

C 490 (4.92), C430 (4.32), C 370 (3.71)

Drive Single-side belt drive Single-side gear drive

Folding dividers ● ●

Spacing: knife bar – intake auger mm 580 480–680, manually adjustable

Cutting frequency strokes/min 1120 1218

Multifinger intake auger ● ●

Reverser, hydraulic ● ●

Automated cutterbar control

CONTOUR ● ●

AUTO CONTOUR ○ ○

Reel speed control ● ●

Reel height adjustment ● ●

Parked position – ●

Replacement knife bar ● ●

Crop lifters ● ●

VARIO cutterbars

Effective cutting widths V 930 (9.22 m), V 770 (7.70 m) V 660 (6.68 m), V 600 (6.07 m), V 540 (5.46 m)

Drive Single-side gear drive Single-side belt drive

Folding dividers ● ●

Spacing: knife bar – intake auger mm 480–1180, 700 mm continuously adjustable

480–780, for rapeseed 1080

travel range

Knife bar Undivided Undivided

Cutting frequency strokes/min 1218 1120

Reel and auger bearing Undivided reel and auger Undivided reel and auger

Intake auger diameter 660 580

Automated cutterbar control

CONTOUR ● ●

AUTO CONTOUR ○ ○

Reel speed control ● ●

Reel height adjustment ● ●

Reel levelling system ● ●

Table positioning ● ●

Parked position ○ –

Replacement knife bar ● ●

Crop lifters ● ●

● Standard ○ Option □ Available – Not available

Page 69

CLAAS KGaA mbH

Postfach 1163

33416 Harsewinkel

Deutschland

Tel. +49 (0)52 47 12-0

claas.com

HRC / 114012000714 KK DC 0714 / 00 0256 175 7

Loading...

Loading...