Claas Targo K50, Targo K60, Targo K70 Repair Manual

HYDRAULICS

ELECTRICS

TECHNICAL DATA

CLCL

CL

CLCL

AA

AS TAS T

A

AS T

AA

AS TAS T

ARGO K50 K60 K70ARGO K50 K60 K70

ARGO K50 K60 K70

ARGO K50 K60 K70ARGO K50 K60 K70

The machines in this handbook are designed essentially for agricultural and associated applications. This is

their intended use.

Any modifications made to the machine without prior written approval from CLAAS or if the machine is used

in any way contrary to the intended use or if the machine is not properly driven or maintained then the

Company will not accept any liability whatsoever for any damage or injury (whether direct or consequential).

The method of operation and maintenance specified in this handbook should be strictly adhered to.

For your parts requirements, it is essential that only genuine CLAAS parts are fitted. Any resultant damage

from non-genuine parts will invalidate your machine warranty.

CLAAS operates a policy of continuous improvement to its products and reserve the right to change specifi-

cations and equipment without notice. Therefore some information within this handbook may differ from your

machine.

This manual is designed to service machines:

from Serial No. 51200011

up to Serial No. 51200727.

from Serial No. K5D00100

from Serial No. K6D00100

from Serial No. K7D00100

CONTENTS

INTRODUCTION

General

Machine identification

Health and Safety

SAFETY WARNINGS

SECTION 1

HYDRAULICS

Description and Operation 1.1

Description 1.1

General 1.1

Dumping (dissipation) of hydraulic pressure 1.1

To dump brake system pressure 1.1

To dump a system pressure 1.1

Hydraulic Circuit - Single Circuit Braking (up to Machines S/No.51200317) 1.2

Hydraulic Circuit - Single Circuit Braking (from Machines S/No.51200318 to 51200471) 1.4

Hydraulic Circuit - Single Circuit Braking (from Machines S/No.51200472 to 51200551) 1.6

Hydraulic Circuit - Single Circuit Braking (from Machines S/No.51200552 to 51200727) 1.8

Hydraulic Circuit - Dual Circuit Braking (up to Machines S/No.51200317) 1.10

Hydraulic Circuit - Dual Circuit Braking (from Machines S/No.51200318 to 51200471) 1.12

Hydraulic Circuit - Dual Circuit Braking (from Machines S/No.51200472 to 51200551) 1.14

Hydraulic Circuit - Dual Circuit Braking (from Machines S/No.51200552 to 51200727) 1.16

Components

General 1.18

Hydraulic tank 1.18

Suction line connections to hydraulic tank 1.18

Return hose connections to hydraulic tank (up to Machines S/No.51200471) 1.18

Return hose connections to hydraulic tank (from Machines S/No.51200472) 1.18

Hydraulic pump (load sensing) 1.19

Pump compensator (load sensing) 1.19

Tank filter 1.19

Filler/Breather 1.19

Auxiliary hydraulic pump 1.19

Fan motor (up to Machines S/No.51200471) 1.20

Fan reverse motor (from Machines S/No.51200472) 1.20

Pressure reducing valve (PRV) for the parking brake (up to Machines S/No.51200551) 1.21

Pressure filter 1.21

Single circuit brake pressure servo valve (MICO) (up to Machines S/No.51200471) 1.22

Duel circuit brake pressure servo valve (MICO) (up to Machines S/No.51200471) 1.22

Single circuit brake pressure servo valve (SAFIM) (from Machines S/No.51200472) 1.23

Duel circuit brake pressure servo valve (SAFIN) (from Machines S/No.51200472) 1.23

Accumulator(s) 1.24

Pressure switch 1.24

Pressure switch (transmission dump) 1.24

Front axle 1.25

Steering cylinder (front) 1.25

Pressure switch (brake light) 1.25

Pressure switch (parking brake) 1.26

Rear axle 1.26

Steering cylinder (rear) 1.26

Non-return valve 1.26

Steering valve 1.27

Steering in Neutral position 1.27

Steering in Operation 1.28

Pressure relief valve 1.28

Steering selector valve 1.29

CONTENTS

Components (continued)

Control valve 1.30

Outlet section (PVP) 1.31

Function 1.31

Extension section 1.32

Function 1.32

Crowd section 1.33

Function 1.33

Lift section 1.34

Function 1.34

1st service/2nd service section 1.35

Function 1.35

Inlet section (PVSP) section 1.36

Function 1.36

Accumulator 1.38

Tap 1.38

Trailer brake valve 1.38

Trailer brake coupling 1.38

Extension cylinder 1.39

Load control valve 1.39

Crowd cylinder 1.40

Load control valve 1.40

Compensator cylinder 1.41

Lift cylinder 1.41

Load control valve 1.42

Diverter valve 1.43

Manifold 1.43

Autohitch cylinder 1.44

1st service couplings 1.44

2nd service couplings 1.44

Trailer tipping connection 1.44

St art-up valve 1.44

Non-return valve (up to Machine S/No.51200317 only) 1.45

Pressure relief valve (up to Machine S/No.51200471 only) 1.45

Breather 1.45

Parking brake valve (from Machine S/No.51200552 only) 1.46

Fan reverse valve (from Machine S/No.51200472 only) 1.47

Oil cooler (from Machine S/No.51200472 only) 1.48

Operation 1.49

General 1.49

Relief valves 1.49

System pressure checks 1.50

LS pump 1.52

LS pump compensator operation 1.52

Standby position (engine switched off) 1.53

Standby position (engine started) 1.54

Pump goes into delivery 1.56

Constant volumetric flow 1.58

Downstroking of the pump 1.59

Maximum pressure limiting (pressure relief valve function) 1.45

Adjusting the pump 1.63

CONTENTS

Maintenance 1.64

Torque tightening 1.64

Hydraulic level 1.66

Check 1.66

Hydraulic tank 1.67

Removal 1.67

Installation 1.67

Hydraulic pump (LS) 1.68

Removal 1.68

Installation 1.68

Auxiliary hydraulic pump 1.69

Removal 1.69

Installation 1.69

Fan motor (up to Machines S/No.51200471 only) 1.70

Removal 1.70

Installation 1.70

Fan motor bearings (up to Machines S/No.51200471 only) 1.71

Removal 1.71

Installation 1.71

Fan motor (from Machines S/No.51200472 only) 1.72

Removal 1.72

Installation 1.72

Fan drive bearings (from Machines S/No.51200472 only) 1.73

Removal 1.73

Installation 1.73

Fan reverse valve (from Machines S/No.51200472 only) 1.74

Removal 1.74

Installation 1.74

Parking brake valve (from Machines S/No.51200472 only) 1.75

Removal 1.75

Installation 1.75

Hydraulic filter 1.76

Removal 1.76

Installation 1.76

Brake valve (MICO) (up to Machines S/No.51200471 only) 1.77

Operation 1.77

Brake valve (SAFIM) (from Machines S/No.51200472 only) 1.77

Operation 1.77

Single brake valve (MICO) (up to Machines S/No.51200471 only) 1.78

Removal 1.78

Installation 1.78

Servicing 1.79

Dismantling 1.79

Assembly 1.80

Single brake valve (SAFIM) (from Machines S/No.51200472 only) 1.81

Removal 1.81

Installation 1.81

Servicing 1.82

Dismantling (General) 1.82

Assembly (General) 1.82

Dismantling (Brake master module) 1.83

Assembly (Brake master module) 1.83

Dismantling (Brake valve module) 1.84

Assembly (Brake valve module) 1.84

CONTENTS

Dual brake valve (MICO) (up to Machines S/No.51200471 only) 1.85

Removal 1.85

Installation 1.85

Servicing 1.86

Dismantling 1.86

Assembly 1.88

Dual brake valve (SAFIM) (from Machines S/No.51200472 only) 1.89

Removal 1.89

Installation 1.89

Servicing 1.90

Removal and installation (General) 1.90

Dismantling (Brake master module) 1.90

Assembly (Brake master module) 1.90

Dismantling (Brake valve module) 1.91

Assembly (Brake valve module) 1.91

Trailer brake valve 1.92

Removal 1.92

Installation 1.92

Servicing 1.93

Dismantling 1.93

Assembly 1.94

Brake system bleeding 1.95

General 1.95

Diverter valve 1.96

Removal 1.96

Installation 1.96

Manifold 1.97

Removal 1.97

Installation 1.97

Control valve 1.98

Removal 1.98

Installation 1.98

Servicing 1.99

Dismantling 1.99

Assembly 1.99

Spool sections 1.101

General 1.101

Dismantling 1.101

Assembly 1.101

Inlet section (PVSP) 1.103

General 1.103

Dismantling 1.103

Assembly 1.103

Outlet section (PVP) 1.104

General 1.104

Dismantling 1.104

Assembly 1.104

Steering 1.105

Description 1.105

Operation 1.105

Checking the steering system 1.107

Steering cylinder 1.107

Steering unit (OSPF) 1.107

Servicing 1.107

Steering valve assembly 1.108

Removal 1.108

Installation 1.108

Servicing 1.109

Dismantling 1.109

Assembly 1.109

CONTENTS

Hydraulic cylinders 1.110

Extension cylinder 1.110

Removal 1.110

Installation 1.111

Crowd cylinder 1.112

Removal 1.112

Installation 1.112

Compensator cylinder 1.113

Removal 1.113

Installation 1.113

Lift cylinder 1.114

Removal 1.114

Installation 1.114

Extension, crowd, compensator and lift cylinder 1.115

Servicing 1.115

Dismantling 1.115

Assembly 1.115

Autohitch cylinder 1.117

Removal 1.117

Installation 1.117

Dismantling 1.117

Assembly 1.118

Carriage locking cylinder 1.119

Removal 1.119

Installation 1.119

Dismantling 1.119

Assembly 1.120

Steering cylinder 1.121

Removal 1.121

Installation 1.121

Dismantling 1.122

Assembly 1.122

SECTION 2

ELECTRICS

Circuit diagrams

Circuit diagram key - Wiring terminations 2.1

Circuit diagram key - Components 2.2

Circuit diagram key - General Information 2.4

Power generation, S tarting, Non APC (Sheet 1) 2.4

Power generation, Starting, With APC (Sheet 1A) 2.5

Hydraulic controls, Steering control, Safe load indicator , Large lock out relay (Sheet 2) 2.6

Hydraulic controls, Steering control, Safe load indicator , Mini lock out relay (Sheet 2A) 2.7

Wipers, Washers, Horn, Worklights (Sheet 3) 2. 8

Wipers, Washers, Horn, Worklights combined boom/side worklights, Switching (Sheet 3A) 2.9

Head/side lights, Fog lights, Number plate lights, Head Flasher (Sheet 4) 2.10

Head/side lights, Fog lights, Number plate lights, Head Flasher (Sheet 4A) 2.11

Turn indicators, Reverse lamps, S teer sensors, S top lights, Radio (Sheet 5) 2.12

Inst display , Sensor switches, Fan motor , Aircon, Interior light, Beacon, Fuel Sender ,

Fan reverse, Hydraulic temp. (Sheet 6) 2.13

APC 50 with Ign controlled APC bat feed, Screened sensor cable, P/brake link (Sheet 7) 2.14

Non APC,Correct P/brake and trans dump, No P/brake controller , Circuit link (Sheet 7A) 2.15

Chassis loom (Illustration) 2.16

Engine loom (Illustration) 2.17

Cab loom (Illustration) 2.18

CONTENTS

Longitudinal stability indicator 2.19

Description 2.19

Sensor 2.20

Specification 2.20

Display Module 2.20

Specification 2.20

Testing and adjustment 2.23

Troubleshooting 2.23

Visual inspection 2.23

System check 2.24

Error indications from the display module 2.25

Sensor - test 2.25

General 2.25

Procedure to test the operation of the sensor 2.26

Procedure to install a sensor 2.27

Procedure to replace the display module 2.28

Calibration 2.29

Calibration procedure 2.29

Resetting the zero point 2.31

Testing load sensor function 2.32

Functional test of load sensor indicator 2.32

Procedure 2.33

Main instrument panel 2.34

Description 2.34

Removal 2.34

Installation 2.34

Functional description 2.35

Solo control joystick 2.36

Removal 2.36

Installation 2.36

Starter 2.37

Removal 2.37

Installation 2.37

Fusebox and relays 2.38

Description 2.38

Removal 2.38

Installation 2.38

Alternator 2.40

Alternator drive belt check 2.40

Removal 2.41

Installation 2.41

Automatic powershift 2.42

Automatic powershift controller 2.42

Removal 2.42

Installation 2.42

Forward / Neutral / Reverse (FNR) switch assembly 2.43

Removal 2.43

Installation 2.43

CONTENTS

SECTION 3

TECHNICAL DATA

Dimensions 3.1

Performance 3.2

Machine speed (km/hr) for 106 hp 3.2

Carriage 3.3

Cycle time 3.3

Engine 3.4

Cooling 3.4

Transmission 3.4

Tyres 3.4

Hydraulics 3.5

Electrics 3.5

Capacities 3.5

INTRODUCTION

General

The contents of this Repair Manual, although correct at the time of publication, may be subject to alteration

by the manufacturer without notice.

This manual assumes that maintenance personnel have a sound knowledge of workshop practices and

safety procedures associated with the repairs of this type of machine. This manual is designed to assist with

the more specialised information required for removal and strip-down of major components.

It is recommended that the relevant part of this Repair Manual is studied carefully before proceeding with

any maintenance.

Machine identification

To make sure that the correct parts are obtained, always quote the machine Serial Number when ordering

parts.

Health and Safety

To prevent injury to personnel and damage to equipment and machinery, care must be taken to operate in a

safe manner. Read the Safety Warnings that follow and always work in a safe manner and obey the relevant

Warnings.

Throughout this manual and on the machine there are safety notes. Each note starts with a single word. The

meaning of these single words is as follows:

Identifies a hazard exists. If proper precautions are not taken, it is highly probable that the

operator (or others) could be killed or seriously injured.

Identifies a reminder of safety practices. Failure to observe these safety practices could result

in injury to the operator (or others) or damage to the machine.

In general these notes are used to indicate that the procedures being described in the manual must be

followed to avoid serious injury or death to yourself or others. The notes are also used to protect the machine from unsafe maintenance practices.

NOTE: An identification number in bold type, after an item, refers to the number of that item in the main

hydraulic schematic illustration.

SAFETY WARNINGS

Always wear correct fitting protective clothing. Loose or baggy clothing can be extremely

dangerous when operating or maintaining a machine.

Where possible, only work on or close to engines or machinery when they are stopped. If this

is not practical, remember to keep tools, test equipment and all parts of your body well away

from moving parts.

Avoid contact with exhaust pipes and exhaust manifolds when the engine is running; these

can be very hot.

Many liquids used on this machine are harmful if taken internally or splashed into the eyes. In

the event of accidentally swallowing oil, diesel fuel, anti-freeze, battery acid etc., DO NOT

induce vomiting, but OBTAIN QUALIFIED MEDICAL ASSISTANCE IMMEDIATELY.

Always obtain advice before mixing oils; some are incompatible.

Never run an engine in an enclosed space unless an exhaust extraction system is used.

Always Disconnect battery cables before using an external charger to prevent damage to

electrical system components.

Always Disconnect battery cables before working on the electrical system to prevent injury

caused by electric shock.

When it is necessary to work on the electrical system with power on, for fault diagnosis,

always have a safety man in attendance

Any dust found on the machine or produced during work on the machine should be removed

by extraction, not by blowing. Dust waste should be dampened, placed in a sealed container

and marked for safe disposal.

Always dump pressure from the hydraulic system before carrying out any maintenance or

adjustment (refer to page 1.1).

Never leave the machine unattended with pressure in the system.

Fine jets of hydraulic fluid at high pressure can penetrate the skin. Do not use your fingers to

check for hydraulic fluid leaks. Do not put your face close to suspected leaks. If hydraulic

fluid penetrates your skin OBTAIN QUALIFIED MEDICAL ASSISTANCE IMMEDIATELY.

Never allow unqualified personnel to attempt to remove or replace any part of the machine.

Always use the correct lifting equipment to remove large or heavy components.

Never attempt to lift or hold up the machine using the lash-down points.

SECTION 1

HYDRAULICS

HYDRAULICS 1.1

DESCRIPTION AND OPERATION

DESCRIPTION

General

The hydraulic system supplies the power for boom

manipulation, attachments, brakes and steering.

A hydraulic oil reservoir has a filter breather cap and

supplies the main and auxiliary hydraulic pumps.

The reservoir is also fitted with a sight gauge. With the

boom in the lower position, retracted and with the carriage

tilted forward, the oil level will be visible in the gauge

above the red line.

The main hydraulic pump is driven from the engine

gearbox and is of the variable displacement type.

Pressurized oil from the hydraulic pump is directed to the

hydraulic control valve assembly (PVG). The control

valve is modular in construction and combines individual

sections (slices), each with a different use. At one end

of the control valve is the priority module (PVSP), which

controls the supply of hydraulic oil to the steering and

brake systems. The remaining oil is supplied to those

sections of the control valve that control each boom

service.

Dumping (dissipation) of hydraulic

pressure

Always dump all hydraulic pressure

from the system before servicing any

hydraulic component.

Ensure there is sufficient space and

headroom around machine before

operating any hydraulic control.

To dump brake system pressure

1. Stop the engine.

2. Make sure the machine is parked on firm and

level ground and chock the wheels.

3. Turn the ignition switch to position (1).

4. Set the parking brake switch, if necessary, to the

parking brake applied position.

The brakes, steering and boom services each supply a

load-sensing signal, hydraulically, to the main hydraulic

pump. This maintains the optimum supply of oil to those

services.

The auxiliary hydraulic pump is driven by the engine

timing case gears and supplies pressurized oil to the

motor of the engine cooling fan. It also supplies oil to the

front axle parking brake units, to keep the parking brake

off. When this hydraulic pressure is released, spring

pressure applies the parking brake.

The hydraulic tank is divided into clean and dirty sides by

a mesh filter. A low-pressure filter is installed in the oil

supply to the cooling fan system. This filter constantly

filters the hydraulic fluid and a blockage indicator, installed

in the filter, operates a warning light in the cab when

servicing is required.

Modifications, such as the introduction of a reverse

cooling fan or different brake servo valves, will change

the basic layout of the system. To obtain the correct

component layout you must refer to the applicable

schematic illustration, which can be located using the

batch Serial Number (S/No.) for the particular machine.

5. Press the brake pedal repeatedly until the brake

charge warning lamp illuminates.

6. Press the brake pedal a further twenty times to

ensure that residual pressure in the brake system is

fully dissipated.

7. Turn the ignition switch to off.

To dump a system pressure

NOTE: This procedure applies to all machine hydraulic

systems, except brakes.

1. Stop the engine.

2. Make sure the machine is parked on firm and

level ground and chock the wheels.

3. Turn the ignition switch to position ‘I’.

3. Operate the applicable system until all hydraulic

pressure has been dissipated.

4. Turn the ignition switch to off.

HYDRAULICS 1.2

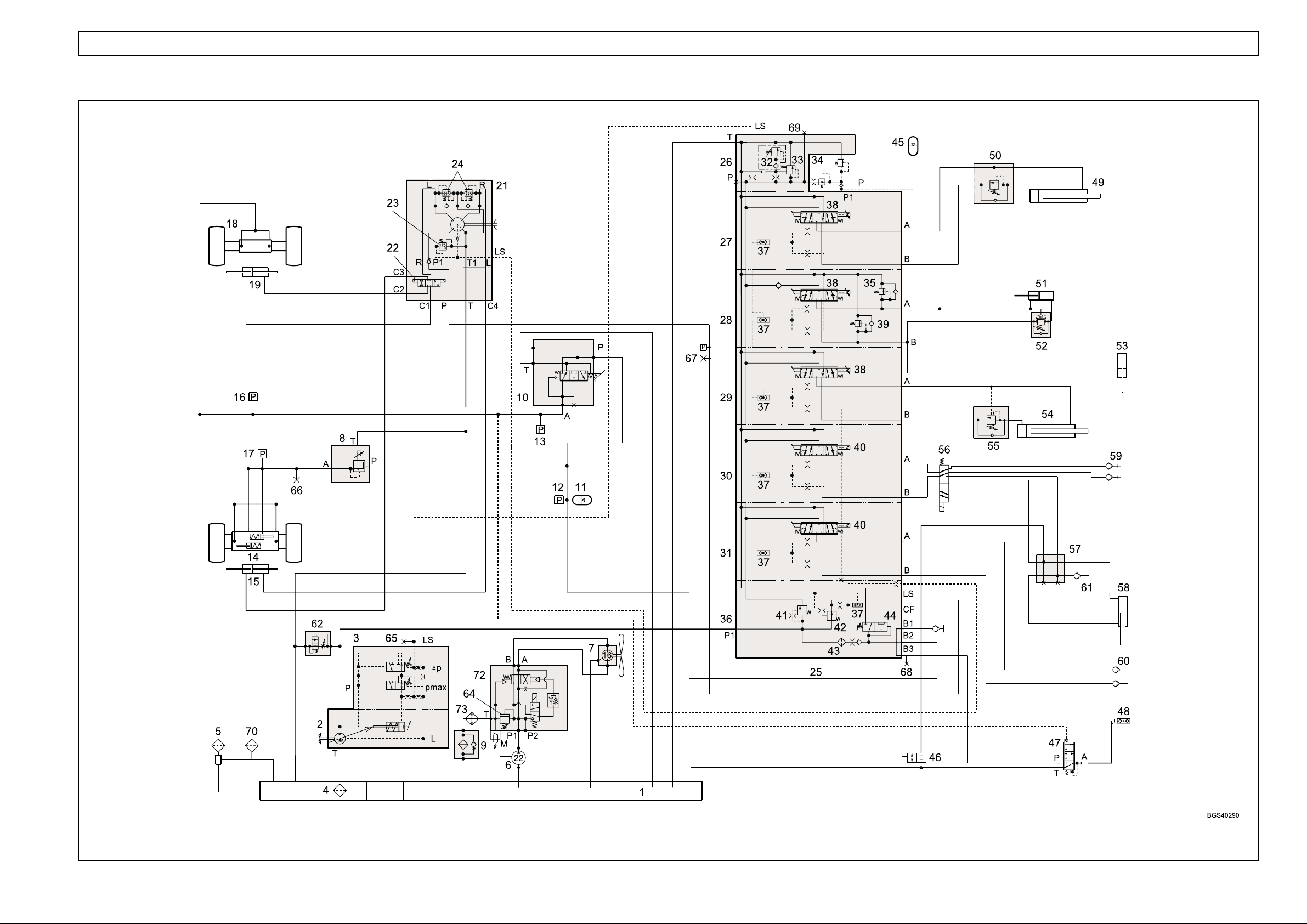

HYDRAULIC CIRCUIT - SINGLE CIRCUIT BRAKING (up to Machine S/No.51200317)

HYDRAULICS 1.3

Key to hydraulic circuit - single circuit braking

1. Hydraulic tank (reservoir)

2. Hydraulic pump, load sensing (LS)

3. LS pump compensator

4. Gauze filter (Not Serviceable)

5. Filler/breather

6. Auxiliary hydraulic pump

7. Fan motor

8. Pressure reducing valve (parking brake control)

9. Pressure filter

10. Brake servo valve

11. Accumulator

12. Pressure switch (116 bar)

13. Pressure switch (15 bar)

14. Front axle (park brake actuators)

15. Steering cylinder (front)

16. Pressure switch (5 bar)

17. Pressure switch (16 bar)

18. Rear axle

19. Steering cylinder (rear)

20. Non-return valve

21. Steering control valve (Danfoss OSPF)

22. Steering selector valve (attached to OSPF

valve)

23. Pressure relief valve (175 bar)

24. Shock valve (225 - 245 bar)

25. Hydraulics control valve (PVG 32)

26. Outlet section (PVP)

27. Extension section

28. Crowd/compensator section

29. Lift section

30. 1st auxiliary section (carriage/autohitch)

31. 2nd auxiliary section

32. Pressure relief valve (290 bar)

33. Pressure raising spool

34. Pilot valve

35. Shock valve (175 bar)

36. Inlet section (PVSP)

37. LS shuttle valve

38. Proportional controller

39. Shock valve (265 bar)

40. Controller (not proportional)

41. Priority valve (brakes and steering)

42. Priority valve (steering)

43. Filter

44. Brake accumulator charge valve (BAC)

45. Accumulator

(up to Machine S/No.51200317)

46. Tap

47. Trailer brake valve

48. Trailer brake coupling

49. Extension cylinder

50. Load control valve

51. Crowd cylinder

52. Load control valve

53. Compensator cylinder

54. Lift cylinder

55. Load control valve

56. Diverter valve

57. Manifold

58. Cylinder, autohitch

59. 1st service couplings

60. 2nd service couplings

61. Trailer tipping coupling

62. Start-up valve

63. Non-return valve

64. Pressure relief valve (160 bar)

65. Test point 1 (main system pressure LS)

66. Test point 2 (parking brake release pressure)

67. Test point 3 (steering system pressure)

68. Test point 4 (brake circuit)

69. Test point 5 (main circuit pressure P)

70. Auxiliary breather

HYDRAULICS 1.4

HYDRAULIC CIRCUIT - SINGLE CIRCUIT BRAKING (from Machine S/No.51200318 to 51200471)

HYDRAULICS 1.5

Key to hydraulic circuit - single circuit braking

1. Hydraulic tank

2. Hydraulic pump, load sensing (LS)

3. LS pump compensator

4. Gauze filter (Not Serviceable)

5. Filler/breather

6. Auxiliary hydraulic pump

7. Fan motor

8. Pressure reducing valve (parking brake control)

9. Pressure filter

10. Brake valve

11. Accumulator

12. Pressure switch (116 bar)

13. Pressure switch (15 bar)

14. Front axle (park brake actuators)

15. Steering cylinder (front)

16. Pressure switch (5 bar)

17. Pressure switch (16 bar)

18. Rear axle

19. Steering cylinder (rear)

20. Non-return valve

21. Steering control valve (Danfoss OSPF)

22. Steering selector valve (attached to OSPF

valve)

23. Pressure relief valve (175 bar)

24. Shock valve (225 - 245 bar)

25. Hydraulic control valve (PVG 32)

26. Outlet section (PVP)

27. Extension section

28. Crowd/compensator section

29. Lift section

30. 1st auxiliary section (carriage/autohitch)

31. 2nd auxiliary section

32. Pressure relief valve (290 bar)

33. Pressure raising spool

34. Pilot valve

35. Shock valve (175 bar)

36. Inlet section (PVSP)

37. LS shuttle valve

38. Proportional controller

39. Shock valve (265 bar)

40. Controller (not proportional)

41. Priority valve (brakes and steering)

42. Priority valve (steering)

43. Filter

44. Brake accumulator charge valve (BAC)

45. Accumulator

(from Machine S/No.51200318 to 51200471)

46. Tap

47. Trailer brake valve

48. Trailer brake coupling

49. Extension cylinder

50. Load control valve

51. Crowd cylinder

52. Load control valve

53. Compensator cylinder

54. Lift cylinder

55. Load control valve

56. Diverter valve

57. Manifold

58. Cylinder (autohitch)

59. 1st service couplings

60. 2nd service couplings

61. Trailer tipping coupling

62. Start-up valve

63. NOT FITTED

64. Pressure relief valve (160 bar)

65. Test point 1 (main system pressure LS)

66. Test point 2 (parking brake release pressure)

67. Test point 3 (steering system pressure)

68. Test point 4 (brake circuit)

69. Test point 5 (main circuit pressure P)

70. Auxiliary breather

HYDRAULICS 1.6

HYDRAULIC CIRCUIT - SINGLE CIRCUIT BRAKING (from Machine S/No. 51200472 to 51200551)

HYDRAULICS 1.7

Key to hydraulic circuit - single circuit braking

1. Hydraulic tank

2. Hydraulic pump, load sensing (LS)

3. LS pump compensator

4. Gauze filter (Not Serviceable)

5. Filler/breather

6. Auxiliary hydraulic pump

7. Fan motor

8. Pressure reducing valve (parking brake control)

9. Pressure filter

10. Brake valve (Safim type)

11. Accumulator

12. Pressure switch (116 bar)

13. Pressure switch (15 bar)

14. Front axle (park brake actuators)

15. Steering cylinder (front)

16. Pressure switch (5 bar)

17. Pressure switch (16 bar)

18. Rear axle

19. Steering cylinder (rear)

20. NOT FITTED

21. Steering control valve (Danfoss OSPF)

22. Steering selector valve (attached to OSPF

valve)

23. Pressure relief valve (175 bar)

24. Shock valve (225 - 245 bar)

25. Hydraulic control valve (PVG 32)

26. Outlet section (PVP)

27. Extension section

28. Crowd/compensator section

29. Lift section

30. 1st auxiliary section (carriage/autohitch)

31. 2nd auxiliary section

32. Pressure relief valve (290 bar)

33. Pressure raising spool

34. Pilot valve

35. Shock valve (175 bar)

36. Inlet section (PVSP)

37. LS shuttle valve

38. Proportional controller

39. Shock valve (265 bar)

40. Controller (not proportional)

41. Priority valve (brakes and steering)

42. Priority valve (steering)

43. Filter

44. Brake accumulator charge valve (BAC)

45. Accumulator

(from Machine S/No.51200472 to 51200551)

46. Tap

47. Trailer brake valve

48. Trailer brake coupling

49. Extension cylinder

50. Load control valve

51. Crowd cylinder

52. Load control valve

53. Compensator cylinder

54. Lift cylinder

55. Load control valve

56. Diverter valve

57. Manifold

58. Cylinder, autohitch

59. 1st service couplings

60. 2nd service couplings

61. Trailer tipping coupling

62. Start-up valve

63. NOT FITTED

64. Pressure regulator, 120 bar

65. Test point 1 (main system pressure LS)

66. Test point 2 (parking brake release pressure)

67. Test point 3 (steering system pressure)

68. Test point 4 (brake circuit)

69. Test point 5 (main circuit pressure P)

70. Auxiliary breather

71. NOT FITTED

72. Fan reverse valve

73. Oil cooler

HYDRAULICS 1.8

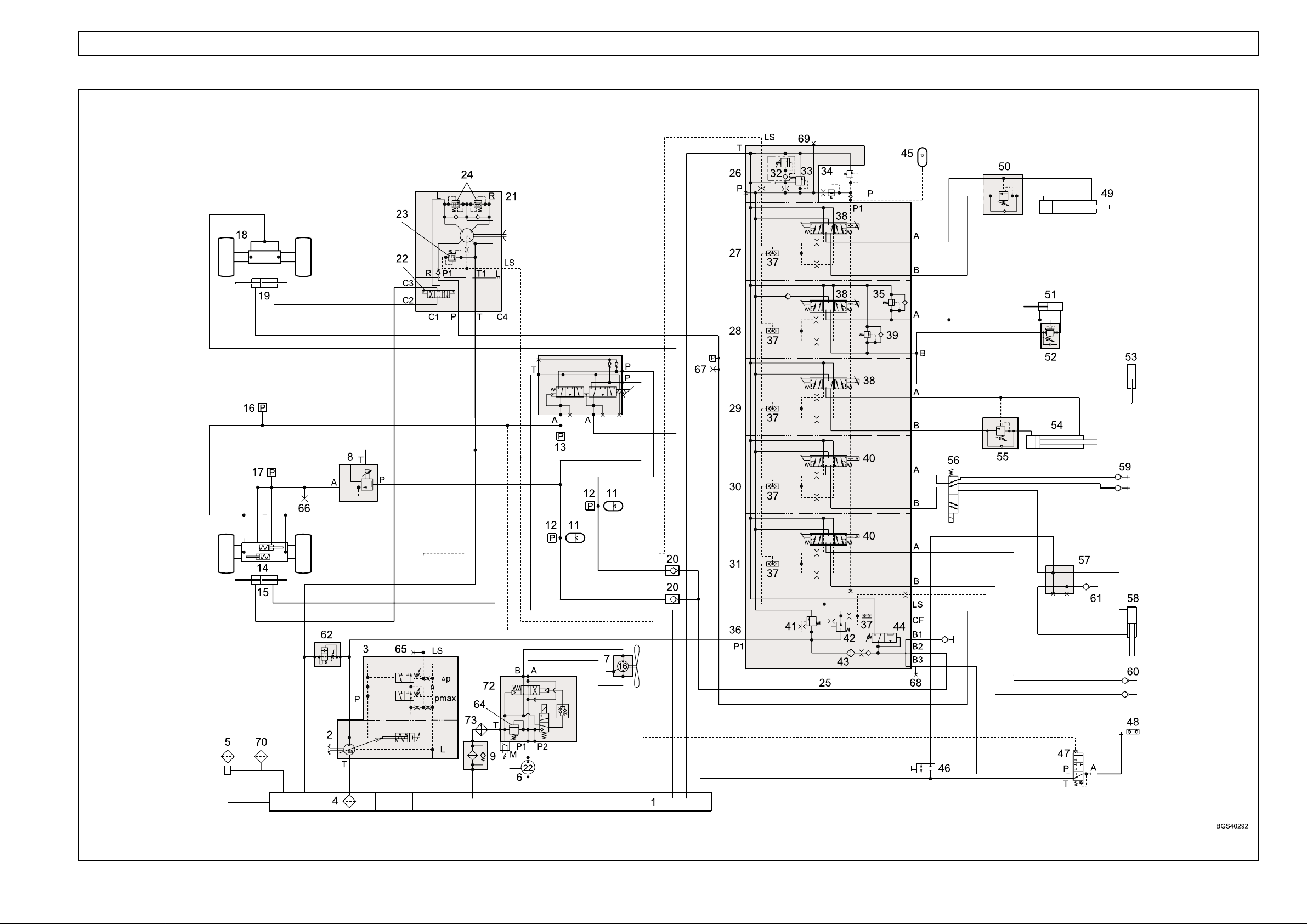

HYDRAULIC CIRCUIT - SINGLE CIRCUIT BRAKING (from Machine S/No. 51200552 to 51200727)

HYDRAULICS 1.9

Key to hydraulic circuit - single circuit braking

1. Hydraulic tank

2. Hydraulic pump, load sensing (LS)

3. LS pump compensator

4. Gauze filter (Not Serviceable)

5. Filler/breather

6. Auxiliary hydraulic pump

7. Fan motor

8. NOT FITTED

9. Pressure filter

10. Brake valve (Safim type)

11. Accumulator

12. Pressure switch (116 bar)

13. Pressure switch (15 bar)

14. Front axle (park brake actuators)

15. Steering cylinder (front)

16. Pressure switch (5 bar)

17. Pressure switch (16 bar)

18. Rear axle

19. Steering cylinder (rear)

20. NOT FITTED

21. Steering control valve (Danfoss OSPF)

22. Steering selector valve (attached to OSPF

valve)

23. Pressure relief valve (175 bar)

24. Shock valve (225 - 245 bar)

25. Hydraulic control valve (PVG 32)

26. Outlet section (PVP)

27. Extension section

28. Crowd/compensator section

29. Lift section

30. 1st auxiliary section (carriage/autohitch)

31. 2nd auxiliary section

32. Pressure relief valve (290 bar)

33. Pressure raising spool

34. Pilot valve

35. Shock valve (175 bar)

36. Inlet section (PVSP)

37. LS shuttle valve

38. Proportional controller

39. Shock valve (265 bar)

40. Controller (not proportional)

41. Priority valve (brakes and steering)

42. Priority valve (steering)

43. Filter

44. Brake accumulator charge valve (BAC)

45. Accumulator

(from Machine S/No.51200552 to 51200727)

46. Tap

47. Trailer brake valve

48. Trailer brake coupling

49. Extension cylinder

50. Load control valve

51. Crowd cylinder

52. Load control valve

53. Compensator cylinder

54. Lift cylinder

55. Load control valve

56. Diverter valve

57. Manifold

58. Cylinder, autohitch

59. 1st service couplings

60. 2nd service couplings

61. Trailer tipping coupling

62. Start-up valve

63. NOT FITTED

64. Pressure regulator, 120 bar

65. Test point 1 (main system pressure LS)

66. Test point 2 (parking brake release pressure)

67. Test point 3 (steering system pressure)

68. Test point 4 (brake circuit)

69. Test point 5 (main circuit pressure P)

70. Auxiliary breather

71. Parking brake valve

72. Fan reverse valve

73. Oil cooler

HYDRAULICS 1.10

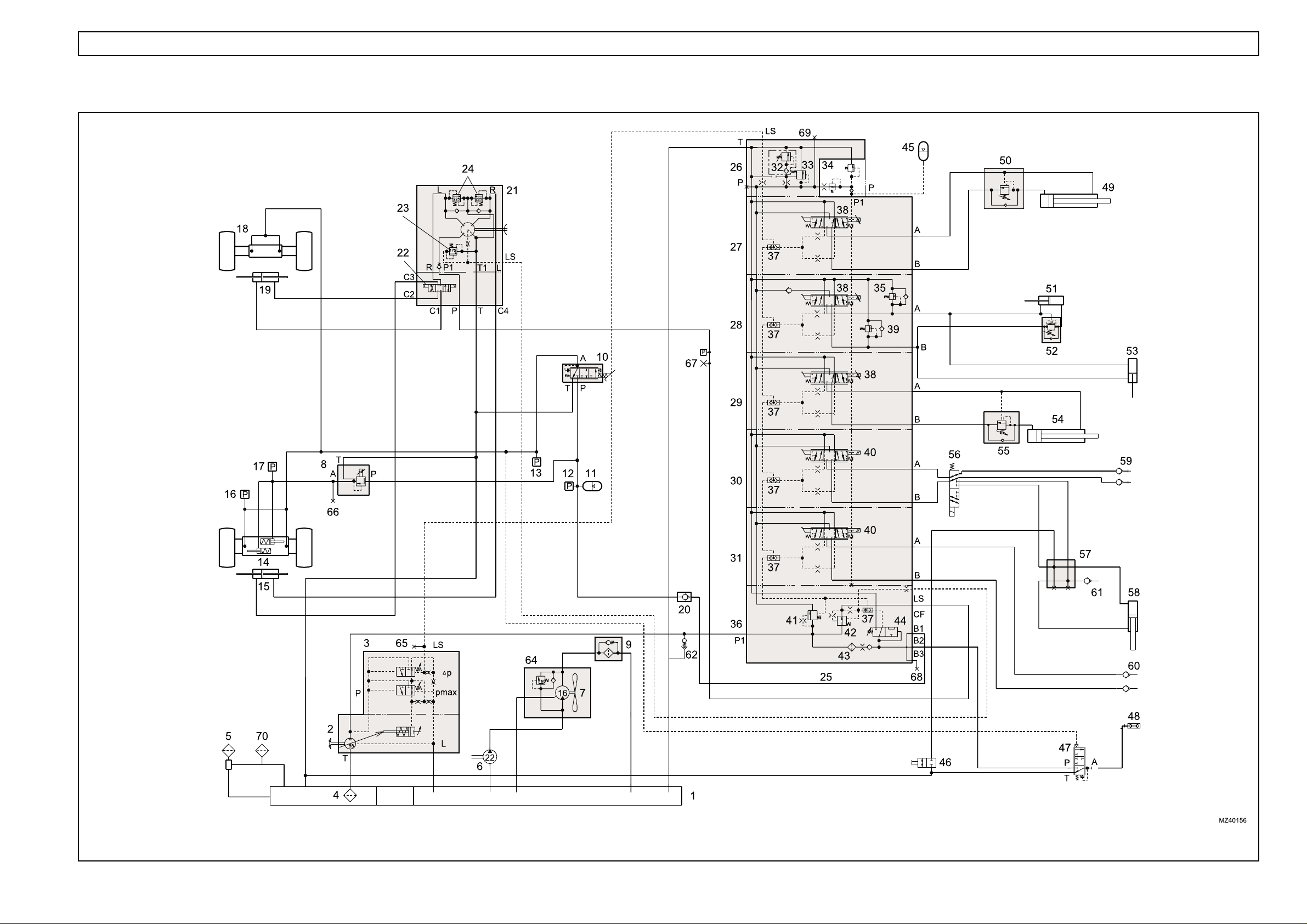

HYDRAULIC CIRCUIT - DUAL CIRCUIT BRAKING (up to Machine S/No.51200317)

HYDRAULICS 1.11

Key to hydraulic circuit - dual circuit braking

1. Hydraulic tank

2. Hydraulic pump, load sensing (LS)

3. LS pump compensator

4. Gauze filter (Not Serviceable)

5. Filler/breather

6. Auxiliary hydraulic pump

7. Fan motor

8. Pressure reducing valve (parking brake control)

9. Pressure filter

10. Brake valve

11. Accumulator

12. Pressure switch (116 bar)

13. Pressure switch (15 bar)

14. Front axle (park brake actuators)

15. Steering cylinder (front)

16. Pressure switch (5 bar)

17. Pressure switch (16 bar)

18. Rear axle

19. Steering cylinder (rear)

20. Non-return valve

21. Steering control valve (Danfoss OSPF)

22. Steering selector valve (attached to OSPF

valve)

23. Pressure relief valve (175 bar)

24. Shock valve (225 - 245 bar)

25. Hydraulic control valve (PVG 32)

26. Outlet section (PVP)

27. Extension section

28. Crowd/compensator section

29. Lift section

30. 1st auxiliary section (carriage/autohitch)

31. 2nd auxiliary section

32. Pressure relief valve (290 bar)

33. Pressure raising spool

34. Pilot valve

35. Shock valve (175 bar)

36. Inlet section (PVSP)

37. LS shuttle valve

38. Proportional controller

39. Shock valve (265 bar)

40. Controller, (not proportional)

41. Priority valve (brakes and steering)

42. Priority valve (steering)

43. Filter

44. Brake accumulator charge valve (BAC)

45. Accumulator

(up to Machine S/No.51200317)

46. Tap

47. Trailer brake valve

48. Trailer brake coupling

49. Extension cylinder

50. Load control valve

51. Crowd cylinder

52. Load control valve

53. Compensator cylinder

54. Lift cylinder

55. Load control valve

56. Diverter valve

57. Manifold

58. Cylinder, autohitch

59. 1st service couplings

60. 2nd service couplings

61. Trailer tipping coupling

62. Start-up valve

63. Non-return valve

64. Pressure relief valve (160 bar)

65. Test point 1 (main system pressure LS)

66. Test point 2 (parking brake release pressure)

67. Test point 3 (steering system pressure)

68. Test point 4 (brake circuit)

69. Test point 5 (main circuit pressure P)

70. Auxiliary breather

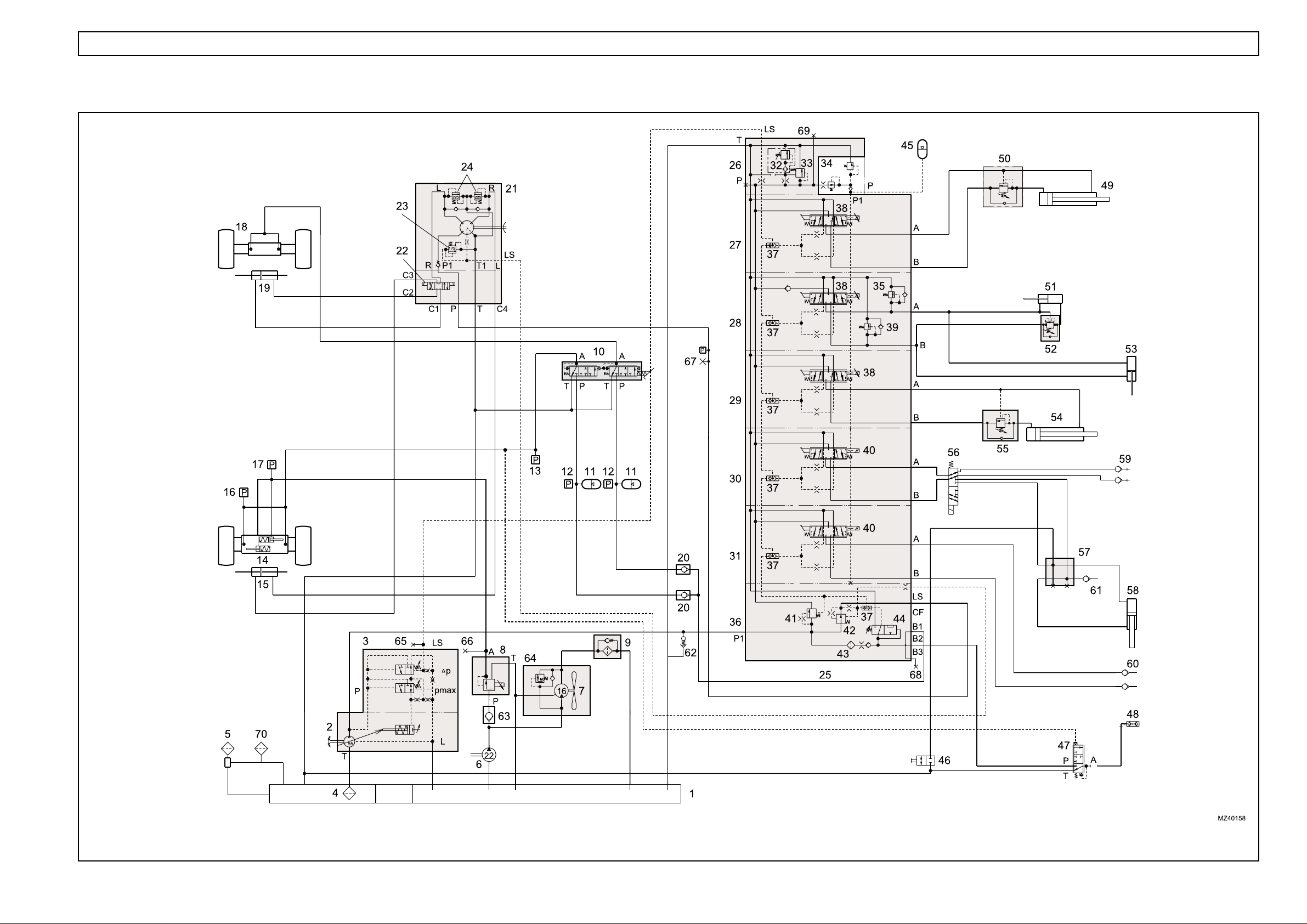

HYDRAULICS 1.12

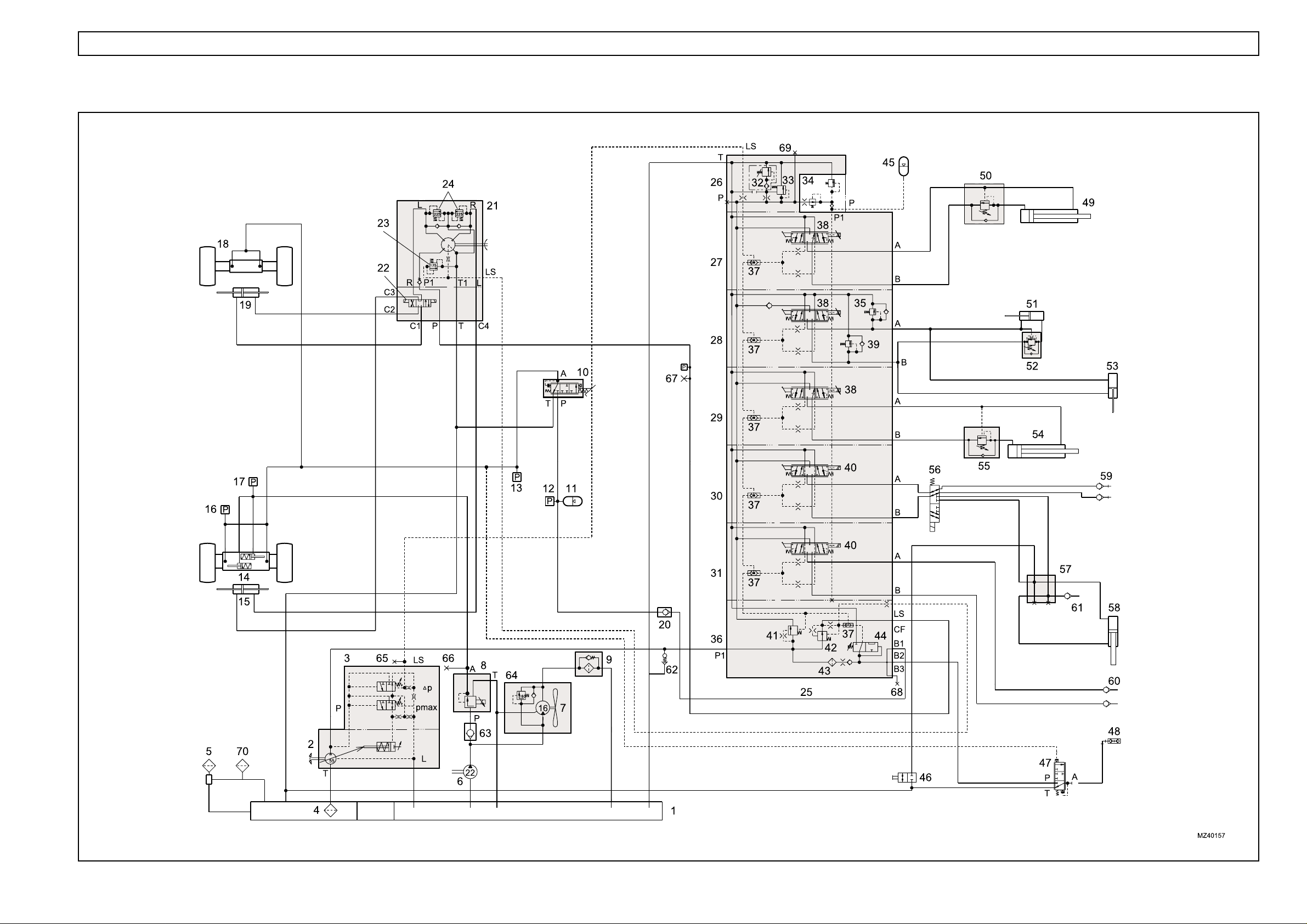

HYDRAULIC CIRCUIT - DUAL CIRCUIT BRAKING (from Machine S/No.51200318 to 51200471)

HYDRAULICS 1.13

Key to hydraulic circuit - dual circuit braking

1. Hydraulic tank

2. Hydraulic pump, load sensing (LS)

3. LS pump compensator

4. Gauze filter (Not Serviceable)

5. Filler/breather

6. Auxiliary hydraulic pump

7. Fan motor

8. Pressure reducing valve (parking brake

control)

9. Pressure filter

10. Brake valve

11. Accumulator

12. Pressure switch (116 bar)

13. Pressure switch (15 bar)

14. Front axle (park brake actuators)

15. Steering cylinder (front)

16. Pressure switch (5 bar)

17. Pressure switch (16 bar)

18. Rear axle

19. Steering cylinder (rear)

20. Non-return valve

21. Steering control valve (Danfoss OSPF)

22. Steering selector valve (attached to OSPF valve)

23. Pressure relief valve (175 bar)

24. Shock valve (225 - 245 bar)

25. Hydraulic control valve (PVG 32)

26. Outlet section (PVP)

27. Extension section

28. Crowd/compensator section

29. Lift section

30. 1st auxiliary section (carriage/autohitch)

31. 2nd auxiliary section

32. Pressure relief valve, 290 bar

33. Pressure raising spool

34. Pilot valve

35. Shock valve (175 bar)

36. Inlet section (PVSP)

37. LS shuttle valve

38. Proportional controller

39. Shock valve (265 bar)

40. Controller (not proportional)

41. Priority valve (brakes and steering)

42. Priority valve, steering

43. Filter

44. Brake accumulator charge valve (BAC)

45. Accumulator

(from Machine S/No.51200318 TO 512471)

46. Tap

47. Trailer brake valve

48. Trailer brake coupling

49. Extension cylinder

50. Load control valve

51. Crowd cylinder

52. Load control valve

53. Compensator cylinder

54. Lift cylinder

55. Load control valve

56. Diverter valve

57. Manifold

58. Cylinder, autohitch

59. 1st service couplings

60. 2nd service couplings

61. Trailer tipping coupling

62. Start-up valve

63. NOT FITTED

64. Pressure relief valve (160 bar)

65. Test point 1 (main system pressure LS)

66. Test point 2 (Park brake release pressure)

67. Test point 3 (steering system pressure)

68. Test point 4 (brake circuit)

69. Test point 5 (main circuit pressure P)

70 Auxiliary breather

HYDRAULICS 1.14

HYDRAULIC CIRCUIT - DUAL CIRCUIT BRAKING (from Machine S/No.51200472 to 51200551)

HYDRAULICS 1.15

Key to hydraulic circuit - dual circuit braking

1. Hydraulic tank

2. Hydraulic pump, load sensing (LS)

3. LS pump compensator

4. Gauze filter (Not Serviceable)

5. Filler/breather

6. Auxiliary hydraulic pump

7. Fan motor

8. Pressure reducing valve (parking brake

control)

9. Pressure filter

10. Brake valve

11. Accumulator

12. Pressure switch (116 bar)

13. Pressure switch (15 bar)

14. Front axle (park brake actuators)

15. Steering cylinder (front)

16. Pressure switch (5 bar)

17. Pressure switch (16 bar)

18. Rear axle

19. Steering cylinder (rear)

20. Non-return valve

21. Steering control valve (Danfoss OSPF)

22. Steering selector valve (attached to OSPF valve)

23. Pressure relief valve (175 bar)

24. Shock valve (225 - 245 bar)

25. Hydraulic control valve (PVG 32)

26. Outlet section (PVP)

27. Extension section

28. Crowd/compensator section

29. Lift section

30. 1st auxiliary section (carriage/autohitch)

31. 2nd auxiliary section

32. Pressure relief valve, 290 bar

33. Pressure raising spool

34. Pilot valve

35. Shock valve (175 bar)

36. Inlet section (PVSP)

37. LS shuttle valve

38. Proportional controller

39. Shock valve (265 bar)

40. Controller (not proportional)

41. Priority valve (brakes and steering)

42. Priority valve, steering

43. Filter

44. Brake accumulator charge valve (BAC)

45. Accumulator

(from Machine S/No.51200472 TO 512551)

46. Tap

47. Trailer brake valve

48. Trailer brake coupling

49. Extension cylinder

50. Load control valve

51. Crowd cylinder

52. Load control valve

53. Compensator cylinder

54. Lift cylinder

55. Load control valve

56. Diverter valve

57. Manifold

58. Cylinder, autohitch

59. 1st service couplings

60. 2nd service couplings

61. Trailer tipping coupling

62. Start-up valve

63. NOT FITTED

64. Pressure regulator, 120 bar

65. Test point 1 (main system pressure LS)

66. Test point 2 (Park brake release pressure)

67. Test point 3 (steering system pressure)

68. Test point 4 (brake circuit)

69. Test point 5 (main circuit pressure P)

70 Auxiliary breather

71. NOT FITTED

72. Fan reverse valve

73. Oil cooler

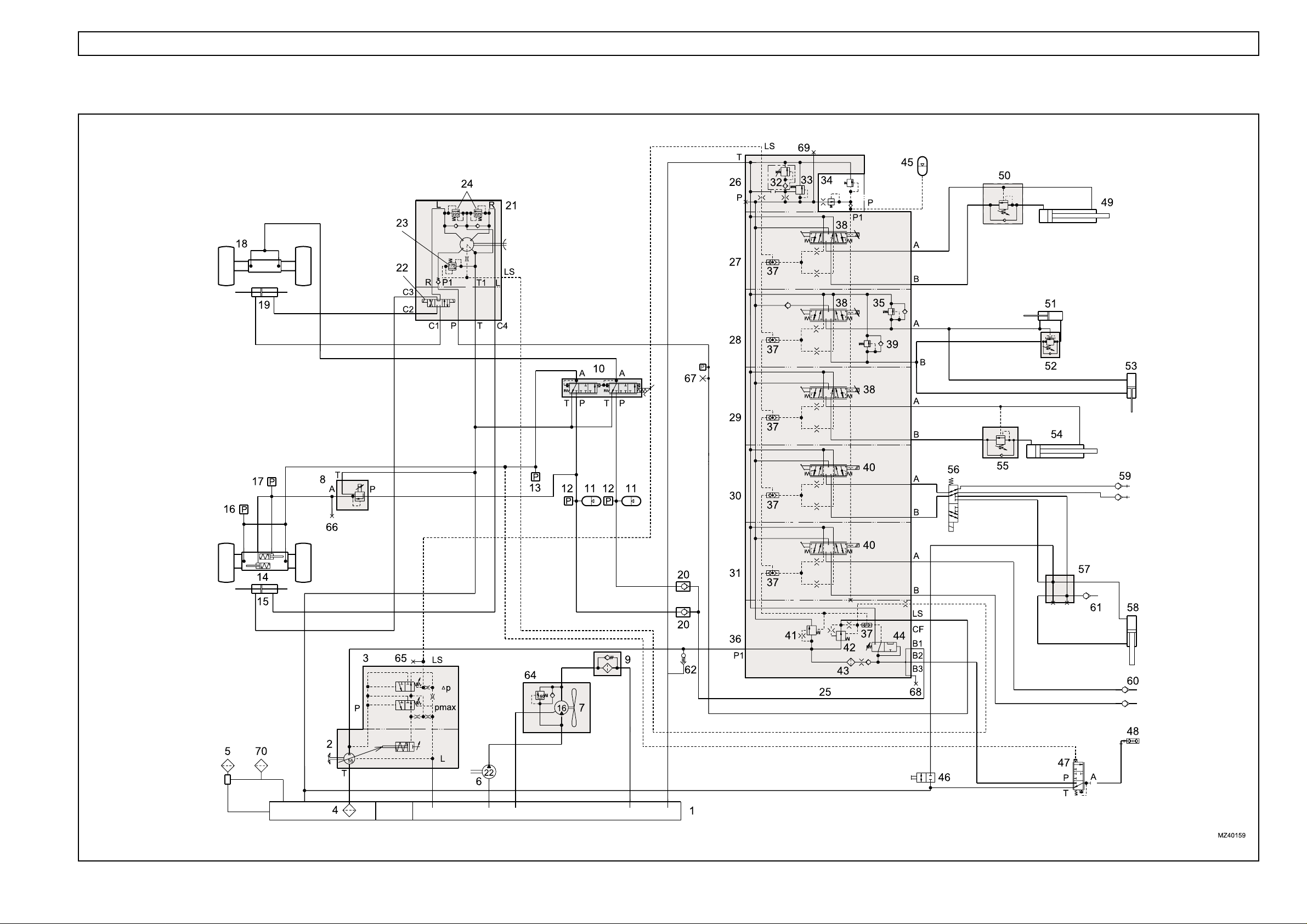

HYDRAULICS 1.16

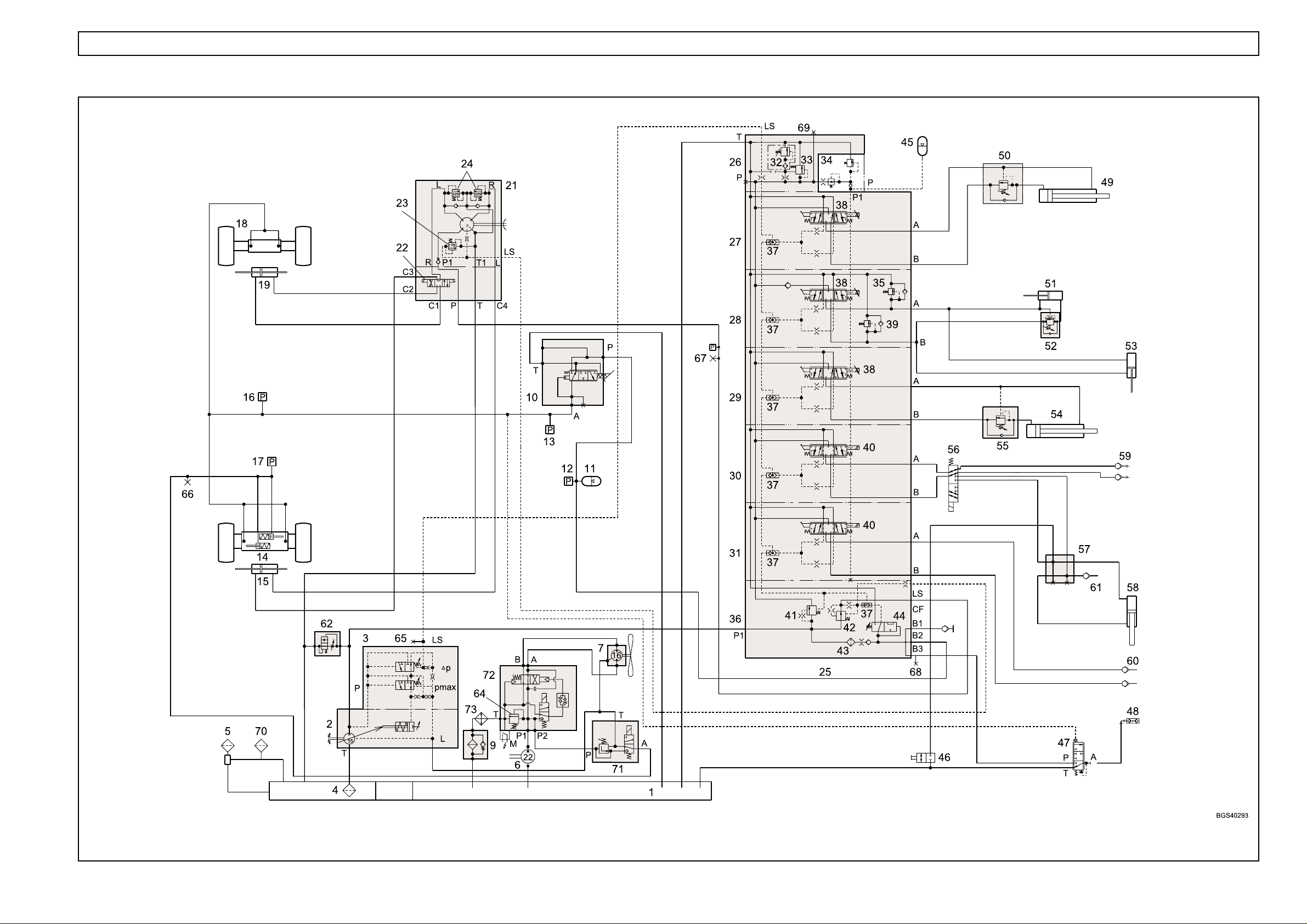

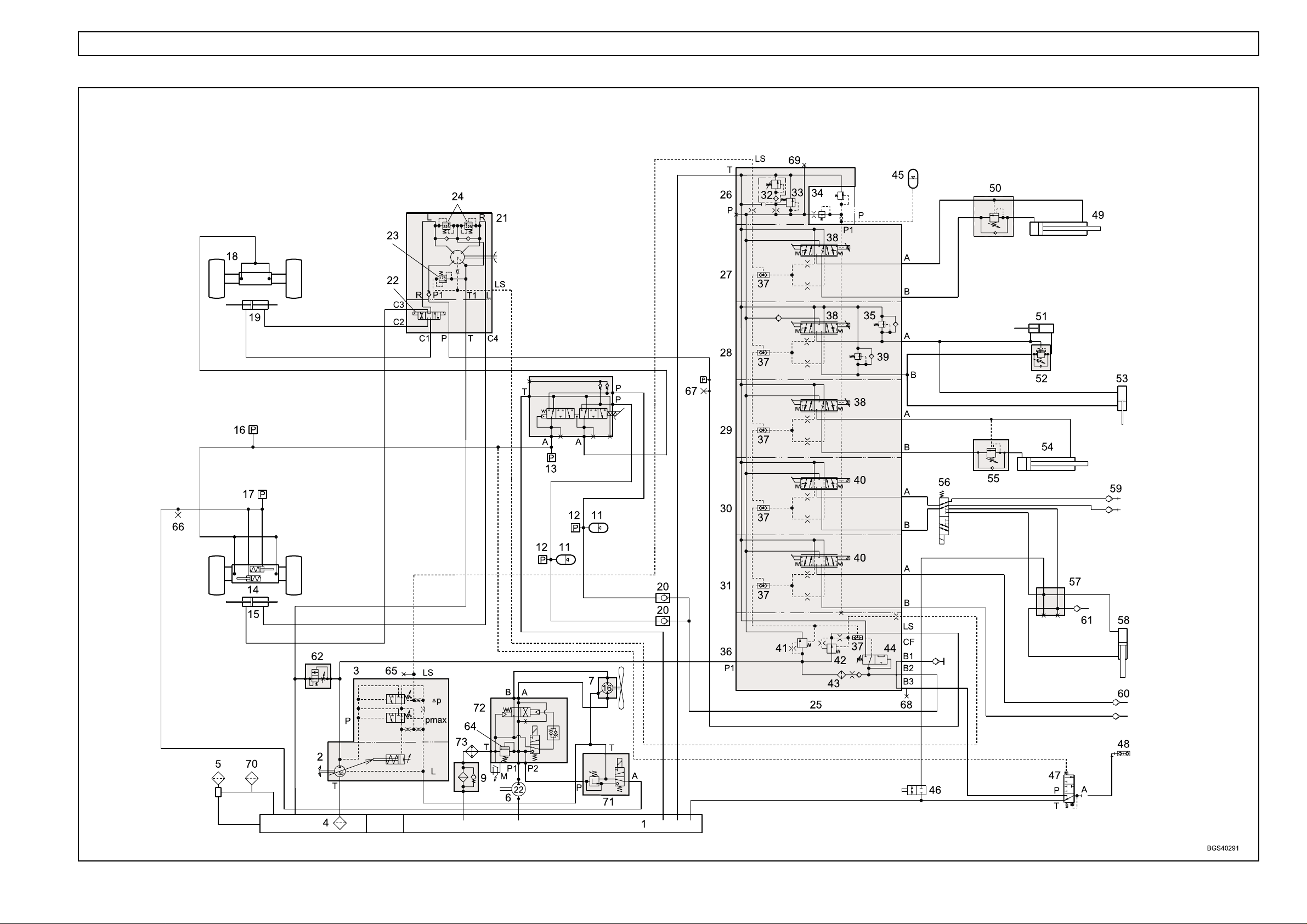

HYDRAULIC CIRCUIT - DUAL CIRCUIT BRAKING (from Machine S/No.51200552 to 51200727)

HYDRAULICS 1.17

Key to hydraulic circuit - dual circuit braking

1. Hydraulic tank

2. Hydraulic pump, load sensing (LS)

3. LS pump compensator

4. Gauze filter (Not Serviceable)

5. Filler/breather

6. Auxiliary hydraulic pump

7. Fan motor

8. NOT FITTED

9. Pressure filter

10. Brake valve (Safim type)

11. Accumulator

12. Pressure switch (116 bar)

13. Pressure switch (15 bar)

14. Front axle (park brake actuators)

15. Steering cylinder (front)

16. Pressure switch (5 bar)

17. Pressure switch (16 bar)

18. Rear axle

19. Steering cylinder (rear)

20. Non-return valve

21. Steering control valve (Danfoss OSPF)

22. Steering selector valve (attached to OSPF valve)

23. Pressure relief valve (175 bar)

24. Shock valve (225 - 245 bar)

25. Hydraulic control valve (PVG 32)

26. Outlet section (PVP)

27. Extension section

28. Crowd/compensator section

29. Lift section

30. 1st auxiliary section (carriage/autohitch)

31. 2nd auxiliary section

32. Pressure relief valve, 290 bar

33. Pressure raising spool

34. Pilot valve

35. Shock valve (175 bar)

36. Inlet section (PVSP)

37. LS shuttle valve

38. Proportional controller

39. Shock valve (265 bar)

40. Controller (not proportional)

41. Priority valve (brakes and steering)

42. Priority valve, steering

43. Filter

44. Brake accumulator charge valve (BAC)

45. Accumulator

(from Machine S/No.51200552 TO 512727)

46. Tap

47. Trailer brake valve

48. Trailer brake coupling

49. Extension cylinder

50. Load control valve

51. Crowd cylinder

52. Load control valve

53. Compensator cylinder

54. Lift cylinder

55. Load control valve

56. Diverter valve

57. Manifold

58. Cylinder, autohitch

59. 1st service couplings

60. 2nd service couplings

61. Trailer tipping coupling

62. Start-up valve

63. NOT FITTED

64. Pressure regulator, 120 bar

65. Test point 1 (main system pressure LS)

66. Test point 2 (Park brake release pressure)

67. Test point 3 (steering system pressure)

68. Test point 4 (brake circuit)

69. Test point 5 (main circuit pressure P)

70 Auxiliary breather

71. Parking brake valve

72. Fan reverse valve

73. Oil cooler

1.18 HYDRAULICS

COMPONENTS

General

NOTE: An identification number in bold type, after an

item, refers to the number of that item in the main

hydraulic schematic illustration.

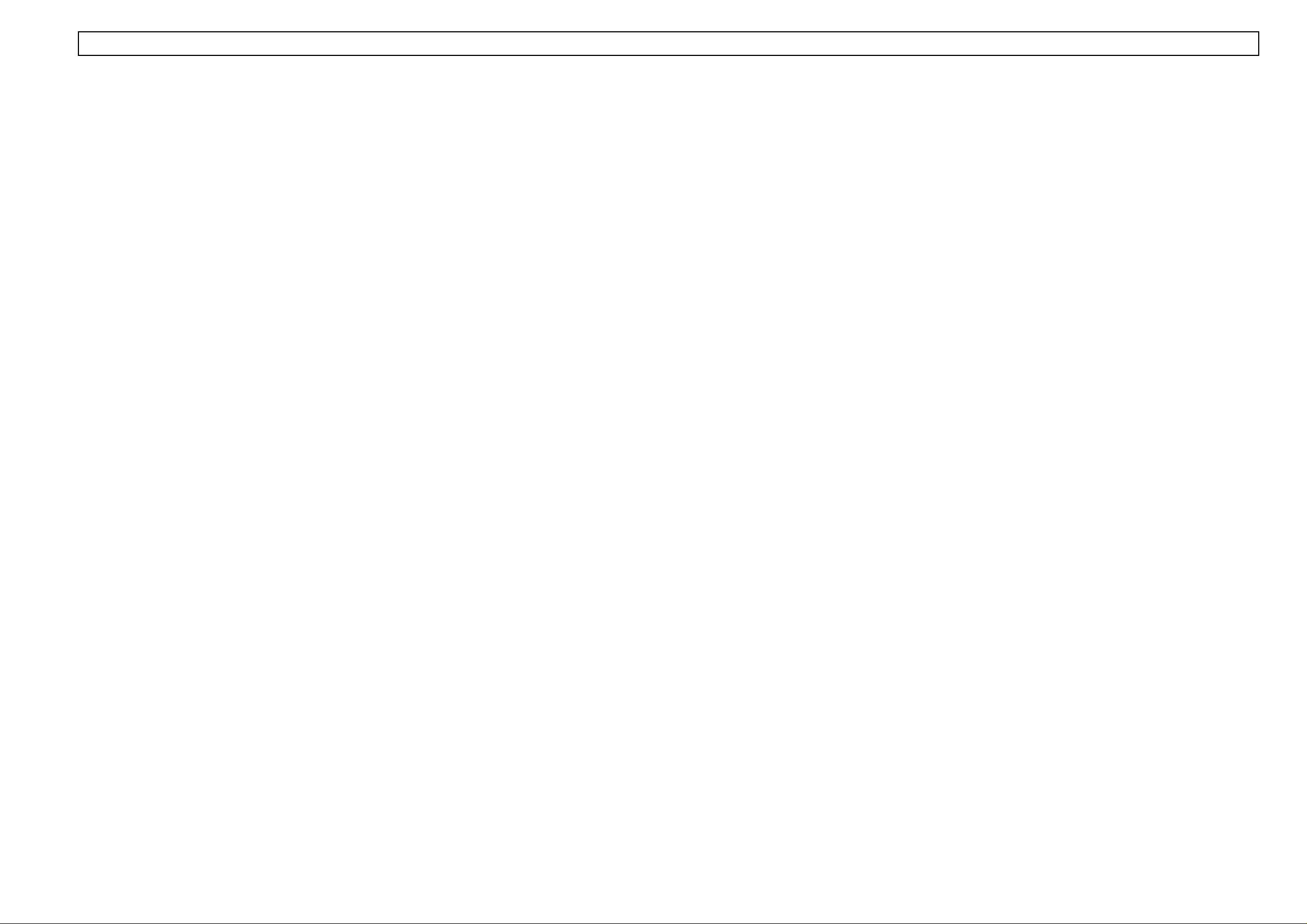

Hydraulic tank (1)

A single hydraulic reservoir feeds the main and

auxiliary systems of the machine. A sight glass is

fitted to check system contents. An internal 40 µm

mesh filter (pre-filtration) separates the clean and

dirty sides of the tank. Both system suction lines are

taken from the clean side of the mesh filter. All

return lines go to a manifold and return fluid to dirty

side of tank for pre filtration.

Specifications:

Nominal tank capacity 67 litres

Total system capacity (oil) 128 litres

Suction line connections to hydraulic tank

1. Sight glass

2. Suction - Main Pump

3. Drain plug

4. Suction - Auxiliary Pump

5. Filler

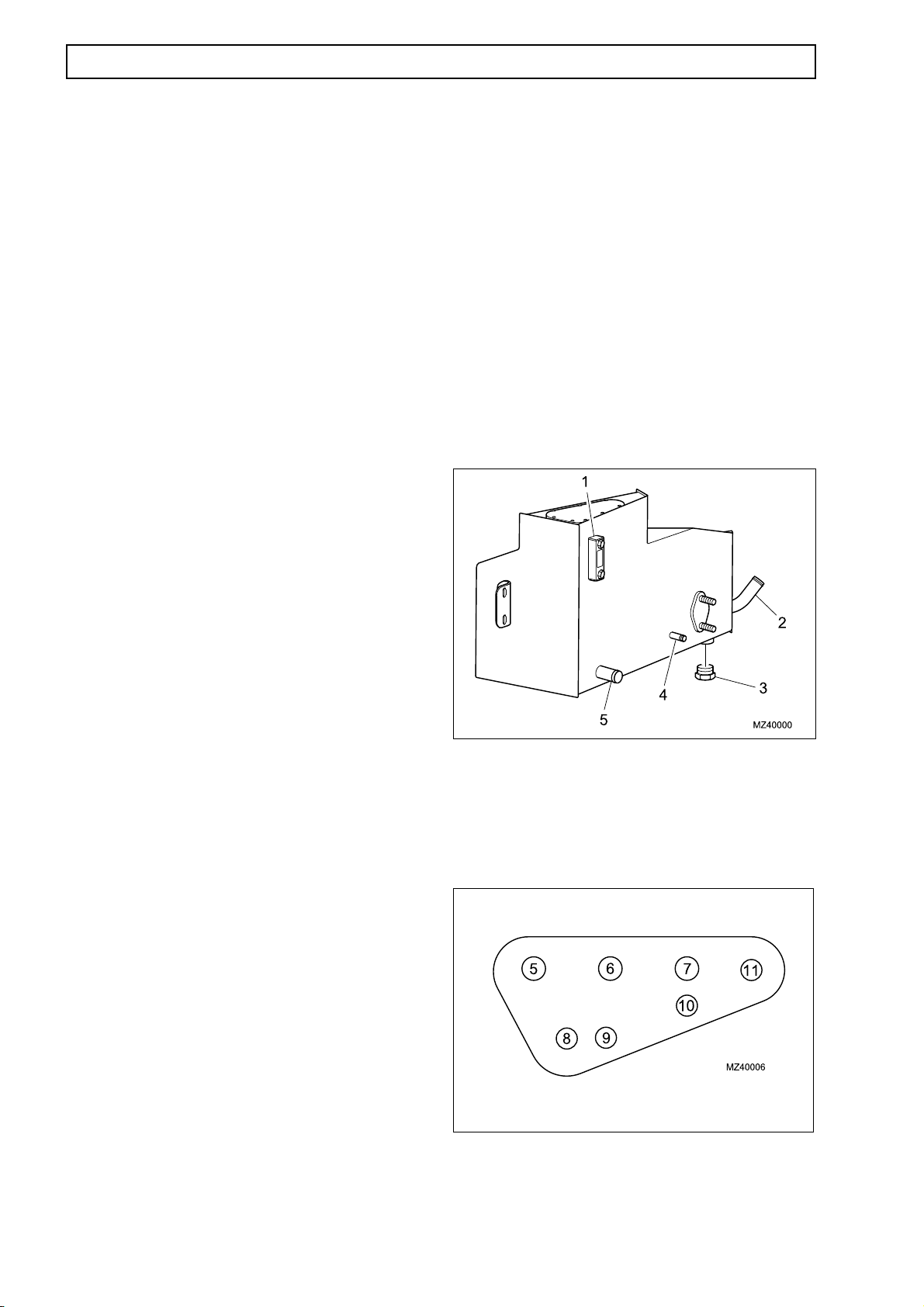

Return hose connections to hydraulic tank

(up to Machine S/No.51200471)

5. Return from PVG (Main Control Valve)

6. Return from LS Pump and Filter

7. From LS Pump Case Drain

8. Breather (connected to Filler)

9. Return from Brake and Steering circuits

10. From Trailer Brake (optional)

11. Return from Parking Brake PRV

Return hose connections to hydraulic tank

(from Machine S/No.51200472)

5. Return from PVG (Main Control Valve)

6. Return from LS Pump and Filter

7. (Blank fitted)

8. Breather (connected to Filler)

9. Return from Brake circuit

10. From Trailer Brake (optional)

11. Return from Brake and Parking Brake circuit

Loading...

Loading...