Claas ROLLANT 240, ROLLANT 250 Repair Manual

ROLLANT 240

ROLLANT 250

ROLLANT 240 with UNIWRAP

ROLLANT 250 with UNIWRAP

Technical Systems

Electric System

Electric System Rollant 240/250 TIC

TIC Rollant 240/250 Electric System

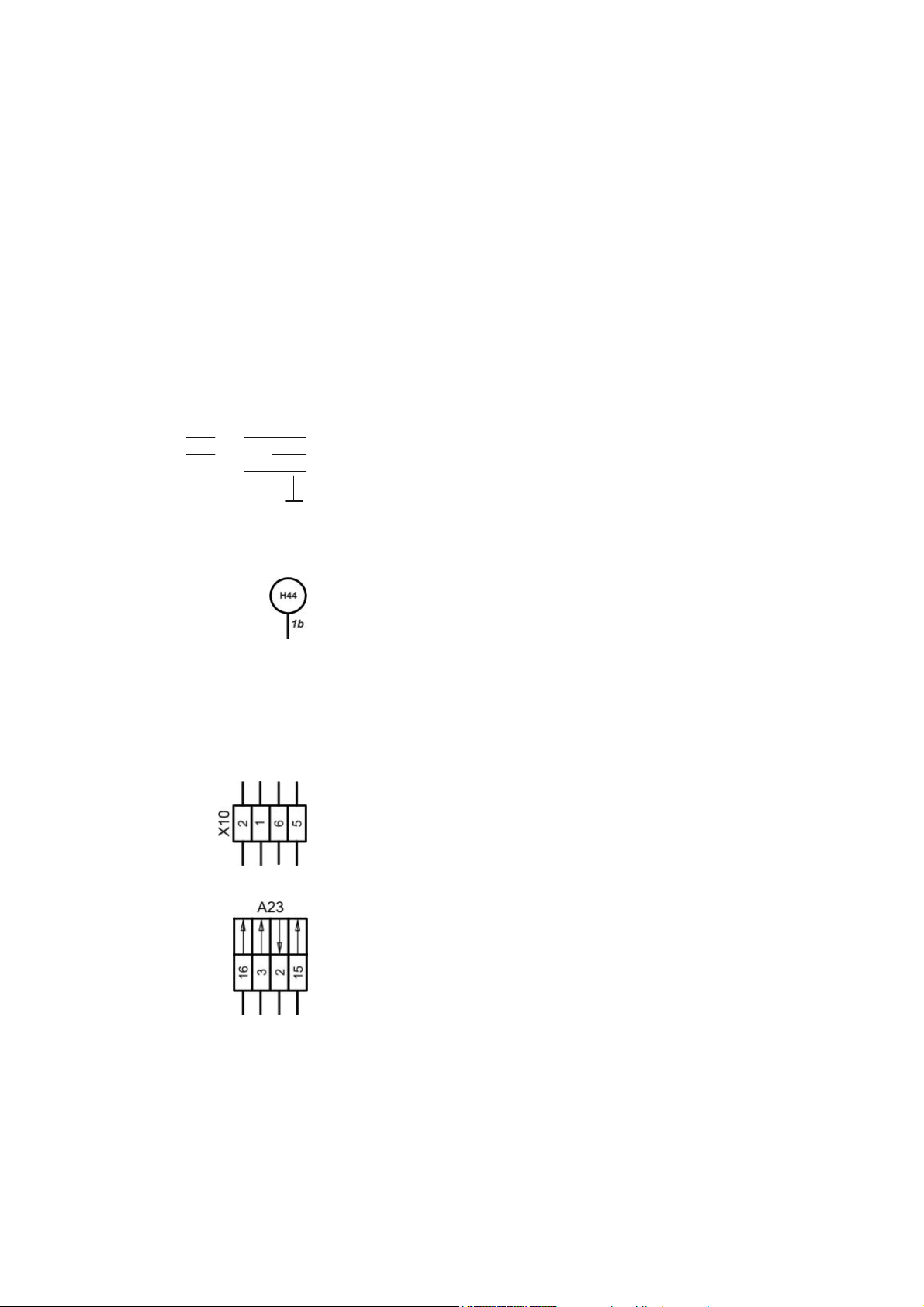

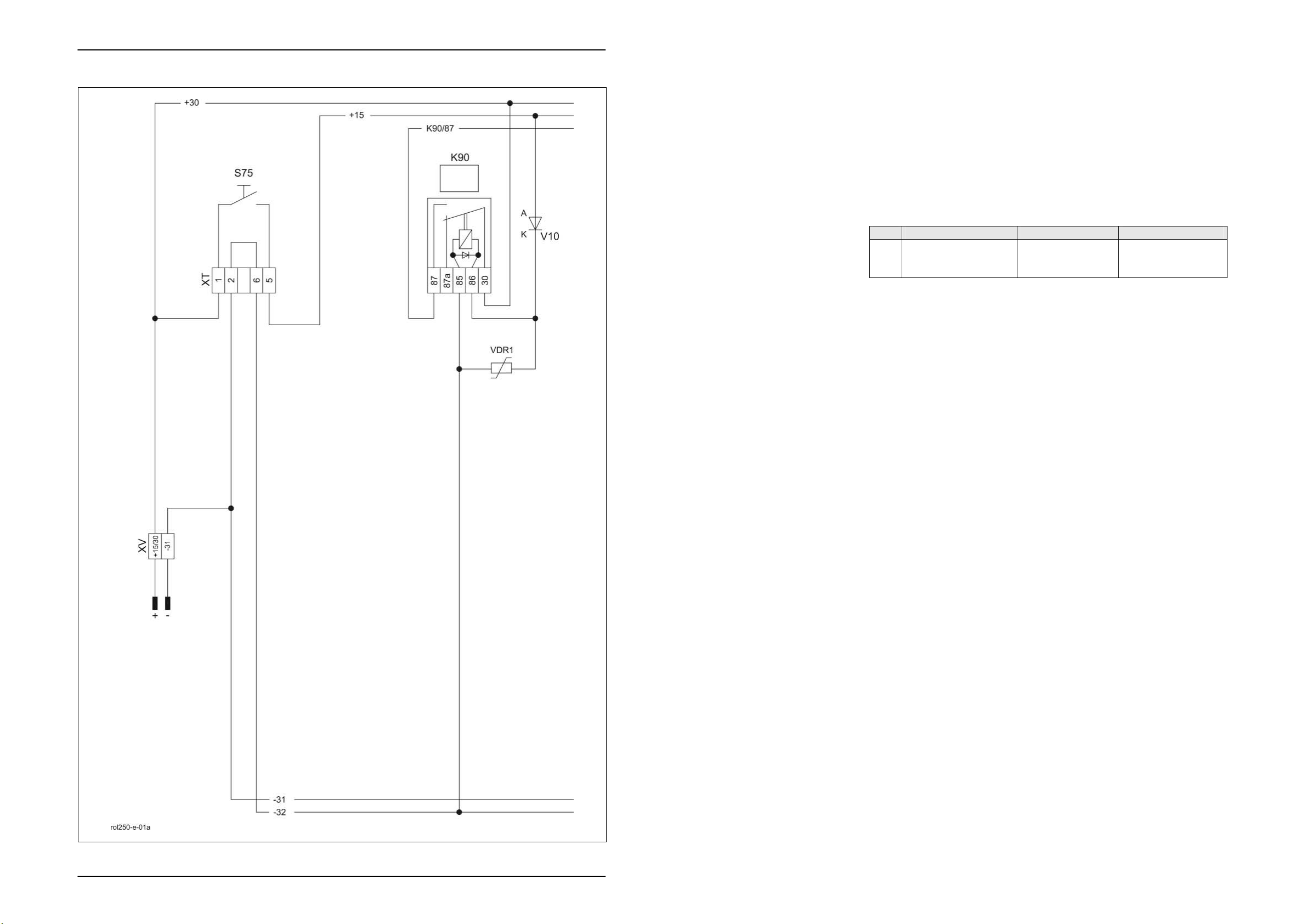

Layout of electric circuit diagrams

01...

01a / 01b ...

+30

+15

K90/87

-31

Wiring loom A

Following the circuit diagram layout, all electric circuits are shown in

individual circuit diagrams. Some explanations are given below to

illustrate the layout.

Numbering of circuit diagrams

-

The respective numbering can be found on the corresponding cover

sheet and in the footer.

-

Depending on the machine no., the components fitted and the

country specification, there may be several individual circuit

diagrams for a given function.

Potentials

- Main power supply (battery)

- Ignition switch power supply (switched)

- Relay-controlled power supply

- Earth

- Housing earth (external)

Connections

-

The description provided inside the circle (e.g. “H44”) defines the

connection.

-

Numbers next to the circle (e.g. “1b”) describe the continuation of

the cabling in accordance with the circuit diagram numbering which

can be taken from the cover sheet or from the footer.

Designations

-

Connectors (e.g. „X10”, pin 2– 1– 6– 5).

Each chapter lists the respective connectors and their pin

assignment in the individual connection tables.

-

Modules (e.g. “A23”)

The arrows identify the functional inputs and outputs according to

the assignment table provided in chapter ZE.

-

Position of components according to wiring looms

Electric System Rollant 240/250 TIC

- A 1 .. Z 99

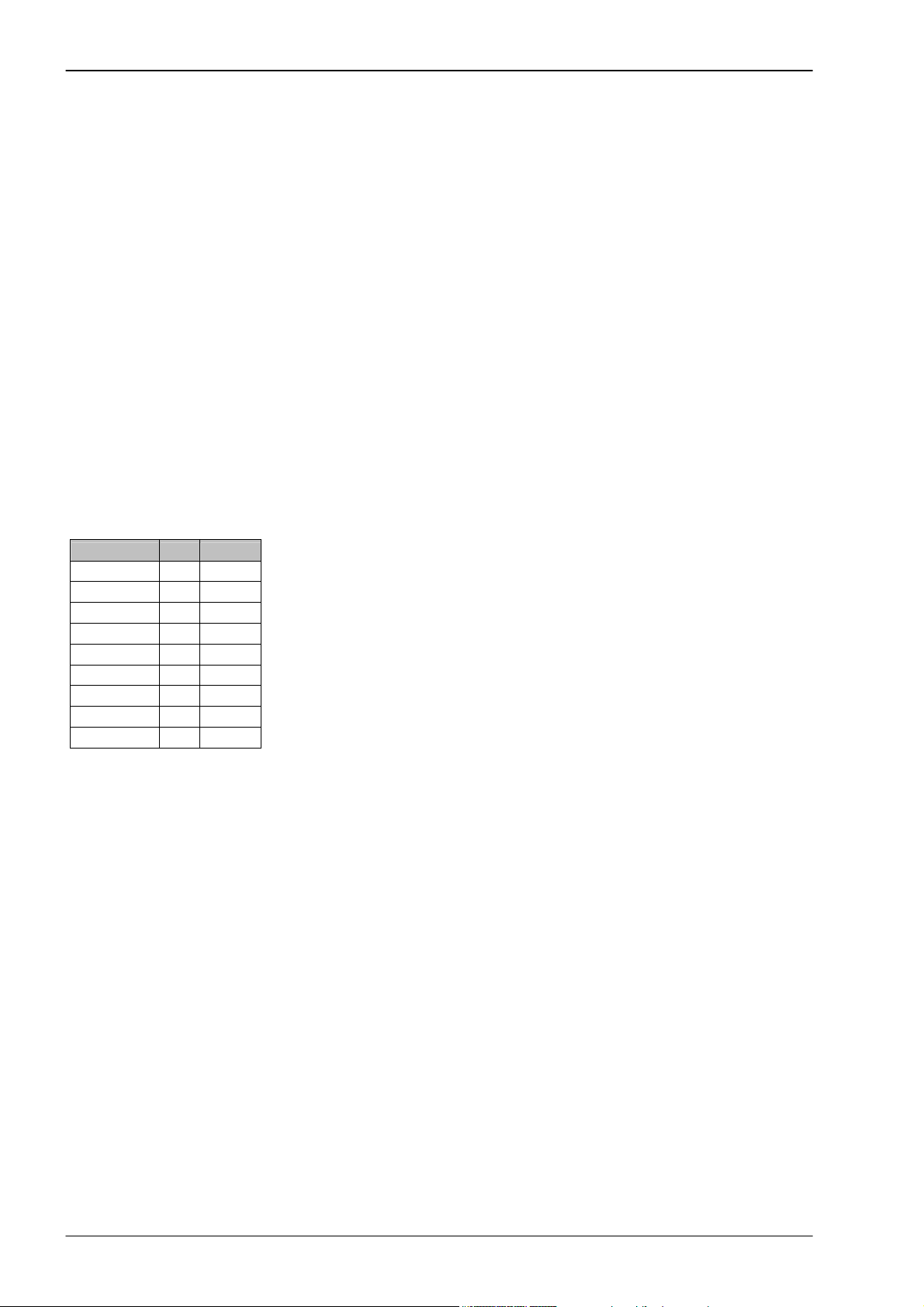

Connector mm² Colour

XT1 – 1 1.5 bk

XT1 – 2 1.5 br

XT1 – 4 1.5 bk-rd

XT1 – 5 1.5 br-rd

XT2 – 1 1.5 bk

XT2 – 2 1.5 bk-rd

XT2 – 3 1.5 br-rd

XT2 – 15 1.5 br

- Component designation according to CLAAS standards catalogue

A - Terminal / Module

B - Sensor

E - Lighting

F - Fuse

G - Voltage Source

H - Signalling Device / Lamp

K - Relay

M - Electric motor

P - Gauge

R - Potentiometer / Resistor

S - Switches – Cab Operation

T - Switches – Terminal Operation

U - Switches – External Operation

V - Electronic Component

W - Antenna

X - Connector

Y - Solenoid Coil

Z - Actual Value Function Switch

Wire colours / Wire cross-sections

- Indication of cross-section (mm²) and colour

rd – red

bk – black

br – brown

wt – white

bl – blue

gr – grey

ye – yellow

gn – green

pi – pink

or – orange

vi – violet

- Meaning of wire colours

bk - +30 Power supply from tractor [12V power]

br - -31 Power supply from tractor [0V power]

bk-rd - +15 switched via CCT [12V electronics]

br-rd - -31 via CCT [0V electronic system]

bk-wt - +30 switched via K90 (polarity reversal

protection) [12V power]

TIC Rollant 240/250 Electric System

Contents

Central terminal compartment.......................................................................................9

Rollant 240 Standard ........................................................................................................... 9

Rollant 250 Standard ........................................................................................................... 9

Central terminal compartment.....................................................................................13

Rollant 250 Comfort ........................................................................................................... 13

Central terminal compartment.....................................................................................17

UNIWRAP .......................................................................................................................... 17

Pin assignment in modules .........................................................................................21

Rollant 240......................................................................................................................... 21

Rollant 250......................................................................................................................... 21

UNIWRAP .......................................................................................................................... 21

1a Main power supply...............................................................................................27

Rollant 240 Standard ......................................................................................................... 27

Rollant 250 Standard ......................................................................................................... 27

1b Main power supply...............................................................................................31

Rollant 250 Comfort ........................................................................................................... 31

1c Main power supply...............................................................................................35

Rollant 250 Comfort for UNIWRAP .................................................................................... 35

1d Main power supply...............................................................................................41

UNIWRAP .......................................................................................................................... 41

4a Circulation shut-off valve ....................................................................................45

Rollant 250 Comfort ........................................................................................................... 45

4b Circulation shut-off valve ....................................................................................49

Rollant 250 Comfort for UNIWRAP .................................................................................... 49

4c Circulation shut-off valve ....................................................................................53

UNIWRAP .......................................................................................................................... 53

5a Terminal ................................................................................................................57

Rollant 250 Comfort ........................................................................................................... 57

5b Terminal ................................................................................................................61

Rollant 250 Comfort for UNIWRAP .................................................................................... 61

6a CAN bus, module power supply .........................................................................65

Rollant 240 Standard ......................................................................................................... 65

Rollant 250 Standard ......................................................................................................... 65

6b CAN bus, module power supply .........................................................................69

Rollant 250 Comfort ........................................................................................................... 69

Electric System Rollant 240/250 TIC

6c CAN bus, module power supply......................................................................... 75

Rollant 250 Comfort for UNIWRAP .................................................................................... 75

6d CAN bus, module power supply......................................................................... 81

UNIWRAP up to serial no. 72900130.................................................................................81

6e CAN bus, module power supply......................................................................... 85

UNIWRAP from serial no. 72900131.................................................................................. 85

7a Rotocut................................................................................................................. 89

Rollant 240 Standard.......................................................................................................... 89

Rollant 250 Standard.......................................................................................................... 89

7b Rotocut................................................................................................................. 93

Rollant 250 Comfort ...........................................................................................................93

Rollant 250 Comfort for UNIWRAP .................................................................................... 93

11a Wrapping release................................................................................................. 99

Rollant 240 Standard.......................................................................................................... 99

Rollant 250 Standard.......................................................................................................... 99

11b Wrapping release............................................................................................... 105

Rollant 250 Comfort .........................................................................................................105

Rollant 250 Comfort for UNIWRAP .................................................................................. 105

12a Open / close tailgate.......................................................................................... 115

Rollant 250 Comfort .........................................................................................................115

Rollant 250 Comfort for UNIWRAP .................................................................................. 115

19a Load / unload bale ............................................................................................. 119

UNIWRAP ........................................................................................................................119

20a Raise / lower pick-up......................................................................................... 127

Rollant 250 Comfort .........................................................................................................127

Rollant 250 Comfort for UNIWRAP .................................................................................. 127

21a Wrapping arm rotation ...................................................................................... 131

UNIWRAP ........................................................................................................................131

22a Open / close film cutter, film break monitoring .............................................. 139

UNIWRAP ........................................................................................................................139

32a Taillight, side light ............................................................................................. 147

40a Additional sockets............................................................................................. 151

Rollant 250 Comfort .........................................................................................................151

40b Additional sockets............................................................................................. 155

Rollant 250 Comfort for UNIWRAP .................................................................................. 155

40c Additional sockets............................................................................................. 161

UNIWRAP up to serial no. 130.........................................................................................161

TIC Rollant 240/250 Electric System

Wiring loom A – part 1 ...............................................................................................166

- Rollant 250 Standard ..................................................................................................... 166

Wiring loom A – part 2 ...............................................................................................168

- Rollant 250 Standard ..................................................................................................... 168

Wiring loom B – part 1 ...............................................................................................170

- Rollant 250 Comfort....................................................................................................... 170

- Rollant 250 Comfort for UNIWRAP................................................................................ 170

Wiring loom B – part 2 ...............................................................................................172

- Rollant 250 Comfort....................................................................................................... 172

- Rollant 250 Comfort for UNIWRAP................................................................................ 172

Wiring loom B – part 3 ...............................................................................................174

- Rollant 250 Comfort....................................................................................................... 174

- Rollant 250 Comfort for UNIWRAP................................................................................ 174

Wiring loom C .............................................................................................................176

- Rollant 250 Comfort....................................................................................................... 176

- Rollant 250 Comfort for UNIWRAP................................................................................ 176

Wiring loom D .............................................................................................................178

- Rollant 250 Comfort for UNIWRAP................................................................................ 178

Wiring loom K .............................................................................................................180

- UNIWRAP...................................................................................................................... 180

Wiring loom L..............................................................................................................182

- UNIWRAP...................................................................................................................... 182

Wiring loom M.............................................................................................................184

- UNIWRAP...................................................................................................................... 184

Index ............................................................................................................................187

Electric System Rollant 240/250 TIC

Central terminal compartment

- Rollant 240 Standard

- Rollant 250 Standard

Electric System Rollant 240/250 TIC

Central terminal compartment Rollant 240/250 Standard

10 rol-e-ze 11/04

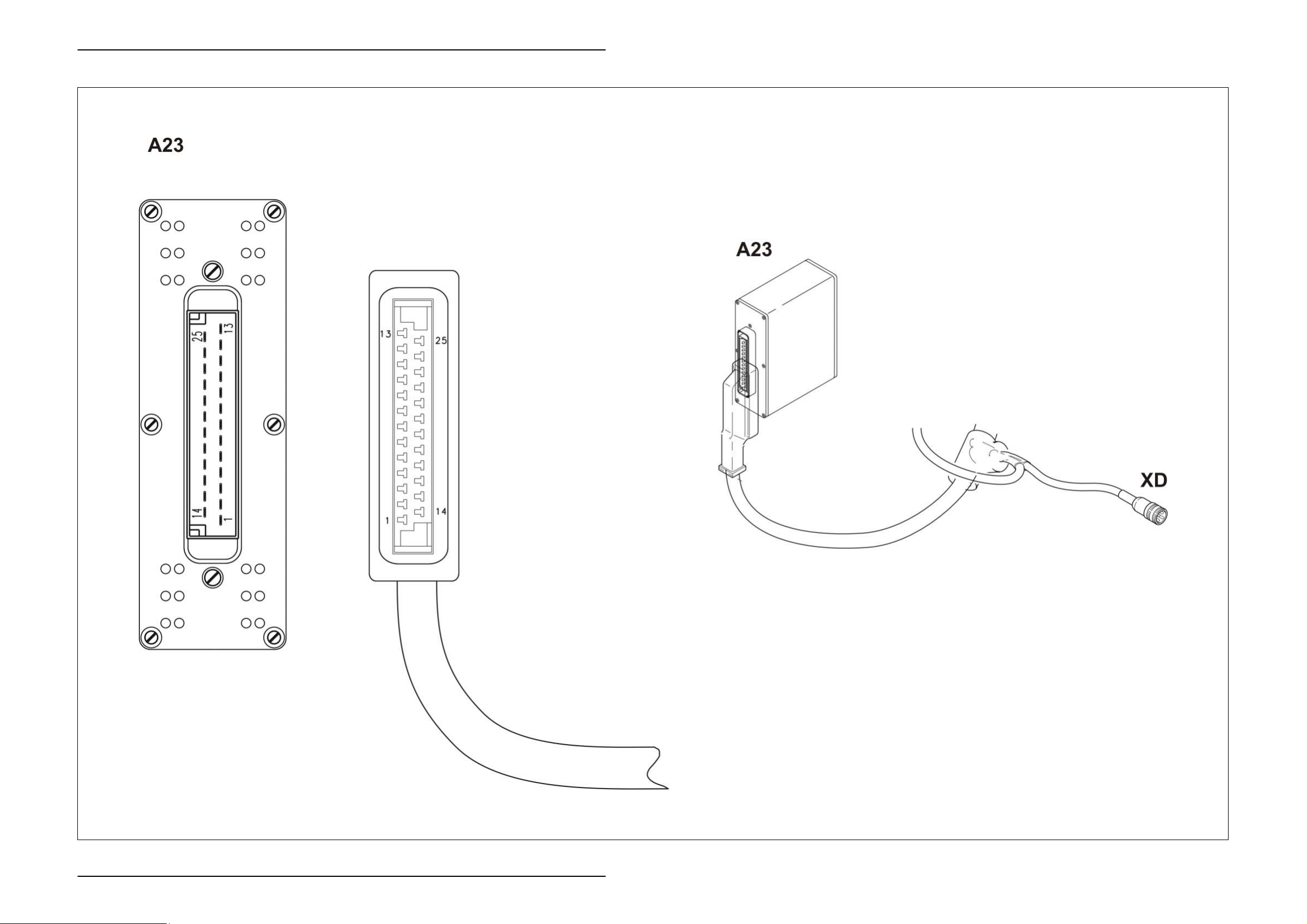

TIC Rollant 240/250 Electric System

Key to diagram:

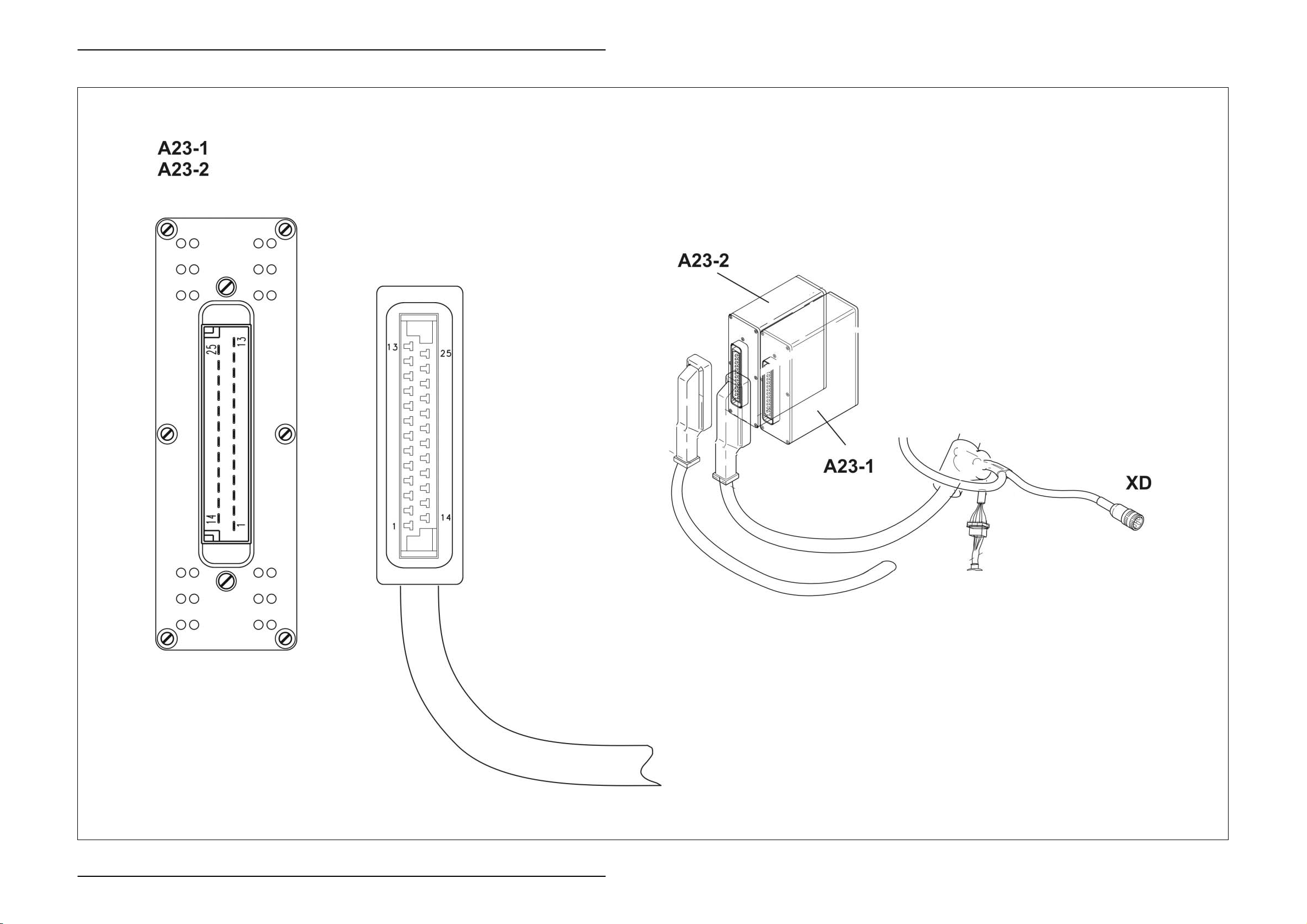

A23 ROLLANT 240/250 Standard

module.............................................Wiring loom A – part 2

XD CAN bus socket (7 pin) ................... Wiring loom A – part 2

11/04 rol-e-ze 11

Electric System Rollant 240/250 TIC

12 rol-e-ze 11/04

Central terminal compartment

- Rollant 250 Comfort

Electric System Rollant 240/250 TIC

Central terminal compartment Rollant 250 Comfort

14 rol-e-ze 11/04

TIC Rollant 240/250 Electric System

Key to diagram:

A23-1 ROLLANT module 1 ........................ Wiring loom B – part 2

A23-2 ROLLANT module 2 ........................ Wiring loom B – part 2

XD CAN bus connector (7 pin)

terminal............................................Wiring loom B – part 2

11/04 rol-e-ze 15

Electric System Rollant 240/250 TIC

16 rol-e-ze 11/04

Central terminal compartment

- UNIWRAP

Electric System UNIWRAP TIC

Central terminal compartment UNIWRAP

18 rol-e-ze 11/04

TIC UNIWRAP Electric System

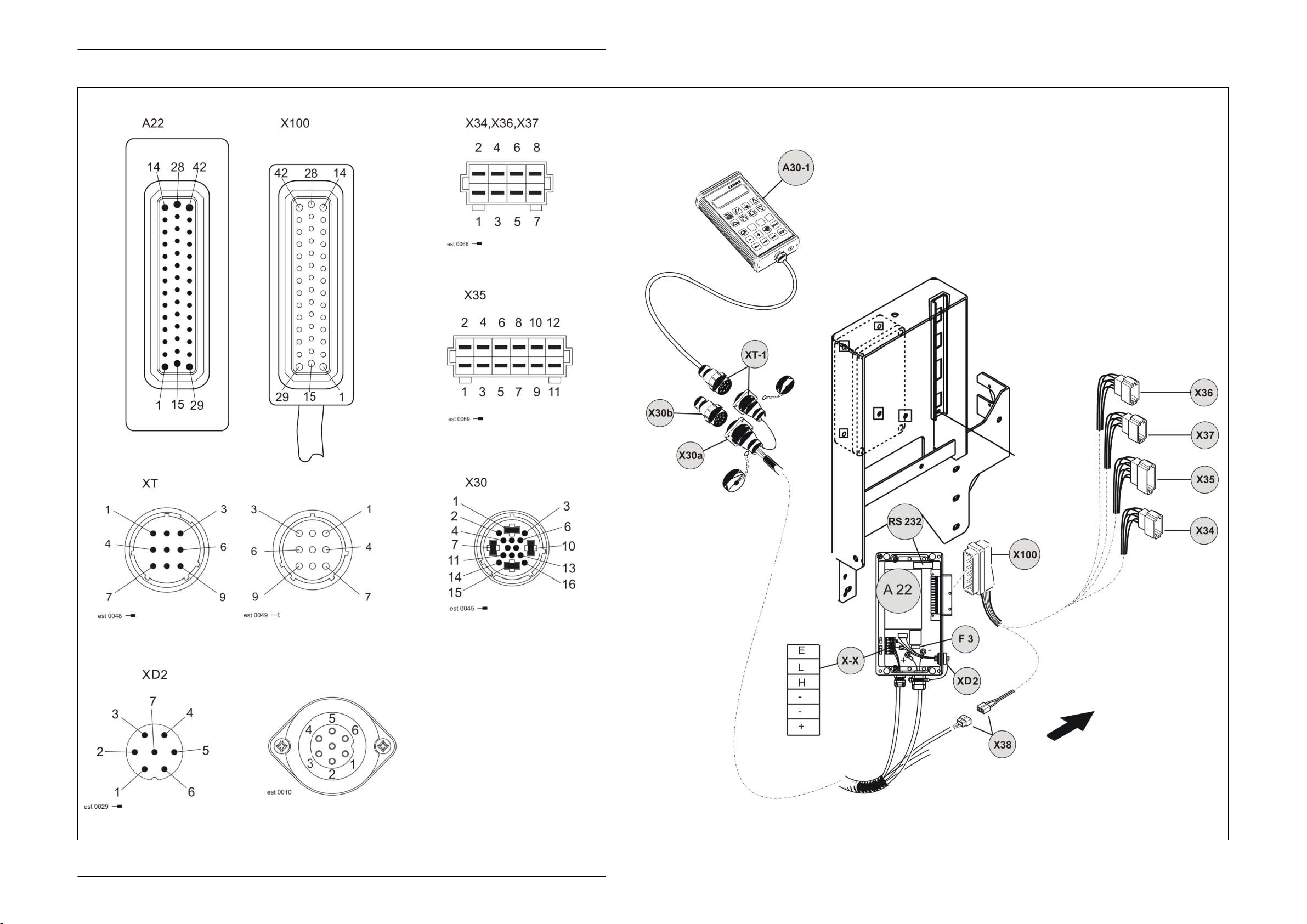

Key to diagram:

A22 UNIWRAP bale wrapper module

Connector mm² Colour

X-X E 0.5 rd

X-X L 0.5 bk

X-X H 0.5 gn-ye

X-X - 0.5 vi

X-X - 0.5 br-rd

X-X + 0.5 bk-rd

A30-1 Bale wrapper terminal

F 3 Fuse (15 Amperes)

RS 232 Data link

XD2 CAN bus socket (7 pin)

X-X Socket

XT-1 Terminal connector

X30a UNIWRAP link connector

X30b Blind connector (on Rollant balers without UNIWRAP)

X34 Hydraulic system connector

X35 Sensor system connector

X36 Hydraulic system connector

X37 Sensor system connector

11/04 rol-e-ze 19

Electric System UNIWRAP TIC

20 rol-e-ze 11/04

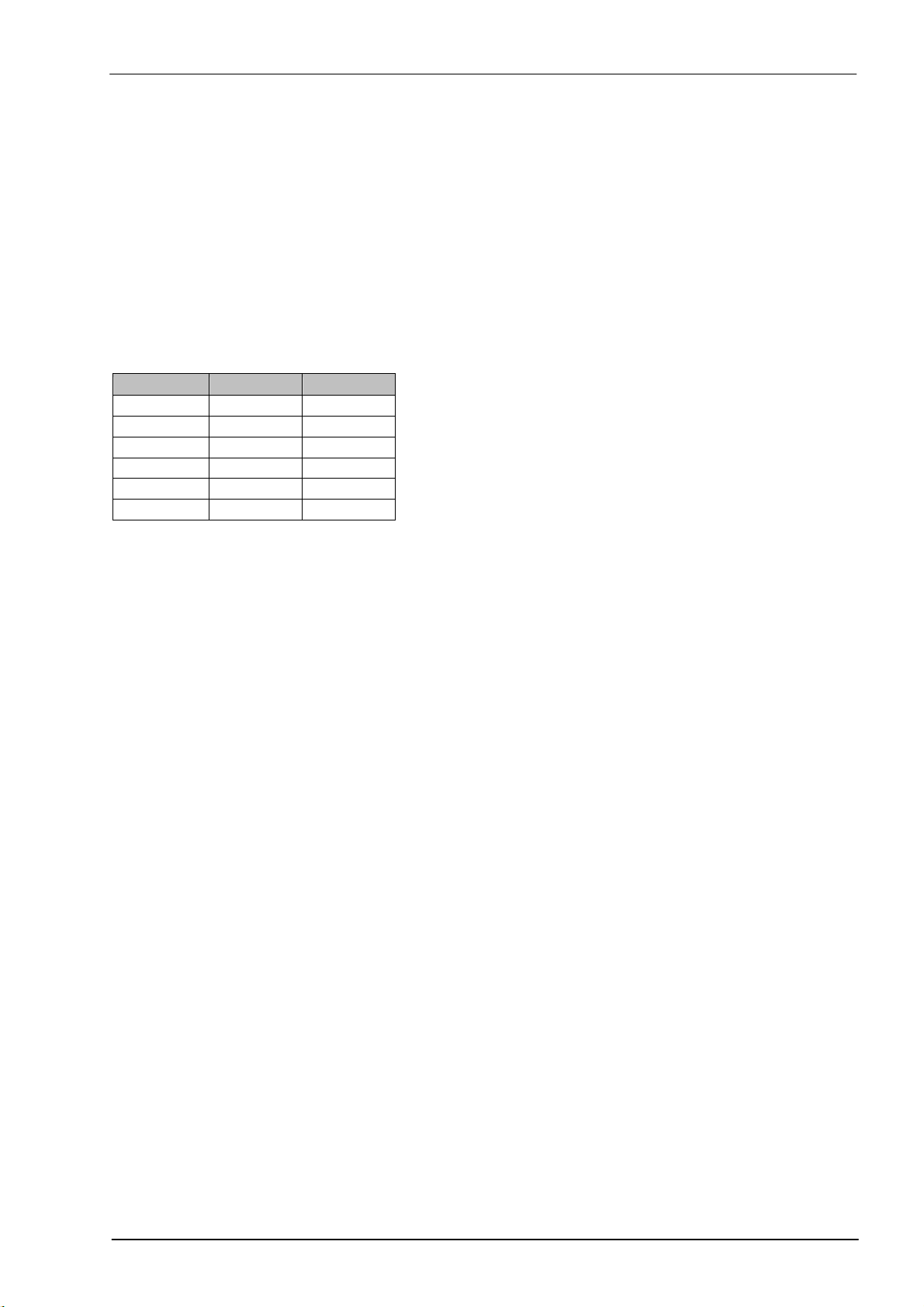

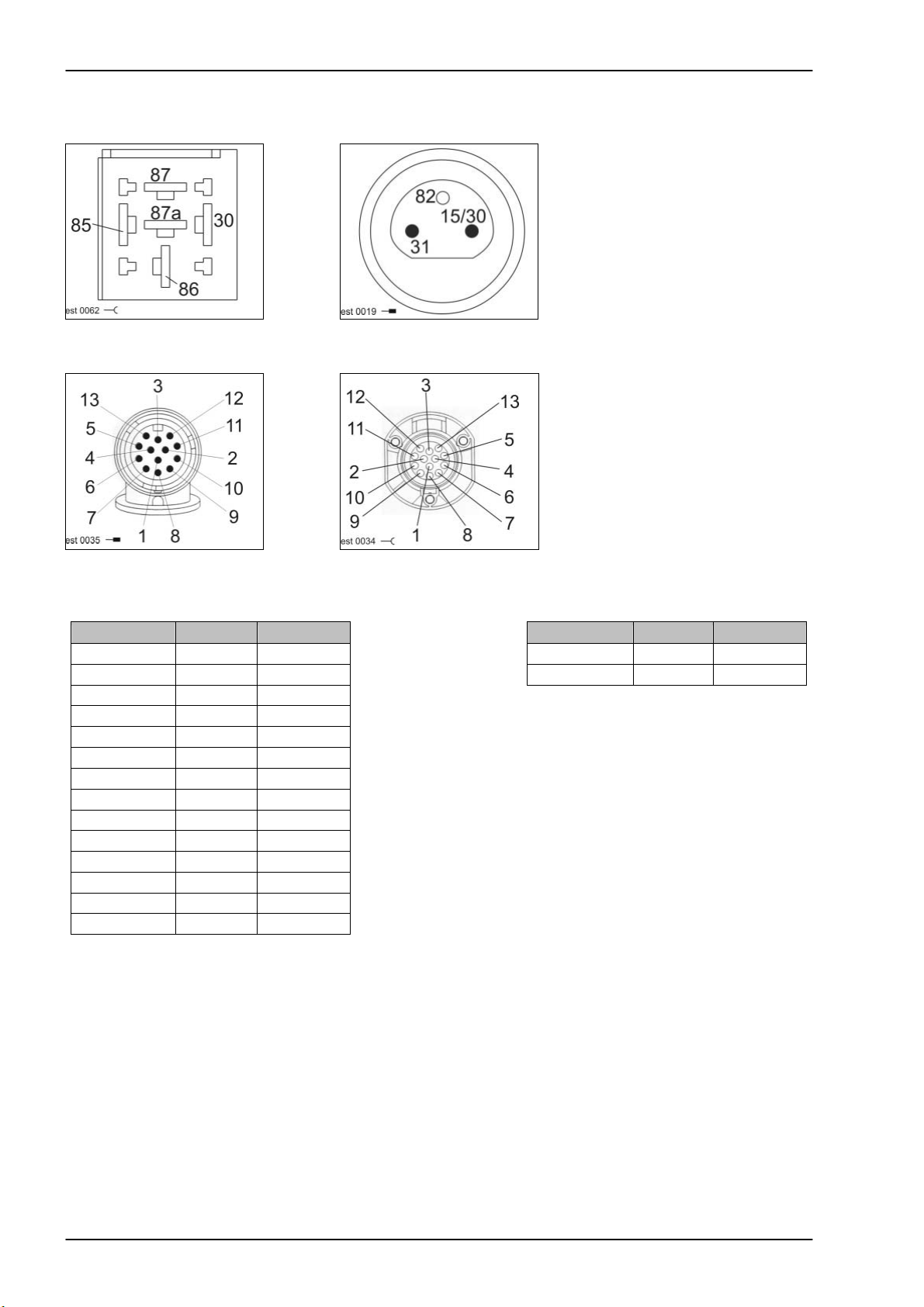

Pin assignment in modules

Rollant 240

Rollant 250

UNIWRAP

Electric System Rollant 240/250 TIC

Module A23 Rollant 240/250 Standard

Pin Function Component Measuring

variable

1 ROTOCUT knives ON solenoid coil Y55 12 V Output 7a

2 Electronics earth 32 Earth Input 6a

3 CAN high - - - 6a

4 Not used - - - 5 Wrapping release switch (manual) S77 Earth Input 11a

6 Not used - - - 7 Not used - - - 8 Not used - - - -

9 Not used - - - 10 Cam track switch Z35 12 V Input 11a

11 Not used - - - 12 Twine/net coupling solenoid coil Y39 12 V Output 11a

13 Buzzer H44 12 V Output 11a

14 ROTOCUT knives OFF Y54 12 V Output 7a

15 Electronics plus 15 12 V Input 6a

16 CAN low - - - 6a

17 No function - - - 18 Wrapping delay switch (manual) S76 Earth Input 11a

19 Wrapping type selector switch S74 Earth Input 11a

20 Power plus

K 90 / 87 12 V Input 7a, 11a

(protected against rev. polarity)

21 Tailgate closed switch Z16 12 V Input 11a

22 Bale ejector switch Z6 12 V Input 11a

23 Main switch ON / OFF - Rotocut ON / OFF S75 12 V Input 7a

24 Not used - - - 25 Operating light H3 12 V Output 11a

Direction Circuit

diagram no.

22 rol-e-ze 11/04

TIC Rollant 240/250 Electric System

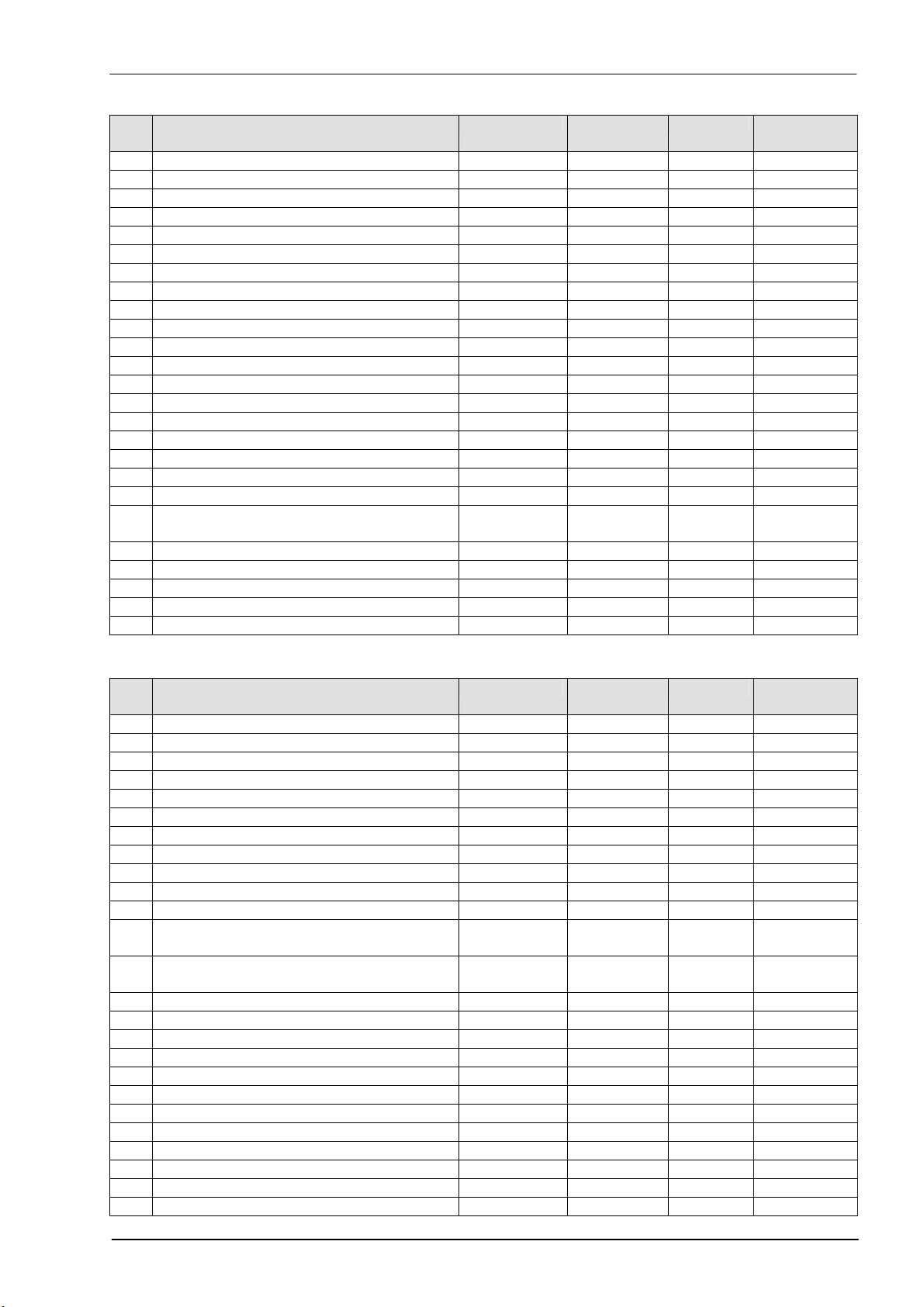

Module A23 –1 Rollant 250 Comfort and Rollant 250 Comfort for Uniwrap

Pin Function Component Measuring

variable

1 Twine coupling Y38 12 V Output 11b

2 Electronics earth 32 Earth Input 6b, 6c

3 CAN high - - - 6b, 6c

4 Amplifier (net cutter motor) V16 5 V Output 11b

5 Drive speed sensor B9 high- low (-) Input 11b

6 Left twine ball speed sensor B13 high- low (-) Input 11b

7 Not used - - - 8 Not used - - - -

9 Tailgate open switch Z17 12 V Input 11b

10 Cam track switch Z35 12 V Input 11b

11 Not used - - - 12 Tailgate open solenoid coil Y27 12 V Output 12a

13 Tailgate close solenoid coil Y28 12 V Output 12a

14 Net coupling solenoid coil Y41 12 V Output 11b

15 Electronics plus 15 12 V Input 6b, 6c

16 CAN low - - - 6b, 6c

17 Buzzer H44 5 V Output 5a, 5b

18 Right twine ball speed sensor B14 high- low (-) Input 11b

19 Net roll speed sensor B22 high- low (-) Input 11b

20 Power plus (protected ag. rev. polarity) K 90 / 87 12 V Input 4a, 4b, 11b,

21 Tailgate closed switch Z16 12 V Input 11b

22 Bale ejector switch Z6 12 V Input 11b

23 No function - - - 40a, 40b

24 Not used - - - 25 Circulation shut-off valve solenoid coil Y77 / Y77-2 12 V Output 4a, 4b

Module A23 – 2 Rollant 250 Comfort and Rollant 250 Comfort for Uniwrap

Pin Function Component Measuring

variable

1 Pick-up lower solenoid coil Y49 12 V Output 20a

2 Electronics earth 32 Earth Input 6b, 6c

3 CAN high - - - 6b, 6c

4 No function - - - 40a, 40b

5 No function - - - 40a, 40b

6 Not used - - - -

7 Not used - - - -

8 Not used - - - -

9 No function - - - 40a, 40b

10 No function - - - 40a, 40b

11 Electronics plus 15 12 V Input 6b, 6c

12 Rotor reverse solenoid coil

Y56 12 V Output 7b

(extend cylinder)

13 Rotor reverse solenoid coil

Y57 12 V Output 7b

(retract cylinder)

14 Pick-up raise solenoid coil Y48 12 V Output 20a

15 Electronics plus 15 12 V Input 6b, 6c

16 CAN low - - - 6b, 6c

17 No function - - - 40a, 40b

18 Not used - - - 19 Not used - - - 20 Power plus (protected ag. rev. polarity) K 90 / 87 12 V Input 7b, 20a

21 Reverser switch Z48 12 V Input 7b

22 No function - - - 40a, 40b

23 Not used - - - 24 Not used - - - 25 Relay K93 (ROTOCUT knives ON/OFF) K93 12 V Output 7b

Direction Circuit

diagram no.

12a

Direction Circuit

diagram no.

11/04 rol-e-ze 23

Electric System Rollant 240/250 TIC

Module A22 – Uniwrap bale wrapper (Pin assignment on connector X100)

Pin Function Component Measuring

variable

1 Not used - - - 2 Rotate wrapping arm forward solenoid coil Y133 12 V PWM Output 21a

3 Not used - - - 4 Wrapping arm basic position sensor B106 high- low (-) Input 21a

5 Film break monitoring receiver V12 high- low (-) Input 22a

6 Not used - - - 7 Not used - - - 8 Rollant circulation shut-off valve solenoid

Y77-1 12 V Output 4c

coil

9 Rotate wrapping arm backward solenoid

Y134 12 V Output 21a

coil

10 Lower tipping cradle solenoid coil Y135 12 V Output 19a

11 No function - - - 40c

12 Raise tipping cradle solenoid coil Y136 12 V Output 19a

13 Close film cutters solenoid coil Y140 12 V Output 22a

14 Raise wrapping table Y138 12 V Output 19a

15 Not used - - - 16 Not used - - - 17 Not used - - - 18 Not used - - - 19 Not used - - - 20 Not used - - - 21 Bale on wrapping table switch Z92 Earth Input 19a

22 Safety bracket switch Z91/91-2 Earth Input 21a

23 Wrapping arm rotations sensor B107 high- low (-) Input 21a

24 Not used - - - 25 Not used - - - 26 Not used - - - 27 Not used - - - 28 Lower wrapping table solenoid coil Y137 12 V Output 19a, 21a, 22a

29 0 Volt power (earth) A22 0 V Output 19a, 21a, 22a

30 Not used - - - 31 12 V (sensor power supply) A22 12 V Output 19a

32 Not used - - - 33 Not used - - - 34 Wrapping table at top switch B105 high- low (-) Input 19a

35 Not used - - - 36 Bale in tipping cradle sensor B102 high- low (-) Input 19a

37 Tipping cradle at bottom sensor B103 high- low (-) Input 19a

38 0 V (sensor power supply) A22 0 V Output 19a, 21a, 22a

39 Not used - - - 40 Not used - - - 41 Open film cutters Y139 12 V Output 22a

42 Not used - - - -

Direction Circuit

diagram no.

24 rol-e-ze 11/04

TIC Rollant 240/250 Electric System

Circuit diagram allocation of fuses and relays

25 A On tractor side (not shown) / protects + 30

K90 1a, 1b, 1c

K93 7b

V16 11b

11/04 rol-e-ze 25

Electric System Rollant 240/250 TIC

26 rol-e-ze 11/04

1a

Main power supply

Rollant 240 Standard

Rollant 250 Standard

Electric System Rollant 240/250 TIC

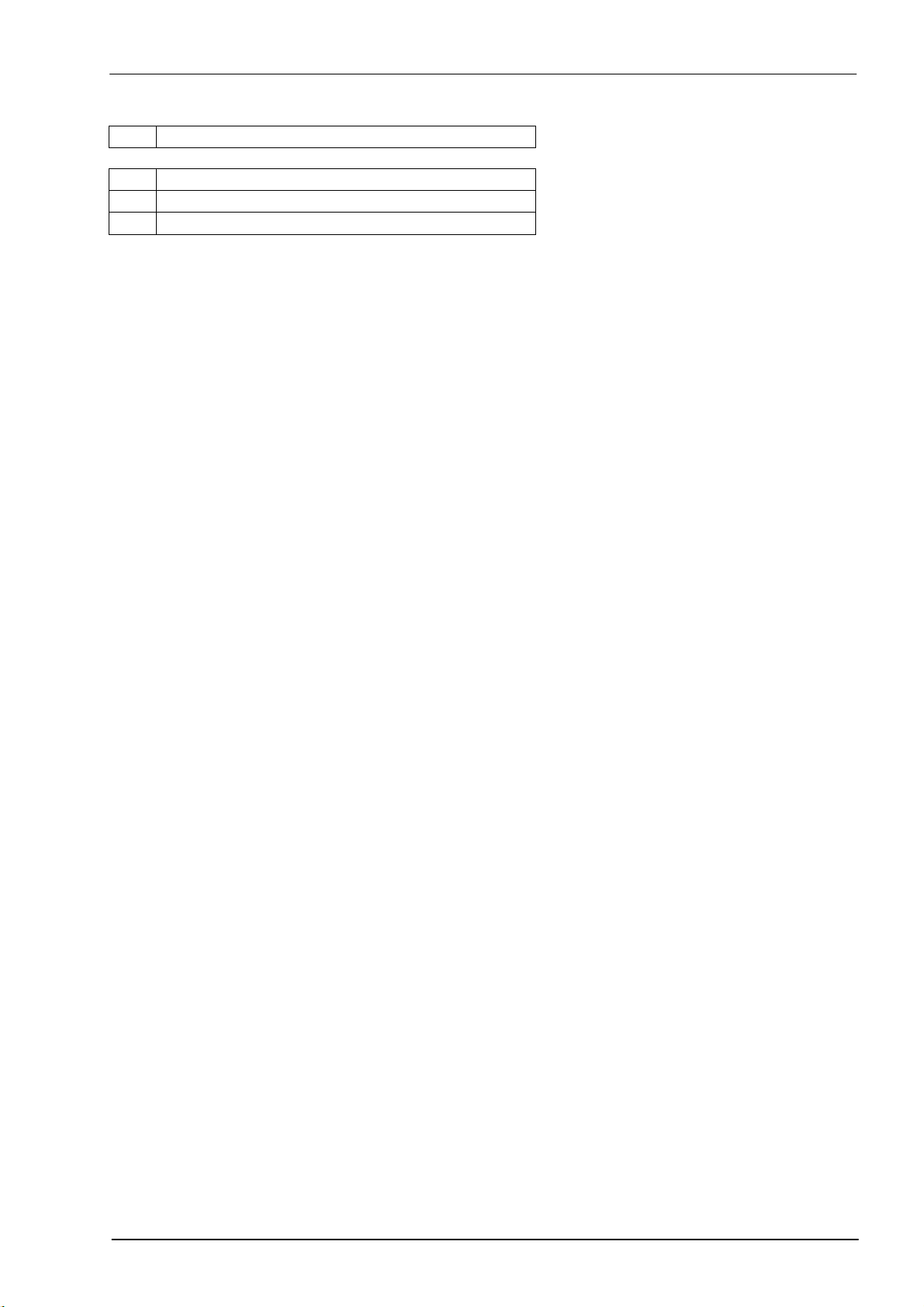

01a - Main power supply Rollant 240/250 Standard

Key to diagram:

Measured value table:

K90 Power supply relay

(protected against reverse polarity).... Wiring loom A-part 2

S75 Main switch......................................... Wiring loom A-part 1

V10 Reverse polarity protection Diode .....Wiring loom A-part 2

VDR1 Varistor ............................................... Wiring loom A-part 2

XT Terminal connector ............................ Wiring loom A-part 1

XV Power supply connector ..................... Wiring loom A-part 1

Item Component Measured value Note

K90 Remote control relay

20 A

30 A

75±10 Ω

(Pin 86/1 – 85/2)

(Pin 87a/4 – 30/3)

(Pin 87/5 – 30/3)

28 rol-e-ze 11/04

TIC Rollant 240/250 Electric System

Description of function:

Main power supply Power supply from the tractor to the baler is via connector XV. On the

tractor, this prower supply should be protected by a fuse of 25 A max.

Potential + 15 This is switched by the main switch T 12 on the control box

(electronics +).

Potential K 90 / 87 Potential K 90/ 87 is a power plus protected against reverse polarity by

diode V10.

Overvoltage protection VDR1 becomes conducting when overvoltage occurs. This smooths the

voltage peaks in the electronics circuit (+15 / -32).

11/04 rol-e-01a 29

Electric System Rollant 240/250 TIC

Connector pin definition

Socket K90 Connector XV

Connector XT Socket XT

Connector mm² Colour

K90/30 2.5 bk

K90/85 1.0 br-rd

Connector mm² Colour

XV - 15/30 2.5 bk

XV - 31 2.5 br

K90/86 0.75 bk-rd

K90/87 2.5 bk-wt

XT1 – 1 1.5 bk

XT1 – 2 1.5 br

XT1 – 5 1.5 bk-rd

XT1 – 6 1.5 br-rd

XT2 – 1 1.5 bk

XT2 – 2 1.5 br

XT2 – 5 1.5 bk-rd

XT2 – 6 1.5 br-rd

30 rol-e-ze 11/04

Loading...

Loading...