Page 1

QUANTUM 6800

P

QUANTUM 3500 - 6800

Technical Systems

Page 2

Technical Systems QUANTUM TIC

10/04

Page 3

TIC QUANTUM Technical Systems

Chapters

1 Technical Data

3 Operation

10 Brakes

11 Hydraulic System

12 Electric System / Diagnosis

10/04

Page 4

Technical Systems QUANTUM TIC

10/04

Page 5

TIC QUANTUM Technical Data

1.0 QUANTUM 2500 K, 2500 P, 3500 K, 3500 P, 3800 K, 3800 P..............................................................2

1.1

QUANTUM 3500 K, 3500 P, 3500 S, 3800 K, 3800 P, 2500 K, 2500 P..............................................2

1.2 QUANTUM 5500 S-18, 5500 S-16, 5500 S, 4500 S, 6800 S ..............................................................5

1.3 QUANTUM 6800 P, 6500 P, 5500 P-18, 5500 GT, 5500 P, 4500 P ...................................................8

10/04 1-1

Page 6

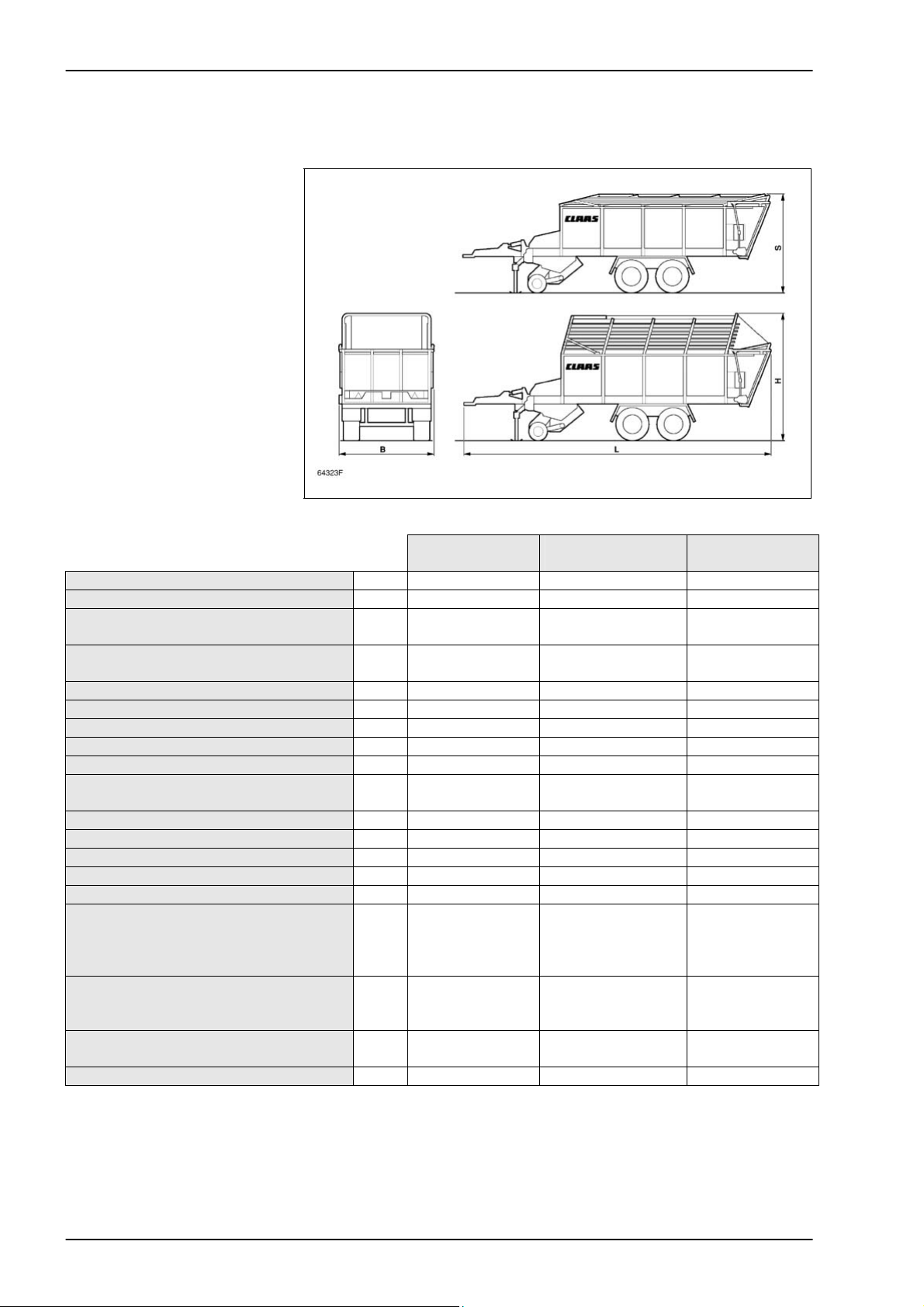

Technical Data QUANTUM TIC

1.0 QUANTUM 2500 K, 2500 P, 3500 K, 3500 P, 3800 K, 3800 P

1.1 QUANTUM 3500 K, 3500 P, 3500 S, 3800 K, 3800 P, 2500 K, 2500 P

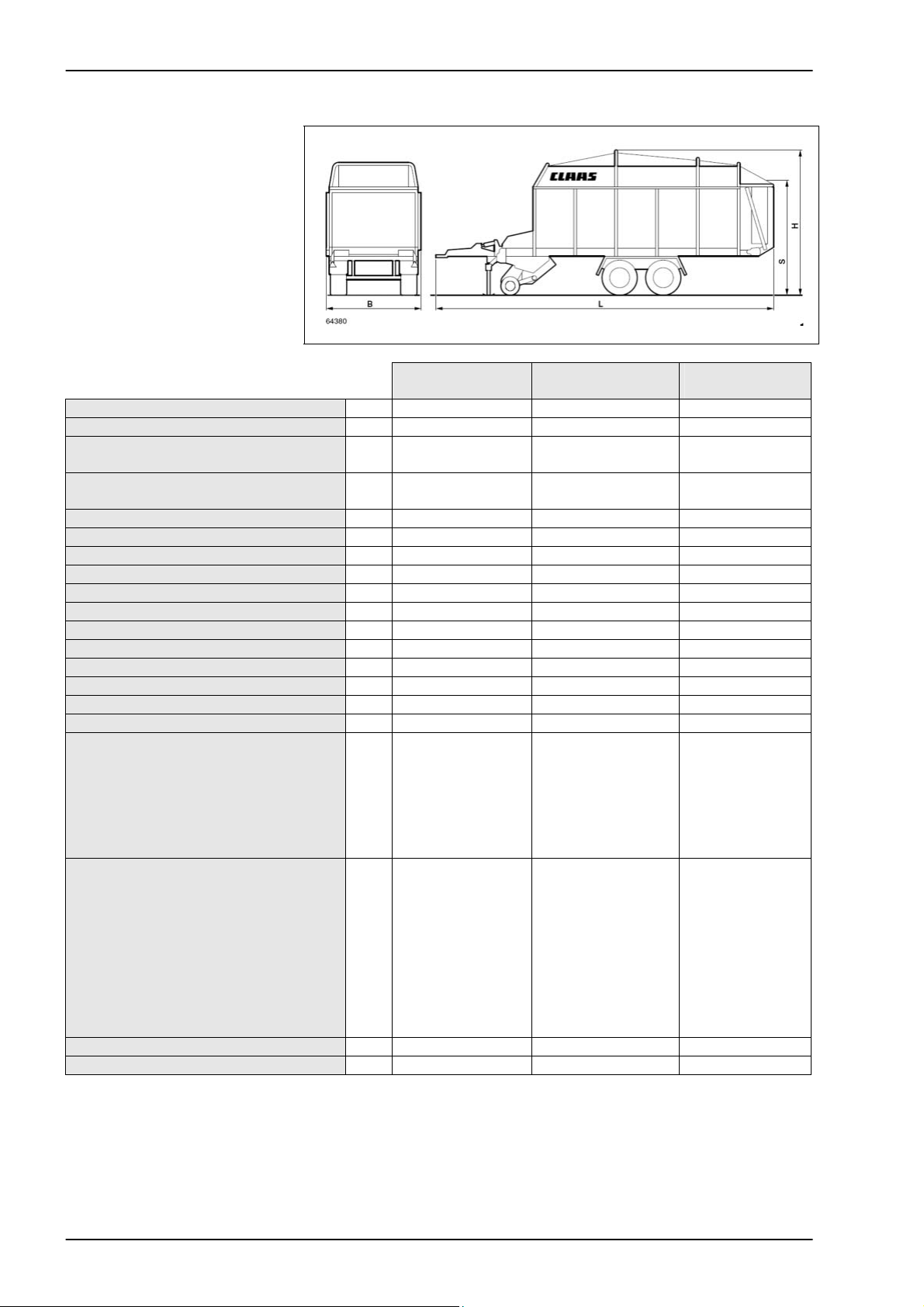

Length (L) mm 8,100 8,100 8,200

Width (B) mm 2,550 2,550 2,550

Height (H) – dry forage assembly folded

up

Height (S) – dry forage assembly folded

down

Track width mm 1,850 1,850 1,850

Pick-up width mm 1,800 1,800 1,800

Platform height mm 1,180 1,180 1,180

Loading capacity (acc. to DIN 11741) m3 26.6 28 25.6

Kerb weight kg 5,160 5,200 5,860

Permissible total weight (Rückmatic /

compressed air)

Number of cutting knives 33 33 33

Shortest theoretical length of cut mm 45 45 45

Number of pick-up tines per tine bar 26 26 26

Tine spacing mm 61 61 61

PTO speed min-1 1,000 1,000 1,000

Tyres - Rückmatic up to 40 km/h

or

- compressed air up to 40 km/h

- compressed air up to 60 km/h

Tyre pressure - with tyres 500/50-17

555/45-17

19.0/45-17

Tightening torque of wheel nuts - wagon

wheels

Sound pressure level dB(A) 70 70 70

QUANTUM

3500 K

QUANTUM

3500 P

QUANTUM

3500 S

mm 3,410 3,600 3,600

mm 2,600 3,050 3,050

8,000/11,000 8,000/11,000 8,000/11,000

19.0/45-17

500/50-17 10 PR

555/45-17 10 PR

500/50-17 10 PR

bar

bar

bar

3.5

3.0

3.0

19.0/45-17

500/50-17 10 PR

500/50-17 10 PR

500/50-17 10 PR

3.5

3.0

3.0

19.0/45-17

500/50-17 10 PR

555/45-17 10 PR

555/45-17 10 PR

3.5

3.0

3.0

Nm 300 300 300

1-2 10/04

Page 7

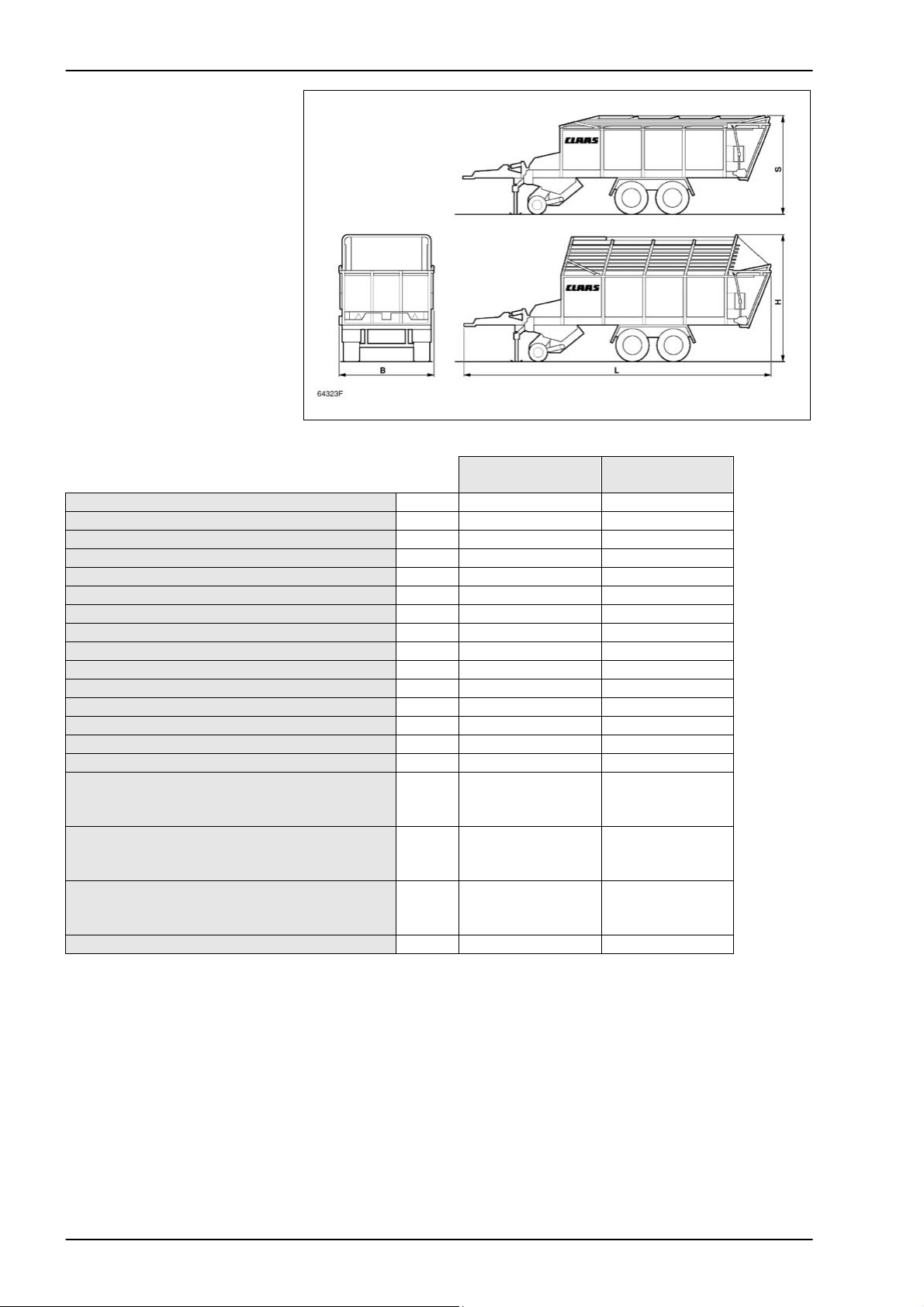

TIC QUANTUM Technical Data

QUANTUM

2500 K

QUANTUM

2500 P

Length (L) mm 8,100 8,100

Width (B) mm 2,550 2,550

Height (H) – dry forage assembly folded up mm 3,410 3,600

Height (S) – dry forage assembly folded down mm 2,600 3,050

Track width mm 1,850 1,850

Pick-up width mm 1,800 1,800

Platform height mm 1,180 1,180

Loading capacity (acc. to DIN 11741) m3 26.6 28

Kerb weight kg 4,500 4,750

Permissible total weight

8,000/11,000 8,000/11,000

(Rückmatic / compressed air)

Number of cutting knives 33 33

Shortest theoretical length of cut mm 40 40

Number of pick-up tines per tine bar 26

Tine spacing mm 61 61

PTO speed min-1 540 540

Tyres - Rückmatic up to 40 km/h

or

- compressed air up to 40 km/h

- compressed air up to 60 km/h

Tyre pressure - with tyres 500/50-17

555/45-17

9.0/45-17

15.0/55-17

Tightening torque of wheel nuts - wagon

wheels M18x1.5

M20x1.5

Sound pressure level dB(A) 70 70

15.0/55-17

19.0/45-17

500/50-17 10 PR

500/50-17 10 PR

555/45-17 10 PR

bar

bar

bar

bar

Nm

Nm

3.5

3.0

3.0

3.5

270

380

15.0/55-17

19.0/45-17

500/50-17 10 PR

500/50-17 10 PR

555/45-17 10 PR

3.5

3.0

3.0

3.5

270

380

10/04 1-3

Page 8

Technical Data QUANTUM TIC

QUANTUM

3800 K

QUANTUM

3800 P

Length (L) mm 9,250 9,250

Width (B) mm 2,550 2,550

Height (H) – dry forage assembly folded up mm 3,410 3,600

Height (S) – dry forage assembly folded down mm 2,600 3,050

Track width mm 1,850 1,850

Pick-up width mm 1,800 1,800

Platform height mm 1,180 1,180

Loading capacity (acc. to DIN 11741) m3 31.8 33.2

Kerb weight kg 5,550 5,650

Permissible total weight (compressed air) 11,000 11,000

Number of cutting knives 33 33

Shortest theoretical length of cut mm 45 45

Number of pick-up tines per tine bar 26 26

Tine spacing mm 61 61

PTO speed min-1 1.000 1.000

Tyres

- compressed air up to 40 km/h

- compressed air up to 60 km/h

Tyre pressure - with tyres 500/50-17

555/45-17

19.0/45-17

Tightening torque of wheel nuts - wagon

wheels M18x1.5

M20x1.5

Sound pressure level dB(A) 70 70

500/50-17 10 PR

555/45-17 10 PR

bar

bar

bar

3.5

3.0

3.0

500/50-17 10 PR

555/45-17 10 PR

Nm

270

300

3.5

3.0

3.0

270

300

1-4 10/04

Page 9

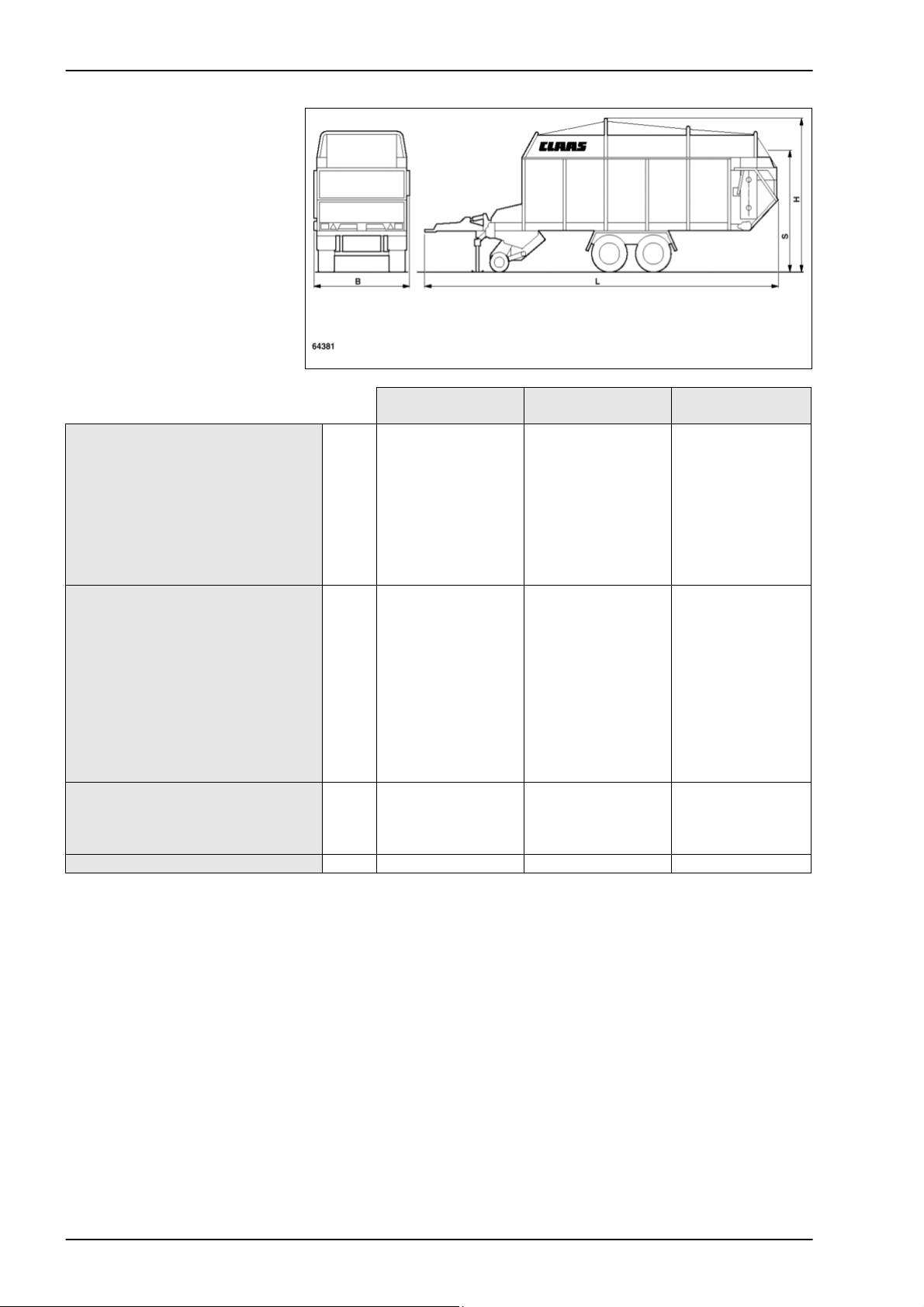

TIC QUANTUM Technical Data

1.2 QUANTUM 5500 S-18, 5500 S-16, 5500 S, 4500 S, 6800 S

QUANTUM

5500 S-18

QUANTUM

5500 S-16

QUANTUM

6800 S

Length (L) mm 9,250 9,250 10,500

Width (B)

- Standard

- with tyres 700/45-22.5

- with tyres 600/55-R26.5

- with tyres 700/50-R26.5

- with tyres 800/40-R26.5

Height (H) - dry forage assembly folded

up

mm

2,550

2,720

-

-

mm

mm

3,990

-

2,550

-

-

-

-

3,930

-

2,550

2,720

2,550

2,750

2,930

3,990

4,000

- with tyres 800/40-R26.5

Height (S) - dry forage assembly folded

up

mm

mm

3,290

-

3,230

-

3,290

3,300

- with tyres 800/40-R26.5

Track width - with tyres 22.5

- with tyres 26.5

mm

mm

1,950

-

1,950

-

1,950

2,000

Pick-up width mm 1,800 1,800 1,800

Platform area mm 2,160 x 5,700 2,160 x 5,700 2,160 x 5,700

Loading capacity (acc. to DIN 11741) m3 31 31 38

Kerb weight

with tyres 800/40-R26.5

incl. forced steering

kg

kg

8,340

-

7,600

-

8,810

9,350

Permissible total weight 18,000 16,000 20,000

Number of cutting knives 33 33 33

Shortest theoretical length of cut mm 45 45 45

Number of pick-up tines per tine bar 26 26 26

Tine spacing mm 61 61 61

PTO speed min-1 1,000 1,000 1,000

10/04 1-5

Page 10

Technical Data QUANTUM TIC

Tyres:

- up to 40 km/h without AGS

- up to 50 km/h without AGS

- up to 60 km/h without AGS

- up to 60 km/h air suspension

- Pick-up wheels

Tyre pressure

- with tyres: 555/45-17

500/55-20

600/55-22.5

550/45-R22.5

650/50-R22.5

700/45-22.5

600/55-R26.5

700/50-R26.5

800/40-R26.5

Pick-up wheels

Tightening torque of wheel nuts

M18 x x1.5

M20 x 1.5

M22 x x1.5

Sound pressure level dB(A) 70 70 70

QUANTUM

5500 S-18

700/45-22.5 12PR

-

-

600/55-22.5 12PR

650/50-R22.5 12PR

-

-

16x6.5-8 4PR

bar

-

-

3.0

-

3.0

1.5

-

-

-

2.5

Nm

380

510

QUANTUM

5500 S-16

555/45-17 154F

-

-

550/45-R22.5

555/45-17 154F

-

500/55-20 12PR

16x6.5-8 4PR

3.0

4.5

-

3.0

-

-

-

-

-

2.5

270

-

-

QUANTUM

6800 S

700/45-22.5 12PR

700/50-R26.5

800/40-R26.5

-

650/50-R22.5 12PR

600/55-R26.5

-

16x6.5-8 4PR

-

-

3.0

-

3.0

1.5

3.0

1.5

1.5

2.5

-

-

510

1-6 10/04

Page 11

TIC QUANTUM Technical Data

QUANTUM

5500 S

QUANTUM

4500 S

Length (L) mm 9,250 8,160

Width (B) mm 2,550 2,550

Height (H)

– dry forage assembly folded up

– dry forage assembly folded down

mm

mm

3,840

3,040

3,840

3,040

Track width mm 1,850 1,850

Pick-up width mm 1,800 1,800

Platform height mm 1,240 1,240

Platform area mm 2,160 x 5,700 2,160 x 4,700

Loading capacity (acc. to DIN 11741) m3 31 26,3

Kerb weight kg 6,920 6,500

Permissible total weight 13,000 11,000

Number of cutting knives 33 33

Shortest theoretical length of cut mm 45 45

Number of pick-up tines per tine bar 26 26

Tine spacing mm 61 61

PTO speed min-1 1,000 1,000

Tyres - up to 40 km/h without AGS

- up to 60 km/h without AGS

- up to 80 km/h with AGS

- up to 60 km/h air suspension

- Pick-up wheels

Tyre pressure - with tyres 500/50-17

555/45-17

500/55-20

16x6.5-8

Tightening torque of wheel nuts – wagon

555/45-17 146F

555/45-17 146F

555/45-17 146F

555/45-17 146F

16x6.5-8 4PR

bar

bar

bar

-

3.0

-

2.5

500/50-17 10PR

555/45-17 146F

555/45-17 146F

-

16x6.5-8 4PR

3.5

3.0

-

2.5

Nm 300 300

wheels

Sound pressure level dB(A) 70 70

10/04 1-7

Page 12

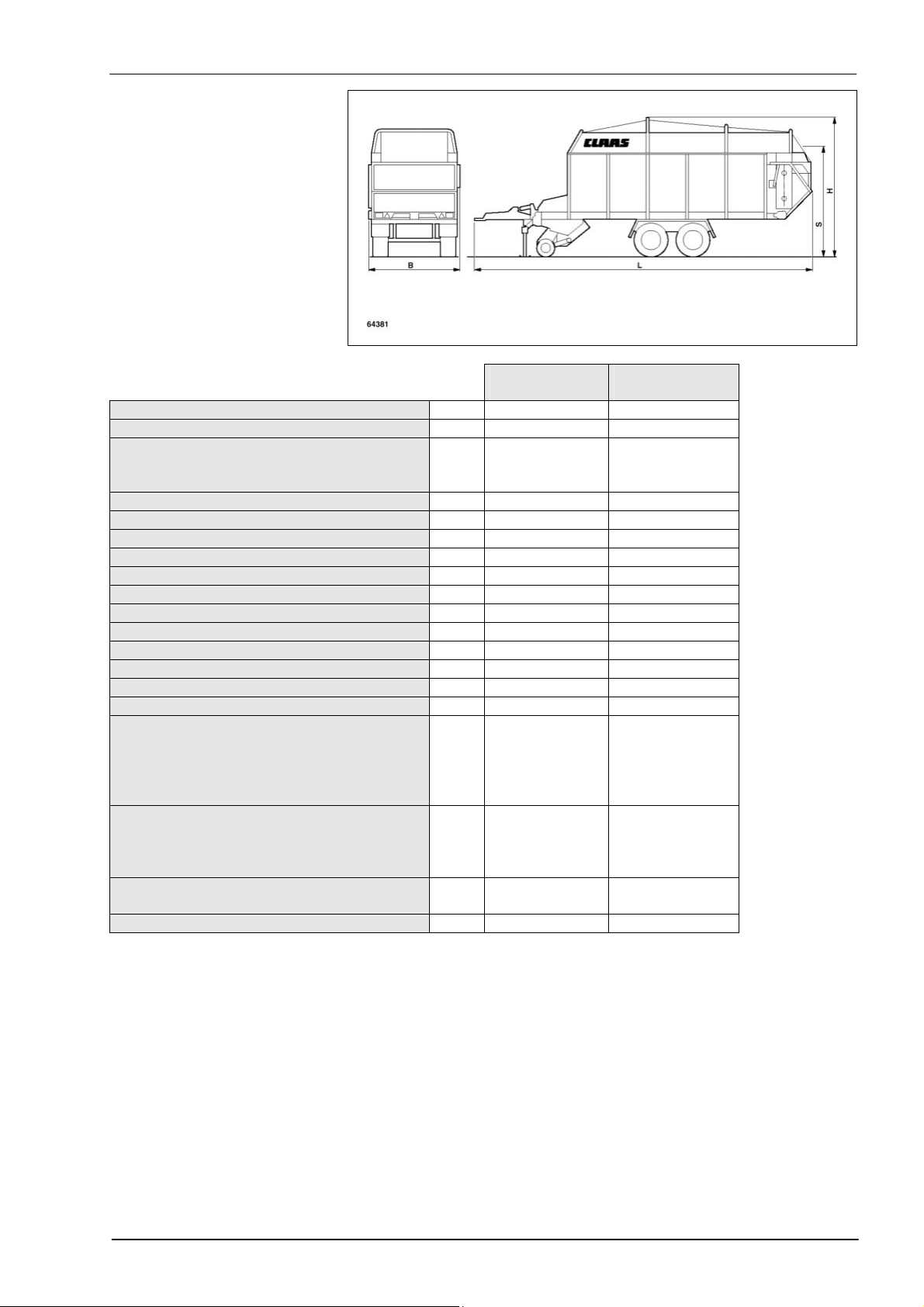

Technical Data QUANTUM TIC

1.3 QUANTUM 6800 P, 6500 P, 5500 P-18, 5500 GT, 5500 P, 4500 P

QUANTUM

6800 P

QUANTUM

6500 P

QUANTUM

5500 P-18

Length (L) mm 10,180 10,019 9,250

Width (B) mm 2,550 2,550 2,550

Height (H) – dry forage assembly

mm 3,990 3,950 3,990

folded up

Height (S) – dry forage assembly

mm 3,290 3,190 3,290

folded down

Track width mm 1,950 1,950 1,950

Pick-up width mm 1,800 1,800 1,800

Platform height mm 1,240 1,240 1,490

Platform area mm 2,160 x 7,600 2,160 x 7,550 2,160 x 6,550

Loading capacity (acc. to DIN 11741) m3 40 45.7 34

Kerb weight kg 8,030 7,440 7,240

Permissible total weight kg 20,000 16,000 18,000

Number of cutting knives 33 33 33

Shortest theoretical length of cut mm 45 45 45

Number of pick-up tines per tine bar 26 26 26

Tine spacing mm 61 61 61

PTO speed min

Tyres - up to 40 km/h without AGS

- up to 50 km/h without AGS

- up to 60 km/h without AGS

- up to 80 km/h with AGS

- up to 60 km/h air suspension

- Pick-up wheels

Tyre pressure - with tyres

555/45-17

500/55-20

600/55-22.5

650/50-R22.5

700/45-22.5

600/55-R26.5

700/50-R26.5

800/40-R26.5

Pick-up wheels

-1

1,000 1,000 1,000

700/45-22.5 12PR

700/50-R26.5

-

650/50-22.5 12PR

-

-

16x6.5-8 4PR

bar

-

-

3.0

3.0

1.5

3.0

1.5

1.5

2.5

2x 500/50-17 14PR

4x 8.25 R70 14PR

-

-

-

-

16x6.5-8 4PR

4.5

4.5

-

-

-

-

2.5

-

600/55-22.5 12PR

650/55-22.5 12PR

-

-

16x6.5-8 4PR

-

-

3.0

3.0

1.5

-

-

-

2.5

Tightening torque of wheel nuts Nm 300 300 300

Sound pressure level dB(A) 70 70 70

1-8 10/04

Page 13

TIC QUANTUM Technical Data

QUANTUM

5500 GT

QUANTUM

5500 P

QUANTUM

4500 P

Length (L) mm 8,860 8,860 7,770

Width (B) mm 2,550 2,550 2,550

Height (H) – dry forage assembly folded up mm 3,800 3,800 3,800

Height (S) – dry forage assembly folded

mm 3,040 3,040 3,040

down

Track width mm 1,900 1,850 1,850

Pick-up width mm 1,800 1,800 1,800

Platform height mm 1,240 1,240 1,240

Platform area mm 2,160 x 6,500 2,160 x 6,550 2,160 x 5,400

Loading capacity (acc. to DIN 11741) m3 34 34 29.3

Kerb weight kg 6,550 6,200 5,740

Permissible total weight kg 16,000 13,000 11,000

Number of cutting knives 33 33 33

Shortest theoretical length of cut mm 45 45 45

Number of pick-up tines per tine bar 26 26 26

Tine spacing mm 61 61 61

PTO speed min-1 1,000 1,000 1,000

Tyres - up to 40 km/h without AGS

- up to 50 km/h without AGS

- up to 60 km/h without AGS

- up to 60 km/h air suspension

- Pick-up wheels

Tyre pressure

- with tyres 500/50-17

550/45-R22.5

555/45-17

500/55-20

550/45-17 154F

Pick-up wheels

Tightening torque of wheel nuts

M18 x 1.5

M20 x 1.5

Sound pressure level dB(A) 70 70 70

555/45-17 154F

550/45-R22.5

555/45-17 145F

500/55-20 12PR

16x6.5-8 4PR

bar

-

-

4.5

3.5

3.0

2.5

Nm

270

380

555/45-17 146F

-

555/45-17 146F

16x6.5-8 4PR

-

-

3.0

3.0

-

2.5

270

380

500/50-17 10PR

-

555/45-17 146F

-

16x6.5-8 4PR

3.5

3.0

3.0

-

-

2.5

270

380

10/04 1-9

Page 14

Technical Data QUANTUM TIC

1-10 10/04

Page 15

TIC QUANTUM Operation

1.0 QUANTUM 2500 K, 2500 P, 3500 K, 3800 K, 3800 P, 3500 S ..........................................................2

1.1 Control box short instructions .....................................................................................................3

1.2 Operation ....................................................................................................................................4

2.0 QUANTUM 4500 S / 5500 S / S-16 / S-18 / 6800 S ............................................................................8

2.1 Control box short instructions .....................................................................................................9

2.2 Operation ..................................................................................................................................11

3.0 QUANTUM 4500 P / 5500 P / 5500 P-16 / 5500 P-18 / 5500 GT / 6800 P.......................................18

3.1 Control box short instructions ...................................................................................................19

3.2 Operation ..................................................................................................................................21

10/04 3-1

Page 16

Operation QUANTUM TIC

1.0 QUANTUM 2500 K, 2500 P, 3500 K, 3800 K, 3800 P, 3500 S

Caution! When draining oil over a more extended period than usual (tractor –

forage wagon – floor conveyor), the pump system of the tractor must be

known (see “Prior to operation – Hydraulic system”).

The buttons on the control box are only used to pre-select the different

functions of the forage wagon. Operating the single-acting control valve

on the tractor will activate the desired function.

Between the different operations, the single-acting control valve of the

tractor must be switched back to the neutral position.

Only then a new function can be pre-selected on the control box.

The floor conveyor is controlled using the double-acting control valve on

the tractor.

On the S-wagon, the floor conveyor speed can be varied using the rotary

knob. This knob has no function on the K and P wagons!

3-2 10/04

Page 17

TIC QUANTUM Operation

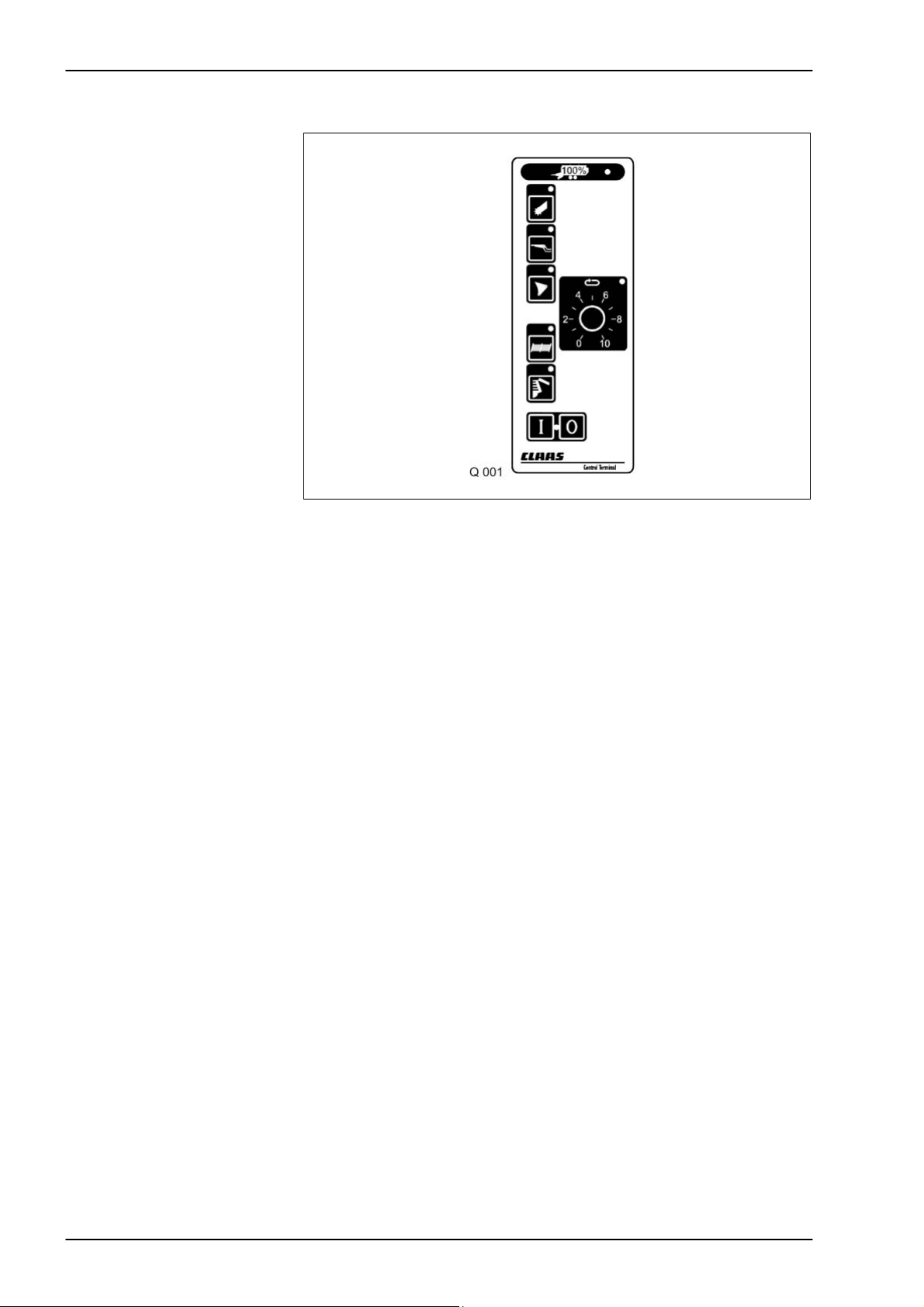

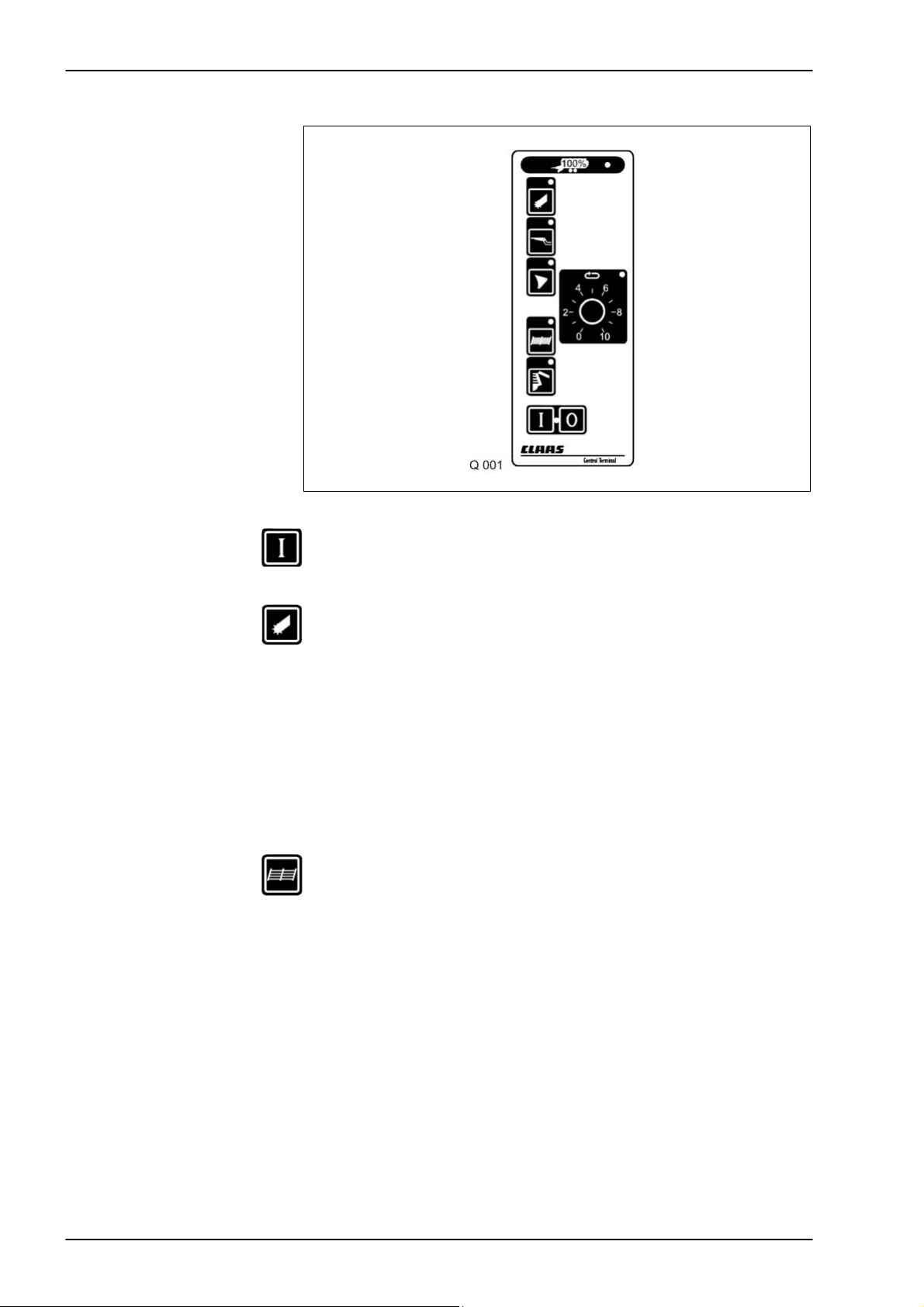

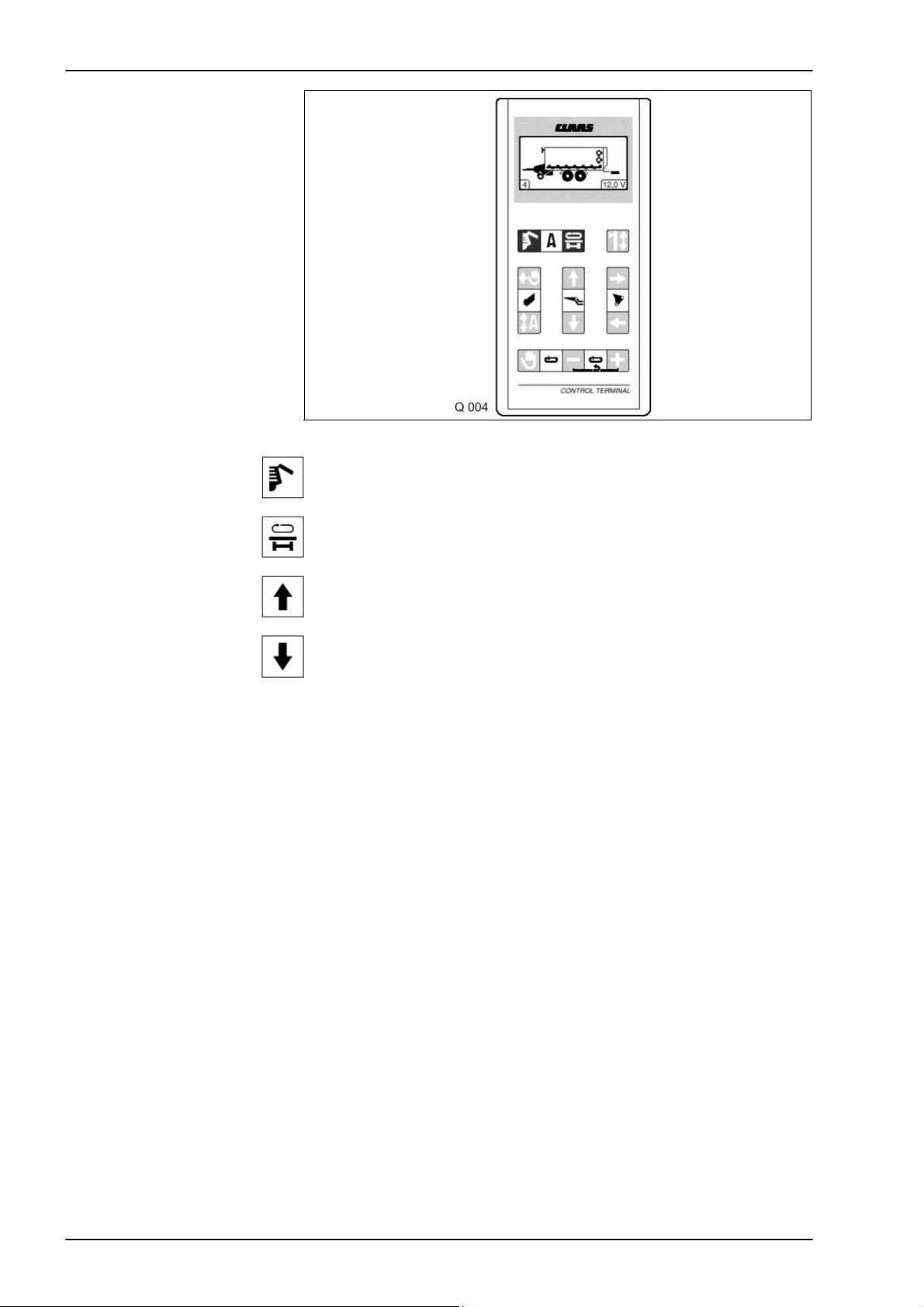

1.1 Control box short instructions

Loading operation

Knife frame

Control system ON

Control system OFF

Pick-up up/down

Dry crop top up/down

(Quantum 3500 K only)

Wagon full indicator

Opens / closes the cutting trough

Opens the cutting trough totally

Unloading operation

Articulated drawbar

Opens / closes the tailgate

Drawbar up/down

10/04 3-3

Page 18

Operation QUANTUM TIC

1.2 Operation

Loading operation

Pick-up

lowered/raised

Use this key of the control box to switch on the control unit. The red

indicator light lights up.

Use this key to pre-select the pick-up mode. The pick-up can now be

raised and lowered using the single-acting control valve. Switch

on the pto for loading.

Attention The pick-up will only remain in floating position if the pick-up mode is pre-

selected on the control box and the single-acting control valve is set to

floating position.

Quantum 3500 K / 3800 K /

To switch off the rotor and the pick-up the pto must be disengaged.

3500 P / 3800 P

Quantum 3500 S Raising the pick-up will automatically disengage the rotor and the pick-up.

Dry crop top

(QUANTUM 2500 K,

3500 K only)

Use this key to pre-select the dry crop top mode. To erect the dry

crop top, pressurize the single-acting control valve. To lower it, set

the system to the float position.

3-4 10/04

Page 19

TIC QUANTUM Operation

Floor conveyor

Floor conveyor speed

Opening the knife frame

The floor conveyor is controlled using the double-acting control valve on

the tractor. To set the floor conveyor to forwards or reverse, set the

double-acting control valve to the raise or lower position.

QUANTUM 3500 S:

The floor conveyor speed can be varied using the rotary knob provided

the pick-up or the tailgate has been pre-selected.

QUANTUM 3500 K / P, 2500 K / P, 3800 K / P:

If the tractor is fitted with a flow rate controller, this can be used to vary

the floor conveyor speed.

The knob on the control unit has no function on the K and P

wagons.

If a blockage occurs in the conveyor channel (cut-out clutch of the

universal drive shaft is activated), switch off the pto.

Use this key to select the cutting mechanism mode. Set the lever

on the single-acting control valve to the float position in order to

open the knife frame.

Engage the pto to clear the blockage. Once the channel is free, close the

knife frame again by moving the lever on the single-acting control valve

to the pressure setting.

If the knife frame has to be totally lowered (e.g. for repair work or for

the replacement of knives), first set the single-acting valve to the

float position and then press these two buttons simultaneously.

Attention If the knife frame is totally open, it must be closed very carefully and

“Wagon full” indicator

To close the knife frame, set the control unit to the pressure setting.

slowly. When folding up the frame, ensure that the cutting knives will not

collide with the rotor tines.

The load space is filled when the “wagon full” indicator of the display

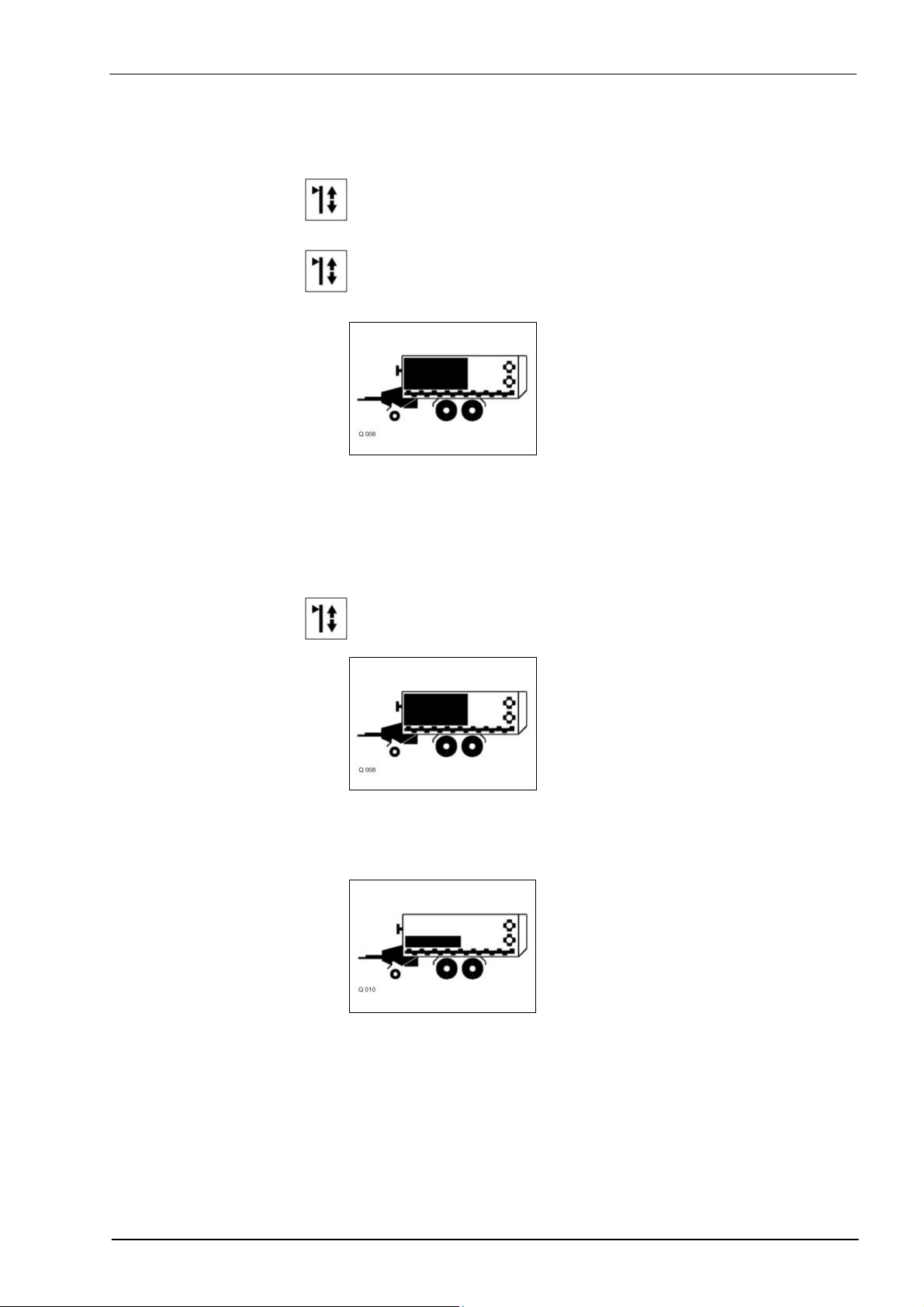

flashes (see figure). Switch off the floor conveyor, raise the pick-up and

switch off the universal drive shaft.

QUANTUM 3500 S QUANTUM 3500 P / K

2500 P / K

3800 P / K

10/04 3-5

Page 20

Operation QUANTUM TIC

Unloading operation

Silo operation

Discharging the load

QUANTUM 3500 S

Attention If the swash plates are folded down, opening the tailgate is not allowed.

Discharging the load

QUANTUM

2500 K / P

3500 K / P

3800 K / P

Use this key of the control box to switch on the control unit. The

indicator light lights up.

For silo operation raise the wagon at the front with the articulated

drawbar. Use this key for pre-selecting the articulated drawbar and

set the single-acting control valve to the pressure setting. When

unloading is complete, lower the wagon again. Set the control unit

to the float position.

Open the tailgate before unloading. Use this key for pre-selecting

the tailgate and set the single-acting control valve to the pressure

setting.

Open the tailgate to enable activation of the shredder drums via the pto.

Then initiate the floor conveyor using the double-acting control valve. The

floor conveyor speed can be varied using the rotary knob. To close the

tailgate, the set the single-acting control valve to the float position until

the tailgate has closed completely.

Open the tailgate before unloading. Use this key for pre-selecting

the tailgate and set the single-acting control valve to the pressure

setting.

Initiate the floor conveyor using the double-acting control valve. To

close the tailgate, the set the single-acting control valve to the float

position until the lock has engaged.

To reverse the floor conveyor, move the lever of the double-acting

control valve to the opposite direction. If the tractor is fitted with a flow

rate controller, this can be used to vary the floor conveyor speed.

3-6 10/04

Page 21

TIC QUANTUM Operation

10/04 3-7

Page 22

Operation QUANTUM TIC

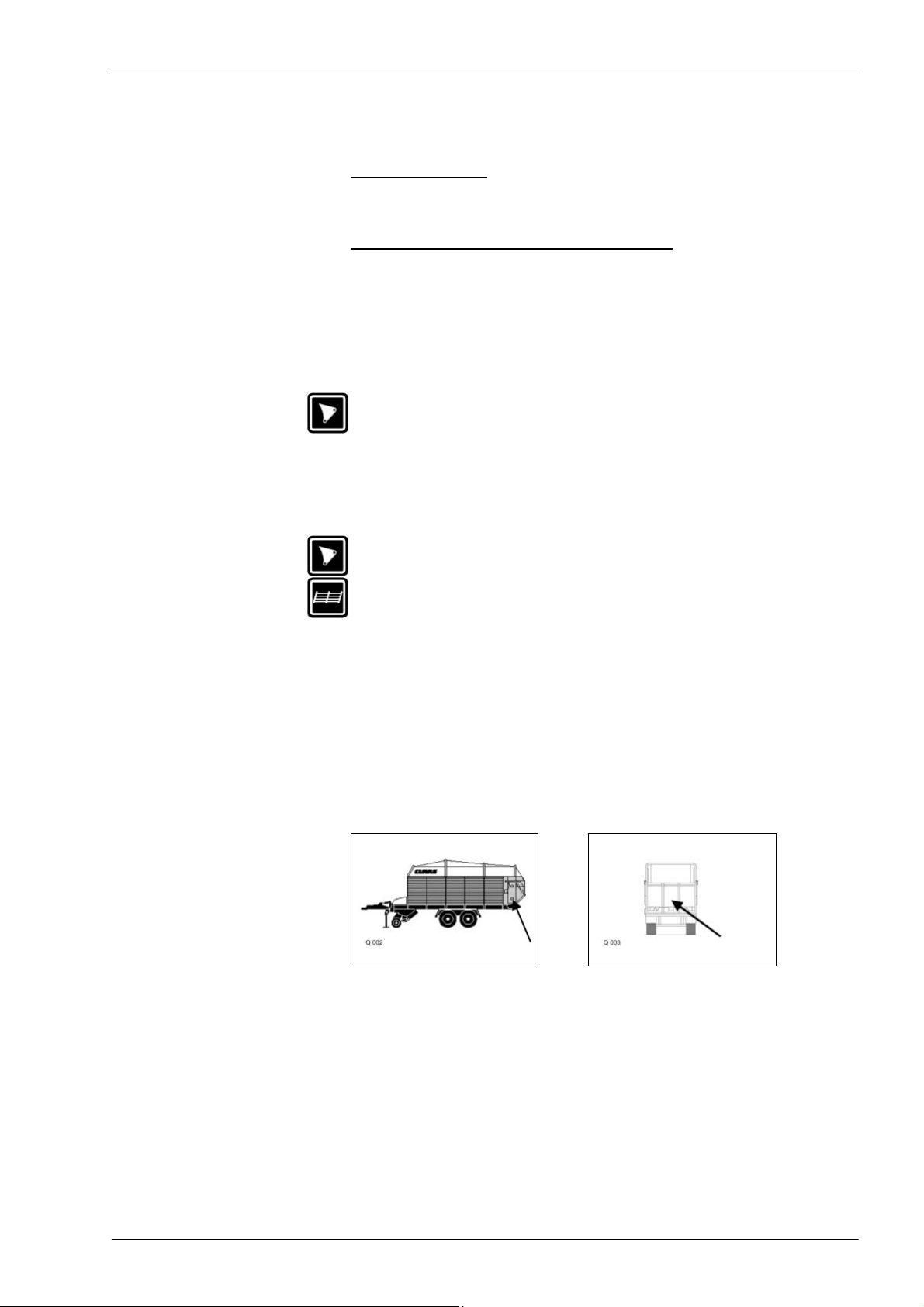

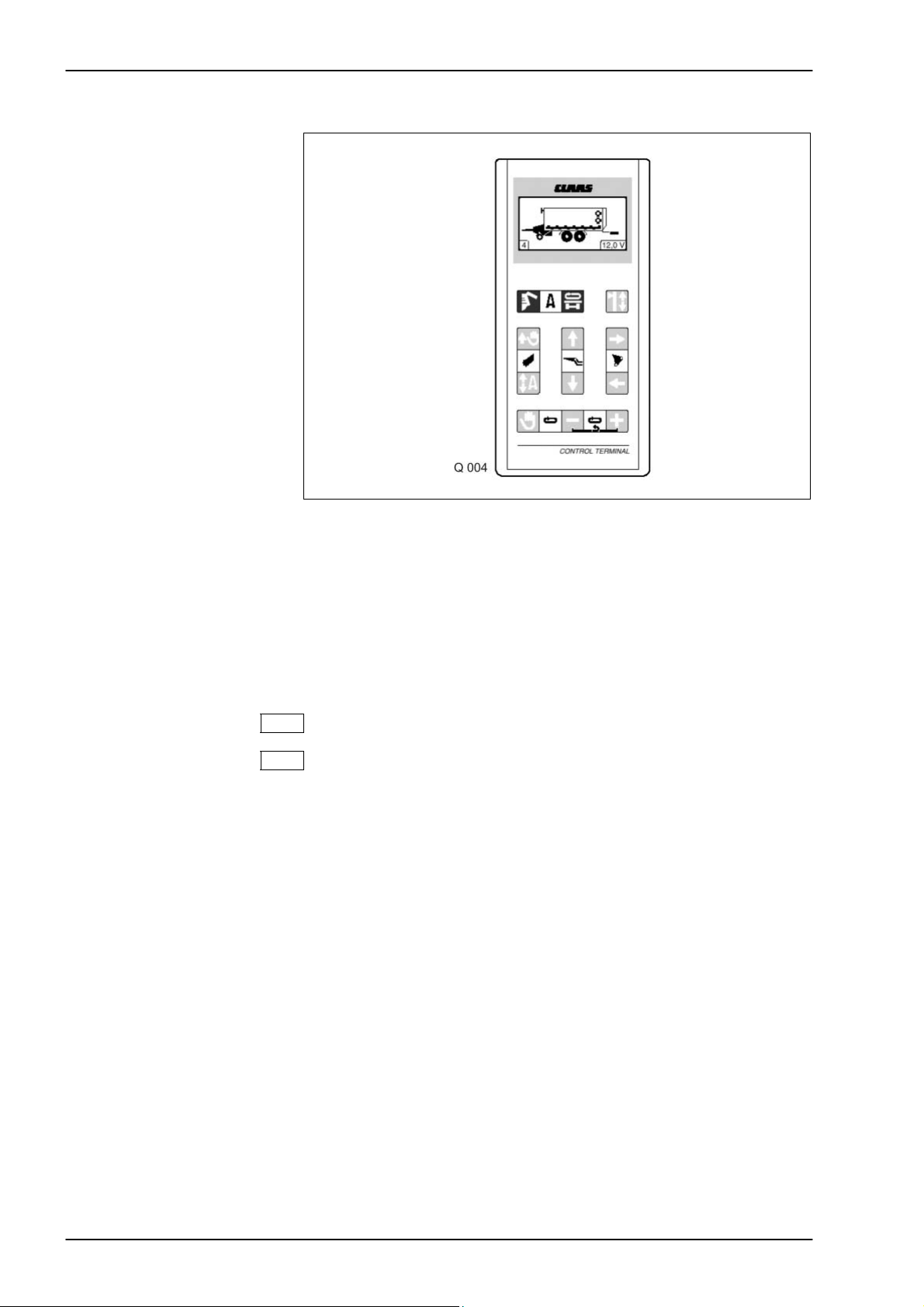

2.0 QUANTUM 4500 S / 5500 S / S-16 / S-18 / 6800 S

Control light (rear wheel)

flashes when steering axle

is locked (reverse travel)

Caution: 1. Electric System

Connect the 2-pole plug with the tractor = on-board voltage to

the distributor box.

2. To switch on the control box, the hydraulic system must be

pressurized = (2 bar switch) on-board voltage from the distributor

box to the control box.

The pump system of the tractor must be known (see chapter “Before

operating the hydraulic system”).

12 V On-board voltage display (10.8 V min., 15.5 V max.)

4 Display of floor conveyor speed

3. Flashing wheel

The axle’s straight position is blocked by means of the cross

conveyor key and a 3/2 way valve = flashing wheel.

QUANTUM with a separate hydraulic connection (single-acting) do not

have this equipment.

3-8 10/04

Page 23

TIC QUANTUM Operation

2.1 Control box short instructions

Loading operation/

manual

Pick-up up/down

The pick-up disengages when raised.

Setting filling mode/

automatic filling ON/OFF

Raise the pick-up.

The pick-up does not disengage when raised,

benefit: this is easier on the dog clutch.

Pick-up down

Floor conveyor ON/

save floor conveyor speed

Floor conveyor speed

Speed down

Speed up

(Option S = quick unloading via 2-speed motor)

Reverse conveyor floor

Cutting mechanism

Open knife frame 1

st

position

Close knife frame 1

st

position

Open knife frame 2

nd

position

Close knife frame 2

nd

position

10/04 3-9

Page 24

Operation QUANTUM TIC

Unloading operation

Articulated drawbar

Unloading operation start/stop

Turning direction of cross conveyor belt and locking/unlocking of

steering axle.

Articulated drawbar up

Articulated drawbar down

3-10 10/04

Page 25

TIC QUANTUM Operation

2.2 Operation

Loading operation

Pick-up

up/down

Manually changing the

pick-up working width

To switch on the control unit, set the hydraulic system to the pressure

setting. The display shows the forage wagon. Switch on the pto shaft.

This button is used for lowering the pick-up to the float position.

The wagon is automatically loaded. Pressing this button again raises

the pick-up and the loading process is stopped. With the pto

switched on, the pick-up drive and the rotor are automatically

switched off when raising the pick-up. They are restarted when

lowering the pick-up.

In difficult ground and crop conditions, the pick-up can be raised

during loading by means of this button. The pick-up is no longer in

the float position.

The pick-up is lowered again using this button.

Adjusting the load space

filling

(up to serial no.)

Attention:

From serial no. … there are no reed switches available for half-loading

the front panel. However, the wiring loom remains unchanged = the plugs

for the reed switches are available. The switching options include only

“Full loading” and “Manual loading”.

This button can be used to vary the loading mode.

Its functions depends on the position of micro switch (3) located in

the front part of the control box (4).

Micro switch (3) in lower position (OFF / standard setting):

This button on the control box enables switching back and forth

between full and half loading.

3 Micro switch 4 Control box

For micro switch position see

chapter 13 “Electric System”.

10/04 3-11

Page 26

Operation QUANTUM TIC

The black filling bar ceases

to apply from serial no. and

installation of EPROM

350 812-5.

Upper position

(e.g. for loading dry fodder): The floor conveyor is switched on when the

cover plates are raised. All 3 plates are linked with one another.

The black filling bar ceases

to apply from serial no. and

installation of EPROM

350 812-5.

Lower position

(e.g. for loading green fodder and silage): The floor conveyor is switched

on when the feelers at the front wall are lifted.

The floor conveyor will run until the feelers and/or the top plate are free

again.

Micro switch (3) in top

position:

Using this button allows switching between fully loading the wagon

and deactivating the automatic filling.

The black filling bar ceases

to apply from serial no. and

installation of EPROM

350 812-5.

Upper position

(e.g. for loading dry fodder): The floor conveyor is switched on when the

centre top plate is raised.

The black filling bar ceases

to apply from serial no. and

installation of EPROM

350 812-5.

The filling indicator disappears:

The automatic filling mode is deactivated; the floor conveyor has to be

operated manually.

To adjust the micro switch, switch off the control box and the oil supply

from the tractor. Then open the distributor box located in the front part of

the wagon and switch over using a small screwdriver. Close the box and

connect the oil supply to the tractor.

3-12 10/04

Page 27

TIC QUANTUM Operation

Adjusting the load space

filling

(from serial no.)

Attention:

From serial no. … there are no reed switches available for half-loading

the front panel. However, the wiring loom remains unchanged = the plugs

for the reed switches are available.

This button can be used to vary the loading mode. Its functions

depends on the position of micro switch (3) located in the front part

of the control box (4).

Micro switch (3) in lower

position (OFF / standard

setting):

Using this button allows switching back and forth between fully

loading the wagon and manual loading (under visual control).

The black filling bar ceases

to apply from serial no. and

installation of EPROM

350 812-5.

Upper position

(e.g. for loading dry fodder): The floor conveyor is switched on when the

cover plates are raised. All 3 plates are linked with one another.

The floor conveyor will run until the feelers and/or the top plate are free

again or the manual actuation is shut down..

Micro switch (3) in top

position:

Using this button allows switching between fully loading the wagon

and deactivating the automatic filling.

The black filling bar ceases

to apply from serial no. and

installation of EPROM

350 812-5.

Upper position

(e.g. for loading dry fodder): The floor conveyor is switched on when the

cover plates are raised. All 3 plates are linked with one another.

The black filling bar ceases

to apply from serial no. and

installation of EPROM

350 812-5.

The filling indicator disappears:

The automatic filling mode is deactivated; the floor conveyor has to be

operated manually.

To adjust the micro switch, switch off the control box and the oil supply

from the tractor. Then open the distributor box located in the front part of

the wagon and switch over using a small screwdriver. Close the box and

connect the oil supply to the tractor.

10/04 3-13

Page 28

Operation QUANTUM TIC

The black filling bar ceases

to apply from serial no. and

installation of EPROM

350 812-5.

Floor conveyor

End of loading operation

When the crop presses against the lower shredder drum, it is moved

backwards slightly. The switch (6) closes and the floor conveyor is

automatically switched off. The filling indicator on the display is flashing.

Raise the pick-up and switch off the universal drive shaft.

Manual operation of floor

conveyor

If the automatic filling mode is not used or the load space is only to

be partially filled, the floor conveyor can be operated manually using

this key. Here the floor conveyor speed is always as previously set.

3-14 10/04

Page 29

TIC QUANTUM Operation

Adjusting the floor conveyor

speed

Pressing this button increases the floor conveyor speed of all further

runs.

Pressing this button decreases the floor conveyor speed of all further

runs.

The floor conveyor can also be reversed during loading by

simultaneously pressing both buttons. Reversing is always carried out at

speed 9.

After the floor conveyor has been reversed, the floor conveyor speed

must be increased by pressing this button.

Open / close knife frame

The floor conveyor speed is displayed at the bottom left in the control

panel display. It can be adjusted within the range from 0 to 9: 0 – 9

(standstill – fast)

Open the cutting frame by means of this button (1

pto to clear the blockage.

As soon as the conveyor channel is free, close the cutting frame by

pressing this key. Press this key until the display shows a totally closed

knife frame.

If the knife frame is to be completely lowered (2

dismounting the rotor), this key must be pressed above the cutting

trough.

Close the knife frame by pressing this key above the knife frame.

st

stage). Engage the

nd

stage, e.g. for repairs or

Attention!

If the knife frame is totally open, it must be closed very carefully and

slowly.

When folding up the frame, ensure that the cutting knives will not collide

with the rotor tines.

10/04 3-15

Page 30

Operation QUANTUM TIC

The black filling bar ceases

to apply from serial no. and

installation of EPROM

350 812-5.

Unloading in silo

operation

To switch on the control unit, set the hydraulic system to the pressure

setting. The display shows the forage wagon.

Press this button to raise the wagon over the articulated drawbar at the

front.

When unloading is complete, use this key to lower the wagon again. The

floor conveyor switches to the 4

Discharge of the load

space

Switch on the pto shaft. Press this button for unloading. The tailgate

opens, the shredder drums start running and the floor conveyor is

switched on after a short delay. To stop the unloading process, press this

button again.

Any blockage of the shredder drums (the cut-out clutch of the universal

drive shaft is activated) by the material requires reversing the floor

conveyor.

Press these buttons simultaneously to reversing the floor conveyor. After

the floor conveyor has been reversed, the floor conveyor speed must be

increased by pressing the + button.

Pressing this button increases the floor conveyor speed. By increasing

the speed numbers up to speed 9 and pressing this key once again, an

“S” appears in the control panel display = quick conveyor speed due to 2speed hydraulic motor.

Pressing this button decreases the floor conveyor speed.

th

stage.

When pressing this key during the whole unloading process, the adjusted

floor conveyor speed is saved for further unloading processes.

3-16 10/04

Page 31

TIC QUANTUM Operation

Unloading by means of

cross conveyor belt

Pull out the cross conveyor belt before unloading and lock it to the lower

back cover. Connect the hydraulic hoses to the hydraulic motor.

Switch on the pto for unloading with the cross conveyor belt and press

this key. The shredder drums start running and the floor conveyor is

switched on after a short delay.

To stop the unloading process, press this button again.

Any blockage of the shredder drums (the cut-out clutch of the universal

drive shaft is activated) by the material requires reversing the floor

conveyor.

Press these buttons simultaneously to reversing the floor conveyor.

Pressing this button increases the floor conveyor speed.

Pressing this button decreases the floor conveyor speed.

When pressing this key during the whole unloading process, the adjusted

floor conveyor speed is saved for further unloading processes.

This key enables changing the direction of rotation of the cross conveyor

belt.

From serial no.: …. with solenoid valve 62, the trailing axle can be

blocked with this key.

10/04 3-17

Page 32

Operation QUANTUM TIC

3.0 QUANTUM 4500 P / 5500 P / 5500 P-16 / 5500 P-18 / 5500 GT / 6800 P

Attention: 1. Electric System

Floor conveyor 2-stage

motor

(option for P forage

wagons)

Connect the control box to the forage wagon by means of the control

cable. Plug the 2-pole plug (series equipment) into the socket outlet

of the tractor and of the forage wagon. On-board voltage from the

distributor box to the control box = 10.8 V min.

2. Hydraulic System

To switch on the control unit, set the hydraulic system to the

pressure setting (2 bar switch).

The pump system of the tractor must be known (see chapter “Prior

to operation”).

The self-loading forage wagon is equipped with a 2-stage motor to double

the speed of the conveyor and shorten the time needed to unload the

remainder.

When unloading starts, the floor conveyor is switched on by this button.

After about two thirds of the crop have been unloaded, the speed of the

floor conveyor can be doubled. To do this, press switch (7).

The second speed stage only runs as long as the switch is being

pressed. When it is released, the conveyor continues to run at normal

speed.

3-18 10/04

Page 33

TIC QUANTUM Operation

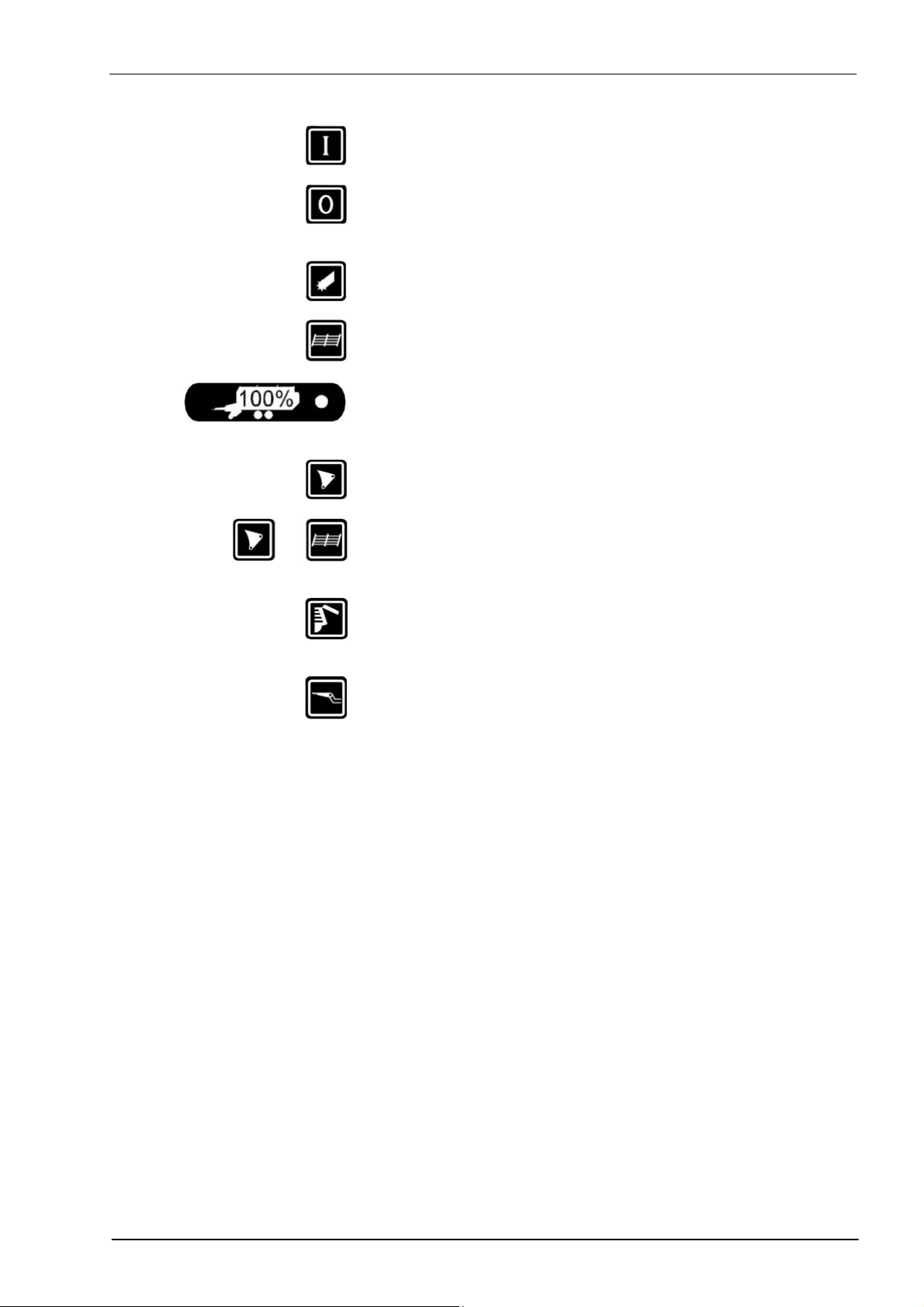

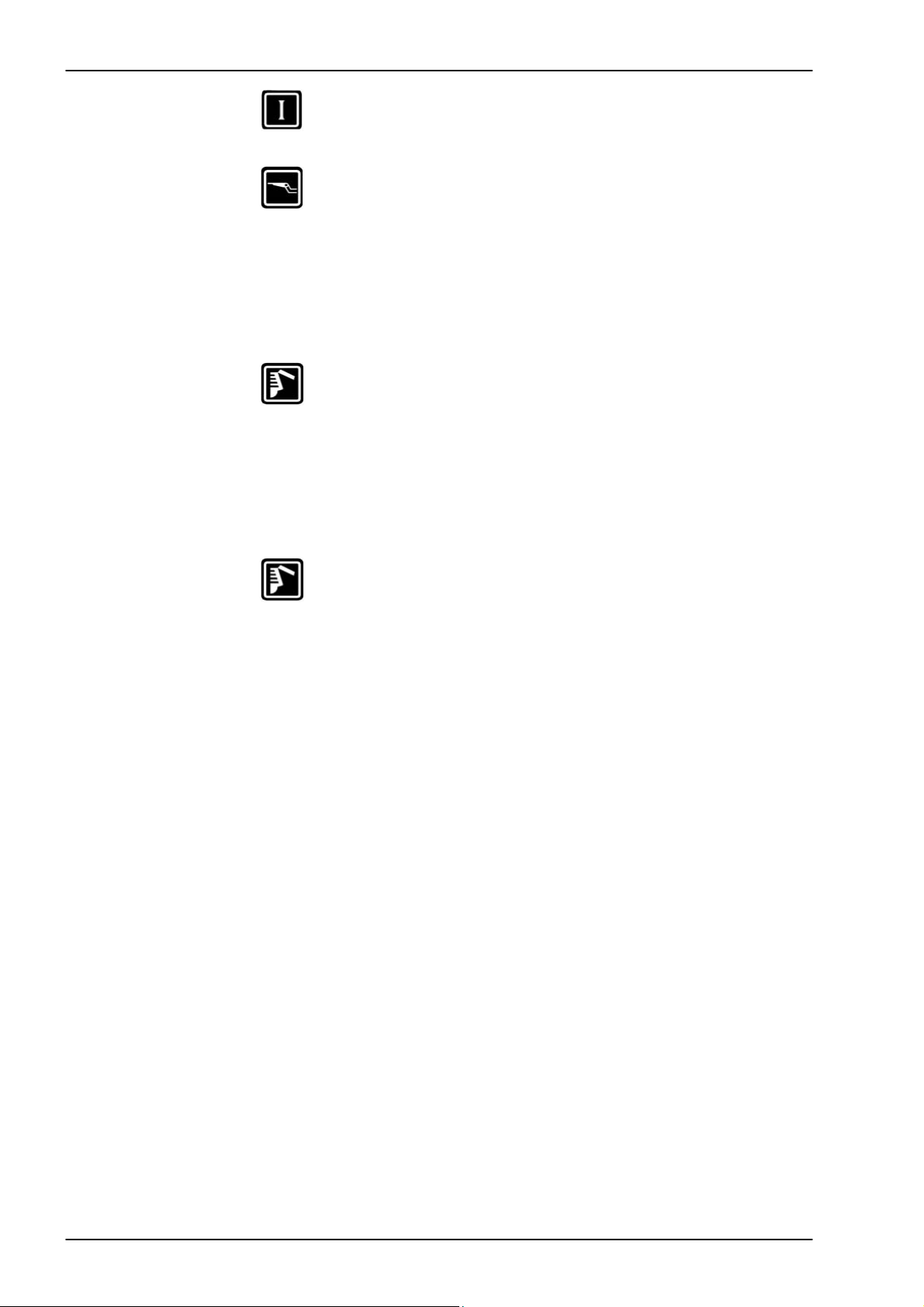

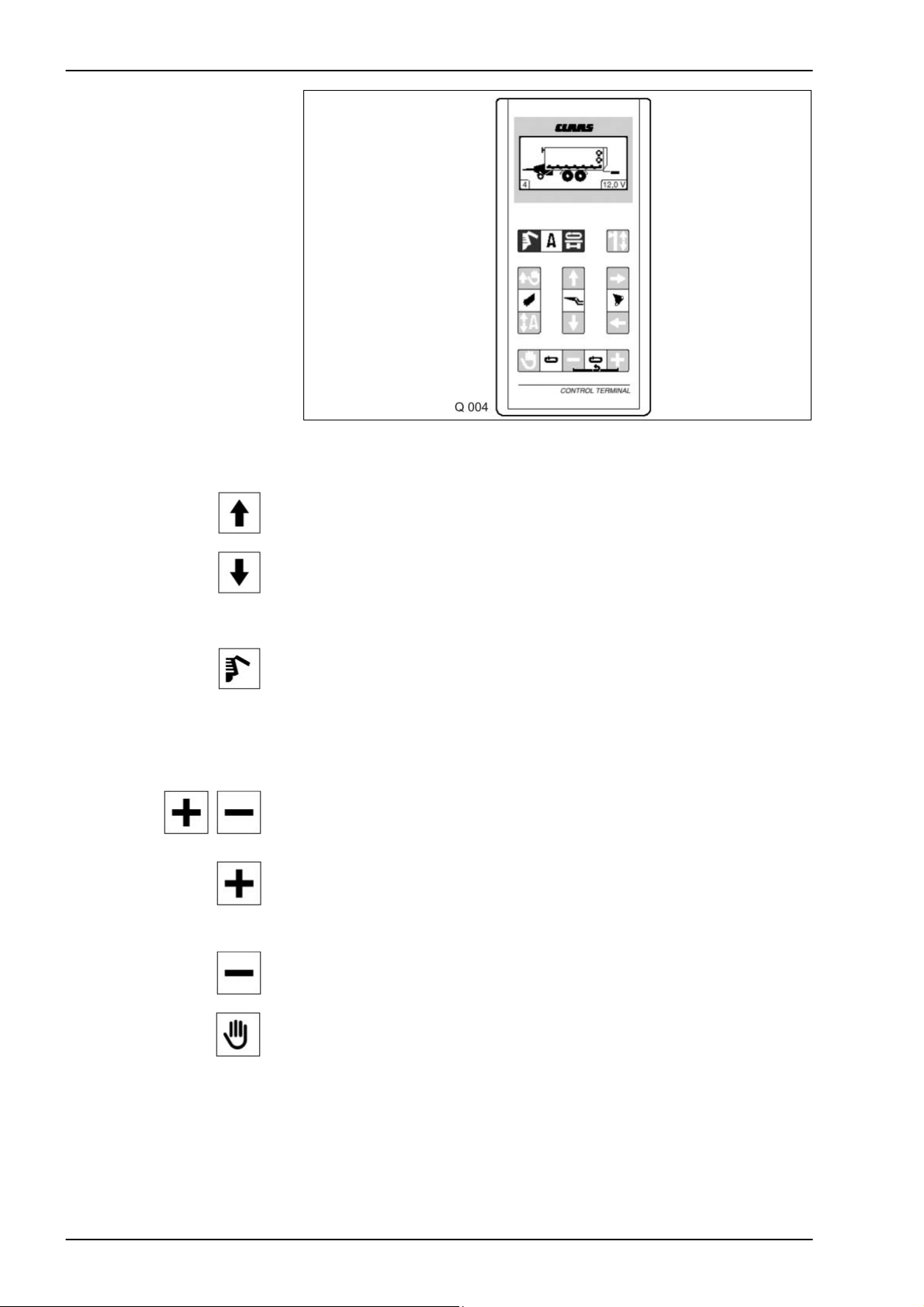

3.1 Control box short instructions

Loading operation

Pick-up down

Pick-up up. The pick-up does not switch off.

Floor conveyor ON/OFF when loading, tailgate must be closed.

Knife frame

Open knife frame

Close knife frame

When pressing both keys simultaneously, the knife frame is opened

completely.

Unloading operation

Open tailgate

Close tailgate

Floor conveyor ON/OFF when unloading, tailgate must be open.

Articulated drawbar

Articulated drawbar up

Articulated drawbar down

10/04 3-19

Page 34

Operation QUANTUM TIC

Indicator lights (LEDs)

1 Green: Pick-up lowered – floating position

2 Red: Knife frame open

3 Red, flashing: Tailgate closed

4 Green, flashing: Tailgate open

5 Red (approx. 3 sec.): Oil in circulation, wagon is ready for use

6 Red, flashing: Wagon is 100% filled

3-20 10/04

Page 35

TIC QUANTUM Operation

3.2 Operation

Loading operation

Pick-up down

Press this key.

The pick-up is lowered and remains in floating position. The green

indicator light on the control box is illuminated.

Pick-up up

Press this key.

The pick-up is raised – it does not switch itself off.

Hydraulic opening of the

knife frame

If a blockage occurs in the conveyor channel (cut-out clutch of the

universal drive shaft is activated), switch off the pto.

Use this key to open the knife frame. The red indicator light is illuminated.

Re-engage the pto. As soon as the conveyor channel is free, close the

knife frame by pressing this key.

If the knife frame has to be totally lowered (e.g. for removing knives or the

rotor), press these two buttons simultaneously.

10/04 3-21

Page 36

Operation QUANTUM TIC

Press this key to close the knife frame again.

Important! If the knife frame is totally open, it must be closed very carefully and

slowly. When folding up the frame, ensure that the cutting knives will not

collide with the rotor tines.

Engaging the floor

conveyor for loading

Press this key to fill the load space. The floor conveyor will run to the rear

as long as the key is pressed.

The floor conveyor speed depends on the tractor’s pto speed.

Important! During the loading operation, the tailgate must be completely closed,

otherwise the floor conveyor cannot be operated with the push button.

As soon as the crop pushes the tailgate slightly to the rear, the floor

conveyor is disengaged by a solenoid switch. The red LED (100%) on the

control box starts flashing. The floor conveyor drive can only be reengaged after the tailgate has been opened.

3-22 10/04

Page 37

TIC QUANTUM Operation

Unloading operation

Opening the tailgate

Press this key until the tailgate is open.

The green indicator light on the control panel will flash.

Discharge of the load

space

Press this key to discharge the load space.

The floor conveyor will travel to the rear as long as this key is pressed

once more.

Control the floor conveyor speed by means of the tractor’s speed.

Important! During the unloading operation the tailgate must be completely open and

the green indicator light must flash, otherwise the floor conveyor cannot

be operated.

Closing the tailgate

Press this key until the red indicator light starts flashing.

The tailgate is lowered due to its weight (i.e. without hydraulic pressure)

as long as this key is pressed.

Release this key when the red indicator light on the control panel starts

flashing. Hydraulic pressure builds up and the tailgate is locked. The red

LED (100%) is no longer illuminated.

10/04 3-23

Page 38

Operation QUANTUM TIC

Floor conveyor 2-stage

motor

(option for P forage

wagons)

The self-loading forage wagon is equipped with a 2-stage motor to double

the speed of the conveyor and shorten the time needed to unload the

remainder.

When unloading starts, the floor conveyor is switched on by this button.

After about two thirds of the crop have been unloaded, the speed of the

floor conveyor can be doubled. To do this, press switch (7).

The second speed stage only runs as long as the switch is being

pressed. When it is released, the conveyor continues to run at normal

speed.

3-24 10/04

Page 39

TIC QUANTUM Brakes

1.0 Compressed air circuit diagrams.........................................................................................................2

1.1

QUANTUM 5500P/S-16 40 km/h, 16 to, (steering axle)..........................................................................2

1.2

QUANTUM 2500K/P, 3500P/S/K, 3800K/P, 4500S/P 40 km/h (steering axle).......................................4

1.3

5500P/S 40 km/h, 13 to, (steering axle) ..................................................................................................6

1.4

5500P-18/S –18, 60 km/h ........................................................................................................................8

1.5

5500P/S 80 km/h (ABS) ........................................................................................................................10

1.5.1 Functional test.............................................................................................................................12

1.6

Compressed air system with level regulating valve...............................................................................14

1.6.1 up to serial no. ............................................................................................................................14

1.6.2 from serial no. .............................................................................................................................16

1.7

5500 P/S 50/60 km/h .............................................................................................................................18

1.8

5500 S, 40/60 km/h................................................................................................................................20

Adjustments .........................................................................................................................................22

2.0

2.1

Diaphragm cylinder................................................................................................................................22

2.2

Adjusting the rod adjuster......................................................................................................................23

2.2.1 Standard rod adjuster .................................................................................................................23

2.2.2 Automatic rod adjuster................................................................................................................24

2.3

Brake-power regulator (ALD).................................................................................................................25

2.4

Air suspension .......................................................................................................................................26

2.4.1 Lifting and lowering device .........................................................................................................26

2.4.2 Air suspension valve...................................................................................................................27

10/04 10-1

Page 40

Brakes QUANTUM TIC

1.0 Compressed air circuit diagrams

1.1 QUANTUM 5500P/S-16 40 km/h, 16 to, (steering axle)

1 Red service line hose coupler “Accumulator”

2 Yellow service line hose coupler “Brake”

3 Filter

4 Trailer brake valve

5 Compressed air accumulator (40 litres)

6 Dewatering valve, manual

7 ALB (automatic load-dependent brake-power), mechanically controlled

8 ALB (automatic load-dependent brake-power), pneumatically controlled

9 Simulation connection (when using item 8)

10 Release valve

11 Link joint (round hole)

12 Diaphragm cylinder (20”)

13 Link joint (elongated hole)

14 Diaphragm cylinder (16”)

15 Test port (M16x1.5) for cylinder pressure

16 Test port (M22x1.5)

17 Test port (M12x1.5)

18 Dummy coupler

19 Block spring (when using item 7 only)

10-2 10/04

Page 41

TIC QUANTUM Brakes

5500P/S-16 40 km/h, 16 to, (Steering axle)

10/04 10-3

Page 42

Brakes QUANTUM TIC

1.2 QUANTUM 2500K/P, 3500P/S/K, 3800K/P, 4500S/P 40 km/h (steering axle)

1 Red service line hose coupler “Accumulator”

2 Yellow service line hose coupler “Brake”

3 Filter

4 Dummy coupler

5 Trailer brake valve with release valve

6 Compressed air accumulator (20 litres)

7 Dewatering valve, manual

8 Test port (M22x1.5)

9 ALB (automatic load-dependent brake-power), mechanically controlled

11 Test port

12 Adjusting valve

13 Link joint

14 Diaphragm cylinder (20”)

15 Link joint

16

Piston cylinder ∅ 80

17 Test port (M16x1.5)

18 Test port (M12x1.5)

19 Block spring

10-4 10/04

Page 43

TIC QUANTUM Brakes

2500K/P, 3500P/S/K, 3800K/P, 4500S/P 40 km/h (steering axle)

10/04 10-5

Page 44

Brakes QUANTUM TIC

1.3 5500P/S 40km/h, 13 to, (steering axle)

1 Red service line hose coupler “Accumulator”

2 Yellow service line hose coupler “Brake”

3 Filter for piping

4 Trailer brake valve

5 Compressed air accumulator (20 litres)

6 Dewatering valve, manual

7 ALB (automatic load-dependent brake-power), mechanically controlled

8 Adjusting valve

9 Dummy coupler

10 Release valve

11 Link joint

12 Diaphragm cylinder (20”)

13 Link joint (elongated hole)

14 Diaphragm cylinder (20”)

15 Test port (M16x1.5)

16 Test port (M22x1.5)

17 Test port (M12x1.5)

18 Block spring for dual-axle steering

19

Tension band ∅ 206

10-6 10/04

Page 45

TIC QUANTUM Brakes

5500P/S 40 km/h, 13 to, (steering axle)

10/04 10-7

Page 46

Brakes QUANTUM TIC

1.4 5500P-18/S –18, 60 km/h

1 Red service line hose coupler “Accumulator”

2 Yellow service line hose coupler “Brake”

3 Filter for piping

4 Trailer brake valve

5 Compressed air accumulator (60 litres)

6 Dewatering valve, manual

7 ALB (automatic load-dependent brake-power), mechanically controlled

8 Adjusting valve

9 Dummy coupler

10 Release valve

11 Link joint

12 Diaphragm cylinder (24”)

13 Link joint (elongated hole)

14 Diaphragm cylinder (24”)

15 Test port (M16x1.5)

16 Test port (M22x1.5)

17 Test port (M12x1.5)

18 Block spring for dual-axle steering

10-8 10/04

Page 47

TIC QUANTUM Brakes

5500 P-18/ S-18, 60 km/h

10/04 10-9

Page 48

Brakes QUANTUM TIC

1.5 5500P/S 80 km/h (ABS)

1 Red service line hose coupler “Accumulator”

2 Yellow service line hose coupler “Brake”

3 Filter

4 Trailer brake valve with release valve

5 ALB (automatic load-dependent brake-power), mechanically controlled

(alternative to item 6)

6 ALB (automatic load-dependent brake-power), pneumatically controlled

(alternative to item 5)

7 Simulation connection (when using item 6 only)

8 Test port (M16x1.5)

9 Compressed air accumulator (60 litres)

10 Dewatering valve, manual

11 Link joint (elongated hole)

12 Diaphragm cylinder (24”)

13 Link joint (elongated hole)

14 Diaphragm cylinder (24”)

15 Test port (M16x1.5)

16 Test port (M22x1.5)

17 Pole and sensor

18 4S/2M – module kit (ABS control unit)

19 12 m power supply cable (ISO 7638) for drawbar trailer / forage wagon

20 12 m power supply cable (ISO 1186) option

21 Warning lamp, green

22 12 m cable for warning lamp

23 Dummy coupler

10-10 10/04

Page 49

TIC QUANTUM Brakes

5500P/S 80 km/h (ABS)

10/04 10-11

Page 50

Brakes QUANTUM TIC

1.5.1 Functional test

Time of testing?

• After assembly of the ABS (anti-lock braking system) on the vehicle

• § 29 inspection of vehicles and trailers (S.I. = Safety inspection)

• In Germany as of 11.2000 / HU)

• When control lamp lights up (see a workshop to find the fault)

Testing possibilities

• with an external test device

• with a multimeter.

10-12 10/04

Page 51

TIC QUANTUM Brakes

• Fault indication via an integrated LED display in the control device. If

an error LED lights up, contact the service dept. of HALDEX in

Denkendorf.

10/04 10-13

Page 52

Brakes QUANTUM TIC

1.6 Compressed air system with level regulating valve

1.6.1 Up to serial no.

1 Overflow valve (6 bar)

2 Compressed air reservoir

3 Tension band with support

4 Filter

5 Dewatering valve, manual

6 Test port (M22x1.5)

7 Compressed air valve

8 Articulation (axle)

9 Test port (M12x1.5)

10 Simulation connection

BBA (service braking system) = Compensating line

10-14 10/04

Page 53

TIC QUANTUM Brakes

A

Compressed air system with level regulating valve, up to serial no.

Air bellows

line

Compensating

LB controller

line

Compensating

Air bellows

system

volume from

Accumulator

service brake

10/04 10-15

Page 54

Brakes QUANTUM TIC

1.6.2 From serial no.

1 Overflow valve (6 bar)

2 Compressed air reservoir

3 Tension band with support

4 Filter

5 Dewatering valve, manual

6 Test port (M22x1.5)

7 Compressed air valve

8 Articulation (axle)

9 Raise/lower control valve

10 Test port (M12x1.5)

11 Simulation connection

10-16 10/04

Page 55

TIC QUANTUM Brakes

Compressed air system with level regulating valve, from serial no.

10/04 10-17

Page 56

Brakes QUANTUM TIC

1.7 5500 P/S 50/60 km/h

1 Red service line hose coupler “Accumulator”

2 Yellow service line hose coupler “Brake”

3 Filter

4 Trailer brake valve

5 Compressed air accumulator (60 litres)

6 Dewatering valve, manual

7 ALB (automatic load-dependent brake-power), mechanically controlled

8 Adjusting valve

9 Dummy coupler

10 Release valve

11 Link joint (round hole)

12 Diaphragm cylinder

13 Link joint (elongated hole)

14 Diaphragm cylinder

15 Test port (M16x1.5) for cylinder pressure

16 Test port (M22x1.5)

17 Test port (M12x1.5)

18 Block spring (M16x1.5)

10-18 10/04

Page 57

TIC QUANTUM Brakes

5500 P/S 50/60 km/h

10/04 10-19

Page 58

Brakes QUANTUM TIC

1.8 5500 S, 40/60 km/h

1 Red service line hose coupler “Accumulator”

2 Yellow service line hose coupler “Brake”

3 Filter

4 Trailer brake valve

5 Compressed air accumulator (60 litres)

6 Dewatering valve, manual

7 ALB (automatic load-dependent brake-power), mechanically controlled

8 Adjusting valve

9 Dummy coupler

10 Release valve

11 Link joint (round hole)

12 Diaphragm cylinder

13 Link joint (elongated hole)

14 Diaphragm cylinder

15 Test port (M16x1.5) for cylinder pressure

16 Test port (M22x1.5)

17 Test port (M12x1.5)

18 Block spring (M16x1.5)

10-20 10/04

Page 59

TIC QUANTUM Brakes

5500 S 40/60 km/h

10/04 10-21

Page 60

Brakes QUANTUM TIC

2.0 Adjustments

2.1 Diaphragm cylinder

With half a piston stroke (H/2), the piston rod must be placed at right

angles (90°) to the brake lever in order to obtain a good mechanical

efficiency.

When the brake is appropriately adjusted, the piston stroke must not

exceed 1/3 to 1/2 of the overall stroke when fully braking the machine.

10-22 10/04

Page 61

TIC QUANTUM Brakes

2.2 Adjusting the rod adjuster

2.2.1 Standard rod adjuster Every 1000 operating hours

Checking and adjusting the

operating clearance of the

wheel brakes

• continuous checks needed

• every 1 to 3 weeks, depending on operating hours

Operate the rod adjuster by hand in direction of pressure. If the free play

of the diaphragm cylinder pressure rod is 35 mm max., the wheel brake

needs to be re-adjusted.

The adjustment is made on the re-adjusting hexagon of the rod adjuster.

Set the free play “a” to 10 ... 12% of the connected brake lever length „B“.

Example: Lever length B = 150 mm corresponds to a free play of

15 ... 18 mm.

With automatic rod adjusters, the re-adjustment of the wheel brake is

made automatically when the brake cams have twisted by approx. 15%.

10/04 10-23

Page 62

Brakes QUANTUM TIC

2.2.2 Automatic rod

adjuster

Checking and adjusting the

operating clearance of the

wheel brakes

Every 1000 operating hours

The basic adjustment is the same as for the standard rod adjuster. The

adjustment is made automatically when the brake cams have twisted by

approx. 15°. The ideal lever adjustment (if the cylinder attachment cannot

be influenced) is approx. 15% before reaching the right angle.

The empty stroke “a” should be approx. 10% of the lever arm.

Functional check

Each time the brake linings are changed, at least once a year. Remove

the rubber cap. Turn back the adjusting screw (arrow) using a ring

spanner by approx. 3/4 turns. The free play should be at least 45 mm,

with a lever length of 150 mm.

Operate the brake lever several times by hand. The automatic adjustment

must run smoothly, i.e. you will hear the gear coupling lock in and the

adjusting screw will turn slightly clockwise on the reverse stroke. Fit the

cap. Grease it using ECO-Li 91.

10-24 10/04

Page 63

TIC QUANTUM Brakes

2.3 Brake-power regulator (ALD)

Identification plate (left) for

ALB regulator and air

suspension

The automatic load-dependent brake-power regulator (ALB) has the

function of automatically adjusting the brake pressure applied, depending

on the load condition of the forage wagon.

To compensate setting of the vehicle’s springs, a 5 mm washer (S) has

been placed under the tension spring of the brake cable. When the

vehicle’s spring has set by approx. 5 mm, this washer (S) can be

removed.

The lever length (dimension L, see identification plate of ALB regulator)

has to be adjusted according to the manufacturer’s instructions.

10/04 10-25

Page 64

Brakes QUANTUM TIC

2.4 Air suspension

2.4.1 Lifting and lowering

device

Forage wagons with air-suspension axles are equipped with valves for

lifting and lowering operations.

Actuate the valve via the rotary slide (3) in order to remove foreign

objects between the rubber bellows (1) and the spring bell (2) (Fig. 18).

After operating the lifting and lowering device, the valve should be set to

the “travel” position before starting. The travelling height is regulated

automatically.

Rotary slide positions: I Lifting

II Stop

III Travelling

IV Stop

V Lowering

10-26 10/04

Page 65

TIC QUANTUM Brakes

2.4.2 Air suspension valve

1 Frame support

2 Valve lever

3 Adjusting screw

4 Drive link

AF Rebounding

EF Compression +

FH Driving height = from lower edge of frame to the centre of the axle body

FR Direction of travel

Check the driving height (FH) given on the identification plate (on the

right-hand side of the axle frame) of the air-suspended assembly at

regular intervals.

The driving height must not be changed, otherwise damage could occur

to the components of the axle assembly.

The angle α (< 90°) between the valve lever and the drive link (4) must

be adjusted in a way so that the valve rod does not turn over if the airsuspended bellows completely rebounds. The driving height can be

adjusted at the adjusting screw (3).

10/04 10-27

Page 66

Brakes QUANTUM TIC

10-28 10/04

Page 67

TIC QUANTUM Hydraulics

1.0 LS pump .................................................................................................................................................4

1.1

Initial position (Motor Off).....................................................................................................................4

1.2

Low pressure standby..........................................................................................................................6

1.3

A control device is actuated = start of LS pump delivery.....................................................................8

1.4

Constant volume flow.........................................................................................................................10

1.5

Downstroking .....................................................................................................................................12

1.6

Maximum pressure limitation (pressure relief valve function)............................................................14

1.7

Connecting the self-loading forage wagon (hydraulic supply) ...........................................................16

1.7.1 Hydraulic supply via the power beyond port...............................................................................16

1.7.2 Hydraulic supply via the power beyond port...............................................................................17

QUANTUM 3500K / 3800K / 3500P / 3500S ........................................................................................18

2.0

2.0.1 Prior to operation ........................................................................................................................18

2.0.1 Fixed displacement pump...........................................................................................................18

2.0.3 Constant-pressure pump ............................................................................................................19

2.0.4 Power beyond port......................................................................................................................19

2.1

3500K, 2500K, 3800K........................................................................................................................20

2.1.1 Circuit Diagram ...........................................................................................................................20

2.1.2 One-way restrictor valve .............................................................................................................22

2.2

3500P, 2500P, 3800P........................................................................................................................24

2.2.1 Circuit Diagram ...........................................................................................................................24

2.2.2 One-way restrictor valve .............................................................................................................26

2.3

3500S.................................................................................................................................................28

2.3.1 Circuit Diagram ...........................................................................................................................28

2.3.2 One-way restrictor valve .............................................................................................................30

2.3.3 Flow control valve with shut-off tap (only on 3500S)..................................................................32

2.3.4 Shut-off tap .................................................................................................................................34

3.0

QUANTUM 4500S / 5500S / S-16 / S-18 / 6800S.................................................................................36

3.0.1 Prior to operation ........................................................................................................................36

3.0.2 Fixed displacement pump...........................................................................................................36

3.0.3 Constant-pressure pump ............................................................................................................37

3.0.4 Power beyond port......................................................................................................................37

3.1

Survey ................................................................................................................................................38

3.1.1 Without 2-speed floor conveyor motor........................................................................................38

3.1.2 With 2-speed floor conveyor motor.............................................................................................40

3.2

Circuit Diagram ..................................................................................................................................42

3.2.1 Without cross conveyor belt (without 2-speed floor conveyor motor).........................................42

3.2.1 Without cross conveyor belt (with 2-speed floor conveyor motor)..............................................46

3.2.3 Without cross conveyor belt (without 2-speed floor conveyor motor).........................................48

3.3

Control block ......................................................................................................................................50

3.4

4/3 way solenoid valve (knife frame, raise/lower articulated drawbar) ..............................................54

3.5

3/3 way solenoid valve (open/close tailgate) .....................................................................................56

3.6

Valve block (pick-up and shredder drum) ..........................................................................................58

10/04 11-1

Page 68

Hydraulics QUANTUM TIC

3.7 Pick-up and shredder drum engagement cylinder ............................................................................ 60

3.8

DANFOSS OMR 125 floor conveyor hydraulic motor (single-speed motor)..................................... 62

3.9

2-speed motor ................................................................................................................................... 64

3.10

3 way cross conveyor belt flow control valve .................................................................................... 68

3.11

4/3 way solenoid valve (cross conveyor belt).................................................................................... 70

3.12

3/2 way solenoid valve (cross conveyor belt) QUANTUM S............................................................. 72

QUANTUM 4500P / 5500P / 5500 P-16 / 5500 P-18 / 5500GT / 6500P / 6800P ............................... 73

4.0

4.0.1 Prior to operation........................................................................................................................ 73

4.1

Circuit Diagram.................................................................................................................................. 76

4.2

Function............................................................................................................................................. 78

4.2.1 Free circulation (solenoids not energized)................................................................................ 78

4.2.2 Loading and unloading the wagon (floor conveyor On)............................................................. 78

4.2.3 Close knife frame ....................................................................................................................... 80

4.2.4 Open knife frame........................................................................................................................ 80

4.2.5 Raise pick-up ............................................................................................................................. 82

4.2.6 Pick-up lower.............................................................................................................................. 82

4.2.7 Floating position ......................................................................................................................... 82

4.2.8 Raise articulated drawbar .......................................................................................................... 84

4.2.9 Lower articulated drawbar.......................................................................................................... 84

4.2.10 Open tailgate.............................................................................................................................. 86

4.2.11 Close tailgate ............................................................................................................................. 86

4.3

Circulation valve with pressure relief valve ....................................................................................... 88

4.4

4/3 way Proportional solenoid valve.................................................................................................. 90

4.5

4/3 way solenoid valve ...................................................................................................................... 92

4.6

2/2 way solenoid valve (seated valve) .............................................................................................. 94

4.6.1 Up to serial no. ........................................................................................................................... 94

4.6.2 From serial no. ........................................................................................................................... 96

4.7

DANFOSS OMR 125 hydraulic motor............................................................................................... 98

4.8

Faults and remedies.......................................................................................................................... 99

4.8.1 Control system (LP/LM08 with SV02) ........................................................................................ 99

4.8.2 No working function LP/LM08 .................................................................................................. 100

4.8.3 No working function with multiple actuation............................................................................. 101

4.8.4 Consumers lower ..................................................................................................................... 101

4.8.5 Oil heating-up........................................................................................................................... 101

4.8.6 External oil leaks ...................................................................................................................... 101

4.9

Arresting cylinder for trailing axle .................................................................................................... 102

5.0

QUANTUM 6800................................................................................................................................. 103

5.1

Forced steering ............................................................................................................................... 103

5.1.1 Function ................................................................................................................................... 103

11-2 10/04

Page 69

TIC QUANTUM Hydraulics

10/04 11-3

Page 70

Hydraulics QUANTUM TIC

1.0 LS pump

1.1 Initial position

(Motor Off)

2 Working hydraulics pump (LS pump)

6 Compensating valve

7 Input (load pressure from signal network)

8 Volume flow controller

14 Control ram

15 Control spring

16 Pump drive

17 Swash plate

18 Ram

19 Pump input

20 Pump output (in the bottom plate of the control devices)

21 Compression spring (margin pressure)

11-4 10/04

Page 71

TIC QUANTUM Hydraulics

As the motor is shut down, there is no pressure in the hydraulic system.

The compression spring (21) has pushed the volume flow controller (8) to

the end stop on the right. Due to this position, the upper side of the

control ram (14) is connected with the tank via the volume flow

controller (8).

The control spring (15) has moved the swash plate (17) to its maximum

position.

10/04 11-5

Page 72

Hydraulics QUANTUM TIC

1.2 Low pressure standby

2 Working hydraulics pump (LS pump)

6 Compensating valve

7 Input (load pressure from signal network)

8 Volume flow controller

14 Control ram

15 Control spring

17 Swash plate

18 Ram

19 Pump input

20 Pump output (in the bottom plate of the control devices)

21 Compression spring (margin pressure)

25 Control edge

AA Oil supply

BB Pressure-reduced oil

EE Feed oil from the feed pump

LL Tank (pressureless)

11-6 10/04

Page 73

TIC QUANTUM Hydraulics

All control units are in their neutral position. At the beginning, the swash

plate (17) is in its maximum swung-out position (see also “Motor OFF”)

As soon as the motor is started, the pump delivers the maximum volume

flow to the spools of all control units.

As the spools completely shut off the flow, the pressure rises the acts

upon the right side of the volume flow controller (8) which is moved to the

left against the compression spring (21).

The control edge (25) is now opened, enabling the pressure to access

the top face of the control ram (14). Now the swash plate (17) is moved to

the “Minimum pump capacity” position against the control spring (15).

This process takes 10 milliseconds.

In this pump position, the following happens:

Only such a volume flow is generated that is enough to compensate

leakage losses;

The pressure required for actuation of a consumer is maintained.

Since each control unit is in its neutral position, the load pressure input

(7) is pressureless (connected to the tank). To move the volume flow

controller, the pump pressure only has to overcome the spring (21). The

pressure required for this is xxx bar (see technical data of tractor) and is

referred to as the “Low-pressure standby”.

The pump remains in the “Low-pressure standby” position until a control

unit is actuated. In this position, the pump requires only little drive energy.

10/04 11-7

Page 74

Hydraulics QUANTUM TIC

1.3 A control device is actuated = start of LS pump delivery

2 Working hydraulics pump (LS pump)

6 Compensating valve

7 Input (load pressure from signal network)

8 Volume flow controller

14 Control ram

15 Control spring

17 Swash plate

18 Ram

19 Pump input

20 Pump output (in the bottom plate of the control devices)

21 Compression spring (margin pressure)

AA Oil supply

BB Pressure-reduced oil

EE Feed oil from the feed pump

LL Tank (pressureless)

11-8 10/04

Page 75

TIC QUANTUM Hydraulics

When a control device is actuated, requiring an increased flow from the

pump, the pump pressure drops slightly.

The following condition results at the volume flow controller (8):

the pump pressure acts on the right-hand face end

the load pressure + the spring force of the compression spring act in the

spring space (Margin pressure) (21).

Since the load pressure + the spring force of the compression spring

(Margin pressure) (21) is higher than the pump pressure on the right face

end, the volume flow controller (8) is moved to the right up to the stop.

As a consequence:

the free circulation of the pump pressure to the control ram is blocked.

the control ram (14) is connected to the tank (no pressure on ram face).

the swash plate (17) is tilted aside by the control spring (15).

The pump now pumps a higher volume flow. This process is referred to as

“Upstroking”. The volume flow of the pump is determined by the restrictor

effect of the open spool cross-section or by the setting of the flow divider

of an additional control unit.

Reduced flow requirement

When the spool cross-section is reduced (the volume flow is to be

reduced), the load pressure at the input (7) drops. This changes the force

ratio at the volume flow controller (8), actuating the volume flow controller

to the left against the spring, according to the pressure drop. The control

ram (14) is pressurized and the swash plate (17) is set to a more

horizontal position - the pump performs a downstroke until the volume flow

requirement is met.

10/04 11-9

Page 76

Hydraulics QUANTUM TIC

1.4 Constant volume flow

2 Working hydraulics pump (LS pump)

6 Compensating valve

7 Input (load pressure from signal network)

8 Volume flow controller

14 Control ram

15 Control spring

17 Swash plate

20 Pump output (in the bottom plate of the control devices)

21 Compression spring (margin pressure)

22 Adjusting screw

AA Oil supply

BB Pressure-reduced oil

DD Control oil

EE Feed oil from the feed pump

LL Tank (pressureless)

11-10 10/04

Page 77

TIC QUANTUM Hydraulics

When a constant load is required from a port (constant consumer), the

volume flow controller (8) is actuated to a stable position.

This keeps both the pressure on the top face of the control ram (14) and

the position of the swash plate (17) constant. As long as the position of

the swash plate (17) remains unchanged, the pump delivers a constant

flow.

The following pressures now result on the volume flow controller (8):

the load pressure (signal) + spring force of the compression spring

(margin pressure) (21) on the left side.

Pump pressure on the right side.

The difference in pressure is the differential pressure corresponding to

the spring force of the compression spring (21).

10/04 11-11

Page 78

Hydraulics QUANTUM TIC

1.5 Downstroking

2 Working hydraulics pump (LS pump)

6 Compensating valve

7 Input (load pressure from signal network)

8 Volume flow controller

14 Control ram

15 Control spring

17 Swash plate

20 Pump output (in the bottom plate of the control devices)

21 Compression spring (margin pressure)

25 Control edge

AA Oil supply

BB Pressure-reduced oil

DD Control oil

EE Feed oil from the feed pump

LL Tank (pressureless)

11-12 10/04

Page 79

TIC QUANTUM Hydraulics

Downstroking of the LS pump is performed under the following

conditions:

• a control unit is set to the neutral position. No volume flow is

required.

• an additional control unit is set to the fine control range. A smaller

volume flow is required.

• in parallel operation, a control unit is actuated to the neutral

position or to the fine control range. A smaller volume flow is

required.

The pump must perform a downstroke whenever a smaller volume flow is

needed.

This will always happen when the pressure on the right face end of the

volume flow controller (8) is higher than on the left face (in the spring

space).

In this case, the volume flow controller (8) is moved to the left against the

compression spring (21), opening the control edge (25).

This results in a rising pressure on the top face of the control ram (14) that

sets the swash plate (17) to a more vertical position against the control

spring (15) – the volume flow is reduced.

When the spool cross-section is reduced (fine control range), the load

pressure at the input (7) drops.

This changes the force ratio at the volume flow controller (8) so that the

volume flow controller is actuated to the left against the spring, according

to the pressure drop.

The control edge (25) is opened, thus pressurizing the control ram (14).

The swash plate (17) is set to a more horizontal position and the pump

performs a downstroke until the volume flow requirement is met.

A pump downstroke is triggered not only by the change of load pressure

(signal).

An example:

When operating two control units in parallel, the load pressure values are