Page 1

QUADRANT 2200 with CCT

QUADRANT 2200 RC with CCT

Technical Systems

Diagnosis

Page 2

Page 3

TIC QUADRANT 2200/ 2200 RC Diagnosis

Contents

1.0 Control terminal service menu

(up to module 1 no. 835024.2)

1.1 Service menu structure . . . . .........................2

1.2 Additional information about page "Service 1" . . . . . . . . . . 3

1.3 Additional information about page "Service RC" . . . . . . . . 3

1.4 Input testing . . . . . . . . . . . . . . .........................4

1.5 Output testing . . . . . . . . . . . . .........................5

1.6 Error display . . . . . . . . . . . . . .........................8

1.7 Key test . . . . . . . . . . . . . . . . . .........................9

2.0 Control terminal service menu

Central terminal

compartment

(from module 1 no. 835024.3)

2.1 Service menu structure . . . . .........................10

2.2 Additional information about page "Service 1" . . . . . . . . . . 11

2.3 Additional information about page "Service RC" . . . . . . . . 11

2.4 Input testing . . . . . . . . . . . . . . .........................12

2.5 Output testing . . . . . . . . . . . . .........................14

2.6 Error display . . . . . . . . . . . . . .........................18

2.7 Key test . . . . . . . . . . . . . . . . . .........................19

CCU

3.0 Control terminal service menu (on CCU module)

3.1 Service menu structure . . . . .........................20

3.2 Additional information about page "Service 1" . . . . . . . . . . 21

3.3 Additional information about page "Service RC" . . . . . . . . 21

3.4 Input testing . . . . . . . . . . . . . . .........................22

3.5 Output testing . . . . . . . . . . . . .........................24

3.6 Error display . . . . . . . . . . . . . .........................26

3.7 Key test . . . . . . . . . . . . . . . . . .........................27

4.0 Additional information

4.1 Testing the baling pressure sensor

(with Central terminal compartment) . . . . . . . . . . . . . . . . . . 28

4.2 Testing the metering wheel / bale length sensor

(with Central terminal compartment) . . . . . . . . . . . . . . . . . . . 29

4.3 General (with Central terminal compartment) . . . . . . . . . . 30

5.0 Information on replacing modules ..................31

08/2002 1

Page 4

W

Diagnosis QUADRANT 2200/ 2200 RC TIC

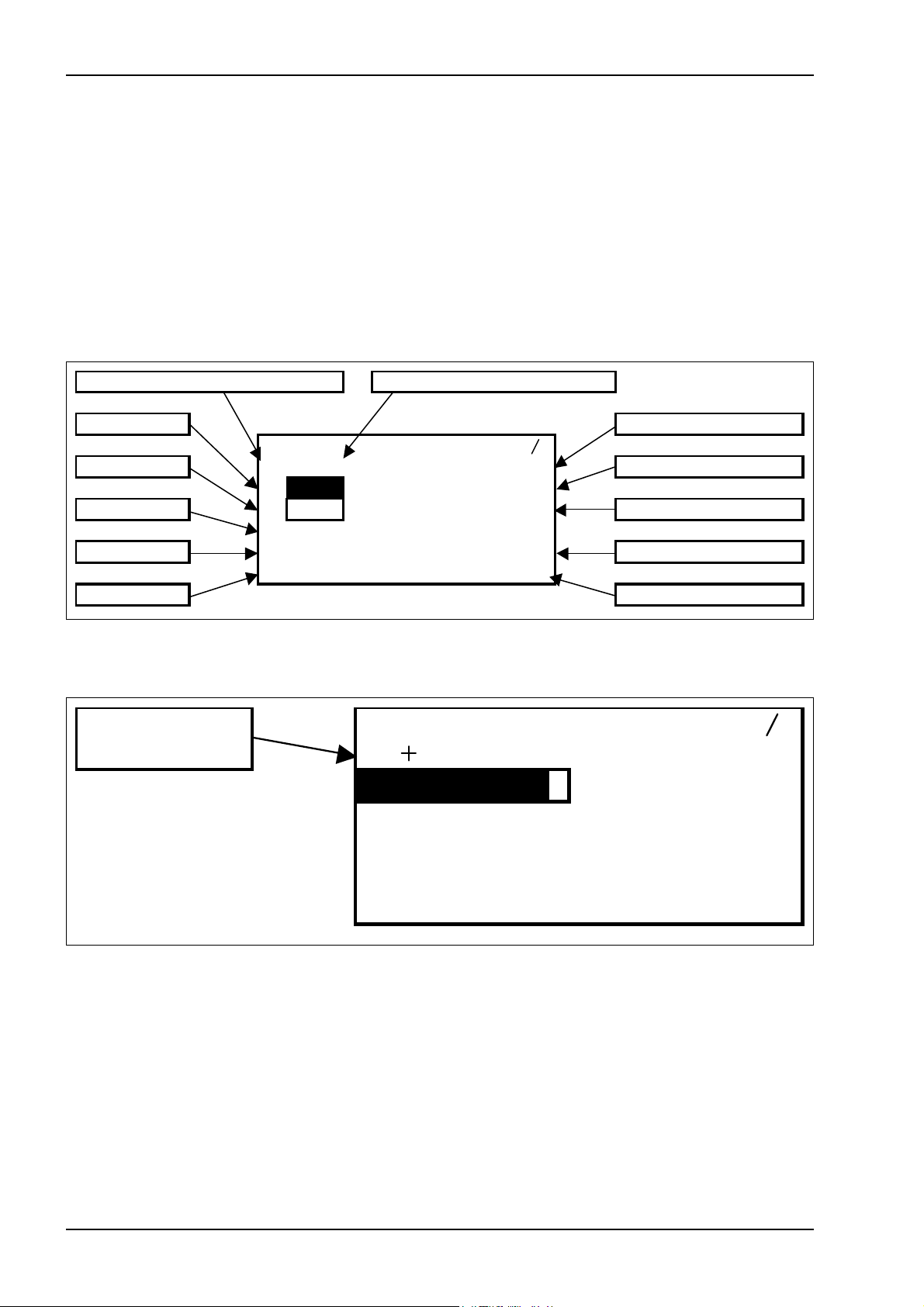

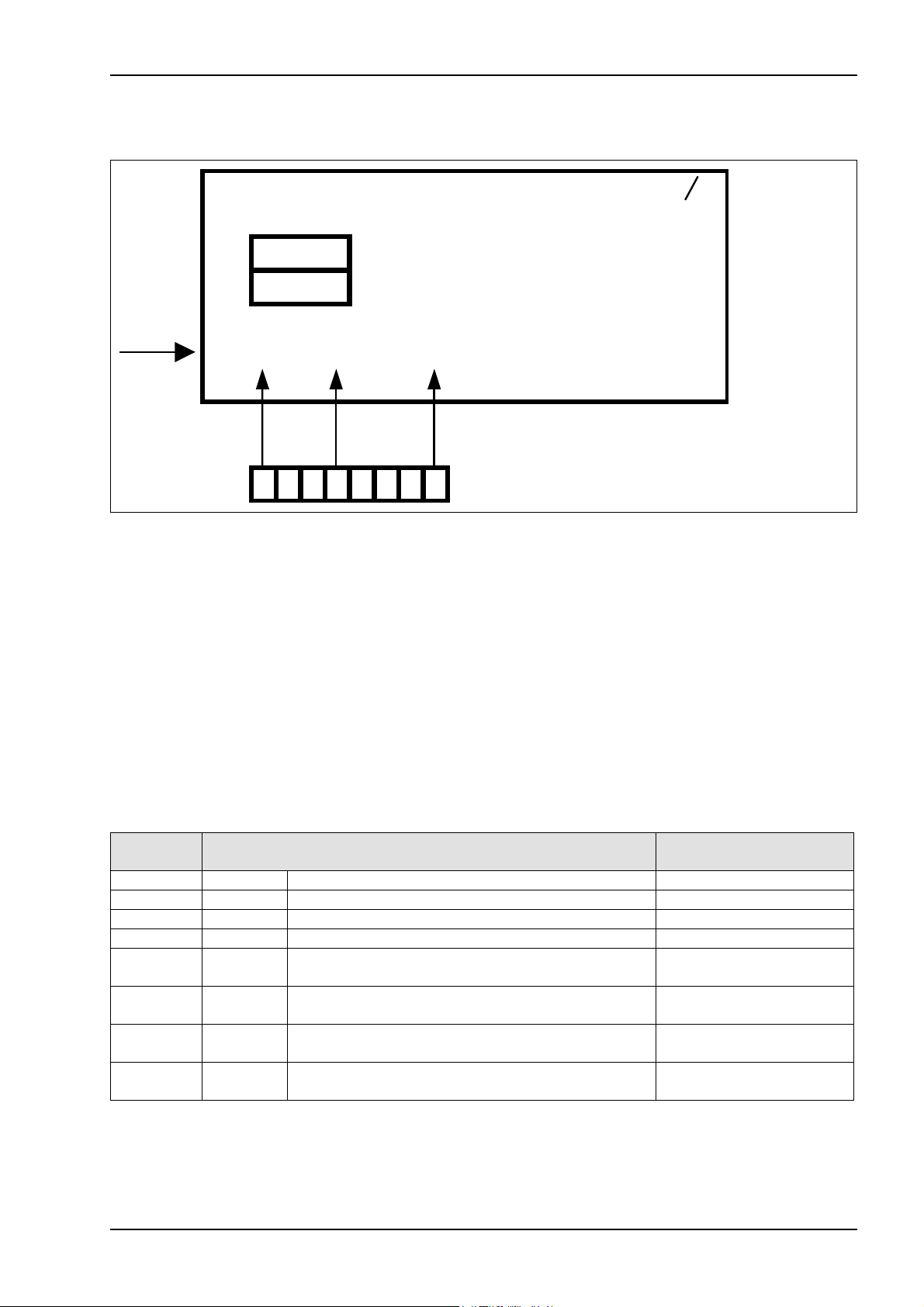

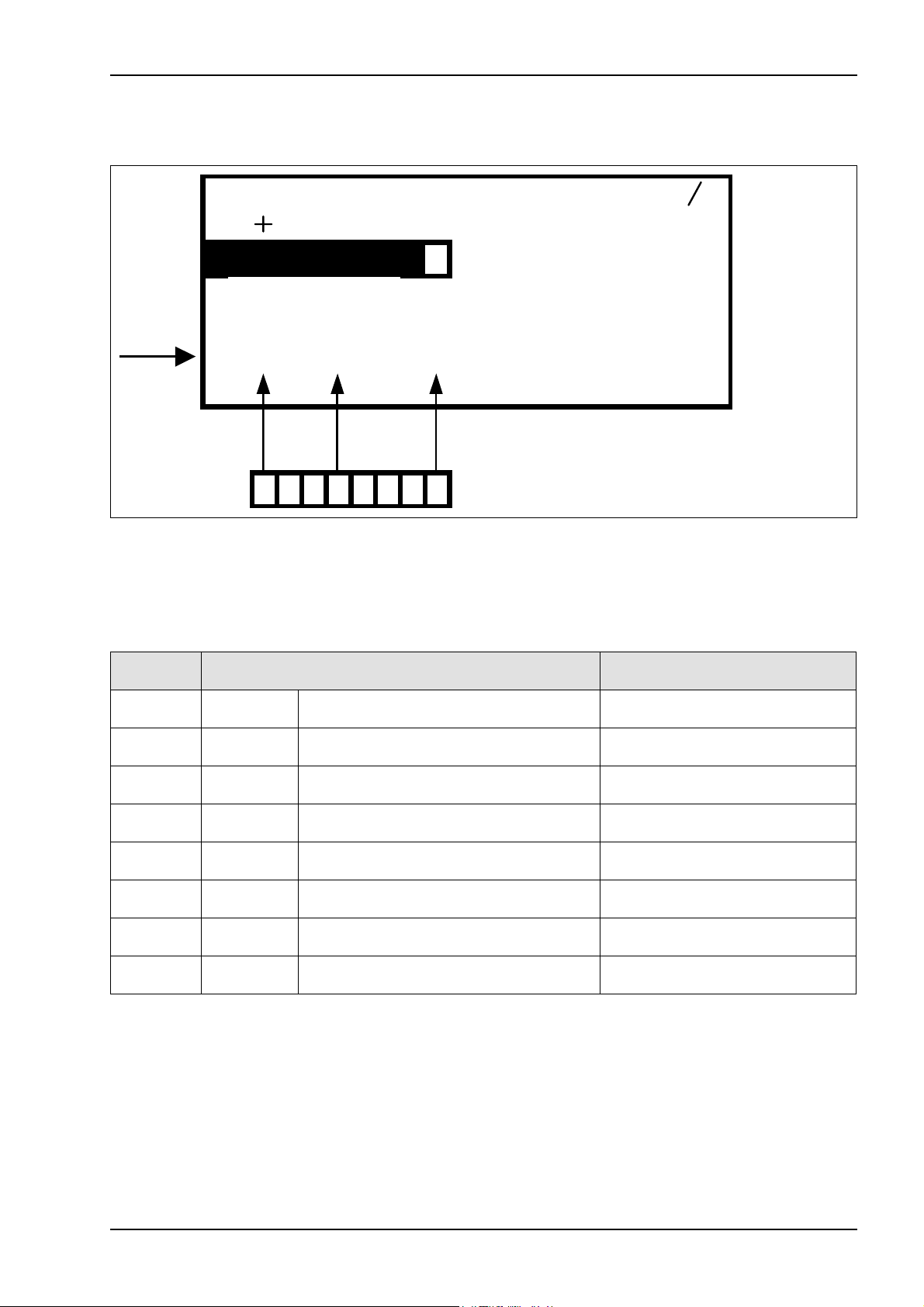

1.0 Control terminal service menu (up to module 1 no. 835024.2)

1.1 Service menu

structure

(up to module 1

no. 835024.2)

Page "8/1 (Service 1)"

Current pressure [bar] Current bale length [m]

Control unit P+ PTO shaft speed [rpm]

Service1 81

Control unit P-

Inputs

Outputs

Error

P= 0 L0 , 0 0 N0= 0

P0 25 5 N1= 0

P1 0 N2= 0

E: 00000000

A:00000000 U:11 ,6

F:00000000 FFFF

This menu serves as a tool in fault-finding. It shows the status of various

electrical components such as e.g. speed, voltage, pressure and switch

positions.

To enter the service menu, press the keys “Scroll main menu”, “Plus

key” and “Minus key” at the same time.

The following mask appears:

Feed rake speed [rpm]

Rotor speed [rpm]

Voltage [V]

Key test

Page "8/2 (Service RC)"

(press "Sub-menu" key one more time)

Cutt ing f r ame

angle

Ser vi c e RC 8 2

=20 N0= 0

255 N1= 0

N2 = 0

E:00000000

A:00000000 U:11 , 6

F:00000000 FFFF

2 08/2002

Page 5

TIC QUADRANT 2200/ 2200 RC Diagnosis

1.2 Additional information about page "8/1 (Service 1)" (up to module 1 no. 835024.2)

RemarkMenu item

The pressure in the baling chamber cylinders is displayed here in bars.(P=) Current pressure

(L) Current bale length

(N0=) PTO shaft speed

(N1=) Feed rake speed

(N2=) Rotor speed

Key test

(P0) Control unit P+

(P1) Control unit P-

The length of the bale in the baling chamber is displayed here in metres

to the second decimal point.

The calculated PTO shaft speed in revolutions per minute is displayed

here (this speed is measured by the drive speed sensor).

The feed rake speed in revolutions per minute is displayed here

(150 rpm at 1000 rpm PTO shaft speed)

The rotor speed in revolutions per minute is displayed here (140 rpm at

1000 rpm PTO shaft speed)

The supply voltage is displayed here in Volt to the first decimal point.(U:) Voltage

A combination of characters and numbers is displayed here to test the

function of the keys on the Control Terminal.

The condition of the baling pressure build-up valve is displayed here.

The displayed number is proportional with the valve actuation and may

assume values from 0 to 255.

0 = Valve not actuated

255 = Valve fully actuated

The condition of the baling pressure relief valve is displayed here. The

displayed number is proportional with the valve actuation and may

assume values from 0 to 255.

0 = Valve not actuated

255 = Valve fully actuated

(E:) Inputs

(A:) Outputs

(F:) Error

The condition of various circuits connected with the modules is

displayed here. Each numeric character corresponds to one circuit.

0 = Circuit open

1 = Circuit closed

The condition of various circuits connected with the modules is

displayed here. Each numeric character corresponds to one circuit.

0 = Circuit open

1 = Circuit closed

Malfunctions are displayed here. Each numeric character corresponds

to one error.

0 = No error

1 = Error

1.3 Additional information about page "8/2 (Service RC)" (up to module 1 no. 835024.2)

(W=) Cutting frame angle

The cutting frame angle in degrees is displayed here. The higher the

value, the wider the cutting frame is open.

08/2002 3

Page 6

Diagnosis QUADRANT 2200/ 2200 RC TIC

1.4 Input testing (up to module 1 no. 835024.2)

Continuity test

Ser v i c e 1 8 1

P= 0L0 , 00 N0= 0

P0 255 N1= 0

P1 0 N2= 0

E:00000000

A: 00000000 U: 11 ,6

F : 00000000 FFFF

12345678

Eight numeric characters are available for input diagnosis in line “E”, each of them being assigned to one

circuit.

The numeric characters may assume the following values:

0 = Circuit open or

1 = Circuit closed.

All numeric characters show the respective state independently of each other. Dependencies and switching

sequences which may occur in normal operation have no influence.

DisplayDesignationNumeric

character

Z11E1

Z49E2

U2E3

U1E4

B23E5

B69E7

B69E8

Twine break left/right actual value

switch

ROTOCUT knives ON actual value

switch

Retract bale ejector cylinder switch

(red)

Extend bale ejector cylinder switch

(blue)

Feed rake speed sensor (blue)

inside

Drive speed sensor (red) outside B9E6

Metering wheel / bale length sensor

signal B

Metering wheel / bale length sensor

signal A

0 = Operating status (normal)

1 = Twine break

0 = Switch not actuated

1 = Switch actuated

0 = Switch not pushed

1 = Switch pushed

0 = Switch not pushed

1 = Switch pushed

0 = Standstill

Changes between 0 and 1 when feed

rake rotates

1 = Wire ends connected

0 = Standstill

Changes between 0 and 1 when PTO

shaft rotates

1 = Wire ends connected

Changes between 0 and 1 when

metering wheel rotates

Changes between 0 and 1 when

metering wheel rotates

4 08/2002

Page 7

A

TIC QUADRANT 2200/ 2200 RC Diagnosis

1.5 Output testing (up to module 1 no. 835024.2)

Testing the actuation by the modules

Ser v i c e 1 8 1

P= 0L0 , 00 N0= 0

P0 0 N1= 0

P1 0 N2= 0

E: 00000000

:00000000

U:11 ,6

F : 00000000 FFFF

12345678

Eight numeric characters are available for output diagnosis in line “A” on page "8 / 1 (Service 1)" and page

"8 / 2 (Service RC)", each of them being assigned to one circuit. It must be ensured that the baling pressure

solenoid valves (P0 and P1) are not activated. To achieve this, press the "Plus key" once.

The numeric characters only indicate if a solenoid valve is actuated by the corresponding module.

For diagnosis purposes, the corresponding function must be activated, i.e. the functions can be

checked only one by one.

The numeric characters may assume the following values:

0 = Solenoid valve is not actuated by the module

or

1 = Solenoid valve is actuated by the module.

Dependencies and switching sequences which may occur in normal operation have an influence.

The table below applies to page "8 / 1 (Service 1)"

DisplayDesignationNumeric

character

No functionFree NoneA1

No functionFree NoneA2

No functionFree NoneA3

No functionFree NoneA4

Retract bale ejector cylinder solenoid coilY12A5

Extend bale ejector cylinder solenoid coilY11 A6

Circulation shut-off valve solenoid coilY77 A7

Rotor blocking solenoid coilY58 A8

08/2002 5

0 = not activated

1 = activated

0 = not activated

1 = activated

0 = not activated

1 = activated

0 = not activated

1 = activated

Page 8

W

A

Diagnosis QUADRANT 2200/ 2200 RC TIC

Output testing, continued (up to module 1 no. 835024.2)

Testing the actuation by the modules

Se r v i c e RC 8 2

=20 N0= 0

255 N1= 0

N2 = 0

E: 00000000

:00000000

U:11 ,6

F : 00000000 FFFF

12345678

The table below applies to page "8 / 2 (Service RC)"

For diagnosis purposes, the corresponding function must be activated, i.e. the functions can be

checked only one by one.

DisplayDesignationNumeric

character

No functionFree NoneA1

No functionFree NoneA2

No functionFree NoneA3

No functionFree NoneA4

Close cutting frame solenoid coilY64 A5

Open cutting frame solenoid coilY63 A6

ROTOCUT knives OFF solenoid coilY54 A7

ROTOCUT knives ON solenoid coilY55 A8

0 = not activated

1 = activated

0 = not activated

1 = activated

0 = not activated

1 = activated

0 = not activated

1 = activated

6 08/2002

Page 9

A

TIC QUADRANT 2200/ 2200 RC Diagnosis

Output testing, continued (up to module 1 no. 835024.2)

Continuity test

Ser v i c e 1 8 1

P= 0L0 , 00 N0= 0

P0 0 N1 = 0

P1 0 N2 = 0

E: 00000000

:00000000

U:11 ,6

F : 00000000 FFFF

12345678

To activate this function, keep the “Minus key” pressed while in the service menu, i.e. a maximum of

eight circuits may be checked at the same time.

Eight numeric characters are available for output diagnosis in line “A”, each of them being assigned to one

circuit.

The numeric characters may assume the following values:

0 = Circuit open or

1 = Circuit closed and/or solenoid coil OK.

All numeric characters show the respective state independently of each other. Dependencies and switching

sequences which may occur in normal operation have no influence.

DisplayDesignationNumeric

character

Not relevantFree NoneA1

Rotor blocking solenoid coilY58 A2

Y77 A3

Y51 A7

Y50 A8

Circulation shut-off valve

solenoid coil

Wrapping release motor relayK92 A6

Baling pressure relief solenoid

coil

Baling pressure build-up

solenoid coil

0 = Circuit interrupted

1 = Solenoid coil circuit OK

0 = Circuit interrupted

1 = Solenoid coil circuit OK

No functionFree None A4

No functionFree None A5

0 = Circuit interrupted

1 = Relay circuit OK (85 to 86)

0 = Circuit interrupted

1 = Solenoid coil circuit OK

0 = Circuit interrupted

1 = Solenoid coil circuit OK

08/2002 7

Page 10

Diagnosis QUADRANT 2200/ 2200 RC TIC

1.6 Error display (up to module 1 no. 835024.2)

Ser v i c e 1 8 1

P= 0L0 , 00 N0= 0

P0 255 N1= 0

P1 0 N2 = 0

E: 00000000

A: 00000000 U: 11 ,6

F:00000000

FFFF

12345678

Eight numeric characters are available for error display in line “F”, each of them being assigned to one error.

This function is available only on page 8/1 "Service 1".

The numeric characters may assume the following values:

0 = No error or

1 = Error.

All numeric characters show the respective state independently of each other. Dependencies and switching

sequences which may occur in normal operation have no influence.

Symbol in

work menu

character

RemarkReason Numeric

Cutting frame not closed F1

System fault (CAN bus)F2

Cutting frame should be closed, but

cutting frame position sensor indicates

an angle above 0°

No signal from CAN bus or module

defective

Rotor overloadF3

Feed rake overloadF4

Tying fault F5

F7

8 08/2002

Circulation shut-off valve

activated too long

Drive speed above 500 rpm and rotor

speed below 56 rpm

Drive speed above 500 rpm and feed

rake speed below 60 rpm

See Electric System documentation

Circuit diagram 11a, b

(Tying fault sequence diagram)

No functionFree F6

Circulation shut-off valve activated

longer than allowed in connection with

baling pressure build-up solenoid coil

(more than 50 % actuated time within

3 min.)

Twine break switch contactTwine break F8

Page 11

TIC QUADRANT 2200/ 2200 RC Diagnosis

1.7 Key test (up to module 1 no. 835024.2)

Ser v i c e 1 8 1

P= 0L0 , 00 N0= 0

P0 255 N1= 0

P1 0 N2 = 0

E:00000000

A:00000000 U:11 ,6

F : 00000000

FFFF

12345

Four numeric characters are available for key testing in line (1) shown above.

Pushing a key on the Control Terminal produces one of the combinations of numbers and characters shown

below which allow checking the function.

The character “G” at the 5

digit remains free.

Example: When the central lubrication system is active and the “Minus” key is pressed, the numeric

characters read “FDFFG”. If the central lubrication system is not active and the “Minus key” is

pressed, the numeric characters read “FDFF”.

th

digit indicates if the central lubrication system is currently active, otherwise this

DisplayDesignationKey

4321

FFFEScroll through main menu

FFFD Scroll through second screen

FFFBROTOCUT knives ON

FFF7ROTOCUT knives OFF

FFEFBuild up / relieve baling pressure

FFDFMinus

FDFFPlus

FFBFClose cutting frame

FF7FOpen cutting frame

FEFFManual tying

FBFFRight arrow key

F7FFLeft arrow key

08/2002 9

Page 12

W

Diagnosis QUADRANT 2200/ 2200 RC TIC

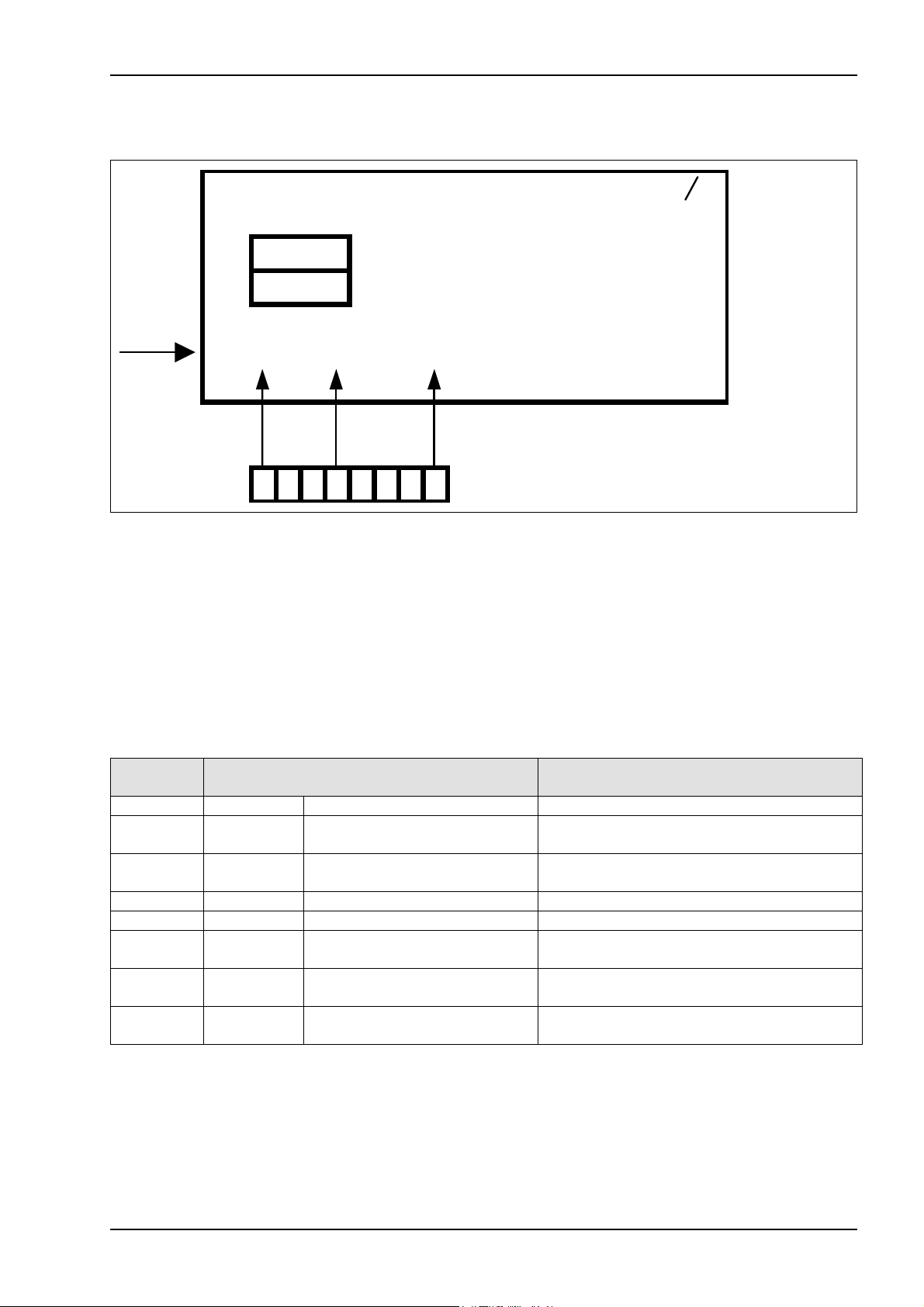

2.0 Control terminal service menu (from module 1 no. 835024.3)

2.1 Service menu

structure

(from module 1

no. 835024.3)

Page "8/1 (Service 1)"

Current pressure [bar] Current bale length [m]

Control unit P+ PTO shaft speed [rpm]

Service1 81

Control unit P-

Inputs

Outputs

Error

P= 0 L0 , 0 0 N0= 0

P0 25 5 N1= 0

P1 0 N2= 0

E: 00000000

A:00000000 U:11 ,6

F:00000000 FFFF

This menu serves as a tool in fault-finding. It shows the status of various

electrical components such as e.g. speed, voltage, pressure, switch

positions.

To enter the service menu, press the keys “Scroll main menu”, “Plus

key” and “Minus key” at the same time.

The following mask appears:

Feed rake speed [rpm]

Rotor speed [rpm]

Voltage [V]

Key test

Page "8/2 (Service RC)"

(press "Sub-menu" key one more time)

Cutting

frame angle

Ser vi c e RC 8 2

=20 N0= 0

255 N1= 0

N2 = 0

E:00000000

A:00000000 U:11 , 6

F:00000000 FFFF

10 08/2002

Page 13

TIC QUADRANT 2200/ 2200 RC Diagnosis

2.2 Additional information about page "8/1 (Service 1)" (from module 1 no. 835024.3)

Remark Menu item

The pressure in the baling chamber cylinders is displayed here in bars.(P=) Current pressure

(L) Current bale length

(N0=) PTO shaft speed

(N1=) Feed rake speed

(N2=) Rotor speed

Key test

(P0) Control unit P+

(P1) Control unit P-

The length of the bale in the baling chamber is displayed here in metres

to the second decimal point.

The calculated PTO shaft speed in revolutions per minute is displayed

here (this speed is measured by the drive speed sensor).

The feed rake speed in revolutions per minute is displayed here

(150 rpm at 1000 rpm PTO shaft speed)

The rotor speed in revolutions per minute is displayed here (140 rpm at

1000 rpm PTO shaft speed)

The supply voltage is displayed here in Volt to the first decimal point.(U:) Voltage

A combination of characters and numbers is displayed here to test the

function of the keys on the Control Terminal.

The condition of the baling pressure build-up valve is displayed here.

The displayed number is proportional with the valve actuation and may

assume values from 0 to 255.

0 = Valve not actuated

255 = Valve fully actuated

The condition of the baling pressure relief valve is displayed here. The

displayed number is proportional with the valve actuation and may

assume values from 0 to 255.

0 = Valve not actuated

255 = Valve fully actuated

(E:) Inputs

(A:) Outputs

(F:) Error

The condition of various circuits connected with the modules is

displayed here. Each numeric character corresponds to one circuit.

0 = Circuit open

1 = Circuit closed

The condition of various circuits connected with the modules is

displayed here. Each numeric character corresponds to one circuit.

0 = Circuit open

1 = Circuit closed

Malfunctions are displayed here. Each numeric character corresponds

to one error.

0 = No error

1 = Error

2.3 Additional information about page "8/2 (Service RC)" (up to module 1 no. 835024.3)

(W=) Cutting frame angle

The cutting frame angle in degrees is displayed here. The higher the

value, the wider the cutting frame is open.

08/2002 11

Page 14

Diagnosis QUADRANT 2200/ 2200 RC TIC

2.4 Input testing (from module 1 no. 835024.3)

Continuity test

Ser v i c e 1 8 1

P= 0L0 , 00 N0= 0

P0 255 N1= 0

P1 0 N2 = 0

E:00000000

A: 00000000 U: 11 ,6

F : 00000000 FFFF

12345678

Eight numeric characters are available for input diagnosis in line “E” on page "8 / 1 (Service 1)" and page

"8 / 2 (Service RC)", each of them being assigned to one circuit.

The numeric characters may assume the following values:

0 = Circuit open or

1 = Circuit closed.

All numeric characters show the respective state independently of each other. Dependencies and switching

sequences which may occur in normal operation have no influence.

The table below applies to page "8 / 1 (Service 1)"

DisplayDesignationNumeric

character

Emergency operation switchU5 E1

Z11 E3

Z63 E4

B23 E5

B9 E6

B69 E7

B69 E8

Twine break left/right actual

value switch

Tying system monitoring actual

value switch

Feed rake speed sensor (blue)

inside

Drive speed sensor (red)

outside

Metering wheel / bale length

sensor - signal B

Metering wheel / bale length

sensor - signal A

1 = Normal operation switch

0 = Emergency operation switch

No functionFree None E2

0 = Operating status (normal)

1 = Twine break

0 = Switch pushed

1 = Switch not pushed

0 = Standstill

Changes between 0 and 1 when feed rake

rotates

1 = Wire ends connected

0 = Standstill

Changes between 0 and 1 when feed rake

rotates

1 = Wire ends connected

Changes between 0 and 1 when metering

wheel rotates

Changes between 0 and 1 when metering

wheel rotates

12 08/2002

Page 15

R

W

TIC QUADRANT 2200/ 2200 RC Diagnosis

Input testing, continued (from module 1 no. 835024.3)

Continuity test

Se r vi c e

C82

=20 N0= 0

255 N1= 0

E:00000000

A: 00000000 U: 11 ,6

F : 00000000 FFFF

12345678

The table below applies to page "8 / 2 (Service RC)"

character

Z49 E4

Z56 E5

U2 E6

U1 E7

ROTOCUT knives ON actual

value switch

Flywheel brake actual value

switch

Retract bale ejector cylinder

switch - (red)

Extend bale ejector cylinder

switch U2 - (blue)

Rotor speed sensor B24 E8

N2 = 0

DisplayDesignationNumeric

No functionFree None E1

No functionFree None E2

No functionFree None E3

0 = Switch not actuated

1 = Switch actuated

1 = Switch actuated

0 = Switch not actuated

1 = Switch actuated

0 = Switch not actuated

1 = Switch actuated

0 = Switch not actuated

0 = Standstill

Changes between 0 and 1 when rotor rotates

1 = Wire ends connected

08/2002 13

Page 16

A

Diagnosis QUADRANT 2200/ 2200 RC TIC

2.5 Output testing (from module 1 no. 835024.3)

Testing the actuation by the modules

Ser v i c e 1 8 1

P= 0L0 , 00 N0= 0

P0 0 N1 = 0

P1 0 N2 = 0

E: 00000000

:00000000

U:11 ,6

F : 00000000 FFFF

12345678

Eight numeric characters are available for output diagnosis in line “A” on page "8 / 1 (Service 1)" and page

"8 / 2 (Service RC)", each of them being assigned to one circuit.

It must be ensured that the baling pressure solenoid valves (P0 and P1) are not activated. To achieve this,

press the "Plus key" once.

The numeric characters only indicate if a solenoid valve is actuated by the corresponding module.

For diagnosis purposes, the corresponding function must be activated, i.e. the functions can be

checked only one by one.

The numeric characters may assume the following values:

0 = Solenoid valve is not actuated by the module

or

1 = Solenoid valve is actuated by the module.

Dependencies and switching sequences which may occur in normal operation have an influence.

The table below applies to page "8 / 1 (Service 1)"

DisplayDesignationNumeric

character

No functionFree None A1

No functionFree None A2

No functionFree None A3

Rotor blocking solenoid coilY58 A4

Y77 A5

Y51 A7

Y50 A8

14 08/2002

Circulation shut-off valve

solenoid coil

Tying release motor relayK92 A6

Baling pressure relief solenoid

coil

Baling pressure build-up

solenoid coil

0 = not activated

1 = activated

0 = not activated

1 = activated

0 = not activated

1 = activated

0 = not activated

1 = activated

0 = not activated

1 = activated

Page 17

W

A

TIC QUADRANT 2200/ 2200 RC Diagnosis

Output testing, continued (from module 1 no. 835024.3)

Testing the actuation by the modules

Se r v i c e RC 8 2

=20 N0= 0

255 N1= 0

N2 = 0

E: 00000000

:00000000

U:11 ,6

F : 00000000 FFFF

12345678

The table below applies to page "8 / 2 (Service RC)"

For diagnosis purposes, the corresponding function must be activated, i.e. the functions can be

checked only one by one.

DisplayDesignationNumeric

character

Open cutting frame solenoid coilY63 A1

Close cutting frame solenoid coilY64 A2

ROTOCUT knives ON solenoid coilY55 A3

ROTOCUT knives OFF solenoid coilY54 A4

Central lubrication system motorM25 A5

Retract bale ejector cylinder solenoid coilY12 A6

Extend bale ejector cylinder solenoid coilY11 A7

Y31 A8

Knotter cleaning solenoid coil

(when set to 2.5 s blowing time)

0 = not activated

1 = activated

0 = not activated

1 = activated

0 = not activated

1 = activated

0 = not activated

1 = activated

0 = not activated

1 = activated

0 = not activated

1 = activated

0 = not activated

1 = activated

0 = not activated

1 = activated

08/2002 15

Page 18

A

Diagnosis QUADRANT 2200/ 2200 RC TIC

Output testing, continued (from module 1 no. 835024.3)

Continuity test

Ser v i c e 1 8 1

P= 0L0 , 00 N0= 0

P0 0 N1 = 0

P1 0 N2 = 0

E: 00000000

:00000000

U:11 ,6

F : 00000000 FFFF

12345678

To activate this function, keep the “Minus key” pressed while in the service menu, i.e. a maximum of

eight circuits may be checked at the same time.

Eight numeric characters are available for output diagnosis in line “A” on page "8 / 1 (Service 1)" and page

"8 / 2 (Service RC)", each of them being assigned to one circuit.

The numeric characters may assume the following values:

0 = Circuit open or

1 = Circuit closed and/or solenoid coil OK.

All numeric characters show the respective state independently of each other. Dependencies and switching

sequences which may occur in normal operation have no influence.

The table below applies to page "8 / 1 (Service 1)"

DisplayDesignationNumeric

character

No functionFree None A1

No functionFree None A2

No functionFree None A3

Rotor blocking solenoid coilY58 A4

Y77 A5

Y51 A7

Y50 A8

16 08/2002

Circulation shut-off valve

solenoid coil

Tying release motor relayK92 A6

Baling pressure relief solenoid

coil

Baling pressure build-up

solenoid coil

0 = Circuit interrupted

1 = Solenoid coil circuit OK

0 = Circuit interrupted

1 = Solenoid coil circuit OK

0 = Circuit interrupted

1 = Relay circuit OK (85 to 86)

0 = Circuit interrupted

1 = Solenoid coil circuit OK

0 = Circuit interrupted

1 = Solenoid coil circuit OK

Page 19

W

A

TIC QUADRANT 2200/ 2200 RC Diagnosis

Output testing, continued (from module 1 no. 835024.3)

Continuity test

Se r v i c e RC 8 2

=20 N0= 0

255 N1= 0

N2 = 0

E: 00000000

:00000000

U:11 ,6

F : 00000000 FFFF

12345678

The table below applies to page "8 / 2 (Service RC)"

To activate this function, keep the “Minus key” pressed while in the service menu, i.e. a maximum of

eight circuits may be checked at the same time.

DisplayDesignationNumeric

character

Open cutting frame solenoid coilY63 A1

Close cutting frame solenoid coilY64 A2

ROTOCUT knives ON solenoid coilY55 A3

ROTOCUT knives OFF solenoid coilY54 A4

Central lubrication system motorM25 A5

Y12 A6

Y11 A7

Y31 A8

Retract bale ejector cylinder

solenoid coil

Extend bale ejector cylinder

solenoid coil

Knotter cleaning solenoid coil (when

set to 2.5 s blowing time)

0 = Circuit interrupted

1 = Solenoid coil circuit OK

0 = Circuit interrupted

1 = Solenoid coil circuit OK

0 = Circuit interrupted

1 = Solenoid coil circuit OK

0 = Circuit interrupted

1 = Solenoid coil circuit OK

0 = Circuit interrupted

1 = Solenoid coil circuit OK

0 = Circuit interrupted

1 = Solenoid coil circuit OK

0 = Circuit interrupted

1 = Solenoid coil circuit OK

0 = Circuit interrupted

1 = Solenoid coil circuit OK

08/2002 17

Page 20

Diagnosis QUADRANT 2200/ 2200 RC TIC

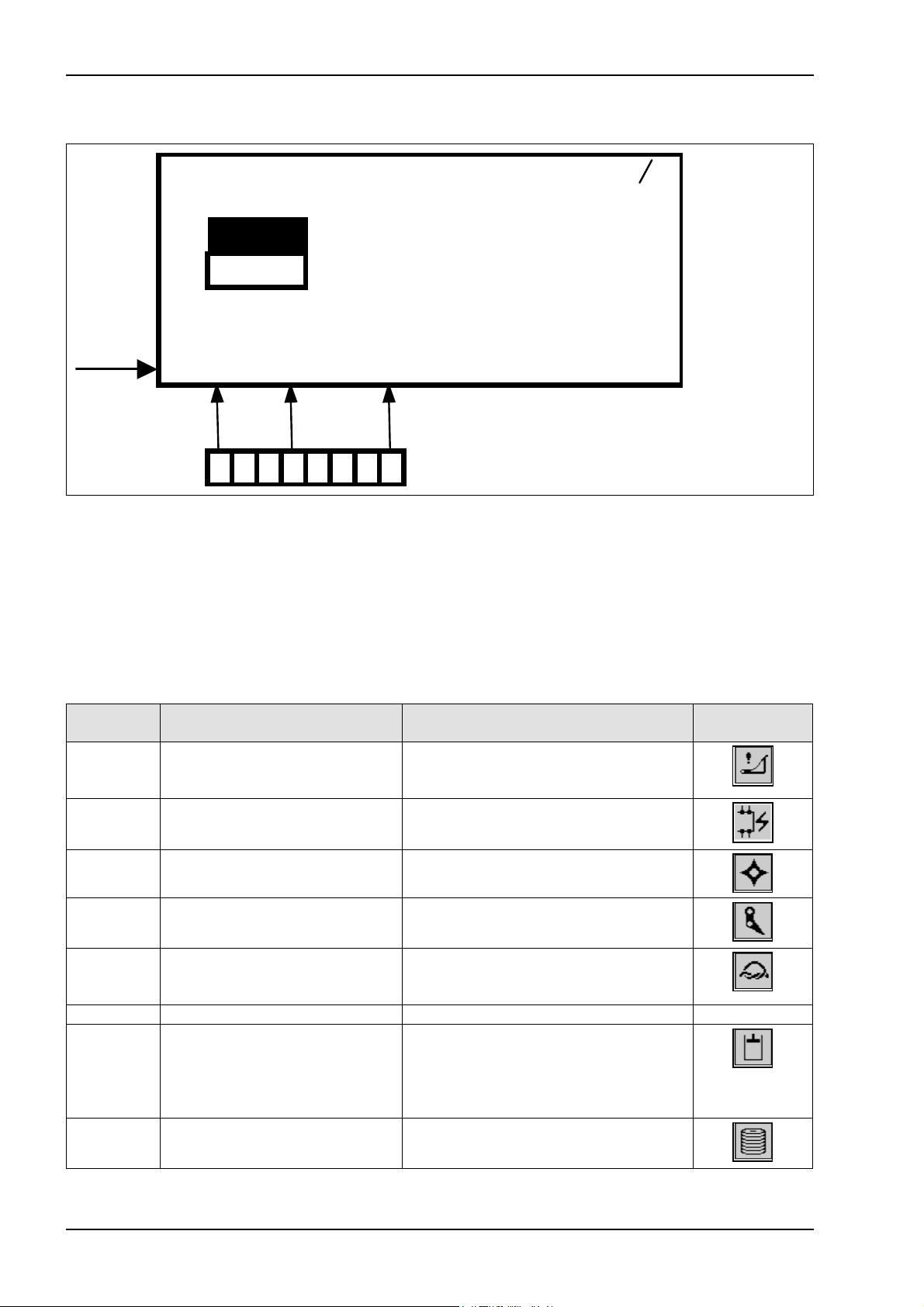

2.6 Error display (from module 1 no. 835024.3)

Ser v i c e 1 8 1

P= 0L0 , 00 N0= 0

P0 255 N1= 0

P1 0 N2 = 0

E: 00000000

A: 00000000 U: 11 ,6

F:00000000

FFFF

12345678

Eight numeric characters are available for error display in line “F”, each of them being assigned to one error.

This function is available only on page 8/1 "Service 1".

The numeric characters may assume the following values:

0 = No error or

1 = Error.

All numeric characters show the respective state independently of each other. Dependencies and switching

sequences which may occur in normal operation have no influence.

Symbol in

work menu

character

RemarkReason Numeric

Cutting frame not closed F1

Cutting frame should be closed, but cutting

frame position sensor indicates an angle

above 0°

No signal from CAN bus or module defectiveSystem fault (CAN bus)F2

Rotor overloadF3

Feed rake overloadF4

Tying fault F5

F7

18 08/2002

Circulation shut-off valve

activated too long

Drive speed above 500 rpm and rotor speed

below 56 rpm

Drive speed above 500 rpm and feed rake

speed below 60 rpm

See Electric System documentation

Circuit diagram 11a, b

(Tying fault sequence diagram)

No functionFree F6

Circulation shut-off valve activated longer

than allowed in connection with baling

pressure build-up solenoid coil (more than

50 % actuated time within 3 min.)

Twine break switch contactTwine break F8

Page 21

TIC QUADRANT 2200/ 2200 RC Diagnosis

2.7 Key test (from module 1 no. 835024.3)

Ser v i c e 1 8 1

P= 0L0 , 00 N0= 0

P0 255 N1= 0

P1 0 N2 = 0

E:00000000

A:00000000 U:11 ,6

F : 00000000

FFFF

12345

Four numeric characters are available for key testing in line (1) shown above.

Pushing a key on the Control Terminal produces one of the combinations of numbers and characters shown

below which allow checking the function.

The character “G” at the 5

digit remains free.

Example: When the central lubrication system is active and the “Minus” key is pressed, the numeric

characters read “FDFFG”. If the central lubrication system is not active and the “Minus key” is

pressed, the numeric characters read “FDFF”.

th

digit indicates if the central lubrication system is currently active, otherwise this

DisplayDesignationKey

4321

FFFEScroll through main menu

FFFD Scroll through second screen

FFFBROTOCUT knives ON

FFF7ROTOCUT knives OFF

FFEFBuild up / relieve baling pressure

FFDFMinus

FDFFPlus

FFBFClose cutting frame

FF7FOpen cutting frame

FEFFManual tying

FBFFRight arrow key

F7FFLeft arrow key

08/2002 19

Page 22

W

Diagnosis QUADRANT 2200/ 2200 RC TIC

3.0 Control terminal service menu (on CCU module)

3.1 Service menu

structure (on

CCU module)

Page "8/1 (Service 1)"

Current pressure [bar] Current bale length [m]

Control unit P+ PTO shaft speed [rpm]

Service1 81

Control unit P-

Inputs

Outputs

Error

P= 0 L0 , 0 0 N0= 0

P0 25 5 N1= 0

P1 0 N2= 0

E: 00000000

A:00000000 U:11 ,6

F:00000000 FFFF

This menu serves as a tool in fault-finding. It shows the status of various

electrical components such as e.g. speed, voltage, pressure, switch

positions.

To enter the service menu, press the keys “Scroll main menu”, “Plus

key” and “Minus key” at the same time.

The following mask appears:

Feed rake speed [rpm]

Rotor speed [rpm]

Voltage [V]

Key test

Page "8/2 (Service RC)"

(press "Sub-menu" key one more time)

Cutting

frame angle

Ser vi c e RC 8 2

=20 N0= 0

255 N1= 0

N2 = 0

E:00000000

A:00000000 U:11 , 6

F:00000000 FFFF

20 08/2002

Page 23

TIC QUADRANT 2200/ 2200 RC Diagnosis

3.2 Additional information about page "8/1 (Service 1)" (on CCU module)

Remark Menu item

The pressure in the baling chamber cylinders is displayed here in bars.(P=) Current pressure

(L) Current bale length

(N0=) PTO shaft speed

(N1=) Feed rake speed

(N2=) Rotor speed

Key test

(P0) Control unit P+

(P1) Control unit P-

The length of the bale in the baling chamber is displayed here in metres

to the second decimal point.

The calculated PTO shaft speed in revolutions per minute is displayed

here (this speed is measured by the drive speed sensor).

The feed rake speed in revolutions per minute is displayed here

(150 rpm at 1000 rpm PTO shaft speed)

The rotor speed in revolutions per minute is displayed here (140 rpm at

1000 rpm PTO shaft speed)

The supply voltage is displayed here in Volt to the first decimal point.(U:) Voltage

A combination of characters and numbers is displayed here to test the

function of the keys on the Control Terminal.

The condition of the baling pressure build-up valve is displayed here.

The displayed number is proportional with the valve actuation and may

assume values from 0 to 255.

0 = Valve not actuated

255 = Valve fully actuated

The condition of the baling pressure relief valve is displayed here. The

displayed number is proportional with the valve actuation and may

assume values from 0 to 255.

0 = Valve not actuated

255 = Valve fully actuated

(E:) Inputs

(A:) Outputs

(F:) Error

The condition of various circuits connected with the modules is

displayed here. Each numeric character corresponds to one circuit.

0 = Circuit open

1 = Circuit closed

The condition of various circuits connected with the modules is

displayed here. Each numeric character corresponds to one circuit.

0 = Circuit open

1 = Circuit closed

Malfunctions are displayed here. Each numeric character corresponds

to one error.

0 = No error

1 = Error

3.3 Additional information about page "8/2 (Service RC)" (on CCU module)

(W=) Cutting frame angle

The cutting frame angle in degrees is displayed here. The higher the

value, the wider the cutting frame is open.

08/2002 21

Page 24

Diagnosis QUADRANT 2200/ 2200 RC TIC

3.4 Input testing (on CCU module)

Continuity test

Ser v i c e 1 8 1

P= 0L0 , 00 N0= 0

P0 255 N1= 0

P1 0 N2 = 0

E:00000000

A: 00000000 U: 11 ,6

F : 00000000 FFFF

12345678

Eight numeric characters are available for input diagnosis in line “E” on page "8 / 1 (Service 1)", each of them

being assigned to one circuit.

The numeric characters may assume the following values:

0 = Circuit open or

1 = Circuit closed.

All numeric characters show the respective state independently of each other. Dependencies and switching

sequences which may occur in normal operation have no influence.

The table below applies to page "8 / 1 (Service 1)"

DisplayDesignationNumeric

character

Z11 E1

Z63 E2

B69 E3

B69 E4

B23 E5

B9 E6

Twine break left/right actual

value switch

Tying system monitoring actual

value switch

Metering wheel / bale length

sensor - signal B

Metering wheel / bale length

sensor - signal A

Feed rake speed sensor

(green) inside

Drive speed sensor (red)

outside

Rotor speed sensorB24 E7

Crop humidity sensorB38 E8

1 = Twine break

0 = No twine break

0 = Switch pushed

1 = Switch not pushed

Changes between 0 and 1 when metering wheel

rotates

Changes between 0 and 1 when metering wheel

rotates

1 = Plug removed

Changes between 0 and 1 when feed rake rotates

0 = Wire ends connected

1 = Plug removed

Changes between 0 and 1 when feed rake rotates

0 = Wire ends connected

1 = Plug removed

Changes between 0 and 1 when feed rake rotates

0 = Wire ends connected

0 = Plug removed

Changes between 0 and 1 when sensor OK

1 = Wire ends connected

22 08/2002

Page 25

R

W

TIC QUADRANT 2200/ 2200 RC Diagnosis

Input testing, continued (on CCU module)

Continuity test

Se r vi c e

C82

=20 N0= 0

255 N1= 0

E:00000000

A: 00000000 U: 11 ,6

F : 00000000 FFFF

12345678

The table below applies to page "8 / 2 (Service RC)"

character

Flywheel brake actual value switchZ56 E3

U1 E4

U2 E5

Z49 E8

Extend bale ejector cylinder switch

(blue)

Retract bale ejector cylinder switch

(red)

Bale discharge sensorB101 E6

ROTOCUT knives ON actual value

switch

N2 = 0

DisplayDesignationNumeric

No functionFree None E1

No functionFree None E2

1 = Switch actuated

0 = Switch not actuated

1 = Switch actuated

0 = Switch not actuated

1 = Switch actuated

0 = Switch not actuated

1 = Sheet metal in front of sensor

0 = No sheet metal in front of sensor

No functionFree None E7

0 = Switch actuated

1 = Switch not actuated

08/2002 23

Page 26

A

Diagnosis QUADRANT 2200/ 2200 RC TIC

3.5 Output testing (on CCU module)

Testing the actuation by the modules

Ser v i c e 1 8 1

P= 0L0 , 00 N0= 0

P0 0 N1 = 0

P1 0 N2 = 0

E: 00000000

:00000000

U:11 ,6

F : 00000000 FFFF

12345678

Eight numeric characters are available for output diagnosis in line “A” on page "8 / 1 (Service 1)" and page

"8 / 2 (Service RC)", each of them being assigned to one circuit.

It must be ensured that the baling pressure solenoid valves (P0 and P1) are not activated. To achieve this,

press the "Plus key" once.

The numeric characters only indicate if a solenoid valve is actuated by the corresponding module.

For diagnosis purposes, the corresponding function must be activated, i.e. the functions can be

checked only one by one.

The numeric characters may assume the following values:

0 = Solenoid valve is not actuated by the module or

1 = Solenoid valve is actuated by the module.

Dependencies and switching sequences which may occur in normal operation have an influence.

The table below applies to page "8 / 1 (Service 1)"

DisplayDesignationNumeric

character

Open cutting frame solenoid coilY63 A1

Close cutting frame solenoid coilY64 A2

ROTOCUT knives OFF solenoid coilY54 A3

Central lubrication system motorM25 A4

Extend bale ejector cylinder solenoid coil Y11 A5

Retract bale ejector cylinder solenoid coil Y12 A6

Rotor blocking solenoid coilY58 A7

Circulation shut-off valve solenoid coilY77 A8

24 08/2002

0 = not activated

1 = activated

0 = not activated

1 = activated

0 = not activated

1 = activated

0 = not activated

1 = activated

0 = not activated

1 = activated

0 = not activated

1 = activated

0 = not activated

1 = activated

0 = not activated

1 = activated

Page 27

A

TIC QUADRANT 2200/ 2200 RC Diagnosis

Output testing, continued (on CCU module)

Testing the actuation by the modules

Ser v i c e 1 8 1

P= 0L0 , 00 N0= 0

P0 0 N1 = 0

P1 0 N2 = 0

E: 00000000

:00000000

U:11 ,6

F : 00000000 FFFF

12345678

The table below applies to page "8 / 2 (Service RC)"

For diagnosis purposes, the corresponding function must be activated, i.e. the functions can be

checked only one by one.

DisplayDesignationNumeric

character

No functionFree None A1

No functionFree None A2

No functionFree None A3

ROTOCUT knives ON solenoid coilY55 A4

Tying release motor relayK92 A5

Baling pressure relief solenoid coilY51 A6

Baling pressure build-up solenoid coilY50 A7

Y31 A8

Knotter cleaning solenoid coil

(when set to 2.5 s blowing time)

0 = not activated

1 = activated

0 = not activated

1 = activated

0 = not activated

1 = activated

0 = not activated

1 = activated

0 = not activated

1 = activated

08/2002 25

Page 28

Diagnosis QUADRANT 2200/ 2200 RC TIC

3.6 Error display (on CCU module)

Ser v i c e 1 8 1

P= 0L0 , 00 N0= 0

P0 255 N1= 0

P1 0 N2 = 0

E: 00000000

A: 00000000 U: 11 ,6

F:00000000

FFFF

12345678

Eight numeric characters are available for error display in line “F”, each of them being assigned to one error.

This function is available only on page 8/1 "Service 1".

The numeric characters may assume the following values:

0 = No error or

1 = Error.

All numeric characters show the respective state independently of each other. Dependencies and switching

sequences which may occur in normal operation have no influence.

Symbol in

work menu

character

F1

F2

Cutting frame not

closed

bus)

RemarkReason Numeric

Cutting frame should be closed, but cutting frame

position sensor indicates an angle above 0°

No signal from CAN bus or module defectiveSystem fault (CAN

Rotor overloadF3

Feed rake overloadF4

Tying fault F5

F7

26 08/2002

Circulation shut-off

valve activated too

long

Overload

Drive speed above 500 rpm and rotor speed

below 56 rpm

Drive speed above 500 rpm and feed rake speed

below 60 rpm

See Electric System documentation

Circuit diagram 11c

(Tying fault sequence diagram)

No functionFree F6

Circulation shut-off valve activated longer than

allowed in connection with baling pressure

build-up solenoid coil (more than 50 % actuated

time within 3 min.)

Twine break switch contactTwine break F8

∆ P > 15 bars in 125 ms (module 3)

∆ P > 20 bars in 125 ms (module 4)

Page 29

TIC QUADRANT 2200/ 2200 RC Diagnosis

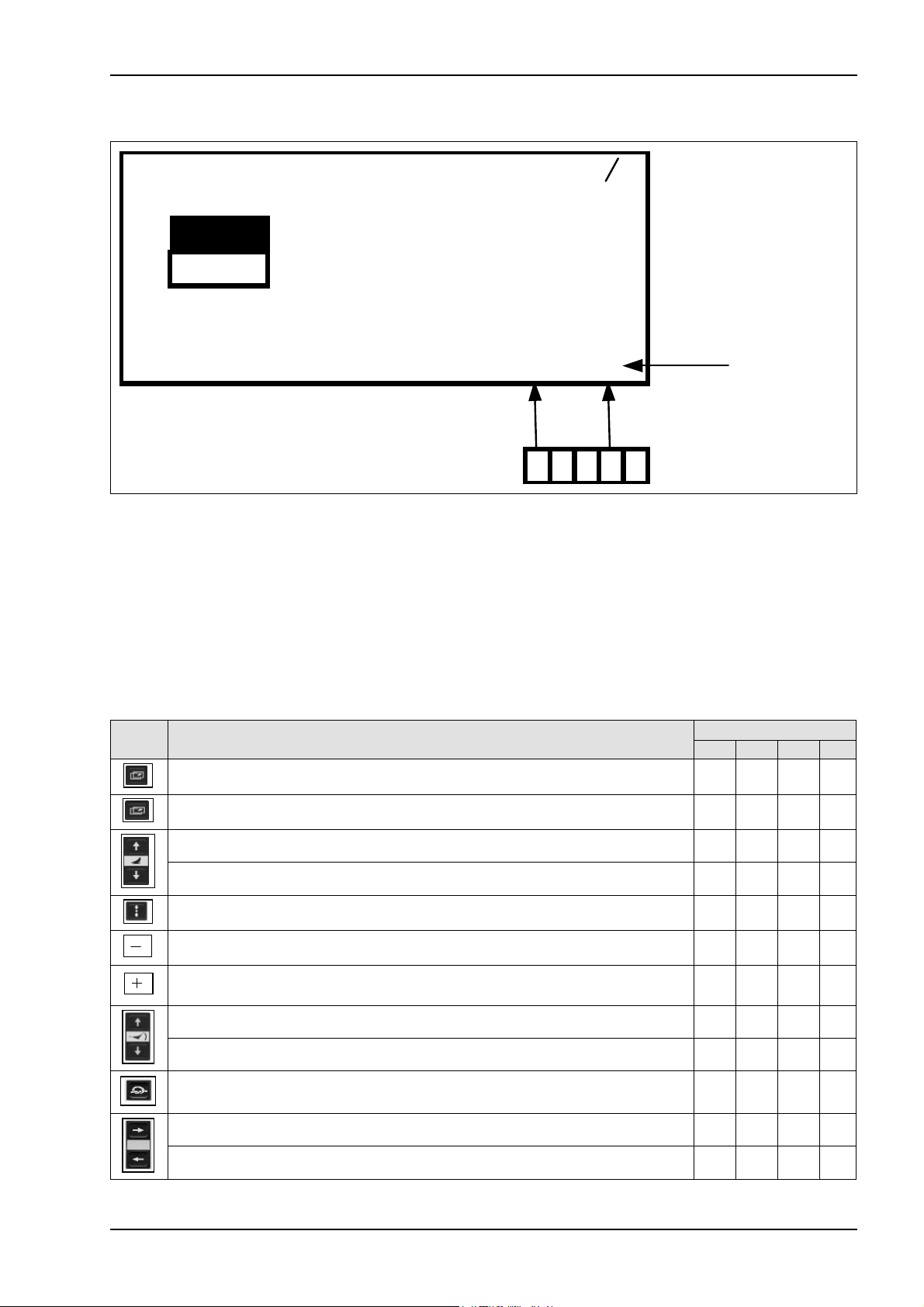

3.7 Key test (on CCU module)

Ser v i c e 1 8 1

P= 0L0 , 00 N0= 0

P0 255 N1= 0

P1 0 N2 = 0

E:00000000

A:00000000 U:11 ,6

F : 00000000

FFFF

12345

Four numeric characters are available for key testing in line (1) shown above.

Pushing a key on the Control Terminal produces one of the combinations of numbers and characters shown

below which allow checking the function.

The character “G” at the 5th digit indicates if the central lubrication system is currently active, otherwise this

digit remains free.

Example: When the central lubrication system is active and the “Minus” key is pressed, the numeric

characters read “FDFFG”. If the central lubrication system is not active and the “Minus key” is

pressed, the numeric characters read “FDFF”.

DisplayDesignationKey

4321

FFFEScroll through main menu

FFFD Scroll through second screen

FFFBROTOCUT knives ON

FFF7ROTOCUT knives OFF

FFEFBuild up / relieve baling pressure

FFDFMinus

FDFFPlus

FFBFClose cutting frame

FF7FOpen cutting frame

FEFFManual tying

FBFFRight arrow key

F7FFLeft arrow key

08/2002 27

Page 30

Diagnosis QUADRANT 2200/ 2200 RC TIC

4.0 Additional information

4.1 Testing the

baling pressure

sensor (B56)

(with central

terminal

compartment)

To check the actual baling pressure, a pressure gauge must be

connected to the measuring port of the baling chamber.

The pressure pre-set in the CCT should not deviate more than +/- 7 bar

from the actual value.

During this test, the pressure sensor should transmit a signal voltage of

approx. 1 V (0 bar baling pressure) and approx. 3V (220 bar baling

pressure) which is proportional to the baling pressure to module 1.

For testing purposes, the voltage between module slot 2 (earth) and

module slot 21 (signal from pressure sensor) can be checked on the

plug of module 1 after removing the module.

If these values are not reached, the supply voltage of the pressure

sensor should be checked.

This can be measured between module slot 1 and 3 of the plug on the

baler side. The value should correspond with the system voltage of the

tractor (approx. 12 V).

28 08/2002

Page 31

TIC QUADRANT 2200/ 2200 RC Diagnosis

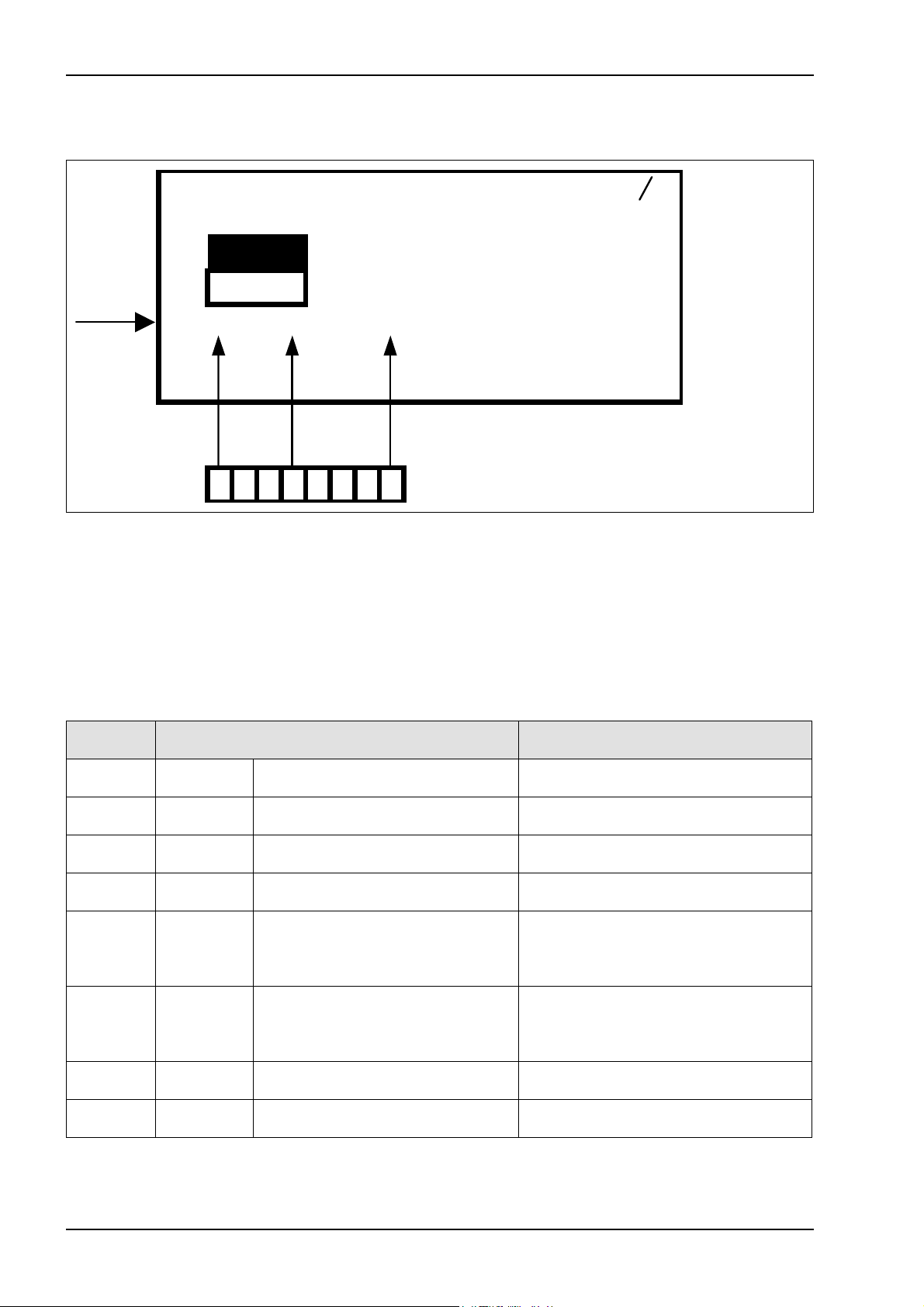

4.2 Testing the

metering

wheel / bale

length sensor

(B69)

(with central

terminal

compartment)

Metering wheel in counting direction

A)

The service menu of the Control Terminal (see description in chapter 3.)

can be used to check the metering wheel sensor.

The pulses of the metering wheel sensor can be tested individually in the

service menu in the "Inputs" line. The numeric characters 7 and 8

change between “1” and “0” in a given pattern, which allows to identify

the sense of rotation of the metering wheel.

To this end, slowly rotate the metering wheel and watch the display in

the Control Terminal. The tables show an extract of the numeric

character sequence which is repeated while the metering wheel rotates.

Metering wheel against counting direction

B)

Sensor Sensor

1SI10 1SI11 1SI10 1SI11

00 00

01 10

11 11

10 01

B)

A)

When the numeric character sequence is displayed in this order, the

sensor is OK.

If the display does not change when the metering wheels is rotated, the

cabling to the metering wheel sensor may be checked as follows:

1. When the plug has been removed from the metering wheel, both

digits must show “0”.

2. When pins 2 and 4 of the plug are connected, digit 7 must be “1”.

3. When pins 3 and 4 of the plug are connected, digit 8 must be “1”.

4. The tractor system voltage (approx. 12V) must be measured

between pin 1 (power supply) and pin 4 (earth) of the plug on the

metering wheel sensor.

In addition, a bale length of 1.28 m should be displayed after one

rotation of the metering wheel (reset the display to zero by one tying

process before this check).

The bale length is now displayed in the service menu under “L=”.

If the length is not shown properly although the sensor and its cabling

are faultless, the problem is in the program of the modules. In this case,

the baler must be newly configured.

08/2002 29

Page 32

Diagnosis QUADRANT 2200/ 2200 RC TIC

4.3 General (with central terminal compartment)

Ejecting bales

Overload protection

Knotter cleaning

Speed sensors

CCT

Bale length display

The bale length determined by the metering wheel when ejecting bales

is saved in the baler module and added to the next bale later during

baling. This value is stored even after switching off the ignition.

The baling pressure is relieved when the bale is ejected.

When the maximum allowed ram force is exceeded, the baling pressure

is abruptly relieved. This shuts down the baling pressure control for 7

seconds. After this, the pre-set baling pressure is built up again.

The knotter is cleaned directly prior to tying the bale and after half the

bale length has been reached.

At a PTO shaft speed of approx. 350 rpm, the speed sensors (drive,

feed rake, rotor) should display a correct value.

The full scope of electronic functions is available when:

the main switch has been switched on for more than 3 seconds and

the baler speed is at least 500 rpm.

When the bale length bar in the Control Terminal remains completely

dark and when bale tying is not possible (e.g. by excessively fast

rotation of the metering wheel by hand), the tying release must be reset.

To do this, proceed as follows:

1. With the CCT switched on, turn back metering wheel until bar

stops being dark

2. Wait for approx. 10 s

3. Switch CCT off / on.

Manual tying start

To be able to carry out a manual tying start on balers from machine no.,

the metering wheel must have measured a bale length of at least

approx. 40 cm.

30 08/2002

Page 33

TIC QUADRANT 2200/ 2200 RC Diagnosis

5.0 Information on replacing modules

A backup of the module data must be created using the CDS. To do this,

start the corresponding program in the CDS.

The data are read out and saved on the CDS harddisk.

Disconnect the power supply of the machine prior to replacing

modules.

After replacing the module, the data from the CDS must be restored to

the machine.

Suitable programs are available in the diagnosis menu. This ensures

that machine-specific data will not be modified.

Do not exchange modules between machines! There is no way to

restore these data.

08/2002 31

Page 34

Diagnosis QUADRANT 2200/ 2200 RC TIC

Notes

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

32 08/2002

Page 35

Following the policy of CLAAS KGaA mbH to improve

their products as technical developments continue,

CLAAS reserve the right to make alterations which

must not necessarily correspond to text and

illustrations contained in this publication, and without

incurring obligation to alter any machines previously

delivered.

Technical data, dimensions and weights are given as

an indication only. Responsibility for errors or

omissions not accepted.

Reproduction or translation of this publication, in whole

or part, is not permitted without the written consent of

the CLAAS KGaA mbH.

All rights under the provision of the Copyright Act are

reserved.

CLAAS KGaA mbH

33426 Harsewinkel

Germany

Our contribution to the environment:

CLAAS has printed this manual

on 100 % chlorine free paper.

Page 36

CLAAS KGaA mbH

Postfach 1163

33426 Harsewinkel

Tel. +49 (0)5247 12-0

www.claas.com

0299 251.2

SYS-D QUADRANT 2200/RC

EN - 05.05 - NF

Printed in Germany

Loading...

Loading...