Page 1

Dominator 140

Dominator 150

Technical Systems

Hydraulic System

Page 2

Page 3

TIC Dominator 140 - 150 Hydraulic System

Contents

Chapter 1 Overall hydraulic system .................................................. 1-1

Chapter 2 Steering hydraulics ........................................................... 2-1

Chapter 3 Working hydraulics ........................................................... 3-1

Chapter 4 Ground drive hydraulics ................................................... 4-1

Position of components ......................................................................R-1

Index ..........................................................................................index-1

04/04 DO-h

Page 4

Hydraulic System Dominator 140 - 150 TIC

DO-h 04/04

Page 5

TIC Dominator 140 - 150 Overall Hydraulic System

Chapter 1

Overall hydraulic

system

1.1

Overall hydraulic system circuit diagram

with 3D sieve pan..................................................................... 1-4

1.2

Overall hydraulic system circuit diagram

without 3D sieve pan................................................................ 1-8

Technical data........................................................................ 1-11

1.3

04/04 DO-h-Kap1 1-1

Page 6

Overall Hydraulic System Dominator 140 - 150 TIC

1-2 DO-h-Kap1 04/04

Page 7

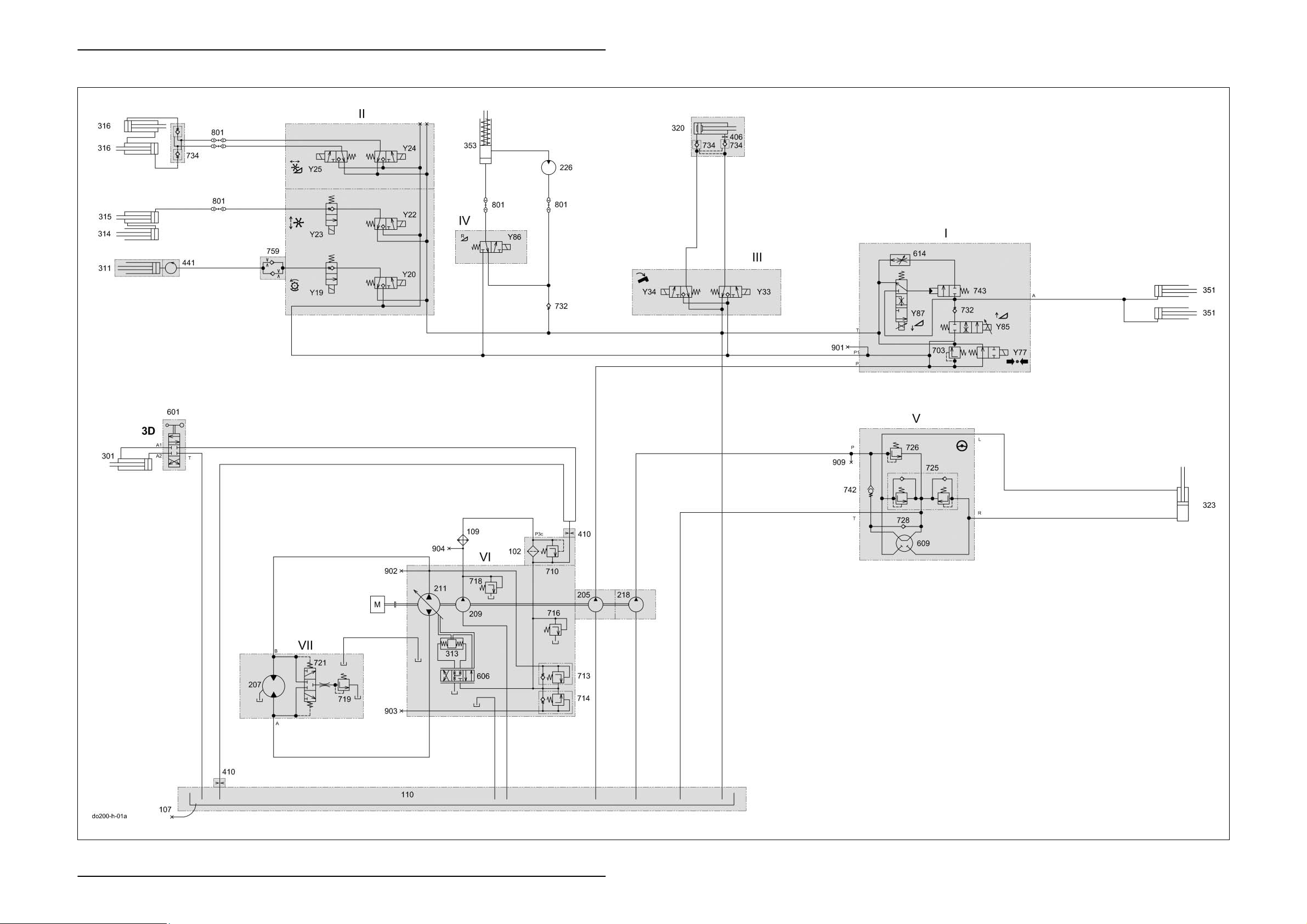

1.1

Overall hydraulic system

circuit diagram

with 3D sieve pan

Page 8

Overall Hydraulic System Dominator 140 - 150 TIC

1.1 Overall hydraulic system circuit diagram with 3D sieve pan

1-4 DO-h-Kap1 04/04

Page 9

TIC Dominator 140 - 150 Overall Hydraulic System

Key to diagram:

I Master valve working hydraulics valve block

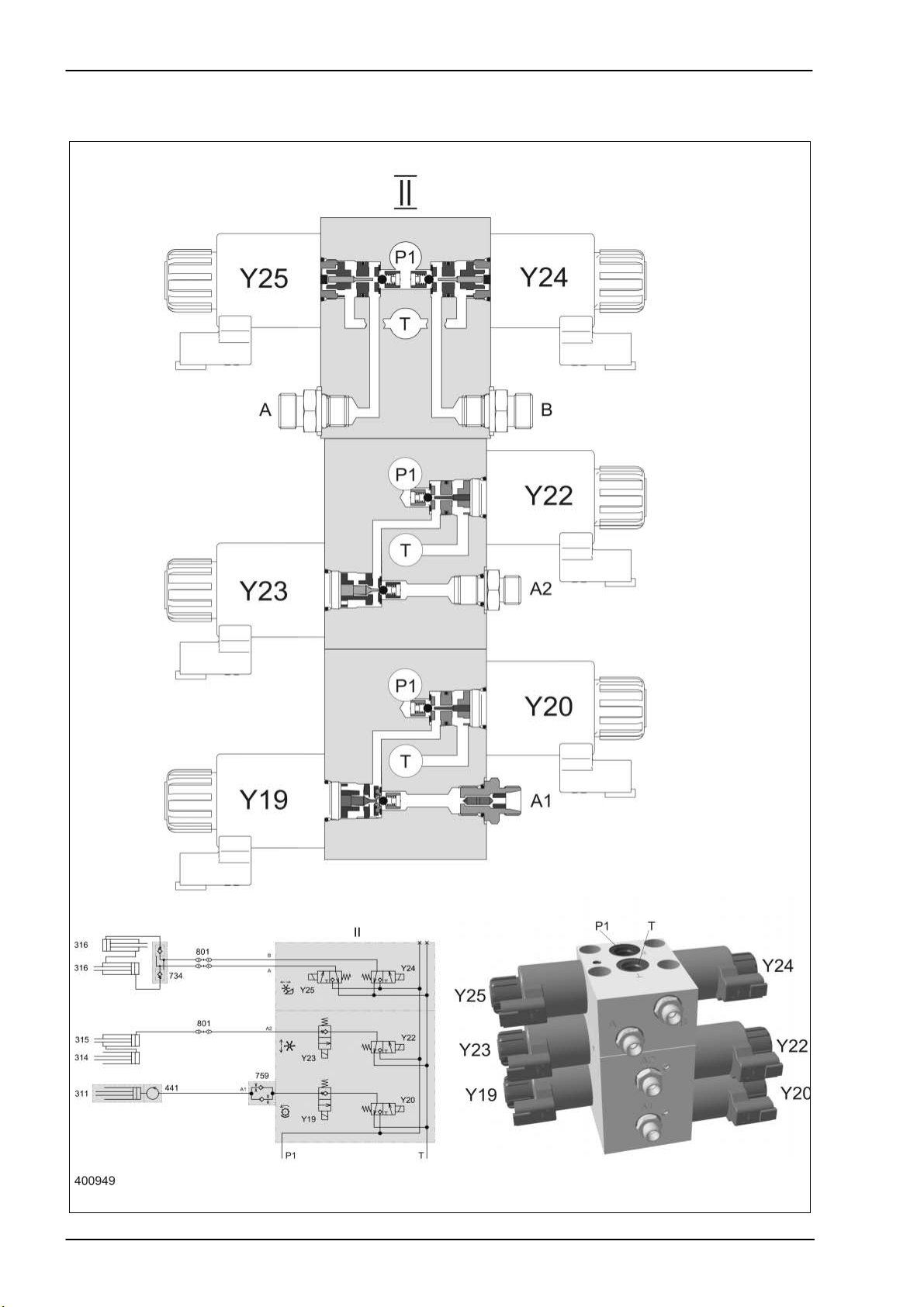

II Front attachment / threshing drum variator working hydraulics

valve block

III Grain tank unloading tube working hydraulics valve block

IV Front attachment reverse working hydraulics valve block

V Orbitrol steering hydraulics

VI Ground drive hydraulics hydrostatic pump

VII Ground drive hydraulics hydrostatic motor

102 Pressure filter.......................................................... 10 µm

107 Oil drain

109 Oil cooler

110 Oil tank

112 Return filter

205 Working hydraulics pump ....................................... 10.8 cm

207 Ground drive fixed displacement motor HMF 75 .... 75 cm

209 Ground drive feed pump ......................................... 22.5 cm

211 Ground drive variable displacement pump

HPV 75 ......................................................... 75 cm

218 Steering hydraulics pump ....................................... 6 cm

3

/rev.

3

/rev.

3

/rev.

3

/rev.

3

/rev.

226 Front attachment reverser drive motor

301 3-D sieve pan hydraulic cylinder

311 Threshing drum variable-speed drive hydraulic cylinder

313 Ground drive servo control pump hydraulic cylinder

314 Reel raise/lower slave cylinder

315 Reel raise/lower main cylinder

316 Horizontal reel adjustment hydraulic cylinder

320 Swing grain tank unloading tube hydraulic cylinder

323 Steering hydraulic cylinder

351 Raise/lower front attachment hydraulic cylinder

353 Reverse front attachment hydraulic cylinder

406 Orifice plate............................................................. Ø 0.8 mm

410 Orifice plate ............................................................ Ø 1.5 mm

441 Rotary coupling

601 3D sieve pan pendulum control 4/3 way valve

606 Ground drive servo control 4/3 way valve

609 Orbitrol steering system rotary valve

614 Front attachment lower flow control valve

04/04 DO-h-Kap1 1-5

Page 10

Overall Hydraulic System Dominator 140 - 150 TIC

10

Key to diagram:

703 Working hydraulics pressure relief valve................ 180

710 Ground drive filter bypass valve ............................. 2 bar

+

713 Ground drive multi-function valve, reverse ............. 420 bar

714 Ground drive multi-function valve, forward ............. 420 bar

716 Ground drive feed pressure relief valve.................. 19 bar

718 Ground drive feed circuit cold start injector ............ 25 bar

719 Ground drive flush pressure control valve.............. 10 bar

721 Ground drive flush-out shuttle valve

725 Steering double shock valve................................... 150

726 Steering pressure relief valve ................................. 90

+5

+15

bar

bar

728 Anti-cavitation valve (non-return valve)

732 Non-return valve

734 Lock-up valve unit (non-return valve)

742 Steering safety valve

743 Front attachment lower valve

759 One-way restrictor valve, two-sided

801 Quick release coupling

901 Working hydraulics measuring point

902 Ground drive hydraulics high pressure backward measuring

point

903 Ground drive hydraulics high pressure forward measuring

point

904 Ground drive hydraulics feed pressure measuring point

909 Steering hydraulics measuring point

Y19 Threshing drum variable-speed drive slow solenoid valve

Y20 Threshing drum variable-speed drive fast solenoid valve

Y22 Reel raise solenoid valve

Y23 Reel lower solenoid valve

Y24 Reel forward solenoid valve

Y25 Reel reverse solenoid valve

Y33 Grain tank unloading tube swing out solenoid valve

Y34 Grain tank unloading tube swing in solenoid valve

Y77 Working hydraulics master valve solenoid valve

Y85 Raise front attachment solenoid valve

Y86 Reverse front attachment solenoid valve

Y87 Lower front attachment solenoid valve

1-6 DO-h-Kap1 04/04

Page 11

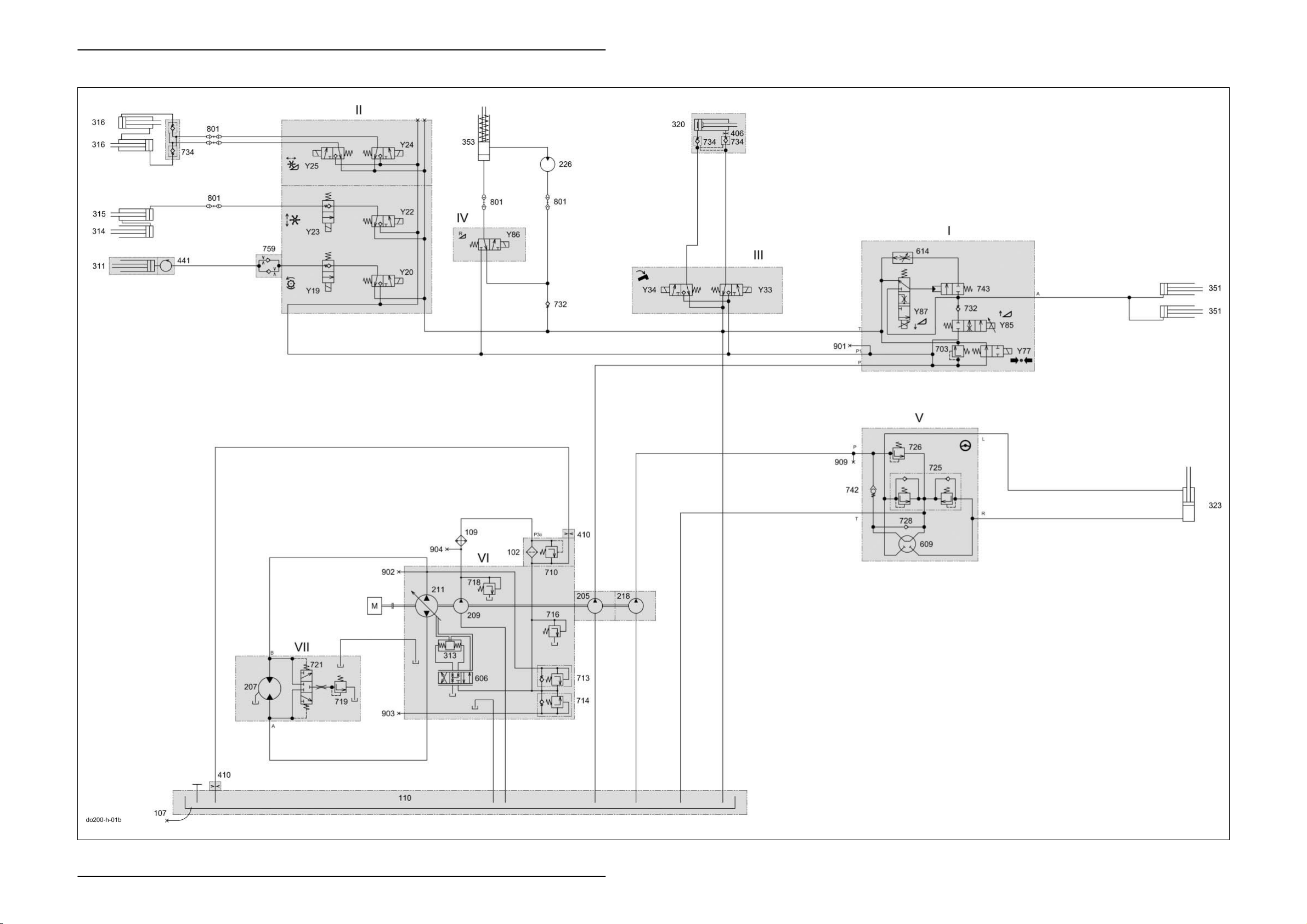

1.2

Overall hydraulic system

circuit diagram

without 3D sieve pan

Page 12

Overall Hydraulic System Dominator 140 - 150 TIC

1.2 Overall hydraulic system circuit diagram without 3D sieve pan

1-8 DO-h-Kap1 04/04

Page 13

TIC Dominator 140 - 150 Overall Hydraulic System

Key to diagram:

I Master valve working hydraulics valve block

II Front attachment / threshing drum variator working hydraulics

valve block

III Grain tank unloading tube working hydraulics valve block

IV Front attachment reverse working hydraulics valve block

V Orbitrol steering hydraulics

VI Ground drive hydraulics hydrostatic pump

VII Ground drive hydraulics hydrostatic motor

102 Pressure filter........................................................ 10 µm

107 Oil drain

109 Oil cooler

110 Oil tank

112 Return filter

205 Working hydraulics pump ..................................... 10.8 cm

207 Ground drive fixed displacement motor HMF 75 .. 75 cm

209 Ground drive feed pump ....................................... 22.5 cm

211 Ground drive variable displacement pump

HPV 75 ....................................................... 75 cm

218 Steering hydraulics pump ..................................... 6 cm

3

/rev.

3

/rev.

3

/rev.

3

/rev.

3

/rev.

226 Front attachment reverser drive motor

311 Threshing drum variable-speed drive hydraulic cylinder

313 Ground drive servo control pump hydraulic cylinder

314 Reel raise/lower slave cylinder

315 Reel raise/lower main cylinder

316 Horizontal reel adjustment hydraulic cylinder

320 Swing grain tank unloading tube hydraulic cylinder

323 Steering hydraulic cylinder

351 Raise/lower front attachment hydraulic cylinder

353 Reverse front attachment hydraulic cylinder

406 Orifice plate........................................................... Ø 0.8 mm

410 Orifice plate .......................................................... Ø 1.5 mm

441 Rotary coupling

606 Ground drive servo control 4/3 way valve

609 Orbitrol steering system rotary valve

614 Front attachment lower flow control valve

04/04 DO-h-Kap1 1-9

Page 14

Overall Hydraulic System Dominator 140 - 150 TIC

10

Key to diagram:

703 Working hydraulics pressure relief valve ...............180

710 Ground drive filter bypass valve ............................2 bar

+

713 Ground drive multi-function valve, reverse ............420 bar

714 Ground drive multi-function valve, forward ............420 bar

716 Ground drive feed pressure relief valve.................19 bar

718 Ground drive feed circuit cold start injector ...........25 bar

719 Ground drive flush pressure control valve.............10 bar

721 Ground drive flush-out shuttle valve

725 Steering double shock valve..................................150

726 Steering pressure relief valve ................................90

+5

+15

bar

bar

728 Anti-cavitation valve (non-return valve)

732 Non-return valve

734 Lock-up valve unit (non-return valve)

742 Steering safety valve

743 Front attachment lower valve

759 One-way restrictor valve, two-sided

801 Quick release coupling

901 Working hydraulics measuring point

902 Ground drive hydraulics high pressure backward measuring

point

903 Ground drive hydraulics high pressure forward measuring

point

904 Ground drive hydraulics feed pressure measuring point

909 Steering hydraulics measuring point

Y19 Threshing drum variable-speed drive slow solenoid valve

Y20 Threshing drum variable-speed drive fast solenoid valve

Y22 Reel raise solenoid valve

Y23 Reel lower solenoid valve

Y24 Reel forward solenoid valve

Y25 Reel reverse solenoid valve

Y33 Grain tank unloading tube swing out solenoid valve

Y34 Grain tank unloading tube swing in solenoid valve

Y77 Working hydraulics master valve solenoid valve

Y85 Raise front attachment solenoid valve

Y86 Reverse front attachment solenoid valve

Y87 Lower front attachment solenoid valve

1-10 DO-h-Kap1 04/04

Page 15

TIC Dominator 140 - 150 Overall Hydraulic System

1.3 Technical data

Working hydraulics Dominator 140 -150 Sense of rotation = Counterclockwise

Drive n

Power = 33 l/min at 10.8 cm3/rev.

max

= 3092 rpm

Steering hydraulics Dominator 140 -150 Sense of rotation = Counterclockwise

Drive n

Power = 18.5 l/min at 6 cm3/rev.

max

= 3092 rpm

Linde ground drive Dominator 140 -150 Sense of rotation = Counterclockwise

Drive n

Power approx. = 230 l/min at 75 cm3/rev.

max

= 3092 rpm

Linde feed pump Dominator 140 -150 Sense of rotation = Counterclockwise

Drive n

max

= 3092 rpm

Power = 69.5 l/min at 22.5 cm3/rev.

Note: The exact pump output can only be determined using a flowmeter.

During this measurement, the output under maximum system

pressure and at operating temperature (60°C) may fall by

15% max.

04/04 DO-h-Kap1 1-11

Page 16

Overall Hydraulic System Dominator 140 - 150 TIC

1-12 DO-h-Kap1 04/04

Page 17

TIC Dominator 140 - 150 Hydraulic System

Chapter 2

Steering

hydraulics

2.1 Steering hydraulics circuit diagram.......................................... 2-4

2.2 Steering valve unit ................................................................... 2-6

2.3 Function of steering ................................................................. 2-8

2.4 Checking the steering ............................................................ 2-12

04/04 DO-h-Kap2 2-1

Page 18

Hydraulic System Dominator 140 - 150 TIC

2-2 DO-h-Kap2 04/04

Page 19

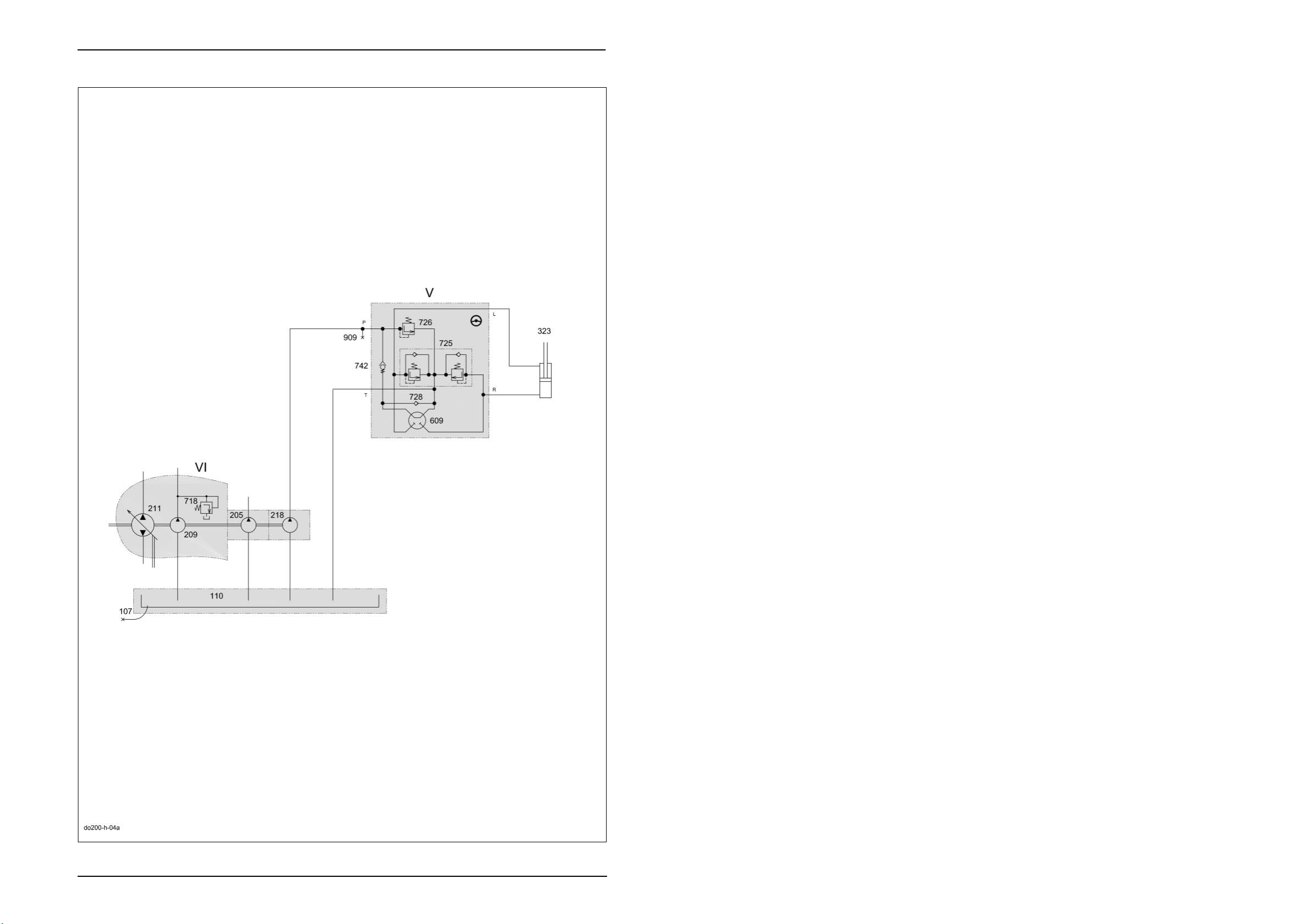

2.1

Steering hydraulics circuit diagram

Page 20

Hydraulic System Dominator 140 - 150 TIC

2.1 Steering hydraulics circuit diagram

Key to diagram:

V Orbitrol steering hydraulics

VI Ground drive hydraulics hydrostatic pump

107 Oil drain

110 Oil tank

205 Working hydraulics pump

209 Ground drive feed pump

211 Ground drive variable displacement pump

218 Steering hydraulics pump

323 Steering hydraulic cylinder

609 Orbitrol steering system rotary valve

718 Ground drive feed circuit cold start injector...................... 25 bar

725 Steering double shock valve ...................................... 150

726 Steering pressure relief valve......................................... 90

+15

+5

bar

bar

728 Anti-cavitation valve (non-return valve)

742 Steering safety valve

909 Steering hydraulics measuring point

Pressure measurement :

Neutral circulation pressure = < 20 bar

System pressure = 90

Shock valve = 150

+15

+5

bar

bar

Note: These values refer to measurements made at the max. no-load

speed of the diesel engine and a hydraulic oil operating

temperature of approx. 60°C.

2-4 DO-h-Kap2 04/04

Page 21

TIC Dominator 140 - 150 Hydraulic System

Description of function:

Steering In the neutral steering position, oil flows freely through the

Turning the steering wheel to one direction causes the spools to rotate

At a rotation of 1.5°, the channels to the chambers start opening.

At 4°, the neutral position channels are completely closed.

At 6°, the channels to the chambers are fully open.

The rotation of the spools relative to each other is limited to ± 8°.

Rotation of rotor: Feed of an oil quantity which is proportional to the

steering control unit = Orbitrol (609).

relative to each other.

A feed of pressurized oil to the rotor set has the following effects:

rotation into the steering cylinder, the rear wheels being influenced. An

internal mechanical return from the rotor to the outside spool so that the

channels in the valve are closed when the rotor rotates to the same angle

as the steering wheel.

04/04 DO-h-Kap2 2-5

Page 22

Hydraulic System Dominator 140 - 150 TIC

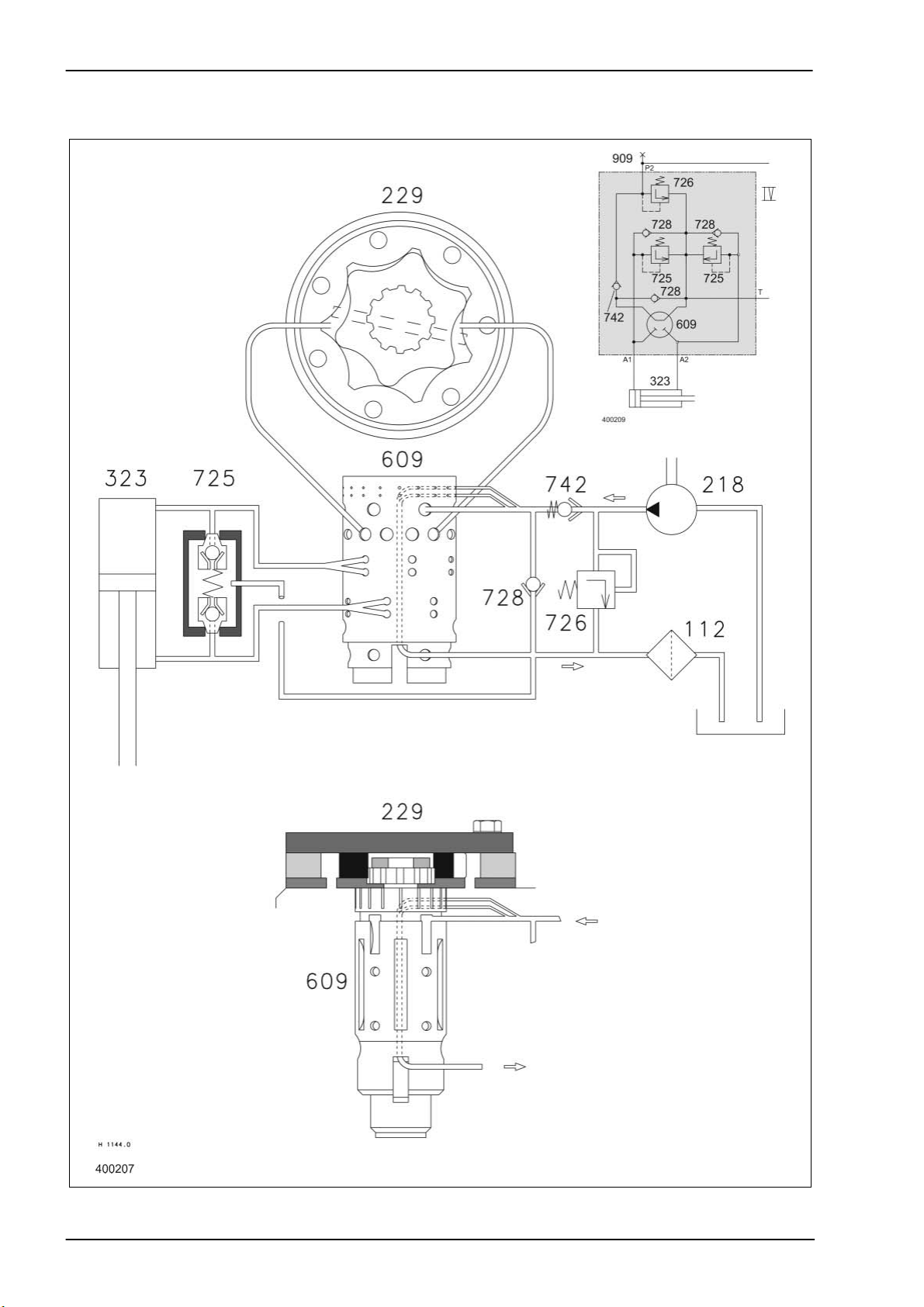

2.2 Steering valve unit

2-6 DO-h-Kap2 04/04

Page 23

TIC Dominator 140 - 150 Hydraulic System

Key to diagram:

112 Return filter (not installed)

218 Steering hydraulics pump ...........................................6 cm

3

229 Steering hydraulics proportioning pump

323 Steering hydraulic cylinder

609 Orbitrol steering system rotary valve

725 Steering double shock valve....................................... 150

726 Steering pressure relief valve ..................................... 90

+5

+15

bar

bar

728 Anti-cavitation valve (non-return valve)

742 Steering safety valve

909 Steering hydraulics measuring point

Steering system

Open center: with the steering in neutral position, there is a connection

between pump P2 and the tank.

Non reaction: when the steering is in neutral position, a force acting on

the steered wheels does not cause any reaction on the

steering wheel.

Valve unit

DANFOSS OSPB 125

O = Orbit (Orbitrol)

S = Steering

P = Pump

B = Version

125 = Oil displacement in cm

3

/rev.

Design of valve unit

The steering valve consists of a steering hydraulics proportioning pump

(229) and an Orbitrol rotary valve (609).

The Orbitrol rotary valve (609) is actuated by the steering gear shaft.

Continued rotary movement of the steering gear shaft drive the steering

hydraulics proportioning pump (229) by means of a socket-type shaft.

04/04 DO-h-Kap2 2-7

Page 24

Hydraulic System Dominator 140 - 150 TIC

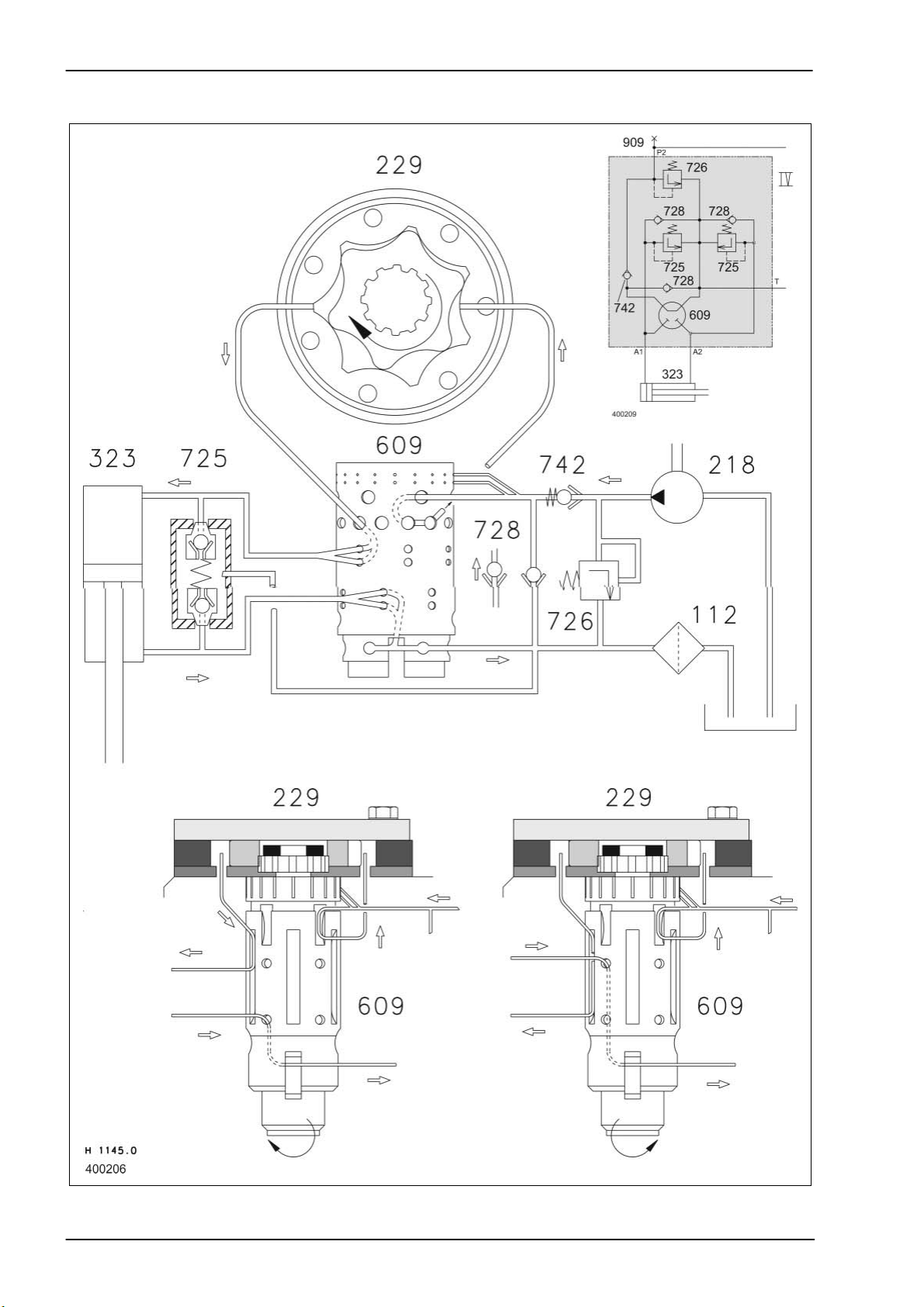

2.3 Function of steering

Neutral

2-8 DO-h-Kap2 04/04

Page 25

TIC Dominator 140 - 150 Hydraulic System

Description of function:

Neutral In neutral position, the oil is directed back to the tank via the steering

safety valve (742) and the Orbitrol rotary disc (609) (open center).

The circulation pressure must not exceed 20 bar.

Both sides of the steering hydraulic cylinder (323) are shut off by the

Orbitrol rotary disc (609). Pressure peaks due to external forces on the

steered axle are relieved to the tank via the steering double shock valves

(725) (non reaction).

04/04 DO-h-Kap2 2-9

Page 26

Hydraulic System Dominator 140 - 150 TIC

Steering actuation

2-10 DO-h-Kap2 04/04

Page 27

TIC Dominator 140 - 150 Hydraulic System

Description of function:

Steering actuation When actuating the steering to one or another direction, the Orbitrol rotary

disc (609) is rotated by up to 8° relative to the outside spool. During this

process, the return line from the steering hydraulics pump (218) to the

tank is closed and the connection to the steering hydraulics proportioning

pump (229) is released.

Via the steering hydraulics proportioning pump (229) and the Orbitrol

rotary disc (609), the volume flow is released as a function of the sense of

rotation, path and speed of steering wheel motion to the ram or the ram

ring surface of the steering hydraulic cylinder (323). Here, the displacing

surface of the steering hydraulic cylinder (323) is connected with the

return line to the tank via the Orbitrol rotary disc (609).

As soon as there is no more steering motion, leaf springs bring the outer

rotary disc of the Orbitrol rotary disc (609) back to neutral position. Now

both sides of the steering cylinder are shut off again and the connection

from the steering hydraulics pump (218) to the tank is re-established.

Emergency steering When the steering system is not supplied any more by the steering

hydraulics pump (218), the steering safety valve (742) closes and thus

ensures that no oil will escape from the steering system.

When the steering is actuated, the inner and outer disc of the Orbitrol

rotary disc (609) are rotated relative to each other. Now the oil can be

conveyed from one side of the steering hydraulic cylinder (323) via anticavitation valve (non-return valve) (728) to the other side through human

power by the drive of the steering hydraulics proportioning pump (229).

04/04 DO-h-Kap2 2-11

Page 28

Hydraulic System Dominator 140 - 150 TIC

2.4 Checking

the steering

Steering gear shaft Height play = 0.1 to 0.3 mm

Clearance from bottom inside rotary disc = 3 mm

Return When the steering wheel is actuated with the diesel engine shut off, the

leaf springs in the rotary disc must bring the steering wheel back to its

neutral position.

Reaction If steering reaction is insufficient, internal leaks in the steering system

must be checked. To do this, disconnect the lines from the steering

cylinder and plug them tightly with plugs.

With the oil at operating temperature and at max. no-load speed of the

diesel engine, the steering wheel must not allow more than 4 turns/minute

in both directions when using a force of approx. 25 Nm.

When the actual number of turns is more than 4/minute, check the

steering valve for leaks.

When the actual number of turns is below 4/minute, check the steering

cylinder for leaks.

Power In case of steering forces above 25 Nm, check tyre size and pressure,

condition of the cylinder rod and if stub axles move smoothly.

A pressure test at the steering hydraulics measuring port must show the

value 90

+5

bar.

To this end move the steering wheel up to the stop and hold it in this

position.

Adjusting the pressure relief valve on the machine in built-in condition is

not possible.

Important! Any installation work on the steering hydraulics must be

followed by venting the system on both hydraulic lines of the

steering cylinder with the diesel engine running.

2-12 DO-h-Kap2 04/04

Page 29

TIC Dominator 140 - 150 Hydraulic System

Chapter 3

Working

hydraulics

3.1

Working hydraulics circuit diagram .......................................... 3-4

3.2

Main valve................................................................................ 3-6

with master valve,

pressure relief valve,

raise/lower front attachment .................................................... 3-6

3.3

Threshing drum speed control

3/3 way solenoid valve Y19/Y20............................................ 3-12

Hydraulic cylinder with rotary coupling .................................. 3-14

3.4 Vertical reel adjustment ......................................................... 3-16

3/3 way valve Y22/Y23 .......................................................... 3-16

Hydraulic cylinders................................................................. 3-18

3.5

Horizontal reel adjustment ..................................................... 3-20

4/3 way valve Y24/Y25 .......................................................... 3-20

Hydraulic cylinders................................................................. 3-22

Lock-up valve unit (734) ........................................................ 3-24

3.6

Swinging the grain tank unloading tube................................. 3-26

4/3 way valve Y33/Y34 .......................................................... 3-26

Hydraulic cylinders................................................................. 3-28

Lock-up valve unit (734) ........................................................ 3-30

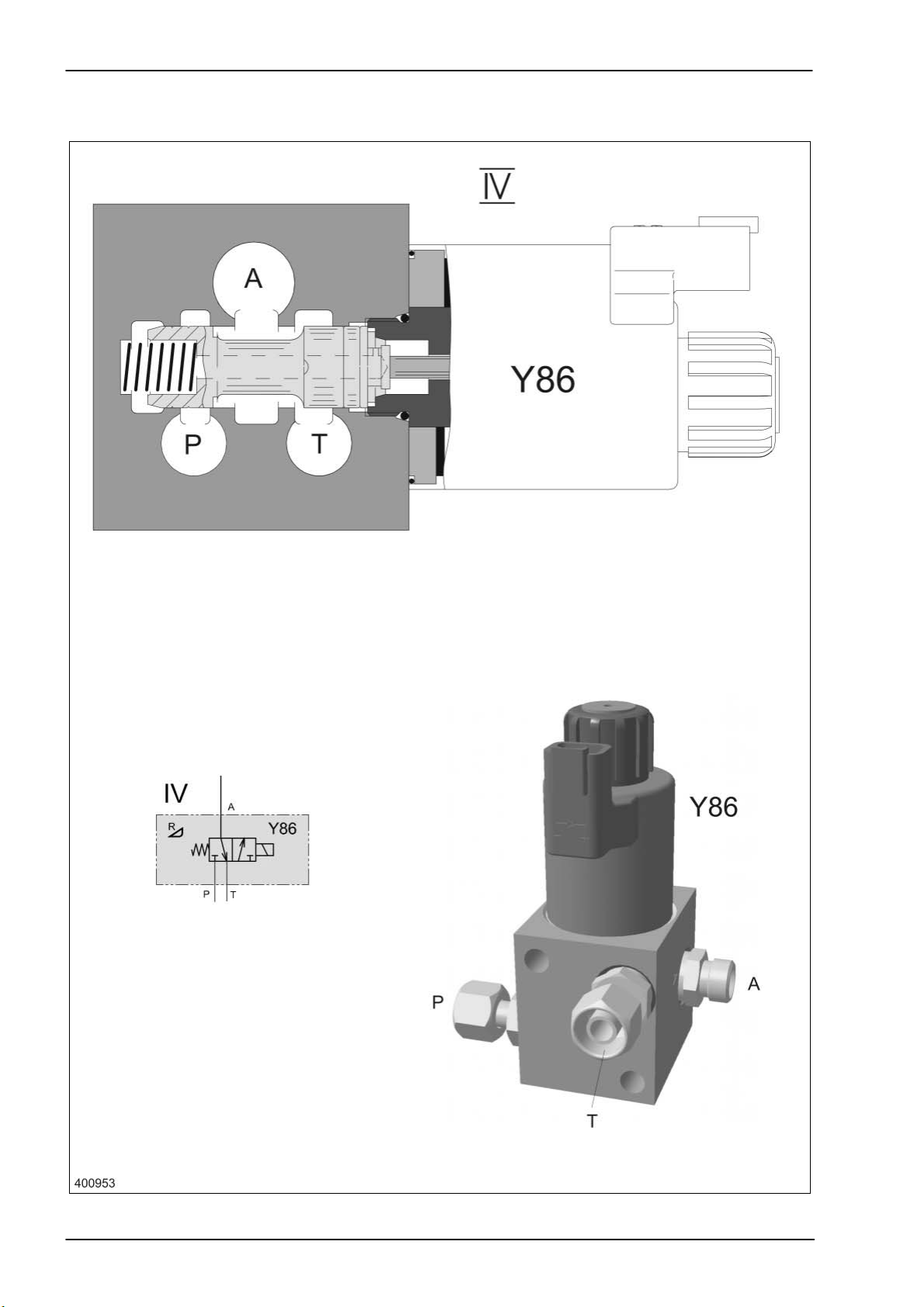

3.7 Reverse front attachment ...................................................... 3-32

3/2-way valve Y86.................................................................. 3-32

Hydraulic cylinders................................................................. 3-34

04/04 DO-h-Kap3 3-1

Page 30

Hydraulic System Dominator 140 - 150 TIC

3-2 DO-h-Kap2 04/04

Page 31

3.1

Working hydraulics circuit diagram

- without straw collector

Page 32

Hydraulic System Dominator 140 - 150 TIC

3.1 Working hydraulics circuit diagram

- without straw collector

Key to diagram:

I Master valve working hydraulics valve block

II Front attachment / threshing drum variator working hydraulics

valve block

III Grain tank unloading tube working hydraulics valve block

IV Front attachment reverse working hydraulics valve block

VI Ground drive hydraulics hydrostatic pump

107 Oil drain

110 Oil tank

112 Return filter

205 Working hydraulics pump ..................................... 10.8 cm

209 Ground drive feed pump ....................................... 22.5 cm

211 Ground drive variable displacement

pump HPV 75 ....................................................... 75 cm

218 Steering hydraulics pump ..................................... 6 cm

3

/rev.

3

/rev.

3

/rev.

3

/rev.

226 Front attachment reverser drive motor

311 Threshing drum variable-speed drive hydraulic cylinder

314 Reel raise/lower slave cylinder

315 Reel raise/lower master cylinder

316 Horizontal reel adjustment hydraulic cylinder

320 Swing grain tank unloading tube hydraulic cylinder

351 Raise/lower front attachment hydraulic cylinder

353 Reverse front attachment hydraulic cylinder

406 Orifice plate........................................................... Ø 0.8 mm

441 Rotary coupling

614 Front attachment lower flow control valve

703 Working hydraulics pressure relief valve .............. 180

+10

718 Ground drive feed circuit cold start injector .......... 25 bar

732 Non-return valve

734 Lock-up valve unit (non-return valve)

743 Front attachment lower valve

759 One-way restrictor valve, two-sided

801 Quick release coupling

901 Working hydraulics measuring point

Y19 Threshing drum variable-speed drive slow solenoid valve

Y20 Threshing drum variable-speed drive fast solenoid valve

Y22 Reel raise solenoid valve

Y23 Reel lower solenoid valve

Y24 Reel forward solenoid valve

Y25 Reel reverse solenoid valve

Y33 Grain tank unloading tube swing out solenoid valve

Y34 Grain tank unloading tube swing in solenoid valve

Y77 Working hydraulics master valve solenoid valve

Y85 Raise front attachment solenoid valve

Y86 Reverse front attachment solenoid valve

Y87 Lower front attachment solenoid valve

3-4 DO-h-Kap2 04/04

Page 33

TIC Dominator 140 - 150 Hydraulic System

Description of function:

The working hydraulics of the Dominator series is an open hydraulic

system.

The maximum system pressure is limited to 180

+10

bar by means of

pressure relief valve (703).

04/04 DO-h-Kap3 3-5

Page 34

Hydraulic System Dominator 140 - 150 TIC

3.2 Main valve with master valve, pressure relief valve, raise/lower front attachment

3-6 DO-h-Kap3 04/04

Page 35

TIC Dominator 140 - 150 Hydraulic System

Key to diagram:

614 Flow control valve ................................................5 - 50 l/min

703 Pressure relief valve ............................................180

732 Non-return valve (inlet valve)

743 Lower front attachment pilot valve

Y77 Master valve solenoid valve

Y85 Raise front attachment solenoid valve

Y87 Lower front attachment solenoid valve

A1 Raise/lower front attachment hydraulic cylinder

P1 Working hydraulics pump port

P2 Parallel port for working hydraulics of other directional control

valves

T Tank port

E Pilot spool

F Compression spring

H Front attachment raise spool

K Front attachment quick lower ram

L Lower front attachment spool

R Control spool........................................................5 - 50 l/min

U Master valve control spool

V Pilot valve

+10

bar

Description of function:

Pressure limitation The spring in the pressure relief valve (703) is pre-stressed for a system

A 0.5 mm shim corresponds to approx. 10 bar

Note: The above values refer to a rated pressure of 180 bar and may

pressure of 180

removing or adding shims.

A 1.2 mm shim corresponds to approx. 23 bar

+10

bar. The pressure setting may be modified by

deviate, depending on the actual system. Each time the setting

has been modified, the system pressure must be checked.

04/04 DO-h-Kap3 3-7

Page 36

Hydraulic System Dominator 140 - 150 TIC

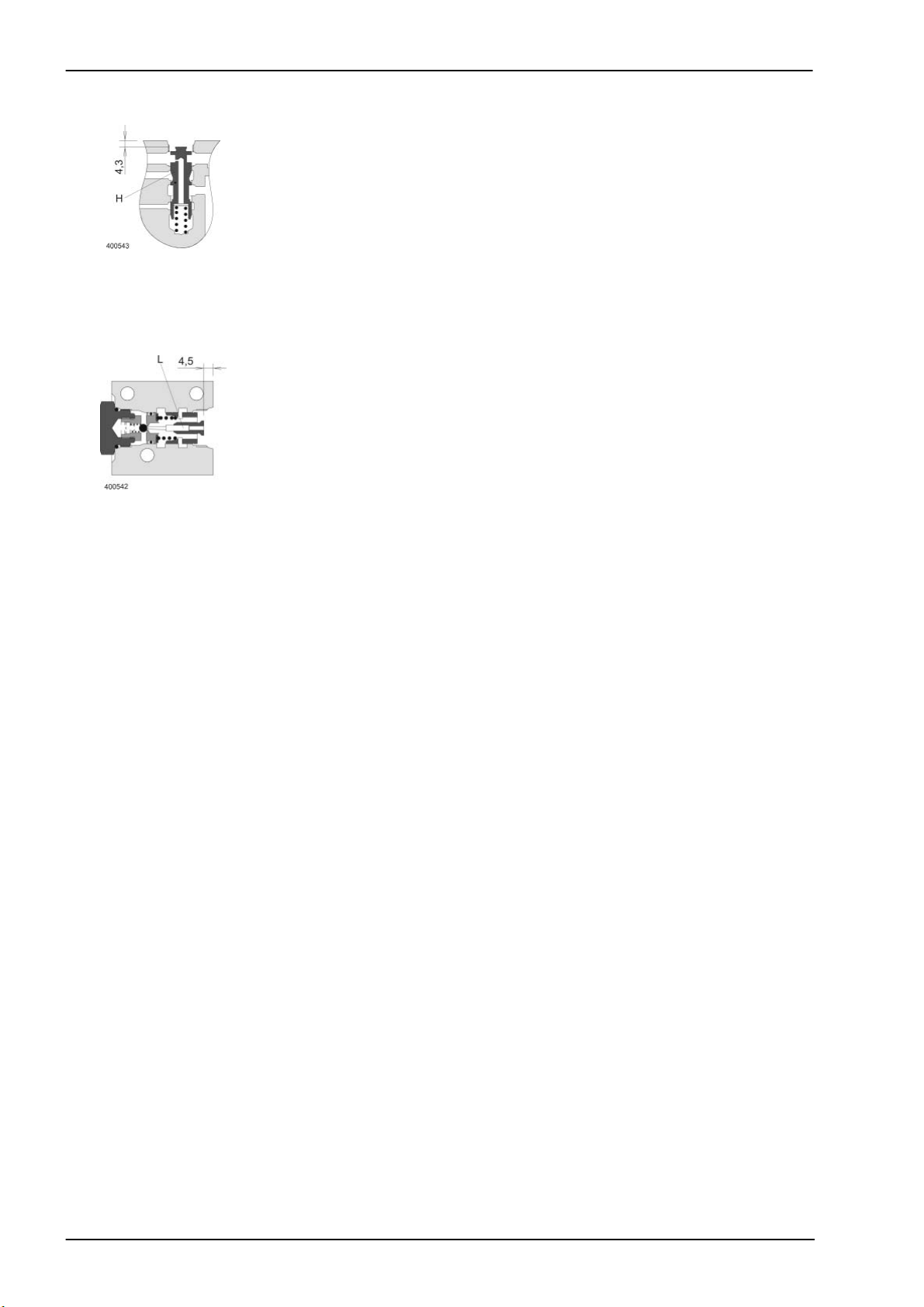

Basic setting

To ensure the position of spool (H) for the function "Raise front

attachment", the dimension from the top edge of the spool (H) to the body

must be 4.3 mm with the coil core (Y85) removed. The position may be

corrected by removing or adding shims above the compression spring.

A weaker compressed spring - as compared to the spool (H) - is located

below the spool of the master valve (U).

In order to guarantee the "Front attachment lower" function, the clearance

between the top edge of spool (L) and the housing must be 4.5 mm with

the coil core (Y87) removed. The position may be corrected by removing

or adding shims.

Spare part no: 0.1 mm = 0218 886.0

0.2 mm = 0218 887.0

The drop rate of the front attachment can be adjusted to a drop time of

5-6 sec. over the entire stroke range.on the flow control valve (614).

3-8 DO-h-Kap3 04/04

Page 37

TIC Dominator 140 - 150 Hydraulic System

Key to diagram:

P Pump port

M Measuring port

R(T) Return line port (tank)

Description of function:

Pressure relief valve The pressure relief valve protects the hydraulic system and thus the

connected mechanical components from damage by excessive forces.

The spring in the pressure relief valve (703) is pre-stressed for a system

pressure of 180

+10

bar. The pressure setting may be modified by removing

or adding shims.

A 0.5 mm shim corresponds to approx. 10 bar

A 1.2 mm shim corresponds to approx. 23 bar

Note: The above values refer to a rated pressure of 180 bar and may

deviate, depending on the actual system. Each time the setting

has been modified, the system pressure must be checked.

Note: These values refer to measurements made at the max. no-load

speed of the diesel engine and a hydraulic oil operating

temperature of approx. 60°C.

04/04 DO-h-Kap3 3-9

Page 38

Hydraulic System Dominator 140 - 150 TIC

Description of function:

Function of master valve The master valve (Y77) blocks the circulating volume flow from P to T of

the open hydraulic system when a working hydraulics function has been

actuated. Single-acting functions are an exception to this if the consumer

is relieved to the tank.

In neutral position, the master valve (Y77) is not actuated, making the oil

flow back to the tank via the ring channels on the spool (U). Due to the

large channel cross-section, the circulation pressure is very low.

When pressure is successfully built up at a consumer, the master valve

(Y77) is actuated simultaneously with the directional control valve of the

corresponding function. Now spool (U) closes the connection from P to T,

and the top ring channel being closed first in order to achieve smooth

switching-over.

The pressure relief valve (703) opens at a maximum system pressure of

180±10 bar and relieves the pressure to the tank.

Raise front attachment

function

Raising When the "Raise" function is used, the directional control valve (Y85) and

the master valve (Y77) are actuated with 12 V DC.

The spool (H) is moved to its end position, making oil flow via both ring

channels on the spool (H). The full volume flow is directed to the

consumer port (A1) via the non-return valve (732) and raises the front

attachment.

Lower front attachment

function

Lowering When the "Lower" function is used, only the directional control valve (Y87)

is actuated with 12 V DC.

The spherical seat in pilot valve (V) is opened and the spring force (F) is

overcome through the force of the solenoid. The spool (E) closes the ring

channel to the return line, making the load pressure of the front

attachment act on the ram top side (K) and open the pilot valve (743). The

oil is now displaced by the front attachment via the pilot valve (743) and

the control spool (R) into the return line to the tank.

3-10 DO-h-Kap3 04/04

Page 39

TIC Dominator 140 - 150 Hydraulic System

Description of function:

Flow control valve When the "Lower front attachment – fast" function is used, the oil

displaced via port A flows to the tank (T) through the restrictor in the

control spool of the flow control valve (614).

This creates a ram pressure ahead of the control spool, making the latter

move against the control spring and restrict the return channel to the tank

(T) as a function of the load pressure.

When the load pressure in port A changes, both the volume flow through

the restrictor and the load pressure against the control spool change, too,

and consequently also the return channel cross-section.

This control function keeps the volume flow and therefore the front

attachment drop rate constant, independent of the load pressure.

The front attachment drop rate is adjusted merely by the pre-stress of the

control spring at the handwheel.

Relieve tension of control spring = lower drop rate

Tensioning the control spring = increase drop rate

04/04 DO-h-Kap3 3-11

Page 40

Hydraulic System Dominator 140 - 150 TIC

3.3 Threshing drum speed control 3/3 way solenoid valve Y19/Y20

3-12 DO-h-Kap3 04/04

Page 41

TIC Dominator 140 - 150 Hydraulic System

Key to diagram:

Description of function:

Neutral function The threshing drum variable-speed drive hydraulic cylinder (311) is tightly

Increase speed function The threshing drum fast solenoid valve (Y20) and the master valve are

Reduce speed function Solenoid valve (Y19) is actuated without the master valve. The pilot spool

Note: To ensure even control function in both directions, volume flow

II Front attachment / threshing drum variator working hydraulics

valve block

311 Threshing drum variable-speed drive hydraulic cylinder

314 Reel raise/lower slave cylinder

315 Reel raise/lower master cylinder

316 Horizontal reel adjustment hydraulic cylinder

441 Rotary coupling

759 One-way restrictor valve, two-sided

801 Quick release coupling

Y19 Threshing drum variable-speed drive slow solenoid valve

Y20 Threshing drum variable-speed drive fast solenoid valve

Y22 Reel raise solenoid valve

Y23 Reel lower solenoid valve

Y24 Reel forward solenoid valve

Y25 Reel reverse solenoid valve

closed by the ball seat in the valve insert of the threshing drum slow

solenoid valve (Y19).

actuated at the same time. The corresponding pilot spool opens the ball in

the valve insert and closes the return line to the tank. The pressure thus

rising opens the ball in the valve insert of the unactuated threshing drum

slow solenoid valve (Y19). The oil flows to consumer port A1 via the notch

in the one-way restrictor valve (759).

in question opens the ball in the valve insert and thus relieves the oil

pressure via the notch of the one-way restrictor valve (759) and the valve

insert of the unactuated threshing drum fast solenoid valve (Y20) to the

tank.

flows via the notches in the one-way restrictor valve (759) when

adjusting the variator.

04/04 DO-h-Kap3 3-13

Page 42

Hydraulic System Dominator 140 - 150 TIC

Threshing drum speed control

Hydraulic cylinder with rotary coupling

3-14 DO-h-Kap3 04/04

Page 43

TIC Dominator 140 - 150 Hydraulic System

Key to diagram:

311 Threshing drum variable-speed drive hydraulic cylinder

441 Rotary coupling

04/04 DO-h-Kap3 3-15

Page 44

Hydraulic System Dominator 140 - 150 TIC

3.4 Vertical reel adjustment 3/3 way valve Y22/Y23

3-16 DO-h-Kap3 04/04

Page 45

TIC Dominator 140 - 150 Hydraulic System

Key to diagram:

Description of function:

Neutral The hydraulic cylinders are tightly closed by the valve insert of solenoid

Raise reel The solenoid valve (Y22) and the master valve (Y77) are actuated at the

Lower reel Solenoid valve (Y23) is actuated without the master valve (Y77). The pilot

II Front attachment / threshing drum variator working hydraulics

valve block

311 Threshing drum variable-speed drive hydraulic cylinder

314 Reel raise/lower slave cylinder

315 Reel raise/lower master cylinder

316 Horizontal reel adjustment hydraulic cylinder

441 Rotary coupling

759 One-way restrictor valve, two-sided

801 Quick release coupling

Y19 Threshing drum variable-speed drive slow solenoid valve

Y20 Threshing drum variable-speed drive fast solenoid valve

Y22 Reel raise solenoid valve

Y23 Reel lower solenoid valve

Y24 Reel forward solenoid valve

Y25 Reel reverse solenoid valve

valve (Y23).

same time. The corresponding pilot spool opens the ball in the valve

insert and closes the return line to the tank.

The pressure P1 which consequently rises opens the valve insert of the

unactuated solenoid valve (Y23) and the oil flows to the consumer

port A2.

spool in question opens the ball in the valve insert and thus relieves the

oil pressure to the tank via the valve insert of the unactuated solenoid

valve (Y22).

04/04 DO-h-Kap3 3-17

Page 46

Hydraulic System Dominator 140 - 150 TIC

Vertical reel adjustment

Hydraulic cylinders

3-18 DO-h-Kap3 04/04

Page 47

TIC Dominator 140 - 150 Hydraulic System

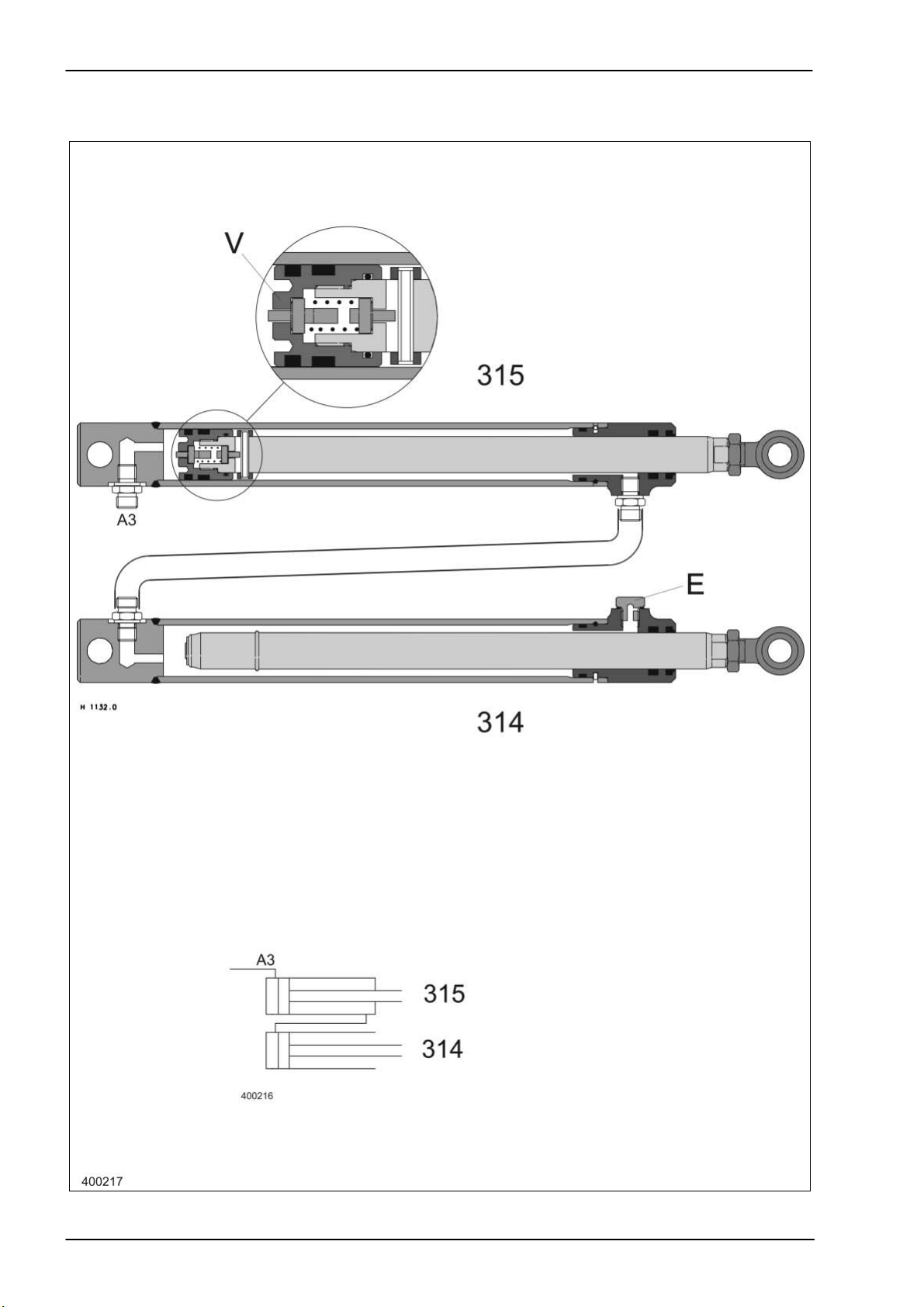

Key to diagram:

Description of function:

Bottom valves The bottom outlet valves (V) in master cylinder (315) are opened upon

Note: For repairs, it is recommended to remove the hydraulic rams in

314 Reel raise/lower slave cylinder

315 Reel raise/lower master cylinder

A3 Hydraulic cylinder port

E Vent plug

V Bottom valves

reaching the upper stop position so that the slave cylinder can be filled

and vented.

the raised reel position since the slave cylinder is filled only with

the master cylinder fully extended. During this process support

and secure the reel properly.

04/04 DO-h-Kap3 3-19

Page 48

Hydraulic System Dominator 140 - 150 TIC

3.5 Horizontal reel adjustment 4/3 way valve Y24/Y25

3-20 DO-h-Kap3 04/04

Page 49

TIC Dominator 140 - 150 Hydraulic System

Key to diagram:

Description of function:

Neutral Both sides of the hydraulic cylinder are tightly closed by the lock-up valve

Reel forward / reverse Depending on the necessary direction of movement, one of the solenoid

The return line of the hydraulic cylinder is relieved to the tank via the valve

II Front attachment / threshing drum variator working hydraulics

valve block

311 Threshing drum variable-speed drive hydraulic cylinder

314 Reel raise/lower slave cylinder

315 Reel raise/lower master cylinder

316 Horizontal reel adjustment hydraulic cylinder

441 Rotary coupling

759 One-way restrictor valve, two-sided

801 Quick release coupling

Y19 Threshing drum variable-speed drive slow solenoid valve

Y20 Threshing drum variable-speed drive fast solenoid valve

Y22 Reel raise solenoid valve

Y23 Reel lower solenoid valve

Y24 Reel forward solenoid valve

Y25 Reel reverse solenoid valve

unit (734).

valves (Y24/Y25) and, at the same time, the master valve (Y77) is

actuated. The corresponding pilot spool opens the ball in the valve insert

and closes the return line to the tank. The pressure which consequently

rises builds up against the ram in lock-up valve unit (734) and thus

unlocks the return line to the tank in the opposite port.

insert of the unactuated solenoid valve (Y24/Y25). The pressure rising

further now opens the lock-up valve unit (734) on the pressure side and

the hydraulic cylinders are retracted or extended.

04/04 DO-h-Kap3 3-21

Page 50

Hydraulic System Dominator 140 - 150 TIC

Horizontal reel adjustment

Hydraulic cylinders

3-22 DO-h-Kap3 04/04

Page 51

TIC Dominator 140 - 150 Hydraulic System

Key to diagram:

Description of function:

Bottom valves The bottom outlet valves (V) open every time an end position is reached

316 Horizontal reel adjustment hydraulic cylinder

A2 Hydraulic cylinder port

A3 Hydraulic cylinder port

V Bottom valves

so that air inclusions in the connection between the two rams can be

flushed out.

After a repair, the cylinders must be flushed in both end positions for

approx. 15 sec.

04/04 DO-h-Kap3 3-23

Page 52

Hydraulic System Dominator 140 - 150 TIC

Horizontal reel adjustment

Lock-up valve unit (734)

3-24 DO-h-Kap3 04/04

Page 53

TIC Dominator 140 - 150 Hydraulic System

Key to diagram:

Description of function:

Lock-up valve units (pilot controlled non-return valves) are used in order

A rising pressure in port (B) moves the internal ram (K). This opens the

The continued pressure increase now opens the non-return valve in

A Hydraulic valve port

B Hydraulic valve port

A1 Consumer port

B1 Consumer port

to lock functions while pressure is relieved and thus to ensure a fixed

position of a consumer.

opposite non-return valve in port A - the return line of the hydraulic

cylinder to the tank is relieved (connection A-A1).

port B. The connection to consumer (B-B1) is relieved.

04/04 DO-h-Kap3 3-25

Page 54

Hydraulic System Dominator 140 - 150 TIC

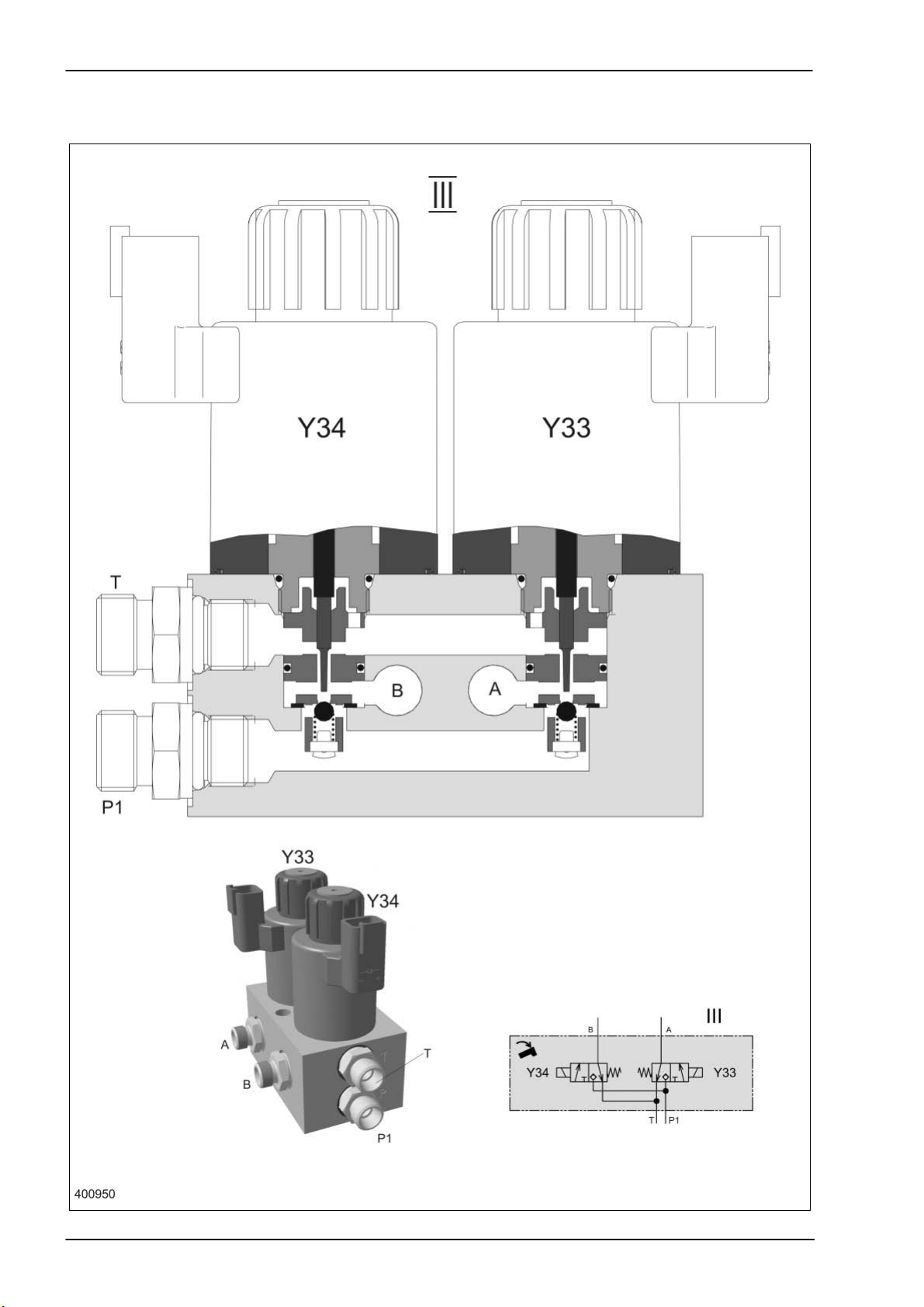

3.6 Swinging the grain tank unloading tube 4/3 way valve Y33/Y34

3-26 DO-h-Kap3 04/04

Page 55

TIC Dominator 140 - 150 Hydraulic System

Key to diagram:

Description of function:

Neutral function Both sides of the hydraulic cylinder (320) are tightly closed by the non-

Description of function Depending on the necessary direction of movement, one of the solenoid

The pressure which consequently rises builds up against the ram in lock-

The return line of the hydraulic cylinder is relieved to the tank via the valve

III Grain tank unloading tube working hydraulics valve block

Y33 Grain tank unloading tube swing out solenoid valve

Y34 Grain tank unloading tube swing in solenoid valve

A Consumer port

B Consumer port

P1 Working hydraulics pump port

T Tank port

return valves (734).

valves (Y33/Y34) and, at the same time, the master valve (Y77) is

actuated. The corresponding pilot spool opens the ball in the valve insert

and closes the return line to the tank.

up valve unit (734) of the swing grain tank unloading tube hydraulic

cylinder (320) and in this process opens port A and/or B.

insert of the unactuated solenoid valve (Y34/Y33). The pressure rising

further now opens the non-return valve (lock-up valve unit 734) at the

opposite port B and/or A and the hydraulic cylinder is retracted or

extended.

04/04 DO-h-Kap3 3-27

Page 56

Hydraulic System Dominator 140 - 150 TIC

Swinging the grain tank unloading tube

Hydraulic cylinders

3-28 DO-h-Kap3 04/04

Page 57

TIC Dominator 140 - 150 Hydraulic System

Key to diagram:

320 Swing grain tank unloading tube hydraulic cylinder

S Securing wire

K Ram thread glued with liquid locking compound

04/04 DO-h-Kap3 3-29

Page 58

Hydraulic System Dominator 140 - 150 TIC

Swinging the grain tank unloading tube

Lock-up valve unit (734)

3-30 DO-h-Kap3 04/04

Page 59

TIC Dominator 140 - 150 Hydraulic System

r

Key to diagram:

Description of function:

Lock-up valve units (pilot controlled non-return valves) are used in order to

A rising pressure in port (B) moves the internal ram (K). This opens the

The continued pressure increase now opens the non-return valve in port

A Hydraulic valve port

B Hydraulic valve port

A1 Consumer port

B1 Consumer port

lock functions while pressure is relieved and thus to ensure a fixed position

of a consumer.

opposite non-return valve in port A - the return line of the hydraulic cylinde

to the tank is relieved (connection A-A1).

B. The connection to consumer (B-B1) is relieved.

04/04 DO-h-Kap3 3-31

Page 60

Hydraulic System Dominator 140 - 150 TIC

3.7 Reverse front attachment

3/2-way valve Y86

3-32 DO-h-Kap3 04/04

Page 61

TIC Dominator 140 - 150 Hydraulic System

Key to diagram:

Description of function:

Neutral The spring force displaces the oil from the reversing cylinder (353) via the

Reversing The solenoid valve (Y86) and the master valve (Y77) are actuated. The

IV Front attachment reverse valve block

Y86 Reverse front attachment solenoid valve

A Consumer port

P1 Working hydraulics pump port

T Tank port

connection A-T in the solenoid valve (Y86) to the tank. During this

process, port P1 is closed by the spool.

return line to the tank is now closed by the spool in solenoid valve (Y86)

and the connection from P to the consumer port A is established. The

reversing cylinder (353) now extends and swings the hydraulic motor

(226) to the drive gearwheel. Just before reaching its end position, the oil

flow from the reversing cylinder (353) to the hydraulic motor (226) is

released, ensuring reliable gearwheel engaging. The non-return valve

(732) keeps the hydraulic motor (226) from starting when pressure peaks

occur in the return line.

04/04 DO-h-Kap3 3-33

Page 62

Hydraulic System Dominator 140 - 150 TIC

Reverse front attachment

Hydraulic cylinders

3-34 DO-h-Kap3 04/04

Page 63

TIC Dominator 140 - 150 Hydraulic System

Key to diagram:

Description of function:

Reversing When the solenoid valve (Y86) is actuated, the reversing cylinder (353)

The non-return valve (732) keeps the hydraulic motor (226) from starting

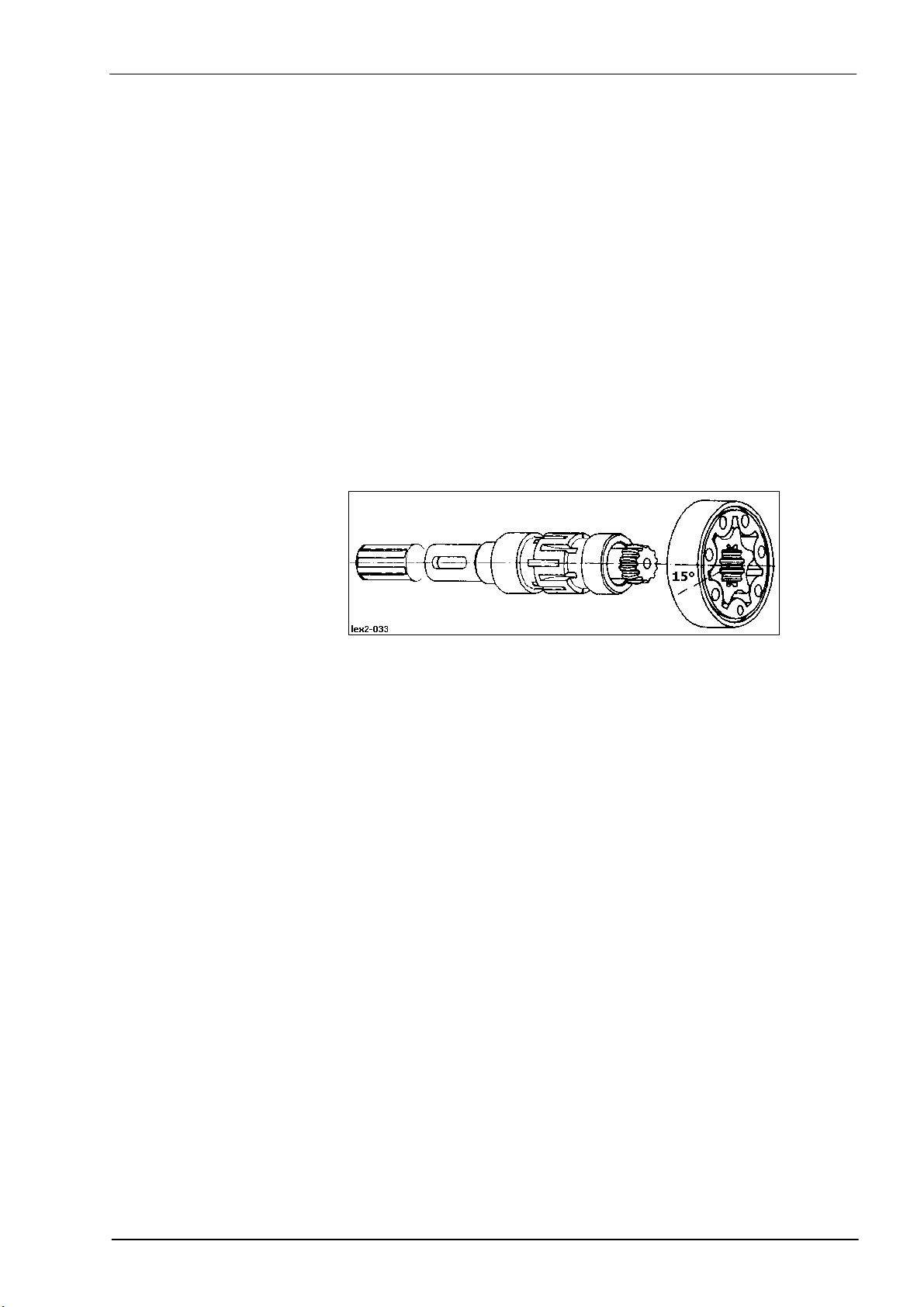

Adjustment The reverser support is aligned towards the feed rake conveyor drive

The piston stroke is adjusted using the set screw (E). With the reverser

Installation position of

reverser motor OMP 200

353 Reverse front attachment hydraulic cylinder

extends and swings the hydraulic motor (226) to the drive gearwheel. Just

before reaching its end position, the oil flow from the reversing cylinder

(353) to the hydraulic motor (226) is released. This ensures reliable

engaging of the gearwheels for the reversing process.

when pressure peaks occur in the return line.

shaft by adjusting an eccentric bushing on the reverser cylinder (353).

swung in, the set screw (E) must have a play of 0.5 mm from the end

stop, then jam the set screw (E).

04/04 DO-h-Kap3 3-35

Page 64

Hydraulic System Dominator 140 - 150 TIC

3-36 DO-h-Kap3 04/04

Page 65

TIC Dominator 140 - 150 Hydraulic System

Chapter 4

Ground drive

hydraulics

4.1

LINDE ground drive hydraulics circuit diagram ....................... 4-4

4.2 Pump unit................................................................................. 4-8

4.3 Servo control valve ................................................................ 4-10

4.4 Ground drive multi-function valve .......................................... 4-12

4.5 Ground drive fixed displacement motor................................. 4-14

4.6 Maintenance .......................................................................... 4-17

4.7 3D cleaning system................................................................ 4-18

04/04 DO-h-Kap4 4-1

Page 66

Hydraulic System Dominator 140 - 150 TIC

4-2 DO-h-Kap4 04/04

Page 67

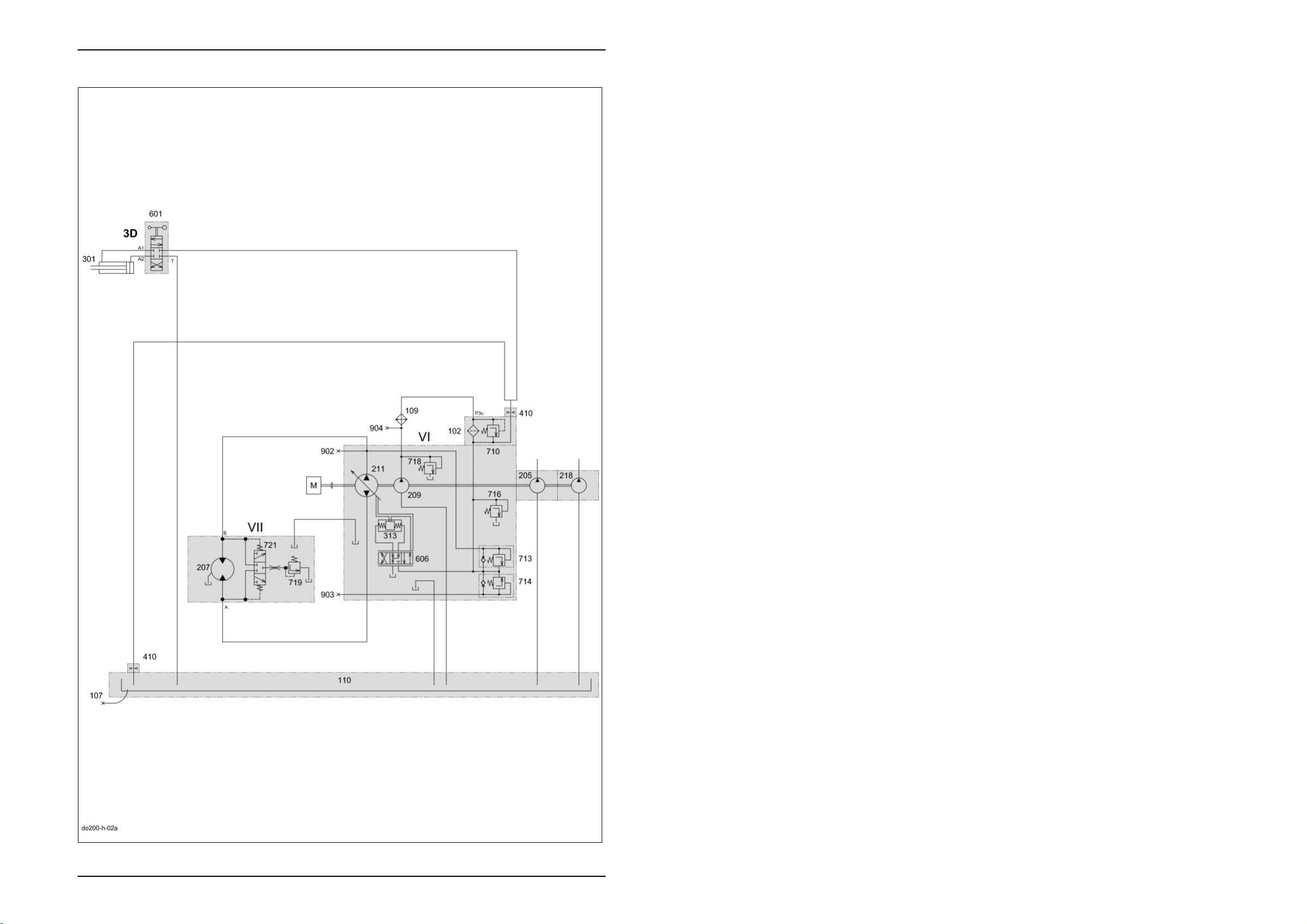

4.1

LINDE ground drive hydraulics circuit diagram

Page 68

Hydraulic System Dominator 140 - 150 TIC

4.1 LINDE ground drive hydraulics circuit diagram

Key to diagram:

VI Ground drive hydraulics hydrostatic pump

VII Ground drive hydraulics hydrostatic motor

102 Pressure filter.............................................................. 10 µm

107 Oil drain

109 Oil cooler

110 Oil tank

205 Working hydraulics pump ........................................... 10.8 cm

207 Ground drive fixed displacement motor HMF 75........ 75 cm

209 Ground drive feed pump............................................. 22.5 cm

211 Ground drive variable displacement pump HPV 75 ... 75 cm

218 Steering hydraulics pump ........................................... 6 cm

3

/rev.

3

/rev.

3

/rev.

3

/rev.

3

/rev.

301 3-D sieve pan hydraulic cylinder

313 Ground drive servo control pump hydraulic cylinder

410 Orifice plate ................................................................ Ø 1.5 mm

601 3D sieve pan pendulum control 4/3 way valve

606 Ground drive servo control 4/3 way valve

710 Ground drive filter bypass valve ................................. 2 bar

713 Ground drive multi-function valve, reverse................. 420 bar

714 Ground drive multi-function valve, forward................. 420 bar

716 Ground drive feed pressure relief valve...................... 19 bar

718 Ground drive feed circuit cold start injector ................ 25 bar

719 Ground drive flush pressure control valve.................. 10 bar

721 Ground drive flush-out shuttle valve

902 Ground drive hydraulics high pressure backward measuring point

903 Ground drive hydraulics high pressure forward measuring point

904 Ground drive hydraulics feed pressure measuring point

4-4 DO-h-Kap4 04/04

Page 69

TIC Dominator 140 - 150 Hydraulic System

Description of function:

Oil supply After starting the diesel engine, the ground drive feed pump (209) is

driven.

In this process, the oil quantity is taken from the housing. The housing is

directly connected with the oil tank (110).

Feed pressure circuit The feed pressure builds up from the oil quantity pumped through the oil

cooler (109) and the pressure filter (102) by the ground drive feed pump

(209) against the ground drive feed pressure relief valve (716).

Depending on the spring setting, the oil flow is pre-stressed and then

relieved to the tank.

The feed pressure is applied at the combined ground drive multi-function

valves (713/714) and at both servo cylinders via the ground drive servo

adjustment valve (606).

When the ground drive variable displacement pump (211) is not swung

out, the feed pressure propagates to both sides of the high-pressure

circuit via ground drive multi-function valves (713/714).

Servo control The cable mounted on the ground speed control lever moves the spool in

the ground drive servo adjustment valve (606) from the neutral position to

one or the other direction.

Depending on the direction of travel, one of the ground drive pump servo

adjustment hydraulic cylinders (313) is pressure-relieved whereas the

other hydraulic cylinder remains connected to the feed pressure circuit.

The motion at the swing disc corresponds to the pressure difference

between the hydraulic cylinders.

The ground drive pump servo adjustment hydraulic cylinders (313) swing

the ground drive variable displacement pump (211) only by the path

defined by the ground speed control lever because there is a mechanical

feedback of the swing angle to the ground drive servo adjustment valve

(606).

This mechanical feedback balances the spool in the ground drive servo

adjustment valve (606) and therefore the pressure level between the two

hydraulic cylinders at the control edge so that the defined swing angle is

maintained.

High-pressure circuit As soon as the ground drive variable displacement pump (211) is swung

out, an axial motion is added to the radial motion of the pump unit.

This axial motion displaces the oil in the cylinder space of the rotor and

thus acts on the motor unit which converts this energy into a rotating

motion by supporting against the fixed inclined disc.

The respective suction side of the ground drive variable displacement

pump (211) is pre-stressed via the feed pressure circuit and the

corresponding ground drive multi-function valve (713/714). This ensures

that the ground drive variable displacement pump (211) is sufficiently filled

and that any occurring leaks are compensated.

Since feed pressure is always applied on the suction side of the ground

drive variable displacement pump (211) as well as on the return flow side

of the ground drive fixed displacement motor (210), this area is referred to

as low-pressure side within the high-pressure circuit.

04/04 DO-h-Kap4 4-5

Page 70

Hydraulic System Dominator 140 - 150 TIC

Description of function:

High-pressure limitation If the system pressure rises above the set maximum value, this

overpressure is relieved to the feed pressure circuit by the ground drive

multi-function valves (713/714).

The high-pressure limitation should only respond for a short time during

operation since the large oil flow which has to be displaced by the heavily

pre-stressed valves would rapidly overheat the system.

Flushing device The respective high-pressure side in the high-pressure circuit actuates the

ground drive purging shuttle valve (721) in the ground drive fixed

displacement motor (210) so the corresponding low-pressure side has a

connection to the motor housing via the ground drive purge pressure

control valve (719).

Since the pressure setting of the ground drive purge pressure control

valve (719) is lower than that of the ground drive feed pressure relief

valve (716), a constant oil quantity is exchanged by the ground drive feed

pump (209) via the restrictor in the ground drive purge pressure control

valve (719).

4-6 DO-h-Kap4 04/04

Page 71

TIC Dominator 140 - 150 Hydraulic System

04/04 DO-h-Kap4 4-7

Page 72

Hydraulic System Dominator 140 - 150 TIC

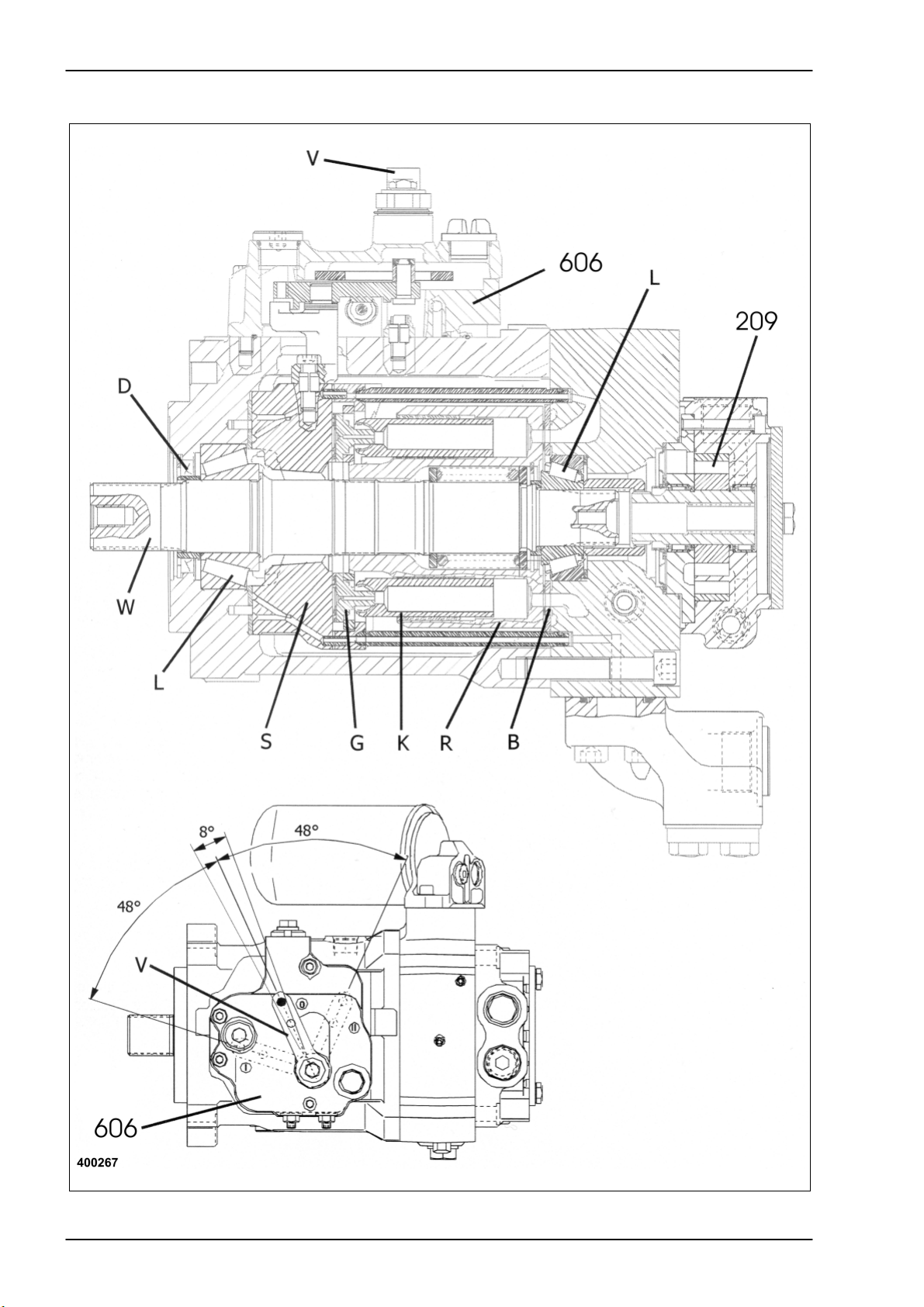

4.2 Pump unit

4-8 DO-h-Kap4 04/04

Page 73

TIC Dominator 140 - 150 Hydraulic System

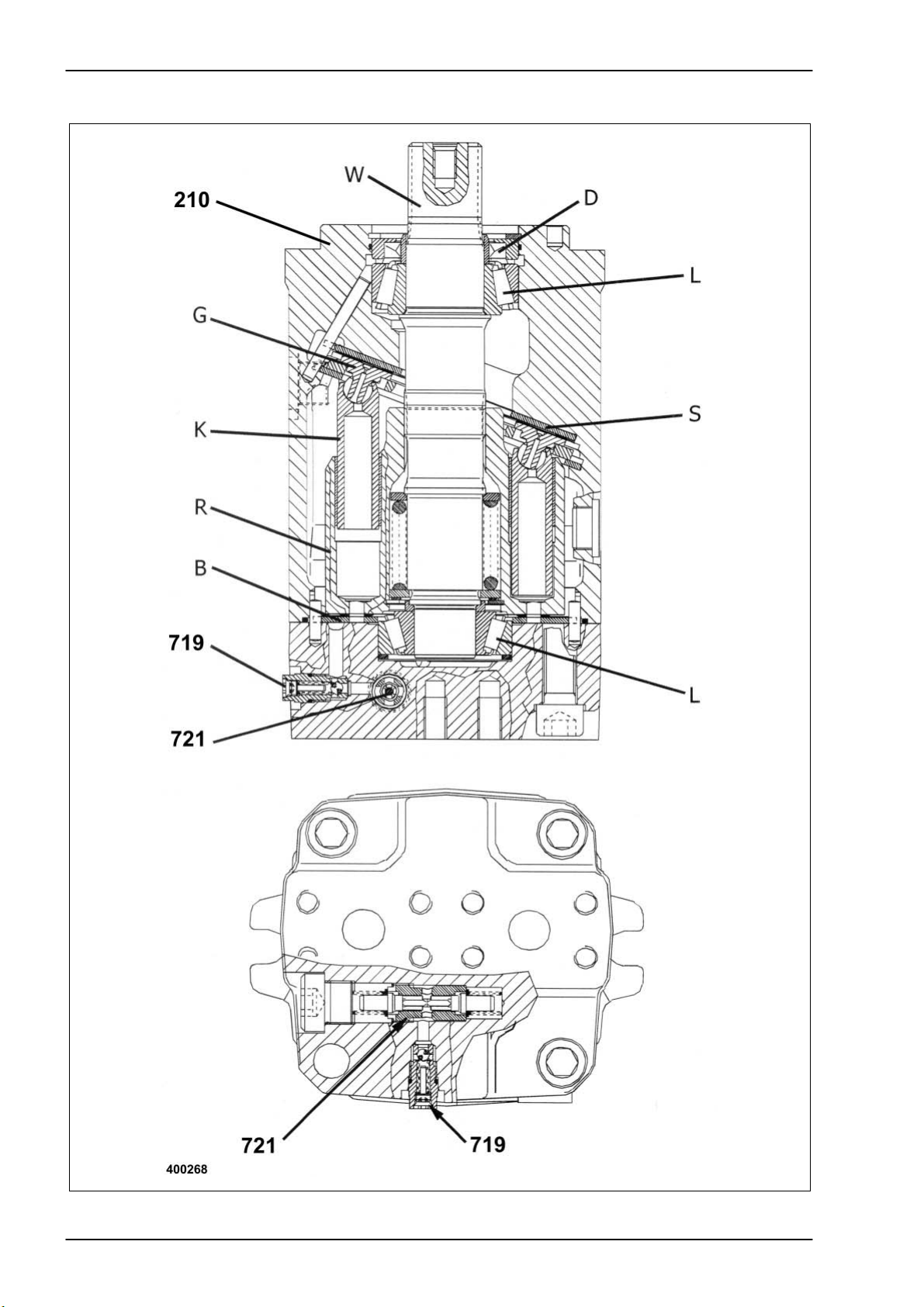

Key to diagram:

Description of function:

As soon as the diesel engine is started, the cylinder rotor (R) as well as

209 Ground drive feed pump ............................................. 22 cm3

606 Ground drive servo adjustment valve

B Control bottom

D Shaft seal

G Slide

K Ram

L Bearing

R Cylinder rotor

S Swing disc

V Adjusting lever

W Drive shaft

the ground drive feed pump (209) are driven by the nine pistons (K)

arranged radially around the drive shaft (W).

In this process, the pistons (K) are pressed against the swing disc (S) by

means of the slides (G) due to the feed pressure applied on both sides of

the high-pressure circuit (H).

One of the servo cylinders is actuated by the ground drive servo

adjustment valve (606) so that this cylinder swings the swing disc (S)

according to the direction of travel and the ground speed.

During the swinging motion, the pistons (K) make an axial movement on

the inclined plane of the swing disc (S) which results in the oil in the filled

cylinder space being displaced and in a pressure building up against the

resistance at the motor.

When the entire oil quantity in the cylinder space has been displaced, the

piston (K) rotating with the rotor (R) is pushed back by the feed pressure

and against the sloping inclined plane of the swing disc (S) on the lowpressure side.

The cylinder spaces in the rotor (R) are thus filled one after the other on

the sloping side of the swing disc (S) (low pressure) and then displace this

oil quantity on the rising side (high pressure) against the motor unit.

According to the direction of travel, the swing disc (S) is moved to one or

the other direction, making high pressure and low pressure change sides

as well. The ground speed depends on the oil flow quantity and

consequently on the swing angle of the swing disc (S). The swing angle

pre-set on the ground speed control lever is maintained by the mechanical

feedback from the swing disc (S) to the servo control valve (606).

The low-pressure side is separated from the high-pressure side inside the

pump unit above the control bottom (B). For sealing purposes, the cylinder

rotor (R) is pushed against the control bottom (B) only by a compression

spring.

The exact return of the swing disc to its neutral position is achieved by

compressed springs, and this factory setting cannot be modified from the

outside.

The position of the adjusting lever (V) on the shaft gearing is marked with

a punch blow on the servo adjustment housing. This position corresponds

to the neutral position of the servo adjustment valve which is achieved

within an angle of 8° of the adjusting range.

04/04 DO-h-Kap4 4-9

Page 74

Hydraulic System Dominator 140 - 150 TIC

“

4.3 Servo control valve

G

313

V

606

X

Z” “Z”

V

P

313

P

M

S

M

Z1023.0

4-10 DO-h-Kap4 04/04

Page 75

TIC Dominator 140 - 150 Hydraulic System

Key to diagram:

Description of function:

Servo control valve In the neutral position of the ground drive servo adjustment valve (606),

Adjusting the hydraulic

neutral position:

To align the mechanical neutral position of the adjusting lever (V) with the

313 Ground drive servo control pump hydraulic cylinder

606 Ground drive servo adjustment valve

G Threaded bushing

M Mechanical feedback

P Spool

S Swing disc

V Adjusting lever

both ground drive pump servo control hydraulic cylinders (313) are

pressure-loaded, keeping the swing disc (S) stable in any position.

The cable mounted on the adjusting lever (V) moves the spool (P) in the

ground drive servo adjustment valve (606) from the neutral position to one

or the other direction. Depending on the direction of travel, one of the

ground drive pump servo adjustment hydraulic cylinders (313) is thus

pressure-relieved whereas the other servo cylinder remains connected to

the feed pressure circuit.

The movement at the swing disc (S) thus corresponds to the pressure

difference between the ground drive pump servo adjustment hydraulic

cylinders (313).

The ground drive pump servo adjustment hydraulic cylinders (313) swing

the variable displacement pump only by the path defined by the adjusting

lever (V) because there is a mechanical feedback (M) of the swing angle

to the ground drive servo adjustment valve (606).

This mechanical feedback (M) balances the spool (P) in the ground drive

servo adjustment valve (606) at the control edge to the neutral position.

The pre-set swing angle is thus maintained by the pressure compensation

in both ground drive pump servo adjustment hydraulic cylinders (313).

hydraulic neutral position of the variable displacement pump, the spool (P)

in the servo adjustment valve is adjusted using the threaded bushing (G).

To do this, the bushing (G) is first set to a clearance of X = 14.75 mm (X)

from the housing of the ground drive servo adjustment valve (606). A

pressure measurement on both sides of the high-pressure circuit

determines the respective pressure rise caused by rotating the bushing

(G) to one or the other direction. The centre position of the path by which

the bushing (G) has been rotated corresponds to the average neutral

position.

04/04 DO-h-Kap4 4-11

Page 76

Hydraulic System Dominator 140 - 150 TIC

4.4 Ground drive multi-function valve

Z1022.0

4-12 DO-h-Kap4 04/04

Page 77

TIC Dominator 140 - 150 Hydraulic System

Key to diagram:

Description of function:

High-pressure limitation High pressure (H) is applied to the valve plunger (1) via the bores in the

Feed As soon as there is no high pressure (N) applied against the valve

1 Valve plunger

2 High-pressure spring

3 Valve insert

4 Feed spring

H High pressure

N No high pressure

S Feed pressure

valve cartridge.

When the system pressure exceeds to pre-set value of the high-pressure

spring (2), the valve plunger (1) backs away to the bottom against the

spring pressure and relieves the high-pressure side towards the feed

pressure circuit (S).

cartridge, the feed pressure (S) presses the entire valve insert (3)

upwards against the feed spring (4) and thus opens the feed pressure

circuit (S) to the low-pressure side (N).

04/04 DO-h-Kap4 4-13

Page 78

Hydraulic System Dominator 140 - 150 TIC

4.5 Ground drive fixed displacement motor

4-14 DO-h-Kap4 04/04

Page 79

TIC Dominator 140 - 150 Hydraulic System

Key to diagram:

Description of function:

See also ground drive

hydraulics circuit diagram

As soon as the diesel engine is started, the feed pump in the pump unit is

210 Ground drive fixed displacement motor ...................... HMF 75

721 Ground drive flush-out shuttle valve

719 Ground drive flush pressure control valve .................. 10 bar

B Control bottom

D Shaft seal

G Slide

K Ram

L Bearing

R Cylinder rotor

S Fixed inclined disc

W Driven shaft

also driven. In this process, the pistons (K) in the cylinder rotor (R) of the

motor unit are pressed against the fixed inclined disc (S) by means of the

slides (G) due to the feed pressure applied on both sides of the highpressure circuit.

As soon as the variable displacement pump is swung out, the pressure

builds up against the nine pistons (K) in the cylinder rotor (R) which is

geared to the driven shaft (W), one after the other. Here the pistons (K)

support themselves against the inclined plane of the fixed inclined disc (S)

and thus convert this energy into a rotating motion against the resistance

at the driven shaft (W).

The direction of rotation here depends on the direction of the oil flow and

thus on the swing direction of the variable displacement pump, with high

pressure and low pressure changing the sides. The motor speed results

from the oil flow quantity therefore from the swing angle of the variable

displacement pump.

The low-pressure side is separated from the high-pressure side inside the

motor unit above the control bottom (B). For sealing purposes, the

cylinder rotor (R) is pushed against the control bottom (B) only by a

compression spring.

The respective high-pressure side in the high-pressure circuit actuates the

ground drive purging shuttle valve (721) in the fixed displacement motor

so the corresponding low-pressure side has a connection to the motor

housing via the ground drive purge pressure control valve (719).

Since the pressure setting of the ground drive purge pressure control

valve (719) is lower than that of the feed pressure relief valve, a constant

oil quantity is exchanged by the feed pump (209) via the restrictor in the

ground drive purge pressure control valve (719).

04/04 DO-h-Kap4 4-15

Page 80

Hydraulic System Dominator 140 - 150 TIC

4-16 DO-h-Kap4 04/04

Page 81

TIC Dominator 140 - 150 Hydraulic System

4.6 Maintenance

Filling instructions Engage 3

rd

gear at the gearshift lever

Disengage all-wheel drive

Apply parking brake

Connect pressure gauges on both high-pressure sides (M1+M2)

Fill tank with hydraulic oil

Pull out engine cut-off system relay and/or cable jumper

Crank the diesel engine for a short period using the electric starting motor

Check and correct the oil level

Repeat procedure until the pressure has risen by approx. 10 bar

Re-install engine cut-off system relay and/or cable jumper

Start diesel engine at min. no-load speed

Load the system with 50-150 bar forward for approx. 1 minute

Load the system with 50-150 bar backward for approx. 1 minute

Shut off diesel engine

Check and correct the oil level if necessary

Set gearshift lever to neutral position

Start diesel engine at min. no-load speed

Swing variable displacement pump forward for approx. 2 minutes

Swing variable displacement pump backward for approx. 2 minutes

Shut off diesel engine

Check and correct the oil level if necessary

Inspection regulations Connect pressure gauges on both high-pressure sides

Apply parking brake

Heat up the system to an operating temperature of approx. 60°C

Move ground speed control lever to neutral position

Set diesel engine to max. no-load speed

Measure the feed pressure: 19 bar

Feed pressure difference on both sides: max. 3 bar

Swing out the variable displacement pump fully to one direction

Pressure drop on low-pressure side: max. 4 bar

Set diesel engine to min. no-load speed

Engage 3

rd

gear in manual transmission

Apply service brake

Slowly swing the variable displacement pump forward for 5 sec. max.

High pressure measurement: 420 to 450 bar

Low pressure measurement: min. 14 bar

Slowly swing the variable displacement pump backward for 5 sec. max.

High pressure measurement: 420 to 450 bar

Low pressure measurement: min. 14 bar

Shut off diesel engine

Remove pressure gauge

04/04 DO-h-Kap4 4-17

Page 82

Hydraulic System Dominator 140 - 150 TIC

4.7 3D cleaning system

4-18 DO-h-Kap4 04/04

Page 83

TIC Dominator 140 - 150 Hydraulic System

Key to diagram:

Description of function:

1 Control head

2 Pendulum

3 Cup

4 Spool

Volumetric flow is applied to port (P) of the control head. When the

pendulum (2) is in the centre position, P is blocked at the spool (4). When

the pendulum changes its position to the right or left, relative to the cup,

the spool (4) is moved. In this process, connections are made between P

and A as well as B and R or between P and B as well as A and R,

depending on the direction in which the pendulum moves.

04/04 DO-h-Kap4 4-19

Page 84

Hydraulic System Dominator 140 - 150 TIC

4-20 DO-h-Kap4 04/04

Page 85

TIC Dominator 140 - 150 Hydraulic System

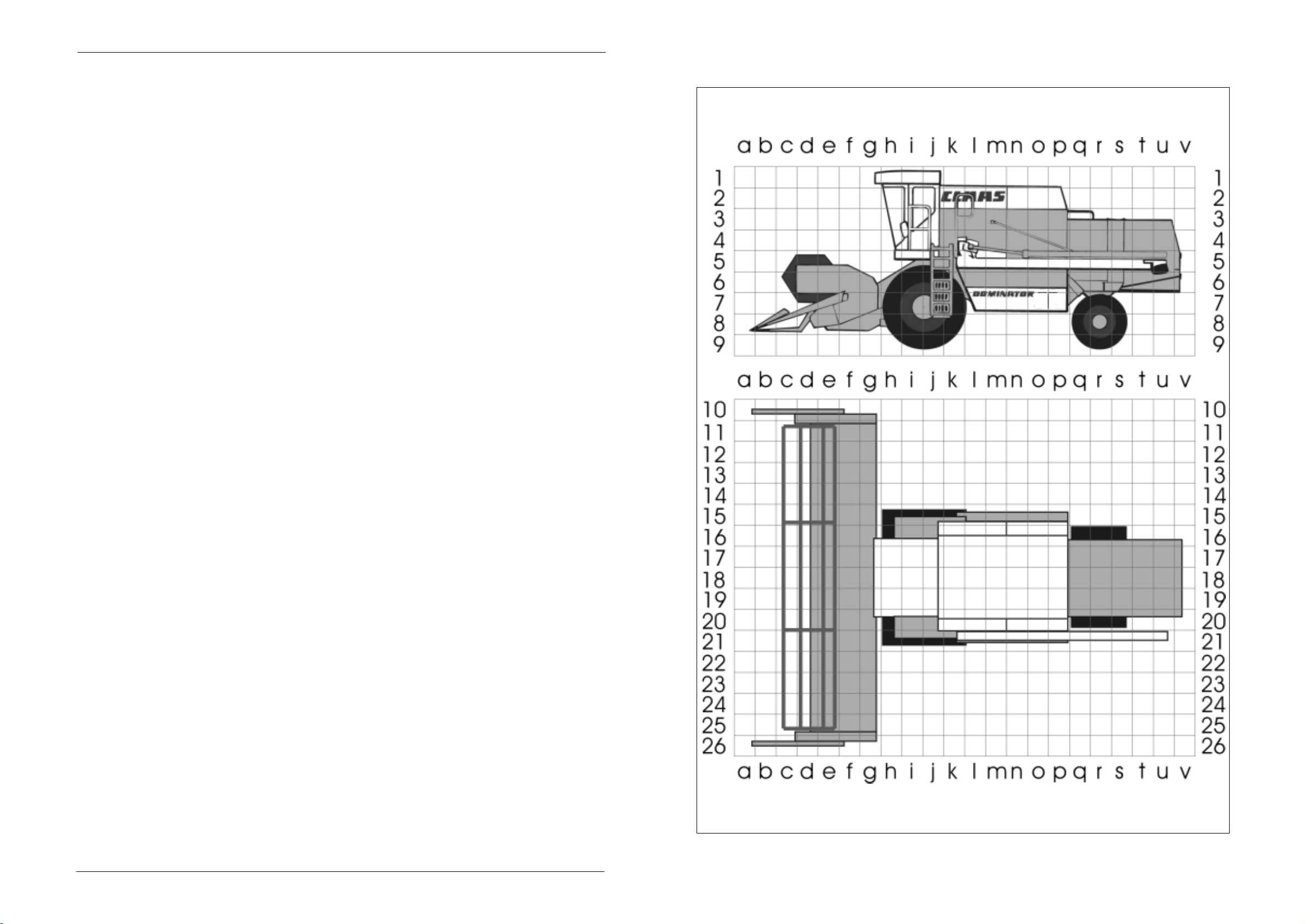

Position of components

04/04 DO-h-Raster R-1

Page 86

Hydraulic System Dominator 140 - 150 TIC

R-2 DO-h-Raster 04/04

Page 87

TIC Dominator 140 - 150 Hydraulic System

5-k-20

5-k-20

4-i-16

4-i-16

5-i-18

3-o-19

04/04 DO-h-Raster R-3

Page 88

Hydraulic System Dominator 140 - 150 TIC

7-j-19

3-o-16

3-o-19

3-o-19

3-o-19

3-o-19

R-4 DO-h-Raster 04/04

Page 89

TIC Dominator 140 - 150 Hydraulic System

7-j-19

6-g-16

3-o-19

6-n-20

4-k-16

4-m-20

04/04 DO-h-Raster R-5

Page 90

Hydraulic System Dominator 140 - 150 TIC

7-r-18

6-g-16

7-i-18

4-k-16

6-n-20

5-i-18

R-6 DO-h-Raster 04/04

Page 91

TIC Dominator 140 - 150 Hydraulic System

5-i-18

04/04 DO-h-Raster R-7

Page 92

Component grid

Page 93

TIC Dominator 140 - 150 Hydraulic System

Component grid

04/04 DO-h-Raster R-9

Page 94

Hydraulic System Dominator 140 - 150 TIC

R-10 DO-h-Raster 04/04

Page 95

Index

Hydraulic System

Page 96

Hydraulic System Dominator 140 - 150 TIC

Index:

3D cleaning system 4-18

Checking the steering 2-13

C

Ground drive hydraulics 4-1

G

Horizontal reel adjustment 3-20

H

Lock-up valve unit 3-30, 3-24

L

Multi-function valve 4-12

M

Oil pressure 1-6

O

Overall hydraulic system 1-3

Overall hydraulic system circuit diagram with 3D 1-4

Overall hydraulic system circuit diagram without 3D 1-8

Position of components R-1

P

Pressure relief valve 3-6

Raise / lower cutterbar 3-10

R

Raise / lower front attachment 3-10

Rotary coupling 3-14

Steering 2-12

S

Steering actuation 2-12

Steering hydraulics 2-1

Steering hydraulics circuit diagram 2-4

Steering valve unit 2-7

Swing grain tank unloading tube 3-26

Vertical reel adjustment 3-16

V

W

Working hydraulics 3-1

Working hydraulics circuit diagram 3-4

Index-2 DO-h-index 04/04

Page 97

Following the policy of the CLAAS KGaA mbH to improve their products as

technical developments continue, CLAAS reserve the right to make

alterations which must not necessarily correspond to text and illustrations

contained in this publication, and without incurring obligation to alter any

machines previously delivered.

Technical data, dimensions and weights are given as an indication only.

Responsibility for errors or omissions not accepted.

Reproduction or translation of this publication, in whole or part, is not

permitted without the written consent of the CLAAS KGaA mbH.

All rights under the provision of the Copyright Act reserved.

CLAAS KGaA mbH

33426 Harsewinkel

Germany

Our contribution to the environment: CLAAS

have printed this manual on 100 % chlorine

free paper.

Page 98

CLAAS KGaA mbH

Postfach 1163

33426 Harsewinkel

Tel. +49 (0)5247 12-0

www.claas.com

0293 151.1

SYS-H DOMINATOR 140- 150

EN - 01.05 - NF

Printed in Germany

Loading...

Loading...