Page 1

DOMINATOR 150 / 140 / 130

Operator’s Manual

Page 2

a

67075

l

a

u

n

r

O

g

i

n

i

a

l

o

p

ra

e

t

o

r

'

s

m

Page 3

2

EC declaration of conformity

corresponds to EC directive 98/37/EC

We CLAAS Selbstfahrende Erntemaschinen Gesellschaft mit beschränkter Haftung

(Name of supplier)

Postfach 11 63

D-33426 Harsewinkel

(full address of the manufacturer - an authorised representative established in the Community must also give the business name and the

address of the manufacturer)

declare under our sole responsibility that the product

Combine harvester - type:

200 / 156

(Make, Type)

67076

to which this declaration relates corresponds to the relevant basic safety and health requirements of the Directive 98/37/EC Appendix I,

(if applicable)

and to the requirements of the other relevant Directives

89/336/EEC in the version 92/31/EEC.

(Title and/or number and date of issue of the other Directives)

For the relevant implementation of the safety and health requirements mentioned in the Directives, the following

standard(s) and/or technical specification(s) has (have) been respected:

EN 632 - August 1995

(Title and/or number and date of issue of standard(s) and/or technical specification(s))

Technical Management

(J.H. Mohr)

(Name, function and signature of the authorized person)

Quality Management

(U. Krieg)

Harsewinkel,

(Place and date of issue)

00 0293 210 2 - BA DOMINATOR 150/140/130 - 12/09 3

Page 4

2.2

EC Declaration of Conformity

This declaration of conformity is the original declaration of conformity according to

Directive 2006/42/EC

We CLAAS Selbstfahrende Erntemaschinen GmbH

Postfach 11 63, D-33416 Harsewinkel

declare under our sole responsibility, that the product Combine harvester

(type - serial number - trade name)

200 - from 200 01217 - DOMINATOR 150 / 140

156 - from 156 10568 - DOMINATOR 130

to which this declaration relates corresponds to the relevant basic safety and health requirements of Directive

2006/42/EC Appendix I and to the requirements of the other relevant Directives 2004/108/EC.

For the relevant implementation of the safety and health requirements mentioned in the Directives, the following

standard(s) and/or technical specification(s) has (have) been respected: EN 632 - August 1995

67076

The person responsible for documentation in the European Community is: J.H. Mohr, CLAAS Selbstfahrende

Erntemaschinen GmbH, Postfach 11 63, D-33416 Harsewinkel

Technical Management

(J.H. Mohr)

Quality Management

(U. Krieg)

Harsewinkel, 01.10.09

4 00 0293 210 2 - BA DOMINATOR 150/140/130 - 12/09

Page 5

Contents

1 Introduction

1.1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.1.1 How to use this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.1.2 Validity of instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.1.3 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.1.4 Road traffic regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.1.5 Note on electronic engine management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1.2 Various components / Machine body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1.2.1 Spare parts and technical questions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

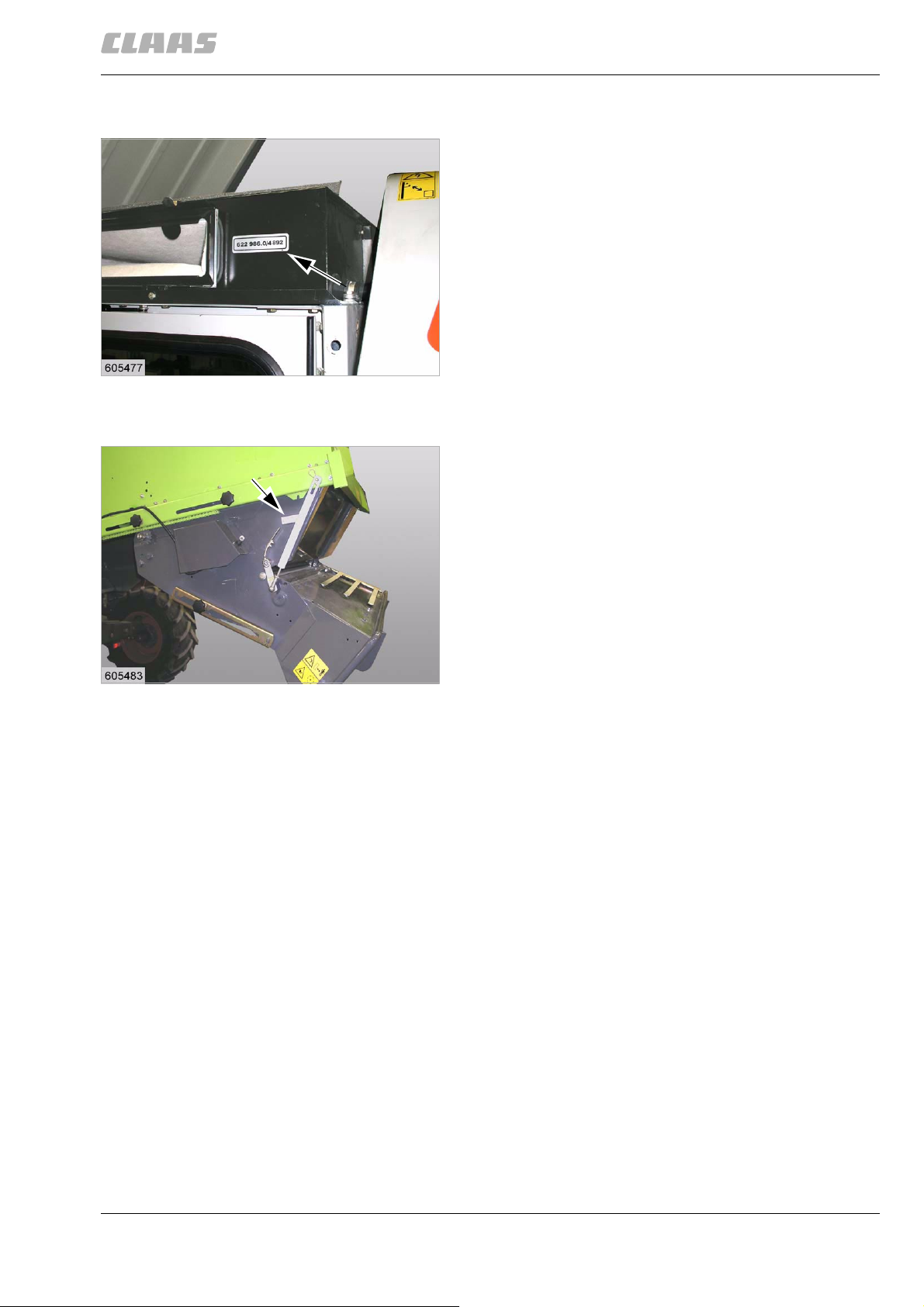

1.2.2 Machine identification plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

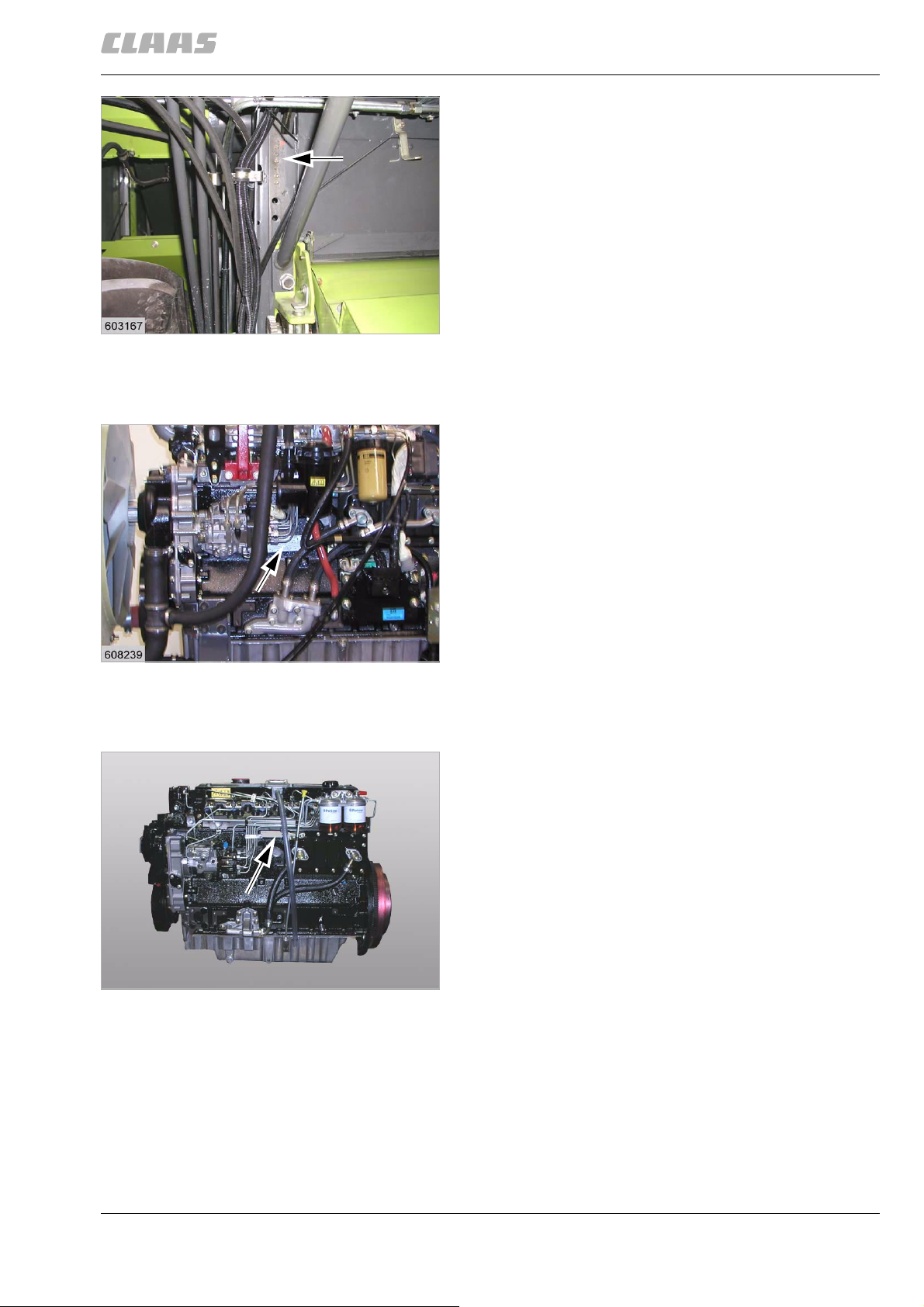

1.2.3 Identification plate of CATERPILLAR 3056 E engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

1.2.4 Identification plate of PERKINS 1006-6T engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

1.2.5 Identification plate of CATERPILLAR C6.6 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1.2.6 Drive axle identification plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1.2.7 Rear axle identification plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1.2.8 Trailer hitch identification plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

1.2.9 Hitch block identification plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

1.2.10 Cab identification plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

1.2.11 Straw chopper identification plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

67075

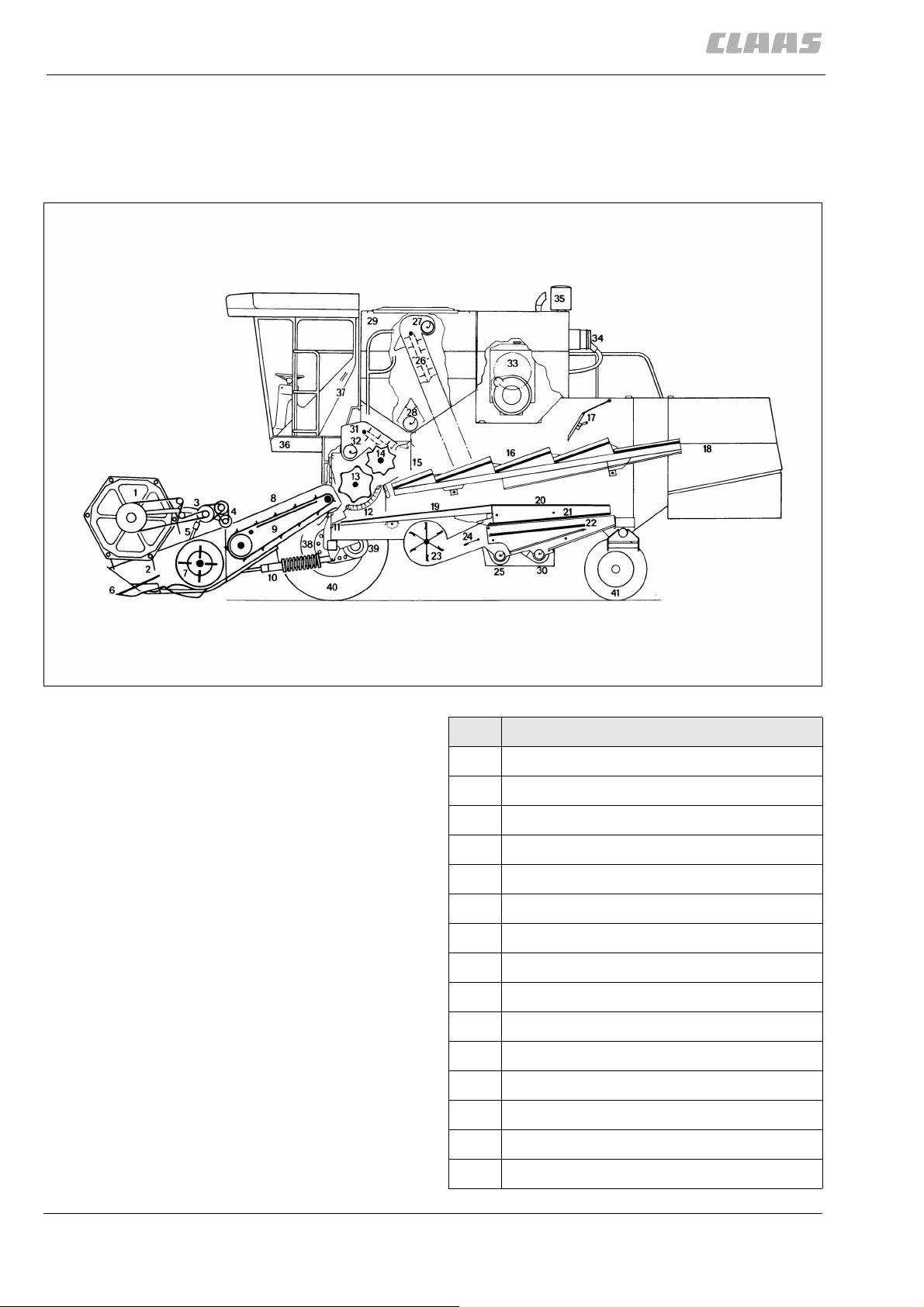

2 Sectional view of machine

2.1 Attachment parts / machine body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.1.1 Machine overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.1.2 Access to the workplace and maintenance areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3 Safety

3.1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.1.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.1.2 Important information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.1.3 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.1.4 Reasonable foreseeable misuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.1.5 Safety and accident prevention regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.1.6 General safety and accident prevention regulations for combine harvesters . . . . . . . . . . . . . . 37

3.1.7 Prior to operation, general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.1.8 Additional weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.1.9 Transporting passengers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.1.10 General driving operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.1.11 Automotive operation of combine harvester . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.1.12 Driving operations on slopes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.1.13 Leaving the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.1.14 Front attachments and trailers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.1.15 Crop receptacle / straw receptacle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.1.16 Grain delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.1.17 Air conditioner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.1.18 Adjustment and maintenance work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.1.19 Accumulators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

00 0293 210 2 - BA DOMINATOR 150/140/130 - 12/09 5

Page 6

3.1.20 Antifreeze . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3.1.21 First aid measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.1.22 Decommissioning and disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.1.23 Applying the feeder housing safety lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3.1.24 Moving out the feed rake conveyor safety lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3.1.25 Secure the machine with wheel chocks so it will not roll away . . . . . . . . . . . . . . . . . . . . . . . . 44

3.1.26 Securing the straw guide apron in raised position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

3.1.27 Jack up the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

3.1.28 Fire extinguisher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

3.1.29 Battery isolating switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

3.1.30 Danger of injury due to escaping hydraulic liquid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

3.1.31 Loading and tying down the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

3.1.32 Removing the lift eyes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

3.2 Safety rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3.2.1 Identification of warning and danger signs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3.3 Safety decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

3.3.1 General information on safety decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

3.3.2 Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

3.3.3 Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

3.3.4 Cab / Operator's platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

3.3.5 Feeder unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

3.3.6 Threshing mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

3.3.7 Separation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

3.3.8 Crop receptacle / straw receptacle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

3.3.9 Grain delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

3.3.10 Various components / Machine body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

3.4 Safety decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

3.4.1 General instructions on safety decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

3.4.2 Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

67075

4 Specifications

4.1 DOMINATOR 150 / 140 / 130 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

4.1.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

4.1.2 CATERPILLAR C6.6 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

4.1.3 CATERPILLAR 3056E engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

4.1.4 Perkins 1006-T6 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

4.1.5 Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

4.1.6 Tyre pressures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

4.1.7 Chassis track width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

4.1.8 Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

4.1.9 Steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

4.1.10 Electric system / Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

4.1.11 Cab / Operator's platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

4.1.12 Intake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

4.1.13 Threshing mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

4.1.14 Separation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

4.1.15 Cleaning unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

4.1.16 Grain delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

6 00 0293 210 2 - BA DOMINATOR 150/140/130 - 12/09

Page 7

4.1.17 Attachment parts / machine body dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

4.1.18 Attachment parts / machine body weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

5 Prior to initial operation

5.1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

5.1.1 General warnings Prior to initial operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

5.1.2 Initial operation check list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

5.2 Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

5.2.1 Removing / installing the wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

5.2.2 Overview of rear axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

5.2.3 Converting the rear axle from transport to working position . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

5.2.4 Rear axle 00 0649 950 1 – Adjusting the track width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

5.3 Hitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

5.3.1 Installing the trailer hitch (accessories) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

5.4 Electrical / electronic equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

5.4.1 Installing the fan / air conditioner fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

5.5 Feeder unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

5.5.1 Fitting / adjusting the mounting plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

5.5.2 Aligning the coupling pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

5.5.3 Checking the front attachment cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

5.5.4 Checking the cutterbar float springs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

5.6 Grain delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

5.6.1 Closing the service aperture on the grain tank unloading tube . . . . . . . . . . . . . . . . . . . . . . . . 99

5.6.2 Installing the grain tank safety device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

67075

6 Prior to each operation

6.1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

6.1.1 General warnings Prior to operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

6.1.2 Check list for daily operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

7 Overview of controls

7.1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

7.1.1 General warnings - Overview of controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

7.2 Cab / Operator's platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

7.2.1 Overview of operator's platform (DOMINATOR 130) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

7.2.2 Overview of operator's platform (DOMINATOR 150/140) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

7.2.3 Hydraulic system control unit (DOMINATOR 130 lift hydraulic system) . . . . . . . . . . . . . . . . . 107

7.2.4 Multifunction handle (DOMINATOR 150 / 140) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

7.2.5 Switch console (DOMINATOR 130) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

7.2.6 Diesel engine speed adjustment rotary switch (DOMINATOR 130,

CATERPILLAR C-6.6, 3056 E) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

7.2.7 Diesel engine speed lever (DOMINATOR 130, Perkins 1006-T6) . . . . . . . . . . . . . . . . . . . . . 109

7.2.8 Function of warning lights 7 and 8 (DOMINATOR 130) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

7.2.9 Switch console (DOMINATOR 150 / 140) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

7.2.10 Diesel engine speed rotary switch (DOMINATOR 150 / 140) . . . . . . . . . . . . . . . . . . . . . . . . . 112

7.2.11 Function of warning lights 15 and 18 (DOMINATOR 150 / 140) . . . . . . . . . . . . . . . . . . . . . . . 113

7.2.12 Overview of steering column . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

7.2.13 Cab roof controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

7.2.14 Cab with fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

00 0293 210 2 - BA DOMINATOR 150/140/130 - 12/09 7

Page 8

7.2.15 Cab with air conditioner (with York compressor) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

7.2.16 Cab with air conditioner (with Sanden compressor) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

7.2.17 Cab with fan and heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

7.2.18 Control levers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

7.2.19 Functions monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

7.3 Attachment parts / machine body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

7.3.1 Worklights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

7.3.2 Cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

7.3.3 Sun roof . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

7.3.4 Tool box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

8 Mounting/removing front attachment

8.1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

8.1.1 General warnings Installing / removing the front attachment . . . . . . . . . . . . . . . . . . . . . . . . . 126

8.2 Installing the front attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

8.2.1 Suspending front attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

8.2.2 Interlocking the front attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

8.2.3 Installing universal drive shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

8.2.4 Connecting the hydraulic system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

8.2.5 Connecting the electric equipment (accessory) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

8.2.6 Removing the stands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

8.3 Removing the front attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

8.3.1 Fitting the stands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

8.3.2 Disconnecting the hydraulic system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

8.3.3 Disconnecting the electric equipment (accessory) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

8.3.4 Removing universal drive shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

8.3.5 Unlocking the front attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

8.3.6 Unhitching front attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

67075

9 Driving and transportation

9.1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

9.1.1 General warnings - Driving and transportation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

9.1.2 Preparing road travel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

9.1.3 Preparing fieldwork . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

9.2 Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

9.2.1 Adjusting the diesel engine speed (DOMINATOR 150 / 140) . . . . . . . . . . . . . . . . . . . . . . . . 143

9.2.2 Starting the diesel engine (DOMINATOR 150 / 140) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

9.2.3 Stopping the diesel engine (DOMINATOR 150 / 140) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

9.2.4 Adjusting the diesel engine speed (DOMINATOR 130) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

9.2.5 Starting the diesel engine (DOMINATOR 130) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

9.2.6 Stopping the diesel engine (DOMINATOR 130) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

9.3 Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

9.3.1 Ground speed control lever (DOMINATOR 150 / 140) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

9.3.2 Shifting a gear (DOMINATOR 150 / 140) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

9.3.3 Ground speed control lever (DOMINATOR 130) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

9.3.4 Shifting a gear (DOMINATOR 130) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

9.3.5 Adjusting the ground speed control lever actuating resistance

(DOMINATOR 150 / 140) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

9.3.6 Driving behaviour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

8 00 0293 210 2 - BA DOMINATOR 150/140/130 - 12/09

Page 9

67075

9.3.7 Towing the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

9.3.8 Forward towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

9.3.9 Reverse towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

9.4 Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

9.4.1 Applying the parking brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

9.4.2 Releasing the parking brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

9.4.3 Foot brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

9.4.4 Braking / stopping the machine (DOMINATOR 150 / 140) . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

9.4.5 Braking / stopping the machine (DOMINATOR 130) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

9.4.6 Parking the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

9.5 Steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

9.5.1 Steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

9.5.2 Adjusting the steering column . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

9.6 Hitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

9.6.1 Hitching the trailer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

9.6.2 Unhitching the trailer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

9.7 Cab / Operator's platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

9.7.1 Adjusting the driver's seat with mechanical suspension (standard version) . . . . . . . . . . . . . . 166

9.7.2 Adjusting the driver's seat with mechanical suspension (standard version) . . . . . . . . . . . . . . 167

9.7.3 Adjusting the mechanically suspended driver's seat (option) . . . . . . . . . . . . . . . . . . . . . . . . . 169

9.8 Various components / Machine body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

9.8.1 Rotating the front ladder (standard) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

9.8.2 Adjusting the rear ladder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

10 Fieldwork settings

10.1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

10.1.1 General warnings - Fieldwork settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

10.2 Feeder unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

10.2.1 Adjusting the cutting height indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

10.2.2 Adjusting the scraper profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

10.2.3 Adjusting the height of the feeder chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

10.2.4 Adjusting the front attachment drop rate (DOMINATOR 150) . . . . . . . . . . . . . . . . . . . . . . . . 176

10.3 Threshing mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

10.3.1 Removing / installing threshing concave segments (Multicrop concave) . . . . . . . . . . . . . . . . 177

10.3.2 Adjusting the basic concave adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

10.4 Separation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

10.4.1 Adjusting the separation performance monitor sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

10.5 Cleaning unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

10.5.1 Checking / adjusting the fan speed display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

10.5.2 Adjusting the cleaning performance monitor sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

10.5.3 Removing the sieves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

10.5.4 Installing the sieves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

10.6 Crop receptacle / straw receptacle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

10.6.1 Removing the straw guide plate (straw chopper with standard spreader) . . . . . . . . . . . . . . . 185

10.6.2 Installing the straw guide plate (straw chopper with standard spreader) . . . . . . . . . . . . . . . . 186

10.6.3 Unscrewing the free-swinging knives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

10.6.4 Bolting down the free-swinging knives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

10.6.5 Straw chopper sieves installation position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

00 0293 210 2 - BA DOMINATOR 150/140/130 - 12/09 9

Page 10

10.7 Grain delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

10.7.1 Adjusting the grain tank full indicator DOMINATOR 150 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

11 Fieldwork

11.1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

11.1.1 General warnings Fieldwork . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

11.2 Description and function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

11.2.1 Cutterbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

11.2.2 Threshing mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

11.2.3 Straw walker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

11.2.4 Cleaning unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

11.2.5 Disawning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

11.3 Considerations before combining . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

11.3.1 When combining, remember: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

11.4 Front attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

11.4.1 Adjusting the reel horizontally (mechanically) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

11.4.2 Adjusting the reel horizontally (hydraulically) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

11.4.3 Adjusting the reel circumferential speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

11.5 Feeder unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

11.5.1 Reading the ground pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

11.5.2 Reading the cutting height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

11.5.3 Reversing the front attachment / feeder unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

11.5.4 Switching on the front attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

11.5.5 Disengaging the front attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

11.6 Threshing mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

11.6.1 Engaging the threshing mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

11.6.2 Disengaging the threshing mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

11.6.3 Adjusting the concave . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

11.6.4 Installing / removing the disawner bars (accessory) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

11.6.5 Unslugging the threshing drum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

11.6.6 Adjusting the threshing drum speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

11.6.7 Threshing drum two-step variable-speed drive (chain drive) . . . . . . . . . . . . . . . . . . . . . . . . . 212

11.7 Separation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

11.7.1 Adjusting the deflector curtain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

11.7.2 Observe the straw blockage warning downstream of the separation stage . . . . . . . . . . . . . 214

11.7.3 Adjusting the separation performance monitor display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

11.7.4 Installing / removing the straw walker fishback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

11.8 Cleaning unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

11.8.1 Adjusting the fan speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

11.8.2 Adjusting the wind board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

11.8.3 Adjusting the sieves manually . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

11.8.4 Adjusting the cleaning performance monitor display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

11.9 Crop receptacle / straw receptacle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

11.9.1 Putting the straw chopper into operation

(swinging the standard spreader to chopping position) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

11.9.2 Putting the straw chopper out of operation

(swinging the standard spreader to swathing position) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

11.9.3 Swinging the standard distributor into the transport trolley transport position . . . . . . . . . . . . 228

11.9.4 Adjusting the stationary knives (standard straw chopper) . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

67075

10 00 0293 210 2 - BA DOMINATOR 150/140/130 - 12/09

Page 11

11.10Grain delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

11.10.1 Inspecting the returns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

11.10.2 Opening / closing the grain tank cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

11.10.3 Swinging the grain tank unloading tube out / in (DOMINATOR 150 / 140) . . . . . . . . . . . . . . . 232

11.10.4 Swinging the grain tank unloading tube out / in (DOMINATOR 130) . . . . . . . . . . . . . . . . . . . 233

11.10.5 Engaging / disengaging the grain tank unloading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

11.10.6 Removing / installing the grain tank auger cover plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

11.10.7 Clean machine for bulk seed change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

11.11Sieve charts / threshing charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

11.11.1 Sieve table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

11.11.2 Threshing table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

11.12Disawning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

11.12.1 Disawner bars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

12 Faults and remedies

12.1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

12.1.1 General warnings Faults and remedy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

12.2 Cab / Operator's platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

12.2.1 Central terminal compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

12.2.2 Air conditioner faults and remedies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

12.3 Front attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

12.3.1 Front attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

12.4 Feeder unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

12.4.1 Feeder unit problem and remedy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

12.5 Threshing mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

12.5.1 Threshing mechanism problem and remedy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

12.5.2 Threshing drum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

12.6 Separation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

12.6.1 Separation problem and remedy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

12.7 Cleaning unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

12.7.1 Cleaning problem and remedy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

12.8 Crop receptacle / straw receptacle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

12.8.1 Crop / straw discharge problems and remedies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

12.9 Grain delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

12.9.1 Grain delivery problems and remedies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

12.9.2 Installing the grain tank unloading shear bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

67075

13 Maintenance

13.1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

13.1.1 General warnings Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

13.2 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

13.2.1 Front attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

13.2.2 Cleaning the engine compartment and hazard areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

13.2.3 Belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

13.2.4 Variable-speed drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

13.2.5 Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

13.2.6 Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

13.2.7 Cleanliness of lubricants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

13.2.8 Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

13.2.9 Wheels / tyres . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

00 0293 210 2 - BA DOMINATOR 150/140/130 - 12/09 11

Page 12

13.2.10Hydraulic system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

13.2.11Electrical system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

13.2.12Air conditioner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

13.2.13Protective guards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

13.2.14Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

13.2.15Unbalance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

13.2.16Welding work on combine harvester . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

13.2.17Putting the machine out of action . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

13.2.18Cleaning of surfaces with decals applied . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

13.2.19Winter storage instructions for combines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

13.2.20Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

13.3 Maintenance schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

13.3.1 Service intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

13.4 Lubricants chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

13.4.1 Lubricants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

13.5 Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

13.5.1 Overview of engine CATERPILLAR C-6.6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

13.5.2 Overview of engine CATERPILLAR 3056 E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

13.5.3 Overview of engine PERKINS 1006-6T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

13.5.4 Overview of cooling units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

13.5.5 Cleaning the diesel engine surroundings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

13.5.6 Draining fuel from the fuel tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

13.5.7 Fill up the machine's fuel tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

13.5.8 Cleaning the fuel tank filler screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

13.5.9 Closing / opening the fuel system shut-off tap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

13.5.10Bleed fuel system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

13.5.11Cleaning the fuel sediment bowl filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

13.5.12Draining condensation at the fuel prefilter (standard equipment) . . . . . . . . . . . . . . . . . . . . . 284

13.5.13Changing the fuel prefilter (standard equipment) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

13.5.14Draining condensation at the fuel prefilter (additional equipment) . . . . . . . . . . . . . . . . . . . . . 286

13.5.15Changing the fuel pre-filter (accessory) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

13.5.16Changing the fuel filter CATERPILLAR C-6.6 / 3056 E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

13.5.17Changing the fuel filter PERKINS 1006-6T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

13.5.18Checking the diesel engine oil level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

13.5.19Changing the diesel engine oil / oil filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

13.5.20Adjusting the diesel engine valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

13.5.21Checking the radiator coolant level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

13.5.22Checking the coolant mixing ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

13.5.23Changing the radiator coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

13.5.24Draining the radiator coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

13.5.25Topping up coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

13.5.26Cleaning the rotary chaff screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

13.5.27Cleaning the cooling unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

13.5.28Changing the coolant hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

13.5.29Cleaning / changing the diesel engine air cleaner with plastic housing . . . . . . . . . . . . . . . . . 301

13.5.30Changing the diesel engine air cleaner safety cartridge with plastic housing . . . . . . . . . . . . 303

13.5.31Cleaning the air filter intake screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

67075

12 00 0293 210 2 - BA DOMINATOR 150/140/130 - 12/09

Page 13

67075

13.5.32Changing the air intake hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

13.5.33Retightening the air intake tube clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

13.6 Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

13.6.1 Wheels / tyres . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

13.6.2 Checking the tightening torque of wheel nuts / wheel bolts . . . . . . . . . . . . . . . . . . . . . . . . . . 307

13.6.3 Cleaning the surroundings of the drive axle manual gearbox . . . . . . . . . . . . . . . . . . . . . . . . 308

13.6.4 Checking the final drive oil level DOMINATOR 150 / 140 . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

13.6.5 Draining the final drive oil DOMINATOR 150 / 140 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

13.6.6 Topping up the final drive oil DOMINATOR 150 / 140 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 310

13.6.7 Checking the final drive oil level DOMINATOR 130 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

13.6.8 Draining the final drive oil DOMINATOR 130 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

13.6.9 Topping up the final drive oil DOMINATOR 130 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

13.6.10Checking the drive axle gearbox oil level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

13.6.11Draining the oil from the drive axle gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 314

13.6.12Topping up oil in the drive axle gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315

13.6.13Adjusting the chassis clutch DOMINATOR 130 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 316

13.6.14Adjusting the short-circuit valve DOMINATOR 130 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 316

13.7 Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 318

13.7.1 Checking / refilling brake fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 318

13.7.2 Adjusting the parking brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 318

13.7.3 Adjusting the foot brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 319

13.8 Drive belts / drive chains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 320

13.8.1 General warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 320

13.8.2 Drive diagram, left side DOMINATOR 150 / 140 / 130 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321

13.8.3 Drive diagram, right side DOMINATOR 150 / 140 / 130 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322

13.8.4 Adjusting belt (R1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 323

13.8.5 Adjusting belt (R2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

13.8.6 Adjusting belt (R3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 325

13.8.7 Adjusting belt (R4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 326

13.8.8 Adjusting belt (R5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327

13.8.9 Adjusting belt (R8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 328

13.8.10Adjusting belt (R9) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 329

13.8.11Adjusting belt (R10) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 330

13.8.12Removing belt (R7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 331

13.8.13Installing belt (R7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 331

13.8.14Adjusting belt (R12) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 333

13.8.15Adjusting belt (R13) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 334

13.8.16Removing belt (R14) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 335

13.8.17Installing belt (R14) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 336

13.8.18Adjusting belt (R14) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 337

13.8.19Removing belt (R42) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 338

13.8.20Installing belt (R42) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 338

13.9 Hydraulic system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 340

13.9.1 Checking the hydraulic system oil level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 340

13.9.2 Changing the hydraulic system oil / oil filter / fresh air filter element

DOMINATOR 150 / 140 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 340

13.9.3 Changing the hydraulic system oil / oil filter / fresh air filter element

DOMINATOR 130 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 343

00 0293 210 2 - BA DOMINATOR 150/140/130 - 12/09 13

Page 14

13.10Electric system / Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

13.10.1Checking the battery electrolyte level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

13.11Cab / Operator's platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 348

13.11.1Cleaning / changing the cab air filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 348

13.11.2Cleaning the cab recirculation air filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 348

13.11.3Cleaning the cab roof units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 349

13.11.4Putting the air conditioner into operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 350

13.11.5Precautions for protecting the air conditioner during extended standstill periods -

DOMINATOR 130 with York compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 350

13.11.6Checking the air conditioner refrigerant moisture saturation . . . . . . . . . . . . . . . . . . . . . . . . . 350

13.11.7Changing the air conditioner refrigerant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 351

13.12Feeder unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 353

13.12.1Cleaning the feed rake conveyor retainers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 353

13.12.2Adjusting the feeder chains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 353

13.12.3Adjusting the feeder chain slip clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 354

13.12.4Checking the rasp plates on the feed rake conveyor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 355

13.13Threshing mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 356

13.13.1Cleaning the stone trap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 356

13.13.2Cleaning the threshing mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 356

13.14Separation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 358

13.14.1Cleaning the straw walker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 358

13.14.2Checking the deflector curtain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 359

13.14.3Cleaning the separation throughput monitor sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 359

13.15Cleaning unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 360

13.15.1Cleaning the cleaning throughput monitor sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 360

13.15.2Cleaning the fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 360

13.15.3Setting the fan speed gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 360

13.15.4Cleaning the stepped preparation floors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 361

13.15.5Cleaning the sieves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 362

13.16Grain delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 363

13.16.1Adjusting the returns elevator chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 363

13.16.2Adjusting the grain elevator chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 363

13.16.3Cleaning the auger troughs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 364

13.16.4Cleaning the grain tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 366

13.16.5Adjusting the grain tank unloading tube support transport position . . . . . . . . . . . . . . . . . . . . 366

13.17Various components / Machine body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 367

13.17.1Checking the fire extinguisher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 367

67075

14 Lubrication chart

14.1 Lubrication points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 368

14.1.1 General warnings Lubrication chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 368

14.1.2 Lubricants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 368

14.1.3 Greasing cycles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 369

14.1.4 Lubrication points - 10 h on the left . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 371

14.1.5 Lubrication points - 10 h on the right . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 372

14.1.6 Lubrication points - 50 h on the left . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 373

14.1.7 Lubrication points - 50 h on the right . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 374

14.1.8 Lubrication points - 100 h on the left . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 375

14.1.9 Lubrication points - 100 h on the right . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 377

14 00 0293 210 2 - BA DOMINATOR 150/140/130 - 12/09

Page 15

67075

14.1.10Lubrication points - 500 h on the left . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 378

14.1.11Lubrication points - 500 h on the right . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 379

00 0293 210 2 - BA DOMINATOR 150/140/130 - 12/09 15

Page 16

1 Introduction

1.1 General Information

1 Introduction

67077

1.1 General Information

102866

1.1.1 How to use this manual

This operator's manual is the original operator's manual. In the following texts, it will be referred to simply as

the operator's manual.

This operator's manual is intended for all users and

provides information on the use, operation, adjustment, maintenance, cleaning and transportation of the

machine.

Provided all instructions regarding proper maintenance

and operation of your machine are followed, you can

count on many years of reliable service.

Failure to perform maintenance or incorrect operation

lead to an increased safety risk, premature wear, a

reduction in performance, loss of earnings and time.

Have the post harvest check / annual check performed

regularly by your CLAAS dealer. A combination of the

prescribed maintenance work with the post harvest

check is recommended.

If you use the latest expertise and experience that

went into this machine, it will render you consistently

excellent service.

There is a separate operator's manual for front attachments and hitched devices.

Texts and figures

Pictures and graphics are neutral. Differences are

pointed out by notes beneath the figure.

Texts are short and not machine-specific as far as possible. Differences are pointed out by intermediate

headings.

Different types of texts can easily be distinguished

from one another by their formats. The following formats are distinguished:

Formatting Meaning Description

Description Text Further information on the subject.

– Instructions Operation Operations which must be carried out one after the

other.

Result Result Consequence of operations carried out.

16 00 0293 210 2 - BA DOMINATOR 150/140/130 - 12/09

Page 17

References can easily be distinguished by suitable

symbols. The following symbols are distinguished:

Symbol Meaning Description

See index The symbol indicates that further information on

this subject can be found at another point in this

manual.

1 Introduction

1.1 General Information

67077

See index of the relevant

Operator's manual

The symbol indicates that further information on

this subject can be found in the Operator's manual of

that machine or equipment.

Document structure based on subassemblies

As far as the contents permit, the chapters of this manual are structured according to subassemblies. The

structure of these subassemblies is the same in all

chapters.

Different product groups have different document

structures based on subassemblies. CLAAS always

takes care to keep these document structures based

on subassemblies identical in any documents.

Search and find

The wanted subject can easily be found with the recurring subassembly structure, using the table of contents

or the header line of this manual.

In addition, the index of this manual is a useful tool for

locating a specific subject. The index can be found on

the last pages of this manual.

Directions

Text elements such as front, rear, right and left always

apply to the direction of travel. In figures, the direction

of travel may be indicated by a direction arrow.

Optional equipment and accessories

Optional equipment includes equipment variants of the

machine where different variants are available, but

only one variant can be fitted.

Accessories are equipment items that may be additionally fitted to the machine, but are not included in

the standard scope of the machine.

Both terms designate possible variants. Standard

scopes and equipment variants may differ in other

countries.

Your CLAAS Service Department

00 0293 210 2 - BA DOMINATOR 150/140/130 - 12/09 17

Page 18

1 Introduction

1.1 General Information

1.1.2 Validity of instructions

The present Manual applies to the following machine /

front attachment:

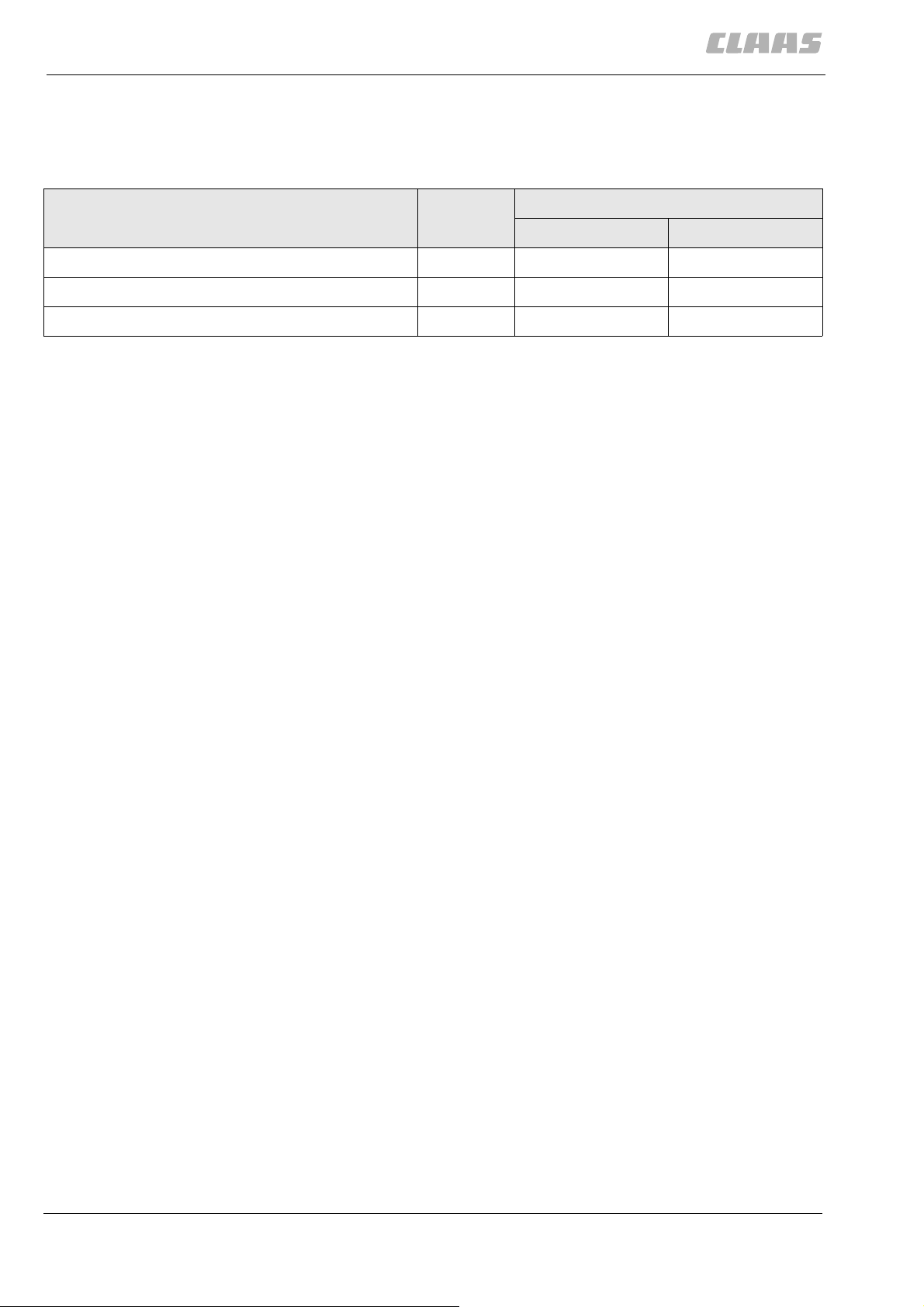

Designation Type Machine serial number

from to

DOMINATOR 150 200 200 00011 ―

DOMINATOR 140 200 200 00011 ―

DOMINATOR 130 156 156 00011 ―

1.1.3 Specifications

Technical data, dimensions and weights are given as

an indication only. CLAAS reserves the right to make

changes subsequently as technical developments continue. Responsibility for errors or omissions not

accepted.

1.1.4 Road traffic regulations

67077

71369

2475

36993

Road traffic regulations may vary between countries.

In case of discrepancies between the instructions provided by the manufacturer and the traffic regulations of

the relevant countries, the traffic regulations of the

countries concerned apply.

The information below mainly refers to the Federal

Republic of Germany.

Before driving on public roads, the self-propelled working machine usually needs an operating permit and a

special approval.

When driving the self-propelled working machine on

public roads and lanes, all conditions of the operating

permit and of the special approval must be observed.

Documents to be carried on the machine

In addition to his driving licence, the operator must

always carry the original of the operating permit and of

the special approvals.

Objects to be carried on the machine

A warning triangle must be carried on all self-propelled

working machines.

On all commercially used machines, a warning

triangle, a warning light and a first-aid box must be

carried along.

Furthermore, at least one wheel chock must be carried

on vehicles with an allowed total weight above 4 t.

CLAAS self-propelled working machines are usually

equipped with 1 rigid or 2 folding wheel chocks. These

may be used on the front wheels only.

18 00 0293 210 2 - BA DOMINATOR 150/140/130 - 12/09

Page 19

1 Introduction

1.1 General Information

67077

Excess-width machines

In case of excess-width self-propelled working

machines (width exceeding 3 m across tyres), an individual operating permit based on an individual expert's

opinion, a special approval according to § 70, sect. 1

of the German Regulations Authorising the Use of

Vehicles for Road Traffic and a special approval

according to § 29 of the German Regulations Authorising the Use of Vehicles for Road Traffic must be

carried along.

All conditions and notes specified there must be

observed. Especially the information regarding the

marking of excess-width road vehicles must be complied with (two red/white marker boards each at the

front and rear, two amber flashing warning beacons).

The granting of the special approval and permits is

subject to different regulations in every Federal State.

Information can usually be obtained from your road

traffic authorities in charge.

Additional weights

Self-propelled machines with rear axle steering and fitted with front attachments approved by CLAAS must

be equipped with additional weights on the rear axle

when driving on public roads.

This is required in order to prevent the machine from

lifting off at the rear when braking and on slopes and to

maintain the steering function.

The required additional weights can be made up of

implements, rear axle weights and liquid filling in the

rear axle tyres.

Depending on the type of front attachment and the

equipment fitted to the machine, the rear of the selfpropelled machine must be ballasted.

Detailed information on this matter can be obtained

from CLAAS.

Modifications to the machine

When parts of the machine whose condition is prescribed are subsequently modified or installed, the

operation of which may endanger other road users, the

Operating permit (individual operating permit) and the

special approval expire.

To obtain a new individual operating permit, it is necessary to present the machine to the responsible

technical inspection agency (TUEV, DEKRA) in order

to prepare an individual expert's opinion according to

§ 19 of the German Regulations Authorising the Use of

Vehicles for Road Traffic.

If you are in any doubt as to whether this situation

applies in your case, please contact CLAAS as the

manufacturers.

00 0293 210 2 - BA DOMINATOR 150/140/130 - 12/09 19

Page 20

1 Introduction

1.1 General Information

67077

Towing a trailer

A trailer for front attachments may be towed in accordance with the permissible trailed load.

If a trailer is towed behind the machine, then the cable

for the entire lighting system must be connected and

the good condition of the lighting system assured.

In addition, particular care should be taken to properly

latch the trailer hitch.

The towing of other trailers in the trailer hitch is not

permitted in self-propelled combine harvesters when

driving on public streets.

Licence plates

All CLAAS self-propelled working machines must be

marked with 3 speed signs at the longitudinal sides

and at the rear according to § 58 of the German Regulations Authorising the Use of Vehicles for Road

Traffic.

As a self-propelled working machine with a maximum

speed of up to 20 km/h, the machine is only subject to

the operating permit. No official licence plate is

required.

According to § 4 FZV however, the machine must be

permanently fitted with the first and last name and the

place of residence (company and headquarters) of the

vehicle owner on the left side which must be clearly

legible.

As a self propelled working machine with an allowed

maximum speed of above 20 km/h, the machine is

subject to having an operating permit and to having