Page 1

DISCO 8500C (Tractor)

DISCO 8500C-6, -8

(until serial no.: 652 01278)

DISCO, CORTO, VOLTO, LINER

(JAGUAR)

Technical Systems

Page 2

Hydraulic / Electric System JAGUAR 8550C TIC

10/04

Page 3

TIC JAGUAR 8550C Hydraulic / Electric System

Chapter 1 JAGUAR 8500 C,

JAGUAR 8500 C- 6,

JAGUAR 8500 C- 8

2 DISCO 8500 C

3 CORTO 8100 F/T

4 LINER 3000,

LINER 1550 TWIN,

LINER 650 TWIN

5 VOLTO 1050,

VOLTO 870H

6 DISCO 3000TC, TRC, AS, FG

CORTO 3100, 300, 252, 250

10/04

Page 4

Hydraulic / Electric System JAGUAR 8550C TIC

10/04

Page 5

TIC JAGUAR 8550C Hydraulic / Electric System

Hydraulic System...................................................................................................................................2

1.0

1.1

JAGUAR 8500C-6, C-8 hydraulic circuit diagram................................................................................2

1.2 Function ...............................................................................................................................................8

Electric system JAGUAR 8500C, CISCO 8500C-6, -8.......................................................................14

2.0

2.1

Electric circuit diagram.......................................................................................................................14

2.2 Function .............................................................................................................................................16

2.3 Central terminal compartment............................................................................................................20

3.0 Installation information.......................................................................................................................24

3.1

Timing of drives..................................................................................................................................24

3.2 Installation of pinion units...................................................................................................................25

3.3 Safety module ....................................................................................................................................26

3.4 Tightening torques .............................................................................................................................27

4.0 Drive diagram.......................................................................................................................................28

Attention The description of the Jaguar 8500C also applies to

- Disco 8500C-6

- Disco 8500C-8

The only exception is: The Reed switch (75) does not exist on the

Disco 8599C-6.

10/04 1-1

Page 6

Hydraulic / Electric System JAGUAR 8550C TIC

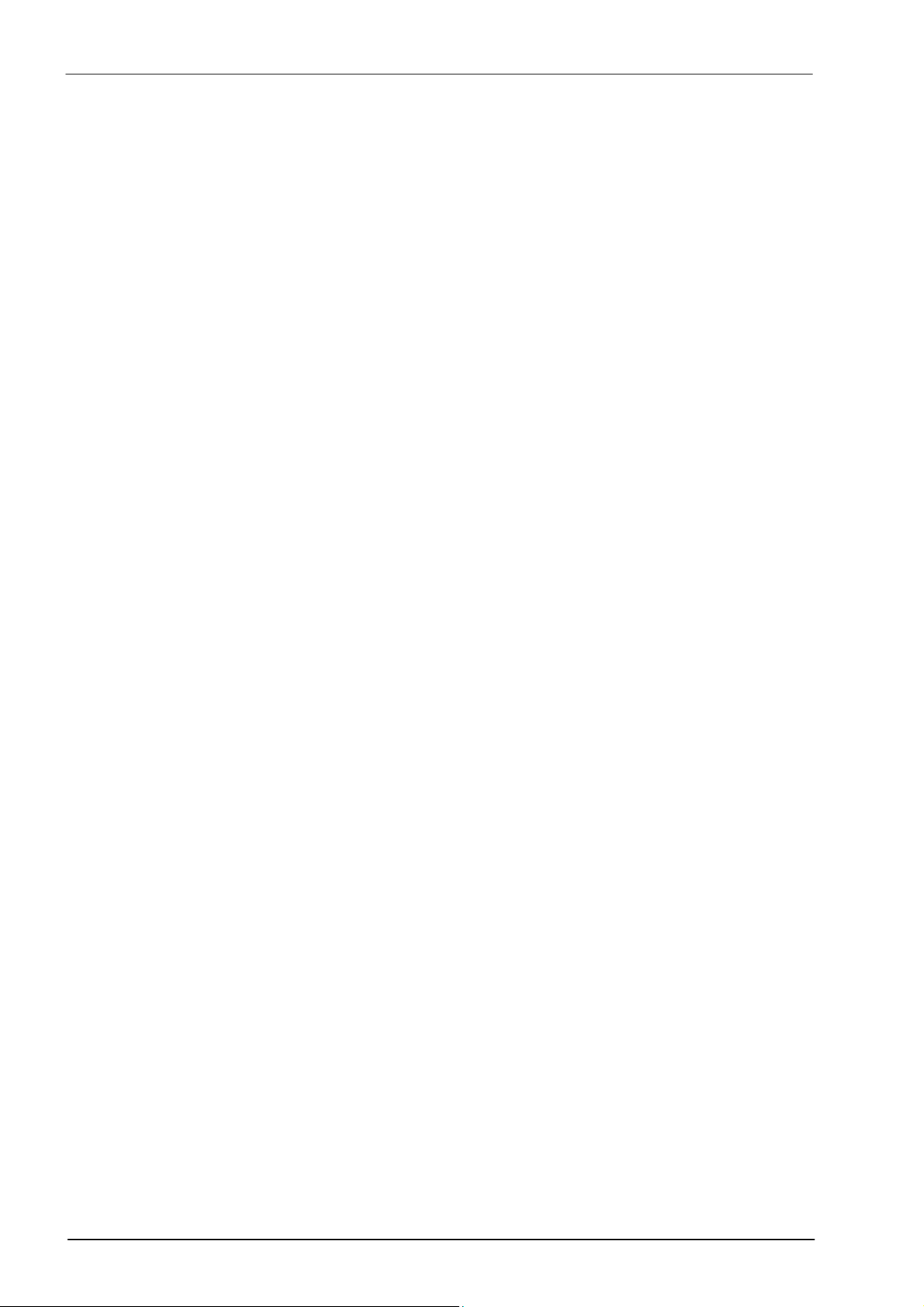

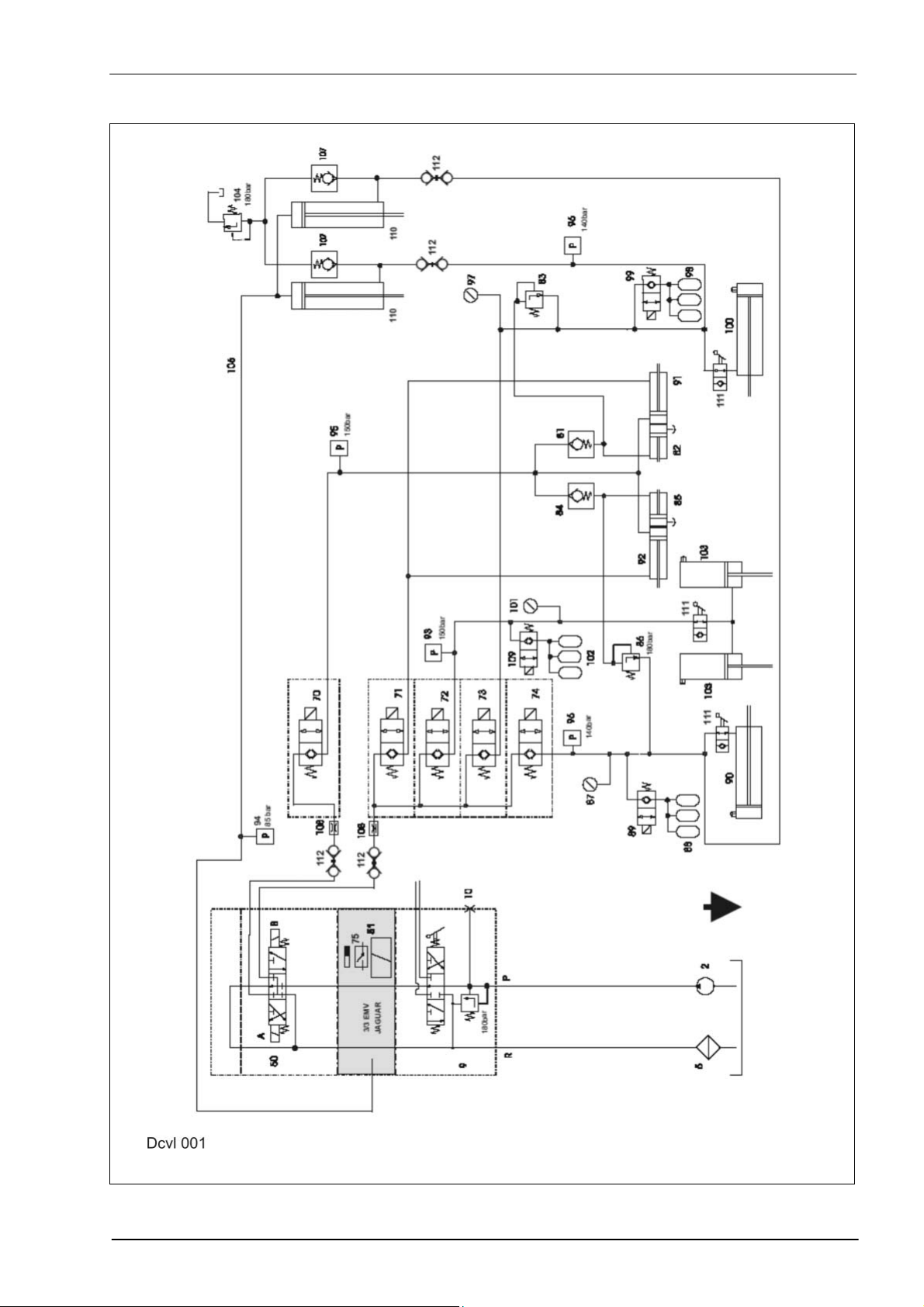

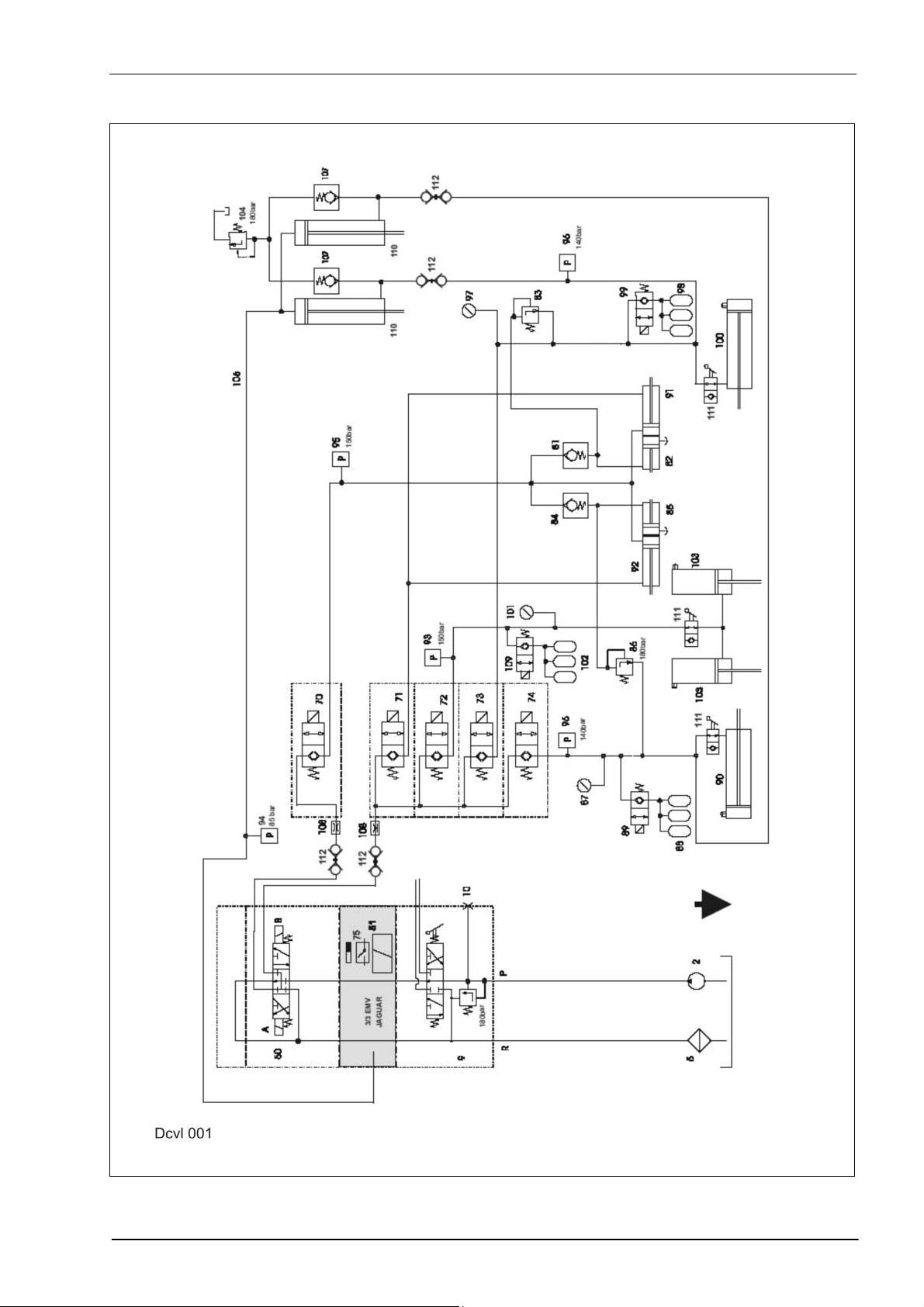

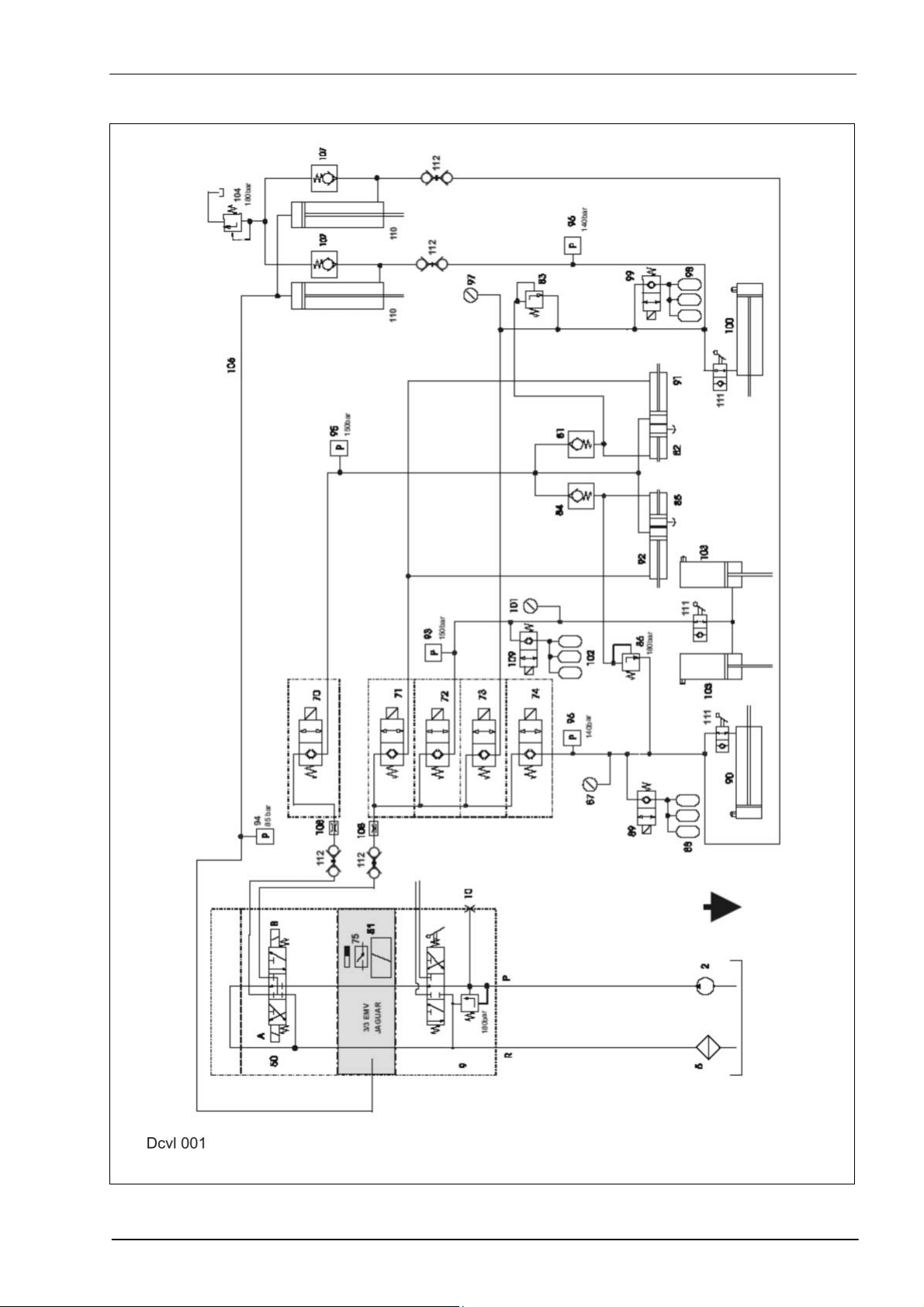

1.0 Hydraulic System

1.1 JAGUAR 8500C-6, C-8 hydraulic circuit diagram

2 Lift hydraulics pump, 12 cm³/rev.

5 Oil filter, lift hydraulics, mesh size 0.06 mm

9 Pressure relief valve with 4/3 way valve, square tube adjustment

10 Pressure gauge connection, lift hydraulics

50 4/3 way solenoid valve, double-acting, for front attachments (series equ.)

51 3/3 way solenoid valve, lift front attachment

70 2/2 way solenoid valve, fold out right and left mower unit

71 2/2 way solenoid valve, fold in right and left Disco

72 2/2 way solenoid valve, raise/lower centre mower unit

73 2/2 way solenoid valve, raise/lower left mower unit

74 2/2 way solenoid valve, raise/lower right mower unit

75 Reed switch (mounted on 3/3 way solenoid valve item 51 = only on

Jaguar 800 series)

81 Non-return valve, left mower unit

82 Hydraulic cylinder, left mower unit, starting protection

83 Pressure relief valve 180 bar

84 Non-return valve, right mower unit

85 Hydraulic cylinder, right mower unit, starting protection

86 Pressure relief valve 180 bar, right mower unit

87 Pressure gauge, right mower unit ground pressure

88 Right mower unit accumulator, charge pressure 35 bar, 0.75 litres

89 Right mower unit lock-up valve unit

(2/2 way solenoid valve, closed when deenergized)

90 Right mower unit raise/lower hydraulic cylinder

91 Left mower unit fold in/out hydraulic cylinder

92 Right mower unit fold in/out hydraulic cylinder

93 Oil pressure switch 150 bar (normally open contact)

94 Oil pressure switch 85 bar (normally open contact)

95 Oil pressure switch 150 bar (normally open contact)

96 2 oil pressure switches 140 bar (normally closed contact)

97 Pressure gauge, left mower unit ground pressure

98 Left mower unit accumulator, charge pressure 35 bar, 0.75 litres

99 Left mower unit lock-up valve unit

(2/2 way solenoid valve, closed when deenergized)

100 Hydraulic cylinder, left mower unit

101 Pressure gauge, centre mower unit ground pressure

102 Centre mower unit accumulator, charge pressure 35 bar, 0.75 litres

103 Centre mower unit raise/lower hydraulic cylinder

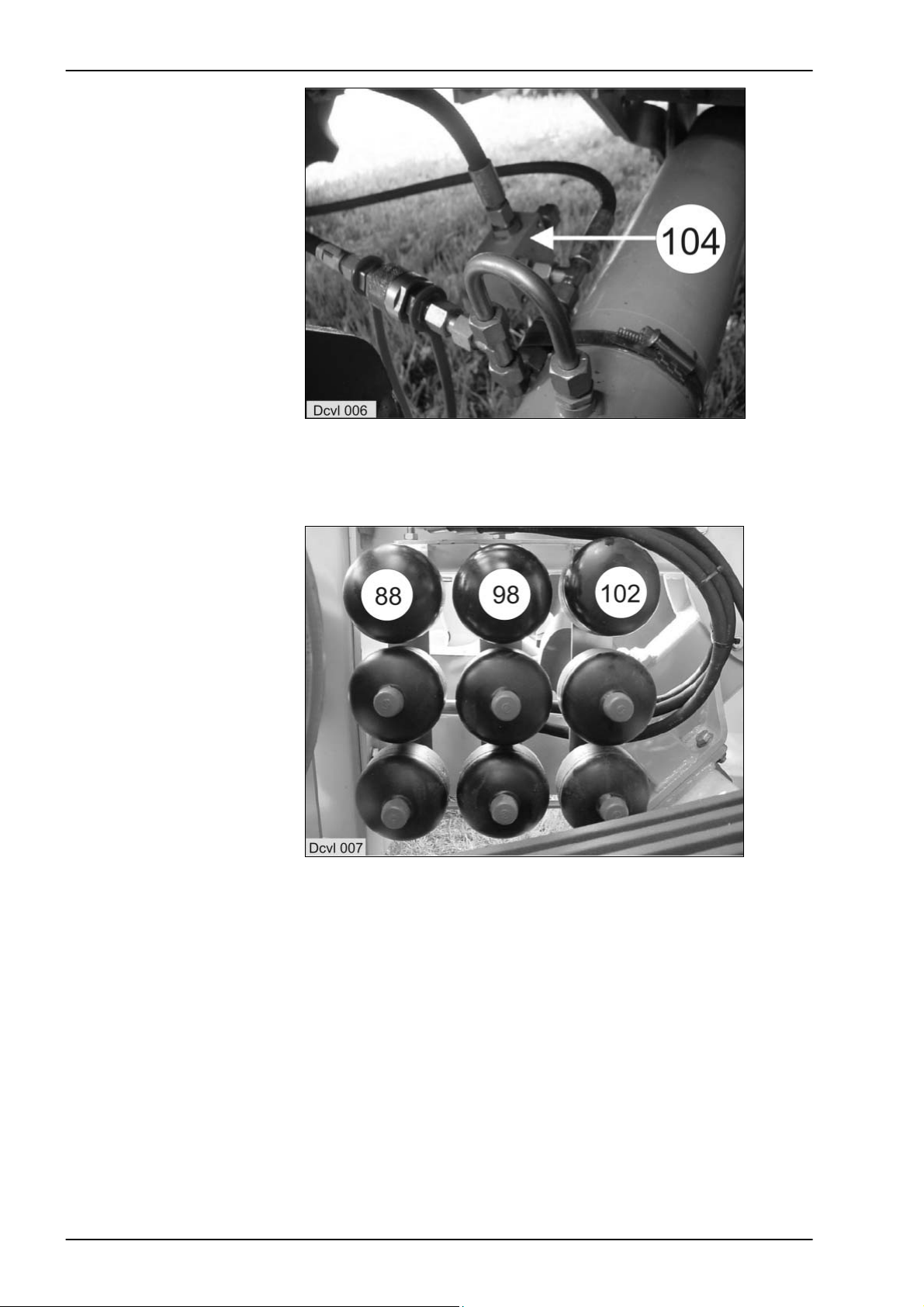

104 Pressure relief valve 180 bar

(Jaguar 800 series on the left of the front attachments cylinder,

Jaguar 600 series on the right of the front attachments cylinder)

106 Line to the front attachment cylinders

107 Non-return valve

108 Orifice plate Ø 1.2 mm

109 Centre (front) mower unit lock-up valve unit

(2/2 way solenoid valve, closed when deenergized)

110 Double acting front attachment cylinder, for 8500C, 8500C-6, -8

111 Shut-off tap

112 Screwed coupling

1-2 10/04

Page 7

TIC JAGUAR 8550C Hydraulic / Electric System

JAGUAR 8500 C-6 / C-8 hydraulic circuit diagram

10/04 1-3

Page 8

Hydraulic / Electric System JAGUAR 8550C TIC

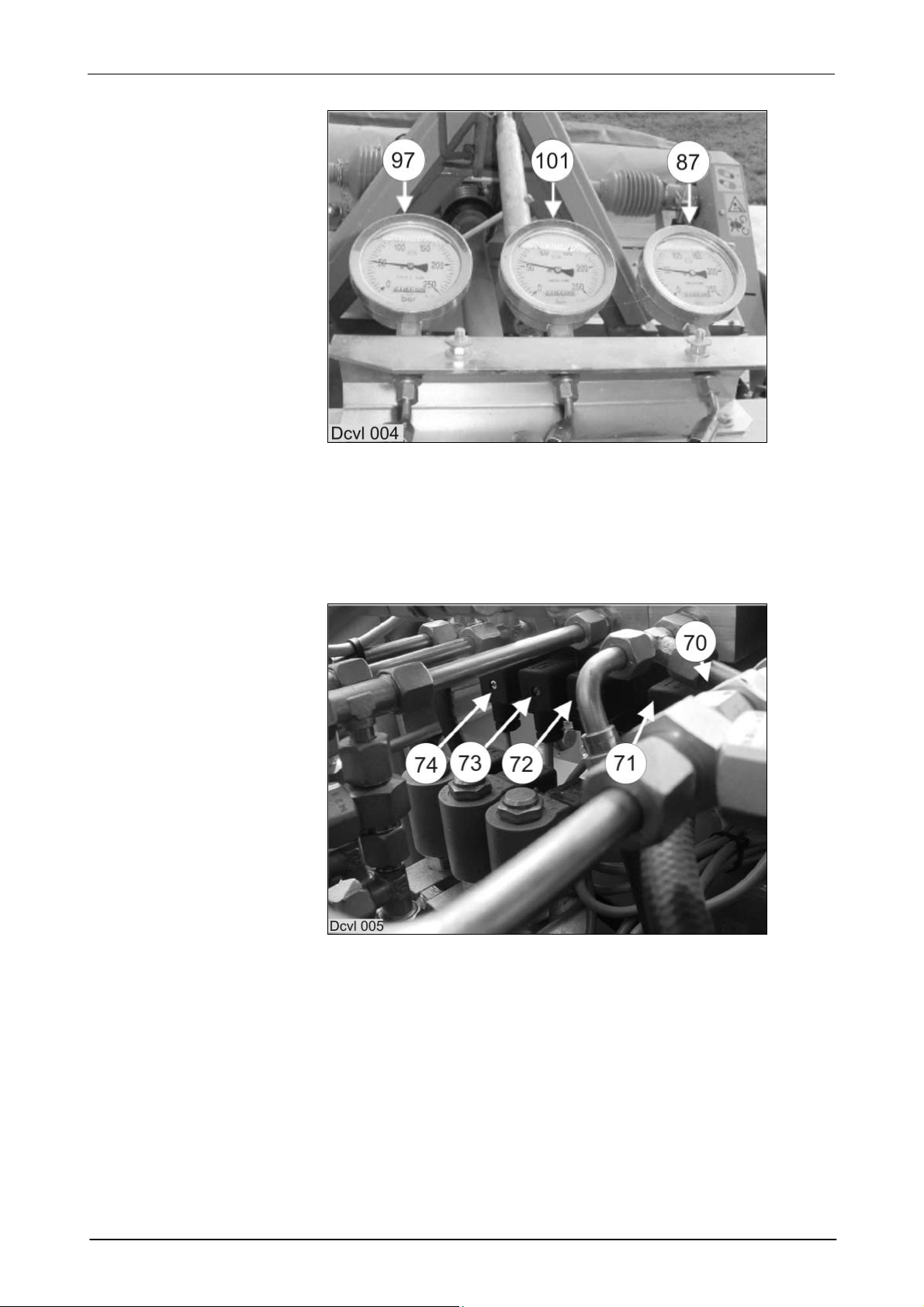

Directional control valves

subassembly

Jaguar 800 series, left side

75 Reed switch

94 Oil pressure switch 85 bar

Attention

The lettering on the Reed switch (75) must face the lift magnet of the 3/3

way solenoid valve = safe switching (the Reed switch in the picture is not

properly mounted).

Directional control valves,

oil pressure switches and

pressure relief valves

(under the cover)

74 2/2 way solenoid valve, raise/lower right mower unit

Next to this: the other Bucher directional control valves 73, 72, 71 and 70.

83 Pressure relief valve 180 bar (left mower unit)

86 Pressure relief valve 180 bar (left mower unit)

89 Right mower unit lock-up valve unit

(2/2 way solenoid valve, closed when deenergized)

93 Oil pressure switch 150 bar (normally open contact), front mower unit

96L Oil pressure switch 140 bar (normally closed contact), left mower unit

96R Oil pressure switch 140 bar (normally closed contact), right mower unit

95 Oil pressure switch 150 bar (normally open contact), fold out mower units

99 Left mower unit lock-up valve unit

(2/2 way solenoid valve, closed when deenergized)

109 Front mower unit lock-up valve unit

(2/2 way solenoid valve, closed when deenergized)

1-4 10/04

Page 9

TIC JAGUAR 8550C Hydraulic / Electric System

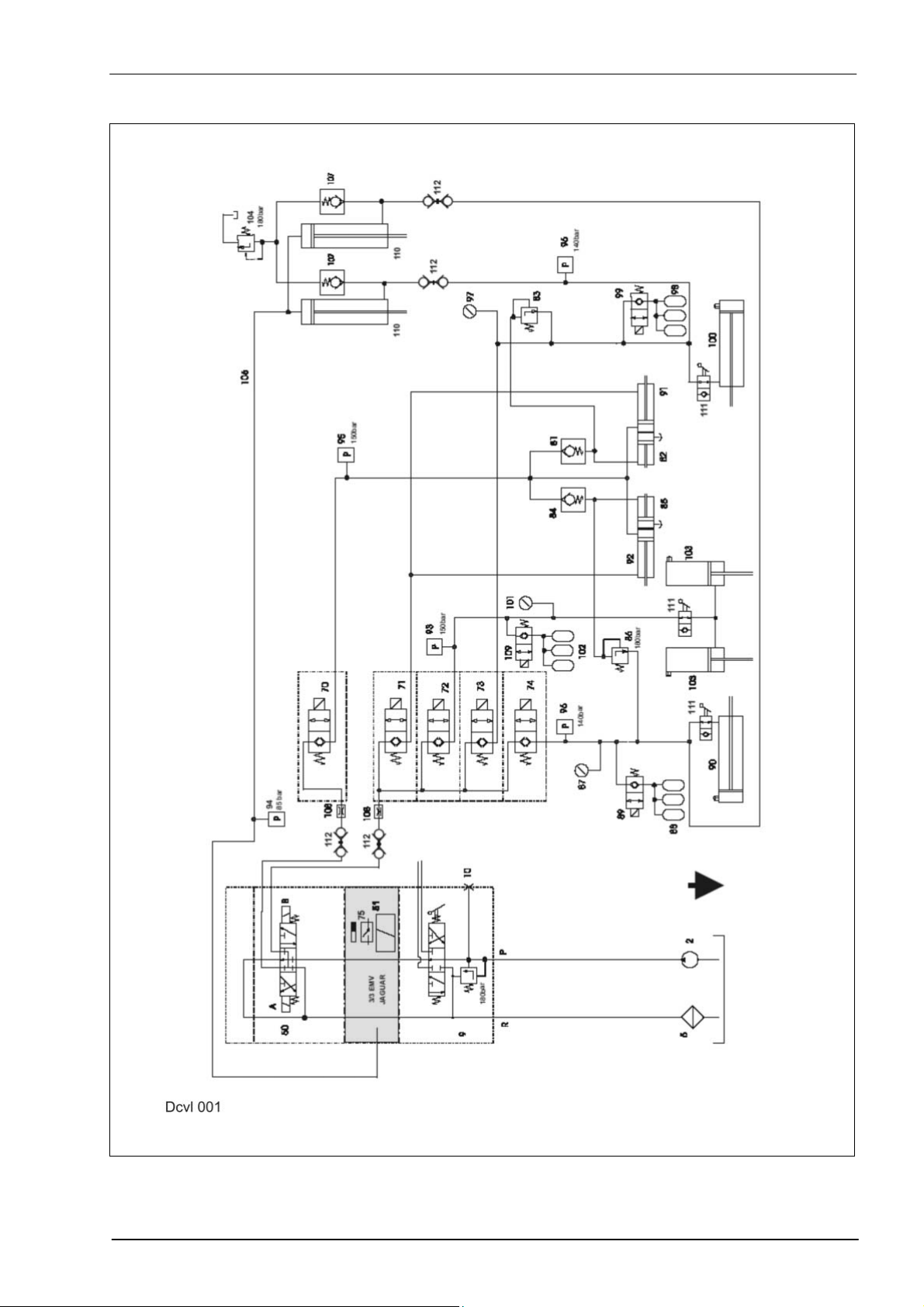

Pressure gauge for

ground pressure

Bucher 2/2 way valves

(under the cover)

87 Pressure gauge, right mower unit ground pressure

97 Pressure gauge, left mower unit ground pressure

101 Pressure gauge, centre mower unit ground pressure

All pressure gauges show a ground pressure of 50 bar with the mower

units lowered (working position).

70 2/2 way solenoid valve, fold out right and left mower unit

71 2/2 way solenoid valve, fold in right and left mower unit

72 2/2 way solenoid valve, raise/lower centre mower unit

73 2/2 way solenoid valve, Disco left load relief

74 2/2 way solenoid valve, Disco right load relief

10/04 1-5

Page 10

Hydraulic / Electric System JAGUAR 8550C TIC

Jaguar front attachment

cylinder pressure relief

valve

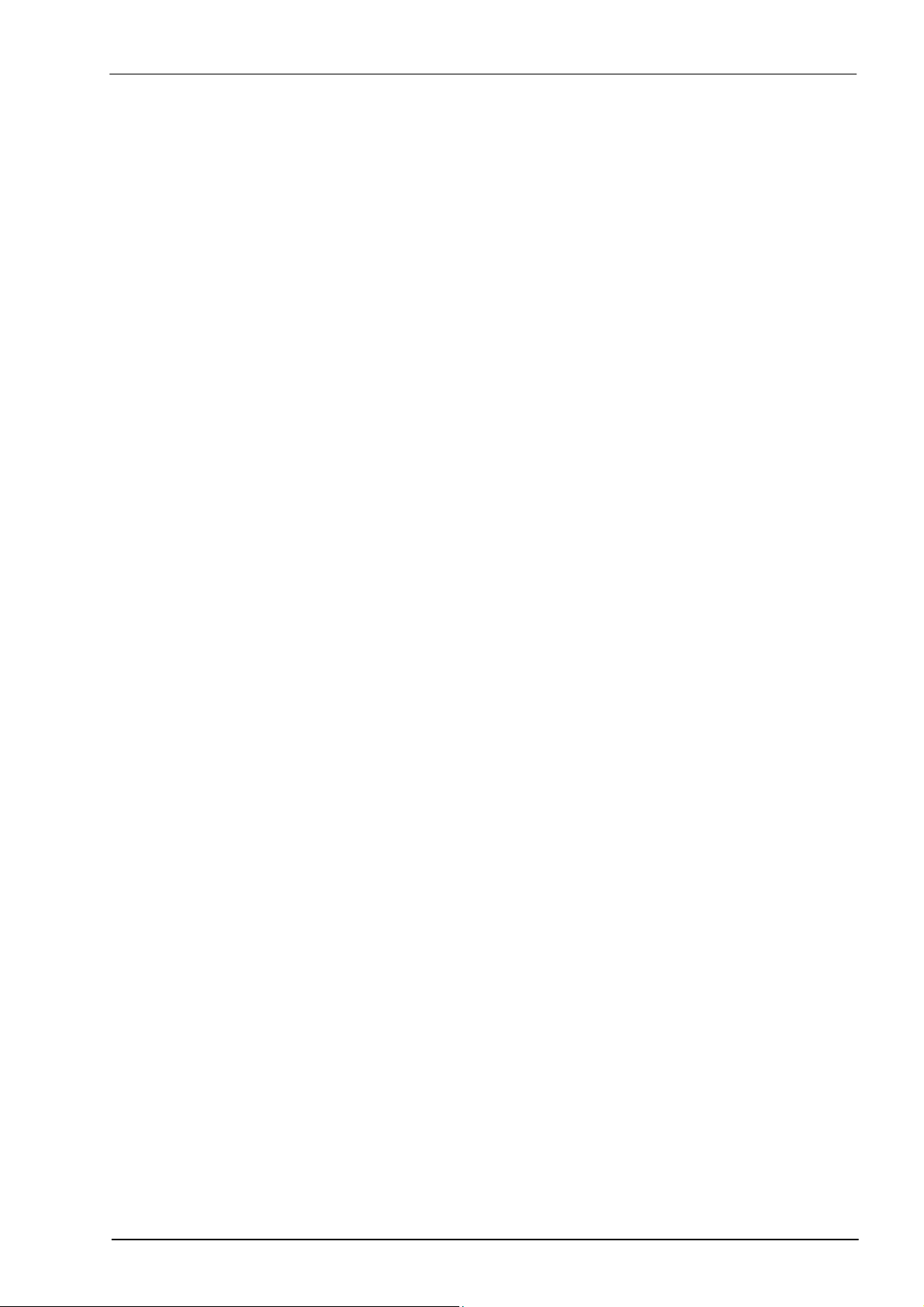

Accumulator

behind the right-hand cover

104 Pressure relief valve 180 bar

Jaguar 800 series on the left of the front attachments cylinder,

Jaguar 600 series on the right of the front attachments cylinder

1-6 10/04

88 3 x right mower unit accumulator, charge pressure 35 bar, 0.75 litres

98 3 x left mower unit accumulator, charge pressure 35 bar, 0.75 litres

102 3 x centre mower unit accumulator, charge pressure 35 bar, 0.75 litres

Page 11

TIC JAGUAR 8550C Hydraulic / Electric System

10/04 1-7

Page 12

Hydraulic / Electric System JAGUAR 8550C TIC

1.2 Function

1.2.1 Actuate from

transport to working

position

Caution:

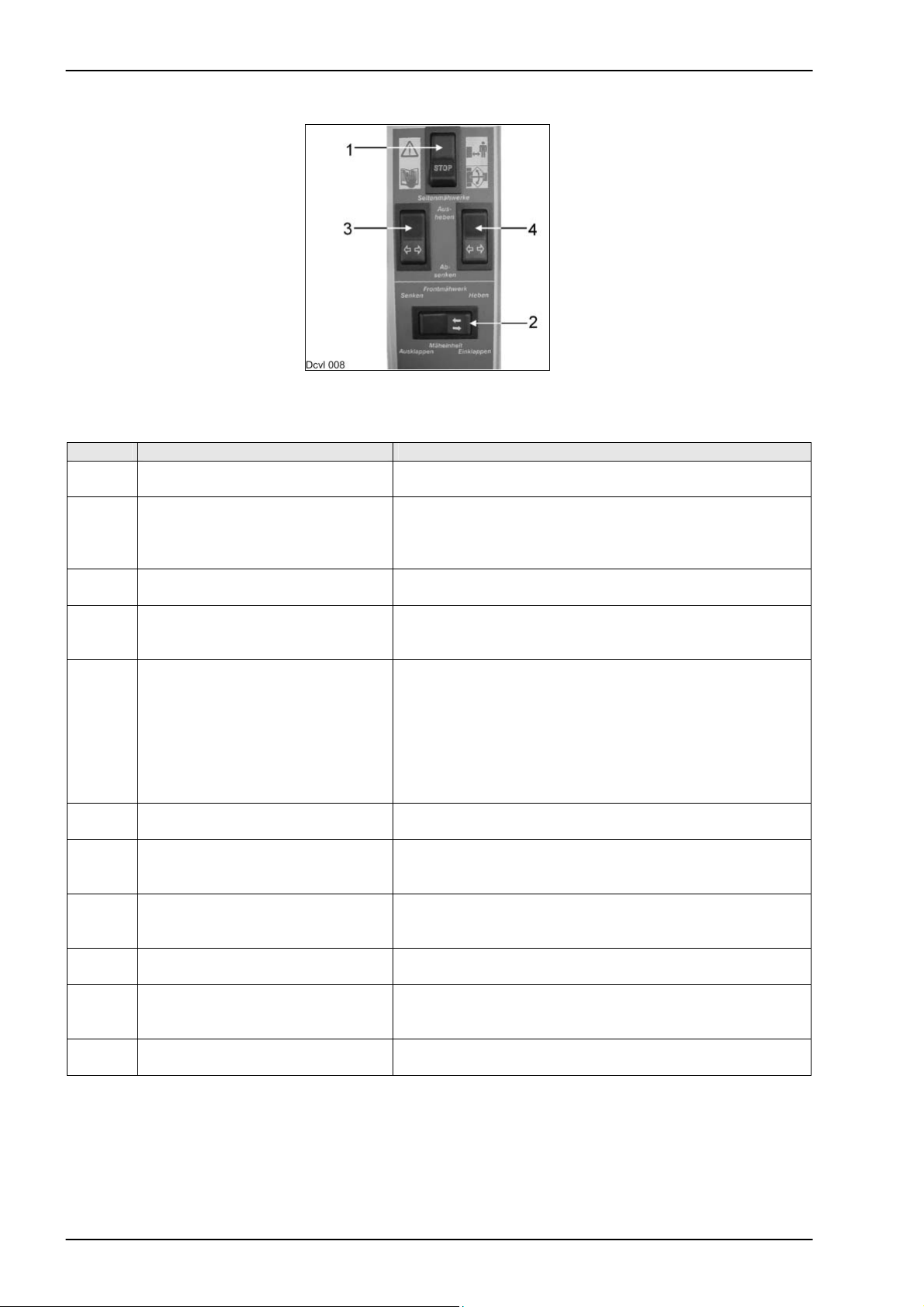

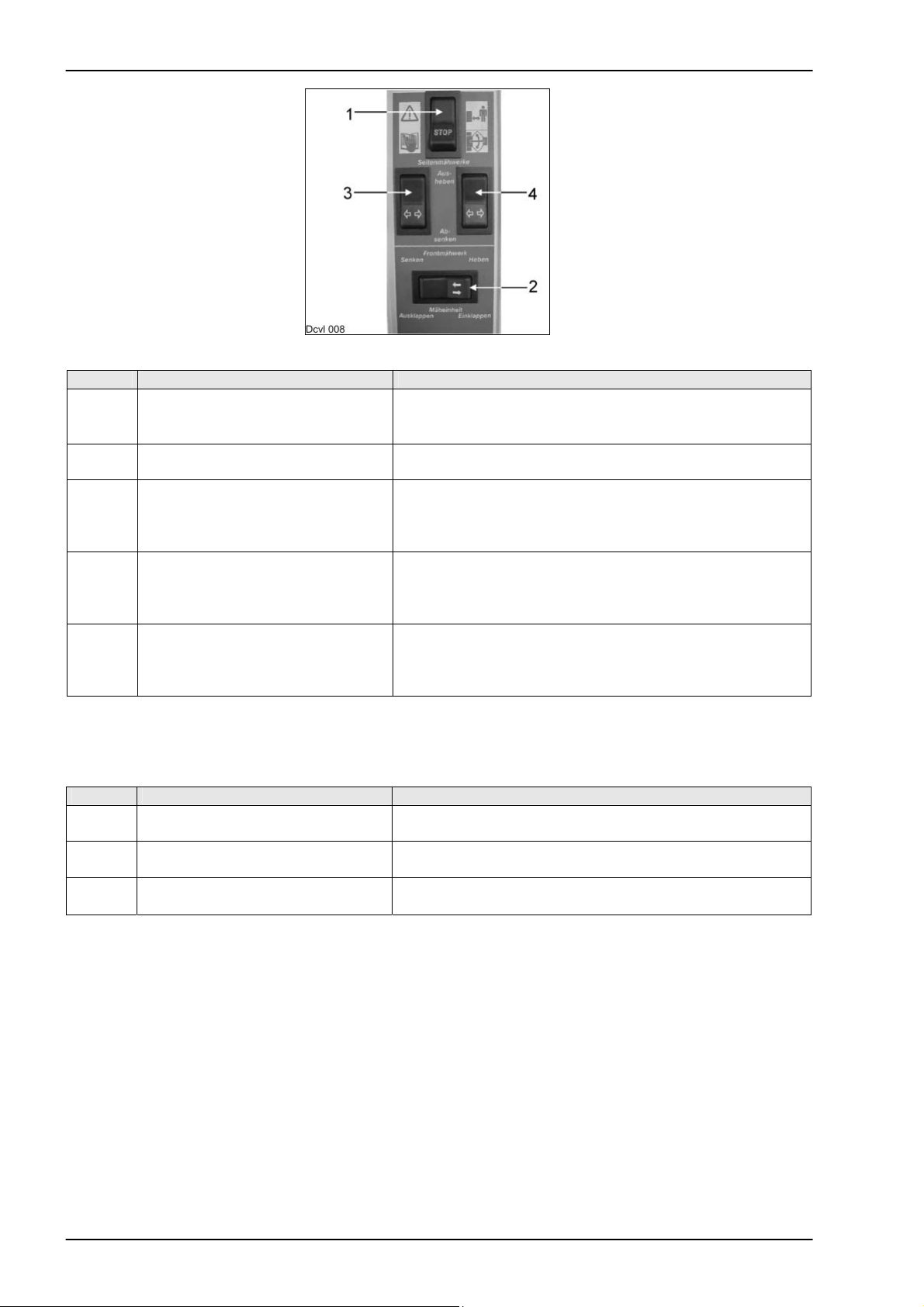

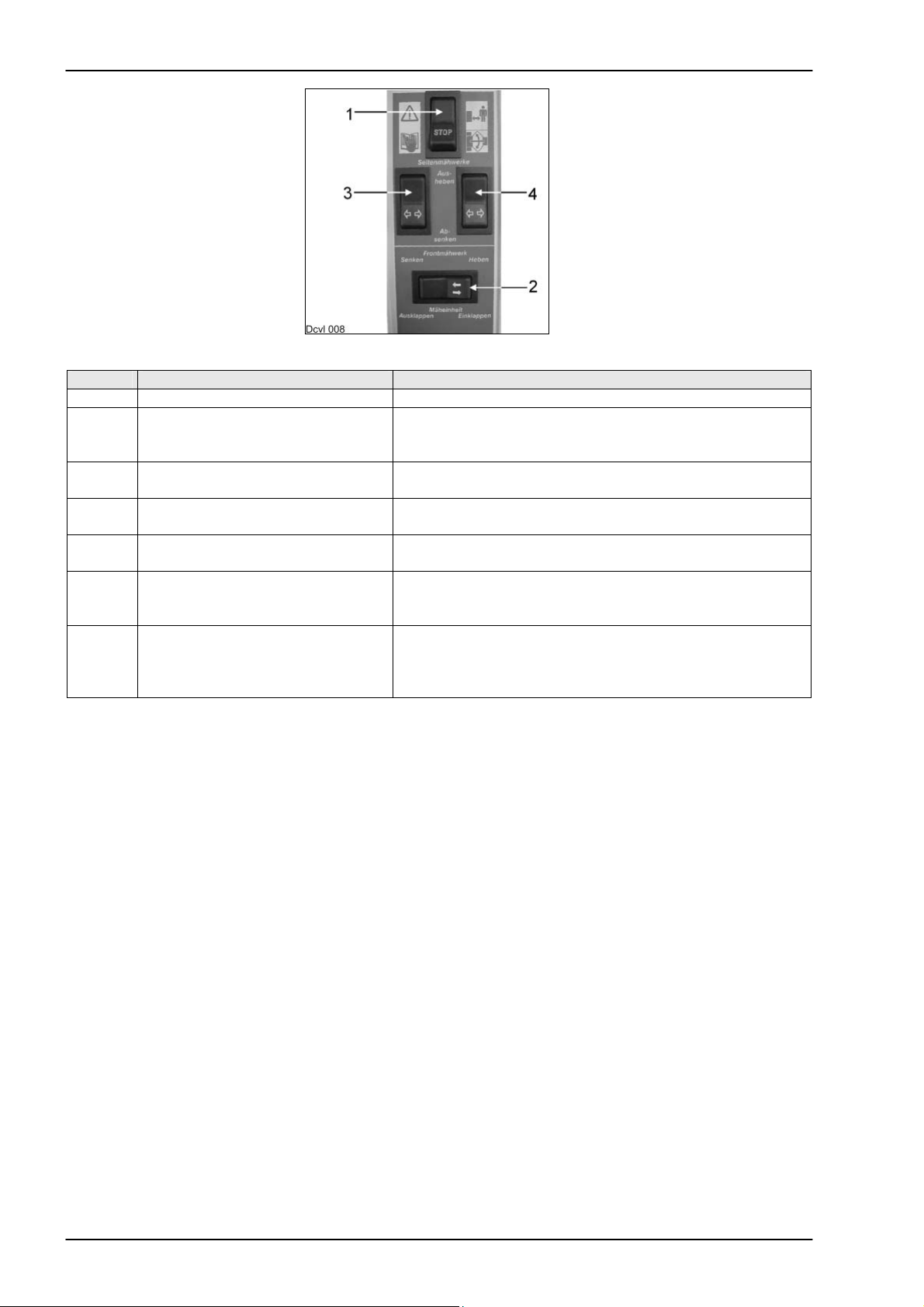

1 = Main switch ON-OFF. Set to OFF when parking the machine.

Step Action Reaction

1 Switch 2 on the CCT is actuated to

the right

Solenoid valve 50 goes to position B.

Volume flow goes to the solenoid valves 71, 72, 73 and 74.

2 Solenoid valve 72 is triggered The applied volume flow goes to cylinder 103.

The front mower unit is raised to its end position = the

pressure rises and oil pressure switch 93 switches at

3 Solenoid valves 70 and 71 are

triggered.

4 The displaced volume flow from the

ram top space flows to the tank via

the energized solenoid valve 70.

5 Switch 2 on the CCT is actuated to

the left

150 bar.

Volume flow goes to the rod spaces of cylinder 91 and 92

via the solenoid valve 71.

The side-mounted mower unit are folded in.

The lock can be released.

Solenoid valve 50 goes to position A.

Solenoid valves 70 and 71 are triggered. This makes

volume flow flow through solenoid valves 70:

into cylinders 82 and 85 (but also the non-return valves 81

and 84).

into cylinders 91 and 92. The side-mounted mower units

are now folded out and the starting protections are

6 Cylinders travel against their end

stop

activated.

Pressure switch 95 switches at a pressure of 150 bar.

7 Solenoid valve 72 is triggered Volume flow from cylinders 103 flows through 72 and

solenoid valve 50 (position A) into the tank. The front

8 The lower command for the left

mower unit is issued on the control

terminal (switch 3).

9 Volume flow from cylinder 100

mower unit is lowered.

Solenoid valve 50 goes to position A.

Solenoid valve 73 is energized.

The left mower unit is lowered.

flows into the tank.

10 The lower command for the right

mower unit is issued on the control

terminal (switch 4).

11 Volume flow from cylinder 90 flows

into the tank.

Solenoid valve 50 goes to position A.

Solenoid valve 74 is energized.

The right mower unit is lowered.

During work, the working pressures of all cylinders are supported by the accumulators 88, 98 and 102. The

lock-up valve units are opened at switch 94 below 80 bar. When the pressure rises to above 85 bar, the

lock-up valve units are closed and the mower units remain in their position. The ground pressure of the

mower units can be seen on pressure gauges 87, 97 and 101.

1-8 10/04

Page 13

TIC JAGUAR 8550C Hydraulic / Electric System

JAGUAR 8500 C-6 / C8 hydraulic circuit diagram

10/04 1-9

Page 14

Hydraulic / Electric System JAGUAR 8550C TIC

1.2.2 Raising the entire

mower unit

Step Action Reaction

1 The “Raise front attachment”

button on the forage harvester is

pressed.

Via the 3/3 way solenoid valve of the jaguar (line 106),

volume flow goes to the ram rod end of lifting cylinders

(110).

2 The mower unit is raised. When a pressure of 85 bar is reached while raising, the

pressure switch 94 (normally open contact) switches.

3 The relays 12 and 15 now cut the

power supply to the lock-up valve

units 89, 99 and 109.

4 The volume flow displaced from the

rod spaces of the cylinders (on the

The lock-up valve units are closed. This is required to keep

all mower units raised while raising the overall mower unit.

(The oil does not flow into the accumulators 88, 98 and

102.)

The cylinders 90 and 100 retract and thus raise the left and

right mower units.

forage harvester) is fed to the

cylinders 90 and 100.

5 When the volume capacity of the

rod spaces of cylinders 90 and 100

is exhausted,

the pressure rises and the pressure switches 96 switch the

lock-up valve units 89 and 99 so that the excess volume

flow is displaced into the accumulators 88 and 98. This

ensures that no oil will escape from this circuit.

1.2.3 Starting protection

Step Action Reaction

1 If e.g. the right mower unit hits an

obstacle.

2 When the pressure reaches

180 bar,

3 Volume flow is displaced from the

rod space of cylinder 85.

The pressure in rod space of cylinder 85 rises.

the pressure relief valve 86 opens.

This volume flow goes to the rod space of cylinder 90. The

right mower unit is raised and folds in.

1-10 10/04

Page 15

TIC JAGUAR 8550C Hydraulic / Electric System

JAGUAR 8500 C-6 / C8 hydraulic circuit diagram

10/04 1-11

Page 16

Hydraulic / Electric System JAGUAR 8550C TIC

1.2.4 Actuating from

working to

transport position

Step Action Reaction

1 Shut down the mower unit. The mower discs must not rotate any more.

2 Push the “Raise” key in the ground

until the mower units have no more ground contact.

speed control lever (3/3 way

solenoid valve is energized)

3 Push switch 2. Solenoid valve 72 is energized.

Solenoid valve 50 goes to switch position B.

4 Volume flow goes to hydraulic

The cylinders 103 raise the centre mower unit.

cylinders 103.

5 Cylinders 103 travel to their end

The pressure rises.

stop.

6 When the pressure reaches

Solenoid valves 70 and 71 are energized.

150 bar, the oil pressure switch 93

switches

7 Volume flow flows through the

energized solenoid valve 71 into

the rod spaces of cylinders 91 and

92.

The volume flow displaced from the ram top spaces flows

into the tank through the energized solenoid valve 70 and

on via the 4/3 way solenoid valve 50B.

The side-mounted mower units are folded in.

1-12 10/04

Page 17

TIC JAGUAR 8550C Hydraulic / Electric System

JAGUAR 8500 C-6 / C8 hydraulic circuit diagram

10/04 1-13

Page 18

Hydraulic / Electric System JAGUAR 8550C TIC

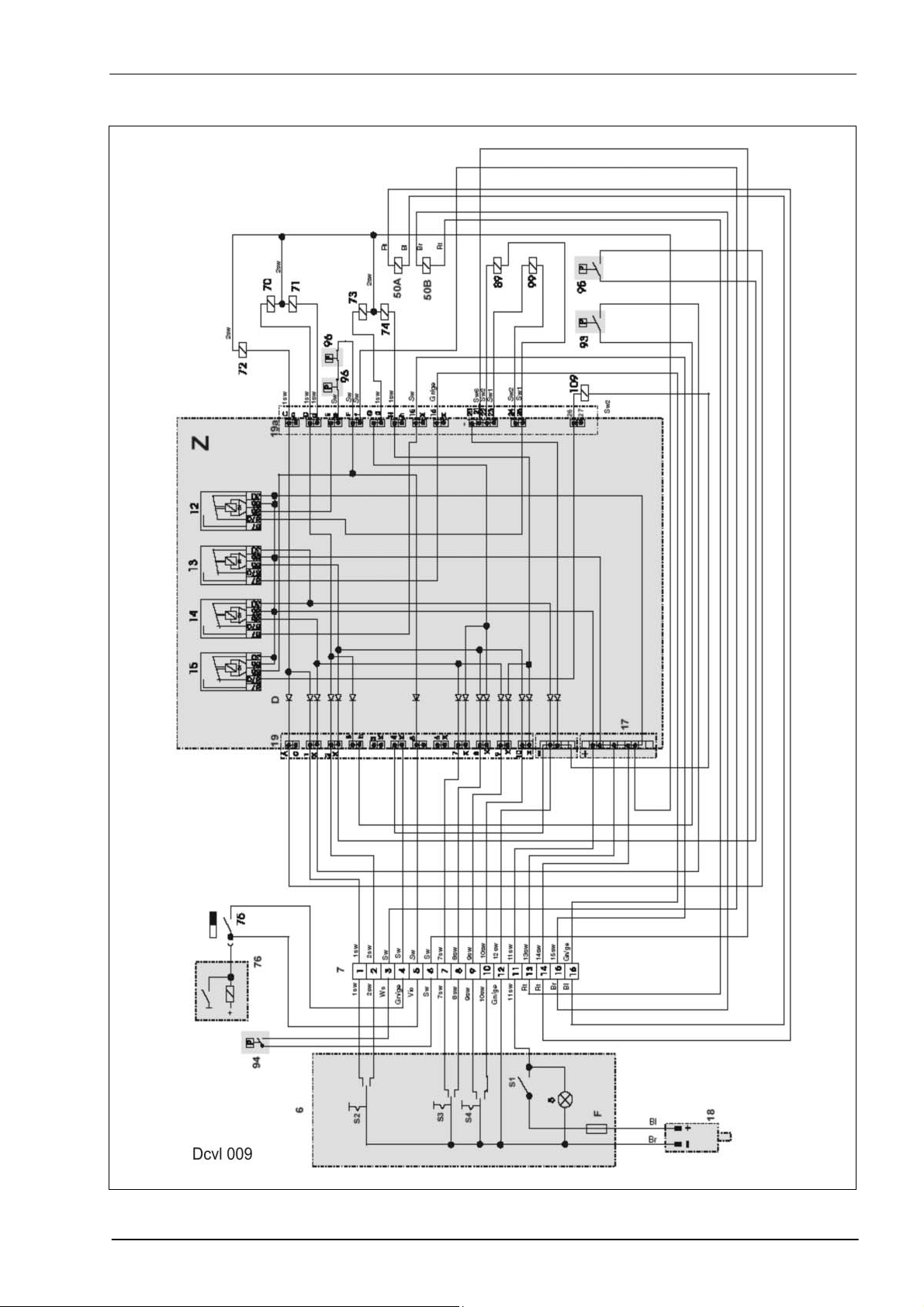

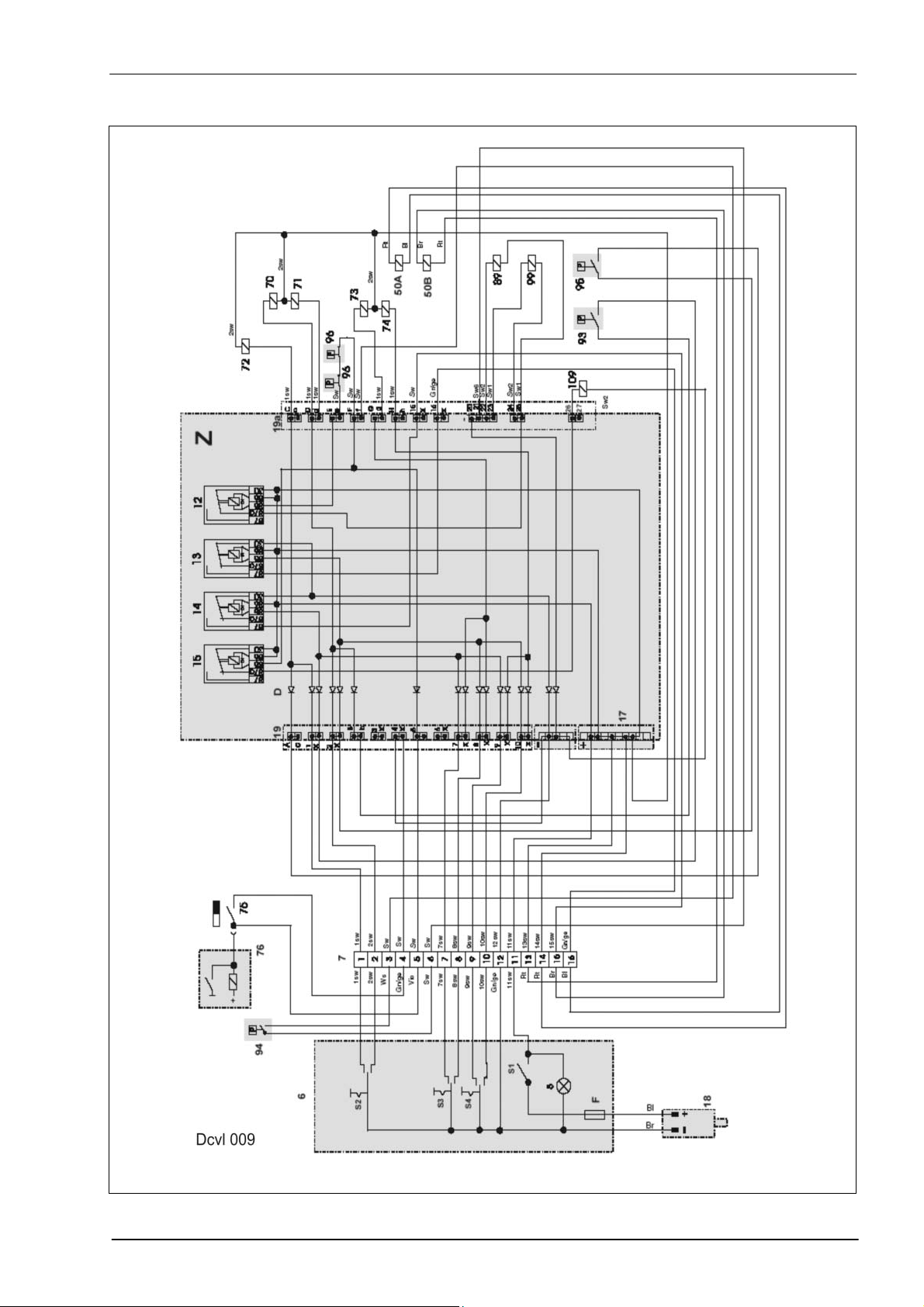

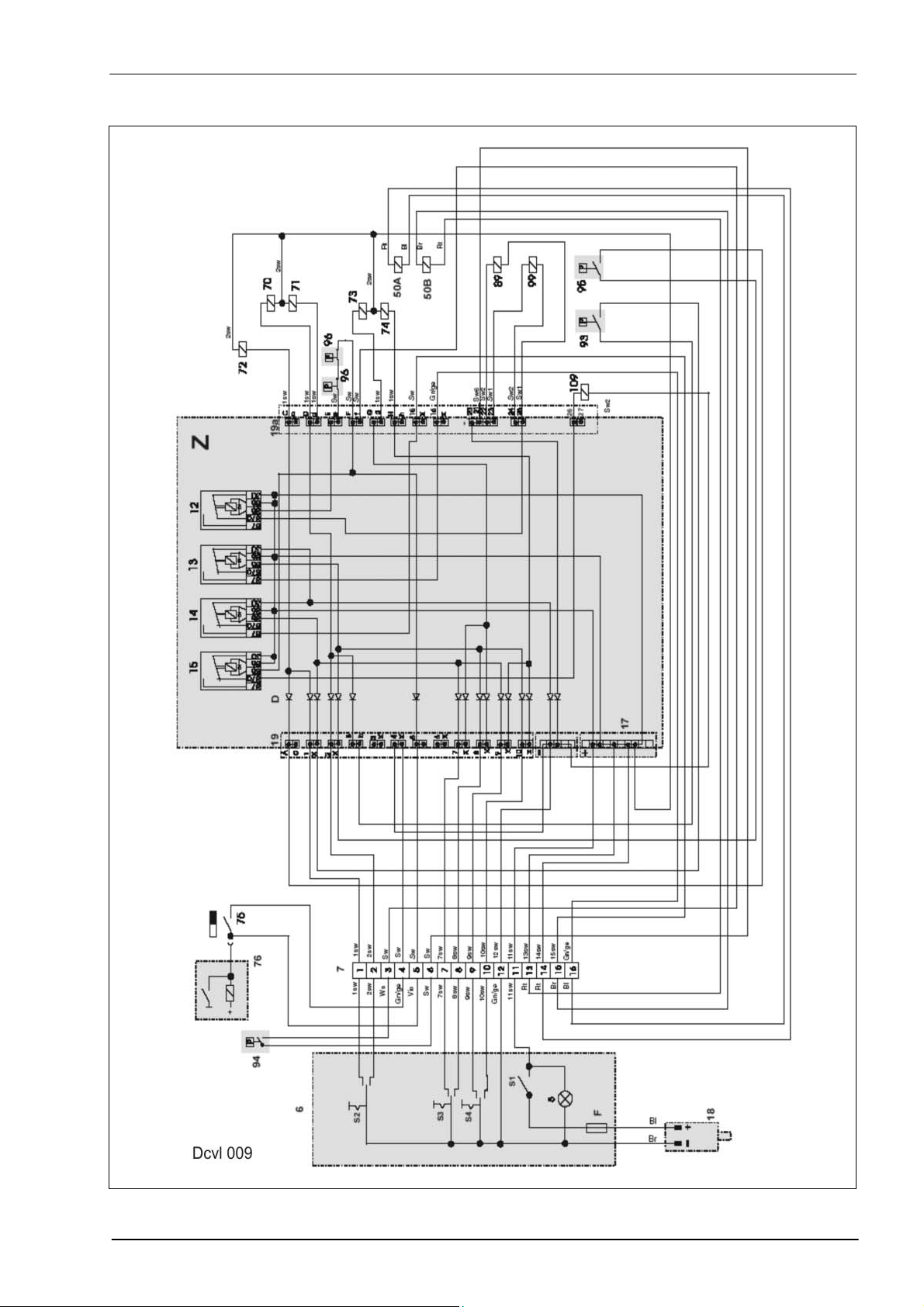

2.0 Electric system JAGUAR 8500C, CISCO 8500C-6, -8

2.1 Electric circuit diagram

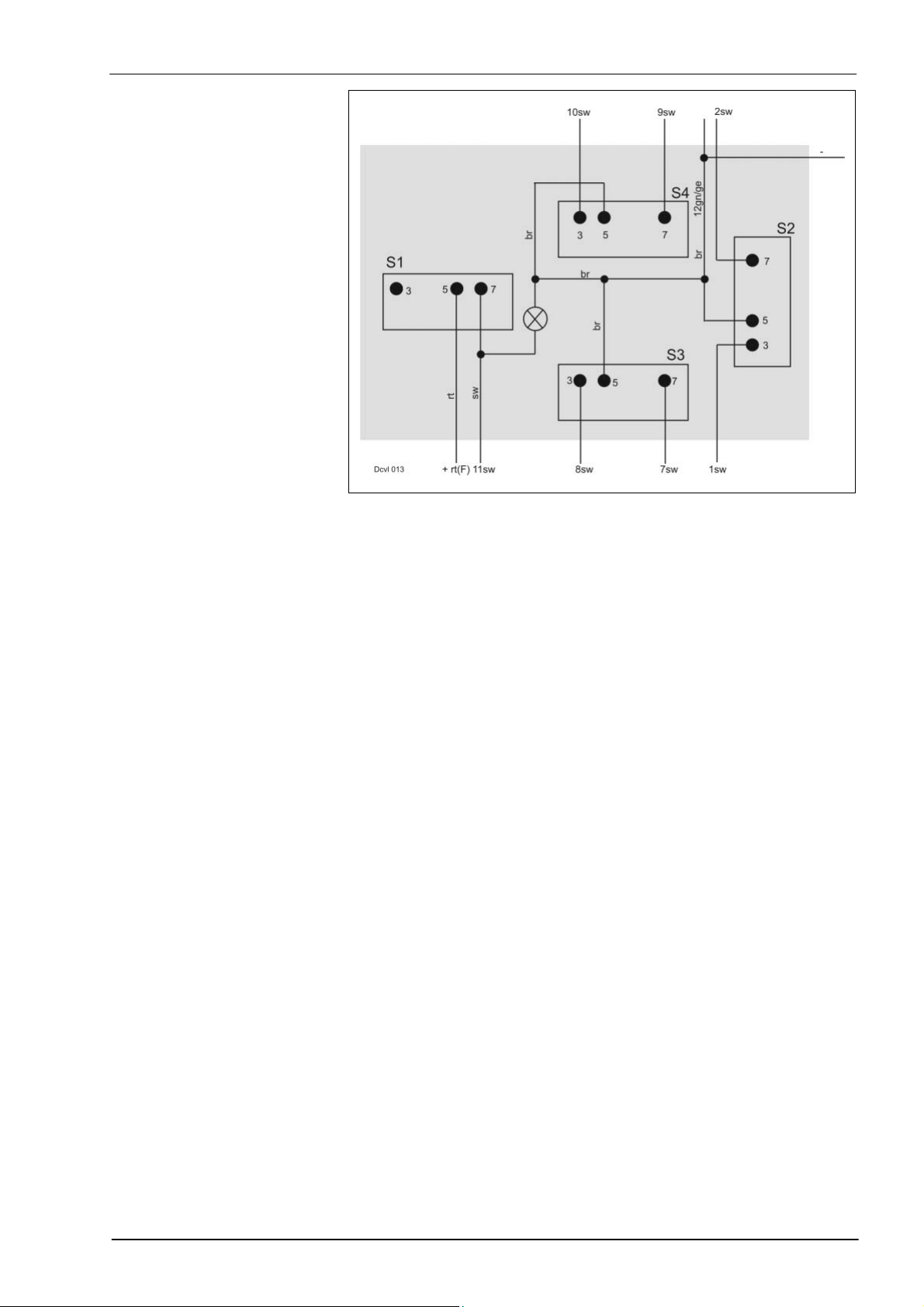

S1 Stop switch

S2 Disco fold in/out switch

S3 Left Disco raise/lower switch

S4 Right Disco raise/lower switch

5 Indicator light, power supply

6 Control box with switches S1, S2, S3 and S4

7 Socket outlet beneath the operator's platform

17 Terminal strip, plus in central terminal compartment

(located above the relays)

19 Left terminal strip

19a Right terminal strip

12 Lock-up valve unit 89 and 99 relay

13 Relay for 4/3 way solenoid valve (item 50A)

14 Relay for 4/3 way solenoid valve (item 50B)

15 Relay for lock-up valve unit 109

50 4/3 way solenoid valve for front attachment (series equipment)

50A Solenoid coil (fold out mower units)

50B Solenoid coil (fold in mower unit, raise/lower)

51 Front attachment raise/lower 3/3 way solenoid valve

70 Solenoid coil, fold out right and left Disco

71 Solenoid coil, fold in right and left Disco

72 Solenoid coil, raise/lower centre Disco

73 Left Disco raise/lower solenoid coil

74 Right Disco raise/lower solenoid coil

75 Reed switch (only Jaguar 800 series)

Mounted to solenoid valve 51 (raise).

Caution: Observe installation position = lettering must face the magnet

76

Switches and 3/3 way raise solenoid valve

(only on Jaguar 600 series)

89 Solenoid coil, right lock-up valve unit (closed when deenergized)

93 Oil pressure switch 150 bar (normally open contact), energizes solenoid

valve 70

94 Oil pressure switch 85 bar (normally open contact), energizes relay 12

95 Oil pressure switch 150 bar (normally open contact), energizes solenoid

valve 72

96 2x oil pressure switch 140 bar (normally closed contact), see chapter

2.2.8.

99 Solenoid coil, left lock-up valve unit (closed when deenergized)

109 Solenoid coil, centre lock-up valve unit (closed when deenergized)

D Diodes

F 10 A fuse

Z Central terminal compartment (the lines in the areas with a grey

background are actually conducting paths on the board).

1-14 10/04

Page 19

TIC JAGUAR 8550C Hydraulic / Electric System

Electric system Jaguar 8500C, Disco 8500C-6, C-8

10/04 1-15

Page 20

Hydraulic / Electric System JAGUAR 8550C TIC

2.2 Function

2.2.1 Putting into operation Switch on stop switch 1.

2.2.2 Raise left Disco Actuate rocker switch 3. Earth is connected to pin 7 in connector 7.

2.2.3 Lower left Disco Actuate rocker switch 3. Earth is connected to pin 7 in connector 8.

2.2.4 Raise right Disco Actuate rocker switch 4.

2.2.5 Lower right Disco Actuate rocker switch 4.

2.2.6 Moving the Disco to

working position

2.2.7 Moving the Disco to

transport position

Current is applied to all relays, terminal 86 and the solenoid valves.

Earth is also connected to relay 14 on terminal 85 and to solenoid valve

73. Relay 14 connects earth to the 4/3 way directional control valve 50B.

Earth is also connected to relay 13 on terminal 85 and to solenoid valve

73. Relay 13 connects earth to the 4/3 way directional control valve 50A.

Earth is connected via pin 9 of connector 7 to relay 14 on terminal 85 and

to the solenoid valve 74. Relay 14 connects earth to the solenoid valve

50 which goes to switch position B.

Earth is connected via pin 10 of connector 7 to relay 13 on terminal 85

and to the solenoid valve 74. Relay 13 connects earth to the solenoid

valve 50 which goes to switch position A.

Actuate rocker switch 2.

Earth is connected via pin 2 of connector 7 to relay 13 on terminal 85 and

to the solenoid valves 70 and 71. Relay 13 connects earth to the solenoid

valve 50 which goes to switch position A.

The mower unit folds out.

Upon reaching the end position and 150 bar, the oil pressure switch 95

connects earth to the solenoid valve 72. The front mower unit is lowered

via the energized solenoid valve 72.

Actuate rocker switch 2.

Earth is connected via pin 1 of connector 7 to relay 14 on terminal 85 and

to the solenoid valve 72.

Relay 14 connects earth to the solenoid valve 50 which goes to switch

position B.

The centre mower unit is raised.

Upon reaching the end position and 150 bar, the oil pressure switch 93

connects earth to the solenoid valves 70 and 71. The mower units are

folded in.

1-16 10/04

Page 21

TIC JAGUAR 8550C Hydraulic / Electric System

Electric system Jaguar 8500C, Disco 8500C-6, C-8

10/04 1-17

Page 22

Hydraulic / Electric System JAGUAR 8550C TIC

2.2.8 Blocking the

accumulator while

raising the entire

mower unit.

(quick lift)

When the 3/3 way raise front attachment solenoid valve is actuated on

the forage harvester, the Reed switch*75 connects earth to relay 15,

terminal 85 and relay 12, terminal 85.

Relay 15 cuts the current to the lock-up valve unit 109.

Relay also cuts the current to the lock-up valve units 89 and 99 (the lockup valve units are closed when deenergized).

When raising is complete, the mower units’ weight generates a pressure

of > 85 bar in the cylinders of the Jaguar front attachment.

The oil pressure switch 94 connects earth to relay 12, terminal 85 as long

as the pressure in the lift cylinders is > 80 bar.

Relay 12 switches and cuts the power supply to the lock-up valve units

89, 99 and 109.

This is necessary to make the mower units remain in their position when

lifting is complete on the turning area. When the pressure in cylinders 90

and 100 rises to above 140 bar, the oil pressure switches 96 open briefly.

Earth connected to relay 12, terminal 85 drops out and the relay connects

the current supply to the lock-up valve units 89 and 99.

The lock-up valve units open and the accumulators receive oil from the

ram rod end (from the front attachment cylinders on the Jaguar) so that

there is no oil loss and no oil can flow from the system into the tank

(pressure relief valve 104).

* On the Jaguar 800, the Reed switch connects earth.

On the Jaguar 600, earth is supplied directly from the 3/3 way „Raise“

solenoid valve.

1-18 10/04

Page 23

TIC JAGUAR 8550C Hydraulic / Electric System

Electric system Jaguar 8500C, Disco 8500C-6, C-8

10/04 1-19

Page 24

Hydraulic / Electric System JAGUAR 8550C TIC

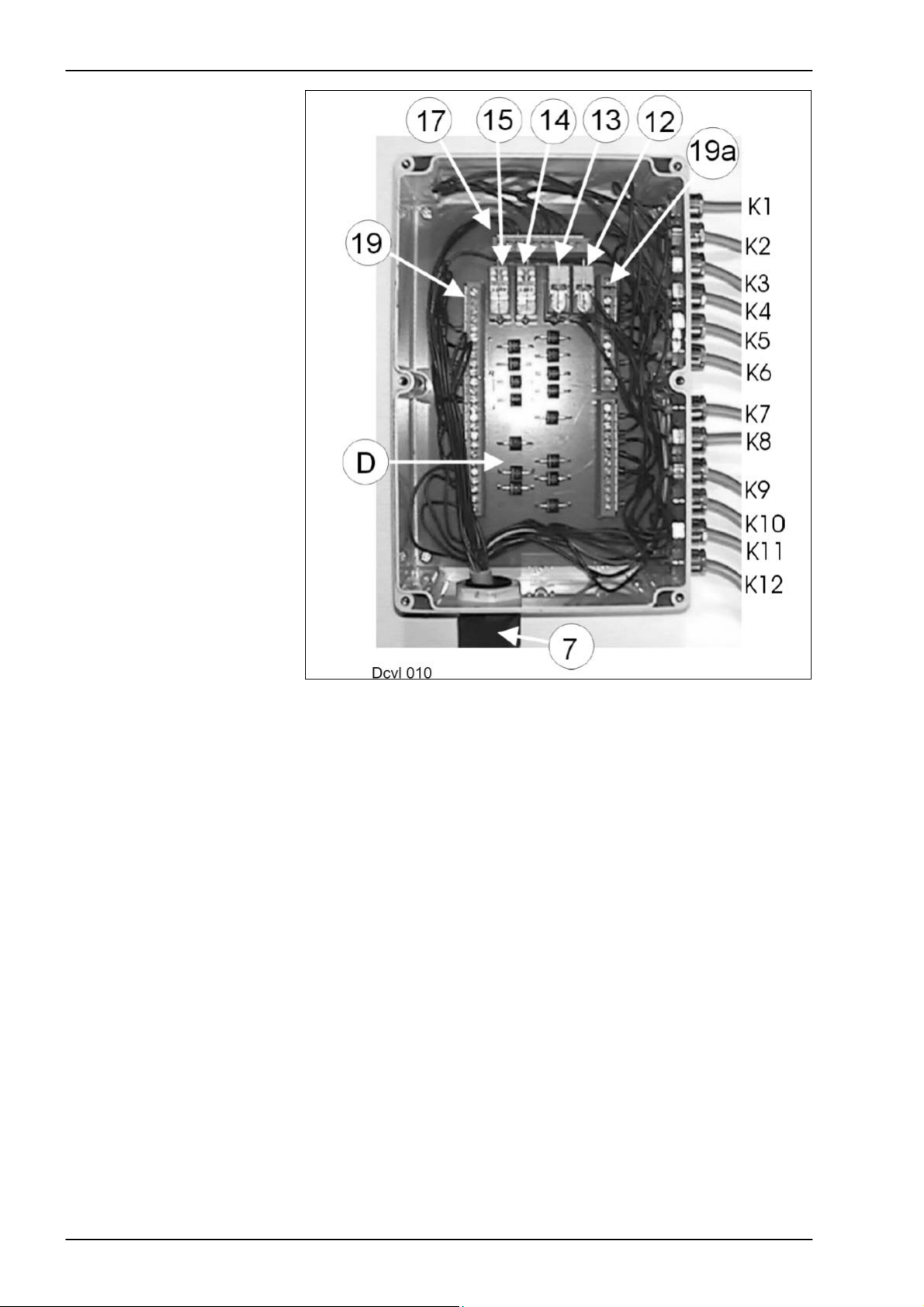

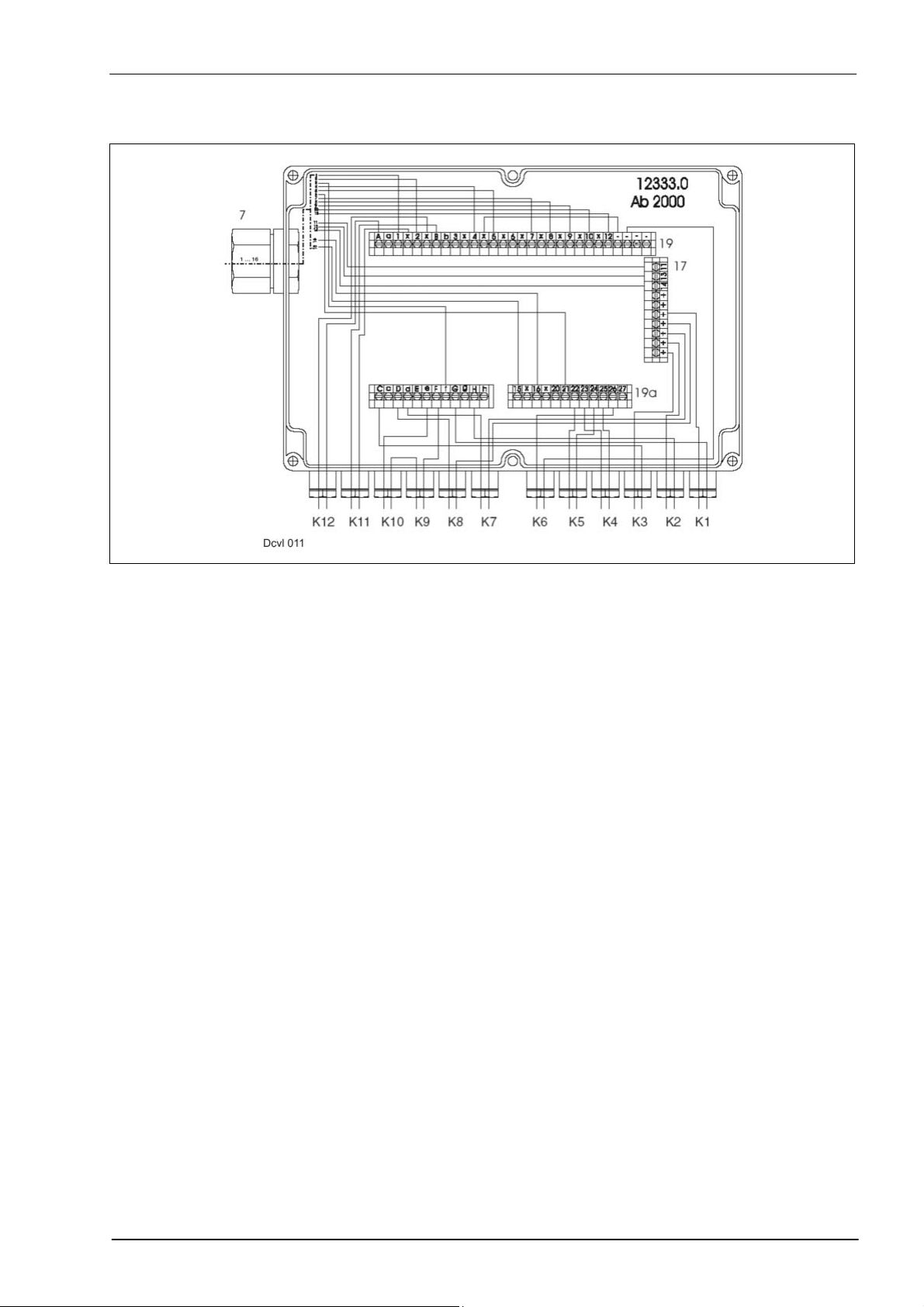

2.3 Central terminal compartment

7 Central terminal compartment connector

12 Lock-up valve unit 89 and 99 relay

13 Relay for 4/3 way solenoid valve (item 50A)

14 Relay for 4/3 way solenoid valve (item 50B)

15 Relay for lock-up valve unit 109

17 Terminal strip, plus in central terminal compartment

(located above the relays)

19 Left terminal strip

19a Right terminal strip

K1 Raise/lower right side-mounted mower unit, solenoid valve 74

K2 Raise/lower left side-mounted mower unit, solenoid valve 73

K3 Front mower unit, solenoid valve 72

K4 Right mower unit lock-up valve unit, solenoid valve 89

K5 Left mower unit lock-up valve unit, solenoid valve 99

K6 Front mower unit lock-up valve unit, solenoid valve 109

K7 Fold out side-mounted mower unit, solenoid valve 70

K8 Fold in side-mounted mower unit, solenoid valve 71

K9 140 bar pressure switch, item 96

K10 140 bar pressure switch, item 96

K11 150 bar pressure switch (fold in side-mounted mower units), item 93

K12 150 bar pressure switch (fold out side-mounted mower units), item 95

D Diodes

1-20 10/04

Page 25

TIC JAGUAR 8550C Hydraulic / Electric System

Central terminal

compartment, from 2000

7 Central terminal compartment connector

12 Lock-up valve unit 89 and 99 relay

13 Relay for 4/3 way solenoid valve (item 50A)

14 Relay for 4/3 way solenoid valve (item 50B)

15 Relay for lock-up valve unit 109

17 Terminal strip, plus in central terminal compartment

(located above the relays)

19 Left terminal strip

19a Right terminal strip

K1 Raise/lower right side-mounted mower unit, solenoid valve 74

K2 Raise/lower left side-mounted mower unit, solenoid valve 73

K3 Front mower unit, solenoid valve 72

K4 Right mower unit lock-up valve unit, solenoid valve 89

K5 Left mower unit lock-up valve unit, solenoid valve 99

K6 Front mower unit lock-up valve unit, solenoid valve 109

K7 Fold out side-mounted mower unit, solenoid valve 70

K8 Fold in side-mounted mower unit, solenoid valve 71

K9 140 bar pressure switch, item 96

K10 140 bar pressure switch, item 96

K11 150 bar pressure switch (fold in side-mounted mower units), item 93

K12 150 bar pressure switch (fold out side-mounted mower units), item 95

10/04 1-21

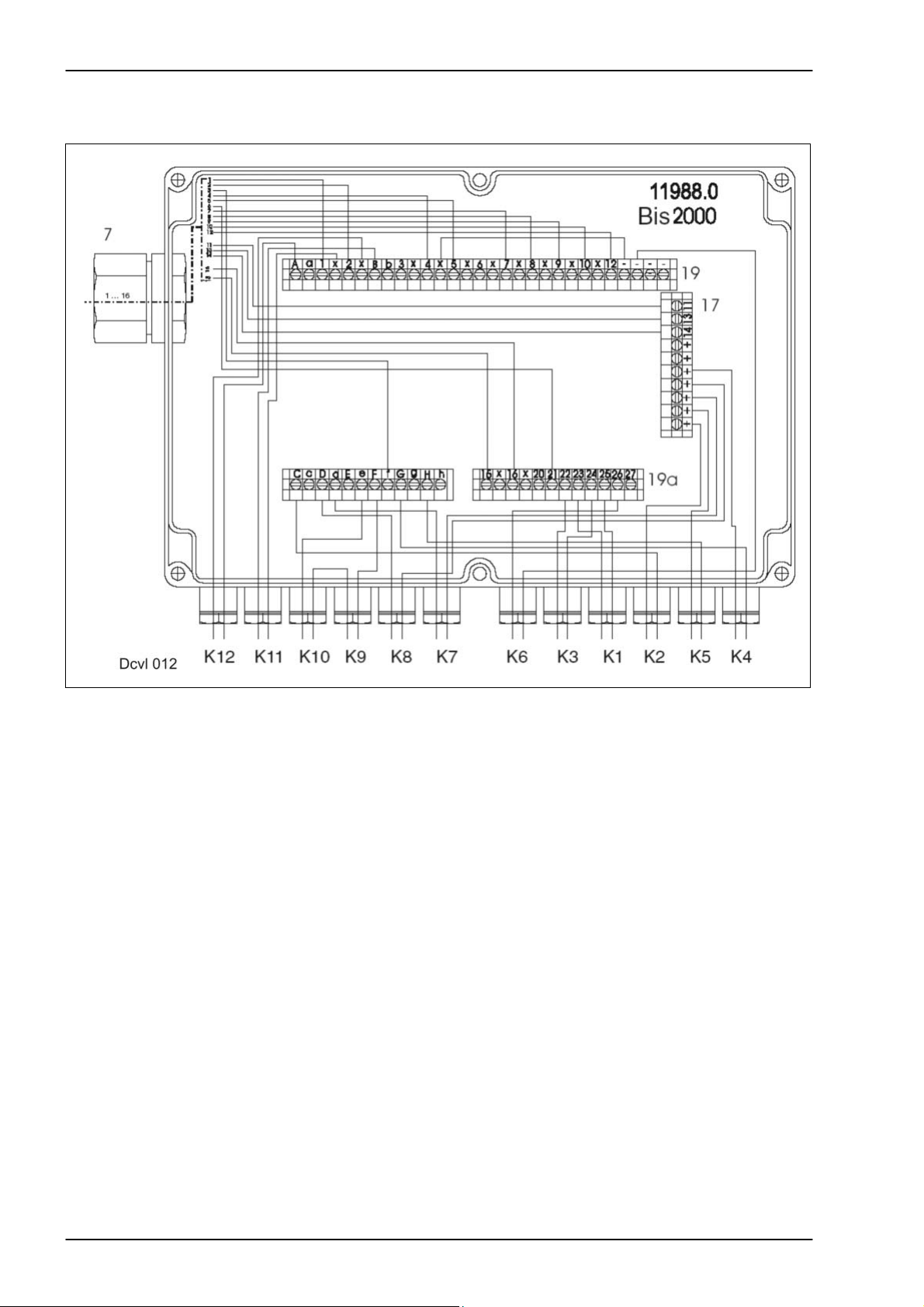

Page 26

Hydraulic / Electric System JAGUAR 8550C TIC

Central terminal

compartment, up to 2000

Differences as compared with central terminal compartment

“from 2000”:

The assignment of inputs 1 to K5 is different.

The connecting terminals on the board have not been changed.

7 Central terminal compartment connector

12 Lock-up valve unit 89 and 99 relay

13 Relay for 4/3 way solenoid valve (item 50A)

14 Relay for 4/3 way solenoid valve (item 50B)

15 Relay for lock-up valve unit 109

17 Terminal strip, plus in central terminal compartment (located above the

relays)

19 Left terminal strip

19a Right terminal strip

K1 Raise/lower right side-mounted mower unit, solenoid valve 74

K2 Raise/lower left side-mounted mower unit, solenoid valve 73

K3 Front mower unit, solenoid valve 72

K4 Right mower unit lock-up valve unit, solenoid valve 89

K5 Left mower unit lock-up valve unit, solenoid valve 99

K6 Front mower unit lock-up valve unit, solenoid valve 109

K7 Fold out side-mounted mower unit, solenoid valve 70

K8 Fold in side-mounted mower unit, solenoid valve 71

K9 140 bar pressure switch, item 96

K10 140 bar pressure switch, item 96

K11 150 bar pressure switch (fold in side-mounted mower units), item 93

K12 150 bar pressure switch (fold out side-mounted mower units), item 95

1-22 10/04

Page 27

TIC JAGUAR 8550C Hydraulic / Electric System

Pin assignment of switches

in the CCT

(as seen from the rear)

S1 Stop switch

S2 Disco fold in/out switch

S3 Left Disco raise/lower switch

S4 Right Disco raise/lower switch

10/04 1-23

Page 28

Hydraulic / Electric System JAGUAR 8550C TIC

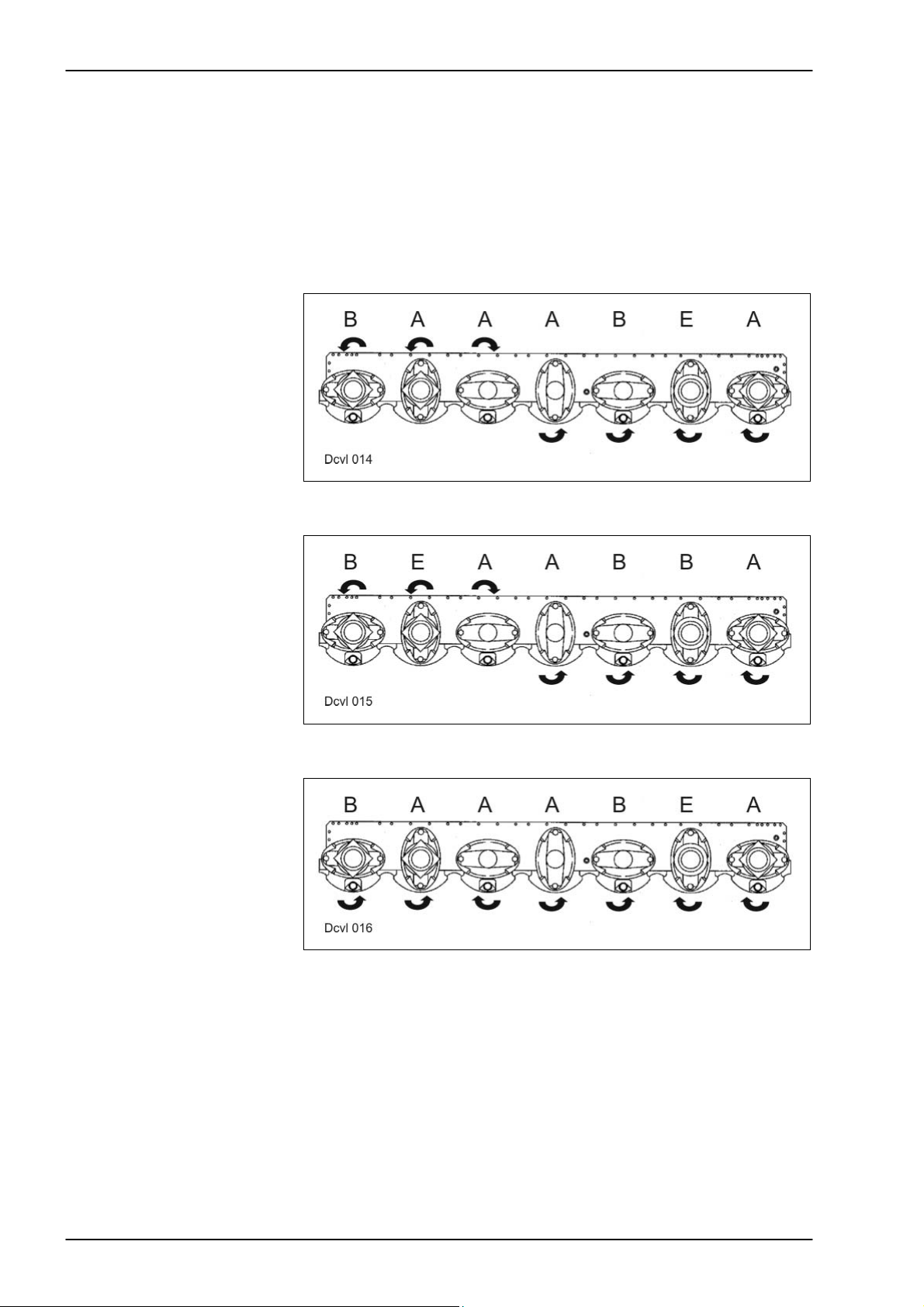

3.0 Installation information

3.1 Timing of drives

Arrangement of pinion units A and B and of drive input module E

Left mower unit

A Pinion unit A

B Pinion unit B

E Drive input module

Right mower unit

A Pinion unit A

B Pinion unit B

E Drive input module

In addition to the drive input module E, 6 rows of pinions are provided in

the mower head.

These are sub-divided into four 4 versions and two B versions. The B

versions are marked with red paint at the bottom.

Centre mower unit

A Pinion unit A

B Pinion unit B

E Drive input module

1-24 10/04

Page 29

TIC JAGUAR 8550C Hydraulic / Electric System

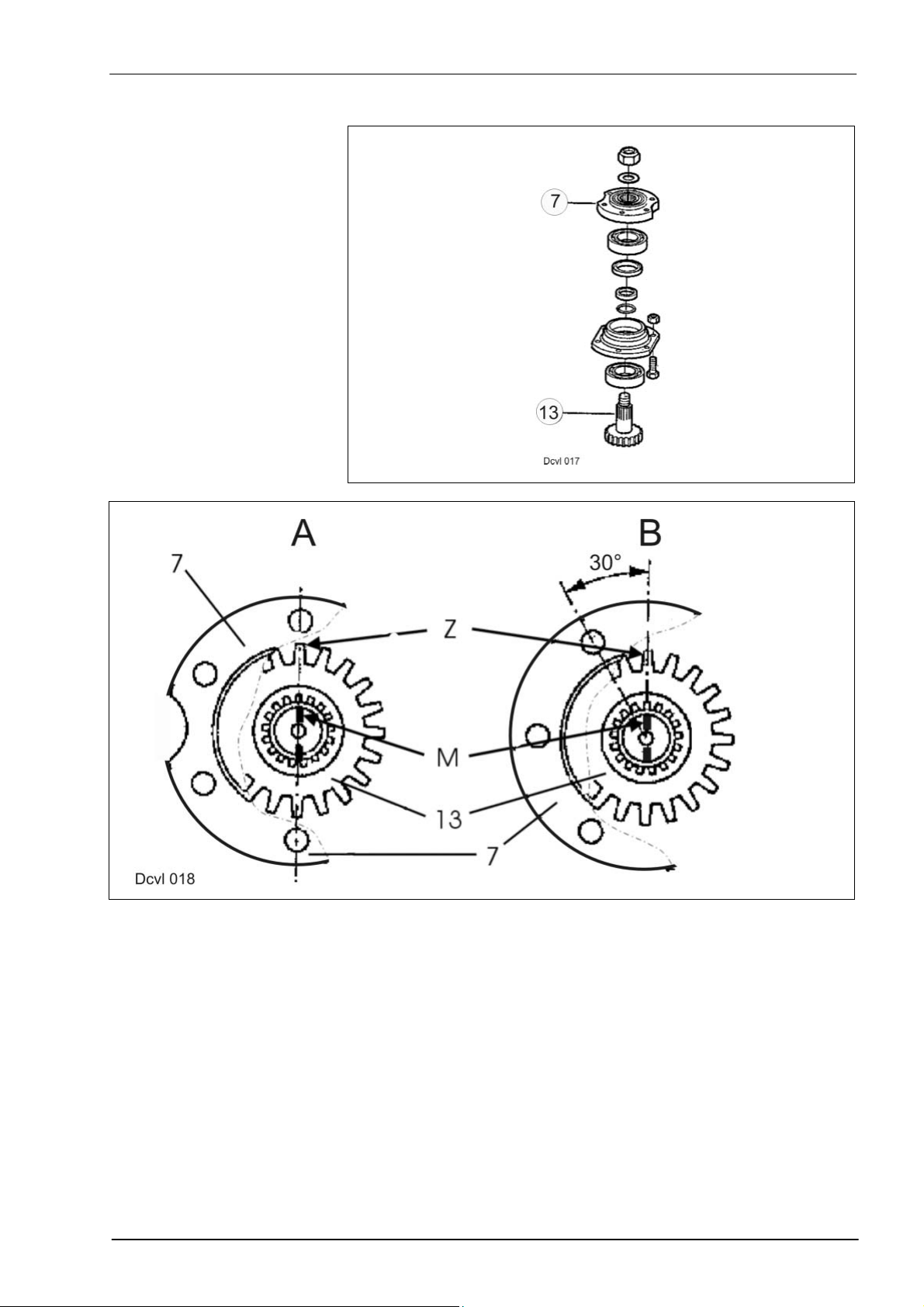

3.2 Installation of pinion units

7 Flange

13 Pinion shaft

Pinion unit A The marking M on the pinion shaft (13), the tooth centre Z and the centre

of the flange bore must be aligned.

Pinion unit B The marking M on the shaft, the tooth centre Z and the centre between

two flange bores must be aligned.

10/04 1-25

Page 30

Hydraulic / Electric System JAGUAR 8550C TIC

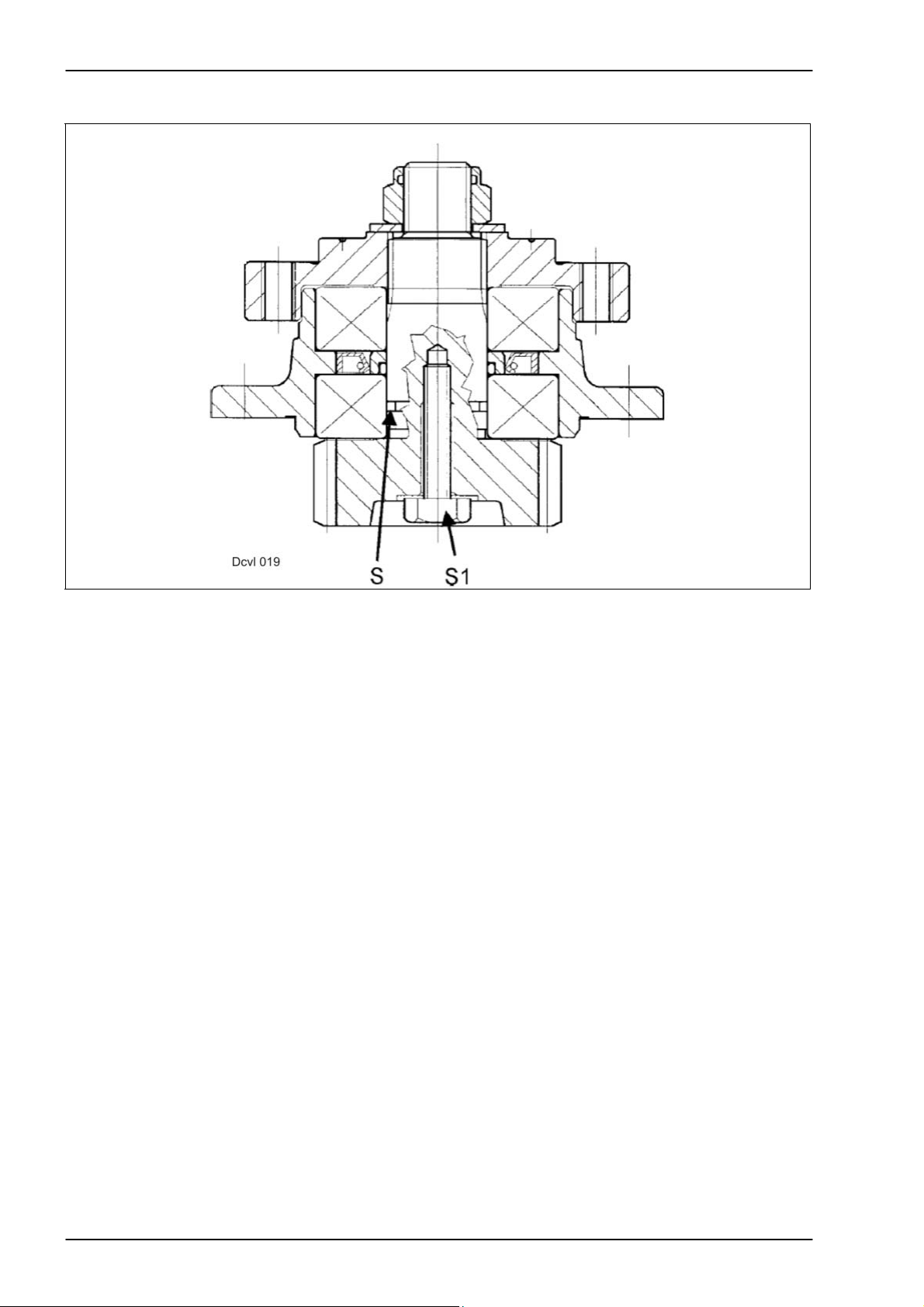

3.3 Safety module

S Breaking point for cases of sudden load

S1 Safety screw (when sudden loads occur and the pinion has been sheared

off the shaft, this screw holds both parts together and thus avoids major

damage in the mower head).

1-26 10/04

Page 31

TIC JAGUAR 8550C Hydraulic / Electric System

3.4 Tightening torques

Item Remark Tightening torque

1 M 10x30 bolt 85 Nm

2 M 10x20 countersunk head bolt 70 Nm

3 M 10x19 bolt 85 Nm

4 M 10x55x45 countersunk head bolt 70 Nm

5 M 20x30 cheese-head screw 650 Nm

6 M 10x40 bolt 85 Nm

10/04 1-27

Page 32

Hydraulic / Electric System JAGUAR 8550C TIC

4.0 Drive diagram

1-28 10/04

Page 33

TIC DISCO 8550C (Tractor) Hydraulic / Electric System

Hydraulic System...................................................................................................................................2

1.0

1.1

Hydraulic circuit diagram......................................................................................................................2

2.0

Electric System ......................................................................................................................................4

2.1

Electric circuit diagram .........................................................................................................................4

3.0 Installation information.........................................................................................................................6

Timing of drives....................................................................................................................................6

3.1

3.2 Installation of pinion units.....................................................................................................................7

3.3 Safety module ......................................................................................................................................8

3.4 Tightening torques ...............................................................................................................................9

4.0 Drive diagram.......................................................................................................................................10

10/04 2-1

Page 34

Hydraulic / Electric System DISCO 8550C (Tractor) TIC

1.0 Hydraulic System

1.1 Hydraulic circuit diagram

1 Coupling, single-acting

2 Cylinder for front mower units

3 Cylinder for front mower units

4 Oil pressure switch, set to 190 bar

5 Flow divider

6 Cylinder with 3/2 way directional control valve – Raise/lower side-

mounted mower units

7 Cylinder with 3/2 way directional control valve – Raise/lower side-

mounted mower units

4 Oil pressure switch, set to 190 bar

5 Flow divider

2-2 10/04

Page 35

TIC DISCO 8550C (Tractor) Hydraulic / Electric System

10/04 2-3

Page 36

Hydraulic / Electric System DISCO 8550C (Tractor) TIC

2.0 Electric System

2.1 Electric circuit diagram

Activating / deactivating the

transport stop

1 Connector – tractor connection

2 Control terminal

3 Cable connections

4 4-pin connector for control terminal – basic machine

5 Oil pressure switch

6 Solenoid valve on cylinder, left

7 Solenoid valve on cylinder, right

Deactivating the transport

stop

Press both “0” keys simultaneously. Both LEDs (L) light up; the two

2/2 way solenoid valves (6 and 7) on the cylinder are energized and are

open.

Activating the transport stop Raise all mower units. This makes the system pressure rise; at 190 bar,

the oil pressure switch (4) activates the transport stop automatically. Both

LEDs have gone out.

or

The transport stop is active whenever one of the two "0" keys is pressed.

Both LEDs have gone out.

2-4 10/04

Page 37

TIC DISCO 8550C (Tractor) Hydraulic / Electric System

DISCO 8500 C (tractor) electric circuit diagram

10/04 2-5

Page 38

Hydraulic / Electric System DISCO 8550C (Tractor) TIC

3.0 Installation information

3.1 Timing of drives

Arrangement of pinion units A and B and of drive input module E

Left mower unit

A Pinion unit A

E Drive input module

Right mower unit

A Pinion unit A

E Drive input module

In addition to the drive input module E, 6 rows of pinions are provided in

the mower head.

These are sub-divided into four 4 versions and two B versions. The B

versions are marked with red paint at the bottom.

Centre mower unit

A Pinion unit A

B Pinion unit B

E Drive input module

2-6 10/04

Page 39

TIC JAGUAR 8550C (Tractor) Hydraulic / Electric System

3.2 Installation of pinion units

7 Flange

13 Pinion shaft

Pinion unit A The marking M on the pinion shaft (13), the tooth centre Z and the centre

of the flange bore must be aligned.

Pinion unit B The marking M on the shaft, the tooth centre Z and the centre between

two flange bores must be aligned.

10/04 2-7

Page 40

Hydraulic / Electric System DISCO 8550C (Tractor) TIC

3.3 Safety module

S Breaking point for cases of sudden load

S1 Safety screw (when sudden loads occur and the pinion has been sheared

off the shaft, this screw holds both parts together and thus avoids major

damage in the mower head).

2-8 10/04

Page 41

TIC JAGUAR 8550C (Tractor) Hydraulic / Electric System

3.4 Tightening torques

Item Remark Tightening torque

1 M 10x30 bolt 85 Nm

2 M 10x20 countersunk head bolt 70 Nm

3 M 10x19 bolt 85 Nm

4 M 10x55x45 countersunk head bolt 70 Nm

5 M 20x30 cheese-head screw 650 Nm

6 M 10x40 bolt 85 Nm

10/04 2-9

Page 42

Hydraulic / Electric System DISCO 8550C (Tractor) TIC

4.0 Drive diagram

2-10 10/04

Page 43

TIC JAGUAR 8550C (Tractor) Hydraulic / Electric System

Figure:

Push-type combination

Front mower unit: Standard Disco 3000FC

Side-mounted mower units: Identical with Disco 300C except for the

frame, the drive and the feed drum.

Figure:

Push-type/pull-type

combination

Front mower unit: Standard Disco 3000FC

Side-mounted mower units: Identical with Disco 300C except for the

frame, the drive and the feed drum.

10/04 2-11

Page 44

Hydraulic / Electric System DISCO 8550C (Tractor) TIC

2-12 10/04

Page 45

TIC CORTO 8100 F/T Hydraulic / Electric System

CORTO 8100F.........................................................................................................................................2

1.0

1.1 CORTO 8100F hydraulic system .........................................................................................................2

1.1.1

Key to diagram..............................................................................................................................2

1.1.2 Function CORTO 8100 F..............................................................................................................4

1.2 CORTO 8100 F electric system ...........................................................................................................6

1.2.1

Putting into operation....................................................................................................................6

1.2.2 Switching on the right-hand drive .................................................................................................6

1.2.3 Shutting down the right-hand drive...............................................................................................6

1.2.4 Switching on the left-hand drive....................................................................................................6

1.2.5 Shutting down the left-hand drive .................................................................................................6

1.2.6 Raising the left CORTO ................................................................................................................6

1.2.7 Lowering the left CORTO .............................................................................................................8

1.2.8 Raising the right CORTO..............................................................................................................8

1.2.9 Lowering the right CORTO ...........................................................................................................8

1.2.10 Folding CORTO to working position .............................................................................................8

1.2.11 Folding CORTO to transport position ...........................................................................................8

1.2.12 Accumulator is blocked when raising the entire mower unit.........................................................8

2.0 CORTO 8100 T......................................................................................................................................10

2.1 Hydraulic System CORTO 8100 T.....................................................................................................10

2.1.1

Key to diagram............................................................................................................................10

2.1.2 Function ......................................................................................................................................12

2.2 Electric System CORTO 8100 T ........................................................................................................14

2.2.1

Key to diagram............................................................................................................................14

2.2.1 Function ......................................................................................................................................14

10/04 3-1

Page 46

Hydraulic / Electric System CORTO 8100 F/T TIC

1.0 CORTO 8100F

1.1 CORTO 8100F hydraulic system

1.1.1 Key to diagram

2 Hydraulic pump (Jaguar)

5 Return line oil filter (Jaguar)

50 4/3 way valve, double-acting (for front attachments = series equipment)

70 2/2 way valve, right-hand drive On/Off

71 2/2 way valve, left-hand drive On/Off

72 2/2 way valve, fold CORTO in/out

73 2/2 way valve, fold CORTO in/out

74 2/2 way valve, raise/lower centre mower unit

75 2/2 way valve, raise/lower left mower unit

76 2/2 way valve, raise/lower right mower unit

77 CORTO right hydraulic cylinder, drive On/Off

78 CORTO left hydraulic cylinder, drive On/Off

79 80 bar oil pressure switch

80 100 bar pressure relief valve, double-acting

81 Non-return valve, left

82 Hydraulic cylinder, left CORTO, starting protection

83 Pressure relief valve 180 bar

84 Non-return valve, right

85 Hydraulic cylinder, right CORTO, starting protection

86 Pressure relief valve 180 bar

87 Pressure gauge, CORTO right-hand load relief

88 Accumulator, right-hand, pre-loaded to 210 bar

89 Lock-up valve unit on right side, electro-magnetic control

90 Hydraulic cylinder, raise and/or load relief of right CORTO

91 Hydraulic cylinder, fold left CORTO in and out

92 Hydraulic cylinder, fold right CORTO in and out

93 160 bar oil pressure switch

94 30 bar oil pressure switch

95 Centre mower unit raise/lower hydraulic cylinder

97 Pressure gauge, CORTO left-hand load relief

98 Accumulator, left-hand, pre-loaded to 210 bar

99 Lock-up valve unit on left side, electro-magnetic control

100 Hydraulic cylinder, raise and/or load relief of left CORTO

(open when deenergized)

(open when deenergized)

3-2 10/04

Page 47

TIC CORTO 8100 F/T Hydraulic / Electric System

CORTO 8100 F

10/04 3-3

Page 48

Hydraulic / Electric System CORTO 8100 F/T TIC

1.1.2 Function

Moving the mower units to transport position

CORTO 8100 F

1 Shut down the side-mounted mower units using switches (2) and (3).

Shut down the main drive The mower drums must stand still. (Solenoid

valves 70 and 71 switch).

2 Raise front attachment completely until the mower units are clear of the

ground.

3 Slightly raise the side-mounted mower units using switches (5) and (6).

(Solenoid valves 50A, 75 and 76 switch).

4 Actuate the fold-in switch (4). The solenoid valves (50A) and (74) switch.

Oil flows to the hydraulic cylinders (95). The centre mower unit is raised.

Oil pressure switch (94) closes at 30 bar. The lock-up valve units (89 and

99) are closed by electro-magnetic means. The oil in the hydraulic

cylinders (90 and 100) is thus locked.

At a pressure of 160 bar, the oil pressure switch (93) actuates the

solenoid valves (72 and 73). Oil flows to the hydraulic cylinders (91 and

92). The hydraulic cylinders retract.

Consequently the side-mounted mower units are folded to the front, i.e. to

transport position. The displaced oil flows back to the tank via the

solenoid valves (72 and 50B).

5 Fit the transport lock (lighting bracket) and connect the lighting system.

6 Fully raise the side-mounted mower units using switches (5) and (6). The

solenoid valves 50 A, 75 and 76 switch.

Oil flows to the hydraulic cylinders (82 and 85). At 80 bar, the oil pressure

switch (79) and the solenoid valve (74) switch.

The oil in the hydraulic cylinders (95) flows back to the tank.

The centre mower unit is lowered onto the folded-in side-mounted mower

units.

Remark: The double-acting pressure relief valve (80) serves for accident

prevention.

When folding in, the mower units can be stopped manually.

The pressure relief valve (80) opens at 100 bar. Personal injury is thus

avoided. The oil displaced by pressure relief valve (80) flows back to the

tank.

3-4 10/04

Page 49

TIC CORTO 8100 F/T Hydraulic / Electric System

CORTO 8100 F

10/04 3-5

Page 50

Hydraulic / Electric System CORTO 8100 F/T TIC

f

1.2 CORTO 8100 F electric system

1.2.1 Putting into

operation

1.2.2 Switching on the

right-hand drive

1.2.3 Shutting down the

right-hand drive

1.2.4 Switching on the

left-hand drive

1.2.5 Shutting down the

left-hand drive

1.2.6 Raising the left

CORTO

Switch on stop switch 1. Current is applied to the relays, terminal 86 and

the solenoid valves.

Actuate rocker switch 3.

Earth is connected to relay 17 on terminal 85 and to solenoid valve 70.

Relay 17 connects earth to relay 15 and to the 4/3 way solenoid valve

50B.

Relay 15 cuts the current supply to the lock-up valve units 89 and 99.

Via the 2/2 way solenoid valve and the 4/3 way solenoid valve, oil flows

into hydraulic cylinder 77. The right-hand drive is now switched on.

Actuate rocker switch 3.

Earth is connected to relay 16 on terminal 85 and to solenoid valve 70.

Relay 16 connects earth to relay 15 and to the 4/3 way solenoid valve

50A.

Relay 15 cuts the current supply to the lock-up valve units 89 and 99.

Via the 2/2 way solenoid valve and the 4/3 way solenoid valve, oil flows

out of hydraulic cylinder 77 – the drive has been shut down.

Actuate rocker switch 2.

Earth is connected to relay 17 on terminal 85 and to solenoid valve 71.

Relay 17 connects earth to relay 15 and to the 4/3 way solenoid valve

50B.

Relay 15 cuts the current supply to the lock-up valve units 89 and 99. Via

the 2/2 way solenoid valve and the 4/3 way solenoid valve, oil flows into

the hydraulic cylinders 78 – the drive is now switched on.

Actuate rocker switch 2.

Earth is also connected to relay 16 on terminal 85 and to solenoid valve

71.

Relay 16 connects earth to relay 15 and to the 4/3 way solenoid valve

50A.

Relay 15 cuts the current supply to the lock-up valve units 89 and 99. Via

the 2/2 way solenoid valve and the 4/3 way solenoid valve, oil flows out o

hydraulic cylinder 78 – the drive is shut down.

Actuate rocker switch 5.

Earth is connected to relay 17 on terminal 85 and to solenoid valve 75.

Relay 17 connects earth to relay 15 and to the 4/3 way solenoid valve

50B.

Relay 15 cuts the current supply to the lock-up valve units 89 and 99. Via

the 2/2 way solenoid valve and the 4/3 way solenoid valve, oil flows into

hydraulic cylinder 100 – the left mower unit is raised.

3-6 10/04

Page 51

TIC CORTO 8100 F/T Hydraulic / Electric System

CORTO 8100 F

10/04 3-7

Page 52

Hydraulic / Electric System CORTO 8100 F/T TIC

f

1.2.7 Lowering the left

CORTO

Actuate rocker switch 5.

Earth is connected to relay 16 on terminal 85 and to solenoid valve 75.

Relay 16 connects earth to relay 15 and to the 4/3 way solenoid valve

50A.

Relay 15 cuts the current supply to the lock-up valve units 89 and 99. Via

the 2/2 way solenoid valve and the 4/3 way solenoid valve, oil flows out o

hydraulic cylinder 100 – the left mower unit is lowered.

1.2.8 Raising the right

CORTO

Actuate rocker switch 6.

Earth is also connected to relay 17 on terminal 85 and to solenoid valve

76.

Relay 17 connects earth to relay 15 and to the 4/3 way solenoid valve

50B.

Relay 15 cuts the current supply to the lock-up valve units 89 and 99.

Via the 2/2 way solenoid valve and the 4/3 way solenoid valve, oil flows

into hydraulic cylinder 90 – the right mower unit is raised.

1.2.9 Lowering the right

CORTO

Actuate rocker switch 6.

Earth is connected to relay 16 on terminal 85 and to solenoid valve 76.

Relay 16 connects earth to relay 15 and to the 4/3 way solenoid valve

50A.

Relay 15 cuts the current supply to the lock-up valve units 89 and 99.

Via the 2/2 way solenoid valve and the 4/3 way solenoid valve, oil flows

out of hydraulic cylinder 90 – the right mower unit is lowered.

1.2.10 Folding CORTO to

working position

Actuate rocker switch 4.

Earth is connected to relay 16 on terminal 85 and to solenoid valves 72

and 73.

Relay 16 connects earth to relay 15 and to the 4/3 way solenoid valve

50A.

Relay 15 cuts the current supply to the lock-up valve units 89 and 99. Via

the 2/2 way solenoid valve and the 4/3 way solenoid valve, oil flows into

the hydraulic cylinders 82, 85, 91 und 92 – the side-mounted mower units

are folded out.

Upon reaching the end position or 80 bar, the oil pressure switch 79

connects earth to the solenoid valve 74. Via the 2/2 way solenoid valve

and the 4/3 way solenoid valve, oil flows into hydraulic cylinders 95.

The centre mower unit is lowered.

1.2.11 Folding CORTO to

transport position

Actuate rocker switch 4.

Earth is also connected to relay 17 on terminal 85 and to solenoid valve

74.

Relay 17 connects earth to relay 15 and to the 4/3 way solenoid valve

50B.

Relay 15 cuts the current supply to the lock-up valve units 89 and 99. Via

the 2/2 way solenoid valve and the 4/3 way solenoid valve, oil flows into

hydraulic cylinders 95 – the centre mower unit is raised.

Upon reaching the end position or 160 bar, the oil pressure switch 93

connects earth to the solenoid valves 72 and 73. The 2/2 way solenoid

valves make the side-mounted mower units fold in.

1.2.12 Accumulator is

blocked when

raising the entire

When raising the complete mower unit, the load from the centre mower

unit on hydraulic cylinder 95 connects earth from oil pressure switch 94 to

the lock-up valve units 89 and 99.

mower unit

3-8 10/04

Page 53

TIC CORTO 8100 F/T Hydraulic / Electric System

CORTO 8100 F

10/04 3-9

Page 54

Hydraulic / Electric System CORTO 8100 F/T TIC

2.0 CORTO 8100 T

2.1 Hydraulic System

CORTO 8100 T

2.1.1 Key to diagram

2 Tractor hydraulic system pump

5 Tractor return line oil filter

50 4/3 way valve, double-acting tractor control unit

70 3/3 way valve, single-acting tractor control unit

72 Pressure relief valve 60 bar, left CORTO drive On/Off

73 Pressure relief valve 60 bar, right CORTO drive On/Off

74 Oil accumulator for Contour device

77 Right CORTO hydraulic cylinder, drive On/Off

78 Left CORTO hydraulic cylinder, drive On/Off

79 80 bar oil pressure switch

80 100 bar pressure relief valve, double-acting

81 Non-return valve, left

82 Hydraulic cylinder, left CORTO, starting protection

83 Pressure relief valve 180 bar

84 Non-return valve, right

85 Hydraulic cylinder, right CORTO, starting protection

86 Pressure relief valve 180 bar

87 Pressure gauge, CORTO right-hand load relief

88 Accumulator, right-hand, pre-loaded to 210 bar

89 Lock-up valve unit on right side, electro-magnetic control

(open when deenergized)

90 Hydraulic cylinder, raise and/or load relief of right CORTO

91 Hydraulic cylinder, fold left CORTO in and out

92 Hydraulic cylinder, fold right CORTO in and out

93 160 bar oil pressure switch

94 30 bar oil pressure switch

95 Centre mower unit raise/lower hydraulic cylinder

96 Lock-up valve unit on left side, electro-magnetic control

(open when deenergized)

97 Pressure gauge, CORTO left-hand load relief

98 Accumulator, left-hand, pre-loaded to 210 bar

99 Lock-up valve unit, oil flow from B to A is possible when deenergized.

100 Hydraulic cylinder, raise and/or load relief of left CORTO

101 Lock-up valve unit, oil flow from B to A is possible when deenergized.

102 Right lock-up valve unit, drive On/Off

103 Left lock-up valve unit, drive On/Off

3-10 10/04

Page 55

TIC CORTO 8100 F/T Hydraulic / Electric System

CORTO 8100 T

10/04 3-11

Page 56

Hydraulic / Electric System CORTO 8100 F/T TIC

2.1.2 Function

Putting into operation Switch on stop switch 1. Current is applied to relays 5, 6, and 7,

terminals 30 and 86.

Switching on/Shutting down

the right-hand drive

Actuate rocker switch 3. Solenoid valve 102 is energized.

Lock-up valve unit 102 is opened and oil can flow into cylinder 77 upon

actuation of the tractor hydraulics and switch on the drive.

The adjustable pressure relief valve 72 opens at 60 bar.

Switching on/Shutting down

the left-hand drive

Actuate rocker switch 2. Solenoid valve 103 is energized.

Lock-up valve unit 103 is opened and oil can flow into cylinder 78 upon

actuation of the tractor hydraulics and switch on the drive.

The adjustable pressure relief valve 72 opens at 60 bar.

Folding the machine to

working position

Actuate the double-acting additional control unit on the tractor.

Oil flows into hydraulic cylinders 82, 85, 91 and 92.

Upon reaching the end position or 80 bar, the oil pressure switch 79

connects earth to relay 6.

Relay 6 connects the current supply to coil 99. Lock-up valve unit 99 is

opened and the front mower unit is lowered.

Folding the machine to

transport position

Actuate the double-acting additional control unit on the tractor.

Oil flows to hydraulic cylinders 95.

Upon reaching the end position or 160 bar, the oil pressure switch 93

connects earth to relay 7.

Relay 7 connects the current supply to coil 101.

Lock-up valve unit 101 is opened and oil flows into the hydraulic cylinders

91 and 92. The side-mounted mower unit are folded in.

The oil accumulator is shut

off while the three-point

hitch is raised

By raising the entire mower unit, using the tractor hydraulics, the oil

pressure switch (94) is actuated due to the load by the front mower unit

on the Hydraulic cylinders.

Relay (5) connects the current supply to coil (89) and (96). This blocks

the oil flow to the oil pressure reservoir (88) and (89.)

3-12 10/04

Page 57

TIC CORTO 8100 F/T Hydraulic / Electric System

CORTO 8100 T

10/04 3-13

Page 58

Hydraulic / Electric System CORTO 8100 F/T TIC

2.2 Electric System CORTO 8100 T

2.2.1 Key to diagram

1 Stop switch in control terminal

2 Left CORTO push switch, drive On/Off

3 Right CORTO push switch, drive On/Off

4 Indicator light in stop switch

5 Relay (switches coils 89 and 96)

6 Relay (switches coil 99)

7 Relay (switches coil 101)

8 Earth point

79 Oil pressure switch 80 bar (switches relay 6)

89 Coil - lock-up valve unit – right side-mounted mower unit

93 Oil pressure switch 160 bar (switches relay 7)

94 Oil pressure switch 30 bar (switches relay 5)

96 Coil - lock-up valve unit – left side-mounted mower unit

99 Coil – lower centre mower unit

101 Coil - side-mounted mower units to transport position

102 Coil – right-hand drive On/Off

103 Coil – left-hand drive On/Off

2.2.1 Function

Putting into operation Switch on stop switch 1.

Current is applied to relays 5, 6, and 7, terminals 30 and 86.

Switching on/Shutting down

the right-hand drive

Actuate rocker switch 3. Solenoid valve 102 is energized.

Lock-up valve unit 102 is opened and oil can flow into cylinder 77 upon

actuation of the tractor hydraulics and switch on the drive.

The adjustable pressure relief valve 72 opens at 60 bar.

Switching on/Shutting down

the left-hand drive

Actuate rocker switch 2. Solenoid valve 103 is energized.

Lock-up valve unit 103 is opened and oil can flow into cylinder 78 upon

actuation of the tractor hydraulics and switch on the drive.

The adjustable pressure relief valve 72 opens at 60 bar.

Folding the machine to

working position

Actuate the double-acting additional control unit on the tractor.

Oil flows into hydraulic cylinders 82, 85, 91 and 92.

Upon reaching the end position or 80 bar, the oil pressure switch 79

connects earth to relay 6.

Relay 6 connects the current supply to coil 99. Lock-up valve unit 99 is

opened and the front mower unit is lowered.

Folding the machine to

transport position

Actuate the double-acting additional control unit on the tractor.

Oil flows to hydraulic cylinders 95.

Upon reaching the end position or 160 bar, the oil pressure switch 93

connects earth to relay 7.

Relay 7 connects the current supply to coil 101.

Lock-up valve unit 101 is opened and oil flows into the hydraulic cylinders

91 and 92. The side-mounted mower unit are folded in.

The oil accumulator is shut

off while the three-point

hitch is raised

By raising the entire mower unit, using the tractor hydraulics, the oil

pressure switch (94) is actuated due to the load by the front mower unit

on the Hydraulic cylinders.

Relay (5) connects the current supply to coil (89) and (96). This blocks

the oil flow to the oil pressure reservoir (88) and (89.)

3-14 10/04

Page 59

TIC CORTO 8100 F/T Hydraulic / Electric System

CORTO 8100 T

10/04 3-15

Page 60

Hydraulic / Electric System CORTO 8100 F/T TIC

3-16 10/04

Page 61

TIC LINER Hydraulic / Electric System

LINER 3000 .............................................................................................................................................2

1.0

1.1

Hydraulic System .................................................................................................................................2

1.1.1 Hydraulic circuit diagram ..............................................................................................................2

1.1.2 Function - valve assignment.........................................................................................................2

1.1.3 Valve block 21...............................................................................................................................4

1.1.4 Valve block 22...............................................................................................................................6

1.1.5 Location of components................................................................................................................8

1.2 Electric System LINER 3000............................................................................................................10

1.2.1 Electric circuit diagram................................................................................................................10

1.3

CCT LINER 3000 .............................................................................................................................12

1.3.1 Manual control ............................................................................................................................14

1.3.2 Emergency program ...................................................................................................................16

1.3.3 Setting the rotor raise height.......................................................................................................18

1.3.4 Working with the rear rotors only ................................................................................................20

1.3.5 Raising the front rotors separately..............................................................................................20

1.3.6 Setting the sequential control on the turning area......................................................................22

1.4 Learning the limit stops (setting of basic values) ...............................................................................24

1.4.1 Execution ....................................................................................................................................24

1.5

Checking in case of malfunctions ......................................................................................................26

1.6

Installing the angle transmitters .........................................................................................................27

1.6.1 Front angle transmitter................................................................................................................27

1.6.2 Rear angle transmitter ...............................................................................................................27

1.6.3 Adjustment of angle transmitters................................................................................................28

1.6.4 Checking the signal voltages .....................................................................................................28

1.6.5 Diagnosis of angle transmitter ....................................................................................................29

1.7

Compressed-air brake system ...........................................................................................................30

LINER 1550 Twin Profile......................................................................................................................32

2.0

2.1

Hydraulic System ...............................................................................................................................32

LINER 650 Twin, LINER 880................................................................................................................34

3.0

3.1

LINER 650 Twin.................................................................................................................................34

3.1.1 Hydraulic System........................................................................................................................34

3.2

LINER 880 Twin.................................................................................................................................35

3.2.1 Hydraulic System........................................................................................................................35

4.0 Flow divider for slopes ............................................................................................................................36

4.2

LINER 1500/1550...............................................................................................................................38

10/04 4-1

Page 62

Hydraulic / Electric System LINER TIC

1.0 LINER 3000

1.1 Hydraulic System

1.1.1 Hydraulic circuit

diagram

1.1.2 Function - valve

assignment

M 1 Circulation blocking solenoid valve (master valve)

M 2 Lower chassis solenoid valve

M 3 Raise chassis solenoid valve

M 4 Lower front rotors solenoid valve

M 5 Raise front rotors solenoid valve

M 6 Front rotors wider solenoid valve

M 7 Front rotors narrower solenoid valve

M 8 Raise rear rotors solenoid valve

M 9 Lower rear rotors solenoid valve

M 10 Lower rear rotors solenoid valve

11 Two-way flow divider

12 Raise/lower chassis hydraulic cylinder

13 Raise/lower front rotors hydraulic cylinder

14 Swath width front narrower/wider hydraulic cylinder

15 Raise/lower rear rotors hydraulic cylinder

16 Quick release coupling on tractor P (pressure)

17 Quick release coupling on tractor T (pressureless return line)

19 Lock-up valve unit

20 One-way restrictor valve (drop rate restrictor)

21 Valve block, complete

22 Valve block, complete

23 Shut-off tap

24 High-pressure filter

X John Deere screw (constant-pressure hydraulic system) via screw on the

solenoid.

Function Valve

Raise front rotors 1 + 5

Lower front rotors 1 + 4

Raise rear rotors 1+ 8

Lower rear rotors 1+ 9 + 10

Raise chassis 1 + 3

Lower chassis 1 + 2

Increase working width 1 + 6

Decrease working width 1 + 7

4-2 10/04

Page 63

TIC LINER Hydraulic / Electric System

LINER 3000

10/04 4-3

Page 64

Hydraulic / Electric System LINER TIC

1.1.3 Valve block 21

Key to diagram M1 Circulation blocking solenoid valve (master valve)

M4 Lower front rotors solenoid valve

M5 Raise front rotors solenoid valve

X John Deere screw (constant-pressure hydraulic system)

4-4 10/04

Page 65

TIC LINER Hydraulic / Electric System

Valve block 21: master valve, raise/lower front rotors

10/04 4-5

Page 66

Hydraulic / Electric System LINER TIC

1.1.4 Valve block 22

Key to diagram M2 Lower chassis solenoid valve

M3 Raise chassis solenoid valve

M6 Front rotors wider solenoid valve

M7 Front rotors narrower solenoid valve

4-6 10/04

Page 67

TIC LINER Hydraulic / Electric System

Valve block 22

10/04 4-7

Page 68

Hydraulic / Electric System LINER TIC

1.1.5 Location of

components

Key to diagram M1 Circulation blocking solenoid valve (master valve)

M2 Lower chassis solenoid valve

M3 Raise chassis solenoid valve

M4 Lower front rotors solenoid valve

M5 Raise front rotors solenoid valve

M6 Front rotors wider solenoid valve

M7 Front rotors narrower solenoid valve

M8 Raise rear rotors solenoid valve

M9 Lower rear rotors solenoid valve

M10 Lower rear rotors solenoid valve

P Pump inlet

T Tank line

Function/valve assignment

Function Valve

Raise front rotors 1 + 5

Lower front rotors 1 + 4

Raise rear rotors 1+ 8

Lower rear rotors 1+ 9 + 10

Raise chassis 1 + 3

Lower chassis 1 + 2

Increase working width 1 + 6

Decrease working width 1 + 7

4-8 10/04

Page 69

TIC LINER Hydraulic / Electric System

Valve inserts

The valve insert part no. 631 444.0 is built into the solenoid valves M3,

M6, M7 and M10.

The valve insert part no. 631 520.0 is built into solenoid valve M2.

Attention

When disassembling or replacing the valve insert, the copper ring

094 001.0 must be replaced.

10/04 4-9

Page 70

Hydraulic / Electric System LINER TIC

1.2 Electric System

LINER 3000

1.2.1 Electric circuit

diagram

Key to diagram - Inputs F 6 A fuse

J 0 2-pin connector – on-board power supply from tractor pin 15/30 = +,

pin 31 = J 1 12-pin round connector – on-board power supply

J 2 3-pin connector for angular sensor of front rotor

J 3 3-pin connector for angular sensor of rear rotor

J 4 Not used

J 5 3-pin connector Reed contact (drive)

J 6 15-pin connector CCT - CCU

J10 3-pin connector Reed contact (chassis)

DS 1 Speed sensor (Reed contact) of front drive shaft

FS 1 Chassis top position sensor (Reed contact) from serial no.

RS 1 Not used

WS 1 Front rotor angular sensor

WS 2 Rear rotor angular sensor

Key to diagram -

Control terminal ST CCT = CLAAS Control Terminal

1 Switch - On/Off

2 Stop switch

3 Working position switch

4 Transport position switch

5 Swath width front + switch

6 Swath width front - switch

7 Raise front rotors switch

8 Lower front rotors switch

9 Turning area switch

10 LED (light-emitting diode)

Key to diagram - Outputs M 1 Circulation blocking solenoid valve (master valve)

M2 Lower chassis solenoid valve

M3 Raise chassis solenoid valve

M4 Lower front rotors solenoid valve

M5 Raise front rotors solenoid valve

M6 Swath width front + solenoid valve

M7 Swath width front - solenoid valve

M8 Raise rear rotors solenoid valve

M9 Lower rear rotors solenoid valve

M10 Lower rear rotors solenoid valve

Key to diagram -

Software download

J 7 Jxx 25-pin connector(download)

RS 232 cable for PC or CDS (CLAAS Diagnosis System)

Key to diagram -

Diagnosis

J 8 7-pin

Diagnosis connector

Key to diagram -

Electronic control system

CCU J 9 Claas Control Unit (control module)

55-pin connected on CCU

4-10 10/04

Page 71

TIC LINER Hydraulic / Electric System

LINER 3000 electric system

10/04 4-11

Page 72

Hydraulic / Electric System LINER TIC

1.3 CCT

LINER 3000

Key to diagram 1 On/Off switch

(press for approx. 3 seconds until LED lights up or goes out)

2 Stop switch (program interruption)

3 Working position switch

4 Transport position switch

5 Swath width front wider switch

6 Swath width front narrower switch

7 Raise front rotors switch

8 Lower front rotors switch

9 Turning area switch

10 LED (light-emitting diode)

After switching on the control terminal, the angle transmitters are

automatically tested:

• LED 10 lights up: no fault

• LED 10 flashing once: front angle transmitter defective.

• LED 10 flashing twice: rear angle transmitter defective.

• LED 10 flashing three times: both angle transmitters defective.

4-12 10/04

Page 73

TIC LINER Hydraulic / Electric System

Control sequence

Switch!on!control!unit

Emergency

program

Normal!operation

Manual!operation

Normal!run!of!control!unit

!!!-!Working!position

!!!-!Road!travel

!!!-!Turning!area

Shut!down!the!control!unit

Setting!the!

basic!values

Setting!the!

raise!height

Setting!the!

turning!are!time

Control!unit!is!shut!down

Dcvl!032!en

10/04 4-13

Page 74

Hydraulic / Electric System LINER TIC

1.3.1 Manual control

Manual control is used for diagnosis purposes.

Individual functions (valves) are checked.

Switching on manual

control:

Press key 3 (working position) and key 6 (front swath width)

simultaneously for approx. 7 seconds.

The flashing mode of LED 10 changes.

Key functions when

manual control is active

Folding up the rear rotors Press key 4 (transport position).

Lowering the rear rotors Press key 3 (working position).

Folding up the front rotors Press key 7 (fold up front rotors).

Lowering the front rotors Press key 8 (lower front rotors).

Increasing the front swath

Press key 5 (increase working width)

width

Decreasing the front swath

Press key 6 (decrease working width)

width

Raising/lowering the

Press key 9 (turning area) and hold it (chassis is raised or lowered).

chassis

Notes:

• All functions only work as long as the corresponding key is pressed.

• When the control unit is in this mode, all safety circuits are shut

down. When the swather is in working position, do not lower the

chassis!

• After shutting down the control unit, it will resume normal operation

when switching it on the next time.

4-14 10/04

Page 75

TIC LINER Hydraulic / Electric System

10/04 4-15

Page 76

Hydraulic / Electric System LINER TIC

1.3.2 Emergency

The emergency program could be used when one angle transmitter fails.

program

Switching on: Press key 3 (working position) and key 5 (increase front swath width)

simultaneously for 7 seconds.

Notes:

• The emergency program goes through the different functions during

the period previously stored. This cannot be changed.

(Basic setting, rotor height adjustment and time adjustment on the

turning are not possible).

• Switching back and forth between the “Raise front rotors” and “Lower

front rotors” functions is not possible.

• The functions “Fold rotors to working position” and “Fold rotors to

transport position” must always be completed. When one process is

stopped by the STOP key, it must be repeated in order to reach the

desired position.

• After shutting down the control unit, it will resume normal operation

when switching it on the next time. The emergency program must

now be re-started.

4-16 10/04

Page 77

TIC LINER Hydraulic / Electric System

10/04 4-17

Page 78

Hydraulic / Electric System LINER TIC

1.3.3 Setting the rotor

raise height

Activating the setting mode: Press key 3 and key 7 simultaneously for approx. 3 seconds.

The flashing mode of LED 10 changes.

Go to the desired rotor

positions using keys 5 – 8:

Key 5: Raising the rear rotors.

Key 6: Lowering the rear rotors.

Key 7: Raising the front rotors

Key 8: Lowering the front rotors

Saving the settings When the desired setting has been reached, save this setting by pressing

key 9.

4-18 10/04

Page 79

TIC LINER Hydraulic / Electric System

10/04 4-19

Page 80

Hydraulic / Electric System LINER TIC

1.3.4 Working with the

rear rotors only

Application:

• for work on narrow plots of land

• for depositing lighter swaths

Operation: First press key 9.

Now press key 7.

The front rotors remain raised, the rear rotors are lowered to their working

position.

Now either press key 9 = all rotors are raised,

or

press key 8 = all rotors are lowered to their working position.

1.3.5 Raising the front

rotors separately

Separately raising the front rotors is only possible when using additional

equipment:

2x 812 987.1 Hose (6 m x 8 NN; 2 union nuts)

1x 904 268.0 Shut-off tap

2x 812 989.0 Coupling plug

The tractor must be equipped with a double-acting additional control unit

for each rotor.

The rear rotors cannot be raised separately.

4-20 10/04

Page 81

TIC LINER Hydraulic / Electric System

10/04 4-21

Page 82

Hydraulic / Electric System LINER TIC

1.3.6 Setting the

sequential control

on the turning area

The sequential control defines the time delay by which the rear rotors are

lowered or raised as compared with the front rotors.

Before the first use, the control unit can be adapted to the individual

ground speed.

Lowering the rotors: Briefly press key 9 when driving on the turning area.

After this (within 3 seconds), press and hold key 6.

The rear rotors will fold down only after this key is released.

The time between lowering the front rotors and lowering the rear rotors

has now been stored.

Raising the rotors: Briefly press key 9 when driving out of the turning area.

After this (within 3 seconds), press and hold key 6.

The rear rotors will fold up only after this key is released.

The time between raising the front rotors and raising the rear rotors has

now been stored.

The basic ex-works setting can be programmed at any time as an alternative to the individual setting:

Basic setting

(3 seconds = ex-works

programming)

Press key 9.

After this (within 3 seconds), press key 5.

The time delay between lowering/raising of the front rotors and

lowering/raising of the rear rotors is set to 3 seconds.

4-22 10/04

Page 83

TIC LINER Hydraulic / Electric System

10/04 4-23

Page 84

Hydraulic / Electric System LINER TIC

A

A

1.4 Learning the limit

stops (setting of

basic values)

This process includes:

• reading in of the individual angle transmitter values,

• setting the sequential control of the rear rotors relating to the front

rotors to the ex-works values (3 seconds).

This process must be

carried out when

• electronic components (module, angle transmitter) have been

replaced,

• trouble in the program run occurs.

1.4.1 Execution

Setting the basic values

from the transport position

The machine is in transport position and on a level surface.

(The arms must be able to fold out completely.)

Switch on the tractor hydraulics.

djusting the engine speed and possibly the volume flow controller of the

tractor hydraulics:

Approx. 35 – 60 l/min. are required for the oil supply.

The setting process is automatic and can only be interrupted with the

STOP key.

1. Switch on the control

Keep key 1 pressed for 3 seconds until LED lights up.

unit.

2.

ctivating the basic value

setting process

Press key 3 (working position) and key 4 (road travel) simultaneously

until the Liner hydraulics is active (hydraulic noise).

During the setting process, first the chassis is raised to working position.

To make the program continue, the Reed switch (on the left axle arm)

must be activated = magnet in front of the Reed switch (from serial no.).

Liner machines without

Reed switch

To allow the setting process to be carried out on machines without Reed

switch, press key 9 after raising the chassis to working position.

(up to serial no.)

3. Program sequence After raising the chassis, all rotors are lowered to working position and,

after a certain time, raised again automatically.

Wait until the Liner 3000 hydraulics is shut down.

Switch off the control unit (press key 1 for more than 3 seconds).

4. Checking Switch on the machine.

Press key 3 (working position).

When all rotors have lowered to their working position, the control unit is

OK.

Setting the basic values

from the working position

Press keys 3 and 4 simultaneously for 10 seconds.

The hydraulic pressure rises and this can be heard. After a short time, all

rotors fold up to transport position, the main chassis remains extended in

working position. The signal lamp constantly lights up after this process is

complete.

4-24 10/04

Page 85

TIC LINER Hydraulic / Electric System

Caution:

Never activate the emergency program directly after setting the basic

values.

When activating the emergency program directly following this setting

process, a malfunction will occur:

When pressing key 9 at the end of the field, all rotors are raised up to the

programmed height; when pressing key 9 (lower rotors to working

position) one more time, the front rotors will not be lowered, but raised up

to their transport position.

Remedy:

Raise and lower the rotors 20 times (using key 9) in normal operating

mode.

10/04 4-25

Page 86

Hydraulic / Electric System LINER TIC

1

1.5 Checking in case of

malfunctions

1. On-board voltage The on-board voltage should be between 10 and 16 volt under load.

2. Oil supply The oil supply from the tractor should be 35-60 litres/minute.

3. Reed switch on chassis

from serial no.

4. Checking the angle

transmitter

5. Manual operation Activate manual operation and perform the individual functions.

6. Re-initialisation If the angle transmitters are OK, the machine should not be set to the

7. Switching on automatic

functions

When no remedy to the fault can be identified, replace the CCU.

Check Reed switch in the end position of chassis

After switching on the control terminal, the angle transmitters are

automatically tested:

LED 10 lights up: no fault

LED 10 flashing once: front angle transmitter defective

LED 10 flashing twice: rear angle transmitter defective.

LED 10 flashing three times: both angle transmitters defective.

The flashing mode is repeated every 15 seconds.

The signal voltage of the angle transmitters should be between 0.5 and

4.5 volt.

Measuring range of angle transmitters: 120°

Signal voltage at 0° = 0.5 volt