Page 1

CROP TIGER 30

Operator’s Manual

Page 2

29482

!

s

n

o

i

t

c

u

r

t

s

n

i

y

t

e

f

a

s

e

h

t

P

l

e

a

s

e

w

o

l

l

o

f

d

n

a

d

a

e

r

Page 3

Contents

1 Introduction

1.1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.1.1 How to use this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.1.2 Validity of instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.1.3 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.1.4 Road traffic regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.1.5 Road traffic regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.2 Identification plates and identification numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.2.1 Spare parts and technical questions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.2.2 Machine identification plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.2.3 Engine identification plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2 Safety Rules

2.1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.1.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.1.2 Important information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.1.3 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.1.4 Safety and accident prevention regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.1.5 General safety and accident prevention regulations for combine harvesters . . . . . . . . . . . . . . 21

2.1.6 Prior to operation, general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.1.7 Transporting passengers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.1.8 General driving operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.1.9 Automotive operation of combine harvester . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.1.10 Driving operations on slopes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.1.11 Leaving the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.1.12 Front attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.1.13 Grain delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.1.14 Adjustment and maintenance work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.1.15 Accumulators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.1.16 Antifreeze . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.1.17 First aid measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.1.18 Applying the feeder housing safety lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.1.19 Disengaging feed rake conveyor safety lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2.1.20 Wheel chocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.1.21 Disconnecting the battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.1.22 Danger of injury due to escaping hydraulic liquid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.1.23 Attaching finger bar safety bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.2 Safety rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.2.1 Identification of warning and danger signs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.3 Safety decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.3.1 General instructions for warning signs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.3.2 Front attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.3.3 Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.3.4 Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.3.5 Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.3.6 Cab / Operator's platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

29482

3

Page 4

2.3.7 Feeder unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2.3.8 Threshing mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2.3.9 Crop receptacle / straw receptacle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2.3.10 Grain delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3 Sectional view of machine

3.1 CROP TIGER 30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.1.1 Overview of machine front and left side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.1.2 Overview of machine rear and right side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3.1.3 Overview of front attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4 Technical specifications

4.1 CROP TIGER 30 - TYPE 35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.1.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.1.2 Front attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.1.3 Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.1.4 Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.1.5 Chassis track width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.1.6 Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.1.7 Tyre pressures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.1.8 Steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.1.9 Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.1.10 Electric system / Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.1.11 Feeder unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.1.12 Threshing mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.1.13 Separation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.1.14 Cleaning unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.1.15 Crop receptacle / straw receptacle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.1.16 Grain delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.1.17 Attachment parts / machine body dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.1.18 Attachment parts / machine body weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

29482

5 Structure and function

5.1 CROP TIGER 30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.1.1 Structure of the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.1.2 Working mode of the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6 Prior to each operation

6.1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.1.1 General warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.1.2 Check list for daily operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7 Prior to initial operation

7.1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7.1.1 General warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7.1.2 Initial operation check list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.2 Front attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

7.2.1 Aligning the front attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

7.2.2 Fitting the crop dividers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4

Page 5

8 Overview of controls

8.1 Cab / Operator's platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

8.1.1 Operator’s platform overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

8.1.2 Switch console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

8.1.3 Ignition switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

8.1.4 Foot brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

8.1.5 Access ladder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

9 Driving and transportation

9.1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

9.1.1 General warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

9.1.2 Preparing road travel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

9.1.3 Preparing fieldwork . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

9.2 Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

9.2.1 Adjusting the diesel engine speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

9.2.2 Start diesel engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

9.2.3 Stopping the diesel engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

9.2.4 Filling up the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

9.3 Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

9.3.1 Adjusting the ground speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

9.3.2 Shifting gears . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

9.3.3 Driving behaviour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

9.3.4 Towing the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

9.4 Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

9.4.1 Applying the parking brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

9.4.2 Releasing the parking brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

9.4.3 Braking the machine using the foot brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

9.4.4 Parking the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

9.5 Steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

9.5.1 Steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

9.6 Cab / Operator's platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

9.6.1 Adjusting the driver's seat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

29482

10 Fieldwork settings

10.1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

10.1.1 General warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

10.1.2 Adjust the machine to the crop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

10.2 Front attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

10.2.1 Installing the crop lifters (optional equipment) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

10.2.2 Removing the crop lifters (optional equipment) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

10.2.3 Adjusting the skids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

10.2.4 Dismounting the front attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

10.2.5 Mounting the front attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

10.3 Threshing mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

10.3.1 Removing the threshing drum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

10.3.2 Installing the threshing drum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

10.3.3 Converting the threshing drum to rice harvesting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

10.3.4 Converting the threshing drum to grain harvesting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

10.3.5 Installing / removing the stone trap and stone trap feed plate . . . . . . . . . . . . . . . . . . . . . . . . . 97

5

Page 6

10.3.6 Removing the threshing concave . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

10.3.7 Threshing concave variants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

10.3.8 Installing the threshing concave . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

10.3.9 Adjusting the distance of the threshing concave . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

11 Fieldwork

11.1 General warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

11.1.1 General warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

11.1.2 Adjust the machine to the crop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

11.2 General operation of front attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

11.2.1 Before working in the field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

11.2.2 Checking the crop intake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

11.3 Front attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

11.3.1 Adjusting the reel tines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

11.3.2 Making the horizontal reel adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

11.3.3 Adjusting the stripper profile of the intake auger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

11.3.4 Adjusting the position of the intake auger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

11.3.5 Adjusting the intake auger fingers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

11.3.6 Adjusting the reel peripheral speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

11.3.7 Switching on the front attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

11.3.8 Switching off the front attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

11.4 Threshing mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

11.4.1 Engaging the threshing mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

11.4.2 Switching off the threshing mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

11.4.3 Installing the disawning bars (additional equipment) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

11.4.4 Adjusting the threshing drum speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

11.4.5 Removing the wrap around from the threshing drum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

11.5 Cleaning unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

11.5.1 Adjusting the sieve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

11.5.2 Adjusting the fan speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

11.5.3 Adjusting the fan blast reduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

11.6 Grain delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

11.6.1 Emptying the grain tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

11.7 Sieve charts / threshing charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

11.7.1 Threshing chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

29482

12 Faults and remedies

12.1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

12.1.1 General warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

12.2 Cab / Operator's platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

12.2.1 Opening the central terminal compartment / Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

12.2.2 Closing the central terminal compartment / Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

12.2.3 Basic central electrics fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

12.3 Front attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

12.3.1 Front attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

12.4 Feeder unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

12.4.1 Feeder unit problem and remedy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

12.5 Threshing mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

12.5.1 Threshing mechanism problem and remedy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

6

Page 7

12.5.2 Threshing drum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

12.6 Separation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

12.6.1 Separation problem and remedy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

12.7 Cleaning unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

12.7.1 Cleaning problem and remedy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

13 Maintenance

13.1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

13.1.1 General warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

13.2 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

13.2.1 Front attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

13.2.2 Cleaning the engine compartment and hazard areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

13.2.3 Belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

13.2.4 Variable-speed drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

13.2.5 Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

13.2.6 Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

13.2.7 Cleanliness of lubricants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

13.2.8 Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

13.2.9 Wheels / tyres . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

13.2.10Hydraulic system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

13.2.11Electrical system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

13.2.12Protective guards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

13.2.13Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

13.2.14Unbalance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

13.2.15Jack up the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

13.2.16Welding work on combine harvester . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

13.2.17Winter storage instructions for combines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

13.2.18Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

13.3 Maintenance schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

13.3.1 Service intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

13.4 Lubricants chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

13.4.1 Lubricants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

13.5 Front attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

13.5.1 Adjusting knife clips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

13.5.2 Setting the reel slip torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

13.6 Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

13.6.1 Engine overview Perkins 1104A-44 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

13.6.2 Overview of cooling units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

13.6.3 Cleaning the diesel engine surroundings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

13.6.4 Draining fuel from the fuel tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

13.6.5 Filling the fuel tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

13.6.6 Cleaning the fuel tank sieve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

13.6.7 Bleed fuel system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

13.6.8 Draining the condensate from the water separator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

13.6.9 Replacing the fuel filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

13.6.10Checking the diesel engine oil level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

13.6.11Changing the diesel engine oil / oil filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

13.6.12Adjusting the diesel engine valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

29482

7

Page 8

13.6.13Checking the radiator coolant level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

13.6.14Checking the coolant mixing ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

13.6.15Changing the radiator coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

13.6.16Draining coolant from the water radiator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

13.6.17Topping up coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

13.6.18Cleaning the rotary chaff screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

13.6.19Cleaning the cooling unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

13.6.20Changing the coolant hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

13.6.21Cleaning/changing the air filter in the diesel engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

13.6.22Replacing the diesel engine air filter safety filter cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . 177

13.6.23Cleaning the air filter intake screen of the diesel engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

13.6.24Changing the air intake hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

13.6.25Retightening the air intake tube clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

13.7 Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

13.7.1 Checking the wheel nuts tightening torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

13.7.2 Cleaning the surroundings of the drive axle manual gearbox . . . . . . . . . . . . . . . . . . . . . . . . 180

13.7.3 Checking the axle drive oil level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

13.7.4 Draining the axle drive oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

13.7.5 Topping up the axle drive oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

13.7.6 Checking the drive axle gearbox oil level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

13.7.7 Draining the oil from the drive axle gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

13.7.8 Topping up oil in the drive axle gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

13.8 Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

13.8.1 Checking the brake fluid level and topping up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

13.8.2 Adjusting the parking brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

13.9 Drive belts / drive chains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

13.9.1 General warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

13.9.2 Adjusting the main drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

13.9.3 Adjusting the threshing drum drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

13.9.4 Adjusting the front attachment drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

13.9.5 Adjusting the grain tank unloading drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

13.9.6 Adjusting the sieve pan drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

13.9.7 Adjusting the grain elevator drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

13.9.8 Adjusting the fan drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

13.9.9 Adjusting the hydraulic pump drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

13.9.10Adjusting the 1st gear of ground drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

13.9.11Adjusting the 2nd gear of ground drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

13.9.12Chain on the knife drive:adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

13.9.13Tensioning intake auger drive chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

13.9.14Adjusting the reel drive chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

13.9.15Adjusting the grain elevator drive chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

13.9.16Adjusting the returns elevator drive chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

13.9.17Adjusting the collecting auger drive chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

13.10Hydraulic system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

13.10.1Relieving the accumulator pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

13.10.2Checking the hydraulic system oil level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

13.10.3Changing the hydraulic system oil / oil filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

29482

8

Page 9

29482

13.11Electric system / Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

13.11.1Checking the battery electrolyte level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

13.12Feeder unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

13.12.1Adjusting the feeder chains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

13.13Threshing mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

13.13.1Cleaning the stone trap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

13.13.2Adjusting the distance of the threshing concave . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

13.14Separation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

13.14.1Cleaning the auger troughs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

13.14.2Checking the deflector curtain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

13.15Cleaning unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

13.15.1Cleaning the fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

13.15.2Cleaning the preparation floor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

13.15.3Cleaning the sieves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

13.16Grain delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

13.16.1Adjusting the returns elevator chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

13.16.2Adjusting the grain elevator chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

13.16.3Cleaning the grain tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

14 Lubrication chart

14.1 Lubrication points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

14.1.1 General warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

14.1.2 Lubricants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

14.1.3 Greasing cycles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

14.1.4 Lubrication points - 10 h on the left . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

14.1.5 Lubrication points - 50 h on the left . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

14.1.6 Lubrication points - 50 h on the right . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

14.1.7 Lubrication points - 100 h on the left . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

14.1.8 Lubrication points - 100 h on the right . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

14.1.9 Lubrication points - 500 h on the left . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

14.1.10Lubrication points - 500 h on the right . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

9

Page 10

1 Introduction

1.1 General Information

1 Introduction

29483

1.1 General Information

2479

1.1.1 How to use this manual

This operator's manual is primarily intended for the

machine operator and provides information on the use,

adjustment and operation of the machine.

Provided all instructions regarding proper maintenance

and operation of your machine are followed, you can

count on many years of reliable service.

Please have your authorised CLAAS dealer carry out

regular inspections. Failure to perform maintenance or

incorrect operation lead to a reduction in performance

and a loss of time.

If you use the latest expertise and experience that

went into this machine, it will render you consistently

excellent service.

There is a separate operator's manual for front attachments and hitched devices.

Texts and figures

Pictures and graphics are neutral. Differences are

pointed out by notes beneath the figure.

Texts are short and not machine-specific as far as possible. Differences are pointed out by intermediate

headings.

Different types of texts can easily be distinguished

from one another by their formats. The following formats are distinguished:

Text type Description

Description Further information on

the subject.

– Instructions Operations which must

be carried out one after

the other.

Result Consequence of opera-

tions carried out.

Document structure based on subassemblies

As far as the contents permit, the chapters of this manual are structured according to subassemblies. The

structure of these subassemblies is the same in all

chapters.

Different product groups have different document

structures based on subassemblies. CLAAS always

takes care to keep these document structures based

on subassemblies identical in any documents.

10 000 295 893 0 - BA CROP TIGER 30 - 12/07

Page 11

1 Introduction

1.1 General Information

29483

Search and find

The wanted subject can easily be found with the recurring subassembly structure, using the table of contents

or the header line of this manual.

In addition, the index of this manual is a useful tool for

locating a specific subject. The index can be found on

the last pages of this manual.

Directions

Text elements such as front, rear, right and left always

apply to the direction of travel. In figures, the direction

of travel may be indicated by a direction arrow.

Your CLAAS Service Department

000 295 893 0 - BA CROP TIGER 30 - 12/07 11

Page 12

1 Introduction

1.1 General Information

1.1.2 Validity of instructions

The present Operator's Manual applies to the following

machine / front attachment:

Designation Type Machine number

from to

CROP TIGER 30 035 03500001 ―

1.1.3 Specifications

Technical data, dimensions and weights are given as

an indication only. CLAAS reserves the right to make

changes subsequently as technical developments continue. Responsibility for errors or omissions not

accepted.

1.1.4 Road traffic regulations

The details of the road vehicle regulations in different

countries may differ. In the event of discrepancies

between the instructions provided by the manufacturer

and the traffic regulations of the relevant countries, the

traffic regulations of the countries concerned apply.

29483

67865

2475

20728

The following information applies to the Federal

Republic of Germany.

As a rule, a self-propelled machine must have an operating licence and a certificate of exemption for driving

on public streets.

When driving on public streets and roads with a selfpropelled machine, all of the requirements relating to

an operating licence and a certificate of exemption

must be observed.

Documents to carry with you

Along with a driving licence, the machine operator

must always carry the originals of his operating licence

and his certificates of exemption.

Objects to carry with you

An advance warning triangle is to be carried with you

in all machines.

An advance warning triangle, a warning light and a

first-aid kit are to be carried with you in all commercially used machines.

Modifications to the machine

If parts of the machine, whose properties are specified,

are modified or fitted retroactively, and the operation of

them can cause a danger to other road users, then the

operating licence (individual operating licence) and the

certificate of exemption expire.

12 000 295 893 0 - BA CROP TIGER 30 - 12/07

Page 13

1 Introduction

1.1 General Information

29483

In order to obtain a renewed individual operating

licence, the machine must be shown to the technical

inspection authority (TÜV, DEKRA) who then issue an

individual approval in accordance with § 19 StVZO

(German Road Traffic Licensing Regulations).

If you are in doubt as to whether such a case exists,

please contact CLAAS as the manufacturer.

Warning beacons

When driving on public streets and roads, the yellow,

flashing warning lights (warning beacons) may only be

operated if this is explicitly specified in the individual

operating licence or in the certificate of exemption (for

example with a wide load).

Work lights

The work lights must be switched off when driving on

public streets and roads.

36993

1.1.5 Road traffic regulations

When driving the machine on public roads, all conditions of the operating permit and of the special

approval must be observed.

Road traffic regulations may vary between countries.

In case of discrepancies between the instructions provided by the manufacturer and the traffic regulations of

the relevant countries, the traffic regulations of the

countries concerned apply.

Documents to be carried on the machine

In addition to his driving licence, the operator must

always carry the original of the operating permit and of

the special approval.

Objects to carry with you

An advance warning triangle is to be carried with you

in all self-propelled work machines.

An advance warning triangle, a warning light and a

first-aid kit are to be carried with you in all commercially used machines.

In addition, at least one wheel chock is to be carried

with you in vehicles with a permitted total weight in

excess of 4 t.

As a rule, CLAAS self-propelled work machines are

equipped with 1 rigid or 2 folding wheel chocks. These

must only be used on the front wheels.

Machine with a wide load

In self-propelled work machines with a wide load

(width more than 3 m beyond the width of the tyres),

you must carry with you an individual operating licence

based on an individual approval, a certificate of

exemption in accordance with § 70, para.1 StVZO

(German Road Traffic Licensing Regulations) and an

exception permit in accordance with § 29 StVZO.

000 295 893 0 - BA CROP TIGER 30 - 12/07 13

Page 14

1 Introduction

1.1 General Information

29483

All of the requirements and obligations listed in these

documents are to be observed. In particular, the

instructions for indicating road vehicles with a wide

load are to be observed. (Two red and white striped

warning plates each in the front and at the rear, two

yellow, flashing warning lights).

Certificates of exception and exception permits are

issued in each state of Germany according to different

regulations. In general, information regarding this is

provided by your nearest road traffic licensing

department.

Additional weights

When driving on public streets, rear steering self-propelled work machines fitted with front attachments that

have received CLAAS approval must be equipped with

additional weights that act on the steering axle.

This is required in order to maintain steering of the

machine and to prevent it from lifting off at the rear

when braking and on slopes.

The required additional weights can be made up of

implements, rear axle weights and liquid filling in the

rear axle wheels.

The rear of self-propelled work machines is to be ballasted in accordance with the type of front attachment

and the equipment on the machine.

Detailed information on this matter can be obtained

from CLAAS.

Changes on the machine

If any parts of the machine are subsequently modified

whose condition is prescribed or the operation of

which (after being modified) could represent a hazard

to other road users, then the vehicle type approval registration shall no longer be valid and application must

be made for a new vehicle type approval registration.

In this case the machine must be presented to the

motor vehicle safety inspection authority responsible

(TÜV) in order to obtain an expert opinion certificate (§

19 section 2 StVZO).

If you are in any doubt as to whether this situation

applies in your case, please contact us as

manufacturers.

Towing a trailer

A trailer for front attachments may be towed in accordance with the permissible trailed load.

If a trailer is towed behind the machine, then the cable

for the entire lighting system must be connected and

the good condition of the lighting system assured.

In addition, particular care should be taken to properly

latch the trailer hitch.

14 000 295 893 0 - BA CROP TIGER 30 - 12/07

Page 15

1 Introduction

1.1 General Information

29483

The towing of other trailers in the trailer hitch is not

permitted in self-propelled combine harvesters when

driving on public streets.

Identification requirements

All CLAAS self-propelled work machines are to be

labelled, in accordance with § 58 StVZO (German

Road Traffic Licensing Regulations), with 3 speed

signs on the sides and on the back.

As a self-propelled work machine with a permitted

maximum speed of up to 20 km/h, the machine is

only subject to operating licence requirements. A registration plate number is not required.

According to § 4 of the FZV (German Motor Vehicle

Registration Regulation), the machine must be permanently and clearly labelled on the left-hand side with

the owner's first and last name as well as the town of

origin (company and registered office).

As a self-propelled work machine with a permitted

maximum speed of over 20 km/h, the machine is

subject to operating licence and registration plate

requirements.

As a part of registration plate requirements, regular

recurrent vehicle inspections are to be carried out by a

technical inspection authority (TÜV, DEKRA).

Warning beacons

When driving on public roads and lanes it is not permitted to have warning beacons installed unless the

machine is of excess width.

Work lights

The work lights must be switched off during road

travel!

Folding front attachments

The retrofitting of folding front attachments will cause

the individual operating licence of the machine and the

certificate of exemption to expire.

In order to obtain a renewed individual operating

licence, the machine must be shown to the technical

inspection authority (TÜV, DEKRA) who then issues

individual approval in accordance with § 19 StVZO

(German Road Traffic Licensing Regulations).

A renewed individual operating licence is to be applied

for at the appropriate administrative agency (vehicle

registration office) and requires new individual

approval and a certificate of exemption to be

submitted.

To facilitate the issuance of individual approval for the

technical inspection authority, CLAAS can issue a

sample certificate on request if provided with the

machine type, the machine number and the year of

manufacture.

000 295 893 0 - BA CROP TIGER 30 - 12/07 15

Page 16

1 Introduction

1.1 General Information

29483

In particular, the required weight increase on the steering axle is to be observed, in order to maintain steering

and to prevent the machine from lifting off when

braking.

In the event that the required additional weights are

missing, the technical inspection authority will generally not issue an individual approval.

If it is a new CLAAS self-propelled work machine with

fitted folding front attachment and the certification was

carried out at the factory by the technical inspection

authority, then the points mentioned above do not

apply.

16 000 295 893 0 - BA CROP TIGER 30 - 12/07

Page 17

1 Introduction

1.2 Identification plates and identification numbers

29483

1.2 Identification plates and identification

numbers

2496

1.2.1 Spare parts and technical questions

Please specify the respective identification nos. when

ordering spare parts and making technical inquiries:

• Machine

• Front attachment

•Engine

• Subassembly

and/or

• Software version / versions

This is necessary as otherwise, incorrect spare part

deliveries may result.

The identification no. can be found on the respective

type plate.

The identification no. / nos. of the software can be

found in the respective menu.

62333

1.2.2 Machine identification plate

21339

1

2

3

4

The identification plate is affixed to the right-hand side

of the machine on the operator's platform.

Designation

1Type

2 Identification no. (machine number)

3 Type of diesel engine

4 Year of manufacture

1

2

21338

000 295 893 0 - BA CROP TIGER 30 - 12/07 17

Page 18

1 Introduction

1.2 Identification plates and identification numbers

1

21352

29483

In addition, the identification number of the machine is

stamped into the frame underneath the flap (1).

3

62312

1.2.3 Engine identification plate

The identification plate of the diesel engine is affixed

above the engine.

21341

4

18 000 295 893 0 - BA CROP TIGER 30 - 12/07

Page 19

2 Safety Rules

2 Safety Rules

2.1 General Information

29484

2.1 General Information

45097

2.1.1 General information

The CE mark and the enclosed declaration of conformity document that the self-propelled machine

fulfils the safety regulations of the EC Machinery

Directive.

Before putting the machine into operation, read and

follow the Operator's manual and the safety

instructions!

857

2.1.2 Important information

The instructions in this operator's manual must be read

and observed, in order to prevent danger to all persons, who operate, maintain, repair and inspect this

CLAAS product.

Please read, in particular, the sections "Safety rules",

"Before commissioning" and "Before putting the

machine into operation" in the machine operator's

manual.

The use of spare parts, accessories and ancillary

equipment that are not original CLAAS parts and not

tested and approved by CLAAS, can have a negative

impact on design specifications of the CLAAS machine

and its operational reliability and thereby impair active

and/or passive driving safety, as well as occupational

safety (accident prevention).

Insofar as damages are caused through the use of

non-CLAAS parts, accessories and ancillary equipment, any liability will be rejected by CLAAS.

858

2.1.3 Intended use

Both the front attachment and the machine are

designed solely for use in customary agricultural operations (intended use).

Use in any other way is considered as contrary to the

intended use. The manufacturer accepts no liability for

any damage or injury resulting from this misuse and

these risks must be born solely by the user.

Compliance and strict adherence to the conditions of

operation, service and repair as specified by the manufacturer also constitute essential elements for the

intended use.

This front attachment and the machine may be operated, serviced and repaired only by persons familiar

with all its particular characteristics and acquainted

with the relevant safety rules.

000 295 893 0 - BA CROP TIGER 30 - 12/07 19

Page 20

2 Safety Rules

2.1 General Information

29484

The accident prevention regulations, all other generally recognised regulations on safety and occupational

medicine and the road traffic regulations must be

observed at all times.

Any arbitrary modifications carried out on the front

attachment and on the machine will relieve the manufacturer of all liability for any resulting damage or

injury.

2413

2.1.4 Safety and accident prevention regulations

• In addition to the information in this operator's

manual, please refer to the general safety and

accident prevention regulations.

• Before putting the machine into operation, check it

for road and operational safety.

• Observe the respective regulations when using

public traffic routes.

• Before work commences, you must familiarise

yourself with all of the control mechanisms and

their function. Once you are driving it is too late.

• Before starting the diesel engine, you must ensure

that all safety devices are attached and in their

protective positions.

• Only start the diesel engine from the driver's seat.

The diesel engine must not be started by shortcircuiting the electrical connections on the starter,

because the machine may immediately start to

move.

• Before starting the diesel engine and before

switching on the machine:

- Ensure that there are no persons, children or

objects in the hazardous area.

- Look out for children.

- Signal by sounding the horn.

• Before pulling away in the machine:

- Ensure that there are no persons, children or

objects in the danger area.

- Ensure adequate visibility.

- Check the immediate vicinity for people and

children.

- Look out for children.

- Signal by sounding the horn.

• Do not let diesel engine run in enclosed spaces.

• The driver should not wear loosing clothing. Avoid

loose-fitting clothing.

• Caution is urged when handling fuel. – Increased

fire hazard. Never pour fuel in close proximity to

open flames or sparks that may cause ignition. Do

not smoke while filling the fuel tank.

• Before filling the fuel tank, always switch off the

diesel engine and remove the ignition key. Do not

fill the fuel tank in an enclosed space. Wipe up

spilled fuel immediately.

20 000 295 893 0 - BA CROP TIGER 30 - 12/07

Page 21

2 Safety Rules

2.1 General Information

29484

• To prevent a risk of fire, keep the machine clean.

• Caution is urged when handling brake fluid and

battery acids.

Toxic and corrosive.

• Ensure there is sufficient safety clearance in

areas with low-hanging power lines. You may

need to look out for radio antenna.

• The warning and information labels affixed to the

machine provide important information regarding

safe operation.

Compliance is for your own safety.

Replace damaged and illegible warning signs /

safety instruction stickers immediately.

If parts with warning signs / safety instruction

stickers are being replaced, ensure that the

appropriate warning signs / safety instruction

stickers are affixed to the new parts.

• Do not stay in the engine compartment while the

diesel engine is running.

• Ensure that the access ladder, the platform and

other access areas of the machine are always free

from oil and grease.

36687

2.1.5 General safety and accident prevention regulations for combine harvesters

• Never stand inside the range of rotation of the

unloading auger tube while the engine is running.

Do not allow any other persons to stand there as

well!

2.1.6 Prior to operation, general

• Observe the maximum permissible axle loads and

total weights.

• Before starting to drive and operate the forage

harvester, adjust the mirrors to give full vision of

the road and of the operating area behind.

• Before driving the forage harvester always check

brakes for correct function and regularly check the

level of the brake fluid. Only use the specified type

of brake fluid and change the brake fluid at the

recommended intervals.

Take care when handling brake fluid.

Toxic and corrosive!

- Dispose of used brake fluid in a way that is

harmless to the environment and in accordance

with existing anti-pollution regulations.

• The left and right brake pedals must be locked

together for transport and road travel so that both

front wheel brakes will be applied simultaneously.

• Projecting parts must be removed or adjusted to

within the normal width of the machine before driving on public roads and lanes.

• Before driving off, always check the front and rear

wheels for the correct tyre pressures!

2414

000 295 893 0 - BA CROP TIGER 30 - 12/07 21

Page 22

2 Safety Rules

2.1 General Information

29484

2416

2.1.7 Transporting passengers

• Only such persons may be transported on the

instructor's seat who provide instructions regarding the machine.

• The carrying of passengers is otherwise not

permitted.

2417

2.1.8 General driving operations

• When driving on the road with a raised front

attachment, the safety switch must be switched

off.

• Never leave the operator's platform while driving.

• The machine is only permitted to drive on public

streets and roads with an empty grain tank / loading hopper.

• On public streets and roads, front attachments

with finger bars, crop lifters or crop divider points

must be covered.

• Be particularly careful at railway crossings. If a

railway crossing cannot be crossed quickly

because of traffic or an obstruction and without

stopping, then you must stop in front of the St.

Andrew's cross. Otherwise, a railway crossing is

to be crossed without stopping.

• The driving behaviour of the machine is affected,

for example, by the road and by implements.

Therefore, adapt your driving style to the actual

terrain and ground conditions. Special care must

be taken when working and turning on a slope or

with a full grain tank / loading hopper. – Never shift

gears on a slope.

• When the diesel engine has stopped or when the

hydraulic steering fails, significantly more force is

required to steer.

• Immediately stop the machine if there is with any

kind of steering or brake problem. Have malfunctions corrected immediately.

62317

2.1.9 Automotive operation of combine harvester

• When travelling on public roads swing in the grain

tank unloading tube all the way.

• Existing traffic regulations must be observed.

3715

2.1.10 Driving operations on slopes

• On surfaces with an incline of over 7 %, you must

shift down the gears (diesel engine braking effect).

62324

2.1.11 Leaving the machine

• Prevent the machine from rolling when you leave

(parking brake, wheel chocks). Turn the engine

off, remove the ignition key and lock the cab, if

necessary.

22 000 295 893 0 - BA CROP TIGER 30 - 12/07

Page 23

2 Safety Rules

2.1 General Information

• Never leave the machine unattended when the

engine is still running.

• Before leaving the machine, lower the front

attachment completely.

2.1.12 Front attachment

• Only carry out work under raised front attachments if they are supported safely.

• Front attachments and feeder units, such as conveyors, rollers, chains, augers, reels and similar

cannot be fully secured using integral design features due to their function. Therefore, during

operation, keep a sufficient safety distance from

the moving parts. The sense of these instructions

applies to all other ancillary attachments.

2.1.13 Grain delivery

• The augers located inside the grain tank

cannot be shielded completely against accidental

contact due to their function.

• Before mounting or entering the grain tank, make

sure that no other person can restart the engine.

• Enter the grain tank only through the opening provided for this purpose.

2.1.14 Adjustment and maintenance work

29484

62327

36728

62347

The drives on the machine will not be automatically

secured from moving after the engine has been

switched off.

Moreover, when it comes to adjustments, it may be

necessary to turn the drives.

For these reasons the following precautions should be

observed:

• Before adjustment, cleaning and maintenance

operations and before correcting malfunctions:

- Switch off the threshing mechanism.

- Disengage the front attachment.

- Switch off the grain tank unloading mechanism.

- Stop the engine.

• Before adjustment, cleaning and maintenance

operations and before correcting malfunctions at

the hydraulic system, lower the front attachment

and/or feeder unit all the way.

• As a rule, always disconnect the cable from the

battery when working on the electrical system.

• Once the threshing unit has been switched off, the

drives will continue turning for a short period of

time. You must wait until all the drives have

stopped before carrying out any work.

• Please ensure that it is not possible for anyone to

accidentally start the machine or turn any of the

drives whilst work is being carried out.

000 295 893 0 - BA CROP TIGER 30 - 12/07 23

Page 24

2 Safety Rules

2.1 General Information

29484

• Escaping fluid (fuel or hydraulic oil) under high

pressure can penetrate the skin and cause serious injury. If any fluid is injected into the skin,

consult a doctor immediately as otherwise serious

infections may result.

• Repair work on the hydraulic system may only be

carried out by specialist workshops.

• Be careful when opening the radiator cap. The

radiator is under pressure when the engine is hot.

• Do not attempt to mount a tyre unless you have

the proper equipment and experience to perform

the job safely.

• Dispose of oil, fuel and filters in a way that is

harmless to the environment and in accordance

with existing anti-pollution regulations!

• Retighten the wheel nuts and wheel bolts

regularly!

62824

2.1.15 Accumulators

Be especially careful when working on hydraulic systems equipped with accumulators. Hydraulic systems

with accumulators are under high pressure!

21510

Only have qualified workshops carry out repair work on

the hydraulic system.

1

2425

2.1.16 Antifreeze

Antifreeze is easily inflammable!

Keep antifreeze away from children!

Vapours may cause sleepiness and a dazed feeling.

Repeated contact may cause chapped or rough skin.

The following problems may arise:

• Irritation of the eyes

• Irritation of the respiratory tract

• Headache

•Giddiness

Effects on the central nervous system in case of high

doses:

• Difficulty in breathing

• Unconsciousness

Swallowing:

• Sickness

• Vomiting

24 000 295 893 0 - BA CROP TIGER 30 - 12/07

Page 25

2 Safety Rules

2.1 General Information

• Liver damage

Antifreeze must not come in contact with the

environment.

– Collect antifreeze in a suitable container!

– Dispose of antifreeze in a way that is harmless to

the environment and in accordance with existing

anti-pollution regulations.

2.1.17 First aid measures

Inhaling:

– Make the person inhale fresh air and consult a

doctor, depending on the symptoms.

– Remove the person from the hazard area.

Eye contact:

– Thoroughly flush with water for several minutes. If

necessary, consult a doctor.

Skin contact:

29484

2427

– Thoroughly clean with plenty of water and soap

and remove polluted and soaked clothing immediately, consult a doctor if skin is irritated (redness

etc.).

Swallowing:

– Do not cause vomiting, consult a doctor

immediately.

62390

2.1.18 Applying the feeder housing safety lock

The engaged safety lock prevents an uncontrolled

drop of the feed rake conveyor and the mounted front

attachment.

Danger!

Only undertake repair, maintenance and

cleaning work and the correction of malfunctions when the machine is stopped.

Death or serious injuries!

– Diesel engine OFF.

– Apply the parking brake.

– Remove ignition key.

– Loosen and remove the cable clamps on

the battery.

– Secure the machine with wheel chocks.

– Ensure that the machine cannot be put

into operation by a third party.

000 295 893 0 - BA CROP TIGER 30 - 12/07 25

Page 26

2 Safety Rules

2.1 General Information

29484

Danger!

The front attachment and / or the feeder unit

2

may drop in an uncontrolled way.

Death or serious injury.

– Keep a safe distance from the hazard

area.

3

1

2

21367

– Fully lower the reel.

– Raise the feeder unit all the way.

– Detach the safety lock (1) from the chain at (2)

and fold down onto the piston (3) of the hydraulic

cylinder.

– Lower the feeder unit onto the secured safety

lock (1).

62397

2.1.19 Disengaging feed rake conveyor safety lock

Danger!

Only undertake repair, maintenance and

cleaning work and the correction of malfunctions when the machine is stopped.

Death or serious injuries!

– Diesel engine OFF.

– Apply the parking brake.

– Remove ignition key.

– Loosen and remove the cable clamps on

the battery.

– Secure the machine with wheel chocks.

– Ensure that the machine cannot be put

into operation by a third party.

– Fully lower the reel.

– Raise the feeder unit all the way.

– Lift the safety lock (1) and hang into the chain at

2

(2).

Danger!

The front attachment and / or the feeder unit

may drop in an uncontrolled way.

3

1

Death or serious injury.

– Support front attachment and / or feeder

3

21367

unit.

– Keep a safe distance from the hazard

area.

26 000 295 893 0 - BA CROP TIGER 30 - 12/07

Page 27

2 Safety Rules

2.1 General Information

29484

62406

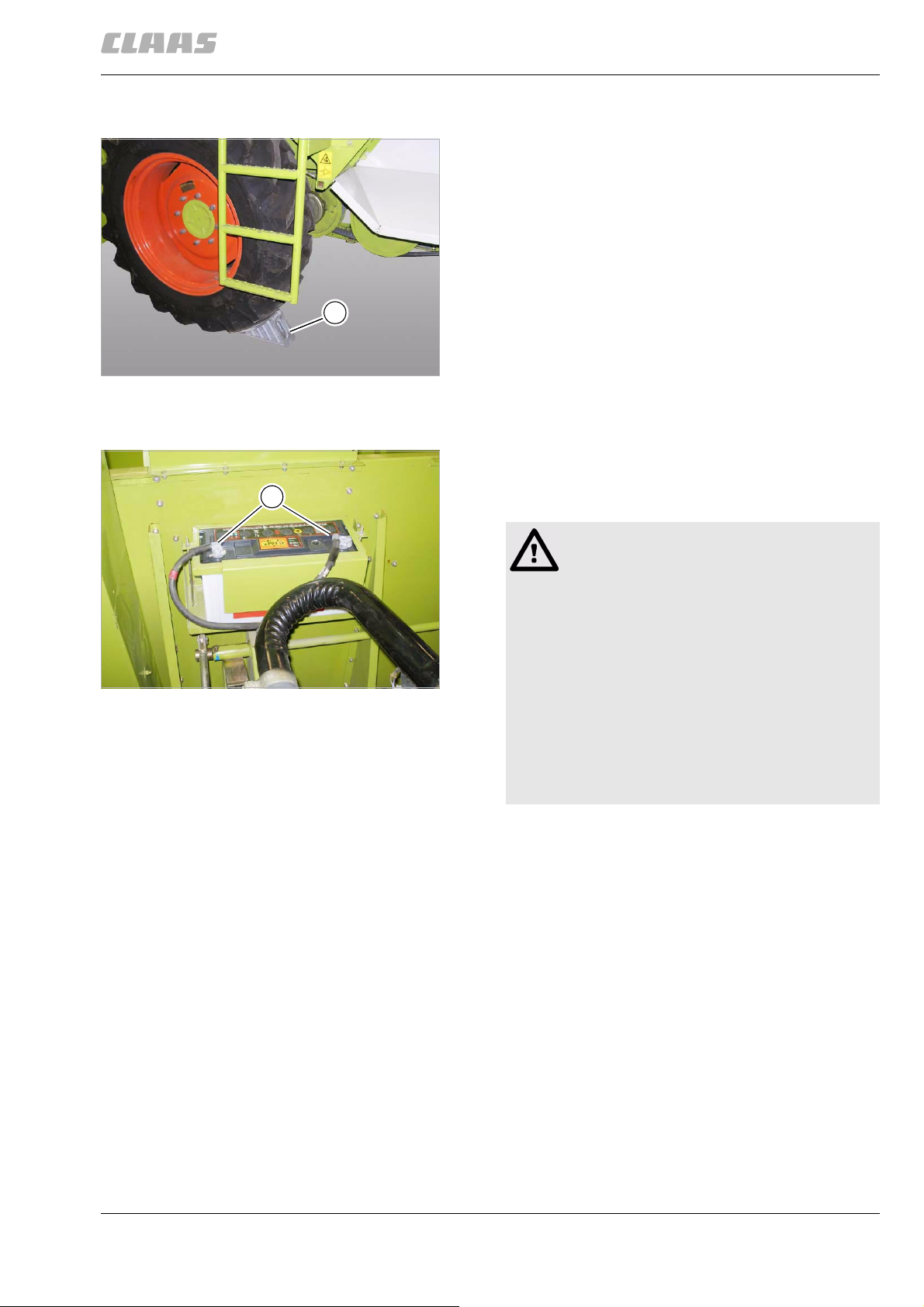

2.1.20 Wheel chocks

The wheel chocks are not included in the scope of

delivery of the machine.

– Place the wheel chock (1) on both sides of the

machine tightly in front of or behind the drive

wheel, depending on the slope.

The machine has been secured against rolling.

1

4

21394

65683

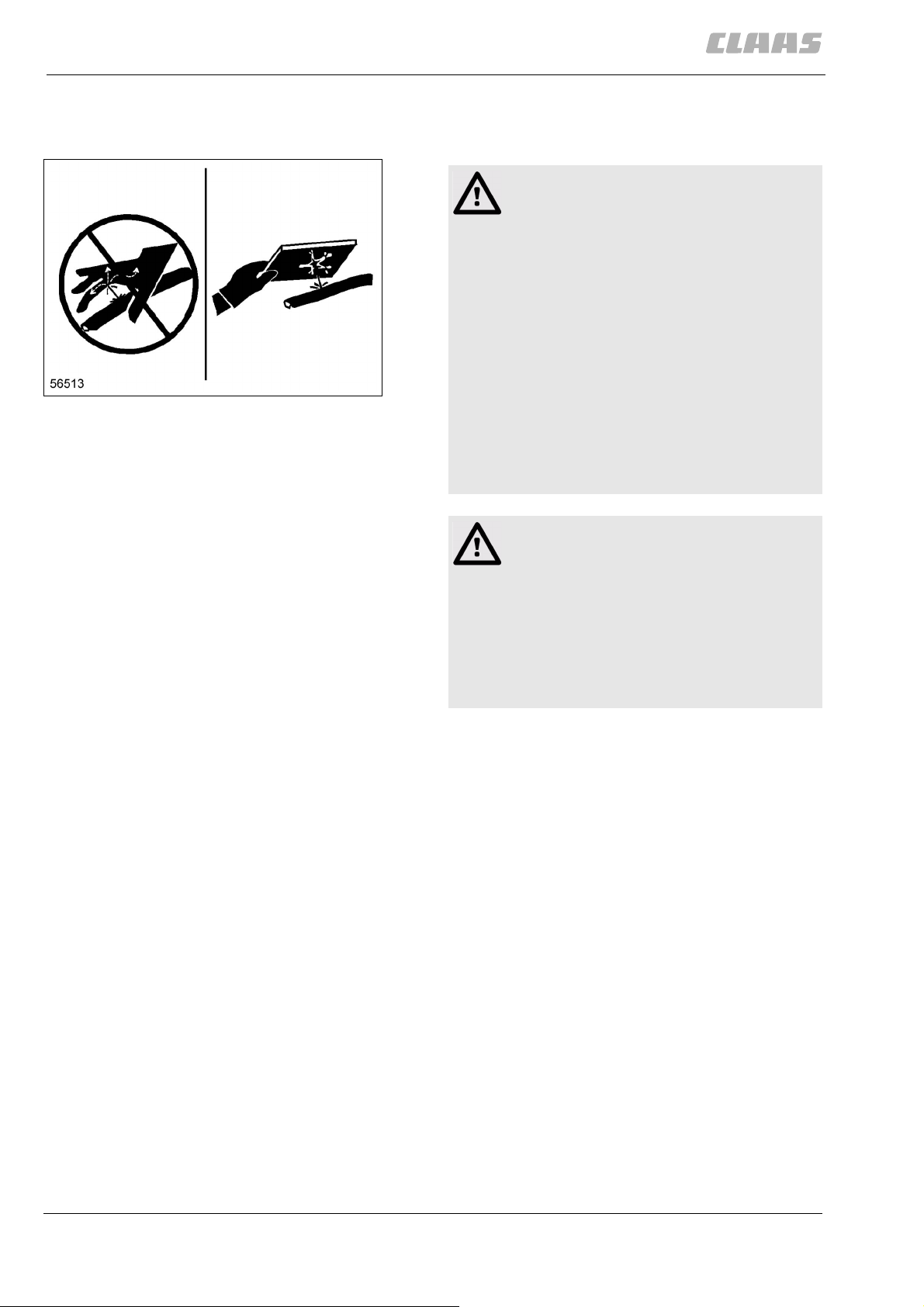

2.1.21 Disconnecting the battery

In order to interrupt the power supply to the machine,

loosen and remove the cable clamps (1) from the

1

battery.

21428

WARNING:

Work on the electrical system.

Machine damage.

– Before starting work, disconnect the cable

from the negative terminal first and then

from the positive terminal of the battery.

5

– When wrk is complete, first connect the

positive terminal and then the negative

terminal to the battery.

– Always disconnect the cables from the

alternator and battery before performing

electrical welding work on the machine

and the front attachment.

Disconnect the battery daily after using the machine

and in case of an emergency.

Do not disconnect the battery when the diesel engine

is running.

000 295 893 0 - BA CROP TIGER 30 - 12/07 27

Page 28

2 Safety Rules

2.1 General Information

740

2.1.22 Danger of injury due to escaping hydraulic liquid

Danger!

Liquids under high pressure.

Liquids penetrate the skin and cause serious

injury.

– Only have authorised and qualified work-

shops carry out work on the hydraulic

system.

– Check hose lines at regular intervals.

Search for leaks using a piece of wood or

6

cardboard.

Ensure that the oil jet will not be directed

towards your body.

– Replace any damaged hose lines.

– Replace hose lines 6 years after the date

of manufacture at the latest.

29484

36998

Danger!

Dealing incorrectly with injuries due to hydraulic fluids.

Death or serious injury.

Even a pinhole can result in severe injuries.

– If hydraulic fluid gets in the skin or eyes,

have the injury treated by a medical spe-

cialist immediately.

2.1.23 Attaching finger bar safety bar

For transporting the front attachment, the safety bar

must be placed on the finger bar.

In addition, the safety bar must be fitted during all

maintenance and repair work near the knives or the

feed mechanism.

On front attachments without a crop lifter fitted, the

safety bar must be attached directly on the knives.

– Raise the front attachment until the finger bar is in

a well-accessible working height.

– Raise the reel completely.

– Putting the machine out of operation.

63221

28 000 295 893 0 - BA CROP TIGER 30 - 12/07

Page 29

2 Safety Rules

2.1 General Information

Danger!

Only undertake repair, maintenance and