Page 1

AXION

950 940 930 920

Page 2

Page 3

The AXION 900.

Ten successful years on the market

speak for themselves: in a very short

time, CLAAS has become established

throughout Europe as one of the

leading tractor manufacturers. In 2011

CLAAS added the AXION 900 to its

family of large tractors delivering over

400 hp. With its enormous pulling

power, ease of operation and wealth

of intelligent systems, the AXION 900

opens up great potential in many

highly demanding applications and has

quickly become a standard feature of

the range.

Note: This brochure uses QR codes, which you

can use to access additional animated content

online using your smartphone. If you are unable to

use QR codes, simply enter the corresponding

URL into your web browser.

go.claas.com/

axion900video

Page 4

For real challenges.

Page 5

When massive pulling power joins

forces with maximum user-friendliness

to deliver unrivalled versatility and

performance –you are sitting in the

AXION 900.

Contents

CPS –

CLAAS POWER SYSTEMS

Engine 8

SCR 10

CMATIC 12

Construction 18

PTO 24

Hydraulics 26

Rear linkage 28

Front linkage 30

Pleasant working environment

Cab 34

CMOTION 40

CEBIS 42

Comfort 44

EASY –

Efficient Agriculture Systems

by CLAAS

CEBIS MOBILE 50

Steering systems 52

CSM 54

Job management and

TELEMATICS 56

Maintenance 58

First CLAAS Service,

MAXI CARE

®

60

Features 62

Specifications 63

Page 6

CPS – CLAAS POWER SYSTEMS.

Optimal drive for best results.

The CLAAS machinery development programme constantly

strives to maximise efficiency, improve reliability and

optimise cost-effectiveness. CLAAS POWER SYSTEMS

(CPS) bring together top-quality components to create a

drive system that sets new standards – and always delivers

maximum power when it is needed. CPS is ideally matched

to the working system, featuring fuel-saving technology that

quickly pays for itself.

Page 7

Page 8

Performance packaged.

Strong at heart.

A 6-cylinder, 8.7 l FPT (Fiat Power Train) Cursor 9 engine

gets to work under a one-piece bonnet. The engine meets

the requirements of the Stage IIIB (Tier 4i) emissions

standard by means of exhaust aftertreatment with urea, and

uses the latest common rail 4-valve technology, charge-air

cooling and a wastegate turbocharger.

Visctronic – economical fan control.

With Visctronic electronic fan control the fan speed can be

precisely aligned with engine temperature and load, directly

linked to the engine ECU, ensuring that the engine always

runs at the optimum temperature. The reduced fan speed

lowers the noise level and saves valuable fuel with no

unnecessary impact on output, which can then be

converted into tractive power.

Constant output.

The CLAAS-specific engine performance curve provides full

torque in a wide engine speed range, guaranteeing constant

output and power delivery when they are needed. This

makes it easy to save fuel while working at a low engine

speed and maximum torque with the ECO PTO, or to work

at rated speed with a full reserve.

8

Page 9

AXION 950

Full potential in any situation.

Nm

rpm

hp

410 hp max

Values in accordance with ECE R 120

The multiple uses of a tractor in this class demand full

potential in every speed range. The AXION's power is

always available, even from a standing start. And the

ECO PTO is designed to work at full torque and maximum

output.

AXION Maximum torque Maximum output

ECE R 120 ECE R 120

950 1650 Nm 410 hp

940 1550 Nm 380 hp

930 1450 Nm 350 hp

920 1350 Nm 320 hp

Engine

9

Page 10

Greatest pollutant reduction of all time.

Fully integrated SCR system.

There is no doubt that the introduction of the Stage IIIB

(Tier4i) emission regulations is the most important step to

date in the control of pollutant emissions. These regulations

require a 90% reduction in particulate matter (PM) as well as

a 50% cut in nitrogen oxide(NO

) content. The

x

implementation of Stage IV (Tier 4) by 2015 will bring a

further reduction in PM and(NO

) emissions to almost zero.

x

SCR – the urea-based solution.

SCR stands for selective catalytic reduction, a process in

which nitrogen oxides are converted into water and pure

nitrogen. This is achieved by using a synthetic aqueous

solution of urea (AdBlue

tank.

®1

),which is carried in an additional

When designing the AXION 900, all the components

required for exhaust aftertreatment were considered from

the outset. This means that full visibility and accessibility are

guaranteed. The SCR catalytic converter is safely housed

under the bonnet where it receives a constant flow of

cooling air.

Never lets you down.

For particularly cold conditions, a cold-start system is

available to heat the engine cooling water, battery, fuel filter

and SCR system. The urea tank is heated as standard and

is also protected from the cold by the insulating effect of

being integrated into the fuel tank. The SCR system lines

are also emptied automatically when the engine is switched

off to protect against freezing.

1

AdBlue® is a registered trade mark of the VDA.

10

go.claas.com/scr

Page 11

Cleaning up.

11

SCR700 l fuel tank with integral 60 l urea tank

Page 12

CMATIC.

Continuously variable

forreal performance.

CMATIC 4-range transmission

Efficient and easy to use.

Power transmission in %Power transmission in %

Ø 82.80

Continuously variable with two mechanical ranges

Ø 36.63

Hydraulic power transmission

Mechanical power transmission

Mechanical component of power transmission

Ø 92.55

Ø 75.00

CMATIC is the name of the continuously variable

transmission technology used in CLAAS tractors. In the

AXION 900 series a ZF Eccom transmission provides

efficient conversion of engine power. In this split-power,

continuously variable transmission, the four mechanical

ranges areautomaticallyselected by multidisc clutches.

There is no need to shift between ranges manually.

km/h

The high mechanical component of the CMATIC

transmissionprovides outstanding efficiency and low fuel

consumption in every speed range.

For instance, when working in the field at between 7 and

15km/h in the main operating range, the CMATIC

transmission averages over 80% mechanical power

transmission, far superior to other continuously variable

transmissions on the market.

And for transport operations on the road, the CMATIC

transmission will be averaging a 90% mechanical situation,

a clear advantage in terms of fuel consumption.

km/h

12

Page 13

Exploiting real potential.

At speeds of 0.05 km/h to 50 km/h, the full power of the

transmission can be used in either direction because power

is transmitted mechanically even in reverse. What's more,

every gear ratio can be used at every engine speed. The

AXION 900 therefore offers enormous potential for use all

year round.

With engine speeds of 1,600 rpm at a top speed of 50km/h

and 1,500 rpm at 40km/h, the AXION 900 also

demonstrates its capabilities in transport operations.

If the accelerator is not depressed, the transmission is in

powered zero mode and maintains its position without

creeping or rolling. This means that the tractor can start up

safely and easily at steep field entrances or road junctions,

even with a full load.

CMATIC

13

Page 14

Simple, straightforward operation.

The CMATIC transmission has three operating modes:

AUTO (foot pedal), CMOTION (hand control)and manual

mode. Forward speed can be controlled by the accelerator

pedal or CMOTION. In these two modes, engine speed and

transmission ratio are adjusted automatically – for optimum

efficiency and optimised fuel consumption.

Accelerator pedal or CMOTION.

A button in the armrest enables the driver to switch

between modes while the tractor is moving. However,

manual mode can only be activated in CEBIS. In manual

mode, the driver chooses the engine speed and

transmission ratio. Automatic engine and transmission

control is not active. The active mode at any given time is

displayed on the CEBIS.

Auto

14

Accelerator

pedal

CMOTION Manual

Page 15

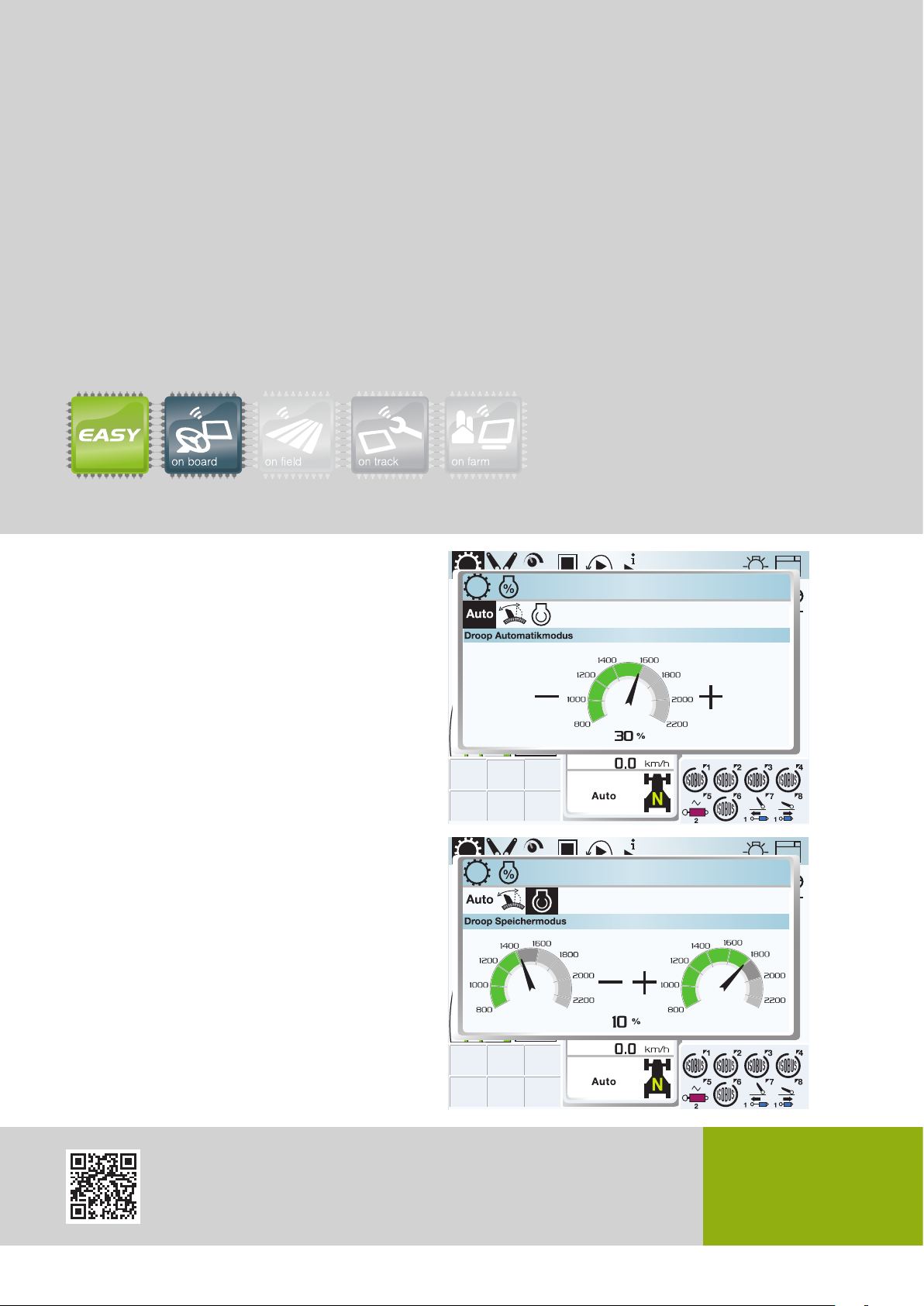

Optimised settings.

At the push of a button.

The engine speed at full load can be adjusted quickly and

easily using the engine droop settings. The CEBIS clearly

displays your set engine loading. When a constant engine

speed is activated, i.e. during PTO work, the driver can

specify a different droop setting, typically one that retains

the engine speed to the required PTO shaft speed.

The engine droop can be specified separately for the

individual drive modes and both engine speed memories.

The engine droop can therefore be tailored to the

application in hand at the push of a button, e.g. when

moving from the road to the field when transporting slurry.

The CMATIC transmission technology from CLAAS enables

you to use all 400 hp economically and productively.

go.claas.com/axion900droop

CMATIC

15

Page 16

No need to stop.

Tailor-made speed ranges.

With theCMATICtransmission, three speed ranges can be

pre-selected in both directions of travel. The active range is

displayed on the CEBIS and can be changed while the

tractor is in motion using the two buttons on the CMOTION

multifunction control lever.

The lower the maximum preset value for the range, the

more accurately the forward speed can be controlled.

Cruise control speeds can be saved in all three ranges while

the tractor is moving, either in CEBIS or using the button on

the CMOTION.

With CMATIC every driver can create his own profile

according to the job in hand. Intelligent CMATIC

transmission technology enables you to use all 400hp

economically and productively – with maximum operator

comfort.

16

Page 17

Stopping power.

The CMATIC transmission offers different ways of adapting

braking to the job in hand:

• Increase the engine braking effect: when the accelerator

pedal is released and the CMOTION is pulled back,the

engine braking effect is intensified and break wear is

reduced

• Driving down an extremely steep hillside with a heavy

trailer: by pressing the CMOTION when the trailer brakes

are on, you can tension the brakes on the tractor/trailer

combination when starting from stationary on hills. This

function can be used at speeds of up to 10 km/h.

CMATIC

17

Page 18

Real stability.

The true sign of a 400 hp tractor.

CLAAS has drawn on experience gained in developing

standard tractors and XERION high-horsepower tractors

delivering up to more than 500 hp to create a completely

new solution for the AXION 900 – for endurance work under

extremely challenging conditions. The engine is housed in a

strong frame section with an integrated engine oil sump

which perfectly absorbs all the forces associated with the

front linkage and front axle carrier. In practice, this means:

• Excellent steering lock angle for maximum

manoeuvrability

• Optimum access to the entire engine compartment and

all maintenance points

• High ground clearance with drive shaft integrated into the

frame section with a bolted cover for protection

• All services securely routed within the frame section

18

go.claas.com/axion900cps

Page 19

CLAAS tractor concept.

400 hp – for real.

Long wheelbase – compact design

To transfer 400 hp to the ground, the design must be just

right. The AXION 900 ticks all the boxes. It has a wheelbase

of 3.15 m, but its outstanding design makes it

manoeuvrable in the field and easy to drive on the road. And

naturally, its overall length with an implement attached

remains within the legal limits.

Additional front ballast is not needed for many tasks –

particularly transport operations – as the long wheelbase

and optimum weight distribution transfer the tractor's

tractive power to the ground. This saves fuel and reduces

tyre wear on the road.

Construction

19

Page 20

Immense tractive power.

Fully balanced.

With so many front and rear axle ballast options, the

AXION 900 is easily adapted to every application. This is

the only way of exploiting its full performance potential

without unnecessary losses.

Wheel weights per rear axle wheel, in kg

38" rim 42" rim

100 400

367 667

634 856

Front weights

600 kg

+ 600 kg

= 1200 kg

+ 600 kg

= 1500 kg

900 kg

20

go.claas.com/axion900ballasting

Page 21

Power and endurance.

All AXION 900 models can be specified with

massive2.15m diameter rear tyres. Tyres up to 1.70m

diameter are used on the front axle. The numerous tyre

options make the AXION 900 capable of any type of work.

Even with the biggest tyres (900/60 R 42) the tractor has an

external width of less than 3.0m, making it flexible on the

road and gentle on the field.

A broad base.

The AXION 900 can be fitted with dual tyres at the factory.

They can be permanently flange mounted or flexibly

mounted using the clamp system.

AXION 900 footprint:

• Rear tyres up to 900 mm wide and 2.15 m in diameter

• Front tyres up to 1.7 m in diameter

• Dual tyres ex factory, with flange mounting or clamp

system

1

1

Dual tyres are not available in all countries. Please refer to your dealer's

price list.

go.claas.com/

Construction

axion900duals

21

Page 22

Safe braking.

All AXION 900 models have a permitted total weight of 18 t

in the 40 km/h and 50 km/h versions. In the 50 km/h

version the front axle is fitted with disc brakes as standard.

The front axle of the 40 km/h version can also be fitted with

disc brakes as an option. The braking systems on the front

and rear axles provide maximum safety and stability on

braking.

Automatic adjustment.

During braking, the front axle suspension automatically

adjusts to the change in load. The tractor therefore retains

its normal stability and safety even during sharp braking

manoeuvres.

22

Page 23

Safe on the road.

REVERSHIFT with park-lock function.

In addition to the familiar, easy-to-use clutchless reverser,

the REVERSHIFT lever also has an integral park-lock

function which provides a very easy way of keeping the

AXION 900 stationary. For even greater safety, the park-lock

function is automatically activated in the following situations:

• When the engine is switched off

• When the engine is switched on

• If the accelerator or CMOTION have not been touched for

a few seconds while the vehicle is stationary, regardless

of the current REVERSHIFT lever position

• As soon as the driver's seat is vacated when the vehicle

is stationary

Trailer brake system.

The AXION 900 can be fitted with a pneumatic and a

hydraulic trailer brake system in order to meet countryspecific requirements. Both systems can be operated

simultaneously and the connections are easily accessible on

both sides of the drawbar.

Construction

23

Page 24

Use 400 hp. For real.

The right speed at the touch of a button.

Three different PTO options are available for the AXION 900:

• 1,000 rpm as standard

• 540 ECO / 1,000 rpm

• 1,000 / 1,000 ECO rpm

The PTO speed is easily pre-selected at the touch of a

button. Another buttonon the armrest activates the PTO.

The integral freewheel on the rear PTO makes implement

hitching simple.

24

External controls for front and rear

PTO

Page 25

AXION 950

Standing start.

AXION 950

The AXION 900 transfers its full power from a standing start

and at low forward speeds.

In ECO mode over 90% of maximumengine power (e.g.

385 hp in the AXION 950) can be transmitted via the PTO

shaft, enabling even heavy implements to be operated at a

reduced engine speed.

Rotational speeds:

• 1,000 rpm ECOat 1,600 enginerpm

• 540 rpm ECO at 1,450 enginerpm

In 1,000 ECO mode the engine can operate at the optimum

engine speed. Four bolt-on PTO stubs ensure that the

AXION 900 can be adapted to any implement.

1700

1650

1600

1500

1400

1300

1200

1100

1000

Nm

800

rpm

1000 ECO

at 1600 enginerpm

hp

450

400

350

300

250

200

150

100

Values in accordance

with ECE R 120

385

PTO

25

Page 26

Excellent hydraulics.

The AXION 900 has a load sensing hydraulic system with

flow volumes of 150 l/min or 220 l/min. It has up to six

electronic spool valves at the rear and a maximum of two

for front mounting. All spool valves have time and volume

control and are suitable for continuous flow volumes during

non-stop operation.

The hydraulics are controlled by proportional rocker

switches in the armrest, the ELECTROPILOT or the

CMOTION. One spool valve can be assigned to the function

buttons on the CMOTION.

External controls at the rear and on the front linkage can

also be assigned to any spool valve.

It's easy to set up spool

valve functions in CEBIS

26

Page 27

Rapid pressure build-up.

Pressure-free connections and no mess.

All the hydraulic couplings at the rear of the AXION 900

have release levers, so they can be connected and

disconnected even under pressure. The coloured+ / –

markings on the inlet and outlet sides make it easier to

attach implements correctly. Oil leakage lines keep the area

around the spool valves free of oil.

Power-beyond connections are provided at the rear for

implements which have their own spool valves. The

advantages of this are as follows:

• Hydraulic oil is supplied to the attached implement as

required

• Large line cross-sections and non-pressurised return flow

reduce power losses

• Fixed mounting plate with couplers for smooth

connection between tractor and attached implement

• Large flat couplings minimise oil heating and prevent oil

losses during coupling

Hydraulics

27

Page 28

Leaves nothing behind.

The rear linkage.

All AXION 900 models have a maximum lifting capacity of

11 t which enables them to carry the heaviest of

implements. The configuration of the rear hydraulic system

can be tailored to individual requirements:

• Cat. III or Cat. IV lower links

• Mechanical or hydraulic top link, Cat. III or Cat. IV

• Manual or automatic stabilisers available for both

lower links

• Wheel slip control available

• External controls on both mudguards

28

External controls for the rear linkage, PTO and one freely

selectable spool valve

Page 29

Direct adjustment.

The main rear linkage functions are directly accessed via

push buttons and dials in the right-hand B-pillar:

• Raise and lower

• Vibration damping on/off

• Lock linkage

• Activate slip control

• Lift height limit

• Lowering speed

• Draught and position control

• Adjustment of wheel slip control

The rear linkage can be moved to the pre-set working depth

or transport position at the touch of a button on the

CMOTION. The current position can be changed manually

at any time via a two-stage incremental adjustment system.

The linkage moves back to the pre-set position when the

working position is activated again.

The working depth of the rear linkage

is set using the dial onthe armrest.

Rear linkage

29

Page 30

Front linkage.

All AXION 900 models can be fitted with two different front

linkages at the factory:

• 5.0 t for implements and ballasting

• 6.5 t for particularly heavy implements

The modular construction means that retrofitting can be

carried out easily.

The AXION 900 series is the first to have a fully integrated

front linkage, designed specifically for this power class.The

front axle carrier and the special structural component for

the engine are designed to absorb any forces generated,

meaning no additional supports or rails are required.

Compact construction

• Short distance between front axle and coupling points

• Good implement handling and short overall length

30

Compact dimensions

Page 31

Fully integrated.

Always connected.

Hydraulic and electrical interfaces for many applications are

incorporated into the front linkage:

• Two double-acting spool valves

• Free flow return line

• 7-pin socket

• ISOBUS socket

Front linkage position control.

The optional front linkage position control system enables

front-mounted implements to work extremely accurately.

The working depth is adjusted via a rotary knob on the

armrest, while the lifting height can be limited and the lifting

and lowering speed set using CEBIS. The front linkage can

be used in single- or double-acting mode.

Front linkageExternal controls for the front linkage and one spool valve

31

Page 32

Pleasant working

environment.

The AXION 900 marks the debut of a completely new

generation of cabs from CLAAS.

• 4-pillar design and convex rear window provide optimum

visibility

• Completely redesigned armrest with integral CMOTION

multifunction control lever

Page 33

Page 34

Newly designed.

Developed with farmers.

When developing the AXION 900, we involved customers

from many countries at a very early stage. We showed them

our initial designs for the new cab so that suggestions and

criticisms from farmers could be taken into account from

the outset. Position and layout of the controls, connections

and brackets, visibility in the cab – these are just some of

the topics that were important to our customers.

The design of many of the controls and the positioning of

the CEBIS screen in the armrest are largely based on the

design of CLAAS harvesters. The CMOTION multifunction

controllever, in particular, has become an essential feature

of CLAAS machines. In theARION 600 / 500, XERION

5000 / 4500 and the LEXION the CMOTION is conquering

the market. The same is true of CEBIS: its controls and

menu structure are the same in all machines. Whether

drilling or harvesting – you always have the upper hand.

34

Page 35

4-pillar concept.

With the launch of the AXION 900 CLAAS introduces a

completely new generation of cabs. The CLAAS 4-pillar cab

offers some distinct advantages:

• Clear view of the full working width of attached

implements

• Large-volume cab creates an extremely spacious working

environment

• Continuouswindscreen

The special positioning of the rear cab pillars gives the driver

an excellent view of the implement and hitch area. The

convex rear window also provides a clear view of the rear

coupling points, allowing safe, accurate implement

attachment.

The convex rear window has a

wide opening angle.

Cab

35

Page 36

Ergonomics made by CLAAS.

Comfort right from the start.

With CLAAS, the driving experience starts even before you

enter the cab. You can reach the door handle from the

ground, enabling you to open and close the door safely.

Wide, self-cleaning steps with grab rails provide hazard-free

access to the cab.

36

A ladder on the left-hand side provides safe access for

cleaning and maintenance work.

Page 37

Clear and logical layout.

When you press the small pedal underneath the steering

column the entire steering column folds out of the way,

allowing plenty of room to enter and leave the cab. The

column can be returned to the optimum position when you

start work. Fully adjustable steering column with tilt and

telescope.

The instrument panel is always in full view because it is

mounted on the steering column and moves with it. This

makes it easy to read all the key information, even during

transport operations on the road. Engine temperature, fuel

tank level, compressed air supply and travel speed are all

available here, as well as on the CEBIS monitor. The curved

design of the instrument panel provides an excellent view of

all displays.

The steering column swings out of the

way when the middle pedal is pressed.

Cab

37

Page 38

A place for everything.

All the main controls are integrated into the right armrest:

1 CMOTION multifunction control lever

2 Control panel for drive mode, ELECTROPILOT

activation, function buttons, engine speed memory

3 CEBIS monitor

4 ELECTROPILOT with up to four double-acting spool

valves

5 CEBIS control panel

6 Working depth adjustment for front and rear linkage

7 Front and rear PTO activation

8 Hand throttle

9 Transmission in neutral, activate front linkage

10 Spool valves

11 Four-wheel drive, differential lock, automatic PTO

engagement/disengagement, front axle suspension

The height and position of the armrest can easily be

adjusted to the driver's requirements.

38

Control panel (11) in the armrest: four-wheel drive,

differential lock, automatic PTO engagement/

disengagement and front axle suspension

Page 39

Logical throughout.

Everything in full view.

Many functions can be controlled using the dials and

buttons on the B-pillar:

1 PTO speed selection

2 Rear linkage settings

3 Rear linkage status display

4 Operation of the electronic linkage control (ELC)

5 Main switch for battery, electronic spool valves, CSM,

steering system

Functions that are used less frequently, such as PTO speed

preselection and the main switches, are located to the right

of the driver's seat. When the driver's seat is rotated, the

electronic linkage control can be operated comfortably with

an excellent view of the attached implement. Fine

adjustment of the electronic linkage control settings can

then take place while work is in progress. Two additional

buttons for raising and lowering the rear linkage also make

implement attachment easier.

39

Cab

Page 40

400 hp at your fingertips.

CMOTION multifunction lever.

The CMOTION makes using the main functions of the

AXION 900 more convenient and more efficient. Functions

are controlled using your thumb and forefingers, allowing

your hand to stay in one place for most of the time and

preventing fatigue.The height and position of the padded

armrest are adjustable.

Rear linkage operation

All the functions needed for the rear linkage are located on

the CMOTION:

• Lower to preset working position

• Raise to the preset lift height position

• Incrementaladjustment of lifting and lowering at two

speeds (slow/fast)

Press and hold the lower button to engage quick entry.

40

Page 41

Everything under control.

1 Start up/change direction

2 Rear linkage

3 GPS PILOT

4 CSM headland management

5 Function buttons F7/F8 and selectable spool valve

6 Cruise control

7 Change range

8 Function buttons F5/F6

The free assignment option for the function buttons on the

CMOTION means that there is no longer any need to

reposition your hands while you work. All implementspecific functions are easily controlled using the CMOTION.

The following functions can be accessed via the function

buttons:

• ISOBUS-enabled implements

• Event counter on/off

• Spool valve

go.claas.com/axion900cmotion

CMOTION

41

Page 42

Reliable operation.

The CEBIS monitor and controls are integrated into the

armrest. The driver's arm lies on the armrest while he enters

the settings in CEBIS so there is no need to compensate for

steering movements. This means that all functions can be

set immediately and accurately while you work.

CEBIS operation.

The basic machine settings are entered using the CEBIS

dial: to select a menu item or set a parameter, turn the dial

to the right or left and confirm your selection by pressing the

dial. Use the ESC button to leave the menu selected.

Press the DIRECT ACCESS button to open the last

activated function, which appears at top right on the CEBIS

(1). This saves time and makes it easy to optimise machine

settings.

42

Page 43

Intelligence comes as standard.

An eye-catching 21 cm screen.

1 Menu bar

2 DIRECT ACCESS display

3 Status of front/rear linkage and spool valves

4 Function button assignment

5 Transmission status, speed, PTO speed, engine speed

memory, job management, wheel slip display,

adjustable display, temperature, time

6 Vehicle status information

7 Driving speed display and cruise control

CEBIS – simply better:

• Only two controls: push/turn dial and ESC

• Quick access to submenus through DIRECT ACCESS

• Integrated performance monitor as standard for checking

area output, fuel consumption, job data

• Two different screen layouts to choose from (road travel

and field work)

CEBIS

43

Page 44

For optimum working conditions.

All AXION 900 models have air conditioning as standard.

The components of the air conditioning system are built into

thedouble insulatedcab floor. This positioning allows

optimum air flow distribution in the cab and significantly

reduces the noise level from the air conditioning system. A

fully automatic climate control system is available in addition

to manual control.

Ventilated and warm: the premium seat.

• Heating and active ventilation make the seat feel good

whatever the weather

• Suspension automatically adjusts to the driver's weight

The cooler compartment under the passenger seat has

room for two 1.5 l bottles and snacks.

44

Document box and removable storage box in left-hand

console

Page 45

Comfort down to the last detail.

Illuminated interior.

By day and night, all the controls are illuminated when the

headlights are switched on. And the symbols on all the

switches are backlit so that they can be operated safely at

all times. The brightness of the CEBIS monitor automatically

adjusts to the lighting conditions, preventing glare within

the cab.

Clear view.

On the right-hand side of the cab, a solid bar extends from

the A to the B pillar. Terminals such as the CEBIS MOBILE

or COMMUNICATOR can be mounted on this bar.

Additional terminals can be attached to the bar individually

using a clamp system. Connections to the power supply

and ISOBUS connections are located below the bar,

preventing unnecessary cable routing and extra hassle

when changing devices.

Connections to the power supply (25 A and cigarette lighter) and ISOBUS

for additional terminals are located below the right-hand console.

Comfort

45

Page 46

Easy on both driver and machine.

Full four-way suspension.

With four suspension points, the cab is fully isolated from

the chassis so impacts and vibration do not reach the

driver. The combination of springs and dampers creates

long suspension travel and operates very effectively thanks

to precise adjustment. The entire suspension system is

completely maintenance-free.

PROACTIV front axle suspension –

complete comfort automatically.

The suspension adjusts to tractor loading and automatically

remains in the central position. Changes in load due to

braking and turning manoeuvres are also compensated.

Parallelogram axle suspension and 90 mm spring travel

guarantee a smooth ride, and the robust construction

means that dual tyres can be used.

46

Switch to activate front axle suspension

Page 47

Top-quality seats.

Three different seats are available – from the air-sprung seat

to the premium seat with heating and ventilation. All the

seats are from Grammer or Sears. In the seat with active

suspension, the suspension is controlled by a sensor which

measures the current position and acceleration.

Vibration damping.

Heavy implements mounted on the front and rear create a

load on both tractor and driver. Both front and rear linkage

are equipped with vibration damping to compensate for

peak loads during transport operations and when the

attached implement is raised at the headland.

go.claas.com/axion900comfort

Comfort

47

Page 48

EASY.

Simply get more done.

Page 49

The name says it all.

Go on. Go easy.

The combined electronics expertise of CLAAS can be

summed up in a single word: EASY

This stands for Efficient Agriculture Systems – and lives up

to its name. Equipment settings, steering systems, software

solutions and more: EASY makes it all simple. Your systems

can be matched perfectly with each other, enabling you to

get the best performance from your machines and top

results for your operation.

EASY can be broken down into four areas – each a

specialisation, together a powerful team.

• on board – machine control and performance

optimisation directly from the cab

• on field – increased productivity directly in the field

• on track – machine monitoring and remote diagnostics

• on farm – software solutions for your business

Page 50

ISOBUS implement control.

Sockets are provided at the front and rear in order to

connect ISOBUS-compatible implements to the tractor. The

terminal can be connected up in the cab using another

socket. In order to meet differing requirements as fully as

possible, CLAAS offers a choice of two terminals: the

CEBIS MOBILE and the COMMUNICATOR. The CEBIS

MOBILE and COMMUNICATOR are mobile components

which can be used on other machines depending on the

season and the work to be done.

The easy way to increase efficiency.

The CEBIS MOBILE and COMMUNICATOR are operated by

a push/turn dial which is used to enter all the settings in the

main menu. Frequently used functions are activated by soft

buttons next to the monitor.

50

Page 51

Flexibility with ISOBUS.

Also suitable for implements from other

manufacturers.

The implement currently in use is controlled via a machinespecific display. Thanks to ISOBUS compatibility,

implements from other manufacturers can also be operated

with the CEBIS MOBILE or COMMUNICATOR.

Function buttons

The AXION 900 has eight F buttons to which different

functions can be assigned in CEBIS. The current

assignment can be viewed at any time via the CEBIS

display. Button assignment to the corresponding function

can be freely selected by the driver, enabling each driver to

customise tractor operation to his individual requirements.

CEBIS MOBILEISOBUS connections at the front and rear

51

Page 52

A perfect line.

Optimise operating costs.

Research into cultivation systems shows that there is often

an increase in overlap for larger working widths when a

guidance system is not used. This means that 7% savings

in terms of diesel fuel, machine costs, fertiliser and pesticide

could easily be achieved with a CLAAS guidance system.

Improve the quality of your work.

CLAASsteering systems take the pressure off the driver.

They show in advance which direction to take, or

automatically steer the tractor along the best possible track.

Mistakes are eliminated, allowing the driver to concentrate

on keeping the tractor running properly, with clear

improvements in results.

Correction signal to meet individual needs.

CLAAS has designed its range so that you can take

advantage of its flexibility to upgrade your system at

any time.

For further information about steering systems, see the

CLAASSteering Systems brochure or ask your CLAAS

dealer.

52

Page 53

GPS PILOT RTK

• Accuracy +/– 2 to 3 cm

• Up to 20 km coverage

• No licence fees

• Maximum steering precision

• Reference signal can be set by the local dealer

• For machinery fleets or use on multiple farms

GPS PILOT RTK NET

• Accuracy +/– 2 to 3 cm

• Charged access to existing RTK networks

• Maximum steering precision

• For machinery fleets, with considerable range

GPS PILOT BASELINE HD

• Accuracy +/–4 to 6 cm

• Farm has its own mobile reference station

• Range 3 to 5 km

• Public reference signal

• Reference station can be used by several machines

at once

GPS PILOT OMNISTAR HP

• Accuracy +/– 5 to 12 cm

• Dual frequency DGPS

• Correction signal received by satellite

• Quarterly or annual licence costs for the reference signal

GPS COPILOT

• Accuracy to within+/–15 to 30 cm

• EGNOS satellite signal

• No licence fees

• Manual guidance

Steering systems

53

Page 54

CLAAS SEQUENCE MANAGEMENT.

CSM headland management takes the load off you

whenever you need to manoeuvre at the headland. By

pressing a button, you can run any of the previously

recorded functions.

CSM offers:

• Recording of up to four sequences per implement

• Sequence activation on CMOTION

• Sequence display on CEBIS

• Time or distance related recording

• Sequences can be changed and optimised

retrospectively

The following functions can be combined in any order:

• Spool valves with time and flow control

• Four-wheel drive, differential lock and front axle

suspension

• Front and rear hydraulics

• Cruise control and range selection

• Front and rear PTO

• Engine speed memory

54

Page 55

CSM.

Makes headlands easy.

Easy to record and run.

Sequences can be recorded on a distance- or time-related

basis.There is also an option of recording sequences when

the machine is stationary. During recording, clear symbols

allow the driver to follow the creation of the sequence step

by step on CEBIS. A sequence that is running can be

paused and restarted by simply pressing a button.

Non-stop optimisation.

The sequences recorded can be changed and optimised

subsequently. Steps can be added and deleted or changed

and adapted in minute detail, allowing times, distances and

flow volumes to be tailored to current conditions.

A sequence that has been recorded for the first time can be

refined down to the last detail as you work.

CSM

55

Page 56

Job management

and TELEMATICS.

Implement management with CEBIS.

With CEBIS, details of up to 20 implements can be

recorded. All the preset values are permanently assigned to

the specific implement.

• Four CSM sequences

• Area calculation – mode and activation

• Working width of attached implement

This saves on unnecessary adjustment tasks when

changing implement or driver. You just attach the

implement, load the device in CEBIS and start work.

Field management.

Up to 20 jobs can be set up and stored on CEBIS in order

to produce documentation for the work done. First you

enter the working width, then you can start area calculation

and the fuel consumption display per hectare. To get the

most accurate results, the speed can be measured by

radar.

56

CEBIS maintenance counter

Page 57

Good reasons to use CLAAS TELEMATICS:

CLAAS TELEMATICS on the AXION 900.

• Improve work processes: operating time analysis

• Optimise settings: remote monitoring

• Simplify documentation: data collection

• Faster servicing: remote diagnostics.

How CLAAS TELEMATICS works.

TELEMATICS allows you to call up any information about

your machine at any time from any location.

The data collected is sent to the TELEMATICS web server

at regular intervals via the cellphone network. This enables

you or an authorised service partner to access and evaluate

the relevant information via the internet.

1 Operating time analysis

• Working time analysis

• Reduce downtime

• Review machine settings

• Optimise fuel consumption

2 Asset protection

• Position indicator in Google Earth

• Current activity

3 Data collection

• Automatic data collection for documentation

• Secure storage on central server

• Standard interfaces for data export from

TELEMATICS

4 Remote monitoring

• Maintenance planning

• Remote diagnostics with CDS

®

Job management and

TELEMATICS

57

Page 58

Fast maintenance.

Daily maintenance work should be as straightforward as

possible – because we know fromexperience that nobody

enjoys doing things that are complicated or inconvenient.

• The large, one-piece bonnet opens at the press

of a button, providing access to all the engine

maintenance points

• The oil can be checked and topped up when

the bonnet is closed

• All daily maintenance tasks can be carried out

without tools

The long oil change intervals (engine 600 h, transmission

and hydraulics 1,200 h) save a great deal of time and

money. This means that less valuable working time is lost

during the season and the tractor is where it should be –

at work.

The battery is housed in a storage compartment on the lefthand side of the tractor. An automatic main battery switch

cuts the power supply 90 s after the engine is switched off.

58

The fuel prefilter is conveniently located by the steps to

the cab.

Page 59

Ready in a flash.

Fresh air for full power.

The large intake panels in the bonnet provide plenty of fresh

air for cooling and for the engine air filter. Low flow rates at

the intake panels help them to stay clean and permeable at

all times.

The radiator assemblies are supported by a robust frame

and gas-filled shock absorbers open the radiator panels to

two positions for thorough cleaning. Cleaning can therefore

be carried out safely and conveniently as required.

Easy access to the cab air filter on

the cab roof

Maintenance

59

Page 60

Truly reliable.

CLAAS Service

Round-the-clock assistance.

You can count on the professionalism and dependability of

our First CLAAS Service

site. CLAAS importers and sales partners provide a full

spare parts supply and reliable round-the-clock customer

service worldwide.

®

team every minute you are out on

We provide accurate diagnoses.

Many years of experience and use of the most advanced

diagnostic systems such as CDS enable our service

engineers to pinpoint malfunctions in no time at all, and set

up dependable configurations and download CEBIS

updates.

We speak the same language.

CLAAS dealers are highly trained and equipped with all the

specialist tools required. Just as important is the fact that

they also have an intimate knowledge of the workings of

your farm or contractor business, and know exactly what

you expect in terms of skill and reliability.

We're there where you need us.

Our central spare parts warehouse delivers all ORIGINAL

CLAAS parts quickly and reliably all over the world. The

extensive network of CLAAS dealers ensures that they

reach their destination as quickly as possible – wherever

you happen to be.

60

Page 61

Service is close, even when it's far away.

MAXI CARE® service.

With CLAAS remote diagnostics, you gain valuable time,

and so do we. Our service staff have direct access via the

internet to all the performance and electronic data of your

AXION, often enabling the problem to be solved remotely. If

a service technician is required on site, we have all the

necessary information in advance and can send any spare

parts required right away.

It's possible to plan for reliability and peace of mind.

Maximum operational reliability combined with maximum

cost security – this is the principle of CLAAS MAXI CARE

With a range of service packages, MAXI CARE

®

offers a

®

.

quality of service tailored perfectly to the needs of each and

every business.

First CLAAS Service

MAXI CARE

®

61

Page 62

Outstanding features.

CPS

• All 400 hp available at all times

• Fully integrated SCR exhaust aftertreatment

• The latest engine technology for high performance and

low fuel consumption

• Self-supporting construction for maximum stability

• Special engine frame section provides manoeuvrability

• Long wheelbase and balanced weight distribution

• Compact design with integral front linkage – fully

road-compatible

• Continuously variable CMATIC transmission with high

mechanical efficiency

Comfort

• Innovative 4-pillar cab

• CMOTION multifunction control lever

• 4-point cab suspension

• Driver's seats with active suspension and ventilation

• Front axle suspension with active height control

• Front and rear linkages with vibration damping

EASY

• Factory-fittedGPS PILOT

• CSM headland management

• Implement management

• TELEMATICS

• ISOBUS

62

Page 63

AXION AXION

950 940 930 920

Engine

Manufacturer FPT FPT FPT FPT

Number of cylinders/intake 6/TI 6/TI 6/TI 6/TI

Cubic capacity cm

3

8710 8710 8710 8710

Nominal engine speed rpm 2150 2150 2150 2150

Output at nominal engine speed (97/68/EC)

Output at nominal engine speed (ECE R 120)

Max. output (ECE R 120)

2

1

2

kW/hp 306/416 282/383 259/353 236/321

kW/hp 298/405 276/375 254/345 232/315

kW/hp 302/410 279/380 257/350 235/320

Constant output range rpm 1800 - 2150 1800 - 2150 1800 - 2150 1800 - 2150

Engine speed at max. torque rpm 1200 - 1600 1200 - 1600 1100 - 1600 1100 - 1600

Max. torque (ECE R 120)

2

Nm 1650 1550 1450 1350

Air filter dust aspiration ● ● ● ●

Fuel tank capacity l 700 700 700 700

Oil-change interval h 600 600 600 600

CMATIC transmission

Transmission type CMATIC CMATIC CMATIC CMATIC

Ground speed (min./max.) 40 km/h version km/h 0.05/40 0.05/40 0.05/40 0.05/40

Ground speed (min./max.) 50 km/h version km/h 0.05/50 0.05/50 0.05/50 0.05/50

REVERSHIFT clutchless reverser ● ● ● ●

Rear axle

Flanged axle – – ● ●

Quick-release axle ● ● ○ ○

Electrohydraulically activated differential locks ● ● ● ●

Automatic differential lock ● ● ● ●

Max. rear tyres 900/60 R 42 900/60 R 42 900/60 R 42 900/60 R 42

Oil-change interval h 1200 1200 1200 1200

PTO

Remote control engagement and emergency stop ● ● ● ●

1000 ● ● ● ●

540 ECO / 1000 ○ ○ ○ ○

1000 / 1000 ECO ○ ○ ○ ○

Changeable PTO shaft stub ● ● ● ●

PTO shaft stub: 1⅜" with 6, 8 or 21 splines

□ □ □ □

and 1¾" with 20 splines

950 940 930 920

4-wheel drive front axle

Max. steering angle Degrees 50 50 50 50

Castor angle Degrees 5 5 5 5

Angle of oscillation Degrees 8 8 8 8

Turning radius m 6.8 6.8 6.8 6.8

Track mm 2190 2190 2190 2190

with tyres 600/70 R 30 600/70 R 30 600/70 R 30 600/70 R 30

PROACTIV suspended front axle ○ ○ ○ ○

PROACTIV suspended and braked front axle ○ ○ ○ ○

Differential lock with multi-disc clutch ● ● ● ●

Designed for dual tyres ● ● ● ●

Pivoting mudguards ● ● ● ●

Hydraulics

Output at nominal speed, standard (option) l/min 150 (220) 150 (220) 150 (220) 150 (220)

Max. operating pressure bar 200 200 200 200

Number of auxiliary spool valves (min./max.) 3–8 3–8 3–8 3–8

ELECTROPILOT 4-way control ○ ○ ○ ○

Rear linkage

Max. lifting capacity at ball ends kg 11250 11250 10950 10950

Continuous lifting power at ball ends kg 7690 7690 7520 7520

Lifting range mm 1060 1060 1060 1060

Category Cat. III/IV Cat. III/IV Cat. III/IV Cat. III/IV

Vibration damping ● ● ● ●

Active slip control ● ● ● ●

Front linkage

Max. lifting power t 6.5 or 5.0 6.5 or 5.0 6.5 or 5.0 6.5 or 5.0

Front PTO 1000 rpm ○ ○ ○ ○

Vibration damping ● ● ● ●

External operation ● ● ● ●

Hydraulic connections ○ ○ ○ ○

Trailer socket and ISOBUS ○ ○ ○ ○

Cab

4-point suspension ● ● ● ●

Multifunction armrest ● ● ● ●

Automatic climate control ○ ○ ○ ○

Passenger seat ● ● ● ●

Cooler compartment ● ● ● ●

● Standard ○ Optional □ Available – Not available

1

Performance data fit criteria for admissibility. Performance as per 97/68/EC is identical to 2000/25/EC. 2 Meets ISO TR 14396

● Standard ○ Optional □ Available – Not available

CLAAS continually develops its products to meet customer requirements. This means that all products are subject to change without notice. All descriptions and specifications in this brochure

should be considered approximate and may include optional equipment that is not part of the standard specifications. This brochure is designed for worldwide use. Please refer to your nearest

CLAAS dealer and their price list for local specification details. Some protective panels may have been removed for photographic purposes in order to present the function clearly. To avoid any

risk of danger, never remove these protective panels yourself. In this respect, please refer to the relevant instructions in the operator’s manual.

All technical specifications relating to engines are based on the European emission regulation standards: Stage. Any reference to the Tier standards in this document is intended solely for

information purposes and ease of understanding. It does not imply approval for regions in which emissions are regulated by Tier.

Page 64

AXION

950 940 930 920

Dimensions and weights

(standard tyres, with oil and fuel, without driver)

Rear wheels 710/85 R 38 710/85 R 38 710/85 R 38 710/85 R 38

Front wheels 620/75 R 30 620/75 R 30 620/75 R 30 620/75 R 30

Length (with front linkage folded and attachment

device) (e)

Centre of rear axle to top of cab (a) mm 2427 2427 2427 2427

Overall height (b) mm 3452 3452 3452 3452

Wheelbase (c) mm 3150 3150 3150 3150

Rear axle to cat. IV lower link (d) mm 1438 1438 1438 1438

Ground clearance, front axle (f) mm 647 647 647 647

Ground clearance, rear axle (excl. drawbar) (g) mm 611 611 611 611

Weight without ballast kg 13060 13060 12840 12840

Max. front ballast with front linkage kg 1500 1500 1500 1500

Weight distribution with front linkage,

without ballast (rear/front)

Max. permissible total weight (40/50 km/h versions) kg 18000 18000 18000 18000

mm 5590 5590 5590 5590

% 56/44 56/44 55/45 55/45

Tyres

(standard axle or suspended front axle)

Rear tyres Front tyres

650/65 R 42

1

650/85 R 38 520/70 R 34 □ □ □ □

650/85 R 38 600/70 R 30 □ □ □ □

710/70 R 42 520/70 R 34 □ □ □ □

710/70 R 42 600/70 R 30 □ □ □ □

800/70 R 38 600/70 R 30 □ □ □ □

800/70 R 38 710/60 R 30 □ □ □ □

710/75 R 42 620/75 R 30 □ □ □ □

710/75 R 42 650/75 R 30 □ □ □ □

710/75 R 42 600/70 R 34 □ □ □ □

710/75 R 42 650/65 R 34 □ □ □ □

710/85 R 38 620/75 R 30 □ □ □ □

710/85 R 38 650/75 R 30 □ □ □ □

900/60 R 42 710/60 R 34 □ □ □ □

540/65 R 30

950 940 930 920

1

□ □ □ □

f

● Standard ○ Optional □ Available – Not available

1

Tyres with industrial tread

a

b

g

c d

e

Page 65

CLAAS UK

Saxham

Bury St. Edmunds

Suffolk

IP28 6QZ

Tel 01284 763100

claas.co.uk

info-uk@claas.com

HRC / LRC / 320012130813 KK DC 1213

Loading...

Loading...