Page 1

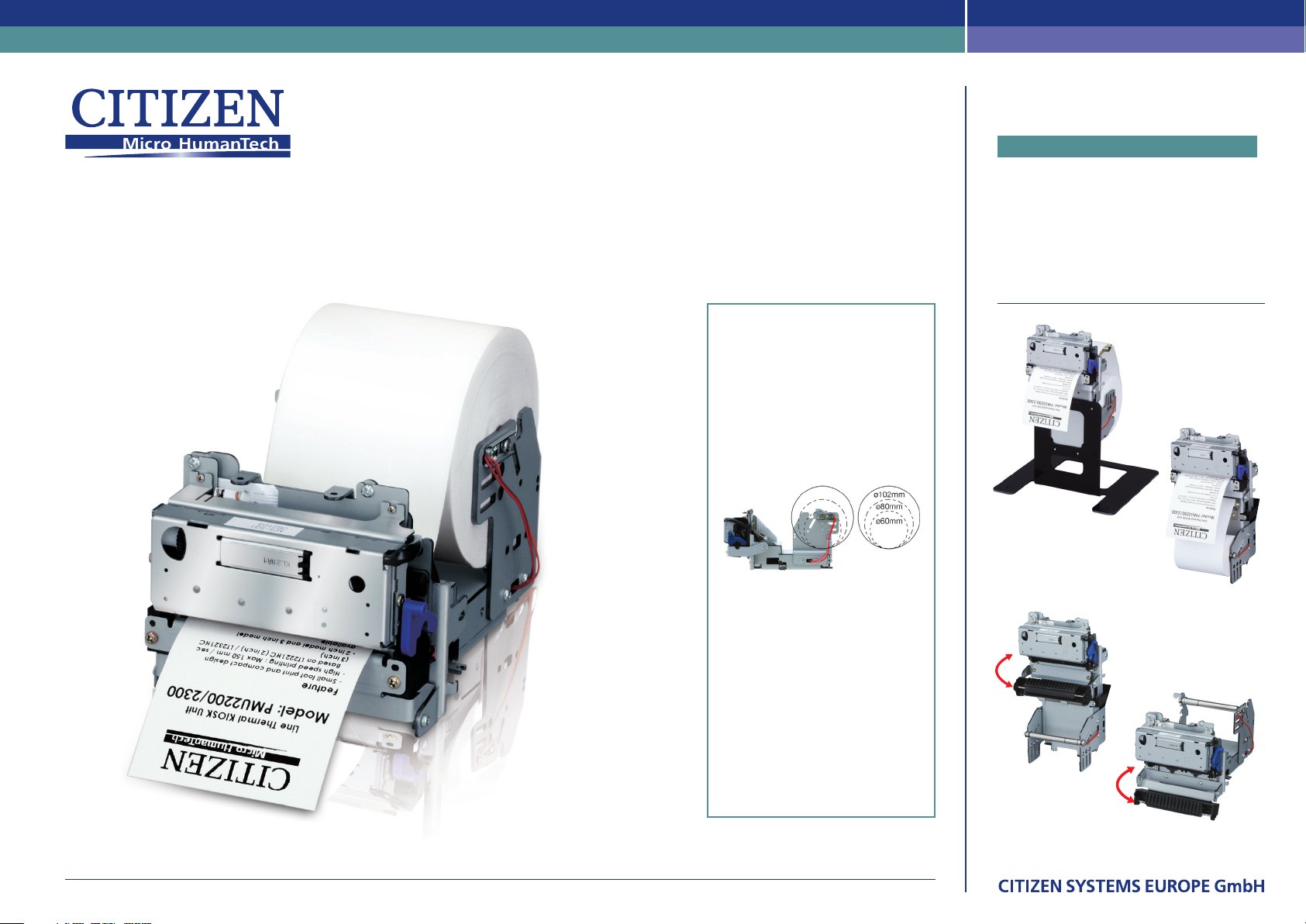

PMU2200II/2300II

POS

28 varieties

The flexible kiosk printer

Horizontal solution

Mettinger Straße 11 • D-73728 Esslingen Germany • Tel.: +49 (0)711/3906-400 • Fax: +49 (0)711/3906-405 • www.citizen-europe.com

Applications

• Kiosk

• Weigh scales

• POS

• Industrial

machine

•ATM

Most Flexible

The unique PMU2200/2300

series offers 28 different

varieties to install the paper.

This makes it the most

flexible kiosk printer in the

market. Ready for installation

without customisation.

3 Different Paper Roll Sizes

The PMU2200/2300 can be

operated with 3 different paper

roll sizes.

Wide Operating Temperature

Operating in temperatures

between -20°C up to 60°C

the PMU2200/2300 is suitable

for indoor as well as for

outdoor applications.

Vertical solution

(back paper hold type)

Vertical solution

(front paper hold type)

easy recover

from paper jam

Page 2

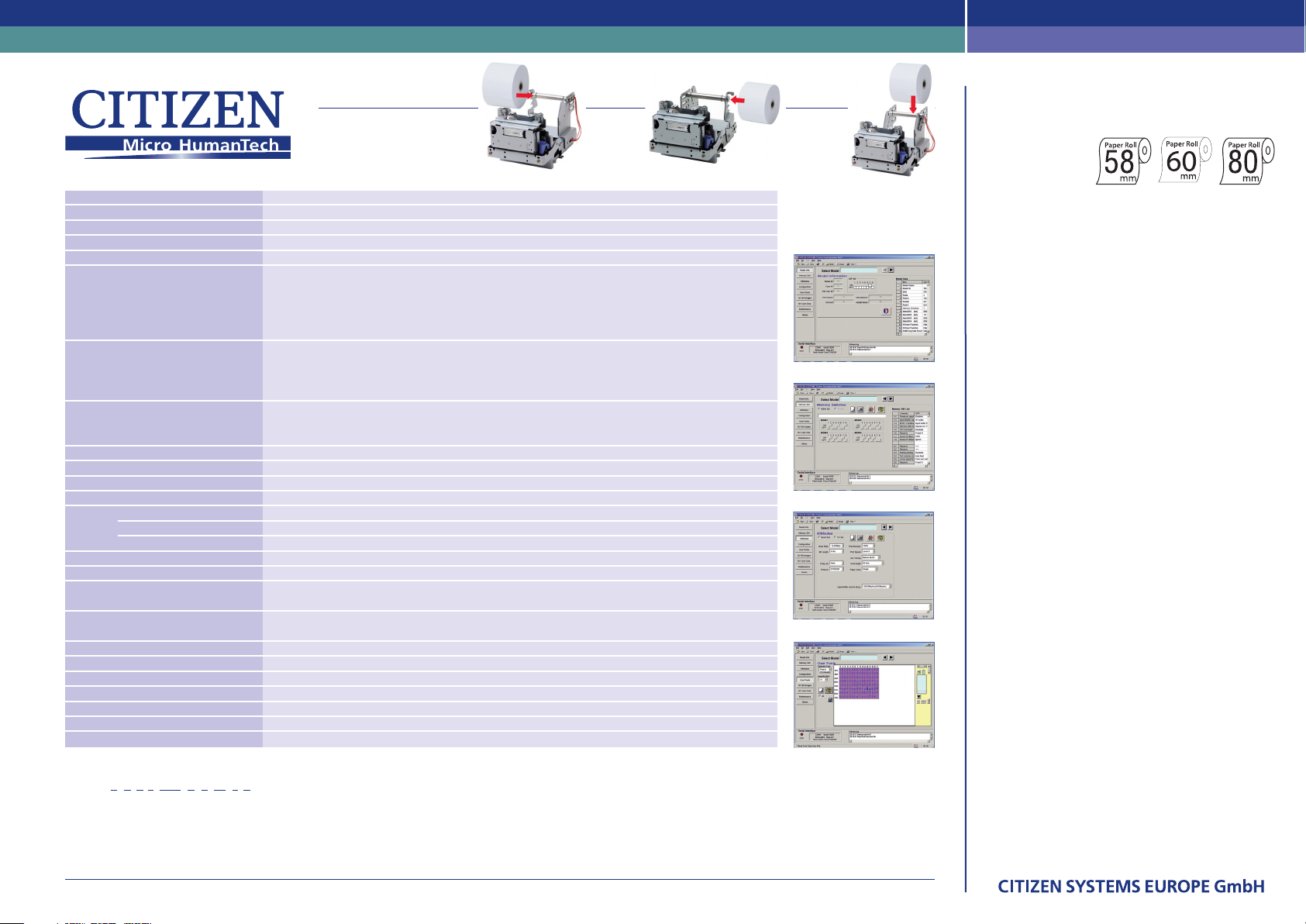

Specifications

Mettinger Straße 11 • D-73728 Esslingen Germany • Tel.: +49 (0)711/3906-400 • Fax: +49 (0)711/3906-405 • www.citizen-europe.com

Features

Model PMU2200 PMU2300

Printing method Line thermal dot printing

Paper width 58mm 80mm

Dot pitch 8 dots/mm (203 dpi)

Printing speed Max. 150mm/sec (1,200 dot lines/sec)

Number of columns Font A: 36 columns Font A: 48 columns

Font B: 48 columns Font B: 64 columns

Font C: 54 columns Font C: 72 columns

Kanji Font A: 18 columns Kanji Font A: 24 columns

Kanji Font C: 27 columns Kanji Font C: 36 columns

Character size (WxH) Font A: 1.50 x 3.00mm (12 x 24 dots)

Font B: 1.13 x 3.00mm (9 x 24 dots) / Font C: 1.00 x 2.00mm (8 x 16 dots)

Kanji Font A: 3.00 x 3.00mm (24 x 24 dots) /Kanji Font C: 2.00 x 2.00mm (16 x 16 dots)

(As the space inside character font is included, actual character is smaller than that in the above table)

Character table Alphanumeric, International character set (12 characters x 16 countries)

Code page 437, 850, 852, 857, 858, 860, 863, 864, 865, 866

WPC1252, Katakana, Thai Code 18, Kanji (JIS Level 1, Level 2), Kana, JIS C 6226-1983

User memory 256 K bytes (User-defined characters and created logo can be registrated.)

Barcode type UPC-A/E, JAN(EAN), 13 columns/8 columns, ITF, Code39, Code128, CODABAR, Code93

Logo registration/print Capable of registering user-defined characters print and logos into flash memory

Line spacing 4.23mm (1/6 inch); can be set by a command

Paper Width 58mm 58mm, 60mm, 80mm

Thickness PMU2xxx: 0.065 – 0.105mm, PMU2xxxA: 0.110 – 0.150mm

Recommanded paper TF-50KS-E-2D, TF62KS-E (Nippon Paper Industries)

Interface Serial (RS-232C compliant), Parallel (IEEE12184 compliant) or USB

Input buffer 4K bytes or 45K bytes

Sensors Paper near end sensor, Platen open sensor / Paper near end sensor (adjustable)

(Photo interrupter): Option / Black mark sensor (Photo interrupter): Option

Input power Input voltage: DC 24V± 7% / Current consumption: 1.9A (peak 6A)

* Option: AC adapter 35AD1 or equivalent

Power consumption 100W

Weight 1.0kg 1.1kg

Dimensions (WxDxH) 101x179x96mm 118x179x96mm

Operating environment -20°C ~ 60°C, 35 ~ 85%RH

Storage environment -25°C ~ 65°C, 10 ~ 90%RH

Reliability Thermal head: 100,000,000 pulses or 100 km / Auto cutter: 1,00,000 cuts

EMC and safety standards UL, C-UL, FCC clacc A, TUV, GS, CE marking

• Small foot print and compact design

• 150mm/sec high-speed printing

• 2 inch model (PMU2200) and

3 inch model (PMU2300) available

• Cutter (full/partial)

• Wider operation temperature range

-20°C

~ 60°C

• Easy recovery from paper jam and

easy head cleaning owing to

removable head design

• Serial/Parallel/USB/

types available

• 8 dots/mm resolution

• Wide variety of paper holding style

28 patterns for 60/80/102mm

diameter paper roll support

• Paper thickness up to 0.150mm

(Option)

• Driver: Win 2000/XP/VISTA/

2003 Server

Type Classification

PMU 2 2 0 0 -RS U P -8 L 2

1) 2) 3) 4)5) 6) 7) 8) 9)10)

1) Mechanism mounted 2) Paper width 3) Base style 4) Special mechanism 5) Interface

2: LT-2221

(2-in. mechanism)

3: LT-2321

(3-in. mechanism)

0: 58mm (with 2-in. mechanism/80mm (with

3-in. mechanism)

1: 60mm (with 2-in. mechanis)/60mm (with 3in. mechanism)* With guide for 60-mm paper

0: Horizontal (Mechanism used:

LT-2X2XV) / 1: Vertical front-mount

(Mechanism used: LT-2X2XH) / 2: Vertical

back-mount (Mechanism used: LT-2X2XV)

No mark: Standard

A. Thick paper

PA: Parallel

RS: Serial

UB: USB

(Virtual COM)

6) Destination 7) Sensor (PNE/Black Mark) 8) Maximum paper 9)Direction of paper insertion 10) Paper holder position

(CG+RS I/F screw) diameter

U: US/Europe/Other

J: Japan

* Dual indication permitted.

No mark: Without sensor

P: PNE sensor / M1: Black Mark (Left)

M2: black Mark (Right)

6: 60mm

8: 80mm

1: 102mm

L: Insert from left (Side without platen open

lever) / R: insert from right (Side with platen

open lever) / T: Insert from top (Hold both

sides, paper diameter fixed at 102mm)

1: A bit (One hole, toward left)

2: Standard (2 holes, toward left)

3: A bit far (One hole, toward right)

4: Far (2 holes, toward right)

Customization

Software

Paper insert

from left

from top

from right

Loading...

Loading...