Page 1

Cisco Catalyst 9800-80 Wireless Controller Hardware Installation Guide

First Published: 2018-11-20

Americas Headquarters

Cisco Systems, Inc.

170 West Tasman Drive

San Jose, CA 95134-1706

USA

http://www.cisco.com

Tel: 408 526-4000

800 553-NETS (6387)

Fax: 408 527-0883

Page 2

THE SPECIFICATIONS AND INFORMATION REGARDING THE PRODUCTS IN THIS MANUAL ARE SUBJECT TO CHANGE WITHOUT NOTICE. ALL STATEMENTS,

INFORMATION, AND RECOMMENDATIONS IN THIS MANUAL ARE BELIEVED TO BE ACCURATE BUT ARE PRESENTED WITHOUT WARRANTY OF ANY KIND,

EXPRESS OR IMPLIED. USERS MUST TAKE FULL RESPONSIBILITY FOR THEIR APPLICATION OF ANY PRODUCTS.

THE SOFTWARE LICENSE AND LIMITED WARRANTY FOR THE ACCOMPANYING PRODUCT ARE SET FORTH IN THE INFORMATION PACKET THAT SHIPPED WITH

THE PRODUCT AND ARE INCORPORATED HEREIN BY THIS REFERENCE. IF YOU ARE UNABLE TO LOCATE THE SOFTWARE LICENSE OR LIMITED WARRANTY,

CONTACT YOUR CISCO REPRESENTATIVE FOR A COPY.

The following information is for FCC compliance of Class A devices: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15

of the FCC rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio-frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference, in which case users will be required to correct the interference at their own expense.

The following information is for FCC compliance of Class B devices: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of

the FCC rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference

will not occur in a particular installation. If the equipment causes interference to radio or television reception, which can be determined by turning the equipment off and on, users are

encouraged to try to correct the interference by using one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Modifications to this product not authorized by Cisco could void the FCC approval and negate your authority to operate the product.

The Cisco implementation of TCP header compression is an adaptation of a program developed by the University of California, Berkeley (UCB) as part of UCB’s public domain version of

the UNIX operating system. All rights reserved. Copyright©1981, Regents of the University of California.

NOTWITHSTANDING ANY OTHER WARRANTY HEREIN, ALL DOCUMENT FILES AND SOFTWARE OF THESE SUPPLIERS ARE PROVIDED "AS IS" WITH ALL FAULTS.

CISCO AND THE ABOVE-NAMED SUPPLIERS DISCLAIM ALL WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING, WITHOUT LIMITATION, THOSE OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE AND NONINFRINGEMENT OR ARISING FROM A COURSE OF DEALING, USAGE, OR TRADE PRACTICE.

IN NO EVENT SHALL CISCO OR ITS SUPPLIERS BE LIABLE FOR ANY INDIRECT, SPECIAL, CONSEQUENTIAL, OR INCIDENTAL DAMAGES, INCLUDING, WITHOUT

LIMITATION, LOST PROFITS OR LOSS OR DAMAGE TO DATA ARISING OUT OF THE USE OR INABILITY TO USE THIS MANUAL, EVEN IF CISCO OR ITS SUPPLIERS

HAVE BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

Any Internet Protocol (IP) addresses and phone numbers used in this document are not intended to be actual addresses and phone numbers. Any examples, command display output, network

topology diagrams, and other figures included in the document are shown for illustrative purposes only. Any use of actual IP addresses or phone numbers in illustrative content is unintentional

and coincidental.

All printed copies and duplicate soft copies of this document are considered uncontrolled. See the current online version for the latest version.

Cisco has more than 200 offices worldwide. Addresses and phone numbers are listed on the Cisco website at www.cisco.com/go/offices.

Cisco and the Cisco logo are trademarks or registered trademarks of Cisco and/or its affiliates in the U.S. and other countries. To view a list of Cisco trademarks, go to this URL: www.cisco.com

go trademarks. Third-party trademarks mentioned are the property of their respective owners. The use of the word partner does not imply a partnership relationship between Cisco and any

other company. (1721R)

©

2018 Cisco Systems, Inc. All rights reserved.

Page 3

CONTENTS

PREFACE

CHAPTER 1

Preface vii

Document Revision History vii

Document Objectives vii

Audience vii

Conventions viii

Related Documentation ix

Obtaining Documentation and Submitting a Service Request ix

Overview 1

Summary of Cisco Catalyst 9800-80 Wireless Controller 1

Front View 2

Built-In SFP and SFP+ Ports 3

Management and Storage Connections 4

LEDs 4

Rear View 7

Cisco Product Identification Standard 7

Unique Device Identifier 7

CHAPTER 2

Serial Number and PID or VID Label Location 9

Supported Hardware Components 11

Supported EPA 11

Supported SFP Models 13

Supported Transceivers 14

Supported Crypto Module 15

Power Supplies 15

Power Supply LEDs 16

Cisco Catalyst 9800-80 Wireless Controller Hardware Installation Guide

iii

Page 4

Contents

Power Supply Fans 16

CHAPTER 3

Preparing Your Site for Installation 17

Prerequisites and Preparation 17

Site Planning Checklist 18

Safety Guidelines 18

Safety Warnings 18

Safety Recommendations 19

Cautions and Regulatory Compliance Statements for NEBS 19

Standard Warning Statements 20

General Safety Warnings 21

Site Planning 24

General Precautions 24

Site Selection Guidelines 24

Site Environmental Requirements 25

Physical Characteristics 25

Site Power Guidelines 26

Electrical Circuit Requirements 27

Site Cabling Guidelines 27

Console Port Connections 28

Interference Considerations 28

Rack-Mounting Guidelines 30

Precautions for Rack-Mounting 30

General Rack-Selection Guidelines 30

Guidelines for 23-in. (Telco) Racks 31

Equipment Rack Guidelines 31

Preventing Electrostatic Discharge Damage 32

Electrical Safety 33

Chassis-Lifting Guidelines 34

Tools and Equipment 34

Unpacking and Verifying Shipping Contents 34

Checking the Shipping Container Contents 35

Installation Checklist 35

Cisco Catalyst 9800-80 Wireless Controller Hardware Installation Guide

iv

Page 5

Contents

CHAPTER 4

Installing the Controller 39

Installation Methods 39

Guidelines for a Standalone Equipment Shelf or Tabletop Installation 40

Installing the Controller on a Standalone Equipment Shelf or Tabletop 40

Guidelines for Rack Installation 41

Verifying Rack Dimensions 42

Attaching Front Rack-Mount Brackets 43

Mounting the Controller in the Rack 44

Two-Post Rack Installation 45

Attaching the Cable Management Bracket 46

Chassis Ground Connection 48

Recommended Tools and Supplies 48

Attaching a Chassis Ground Connection 48

Connecting Cables 50

Connecting the Console Port Cable 51

Procedure for Connecting the Console Port Cable 51

CHAPTER 5

Connecting to the Mini USB Console Port 51

Management Ethernet Port Cable Connection 52

Power Up and Initial Configuration 53

Checking Conditions Prior to System Startup 53

Powering Up the Controller 54

Performing the Initial Configuration on the Controller 57

Using the Cisco Setup Command Facility 57

Completing the Configuration 59

Using the Cisco IOS-XE CLI—Manual Configuration 60

Configuring the Controller Hostname 61

Configuring the Enable and Enable Secret Passwords 61

Configuring the Console Idle Privileged EXEC Timeout 62

Gigabit Ethernet Management Interface Overview 63

Default Gigabit Ethernet Configuration 64

Configuring Gigabit Ethernet Interfaces 64

Saving Your Controller Configuration 65

Cisco Catalyst 9800-80 Wireless Controller Hardware Installation Guide

v

Page 6

Contents

Verifying the Initial Configuration 66

Powering Off the Controller Safely 66

Environmental Monitoring and Reporting Functions 67

Alarm Monitoring 67

Environmental Monitoring 68

Fan Failures 69

Reporting Functions 69

CHAPTER 6

CHAPTER 7

APPENDIX A

License Verification 75

Viewing the Cisco IOS License Level 75

Viewing License Information 76

Evaluation License Features 76

Removing and Replacing FRUs 77

Removing AC Power Supplies 77

Installing AC Power Supplies 77

Removing DC Input Power Supplies 78

Installing DC Input Power Supplies 78

Wiring the DC Input Power Source 80

Removing and Replacing USB Flash Memory Stick 82

Repacking the Controller 82

Technical Specifications 83

Technical Specifications 83

APPENDIX B

vi

Port Signals and Pinouts 85

Management Ethernet Port Signals and Pinouts 85

Console Port Signals and Pinouts 85

Cisco Catalyst 9800-80 Wireless Controller Hardware Installation Guide

Page 7

Preface

This preface describes this guide and provides information about the conventions used in this guide, along

with details about related documentation. It includes the following sections:

• Document Revision History, on page vii

• Document Objectives, on page vii

• Audience, on page vii

• Conventions, on page viii

• Related Documentation, on page ix

• Obtaining Documentation and Submitting a Service Request, on page ix

Document Revision History

The following table shows the changes made to this document:

Document Objectives

Change SummaryDate

First version of the document.November 2018

Audience

This publication describes the installation of the Cisco Catalyst 9800-80 Wireless Controller.

This publication is primarily designed for persons responsible for installing, maintaining, and troubleshooting

the Cisco Catalyst 9800-80 Wireless Controller. The users of this guide should:

• Be familiar with electronic circuitry and wiring practices.

• Have experience working as electronic or electromechanical technicians.

• Have experience in installing high-end networking equipment.

Cisco Catalyst 9800-80 Wireless Controller Hardware Installation Guide

vii

Page 8

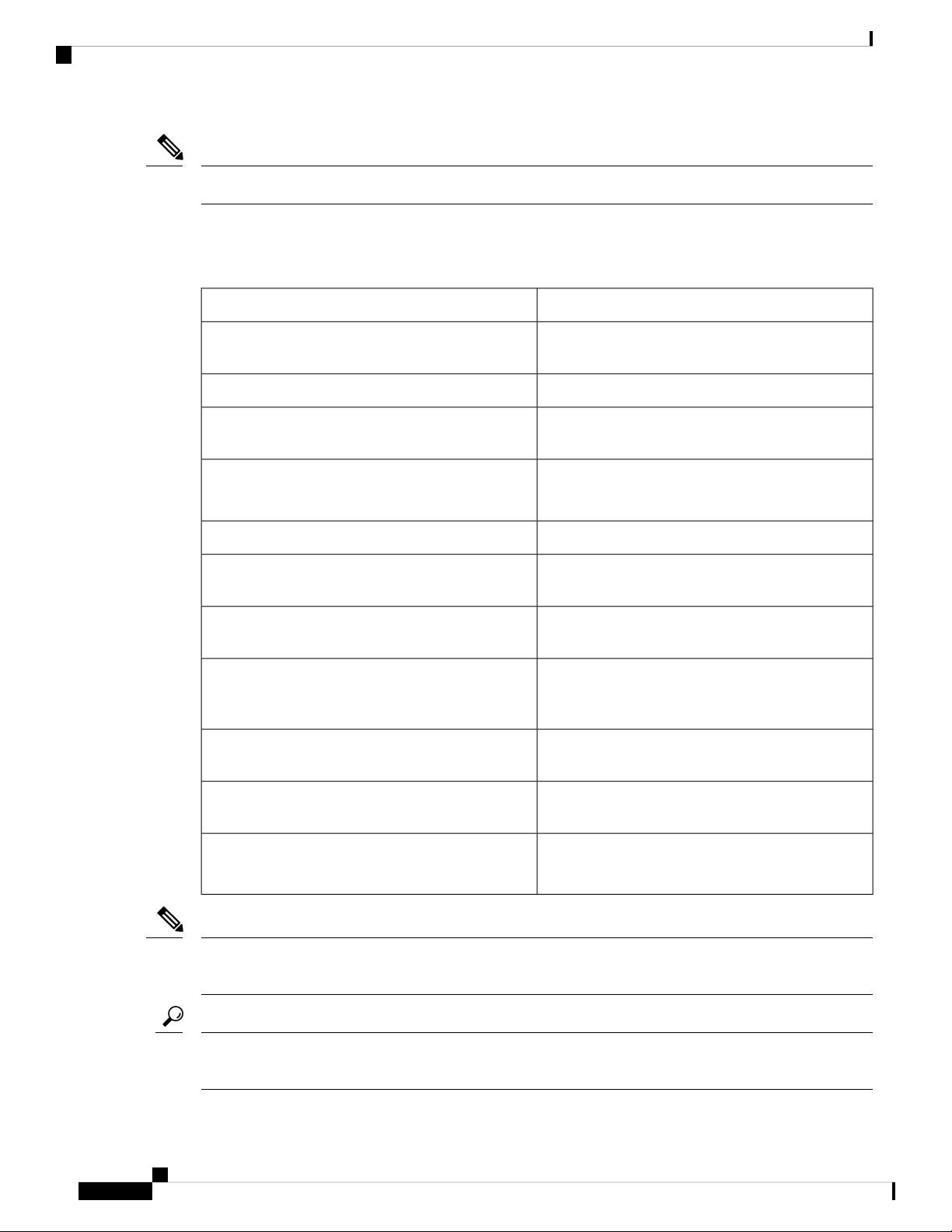

Conventions

Note

Some procedures described in this guide require a certified electrician.

Conventions

Preface

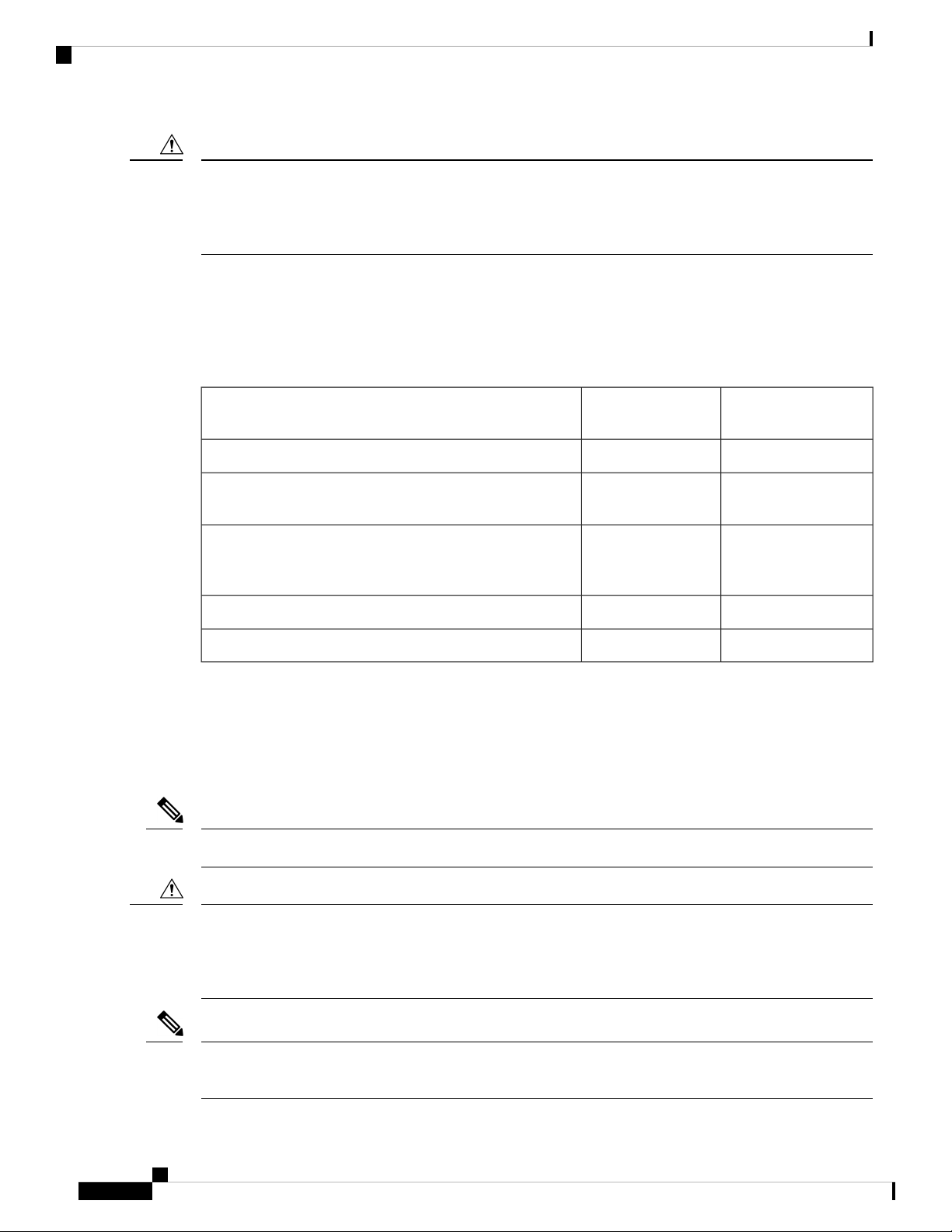

IndicationText Type

User input

Document titles

System output

CLI commands

{x | y | z}

[x | y | z]

String

< >

Text the user should enter exactly as shown or keys

a user should press appear in this font.

Document titles appear in this font.

Terminal sessions and information that the system

displays appear in this font.

CLI command keywords appear in this font.

Variables in a CLI command appear in this font.

Elements in square brackets are optional.[ ]

Required alternative keywords are grouped in braces

and separated by vertical bars.

Optional alternative keywords are grouped in brackets

and separated by vertical bars.

A nonquoted set of characters. Do not use quotation

marks around the string or the string will include the

quotation marks.

Nonprinting characters such as passwords are in angle

brackets.

viii

[ ]

!

#

Note

Means reader take note. Notes contain helpful suggestions or references to material not covered in the

document.

Tip

Means the following information will help you solve a problem. The tips information might not be

troubleshooting or even an action, but could be useful information, similar to a Timesaver.

Cisco Catalyst 9800-80 Wireless Controller Hardware Installation Guide

Default responses to system prompts are in square

brackets.

An exclamation point (!) or a pound sign (#) at the

beginning of a line of code indicates a comment line.

Page 9

Preface

Related Documentation

Caution

Warning

Means reader be careful. In this situation, you might perform an action that could result in equipment damage

or loss of data.

Timesaver: Means the described action saves time. You can save time by performing the action described

in the paragraph.

IMPORTANT SAFETY INSTRUCTIONS

This warning symbol means danger. You are in a situation that could cause bodily injury. Before you work

on any equipment, be aware of the hazards involved with electrical circuitry and be familiar with standard

practices for preventing accidents. Use the statement number provided at the end of each warning to locate

its translation in the translated safety warnings that accompanied this device.

SAVE THESE INSTRUCTIONS

Related Documentation

See the following documentation for more information about the Cisco Catalyst 9800 Wireless ControllerCisco

Catalyst 9800-80 Wireless Controller:

• Release Notes for Cisco Catalyst 9800 Wireless Controller Cisco Catalyst 9800-80 Wireless Controller

• Cisco Catalyst 9800 Series Wireless Controller Software Configuration Guide

• Cisco Catalyst 9800 Series Wireless Controller Command Reference

• Cisco Wireless Solutions Software Compatibility Matrix

Obtaining Documentation and Submitting a Service Request

For information on obtaining documentation, using the Cisco Bug Search Tool (BST), submitting a service

request, and gathering additional information, see What's New in Cisco Product Documentation.

To receive new and revised Cisco technical content directly to your desktop, you can subscribe to the What's

New in Cisco Product Documentation RSS feed. RSS feeds are a free service.

Cisco Catalyst 9800-80 Wireless Controller Hardware Installation Guide

ix

Page 10

Obtaining Documentation and Submitting a Service Request

Preface

Cisco Catalyst 9800-80 Wireless Controller Hardware Installation Guide

x

Page 11

CHAPTER 1

Overview

The Cisco Catalyst 9800-80 Wireless Controller is an 80-G wireless controller that occupies two rack unit

space and supports a single Ethernet Port Adapter (EPA) slot, and eight built-in 10-GE or 1-GE interfaces.

The Cisco Catalyst 9800-80 Wireless Controller portfolio comes with a 30-G Crypto processor that aggregates

services at scale.

• Summary of Cisco Catalyst 9800-80 Wireless Controller, on page 1

• Cisco Product Identification Standard, on page 7

• Serial Number and PID or VID Label Location, on page 9

Summary of Cisco Catalyst 9800-80 Wireless Controller

The Cisco Catalyst 9800-80 Wireless Controller supports:

• Up to 32 GB (16 GB in the base configuration) of DDR3 error-correcting code-protected field-replaceable

memory, with single-bit error correction and multi-bit error detection.

• A fixed forwarding processor with up to 100 Gbps sustained forwarding data traffic through the chassis.

• Up to 25 Gbps security and crypto processing through a dedicated security processor.

• RJ-45 console ports and a mini USB console port.

• 32 GB internal bootflash storage.

• One copper Ethernet 10/100/1000 Mbps network management port.

• An embedded USB (eUSB) flash module that supports 32 GB of nonvolatile Flash storage.

• Two USB 3.0 ports that are backward compatible with USB 2.0.

• SATA hard disk.

• Eight built-in 10 GE SFP+ interfaces.

Note

The Te0/0/6 and Te0/0/7 ports support 10 GE and 1 GE SFP+ interfaces.

• One Ethernet Port Adapter (EPA) bay.

Cisco Catalyst 9800-80 Wireless Controller Hardware Installation Guide

1

Page 12

Front View

Front View

Overview

• Stratum 3E network clocking per GR-1244-CORE, using 1 GE, 10 GE, or EPA interfaces as timing

sources.

• LED indicators for Ethernet and console status, as well as visual system state indications.

• Command-line interface (CLI), alarm, network management, logging, statistics aggregation, and on-board

failure logging (OBFL).

• Environmental chassis management.

• 80 Mb ternary content-addressable memory (TCAM).

• Field-replaceable units (FRU).

See Chapter 2, Supported Hardware Components for information on supported FRUs.

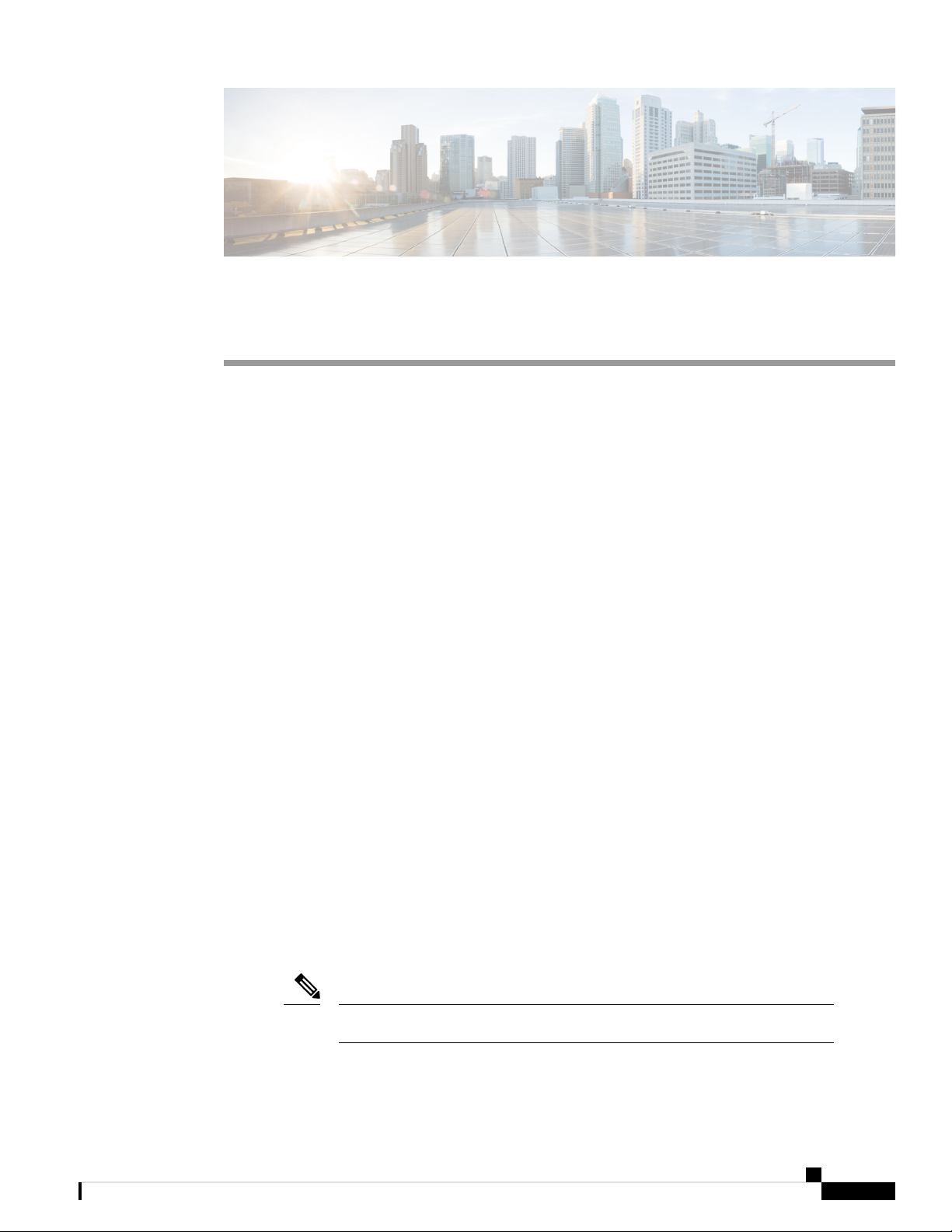

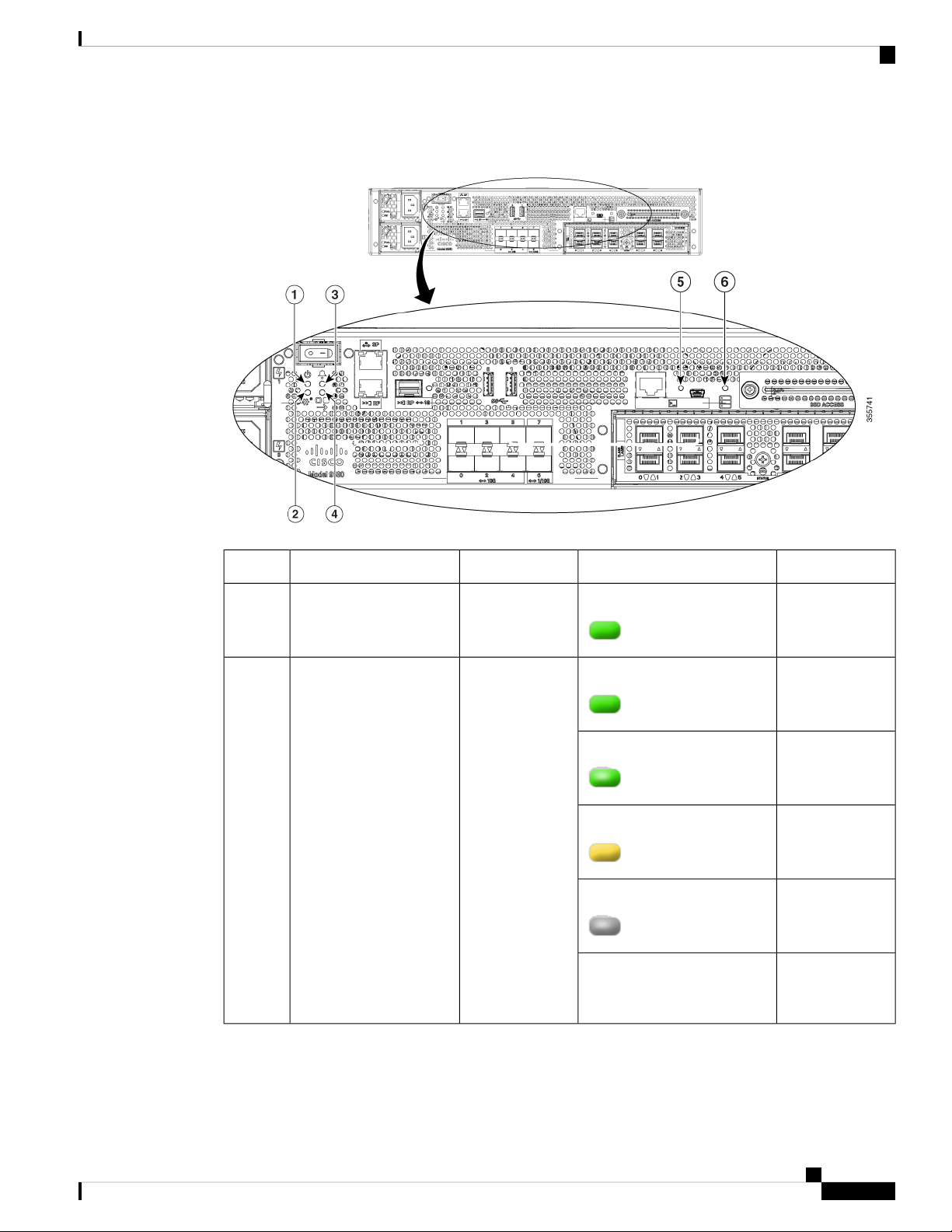

The following figure shows the front of the Cisco Catalyst 9800-80 Wireless Controller.

Figure 1: Cisco Catalyst 9800-80 Wireless Controller Front View

RP— 1-GE SFP port10Power supply (PEM 0)1

USB ports 0 and 111Power supply (PEM 1)2

Bay 0—8 X 10GE SFP+ ports (Fixed EPA)12Power (PWR) switch3

CON— RJ-45 compatible console port13PWR— Power LED4

LINK— RJ-45 connector LED14SYS— System LED5

CON— Mini USB console port15ALM— Alarm LED6

SSD— SSD activity LED16HA— High-Availability LED7

8

SSD Access17SP— RJ-45 10/100/1000 management

Ethernet

port

Cisco Catalyst 9800-80 Wireless Controller Hardware Installation Guide

2

Page 13

Overview

Built-In SFP and SFP+ Ports

9

Ethernet

port

Two power supplies (AC or DC) are accessed from the front of the controller and are hot-swappable.

Caution

The Cisco Catalyst 9800-80 Wireless Controller supports two AC or DC power supplies. Do not install mixed

AC and DC power supply units in the same chassis.

Built-In SFP and SFP+ Ports

The following figure shows the port numbering for the built-in ports.

Figure 2: Cisco Catalyst 9800-80 Wireless Controller Port Numbering

Bay 1 or Hot-Swap EPA18RP— RJ-45 10/100/1000 redundancy

1

2Bay 0—The ports in Bay 0 use 1GE or 10GE

SFP+ transceivers and are labeled TE0 - TE7.

Note

By default, the interfaces from 0 to 3 on both Bay 0 and Bay 1 on the Cisco Catalyst 9800-80 Wireless

Bay 1—The ports in Bay 1 use 10GE SFP+

transceivers.

Controller are enabled. You can enable the interfaces from 4 to 7 by purchasing the Paired Port License.

The port LEDs behave as follows:

Cisco Catalyst 9800-80 Wireless Controller Hardware Installation Guide

3

Page 14

Management and Storage Connections

• Off—Indicates the port is not enabled by software.

• Amber—Indicates the port is enabled by software but there is a problem with the link.

• Green—Indicates the port is enabled by software and there is valid link.

Management and Storage Connections

The following figure shows the management and storage connections for the Cisco Catalyst 9800-80 Wireless

Controller.

Figure 3: Management and Storage Connections for the Cisco Catalyst 9800-80 Wireless Controller

Overview

LEDs

1

USB port 15MGMT— RJ-45 10/100/1000 management

Ethernet port.

2

CON— Mini USB connector console port.6RDCY— RJ-45 10/100/1000 redundancy

Ethernet port.

CON— RJ-45 compatible console port.7RDCY— 1-GE SFP+ port.3

SSD Access8USB port 04

The following figure shows the LEDs on the front panel of the Cisco Catalyst 9800-80 Wireless Controller.

Cisco Catalyst 9800-80 Wireless Controller Hardware Installation Guide

4

Page 15

Overview

LEDs

Figure 4: Cisco Catalyst 9800-80 Wireless Controller LEDs

GreenPowerPWR1

OnSystemSYS2

Blinking Green

Amber

Blinking Amber

Off

BehaviorLED ColorDescriptionLED LabelNo.

If all the power

rails are based on

the specification.

Remains ON

during IOS boot

complete.

Remains blinking

when IOS booting

is in progress.

Remains ON

during system

crash.

Remains blinking

during secure

boot failure.

Remains OFF

during

ROMMON boot.

Cisco Catalyst 9800-80 Wireless Controller Hardware Installation Guide

5

Page 16

LEDs

Overview

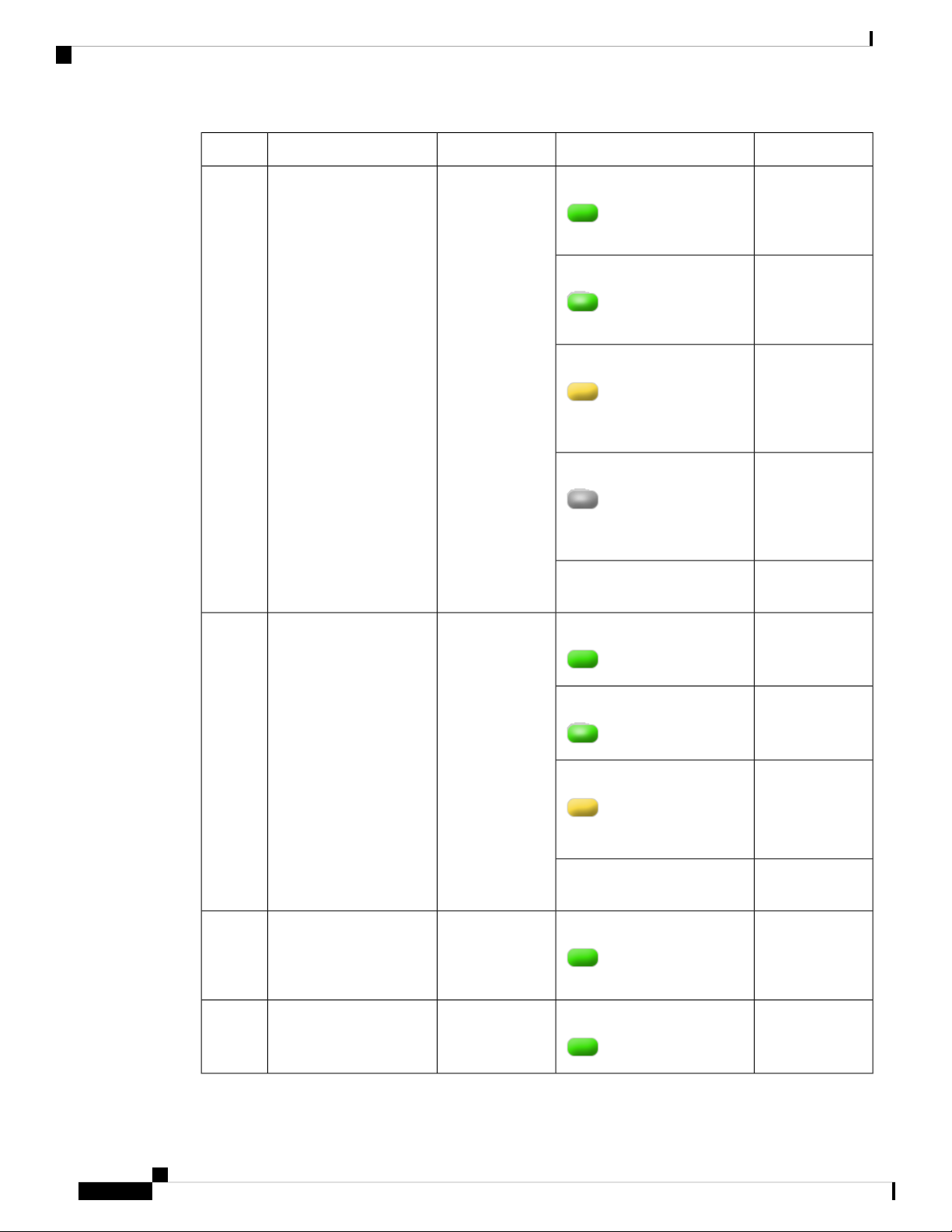

BehaviorLED ColorDescriptionLED LabelNo.

ALM3

GreenAlarm

Remains ON

during

ROMMON boot

complete.

Blinking Green

Remains blinking

when system

upgrade is in

progress.

Amber

Remains ON

during

ROMMON and

SYSTEM

bootups.

Blinking Amber

Remains blinking

during

temperature error

and secure boot

failure.

Off

Remains OFF

during IOS boot.

HA4

GreenHigh Availability

Remains ON

when HA is

active.

Blinking Green

Remains blinking

when HA

Standby Hot.

Amber

Blinks slowly

when booted or

HA Standby

Cold.

Blinks Fast

Blinks fast during

HA maintenance.

5

GreenUSB console

enabled

Indicates that the

mini USB

connector is used

as the console.

GreenSSD ActivitySSD6

Remains ON

during the SSD

activity.

Cisco Catalyst 9800-80 Wireless Controller Hardware Installation Guide

6

Page 17

Overview

Rear View

Rear View

The following figure shows the rear of the Cisco Catalyst 9800-80 Wireless Controller.

Figure 5: Cisco Catalyst 9800-80 Wireless Controller Rear View

The chassis has a front-to-rear airflow. Four internal fans draw cooling air in through the front of the chassis

and across internal components to maintain an acceptable operating temperature. The fans are located at the

rear of the chassis. The fans are numbered from 0 to 3, right to left.

Caution

The power supplies used in Cisco Catalyst 9800-80 Wireless Controllers are different and they should not be

mixed or swapped. The size and structural dimensions are the same, therefore they both look alike. It would

be hazardous, if you accidentally inserted the wrong power supply into the PEM slot.

Cisco Product Identification Standard

This section describes the Cisco products and services product identification standard. This feature provides

you with the ability to effectively integrate and manage Cisco products in your network and business operations.

Unique Device Identifier

The Unique Device Identifier (UDI) is the Cisco product identification standard for hardware products. A

product identification standard removes barriers to enterprise automation and can help you reduce operating

expenses.

The UDI provides a consistent electronic, physical, and associated business-to-business information product

identification standard.

The UDI is a combination of five data elements. The following table lists the UDI elements.

Cisco Catalyst 9800-80 Wireless Controller Hardware Installation Guide

7

Page 18

Unique Device Identifier

Overview

Table 1: UDI Elements

UDI Data Element

Electronic

Visibility

Visibility

YesYesPID

DescriptionPhysical

Product ID, also known as product name, model

name, product number

Version IDYesYesVID

Serial number, the unique instance of the PIDYesYesSN

Type, such as chassis, slot, or power supply—YesEntity Name

Additional product information—YesProduct

Description

The combination of serial number and product ID (PID) is unique and consistent across all Cisco products.

The PID that is coded on hardware is called a base product identifier.

Additional orderable PIDs can be associated to a base PID. For instance, an orderable PID may describe a

packaging configuration for a product or a bundled group of products sold, tested, and shipped together.

Specific unique device identifier (UDI) benefits include the following:

• Identifies:

• Individual Cisco products in your networks

• PIDs and serial numbers for service and replaceable products

• Version IDs (VIDs) for product version visibility

• Facilitates discovery of products subject to recall or upgrade

• Enhances inventory automation of Cisco products

The Cisco product identification standard provides the following features:

• Version visibility—Cisco continuously improves products through feature additions. Product changes

are indicated by incrementing the VID, which provides version visibility to help you understand and

manage product changes. VID management ensures consistency of changes from product to product.

• Operating expense reduction—Cisco UDIs provide accurate and detailed network inventory information;

identifying each Cisco product in a network element through a standard interface. Cisco operating systems

can view and use this data, allowing you to automate your electronic inventory.

• Consistency across product layers—The UDIs are embedded in the hardware products and cannot be

overwritten. Operating and management systems discover UDIs through standard interfaces and display

UDIs in standard outputs. Standard interfaces include the IETF standard ENTITY-MIB.

show diag chassis eeprom detail Command

The show diag chassis eeprom command displays the PID, VID, PCB serial number, hardware revision, and

other such information.

The following is sample output from the show diag chassis eeprom command:

Cisco Catalyst 9800-80 Wireless Controller Hardware Installation Guide

8

Page 19

Overview

Serial Number and PID or VID Label Location

WLC# show diag chassis eeprom

MIDPLANE EEPROM data:

Product Identifier (PID) : C9800-80-K9

Version Identifier (VID) : V01

PCB Serial Number : xxxxxxxxxx

Top Assy. Part Number : 68-8888-68

Hardware Revision : 0.2

Asset ID :

Power/Fan Module P0 EEPROM data:

Power/Fan Module P1 EEPROM data is not initialized

Note

Common Language Equipment Identification (CLEI) code is a ten-digit character code that identifies a specific

CLEI Code : UNASSIGNED

Product Identifier (PID) : C9800-AC-750W

Version Identifier (VID) : V01

PCB Serial Number : xxxxxxxxxx

Hardware Revision : 1.0

Asset ID :

CLEI Code : xxxxxxxxxx

product. A CLEI code is applied to each part within a Cisco Catalyst 9800-80 Wireless Controller as they are

programmed in manufacturing for shipment to customers.

show license udi Command

The show license udi command displays UDI information.

The following is sample output from the show license udi command:

WLC# show license udi

SlotID PID SN UDI

-------------------------------------------------------------------------------* C9800-80-K9 xxxxxxxxxx C9800-80-K9:xxxxxxxxxx

Note

For complete information on the product identification standard, see https://www.cisco.com/c/en/us/products/

unique-device-identifier-udi.html.

Serial Number and PID or VID Label Location

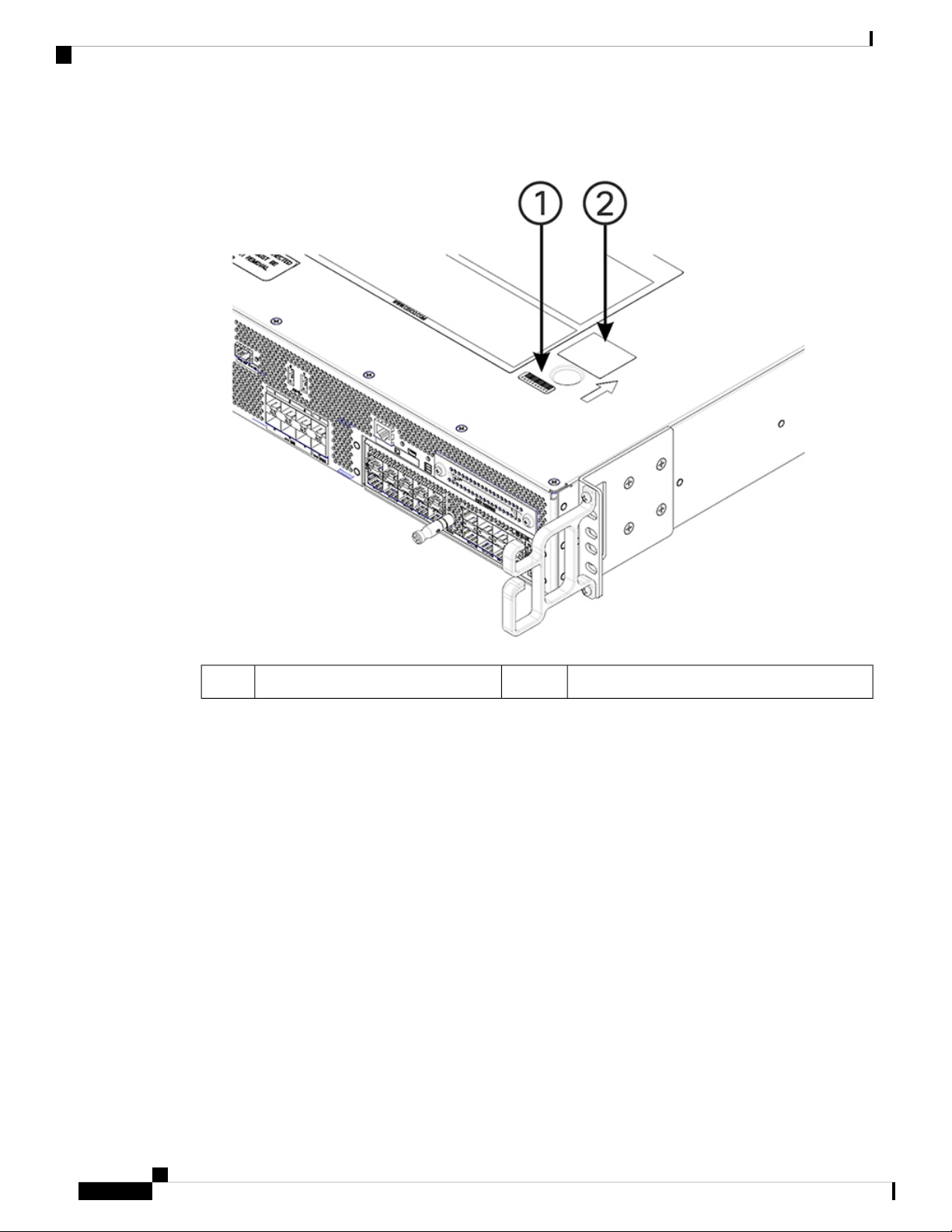

The following figures show the location of the serial number and the PID/VID label on the Cisco Catalyst

9800-80 Wireless Controller.

Cisco Catalyst 9800-80 Wireless Controller Hardware Installation Guide

9

Page 20

Serial Number and PID or VID Label Location

Figure 6: Cisco Catalyst 9800-80 Wireless Controller Serial Number and PID/VID Label Location

Overview

PID/VID Label2Serial Number1

Cisco Catalyst 9800-80 Wireless Controller Hardware Installation Guide

10

Page 21

Supported Hardware Components

This chapter contains information about the supported hardware components on the Cisco Catalyst 9800-80

Wireless Controller.

• Supported EPA, on page 11

• Supported SFP Models, on page 13

• Supported Transceivers, on page 14

• Supported Crypto Module, on page 15

• Power Supplies, on page 15

Supported EPA

The following table lists the supported EPA on the Cisco Catalyst 9800-80 Wireless Controller.

CHAPTER 2

DescriptionPID

EPA-18X1GE

EPA-10X10GE

EPA-1X40GE

EPA-2X40GE

EPA-1X100GE

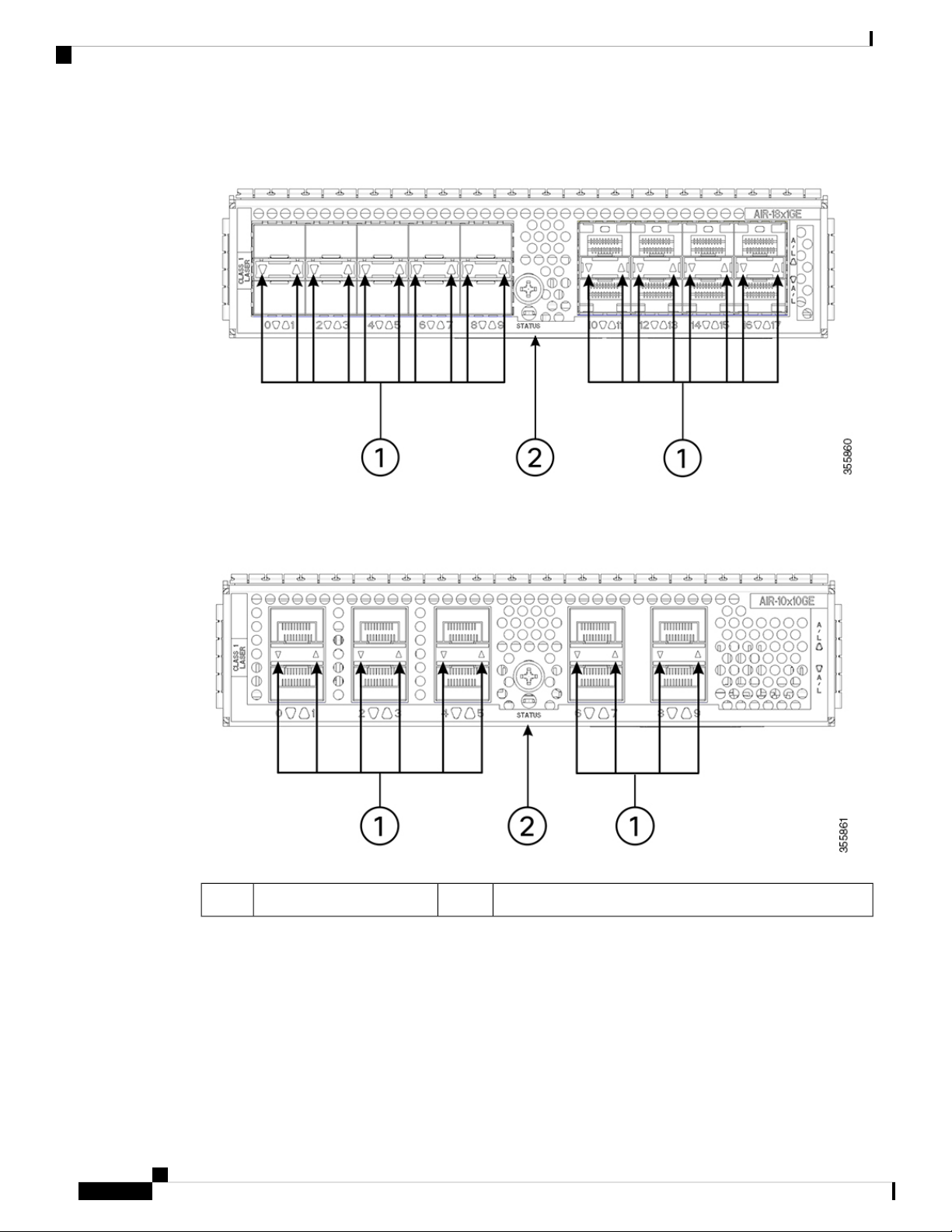

An EPA has two types of LEDs: an A/L (Active/Link) LED for each port on the EPA, and a STATUS LED,

as shown in the following figure.

Eighteen 1GE-ports that support small form-factor pluggable (SFP)

optical transceivers to provide network connectivity. Ports are numbered

0 – 17.

See the Supported SFP Transceivers section, for supported transceivers.

Ten 10GE-ports that support small form-factor pluggable (SFP+) optical

transceivers to provide network connectivity. Ports are numbered 0 – 9.

See Table 3: Supported SFP Transceivers, for supported transceivers.

EPA-1X100GE uses a CPAK module to provide network connectivity.

See Table 5: Supported CPAK Interface, for supported

CPAKs.

Cisco Catalyst 9800-80 Wireless Controller Hardware Installation Guide

11

Page 22

Supported EPA

Supported Hardware Components

Figure 7: EPA-18X1GE LEDs

Figure 8: EPA-10X10GE LEDs

STATUS2A/L1

Cisco Catalyst 9800-80 Wireless Controller Hardware Installation Guide

12

Page 23

Supported Hardware Components

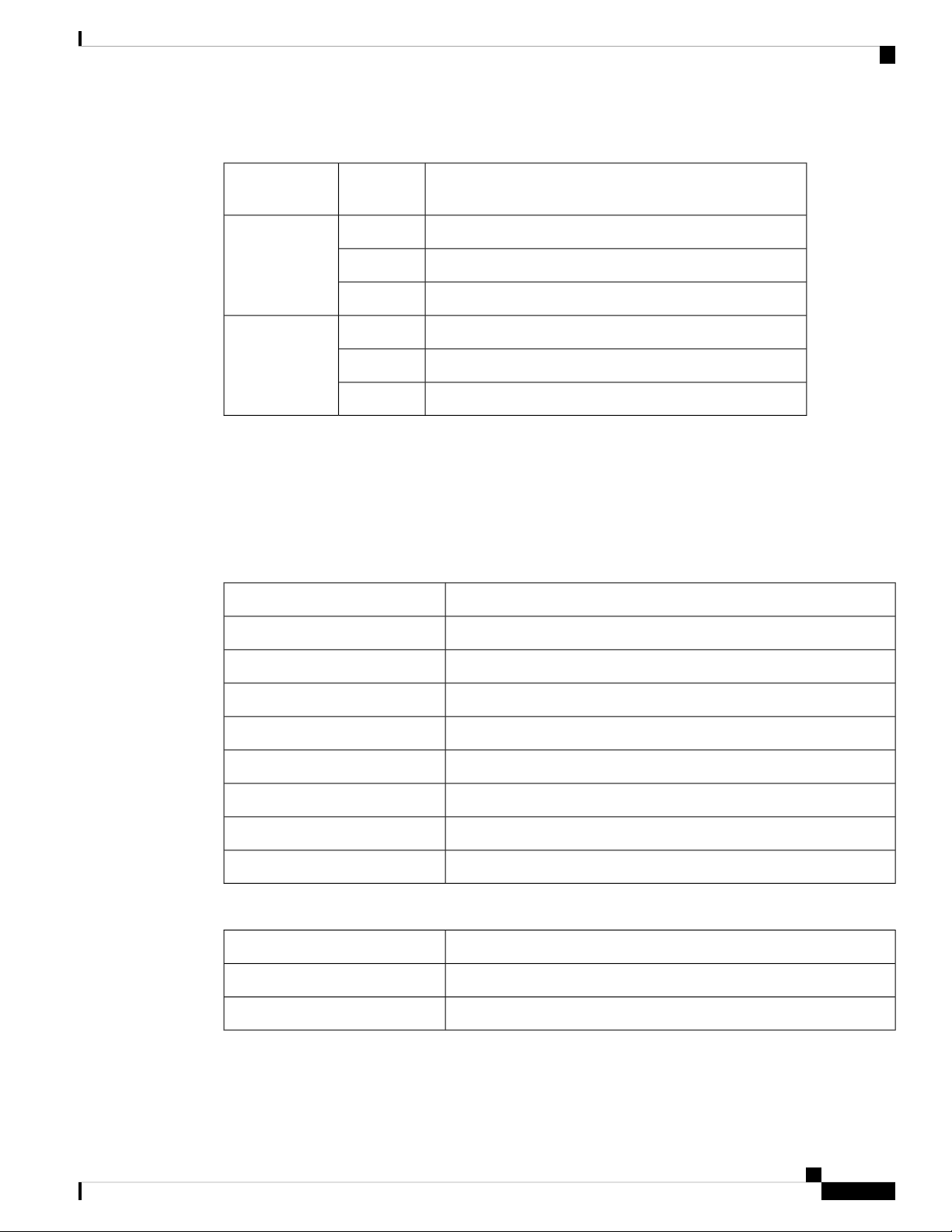

Table 2: EPA LEDs

Supported SFP Models

Function

State

(Active/Link)

GreenStatus

Supported SFP Models

The following table lists the supported SFP models [40-GB and 100-GB] on the Cisco Catalyst 9800-80

Wireless Controller.

Table 3: SFP Model [40-GB]

DescriptionColor or

Port is enabled and the link is up.GreenA/L

Port is enabled and the link is down.Amber

Port is not enabled.Off

EPA is ready and operational.

EPA power is on and good, and the EPA is being configured.Amber

EPA power is off.Off

DescriptionSFP Model

Table 4: SFP Model [100-GB]

40-GB SFP model for SR4QSFP-40G-SR4

40-GB SFP model for LR4QSFP-40G-LR4

40-GE SFP model for LR4QSFP-40GE-LR4

40-GB SFP model for ER4QSFP-40G-ER4

40-GB SFP model for SR4-SQSFP-40G-SR4-S

40-GB SFP model for LR4-SQSFP-40G-LR4-S

40-GB SFP model for SR-BDQSFP-40G-SR-BD

40-GB SFP model for BD-RXQSFP-40G-BD-RX

DescriptionSFP Model

100-GB SFP model for SR4-SQSFP-100G-SR4-S

100-GB SFP model for LR4-SQSFP-100G-LR4-S

Cisco Catalyst 9800-80 Wireless Controller Hardware Installation Guide

13

Page 24

Supported Transceivers

Supported Transceivers

The Cisco Catalyst 9800-80 Wireless Controller supports the following small form-factor pluggable (SFP)

and CPAK optical transceiver types:

0

Supported Hardware Components

Cisco Catalyst 9800-80 Wireless ControllerPortsBay

SFP+Ports TE0 – TE7 use 1GE or 10GE SFP+Bay

EPA-18X1GE— Ports 0 – 17

Bay

1

EPA-10X10GE— Ports 0 – 9

EPA-1X40GE— Port 0

EPA-2X40GE— Port 0 – 1

EPA-1X100GE— Port 0

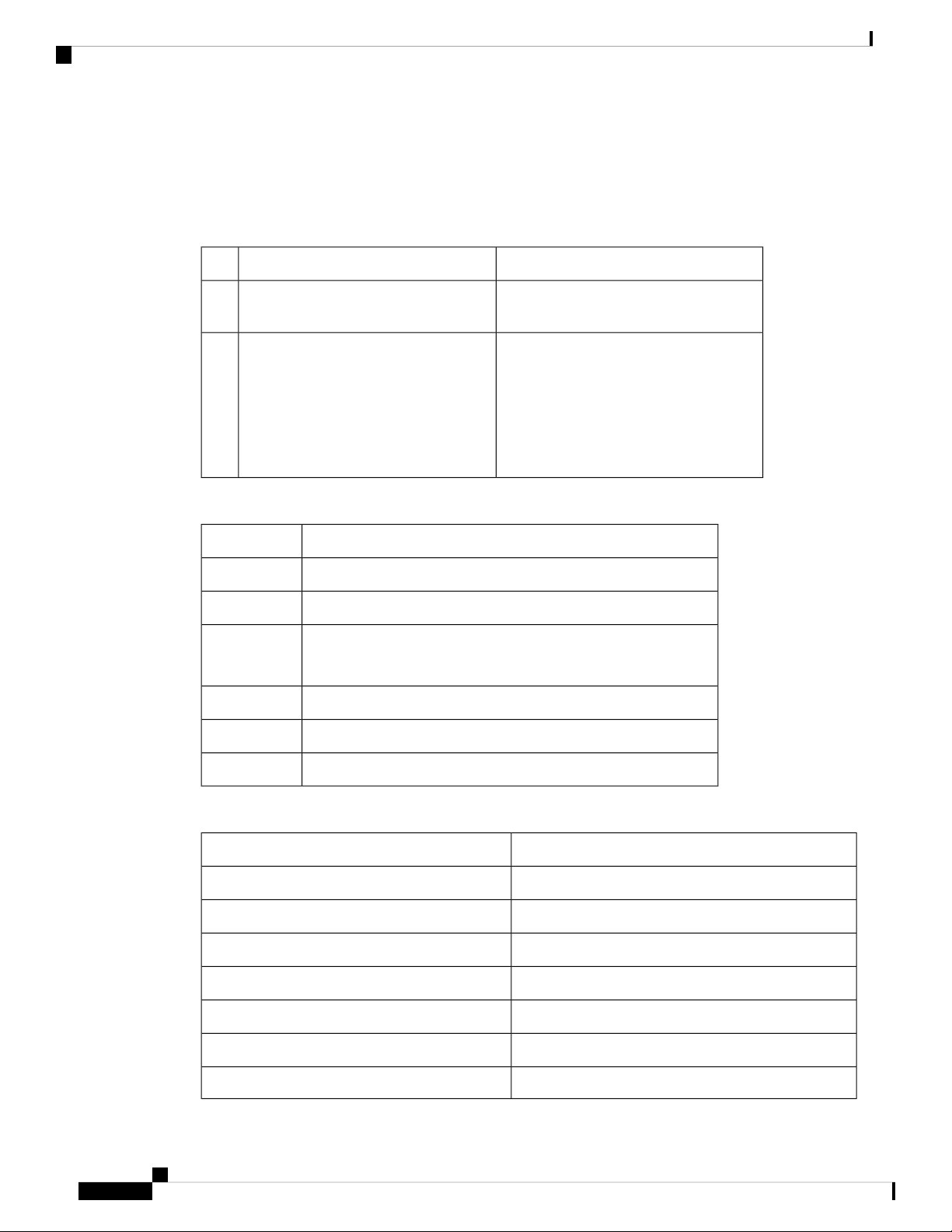

Table 5: Supported SFP Transceivers

DescriptionPID

1000BASE-BX SFP, 1490nmGLC-BX-D

1000BASE-BX SFP, 1310nmGLC-BX-U

GLC-LH-SMD

1000BASE-LX/LH SFP transceiver module, MMF/SMF, 1310nm,

DOM

1000BASE-SX SFP transceiver module, MMF, 850nm, DOMGLC-SX-MMD

1000BASE-ZX SFP transceiver module, SMF, 1550nm, DOMGLC-ZX-SMD

1000BASE-T SFP transceiver module for category 5 copper wireGLC-TE

SFP

SFP+

Table 6: Supported SFP+ Transceiver

DescriptionPID

10GBASE-SR SFP+ Module for MMFSFP-10G-SR

10GBASE-SR SFP+ Module for Extended Temp rangeSFP-10G-SR-X

10GBASE-LR SFP+ Module for SMFSFP-10G-LR

10GBASE-LRM SFP+SFP-10G-LRM

10GBASE-LR SFP+ Module for Extended Temp rangeSFP-10G-LR-X

10GBASE-ER SFP+ Module for SMFSFP-10G-ER

10GBASE-ZR SFP+SFP-10G-ZR

Cisco Catalyst 9800-80 Wireless Controller Hardware Installation Guide

14

Page 25

Supported Hardware Components

Supported Crypto Module

The Cisco Catalyst 9800-80 Wireless Controller supports the following crypto module:

Supported Crypto Module

DescriptionPID

10GBASE-CU SFP+ Cable 7 Meter, activeSFP-H10GB-ACU7M

10GBASE-CU SFP+ Cable 10 Meter, activeSFP-H10GB-ACU10M

10GBASE DWDMDWDM-SFP10G-30.33 –DWDM-SFP10G-61.41

DescriptionPID

Octeon-II CN6880-1400

Power Supplies

The Cisco Catalyst 9800-80 Wireless Controllers support AC or DC power supply options. The modular

chassis configurations support the installation of two power supplies for redundancy. When an external power

supply fails or is removed, the other power supply provides power requirements for the chassis. This allows

you to hot-swap the power supply without impacting the functionality of the controller.

Caution

A controller can support two AC or DC power supplies. Do not install mixed AC and DC power supply units

in the same chassis.

The power supplies are used in a 1 + 1 redundant configuration. There is no input switch on the faceplate of

the power supplies. A power supply is switched from Standby to On by way of a system chassis power switch.

The following table lists the power supplies that you can order:

C9800-AC-1100W

A 32-core network processor running at 1400-MHz, which allows 30G of

Crypto performance.

Power SupplyPart Number

Cisco Catalyst 9800-80 Wireless Controller power supply module with plug-side intake

airflow, AC, 1100W, 85-264V

C9800-AC-1100W=

C9800-DC-950W

C9800-DC-950W=

Cisco Catalyst 9800-80 Wireless Controller power supply module with plug-side intake

airflow, AC, 1100W, 85-264V, spare

Cisco Catalyst 9800-80 Wireless Controller power supply module with plug-side intake

airflow, DC 950W

Cisco Catalyst 9800-80 Wireless Controller power supply module with plug-side intake

airflow, DC 950W, spare

Cisco Catalyst 9800-80 Wireless Controller Hardware Installation Guide

15

Page 26

Power Supply LEDs

Supported Hardware Components

Caution

The chassis has a front-to-rear airflow. All of the power supplies and fan modules in the chassis must use the

same airflow direction or an error will occur with possible overheating and shut down of the controller. If you

power up the controller with more than one airflow direction, you must power down the controller and replace

the modules with the wrong airflow direction before powering up the controller.

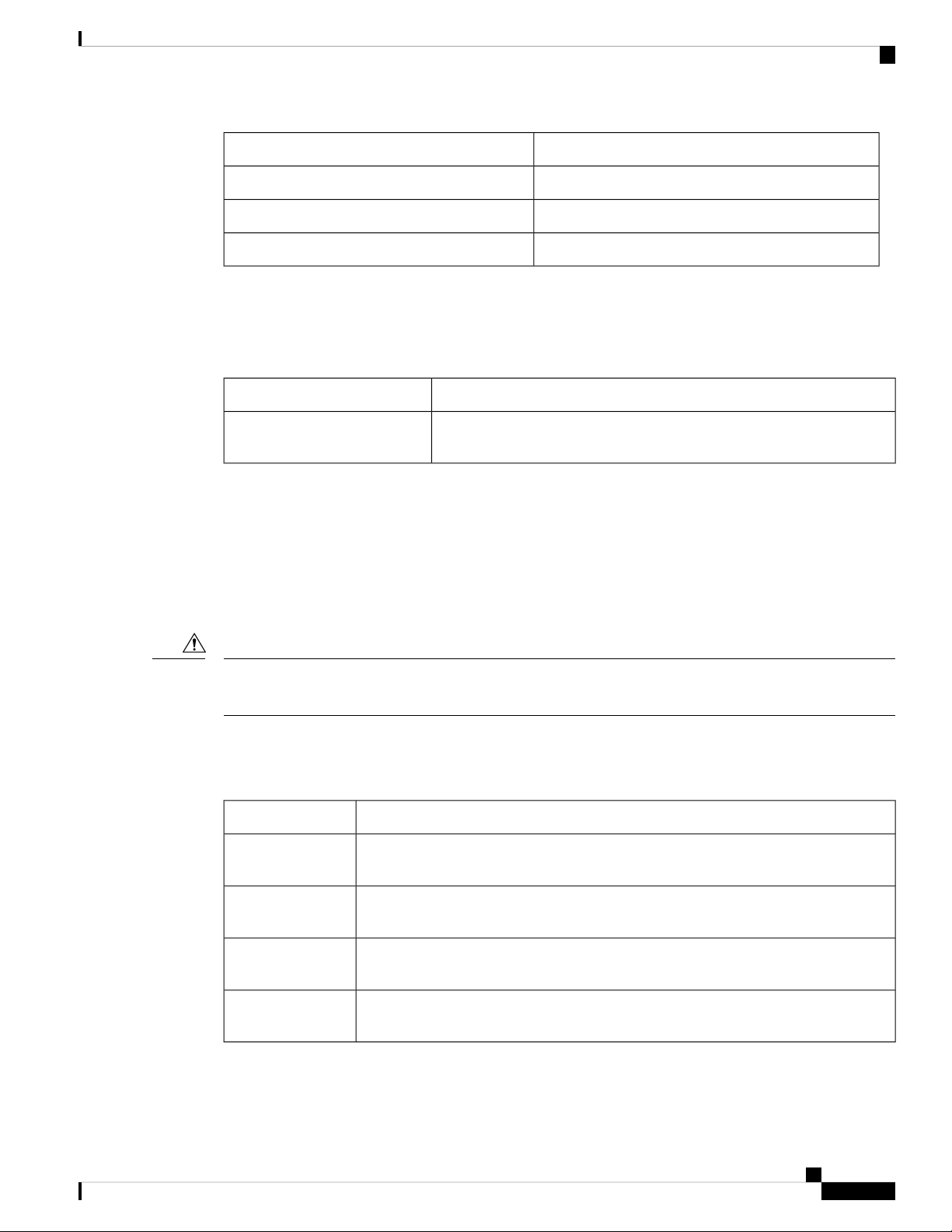

Power Supply LEDs

The following table describes the power supply LEDs.

Table 7: AC Power Supply LEDs

Power Supply Condition

over temperature and fan failure)

continues to operate (high temperature, high power and slow

fan)

Green (OK) LED

Status

Amber (FAIL) LED

Status

OFFOFFNo AC power to all power supplies

ONOFFPower Supply Failure (includes over voltage, over current,

1Hz BlinkingOFFPower Supply Warning events where the power supply

OFF1Hz BlinkingAC Present/3.3VSB on (PSU OFF)

Power Supply Fans

The fans in the power supply module are used for cooling the power supply module itself while system-level

cooling is provided by fans within the chassis. The power supplies do not depend on the system-level fans

for cooling. Fan failure is determined by fan-rotation sensors.

Note

The fans in the Cisco Catalyst 9800-80 Wireless Controller power supplies have plug-side intake airflow.

Caution

The chassis has a front-to-rear airflow. All of the power supplies and fan modules in the same chassis must

use the same airflow direction or an error will occur with possible overheating and shut down of the controller.

If you power up the controller with more than one airflow direction, you must power down the controller and

replace the modules with the wrong airflow direction before powering up the controller.

Note

The fans in the power supply modules will run as soon as the power supply is plugged in, even if the power

switch is in the Standby position.

OFFONPower Supply ON and OK

Cisco Catalyst 9800-80 Wireless Controller Hardware Installation Guide

16

Page 27

CHAPTER 3

Preparing Your Site for Installation

This chapter contains important safety information you should know before working with the Cisco Catalyst

9800-80 Wireless Controller, and guides you through the process of preparing your site for wireless controller

installation.

• Prerequisites and Preparation, on page 17

• Safety Guidelines, on page 18

• Cautions and Regulatory Compliance Statements for NEBS, on page 19

• Standard Warning Statements, on page 20

• Site Planning, on page 24

• Site Cabling Guidelines, on page 27

• Rack-Mounting Guidelines, on page 30

• Preventing Electrostatic Discharge Damage, on page 32

• Electrical Safety, on page 33

• Chassis-Lifting Guidelines, on page 34

• Tools and Equipment, on page 34

• Unpacking and Verifying Shipping Contents, on page 34

• Installation Checklist, on page 35

Prerequisites and Preparation

Before you perform the procedures in this guide, we recommend that you:

• Read the safety guidelines in the next section and review the electrical safety and ESD-prevention

guidelines in this guide.

• Ensure that you have all of the necessary tools and equipment (see the Tools and Equipment section).

• Ensure that you have access to the Cisco Catalyst 9800-80 Wireless Controller Software Configuration

Guide (an online document that is available for viewing or download at Cisco.com) during the installation.

• Ensure that the power and cabling requirements are in place at your installation site.

• Ensure that the equipment required to install the controller is available.

• Ensure that your installation site meets the environmental conditions to maintain normal operation.

Cisco Catalyst 9800-80 Wireless Controller Hardware Installation Guide

17

Page 28

Site Planning Checklist

Before installing the controller, you must consider power and cabling requirements that must be in place at

your installation site, special equipment for installing the controller, and the environmental conditions your

installation site must meet to maintain normal operation.

The shipping package for the controller is engineered to reduce the chances of product damage associated

with routine material handling experienced during shipment:

• Controller should always be transported or stored in its shipping package in the upright position.

• Keep the controller in the shipping container until you have determined the installation site.

Note

Inspect all items for shipping damage. If an item appears damaged, contact a Cisco customer service

representative immediately.

Site Planning Checklist

Use the following checklist to perform and account for all the site-planning tasks described in this chapter:

Preparing Your Site for Installation

• The site air conditioning system can compensate for the heat dissipation of the controller.

• Electrical service to the site complies with the requirements.

• The electrical circuit servicing the controller complies with the requirements.

• Consideration has been given to console port wiring and limitations of the cabling involved, according

to TIA/EIA-232F.

• The Ethernet cabling distances are within limitations.

• The equipment rack in which you plan to install the controller chassis complies with requirements. Careful

consideration has been given for safety, ease of maintenance, and proper airflow in selecting the location

of the rack.

Safety Guidelines

Before you begin the installation or replacement procedure, review the safety guidelines in this section to

avoid injuring yourself or damaging the equipment.

Note

This section contains guidelines, and do not include every potentially hazardous situation. When you install

a controller, always use common sense and caution.

Safety Warnings

Safety warnings appear throughout this publication in procedures that, if performed incorrectly, might harm

you. A warning symbol precedes each warning statement.

Cisco Catalyst 9800-80 Wireless Controller Hardware Installation Guide

18

Page 29

Preparing Your Site for Installation

Before you install, configure, or perform maintenance on the controller, review the documentation for the

procedure you are about to perform, paying special attention to the safety warnings.

Note

Do not unpack the system until you are ready to install it. Keep the chassis in the shipping container to prevent

accidental damage until you determine an installation site. Use the appropriate unpacking documentation

included with the system.

Read the installation instructions in this document before you connect the system to its power source. Failure

to read and follow these guidelines could lead to an unsuccessful installation and possibly damage the system

and components.

Safety Recommendations

The following guidelines will help to ensure your own safety and protect your Cisco equipment. This list does

not cover all potentially hazardous situations, so be alert.

• Cisco safety policy mandates that all its controllers must conform to the requirements of IEC 60950,

with appropriate national deviations, as a minimum. In addition, Cisco controllers must also meet the

requirements of any other normative documents, for example, standards, technical specifications, laws

or regulations.

Safety Recommendations

• Review the safety warnings listed in Regulatory Compliance and Safety Information - Cisco Catalyst

9800-80 Wireless Controller (available online at cisco.com) before installing, configuring, or maintaining

the controller.

• Never attempt to lift an object that might be too heavy for you to lift by yourself.

• Always turn all power supplies off and unplug all power cables before opening the chassis.

• Always unplug the power cable before installing or removing a chassis.

• Keep the chassis area clear and dust free during and after installation.

• Keep tools and chassis components away from walk areas.

• Do not wear loose clothing, jewelry (including rings and chains), or other items that could get caught in

the chassis. Fasten your tie or scarf and sleeves.

• The controller operates safely when it is used in accordance with its marked electrical ratings and

product-usage instructions.

Cautions and Regulatory Compliance Statements for NEBS

The following table lists cautions, regulatory compliance statements, and requirements for the Network

Equipment Building System (NEBS) certification from the Telcordia Electromagnetic Compatibility and

Electrical Safety – Generic Criteria for Network Telecommunications Equipment (A Module of LSSGR,

FR-64; TSGR, FR-440; and NEBSFR, FR-2063) Telcordia Technologies Generic Requirements,

GR-1089-CORE.

Attach an ESD-preventive wrist strap to your wrist and to a bare metal surface.

Cisco Catalyst 9800-80 Wireless Controller Hardware Installation Guide

19

Page 30

Standard Warning Statements

Preparing Your Site for Installation

Caution

Products that have an AC power connection are intended for deployments where an external surge protective

device (SPD) is used at the AC power service equipment as defined by the National Electric Code (NEC).

This product is designed for a common bonding network (CBN) installation.

This product can be installed in a network telecommunication facility or location where the NEC applies.

An electrical conducting path shall exist between the product chassis and the metal surface of the enclosure

or rack in which it is mounted or to a grounding conductor. Electrical continuity shall be provided by using

thread-forming type mounting screws that remove any paint or nonconductive coatings and establish a

metal-to-metal contact. Any paint or other nonconductive coatings shall be removed on the surfaces between

the mounting hardware and the enclosure or rack. The surfaces shall be cleaned and an antioxidant applied

before installation.

The grounding architecture of this product is DC-isolated (DC-I).

DC-powered products have a nominal operating DC voltage of 48 VDC. Minimal steady-state DC operating

voltage is 40.5 VDC. Reference American National Standards Institute (ANSI) T1.315, Table 1.

The intrabuilding ports of the equipment or subassembly are only suitable for connection to

intrabuilding or unexposed wiring or cabling. The intrabuilding ports of the equipment or

subassembly must not be metallically connected to interfaces that connect to the OSP or its wiring.

These interfaces are designed for use only as intrabuilding interfaces (Type 2 or Type 4 ports as

described in GR-1089-CORE), and require isolation from the exposed OSP cabling. The addition

of primary protectors is not sufficient protection to connect these interfaces metallically to OSP

wiring.

Standard Warning Statements

Note

The English warnings in this document are preceded by a statement number. To see the translations of a

warning in other languages, look up its statement number in the Regulatory Compliance and Safety Information

- Cisco Catalyst 9800-80 Wireless Controller.

This section describes the warning definition and then lists core safety warnings grouped by topic.

Warning

Statement 1071—Warning Definition IMPORTANT SAFETY INSTRUCTIONS

This warning symbol means danger. You are in a situation that could cause bodily injury. Before you work

on any equipment, be aware of the hazards involved with electrical circuitry and be familiar with standard

practices for preventing accidents. Use the statement number provided at the end of each warning to locate

its translation in the translated safety warnings that accompanied this device.

SAVE THESE INSTRUCTIONS

Cisco Catalyst 9800-80 Wireless Controller Hardware Installation Guide

20

Page 31

Preparing Your Site for Installation

General Safety Warnings

General Safety Warnings

Warning

Warning

Warning

Warning

Warning

Statement 1004—Installation Instructions

Read the installation instructions before connecting the system to the power source

Statement 1040—Product Disposal

Ultimate disposal of this product should be handled according to all national laws and regulations

Statement 1073—No User-Serviceable Parts

No user-serviceable parts inside. Do not open.

Statement 1074—Comply with Local and National Electrical Codes

Installation of the equipment must comply with local and national electrical codes.

Statement 1030—Equipment Installation

Only trained and qualified personnel should be allowed to install, replace, or service this equipment.

Warning

Warning

Statement 1005—Circuit Breaker

This product relies on the building's installation for short-circuit (overcurrent) protection. Ensure that the

protective device is rated not greater than:

AC:

• 20 A U.S. maximum

Statement 1045—Short-circuit Protection

This product requires short-circuit (overcurrent) protection to be provided as part of the building installation.

Install only in accordance with national and local wiring regulations.

Cisco Catalyst 9800-80 Wireless Controller Hardware Installation Guide

21

Page 32

General Safety Warnings

Preparing Your Site for Installation

Warning

Warning

Warning

Warning

Statement 1028—More Than One Power Supply

This unit might have more than one power supply connection. All connections must be removed to de-energize

the unit.

Statement 1017—Restricted Area

This unit is intended for installation in restricted access areas. A restricted access area can be accessed only

through the use of a special tool, lock and key, or other means of security.

Statement 1019—Main Disconnecting Device

The plug-socket combination must be accessible at all times, because it serves as the main disconnecting

device.

Statement 1086—Power Terminals, Replace Cover

Hazardous voltage or energy may be present on power terminals. Always replace cover when terminals are

not in service. Be sure uninsulated conductors are not accessible when cover is in place.

Warning

Warning

Warning

Warning

Statement 1025—Use Copper Conductors Only

Use copper conductors only.

Statement 1024—Ground Conductor

This equipment must be grounded. Never defeat the ground conductor or operate the equipment in the absence

of a suitably installed ground conductor. Contact the appropriate electrical inspection authority or an electrician

if you are uncertain that suitable grounding is available.

Statement 1034—Backplane Voltage

Hazardous voltage or energy is present on the backplane when the system is operating. Use caution when

servicing.

Statement 1008—Class 1 Laser Product

Class 1 laser product.

Cisco Catalyst 9800-80 Wireless Controller Hardware Installation Guide

22

Page 33

Preparing Your Site for Installation

General Safety Warnings

Warning

Warning

Warning

Warning

Warning

Statement 1027—Class 1 LED Product

Class 1 LED product.

Statement 1009—Laser Radiation

Laser radiation is present when the system is open

Statement 1010—Staring into Laser Beam

Do not stare into the laser beam

Statement 1055—Class I and Class 1M Laser

Class I (CDRH) and Class 1M (IEC) laser products

Statement 1056—Unterminated Fiber Cable

Invisible laser radiation may be emitted from the end of the unterminated fiber cable or connector. Do not

view directly with optical instruments. Viewing the laser output with certain optical instruments (for example,

eye loupes, magnifiers, and microscopes) within a distance of 100 mm may pose an eye hazard.

Warning

Warning

Warning

Statement 1015—Battery Handling

There is the danger of explosion if the battery is replaced incorrectly. Replace the battery only with the same

or equivalent type recommended by the manufacturer. Dispose of used batteries according to the manufacturer's

instructions

Statement 341—Metal Contacts on the Battery

Do not touch or bridge the metal contacts on the battery. Unintentional discharge of the batteries can cause

serious burns

Statement 1032—Lifting the Chassis

To prevent personal injury or damage to the chassis, never attempt to lift or tilt the chassis using the handles

on modules (such as power supplies, fans, or cards); these types of handles are not designed to support the

weight of the unit.

Cisco Catalyst 9800-80 Wireless Controller Hardware Installation Guide

23

Page 34

Site Planning

Preparing Your Site for Installation

Warning

Warning

Statement 1047—Overheating Prevention

To prevent the system from overheating, do not operate it in an area that exceeds the maximum recommended

ambient temperature of:

104° F (40° C)

Statement 1029—Blank Faceplates and Cover Panels

Blank faceplates and cover panels serve three important functions: they prevent exposure to hazardous voltages

and currents inside the chassis; they contain electromagnetic interference (EMI) that might disrupt other

equipment; and they direct the flow of cooling air through the chassis. Do not operate the system unless all

cards, faceplates, front covers, and rear covers are in place

Site Planning

This section contains site-planning information, and will help you plan for the installation of the controller.

General Precautions

Observe the following general precautions when using and working with the controller:

• Keep your system components away from radiators and heat sources and do not block cooling vents.

• Do not spill food or liquids on your system components and never operate the product in a wet

environment.

• Do not push any objects into the openings of your system components. Doing so can cause fire or electric

shock by shorting out interior components.

• Position system cables and power supply cable carefully. Route system cables and power supply cable

and plug such that they cannot be stepped on or tripped over. Be sure that nothing else rests on your

system component cables or power cable.

• Do not modify power cables or plugs. Consult a licensed electrician or your power company for site

modifications. Always follow your local and national wiring rules.

• If you turn off your system, wait at least 30 seconds before turning it on again to avoid system component

damage.

Site Selection Guidelines

The Cisco Catalyst 9800-80 Wireless Controller requires specific environmental operating conditions.

Temperature, humidity, altitude, and vibration can affect the performance and reliability of the controller.

The following sections provide specific information to help you plan for a proper operating environment.

Cisco Catalyst 9800-80 Wireless Controller Hardware Installation Guide

24

Page 35

Preparing Your Site for Installation

The Cisco Catalyst 9800-80 Wireless Controller are designed to meet the industry EMC, safety, and

environmental standards described in the Regulatory Compliance and Safety Information - Cisco Catalyst

9800-80 Wireless Controller document.

Site Environmental Requirements

Environmental monitoring protects the system and components from damage caused by excessive voltage

and temperature conditions. To ensure normal operation and avoid unnecessary maintenance, plan and prepare

your site configuration before installation. After installation, make sure the site maintains the environmental

characteristics, as shown in the following table.

Table 8: Cisco Catalyst 9800-80 Wireless Controller Environmental Tolerance

Site Environmental Requirements

MaximumMinimumEnvironmental Characteristic

(relative humidity)

humidity)

temperature range (0° to 50° C)

allowable temperature range

change over time of 3 minutes

C per minute

32° F (0° C)Operating temperature (nominal)

104° F (40° C)

(40° C up to 10,000 feet)

122° F (50° C)32° F (0° C)Operating temperature (short term)

158° F (70° C)–4° F (–20° C)Storage temperature

90%10%Operative humidity (nominal)

90%5%Operative humidity (short term)

95%5%Storage humidity (relative

6,000 feet (1829 meters)–500 feet (–152.4 meters)Altitude, operating: over allowable

50,000 feet (15240 meters)–1000 feet (–304.8 meters)Altitude, nonoperating: over

158° F (70° C)–13° F (–25° C)Thermal shock nonoperating with

122° F (50° C)32° F (0° C)Thermal Shock - Operating at 2.5°

Physical Characteristics

Be familiar with the physical characteristics of the Cisco Catalyst 9800-80 Wireless Controller to assist you

in placing the system at a proper location.

Note

For information regarding rack widths supported for the controller, see the following sections:

• General Rack-Selection Guidelines

• Guidelines for 23-in. (Telco) Racks

Cisco Catalyst 9800-80 Wireless Controller Hardware Installation Guide

25

Page 36

Site Power Guidelines

Preparing Your Site for Installation

The following table shows the weight and dimensions of the Cisco Catalyst 9800-80 Wireless Controller:

Table 9: Physical Characteristics of the Cisco Catalyst 9800-80 Wireless Controller

Cisco Catalyst 9800-80 Wireless ControllerCharacteristic

Height

3.5 in. (88.9 mm)— 2RU; rack-mount per

EIA RS-310

17.3 in. (439.42 mm)Width

Depth

22.0 in. (558.8 mm)

Depth includes card handles,

cable-management brackets, and

power-supply handles

34 lb (15.42 kg) fully loadedWeight

The following list describes additional characteristics:

• Chassis height meets EIA-310 rack spacing, universal rack mount

• Cisco Catalyst 9800-80 Wireless Controller—2RU (3.5 in. or 88.9 mm)

• Chassis width meets EIA-310 19 in. (17.3 in. or 439.42 mm) wide with rack brackets

• Cable-management brackets allow a bend radius of 1.5 in. (38.1 mm) for cables

• Ships with forward rack-mount brackets installed and an extra set included in the accessory kit

Site Power Guidelines

The Cisco Catalyst 9800-80 Wireless Controller has specific power and electrical wiring requirements.

Adhering to these requirements ensures reliable operation of the system. Follow these precautions and

recommendations when planning your site for the controller:

• The redundant power option provides a second, identical power supply to ensure that power to the chassis

continues uninterrupted if one power supply fails or input power on one line fails.

• In systems configured with the redundant power option, connect each of the two power supplies to a

separate input power source. If you fail to do this, your system might be susceptible to total power failure

due to a fault in the external wiring or a tripped circuit breaker.

• To prevent a loss of input power, be sure the total maximum load on each circuit supplying the power

supplies is within the current ratings of the wiring and breakers.

• Check the power at your site before installation, and periodically after installation, to ensure that you are

receiving clean power. Install a power conditioner if necessary.

• Provide proper grounding to avoid personal injury and damage to the equipment due to lightning striking

power lines or due to power surges. The chassis ground must be attached to a central office or other

interior ground system.

Cisco Catalyst 9800-80 Wireless Controller Hardware Installation Guide

26

Page 37

Preparing Your Site for Installation

Electrical Circuit Requirements

Caution

This product requires short-circuit (overcurrent) protection to be provided as part of the building installation.

Install only in accordance with national and local wiring regulations.

Note

The Cisco Catalyst 9800-80 Wireless Controller installation must comply with all applicable codes and is

approved for use with copper conductors only. The ground bond fastening hardware should be of compatible

material and preclude loosening, deterioration, and electrochemical corrosion of hardware and joined material.

Attachment of the chassis ground to a central office or other interior ground system must be made with an

AWG #6 gauge wire, copper ground conductor at a minimum.

Electrical Circuit Requirements

The Cisco Catalyst 9800-80 Wireless Controller requires a dedicated electrical circuit. If you equip it with

dual-power feeds, you must provide a separate circuit for each power supply to avoid compromising the power

redundancy feature.

The Cisco Catalyst 9800-80 Wireless Controller can only be powered by an AC source. Ensure that equipment

grounding is present and observe power-strip ratings. Make sure that the total ampere rating of all the products

plugged into the power strip does not exceed 80 percent of the rating.

Note

The Cisco Catalyst 9800-80 Wireless Controller can support two AC power supplies. The AC power supply

requires a 20 A circuit breaker.

The following table lists the power supply system rating requirements for the Cisco Catalyst 9800-80 Wireless

Controller.

Table 10: AC Power Supply System Rating Specifications for the Cisco Catalyst 9800-80 Wireless Controller

Power supply declared

ratings

Site Cabling Guidelines

This section contains guidelines for wiring and cabling at your site. When preparing your site for network

connections to the Cisco Catalyst 9800-80 Wireless Controller, consider the type of cable required for each

component, and the cable limitations. Consider the distance limitations for signaling, EMI, and connector

compatibility. Possible cable types are fiber, thick or thin coaxial, foil twisted-pair cabling, or unshielded

twisted-pair cabling.

Also consider any additional interface equipment you need, such as transceivers, hubs, switches, modems,

channel service units (CSUs), or data service units (DSUs).

SpecificationDescription

AC = 85–264 VAC

DC = –40–72 VDC

50/60 Hz for AC power suppliesLine frequency rating

Cisco Catalyst 9800-80 Wireless Controller Hardware Installation Guide

27

Page 38

Console Port Connections

Preparing Your Site for Installation

Before you install the controller, have all the additional external equipment and cables at hand. For ordering

information, contact a Cisco customer service representative.

The extent of your network and the distances between network interface connections depend in part on the

following factors:

• Signal type

• Signal speed

• Transmission medium

The distance and rate limits referenced in the following sections are the IEEE-recommended maximum speeds

and distances for signaling purposes. Use this information as guidelines when planning your network

connections prior to installing the Cisco Catalyst 9800-80 Wireless Controller.

If wires exceed recommended distances, or if wires pass between buildings, give special consideration to the

effect of a lightning strike in your vicinity. The electromagnetic pulse caused by lightning or other high-energy

phenomena can easily couple enough energy into unshielded conductors to destroy electronic devices. If you

have had problems of this sort in the past, you may want to consult experts in electrical surge suppression and

shielding.

Console Port Connections

The Cisco Catalyst 9800-80 Wireless Controller provides console ports to connect a terminal or computer for

local console access.

Both ports have RJ-45 connectors, support RS-232 asynchronous data, and have distance recommendations

specified in the IEEE RS-232 standard.

USB Serial Console

The USB serial console port connects directly to the USB connector of a PC using a USB Type A to 5-pin

mini USB Type-B cable. The USB Console supports full speed (12Mbps) operation. The console port does

not support hardware flow control.

Note

• Always use shielded USB cables with a properly terminated shield. The USB serial console interface

cable must not exceed 3 meters in length.

• Only one console port can be active at a time. When a cable is plugged into the USB console port, the

RJ-45 port becomes inactive. Conversely, when the USB cable is removed from the USB port, the RJ-45

port becomes active.

• 4-pin mini USB Type-B connectors are easily confused with 5-pin mini USB Type-B connectors. Only

5-pin mini USB Type-B is supported.

Interference Considerations

When wires are run for a significant distance, there is a risk that stray signals will be induced on the wires as

interference. If interference signals are strong, they can cause data errors or damage to the equipment.

Cisco Catalyst 9800-80 Wireless Controller Hardware Installation Guide

28

Page 39

Preparing Your Site for Installation

The following sections describe sources of interference and how to minimize its effects on Cisco Catalyst

9800-80 Wireless Controller.

Electromagnetic Interference

All the equipment powered by AC current can propagate electrical energy that can cause electromagnetic

interference (EMI) and possibly affect the operation of other equipment. The typical sources of EMI are

equipment power cords and power service cables from electric utility companies.

Strong EMI can destroy the signal drivers and receivers in the controller and even create an electrical hazard

by causing power surges through power lines into installed equipment. These problems are rare, but could be

catastrophic.

To resolve these problems, you need specialized knowledge and equipment, which could consume substantial

time and money. However, you should ensure that you have a properly grounded and shielded electrical

environment, paying special attention to the need for electrical surge suppression.

The following table lists electrode magnetic compliance standards for the controller.

Table 11: EMC and Safety Standards

Interference Considerations

EMC Standards

FCC 47 CFR

Part 15 Class A

VCCI Class A

AS/NSZ Class A

ICES-003 Class A

EN55022/CISPR 22 Information Technology Equipment (Emissions)

EN55024/CISPR 24 Information Technology Equipment (Immunity)

EN300 386 Telecommunications Network Equipment (EMC)

EN50082-1/EN61000-6-1 Generic Immunity Standard

Safety

Standards

UL60950-1

CSA C22.2 No. 60950-1-03

EN 60950-1

IEC 60950-1

AS/NZS 60950.1

Radio Frequency Interference

When electromagnetic fields act over a long distance, radio frequency interference (RFI) can be propagated.

Building wiring can often act as an antenna, receiving the RFI signals and creating more EMI on the wiring.

If you use twisted-pair cable in your plant wiring with a good distribution of grounding conductors, the plant

wiring is unlikely to emit radio interference. If you exceed the recommended distances, use a high-quality

twisted-pair cable with one ground conductor for each data signal.

Cisco Catalyst 9800-80 Wireless Controller Hardware Installation Guide

29

Page 40

Rack-Mounting Guidelines

Lightning and AC Power Fault Interference

If signal wires exceed recommended cabling distances, or if signal wires pass between buildings, you should

consider the effect that a lightning strike in your vicinity might have on the controller.

The electromagnetic pulse (EMP) generated by lightning or other high-energy phenomena can couple enough

energy into unshielded conductors to damage or destroy electronic equipment. If you have previously

experienced such problems, you should consult with RFI/EMI experts to ensure that you have adequate

electrical surge suppression and shielding of signal cables in your controller operating environment.

Rack-Mounting Guidelines

This section describes guidelines on rack-mounting.

Precautions for Rack-Mounting

The following rack-mounting guidelines are provided to ensure your safety:

• Do not move large racks by yourself. Due to the height and weight of a rack, a minimum of two people

are required to accomplish this task.

Preparing Your Site for Installation

• Ensure that the rack is level and stable before extending a component from the rack.

• Ensure that proper airflow is provided to the components in the rack.

• Do not step or stand on any component or system when servicing other systems or components in a rack.

• When mounting the controller in a partially filled rack, load the rack from the bottom to the top with the

heaviest component at the bottom of the rack.

• If the rack is provided with stabilizing devices, install the stabilizers before mounting or servicing the

unit in the rack.

General Rack-Selection Guidelines

The Cisco Catalyst 9800-80 Wireless Controller can be mounted in most two-post or four-post, 19-in. equipment

racks that comply with the Electronics Industries Association (EIA) standard for equipment racks (EIA-310-D

19-in.). The rack must have at least two posts with mounting flanges to mount the chassis.

Caution

When mounting a chassis in any type of rack equipment, ensure that the inlet air to the chassis does not exceed

131°F (55°C).

The distance between the center lines of the mounting holes on the two mounting posts must be 18.31 in. ±

0.06 in. (46.50 cm ± 0.15 cm). The rack-mounting hardware included with the chassis is suitable for most

19-in. (48.3-cm) equipment racks.

Consider installing the Cisco Catalyst 9800-80 Wireless Controller in a rack with the following features:

• NEBS-compliant, 19-in. (48.3-cm) wide rack.

Cisco Catalyst 9800-80 Wireless Controller Hardware Installation Guide

30

Page 41

Preparing Your Site for Installation

• EIA or ETSI hole patterns in the mounting rails. Required mounting hardware is shipped with the

controller. If the rack that you plan to install the system in has metric-threaded rails, you must provide

your own metric-mounting hardware.

• Perforated top and open bottom for ventilation to prevent overheating.

• Leveling feet for stability.

Note

The controller must not be installed in an enclosed rack because the chassis requires an unobstructed flow of

cooling air to maintain acceptable operating temperatures for its internal components. Installing the controller

in any type of enclosed rack—even with the front and back doors removed—could disrupt the air flow, trap

heat next to the chassis, and cause an over temperature condition inside the controller. If you use an enclosed

rack, make certain that there are air vents on all sides of the rack and there is proper ventilation.

Guidelines for 23-in. (Telco) Racks

If needed, you can also install the Cisco Catalyst 9800-80 Wireless Controller in 23-in. (Telco) racks. For

information on the adapters needed for 23 in. racks, contact the Newton Instrument Company:

http://www.enewton.com

111 East A Street, Butner NC, USA, 27509

919 575-6426

Guidelines for 23-in. (Telco) Racks

Equipment Rack Guidelines

The placement of racks can affect personnel safety, system maintenance, and the system’s ability to operate

within the environmental characteristics described in Table: Cisco Catalyst 9800-80 Wireless Controller

Environmental Tolerance. Choose a proper location for the controller by following the guidelines below.

Locating for Safety

If the Cisco Catalyst 9800-80 Wireless Controller is the heaviest or the only piece of equipment in the rack,

consider installing it at or near the bottom to ensure that the rack’s center of gravity is as low as possible.

For additional information about the proper placement of electronic equipment, see the document GR-63-CORE,

Network Equipment Building System (NEBS) Requirements: Physical Protection.

Locating for Easy Maintenance

Keep at least 3 feet of clear space in front of and behind the rack. This space ensures that you can remove the

Cisco Catalyst 9800-80 Wireless Controller components and perform routine maintenance and upgrades easily.

Avoid installing the controller in a congested rack and consider how the routing of cables from other pieces

of equipment in the same rack might affect access to the controller’s cards.

The front and top of the chassis must remain unobstructed to ensure adequate airflow and prevent overheating

inside the chassis.

Allow the following clearances for normal system maintenance:

• At the top of the chassis—At least 3 in. (7.6 cm)

• In front of the chassis—3 to 4 ft (91.44 cm to 121.92 cm)

Cisco Catalyst 9800-80 Wireless Controller Hardware Installation Guide

31

Page 42

Preventing Electrostatic Discharge Damage

To avoid problems during installation and ongoing operation, follow these general precautions when you plan

the equipment locations and connections:

• Use the show environment all and the show facility-alarm status commands regularly to check the

internal system status. The environmental monitor continually checks the interior chassis environment;

it provides warnings for high temperature and creates reports on any occurrences. If warning messages

are displayed, take immediate action to identify the cause and correct the problem. For more information

on these commands, see the Environmental Monitoring and Reporting Functions section.

• Keep the Cisco Catalyst 9800-80 Wireless Controller off the floor and out of the areas that collect dust.

• Follow ESD-prevention procedures to avoid damage to equipment. Damage from static discharge can

cause immediate or intermittent equipment failure.

Locating for Proper Airflow

Ensure that the location of the Cisco Catalyst 9800-80 Wireless Controller has enough airflow to keep the

system operating within the environmental characteristics, and the air temperature is sufficient to compensate

for the heat dissipated by the system.

Avoid locating the Cisco Catalyst 9800-80 Wireless Controller in a location in which the chassis air intake

vents could draw in the exhaust air from adjacent equipment. Consider how the air flows through the controller.

The airflow direction is front to back with ambient air drawn in from the venting located on the chassis’ front

sides.

Preparing Your Site for Installation

Preventing Electrostatic Discharge Damage

Electrostatic discharge (ESD) damage occurs when electronic cards or components are improperly handled

resulting in complete or intermittent failures. Static electricity can harm delicate components inside your

system. To prevent static damage, discharge static electricity from your body before you touch any of your

system components, such as a microprocessor. As you continue to work on your system, periodically touch

an unpainted metal surface on the computer chassis.

The following are guidelines for preventing ESD damage:

• Always use an ESD-preventive wrist or ankle strap and ensure that it makes good skin contact. Before

removing a card from the chassis, connect the equipment end of the strap to the ESD plug at the bottom

of the chassis below the power entry modules.

• Handle line cards by faceplates and carrier edges only; avoid touching the card components or connector

pins.

• When removing a module, place the removed module component-side-up on an antistatic surface or in

a static-shielding bag. If the module is to be returned to the factory, immediately place it in a

static-shielding bag.

• Avoid contact between the modules and clothing. The wrist strap protects the card from ESD voltages

only on the body; ESD voltages on clothing can still cause damage.

• When transporting a sensitive component, place it in an antistatic container or packaging.

• Handle all sensitive components in a static-safe area. If possible, use antistatic floor pads and workbench

pads.

Cisco Catalyst 9800-80 Wireless Controller Hardware Installation Guide

32

Page 43

Preparing Your Site for Installation

Electrical Safety

Caution

Caution

For safety, periodically check the resistance value of the antistatic strap. The measurement should be between

1 and 10 ohms.

Always tighten the captive installation screws on all the system components when you are installing them.

These screws prevent accidental removal of the module, provide proper grounding for the system, and help

ensure that the bus connectors are properly seated in the backplane.

Electrical Safety

All the system components are hot-swappable. They are designed to be removed and replaced while the system

is operating, without presenting an electrical hazard or damage to the system.

Follow these basic guidelines when you are working with any electrical equipment:

• Before beginning any procedures requiring access to the chassis interior, locate the emergency power-off

switch for the room in which you are working.

• Disconnect all power and external cables before installing or removing a chassis.

• Do not work alone when potentially hazardous conditions exist.

• Never assume that power has been disconnected from a circuit; always check.

Warning

• Do not perform any action that creates a potential hazard to people or makes the equipment unsafe. Never

install equipment that appears damaged.