Page 1

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

First Published: 2019-04-15

Americas Headquarters

Cisco Systems, Inc.

170 West Tasman Drive

San Jose, CA 95134-1706

USA

http://www.cisco.com

Tel: 408 526-4000

800 553-NETS (6387)

Fax: 408 527-0883

Page 2

Contents

CONTENTS

CHAPTER 1

CHAPTER 2

Product Overview 1

Chassis Overview 1

Fan Tray Assembly 3

High Availability 5

Thresholds, Alarms, and Abnormal Acoustic Conditions 6

Power Supply Module Overview 6

AC Power Supply Module 7

DC Power Supply Module 8

Power Supply Modes 9

Preparing for Installation 11

Safety Warnings 11

Site Requirements 14

Temperature 14

Air Flow 15

Humidity 17

Altitude 17

Dust and Particles 17

Corrosion 18

EMI and Radio Frequency Interference 18

Shock and Vibration 19

Power Source Interruptions 19

System Grounding 20

Maintaining Safety with Electricity 22

Preventing Electrostatic Discharge Damage 23

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

ii

Page 3

Power Requirements 23

Cabling Requirements 23

Rack-Mounting Guidelines 24

Site Preparation Checklist 25

Contents

CHAPTER 3

Installing the Switch 29

Unpacking the Switch 29

Install the Switch as Shipped 30

Installing the Cable Guide on the Chassis with L-Brackets Preinstalled on the Chassis 30

Rack-Mounting the Chassis as Shipped 32

Install the Switch with Shelf Brackets 36

Installing the Shelf Kit L-Brackets 36

Installing the Shelf Brackets and the Crossbar 40

Installing the Cable Guide on the Chassis with Shelf Kit L-Bracket 42

Rack-Mounting the Chassis 43

Install the Switch in NEBS-Compliant Mode 50

NEBS-Compliant Air Filter 50

Rack-Mounting the Chassis in NEBS-Compliant Mode 50

Establishing System Ground 57

Attaching an ESD Strap 60

Verifying the Switch Chassis Installation 61

CHAPTER 4

Installing the Fan Tray 63

Guidelines for Removing and Installing a Fan Tray 63

Removing a Fan Tray 63

Information About Replacing a Fan Tray 64

Enabling the Service Mode Before Removing the Fan Tray 64

Removing the Fan Tray from the Front of the Chassis 65

Removing the Fan Tray from the Rear of the Chassis 67

Installing a Fan Tray 70

Installing the Fan Tray from the Front Panel of the Chassis 71

Installing the Fan Tray from the Rear of the Chassis 72

Verifying Fan Tray Installation 73

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

iii

Page 4

Contents

CHAPTER 5

APPENDIX A

Installing a Power Supply Unit 75

Required Tools and Equipment 75

Removing and Installing Power Supply Modules 75

Removing a Power Supply Module 77

Installing a Power Supply Module 79

Connecting to a Power Source 82

Connecting to an AC Power Source 82

Connecting to a DC Power Source 83

Verifying the Power Supply Installation 86

Removing and Installing Power Supply Blanks 86

Finding the Serial Number 90

Technical Specifications 91

C9606R Switch Chassis Specifications 91

Power Supply Specifications 93

2000W AC-Input Power Supply Specifications 93

2000W DC-Input Power Supply Specifications 94

APPENDIX B

APPENDIX C

Chassis and Module Power and Heat Values 95

Weight Specifications 96

LEDs 97

Fan Tray LEDs 97

Power Supply Modules LEDs 97

Supervisor Module LEDs 98

Line Card LEDs 99

Accessory Kit and Shelf Kit Contents 101

Standard Accessory Kit Contents 101

Shelf Kit Contents 102

23-Inch Rack Mount Kit Contents 102

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

iv

Page 5

Product Overview

• Chassis Overview, on page 1

• Fan Tray Assembly, on page 3

• Power Supply Module Overview, on page 6

Chassis Overview

The Cisco Catalyst 9606R Switch is a six-slot chassis, with two redundant supervisor module slots, four

module slots, four power supply modules and a fan tray.

Table 1: Cisco Catalyst 9600R Switch Features

CHAPTER 1

DescriptionFeature

Cisco Catalyst 9606RProduct ID

Has six horizontal slots. Slots are numbered 1 to 6 from top to bottom.Chassis

Supervisor modules

Line Cards

Fan tray assembly

Supports two supervisor modules. The following is the supported model

— Cisco Catalyst 9600 Series Supervisor 1 Module (C9600-SUP-1).

For more information about installing a supervisor module, see the Cisco

Catalyst 9600 Series Switch Supervisor Module Installation Note.

Supports upto four line cards. The following are the supported line cards:

• Cisco Catalyst 9600 Series 48-Port 25GE/10GE/1GE

(C9600-LC-48YL — 48 ports that support SFP56 (48x1G/10G/25G

ports)

• Cisco Catalyst 9600 Series 24-Port 40GE/12-Port 100GE

(C9600-LC-24C) — 24 ports that support QSFP28 (24x40G or

12x100G)

For more information about installing a line card, see the Cisco Catalyst

9600 Series Switch Line Card Installation Note.

Provides a single front and rear serviceable and hot-swappable fan tray

with 9 fans.

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

1

1

Page 6

Chassis Overview

Product Overview

DescriptionFeature

Power supplies

1

1G is currently not supported.

Figure 1: Front view of a Cisco Catalyst 9606R

Has 4 power supply slots that supports upto 4 AC/DC power supply

modules.

Provides 6.4Tbps bandwidth per slot.Backplane

Power switches5Chassis handholds1

2

6Chassis Radio Frequency ID

(RFID)

System ground with ground lug

screw holes on each side

Power Supply modules7Line card slots3

Fan tray assembly8Supervisor Module slots4

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

2

Page 7

Product Overview

Fan Tray Assembly

Rear View of a Cisco Catalyst 9606R

The figure shows a rear view of the chassis, with the major components identified:

Figure 2: Rear View of a Cisco Catalyst 9606R

1

2

Fan Tray Assembly

The fan tray assembly (C9606-FAN) in Cisco Catalyst 9600 Series Switches consists of a fan tray and a

connector that is attached to the fan tray. It is responsible for cooling the entire chassis and interfacing with

environmental monitors to trigger alarms when conditions exceed thresholds. The fan tray provides cooling

remove the fan tray assembly.

panel of the fan tray (always

matches the blue beacon on the

front panel of the fan tray)

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

Fan tray assembly handle3Captive installation screws to

4Blue beacon LED on the rear

Rear exhaust for the power

supply modules

3

Page 8

Fan Tray Assembly

Product Overview

that is critical for the switch operation which could otherwise result in a switch being non-operational or

causing permanent damage to the modules or components.

The following lists the features and functionalities of a Cisco Catalyst 9600 fan tray:

• Has nine individual fans (three rows of three each) and supports a minimum airflow of 720 cubic feet

per minute (cfm) at 100 percent fan throttle.

• Has side-to-side airflow for balanced airflow across the inserted cards. When facing the front of the

chassis, airflow direction is right to left.

• You can install and remove from the front and the rear.

• Has a built-in, front-facing, passive RFID tag that uses Ultra High Frequency (UHF) RFID technology

and requires an RFID reader with a compatible software.

• Provides N+1 redundancy with individual fans. Fan tray does not support redundancy; however with

N+1 redundancy using individual fans, system ensures that there is no impact to system performance

even if one of the fans fail.

• Optimizes the fan-speed for temperature and pressure and maintains the minimum fan speeds and

temperatures that the chassis requires, in ambient conditions.

The following figure shows C9606-FAN with the major components identified.

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

4

Page 9

Product Overview

High Availability

Figure 3: Fan Tray Assembly

1

High Availability

To ensure high availability, the system is designed to respond to fan failures by either minimising impact or

by compensating and operating at a worst case scenario specification.

Fan tray RFID5Captive installation screws on the front and

the rear of the fan tray.

Fan tray connector6Fan status LED2

Fan tray serial number7Switch to turn on the Blue Beacon LED.3

Blue beacon LED on the rear of the fan tray8Front fan tray handle.4

• If a single fan fails, the remaining fans in the row compensate with increased speed.

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

5

Page 10

Thresholds, Alarms, and Abnormal Acoustic Conditions

• If two or more fans fail, the entire fan tray operates at full speed after one minute. Further, the fan tray

must be replaced. The individual fans are not field replaceable, you must replace the fan tray.

• If the temperature sensor fails or communication with the temperature sensor fails, the worst case operating

temperature is assumed.

• If the pressure sensor fails or communication with the pressure sensor fails, the worst case operating

pressure is assumed.

Thresholds, Alarms, and Abnormal Acoustic Conditions

Under normal operating conditions, when none of the temperature alarms have been triggered, hardware

controls fan speed. If any of the system temperature alarms are triggered, software displays a syslog message

indicating that the temperature is high and the fans are operating at higher speed. Refer to the System

Management section of the software configuration guide for more information.

In case of a fan failure, you must replace the fan tray within 120 seconds or power down the system. If the

temperature exceeds the shutdown threshold, software powers the system down.

When the fan tray operates at full speed, increased noise levels may be expected. The fan tray may operate

at full speed in these circumstances:

Product Overview

• If two or more fans have failed

• If the STATUS LED remains red for more than one minute

• If there is a hardware failure

• If the software watchdog timer is triggered

Power Supply Module Overview

The switch chassis has four redundant power supply slots that operates with one to four power supply modules.

The chassis supports field-replaceable AC-input and DC-input power supply modules.

The power supply modules generates 12Vdc output power and distributes it to the line cards and supervisor

modules. The power supplies distribute power to all slots using an internal bus-bar based power distribution

mechanism. All power supply modules have internal fans and support front-to-rear airflow.

The following are the supported power supply modules:

Table 2: Power Supply Modules Supported on Cisco Catalyst 9600 Series Switches

DescriptionPart Number

Cisco Catalyst 9600 Series 2000W AC Power SupplyC9600-PWR-2KWAC (=)

Cisco Catalyst 9600 Series 2000W DC Power SupplyC9600-PWR-2KWDC (=)

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

6

Page 11

Product Overview

AC Power Supply Module

Figure 4: Cisco Catalyst 9600 Series 2000W AC Power Supply

AC Power Supply Module

Status LED5PSU fan1

Retainer clips6Release handle2

Power cord connector7Power cord retainer3

--Release latch4

The following are the features supported by a Cisco Catalyst 9600 Series AC power supply module:

• Self-cooling, with a minimum airflow of 17 cubic feet per minute (CFM) at 100 percent load.

• Supports only single-phase source AC. Source AC can be out of phase between multiple power supplies

or multiple AC-power plugs on the same power supply because all AC power supply inputs are isolated.

• Has a release latch and cord-retention mechanism on the front panel of the module, to avoid accidental

removal of the module or the attached power cord.

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

7

Page 12

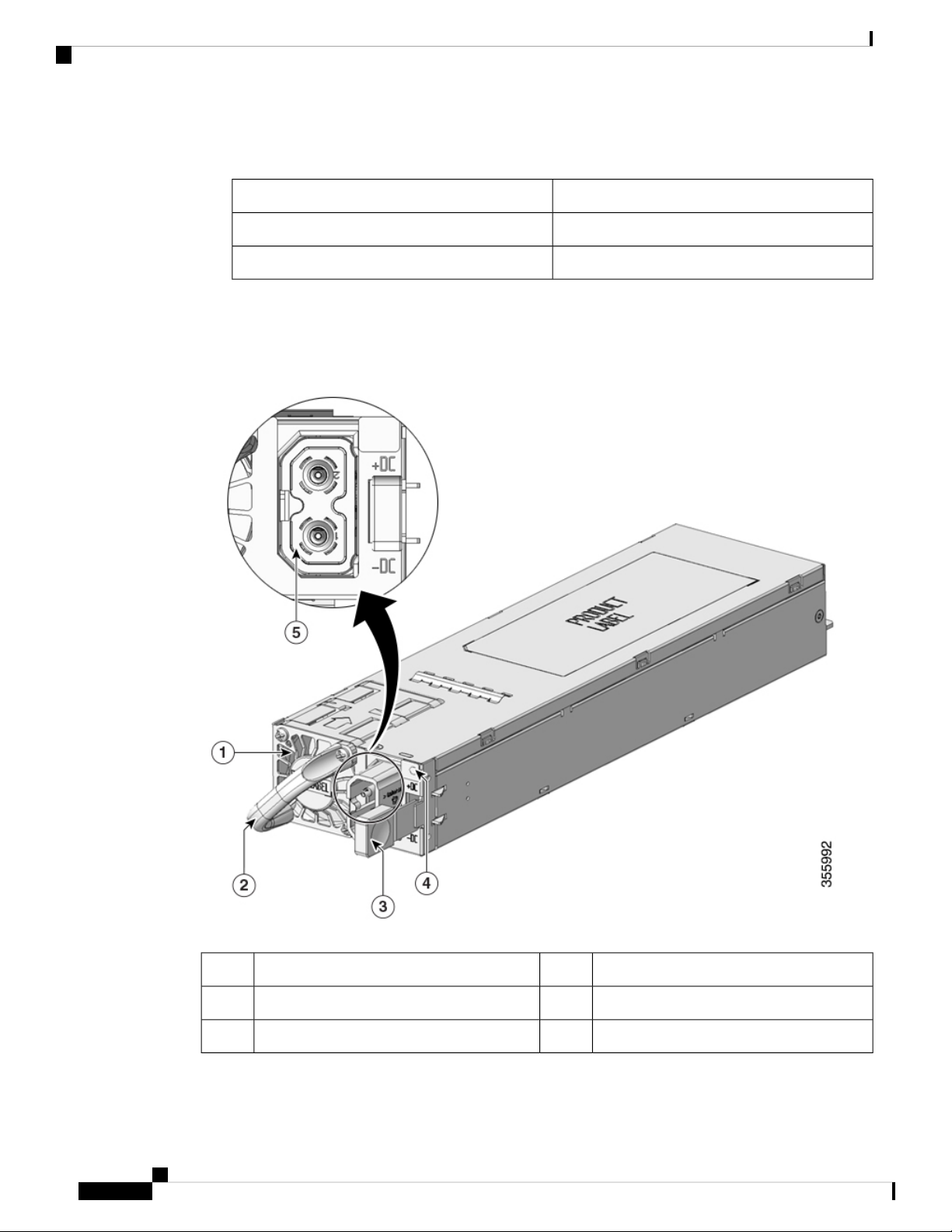

DC Power Supply Module

• Supports redundant and combined configuration modes. A single (non-redundant) or a dual (redundant)

power supply configuration, can support the following loads:

DC Power Supply Module

Figure 5: Cisco Catalyst 9600 Series 2000W DC Power Supply

Product Overview

Output Power in WattsInput Voltage (VAC)

2000W220VAC

1050W110VAC

LED4PSU fan1

Power cord connector5Release handle2

--Release latch3

The following are the features supported by a Cisco Catalyst 9600 Series DC power supply module:

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

8

Page 13

Product Overview

• Self-cooling, with a minimum airflow of 9.5 cubic feet per minute (CFM) at 100 percent load.

• Has a release latch mechanism on the side of the module, to avoid accidental removal of the module.

• Has DC-input reversal protection such that the unit will survive this condition up to the full input voltage

rating.

• Supports redundant and combined configuration modes. A single (non-redundant) or a dual (redundant)

power supply configuration, can support the following loads:

Voltage differential between inputs is unlimited.

Power Supply Modes

Cisco Catalyst 9600 Series Switches offer redundant and combined configuration modes for power supplies.

In both the modes, the power supplies will share the load equally.

Power Supply Modes

Output PowerInput Voltage (VDC)

2000W-40 to -72VDC (with extended range to -75VDC)

Warning

The number of power supply modules installed and the system load determine the power-level that the system

expects to draw from each power supply module and consequently, the power supply mode that will be suitable.

For system power budgeting estimates and to determine power supply requirements, use the Cisco Power

Calculator.

To configure a power supply mode, enter the power redundancy-mode command in global configuration

mode. If you do not configure a mode, the default mode applies.

Combined Mode

This is the default power supply mode.

The system operates with one to four power supply modules. The power available to the system is the sum

of power outputs of all the power supply modules in the chassis multiplied by the share ratio. All available

power supply modules are active and sharing power, and can operate at up to 100 percent capacity. Additional

power supply units operate at 97 percent capacity. In combined mode, you can use a combination of AC and

DC power supplies provided the AC input voltage is 220V and that the power supplies are of equal wattage.

However, you cannot combine two AC power supplies of 110V input and 220V input.

Total combined mode power = P + (N-1) * P * (share ratio)

where P = Power output of one of the power supply units and N is the number of power supply modules used.

In case of failure in the combined mode, each operational power supply increases its output. If the output

power does not meet system requirements, then all the operational power supply modules may be overloaded

and go into overcurrent shutdown. All system power is then lost.

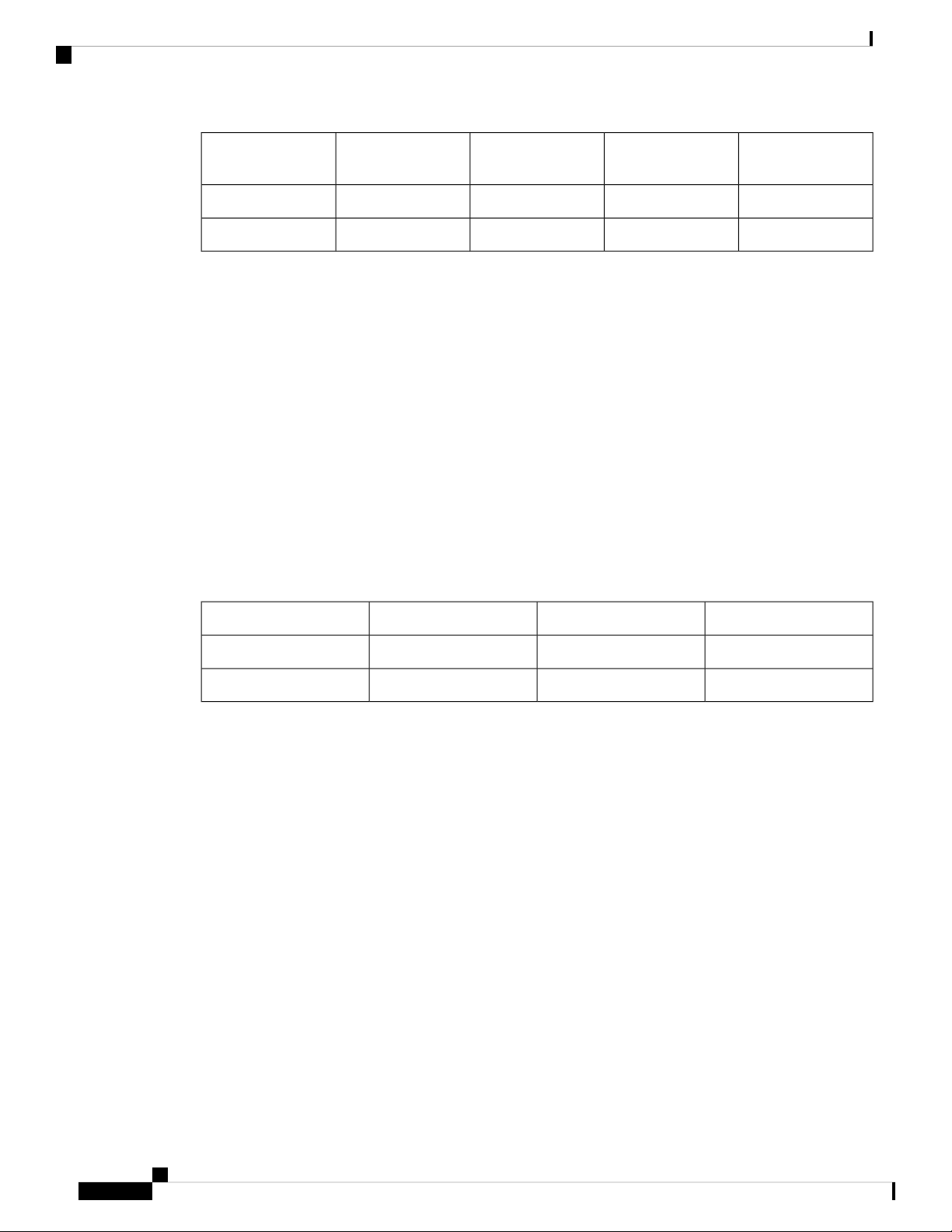

The following table provides details about the power output in combined mode:

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

9

Page 14

Power Supply Modes

Product Overview

One Power SupplyInput voltage

Two Power

Supplies

Three Power

Supplies

Four Power

Supplies

4020W3030W2040W1050W110V

7820W5880W3940W2000W220V

Redundant (N+1) Mode

In a redundant configuration, a given power supply module can either be active, or in standby mode. In N+1

redundant mode, N is the number of active power supply modules and +1 is the power supply module configured

as the standby module.

You can configure redundancy mode in the software. When the switch is configured with N+1 redundancy,

software ensures that there is a standby power supply available and there is sufficient power available with

the active power supply modules (N). All the power supplies including active and standby will share the load

equally. . However, with a standby power supply installed, system ensures that the additional output power

available with a standby is always reserved for use in case of a failure. If the power supply mode is set to

redundant mode and the total active output power is not sufficient to meet the power requirements, the switch

will not enter the redundant mode.

You can use a combination of AC and DC power supplies provided the AC input voltage is 220V and the

power supplies must be of equal wattage. However, you cannot combine two AC power supplies of 110V

input and 220V input.

The following table provides details about the power output in N+1 redundant mode:

Four Power SuppliesThree Power SuppliesTwo Power SuppliesInput voltage

3030W2040W1050W110V

5880W3940W2000W220V

For detailed software configuration information, see the required version of the Software Configuration Guide.

In the guide, go to Contents → System Management → Environmental Monitoring and Power Management.

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

10

Page 15

Preparing for Installation

• Safety Warnings, on page 11

• Site Requirements, on page 14

• Power Requirements, on page 23

• Cabling Requirements, on page 23

• Rack-Mounting Guidelines, on page 24

• Site Preparation Checklist, on page 25

Safety Warnings

Safety warnings appear throughout this publication in procedures that may harm you if you perform them

incorrectly. A warning symbol precedes each warning statement. The warnings below are general warnings

that are applicable to the entire publication.

CHAPTER 2

Warning

Warning

Warning

Warning

An exposed wire lead from a DC-input power source can conduct harmful levels of electricity. Be sure that

no exposed portion of the DC-input power source wire extends from the connector(s) or terminal block(s).

Statement 122

AC connected units must have a permanent ground connection in addition to the power cable ground wire.

NEBS-compliant grounding satisfies this requirement. Statement 284

High leakage current—earth connection essential before connecting to system power supply. Statement 342

Power Cable and AC Adapter - When installing the product, please use the provided or designated connection

cables/power cables/AC adaptors.Using any other cables/adaptors could cause a malfunction or a fire. Electrical

Appliance and Material Safety Law prohibits the use of UL-certified cables (that have the "UL or CSA" shown

on the code) for any other electrical devices than products designated by CISCO. The use of cables that are

certified by Electrical Appliance and Material Safety Law (that have "PSE" shown on the code) is not limited

to CISCO-designated products. Statement 371

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

11

Page 16

Safety Warnings

Preparing for Installation

Warning

Warning

Warning

Warning

Warning

To reduce the risk of electric shock, the chassis of this equipment needs to be connected to permanent earth

ground during normal use. Statement 0445

Read the installation instructions before using, installing or connecting the system to the power source.

Statement 1004

Class 1 laser product. Statement 1008

There is the danger of explosion if the battery is replaced incorrectly. Replace the battery only with the same

or equivalent type recommended by the manufacturer. Dispose of used batteries according to the manufacturer’s

instructions. Statement 1015

This unit is intended for installation in restricted access areas. A restricted access area can be accessed only

through the use of a special tool, lock and key, or other means of security. Statement 1017

Warning

Warning

Warning

Warning

Warning

This equipment must be grounded. Never defeat the ground conductor or operate the equipment in the absence

of a suitably installed ground conductor. Contact the appropriate electrical inspection authority or an electrician

if you are uncertain that suitable grounding is available. Statement 1024

Class 1 LED product. Statement 1027

Blank faceplates and cover panels serve three important functions: they prevent exposure to hazardous voltages

and currents inside the chassis; they contain electromagnetic interference (EMI) that might disrupt other

equipment; and they direct the flow of cooling air through the chassis. Do not operate the system unless all

cards, faceplates, front covers, and rear covers are in place. Statement 1029

Only trained and qualified personnel should be allowed to install, replace, or service this equipment. Statement

1030

Hazardous voltage or energy is present on the backplane when the system is operating. Use caution when

servicing. Statement 1034

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

12

Page 17

Preparing for Installation

Safety Warnings

Warning

Warning

Warning

Warning

Warning

Ultimate disposal of this product should be handled according to all national laws and regulations. Statement

1040

To prevent the system from overheating, do not operate it in an area that exceeds the maximum recommended

ambient temperature of 104°F (40°C). Statement 1047

Stability hazard. The rack stabilizing mechanism must be in place, or the rack must be bolted to the floor

before you slide the unit out for servicing. Failure to stabilize the rack can cause the rack to tip over. Statement

1048

The chassis should be mounted on a rack that is permanently affixed to the building. Statement 1049

Invisible laser radiation may be emitted from disconnected fibers or connectors. Do not stare into beams or

view directly with optical instruments. Statement 1051

Warning

Warning

Warning

Class 1M laser radiation when open. Do not view directly with optical instruments. Statement 1053

Class I (CDRH) and Class 1M (IEC) laser products. Statement 1055

Invisible laser radiation may be emitted from the end of the unterminated fiber cable or connector. Do not

view directly with optical instruments. Viewing the laser output with certain optical instruments (for example,

eye loupes, magnifiers, and microscopes) within a distance of 100 mm may pose an eye hazard. Statement

1056

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

13

Page 18

Site Requirements

Preparing for Installation

Warning

Warning

IMPORTANT SAFETY INSTRUCTIONS

This warning symbol means danger. You are in a situation that could cause bodily injury. Before you

work on any equipment, be aware of the hazards involved with electrical circuitry and be familiar with

standard practices for preventing accidents. Use the statement number provided at the end of each

warning to locate its translation in the translated safety warnings that accompanied this device. Statement

1071

SAVE THESE INSTRUCTIONS

The covers are an integral part of the safety design of the product. Do not operate the unit without the covers

installed. Statement 1077

Site Requirements

Planning a proper location for the switch and layout of the equipment rack or wiring closet is essential for

successful system operation. These sections describe some of the basic site requirements that you should be

aware of as you prepare to install your switch, including the following:

• Environmental factors can adversely affect the performance and longevity of your system.

• Install the switch in an enclosed, secure area, ensuring that only qualified personnel have access to the

switch and control of the environment.

Temperature

• Equipment that is placed too closely together or that is inadequately ventilated may cause system

over-temperature conditions, leading to premature component failure.

• Poor equipment placement can make chassis panels inaccessible and difficult to maintain.

• The switch requires a dry, clean, well-ventilated, and air-conditioned environment.

• To ensure normal operation, maintain ambient airflow. If the airflow is blocked or restricted, or if the

intake air is too warm, an over-temperature condition may occur. The switch environmental monitor may

then shut down the system to protect the system components.

• Multiple switches can be rack mounted with little or no clearance above and below the chassis. However,

when mounting a switch in a rack with other equipment, or when placing it on the floor near other

equipment, ensure that the exhaust from other equipment does not blow into the air intake vent of the

switch chassis.

Temperature extremes may cause a system to operate at reduced efficiency and cause a variety of problems,

including premature aging and failure of chips, and failure of mechanical devices. Extreme temperature

fluctuations may also cause chips to become loose in their sockets. Observe the following guidelines:

• Ensure that the system is operating in an environment that is—

• 23 to 113 °F (-5 to 45 °C) up to 6000 feet (1800m)

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

14

Page 19

Preparing for Installation

Air Flow

• 23 to 104 °F (-5 to 40 °C) up to 10000 feet (3000m)

• Ensure that the chassis has adequate ventilation.

• Do not place the chassis within a closed-in wall unit or on top of cloth, which can act as insulation.

• Do not place the chassis where it will receive direct sunlight, particularly in the afternoon.

• Do not place the chassis next to a heat source of any kind, including heating vents.

• Adequate ventilation is particularly important at high altitudes. Make sure that all the slots and openings

on the system remain unobstructed, especially the fan vent on the chassis.

• Clean the installation site at regular intervals to avoid buildup of dust and debris, which may cause a

system to overheat.

• If system is exposed to abnormally low temperatures, allow a two hour warm up period, in ambient

temperature no lower than 32°F (0 °C) before turning on.

Warning

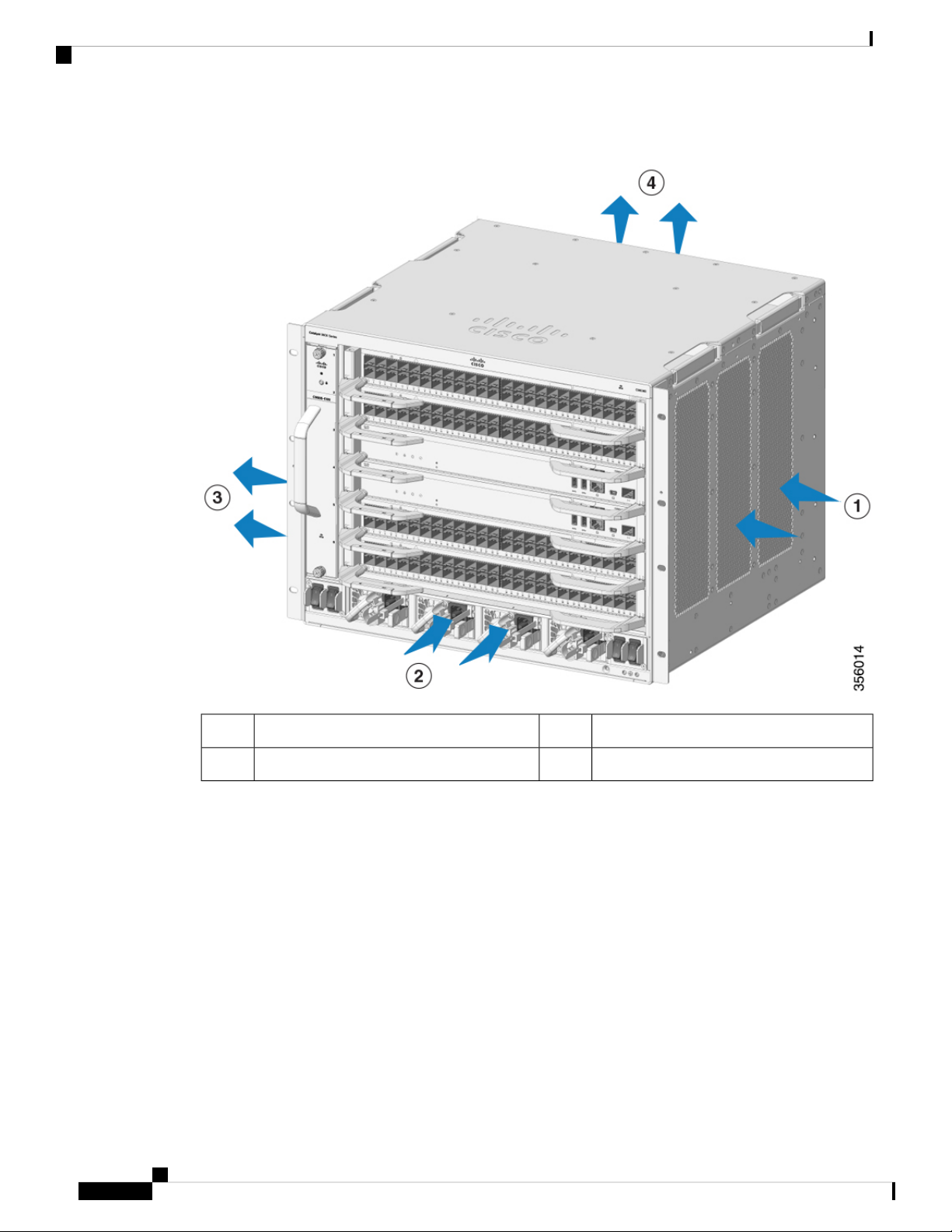

Air Flow

Do not operate the system if the fan assembly is removed or if it is not functioning properly. An overtemperature

condition can cause severe equipment damage or an unscheduled system shutdown.

Failure to observe these guidelines may damage the chassis' internal components.

The switch is designed to be installed in an environment where there is a sufficient volume of air available to

cool the supervisor engines, modules, and power supplies. If there are any constraints with regard to the free

flow of air through the chassis, or if the ambient air temperature is elevated, the switch environmental monitor

may then shut down the system to protect the system components.

To maintain proper air circulation through the switch chassis, we recommend that you maintain a minimum

space of 6 inches (15 cm) between a wall and the chassis and power supply unit air intakes or a wall and the

chassis and power supply unit hot air exhausts. In situations where the switch chassis are installed in adjacent

racks, you should allow a minimum space of 12 inches (30.5 cm) between the air intake of one chassis and

the hot air exhaust of another chassis.

Note

Failure to maintain adequate spacing between chassis may cause the switch chassis that is drawing in the hot

exhaust air to overheat and fail.

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

15

Page 20

Air Flow

Preparing for Installation

Figure 6: Air Flow Direction - Cisco Catalyst 9600 Series Switches

Chassis air exhaust3Chassis air intake1

Power supply air exhaust4Power supply air intake2

If you are installing your switch in an enclosed or partially enclosed rack, we strongly recommend that you

verify that your site meets the following guidelines:

• Verify that there is a minimum of 6 inches (15 cm) of clearance between the sides, front, and back of

any enclosure, and both the chassis air intake grill and the chassis air exhaust grill along with the power

supply unit intakes and exhausts. The upright columns of a relay rack may be located less than the

recommended side spacing provided there are substantial cutouts, holes, or vents in the structure to allow

adequate air flow through the chassis.

• Verify that the ambient air temperature within the enclosed or partially enclosed rack is within the chassis

operating temperature limits. After installing the chassis in the rack, power up the chassis and allow the

chassis temperature to stabilize (approximately 2 hours).

Measure the ambient air temperature at the chassis air intake grill by positioning an external temperature

probe 1 inch (2.5 cm) away from the chassis left side, and centered on the chassis both horizontally and

vertically.

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

16

Page 21

Preparing for Installation

Humidity

Measure the ambient air temperature at the power supply unit air intake grill by positioning an external

temperature probe 1 inch (2.5 cm) away from the chassis front, centered on the power supply unit section

located above the card slots.

• If the ambient intake air temperature is less than 113°F (45°C) at altitudes of 6,000 feet and below,

the rack meets the intake air temperature criterion. At altitudes above that threshold and up to 10,000

feet (3000 m), the air intake should not exceed 104°F (40°C).

• If the ambient intake air temperature exceeds this recommendation, the system may experience

minor temperature alarms and increase fan speeds in response.

• If the ambient intake air temperature equals or is greater than 131°F (55°C), the system may

experience a major temperature alarm with maximum fan speeds in response. If ambient temperature

continues to increase, system will respond with protective shut down.

• Plan ahead. A switch that is currently installed in an enclosed or partially enclosed rack might meet

ambient air temperature and air flow requirements at present. However, if you add more chassis to the

rack or more modules to a chassis in the rack, the additional heat generated might cause the ambient air

temperature at the chassis or power supply unit inlets to exceed recommended conditions which may

trigger thermal alarms.

Humidity

High-humidity conditions may cause moisture to enter the system, and cause corrosion of internal components

and degradation of properties such as electrical resistance, thermal conductivity, physical strength, and size.

Extreme moisture buildup inside the system may result in electrical short circuit, which may cause serious

damage to the system. Each system is rated for storage and operation in 10 to 95 percent relative humidity,

non-condensing with a humidity gradation of 10 percent per hour. Buildings in which climate is controlled

by air-conditioning in the warmer months and by heat during the colder months usually maintain an acceptable

level of humidity for system equipment. However, if a system is located in an unusually humid location, a

dehumidifier should be used to maintain the humidity within an acceptable range.

Altitude

Operating a system at high altitude (low pressure) reduces the efficiency of forced and convection cooling

and may result in electrical problems related to arcing and corona effects. This condition may also cause sealed

components with internal pressure, such as electrolytic capacitors, to fail or perform at reduced efficiency.

Dust and Particles

Fans cool power supplies and system components by drawing in room-temperature air and exhausting heated

air out through various openings in the chassis. However, fans also ingest dust and other particles, causing

contaminant buildup in the system and increased internal chassis temperature. A clean operating environment

can greatly reduce the negative effects of dust and other particles, which act as insulators and interfere with

the mechanical components in the system. The standards listed below provide guidelines for acceptable

working environments and acceptable levels of suspended particulate matter:

• National Electrical Manufacturers Association (NEMA) Type 1

• International Electrotechnical Commission (IEC) IP-20

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

17

Page 22

Corrosion

Corrosion

Corrosion of system connectors is a gradual process that may eventually lead to intermittent failures of electrical

circuits. The oil from a person’s fingers or prolonged exposure to high temperature or humidity may corrode

the gold-plated edge connectors and pin connectors on various components in the system. To prevent corrosion,

avoid touching contacts on boards and cards, and protect the system from extreme temperatures and moist,

salty environments.

EMI and Radio Frequency Interference

Electro-Magnetic interference (EMI) and radio frequency interference (RFI) from a system can adversely

affect devices such as radio and television (TV) receivers operating near the system. Radio frequencies

emanating from a system can also interfere with cordless and low-power telephones. Conversely, RFI from

high-power telephones can cause spurious characters to appear on the system monitor. RFI is defined as any

EMI with a frequency above 10 kilohertz (kHz). This type of interference can travel from the system to other

devices through the power cable and power source, or through the air in the form of transmitted radio waves.

The Federal Communications Commission (FCC) publishes specific regulations to limit the amount of EMI

and RFI emitted by computing equipment. Each system meets these FCC regulations. To reduce the possibility

of EMI and RFI, follow these guidelines:

Preparing for Installation

• Always operate the system with the chassis covers installed.

• Ensure that all chassis slots are covered by a metal filler bracket and that an unused power supply bay

has a metal cover plate installed.

• Ensure that the screws on all peripheral cable connectors are securely fastened to their corresponding

connectors on the back of the chassis.

• Always use shielded cables with metal connector shells for attaching peripherals to the system.

When wires are run for any significant distance in an electromagnetic field, interference can occur between

the field and the signals on the wires. This fact has two implications for the construction of plant wiring:

• Bad wiring practice can result in radio interference emanating from the plant wiring.

• Strong EMI, especially when it is caused by lightning or radio transmitters, can destroy the signal drivers

and receivers in the chassis, and even create an electrical hazard by conducting power surges through

lines into equipment.

Note

To predict and provide a remedy for strong EMI, consult experts in RFI.

If you use twisted-pair cable in your plant wiring with a good distribution of grounding conductors, the plant

wiring is unlikely to emit radio interference. If you exceed the recommended distances, use a high-quality

twisted-pair cable with one ground conductor for each data signal when applicable.

18

Caution

Category 5e, Category 6, and Category 6a cables can store large levels of static electricity because of the

dielectric properties of the materials used in their construction. Always ground the cables (especially in new

cable runs) to a suitable and safe earth ground before connecting them to the module.

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

Page 23

Preparing for Installation

Shock and Vibration

If the wires exceed the recommended distances, or if wires pass between buildings, give special consideration

to the effect of a lightning strike in your vicinity. The electromagnetic pulse caused by lightning or other

high-energy phenomena can easily couple enough energy into unshielded conductors to destroy electronic

devices. If you have had problems of this sort in the past, you may want to consult experts in electrical surge

suppression and shielding.

Warning

The intra-building ports (Copper Based Ethernet Ports) of the equipment or subassembly is suitable for

connection to intra-building or unexposed wiring or cabling only. The intra-building ports of the equipment

or subassembly MUST NOT be metallically connected to interfaces that connect to the Out Side Plant (OSP)

or its wiring for more than 6 meters (approximately 20 feet). These interfaces are designed for use as

intra-building interfaces only (Type 2, 4, or 4a ports as described in GR-1089) and require isolation from the

exposed OSP cabling. The addition of Primary Protectors is not sufficient protection in order to connect these

interfaces metallically to an OSP wiring system.

Shock and Vibration

The equipment complies with the Earthquake, Office, and Transportation Vibration, and Equipment Handling

Criteria of GR-63-CORE.

Power Source Interruptions

Systems are especially sensitive to variations in voltage supplied by the AC power source. Overvoltage,

undervoltage, and transients (or spikes) can erase data from memory or even cause components to fail. To

protect against these types of problems, power cables should always be properly grounded. Also, place the

system on a dedicated power circuit (rather than sharing a circuit with other heavy electrical equipment). In

general, do not allow the system to share a circuit with any of the following:

• Copy machines

• Air conditioners

• Vacuum cleaners

• Space heaters

• Power tools

• Teletype machines

• Laser printers

• Facsimile machines

• Any other motorized equipment

Besides these appliances, the greatest threats to a system's power supply are surges or blackouts that are caused

by electrical storms. Whenever possible, turn off the system and peripherals, if any, and unplug them from

their power sources during thunderstorms. If a blackout occurs—even a temporary one—while the system is

turned on, turn off the system immediately and disconnect it from the electrical outlet. Leaving the system on

may cause problems when the power is restored; all other appliances left on in the area may create large

voltage spikes that may damage the system.

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

19

Page 24

System Grounding

System Grounding

Preparing for Installation

Warning

Warning

Caution

When installing or replacing the unit, the ground connection must always be made first and disconnected last.

Statement 1046

Use copper conductors only. Statement 1025

You must install a system ground as part of the chassis installation process. Chassis installations that rely only

on the AC third-prong ground are insufficient to adequately ground the systems.

Proper grounding practices ensure that the buildings and the installed equipment within them have

low-impedance connections and low-voltage differentials between chassis. When you install a system ground,

you reduce or prevent shock hazards, chances of equipment damage due to transients, and the potential for

data corruption.

Without proper and complete system grounding, you run the risk of increased component damage due to ESD.

Additionally, you have a greatly increased chance of data corruption, system lockup, and frequent system

reboot situations by not using a system ground.

Installations that rely solely on system grounding that uses only an AC third-prong ground run a substantially

greater risk of equipment problems and data corruption than those installations that use both the AC third-prong

ground and a properly installed system ground.

The following table lists some general grounding practice guidelines.

Table 3: Grounding Practice Guidelines

Environment

direct lightning strikes.

For example, some places in the United

States, such as Florida, are prone to

more lightning strikes than other areas.

area where lightning storms occur

frequently, but is not prone to direct

lightning strikes.

Severity Level

HighCommercial building is subjected to

HighCommercial building is located in an

Grounding RecommendationsElectromagnetic Noise

All lightning protection devices must be

installed in strict accordance with

manufacturer recommendations.

Conductors carrying lightning current

should be spaced away from power and

data lines in accordance with applicable

recommendations and codes. Best

grounding practices must be closely

followed.

Best grounding practices must be closely

followed.

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

20

Page 25

Preparing for Installation

System Grounding

Environment

of information technology equipment

and industrial equipment, such as

welding.

subject to natural environmental noise

or man-made industrial noise. This

building contains a standard office

environment. This installation has a

history of malfunction due to

electromagnetic noise.

to natural environmental noise or

man-made industrial noise. This

building contains a standard office

environment.

subject to natural environmental noise

or man-made industrial noise. This

building contains a standard office

environment.

Severity Level

Medium to HighCommercial building contains a mix

MediumExisting commercial building is not

LowNew commercial building is not subject

LowExisting commercial building is not

Grounding RecommendationsElectromagnetic Noise

Best grounding practices must be closely

followed.

Best grounding practices must be closely

followed. Determine source and cause of

noise if possible, and mitigate as closely as

possible at the noise source or reduce

coupling from the noise source to the

victim equipment.

Best grounding practices should be

followed as closely as possible.

Electromagnetic noise problems are not

anticipated, but installing a best-practice

grounding system in a new building is often

the least expensive route, and the best way

to plan for the future.

Best grounding practices should be

followed as much as possible.

Electromagnetic noise problems are not

anticipated, but installing a best-practice

grounding system is always recommended.

Note

Note

Caution

In all situations, grounding practices must comply with Section 250 of the National Electric Code (NEC)

requirements or local laws and regulations. A 6 AWG grounding wire is preferred from the chassis to the rack

ground or directly to the common bonding network (CBN). The equipment rack should also be connected to

the CBN with a 6 AWG grounding wire.

Always ensure that all of the modules are completely installed and that the captive installation screws are

fully tightened. In addition, ensure that all the I/O cables and power cords are properly seated. These practices

are normal installation practices and must be followed in all installations.

Category 5e, Category 6, and Category 6a cables can store large levels of static electricity because of the

dielectric properties of the materials used in their construction. Always ground the cables (especially in new

cable runs) to a suitable and safe earth ground before connecting them to the module.

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

21

Page 26

Maintaining Safety with Electricity

Maintaining Safety with Electricity

When working on electrical equipment, follow these guidelines:

• Do not work alone if potentially hazardous conditions exist anywhere in your work space.

• Never assume that power is disconnected from a circuit; always check the circuit before working on it.

• Look carefully for possible hazards in your work area, such as damp floors, ungrounded power extension

cables, frayed or damaged power cords, and missing safety grounds.

• If an electrical accident occurs, proceed as follows:

• Use extreme caution; do not become a victim yourself.

• Disconnect power from the system.

• If possible, send another person to get medical aid. Otherwise, assess the condition of the victim

and then call for help.

• Determine if the person needs rescue breathing or external cardiac compressions; then take appropriate

action.

Preparing for Installation

• Use the product within its marked electrical ratings and product usage instructions.

• Install the product in compliance with local and national electrical codes.

• If any of the following conditions occur, contact the Cisco Technical Assistance Center:

• The power cable or plug is damaged.

• An object has fallen into the product.

• The product has been exposed to water or other liquids.

• The product has been dropped or shows signs of damage.

• The product does not operate correctly when you follow the operating instructions.

• Use the correct external power source. Operate the product only from the type of power source indicated

on the electrical ratings label. If you are not sure of the type of power source required, consult the Cisco

Technical Assistance Center or a local electrician.

• Use approved power cables only. You have been provided with one or more power cables with your

chassis power supply that are intended for use in your country, based on the shipping location. Should

you need to purchase additional power cables, ensure that they are rated for the product and for the

voltage and current marked on the product’s electrical ratings label. The voltage and current rating of

the power cable should be greater than the ratings marked on the label.

• To help prevent electrical shock, plug all the power cables into properly grounded electrical outlets.

These power cables are equipped with three-prong plugs to ensure proper grounding. Do not use adapter

plugs or remove the grounding prong from a power cable.

• Observe power strip ratings. Make sure that the total current rating of all products that are plugged into

the power strip does not exceed 80 percent of the power strip rating.

• Do not modify power cables or plugs yourself. Consult with a licensed electrician or your power company

for site modifications. Always follow your local and national wiring codes.

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

22

Page 27

Preparing for Installation

Preventing Electrostatic Discharge Damage

Electrostatic discharge (ESD) damage may occur when modules or other FRUs are improperly handled, and

result in intermittent or complete failure of the modules or FRUs. Modules consist of printed circuit boards

that are fixed in metal carriers. EMI shielding and connectors are integral components of a carrier. Although

the metal carrier helps to protect the board from ESD, always use an ESD-grounding strap when handling

modules. To prevent ESD damage, follow these guidelines:

• Always use an ESD wrist or ankle strap and ensure that it makes good skin contact.

• Connect the equipment end of the strap to an unfinished chassis surface.

• When installing a component, use any available ejector levers to properly seat the bus connectors in the

backplane or midplane. These devices prevent accidental removal, provide proper grounding for the

system, and help to ensure that bus connectors are properly seated.

• When removing a component, use any available ejector levers to release the bus connectors from the

backplane or midplane.

• Handle carriers by available handles or edges only; avoid touching the printed circuit boards or connectors.

Preventing Electrostatic Discharge Damage

• Place a removed component board-side-up on an antistatic surface or in a static shielding container. If

you plan to return the component to the factory, immediately place it in a static shielding container.

• Avoid contact between the printed circuit boards and clothing. The wrist strap only protects components

from ESD voltages on the body; ESD voltages on clothing can still cause damage.

• Never attempt to remove the printed circuit board from the metal carrier.

Power Requirements

Power supplies installed on the switch chassis can be all AC-input, all DC-input, or a mix of both. When

preparing your site for switch installation, adhere to these requirements:

• In systems configured with more than one power supply, connect each of the power supplies to a separate

input power source. If you fail to do this, your system might be susceptible to total power failure due to

a fault in the external wiring or a tripped circuit breaker

• To prevent loss of input power, be sure that the total maximum load on each source circuit is within the

current ratings of the wiring and breakers.

• In some systems, you may decide to use an uninterrupted power supply (UPS) to protect against power

failures at your site. Be aware when selecting a UPS that some UPS models that use ferroresonant

technology may become unstable when operating with the switch power supplies that use power factor

correction. This may cause the output voltage waveform to the switch to become distorted, resulting in

an undervoltage situation in the system.

Cabling Requirements

When running power and data cables together in overhead cable trays or subfloor cable trays, be aware of the

following caution:

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

23

Page 28

Rack-Mounting Guidelines

Preparing for Installation

Caution

Caution

We strongly recommend that power cabling runs and other potential noise sources be located as far away as

practical from LAN cabling that terminates on Cisco equipment. In situations where this type of long parallel

cable runs exist and cannot be separated by at least 3.3 feet (1 meter), we recommend that you shield these

potential noise sources. To avoid interference, the source should be shielded by housing it in a grounded

metallic conduit.

Also be aware of the following caution concerning the use of Category 5e and Category 6 Ethernet cables:

Category 5e, Category 6, and Category 6a cables can store large levels of static electricity because of the

dielectric properties of the materials used in their construction. Always ground the cables (especially in new

cable runs) to a suitable and safe earth ground before connecting them to the module.

Rack-Mounting Guidelines

Rack Specifications

Cisco Catalyst 9600 Series Switches are designed to be installed in standard, 19-inch equipment racks that

meet EIA-310-D specifications. In Network Equipment Building Systems (NEBS) compliant installation, you

can use only a 23-inch rack mount. Before rack-mounting the chassis, ensure that the equipment rack complies

with all requirements and guidelines

Mounting Location Guidelines

Cisco Catalyst 9600 Series Switches must be front-mounted.

Accordingly, you can install the chassis in 2-post or 4-post racks, but in a 4-post rack, the rear posts are not

used for mounting.

Width and Depth Requirements

Use a tape measure to verify the interior dimensions of the rack.

• Measure the space between the inner edges of the left front and right front mounting posts. The chassis

is 19 inches (48.26 cm) wide and must fit between the mounting posts.

• Measure the depth of the rack from the outside of the front mounting posts to the outside of the rear

mounting strip. The chassis is 18.8 inches (47.75 cm) deep.

Height Requirements

The rack must have sufficient clearance in terms of height, to insert the chassis. Chassis height is also measured

in rack units (RU or just U) where 1 RU or 1 U equals 1.75 inches (44.45 mm). A typical server rack is 42

RU or 42 U in height.

The chassis height of Catalyst 9606R Switch is 8 RU with a depth of 18.8 inches.

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

24

Page 29

Preparing for Installation

Site Preparation Checklist

Other General Guidelines

Caution

Warning

Warning

Warning

If the equipment rack is on wheels, ensure that the brakes are engaged and that the rack is stabilized.

To prevent bodily injury when mounting or servicing this unit in a rack, you must take special precautions to

ensure that the system remains stable. The following guidelines are provided to ensure your safety:

• This unit should be mounted at the bottom of the rack if it is the only unit in the rack.

• When mounting this unit in a partially filled rack, load the rack from the bottom to the top with the

heaviest component at the bottom of the rack.

• If the rack is provided with stabilizing devices, install the stabilizers before mounting or servicing the

unit in the rack. Statement 1006

Take care when connecting units to the supply circuit so that wiring is not overloaded. Statement 1018

To prevent the system from overheating, do not operate it in an area that exceeds the maximum recommended

ambient temperature of: 104oF (40oC) Statement 1047

Note

To maintain proper air circulation through the switch chassis, we recommend that you maintain a minimum

space of 6 inches (15 cm) between a wall and the chassis and power supply unit air intakes or a wall and the

chassis and power supply unit hot air exhausts. In situations where the switch chassis are installed in adjacent

racks, you should allow a minimum space of 12 inches (30.5 cm) between the air intake of one chassis and

the hot air exhaust of another chassis. Failure to maintain adequate spacing between chassis may cause the

switch chassis that is drawing in the hot exhaust air to overheat and fail.

Site Preparation Checklist

The following table lists the site-planning activities that you should perform prior to installing the switch.

Completing each activity helps ensure a successful switch installation.

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

25

Page 30

Site Preparation Checklist

Table 4: Site Preparation Checklist

Preparing for Installation

ActivityTask No.

DateTimeVerified

By

1

Space evaluation

• Space and layout

• Floor covering

• Impact and vibration

• Lighting

• Maintenance access

2

Environmental evaluation

• Ambient temperature

• Humidity

• Altitude

• Atmospheric contamination

• Airflow

3

Power evaluation

• Input power type

• Power receptacles (Depends on power supply)

2

• Receptacle proximity to the equipment.

• Dedicated (separate) circuits for redundant power supplies.

• UPS for power failures

4

Grounding evaluation

3

• Circuit breaker size

• CO ground (AC powered systems)

5

Cable and interface equipment evaluation

• Cable type

• Connector type

• Cable distance limitations

• Interface equipment (transceivers)

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

26

Page 31

Preparing for Installation

Site Preparation Checklist

ActivityTask No.

By

6

EMI evaluation

• Distance limitations for signaling

• Site wiring

• RFI levels

2

Verify that each power supply installed in the chassis has a dedicated AC source circuit.

3

Refer to the power supply'VA rating as a sizing criteria in determining the output required by the UPS.

The power supply kVA rating value is listed in the specifications table for each power supply in Appendix

A (power supply specifications).

DateTimeVerified

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

27

Page 32

Site Preparation Checklist

Preparing for Installation

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

28

Page 33

Installing the Switch

• Unpacking the Switch, on page 29

• Install the Switch as Shipped, on page 30

• Install the Switch with Shelf Brackets, on page 36

• Install the Switch in NEBS-Compliant Mode, on page 50

• Establishing System Ground, on page 57

• Attaching an ESD Strap, on page 60

• Verifying the Switch Chassis Installation, on page 61

Unpacking the Switch

Check the contents of the shipping container:

Procedure

Step 1 Check the contents of the accessory kit. Verify that you have received all the listed equipment, including any

optional equipment you may have ordered, such as, network interface cables, transceivers, or special connectors.

Step 2 Check the modules in each slot. Ensure that the configuration matches the packing list and that all of the

specified interfaces are included.

Step 3 Store the shipping carton.

CHAPTER 3

Tip

Do not discard the shipping container when you unpack the switch. Flatten the shipping cartons and

store them with the pallet. You will require these containers if you have to move or ship the switch

in the future.

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

29

Page 34

Installing the Switch

Install the Switch as Shipped

Install the Switch as Shipped

Installing the Cable Guide on the Chassis with L-Brackets Preinstalled on the Chassis

Procedure

Step 1 Position the cable guides to align with the L-brackets preinstalled on the chassis and secure the cable guides

to the L-brackets using the screws provided.

Figure 7: Attaching the Cable Guides

1

L-brackets on the chassis

Step 2 Secure the chassis to the rack rails with four screws on each side.

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

30

Cable guides2Screws to attach the cable guides to the

Page 35

Installing the Switch

Installing the Cable Guide on the Chassis with L-Brackets Preinstalled on the Chassis

Figure 8: Mounting the Chassis to the Rack

Cable guide installation is complete.

Cable guide installed2Screws to attach the chassis to the rack post1

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

31

Page 36

Rack-Mounting the Chassis as Shipped

Figure 9: Chassis with Cable Guide Attached

Installing the Switch

Rack-Mounting the Chassis as Shipped

This procedure shows how to rack mount the chassis as shipped.

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

32

Page 37

Installing the Switch

Rack-Mounting the Chassis as Shipped

Before you begin

Warning

To prevent bodily injury when mounting or servicing this unit in a rack, you must take special precautions to

ensure that the system remains stable. The following guidelines are provided to ensure your safety:

• This unit should be mounted at the bottom of the rack if it is the only unit in the rack.

• When mounting this unit in a partially filled rack, load the rack from the bottom to the top with the

heaviest component at the bottom of the rack.

If the rack is provided with stabilizing devices, install the stabilizers before mounting or servicing the

unit in the rack.

Statement 1006

Procedure

Step 1 Insert the rear of the chassis between the mounting posts of the rack.

Step 2 Align the mounting holes in the L bracket on the switch or on the cable mount (if installed) with the mounting

holes in the equipment rack.

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

33

Page 38

Rack-Mounting the Chassis as Shipped

Figure 10: Securing the Chassis to the Rack Posts

Installing the Switch

Cable guides210-32 or 12-24 pan head screws1

Step 3 Secure the chassis to the rack with either 10-32 or 12-24 pan head screws from the chassis standard accessory

kit.

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

34

Page 39

Installing the Switch

Rack-Mounting the Chassis as Shipped

Figure 11: Chassis Secured to the Rack Posts

Step 4 4. Use a tape measure and level to ensure that the chassis is installed straight and level..

What to do next

After installing the chassis in its location, complete the installation process by:

1. Connecting the chassis to system ground.

2. Installing and connecting the power supplies to the power source.

3. Connecting the network interface cables to the supervisor module and line card modules. This may involve

installing transceivers before you attach the network interface cables.

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

35

Page 40

Install the Switch with Shelf Brackets

4. Powering up the chassis and verifying the installation.

Install the Switch with Shelf Brackets

Installing the Shelf Kit L-Brackets

The switch chassis is shipped with two L-brackets installed on the front sides of the chassis. If you are

rack-mounting the switch using the shelf kit, these L-brackets must be removed and replaced with L-brackets

that are part of the shelf kit.

Before you begin

You have ordered and received the shelf kit.

Procedure

Installing the Switch

Step 1 Remove and discard the L-brackets and the ten mounting screws that the chassis is shipped with. Do not re-use

them during any part of the installation process.

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

36

Page 41

Installing the Switch

Installing the Shelf Kit L-Brackets

Figure 12: L-Brackets the Chassis is Shipped with

Right L-bracket2Left L-bracket1

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

37

Page 42

Installing the Shelf Kit L-Brackets

Figure 13: Removing L-Brackets the Chassis is Shipped With

Installing the Switch

--Mounting screws the chassis is shipped with1

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

38

Page 43

Installing the Switch

Installing the Shelf Kit L-Brackets

Figure 14: Chassis Without L-Brackets

Chassis without right L-bracket2Chassis without left L-bracket1

Step 2 Unpack the L-brackets from the shelf kit.

Step 3 Using the M4 x 8 mm Phillips flat head screws in the shelf kit, secure the L-brackets to the front-left and

front-right sides of the chassis (four on each side).

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

39

Page 44

Installing the Shelf Brackets and the Crossbar

Figure 15: Installing Shelf Kit L-Brackets

Installing the Switch

What to do next

Install the shelf brackets on the rack.

Installing the Shelf Brackets and the Crossbar

Install the shelf brackets and the crossbar before you install the chassis in the rack to help support the weight

of the chassis while you secure the L-brackets to the rack enclosure.

You have to front-mount the shelf brackets.

Before you begin

Determine the clearance between the insides of the left and right rails of your rack system and install the shelf

brackets accordingly. Keep these tools handy:

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

40

--M4 x 8 mm Phillips flat head screws1

Page 45

Installing the Switch

Step 1 Position the support flange of the left shelf bracket on the front of the left rail. Align and secure the bracket

Step 2 Position the support flange of the right shelf bracket on the front of the right rail — make sure that it is level

Installing the Shelf Brackets and the Crossbar

• Number 1 and Number 2 Phillips screwdrivers

• 3/16-inch flat-blade screwdriver

• Tape measure and level

Procedure

to the rack by using three screws. Use either 10-32 or 12-24 pan head screws from the shelf kit.

with the left shelf bracket. Align and secure the bracket to the rack by using three screws.

Use the same type of screws for the left and right shelf bracket.

Figure 16: Installing the Shelf Brackets

1

Shelf brackets2Pan head screws from the shelf kit to secure

the shelf brackets to the rack posts

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

41

Page 46

Installing the Cable Guide on the Chassis with Shelf Kit L-Bracket

Step 3 Secure the crossbar to the shelf brackets by using two M4 screws, with one screw on each side.

Figure 17: Securing the crossbar to the shelf brackets

Installing the Switch

Crossbar2M4 x 5 mm flat-head screw1

The shelf brackets and the crossbar are now securely mounted to the rack posts.

What to do next

Install the cable guide to the chassis. Two people will be required for this task.

Installing the Cable Guide on the Chassis with Shelf Kit L-Bracket

Procedure

Step 1 Position the cable guides and align with the shelf kit L-brackets installed on the chassis.

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

42

Page 47

Installing the Switch

Rack-Mounting the Chassis

Figure 18: Installing the Cable Guide

Screws to mount the cable guide1

Step 2 Secure the cable guides to the L brackets using the screws (one on each side) provided.

What to do next

Rack mount the chassis to a rack installed with shelf brackets and a crossbar.

Rack-Mounting the Chassis

This procedure shows how to rack mount the chassis with shelf brackets.

Warning

Two people are required to lift the chassis. To prevent injury, keep your back straight and lift with your legs,

not your back. Statement 164

Tip

We recommend that you have a third person to assist in this procedure.

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

43

Page 48

Rack-Mounting the Chassis

Installing the Switch

Warning

To prevent bodily injury when mounting or servicing this unit in a rack, you must take special precautions to

ensure that the system remains stable. The following guidelines are provided to ensure your safety:

• This unit should be mounted at the bottom of the rack if it is the only unit in the rack.

• When mounting this unit in a partially filled rack, load the rack from the bottom to the top with the

heaviest component at the bottom of the rack.

If the rack is provided with stabilizing devices, install the stabilizers before mounting or servicing the

unit in the rack.

Statement 1006

To install the switch chassis in the equipment rack, perform these steps:

Before you begin

• Install the shelf kit L brackets on the chassis and the shelf brackets and crossbar on the rack posts.

• Install the cable guide.

Procedure

Step 1 Pull out all four of the handholds on the chassis.

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

44

Page 49

Installing the Switch

Rack-Mounting the Chassis

Figure 19: Chassis handholds

1

--All four of the chassis handholds pulled out and the

back end of the chassis resting on the edges of the

shelf bracket rails.

Step 2 With a person standing at each side of the chassis, insert one hand into each handhold. Slowly lift the chassis.

Avoid sudden twists or moves to prevent injury.

Step 3 Rest the back end of the chassis on the edges of the shelf bracket rails and slide it in until the first pair of

handles on both sides of the chassis are near the rack posts.

Step 4 Push in the handholds that are closest to the rack posts.

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

45

Page 50

Rack-Mounting the Chassis

Figure 20: Sliding the Chassis in - Part 1

Installing the Switch

1

--Handholds closest to the rack posts, pushed

in.

Step 5 Continue sliding the chassis in until the second pair of handholds are near the rack posts. Push in the second

pair of handholds.

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

46

Page 51

Installing the Switch

Rack-Mounting the Chassis

Figure 21: Sliding the Chassis in - Part 2

Second pair of handholds, pushed in.1

Step 6 Continue sliding the chassis rests completely on the shelf brackets and the crossbar. Slide in further until the

L brackets make contact with the rack posts.

Step 7 Secure the chassis to the rack with either the 10-32 or 12-24 pan head screws from the chassis standard

accessory kit.

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

47

Page 52

Rack-Mounting the Chassis

Figure 22: Securing the Chassis to the Rack Posts

Installing the Switch

10-32 or 12-24pan head screws1

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

48

Page 53

Installing the Switch

Rack-Mounting the Chassis

Figure 23: Chassis Secured to the Rack Posts

What to do next

After installing the chassis in its location, complete the installation process by:

1. Connecting the chassis to system ground.

2. Installing and connecting the power supplies to the power source.

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

49

Page 54

Install the Switch in NEBS-Compliant Mode

3. Connecting the network interface cables to the supervisor module and line card modules. This may involve

installing transceivers before you attach the network interface cables.

4. Powering up the chassis and verifying the installation.

Install the Switch in NEBS-Compliant Mode

NEBS-Compliant Air Filter

A Network Equipment-Building System (NEBS) compliant installation allows filtered, front-to-rear airflow.

To mount the chassis in a NEBS-compliant mode with the air filter, use a 23-inch rack mount. Filter brackets

that are mounted on the side of the chassis hold the air filter.

A 23-inch rack mount is used for mounting the switch in a standard 23 inch (58.4 cm) equipment rack with

two unobstructed outer posts. This kit is not suitable for racks with obstructions (such as a power strip) that

could impair access to the field-replaceable units (FRUs) of the switch.

Installing the Switch

Rack-Mounting the Chassis in NEBS-Compliant Mode

Warning

Warning

Take care when connecting units to the supply circuit so that wiring is not overloaded. Statement 1018

To prevent the system from overheating, do not operate it in an area that exceeds the maximum recommended

ambient temperature of 40°C. Statement 1047

Before you begin

• Read Safety Warnings carefully before starting with any installation procedure to make sure you understand

the hazards and precautions.

• Place the chassis on the floor or on a sturdy table as close as possible to the rack. Leave enough clearance

to allow you to move around the chassis.

• Open the rack-mount kit and verify that all parts are included.

Note

Some equipment racks provide a power strip along the length of one of the rear posts. If your rack has this

feature, consider the position of the strip when planning fastener points. Before installing the brackets on the

chassis, determine whether to install the chassis from the front or the rear of the rack.

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

50

Page 55

Installing the Switch

Step 1 Remove and discard the mounting ears and the ten mounting screws of the chassis. Do not reuse them during

Rack-Mounting the Chassis in NEBS-Compliant Mode

Procedure

any part of the installation process.

Figure 24: Remove the Mounting Ears

Mounting screws1

Step 2 Install the rack ear brackets on the left and right sides of the chassis. These brackets connect the chassis to

the rack.

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

51

Page 56

Rack-Mounting the Chassis in NEBS-Compliant Mode

Figure 25: Install the Rack Ear Brackets

Installing the Switch

1

brackets

Step 3 Install the filter brackets.

Rack ear brackets2Screws to secure the rack ear

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

52

Page 57

Installing the Switch

Rack-Mounting the Chassis in NEBS-Compliant Mode

Figure 26: Install the Filter Brackets

M3x6mm flat head screws1

Step 4 Install the right and the left wall covers.

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

53

Page 58

Rack-Mounting the Chassis in NEBS-Compliant Mode

Figure 27: Install the Wall Covers

Installing the Switch

M4x12mm pan head screws2M4x5mm flat head screws1

Step 5 Secure the chassis to the rack with either 10-32 or 12-24 pan head screws from the chassis standard accessory

kit.

Figure 28: Secure the Chassis to Rack

10-32 or 12-24 pan head screws1

Step 6 Align the air filter with the top and the bottom edges of the air filter slot.

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

54

Page 59

Installing the Switch

Rack-Mounting the Chassis in NEBS-Compliant Mode

Step 7 Insert the air filter into its housing with the arrows pointing toward the chassis. The arrows on the top edge

of the air filter note the direction of airflow. Airflow direction is from right to left, when you stand facing the

chassis.

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

55

Page 60

Rack-Mounting the Chassis in NEBS-Compliant Mode

Figure 29: NEBS-Compliant Air Filter

Installing the Switch

Note

We recommend that you change the air filter every 3 months. However, examine the air filter once

a month (or more often in dusty environments) and replace it if it appears to be excessively dirty

or damaged. To comply with Telecordia GR-63-Core standard air filter requirements for NEBS

deployments, the air filter must be replaced, not cleaned.

Step 8 Install the top and base covers as shown in the illustrations:

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

56

Page 61

Installing the Switch

Establishing System Ground

Figure 30: Top Cover and Base Cover

10-32 or 12-24 pan head screws1

Establishing System Ground

To attach the grounding lug and cable to the grounding pad, perform these steps:

Cisco Catalyst 9600 Series Switches Hardware Installation Guide

57

Page 62

Establishing System Ground

Before you begin

Installing the Switch

Warning

Warning

Warning

Warning

Before performing any of the following procedures, ensure that power is removed from the DC circuit.

Statement 1003

Use copper conductors only. Statement 1025

When stranded wiring is required, use approved wiring terminations, such as closed-loop or spade-type with