Page 1

Catalyst 6800IA Switch Hardware Installation Guide

First Published: 2013-09-23

Last Modified: 2014-07-28

Americas Headquarters

Cisco Systems, Inc.

170 West Tasman Drive

San Jose, CA 95134-1706

USA

http://www.cisco.com

Tel: 408 526-4000

800 553-NETS (6387)

Fax: 408 527-0883

Text Part Number: OL-30278-02

Page 2

THE SPECIFICATIONS AND INFORMATION REGARDING THE PRODUCTS IN THIS MANUAL ARE SUBJECT TO CHANGE WITHOUT NOTICE. ALL STATEMENTS,

INFORMATION, AND RECOMMENDATIONS IN THIS MANUAL ARE BELIEVED TO BE ACCURATE BUT ARE PRESENTED WITHOUT WARRANTY OF ANY KIND,

EXPRESS OR IMPLIED. USERS MUST TAKE FULL RESPONSIBILITY FOR THEIR APPLICATION OF ANY PRODUCTS.

THE SOFTWARE LICENSE AND LIMITED WARRANTY FOR THE ACCOMPANYING PRODUCT ARE SET FORTH IN THE INFORMATION PACKET THAT SHIPPED WITH

THE PRODUCT AND ARE INCORPORATED HEREIN BY THIS REFERENCE. IF YOU ARE UNABLE TO LOCATE THE SOFTWARE LICENSE OR LIMITED WARRANTY,

CONTACT YOUR CISCO REPRESENTATIVE FOR A COPY.

The following information is for FCC compliance of Class A devices: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15

of the FCC rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio-frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference, in which case users will be required to correct the interference at their own expense.

The following information is for FCC compliance of Class B devices: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15

of the FCC rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference

will not occur in a particular installation. If the equipment causes interference to radio or television reception, which can be determined by turning the equipment off and on, users are

encouraged to try to correct the interference by using one or more of the following measures:

Reorient or relocate the receiving antenna.

•

Increase the separation between the equipment and receiver.

•

Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

•

Consult the dealer or an experienced radio/TV technician for help.

•

Modifications to this product not authorized by Cisco could void the FCC approval and negate your authority to operate the product

The Cisco implementation of TCP header compression is an adaptation of a program developed by the University of California, Berkeley (UCB) as part of UCB’s public domain version

of the UNIX operating system. All rights reserved. Copyright©1981, Regents of the University of California.

NOTWITHSTANDING ANY OTHER WARRANTY HEREIN, ALL DOCUMENT FILES AND SOFTWARE OF THESE SUPPLIERS ARE PROVIDED "AS IS" WITH ALL FAULTS.

CISCO AND THE ABOVE-NAMED SUPPLIERS DISCLAIM ALL WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING, WITHOUT LIMITATION, THOSE OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE AND NONINFRINGEMENT OR ARISING FROM A COURSE OF DEALING, USAGE, OR TRADE PRACTICE.

IN NO EVENT SHALL CISCO OR ITS SUPPLIERS BE LIABLE FOR ANY INDIRECT, SPECIAL, CONSEQUENTIAL, OR INCIDENTAL DAMAGES, INCLUDING, WITHOUT

LIMITATION, LOST PROFITS OR LOSS OR DAMAGE TO DATA ARISING OUT OF THE USE OR INABILITY TO USE THIS MANUAL, EVEN IF CISCO OR ITS SUPPLIERS

HAVE BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

Any Internet Protocol (IP) addresses and phone numbers used in this document are not intended to be actual addresses and phone numbers. Any examples, command display output, network

topology diagrams, and other figures included in the document are shown for illustrative purposes only. Any use of actual IP addresses or phone numbers in illustrative content is unintentional

and coincidental.

Cisco and the Cisco logo are trademarks or registered trademarks of Cisco and/or its affiliates in the U.S. and other countries. To view a list of Cisco trademarks, go to this URL: http://

www.cisco.com/go/trademarks. Third-party trademarks mentioned are the property of their respective owners. The use of the word partner does not imply a partnership

relationship between Cisco and any other company. (1110R)

©

2013 – 2014 Cisco Systems, Inc. All rights reserved.

Page 3

CONTENTS

Preface

CHAPTER 1

Preface vii

Document Conventions vii

Related Documentation ix

Obtaining Documentation and Submitting a Service Request ix

Product Overview 1

Switch Models 1

Front Panel 2

PoE and PoE+ Ports 3

10/100/1000 Ports 3

Management Ports 3

SFP+ Module Slots 4

LEDs 4

System LED 6

RPS LED 6

IRPS LED 6

Master LED 7

Port LEDs and Modes 7

STACK LED 9

Console LEDs 10

Ethernet Management Port LED 11

Rear Panel 11

FlexStack-Plus Ports and LEDs 13

RPS Connector 13

Cisco RPS 2300 14

AC Power Connector 14

Power Supply Modules (Applies to the Catalyst 6800IA-48FPDR Switches) 14

OL-30278-02 iii

Catalyst 6800IA Switch Hardware Installation Guide

Page 4

Contents

CHAPTER 2

Switch Installation 17

Safety Warnings 17

Tools and Equipment 20

Installation Guidelines 20

Verifying Switch Operation 21

Planning and Installing a Switch Stack (Optional) 21

Stack Guidelines 21

Stack Cabling 22

Stack Bandwidth and Partitioning Examples 25

Power-On Sequence for Switch Stacks 26

Installing the Switch 26

Rack-Mounting 26

Attaching the Rack-Mount Brackets 28

Mounting in a Rack 29

Wall-Mounting 31

Attaching the Brackets for Wall-Mounting 31

Attaching the RPS Connector Cover 31

Mounting on a Wall 32

Installing the Switch on a Table or Shelf 34

After Switch Installation 34

Connecting FlexStack-Plus modules (Optional) 34

Removing a FlexStack Cable 35

Installing the Power Cord Retainer (Optional) 36

Installing SFP Modules 38

Installing an SFP or SFP+ Module 38

Removing an SFP Module 40

Connecting to SFP and SFP+ Modules 40

Connecting to Fiber-Optic SFP and SFP+ Modules 40

Connecting to 1000BASE-T SFP 41

10/100/1000 PoE and PoE+Port Connections 43

10/100/1000 Port Connections 44

Auto-MDIX Connections 44

Where to Go Next 44

Catalyst 6800IA Switch Hardware Installation Guide

iv OL-30278-02

Page 5

Contents

CHAPTER 3

CHAPTER 4

Power Supply Installation 45

Power Supply Module Overview 45

Installation Guidelines 47

Installing or Replacing an AC Power Supply 48

Finding the Serial Number 49

Troubleshooting 51

Diagnosing Problems 51

Switch POST Results 51

Switch LEDs 51

Switch Connections 51

Bad or Damaged Cable 51

Ethernet and Fiber-Optic Cables 52

Link Status 52

10/100/1000 Port Connections 52

10/100/1000 PoE+ Port Connections 53

APPENDIX A

APPENDIX B

SFP and SFP+ Module 53

Interface Settings 53

Ping End Device 54

Spanning Tree Loops 54

Switch Performance 54

Speed, Duplex, and Autonegotiation 54

Autonegotiation and Network Interface Cards 54

Cabling Distance 55

Finding the Serial Number 55

Technical Specifications 57

Environmental Specifications 57

Specifications for the Catalyst 6800IA Switches 58

Connector and Cable Specifications 61

Connector Specifications 61

10/100/1000 Ports (Including PoE) 61

SFP Module Connectors 62

OL-30278-02 v

Catalyst 6800IA Switch Hardware Installation Guide

Page 6

Contents

Cables and Adapters 62

SFP Module Cables 62

Cable Pinouts 64

Console Port Adapter Pinouts 65

Catalyst 6800IA Switch Hardware Installation Guide

vi OL-30278-02

Page 7

Preface

Document Conventions, page vii

•

Related Documentation, page ix

•

Obtaining Documentation and Submitting a Service Request, page ix

•

Document Conventions

This document uses the following conventions:

DescriptionConvention

^ or Ctrl

Italic font

...

|

[x | y]

Both the ^ symbol and Ctrl represent the Control (Ctrl) key on a keyboard. For

example, the key combination ^D or Ctrl-D means that you hold down the Control

key while you press the D key. (Keys are indicated in capital letters but are not

case sensitive.)

Commands and keywords and user-entered text appear in bold font.bold font

Document titles, new or emphasized terms, and arguments for which you supply

values are in italic font.

Terminal sessions and information the system displays appear in courier font.Courier font

Bold Courier font indicates text that the user must enter.Bold Courier font

Elements in square brackets are optional.[x]

An ellipsis (three consecutive nonbolded periods without spaces) after a syntax

element indicates that the element can be repeated.

A vertical line, called a pipe, indicates a choice within a set of keywords or

arguments.

Optional alternative keywords are grouped in brackets and separated by vertical

bars.

OL-30278-02 vii

Catalyst 6800IA Switch Hardware Installation Guide

Page 8

Document Conventions

Preface

DescriptionConvention

Note

{x | y}

Required alternative keywords are grouped in braces and separated by vertical

bars.

[x {y | z}]

Nested set of square brackets or braces indicate optional or required choices

within optional or required elements. Braces and a vertical bar within square

brackets indicate a required choice within an optional element.

string

A nonquoted set of characters. Do not use quotation marks around the string or

the string will include the quotation marks.

Nonprinting characters such as passwords are in angle brackets.< >

Default responses to system prompts are in square brackets.[ ]

!, #

An exclamation point (!) or a pound sign (#) at the beginning of a line of code

indicates a comment line.

Reader Alert Conventions

This document may use the following conventions for reader alerts:

Means reader take note. Notes contain helpful suggestions or references to material not covered in the

manual.

Tip

Caution

Timesaver

Warning

Means the following information will help you solve a problem.

Means reader be careful. In this situation, you might do something that could result in equipment damage

or loss of data.

Means the described action saves time. You can save time by performing the action described in the

paragraph.

IMPORTANT SAFETY INSTRUCTIONS

This warning symbol means danger. You are in a situation that could cause bodily injury. Before you

work on any equipment, be aware of the hazards involved with electrical circuitry and be familiar with

standard practices for preventing accidents. Use the statement number provided at the end of each warning

to locate its translation in the translated safety warnings that accompanied this device. Statement 1071

SAVE THESE INSTRUCTIONS

Catalyst 6800IA Switch Hardware Installation Guide

viii OL-30278-02

Page 9

Preface

Related Documentation

Related Documentation

Cisco SFP modules documentation, including compatibility matrixes, located at:

•

http://www.cisco.com/en/US/products/hw/modules/ps5455/tsd_products_support_series_home.html

Cisco Validated Designs documents at this URL:

•

http://www.cisco.com/go/designzone

Obtaining Documentation and Submitting a Service Request

For information on obtaining documentation, submitting a service request, and gathering additional information,

see the monthly What's New in Cisco Product Documentation, which also lists all new and revised Cisco

technical documentation, at:

http://www.cisco.com/c/en/us/td/docs/general/whatsnew/whatsnew.html

Subscribe to the What's New in Cisco Product Documentation as a Really Simple Syndication (RSS) feed

and set content to be delivered directly to your desktop using a reader application. The RSS feeds are a free

service and Cisco currently supports RSS version 2.0.

OL-30278-02 ix

Catalyst 6800IA Switch Hardware Installation Guide

Page 10

Obtaining Documentation and Submitting a Service Request

Preface

Catalyst 6800IA Switch Hardware Installation Guide

x OL-30278-02

Page 11

Product Overview

The Catalyst 6800IA switches are Ethernet switches to which you can connect devices such as Cisco IP

Phones, Cisco Wireless Access Points, workstations, and other network devices such as servers, routers, and

other switches.

The switches support stacking through the Cisco FlexStack technology. Unless otherwise noted, the term

switch refers to a standalone switch and to a switch stack.

This chapter contains these topics:

Switch Models, page 1

•

Front Panel, page 2

•

Rear Panel, page 11

•

Switch Models

CHAPTER 1

Table 1: Catalyst 6800IA Switch Models and Descriptions

Catalyst

6800IA-48FPDR

6800IA-48FPD

6800IA-48TD

1

SFP+ = 10-Gigabit uplink.

OL-30278-02 1

DescriptionSwitch Model

48 10/100/1000 Power over Ethernet Plus (PoE+) ports (PoE budget of 740 W) and 2

small form-factor pluggable (SFP)+1module slots, 1025-W power supply.

48 10/100/1000 PoE+ ports (PoE budget of 740 W) and 2 SFP+ module slots.Catalyst

48 10/100/1000 ports and 2 SFP+ module slots.Catalyst

Catalyst 6800IA Switch Hardware Installation Guide

Page 12

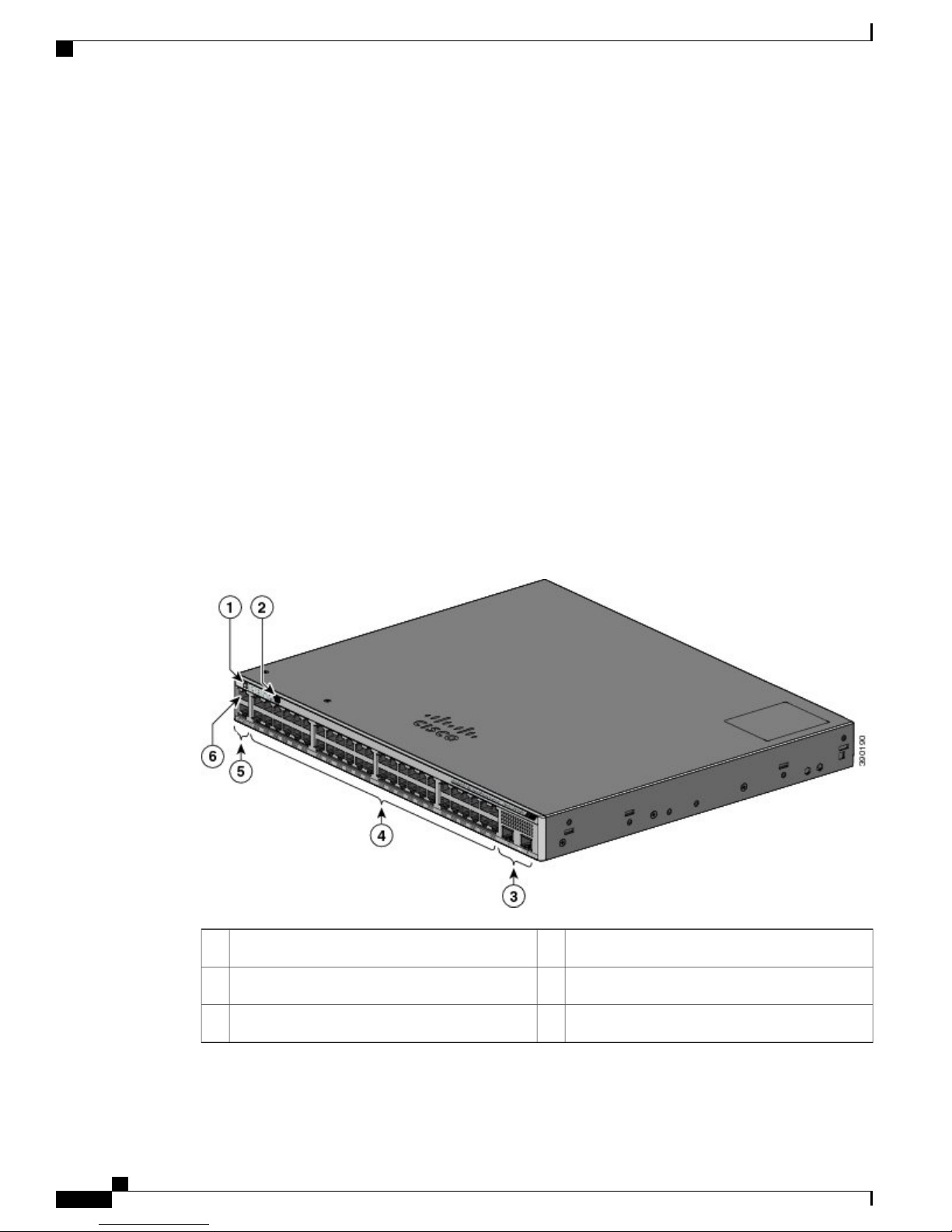

Front Panel

Front Panel

This section describes the front panel components:

48 downlink ports of one of these types:

•

10/100/1000

◦

10/100/1000 PoE+

◦

SFP+ ports

•

USB mini-Type B (console) port

•

Ethernet management port

•

RJ-45 console port

•

LEDs

•

Mode button

•

Product Overview

The Catalyst 6800IA-48FPD switch is shown here as an example. Other switches have similar components.

Figure 1: Catalyst 6800IA-48FPD Front Panel

10/100/1000 PoE+ ports4Mode button and switch LEDs1

Catalyst 6800IA Switch Hardware Installation Guide

2 OL-30278-02

RJ-45 console port5USB mini-Type B (console) port2

Ethernet management port6SFP+ module slots3

Page 13

Product Overview

PoE and PoE+ Ports

The ports provide PoE+ support for devices compliant with IEEE 802.3af, IEEE 802.3at, and ePoE and also

provide Cisco prestandard PoE support for Cisco IP Phones and Cisco Aironet Access Points.

The maximum switch power output is 740 W. Intelligent power management allows flexible power allocation

across all ports.

For switches with a 740 W power budget, you can budget the PoE and PoE+:

15.4 W of PoE output on 48 ports

•

30 W of PoE+ on 24 ports

•

On a per-port basis, you control whether or not a port automatically provides power when an IP phone or an

access point is connected.

The PoE ports use RJ-45 connectors with Ethernet pinouts. The maximum cable length is 328 feet (100 meters).

The 10BASE-T, 100BASE-TX, 1000BASE-T traffic requires Category 5, Category 5e, or Category 6 unshielded

twisted pair (UTP) cable. The 10BASE-T traffic can use Category 3 or Category 4 UTP cable.

Cisco intelligent power management capabilities include enhanced power negotiation, power reservation, and

per-port power policing. For information about configuring and monitoring PoE ports, see the switch software

configuration guide on Cisco.com.

PoE and PoE+ Ports

The output of the PoE circuit has been evaluated as a Limited Power Source (LPS) per IEC 60950-1.Note

10/100/1000 Ports

The 10/100/1000 ports use RJ-45 connectors with Ethernet pinouts. The maximum cable length is 328 feet

(100 meters). The 10BASE-T, 100BASE-TX, 1000BASE-T traffic requires Category 5 or Category 5e twisted

pair (UTP) cable. The 10BASE-T traffic can use Category 3 or Category 4 UTP cable.

Management Ports

The management ports connect the switch to a PC running Microsoft Windows or to a terminal server.

Ethernet management port.

•

RJ-45 console port (EIA/TIA-232).

•

USB mini-Type B console port (5-pin connector).

•

The 10/100 Ethernet management port connection uses a standard RJ-45 crossover or straight-through cable.

The RJ-45 console port connection uses the supplied RJ-45-to-DB-9 female cable. The USB console port

connection uses a USB Type A to 5-pin mini-Type B cable. The USB console interface speeds are the same

as the RJ-45 console interface speeds.

OL-30278-02 3

Catalyst 6800IA Switch Hardware Installation Guide

Page 14

SFP+ Module Slots

Product Overview

If you use the USB mini-Type B console port, the Cisco Windows USB device driver must be installed on

any PC connected to the console port (for operation with Microsoft Windows). Mac OS X or Linux do not

require special drivers.

The 4-pin mini-Type B connector resembles the 5-pin mini-Type B connectors. They are not compatible. Use

only the 5-pin mini-Type B.

This illustration shows a 5-pin mini-Type B USB port.

Figure 2: USB Mini-Type B Port

With the Cisco Windows USB device driver, you can connect and disconnect the USB cable from the console

port without affecting Windows HyperTerminal operations.

The console output always goes to both the RJ-45 and the USB console connectors, but the console input is

active on only one of the console connectors at any one time. The USB console takes precedence over the

RJ-45 console. When a cable is connected into the USB console port, the RJ-45 console port becomes inactive.

Conversely, when the USB cable is disconnected from the USB console port, the RJ-45 port becomes active.

You can use the command-line interface (CLI) to configure an inactivity timeout which reactivates the RJ-45

console if the USB console has been activated and no input activity has occurred on the USB console for a

specified time.

After the USB console deactivates due to inactivity, you cannot use the CLI to reactivate it. Disconnect and

reconnect the USB cable to reactivate the USB console. For information on using the CLI to configure the

USB console interface, see the software guide.

SFP+ Module Slots

The switch has two 10-Gigabit SFP+ module slots that support both SFP and SFP+ modules.

For Cisco SFP and SFP+ modules documentation, including compatibility matrixes, refer to this URL: http:/

/www.cisco.com/en/US/products/hw/modules/ps5455/products_device_support_tables_list.html

LEDs

You can use the switch LEDs to monitor switch activity and its performance.

Catalyst 6800IA Switch Hardware Installation Guide

4 OL-30278-02

Page 15

Product Overview

LEDs

This figure shows the switch LEDs and the Mode button that you use to select a port mode.

Figure 3: Switch LEDs and Mode Button for the Catalyst 6800IA Switches

OL-30278-02 5

STACK LED7RPS2or IRPS3LED1

8SPEED LED2

PoE LED

4

USB mini-Type B console port LED9STAT LED3

MGMT LED10SYS LED4

CONSOLE LED11Mode button5

Port LEDs12Master LED6

Catalyst 6800IA Switch Hardware Installation Guide

Page 16

LEDs

2

RPS = redundant power system

3

IRPS = inline redundant power system

4

only on switch models that support PoE.

System LED

Table 2: System LED

Product Overview

System StatusColor

System is not powered on.Off

System is operating normally.Green

POST in progress.Blinking green

System is receiving power but is not functioning properly.Amber

RPS LED

System is sleep mode.Blinking amber

The RPS LED is only available on switch models that have an RPS port (Catalyst 6800IA-48FPD and

6800IA-48TD switches).

Table 3: RPS LED

RPS StatusColor

RPS is off or not properly connected.Off

RPS is connected and can provide back-up power.Green

Blinking green

RPS is connected but is unavailable. It is providing power to another device (redundancy

has been allocated to the other device).

The RPS is in standby mode or in a fault condition. See the RPS documentation.Amber

Blinking amber

The power supply in a switch has failed, and the RPS is providing power to the switch

(redundancy has been allocated to this device).

IRPS LED

The IRPS LED is only available on the Catalyst 6800IA-48FPDR switch.

Catalyst 6800IA Switch Hardware Installation Guide

6 OL-30278-02

Page 17

Product Overview

Master LED

LEDs

Table 4: IRPS LED

RPS StatusColor

Second power supply is not present.Off

Both power supplies are present and operating.Green

The second power supply is present, but the input is not connected.Amber

The second power supply is present, but the signal is faulty.Blinking amber

This table describes the master LEDs.

Table 5: Master LED

Amber

Port LEDs and Modes

The port and module slots each has a port LED. As a group or individually, the LEDs show information about

the switch and about the ports.

Table 6: Port Mode LEDs

STACK

DescriptionPort Mode

Switch is not the stack master.Off

Switch is the stack master or a standalone switch.Green

An error occurred when the stack was electing the stack master switch, or another type of

stack error occurred.

DescriptionPort ModeMode LED

The port status. This is the default mode.Port statusSTAT

The port operating speed: 10, 100, 1000 Mb/s, or 10 Gb/s.Port speedSPEED

Stack member status

Stack port status

The stack member status.

The stack port status.

OL-30278-02 7

The PoE status.PoE port powerPoE

Catalyst 6800IA Switch Hardware Installation Guide

Page 18

LEDs

Product Overview

To select or change a mode, press the Mode button until the desired mode is highlighted. When you change

port modes, the meanings of the port LED colors also change.

Table 7: Meanings of LED Colors in Different Modes

MeaningPort LED ColorPort Mode

STAT (port

status)

OffPoE

Green

Alternating

green and amber

Blinking amber

PoE is off. If the powered device is receiving power from an AC power

source, the port LED is off even if the powered device is connected to

the switch port.

PoE is on. The port LED is green only when the switch port is providing

power.

PoE is denied because providing power to the powered device will

exceed the switch power capacity.

PoE is off due to a fault.

Noncompliant cabling or powered devices can cause a PoE port fault.

Use only standard-compliant cabling to connect Cisco prestandard IP

Phones and wireless access points or IEEE 802.3af-compliant devices.

You must remove any cable or device that causes a PoE fault.

PoE for the port is disabled. (PoE is enabled by default.)Amber

No link or port was administratively shut down.Off

Link present.Green

Activity. Interface is sending or receiving data.Blinking green

Alternating

green-amber

Amber

Catalyst 6800IA Switch Hardware Installation Guide

8 OL-30278-02

Link fault. Error frames can affect connectivity, and errors such as

excessive collisions, cyclic redundancy check (CRC) errors, and

alignment and jabber errors are monitored for a link-fault indication.

Port is blocked by Spanning Tree Protocol (STP) and is not forwarding

data.

After a port is reconfigured, the port LED can remain amber for up to

30 seconds as STP searches the switch for possible loops.

Port is blocked by STP and is sending and receiving packets.Blinking amber

Page 19

Product Overview

LEDs

MeaningPort LED ColorPort Mode

10/100/1000 portsSPEED

Port is operating at 10 Mb/s.Off

Port is operating at 100 Mb/s.Green

Port is operating at 1000 Mb/s.Blinking green

SFP+ module ports

Port is not operating.Off

Port is operating at 10 Gb/s.Blinking green

Port is operating at 1 Gb/s.Green

Note

STACK LED

STACK (stack

No stack member has that member number.Off

member)

Stack member number.Blinking green

Member numbers of other stack member switches.Green

If your switches are stacked and you press the Mode button on any switch, all the switches display the same

selected mode. For example, if you press the Mode button on the stack master to display SPEED, all the other

stack members display SPEED.

If you press the Mode button for more than 3 seconds on any switch or the stack master, the switch enters

the Express Setup mode which will reset and reboot the FEX or the FEX stack. Express Setup is enabled

by default and you must disable it to prevent the switch from accidentally entering the Express Setup

mode. To disable Express Setup, Contact Cisco TAC.

Even if PoE mode is not selected, this LED still shows PoE problems if they are detected.

The STACK LED shows the sequence of member switches in a stack. Up to five switches can be members

of a stack. The first five port LEDs show the switch member number. For example, if you press the Mode

button and select Stack, the port LED 1 blinks green. The LEDs for port 2 and 3 are solid green, as these

represent the member numbers of other stack members. The other port LEDs are off because there are no

more members in the stack.

OL-30278-02 9

Catalyst 6800IA Switch Hardware Installation Guide

Page 20

LEDs

Product Overview

This figure shows the LEDs on the first switch, which is stack member number 1.

Figure 4: STACK LED

Console LEDs

Stack member 33Stack member 11

Stack member 22

When you select the STACK LED, the respective STACK LEDs are green when the stack ports (on the switch

rear panel) are up, and the respective Stack LEDs are amber when the ports are down. SFP+ module port

LEDs 1 and 2 on the switch show the status for stack ports 1 and 2, respectively.

If the port LEDs are green on all the switches in the stack, the stack is operating at full bandwidth. If any port

LED is not green, the stack is not operating at full bandwidth.

The console LEDs show which console port is in use. If you connect a cable to a console port, the switch

automatically uses that port for console communication. If you connect two console cables, the USB console

port has priority.

Table 8: RJ-45 and USB Console LEDs

DescriptionColorLED

GreenRJ-45 console port

RJ-45 console port is active.

When this LED is on, the USB console port LED is off.

Catalyst 6800IA Switch Hardware Installation Guide

10 OL-30278-02

The port is not active, and the USB console port is active.Off

Page 21

Product Overview

Rear Panel

DescriptionColorLED

Ethernet Management Port LED

Table 9: Ethernet Management Port LED

Rear Panel

GreenUSB console port

DescriptionColor

Active link to PC.Green

Inactive link.Off

POST failure.Amber

USB console port is active.

When this LED is on, the RJ-45 console port LED is off.

The port is not active, and the RJ-45 console port is active.Off

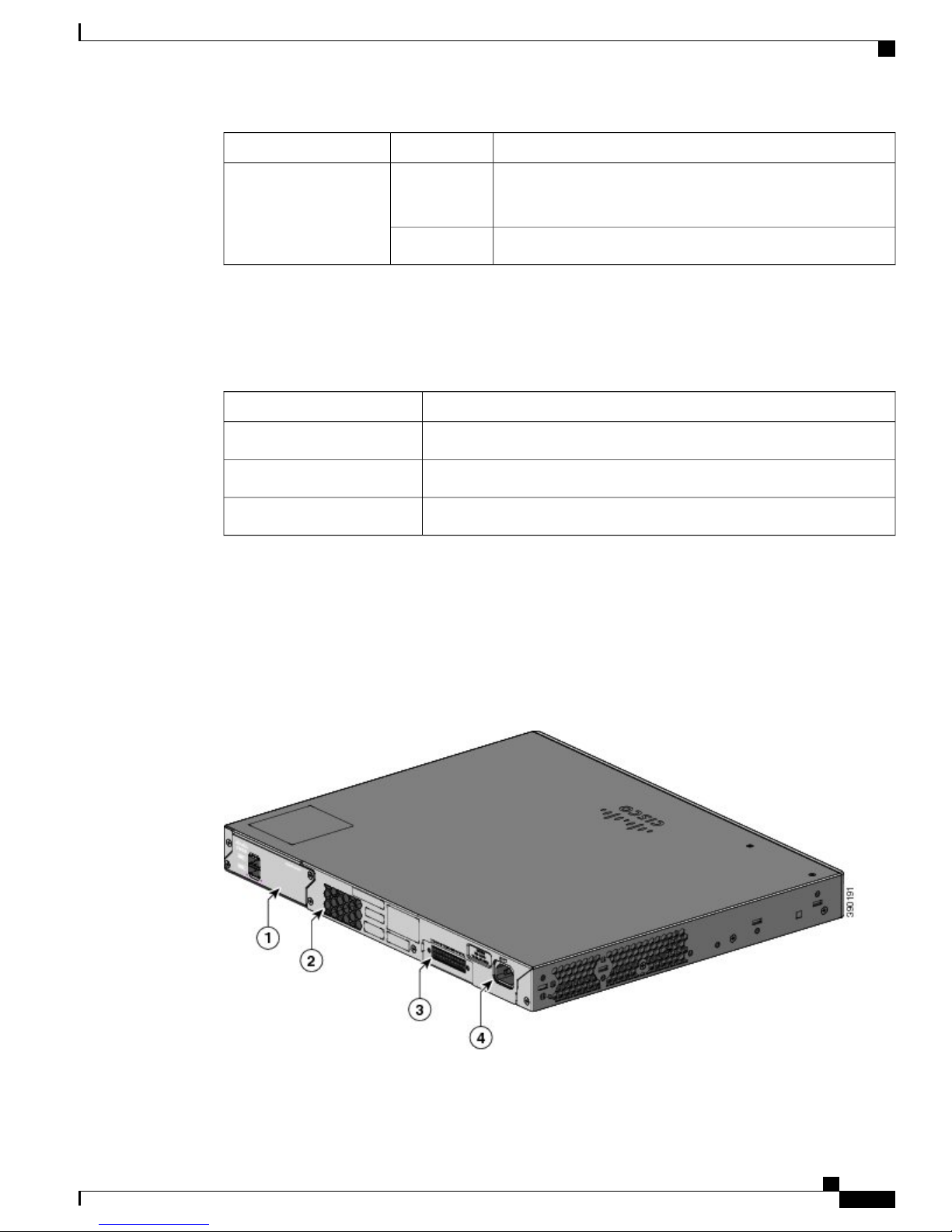

The rear panel of the Catalyst 6800IA-48FPD and 6800IA-48TD switches have FlexStack-Plus ports, a fan

exhaust, an RPS connector, and an AC power connector.

Figure 5: Catalyst 6800IA Switch Rear Panel

OL-30278-02 11

Catalyst 6800IA Switch Hardware Installation Guide

Page 22

Rear Panel

Product Overview

RPS Connector3FlexStack-Plus ports1

AC power connector4Fan Exhaust2

The rear panel of the Catalyst 6800IA-48FPDR switches have FlexStack-Plus ports and power supply module

slots.

Figure 6: Catalyst 6800IA Switch Rear Panel

PS OK LED4FlexStack-Plus ports1

AC power connector on the power supply module5Power supply slot (with blank module)2

AC OK LED3

Catalyst 6800IA Switch Hardware Installation Guide

12 OL-30278-02

Page 23

Product Overview

FlexStack-Plus Ports and LEDs

The Catalyst 6800IA switches support stacking with the FlexStack-Plus ports on the switch rear panel and a

0.5-meter FlexStack cable.

Figure 7: FlexStack-Plus Ports

FlexStack-Plus Ports and LEDs

Table 10: FlexStack-Plus Port LEDs

Table 11: Stack Configurations

RPS Connector

Switch

6800IA switches

LED for Stack port 22LED for Stack port 11

DescriptionColor

Port is active, cable is attached.Green

The port is not active, no cable is attached.Off

BandwidthNumber of Switches in

the Stack

80 G3Stack with Catalyst

The Cisco RPS 2300 (model PWR-RPS2300) supports the Catalyst 6800IA-48FPD and 6800IA-48TD switches

.

OL-30278-02 13

Catalyst 6800IA Switch Hardware Installation Guide

Page 24

AC Power Connector

Attach only the following Cisco RPS model to the RPS receptacle: RPS2300. Statement 370Warning

Connect the switch and the redundant power system to different AC power sources.

Use this cable for the RPS: CAB-RPS2300-E.

Cisco RPS 2300

The Cisco RPS 2300 is a redundant power system that can support six external network devices and provide

power to one or two failed devices at a time. It senses when the internal power supply of a connected device

fails and provides power to the failed device, preventing loss of network traffic. For more information, see

the Cisco Redundant Power System 2300 Hardware Installation Guide on Cisco.com at this URL: http://

www.cisco.com/en/US/products/ps7148/prod_installation_guides_list.html

The Cisco RPS 2300 has two output levels: –52 V and 12 V with a total maximum output power of 2300 W.

All supported and connected switches can simultaneously communicate with the RPS 2300. You can configure

these RPS 2300 features through the switch software:

Product Overview

Enable RPS active or standby mode for each connected switch

•

Configure switch priority for RPS support

•

List the connected switches and the power-supply module sizes

•

Obtain reports when a switch is powered by the RPS

•

Obtain status reports for the RPS power-supply module

•

Read and monitor backup, failure, and exception history

•

AC Power Connector

This applies to the Catalyst 6800IA-48FPD and Catalyst 6800IA-48TD switches.Note

The switch is powered through the internal power supply. The internal power supply is an autoranging unit

that supports input voltages between 100 and 240 VAC. Use the supplied AC power cord to plug it into an

AC power outlet.

Power Supply Modules (Applies to the Catalyst 6800IA-48FPDR Switches)

The switch operates with either one or two active power supply modules. You can use two AC modules, or

one module and a blank cover.

Table 12: Power Supply Model Numbers and Description

Catalyst 6800IA Switch Hardware Installation Guide

14 OL-30278-02

DescriptionPart Number

1025-W AC power supply module.PWR-C2-1025WAC=

Page 25

Product Overview

Power Supply Modules (Applies to the Catalyst 6800IA-48FPDR Switches)

The 1025-W power supply module is an autoranging unit that supports input voltages between 115 and 240

VAC. All power supply modules have internal fans. All switches ship with a blank cover in the second power

supply slot.

Table 13: Available PoE with Different Combinations of Power Supplies

Primary Power

Supply

PWR-C2-1025WAC=

Secondary Power

Supply

—

Available Power for

PoE+

Switch Power

Redundancy

No740 W

Available PoE

Power when One PS

Fails

—

740 WYes740 WPWR-C2-1025WAC=PWR-C2-1025WAC=

OL-30278-02 15

Catalyst 6800IA Switch Hardware Installation Guide

Page 26

Power Supply Modules (Applies to the Catalyst 6800IA-48FPDR Switches)

Product Overview

Catalyst 6800IA Switch Hardware Installation Guide

16 OL-30278-02

Page 27

Switch Installation

Safety Warnings, page 17

•

Tools and Equipment, page 20

•

Installation Guidelines, page 20

•

Verifying Switch Operation, page 21

•

Planning and Installing a Switch Stack (Optional), page 21

•

Installing the Switch, page 26

•

Connecting FlexStack-Plus modules (Optional), page 34

•

Installing the Power Cord Retainer (Optional), page 36

•

Installing SFP Modules, page 38

•

Connecting to SFP and SFP+ Modules, page 40

•

10/100/1000 PoE and PoE+Port Connections, page 43

•

CHAPTER 2

10/100/1000 Port Connections, page 44

•

Where to Go Next, page 44

•

Safety Warnings

This section includes the basic installation caution and warning statements. Read this section before you start

the installation procedure. Translations of the warning statements appear in the RCSI guide on Cisco.com.

Warning

OL-30278-02 17

Before working on equipment that is connected to power lines, remove jewelry (including rings, necklaces,

and watches). Metal objects will heat up when connected to power and ground and can cause serious burns

or weld the metal object to the terminals. Statement 43

Catalyst 6800IA Switch Hardware Installation Guide

Page 28

Safety Warnings

Switch Installation

Warning

Warning

Warning

Warning

Warning

Do not stack the chassis on any other equipment. If the chassis falls, it can cause severe bodily injury and

equipment damage. Statement 48

This product must be connected to a power-over-ethernet (PoE) IEEE 802.3af compliant power source or

an IEC60950 compliant limited power source. Statement 353

Read the wall-mounting instructions carefully before beginning installation. Failure to use the correct

hardware or to follow the correct procedures could result in a hazardous situation to people and damage

to the system. Statement 378

Attach only the following Cisco external power system to the switch: PWR-RPS2300 Statement 387

Do not work on the system or connect or disconnect cables during periods of lightning activity. Statement

1001

Read the installation instructions before connecting the system to the power source. Statement 1004Warning

Warning

Warning

To prevent bodily injury when mounting or servicing this unit in a rack, you must take special precautions

to ensure that the system remains stable. The following guidelines are provided to ensure your safety:

This unit should be mounted at the bottom of the rack if it is the only unit in the rack.

•

When mounting this unit in a partially filled rack, load the rack from the bottom to the top with the

•

heaviest component at the bottom of the rack.

If the rack is provided with stabilizing devices, install the stabilizers before mounting or servicing

•

the unit in the rack.

Statement 1006

Class 1 laser product. Statement 1008Warning

This unit is intended for installation in restricted access areas. A restricted access area can be accessed

only through the use of a special tool, lock and key, or other means of security. Statement 1017

Catalyst 6800IA Switch Hardware Installation Guide

18 OL-30278-02

Page 29

Switch Installation

Safety Warnings

Warning

Warning

Warning

Warning

Warning

The plug-socket combination must be accessible at all times, because it serves as the main disconnecting

device. Statement 1019

This equipment must be grounded. Never defeat the ground conductor or operate the equipment in the

absence of a suitably installed ground conductor. Contact the appropriate electrical inspection authority

or an electrician if you are uncertain that suitable grounding is available. Statement 1024

This unit might have more than one power supply connection. All connections must be removed to

de-energize the unit. Statement 1028

Only trained and qualified personnel should be allowed to install, replace, or service this equipment.

Statement 1030

Ultimate disposal of this product should be handled according to all national laws and regulations. Statement

1040

Warning

Warning

Warning

Warning

For connections outside the building where the equipment is installed, the following ports must be connected

through an approved network termination unit with integral circuit protection: 10/100/1000 Ethernet.

Statement 1044

When installing or replacing the unit, the ground connection must always be made first and disconnected

last. Statement 1046

To prevent the system from overheating, do not operate it in an area that exceeds the maximum

recommended ambient temperature of: <113°F (45°C). Statement 1047

This warning symbol means danger. You are in a situation that could cause bodily injury. Before you

work on any equipment, be aware of the hazards involved with electrical circuitry and be familiar with

standard practices for preventing accidents. Use the statement number provided at the end of each warning

to locate its translation in the translated safety warnings that accompanied this device. Statement 1071

OL-30278-02 19

Catalyst 6800IA Switch Hardware Installation Guide

Page 30

Tools and Equipment

Switch Installation

Warning

Warning

Voltages that present a shock hazard may exist on Power over Ethernet (PoE) circuits if interconnections

are made using uninsulated exposed metal contacts, conductors, or terminals. Avoid using such

interconnection methods, unless the exposed metal parts are located within a restricted access location

and users and service people who are authorized within the restricted access location are made aware of

the hazard. A restricted access area can be accessed only through the use of a special tool, lock and key

or other means of security. Statement 1072

No user-serviceable parts inside. Do not open. Statement 1073Warning

Installation of the equipment must comply with local and national electrical codes. Statement 1074Warning

To prevent airflow restriction, allow clearance around the ventilation openings to be at least: 3 inches (7.6

cm). Statement 1076

Hot surface. Statement 1079Warning

Tools and Equipment

Obtain these necessary tools:

A Number-2 Phillips screwdriver to rack-mount the switch

•

Installation Guidelines

When determining where to install the switch, verify that these guidelines are met:

Clearance to the switch front and rear panel meets these conditions:

•

Front-panel LEDs can be easily read.

◦

Access to ports is sufficient for unrestricted cabling.

◦

AC power cord can reach from the AC power outlet to the connector on the switch rear panel.

◦

Cabling is away from sources of electrical noise, such as radios, power lines, and fluorescent lighting

•

fixtures. Make sure that the cabling is safely away from other devices that might damage the cables.

Airflow around the switch and through the vents is unrestricted.

•

Temperature around the unit does not exceed 113°F (45°C). If the switch is installed in a closed or

•

multirack assembly, the temperature around it might be greater than normal room temperature.

Catalyst 6800IA Switch Hardware Installation Guide

20 OL-30278-02

Page 31

Switch Installation

Humidity around the switch does not exceed percent.

•

Altitude at the installation site is not greater than 10,000 feet.

•

For 10/100/1000 fixed ports, the cable length from a switch to a connected device cannot exceed 328

•

feet (100 meters).

Cooling mechanisms, such as fans and blowers in the switch, can draw dust and other particles causing

•

contaminant buildup inside the chassis, which can result in system malfunction. You must install this

equipment in an environment as free from dust and foreign conductive material (such as metal flakes

from construction activities) as is possible.

Verifying Switch Operation

Before you install the switch in a rack, on a wall, or on a table or shelf, power on the switch and verify that

it passes POST.

To power on the switch, plug one end of the AC power cord into the switch AC power connector, and plug

the other end into an AC power outlet.

As the switch powers on, it begins the POST, a series of tests that runs automatically to ensure that the switch

functions properly. LEDs can blink during the test. POST lasts approximately 1 minute. The SYST LED

blinks green, and the other LEDs remain solid green.

When the switch completes POST successfully, the SYST LED remains green. The RPS LED remains green

for some time and then reflects the switch operating status. The other LEDs turn off and then reflect the switch

operating status. If a switch fails POST, the SYST LED turns amber.

POST failures are usually fatal. Call Cisco technical support representative if your switch fails POST.

After a successful POST, unplug the power cord from the switch and install the switch in a rack, on a wall,

on a table, or on a shelf.

Verifying Switch Operation

If your configuration has an RPS, connect the switch and the RPS to different AC power sources. See the

Cisco RPS documentation for information.

Note

Warning

When you connect the RPS to the switch, put the RPS in standby mode. Set the RPS to active mode during

normal operation.

Attach only the following Cisco external power system to the switch: Cisco XPS 2200 Statement 387

Planning and Installing a Switch Stack (Optional)

Stack Guidelines

Order the appropriate cable from your Cisco sales representative. The length of FlexStack cable depends

•

on your configuration. These are the different sizes available:

OL-30278-02 21

Catalyst 6800IA Switch Hardware Installation Guide

Page 32

Stack Cabling

Stack Cabling

Switch Installation

CAB-STK-E-0.5M= (0.5-meter cable)

◦

CAB-STK-E-1M= (1-meter cable)

◦

CAB-STK-E-3M= (3-meter cable)

◦

Make sure that you have access to the switch rear panel and to the rear of the rack.

•

Stacking using FlexStack-Plus Modules

These figures show the switches stacked in a vertical rack or on a table. The connections are redundant.A

Catalyst 6800IA-48FPD switch is shown in the examples, the Catalyst 6800IA-48FPDR switch can be stacked

the same way.

Figure 8: Stacking Switches with the 0.5-meter FlexStack Cable

Figure 9: Stacking Switches with 0.5-meter and 3-meter FlexStack Cables

Stacking using FlexStack-Extended Modules

This section explains the supported stacking topologies using FlexStack-Extended Modules.

Catalyst 6800IA Switch Hardware Installation Guide

22 OL-30278-02

Page 33

Switch Installation

Stack Cabling

The following topology is created by stacking switches with FlexStack-Extended Fiber modules that are

deployed across different floors of a building. The SFP+ module ports are connected using fiber cables.

Figure 10: Stacking with FlexStack-Extended Fiber Modules Across Floors of a Building

The following topology is created by stacking switches with FlexStack-Extended Fiber modules that are

deployed across multiple buildings of a campus and different floors of a building.

Figure 11: Stacking with FlexStack-Extended Fiber Modules Across Floors and Buildings

Using FlexStack-Extended Hybrid module, you can combine existing stack of switches and new switches

spread across multiple wiring closets into one single stack. To achieve this, the copper port on the

FlexStack-Extended Hybrid module should be connected to the FlexStack-Plus port on a switch in your

OL-30278-02 23

Catalyst 6800IA Switch Hardware Installation Guide

Page 34

Stack Cabling

Switch Installation

existing network. The fiber port on the Cisco FlexStack-Extended Fiber module can be used to connect

switches over long distances. You can stack up to eight switches.

Figure 12: Extending Traditional FlexStack-Plus Stacks using FlexStack-Extended Modules

The following image shows a mixed stack network using FlexStack-Plus, FlexStack-Extended Fiber and

Hybrid modules. This is one of the supported topologies using FlexStack modules. Typically, fiber modules

are used to extend a network for long distance communication across buildings or floors in a building.

Figure 13: Mixed Stacking with FlexStack Modules

Catalyst 6800IA Switch Hardware Installation Guide

24 OL-30278-02

Page 35

Switch Installation

Stack Bandwidth and Partitioning Examples

This figure shows a stack that provides full bandwidth with redundant connections.

Figure 14: Stack with Full Bandwidth Connections

This figure shows a stack with incomplete stack cabling connections. This stack provides only half bandwidth

and does not have redundant connections.

Figure 15: Stack with Half Bandwidth Connections

Stack Bandwidth and Partitioning Examples

This figure shows a stack with a bad FlexStack cable in link B. This stack provides only half bandwidth and

does not have redundant connections.

Figure 16: Stack with a Failover Condition

OL-30278-02 25

Catalyst 6800IA Switch Hardware Installation Guide

Page 36

Power-On Sequence for Switch Stacks

This figure shows a stack with a bad link B. This stack partitions into two stacks, and switch 1 and switch 3

are stack masters.

Figure 17: Partitioned Stack with a Failover Condition

Power-On Sequence for Switch Stacks

Switch Installation

Consider these guidelines before you power on the switches in a stack:

The sequence in which the switches are first powered on might affect the switch that becomes the stack

•

master.

If you want a particular switch to be the stack master, power on that switch first. This switch becomes

•

the stack master and remains the stack master until a master reelection. After 2 minutes, power on the

other stack switches.

If you have no preference as to which switch becomes the stack master, power on all the switches in the

•

stack within a 1-minute timeframe. These switches participate in the stack master election. Switches

powered on after the 1-minute timeframe do not participate in the election.

Power off a switch before you add it to or remove it from an existing switch stack.

•

For conditions that can cause a stack master reelection or to manually elect the stack master, see the Catalyst

2960-X Switch Stacking Configuration Guide on Cisco.com.

Installing the Switch

Rack-Mounting

Installation in other than 19-inch racks requires a bracket kit not included with the switch.

Catalyst 6800IA Switch Hardware Installation Guide

26 OL-30278-02

Page 37

Switch Installation

Rack-Mounting

Warning

To prevent bodily injury when mounting or servicing this unit in a rack, you must take special precautions

to ensure that the system remains stable. The following guidelines are provided to ensure your safety:

This unit should be mounted at the bottom of the rack if it is the only unit in the rack.

•

When mounting this unit in a partially filled rack, load the rack from the bottom to the top with the

•

heaviest component at the bottom of the rack.

If the rack is provided with stabilizing devices, install the stabilizers before mounting or servicing

•

the unit in the rack.

Statement 1006

This figure shows the standard 19-inch brackets and other optional mounting brackets. You can order the

optional brackets from your Cisco sales representative.

Figure 18: Rack-Mounting Brackets

OL-30278-02 27

23-inch brackets319-inch brackets1

24-inch brackets4ETSI brackets2

Catalyst 6800IA Switch Hardware Installation Guide

Page 38

Rack-Mounting

Attaching the Rack-Mount Brackets

Procedure

Use two Phillips flat-head screws (for Catalyst 6800IA-48FPD and 6800IA-48TD) or four Phillips flat-head

screws (for Catalyst 6800IA-48FPDR) to attach the long side of the bracket to each side of the switch.

Figure 19: Attaching Brackets for 19-inch Racks (Catalyst 6800IA-48FPD and 6800IA-48TD)

Switch Installation

Figure 20: Attaching Brackets for 19-inch Racks (Catalyst 6800IA-48FPDR)

Catalyst 6800IA Switch Hardware Installation Guide

28 OL-30278-02

Page 39

Switch Installation

Rack-Mounting

Mounting in a Rack

Procedure

Step 1

Step 2

OL-30278-02 29

Use the four supplied Phillips machine screws to attach the brackets to the rack.

Use the black Phillips machine screw to attach the cable guide to the left or right bracket.

Mid-mounting position3Front-mounting position1

Rear-mounting position4Number-8 Phillips flat-head screws (48-2927-01)2

Catalyst 6800IA Switch Hardware Installation Guide

Page 40

Rack-Mounting

Switch Installation

Catalyst 6800IA Switch Hardware Installation Guide

30 OL-30278-02

Number-12 Phillips pan-head screws

4Cable guide1

(48-0523-01) or Number-10 Phillips pan-head

screws (48-0627-01)

Mid-mounting position5Phillips machine screw, black (48-0654-01)2

Rear-mounting position6Front-mounting position3

Page 41

Switch Installation

Wall-Mounting

Wall-Mounting

Warning

Read the wall-mounting instructions carefully before beginning installation. Failure to use the correct

hardware or to follow the correct procedures could result in a hazardous situation to people and damage

to the system. Statement 378

Attaching the Brackets for Wall-Mounting

Procedure

Step 1

Step 2

Attach a 19-inch bracket to one side of the switch.

Follow the same steps to attach the second bracket to the opposite side.

Figure 21: Attaching the 19-inch Brackets for Wall-Mounting

Number-8 phillips flat-head screws (48-2927-01)1

Attaching the RPS Connector Cover

Warning

OL-30278-02 31

If an RPS is not connected to the switch, install an RPS connector cover on the back of the switch. Statement

265

Catalyst 6800IA Switch Hardware Installation Guide

Page 42

Wall-Mounting

Switch Installation

Procedure

If you are not using an RPS with your switch, use the two Phillips pan-head screws to attach the RPS connector

cover to the back of the switch.

Figure 22: Attaching the RPS Connector Cover

RPS connector cover2

Mounting on a Wall

For the best support of the switch and cables, make sure that the switch is attached securely to wall studs or

to a firmly attached plywood-mounting backboard. Mount the switch with the front panel facing down.

Warning

Read the wall-mounting instructions carefully before beginning installation. Failure to use the correct

hardware or to follow the correct procedures could result in a hazardous situation to people and damage

to the system. Statement 378

RPS connector3Phillips pan-head screws (48-0482-01)1

Catalyst 6800IA Switch Hardware Installation Guide

32 OL-30278-02

Page 43

Switch Installation

Wall-Mounting

Following safety regulations, wall-mount the switch with its front panel facing down.Caution

Figure 23: Mounting on a Wall

1

When you complete the switch installation, see After Switch Installation, on page 34 for information on

switch configuration.

OL-30278-02 33

User-supplied screws (for example, you can use # 6 wood screws with a washer head 1-inch

long).

Catalyst 6800IA Switch Hardware Installation Guide

Page 44

Installing the Switch on a Table or Shelf

Installing the Switch on a Table or Shelf

Procedure

Switch Installation

Step 1

Step 2

Step 3

Step 4

To install the switch on a table or shelf, locate the adhesive strip with the rubber feet in the mounting-kit

envelope.

Attach the four rubber feet to the four circular etches on the bottom of the chassis.

Place the switch on the table or shelf near an AC power source.

When you complete the switch installation, see After Switch Installation, on page 34for information on

switch configuration.

After Switch Installation

Install the power cord retainer (optional).

•

Connect to the front-panel ports.

•

Connecting FlexStack-Plus modules (Optional)

Always use a Cisco-approved FlexStack cable to connect the switches.

This is only supported on the stack-capable switches.Note

Caution

Use only approved cables, and connect only to other Catalyst 6800IA switches. Equipment might be

damaged if connected to other nonapproved Cisco cables or equipment.

Procedure

Step 1

Step 2

Catalyst 6800IA Switch Hardware Installation Guide

34 OL-30278-02

Remove the dust covers from the FlexStack cables, and store them for future use.

Insert one end of the FlexStack cable into the stack port of the first switch. Insert the other end of the cable

into the stack port on the other switch. Make sure that you insert the cables in completely until you feel them

snap into place.

Page 45

Switch Installation

Removing a FlexStack Cable

Note

When you connect the FlexStack cable to the STACK 1 port, the tab should be above the connector.

When you connect the FlexStack cable to the STACK 2 port, the tab should be below the connector.

Step 3

Replace the dust covers when you remove the FlexStack cables from the connectors.

Caution

Removing and installing the FlexStack cable can shorten its useful life. Do not remove and insert

the cable more often than is absolutely necessary.

Removing a FlexStack Cable

Procedure

Step 1

Step 2

To remove a FlexStack cable, grasp the tab on the cable connector and gently pull straight out.

When you remove the FlexStack cables from the connectors, replace the dust covers to protect them from

dust.

Caution

Removing and installing the FlexStack cable can shorten its useful life. Do not remove and insert

the cable more often than is absolutely necessary.

OL-30278-02 35

Catalyst 6800IA Switch Hardware Installation Guide

Page 46

Installing the Power Cord Retainer (Optional)

Installing the Power Cord Retainer (Optional)

This section applies only to the Catalyst 6800IA-48FPD and 6800IA-48TD switches.Note

The power cord retainer is optional (part number [PWR-CLP=]). You can order it when you order your switch,

or you can order it later from your Cisco representative.

Procedure

Switch Installation

Step 1

Step 2

Choose the sleeve size of the power cord retainer based on the thickness of the cord. The smaller sleeve can

be snapped off and used for thin cords.

Slide the retainer around the AC power cord, and pass it around the loop on the switch.

Figure 24: Inserting the Retainer Through the Lanced Loop

Sleeve for thinner power cords3AC power cord1

Loop4Power cord retainer2

Catalyst 6800IA Switch Hardware Installation Guide

36 OL-30278-02

Page 47

Switch Installation

Installing the Power Cord Retainer (Optional)

Step 3

Slide the retainer through the first latch.

Figure 25: Sliding the Retainer Through the Latch

Latch3AC power cord1

Smaller sleeve for thin power cords2

Step 4

Slide the retainer through the other latches to lock it.

Figure 26: Locking the Retainer

Latches3AC power cord1

Sleeve for thin power cords2

OL-30278-02 37

Catalyst 6800IA Switch Hardware Installation Guide

Page 48

Installing SFP Modules

Switch Installation

Step 5

Step 6

(Optional) Use the small sleeve for thin power cords. Use the small sleeve to provide greater stability for thin

cords. Detach the sleeve, and slide it over the power cord.

Figure 27: Sleeve Around the Power Cord

AC power cord2Sleeve for thin power cords1

Secure the AC power cord by pressing on the retainer.

Figure 28: Securing the Power Cord in the Retainer

Installing SFP Modules

Installing an SFP or SFP+ Module

Before You Begin

When installing SFP or SFP+ modules, observe these guidelines:

Catalyst 6800IA Switch Hardware Installation Guide

38 OL-30278-02

Page 49

Switch Installation

Installing an SFP or SFP+ Module

Do not remove the dust plugs from the modules or the rubber caps from the fiber-optic cable until you

•

are ready to connect the cable. The plugs and caps protect the module ports and cables from contamination

and ambient light.

To prevent ESD damage, follow your normal board and component handling procedures when connecting

•

cables to the switch and other devices.

Step 1

Step 2

Step 3

Step 4

Step 5

Step 6

Step 7

Caution

Removing and installing an SFP or SFP+ module can shorten its useful life. Do not

remove and insert any module more often than is absolutely necessary.

Procedure

Attach an ESD-preventive wrist strap to your wrist and to a bare metal surface.

Find the send (TX) and receive (RX) markings on the module top.

On some SFP or SFP+ modules, the send and receive (TX and RX) markings might be replaced by arrows

that show the direction of the connection.

If the module has a bale-clasp latch, move it to the open, unlocked position.

Align the module in front of the slot opening, and push until you feel the connector snap into place.

If the module has a bale-clasp latch, close it.

For fiber-optic SFP or SFP+ modules, remove the dust plugs and save.

Connect the SFP cables.

Figure 29: Installing an SFP Module

OL-30278-02 39

Catalyst 6800IA Switch Hardware Installation Guide

Page 50

Removing an SFP Module

Removing an SFP Module

Connecting to SFP and SFP+ Modules

Connecting to Fiber-Optic SFP and SFP+ Modules

Class 1 laser product. Statement 1008Warning

Switch Installation

Caution

Step 1

Step 2

Step 3

Do not remove the rubber plugs from the SFP or SFP+ module port or the rubber caps from the fiber-optic

cable until you are ready to connect the cable. The plugs and caps protect the SFP module ports and cables

from contamination and ambient light. Before connecting to the SFP module, be sure that you understand

the port and cabling stipulations.

Procedure

Remove the rubber plugs from the module port and fiber-optic cable, and store them for future use.

Insert one end of the fiber-optic cable into the SFP or SFP+ module port.

Insert the other cable end into a fiber-optic receptacle on a target device.

Figure 30: Connecting to a Fiber-Optic SFP Module Port

Step 4

Catalyst 6800IA Switch Hardware Installation Guide

40 OL-30278-02

Observe the port status LED.

Page 51

Switch Installation

The LED turns green when the switch and the target device have an established link.

The LED turns amber while the STP discovers the network topology and searches for loops. This process

takes about 30 seconds, and then the port LED turns green.

If the LED is off, the target device might not be turned on, there might be a cable problem, or there might be

problem with the adapter installed in the target device.

Connecting to 1000BASE-T SFP

When connecting to a 1000BASE-T device, be sure to use a four twisted-pair, Category 5 or higher cable.

Connecting to 1000BASE-T SFP

Note

The automatic medium-dependent interface crossover (auto-MDIX) feature is enabled by default. For

configuration information for this feature, see the switch software configuration guide or the switch

command reference on Cisco.com.

To prevent ESD damage, follow your normal board and component handling procedures.Caution

OL-30278-02 41

Catalyst 6800IA Switch Hardware Installation Guide

Page 52

Connecting to 1000BASE-T SFP

Procedure

Switch Installation

Step 1

Step 2

Connect one end of the cable to the SFP module port. Insert a four twisted-pair, straight-through cable when

you connect to servers, workstations, and routers. Insert a four twisted-pair, crossover cable when you connect

to switches or repeaters.

Connect the other end of the cable to an RJ-45 connector on the other device.

Figure 31: Connecting to a 1000BASE-T SFP Module

RJ-45 connector1

Step 3

Observe the port status LED.

The LED turns green when the switch and the other device have an established link.

•

The LED turns amber while the STP discovers the network topology and searches for loops. This process

•

takes about 30 seconds, and then the port LED turns green.

If the LED is off, the other device might not be turned on, there might be a cable problem, or there might

•

be a problem with the adapter in the other device.

Step 4

Catalyst 6800IA Switch Hardware Installation Guide

42 OL-30278-02

If necessary, reconfigure and restart the switch or other device.

Page 53

Switch Installation

10/100/1000 PoE and PoE+Port Connections

The ports provide PoE support for devices compliant with IEEE 802.3af and 802.3at (PoE+), and also provide

Cisco prestandard PoE support for Cisco IP Phones and Cisco Aironet Access Points.

On a per-port basis, you can control whether or not a port automatically provides power when an IP phone

or an access point is connected.

To access an advanced PoE planning tool, use the Cisco Power Calculator available on Cisco.com at this

URL: http://tools.cisco.com/cpc/launch.jsp

You can use this application to calculate the power supply requirements for a specific PoE configuration. The

results show output current, output power, and system heat dissipation.

10/100/1000 PoE and PoE+Port Connections

Warning

Caution

Caution

Step 1

Step 2

Voltages that present a shock hazard may exist on Power over Ethernet (PoE) circuits if interconnections

are made using uninsulated exposed metal contacts, conductors, or terminals. Avoid using such

interconnection methods, unless the exposed metal parts are located within a restricted access location

and users and service people who are authorized within the restricted access location are made aware of

the hazard. A restricted access area can be accessed only through the use of a special tool, lock and key

or other means of security. Statement 1072

Category 5e and Category 6 cables can store high levels of static electricity. Always ground the cables to

a suitable and safe earth ground before connecting them to the switch or other devices.

Noncompliant cabling or powered devices can cause a PoE port fault. Use only standard-compliant cabling

to connect Cisco prestandard IP Phones and wireless access points, IEEE 802.3af, or 802.3at (PoE+)

compliant devices. You must remove any cable or device that causes a PoE fault.

Procedure

Connect one end of the cable to the switch PoE port.

Connect the other end of the cable to an RJ-45 connector on the other device. The port LED turns on when

both devices have established link.

The port LED is amber while STP discovers the topology and searches for loops. This process takes about

30 seconds, and then the port LED turns green. If the LED is off, the other device might not be turned on,

there might be a cable problem, or there might be a problem with the adapter in the other device.

Step 3

Step 4

Reconfigure and reboot the connected device, if needed.

Repeat Steps 1 through 3 to connect each device.

Note

Many legacy powered devices, including older Cisco IP phones and access points that do not fully

support IEEE 802.3af, might not support PoE when connected to the switches by a crossover cable.

OL-30278-02 43

Catalyst 6800IA Switch Hardware Installation Guide

Page 54

10/100/1000 Port Connections

10/100/1000 Port Connections

The switch 10/100/1000 port configuration changes to operate at the speed of the attached device. If the

attached ports do not support autonegotiation, you can manually set the speed and duplex parameters.

Connecting devices that do not autonegotiate or that have the speed and duplex parameters manually set can

reduce performance or result in no linkage.

To maximize performance, choose one of these methods for configuring the Ethernet ports:

Let the ports autonegotiate both speed and duplex.

•

Set the interface speed and duplex parameters on both ends of the connection.

•

Auto-MDIX Connections

The autonegotiation and the auto-MDIX features are enabled by default on the switch.

With autonegotiation, the switch port configurations change to operate at the speed of the attached device. If

the attached device does not support autonegotiation, you can manually set the switch interface speed and

duplex parameters.

With auto-MDIX, the switch detects the required cable type for copper Ethernet connections and configures

the interface accordingly.

If auto-MDIX is disabled, use the guidelines in this table to select the correct cable.

Switch Installation

Table 14: Recommended Ethernet Cables (When Auto-MDIX is Disabled)

Device

5

100BASE-TX and 1000BASE-T traffic requires twisted four-pair, Category 5 or higher. 10BASE-T traffic can use Category 3 cable or higher.

5

Straight-Through CableCrossover Cable

NoYesSwitch to switch

NoYesSwitch to hub

YesNoSwitch to computer or server

YesNoSwitch to router

YesNoSwitch to IP phone

Where to Go Next

Refer to the "Instant Access" chapter in the Release 15.1SY Supervisor Engine 2T Software Configuration

Guide.

Catalyst 6800IA Switch Hardware Installation Guide

44 OL-30278-02

Page 55

Power Supply Installation

This chapter applies only to the Catalyst 6800IA-48FPDR switch. It contains these topics:

Power Supply Module Overview, page 45

•

Installation Guidelines, page 47

•

Installing or Replacing an AC Power Supply, page 48

•

Finding the Serial Number, page 49

•

Power Supply Module Overview

The switch operates with either one or two active power supply modules. You can use two AC modules, or

one module and a blank cover.

Table 15: Power Supply Model Numbers and Description

CHAPTER 3

The 1025-W power supply module is an autoranging unit that supports input voltages between 115 and 240

VAC. All power supply modules have internal fans. All switches ship with a blank cover in the second power

supply slot.

OL-30278-02 45

DescriptionPart Number

1025-W AC power supply modulePWR-C2-1025WAC=

Catalyst 6800IA Switch Hardware Installation Guide

Page 56

Power Supply Module Overview

Each AC power supply module has a power cord for connection to an AC power outlet.

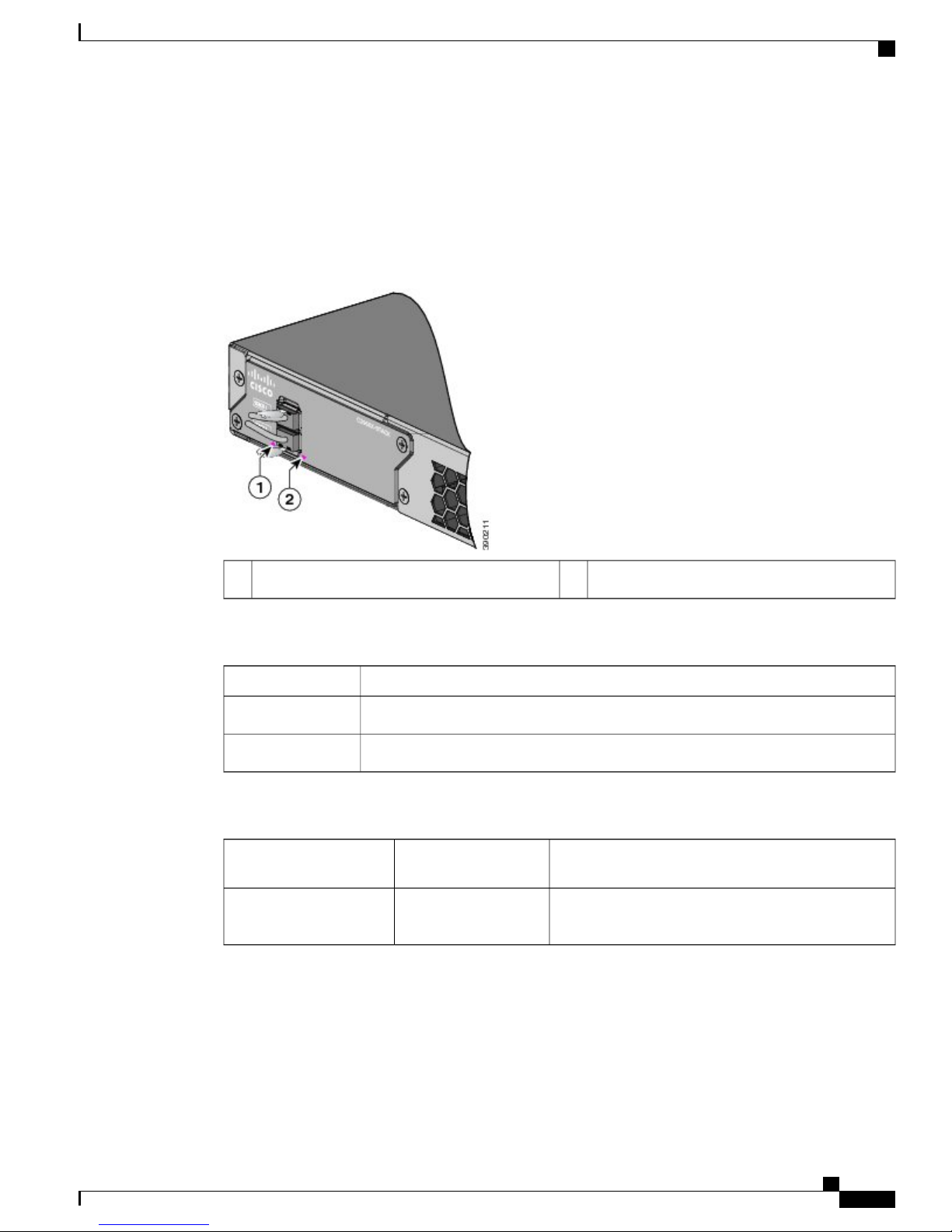

Figure 32: PWR-C2-1025WAC Power Supply

Power Supply Installation

AC power cord connector4AC OK LED1

Release latch5PS OK LED2

Power supply6AC power cord retainer3

If no power supply is installed in a power supply slot, install a power supply slot cover.

Figure 33: Power Supply Slot Cover

Catalyst 6800IA Switch Hardware Installation Guide

46 OL-30278-02

Page 57

Power Supply Installation

Installation Guidelines

Retainer clips2Release handles1

The power supply modules have two status LEDs.

DescriptionPS OKDescriptionAC OK

Green

Installation Guidelines

Observe these guidelines when removing or installing a power supply module:

Do not force the power supply module into the slot. This can damage the pins on the switch if they are

•

not aligned with the module.

A power supply that is only partially connected to the switch can disrupt the system operation.

•

Remove power from the power-supply module before removing or installing the module.

•

The power supply is hot-swappable.

•

present.

OffNo AC input power.Off (AC LED is off)

Output is disabled, or

input is outside operating

range.

Power output to switch.GreenAC input power is

Output has failed.Red

Caution

Do not operate the switch with one power-supply module slot empty. For proper chassis cooling, both

module slots must be populated, with either a power supply or a blank module.

Warning

Blank faceplates and cover panels serve three important functions: they prevent exposure to hazardous

voltages and currents inside the chassis; they contain electromagnetic interference (EMI) that might disrupt

other equipment; and they direct the flow of cooling air through the chassis. Do not operate the system

unless all cards, faceplates, front covers, and rear covers are in place. Statement 1024

Warning

Do not reach into a vacant slot or chassis while you install or remove a module. Exposed circuitry could

constitute an energy hazard. Statement 206

Warning

Only trained and qualified personnel should be allowed to install, replace, or service this equipment.

Statement 1030

OL-30278-02 47

Catalyst 6800IA Switch Hardware Installation Guide

Page 58

Installing or Replacing an AC Power Supply

Power Supply Installation

Warning

If a Cisco external power system is not connected to the switch, install the provided connector cover on

the back of the switch. Statement 386

Installing or Replacing an AC Power Supply

Procedure

Step 1

Step 2

Step 3

Step 4

Step 5

Turn off the power at its source.

Remove the power cord from the power cord retainer.

Remove the power cord from the power connector.

Press the release latch at the right side of the power supply module inward and slide the power supply out.

Do not leave the power-supply slot open for more than 90 seconds while the switch is operating.Note

Warning

This unit might have more than one power supply connection. All connections must be removed

to de-energize the unit. Statement 1028

Insert the new power supply into the power-supply slot, and gently push it into the slot. The 1025-W

power-supply module extends inches from the switch rear panel.

Figure 34: Inserting the AC-Power Supply in the Switch

Catalyst 6800IA Switch Hardware Installation Guide

48 OL-30278-02

Page 59

Power Supply Installation

Finding the Serial Number

Step 6

Step 7

Step 8

Step 9

(Optional) Make a loop in the power cord and thread it through the power cord retainer.

Figure 35: AC-Power Supply with Power Cord Retainer

Connect the power cord to the power supply and to an AC power outlet. Turn on the power at the power

source.

Confirm that the power supply AC OK and PS OK LEDs are green.

Repeat the steps to install a second power supply.

When you install the second power supply the LEDs on the power supply might blink momentarily.Note

Finding the Serial Number

If you contact Cisco Technical Assistance, you need to know the switch serial number. You can also use the

show version privileged EXEC command to see the switch serial number.

Figure 36: 1025-W AC Power Supply Serial Number

OL-30278-02 49

Catalyst 6800IA Switch Hardware Installation Guide

Page 60

Finding the Serial Number

Power Supply Installation

Catalyst 6800IA Switch Hardware Installation Guide

50 OL-30278-02

Page 61

Troubleshooting

This chapter contains these topics:

Diagnosing Problems, page 51

•

Finding the Serial Number, page 55

•

Diagnosing Problems

The LEDs on the front panel provide troubleshooting information about the switch. They show POST failures,

port-connectivity problems, and overall switch performance. You can also get statistics from Device Manager,

from the CLI, or from an SNMP workstation.

Switch POST Results

CHAPTER 4

POST failures are usually fatal. Contact your Cisco technical support representative if your switch does not

pass POST.

Switch LEDs

If you have physical access to the switch, look at the port LEDs for troubleshooting information about the

switch. See the LED section for a description of the LED colors and their meanings.

Switch Connections

Bad or Damaged Cable

Always examine the cable for marginal damage or failure. A cable might be just good enough to connect at

the physical layer, but it could corrupt packets as a result of subtle damage to the wiring or connectors. You

can identify this situation because the port has many packet errors or the port constantly flaps (loses and

regains link).

OL-30278-02 51

Catalyst 6800IA Switch Hardware Installation Guide

Page 62

Switch Connections

Examine or exchange the copper or fiber-optic cable with a known, good cable.

•

Look for broken or missing pins on cable connectors.

•

Rule out any bad patch panel connections or media convertors between the source and the destination.

•

If possible, bypass the patch panel, or eliminate faulty media convertors (fiber-optic-to-copper).

Try the cable in another port or interface, if possible, to see if the problem follows the cable.

•

Remove and inspect the stack cable and stack port for bent pins or damaged connectors. If the cable is

•

bad, replace it with a known good cable.

Ethernet and Fiber-Optic Cables

Make sure that you have the correct cable for the connection.

For Ethernet, use Category 3 copper cable for 10 Mb/s UTP connections. Use either Category 5, Category

•

5e, or Category 6 UTP for 10/100/1000 Mb/s connections.

For fiber-optic cables, verify that you have the correct cable for distance and port type. Ensure that the

•

connected device ports match and use the same type of encoding, optical frequency, and fiber type.

Troubleshooting

For copper connections, determine if a crossover cable was used when a straight-through was required

•

or the reverse. Enable auto-MDIX on the switch, or replace the cable.

Link Status

Verify that both sides have link. A single broken wire or a shutdown port can cause one side to show link

even though the other side does not have link.

A port LED that is on does not guarantee that the cable is fully functional. The cable might have encountered

physical stress that causes it to function at a marginal level. If the port LED does not turn on:

Connect the cable from the switch to a known good device.

•

Ensure that both ends of the cable are connected to the correct ports.

•

Verify that both devices have power.

•

Verify that you are using the correct cable type.

•