Page 1

Catalyst 4900 Series Switch Installation Guide

August 2008

Americas Headquarters

Cisco Systems, Inc.

170 West Tasman Drive

San Jose, CA 95134-1706

USA

http://www.cisco.com

Tel: 408 526-4000

800 553-NETS (6387)

Fax: 408 527-0883

Text Part Number: 78-18039-02

Page 2

THE SPECIFICATIONS AND INFORMATION REGARDING THE PRODUCTS IN THIS MANUAL ARE SUBJECT TO CHANGE WITHOUT

NOTICE. ALL STATEMENTS, INFORMATION, AND RECOMMENDATIONS IN THIS MANUAL ARE BELIEVED TO BE ACCURATE BUT

ARE PRESENTED WITHOUT WARRANTY OF ANY KIND, EXPRESS OR IMPLIED. USERS MUST TAKE FULL RESPONSIBILITY FOR

THEIR APPLICATION OF ANY PRODUCTS.

THE SOFTWARE LICENSE AND LIMITED WARRANTY FOR THE ACCOMPANYING PRODUCT ARE SET FORTH IN THE INFORMATION

PACKET THAT SHIPPED WITH THE PRODUCT AND ARE INCORPORATED HEREIN BY THIS REFERENCE. IF YOU ARE UNABLE TO

LOCATE THE SOFTWARE LICENSE OR LIMITED WARRANTY, CONTACT YOUR CISCO REPRESENTATIVE FOR A COPY.

The following information is for FCC compliance of Class A devices: This equipment has been tested and found to comply with the limits for a Class

A digital device, pursuant to part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio-frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference, in which case users will be required to correct the interference at their own expense.

The following information is for FCC compliance of Class B devices: The equipment described in this manual generates and may radiate

radio-frequency energy. If it is not installed in accordance with Cisco’s installation instructions, it may cause interference with radio and television

reception. This equipment has been tested and found to comply with the limits for a Class B digital device in accordance with the specifications in

part 15 of the FCC rules. These specifications are designed to provide reasonable protection against such interference in a residential installation.

However, there is no guarantee that interference will not occur in a particular installation.

Modifying the equipment without Cisco’s written authorization may result in the equipment no longer complying with FCC requirements for Class

A or Class B digital devices. In that event, your right to use the equipment may be limited by FCC regulations, and you may be required to correct

any interference to radio or television communications at your own expense.

You can determine whether your equipment is causing interference by turning it off. If the interference stops, it was probably caused by the Cisco

equipment or one of its peripheral devices. If the equipment causes interference to radio or television reception, try to correct the interference by

using one or more of the following measures:

• Turn the television or radio antenna until the interference stops.

• Move the equipment to one side or the other of the television or radio.

• Move the equipment farther away from the television or radio.

• Plug the equipment into an outlet that is on a different circuit from the television or radio. (That is, make certain the equipment and the television

or radio are on circuits controlled by different circuit breakers or fuses.)

Modifications to this product not authorized by Cisco Systems, Inc. could void the FCC approval and negate your authority to operate the product.

The Cisco implementation of TCP header compression is an adaptation of a program developed by the University of California, Berkeley (UCB) as

part of UCB’s public domain version of the UNIX operating system. All rights reserved. Copyright © 1981, Regents of the University of California.

NOTWITHSTANDING ANY OTHER WARRANTY HEREIN, ALL DOCUMENT FILES AND SOFTWARE OF THESE SUPPLIERS ARE

PROVIDED “AS IS” WITH ALL FAULTS. CISCO AND THE ABOVE-NAMED SUPPLIERS DISCLAIM ALL WARRANTIES, EXPRESSED

OR

IMPLIED, INCLUDING, WITHOUT LIMITATION, THOSE OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE AND

NONINFRINGEMENT OR ARISING FROM A COURSE OF DEALING, USAGE, OR TRADE PRACTICE.

IN NO EVENT SHALL CISCO OR ITS SUPPLIERS BE LIABLE FOR ANY INDIRECT, SPECIAL, CONSEQUENTIAL, OR INCIDENTAL

DAMAGES, INCLUDING, WITHOUT LIMITATION, LOST PROFITS OR LOSS OR DAMAGE TO DATA ARISING OUT OF THE USE OR

INABILITY TO USE THIS MANUAL, EVEN IF CISCO OR ITS SUPPLIERS HAVE BEEN ADVISED OF THE POSSIBILITY OF SUCH

DAMAGES.

Page 3

CCDE, CCENT, Cisco Eos, Cisco Lumin, Cisco Nexus, Cisco StadiumVision, Cisco TelePresence, the Cisco logo, DCE, and Welcome to the

Human Network are trademarks; Changing the Way We Work, Live, Play, and Learn and Cisco Store are service marks; and Access Registrar,

Aironet, AsyncOS, Bringing the Meeting To You, Catalyst, CCDA, CCDP, CCIE, CCIP, CCNA, CCNP, CCSP, CCVP, Cisco, the Cisco

Internetwork Expert logo, Cisco

Without Limitation, EtherFast, EtherSwitch, Event Center, Fast Step, Follow Me Browsing, FormShare, GigaDrive, HomeLink, Internet Quotient,

IOS, iPhone, iQ Expertise, the iQ logo, iQ

MeetingPlace, MeetingPlace Chime Sound, MGX, Networkers, Networking Academy, Network Registrar, PCNow, PIX, PowerPanels, ProConnect,

ScriptShare, SenderBase, SMARTnet, Spectrum Expert, StackWise, The Fastest Way to Increase Your Internet Quotient, TransPath, WebEx, and

the WebEx

All other trademarks mentioned in this document or Website are the property of their respective owners. The use of the word partner does not imply

a partnership relationship between Cisco and any other company. (0807R)

Catalyst 4900 Series Switch Installation Guide

Copyright © 2008 Cisco Systems, Inc. All rights reserved.

logo are registered trademarks of Cisco Systems, Inc. and/or its affiliates in the United States and certain other countries.

IOS, Cisco Press, Cisco Systems, Cisco Systems Capital, the Cisco Systems logo, Cisco Unity, Collaboration

Net Readiness Scorecard, iQuick Study, IronPort, the IronPort logo, LightStream, Linksys, MediaTone,

Certified

Page 4

Page 5

CONTENTS

Preface ix

Audience ix

Organization ix

Related Documentation x

Command Syntax Conventions xi

Statement 1071—Warning Definition xii

Obtaining Documentation and Submitting a Service Request xxi

CHAPTER

CHAPTER

1 Product Overview 1-1

Catalyst 4900 Series Switch Applications 1-2

Catalyst 4948 Switch Software Features 1-3

Catalyst 4948-10GE and Catalyst 4928-10GE Switch Software Features 1-4

Hardware System Features 1-6

Switch Components 1-7

Traffic Ports on the Catalyst 4948 1-7

Traffic Ports on the Catalyst 4948-10GE 1-7

Traffic Ports on the Catalyst 4928-10GE 1-7

Console Port 1-7

Front Panel LEDs 1-9

Chassis Cooling 1-11

Power Supplies 1-12

Environmental Monitoring of the Power Supplies 1-13

Power Management for the Switch 1-14

Power Management Modes 1-14

2 Site Planning 2-1

78-18039-02

Site Environmental Requirements 2-1

Site Power Requirements 2-2

Pre-installation Requirements 2-3

Warnings and Cautions 2-3

Catalyst 4900 Series Switch Installation Guide

v

Page 6

EMI Recommendations 2-4

Power Requirements and Heat Dissipation 2-4

Grounding Requirements 2-6

Safety Overview 2-7

Ensuring Safety 2-7

Working Safely with Electricity 2-8

Preventing Electrostatic Discharge Damage 2-9

Site Planning Checklist 2-9

CHAPTER

CHAPTER

3 Installing the Switch 3-1

Verifying the Contents 3-1

Rack-Mounting the Switch 3-2

Rack-Mounting Guidelines 3-3

Lifting the Chassis Safely 3-5

Required Installation Tools 3-5

Rack-Mounting the Switch 3-6

Connecting AC Power to the Switch 3-9

Connecting DC Power to the Switch 3-11

4 Transceiver Modules 4-1

SFP Modules 4-1

SFP Modules and Alternative Wiring 4-1

X2 Modules 4-2

Module Maintenance Guidelines 4-5

Cleaning the Fiber-Optic Connectors 4-5

Additional Guidelines 4-7

CHAPTER

APPENDIX

vi

5 Troubleshooting the Installation 5-1

Getting Started 5-2

Problem Solving to the System Component Level 5-2

Identifying Startup Problems 5-3

LED Readings 5-3

Troubleshooting the Power Supply 5-5

Contacting Customer Service 5-6

A Specifications A-1

Console Port A-1

Catalyst 4900 Series Switch Installation Guide

78-18039-02

Page 7

Management Port A-2

Catalyst 4900 Series Switch Specifications A-3

APPENDIX

APPENDIX

B Initial Configuration for the Switch B-1

Connecting to the Switch B-2

Starting the Terminal-Emulation Software B-3

Connecting to a Power Source B-3

Entering the Initial Configuration Information B-4

IP Settings B-4

Performing the Initial Configuration B-5

C Compliance Information and Translated Safety Warnings C-1

Translated Safety Warnings C-2

Statement 1003—DC Power Disconnection C-2

Statement 1004—Installation Instructions C-4

Statement 1006—Chassis Warning for Rack-Mounting and Servicing C-6

Statement 1008—Class 1 Laser Product C-14

Statement 1011—Staring into Laser Beam C-16

Statement 1017—Restricted Area C-18

Statement 1019—Main Disconnecting Device C-21

Statement 1024—Ground Conductor C-23

Statement 1030—Equipment Installation C-25

Statement 1040—Product Disposal C-27

Statement 1045—Short-circuit Protection C-30

Statement 1051—Laser Radiation C-33

Statement 1074—Comply with Local and National Electrical Codes C-36

Statement 1075—Hazardous Voltage or Energy Present on DC Power Terminals C-37

78-18039-02

Regulatory Standards Compliance C-39

European Directives C-42

Statement 287—Declaration of Conformity to R&TTE Directive 1999/5/EC for the European

Community, Switzerland, Norway, Iceland and Liechtenstein C-42

Statement 275—Declaration of Conformity with Regard to the Directives 73/23/EEC and 89/336/EEC

as amended by Directive 93/68/EEC C-44

California Perchlorate Contamination Prevention Act (Title 22, California Code of Regulations,

Chapter 33) C-46

EMC Class A Notices and Warnings C-46

Class A Notice for FCC C-46

Class A Notice for Canada C-47

Statement 340—Class A Warning for CISPR22 C-47

Catalyst 4900 Series Switch Installation Guide

vii

Page 8

I

NDEX

Statement 191—VCCI Class A Warning for Japan C-50

Statement 256—Class A Warning for Hungary C-51

Statement 294—Class A Warning for Korea C-51

Statement 257—Class A Notice for Taiwan and Other Traditional Chinese Markets C-52

Statement 371—Power Cable and AC Adapter C-52

viii

Catalyst 4900 Series Switch Installation Guide

78-18039-02

Page 9

Audience

Preface

This preface describes the audience, organization, and conventions of the

Catalyst

to obtain related documentation.

Only trained and qualified service personnel (as defined in IEC60950-1 and

AZ/NZS 60950-1) should install, replace, or service the equipment.

4900 Series Switch Installation Guide and provides information on how

Organization

This guide is organized as follows:

Chapter Title Description

Chapter 1 Product Overview Describes the hardware features and functionality of the

Catalyst

Chapter 2 Site Planning Describes how to prepare your site for the installation of the

switch.

Chapter 3 Installing the Switch Details how to install the switch.

Chapter 4 Transceiver Mod ules Describes how to install, remove, and maintain transceiver

modules.

78-18039-02

4900 series switches.

Catalyst 4900 Series Switch Installation Guide

ix

Page 10

Chapter Title Description

Chapter 5 Troubleshooting the

Installation

Appendix A Specifications Lists the switch system specifications.

Appendix B Initial Configuration

for the Switch

Appendix C Compliance

Information and

Translated Safety

Warn in g s

Provides troubleshooting guidelines for the initial hardware

installation and suggests steps to help isolate and resolve

problems.

Details initial setup of a system that will allow further

configuration via Telnet.

States compliance information for the switches and repeats in

multiple languages the warnings in this guide.

Related Documentation

The Catalyst 4900 series switches use software that also runs on the Catalyst 4500

series switches. Refer to the version of these documents appropriate for your

software release:

• Catalyst 4500 Series Switch Cisco IOS Software Configuration Guide

http://www.cisco.com/en/US/products/hw/switches/ps4324/products_install

ation_and_configuration_guides_list.html

Preface

• Catalyst 4500 Series Switch Cisco IOS Command Reference

http://www.cisco.com/en/US/products/hw/switches/ps4324/prod_command

_reference_list.html

• Catalyst 4500 Series Switch Cisco IOS System Message Guide

http://www.cisco.com/en/US/products/hw/switches/ps4324/products_system

_message_guides_list.html

There is a distinct release note for the Catalyst 4900 switches. It is available at:

http://www.cisco.com/en/US/docs/switches/lan/catalyst4500/release/note/O

L_9592.html

Catalyst 4900 Series Switch Installation Guide

x

78-18039-02

Page 11

Preface

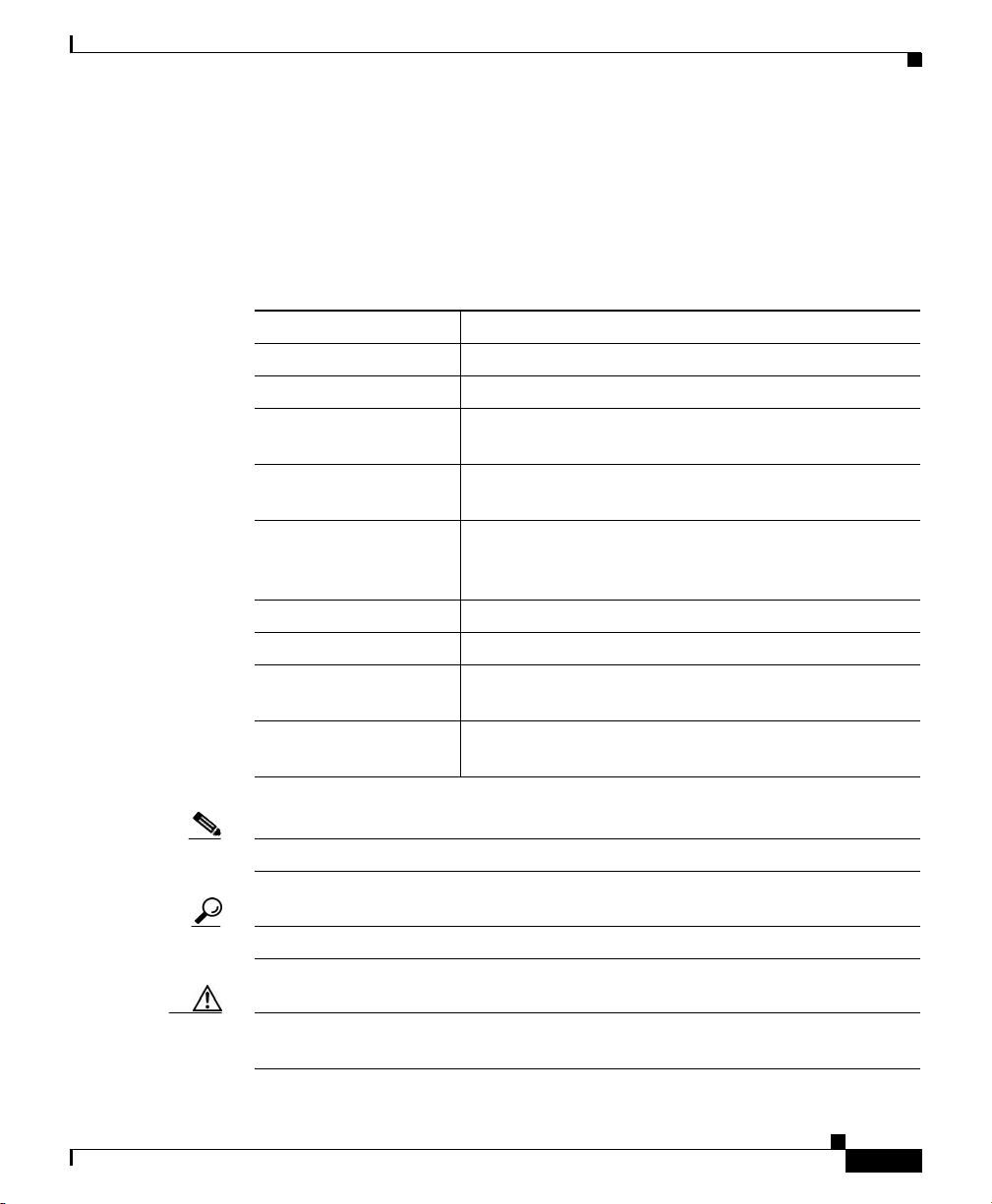

Command Syntax Conventions

This sectionTab le 1 describes the syntax used with the commands in this

document.

Ta b l e 1 Command Syntax Guide

Convention Description

boldface Commands and keywords.

italic Command input that is supplied by you.

[ ] Keywords or arguments that appear within square

brackets are optional.

{ x | x | x } A choice of keywords (represented by x) appears in

braces separated by vertical bars. You must select one.

^ or Ctrl Represent the key labeled Control. For example, when

you read ^D or Ctrl-D, you should hold down the

Control key while you press the D key.

screen font Examples of information displayed on the screen.

boldface screen font Examples of information that you must enter.

< > Nonprinting characters, such as passwords, appear in

angled brackets.

[ ] Default responses to system prompts appear in square

brackets.

78-18039-02

Note Means reader take note.

Tip Means the following information will help you solve a problem.

Caution Means reader be careful. In this situation, you might perform an action that could

result in equipment damage or loss of data.

Catalyst 4900 Series Switch Installation Guide

xi

Page 12

Timesaver Means the described action saves time. You can save time by performing the

action described in the paragraph.

Preface

Warning

Means reader be warned. In this situation, you might perform an action that

could result in bodily injury.

Statement 1071—Warning Definition

Warning

Waarschuwing

IMPORTANT SAFETY INSTRUCTIONS

This warning symbol means danger. You are in a situation that could cause

bodily injury. Before you work on any equipment, be aware of the hazards

involved with electrical circuitry and be familiar with standard practices for

preventing accidents. Use the statement number provided at the end of each

warning to locate its translation in the translated safety warnings that

accompanied this device.

SAVE THESE INSTRUCTIONS

BELANGRIJKE VEILIGHEIDSINSTRUCTIES

Dit waarschuwingssymbool betekent gevaar. U verkeert in een situatie die

lichamelijk letsel kan veroorzaken. Voordat u aan enige apparatuur gaat

werken, dient u zich bewust te zijn van de bij elektrische schakelingen

betrokken risico's en dient u op de hoogte te zijn van de standaard praktijken

om ongelukken te voorkomen. Gebruik het nummer van de verklaring

onderaan de waarschuwing als u een vertaling van de waarschuwing die bij

het apparaat wordt geleverd, wilt raadplegen.

Statement 1071

xii

BEWAAR DEZE INSTRUCTIES

Catalyst 4900 Series Switch Installation Guide

78-18039-02

Page 13

Preface

Varoitus

Attention

Warnung

TÄRKEITÄ TURVALLISUUSOHJEITA

Tämä varoitusmerkki merkitsee vaaraa. Tilanne voi aiheuttaa ruumiillisia

vammoja. Ennen kuin käsittelet laitteistoa, huomioi sähköpiirien

käsittelemiseen liittyvät riskit ja tutustu onnettomuuksien yleisiin

ehkäisytapoihin. Turvallisuusvaroitusten käännökset löytyvät laitteen

mukana toimitettujen käännettyjen turvallisuusvaroitusten joukosta

varoitusten lopussa näkyvien lausuntonumeroiden avulla.

SÄILYTÄ NÄMÄ OHJEET

IMPORTANTES INFORMATIONS DE SÉCURITÉ

Ce symbole d'avertissement indique un danger. Vous vous trouvez dans une

situation pouvant entraîner des blessures ou des dommages corporels. Avant

de travailler sur un équipement, soyez conscient des dangers liés aux circuits

électriques et familiarisez-vous avec les procédures couramment utilisées

pour éviter les accidents. Pour prendre connaissance des traductions des

avertissements figurant dans les consignes de sécurité traduites qui

accompagnent cet appareil, référez-vous au numéro de l'instruction situé à la

fin de chaque avertissement.

CONSERVEZ CES INFORMATIONS

WICHTIGE SICHERHEITSHINWEISE

78-18039-02

Dieses Warnsymbol bedeutet Gefahr. Sie befinden sich in einer Situation, die

zu Verletzungen führen kann. Machen Sie sich vor der Arbeit mit Geräten mit

den Gefahren elektrischer Schaltungen und den üblichen Verfahren zur

Vorbeugung vor Unfällen vertraut. Suchen Sie mit der am Ende jeder Warnung

angegebenen Anweisungsnummer nach der jeweiligen Übersetzung in den

übersetzten Sicherheitshinweisen, die zusammen mit diesem Gerät

ausgeliefert wurden.

BEWAHREN SIE DIESE HINWEISE GUT AUF.

Catalyst 4900 Series Switch Installation Guide

xiii

Page 14

Preface

Avvertenza

Advarsel

Aviso

IMPORTANTI ISTRUZIONI SULLA SICUREZZA

Questo simbolo di avvertenza indica un pericolo. La situazione potrebbe

causare infortuni alle persone. Prima di intervenire su qualsiasi

apparecchiatura, occorre essere al corrente dei pericoli relativi ai circuiti

elettrici e conoscere le procedure standard per la prevenzione di incidenti.

Utilizzare il numero di istruzione presente alla fine di ciascuna avvertenza per

individuare le traduzioni delle avvertenze riportate in questo documento.

CONSERVARE QUESTE ISTRUZIONI

VIKTIGE SIKKERHETSINSTRUKSJONER

Dette advarselssymbolet betyr fare. Du er i en situasjon som kan føre til skade

på person. Før du begynner å arbeide med noe av utstyret, må du være

oppmerksom på farene forbundet med elektriske kretser, og kjenne til

standardprosedyrer for å forhindre ulykker. Bruk nummeret i slutten av hver

advarsel for å finne oversettelsen i de oversatte sikkerhetsadvarslene som

fulgte med denne enheten.

TA VARE PÅ DISSE INSTRUKSJONENE

INSTRUÇÕES IMPORTANTES DE SEGURANÇA

Este símbolo de aviso significa perigo. Você está em uma situação que poderá

ser causadora de lesões corporais. Antes de iniciar a utilização de qualquer

equipamento, tenha conhecimento dos perigos envolvidos no manuseio de

circuitos elétricos e familiarize-se com as práticas habituais de prevenção de

acidentes. Utilize o número da instrução fornecido ao final de cada aviso para

localizar sua tradução nos avisos de segurança traduzidos que acompanham

este dispositivo.

xiv

GUARDE ESTAS INSTRUÇÕES

Catalyst 4900 Series Switch Installation Guide

78-18039-02

Page 15

Preface

¡Advertencia!

Varning!

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

Este símbolo de aviso indica peligro. Existe riesgo para su integridad física.

Antes de manipular cualquier equipo, considere los riesgos de la corriente

eléctrica y familiarícese con los procedimientos estándar de prevención de

accidentes. Al final de cada advertencia encontrará el número que le ayudará

a encontrar el texto traducido en el apartado de traducciones que acompaña

a este dispositivo.

GUARDE ESTAS INSTRUCCIONES

VIKTIGA SÄKERHETSANVISNINGAR

Denna varningssignal signalerar fara. Du befinner dig i en situation som kan

leda till personskada. Innan du utför arbete på någon utrustning måste du vara

medveten om farorna med elkretsar och känna till vanliga förfaranden för att

förebygga olyckor. Använd det nummer som finns i slutet av varje varning för

att hitta dess översättning i de översatta säkerhetsvarningar som medföljer

denna anordning.

SPARA DESSA ANVISNINGAR

78-18039-02

Catalyst 4900 Series Switch Installation Guide

xv

Page 16

Preface

Aviso

Advarsel

INSTRUÇÕES IMPORTANTES DE SEGURANÇA

Este símbolo de aviso significa perigo. Você se encontra em uma situação em

que há risco de lesões corporais. Antes de trabalhar com qualquer

equipamento, esteja ciente dos riscos que envolvem os circuitos elétricos e

familiarize-se com as práticas padrão de prevenção de acidentes. Use o

número da declaração fornecido ao final de cada aviso para localizar sua

tradução nos avisos de segurança traduzidos que acompanham o dispositivo.

GUARDE ESTAS INSTRUÇÕES

VIGTIGE S

IKKERHEDSANVISNINGER

Dette advarselssymbol betyder fare. Du befinder dig i en situation med risiko

for legemesbeskadigelse. Før du begynder arbejde på udstyr, skal du være

opmærksom på de involverede risici, der er ved elektriske kredsløb, og du

skal sætte dig ind i standardprocedurer til undgåelse af ulykker. Brug

erklæringsnummeret efter hver advarsel for at finde oversættelsen i de

oversatte advarsler, der fulgte med denne enhed.

GEM DISSE ANVISNINGER

xvi

Catalyst 4900 Series Switch Installation Guide

78-18039-02

Page 17

Preface

78-18039-02

Catalyst 4900 Series Switch Installation Guide

xvii

Page 18

Preface

xviii

Catalyst 4900 Series Switch Installation Guide

78-18039-02

Page 19

Preface

78-18039-02

Catalyst 4900 Series Switch Installation Guide

xix

Page 20

Preface

xx

Catalyst 4900 Series Switch Installation Guide

78-18039-02

Page 21

Preface

Obtaining Documentation and Submitting a Service

Request

For information on obtaining documentation, submitting a service request, and

gathering additional information, see the monthly What’s

Documentation, which also lists all new and revised Cisco

documentation, at:

http://www.cisco.com/en/US/docs/general/whatsnew/whatsnew.html

Subscribe to the What’s New in Cisco Product Documentation as a Really Simple

Syndication (RSS) feed and set content to be delivered directly to your desktop using

a reader application. The RSS feeds are a free service and Cisco currently supports

RSS version 2.0.

Catalyst 4900 Series Switch Installation Guide

78-18039-02

New in Cisco Product

technical

xxi

Page 22

Preface

xxii

Catalyst 4900 Series Switch Installation Guide

78-18039-02

Page 23

CHAPTER

1

Product Overview

This chapter describes the Catalyst 4900 series switches, as well as system

features and components.

This chapter contains these sections:

• Catalyst 4900 Series Switch Applications, page 1-2

• Catalyst 4948 Switch Software Features, page 1-3

• Catalyst 4948-10GE and Catalyst 4928-10GE Switch Software Features,

page 1-4

• Hardware System Features, page 1-6

• Hardware System Features, page 1-6

• Switch Components, page 1-7

78-18039-02

Catalyst 4900 Series Switch Installation Guide

1-1

Page 24

Chapter 1 Product Overview

Catalyst 4900 Series Switch Applications

Catalyst 4900 Series Switch Applications

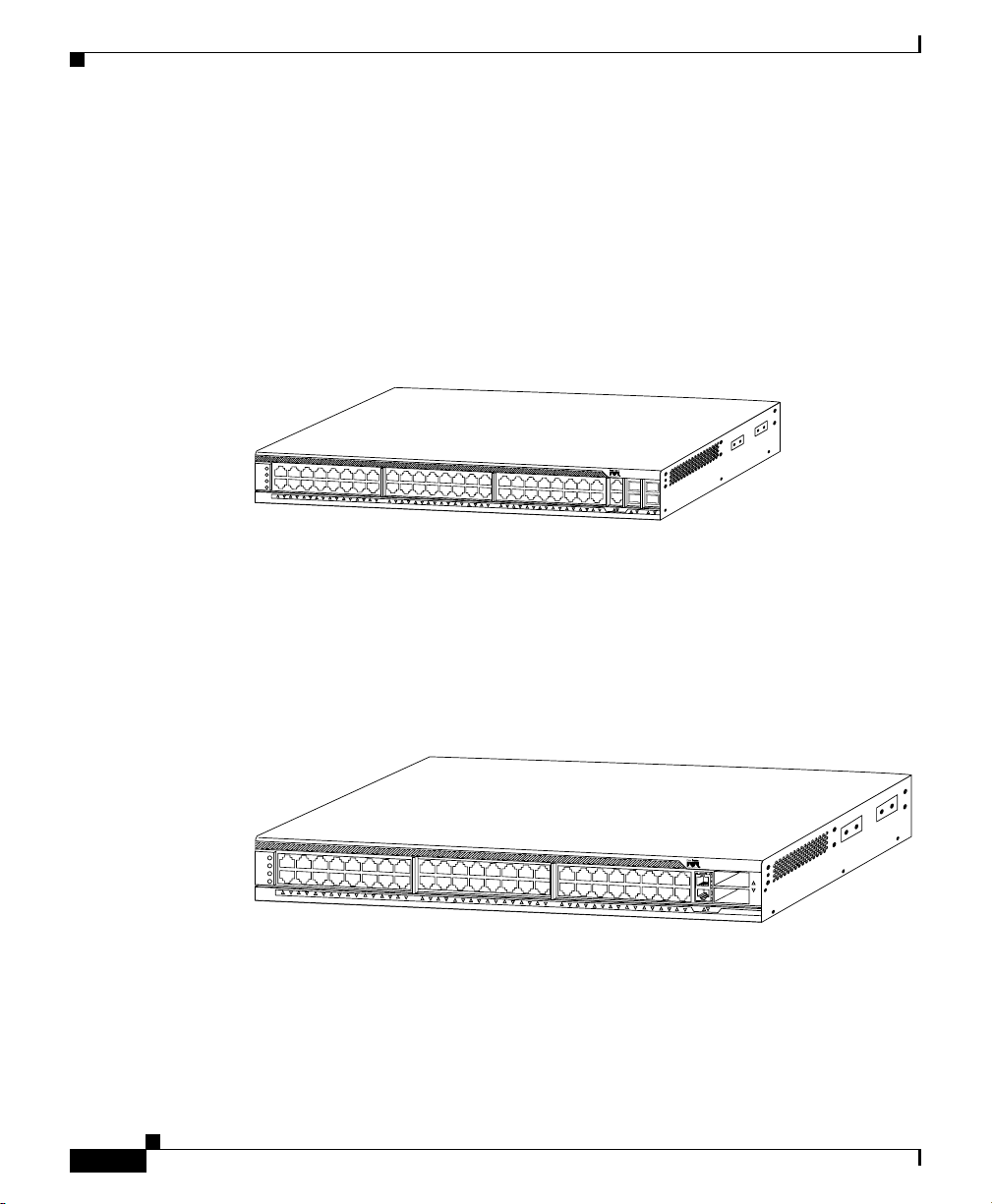

The Catalyst 4900 series switches (see Figure 1-1, Figure 1-2, and Figure 1-3) are

designed for high-performance, high-density edge switching applications. They

are fixed configuration switching solutions delivering 10/100/1000 connectivity

on all ports, supporting hot swappable, redundant power supplies in a compact

one rack-unit size for applications where space is limited.

Figure 1-1 Catalyst 4948 Switch

PS1

PS2

FAN

STATUS

1

1

6

17

32

33

C

a

ta

ly

s

t 4

9

4

8

C

O

N

M

G

T

48

45

46

47

48

113139

The Catalyst 4948 switch has a 96-Gbps, nonblocking, full-duplex switching

fabric, providing 72 million packets-per-second of switching capacity for

high-speed applications. The Catalyst

4948 chassis has 44

10BASE-T/100BASE-TX/1000BASE-T Ethernet ports and four ports that can be

either 1000BASE-X SFP ports or 10BASE-T/100BASE-TX/1000BASE-T

Ethernet ports.

Figure 1-2 Catalyst 4948-10GE Switch

P

S

1

P

S

2

F

A

N

S

T

A

T

U

S

1

1

6

1

7

3

2

3

3

C

ata

ly

st W

S

-C

4

9

4

8

1

0

G

E

X

2

-

1

X

2

-

C

48

2

O

N

M

G

T

The Catalyst 4948-10GE switch has a 136-Gbps, nonblocking, full-duplex

switching fabric, providing 102 million packets-per-second of switching capacity

for high-speed applications. The Catalyst

4948-10GE chassis has 48

10/100/1000BASE-T Ethernet ports and two 10-Gigabit Ethernet uplink ports.

130083

1-2

Catalyst 4900 Series Switch Installation Guide

78-18039-02

Page 25

Chapter 1 Product Overview

Figure 1-3 Catalyst 4928-10GE Switch

P

S

P

S

F

A

S

T

A

T

U

S

The Catalyst 4928-10GE switch has a 48-Gbps, nonblocking, full-duplex

switching fabric, providing 102 million packets-per-second of switching capacity

for high-speed applications. The Catalyst

SFP ports, and two X2 10-Gigabit Ethernet uplink ports.

All three switches have a removable automatic variable speed fan tray for low

noise operation at room temperature and removable and redundant 300

300

the

Catalyst 4948 Switch Software Features

C

a

t

a

ly

s

t

1

2

N

1

8

9

1

6

1

7

CON

MGMT

2

4

2

5

ENABLED

2

6

2

7

2

8

4928-10GE chassis has 28 1000BASEX

W DC power supply provides fault-tolerance protection for the switch. See

“Connecting AC Power to the Switch” section on page 3-9.

M

E

4

9

2

4

1

0

G

E

2

9

ENABLED

3

0

W AC or

271710

Catalyst 4948 Switch Software Features

The following is an overview of Catalyst 4948 features:

• Layer 2, Layer 3, and Layer 4 switching services

• Support for 32,768 MAC addresses for Layer 2 switching

• Support for 2,048 VLANs and 4,096 VLAN IDs

–

IEEE 802.1Q VLAN tagging on all ports

–

Q-in-Q for EFM

–

Cisco Inter Switch Link (ISL) tagging on all ports

• 16,000 multicast forwarding entries and 16,000 unicast forwarding entries

• 512 ingress policers and 512 egress policers

• 8,000 ingress Security ACEs (Access Control Entries) and 8,000 egress

Security ACEs

• Support for port aggregation using Port Aggregation Protocol (PAgP) for

Gigabit EtherChannel

Catalyst 4900 Series Switch Installation Guide

78-18039-02

1-3

Page 26

Catalyst 4948-10GE and Catalyst 4928-10GE Switch Software Features

• Catalyst 4500 series management software features include the following:

–

Command-line interface (CLI) and Simple Network Management

Protocol (SNMP) interfaces consistent with the Catalyst 4500 series

switches

–

Compatible development of new features with the Catalyst 4500 series

switches

–

Support for out-of-band management over serial lines through a terminal

attached to the console interface

–

Support for in-band management through any switch port through SNMP,

Telnet client, and Trivial File Transfer Protocol (TFTP)

–

Remote Monitoring (RMON) with RMON-1

–

Support for standard Layer 2 features: 802.1D Spanning Tree, Cisco

Discovery Protocol (CDP), VTP version 2 with pruning extensions, and

Cisco Group Management Protocol (CGMP) client

• Embedded management features include the following:

–

Full SNMP instrumentation including entity-Management Information

Base (MIB), all relevant standard MIBs, and all relevant Cisco MIBs

Chapter 1 Product Overview

–

Support for the first four RMON groups (Ethernet Statistics, Alarms,

Events, and History) on a per-port basis without the need for an optional

RMON processing module

–

Performance management information

–

Embedded CiscoView support

Catalyst 4948-10GE and Catalyst 4928-10GE Switch

Software Features

The following is an overview of Catalyst 4948-10GE features:

• Layer 2, Layer 3, and Layer 4 switching services

• Support for 55,000 MAC addresses for Layer 2 switching

• Support for 4,096 VLANs and 4,096 VLAN IDs

–

IEEE 802.1Q VLAN tagging on all ports

Catalyst 4900 Series Switch Installation Guide

1-4

78-18039-02

Page 27

Chapter 1 Product Overview

• 16,000 multicast forwarding entries and 16,000 unicast forwarding entries

• 1022 ingress policers and 1022 egress policers

• 32,000 ingress Security ACEs and 32,000 egress Security ACEs

• Support for port aggregation using Port Aggregation Protocol (PAgP) for

• Catalyst 4500 series management software features include the following:

Catalyst 4948-10GE and Catalyst 4928-10GE Switch Software Features

–

Q-in-Q for EFM

–

Cisco Inter Switch Link (ISL) tagging on all ports

Gigabit EtherChannel

–

Command-line interface (CLI) and Simple Network Management

Protocol (SNMP) interfaces consistent with the Catalyst 4500 series

switches

–

Compatible development of new features with the Catalyst 4500 series

switches

–

Support for out-of-band management over serial lines through a terminal

attached to the console interface

–

Support for in-band management through any switch port through SNMP,

Telnet client, and Trivial File Transfer Protocol (TFTP)

78-18039-02

–

Remote Monitoring (RMON) with RMON-1

–

Support for standard Layer 2 features: 802.1D Spanning Tree, Cisco

Discovery Protocol (CDP), VTP version 2 with pruning extensions, and

Cisco Group Management Protocol (CGMP) client

• Embedded management features include the following:

–

Full SNMP instrumentation including entity-Management Information

Base (MIB), all relevant standard MIBs, and all relevant Cisco MIBs

–

Support for the first four RMON groups (Ethernet Statistics, Alarms,

Events, and History) on a per-port basis without the need for an optional

RMON processing module

–

Performance management information

–

Embedded CiscoView support

Catalyst 4900 Series Switch Installation Guide

1-5

Page 28

Hardware System Features

Hardware System Features

The Catalyst 4900 series switches are high-performance dedicated Ethernet

switches that fully integrate into the Catalyst family of switches using Catalyst

4500 series system software.

The following is an overview of the Catalyst 4900 series hardware features:

• (Catalyst 4948 and 4948-10GE) 48 10BASE-T/100BASE-TX/1000BASE-T

Ethernet ports using RJ-45 interfaces. The following standards are supported:

–

IEEE 802.3 10BASE-T

–

IEEE 802.3u 100BASE-TX

–

IEEE 802.3z 1000BASE-X

–

IEEE 802.3x Pause and/or Full Duplex

–

IEEE 802.1Q

–

IEEE 802.3ab 1000BASE-T

–

IEEE 802.3ae

Chapter 1 Product Overview

1-6

–

IEEE 802.1p

• (Catalyst 4948) Four 1000BASE-X Ethernet ports using SFP interfaces

(These ports share MAC addresses with the last four

10BASE-T/100BASE-TX/1000BASE-T Ethernet ports.)

• (Catalyst 4928-10GE) 28 1000BASE-X Ethernet ports using SFP interfaces

• (Catalyst 4948-10GE and Catalyst 4928-10GE) Two 10-Gigabit Ethernet

uplink ports using X2 interfaces

• Serial console management port using an RJ-45 interface

• A removable automatic variable speed fan tray for low noise (no more than

48

dB) operation at room temperature

• Redundant and removable 300 W AC or 300 W DC power supplies

• 256-MB SDRAM (fixed), 64-MB embedded Flash memory

• EtherChannel at 10/100/1000 Mbps (and 10 Gbps for the Catalyst 4948-10GE

and Catalyst 4928-10GE)

• Hardware-based access lists

• Storm control in hardware

Catalyst 4900 Series Switch Installation Guide

78-18039-02

Page 29

Chapter 1 Product Overview

Switch Components

This section describes the hardware components.

Traffic Ports on the Catalyst 4948

There are 48 10/100/1000BASE-T Ethernet ports using RJ-45 interfaces and four

1000BASE-X Ethernet ports using SFP interfaces. These SFP ports share MAC

addresses with the last four 10/100/1000BASE-T ports. The interface

configuration mode command media-type sfp | rj45 can be used to configure the

media type for these ports in the switch software and to determine whether the

SFP connector or the RJ-45 connector is used. The default is SFP.

Traffic Ports on the Catalyst 4948-10GE

There are 48 10/100/1000BASE-T Ethernet ports using RJ-45 interfaces and two

10-Gigabit Ethernet uplink ports using X2 interfaces.

Switch Components

Traffic Ports on the Catalyst 4928-10GE

There are 28 1000BASE-X Ethernet ports using SFP interfaces.

Console Port

A console serial port (RJ-45) provides for switch management using standard

console equipment. (See

Appendix A, “Specifications,” for the console and management ports.

The Management port on the front panel is only operational when the switch is in

rommon mode. When in use, it offers the same TCP/IP based management

services available using inband access (Telnet, SNMP, etc.). IP address

configuration using BOOTP is supported on the Management port; it also

supports image download to the switch.

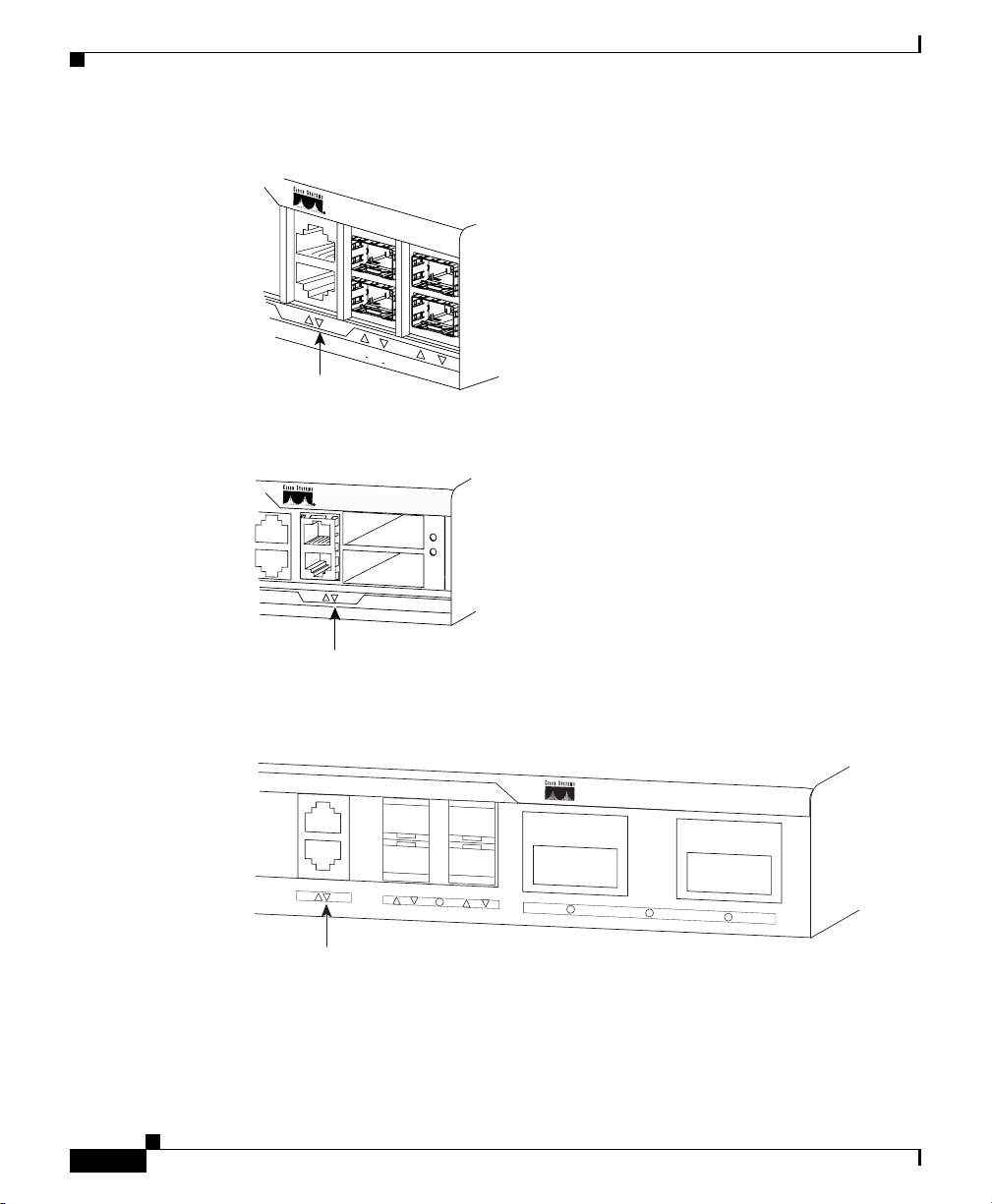

Figure 1-4 and Figure 1-5 show the location of the management and console ports

on the switches.

78-18039-02

Figure 1-4.) A connector pinout table is provided in

Catalyst 4900 Series Switch Installation Guide

1-7

Page 30

Switch Components

Chapter 1 Product Overview

Figure 1-4 (Catalyst 4948) Management Port LEDs Detailed View

Catalyst 4948

CO

N

MGT

45 46 47 48

MGT port LED

Figure 1-5 (Catalyst 4948-10GE) Management Port LEDs Detailed View

Catalyst WS-C4948 10GE

X2-1

X2-2

C

O

N

M

G

T

113140

1-8

MGT port LED

Figure 1-6 (Catalyst 4928-10GE) Management Port Detailed View

CON

MGMT

25

E

26

NABLED

Management

Port LED

Catalyst 4900 Series Switch Installation Guide

27

130084

28

C

at

alyst ME 4924 10GE

271711

29

E

NABLED

30

78-18039-02

Page 31

Chapter 1 Product Overview

Front Panel LEDs

The LEDs on the front panel of the switch (see Figure 1-4 and Figure 1-7) provide

status information as follows:

Figure 1-7 Detailed View of the STATUS LEDs

Switch Components

STA

PS1

PS2

FAN

TUS

1

113141

Power supply 1 LED

Power supply 2 LED

Fan LED

Port LEDs

STATUS LED

• STATUS LED indicates the operating state of the switch.

• PS1 LED indicates the internal power supply status.

• PS2 LED indicates the internal power supply status.

• FAN LED indicates the fan tray status.

• A link status LED is below the management port.

78-18039-02

Catalyst 4900 Series Switch Installation Guide

1-9

Page 32

Switch Components

Table 1-1 describes LED functions.

Ta b l e 1-1 LED Functions

LED Color or State Description

STATUS

Green

Red

Flashing

Yel low

Off

CON Green

At startup, the switch performs a series of

diagnostic tests:

All tests pass

A test other than an individual port test fails

System boot or diagnostic tests in progress

System is in rommon mode or a power supply

has failed

Switch is disabled

10/100 BASE-T console port is in link-up

state

Chapter 1 Product Overview

1-10

Off

MGT Green

Off

Port 1-48 Green

Yel low

Flashing yellow

Off

Catalyst 4900 Series Switch Installation Guide

10/100 BASE-T console port is in link-down

state or not connected

There are no blinking, red, or yellow states

for this port

10/100 BASE-T Management port is in

link-up state

10/100 BASE-T Management port is in

link-down state or not connected

There are no blinking, red, or yellow states

for this port

Port is operational

Port is disabled by user

Power-on self-test indicates faulty port

No signal detected or link configuration

failure

78-18039-02

Page 33

Chapter 1 Product Overview

Table 1-1 LED Functions (continued)

LED Color or State Description

FAN Off

PS1 and

PS2

1. If either LED is green and the other is OFF the power supply is probably not plugged in. If it is

Chassis Cooling

Switch Components

No power to the switch or fans (the tray may

Green

Red

Off

Green

Red

red, the supply is either plugged in and not switched on or it is faulty. It may be necessary to use

the CLI for further status information.

not be plugged in especially if one or more of

the power supplies status LED is green)

Fan tray operational

Fault detected

No power to the PS

Operational1

Fault detected or the on/off switch is set to

off while the power supply is plugged in

78-18039-02

Note For environmental specifications, see Chapter 2, “Site Planning.”

The hot-swappable system fan tray provides cooling air for the internal chassis

components. The fans exhaust air to the rear, and fresh air is drawn in from the

sides of the chassis.

Caution When the fan tray is removed, internal circuitry is exposed that should not be

touched by tools or fingers. The system should not be left operating without a fan

tray for longer than is necessary to replace a faulty fan tray with a new one.

Figure 1-8 shows the direction of airflow going in and out of the switch.

Catalyst 4900 Series Switch Installation Guide

1-11

Page 34

Switch Components

Figure 1-8 Airflow (Catalyst 4948-10GE shown)

S

T

There are four fans in the fan tray. If an individual fan fails, the other fans continue

to run. Sensors monitor the internal air temperatures. The number of fans in

operation and their speed varies according to the internal temperature for the

quietest operation possible. If the air temperature exceeds a desired threshold, the

environmental monitor displays warning messages.

Power Supplies

Chapter 1 Product Overview

P

S

1

P

S

2

F

A

N

A

T

U

S

1

1

6

1

7

3

2

3

3

C

a

ta

ly

s

t W

S

-C

49

4

8 1

0G

E

X

2

-

1

X

2

-

C

O

48

2

N

M

G

T

130085

1-12

Note For complete power specifications for the switch, see Appendix A,

“Specifications.”

The Catalyst 4900 series switches have two redundant internal 300 W AC or 300

W

DC power supplies.

The internal power supplies have individual power cords and status LEDs (PS1

and PS2 on the front panel). There are also LEDs on the power supplies that show

status for the input (Input OK) and output (Output OK) currents. A power cord is

used to connect the power supplies to the site power source. There is a power

switch on the AC power supplies; AC power is present when a power cord is

plugged into a power supply and the switch is set to the On position. DC power

supplies do not have an on/off switch and do not provide a cable for connection

to a DC power source.

Catalyst 4900 Series Switch Installation Guide

78-18039-02

Page 35

Chapter 1 Product Overview

Figure 1-9 On/Off Switch Locations

The switch will start with only one power supply plugged in, but redundant

failover and load sharing will not be available in this configuration. We

recommend that you always connect both power supplies to separate AC or DC

circuits for optimal power reliability.

For safety reasons, the AC power supply needs to be switched off and unplugged

before it is removed from a chassis or inserted into a chassis. DC supplies should

have power shut off from the source before they are removed.

If only one power supply will be used, you must use the blank faceplate supplied

to cover the empty power bay.

Switch Components

On/Off Switch

113143

Environmental Monitoring of the Power Supplies

Using the environmental monitoring and reporting functions, you can maintain

normal system operation by resolving adverse environmental conditions prior to

loss of operation.

Each power supply monitors its own temperature and output voltages. The switch

senses the operating condition of the power supply and reports status through

software.

Catalyst 4900 Series Switch Installation Guide

78-18039-02

1-13

Page 36

Switch Components

Power Management for the Switch

You can choose AC or DC power supplies for your switch. The Catalyst 4900

series switches support the following power supplies:

• 300 W AC

• 300 W DC

A redundant power supply can be identified and diagnosed by a running system

regardless of its input status. AC and DC supplies are interchangeable.

Power Management Modes

Catalyst 4900 series switches support the redundant power management mode. In

this mode, if both power supplies are operating normally, each provides from

20/80 to 45/55 percent of the total system power requirements at all times. If one

power supply fails, the other unit increases power to 100 percent of the total power

requirement.

Chapter 1 Product Overview

1-14

Catalyst 4900 Series Switch Installation Guide

78-18039-02

Page 37

CHAPTER

2

Site Planning

This chapter describes how to prepare your site for installation of the switch and

contains these sections:

• Site Environmental Requirements, page 2-1

• Site Power Requirements, page 2-2

• Grounding Requirements, page 2-6

• Safety Overview, page 2-7

• Site Planning Checklist, page 2-9

For detailed information about cabling requirements, see Chapter 4, “Transceiver

Modules.”

Note A site planning checklist is provided on page 3-5 to help ensure that you complete

all site planning activities before you install the switch.

Site Environmental Requirements

Planning a proper location for the switch and layout for your equipment rack or

wiring closet is essential for successful system operation. You should install the

switch in an enclosed, secure area, ensuring that only qualified personnel have

access to the switch and control of the environment. Equipment that is placed too

closely together or that is inadequately ventilated can cause system

overtemperature conditions. In addition, poor equipment placement can make

chassis panels inaccessible and difficult to maintain.

Catalyst 4900 Series Switch Installation Guide

78-18039-02

2-1

Page 38

Site Power Requirements

The switch operates as a standalone system mounted in a rack in a secure wiring

closet. It requires a dry, clean, well-ventilated, and air-conditioned environment.

To ensure normal operation, maintain ambient airflow. If the airflow is blocked or

restricted, or if the intake air is too warm, an overtemperature condition can occur.

The switch environmental monitor can then shut down the system to protect the

system components.

To ensure normal operation and avoid unnecessary maintenance, plan your site

configuration and prepare your site before installation. After installation, make

sure that the site maintains an ambient temperature of 0 to 40° C (32 to 104° F). It

is essential to keep the area around the chassis as free from dust and foreign

conductive material (such as metal flakes from nearby construction activity) as is

possible.

Multiple switches can be rack-mounted with little or no clearance above and

below the chassis. However, when mounting a switch in a rack with other

equipment, or when placing it on the floor near other equipment, ensure that the

exhaust from other equipment does not blow into the intake vents of the chassis.

Cooling air is drawn in through the sides and exhausted through the rear of the

chassis. Keep the sides and rear clear of obstructions, including dust and foreign

conductive material, and away from the exhaust ports of other equipment.

Appendix A, “Specifications,” lists the operating and nonoperating environmental

site requirements for the switches. To maintain normal operation and ensure high

system availability, maintain an ambient temperature and EMI-free and

continuous power at your site. The environmental ranges listed in

those within which the switch will continue to operate; however, a measurement

that approaches the minimum or maximum of a range indicates a potential

problem. You can maintain normal operation by anticipating and correcting

environmental anomalies before they exceed the maximum operating range.

Chapter 2 Site Planning

Appendix A are

Site Power Requirements

This section describes the installation site power requirements for the switch.

Verify your site power before you install the switch.

This section consists of the following sections:

• Pre-installation Requirements, page 2-3

• Warnings and Cautions, page 2-3

Catalyst 4900 Series Switch Installation Guide

2-2

78-18039-02

Page 39

Chapter 2 Site Planning

• EMI Recommendations, page 2-4

• Power Requirements and Heat Dissipation, page 2-4

Pre-installation Requirements

Follow these requirements when preparing your site for the switch installation:

• Connect each switch to separate wiring on a dedicated circuit; provide each

switch with its own branch circuit connection with sufficient overcurrent

protection and direct grounding to the branch circuit.

• To prevent a loss of input power, be sure the total maximum load on each AC

circuit is within the current ratings of the wiring and breakers.

Warnings and Cautions

Follow these precautions when preparing your site for the switch installation:

Site Power Requirements

78-18039-02

Caution The total maximum load on each AC-input power circuit must be within the rating

of the wiring and breaker. An overload of input power can result if this

requirement is not met.

Warning

Warning

Warning

Read the installation instructions before connecting the system to the power

source.

Installation of the equipment must comply with local and national electrical

codes.

Ultimate disposal of this product should be handled according to all national

laws and regulations.

Statement 1004

Statement 1074

Statement 1040

Catalyst 4900 Series Switch Installation Guide

2-3

Page 40

Site Power Requirements

EMI Recommendations

Follow these guidelines when setting up the site wiring. When planning the

location of the new system, consider electromagnetic interface (EMI), the

distance limitations for signaling, and connector compatibility.

When wires are run for any significant distance in an electromagnetic field, radio

frequency interference (RFI) can occur between the field and the signals on the

wires.

• Bad plant wiring can result in radio frequency interference.

• Strong EMI, especially when caused by lightning or radio transmitters, can

destroy the signal drivers and receivers in the switch and can create an

electrical hazard by conducting power surges through lines and into

equipment.

Note To predict and remedy strong EMI, you might need to consult RFI experts.

Chapter 2 Site Planning

Power Requirements and Heat Dissipation

The power requirements might be useful for planning the power distribution

system needed to support the switches. Heat dissipation is an important

consideration for sizing the air-conditioning requirements for an installation.

Refer to

switch.

Catalyst 4900 Series Switch Installation Guide

2-4

Appendix A, “Specifications,” for the power and heat ratings for a

78-18039-02

Page 41

Chapter 2 Site Planning

Site Power Requirements

You will also need to provide power to the switch with the appropriate AC power

cord for your location.

power supply.

Ta b l e 2-1 AC-Input Power Cord Options

Locale Part Number Length Plug Rating Plug Type

300 W AC Power Supply

North America CAB-US515-C15-US=

(was CAB-7KAC=)

Table 2-1 lists the power cords that are used with the AC

Appliance

Coupler

8.2 ft (2.5 m) 125 VAC, 15 A NEMA 5-15P

120352

120354

Australia,

New

Zealand

Europe (except

Italy)

CAB 13.2 ft

(4.0

m)

CAB 13.6 ft

(4.1

m)

CAB-AS3112-C15-AU=

8.2 ft (2.5 m) 250 VAC, 15 A SAA/3,

(was CAB-7ACA=)

CAB-CEE77-C15-EU=

8.2 ft (2.5 m) 250 VAC, 16 A CEE 7/7

(was CAB-7ACE=)

250 VAC, 16 A NEMA 6-20

non-locking

120355

250 VAC, 16 A NEMA L6-20

120361

AS/NZS 3112-1993

120356

120357

78-18039-02

Catalyst 4900 Series Switch Installation Guide

2-5

Page 42

Chapter 2 Site Planning

Grounding Requirements

Table 2-1 AC-Input Power Cord Options (continued)

Locale Part Number Length Plug Rating Plug Type

Italy CAB-C2316-C15-IT=

(was CAB-7ACI=)

8.2 ft (2.5 m) 250 VAC, 16 A 1/3/16 CEI 23-16

120358

United

Kingdom

Argentina CAB-IR2073-C15-AR=

CAB-BS1363-C15-UK=

(was CAB-7ACU=)

8.2 ft (2.5 m) 250 VAC, 13 A BS 89/13

8.2 ft (2.5 m) 250 VAC, 10 A IRAM 2073

(was CAB-7KACR=)

South Africa,

India

CAB-BS546-C15-SA=

(was CAB-7KACSA=)

8.2 ft (2.5 m) 250 VAC, 10 A BS 546

Grounding Requirements

Grounding is recommended on all AC or DC installations, using only approved

copper connectors. Attach the provided two hole ground lug to the chassis using

M4x 8mm bolts and then to the central office (CO) or other interior ground system

with number 6

chassis, and either one may be used. (See

AWG wire. The grounding connectors are on the right side of the

BS 1363/A

120359

120356

203795

Figure 2-1.)

2-6

Catalyst 4900 Series Switch Installation Guide

78-18039-02

Page 43

Chapter 2 Site Planning

Figure 2-1 Grounding Pad Locations (Catalyst 4849-10GE shown)

P

S

1

P

S

2

F

A

N

S

T

A

T

U

S

1

Safety Overview

This section provides safety information that you should read and understand to

ensure a safe switch installation.

Safety Overview

Grounding pads

C

a

ta

ly

st W

S

-C

4

9

48

1

0

G

E

X

2

-

1

X

2

-

1

6

1

7

3

2

3

3

C

48

2

O

N

M

G

T

130180

Ensuring Safety

Follow these guidelines to ensure your safety and protect the equipment. This list

is not inclusive of all potentially hazardous situations that you may be exposed to

as you install the switch, so be alert.

Warning

Warning

78-18039-02

Only trained and qualified personnel should be allowed to install, replace, or

service this equipment.

The plug-socket combination must be accessible at all times, because it serves

as the main disconnecting device.

Statement 1030

Statement 1019

Catalyst 4900 Series Switch Installation Guide

2-7

Page 44

Safety Overview

Chapter 2 Site Planning

Warning

Note To completely de-energize the system, unplug the power cord.

This equipment must be grounded. Never defeat the ground conductor or

operate the equipment in the absence of a suitably installed ground conductor.

Contact the appropriate electrical inspection authority or an electrician if you

are uncertain that suitable grounding is available.

• Always use caution when lifting heavy equipment. See the “Lifting the

Statement 1024

Chassis Safely” section on page 3-5 before lifting the switch.

• Always turn all power supplies off by unplugging all power cords before

installing or removing a chassis.

• Keep the chassis area clear and free of dust during and after installation.

• Keep tools and chassis components off of the floor and away from foot traffic.

• Avoid wearing jewelry (including rings and chains) or other items that could

get caught in the chassis. Avoid wearing any loose clothing, or securely fasten

items such as ties, scarves, or sleeves.

• Install the system in compliance with the following local and national

electrical codes:

–

United States—National Fire Protection Association (NFPA 70); United

States National Electrical Code

–

Canada—Canadian Electrical Code, Part I, CSA C22.1

–

Other countries—International Electrotechnical Commission (IEC)

60364, Part 1 through Part 7

Working Safely with Electricity

Follow these basic guidelines when working with any electrical equipment:

• Locate the emergency power-off switch for the room in which you are

working before beginning installation.

• Disconnect all power and external cables before installing or removing a

chassis.

Catalyst 4900 Series Switch Installation Guide

2-8

78-18039-02

Page 45

Chapter 2 Site Planning

• Do not work alone when potentially hazardous conditions exist.

• Never assume that power has been disconnected from a circuit; always check.

• Do not perform any action that creates a potential hazard to people or makes

the equipment unsafe.

• Examine your work area carefully for possible hazards such as moist floors,

ungrounded power extension cables, and missing safety grounds.

Preventing Electrostatic Discharge Damage

Electrostatic discharge (ESD) damage occurs when electronic cards or

components are improperly handled and can result in complete or intermittent

failures. Follow these guidelines to prevent ESD damage:

• Always use an ESD-preventive wrist or ankle strap, and ensure that it makes

maximum contact with the skin.

• When coming into contact with any internal components, always use a wrist

strap connected to one of the following:

Site Planning Checklist

–

ESD wrist strap connector

–

Any unpainted grounded surface on the chassis or equipment rack

Caution Periodically check the resistance value of the antistatic strap. The measurement

should be between 1 and 10 megohms (Mohms).

• Handle cards by the edges only.

• Avoid contact between the modules and clothing. The wrist strap protects

only the card from ESD voltages on the body; ESD voltages on clothing can

still cause damage.

Site Planning Checklist

Table 2-2 lists the site planning activities that you should perform before you

install the switch. Completing each activity helps to ensure a successful switch

installation.

78-18039-02

Catalyst 4900 Series Switch Installation Guide

2-9

Page 46

Chapter 2 Site Planning

Site Planning Checklist

Ta b l e 2-2 Site Planning Checklist

Task No. Planning Activity Verified By Time Date

1 Space evaluation:

Space and layout

Floor covering

Shock and vibration

Lighting

Maintenance access

2 Environmental evaluation:

Ambient temperature

Humidity

Altitude

Atmospheric contamination

Airflow

3 Power evaluation:

Input power type

Receptacle proximity to the equipment

Dedicated (separate) circuits for redundant power

supplies

UPS for power failures

4 Grounding evaluation:

Circuit breaker size

5 Cable and interface equipment evaluation:

Cable type

Connector type

Cable distance limitations

Interface equipment (transceivers)

6 EMI evaluation:

2-10

Distance limitations for signaling

Site wiring

RFI levels

Catalyst 4900 Series Switch Installation Guide

78-18039-02

Page 47

CHAPTER

3

Installing the Switch

This chapter describes how to install the Catalyst 4900 series switch. For

first-time installations, perform the procedures in the following sections in the

order listed.

• Verifying the Contents, page 3-1

• Rack-Mounting the Switch, page 3-2

• Connecting AC Power to the Switch, page 3-9

• Connecting DC Power to the Switch, page 3-11

Note Before starting the installation procedures in this chapter, complete the site

planning checklist in

activities were completed.

Chapter 2, “Site Planning,” to verify that all planning

Verifying the Contents

Note Do not discard the shipping container when you unpack the switch. Flatten the

shipping cartons and store them. You will need the container if you need to move

or ship the switch in the future.

78-18039-02

Catalyst 4900 Series Switch Installation Guide

3-1

Page 48

Rack-Mounting the Switch

To verify the contents of the shipping container follow these steps:

Step 1 Compare the contents of the accessories kit to the packing slip. Verify that you

received all listed equipment, which should include the following:

• Switch hardware and software documentation, if ordered

• Optional equipment that you ordered, such as network interface cables,

transceivers, or special connectors

Step 2 To begin installation, proceed to the “Rack-Mounting the Switch” section on

page 3-2.

Rack-Mounting the Switch

A standard rack-mount kit is included for mounting the switch in a standard

19-inch (48.3

unobstructed outer posts, a minimum depth between the front and rear mounting

posts of 19.25

This kit is not suitable for racks with obstructions (such as a power strip) that

could impair access to the switch.

cm) equipment rack. A standard equipment rack has two

inches (48.9 cm), and a maximum depth of 32 inches (81.3 cm).

Chapter 3 Installing the Switch

3-2

Caution Before installing the chassis in a rack, read the “Site Environmental

Requirements” section on page 2-1 to familiarize yourself with the proper site and

environmental conditions. Failure to read and follow these guidelines could lead

to an unsuccessful installation and possible damage to the system and

components.

Caution This unit is meant to be rack-mounted, and is not intended to bear more than its

own weight. Do not stack more than two on a table top, the added weight may

damage the bottom chassis.

Catalyst 4900 Series Switch Installation Guide

78-18039-02

Page 49

Chapter 3 Installing the Switch

Rack-Mounting the Switch

Warning

To prevent bodily injury when mounting or servicing this unit in a rack, you

must take special precautions to ensure that the system remains stable. The

following guidelines are provided to ensure your safety:

• This unit should be mounted at the bottom of the rack if it is the only unit in the rack.

• When mounting this unit in a partially filled rack, load the rack from the bottom to the

top with the heaviest component at the bottom of the rack.

• If the rack is provided with stabilizing devices, install the stabilizers before mounting

or servicing the unit in the rack.

Rack-Mounting Guidelines

Before rack-mounting the switch, ensure the following:

• The equipment rack is the proper size.

–

The width of the rack, between the two front mounting strips or rails,

must be 17.75

–

The depth of the rack, between the front and rear mounting strips, must

be at least 19.25

–

The rack must have sufficient vertical clearance to insert the chassis. The

chassis height is 1.75 inches (4.45 cm).

Statement 1006

inches (45.09 cm).

inches (48.9 cm) but not more than 32 inches (81.3 cm).

78-18039-02

• The equipment rack is stable and in no danger of falling over.

–

Ensure that the shelf is constructed to support the weight and dimensions

of the chassis. For physical specifications, see

Appendix A,

“Specifications.”

–

We recommend that you bolt the rack to the floor.

–

Mount the unit at the bottom of the rack if it is the only unit in the rack.

–

Install heavier equipment in the lower half of the rack to maintain a low

center of gravity and prevent the rack from becoming top-heavy and

tipping over.

Catalyst 4900 Series Switch Installation Guide

3-3

Page 50

Rack-Mounting the Switch

• The equipment rack is properly ventilated.

Chapter 3 Installing the Switch

–

Install the stabilizers before mounting or servicing the switch in the rack

(if the rack is provided with stabilizing devices).

–

Install the chassis in an enclosed rack only if it has adequate ventilation

or an exhaust fan; use an open rack whenever possible.

–

Ensure that the ambient temperature of the rack environment does not

exceed a maximum temperature of 104° F (40° C). Note that if the switch

is installed in a closed or multiunit rack assembly, the ambient operating

temperature of the rack environment might be higher than the ambient

room temperature.

–

Note that a ventilation system in a closed rack that is too powerful might

also prevent cooling by creating negative pressure around the chassis and

redirecting the air away from the chassis intake vent. If necessary,

operate the chassis with the rack open.

–

To prevent airflow restriction, allow at least 3 inches (7.6 cm) of

clearance around the ventilation openings on the sides of the chassis.

–

Use baffles correctly to assist in cooling the chassis.

–

Note that equipment near the bottom of a rack may generate excessive

heat that is drawn upward and into the intake ports of equipment above,

leading to overtemperature conditions in the chassis at or near the top of

the rack.

3-4

–

Consider the equipment and cabling that is already installed in the rack.

Ensure that cables from other equipment will not obstruct the airflow

through the chassis or impair access to the power supplies or switching

modules. Route cables away from field-replaceable components to avoid

disconnecting cables unnecessarily for equipment maintenance or

upgrades.

–

Allow at least 3 to 4 feet (91.4 to 121.9 cm) of clearance behind the rack

for maintenance and removal of switch assemblies. If the rack is mobile,

you can push it back within 1 foot (30.45 cm) of a wall or cabinet for

normal operation and pull it out when necessary for maintenance.

Catalyst 4900 Series Switch Installation Guide

78-18039-02

Page 51

Chapter 3 Installing the Switch

Lifting the Chassis Safely

The chassis is not intended to be moved frequently. Before you install the switch,

ensure that your site is properly prepared so that you can avoid moving the chassis

later to accommodate power sources and network connections.

Whenever you lift a chassis or any heavy object, follow these guidelines:

• Ensure that your footing is solid, and balance the weight of the chassis

between your feet.

• Lift the chassis slowly; never move suddenly or twist your body as you lift.

• Keep your back straight and lift with your legs, not your back. If you must

bend down to lift the chassis, bend at the knees, not at the waist, to reduce the

strain on your lower back muscles. (See

• Always disconnect all external cables before lifting or moving the chassis.

Figure 3-1 Unsafe Lifting Practices

Rack-Mounting the Switch

Figure 3-1.)

Required Installation Tools

The following tools and equipment are required to install the chassis:

• Number 1, number 2 Phillips, and 3/16-inch flat-blade screwdriver

• Antistatic mat or antistatic foam

78-18039-02

H1369a

Catalyst 4900 Series Switch Installation Guide

3-5

Page 52

Rack-Mounting the Switch

• Your own ESD grounding strap or the disposable ESD strap included with the

system

The following tools and equipment are required to install the chassis in a rack:

• Rack-mount kit

• Tape measure and level

Rack-Mounting the Switch

Note The illustrations shown are of a Catalyst 4948-10GE switch. The process for the

Catalyst 4948 and Catalyst 4928-10GE is identical.

Follow these steps to install the switch in a rack.

Step 1 Prepare for installation:

a. Place the chassis on the floor or on a sturdy table as close as possible to the

rack. Leave enough clearance to allow you to move around the chassis.

Chapter 3 Installing the Switch

3-6

b. Use a tape measure to measure the depth of the rack. Measure from the

outside of the front mounting posts to the outside of the rear mounting strip.

The depth must be at least 19.25

32

inches (81.3 cm).

c. Measure the space between the inner edges of the left front and right front

mounting posts to ensure that it is 17.75

is 17.5

inches [44 cm] wide and must fit between the mounting posts.)

d. Open the rack-mount kit, and refer to Table 3-1 to verify that all parts are

included.

Ta b l e 3-1 Rack-Mount Kit Checklist

Quantity Part Description Received

2 L brackets

8 M4 x 8 mm Phillips flat-head screws

Catalyst 4900 Series Switch Installation Guide

inches (48.9 cm) but not greater than

inches (45.09 cm) wide. (The chassis

78-18039-02

Page 53

Chapter 3 Installing the Switch

Table 3-1 Rack-Mount Kit Checklist

Quantity Part Description Received

4 12-24 x 3/4-inch Phillips binder-head screws

4 10-32 x 3/4-inch Phillips binder-head screws

Note Figure 3-2 illustrates how to attach the front of the switch to the rack. You

Step 2 Note that the L brackets connect the chassis to the rack. You can mount the

L

brackets to the front or rear mounting holes of the chassis, depending on which

end is in the front of the rack.

Note Some equipment racks provide a power strip along the length of one of

Rack-Mounting the Switch

can also attach the rear of the switch to the rack, depending on the

configuration of your rack.

the rear posts. If the rack has this feature, consider the position of the strip

when planning fastener points. Before installing the L brackets on the

chassis, determine whether to install the chassis from the front or the rear

of the rack.

78-18039-02

Attach the left and right L brackets using the M4 Phillips flat-head screws

provided in the rack-mount kit. (See

Figure 3-2 Attaching the L Brackets to the Switch

P

S

1

P

S

2

F

A

N

S

T

A

T

U

S

1

Step 3 Install the chassis in the rack as:

a. Position the chassis in the rack as follows (see Figure 3-3):

1

6

1

7

Figure 3-2.)

C

a

ta

ly

s

t W

S

-C

4

9

4

8

1

0

G

E

X2-1

X2-2

C

O

3

2

3

3

Catalyst 4900 Series Switch Installation Guide

N

M

G

T

48

130086

3-7

Page 54

Rack-Mounting the Switch

b. Align the mounting holes in the L bracket with the mounting holes in the

c. Secure the chassis using four (two on each side) 12-24 x 3/4-inch screws

d. Use a tape measure and level to ensure that the chassis is installed straight and

Figure 3-3 Installing the Switch in the Rack

Chapter 3 Installing the Switch

–

If the chassis front panel is in the front of the rack, insert the rear of the

chassis between the mounting posts.

–

If the rear of the chassis is in the front of the rack, insert the front of the

chassis between the mounting posts.

equipment rack.

through the elongated holes in the L bracket and into the threaded holes in the

mounting post.

level.

3-8

P

S

1

P

S

2

F

A

N

S

T

A

T

U

S

1

1

6

1

7

3

2

3

3

C

a

t

a

l

y

s

t

W

S

-

C

4

9

4

8

1

0

G

E

X2-1

X2-2

C

O

N

M

G

T

48

Step 4 Attach the cable guide to the right or left side of the chassis mount.

Catalyst 4900 Series Switch Installation Guide

130087

78-18039-02

Page 55

Chapter 3 Installing the Switch

Figure 3-4 Installing the Cable Guide

Step 5 Do not connect the power cord at this time. Proceed to the “Connecting AC Power

to the Switch” section on page 3-9.

Connecting AC Power to the Switch

P

S

1

P

S

2

F

A

N

S

T

A

T

U

S

1

1

6

1

7

3

2

3

3

C

a

t

a

l

y

s

t

W

S

-

C

4

9

4

8

1

0

G

E

X

2

-

1

X

2

-2

C

O

N

M

G

T

48

130089

Connecting AC Power to the Switch

Follow these steps and warnings when connecting power to a Catalyst 4900 series

switch:

Step 1 Prior to connecting the power supply to a power source, ensure that all of the site

power and grounding requirements described in

been met and the chassis is properly grounded as described in the “Grounding

Requirements” section on page 2-6.

Warning

Step 2 Plug the power cords into the power supplies. (Figure 3-6 shows plug locations.)

78-18039-02

The plug-socket combination must be accessible at all times, because it serves

as the main disconnecting device.

Statement 1019

Catalyst 4900 Series Switch Installation Guide

Chapter 2, “Site Planning,” have

3-9

Page 56

Connecting AC Power to the Switch

Figure 3-5 AC Power Supply

On/off switch

AC power plug

Chapter 3 Installing the Switch

Handle

3-10

Status LEDs

Step 3 Connect the other end of the power cords to an AC-power input source. If both

120696

power supplies will be used, make sure they are on different circuits.

Step 4 Turn the power switches to the ON position.

Step 5 Verify power supply operation by looking at the front panel power supply LEDs:

• The PS1 or PS2 LED is green when the power supply and fans are functioning

normally.

• The PS1 or PS2 LED is red when the power supply is not functioning

normally. The on/off switch may be set to off while the power supply is

plugged in, or the power supply may be defective and not providing DC

power to the switch. There may also be a fan failure.

• The PS1 or PS2 LED is off when there is no power supply installed.

Catalyst 4900 Series Switch Installation Guide

78-18039-02

Page 57

Chapter 3 Installing the Switch

From the system console, enter the show power command to display the power

supply and system status. For more information on this command, see the

command reference publication for your software release.

If the LEDs or show power command indicate a power or other system problem,

see

Chapter 5, “Troubleshooting the Installation,” for troubleshooting

information.

Connecting DC Power to the Switch

Follow these steps and warnings when connecting DC power to the Catalyst 4900

series switch:

Connecting DC Power to the Switch

Warning

Warning

Warning

Warning

Before performing any of the following procedures, ensure that power is

removed from the DC circuit.

This unit is intended for installation in restricted access areas. A restricted

access area can be accessed only through the use of a special tool, lock and

key, or other means of security.

This product requires short-circuit (overcurrent) protection, to be provided as

part of the building installation. Install only in accordance with national and

local wiring regulations.

Hazardous voltage or energy may be present on DC power terminals. Always

replace cover when terminals are not in service. Be sure uninsulated

conductors are not accessible when cover is in place.

Statement 1003

Statement 1017

Statement 1045

Statement 1075

78-18039-02

Catalyst 4900 Series Switch Installation Guide

3-11

Page 58

Connecting DC Power to the Switch

Step 1 Prior to connecting the power supply to a power source, ensure that all of the site

power and grounding requirements described in

been met and the chassis is properly grounded as described in the “Grounding

Requirements” section on page 2-6.

Step 2 Remove the safety cover from the power terminal.