Page 1

AT10.1 SERIES

Operating and Service Instructions

MICROPROCESSOR-CONTROLLED

FLOAT BATTERY CHARGER

SINGLE PHASE INPUT

GROUP I

(6 - 25 Adc)

Page 2

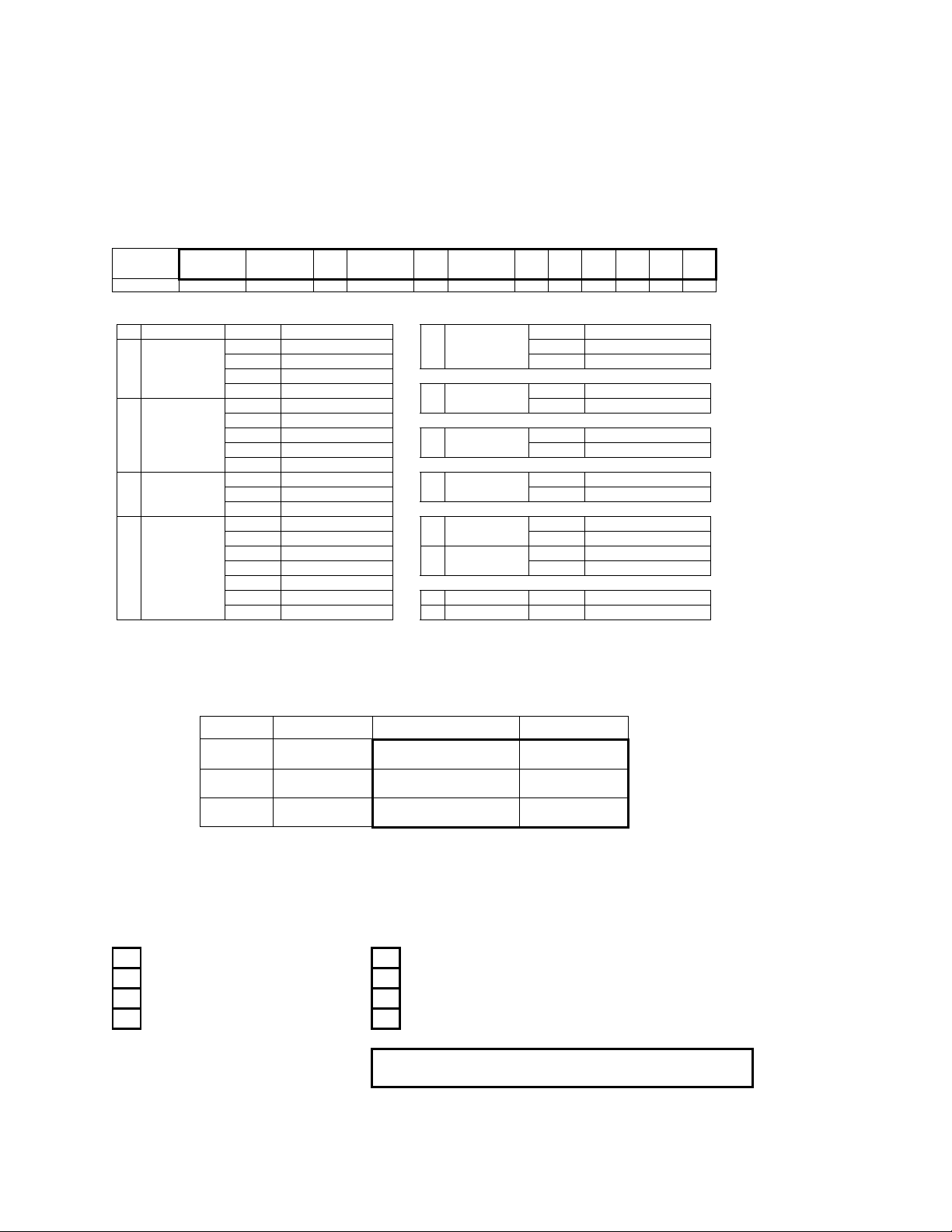

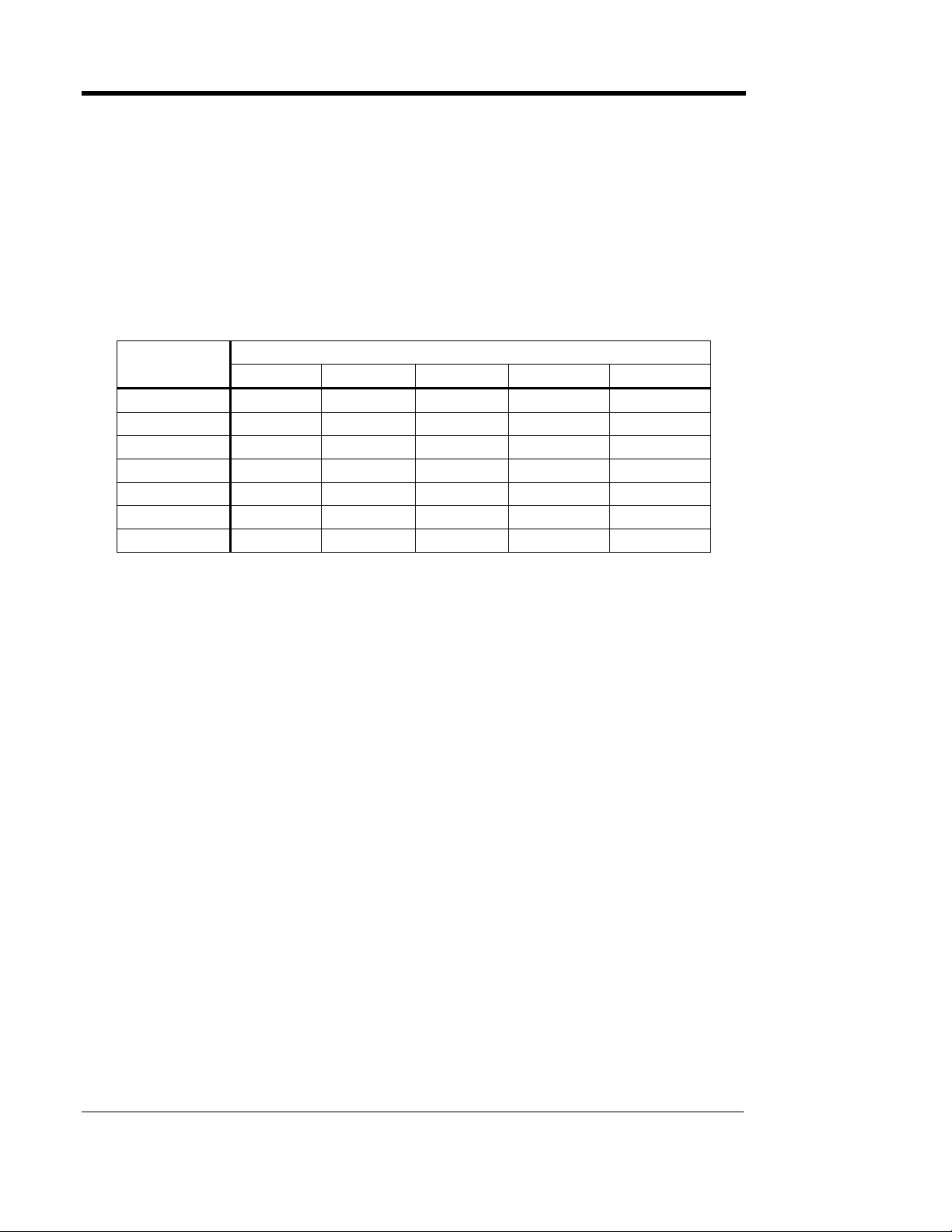

HOW TO READ THE AT10.1 MODEL NUMBER

GROUP I RATINGS (6-25 Adc)

Your AT10.1 model number is coded to describe the options that are included. Please find the model

number on the data nameplate and write it in the spaces provided below. Then follow the chart to

determine the configuration of your battery charger.

AT10

A B C D E F K L M N P Q R

DESCRIPTION CODE FEATURE

A

SERIES AT10 AT10.1 CHARGER S STANDARD

NOMINAL

B

DC OUTPUT

VOLTAGE

NOMINAL

C

DC OUTPUT

CURRENT

D

FILTERING

AC INPUT

E

VOLTAGE

4 - Rating applies to 130Vdc 16-25 Adc units.

5 - Approximate rating applies to all other units.

DESCRIPTION CODE FEATURE

1 - 120/208/240 Vac multi-tap input - Unit is wired and shipped from factory at specified voltage.

2 - 480 Vac input requires addition of medium or high ampere interrupting capacity circuit breakers.

3 - Special order - Please consult factory for availability.

INPUT AND OUTPUT CIRCUIT BREAKER INTERRUPTING RATINGS

012 12 Vdc M MEDIUM AIC

024 24 Vdc

048 48 Vdc

130 130 Vdc AUX SUPPLIED

006 6 Adc

012 12 Adc

016 16 Adc G SUPPLIED

020 20 Adc

025 25 Adc

U UNFILTERED L SUPPLIED

F FILTERED

E ELIMINATOR

120 120 Vac 60 Hz 1 F INCLUDED

208 208 Vac 60 Hz 1

240 240 Vac 60 Hz 1 S INCLUDED

480 480 Vac 60 Hz 2

220 220 Vac 50/60 Hz 3

380 380 Vac 50/60 Hz 3

416 416 Vac 50/60 Hz 3

CODE TYPE

S STANDARD 240 Vac: 10,000 AIC

M MEDIUM AIC

H HIGH AIC

DESCRIPTION CODE FEATURE

CIRCUIT

BREAKER

F

RATING

(SEE TABLE)

AUX ALARM

K

RELAY BOARD

L

GROUND PAD

LIGHTNING

M

ARRESTOR

FUNGUS

N

PROOFING

STATIC

P

PROOFING

Q

NOT USED X

R

CANADIAN C BILINGUAL LABELING

DESCRIPTION CODE FEATURE

AC RATINGS

(ALL INPUT VOLTAGES)

240 Vac: 25,000 AIC

480 Vac: 18,000 AIC

240 Vac: 65,000 AIC

480 Vac: 25,000 AIC

H HIGH AIC

XXX NOT SUPPLIED

X NOT SUPPLIED

X NOT SUPPLIED

X NOT INCLUDED

X NOT INCLUDED

DC RATINGS

(125 Vdc)

10,000 AIC 4

5,000 AIC 5

10,000 AIC

25,000 AIC

NOTE:

The model number listed on the charger data nameplate does not include any field-installed

options. Also, certain accessories are not included in the model number, even if they are shipped with the

charger. Check off below any accessories that were included, or that you install yourself.

Enclosure drip shield assembly NEMA-4/12/13 type enclosure

Floor mounting brackets Pad lock for front panel door

Rack mounting brackets External temperature compensation probe

Cabinet heater assembly DNP3 Level 2 / Modbus communications module

Please find the serial number on the

data nameplate and record it here:

Page 3

IMPORTANT SAFETY INSTRUCTIONS

1. Before using this equipment, read all instructions and cautionary

markings on: A) this equipment, B) battery, and C) any other equipment

to be used in conjunction with this equipment.

2. This manual contains important safety and operating instructions, and

therefore should be filed for easy access.

3. Remove all jewelry, watches, rings, etc. before proceeding with

installation or service.

4. Do not touch any uninsulated parts of this equipment, especially the

input and output connections, as there is the possibility of electrical

shock.

5. During normal operation, batteries may produce explosive gas. Never

smoke, use an open flame, or create arcs in the vicinity of this equipment

or the battery.

6. Maintain at least 6in / 152mm clearance from all obstructions on the top,

bottom and sides of this equipment. Allow sufficient clearance to open

the front panel for servicing.

7. Turn this equipment off before connecting or disconnecting the battery

to avoid a shock hazard and/or equipment damage.

8. Connect or disconnect the battery only when the battery charger is off to

prevent arcing or burning.

9. De-energize all ac and dc inputs to the battery charger before servicing.

10. Do not operate battery charger if it has been damaged in any way. Refer

to qualified service personnel.

11. Do not disassemble battery charger. Only qualified service personnel

should attempt repairs. Incorrect reassembly may result in explosion,

electrical shock, or fire.

12. Do not install the battery charger outdoors, or in wet or damp locations

unless specifically ordered for that environment.

PLEASE READ AND FOLLOW

ALL SAFETY INSTRUCTIONS

i

Page 4

TABLE OF CONTENTS

QUICK OPERATION ..................................................................................................Back Cover

HOW TO READ THE AT10.1 MODEL NUMBER ..........................................Inside Front Cover

IMPORTANT SAFETY INSTRUCTIONS ......................................................................................i

1 Receiving and Installing the AT10.1 Battery Charger

1.1 Storing the AT10.1 .................................................................................................2

1.2 Reporting shipping damage ...................................................................................2

1.3 Unpacking and inspecting the AT10.1 ...................................................................2

Inspection checklist ................................................................................................2

1.4 Moving the AT10.1 .................................................................................................3

Enclosure type and weight table ............................................................................3

1.5 Mounting the AT10.1 .............................................................................................. 3

1.5.1 Wall-Mounting the AT10.1 ............................................................................... 4

1.5.2 Floor-Mounting the AT10.1..............................................................................6

1.5.3 Rack-Mounting the AT10.1..............................................................................8

1.6 Changing transformer taps...................................................................................10

1.7 Making the ac input connections ..........................................................................12

1.8 Making the dc output connections........................................................................14

1.9 Wiring the AT10.1 for remote sensing.................................................................. 16

1.10 Wiring to the remote alarm contacts ....................................................................18

Auxiliary Relay Board (optional)...........................................................................19

1.11 Installing the temperature compensation assembly (optional).............................20

Using temperature compensation ........................................................................22

2 Operating the AT10.1 Battery Charger

2.1 Starting the AT10.1

2.1.1 Understanding the start-up sequence............................................................24

2.1.2 Checking the installation................................................................................ 24

2.1.3 Starting the AT10.1........................................................................................ 24

Using the digital meter ...................................................................................24

Factory settings table..................................................................................... 25

2.2 Using the AT10.1 front panel features

2.2.1 If the meter displays an error message ......................................................... 26

2.2.2 Selecting the meter mode..............................................................................26

2.2.3 Selecting the Float or Equalize mode............................................................ 27

2.2.4 Choosing the Equalize method......................................................................27

Manual Timer method....................................................................................27

Manual Equalize method ...............................................................................28

Auto-Equalize Timer method .........................................................................28

2.2.5 Testing the front panel indicators & Summary Alarm Relays ........................29

2.2.6 Testing the Auxiliary Relay Board..................................................................29

2.2.7 Interpreting the alarm indicators ....................................................................29

ii

Page 5

TABLE OF CONTENTS

2.3 Setting the AT10.1 parameters

2.3.1 Understanding parameter settings.................................................................30

2.3.2 Setting the Float and Equalize voltages.........................................................31

2.3.3 Setting the Equalize timer ..............................................................................32

2.3.4 Setting the Alarms..........................................................................................32

Setting the high and low dc voltage alarms ...................................................33

Adjusting ground detection sensitivity............................................................34

Disabling the ground detection alarm ............................................................35

2.3.5 Setting the current limit value.........................................................................35

2.3.6 Enabling the high dc voltage shutdown feature.............................................36

2.3.7 Adjusting the Voltmeter accuracy ..................................................................37

2.3.8 Using the Low Level Detector (LLD)..............................................................38

2.3.9 Using the front panel security feature ............................................................39

2.4 Performing routine maintenance ..........................................................................40

Sample preventive maintenance procedure ..................................................42

3 Servicing the AT10.1 Battery Charger

3.1 A step-by-step troubleshooting procedure ...........................................................44

3.2 Interpreting front panel error messages ...............................................................45

3.3 Using the troubleshooting chart............................................................................48

3.4 Troubleshooting chart begins on ..........................................................................49

3.5 Replacing defective components..........................................................................58

3.6 Ordering replacement parts..................................................................................64

Replacement parts tables (begin on)....................................................................64

APPENDIX A: AT10.1 Performance Specifications................................................................70

APPENDIX B: Field Installable Accessories...........................................................................71

APPENDIX C: Standard Drawings

Standard NEMA-1 Enclosure Outline (Style-586) ..........................................................72

Standard NEMA-1 Enclosure Outline (Style-594) ..........................................................73

Optional Enclosure Outline Drawings (with penthouse and/or drip shield) ....................74

Internal Component Layout Detail w/Common Options .................................................76

Instrument Panel Detail w/Optional Auxiliary Relay PC Board ......................................78

Schematic - AT10.1 Group I Battery Charger - Standard w/o Options ..........................80

Schematic - AT10.1 Group I Battery Charger - with Common Options .........................82

Connection Diagram - AT10.1 Group I Battery Charger - Standard w/o Options ..........84

APPENDIX D: Recommended Float / Equalize Voltages .......................................................88

APPENDIX E: DNP3 Level 2 / Modbus Communications Module.........................................89

APPENDIX F: UL Data ...............................................................................................................89

CUSTOMER NOTES (manual specifications).............................................................................90

Connection Diagram - AT10.1 Group I Battery Charger - with Common Options .........86

iii

Page 6

TABLE OF CONTENTS

1. RECEIVING THE AT10.1

1.1. STORING THE AT10.1

If you store the AT10.1 for more than a few days before installation, you

should store it in its original shipping container, and in a temperature

controlled, dry climate. Ambient temperatures of 32 to 122° F / 0 to 50° C

are acceptable. Storage should not exceed 2 years due to the limited shelf

life of the dc filter capacitors when they are not in service.

1.2. REPORTING SHIPPING DAMAGE

If, on delivery of the AT10.1 or related goods, you discover any damage

or shortage, make notation on all copies of delivering carrier's delivery

receipt before signing, and notify the delivery person of your findings. If

loss or damage is discovered after delivery, notify delivering carrier

immediately and request an inspection. The manufacturer does not assume

any liability for damage during transportation or handling.

Should the goods require an inspection by or return to the manufacturer,

please contact your sales representative for further instructions. Any

returned material must be properly packed in compliance with shipping

regulations. It is preferable to use the original shipping materials if

possible. Mark the outside of the shipping container with the Return

Material Authorization (RMA) number issued by the manufacturer.

1.3. UNPACKING AND INSPECTING THE AT10.1

Carefully remove all shipping materials from the AT10.1. Remove the

AT10.1 from the shipping pallet for inspection. Save all shipping

materials until you are sure that there is no shipping damage.

Once the AT10.1 is unpacked, inspect the unit for possible shipping

damage, using the checklist below. If shipping damage has occurred,

please refer to section 1.2 on this page for proper reporting.

INSPECTION CHECKLIST

o Enclosure exterior and interior are not marred or dented.

o There is no visible damage to exterior or interior components.

o All internal components are secure.

o Printed circuit boards are firmly seated on their standoffs.

o All hardware is tight.

o All wire terminations are secure.

o The User's Manual is included.

o You received all items on the packing list.

2

Page 7

RECEIVING THE AT10.1

1.4. MOVING THE AT10.1

Once you have established that the AT10.1 is undamaged, identify the

enclosure style and weight of your unit. Refer to the table below.

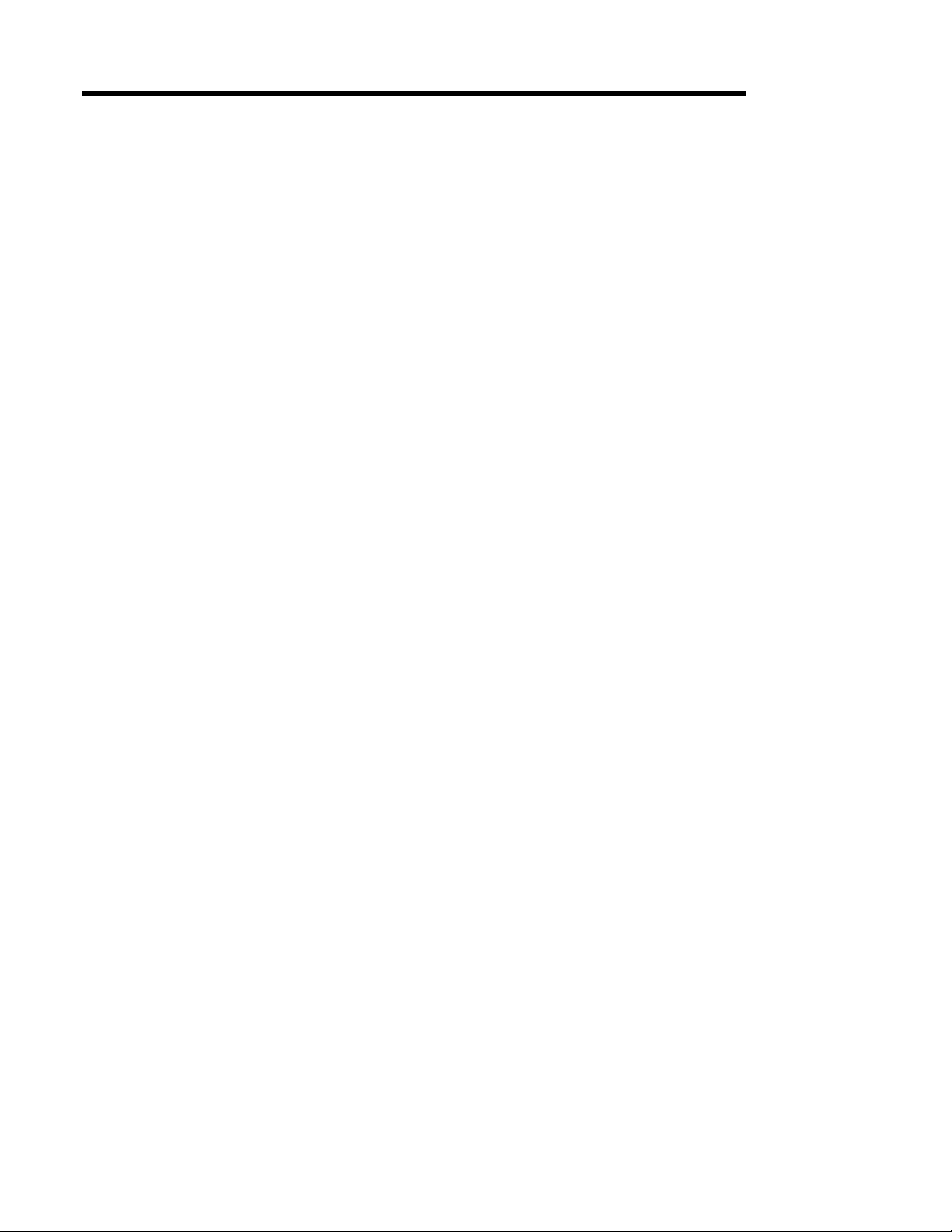

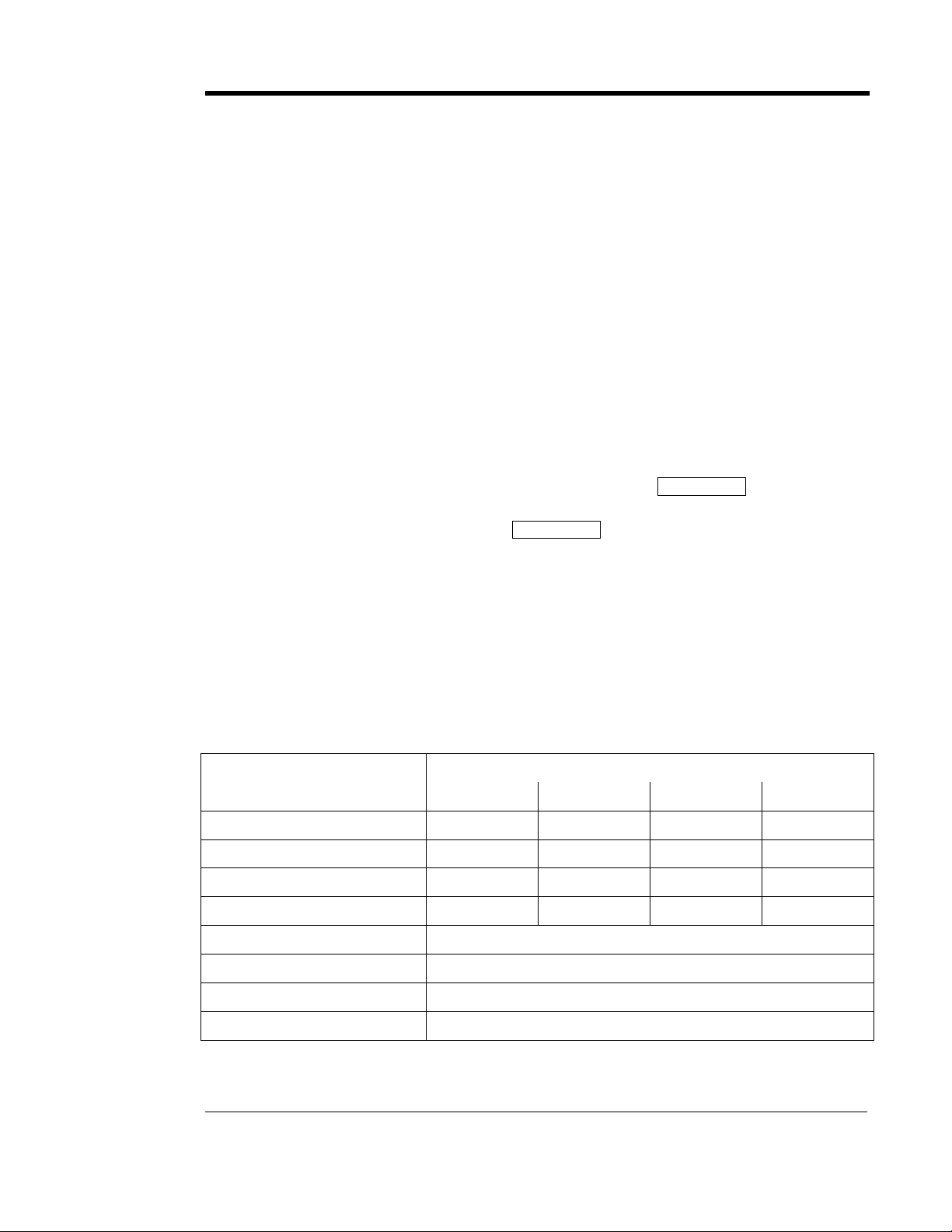

AT10.1 Enclosure Type And Shipping Weight Table

Group I Cabinet Styles (586 / 594)

Output

Voltage

6 Adc 126 Adc 16 Adc 20 Adc 25 Adc

Ampere Rating

Style-586

12 Vdc

24 Vdc

48 Vdc

130 Vdc

NOTE: Actual unit is approximately 20 lbs / 9kg below listed shipping weight in table.

44 lbs

20 kg

Style-586

44 lbs

20 kg

Style-586

58 lbs

26 kg

Style-586

80 lbs

36 kg

Style-586

44 lbs

20 kg

Style-586

58 lbs

26 kg

Style-586

75 lbs

34 kg

Style-594

147 lbs

67 kg

Style-586

67 lbs

30 kg

Style-586

75 lbs

34 kg

Style-594

110 lbs

50 kg

Style-594

193 lbs

88 kg

Style-586

67 lbs

30 kg

Style-586

75 lbs

34 kg

Style-594

110 lbs

50 kg

Style-594

193 lbs

88 kg

Style-586

67 lbs

30 kg

Style-586

75 lbs

34 kg

Style-594

110 lbs

50 kg

Style-594

193 lbs

88 kg

The Style-586 & 594 enclosures do not feature lifting eyes for moving.

Instead, whenever possible move the unit with a forklift truck using the

supplied shipping pallet. To hoist the unit into a wall-mount or rackmount location, use a heavy-duty sling applicable to the enclosure size

and unit weight. To relocate the Style-586 & 594 enclosures, use the

aforementioned sling on a hoist or forklift truck.

1.5. MOUNTING THE AT10.1

Chose the mounting method for the unit enclosure from the table below.

MANUAL

SECTION

1.5.1 Wall-Mounting STANDARD STANDARD

1.5.2 Floor-Mounting OPTIONAL OPTIONAL

1.5.3

MOUNTING METHOD

19in / 483mm Rack-Mounting OPTIONAL OPTIONAL

23-24in / 584-610mm

Rack-Mounting

OPTIONAL OPTIONAL

ENCLOSURE

Style-586 Style-594

3

Page 8

INSTALLING THE AT10.1

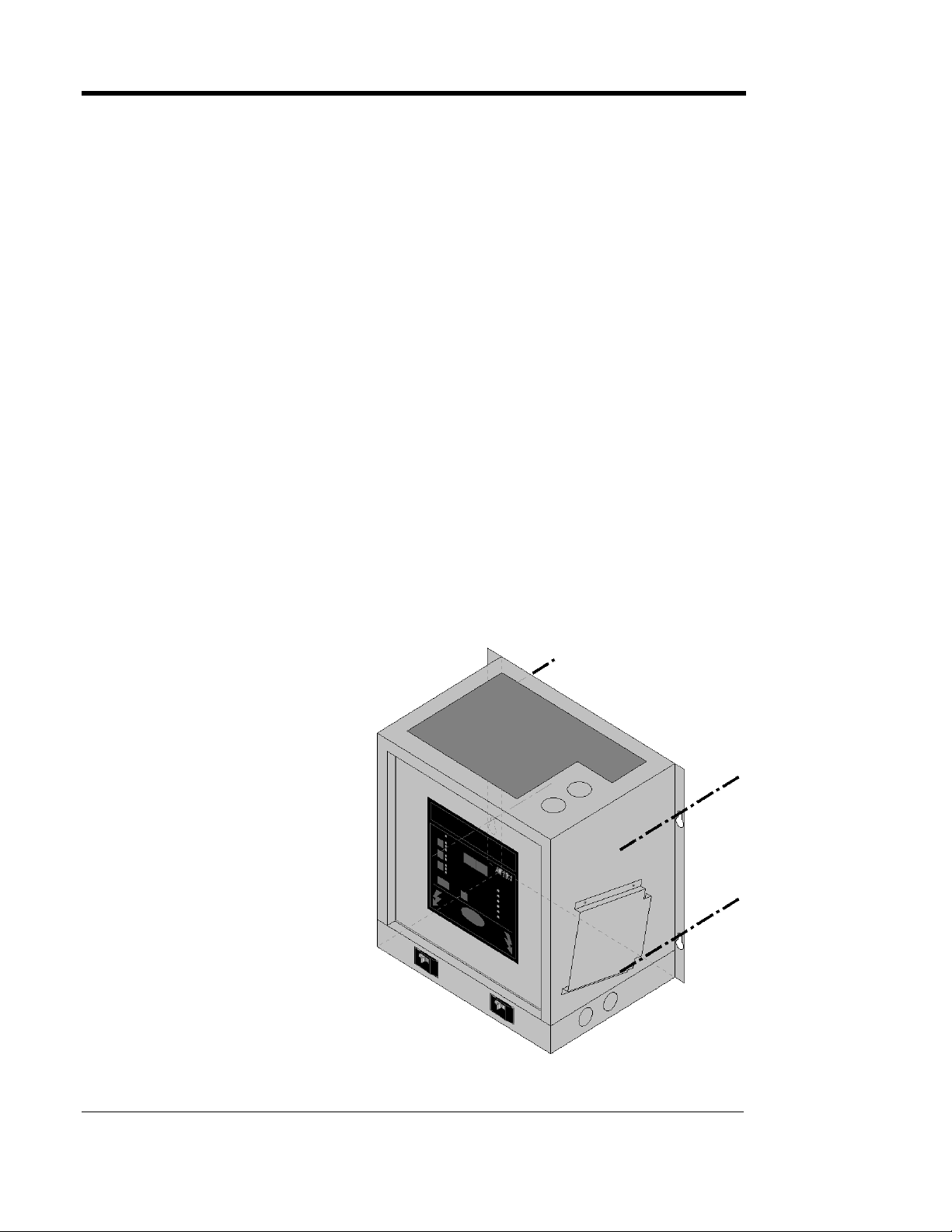

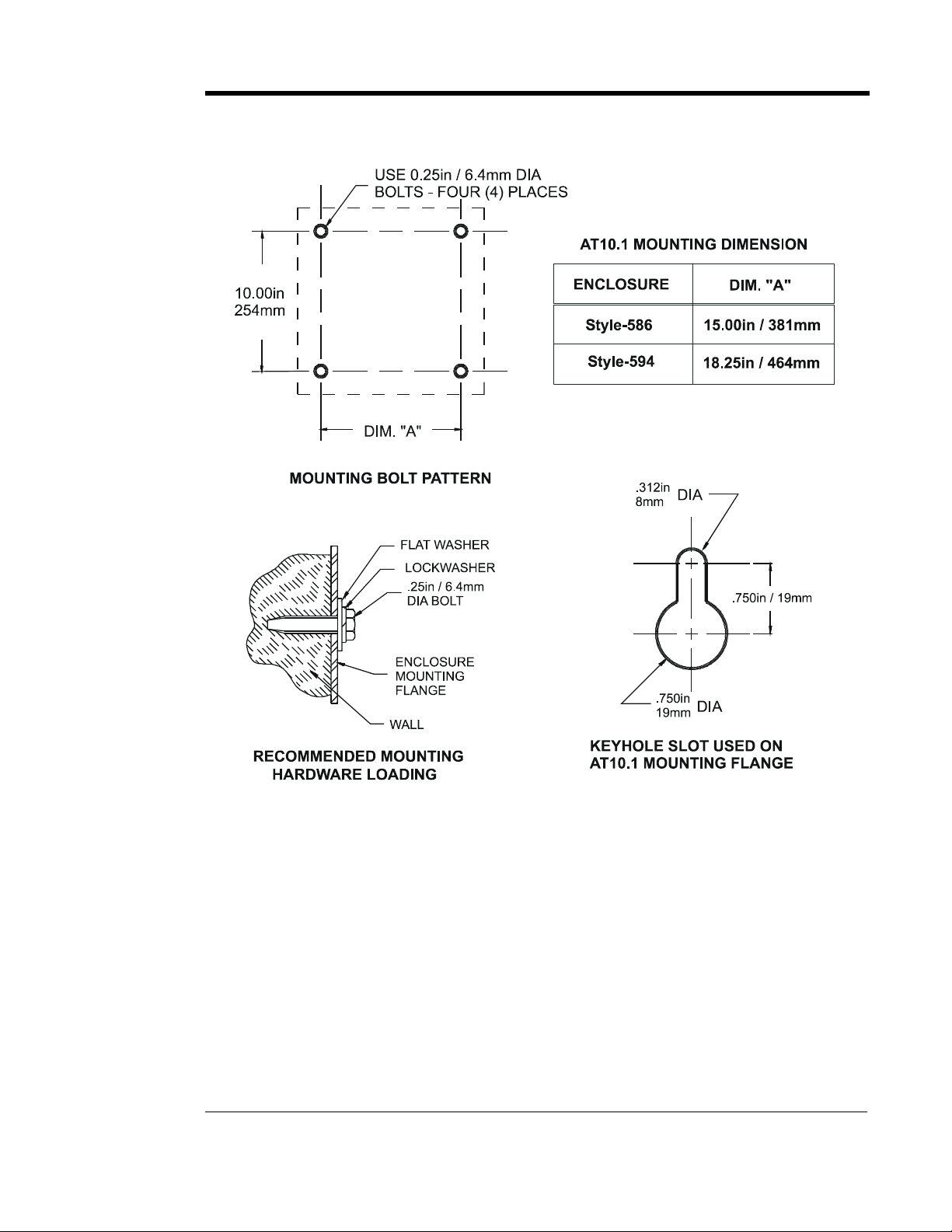

1.5.1. Wall-Mounting the AT10.1

Wall-mounting the AT10.1 battery charger is the standard way to install

the Group I enclosures (Style-586/594). In planning for wall mounting of

the AT10.1 consider the following:

1. The wall must be strong enough to properly support the weight of the

AT10.1. See the Weight Table located in section 1.4 on page 3. The weight

of your AT10.1 may be different from the table value, depending on options

or accessories you ordered.

2. Select conduit entrances carefully. Use of the pref-fab knockouts on the

sides or bottom of the enclosure will allow removal of the cabinet shroud

(and internal access for servicing) without removal of unit from the wall.

3. The location:

• Should be free of drips and splatter. If dripping liquids are a problem,

install a drip shield kit (part number EI0191-00). For kit availability, see

ordering information in Appendix B on page 71.

• Should be between 32 and 122 °F / 0 and 50 °C, with relative humidity

between 5 and 95% non-condensing.

• Must be free of explosive materials.

4. Maintain at least 6in / 152mm of free air on top, bottom and both sides for

cooling air.

5. Allow 36in / 914mm front clearance for operation and maintenance.

PROCEDURE

To wall-mount the

AT10.1, install four (4)

.25in / 6.4mm bolts on

the wall rated to support

the AT10.1 weight plus a

safety factor of at least 2

times. Place the AT10.1

on the bolts, add

appropriate mounting

hardware and tighten.

Reference the graphics on

the next page. For more

information, see Outline

Drawings in Appendix C

on page 72.

4

Page 9

INSTALLING THE AT10.1

WALL-MOUNTING THE AT10.1 - GRAPHICS

5

Page 10

INSTALLING THE AT10.1

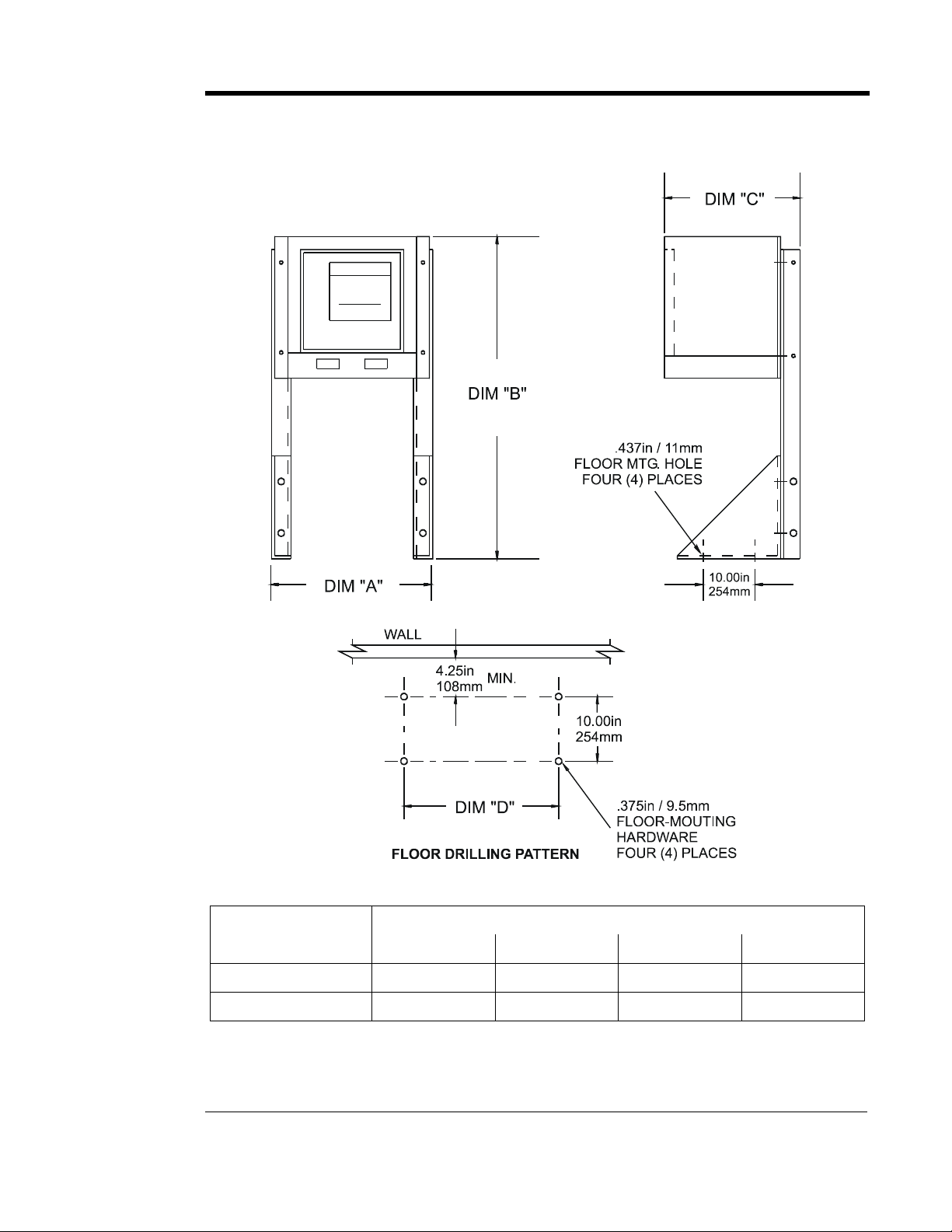

1.5.2. Floor-Mounting the AT10.1

To floor mount the AT10.1, you must use the floor mounting accessory kit

(part number EI0192-00). For kit availability, see ordering information in

Appendix B on page 71. The kit contains brackets that elevate the top of

the AT10.1 approximately 47in / 1194mm above floor level, with

provision for floor anchoring. The kit includes an instruction sheet

(JA0083) showing assembly dimensions and mounting details.

You must locate the anchor-bolt holes at least 4.25in / 108mm from any

wall, to allow clearance for the charger enclosure behind the mounting

brackets. In addition, you must consider the following:

1. Placement of conduit entrances (use the knockouts on the sides or bottom of

the charger to allow access for servicing without removing the unit from the

mounting brackets).

2. The location:

• Should be free of drips and splatter. If dripping liquids are a problem,

install a drip shield kit (part number EI0191-00). For kit availability, see

ordering information in Appendix B on page 71.

• Should be between 32 and 122 °F / 0 and 50 °C, with relative humidity

between 5 and 95% non-condensing.

• Must be free of explosive materials.

3. Maintain at least 6in / 152mm of free air on top, bottom and both sides for

cooling air.

4. Allow 36in / 914mm front clearance for operation and maintenance.

PROCEDURE

To floor-mount the AT10.1,

follow the directions featured in

instruction sheet (JA0083),

included with your floormounting kit (part number

EI0192-00). These instructions

showing assembly dimensions

and mounting details.

Place the AT10.1 assembly on

the mounting bolts, add

appropriate mounting hardware

and tighten.

Reference the graphics on the

next page.

6

Page 11

INSTALLING THE AT10.1

FLOOR-MOUNTING THE AT10.1 - GRAPHICS

DIMENSION (in / mm)

ENCLOSURE

Style-586

Style-594

A B C D

16.50 / 419 46.63 / 1184 11.75 / 298 15.00 / 381

19.75 / 502 47.75 / 1213 14.25 / 361 18.25 / 463

7

Page 12

INSTALLING THE AT10.1

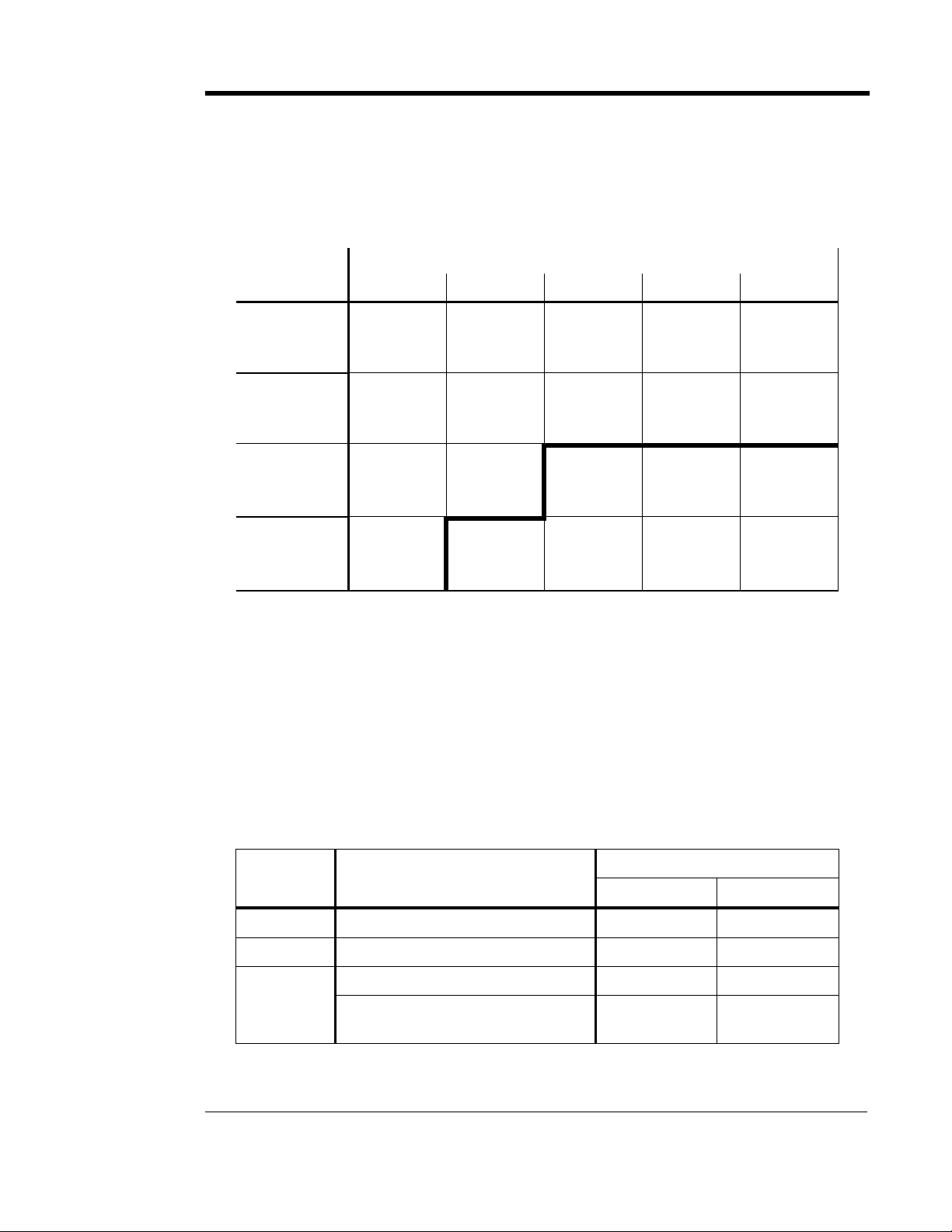

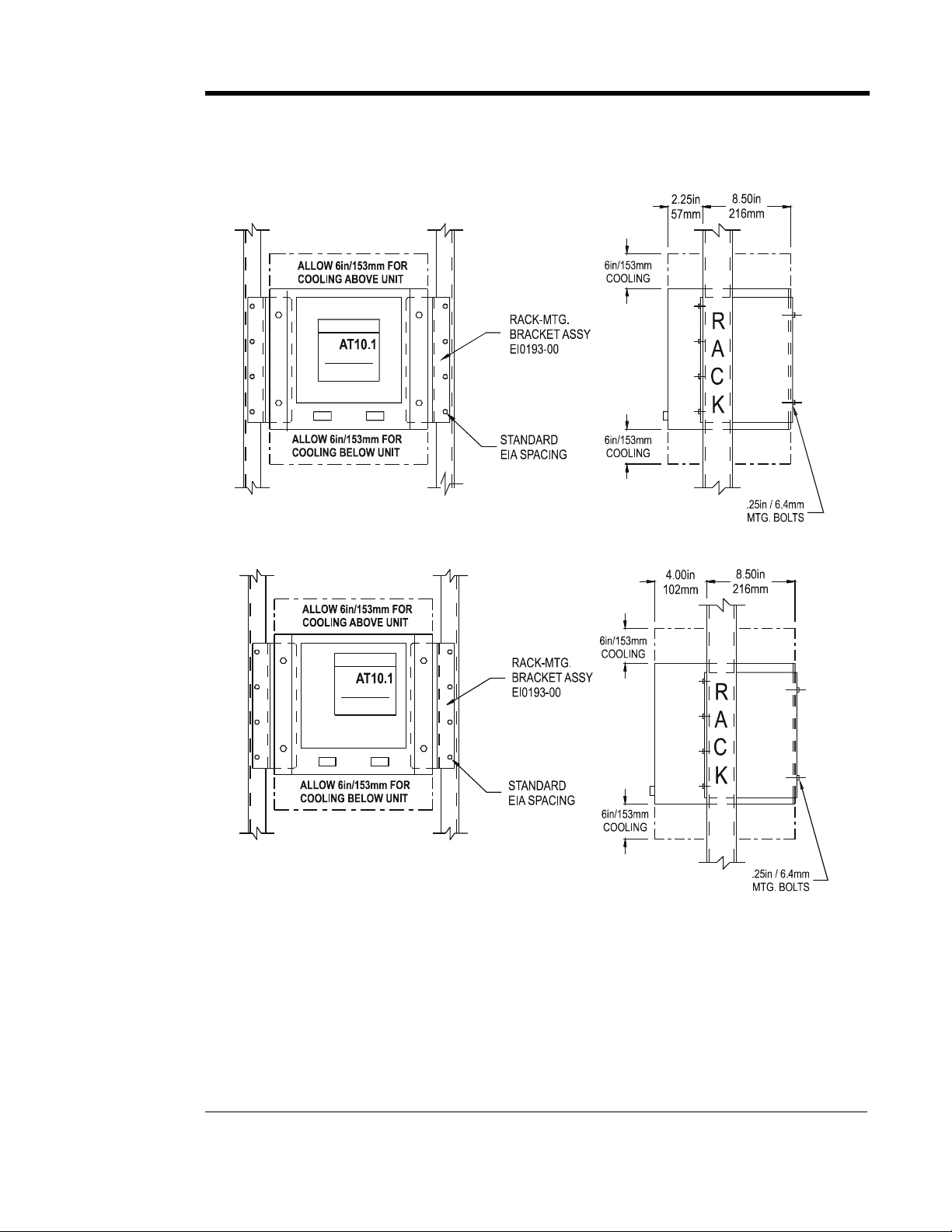

1.5.3. Rack-Mounting the AT10.1

The AT10.1 can be installed in most relay racks with standard EIA hole

spacing (see the table below for the allowable combinations). The rack

mounting kit (part number EI0193-00), includes mounting brackets and

the necessary hardware to install one AT10.1 battery charger. The kit

includes an instruction sheet (JA0091) showing installation details. For kit

availability see ordering information in Appendix B on page 71.

When rack mounting the AT10.1, you must consider the following:

1. The rack must be strong enough to properly support the weight of the

AT10.1. See the Weight Table located in section 1.4 on page 3.

2. Placement of conduit entrances (be sure the knockouts on the sides or

bottom of the charger are accessible after the charger is rack-mounted).

3. The location:

• Should be free of drips and splatter. If dripping liquids are a problem,

install a drip shield kit (part number EI0191-00). For kit availability, see

ordering information in Appendix B on page 71.

• Should be between 32 and 122 °F / 0 and 50 °C, with relative humidity

between 5 and 95% non-condensing.

• Must be free of explosive materials.

4. Maintain at least 6in / 152mm of free air on top, bottom and both sides for

cooling air.

5. Allow 36in / 914mm front clearance for operation and maintenance.

PROCEDURE

To rack mount the AT10.1, first install the brackets onto the rack. Second,

mount the AT10.1 onto the rack-mounting brackets using the hardware

supplied. Provide at least 6in / 152mm of air space above and below the

AT10.1 in the rack for cooling. You do not need to modify the AT10.1

enclosure. Rack-mount outline dimensions are shown on the next page.

Vdc Adc

12 Vdc all

24 Vdc all

48 Vdc 6-12 Adc

48 Vdc 16-25 Adc

130 Vdc 6 Adc

130 Vdc 12-25 Adc

8

RACK WIDTH CHARGER RATING

19in / 483mm 23in / 584mm 24in / 610mm

Yes Yes Yes

Yes Yes Yes

Yes Yes Yes

No Yes Yes

Yes Yes Yes

No Yes Yes

Page 13

INSTALLING THE AT10.1

RACK-MOUNTING THE AT10.1 - GRAPHICS

Style-586 Enclosure

Style-594 Enclosure

NOTES:

1. Units are installed from the front.

2. Units shown above without penthouse enclosure. If penthouse is used, add

7in / 178mm to top of enclosure.

3. Refer to the outline drawings in Appedix C for enclosure dimensions.

9

Page 14

INSTALLING THE AT10.1

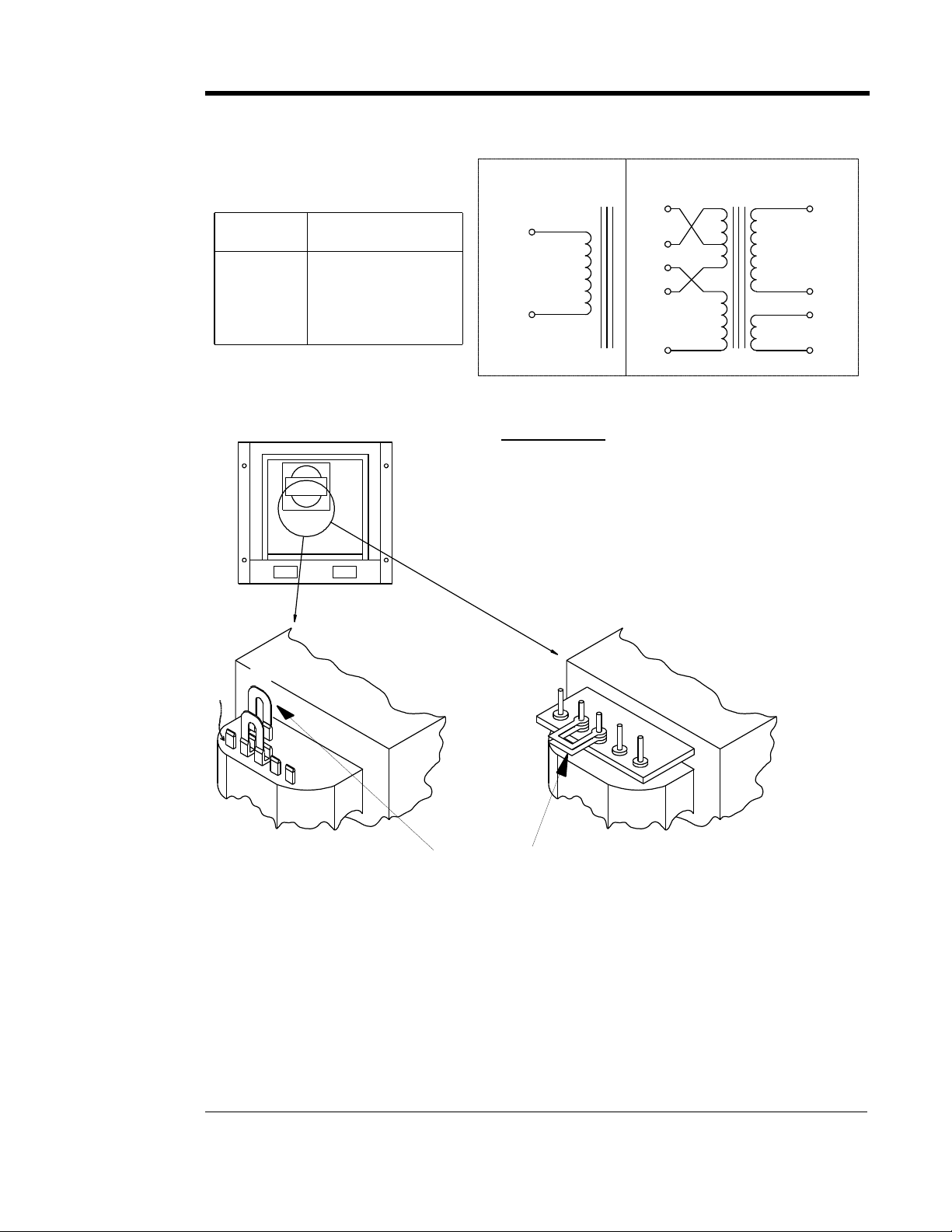

1.6. CHANGING TRANSFORMER TAPS

Before you wire ac power to the AT10.1, check the wiring of the main

transformer T1, to be sure it is connected for your ac input voltage. The

AT10.1 accepts standard input voltages of 120, 208 or 240 Vac by

changing jumpers on T1. No other changes are required. The AT10.1 is

wired at the factory for 240 Vac, except on special order. Models for 220,

380 or 416 Vac at 50/60 Hz are available on special order.

EXCEPTION: An AT10.1 battery charger rated for 480 Vac input uses a

special transformer that has no taps or jumpers. The 480 Vac

transformer cannot be used for any other input voltage.

Before changing the T1 taps, be sure that ac and dc supplies to the AT10.1

are turned off and locked out. Verify that no voltage is present by using a

voltmeter at terminals TB1-L1 and TB1-L2 (ac), TB1(+) and TB1(-) (dc)

and remote sense terminals (dc). Note that turning off the ac and dc circuit

breakers on the AT10.1 does not eliminate live voltages inside the

enclosure. Also de-energize any external wiring to the alarm relay

contacts.

Verify that all voltages within the enclosure are de-energized and locked

out. See section 3.5 for necessary steps to follow when accessing internal

components within the AT10.1. Change the jumpers on T1 as shown in

the table on the next page. All transformers have (2) jumpers; always use

both as specified in the table. The transformers used in the small enclosure

(586) use piggyback quick-connect terminals. The transformers in the

larger enclosure (594) use 10-32 stud terminals.

Models designed for 220 Vac, 50/60 Hz have no jumpers, and can be used

only for that voltage. Models designed for 380 or 416 Vac also have no

jumpers, and can be operated on either voltage.

NOTE: This procedure refers only to Group I AT10.1 battery chargers

(rated 6-25 Adc). A different procedure exists for Group II AT10.1

battery chargers (rated 30-100 Adc). Please refer to the Operating and

Service Instructions specific to the Group II AT10.1 battery charger for

changing the transformer taps on these larger units. Otherwise, damage

to your charger and equipment may occur.

10

Page 15

INSTALLING THE AT10.1

CHANGING TRANSFORMER TAPS - GRAPHICS

T1 CONNECTION TABLE

INPUT VAC JUMPERS

120 H1-H3, H2-H5

208 H2-H4 (2) JUMPERS

240 H2-H3 (2) JUMPERS

480 NONE

TYPICAL FOR TRANSFORMER

IN 586 ENCLOSURE

480 V

PRIMARY

120/208/240 V

PRIMARY

SECONDARY

H4

H5

H5

H2

H3

H1

H1

TRANSFORMER SCHEMATIC

PROCEDURE:

1) BE SURE ALL VOLTAGES ARE DE-ENERGIZED AND LOCKED OUT.

2) BE SURE TERMINALS ARE FULLY SEATED (586 ENCL).

3) BE SURE STUD TERMINALS ARE TIGHT (594 ENCL).

4) CHECK YOUR WORK AFTER COMPLETION.

5) FOR ADDITIONAL INFORMATION, SEE WIRING DIAGRAM

IN APPENDIX.

TYPICAL FOR TRANSFORMER

IN 594 ENCLOSURE

.

X1

X4

Y2

Y1

H1

H3

H2

H5

H4

JUMPERS (2)

H1

H3

H2

H5

H4

F1-5R2

11

Page 16

INSTALLING THE AT10.1

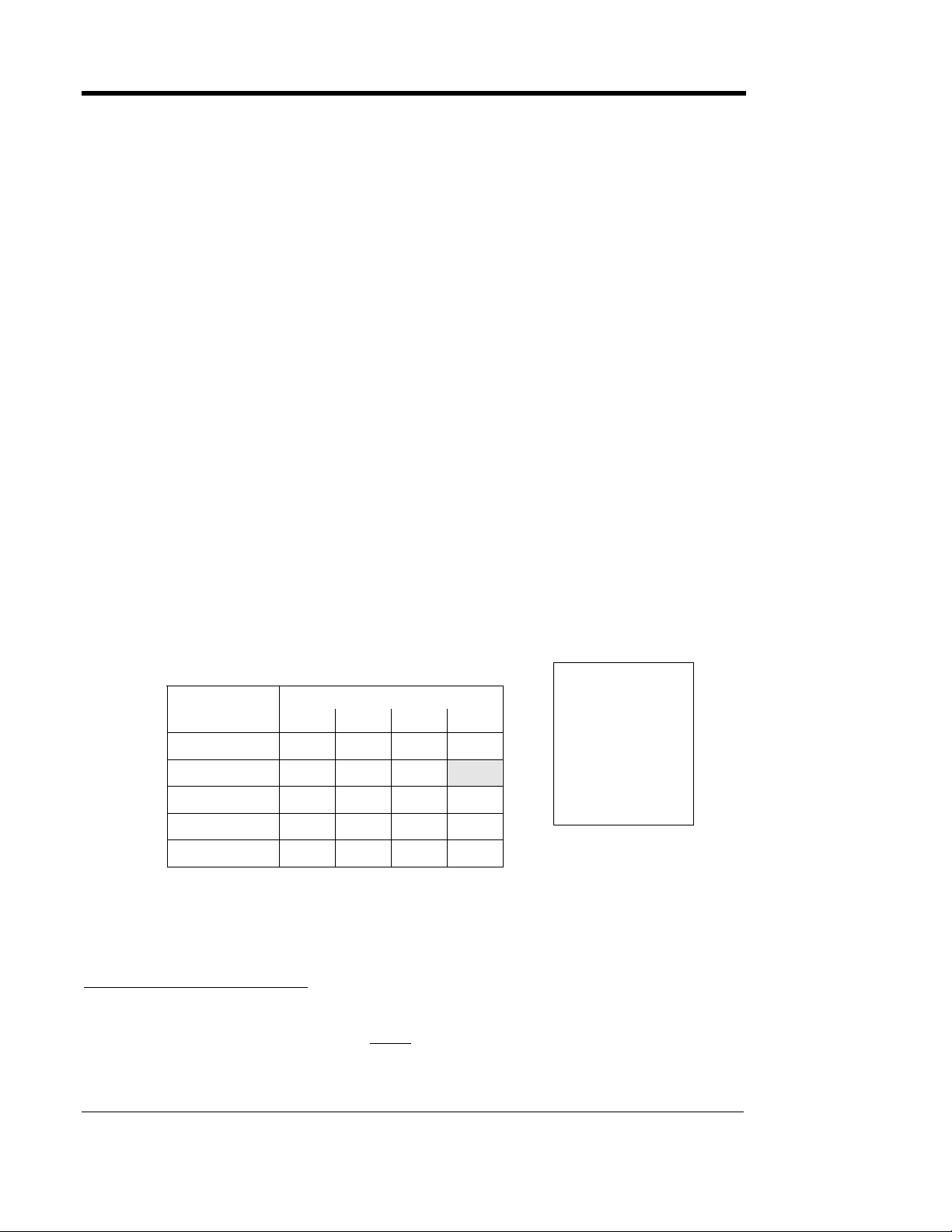

1.7. MAKING THE AC INPUT CONNECTIONS

Follow these steps to connect ac power to the AT10.1:

1. Use a branch circuit breaker or fused disconnect switch, properly sized for

the maximum input current of the AT10.1, as shown in the table below. This

device should have lockout capability so that the ac input can be deenergized and locked out for maintenance. A time delay circuit breaker or

slow-blow fuse is recommended.

2. Size the ac input wiring per the National Electric Code (NEC) and local

codes for the rating of the branch circuit breaker or fused disconnect switch.

3. All specific requirements of your facility take precedence over these

instructions.

4. Be sure the AT10.1 main transformer, T1, is properly connected for your ac

input voltage. See section 1.6 for details.

5. Remove the safety cover.

6. Run the ac wiring to terminals TB1-L1, TB1-L2 and TB1-GND on the I/O

panel in the enclosure. Compression lugs accepting wire sizes #14-6 AWG.

wire are supplied for your convenience. To make these connections, strip the

insulation .50in / 13mm on the incoming wires and connect the wires to the

appropriate lugs as shown on the next page.

7. Using a flat-head screwdriver, securely tighten the compression screws on

the lugs to 35-45 in-lb / 4.0-5.1 Nm.

8. Reinstall the safety cover after you have made and checked all connections.

MAXIMUM INPUT CURRENT AT 120 Vac1

OUTPUT

CURRENT

6

12

16

20

1

To determine the input current, Iac, for other input voltages, use the formula:

where Vac is the new input voltage, and IT is the input current from the table above.

12

25

OUTPUT VOLTAGE

12 24 48 130

2 4 8 14

3 7 14

4 9 18 32

5 11 23 39

6 14 29 49

II

120

×=

Tac

V

ac

30

Example (shaded):

A 130 Vdc/12 Adc

battery charger

draws 30 Aac at

120 Vac.

All currents shown

are ±10%.

Page 17

INSTALLING THE AT10.1

MAKING THE AC INPUT CONNECTIONS - GRAPHICS

NOTES:

1. The drawing above does not show other components mounted to the I/O

panel. Be careful not to disconect any other component leads.

2. Always use a proper ground.

3. On 120 Vac input, connect the neutral leg to the terminal L2.

4. Wire insulation must be rated for 194° F / 90° C or better.

5. Use copper or aluminum conductors only.

13

Page 18

INSTALLING THE AT10.1

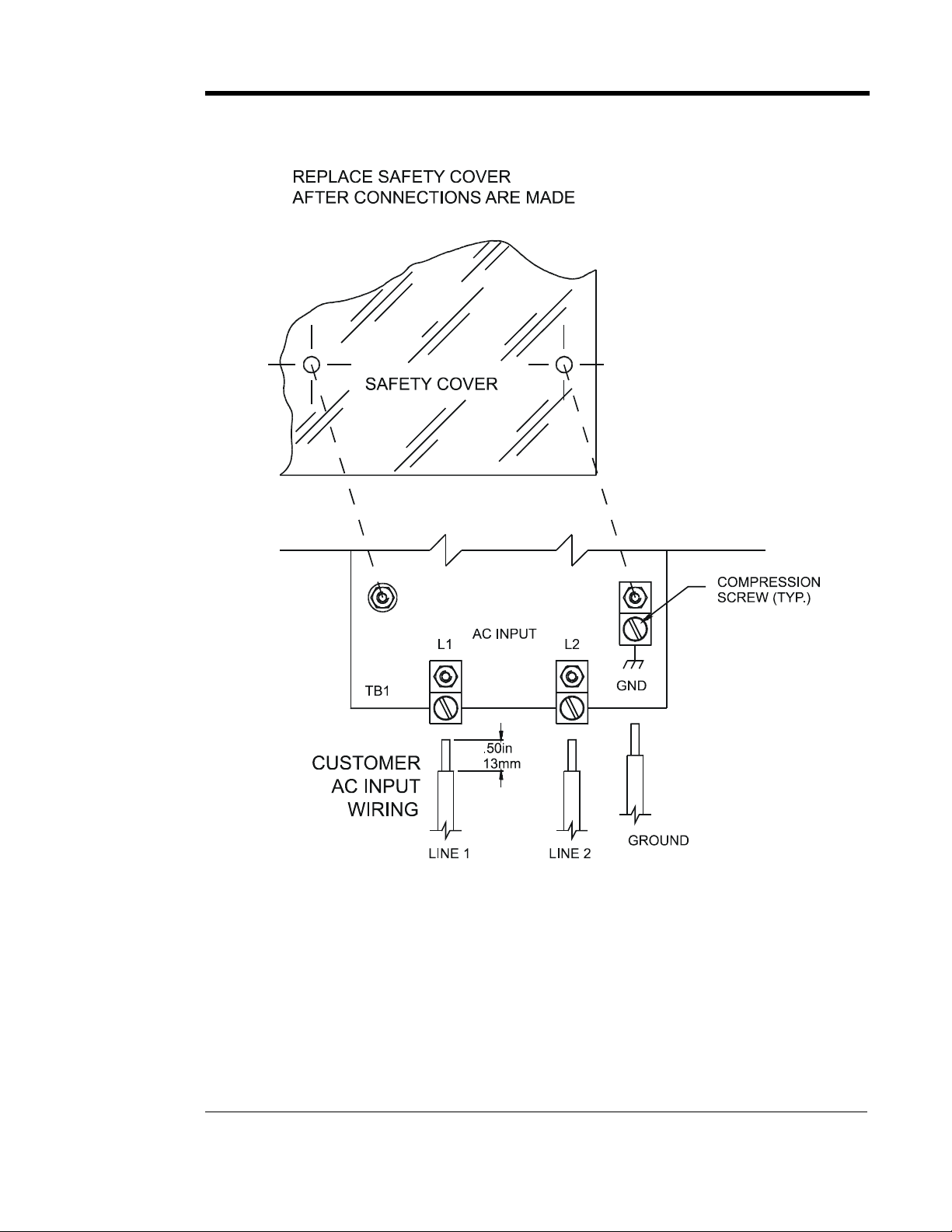

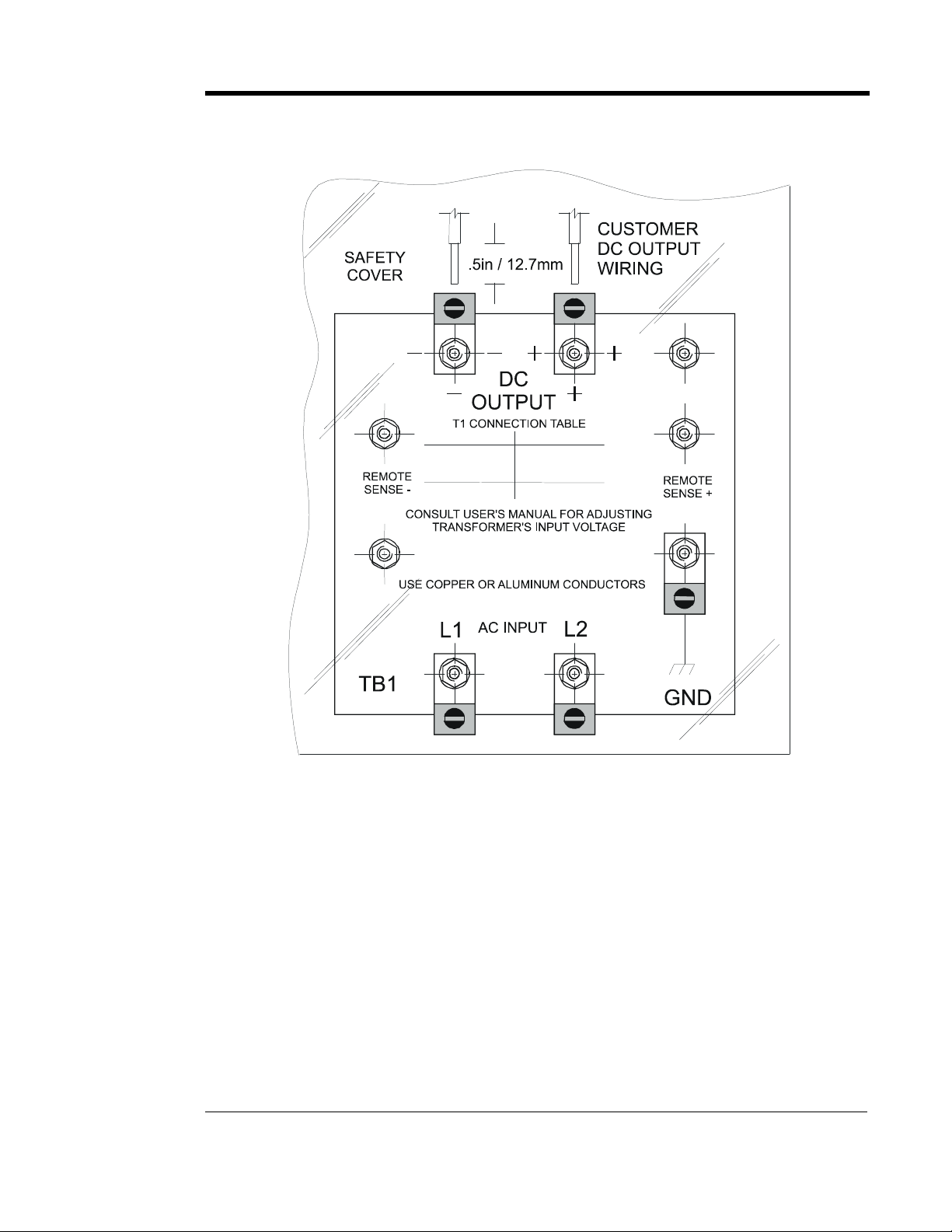

1.8. MAKING THE DC OUTPUT CONNECTIONS

Follow these steps to connect the battery to the AT10.1:

1. Size the dc wiring to minimize voltage drop. The acceptable wire size

depends on your installation. As a guideline, the voltage drop should not

exceed 1% of nominal output voltage at full current. Refer to the table below

to determine the voltage drops for various wire sizes, currents and distances.

WIRE SIZING CHART

VOLTAGE DROP PER 100ft / 30.5m OF WIRE (FOR COPPER AT 68° F / 20° C)

DC CURRENT (AMPERES) WIRE SIZE

(AWG.)

16

14

12

10

8

6

4

EXAMPLE: 100ft / 30.5m of #8 AWG. wire at 16A has a 1.1V drop.

2. All specific requirements of your facility take precedence over these

instructions.

3. The AT10.1 is factory wired to regulate output voltage at the output

terminals. If the total voltage drop is greater than 1% (e.g., 1.3V for a 130

Vdc system), remote sense wiring is recommended, see section 1.9.

6 12 16 20 25

2.5V 5.0V 6.7V 8.2V 10.5V

1.6V 3.2V 4.2V 5.3V 6.6V

1.0V 2.0V 2.6V 3.3V 4.2V

0.63V 1.3V 1.7V 2.1V 2.6V

0.40V 0.80V 1.1V 1.3V 1.7V

0.25V 0.50V 0.66V 0.83V 1.1V

0.16V 0.32V 0.42V 0.52V 0.65V

PROCEDURE

1. Use a dc disconnect switch or circuit breaker between the AT10.1 and dc

bus. This device should have lockout capability to allow the AT10.1 to be

disconnected from the dc bus for maintenance.

2. Remove the safety cover.

3. Run the dc wiring to terminals TB1(+) and TB1(-) on the I/O panel in the

enclosure. Compression lugs, accepting wire sizes #14-6 AWG., are

supplied for your convenience. To make these connections, strip the

insulation .50in / 12.7mm on the incoming wires. Connect the wires to the

appropriate lugs as shown on the next page.

4. Using a flat-head screwdriver, securely tighten the compression screws on

the lugs to 35-45 in-lb / 4.0-5.1 Nm.

5. Reinstall the safety cover after you have made and checked all connections.

14

Page 19

INSTALLING THE AT10.1

MAKING THE DC OUTPUT CONNECTIONS - GRAPHICS

NOTES:

1. The drawing above does not show other components mounted to the I/O

panel. Be careful not to disconect any other component leads.

2. Always use a proper ground.

3. Wire insulation must be rated for 194° F / 90° C or better.

4. Use copper or aluminum conductors only.

15

Page 20

INSTALLING THE AT10.1

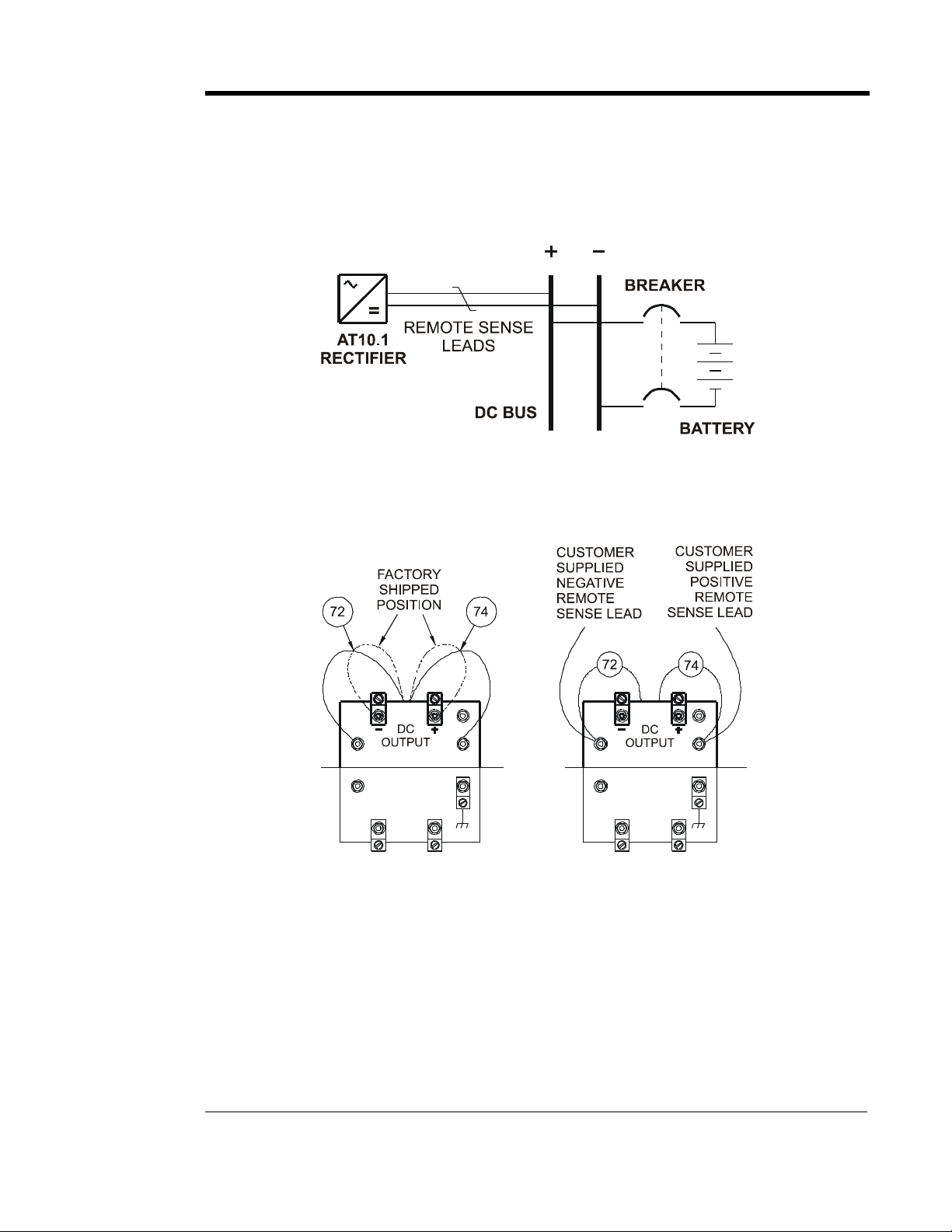

1.9. WIRING THE AT10.1 FOR REMOTE SENSING

You can wire the AT10.1 to regulate the output voltage at the battery

terminals, instead of at the charger output terminals. Remote sensing does

the following:

1. Compensates for voltage drop in the dc wiring between the AT10.1 and the

battery.

2. Directly monitors the battery or dc bus voltage. The front panel meter

displays the actual voltage on the dc bus.

You wire the AT10.1 for remote sensing by installing a two-wire cable

from the AT10.1 remote sense terminals to the battery terminals. The

AT10.1 control circuitry then measures the dc voltage at the battery

terminals, and controls the output of the charger to maintain the battery

voltage at the desired float or equalize voltage.

NOTE: If the remote sense wiring fails, the AT10.1 detects the fault,

and displays E 06 on the front panel meter. See section 3.2 for details.

CAUTION: The AT10.1 cannot protect against short circuits in the

remote sense wiring. You should install a 1.0A fuse at the battery or dc

bus end of the remote sense cable.

To wire the AT10.1 for remote sensing, follow the procedure and diagram

on the next page.

If you ever need to disable remote sense, follow the steps below:

• De-energize and lock out all ac and dc voltages to the AT10.1. Check

with a voltmeter.

• Disconnect the remote sense wires from the battery or dc bus terminals

first.

CAUTION: You must do the steps above first.

• Remove the remote sense leads from the remote sense (+) and (-)

terminals on the I/O panel. Insulate each lead separately. Coil up the

wires and leave them in the bottom of the charger, in case you want to

wire for remote sense again in the future.

• Reconnect wire # 74 to the dc output (+) terminal.

• Reconnect wire # 72 to the dc output (-) terminal.

• Restart the AT10.1 according to the instructions in section 2.1.

16

Page 21

INSTALLING THE AT10.1

PROCEDURE

1. De-energize and lock out all ac and dc voltages within the AT10.1 enclosure.

Check with a voltmeter.

2. Remove safety shield.

3. Wire the AT10.1 remote sense to the dc bus as shown in the figure below.

4. Move wires # 72 and # 74 from the TB1 (-) and (+) dc output terminals to

the corresponding remote sense terminals as shown in the lower left figure.

5. Connect the external remote sense leads from the battery or dc bus to the

remote sense terminals on the I/O panel as shown in the lower right figure.

6. Check your work thoroughly. Replace the safety shield before reeneregizing

the charger.

7. Restart the AT10.1 according to the instructions in section 2.1.

NOTES:

1. Use #16 AWG. twisted pair.

2. Maximum current is 150 mA.

3. Run leads in their own conduit.

4. Fuse the wiring at the battery or dc bus.

17

Page 22

INSTALLING THE AT10.1

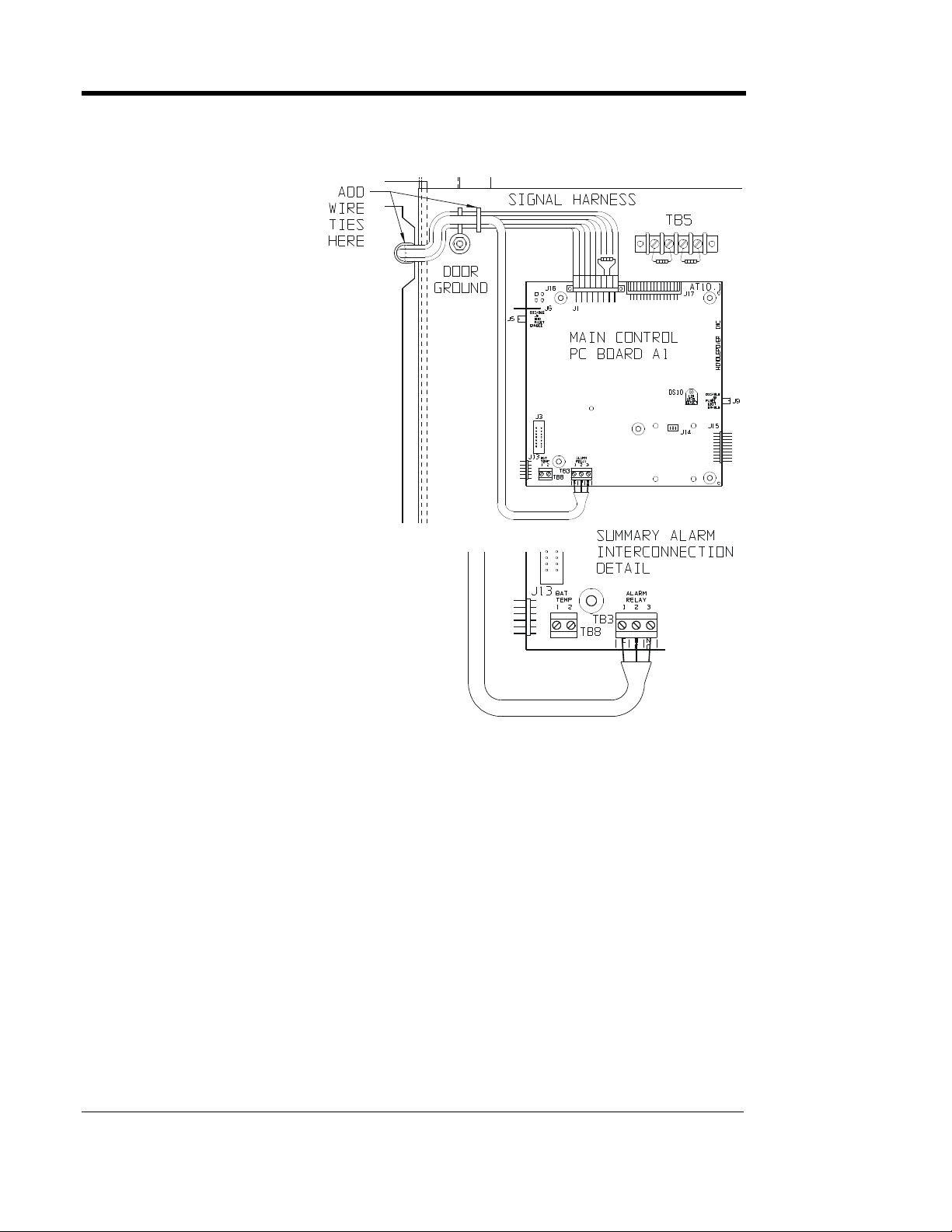

1.10. WIRING TO THE REMOTE ALARM CONTACTS

Built-in common alarm relay

The Primary Alarm

functions are

included as standard

equipment with the

AT10.1. The

Common Alarm

relay, located on the

main control circuit

board on the back of

the door, provides

one form C

summary alarm

(common alarm)

contact that

transfers for any

alarm. Follow the

procedure below to

wire a remote

annunciator to this

contact. See section

2.2.7 for a

description of the

alarm functions.

PROCEDURE

1. Allow 30in / 762mm of wire inside the enclosure (excess will be trimmed).

2. Route wires to front door by following the existing harness through the door

hinge as shown. Use (2) wire ties and allow a 4-6in / 102-153mm loop for

the hinge.

3. Trim wires to the proper length for connecting to TB3. Strip .25in / 6.4mm

of insulation from the wires. Make the connections at TB3, and securely

tighten the screws.

NOTES:

1. Alarm contacts are rated at 0.5A / 125 Vac or Vdc.

2. Terminal block is a compression type, accepting wire sizes #22-14 AWG.

3. Terminals are labeled in non-alarm condition.

18

Page 23

INSTALLING THE AT10.1

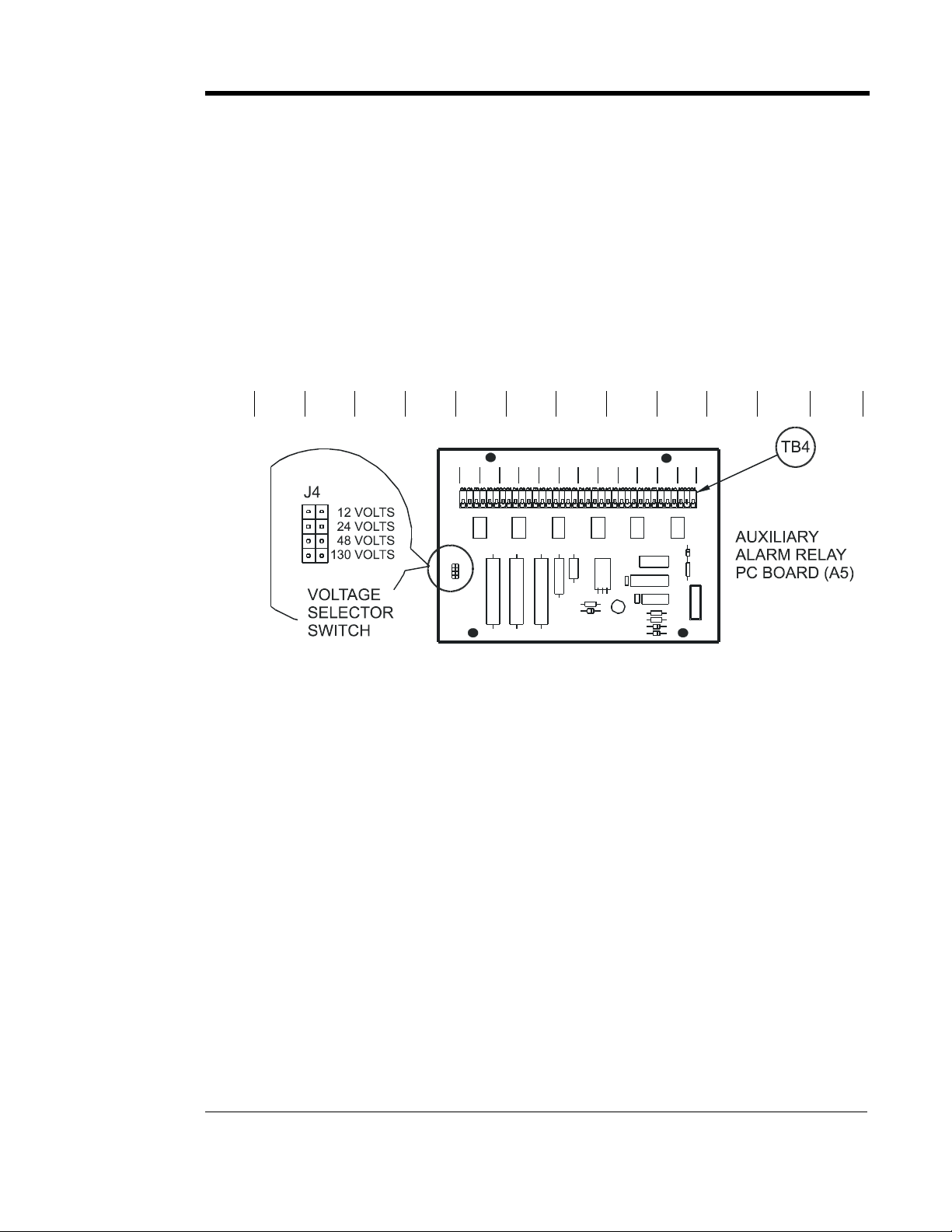

Auxiliary Relay Board (optional)

The Auxiliary Alarm Relay PC Board (A5), mounted inside the separate

top enclosure (penthouse), provides two form C contacts (TB4-1 through

TB4-36) for each of the following individual alarms:

• High DC Voltage

• Low DC Voltage

• DC Output Failure

• AC Failure

• Ground Fault Detection (positive or negative)

• Summary Alarm

HVDC HVDC LVDC LVDC

C, NC, NO C, NC, NO C, NC, NO C, NC, NO C, NC, NO C, NC, NO C, NC, NO C, NC, NO C, NC, NO C, NC, NO C, NC, NO C, NC, NO

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

DC OUT

FAILURE

DC OUT

FAILURE AC FAIL AC FAIL

GROUND

DETECT

GROUND

DETECT SUMMARY SUMMARY

Follow the procedure below to wire annunciators to one or more of these

alarm contacts.

PROCEDURE

1. Remove the top panel from the penthouse enclosure (on top of the main

charger enclosure).

2. Route your remote annunciator wiring into the penthouse enclosure through

one of the unused knockouts in the side of the enclosure.

3. Connect the wiring (use #22-14 AWG.) to the appropriate terminals of TB4

on the back wall of the penthouse enclosure (as shown in the drawing at the

right). Strip each wire .25in / 6.4mm, and securely tighten the terminal

screws. The terminals are labeled in the non-alarm condition.

4. Replace the top panel on the penthouse enclosure.

NOTES:

1. Alarm contacts are rated at 0.5A / 125 Vac or Vdc.

2. Terminal block is a compression type, accepting wire sizes #22-14 AWG.

3. Terminals are labeled in non-alarm condition.

19

Page 24

INSTALLING THE AT10.1

1.11. INSTALLING TEMP. COMPENSATION ASSEMBLY (OPTIONAL)

The temperature compensation assembly consists of a probe containing a

temperature-dependent resistor in an epoxy module that you install near

your battery. There are three steps in installing the assembly:

1. Mounting the probe assembly near the battery.

2. Installing an interconnection cable from the probe assembly to the AT10.1.

3. Wiring the charger end of the cable to a terminal block on the main control

circuit board.

The actual tempco probe is the same for all battery types and all output

voltages of the AT10.1. The kit part numbers differ depending on cable

length ordered. See the tables in Appendix B on page 71 for ordering

information. Each kit contains detailed installation instructions (JA5015-

00). The main elements of the installation are outlined below.

WARNING:

High voltages appear at several points inside the battery charger. Use

extreme caution when working inside the charger. Do not attempt to

work inside the charger unless you are a qualified technician or

electrician.

Disconnect and lock out all power to the battery charger before starting

to remove or replace any components. Turn the ac power off at the

distribution panel upstream from the battery charger. Disconnect the

battery from the charger output terminals.

1. De-energize and lock out all ac and dc voltage sources to the AT10.1. Check

with a voltmeter before proceeding.

2. Mount the probe on a clean, dry surface as close to the battery as possible,

such as the battery rack. Do not mount the probe:

• on the battery itself

• on unpainted wood or bare galvanized metal.

• on plastic surfaces

3. To apply the probe, clean the mounting surface with isopropyl alcohol, and

allow to dry thoroughly. Remove the protective backing from the doublefaced adhesive tape on the probe, and securely press it onto the surface.

4. Install the cable supplied with the temperature compensation probe kit:

• Start at the AT10.1. The end of the cable with two stripped wires and one

lead with a quick-connect terminal will be connected inside the

enclosure. Leave 30in / 762mm of cable inside the enclosure, and route

the other end to the probe at the battery.

20

Page 25

INSTALLING THE AT10.1

• Run the cable though a conduit if possible, but not through a conduit

containing any power wiring.

• Route the other end to the probe at the battery and coil up excess cable.

NOTE: If the standard (25ft / 7.6m) cable isn't long enough, longer

cable assemblies are available in lengths of 50, 100 & 200ft / 15.2,

30.5 & 61.0m. See Appendix B on page 71 for ordering information.

• Be sure your wiring conforms to the NEC and your facility requirements.

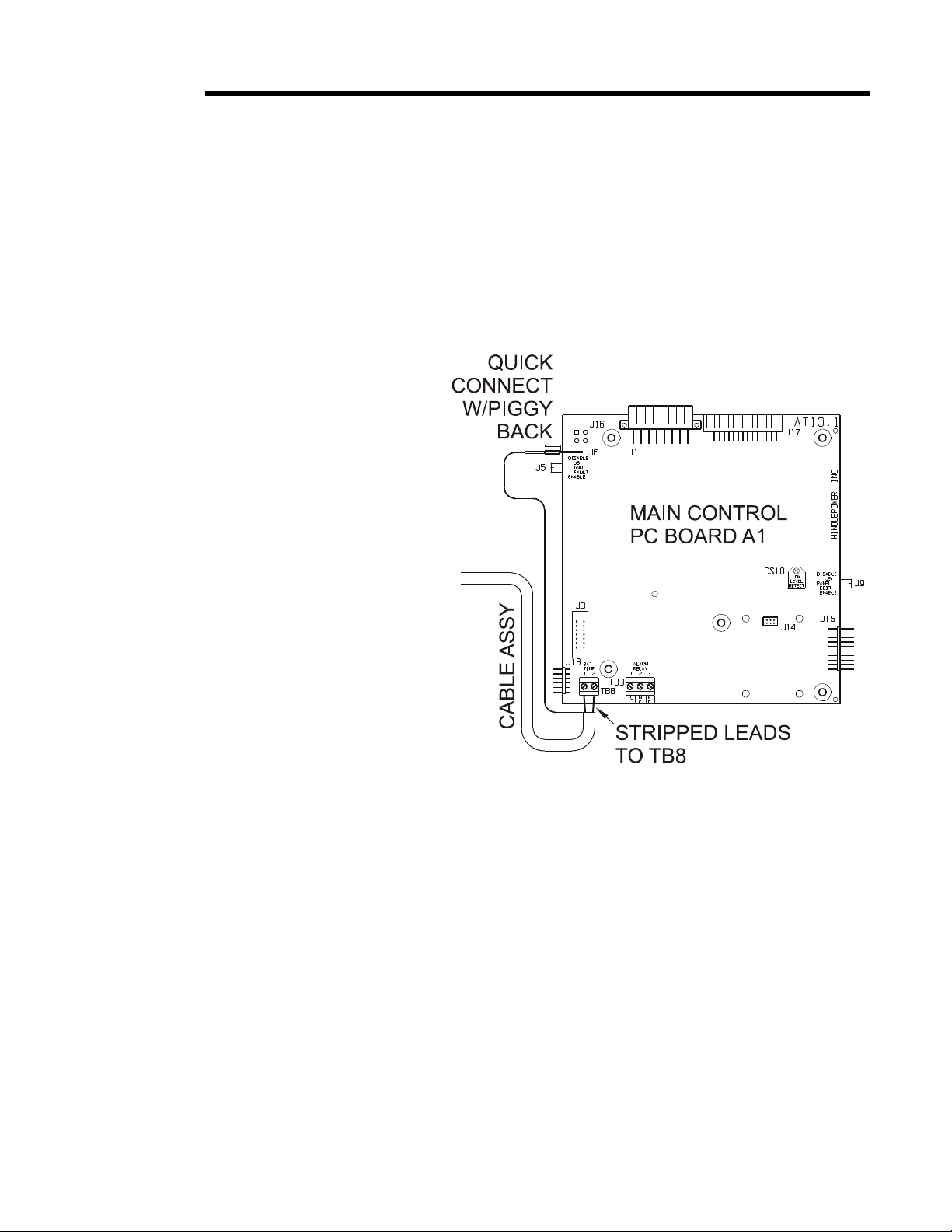

5. Attach the interconnection cable to the AT10.1 as shown in the figure below:

• Route the

cable within

the AT10.1

enclosure so

that it runs

with the wire

harness to the

back of the

front panel,

and easily

reaches the

main control

circuit board.

• At the main

control circuit

board, insert

one of the bare

wires from the

cable into each

terminal of

TB8. Polarity

is not

important.

• Unplug the harness ground wire # 30 from terminal J6 on the left edge of

the main control circuit board. Plug the connector at the end of the

nylon-shielded wire of the cable assembly onto J6. Reconnect the ground

wire # 30 from the system harness onto the piggy-back connector

featured at the end of the nylon-shielded wire.

• Using plastic wire ties, tie the interconnection cable loosely to the

existing wire harness. Be especially sure that the cable conforms to the

service loop at the hinge end of the door.

6. At the battery, connect the quick-connect terminals to the temperature

compensation probe. Polarity is not important. Coil up any excess wire and

tape or tie it together to prevent damage.

21

Page 26

INSTALLING THE AT10.1

7. Check your work. Be sure that:

• All connections are secure.

• The shield is connected to ground at the charger end only (on the main

circuit board).

• The cable is connected to TB8 on the circuit board. Other terminal

blocks may look similar.

8. Restart the AT10.1 using the startup procedure in section 2.1. During

startup, the AT10.1 displays LEAD on the front panel, indicating that the

temperature compensation is set up for lead-acid batteries. While this is

being displayed, you can press any front panel key to change the display to

read NICD, to change the temperature compensation setup for nickel

cadmium batteries. The choice you make is saved internally, and will be

used again by the AT10.1 the next time it starts.

9. Adjust the output float and equalize voltages to the battery manufacturer's

recommended values, using the AT10.1's front panel meter, as described in

section 2.3.2.

NOTE: If the temperature compensation probe, or the wiring

from the probe to the AT10.1, is damaged and becomes an

open circuit, the AT10.1 detects the damage and displays

E 08 on the display. The charger then reverts to normal non-

temperature-compensated operation until the probe or wiring

is repaired. Once the probe is repaired, you must restart the

AT10.1 to activate the probe, as described in section 2.1.

Using temperature compensation

22

Whenever an electric storage battery is being charged, the terminal

voltage of the battery changes a small amount whenever the battery

temperature changes. As the battery temperature increases, its terminal

voltage decreases. When the battery is being charged with a float type

charger, with a constant output voltage, the float current increases when

the temperature increases. This results in overcharging the battery, which

can result in damage to the materials, or at least the need for more

frequent maintenance.

When the AT10.1 is equipped with a temperature compensation probe, it

is able to adjust the output voltage applied to the battery to keep the float

current constant, thereby avoiding overcharging. The probe senses the

ambient temperature at the battery, and adjusts the output float/equalize

voltages to compensate for variations in temperature. If the ambient

temperature increases, the AT10.1 output voltage decreases.

Page 27

INSTALLING THE AT10.1

Please note the following:

• You should set the Float and Equalize voltages to the values

recommended by your battery manufacturer for 77° F (25° C).

• When you enter the Edit mode to adjust the Float or Equalize voltage

(see section 2.3.2), the front panel meter shows the 77° F (25° C) value

for the Float or Equalize voltage, even if the battery is warmer or cooler

than 77° F (25° C).

• The actual output voltage of the AT10.1 may be different from the value

shown on the front panel meter, if the battery is warmer or cooler than

77° F (25° C).

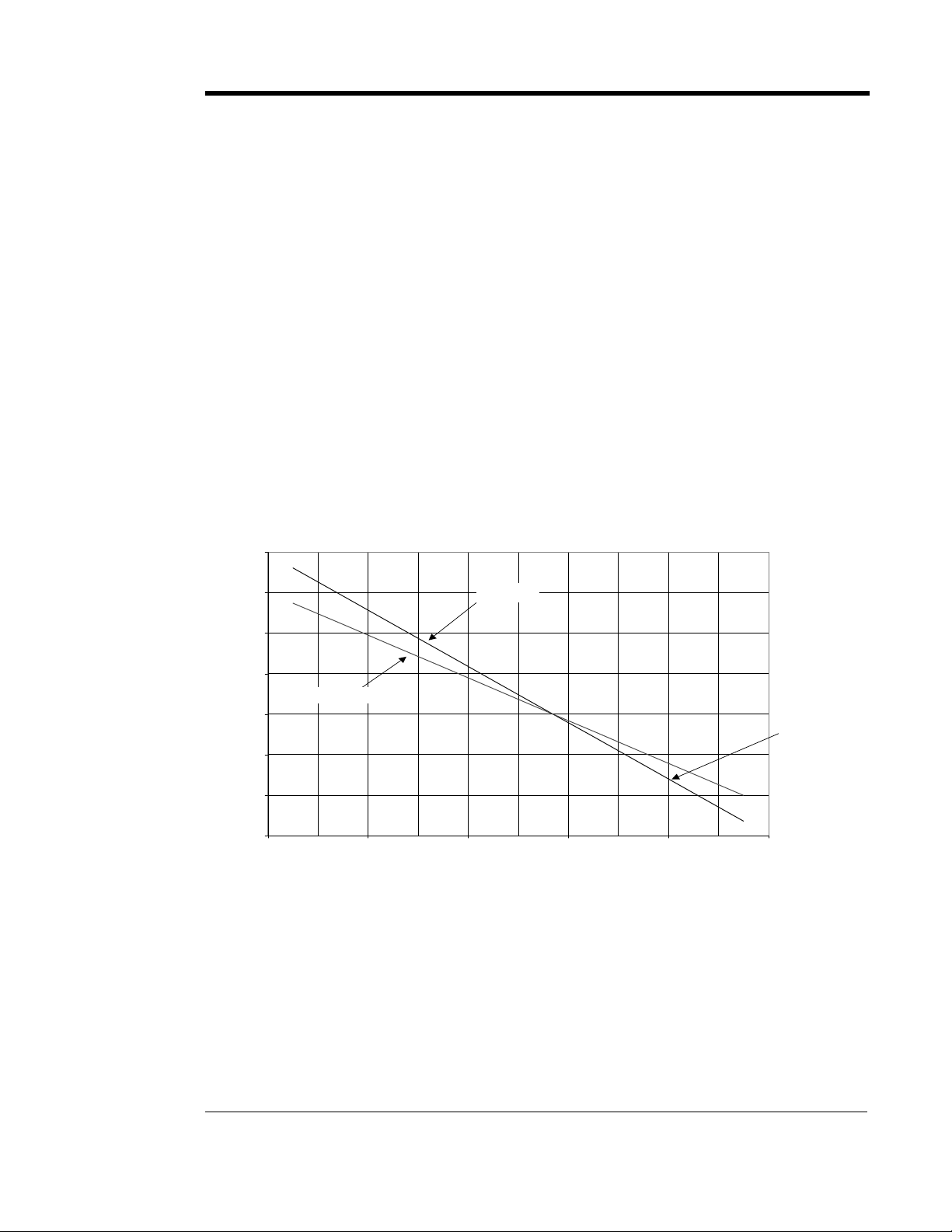

• Use a digital meter to measure the actual output voltage of the AT10.1. If

you know the temperature at the temperature compensation probe, you

can use the graph below to determine that the output voltage is correct.

• If the battery temperature goes below 32° F (0° C), there will be no

further increase in charger output voltage. Likewise, if the battery

temperature goes above 122° F (50° C), there is no further decrease in

output voltage.

OUTPUT VOLTAGE VS BATTERY TEMPERATURE

108

106

104

102

100

Percent Output Voltage

98

96

94

20 40 60 80 100 120

Lead-Acid

Nickel-Cadmium

Example:

100 Deg. F

97% Output

Voltage

Temperature, Degrees Fahrenheit

EXAMPLE: Suppose you have a lead-acid battery whose temperature

is 100° F / 37.8° C. As shown on the graph, the output voltage should

be approximately 97% of the 77° F voltage. If the float voltage is set

on the front panel to 132 Vdc, the actual output voltage will be:

132 x 0.97 = 128 Vdc

23

Page 28

OPERATING THE AT10.1

2. OPERATING THE AT10.1 BATTERY CHARGER

2.1. STARTING THE AT10.1

2.1.1. Understanding the startup sequence

The AT10.1 is set up at the factory to work with most common batteries

and loads without further adjustment. When you start the AT10.1 for the

first time, the factory settings (float voltage, equalize voltage, etc.) control

the operation of the charger. You can change the settings after you start

the charger. The FACTORY SETTINGS are shown in table on page 25.

The AT10.1 startup routine takes about five seconds. The microprocessor

that controls the AT10.1 initializes the charger by reading the settings that

are stored internally. The control circuit then "soft starts" the charger, and

the dc output voltage and current increase gradually to the rated value.

2.1.2. Checking the installation

Be sure that you have followed the installation

instructions carefully. Check the ac input

supply voltage and the battery voltage, and be

sure that they match the information on the

AT10.1 nameplate. Verify that the jumpers on

the main transformer T1 are correct for your

ac supply voltage. Open the front panel, and

check the battery polarity at the TB1 (+) and (-)

terminals.

2.1.3. Starting the AT10.1

When you are sure that all connections to the

AT10.1 are properly made, follow these steps

to start up the AT10.1:

• Turn on the front panel dc circuit breaker. The digital meter indicates the

battery voltage only. If the meter display doesn't light, do not proceed.

Turn off the dc breaker, and check all connections and the battery

polarity again. Also check the battery voltage. It must be above 50% of

nominal voltage to turn on the display. If you can't find the problem,

refer to the Troubleshooting Procedure in section 3.1 on page 44.

Using the Digital Meter

When you first start the

AT10.1, the meter display

alternates between dc output

voltage and dc output current.

Each reading is held for two

seconds; lights to the left of

the display indicate whether

the meter is displaying

voltage or current.

If you want to “freeze” the

meter to display only voltage,

press the METER MODE

key on the front panel. To

freeze the meter to display

only current, press the key

again. Press the key twice

more to revert to the

alternating display.

CAUTION: If you try to turn on the dc circuit breaker with the battery

connected in reverse polarity, the circuit breaker will immediately

trip. Do not try to close the dc breaker again, since this may damage

the battery charger. Correct the battery polarity before proceeding.

24

Page 29

OPERATING THE AT10.1

• If you have an optional temperature compensation probe installed, the

front panel displays LEAD during startup, indicating that the

temperature compensation is set up for lead-acid batteries. While this is

being displayed, you can press any front panel key to change the display

to read NICD, to change the temperature compensation setup for nickel

cadmium batteries. The choice you make is saved internally, and will be

used again by the AT10.1 then next time it starts.

• Turn on the front panel ac circuit breaker. The digital meter displays the

output voltage and current. See Using the Digital Meter on page 24. You

should hear a soft hum from the AT10.1 as the output current increases.

NOTE: If you turn on the ac breaker before the dc breaker,

and you have a filtered model of the AT10.1, there is a

possibility that the dc breaker will trip when you try to turn it

on. This is caused by the filter capacitors discharging into the

battery. To get around this problem, turn off the ac breaker.

Restart the AT10.1 by turning on the dc breaker first.

• The green FLOAT indicator lights. Press the CHRG MODE key on the

front panel. The FLOAT indicator goes off, and the yellow EQLZ

indicator lights. Press the CHRG MODE key again to return the charger to

the float mode.

The table below shows the normal factory settings for float and equalize

voltages, equalize time, current limit setting, and alarm settings. If your

purchase order specified other float or equalize voltage settings, a tag

attached to the front panel of the AT10.1 lists the actual voltage settings.

FACTORY SETTINGS FOR ALL PARAMETERS

Parameter

Float Voltage

Equalize Voltage

HVDC Alarm

LVDC Alarm

Equalize Time

Equalize Method

Current Limit

HVDC Shutdown

Nominal Vdc

12 24 48 130

13 26 52 131

14 28 56 139

14.4 28.8 57.6 144

12 24 48 120

24 Hours

Manual Timer

110% of nominal output current

Disabled

25

Page 30

OPERATING THE AT10.1

2.2. USING THE AT10.1 FRONT PANEL FEATURES

2.2.1. If the meter displays an error message

When you apply power to the AT10.1 for the first time, the microprocessor control circuit performs a diagnostic check of the system. If it

finds anything wrong, it writes an error code to the display, such as E 01.

Below is a list of the error codes. See section 3.2 for a full explanation of

each error code.

Error Code Explanation

E 01

E 02

E 03

E 04

E 05

E 06

E 07

Resistor R2 is open or defective.

Short circuit on output

HVDC Shutdown has occurred

Internal memory failure

Not used

Failure in Remote Sense wiring

DC breaker is open, or internal or external

output wiring is defective.

E 08

E 09

E 10

A 02

Defective temperature compensation probe

Misadjusted current limit

Open internal feedback loop

Equalize mode is inhibited

2.2.2. Selecting the meter mode

• Press the METER MODE key to change the meter display mode. The digital

meter has four operating modes:

1. Alternating between output voltage and output current. When the

charger is in a timed equalize mode, the meter alternates between

output voltage, output current, and equalize hours remaining.

2. Displaying output voltage only. The DC Volts indicator lights.

3. Displaying output current only. The DC Amps indicator lights.

4. Displaying equalize hours remaining only. The EQLZ HRS

REMAINING indicator lights. If the AT10.1 is not in a timed

equalize mode, the meter displays the full programmed equalize

time.

• When the charger starts initially, the meter alternates, showing output

voltage and output current. The DC Volts and DC Amps indicators light

alternately to indicate what is being displayed.

26

Page 31

OPERATING THE AT10.1

2.2.3. Selecting the Float or Equalize mode

The AT10.1 has 2 output voltage settings, Float and Equalize. Use the

Float mode for all normal battery charging and to operate your dc system.

Use the Equalize mode if it is necessary to balance the level of charge

among the cells of the battery. Consult your battery data sheets for

information on equalize-charging your battery.

• Press the CHRG MODE key to change to the equalize mode.

If the equalize method is set to manual timer or auto-equalize timer, the

charger will revert to the float mode at the end of the selected equalize

time.

• You can press the CHRG MODE key at any time to change back to the float

mode.

2.2.4. Choosing the Equalize method

Press the EQLZ MTHD key to choose the desired equalize method. The

indicator next to the desired equalize method will light. Three equalize

methods are available in the AT10.1:

• Manual Timer

• Manual Equalize

• Auto-Equalize Timer

These equalize methods are described below.

Manual Timer Method

Choose the manual timer method if you perform regularly scheduled

equalize charging, or if you base your equalize charging on regular

readings of the specific gravity of each cell of your battery (for lead-acid

batteries). When your battery requires equalize charging, adjust the

manual timer to 1-2 hours for each 100 AH of battery capacity (see

section 2.3.3 to learn how to adjust the equalize time). The battery

manufacturer can help you determine the best equalizing schedule for

your battery.

After you select the manual timer method, press the CHRG MODE key to put

the charger into the equalize mode. The EQLZ indicator will light. When

the equalize timer is finished, the charger reverts automatically to the float

mode, and the FLOAT indicator lights.

At any time during the equalize charge, you can switch the charger back

to float mode by pressing the CHRG MODE key. The FLOAT indicator will

light.

If there is an ac power failure during a timed equalize charge, the AT10.1

remembers the remaining equalize time. When ac power is restored, it

resumes the equalize charge where it left off.

27

Page 32

OPERATING THE AT10.1

Manual Equalize Method

Choose the manual equalize method when you want to equalize charge the

battery, but only when you are able to monitor the battery voltage and

gassing rate. After you select the manual equalize method, press the

CHRG MODE key to put the charger into the equalize mode. The EQLZ

indicator will light.

Press the CHRG MODE key again to return the charger to the float mode. The

FLOAT indicator will light.

NOTE: Never leave the AT10.1 unattended in the equalize mode with the

manual equalize method selected, because a sustained overcharge may

cause permanent damage to the battery.

Auto-Equalize Timer Method

Choose the auto-equalize timer method if you have a flooded (non-sealed)

battery that is subject to infrequent discharges, or when the battery will be

discharged by at least half of its rated capacity during an ac power failure.

When ac power is restored to the charger, it turns on in the equalize mode

automatically, and the EQLZ indicator lights. At the end of the equalize

charging-time that you select, the charger reverts automatically to the float

mode, and the FLOAT indicator lights. At any time during the equalize

charge, you can switch the charger back to float mode by pressing the

CHRG MODE key. The FLOAT indicator will light.

Consult your battery manufacturer's instructions before using the autoequalize timer method with sealed (valve-regulated) lead-acid batteries.

Whenever the ac supply fails for 12 seconds or longer, the auto-equalize

timer is enabled. For shorter periods, the timer behaves as shown below:

Mode before

ac failure

FLOAT

EQUALIZE

FLOAT or

EQUALIZE

AC falure

duration

less than

12 seconds

less than

12 seconds

12 seconds

or greater

Mode after

ac failure

FLOAT

Resume EQUALIZE

with time remaining

EQUALIZE

with full time

Switching to Equalize Mode with Auto-Equalize Timer Method Selected

You can start an equalize charge at any time.

• Press the CHRG MODE key. The EQLZ indicator lights.

When the equalize timer is finished, the charger reverts automatically to

the float mode, and the FLOAT indicator lights.

28

Page 33

OPERATING THE AT10.1

2.2.5. Testing the front panel indicators

• Press the DOWN key. This is also the LAMP TEST key.

The meter will display 8888, and all status & alarm indicators will light.

The LAMP TEST key does not test the AC ON indicator. The AC ON

indicator lights whenever ac power is present, and the ac circuit breaker is

turned on. The LAMP TEST key does not operate when ac power is off.

To test the action of the summary alarm relay, press and hold the

LAMP TEST key for four seconds. The relay transfers. If you are monitoring

the relay with a remote annunciator, it detects the alarm condition.

2.2.6. Testing the Auxiliary Relay Board (optional)

If you have the optional Auxiliary Relay Board installed, you can test the

action of the alarm relays. Press and hold the LAMP TEST key for four

seconds. The six auxiliary alarm relays on the Auxiliary Relay Board

transfer. Remote annunciators connected to these relays will indicate this.

2.2.7. Interpreting the alarm indicators

There are six alarm indicators at the right side of the front panel. An

indicator lights for each of the following alarm conditions:

• HIGH DC VOLTAGE: lights whenever the dc output voltage exceeds

the specified alarm voltage setting. See section 2.3.4 to learn how to

adjust the HVDC alarm setting.

• LOW DC VOLTAGE: lights whenever the dc output voltage is below

the specified alarm voltage setting. See section 2.3.4 to learn how to

adjust the LVDC alarm setting.

• DC OUTPUT FAILURE: lights whenever the charger cannot provide

its full rated output voltage or its full rated output current. You cannot

adjust this alarm setting.

• AC INPUT FAILURE: lights whenever the ac power supply to the

charger is interrupted.

• POS GND: lights whenever leakage current from the battery positive

terminal to ground exceeds a specified threshold (see note).

• NEG GND: lights whenever leakage current from the battery negative

terminal to ground exceeds a specified threshold (see note).

NOTE: You can adjust the sensitivity of the ground fault detection

from 5K to 50k ohms. Adjusting the ground fault sensitivity affects

the positive and negative ground fault sensitivities equally.

The indicators light immediately when an alarm occurs. The AT10.1 also

has a summary alarm relay with one form C contact, rated 0.5A @ 125

Vac/Vdc. If an alarm condition lasts for 30 seconds or longer, the

summary alarm relay contact transfers. When the alarm condition is

corrected, the relay and all indicators reset automatically.

29

Page 34

OPERATING THE AT10.1

2.3. SETTING PARAMETERS IN THE AT10.1

2.3.1. Understanding Parameter Settings

You can change the settings of the AT10.1 while the charger is operating,

using the front panel controls. The changes you make take effect

immediately, and are saved internally. If the charger is taken out of

service, and then later returned to service, it restarts using the last values

you set. You can adjust the following parameters:

• Float voltage

• Equalize voltage

• Equalize timer (in hours)

• High dc voltage alarm setting

• Low dc voltage alarm setting

• Current limit value (in Amperes)

• High dc voltage shutdown feature (on or off)

Your choice of equalize method is also saved internally.

When you want to change any parameter, press the EDIT/ENTER key to put

the AT10.1 into EDIT mode. The meter display flashes about once per

second, and the status indicators prompt you to adjust the respective

parameter. You adjust each parameter by pressing the UP or DOWN key

until the reading you want shows on the meter display. You can make the

display scroll up or down continuously by pressing and holding the UP or

DOWN key.

30

You cannot exceed certain upper and lower limits for the operating

parameters. To see what the limits are for your charger, refer to the

AT10.1 Specifications in Appendix A on page 70.

When you first press the EDIT/ENTER key, the AT10.1 prompts you to

adjust the first parameter in the list above (float voltage). When you obtain

the value you want on the display, press the EDIT/ENTER key again. The

AT10.1 saves the new setting internally, and then prompts you to adjust

the second parameter. You continue this way to adjust the first six

parameters in the list above. If you want to skip adjusting any parameter,

just press the EDIT/ENTER key again. The AT10.1 moves to the next

parameter.

When you are finished adjusting the sixth parameter (current limit), press

the EDIT/ENTER key again. The AT10.1 saves all adjustments you made

internally, and reverts to normal operation. The new settings take effect

immediately.

Edit mode ends automatically if you don't press any front panel key within

25 seconds, and any change you made to the last setting is not saved.

Page 35

OPERATING THE AT10.1

2.3.2. Setting the Float and Equalize voltages

• Press the EDIT/ENTER key.

The FLOAT and DC VOLTS indicators light, and the display flashes the

present value of the float voltage. Press and release the UP or DOWN key to

increase or decrease the value in the display by one count, or press and

hold the UP or DOWN key to scroll the value in the display upward or

downward. When the display shows the float voltage you want to set,

release the UP or DOWN key. If you go past the voltage you want, press the

UP or DOWN key again to reach the voltage you want to set.

• Press the EDIT/ENTER key. The new float voltage setting is saved

internally.

The EQLZ and DC VOLTS indicators light, and the display flashes the

present value of the equalize voltage. Press and release the UP or DOWN

key to increase or decrease the value in the display by one count, or press

and hold the UP or DOWN key to scroll the value in the display upward or

downward. When the display shows the equalize voltage you want to set,

release the UP or DOWN key. If you go past the voltage you want, press the

UP or DOWN key again to reach the voltage you want to set.

• Press the EDIT/ENTER key. The new equalize voltage setting is saved

internally.

If you want to adjust the equalize timer duration, skip to section 2.3.3.

OR

If you want to exit the Edit mode now, press the EDIT/ENTER key four more

times until the charger returns to normal operation.

Edit mode ends automatically if you don't press any front panel key within

25 seconds, and any change you made to the last setting is not saved.

31

Page 36

OPERATING THE AT10.1

2.3.3. Setting the Equalize Timer

• Press the EDIT/ENTER key until the EQLZ HRS REMAINING,

MANUAL TIMER and AUTO EQLZ TIMER indicators light, and the

display flashes the present value of the equalize timer duration in hours.

Press and release the UP or DOWN key to increase or decrease the value in

the display by one count, or press and hold the UP or DOWN key to scroll

the value in the display upward or downward. When the display shows the

equalize time, in hours, that you want to set, release the UP or DOWN key.

If you go past the number of hours you want, press the UP or DOWN key

again to reach the number you want to set.

If you set the equalize time to zero hours, the equalize mode is disabled.

• Press the EDIT/ENTER key. The new equalize timer duration is saved

internally. The timer setting works for both the manual timer and the

auto-equalize timer.

If you want to adjust the alarm settings, skip to section 2.3.4.

OR

If you want to exit the Edit mode now, press the EDIT/ENTER key three

more times until the charger returns to normal operation.

2.3.4. Setting the Alarms

After you save the equalize timer setting, the Edit mode automatically

prompts you to adjust the high dc voltage and low dc voltage alarms.

There is a red indicator on the front panel of the AT10.1 for each of the

following alarm conditions:

• High DC Voltage

• Low DC Voltage

• DC Output Failure

• AC Input Failure

• Ground Fault Detection (+)

• Ground Fault Detection (-)

The indicators light immediately when an alarm occurs. The AT10.1 also

has a summary alarm relay with one form C contact rated 0.5A / 125

Vac/Vdc. If an alarm condition lasts for 30 seconds or longer, the

summary alarm relay contact transfers. When the alarm condition is

corrected, the relay and all indicators reset automatically. The relay

contact also transfers if the AT10.1 detects certain errors, and displays

E 03, E 06, E 07 or E 10 on the front panel meter.

32

Page 37

OPERATING THE AT10.1

Setting the High DC Voltage Alarm

• Press the EDIT/ENTER key until the HIGH DC VOLTAGE indicator

flashes, and the display flashes the present value of the high dc voltage

alarm.

Press and release the UP or DOWN key to increase or decrease the value in

the display by one count, or press and hold the UP or DOWN key to scroll

the value in the display upward or downward. When the display shows the

high dc voltage alarm point that you want to set, release the UP or DOWN

key. If you go past the voltage you want, press the UP or DOWN key again

to reach the voltage you want to set.

• Press the EDIT/ENTER key. The new high dc voltage alarm setting is

entered into permanent memory.

Setting the low DC Voltage Alarm

• Press the EDIT/ENTER key until the LOW DC VOLTAGE indicator

flashes, and the display flashes the present value of the low dc voltage

alarm.

Press and release the UP or DOWN key to increase or decrease the value in

the display by one count, or press and hold the UP or DOWN key to scroll

the value in the display upward or downward. When the display shows the

low dc voltage alarm point that you want to set, release the UP or DOWN

key. If you go past the voltage you want, press the UP or DOWN key again

to reach the voltage you want to set.

• Press the EDIT/ENTER key. The new low dc voltage alarm setting is

entered into permanent memory.

If you want to adjust the current limit setting, skip to section 2.3.5.

OR

If you want to exit the Edit mode now, press the EDIT/ENTER key again to

return the charger to normal operation.

33

Page 38

OPERATING THE AT10.1

Adjusting Ground Detection Sensitivity

You can adjust the sensitivity of

the ground detection alarm circuit.

You must have a test resistor

whose value is the sensitivity you

want. You can adjust the

sensitivity from 5 to 50 kΩ.

The potentiometer for adjusting

ground detection circuit

sensitivity is located on the main

control circuit board. It is the

lower of the two potentiometers

labeled RA3 SENS, as shown in

the figure at the right.

NOTE: Do not try to adjust the upper potentiometer labeled RA2

BALANCE. This adjustment is made at the factory for proper

circuit operation.

CAUTION: Before connecting or disconnecting a test resistor,

de-energize and lock out all ac and dc voltage sources to the

AT10.1. Check with a voltmeter before proceeding. Restart the

AT10.1 only when necessary to make the sensitivity adjustment.

If your battery is grounded, do not attempt this procedure.

Remove the safety cover. Connect

the test resistor between TB1(+)

and chassis ground, as shown to

the right. Adjust RA3

counterclockwise until the front

panel indicator goes out, then

adjust slowly clockwise until the

POS GND indicator just lights.

Make this adjustment slowly; the

indicator is updated once in every

four seconds. De-energize and

lock out power to the AT10.1,

then remove the test resistor and

verify that the indicator goes out.

Now connect the test resistor between TB1(-) and chassis ground. Verify

that the NEG GND indicator lights. If not, adjust RA3 clockwise until it

does. Remove the test resistor.

34

Page 39

OPERATING THE AT10.1

Disabling the Ground Detection Alarm

You can disable the ground detection alarm circuit, and isolate the circuit

from chassis ground. If your battery is normally grounded, or you want to

defeat the alarm for any other reason, follow these steps:

• De-energize and lock out all ac and dc voltage sources to the AT10.1.

Check with a voltmeter before proceeding. This includes remote sense

wires if they were installed.

• Open the AT10.1 front panel, and locate jumper J5 at the top left of the

Control Circuit Board (shown on the previous page). Move the jumper to

the DISABLE position. The POS GND and NEG GND indicators and

the summary alarm relay will not respond to a ground fault.

Restart the AT10.1, following the instructions in section 2.1.

2.3.5. Setting the current limit value

The AT10.1 automatically limits its dc output current in case of overload

or battery discharge. You can adjust the value of the current limit from

50% to 110% of rated current. The factory setting is 110%.

The current limit adjustment is the last step in the normal Edit sequence. If

the AT10.1 is not in the Edit mode, press the EDIT/ENTER key five times,

until the meter display flashes the value of current limit, in Amperes. Press

and release the UP or DOWN key to increase or decrease the value in the

display by one count, or press and hold the UP or DOWN key to scroll the

value in the display upward or downward. When the display shows the

current limit value that you want to set, release the UP or DOWN key. If you

go past the number you want, press the UP or DOWN key again to reach the

number you want to set.

• Press the EDIT/ENTER key. The new current limit setting is saved

internally.

Edit mode ends automatically if you don't press any front panel key within

25 seconds, and any change you made to the last setting is not saved.

35

Page 40

OPERATING THE AT10.1

2.3.6. Enabling the High DC Voltage shutdown feature

The AT10.1 has a built-in high dc voltage shutdown feature. In case of

any maladjustment or internal failure that results in a continuous output

voltage that is too high, the AT10.1 shuts down after 30 seconds to protect

the battery. The digital display reads E 03, and the summary alarm relay

contact transfers.

The AT10.1 is shipped with the high dc voltage shutdown feature disabled.

You can adjust the high dc voltage shutdown

(the setting is the same as the high dc voltage

alarm setting). Refer to section 2.3.4.

The charger must be in normal operation (not

the Edit mode) to enable the high dc voltage

shutdown.

To enable the shutdown feature:

• Press and hold the UP key, then

• Press the CHRG MODE key.

The HIGH DC VOLTAGE indicator lights, and

the display flashes ON. You can toggle the

shutdown feature OFF and ON by pressing the

CHRG MODE key repeatedly.

Parallel Operation

If two (or more) AT10.1

chargers are connected in

parallel, both sense the

output voltage. If one

charger runs away, it will

supply all the output

current; the other has zero

output current. The high dc

voltage shutdown does not

operate in a charger with

zero output current, so that

only the defective charger

(of two or more in parallel)

shuts down. The other

charger continues to supply

the load normally.

If you don't press any key within 4 seconds, the last state indicated (ON or

OFF) is saved internally. Note that you don't use the EDIT/ENTER key for

this feature.

If the AT10.1 shuts down because of a high dc voltage, the meter display

shows error code E 03. Reset the charger by turning the ac breaker off,

then on again.

36

Page 41

OPERATING THE AT10.1

2.3.7. Adjusting the Voltmeter Accuracy

The AT10.1 voltmeter is adjusted at the factory to display the actual

output voltage within ±1%. If you replace any component that affects

meter accuracy, such as the main control PC board or R4, you should

readjust the meter. This adjustment procedure is different from all others,

because the meter reading remains constant, while the output voltage of

the charger changes. Do this adjustment with a fully charged battery and

with no load connected.

First, use the Edit procedure to adjust the float voltage to the desired

value. See section 2.3.2 for instructions on setting the float voltage.

Second, press and hold the UP key, then press the EQLZ MTHD key.

The DC VOLTS METER MODE indicator will light, and the meter display

flashes the output voltage reading. Measure the output voltage of the

AT10.1 using a dc meter accurate to ±0.25% or better.

While watching the meter connected to the AT10.1 output (not the front

panel meter), press the UP or DOWN key until the actual output voltage

matches the float setting on the front panel meter.

Each time you press UP or DOWN, you change the AT10.1 output voltage

by a small amount. Continue to press UP or DOWN until the actual output

voltage agrees with the front panel reading within ±1%

NOTE: Allow one or two seconds for the output voltage to stabilize

each time you press the UP or DOWN key.

When you are finished adjusting the output voltage, the AT10.1 waits 5

seconds, then the display returns to normal operation.

37

Page 42

OPERATING THE AT10.1

2.3.8. Using the Low Level Detector (LLD)

The AT10.1 charger is equipped with a summary alarm safety override

circuit. This safety feature forces the summary alarm (common alarm)

relay contact to transfer, sending an alarm, even if there is a catastrophic