Page 1

Doc. No.

78-4337-02

Cisco 12012 Gigabit Switch Router Card Cage Assembly Replacement Instructions

Product Number: GSR12-CARDCAGE=

This document contains instructions for removing and replacing a card cage assembly in the

Cisco 12012 Gigabit Switch Router (GSR).

The sections in this document include the following:

• Product Overview, page 1

• Safety Guidelines, page 3

• Tools and Parts Required, page 6

• Removing and Replacing a Card Cage Assembly, page 7

• FCC Class A Compliance, page 32

• Cisco Connection Online, page 33

Product Overview

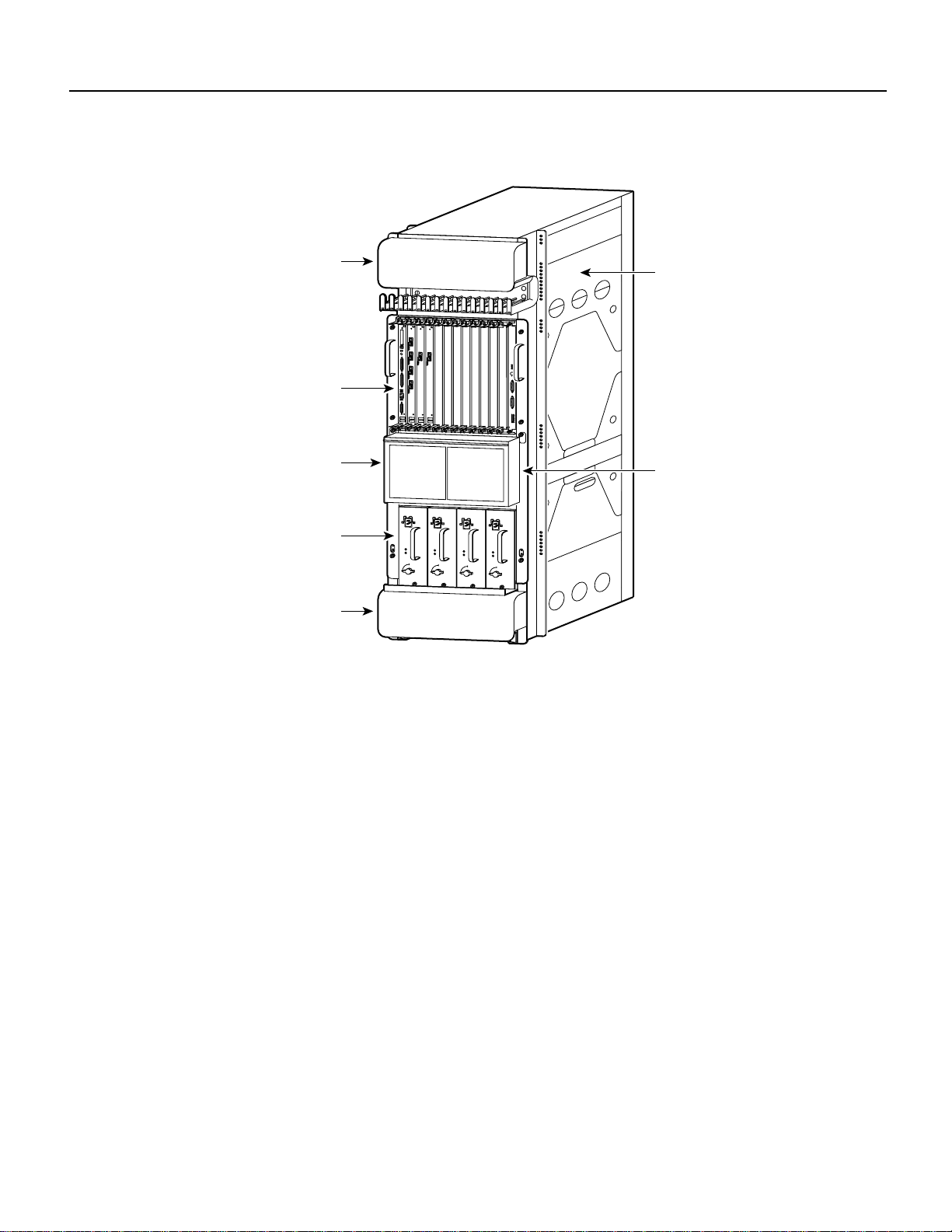

The Cisco 12012 has two card cages; the upper card cage and the lower card cage. (Refer to

Figure 1.) The upper card cage has 12 user-configurable slots available for line cards and a route

processor (RP). One additional slot (rightmost slot) in the uppercard cage is non-configurable; it is

reserved for an alarm card. The line cards and the RP are not slot dependent; you can install the line

cards and the RP in any of the first 12 available slots.

Corporate Headquarters

Cisco Systems, Inc.

170 West Tasman Drive

San Jose, CA 95134-1706

USA

Copyright © 1997-2002

Cisco Systems, Inc.

All rights reserved.

1

Page 2

Product Overview

Figure 1 Cisco 12012—Front View

Top blower module

(behind front cover)

Upper card cage

Air filter tray

0

ACTIVE

CARRIER

EJECT

RX PKT

SLOT-0

SLOT-1

RESET

AUX

1

0

0

ACTIVE

ACTIVE

ACTIVE

CARRIER

CARRIER

CARRIER

RX PKT

RX CELL

RX CELL

CONSOLE

2

ACTIVE

CARRIER

RX PKT

3

LINK

ACTIVE

COLL

TX

CARRIER

RX

RX PKT

MII

RJ-45

ROUTE PROCESSOR

OC-12/STM-4 ATM

Q OC-3/STM-POS

OC-12/STM-4 POS

CRITICAL

MAJOR

MINOR

ACO/LT

ALARM 1 ALARM 2

ENABLED

FAIL

0

CSC

1

0

1

SFC

ALARM

2

Frame

Lower card cage

(behind air filter)

INPUT:

200-240V

~

INPUT:

10 A

200-240V

~

INPUT:

10 A

200-240V

~

50/60 HZ

2000 W

AC

OK

OUTPUT

FAIL

INPUT:

10 A

200-240V

~

50/60 HZ

10 A

2000 W

50/60 HZ

2000 W

AC

OK

AC

OK

OUTPUT

FAIL

OUTPUT

FAIL

Power supply bay

50/60 HZ

2000 W

AC

OK

OUTPUT

FAIL

Bottom blower module

(behind front cover)

H10476

The lower card cage, located behind the air filter,has fivekeyedhorizontal slots for cards containing

theswitchfabriccircuitry.Thecardsprovidethephysicalpathwayfordatapacketexchangebetween

the line cards in the upper card cage.

There are two types of cards installed in the lower card cage; the clock and scheduler card (CSC)

and the switch fabric card (SFC). Both types of cards are keyed to fit into specific slots in the lower

card cage. You can install the clock and scheduler card only in the top two slots and the switch fabric

card only in the lower three slots. The clock and scheduler card contains the system clock, switch

fabric scheduler circuitry, and the switch fabric. The switch fabric card contains only switch fabric

circuitry.

Below the lower card cage is a power supply bay.The Cisco 12012 can be configured for source AC

or source DC operation. A system configured for source AC operation must have a minimum of two

AC-input power supplies installed. You can install two additional AC-input power supplies for

redundancy and current sharing. Systems configured for source DC operation have one DC-input

power supply installed. Youcaninstall a second DC-input power supply for redundancy and current

sharing.

The Cisco 12012 has two blower modules; one located above the upper card cage and one located

belowthe powersupply bay.Theydrawfilteredcoolingairin through both card cages and the power

supply bay to maintain acceptable operating temperatures for the internal components.

2 Cisco 12012 Gigabit Switch Router Card Cage Assembly Replacement Instructions

Page 3

Safety Guidelines

Before you begin the replacement procedure, review the safety guidelines in this section to avoid

injuring yourself or damaging the equipment. This section also repeats in multiple languages the

warnings in this document.

In addition, review the safety warnings listed in the document Regulatory Compliance and Safety

Information for the Cisco 12012 Gigabit Switch Router (Document Number 78-4347-xx) that

supports your Cisco 12012 before installing, configuring, or maintaining the router.

Following are translations for the warning statements used in this document.

Safety Warnings

Warning Thiswarning symbol means danger. You are in a situation that could cause bodily injury.

Before you work on any equipment, be aware of the hazards involved with electrical circuitry and

be familiar with standard practices for preventing accidents. Tosee translations of the warnings that

appear in this publication, refer to the Regulatory Compliance and Safety Information document that

accompanied this device.

Waarschuwing Dit waarschuwingssymbool betekent gevaar. U verkeert in een situatie die

lichamelijk letsel kan veroorzaken.Voordat u aan enige apparatuur gaat werken, dient u zich bewust

te zijn van de bij elektrische schakelingen betrokken risico's en dient u op de hoogte te zijn van

standaard maatregelen om ongelukken te voorkomen. Voor vertalingen van de waarschuwingen die

in deze publicatie verschijnen, kunt u het document Regulatory Compliance and Safety Information

(Informatie over naleving van veiligheids- en andere voorschriften) raadplegen dat bij dit toestel is

ingesloten.

Safety Guidelines

Varoitus Tämä varoitusmerkki merkitsee vaaraa.Olettilanteessa,jokavoijohtaaruumiinvammaan.

Ennen kuin työskentelet minkään laitteiston parissa, ota selvää sähkökytkentöihin liittyvistä

vaaroista ja tavanomaisista onnettomuuksien ehkäisykeinoista. Tässä julkaisussa esiintyvien

varoitusten käännökset löydät laitteen mukana olevasta Regulatory Compliance and Safety

Information -kirjasesta (määräysten noudattaminen ja tietoa turvallisuudesta).

Attention Ce symbole d'avertissement indique un danger. Vous vous trouvez dans une situation

pouvant causer des blessures ou des dommages corporels. Avant de travailler sur un équipement,

soyez conscient des dangers posés par les circuits électriques et familiarisez-vous avec les

procédures couramment utilisées pour éviter les accidents. Pour prendre connaissance des

traductions d’avertissements figurant dans cette publication, consultez le document Regulatory

Compliance and Safety Information (Conformité aux règlements et consignes de sécurité) qui

accompagne cet appareil.

Cisco 12012 Gigabit Switch Router Card Cage Assembly Replacement Instructions 3

Page 4

Safety Guidelines

Warnung Dieses Warnsymbol bedeutet Gefahr. Sie befinden sich in einer Situation, die zu einer

Körperverletzungführen könnte. BevorSie mit der Arbeit an irgendeinem Gerät beginnen, seien Sie

sich der mit elektrischen Stromkreisen verbundenen Gefahren und der Standardpraktiken zur

Vermeidung von Unfällen bewußt. Übersetzungen der in dieser Veröffentlichung enthaltenen

Warnhinweise finden Sie im Dokument Regulatory Compliance and Safety Information

(Informationen zu behördlichen Vorschriften und Sicherheit), das zusammen mit diesem Gerät

geliefert wurde.

Avvertenza Questo simbolo di avvertenza indica un pericolo. La situazione potrebbe causare

infortuni alle persone. Prima di lavorare su qualsiasi apparecchiatura, occorre conoscere i pericoli

relativiaicircuitielettriciedesserealcorrentedellepratichestandardperlaprevenzionedi incidenti.

La traduzione delle avvertenze riportate in questa pubblicazione si trova nel documento Regulatory

Compliance and Safety Information (Conformità alle norme e informazioni sulla sicurezza) che

accompagna questo dispositivo.

Advarsel Dette varselsymbolet betyr fare. Du befinner deg i en situasjon som kan føre til

personskade. Før du utfører arbeid på utstyr, må du vare oppmerksom på de faremomentene som

elektriskekretser innebærer,samt gjøre deg kjent med vanlig praksis når det gjelder å unngå ulykker.

Hvis du vil se oversettelser av de advarslene som finnes i denne publikasjonen, kan du se i

dokumentet Regulatory Compliance and Safety Information (Overholdelse av forskrifter og

sikkerhetsinformasjon) som ble levert med denne enheten.

Aviso Este símbolo de aviso indica perigo. Encontra-se numa situação que lhe poderá causar danos

físicos. Antes de começar a trabalhar com qualquer equipamento, familiarize-se com os perigos

relacionados com circuitos eléctricos, e com quaisquer práticas comuns que possam prevenir

possíveis acidentes. Para ver as traduções dos avisos que constam desta publicação, consulte o

documento Regulatory Compliance and Safety Information (Informação de Segurança e

Disposições Reguladoras) que acompanha este dispositivo.

¡Advertencia! Este símbolo de aviso significa peligro. Existe riesgo para su integridad física.

Antes de manipular cualquier equipo, considerar los riesgos que entraña la corriente eléctrica y

familiarizarse con los procedimientos estándar de prevención de accidentes. Para ver una traducción

de las advertencias que aparecen en esta publicación, consultar el documento titulado Regulatory

Compliance and Safety Information (Información sobre seguridad y conformidad con las

disposiciones reglamentarias) que se acompaña con este dispositivo.

Varning! Denna varningssymbol signalerar fara. Du befinner dig i en situation som kan leda till

personskada. Innan du utför arbete på någon utrustning måste du vara medveten om farorna med

elkretsar och känna till vanligt förfarande för att förebygga skador. Se förklaringar av de varningar

som förkommer i denna publikation i dokumentet Regulatory Compliance and Safety Information

(Efterrättelse av föreskrifter och säkerhetsinformation), vilket medföljer denna anordning.

Safety with Equipment

The following guidelines will help ensure your safety and protect the equipment. This list is not

inclusive of all potentially hazardous situations, so be alert.

• Always disconnect all power cords and interface cables before moving the system.

• Keep tools and assembly components away from walk areas.

• Do not work alone if potentially hazardous conditions exist.

• Do not perform any action that creates a potential hazard to people or makes the equipment

unsafe.

• Carefully examine your work area for possible hazards such as moist floors, ungrounded power

extension cables, and missing safety grounds.

4 Cisco 12012 Gigabit Switch Router Card Cage Assembly Replacement Instructions

Page 5

Safety with Electricity

The line cards, RP, switch fabric cards, blower modules, and redundant power supplies are designed

to be removed and replaced while the system is operating without presenting an electrical hazard or

damage to the system.

Follow these basic guidelines when working with any electrical equipment:

• Before beginning any procedures requiring access to the interior of the Cisco 12012, locate the

emergency power-off switch for the room in which you are working.

• Look carefully for possible hazards in your work area, such as moist floors, ungrounded power

extension cables, and missing safety grounds.

• If an electrical accident occurs, proceed as follows:

— Use caution; do not become a victim yourself. Disconnect power to the system.

— If possible, send another person to get medical aid. Otherwise, assess the condition of the

— Determine if the person needs rescue breathing or external cardiac compressions; then take

• Disconnect all power and external cables before installing or removing a router.

Safety Guidelines

victim and then call for help.

appropriate action.

• Never assume that power has been disconnected from a circuit; always check.

• Do not perform any action that creates a potential hazard to people or makes the equipment

unsafe.

• Never install equipment that appears damaged.

In addition, use the guidelines that follow when working with any equipment that is disconnected

from a power source, but still connected to telephone or network wiring:

• Never install telephone wiring during a lightning storm.

• Never install telephone jacks in wet locations unless the jack is specifically designed for wet

locations.

• Never touch uninsulated telephone wires or terminals unless the telephone line has been

disconnected at the network interface.

• Use caution when installing or modifying telephone lines.

Cisco 12012 Gigabit Switch Router Card Cage Assembly Replacement Instructions 5

Page 6

Tools and Parts Required

Preventing Electrostatic Discharge Damage

Electrostatic discharge damage, which can occur when electronic boards or components are handled

improperly, can result in complete or intermittent failures.

Following are guidelines for preventing ESD damage:

• Always use an ESD-preventive wrist strap or ankle strap and ensure that it makes good skin

contact.

• When removing or installing a component, connect the equipment end of a ground strap to one

of the two ESD ground sockets located on the front sides of the upper card cage or to a bare metal

surface on the frame.

• Ifyouplan to return a replaced component to the factory,immediately place it in a static shielding

bag to avoid ESD damage to the component.

• The wrist strap only protects the component from ESD voltages on the body; ESD voltages on

clothing can still cause damage.

Caution You should periodically check the resistance value of the antistatic strap. The

measurement should be between 1 and 10 megohms.

Tools and Parts Required

You need the following tools and parts to remove and replace the card cage assembly:

• ESD-preventive wrist strap

• 1/4-inch flat-blade screwdriver

• 3/16-inch flat-blade screwdriver

• 10-mm nutdriver

• Antistatic mat

• The replacement card cage assembly (Product Number: GSR12-CARDCAGE=)

You must remove all cards and power supplies from the old card cage assembly and install them in

the replacement card cage assembly.The replacement card cage ships with a new air filter installed.

6 Cisco 12012 Gigabit Switch Router Card Cage Assembly Replacement Instructions

Page 7

Removing and Replacing a Card Cage Assembly

This section covers removing and replacing of the card cage assembly. The card cage assembly

comprises a single assembly that includes the upper card cage, the lower card cage, and the power

supply bays. The assembly slides into and out of the frame and attaches to the frame with six captive

screws. An empty card cage assembly weighs 65 lb (29.5 kg).

The replacement card cage assembly is shipped with only a new air filter; you must remove the

following components from the old card cage assembly:

• Line cards

• route processor (RP)

• Clock and scheduler cards, and switch fabric cards

• Alarm card

• Any installed card blanks

• Power supplies and power supply blanks

Store them carefully while you install the new card cage assembly in the frame, then replace the

components in the new card cage assembly.

Removing and Replacing a Card Cage Assembly

Powering Down the Cisco 12012

Perform the following steps to power down the Cisco 12012:

Step 1 Turn the DC-input power supply power switch to the OFF (O) position (on AC-input

power supplies, turn the power switch counterclockwise to the STANDBY position) on

all power supplies installed in the Cisco 12012.

Step 2 Verify that the system has powered down by checking that the LEDs on the power

supplies are off and the green LEDs on both blower modules are off.

Warning This unit has more than one power supply connection; all connections must be removed

completely to completely remove power from the unit.

Removing a Power Supply

This section provides procedures for removing an AC-input power supply and a DC-input power

supply. Select the procedure appropriate for your system.

Caution Always wear an antistatic wrist strap to prevent ESD when removing and replacing a

power supply.

Cisco 12012 Gigabit Switch Router Card Cage Assembly Replacement Instructions 7

Page 8

Removing and Replacing a Card Cage Assembly

Removing an AC-Input Power Supply

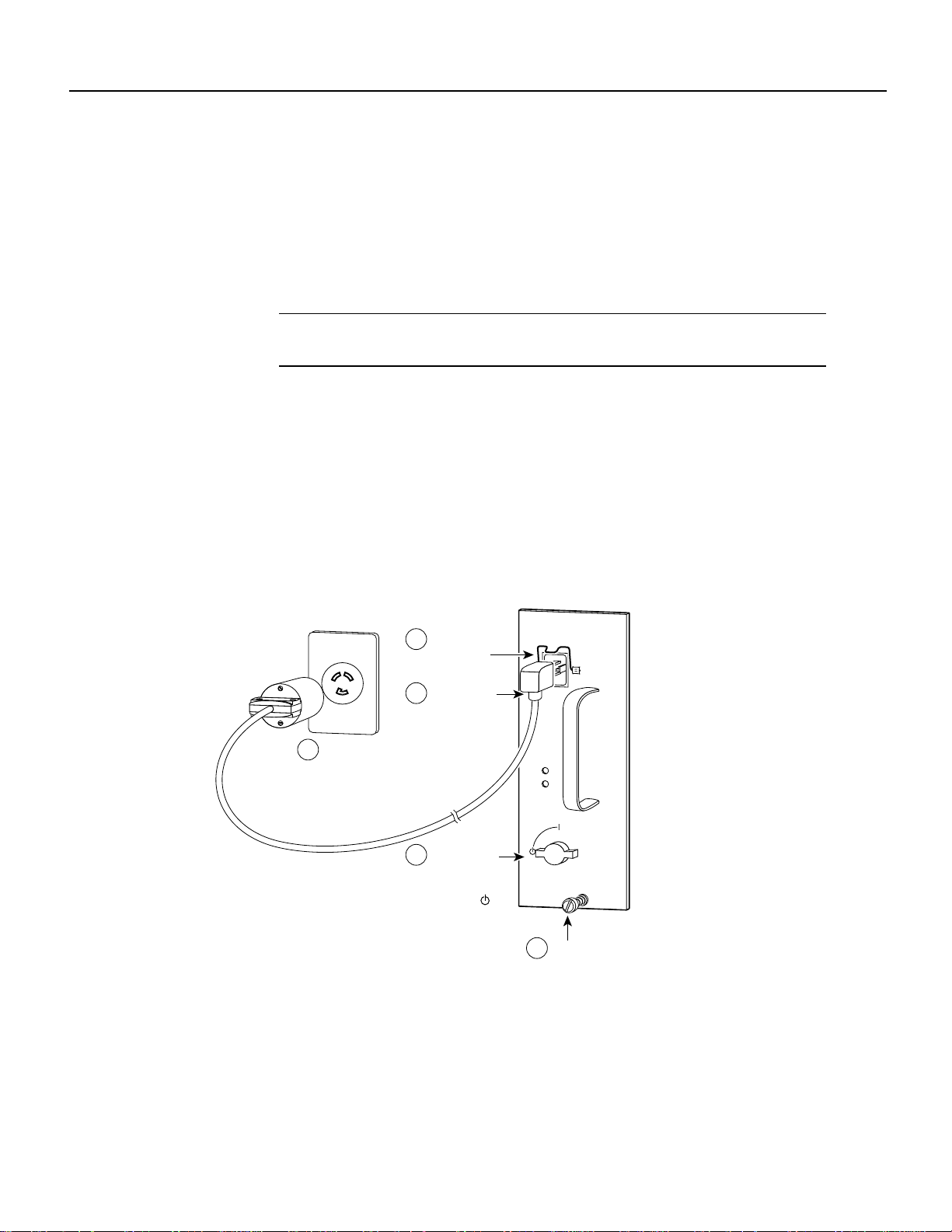

Perform the following steps to remove an AC-input power supply:

Step 1 Attach an antistatic wrist strap to yourself and to one of the two ESD connection sockets

located on the front edges of the upper card cage or to bare metal on the frame.

Step 2 If you have not already done so, turn the power supply power switch to the STANDBY

position on the power supply you want to remove. (Refer to Figure 2a.)

Note Turning the power supply switch to STANDBY also releases a latch that secures

the power supply in the power supply bay slot.

Step 3 Release the spring clip on the power supply faceplate. (Refer to Figure 2b.)

Step 4 Disconnect the AC power cord from the power supply AC receptacle. (Refer to

Figure 2c.)

Step 5 Disconnect the AC power cord from the source AC receptacle. (Refer to Figure 2d.)

Step 6 Loosen the captive screw on the power supply faceplate. (Refer to Figure 2e.)

Figure 2 Disconnecting an AC-Input Power Supply

b

Release

spring clip

c

Disconnect

power cord

d

Disconnect

power cord from

source AC

a

Turn power

switch to

standby

position ( )

AC

OK

OUTPUT

FAIL

e

INPUT:

200-240V

10 A

50/60 HZ

2000 W

Loosen

captive

screw

~

H10375

8 Cisco 12012 Gigabit Switch Router Card Cage Assembly Replacement Instructions

Page 9

Removing and Replacing a Card Cage Assembly

AC

OK

OUTPUT

FAIL

INPUT:

200-240V

~

10 A

50/60 HZ

2000 W

AC

OK

OUTPUT

FAIL

INPUT:

200-240V

~

10 A

50/60 HZ

2000 W

Step 7 Grasp the power supply handle and pull straight out to disconnect the power supply from

the backplane connector. Slide the power supply halfway out of the bay slot. (Refer to

Figure 3.)

Figure 3 Removing an AC-Input Power Supply

AC-input

power

INPUT:

200-240V

~

10 A

50/60 HZ

2000 W

supply

AC

OK

OUTPUT

FAIL

H10376

Use two hands to slide power supply out of bay

Caution

supply.

The AC-input power supply weighs 18 lb (8 kg). Use two hands when handling the power

Step 8 Place your free hand underneath the power supply for support and slide the power supply

Repeat Step 2 through Step 8 for the rest of the AC-input power supplies.

completely out of the bay slot. Set the power supply aside

Note If there are any power supply blanks installed, remove them by loosening the captive screw

on the power supply blank faceplate. Slide the power supply blank out of the power supply bay slot.

Set the power supply blank aside; you will replace the power supply blank in the replacement card

cage assembly.

Cisco 12012 Gigabit Switch Router Card Cage Assembly Replacement Instructions 9

Page 10

Removing and Replacing a Card Cage Assembly

Removing a DC-Input Power Supply

Perform the following steps to remove a DC-input power supply:

Caution Before performing any of the followingprocedure, ensure that power is removed from the

DC circuit. To ensure that all power is OFF,locate the circuit breaker on the panel board that services

the DC circuit, switch the circuit breaker to the OFF position, and tape the switch handle of the

circuit breaker in the OFF position.

Step 1 Attach an antistatic wrist strap to yourself and to one of the two ESD connection sockets

located on the front edges of the upper card cage or to bare metal on the frame.

Step 2 If you have not already done so, turn OFF (O) the power switch on the DC-input power

supply.

Warning Voltages might be present on the DC-input power supply terminals. Turn off the power

source circuit breaker and remove the power supply before accessing the terminals.

Note Turningthe powersupply switch to OFF (O) releases a latch that secures the power

supply in the power supply bay.

Step 3 Locate and turn off the source DC circuit breaker that services the powersupply you want

to remove. As an added precaution, tape the circuit breaker handle in the off position.

Step 4 Using a flat-blade screwdriver or a 10-mm nutdriver, turn the captive jackscrew

counterclockwise (eject) on the power supply faceplate to unseat the power supply from

the backplane power connector. Continue turning the jackscrew to disengage the

jackscrew from the power supply bay (approximately 12 revolutions).

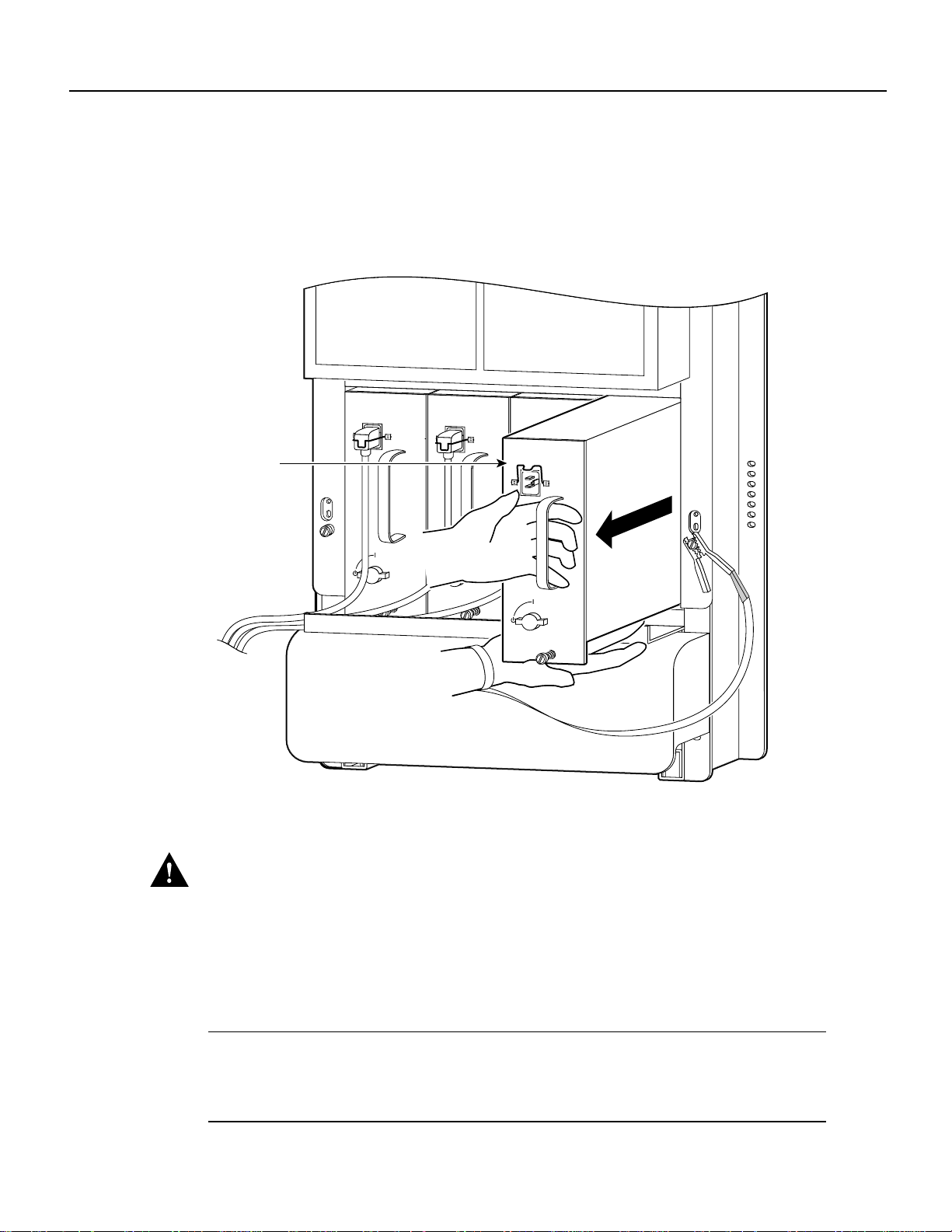

Step 5 Grasp the power supply handle and slide the power supply halfway out of the bay. (Refer

to Figure 4.)

10 Cisco 12012 Gigabit Switch Router Card Cage Assembly Replacement Instructions

Page 11

Figure 4 Removing a DC-Input Power Supply

DC-input

power

supply

Removing and Replacing a Card Cage Assembly

H10600

Use two hands to slide power supply out of bay

Caution

The DC-input power supply weighs 19 lb (8.3 kg). Use two hands when handling the

power supply.

Step 6 Place your free hand underneath the power supply for support and slide the power supply

completely out of the bay. Set the power supply aside

Repeat Step 2 through Step 6 for the rest of the DC-input power supplies.

Cisco 12012 Gigabit Switch Router Card Cage Assembly Replacement Instructions 11

Page 12

Removing and Replacing a Card Cage Assembly

Removing the Cards From the Upper Card Cage

This section provides the procedures for removing the line cards, RP, and alarm card from the upper

card cage.

Note You must remove any blank cards installed in the upper card cage and retain them for use in

the replacement card cage. Blank cards must be installed in slots without cards to maintain proper

air flow and for EMI considerations.

Removing a Line Card From the Upper Card Cage

Perform the following steps to remove a line card from the upper card cage:

Step 1 Attach an ESD wrist strap to your wrist and to one of the two ESD connection sockets

located on the front edges of the upper card cage or to bare metal on the frame.

Step 2 Proceeding from left to right, identify each line card and write down the following

information:

• The line card’s slot number. When you install the line cards in the replacement card

cage assembly, install them in the same card slots.

• The interface cable connections to the line card ports. Youwill reconnect the interface

cables to the same line card ports.

12 Cisco 12012 Gigabit Switch Router Card Cage Assembly Replacement Instructions

Page 13

Removing and Replacing a Card Cage Assembly

Step 3 Proceeding from left to right in the upper card cage, select a line card. Starting with the

bottom port on the line card, disconnect the network interface cable from the bottom port

on the line card. (Refer to Figure 5a.)

Step 4 Carefully remove the interface cable from the vertical cable-management bracket clips.

(Refer to Figure 5b.)

Step 5 Carefully remove the interface cable from the vertical cable-management bracket clip

nearest the line card port. (Refer to Figure 5c.)

Figure 5 Removing the Interface Cables From a Line Card

Chassis

cable-management

tray

a

b

c

0

ACTIVE

CARRIER

RX PKT

0

ACTIVE

CARRIER

RX PKT

0

1

ACTIVE

CARRIER

RX PKT

2

ACTIVE

CARRIER

RX PKT

3

ACTIVE

CARRIER

RX PKT

0

ACTIVE

ACTIVE

CARRIER

CARRIER

RX PKT

RX PKT

1

1

ACTIVE

ACTIVE

CARRIER

CARRIER

RX PKT

RX PKT

2

2

ACTIVE

ACTIVE

CARRIER

CARRIER

RX PKT

RX PKT

3

3

ACTIVE

ACTIVE

CARRIER

CARRIER

RX PKT

RX PKT

cable-management

Interface

cable

1

ACTIVE

CARRIER

RX PKT

2

ACTIVE

CARRIER

RX PKT

3

ACTIVE

CARRIER

RX PKT

Line card

bracket

Cable clip Cable clips

Step 6 Carefully remove the interface cable from the horizontal cable-management tray and set

the interface cable aside.

Repeat Step 3 through Step 6 for rest of the interface cables on that line card, then proceed to the

next line card in the upper card cage. Continue the procedure until you have disconnected and

removed all the line card interface cables from the cable-management system. Do not remove the

vertical cable-management bracket from the line card.

H10880

Cisco 12012 Gigabit Switch Router Card Cage Assembly Replacement Instructions 13

Page 14

Removing and Replacing a Card Cage Assembly

Step 7 Proceeding from left to right in the upper card cage, select a line card and loosen the two

captive screws located at the top and bottom of the line card (Refer to Figure 6a.)

Step 8 Pivot the two card ejector levers out, away from the card to unseat the card from the

backplane connector. (Refer to Figure 6b.)

Step 9 Grasp the card carrier edge with one hand and place your other hand under the carrier to

support it. (Refer to Figure 6c.) Slide the card out of the slot and place it immediately on

the antistatic mat.

Repeat Step 7 through Step 9 for the rest of the line cards.

Figure 6 Removing a Line Card From the Upper Card Cage

a

Loosen

captive

screws

b

Pivot ejector

levers away

from card to

unseat card

Line card

c

Grasp card carrier to

slide card out of slot

Removing a RP From the Upper Card Cage

The RP can occupy slot 0 through 11 in the upper card cage. Perform the following steps to remove

a RP from the upper card cage:

Step 1 Attach an antistatic wrist strap to yourself and to one of the two ESD connection sockets

located on the front edges of the upper card cage or to bare metal on the frame.

Step 2 Disconnect all of the interface cables attached to RP interface connector. Carefully set the

interface cables aside.

0

ACTIVE

CARRIER

RX PKT

1

ACTIVE

CARRIER

RX PKT

2

ACTIVE

CARRIER

RX PKT

3

ACTIVE

CARRIER

RX PKT

Q OC-3/STM-POS

EJECT

SLOT-0

SLOT-1

RESET

AUX

CONSOLE

LINK

COLL

TX

RX

MII

RJ-45

GIGABIT ROUTE PROCESSOR

0

ACTIVE

CARRIER

RX PKT

1

ACTIVE

CARRIER

RX PKT

2

ACTIVE

CARRIER

RX PKT

3

ACTIVE

CARRIER

RX PKT

Q OC-3/STM-POS

0

0

ACTIVE

ACTIVE

CARRIER

CARRIER

RX CELL

RX CELL

OC-12/STM-4 ATM

OC-12/STM-4 POS

CRITICAL

MAJOR

MINOR

ACO/LT

ALARM 1 ALARM 2

ENABLED

FAIL

0

CSC

1

0

1

SFC

ALARM

2

H10705

14 Cisco 12012 Gigabit Switch Router Card Cage Assembly Replacement Instructions

Page 15

Removing and Replacing a Card Cage Assembly

Step 3 Loosen the two captive screws at the top and bottom of the RP. (Refer to Figure 7a.)

Step 4 Pivotthe two ejector leversout, awayfrom the card, to unseat the card from the backplane

connector. (Refer to Figure 7b.)

Step 5 Grasp the card carrier edge with one hand and place your other hand under the carrier to

support it. (Refer to Figure 7c.) Slide the card out of the slot and place it immediately on

the antistatic mat.

Figure 7 Removing a RP From the Upper Card Cage

a

Loosen

captive

screws

0

ACTIVE

CARRIER

EJECT

RX PKT

SLOT-0

SLOT-1

RESET

AUX

1

0

0

ACTIVE

ACTIVE

ACTIVE

b

Pivot ejector

levers away

from card to

unseat card

GRP

CARRIER

CARRIER

CARRIER

RX PKT

RX CELL

2

ACTIVE

CARRIER

RX PKT

3

ACTIVE

CARRIER

RX PKT

Q OC-3/STM-POS

RX CELL

OC-12/STM-4 ATM

OC-12/STM-4 POS

CONSOLE

EJECT

SLOT-0

SLOT-1

RESET

AUX

LINK

COLL

TX

RX

CONSOLE

MII

RJ-45

GIGABIT ROUTE PROCESSOR

LINK

COLL

TX

RX

MII

RJ-45

GIGABIT ROUTE PROCESSOR

CRITICAL

MAJOR

MINOR

ACO/LT

ALARM 1 ALARM 2

ENABLED

FAIL

0

CSC

1

0

1

SFC

ALARM

2

c

Grasp card carrier to

slide card out of slot

Removing an Alarm Card From the Upper Card Cage

The alarm card occupies the rightmost slot (labeled alarm) in the upper card cage.

Perform the following steps to remove an alarm card from the upper card cage:

Step 1 Attach an antistatic wrist strap to yourself and to one of the two ESD connection sockets

located on the front edges of the upper card cage or to bare metal on the frame.

Step 2 Disconnect any interface cables attached to the alarm card connectors.

H10704

Cisco 12012 Gigabit Switch Router Card Cage Assembly Replacement Instructions 15

Page 16

Removing and Replacing a Card Cage Assembly

Step 3 Loosen the two captive screws at the top and bottom of the alarm card. (Refer to

Figure 8a.)

Note Unlike the line cards and RP, the alarm card does not have card ejector levers. The

alarm card backplane connector is smaller,has fewerpins, and is easier to seat and unseat

than the line cards and the RP.

Step 4 Using a flat-blade screwdriver, gently pry at the top and bottom of the alarm card carrier

to unseat the card from the backplane connector.

Step 5 Grasp the card carrier edge with one hand and place your other hand under the carrier to

support it (refer to Figure 8b.) Slide the alarm card out of the card slot and place it

immediately on the antistatic mat.

Figure 8 Removing an Alarm Card

a

Loosen

captive

screws

b

Grasp card carrier to

slide card out of slot

Upper card cage

Alarm card

Removing the Cards From the Lower Card Cage

The lower card cage is located directly behind the air filter tray and an air deflector. To access the

lower card cage, you must first lower the air filter tray and raise and secure the air deflector.

0

ACTIVE

CARRIER

RX PKT

1

ACTIVE

CARRIER

RX PKT

2

ACTIVE

CARRIER

RX PKT

3

ACTIVE

CARRIER

RX PKT

Q OC-3/STM-POS

0

0

ACTIVE

ACTIVE

CARRIER

CARRIER

RX PKT

RX PKT

CRITICAL

MAJOR

MINOR

ACO/LT

ALARM 1 ALARM 2

OC-12/STM-4 ATM

OC-12/STM-4 POS

ENABLED

FAIL

0

CSC

1

0

1

SFC

ALARM

2

H10906

Performthefollowing steps to removetheclock and scheduler cards and the switch fabric cards from

the lower card cage:

Step 1 Attach an antistatic wrist strap to yourself and to one of the two ESD connection sockets

located on the front edges of the upper card cage or to bare metal on the frame.

16 Cisco 12012 Gigabit Switch Router Card Cage Assembly Replacement Instructions

Page 17

Removing and Replacing a Card Cage Assembly

GIGABIT ROUTE PROCESSOR

Q OC-3/STM-POS

OC-12/STM-4 ATM

OC-12/STM-4 POS

ALARM

CSC

0

FAIL

1

0

1

2

ENABLED

SFC

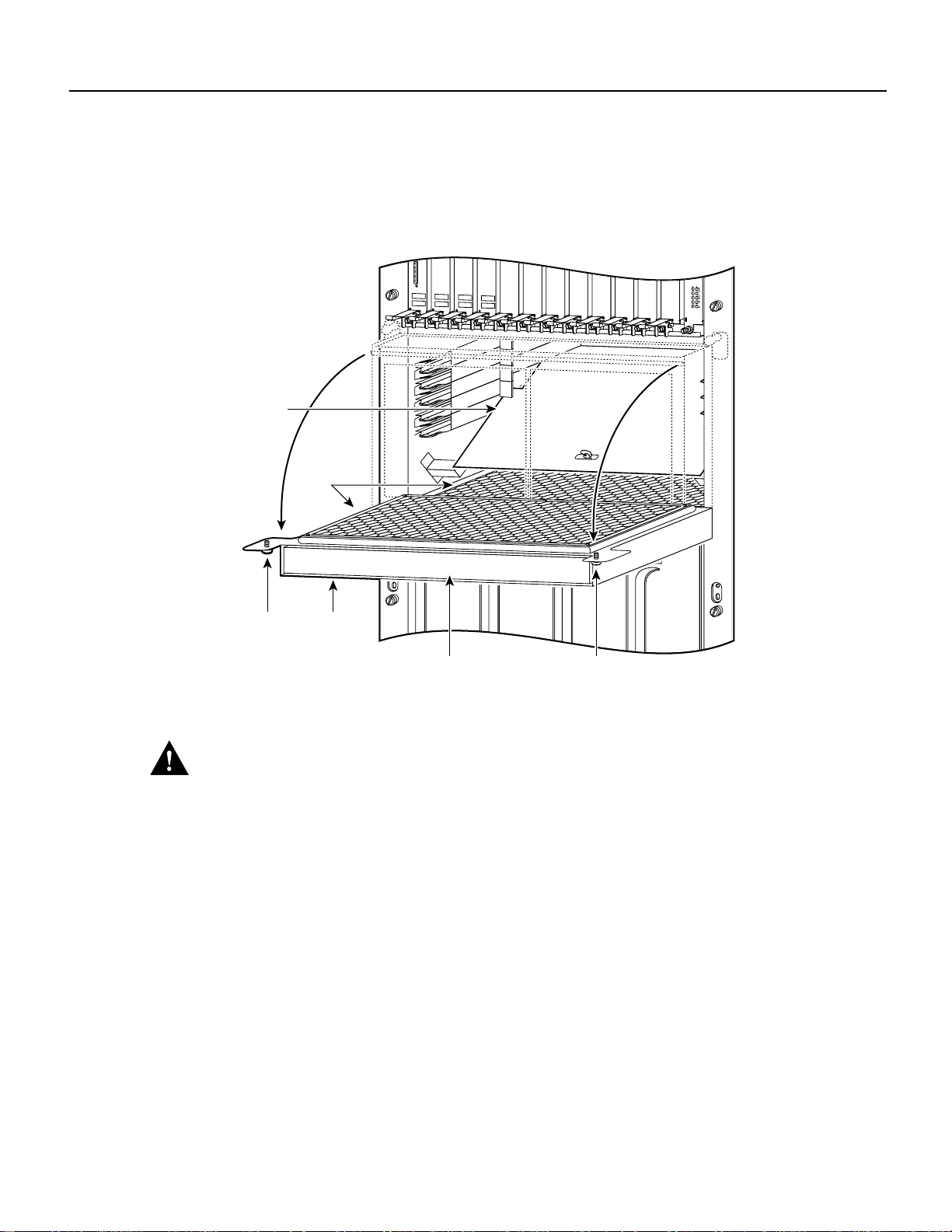

Step 2 To gain access to the lower card cage, loosen the two captive screws at the top of the air

filter tray and pivot the tray down, away from the lower card cage. (Refer to Figure 9.)

Figure 9 Opening the Air Filter Tray

Air deflector

Honeycomb

screen

Captive

screw

Air filter

tray

Air filter

Captive

screw

Caution

To prevent damage, do not place any tools on the air filter tray or in the lower card cage.

Damaging the honeycomb screen on the air filter tray or in the lower card cage could restrict the air

flow causing an overtemperature condition in the Cisco 12012.

H10472

Cisco 12012 Gigabit Switch Router Card Cage Assembly Replacement Instructions 17

Page 18

Removing and Replacing a Card Cage Assembly

GIGABIT ROUTE PROCESSOR

Q OC-3/STM-POS

OC-12/STM-4 ATM

OC-12/STM-4 POS

ALARM

CSC

0

FAIL

1

0

1

2

ENABLED

SFC

Step 3 To access the cards in the lower card cage, you must first move the air deflector up, out

of the way. Lift the air deflector up and secure it to the top of the lower card cage by

turning the air deflector latch knob counterclockwise. (Refer to Figure 10.)

Figure 10 Lower Card Cage Air Deflector

Air deflector

latch

Air filter

tray

Air deflector

H10473

18 Cisco 12012 Gigabit Switch Router Card Cage Assembly Replacement Instructions

Page 19

Removing and Replacing a Card Cage Assembly

GIGABIT ROUTE PROCESSOR

Q OC-3/STM-POS

OC-12/STM-4 ATM

OC-12/STM-4 POS

ALARM

CSC

0

FAIL

1

0

1

2

ENABLED

SFC

Step 4 Select one of the cards in the lower card cage to remove. Grasp the two card ejector levers

and simultaneously pivot both ejector levers ninety degrees inward (away from the sides

of the card cage) to unseat the card from the backplane connector. (Refer to Figure 11.)

Figure 11 Removing Cards From the Lower Card Cage

Card ejector lever Card ejector lever

Lower card

cage

Switch fabric

card

H10474

Step 5 Touchingonly the metal card carrier, slidethecard out of the slot and place it immediately

on the antistatic mat.

Repeat Step 4 and Step 5 for the rest of the cards in the lower card cage.

Cisco 12012 Gigabit Switch Router Card Cage Assembly Replacement Instructions 19

Page 20

Removing and Replacing a Card Cage Assembly

Removing the System Grounding

Your system might havetwo system grounding cable lugs attached to two system receptacles located

on the card cage assembly side flanges between the air filter tray and the power supply bays. (Refer

to Figure 12.) You must remove the system grounding connector before you can remove card cage

assembly.

Figure 12 System Grounding Receptacles

0

ACTIVE

CARRIER

EJECT

RX PKT

SLOT-0

SLOT-1

RESET

AUX

1

0

0

ACTIVE

ACTIVE

ACTIVE

CARRIER

CARRIER

CARRIER

RX PKT

RX CELL

RX CELL

CONSOLE

2

ACTIVE

CARRIER

RX PKT

3

LINK

ACTIVE

COLL

TX

CARRIER

RX

RX PKT

MII

RJ-45

ROUTE PROCESSOR

OC-12/STM-4 ATM

Q OC-3/STM-POS

OC-12/STM-4 POS

CRITICAL

MAJOR

MINOR

ACO/LT

ALARM 1 ALARM 2

ENABLED

FAIL

0

CSC

1

0

1

SFC

ALARM

2

H10899

System grounding

receptacles

Perform the following steps to remove a system grounding lug from the card cage assembly:

Step 1 Remove the two screws, washers, and nuts that secure the system grounding lug to the

card cage assembly.(Refer to Figure 13.) Save the mounting hardware, you will use it in

a later procedure.

Step 2 Remove the system grounding cable and set it aside.

Repeat Step 1 and Step 2 for a second system grounding connector.

20 Cisco 12012 Gigabit Switch Router Card Cage Assembly Replacement Instructions

Page 21

Figure 13 Removing a System Grounding Cable

Bolts

System

grounding

Grounding lug

receptacles

H10898

Removing and Replacing a Card Cage Assembly

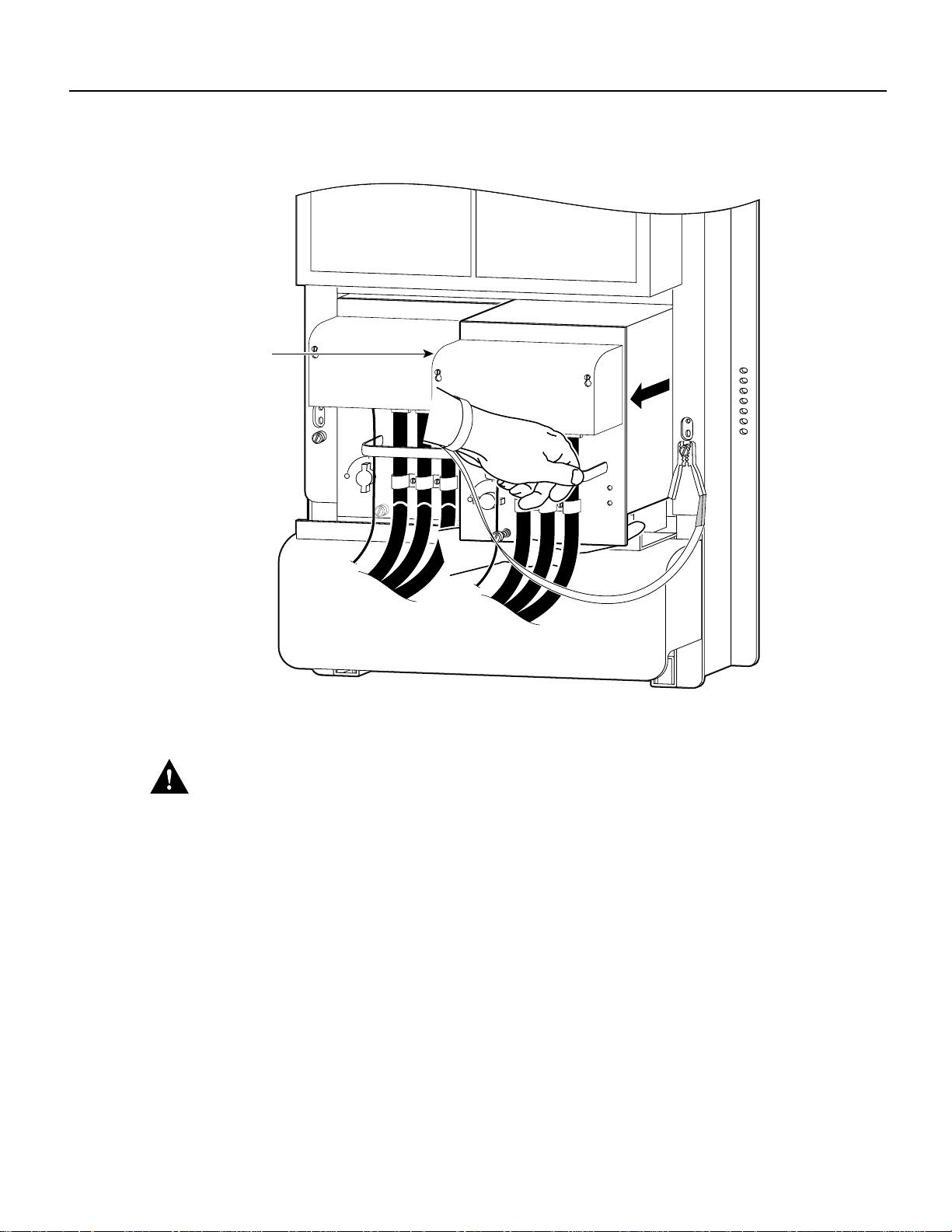

Removing the Card Cage Assembly

Perform the following steps to remove the card cage assembly (refer to Figure 14):

Caution An empty card cage assembly weighs 65 lb (29.5 kg). Youneed two people to safely lift

the assembly. To prevent injury, keep your back straight and lift with your legs, not your back.

Step 1 Loosen the six captive screws on the front edges of the card cage assembly that secure it

to the frame.

Step 2 Withone person positioned on each side of the frame, grasp the handle at the top of each

side of the card cage assembly and carefully slide the card cage assembly half way out of

the front of the frame.

Step 3 With your free hand, grasp the handhold cutout on each side of the card cage assembly

and carefully slide the card cage assembly completely out of the front of the frame.

If you plan to return the old card cage assembly to the factory, repackage it in the shipping container

you received with the replacement card cage assembly.

Cisco 12012 Gigabit Switch Router Card Cage Assembly Replacement Instructions 21

Page 22

Removing and Replacing a Card Cage Assembly

Figure 14 Removing the Card Cage Assembly From the Frame

Front handle

(2 places)

Card cage

assembly

Frame

Captive screw

(6 places)

Handhold

cutout

22 Cisco 12012 Gigabit Switch Router Card Cage Assembly Replacement Instructions

H10475

Page 23

Installing a New Card Cage Assembly

The new card cage assembly is shipped with a new air filter installed in the air filter tray. You must

replace the components you removed from the old card cage assembly in the new card cage

assembly.

Caution An empty card cage assembly weighs 65 lb (29.5 kg). Youneed two people to safely lift

the assembly. To prevent injury, keep your back straight and lift with your legs, not your back.

Perform the following steps to install the replacement card cage assembly:

Step 1 With one person positioned on each side of the card cage assembly, grasp the handle on

the front of the card cage assembly and the handhold cutout on the side of the card cage

assembly.

Step 2 Lift the card cage assembly and position it on the frame rails. Slide the card cage

assembly fully into the front of the frame until the card cage assembly flanges make

contact with the frame.

Removing and Replacing a Card Cage Assembly

Note All electrical connections between the card cage assembly and the blower module

harnesses on the frame are made automatically when the card cage assembly is fully

inserted in the frame.

Step 3 Secure the card cage assembly to the frame by tightening the six captive screws.

Replacing the Cards in the Lower Card Cage

Perform the following steps to replace the cards in the lower card cage:

Step 1 Attach an antistatic wrist strap to yourself and to one of the two ESD connection sockets

located on the front edges of the upper card cage or to bare metal on the frame.

Step 2 To access the lower card cage card slots, perform the following steps:

(a) Loosen the two captivescrews at the top of the air filter tray and pivot the tray down,

away from the lower card cage. (Refer to Figure 9.)

(b) Lift the air deflector up and secure it to the top of the lower card cage by turning the

air deflector latch knob counterclockwise. (Refer to Figure 10.)

Step 3 Select a card from the antistatic mat. Determine which lower card cage slot the card

should be installed in by checking the color of the label attached to the edge of the card

carrier (near the ejector levers). Light blue labels identify clock and scheduler cards

(installed in the upper two slots), and magenta labels identify switch fabric cards

(installed in the lower three slots).

Note Lower card cage slots are keyed to prevent you from inserting cards in the wrong

slots. You can install clock and scheduler cards only in the upper two card slots; switch

fabric cards only in the lower three slots.

Cisco 12012 Gigabit Switch Router Card Cage Assembly Replacement Instructions 23

Page 24

Removing and Replacing a Card Cage Assembly

Step 4 Grasp the card carrier edge with one hand and place your other hand under the carrier to

support and guide it into a matching color-coded slot. Slide the card halfway into the

lower card cage slot. Avoid touching the card circuitry or any connectors.

Note When you install a clock and scheduler card or a switch fabric card in the lower

card cage make sure that you keep the card centered in the slot by applying even pressure

to both sides of the card carrier as you slide it into the slot.

Step 5 Pivotthe two card ejector leversout ninety degrees awayfrom the sides of the card carrier.

Step 6 Continue sliding the card into the slot until the card ejector levers engage the edges of the

lower card cage slot and both ejector levers begin to pivot.

Note Both types of cards have guide pins that make initial contact with the backplane

connector. After the guide pins make contact, continue pushing on the card carrier until

the card ejector levers start pivoting forward. Then use the card ejector levers to fully

insert the card in the backplane connector.

Step 7 Grasp both card ejector levers and pivot them toward the sides of the card cage until they

are parallel to the card carrier edge, to seat the card in the backplane connector. Press on

the ejector levers until they snap into the card carrier.

Step 8 Release the air deflector latch (turn the latch clockwise) and lower the air deflector down

to its stops.

Repeat Step 3 through Step 7 for the rest of the cards in the lower card cage.

Step 9 Pivotthe air filter tray up so that it is flush with the front of the lowercard cage and tighten

the two captive screws.

Replacing the Cards in the Upper Card Cage

This section provides the procedures for replacing the line cards, RP, and alarm card in the upper

card cage.

Replacing a Line Card in the Upper Card Cage

Perform the following steps to replace a line card in the upper card cage:

Step 1 Attach an antistatic wrist strap to yourself and to one of the two ESD connection sockets

located on the front edges of the upper card cage or to bare metal on the frame.

Step 2 Selecta line card from the antistatic card mat. Check your list of occupied upper card cage

slots to determine which slot the line card goes in. Grasp the front edge of the metal card

carrier with one hand and place your other hand under the carrier to support and guide it

into the upper card cage slot.

Step 3 Carefully slide the line card carrier into the slot until the ejector leversmake contact with

the front of the card cage, then stop.

24 Cisco 12012 Gigabit Switch Router Card Cage Assembly Replacement Instructions

Page 25

Removing and Replacing a Card Cage Assembly

Step 4 Grasp the two line card ejector levers and pivot them away from the card until they are

perpendicular to the line card faceplate to completely seat the card in the backplane

connector.

Step 5 Tighten the two captive screws at the top and bottom of the line card.

Repeat Step 2 through Step 5 for the rest of the line cards.

Step 6 Proceeding from left to right in the upper card cage, check your list of interface cable

connections and identify the interface cables that attach to the first line card.

Step 7 One interface cable at a time, carefully route the identified interface cable through the

horizontal cable tray and down to the line card interface port.

Note On line cards with multiple ports, route and connect the interface cables to the line

cards starting at the bottom port and working up.

Cisco 12012 Gigabit Switch Router Card Cage Assembly Replacement Instructions 25

Page 26

Removing and Replacing a Card Cage Assembly

Step 8 Proceeding from bottom port to the top port (line cards with multiple ports only) identify

the interface cable that connects to each line card port. Connect the interface cable to the

line card port. (Refer to Figure 15a.)

Step 9 Proceeding from bottom port to the top port (line cards with multiple ports only),

carefully press the interface cable into the vertical cable bracket cable clip. (Refer to

Figure 15b.) Avoid any kinks or sharp bends in the interface cable.

Step 10 Proceeding from bottom port to the top port (line cards with multiple ports only), route

the interfacecable upthe verticalcable bracket and carefully press the interface cable into

the rest of the cable clips. (Refer to Figure 15c.) Avoid any kinks or sharp bends in the

interface cable.

Figure 15 Attaching an Interface Cable to a Line Card

Chassis

cable-management

tray

a

b

Interface

cable

Line card

cable-management

bracket

c

0

ACTIVE

CARRIER

RX PKT

1

ACTIVE

CARRIER

RX PKT

2

ACTIVE

CARRIER

RX PKT

3

ACTIVE

CARRIER

RX PKT

Cable clip

0

ACTIVE

CARRIER

RX PKT

1

ACTIVE

CARRIER

RX PKT

2

ACTIVE

CARRIER

RX PKT

3

ACTIVE

CARRIER

RX PKT

0

ACTIVE

CARRIER

RX PKT

1

ACTIVE

CARRIER

RX PKT

2

ACTIVE

CARRIER

RX PKT

3

ACTIVE

CARRIER

RX PKT

H10879

26 Cisco 12012 Gigabit Switch Router Card Cage Assembly Replacement Instructions

Cable clips

Page 27

Note Adjust the interface cable in the vertical cable bracket cable clips to prevent any

kinks or sharp bends in the interface cable. Allow adequate strain relief in the interface

cable.

Repeat Step 6 through Step 10 for the rest of the interface cables and line cards.

Note Blank cards must be installed in the upper card cage to fill any open slots. The blank cards

are used to maintain proper air flow and for EMI considerations.

Replacing the RP in the Upper Card Cage

Perform the following steps to replace the RP in the upper card cage:

Step 1 Attach an antistatic wrist strap to yourself and to one of the two ESD connection sockets

located on the front edges of the upper card cage or to bare metal on the frame.

Step 2 Grasp the card carrier edge with one hand and place your other hand under the carrier to

support and guide it into the slot. Carefully slide the RP carrier into the slot until the

ejector levers make contact with the front of the card cage, then stop.

Removing and Replacing a Card Cage Assembly

Step 3 Grasp the two card ejector levers and pivot them toward the RP until they are

perpendicular to the card faceplate to completely seat the RP in the backplane connector.

Step 4 Tighten the two captive screws at the top and bottom of the RP.

Step 5 Connect the console terminal and any auxiliary and Ethernet devices to their respective

connectors on the RP. Verify that the console terminal is on.

Replacing the Alarm Card in the Upper Card Cage

The alarm card is installed in the rightmost slot in the upper card cage.

Perform the following steps to replace the alarm card in the upper card cage:

Step 1 Attach an antistatic wrist strap to yourself and to one of the two ESD connection sockets

located on the front edges of the upper card cage or to bare metal on the frame.

Step 2 Grasp the alarm card faceplate with one hand and place your other hand under the card

carrier to support and guide it into the card cage slot labeled alarm card.

Step 3 Carefully slide the alarm card carrier into the slot until it makes contact with the

backplane connector, then stop. Avoid touching the card circuitry or any connectors.

Step 4 Carefully push on the top and bottom of the alarm card to seat it in the backplane

connector.

Step 5 Tighten the two captive screws to secure the alarm card in the upper card cage slot.

Step 6 Connect any external devices to their respective connectors on the alarm card

Cisco 12012 Gigabit Switch Router Card Cage Assembly Replacement Instructions 27

Page 28

Removing and Replacing a Card Cage Assembly

Installing the System Grounding

Your system might have two system grounding cable lugs. The system grounding receptacles are

located on the card cage assembly side flanges between the air filter tray and the power supply bay.

(Refer to Figure 12.)

Perform the following steps to install the system grounding lugs to the card cage assembly:

Step 1 Position the system ground lug over the card cage assembly system grounding receptacle.

Step 2 Secure the system grounding lug to the receptacle with two sets of screws, washers, and

nuts. (Refer to Figure 13.)

Repeat Step 1 and Step 2 for a second system grounding connection.

Replacing the Power Supplies

This section provides procedures for replacing an AC-input power supply and a DC-input power

supply. Select the procedure appropriate for your system.

Caution Always wear an antistatic wrist strap to prevent ESD when removing and replacing a

power supply.

Replacing an AC-Input Power Supply

Perform the following steps to replace an AC-input power supply:

Step 1 Attach an antistatic wrist strap to yourself and to one of the two ESD connection sockets

located on the front edges of the upper card cage or to bare metal on the frame.

Step 2 Verify that the power switch on the power supply is in the STANDBY position.

Caution To prevent damaging the power supply backplane connector, do not use excessive force

when installing a power supply into the bay.

Note The power supply bay positions are designated A1, A2, B1, and B2, from left to

right. Install power supplies in the bay in the following order: A1, B1, A2, and B2. Any

powersupply bay position that does not havea power supply installed must have a power

supply blank installed to maintain airflow and for EMI considerations.

28 Cisco 12012 Gigabit Switch Router Card Cage Assembly Replacement Instructions

Page 29

Removing and Replacing a Card Cage Assembly

Step 3 Using two hands to support and guide the power supply, slide it into the vacant power

supply bay position. Push the power supply all the way into the power supply bay until

the faceplate makes contact with the front of the bay.

Note All electrical connections between the power supply and the backplane are made

automatically when the power supply is fully inserted in the power supply bay.

Step 4 Tighten the captive screw on the power supply faceplate.

Step 5 Connect the AC power cord to the power supply AC receptacle. Clip the spring clip over

the power cord plug.

Step 6 Connect the other end of the AC power cord to the source AC receptacle.

Note Do not turn on the power supply power switch at this time.

Repeat Step 2 through Step 6 for the rest of the AC-input power supplies.

Step 7 Verify that any empty power supply bay slots have power supply blanks installed.

Proceed to the section “Checking the Installation” to verify the installation

Replacing a DC-Input Power Supply

Perform the following steps to replace a DC-input power supply:

Step 1 Attach an antistatic wrist strap to yourself and to one of the two ESD connection sockets

located on the front edges of the upper card cage or to bare metal on the frame.

Caution To prevent damaging the power supply backplane connector, do not use excessive force

when installing a power supply into the bay.

Step 2 Verify that the power switch on the power supply is in the OFF position.

Cisco 12012 Gigabit Switch Router Card Cage Assembly Replacement Instructions 29

Page 30

Removing and Replacing a Card Cage Assembly

Step 3 Using two hands to support and guide the power supply, carefully slide it into the vacant

bay. (Refer to Figure 16.) Stop when the power supply captive jackscrew makes contact

with the front of the power supply bay.

Figure 16 Installing a DC-Input Power Supply

DC-input

power supply

Use two hands to slide power supply into bay

30 Cisco 12012 Gigabit Switch Router Card Cage Assembly Replacement Instructions

H10612

Page 31

Removing and Replacing a Card Cage Assembly

Note The captive jackscrew is used to align and draw the power supply connector into

the backplane connector. Toprevent connector alignment problems, apply even pressure

on the power supply handle as you turn the captive jackscrew.

Step 4 Keep one hand on the power supply handle and apply even pressure to the power supply

as you turn the captivejackscrewclockwise (insert) using a 10-mm nutdriveror flat-blade

screwdriver. Do not overtighten the jackscrew.

Note All electrical connections between the power supply and the backplane are made

automatically when the power supply is fully inserted in the power supply bay.

Repeat Step 2 through Step 4 for a second DC-input power supply.

Step 5 Turn on the source DC circuit breaker servicing the DC-input power supply.Do not turn

on the power supply power switch at this time.

Proceed to the next section to verify the installation

Checking the Installation

To complete the installation, perform a check of all connections, then power up the system.

Follow these steps to restart the system and verify that the system restarts successfully:

Step 1 Check the following components to make sure they are secure:

Step 2 Ensure that a console terminal is connected to the RP console port and turned on, or that

• Line cards are fully inserted in the slots and all captive screws are tightened.

• Vertical cable bracketsare attached to their respectiveline cards and all captive screws

are tightened.

• Interface cable connections are secured.

• Interface cables are routed neatly through the cable-management system.

• Anyempty card slots or powersupply bays are filled with card blanks or power supply

blanks.

• Power supplies are fully inserted in the bays and the captive screws are tightened.

• Power supply cables are fully connected to the power supplies and the power source,

and secured with appropriate strain relief.

• Front covers are installed on the DC-input power supplies.

• The air deflector in the lower card cage is down, resting on its stops.

• The air filter tray is up and the two captive screws are tightened.

you have a remote login to the router from another device through a telnet session. (You

will need to check the startup banner and displays to ensure that the system restarts

properly and that all the interfaces reinitialize in the proper state.)

Cisco 12012 Gigabit Switch Router Card Cage Assembly Replacement Instructions 31

Page 32

FCC Class A Compliance

Step 3 Verify that all source voltage circuit breakers supplying power to your system are on.

Step 4 Turn the power switch on each power supply to ON (|). The input OK LED on each

Step 5 Listen for the blower modules to power up. The green fans OK LED on the front cover of

Step 6 On the console terminal, verify that the console displays the system banner and that the

If the power supplies do not power up, or if the system or any interfaces do not initialize properly,

refer to the Cisco 12012 Gigaswitch Router Installation and Configuration Guide that shipped with

your router for additional information and installation troubleshooting procedures. If you are still

unable to resolve the problem, contact your service representative for assistance.

DC-input power supply (AC OK LED on each AC-input power supply) should go on.

Note Turningthe power supply switch to ON (|) also engages a latch securing the power

supply in place.

each blower module should go on.

system and all interfaces initialize successfully.

FCC Class A Compliance

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio-frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference, in which

case users will be required to correct the interference at their own expense.

You can determine whether your equipment is causing interference by turning it off. If the

interference stops, it was probably caused by the Cisco equipment or one of its peripheral devices.

If the equipment causes interference to radio or television reception, try to correct the interference

by using one or more of the following measures:

• Turn the television or radio antenna until the interference stops.

• Move the equipment to one side or the other of the television or radio.

• Move the equipment farther away from the television or radio.

• Plug the equipment into an outlet that is on a different circuit from the television or radio. (That

is, make certain the equipment and the television or radio are on circuits controlled by different

circuit breakers or fuses.)

Modifications to this product not authorized by Cisco Systems, Inc. could void the FCC approval

and negate your authority to operate the product.

32 Cisco 12012 Gigabit Switch Router Card Cage Assembly Replacement Instructions

Page 33

Cisco Connection Online

CiscoConnectionOnline (CCO) is Cisco Systems’ primary,real-time support channel. Maintenance

customers and partners can self-register on CCO to obtain additional information and services.

Available 24 hours a day, 7 days a week, CCO provides a wealth of standard and value-added

services to Cisco’s customers and business partners. CCO services include product information,

product documentation, software updates, release notes, technical tips, the Bug Navigator,

configuration notes, brochures, descriptions of service offerings, and download access to public and

authorized files.

CCO serves a wide variety of users through two interfaces that are updated and enhanced

simultaneously: a character-based version and a multimedia version that resides on the World Wide

Web (WWW). The character-based CCO supports Zmodem, Kermit, Xmodem, FTP, and Internet

e-mail,anditisexcellentfor quick access to information over lowerbandwidths. The WWW version

of CCO provides richly formatted documents with photographs, figures, graphics, and video, as well

as hyperlinks to related information.

You can access CCO in the following ways:

• WWW: http://www.cisco.com

• WWW: http://www-europe.cisco.com

• WWW: http://www-china.cisco.com

Cisco Connection Online

• Telnet: cco.cisco.com

• Modem: From North America, 408 526-8070; from Europe, 33 1 64 46 40 82. Use the

following terminal settings: VT100 emulation; databits: 8; parity: none; stop bits: 1; and

connection rates up to 28.8 kbps.

For a copy of CCO’s Frequently Asked Questions (FAQ), contact cco-help@cisco.com. For

additional information, contact cco-team@cisco.com.

Note If you are a network administrator and need personal technical assistance with a Cisco

product that is under warranty or covered by a maintenance contract, contact Cisco’s Technical

Assistance Center (TAC) at 800 553-2447, 408 526-7209, or tac@cisco.com. To obtain general

information about Cisco Systems, Cisco products, or upgrades, contact 800 553-6387,

408 526-7208, or cs-rep@cisco.com.

This document is to be used in conjunction with the Cisco 12012 Gigabit Switch Router Installation and Configuration Guide.

CCIP, the Cisco Powered Network mark, the Cisco Systems Verified logo, Cisco Unity, Follow Me Browsing, FormShare, Internet Quotient, iQ Breakthrough, iQ Expertise, iQ

FastTrack, the iQ Logo, iQ Net Readiness Scorecard, Networking Academy, ScriptShare, SMARTnet, TransPath, and Voice LAN are trademarks of Cisco Systems, Inc.; Changing

the Way We Work, Live, Play, and Learn, Discover All That’s Possible, The Fastest Way to Increase Your Internet Quotient, and iQuick Study are service marks of Cisco Systems,

Inc.; and Aironet, ASIST, BPX, Catalyst, CCDA, CCDP, CCIE, CCNA, CCNP, Cisco, the Cisco Certified Internetwork Expert logo, Cisco IOS, the Cisco IOS logo, Cisco Press,

Cisco Systems, Cisco Systems Capital, the Cisco Systems logo, Empowering the Internet Generation, Enterprise/Solver, EtherChannel, EtherSwitch, Fast Step, GigaStack, IOS,

IP/TV, LightStream, MGX, MICA, the Networkers logo, Network Registrar, Packet, PIX, Post-Routing, Pre-Routing, RateMUX, Registrar, SlideCast, StrataView Plus, Stratm,

SwitchProbe, TeleRouter, and VCO are registered trademarks of Cisco Systems, Inc. and/or its affiliates in the U.S. and certain other countries.

All other trademarks mentioned in this document or Web site are the property of their respective owners. The use of the word partner does not imply a partnership relationship

between Cisco and any other company. (0203R)

Copyright © 1997-2002, Cisco Systems, Inc.

All rights reserved.

Cisco 12012 Gigabit Switch Router Card Cage Assembly Replacement Instructions 33

Page 34

Cisco Connection Online

34 Cisco 12012 Gigabit Switch Router Card Cage Assembly Replacement Instructions

Loading...

Loading...