Page 1

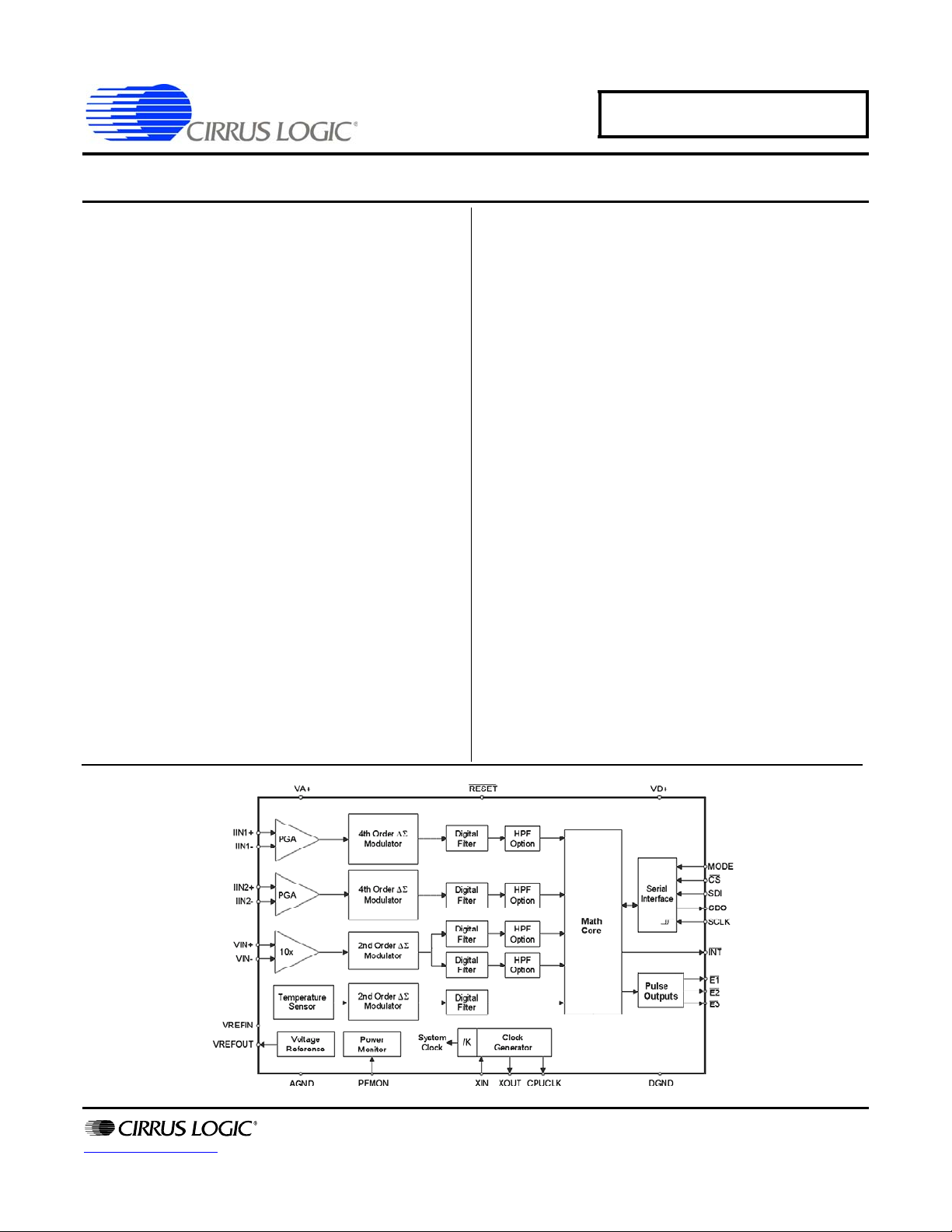

CS5464

Three-channel, Single-phase Power/Energy IC

Features & Description

• Energy Linearity: ±0.1% of Reading over

1000:1 Dynamic Range

• On-chip Functions:

- Voltage and Current Measurement

- Active, Reactive, and Apparent Power/Energy

- RMS Voltage and Current Calculations

- Current Fault and Voltage Sag Detection

- Calibration

- Phase Compensation

- Temperature Sensor

- Energy Pulse Outputs

• Meets Accuracy Spec for IEC, ANSI, & JIS

• Low Power Consumption

• Tamper Detection and Correction

• Ground-referenced Inputs with Single

Supply

• On-chip 2.5 V Reference (40 ppm / °C typ.)

• Power Supply Monitor Function

• Three-wire Serial Interface to

Microcontroller or E2PROM

Description

The CS5464 is a watt-hour meter on a chip. It

measures line voltage and current and calculates active, reactive, apparent power, energy,

power factor, and RMS voltage and current.

There are two separate inputs to measure line,

ground, and/or neutral current enabling the meter to detect tampering and to continue

operating. An internal RMS voltage reference

can be used if voltage measurem ent is disabled

by tampering.

Four analog-to-digital converters are used to

measure voltage, two currents, and temperature.

The CS5464 is designed to interface to a variety

of voltage and current sensors.

Additional features include system-level calibration, voltage sag and current fault detection,

peak detection, phase compensation, and energy pulse outputs.

• Power Supply Configurations

GND: 0 V, VA+: +5 V, VD+: +3.3 V to +5 V

http://www.cirrus.com

ORDERING INFORMATION

See Page 44.

Copyright Cirrus Logic, Inc. 2011

(All Rights Reserved)

APR ‘11

DS682F3

Page 2

CS5464

TABLE OF CONTENTS

1. Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2. Pin Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Clock Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Control Pins and Serial Data I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Analog Inputs/Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Other Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3. Characteristics & Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Recommended Operating Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Analog Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Analog Inputs (All Inputs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Analog Inputs (Current Inputs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Analog Inputs (Voltage Inputs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Voltage Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Reference Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Reference Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Digital Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Master Clock Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Filter Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Input/Output Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

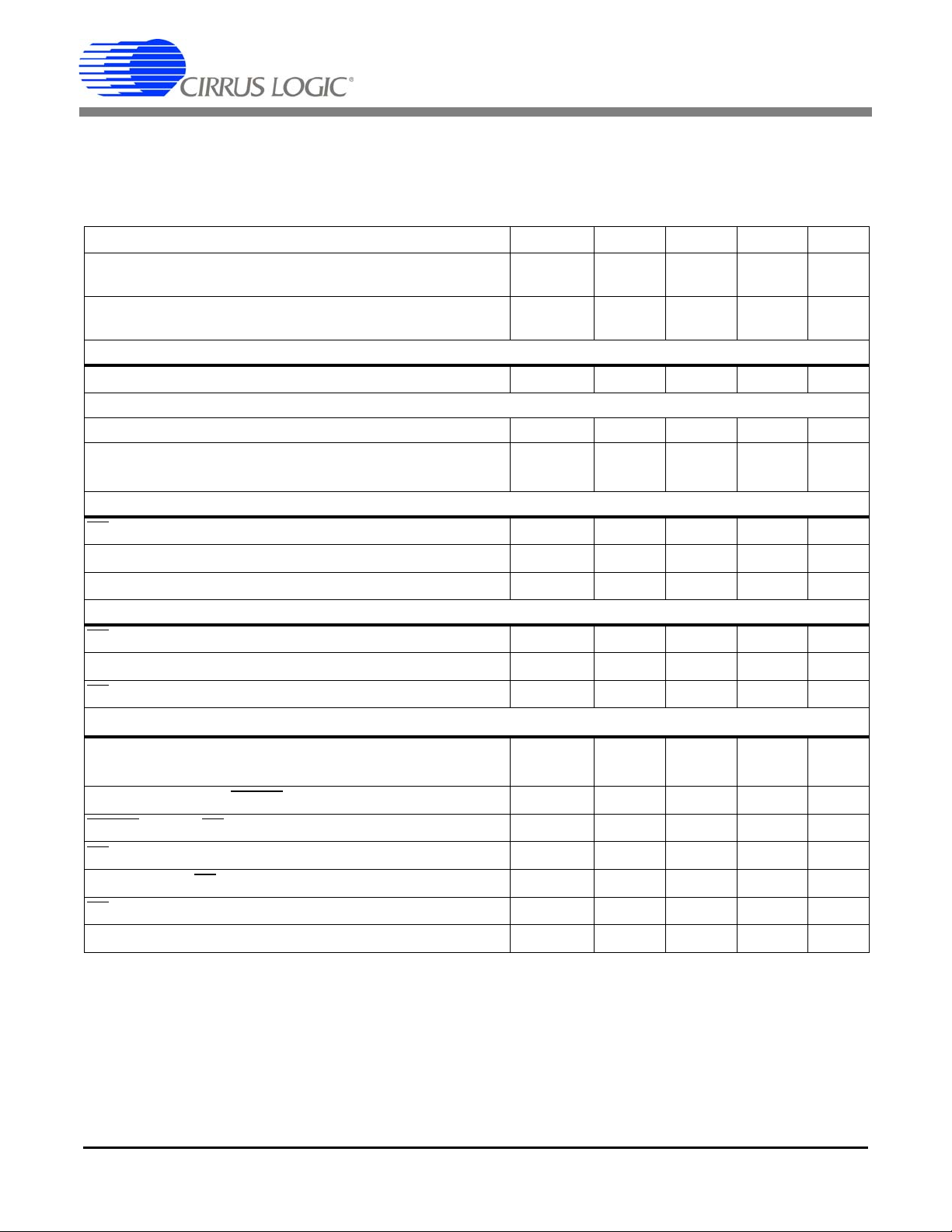

Switching Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Serial Port Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

SDI Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

SDO Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

E2PROM mode Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

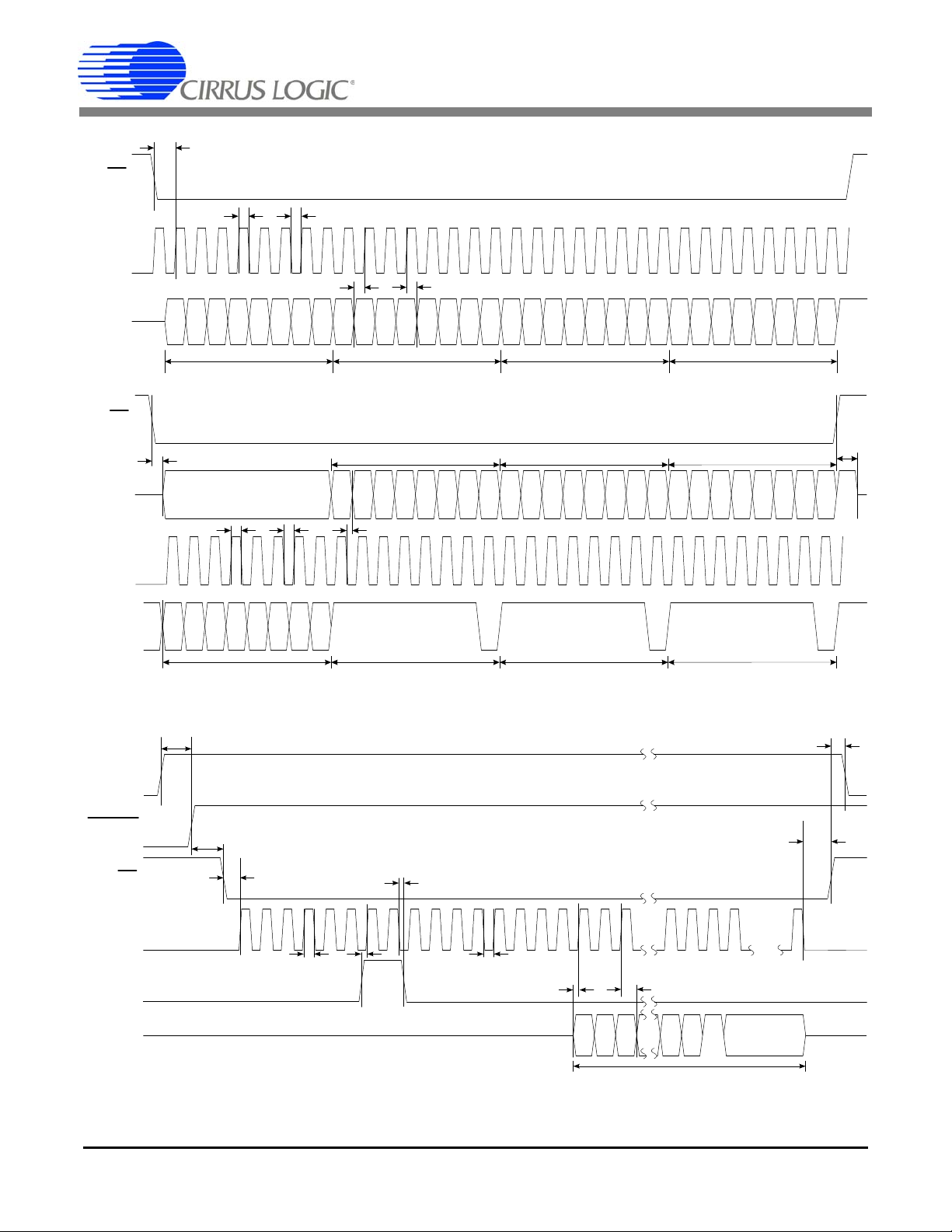

E1

, E2, and E3 Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Absolute Maximum Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

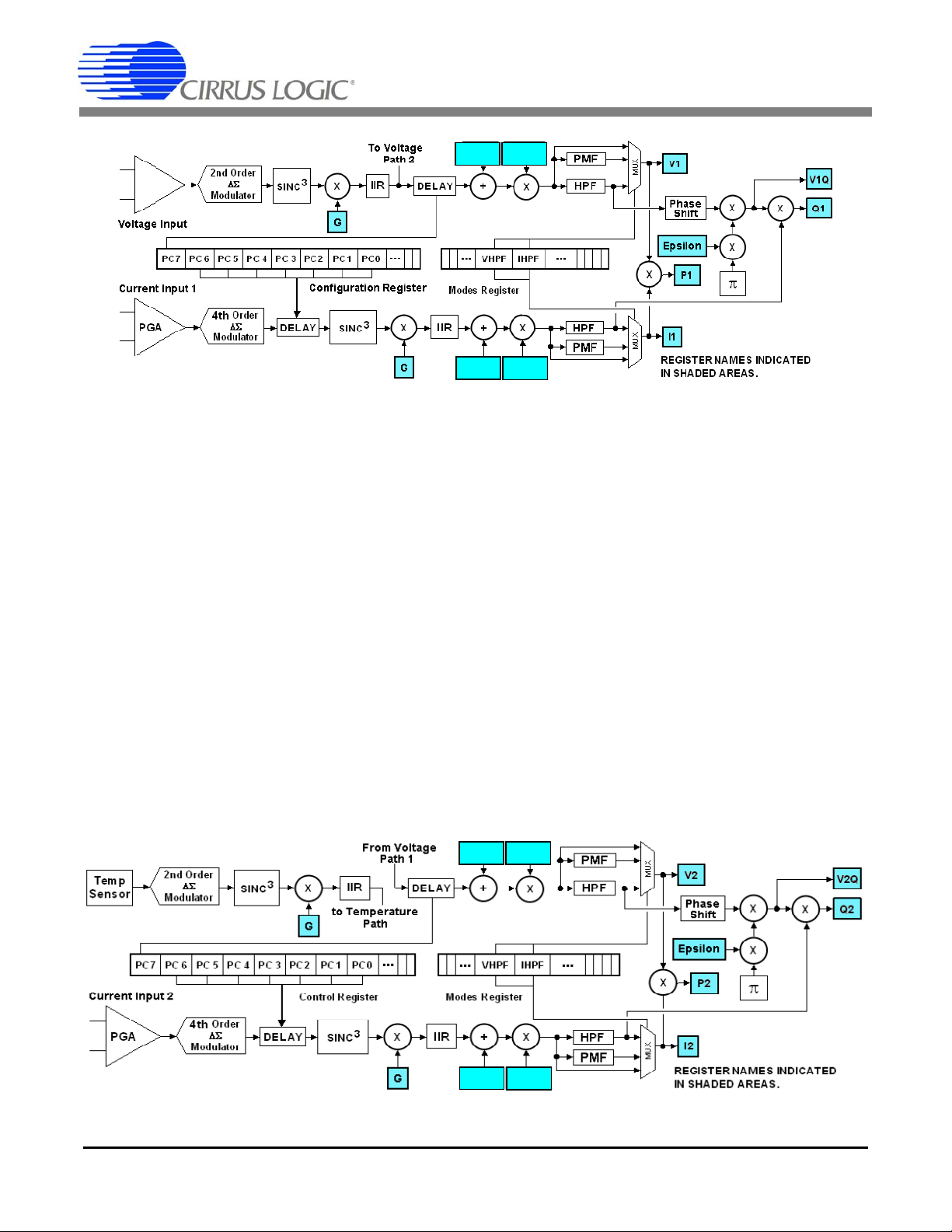

4. Signal Path Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.1 Analog-to-Digital Converters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.2 Decimation Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.3 Phase Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.4 DC Offset and Gain Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.5 High-pass Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.6 Low-Rate Calculations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.7 RMS Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.8 Power and Energy Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.9 Peak Voltage and Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.10 Power Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5. Pin Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1 Analog Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1.1 Voltage Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1.2 Current1 and Current2 Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1.3 Power Fail Monitor Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2 DS682F3

Page 3

CS5464

5.1.4 Voltage Reference Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1.5 Voltage Reference Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1.6 Crystal Oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.2 Digital Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.2.1 Reset Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.2.2 CPU Clock Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.2.3 Interrupt Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.2.4 Energy Pulse Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.2.5 Serial Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6. Setting Up the CS5464 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.1 Clock Divider . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.2 CPU Clock Inversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.3 Interrupt Pin Behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.4 Current Input Gain Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.5 High-pass Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.6 Cycle Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.7 Energy Pulse Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.8 No Load Threshold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.9 Energy Pulse Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.10 Energy Pulse Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.11 Voltage Sag/Current Fault Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.12 Epsilon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.13 Temperature Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7. Using the CS5464 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7.1 Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7.2 Power-down States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7.3 Tamper Detection and Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7.4 Command Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.5 Register Paging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.6 Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8. Register Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

8.1 Page Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

8.2 Page 0 Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

8.3 Page 1 Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8.4 Page 2 Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

9. System Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

9.1 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

9.1.1 Offset Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

9.1.1.1 DC Offset Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

9.1.1.2 AC Offset Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

9.1.2 Gain Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

9.1.2.1 AC Gain Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

9.1.2.2 DC Gain Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

9.1.3 Calibration Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

DS682F3 3

Page 4

CS5464

9.1.4 Temperature Sensor Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

9.1.4.1 Temperature Offset Calibration . . . . . . . . . . . . . . . . . . . . . . . 40

9.1.4.2 Temperature Gain Calibration . . . . . . . . . . . . . . . . . . . . . . . . 40

10. E2PROM Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

10.1 E2PROM Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

10.2 E2PROM Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

10.3 Which E2PROMs Can Be Used? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

11. Basic Application Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

12. Package Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

13. Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

14. Environmental, Manufacturing, & Handling Information . . . . . . . . . . . . . . . . . 44

15. Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

LIST OF FIGURES

Figure 1. CS5464 Read and Write Timing Diagrams ................................................................. 12

Figure 2. Timing Diagram for

Figure 3. Signal Flow for V1, I1, P1, Q1 Measurements ............................................................ 14

Figure 4. Signal Flow for V2, I2, P2, Q2 Measurements ............................................................ 14

Figure 5. Low-rate Calculations.................................................................................................. 16

Figure 6. Oscillator Connections................................................................................................. 17

Figure 7. Sag and Fault Detect................................................................................................... 21

Figure 8. Energy Channel Selection........................................................................................... 22

Figure 9. Fixed RMS Voltage Selection......................................................................................22

Figure 10. Calibration Data Flow................................................................................................39

Figure 11. System Calibration of Offset ...................................................................................... 39

Figure 12. System Calibration of Gain. ....................................................................................... 40

Figure 13. Typical Interface of E

Figure 14. Typical Connection Diagram .................................................................................... 42

E1, E2, and E3.............................................................................. 13

2

PROM to CS5464 .................................................................. 41

LIST OF TABLES

Table 1. Interrupt Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 2. Current Input Gain Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 3. High-pass Filter Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 4. E2

Table 5. E3

Table 6. E1

Table 7. E3

4 DS682F3

Pin Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Pin Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

/ E2 Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Pin with E1MODE enabled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Page 5

CS5464

1. OVERVIEW

The CS5464 is a CMOS power measurement integrated circuit utilizing four analog-to-digital convert-

ers to measure line voltage, temperature, and current from up to two sources. It calculates active, reactive,

and apparent power as well as RMS and peak vo ltage an d curren t. It handles other system-related functions, such as pulse output conversion, voltage sag, current fault, voltage zero crossing, line frequency,

and tamper detection.

The CS5464 is optimized to interface to current transformers or shunt resistors for current measurement,

and to a resistive divider or voltage transformer for voltage measurement. Two full-scale ranges are provided on the current inputs to accommodate both types of current sensors. The second current channel

can be used for tamper detection or as a second current input. The CS5464’s three differential inputs have

a common-mode input range from analog ground (AGND) to the positive analog supply (VA+).

An additional analog input (PFMON) is provided to allow the application to determine when a power failure

is in progress. By monitoring the unregulated power supply, the application can take any required action

when a power loss occurs.

An on-chip voltage reference (nominally 2.5 volts) is generated and provided at analog output, VREFOUT.

This reference can be supplied to the chip by connecting it to the reference voltage input, VREFIN. Alternatively, an external voltage reference can be supplied to the reference input.

Three digital outputs (E1

ed, provide energy pulses, power failure indication, or other choices.

The CS5464 includes a three-wire serial host interface to an external microcontroller or serial E

Signals include serial data input (SDI), serial data output (SDO), serial clock (SCLK), and optionally, a

chip select (CS

used to control whether an E

), which allows the CS5464 to share the SDO signal with other devices. A MODE input is

, E2, E3) provide a variety of output signals and, depending on the mode select-

2

PROM.

2

PROM will be used instead of a host microcontroller.

DS682F3 5

Page 6

CS5464

VREFIN 12Voltage Reference Input

VREFOUT 11Voltage Reference Output

VIN- 10Differential Voltage Input

VIN+ 9Differential Voltage Input

MODE 8Mode Select

CS 7Chip Select

SDO 6Serial Data Ouput

SCLK 5Serial Clock

DGND 4Digital Ground

VD+ 3Positive Digital Supply

CPUCLK 2CPU Clock Output

XOUT 1Crystal Out

AGND17 Analog Ground

VA+

18 Positive Analog Supply

IIN1-19 Differential Current Input

IIN1+20 Differential Current Input

PFMON21 P o w e r F a il M o nitor

E322 Energy Output 3

RESET23 Reset

INT24 Interrupt

E125 Energy Output 1

26

SDI27 Serial Data Input

XIN28 Crystal In

E2

Energy Output 2

TEST2 14Factory Test

TEST1 13Factory Test

IIN2 -15 Differential Current Input

IIN2 +16 Differential Current Input

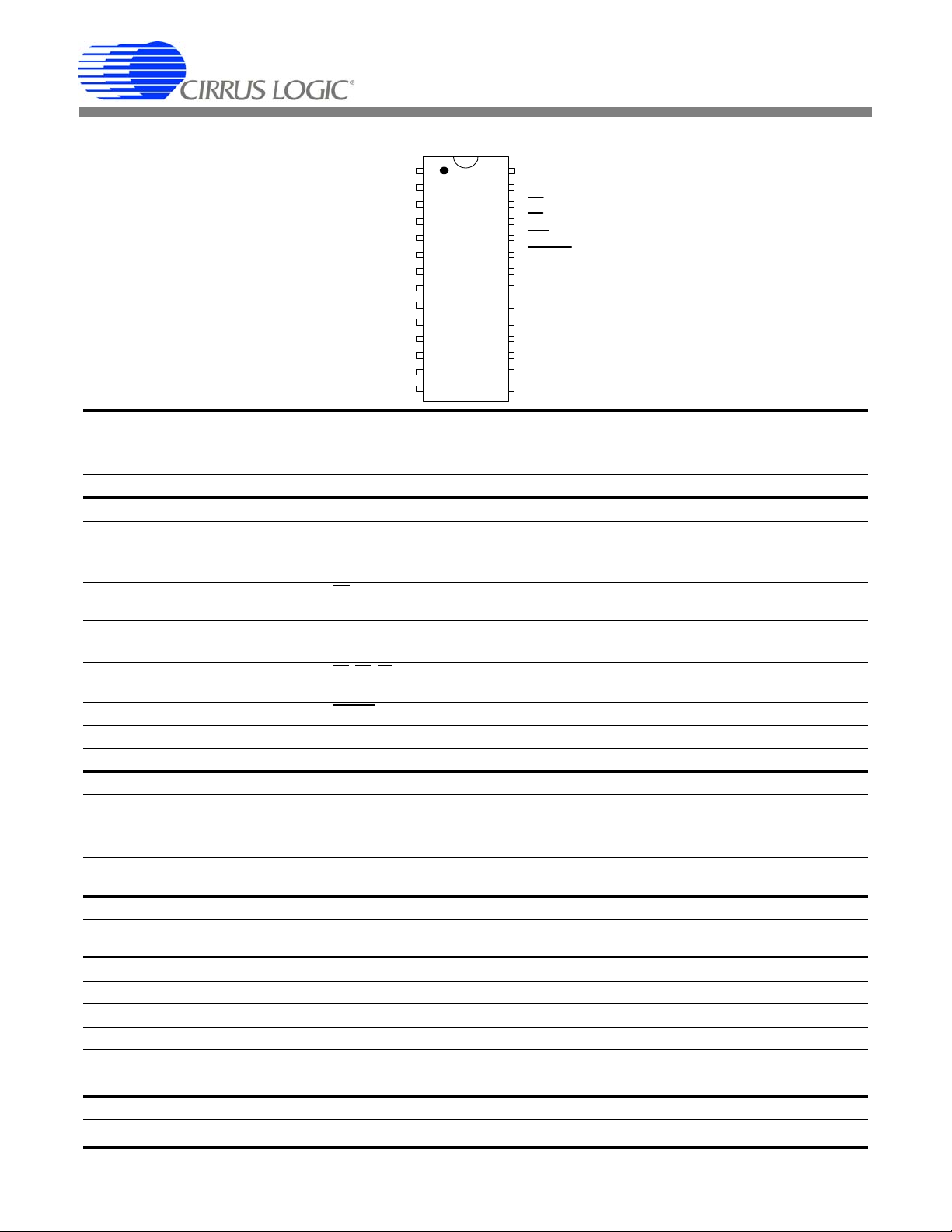

2. PIN DESCRIPTION

Clock Generator

Crystal Out

Crystal In

CPU Clock Output 2

Control Pins and Serial Data I/O

Serial Clock 5

Serial Data Output 6

Chip Select 7

Mode Select 8

Energy Outputs 22, 25,

Reset 23

Interrupt 24

Serial Data Input 27

Analog Inputs/Outputs

Differential V ol tage Inputs 9,10

Differential Current Inputs 20,19,

Power Fail Monitor 21

Voltage Reference Output 11

Voltage Reference Input 12

Power Connections

Positive Digital Supply 3

Digital Ground 4

Positive Analog Supply 18

Analog Ground 17

Other Pins

Test1, Test2 13,14

6 DS682F3

1,28

XOUT, XIN — Connect to an external quartz crystal. Alternatively, an external clock can be supplied to the XIN pin to provide the system clock for the device.

CPUCLK - Logic-level output from crystal oscillator. Can be used to clock an external CPU.

SCLK — Clocks serial data from the SDI pin and to the SDO pin when CS is low. SCLK is a

Schmitt-trigger input when MODE is low and a driven output when MODE is high.

SDO — Serial data output. Data is clocked out by SCLK.

CS — An input that enables the serial interface when MODE is low and a driven output when

MODE is high.

MODE — High selects external E2PROM, Low selects external microcontroller. MODE includes a

weak internal pull-down and therefore selects microcontroller mode if not connected.

E3, E1, E2 — Primarily active-low energy pulse outputs. These can be programmed to output

other conditions.

26

RESET — An active-low Schmitt-trigger input used to reset the chip.

INT — Active-low output, indicates that an enabled condition has occurred.

SDI — Serial data input. Data is clocked in by SCLK.

VIN+, VIN- — Differential analog inputs for the voltage channel.

IIN1+, IIN1-, IIN2+, IIN2- — Differential analog inputs for the current channels.

16,15

PFMON — Used to monitor the unregulated power supply via a resistive divider. If the PFMON

voltage drops below its low limit, the low-supply detect (LSD) bit is set in the Status register.

VREFOUT — The on-chip voltage reference output. Nominally 2.5 V, referenced to AGND.

VREFIN — The voltage reference input. Can be connected to VREFOUT or external 2.5 V refer-

ence.

VD+ — The positive digital supply.

DGND — Digital ground.

VA+ — The positive analog supply.

AGND — Analog ground.

NC — Factory use only. Connect to AGND.

Page 7

CS5464

3. CHARACTERISTICS & SPECIFICATIONS

RECOMMENDED OPERATING CONDITIONS

Parameter Symbol Min Typ Max Unit

Positive Digital Power Supply VD+ 3.135 5.0 5.25 V

Positive Analog Power Supply VA+ 4.75 5.0 5.25 V

Voltage Reference VREFIN - 2.5 - V

Specified Temperature Range T

A

ANALOG CHARACTERISTICS

• Min / Max characteristics and specifications are guaranteed over all Recommended Operating Conditions .

• Typical characteristics and specifications are measured at nominal supply voltages and TA = 25 °C.

• VA+ = VD+ = 5 V ±5%; AGND = DGND = 0 V; VREFIN = +2.5 V. All voltages with respect to 0 V.

• DCLK = 4.096 MHz.

Parameter Symbol Min Typ Max Unit

Accuracy

Active Power

(Note 1) Input Range 0.1% - 100%

Reactive Power

(Note 1 and 2) Input Range 0.1% - 100%

Power Factor

(Note 1 and 2) Input Range 1.0% - 100%

Input Range 0.1% - 1.0%

Current RMS

(Note 1) Input Range 1.0% - 100%

Input Range 0.1% - 1.0%

Volt age RMS

(Note 1) Input Range 5% - 100%

Analog Inputs (All Inputs)

Common Mode Rejection

Common Mode + Signal -0.25 - VA+ V

Analog Inputs (Current Inputs)

Differential Input Range

[(IIN+) – (IIN-)] (Gain = 50)

Total Harmonic Distortion (Gain = 50) THD 80 94 - dB

Crosstalk from Voltage Input at Full Scale

Input Capacitance IC - 27 - pF

Effective Input Impedance EII 30 - - k

Noise (Referred to Input)

Offset Drift (Without the High-pass Filter) OD - 4.0 - µV/°C

Gain Error

Notes: 1. Applies when the HPF option is enabled.

2. Applies when the line frequency is equal to the product of the output word rate (OWR) and the value of

Epsilon.

All Gain Ranges

All Gain Ranges

All Gain Ranges

P

Active

Q

Avg

PF -

All Gain Ranges

I

RMS

All Gain Ranges

(DC, 50, 60 Hz) CMRR 80 - - dB

(Gain = 10)

(50, 60 Hz) --115-dB

(Gain = 10)

(Gain = 50)

(Note 3) GE - ±0.4 %

V

RMS

IIN

N

I

-40 - +85 °C

-±0.1-%

-±0.2-%

±0.2

-

±0.27

-

-

%

%

%

-

-

±0.1

±0.17

-

-

%

%

-±0.1-%

-

-

-

-

500

100

-

-

-

-

22.5

4.5

mV

mV

µV

µV

P-P

P-P

rms

rms

DS682F3 7

Page 8

CS5464

PSRR 20

150

V

eq

--------- -

log=

ANALOG CHARACTERISTICS (Continued)

Parameter Symbol Min Typ Max Unit

Analog Inputs (Voltage Inputs)

Differential Input Range

Total Harmonic Distortion THD 65 75 - dB

Crosstalk from Current Inputs at Full Scale

Input Capacitance

Effective Input Impedance EII 2 - - M

Noise (Referred to Input) N

Offset Drift (Without the High-pass Filter) OD - 16.0 - µV/°C

Gain Error

Temperature

Temperature Accuracy T - ±5 - °C

Power Supplies

Power Supply Currents (Active State)

(VA+ = 5V, VD+ = 3.3 V)

I

D+

Power Consumption

(Note 4) Active State (VA+ = 5 V, VD+ = 3.3 V)

Power Supply Rejection Ratio

(Note 5)

Active State (VA+ = VD+ = 5 V)

(50, 60 Hz)

PFMON Low-voltage Trigger Threshold

PFMON High-voltage Power-on Trip Point

[(VIN+) – (VIN-)] VIN - 500 - mV

(50, 60 Hz) --70-dB

All Gain Ranges IC - 2.0 - pF

--140µV

-

-

-

-

-

-

-

48

68

60

1.5

3.5

2.3

25

15

7

10

55

75

65

33

20

(Note 3) GE - ±3.0 %

I

I

(VA+ = VD+ = 5V)

D+

Stand-by State

Sleep State

Voltage

Current

(Gain = 50x)

Current (Gain = 10x)

(Note 6) PMLO 2.3 2.45 - V

(Note 7) PMHI - 2.55 2.7 V

V

PSCA

A+

PSCD

PSCD

PC

PSRR

P-P

rms

-

-

-

mA

mA

mA

mW

mW

-

-

-

-

-

mW

uW

dB

dB

dB

Notes: 3. Applies before system calibration.

4. All outputs unloaded. All inputs CMOS level.

5. Measurement method for PSRR: VREFIN tied to VREFOUT, VA+ = VD+ = 5 V, a 150 mV

(zero-to-peak) (60 Hz) sinewave is imposed onto the +5 V DC supply voltage at VA+ and VD+ pins. The

“+” and “-” input pins of both input ch annels a re sh or ted to AGND. T he CS5 464 is then command ed to

continuous conversion acquisition mode, and digital output data is collected for the chan nel under test.

The (zero-to-peak) value of the digital sinusoidal out put signal is determined, and this value is converted

into the (zero-to-peak) value of the sinusoidal voltage (me asured in m V) that would need to be applied

at the channel’s inputs, in order to cause the sa me digital sinusoidal output. This voltage is then defined

as Veq. PSRR is (in dB)

:

6. When voltage level on PFMON is sagging, and LSD bit = 0, the voltage at which LSD is set to 1.

7. If the LSD bit has been set to 1 (because PFMON voltage fell below PMLO), this is the voltage level on

PFMON at which the LSD bit can be permanently reset back to 0.

8 DS682F3

Page 9

CS5464

(VREFOUTMAX - VREFOUTMIN)

VREFOUT

AVG

(

(

1

T

A

MAX

- T

A

MIN

(

(

1.0 x 10

(

(

6

TC

VREF

=

VOLTAGE REFERENCE

Parameter Symbol Min Typ Max Unit

Reference Output

Output Voltage VREFOUT +2.4 +2.5 +2.6 V

Temperature Coefficient

Load Regulation

Reference Input

Input Voltage Range VREFIN +2.4 +2.5 +2.6 V

Input Capacitance - 4 - pF

Input CVF Current - 100 - nA

Notes: 8. The voltage at VREFOUT is measured across the temperature range. From these measurements the

following formula is used to calculate the VREFOUT temperature coefficient:.

9. Specified at maximum recommended output of 1 µA, source or sink.

(Note 8) TC

(Note 9) V

VREF

R

- 40 - ppm/°C

-610mV

DS682F3 9

Page 10

CS5464

DIGITAL CHARACTERISTICS

• Min / Max characteristics and specifications are guaranteed over all Recommended Operating Conditions .

• Typical characteristics and specifications are measured at nominal supply voltages and TA = 25 °C.

• VA+ = VD+ = 5V ±5%; AGND = DGND = 0 V. All voltages with respec t to 0 V.

• DCLK = 4.096 MHz.

Parameter Symbol Min Typ Max Unit

Master Clock Characteristics

Master Clock Frequency

Master Clock Duty Cycle 40 - 60 %

CPUCLK Duty Cycle

Filter Characteristics

Phase Compensation Range

Input Sampling Rate

Digital Filter Output Word Rate

High-pass Filter Corner Frequency

Full-scale DC Calibration Range (Referred to Input)

Channel-to-channel Time-shift Error

Input/Output Characteristics

High-level Input Voltage

All Pins Except XIN and SCLK and RESET

Low-level Input Voltage (VD = 5 V)

All Pins Except XIN and SCLK and RESET

Low-level Input Voltage (VD = 3.3 V)

All Pins Except XIN and SCLK and RESET

High-level Output Voltage

Low-level Output Voltage

Input Leakage Current

3-state Leakage Current I

Digital Output Pin Capacitance C

Internal Gate Oscillator (Note 11) DCLK 2.5 4.096 20 MHz

(Note 12 and 13) 40 - 60 %

(60 Hz, OWR = 4000 Hz) -5.4 - +5.4 °

DCLK = MCLK/K - DCLK/8 - Hz

(Both channels) OWR - DCLK/1024 - Hz

-3 dB -0.5-Hz

(Note 14) FSCR 25 - 100 %FS

(Note 15) 1.0 µs

SCLK and RESET

SCLK and RESET

SCLK and RESET

I

out

I

=-5mA(VD=+5V)

out

= -2.5 mA (VD = +3.3V)

I

out

XIN

XIN

XIN

= +5 mA V

(Note 16) I

V

IH

0.6 VD+

(VD+) – 0.5

0.8VD+

V

IL

-

-

-

V

IL

-

-

-

(VD+) - 1.0 - - V

OH

V

OL

-

-

in

OZ

out

-±1±10µA

--±10µA

-5-pF

-

-

-

-

-

-

-

-

-

-

-

-

-

-

0.8

1.5

0.2VD+

0.48

0.3

0.2VD+

0.4

0.4

V

V

V

V

V

V

V

V

V

V

V

Notes: 10. All measurements performed under static conditions.

11. If a crystal is used, XIN frequency must remain between 2.5 MHz - 5.0 MHz. If an external oscillator is

used, XIN frequency range is 2.5 MHz - 20 MHz, but K must be set so that MCLK is between

2.5 MHz - 5.0 MHz.

12. If external MCLK is used, the duty cycle must be between 45% and 55% to maintain this specification.

13. The frequency of CPUCLK is equal to MCLK.

14. The minimum FSCR is limited by the maximum allowed gain register value. The maximum FSCR is

limited by the full-scale signal applied to the input.

15. Configuration register (Config) bits PC[6:0] are set to “0000000”.

16. The MODE pin is pulled low by an internal resistor.

10 DS682F3

Page 11

CS5464

SWITCHING CHARACTERISTICS

• Min / Max characteristics and specifications are guaranteed over all Recommended Operating Conditions.

• Typical characteristics and specifications are measured at nominal supply voltages and TA = 25 °C.

• VA+ = 5 V ±5% VD+ = 3.3 V ±5% or 5 V ±5%; AGND = DGND = 0 V. All voltages with respect to 0 V.

• Logic Levels: Logic 0 = 0 V, Logic 1 = VD+.

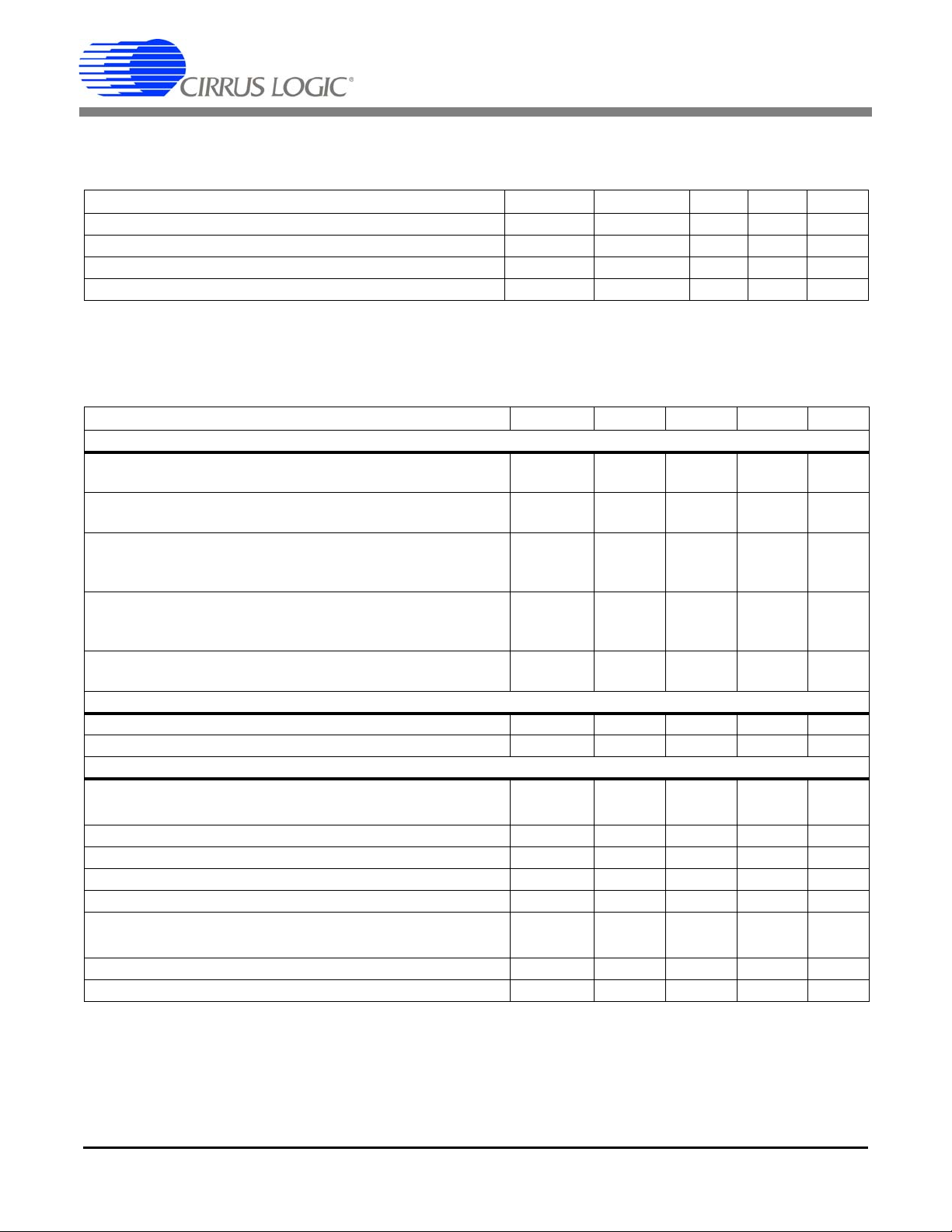

Parameter Symbol Min Typ Max Unit

Rise Times

(Note 17)

Any Digital Output

Fall Times

(Note 17)

Any Digital Output

Start-up

Oscillator Start-up Time

XTAL = 4.096MHz (Note 11) t

Serial Port Timing

Serial Clock Frequency SCLK - - 2 MHz

Serial Clock

Pulse Width High

Pulse Width Low

SDI Timing

CS

Falling to SCLK Rising t

Data Set-up Time Prior to SCLK Rising t

Data Hold Time After SCLK Rising t

SDO Timing

Falling to SDO Driving t

CS

SCLK Falling to New Data Bit (hold time) t

Rising to SDO Hi-Z t

CS

2

E

PROM mode Timing

Serial Clock

MODE setup time to RESET

RESET

CS

SCLK falling to CS

CS

rising to CS falling t

falling to SCLK rising t

rising t

rising to driving MODE low t

Rising t

Pulse Width Low

Pulse Width High

SDO setup time to SCLK rising t

Notes: 17. Specified using 10% and 90% points on waveform of interest. Output loaded with 50 pF.

18. Oscillator start-up time varies with crystal parameters. This specification does not apply when using an

external clock source.

t

rise

t

t

fall

ost

t

1

t

2

3

4

5

6

7

8

t

9

10

11

12

13

14

15

16

-

-

-

-

50

50

-

-

1.0

-

1.0

-

µs

ns

µs

ns

-60-ms

200

200

-

-

-

-

ns

ns

50 - - ns

50 - - ns

100 - - ns

-2050ns

-2050ns

-2050ns

8

8

DCLK

DCLK

50 ns

48 DCLK

100 8 DCLK

16 DCLK

50 ns

100 ns

DS682F3 11

Page 12

t

1

t

2

t

3

t

4

t

5

MSB

MSB-1

LSB

MSB

MSB-1

LSB

MSB

MSB-1

LSB

MSB

MSB-1

LSB

Com m and Tim e 8 SC LKs H igh Byte Mid Byte Low Byte

CS

SCLK

SDI

t

10

t

9

RESET

SDO

SCLK

CS

Last 8

Bits

SDI

MODE

STOP bit

D a ta fro m EE P R O M

t

16

t

4

t

5

t

14

t

15

t

7

t

13

t

12

t

11

(INPUT)

(INPUT)

(O UT P U T )

(O UT P U T )

(O UT P U T )

(INPUT)

t

1

t

2

MSB

MSB-1

LSB

Comm and Time 8 SC LKs

SYNC0 or SYNC1

Command

SYNC0 or SYNC1

Comm and

MSB

MSB-1

LSB

MSB

MSB-1

LSB

MSB

MSB-1

LSB

Hig h Byte M id B yte Low B yte

CS

SDO

SCLK

SDI

t

6

t

7

t

8

SYNC0 or SYNC1

Comm and

UNKNOWN

SDI Write Timing (Not to Scale)

SDO Read Timing (Not to Scale)

Figure 1. CS5464 Read and Write Timing Diagrams

E2PROM mode Sequence Timing (Not to Scale)

CS5464

12 DS682F3

Page 13

CS5464

t

period

E1

t

3

t

4

t

5

t

3

t

5

t

4

E2

E3

t

pw

t

period

t

pw

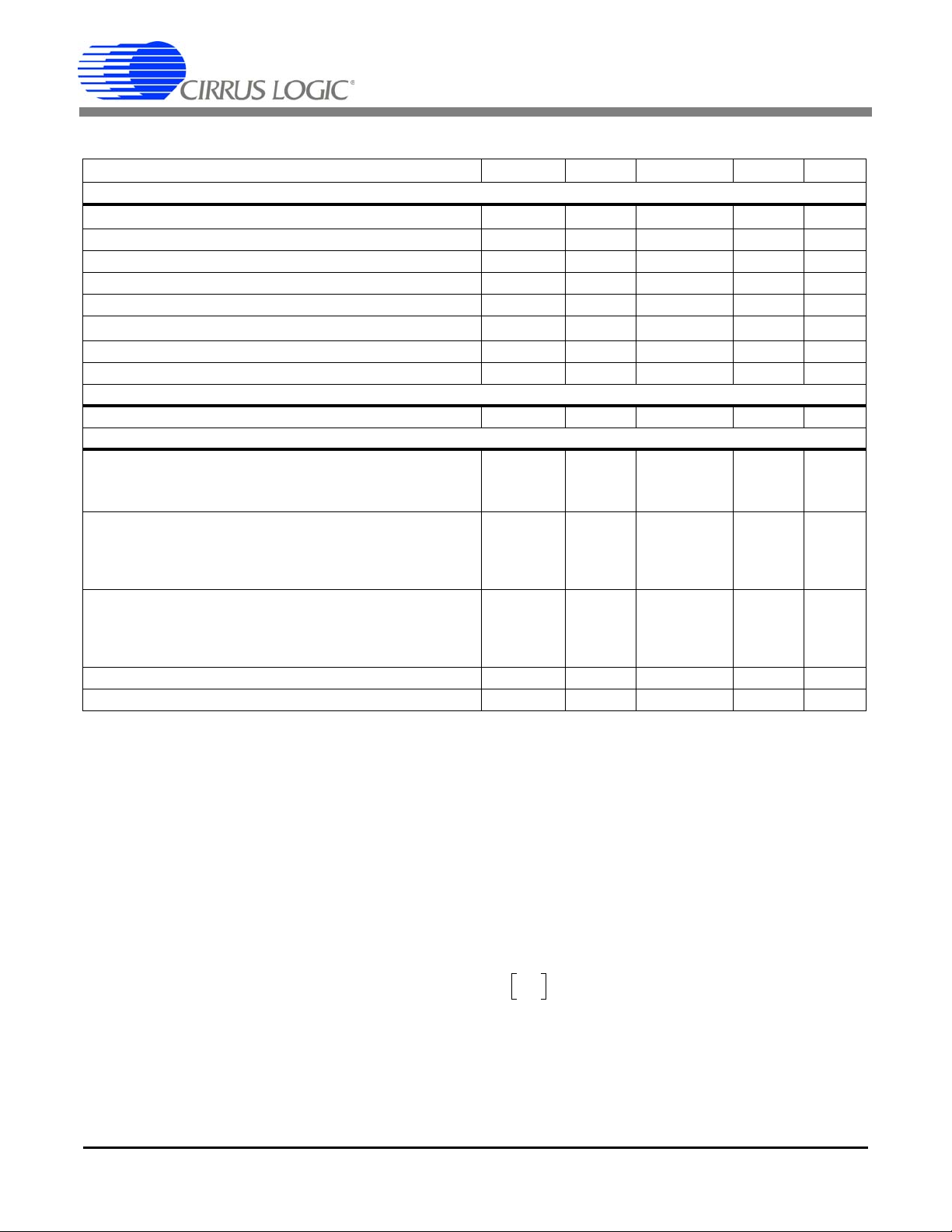

Figure 2. Timing Diagram for E1, E2, and E3

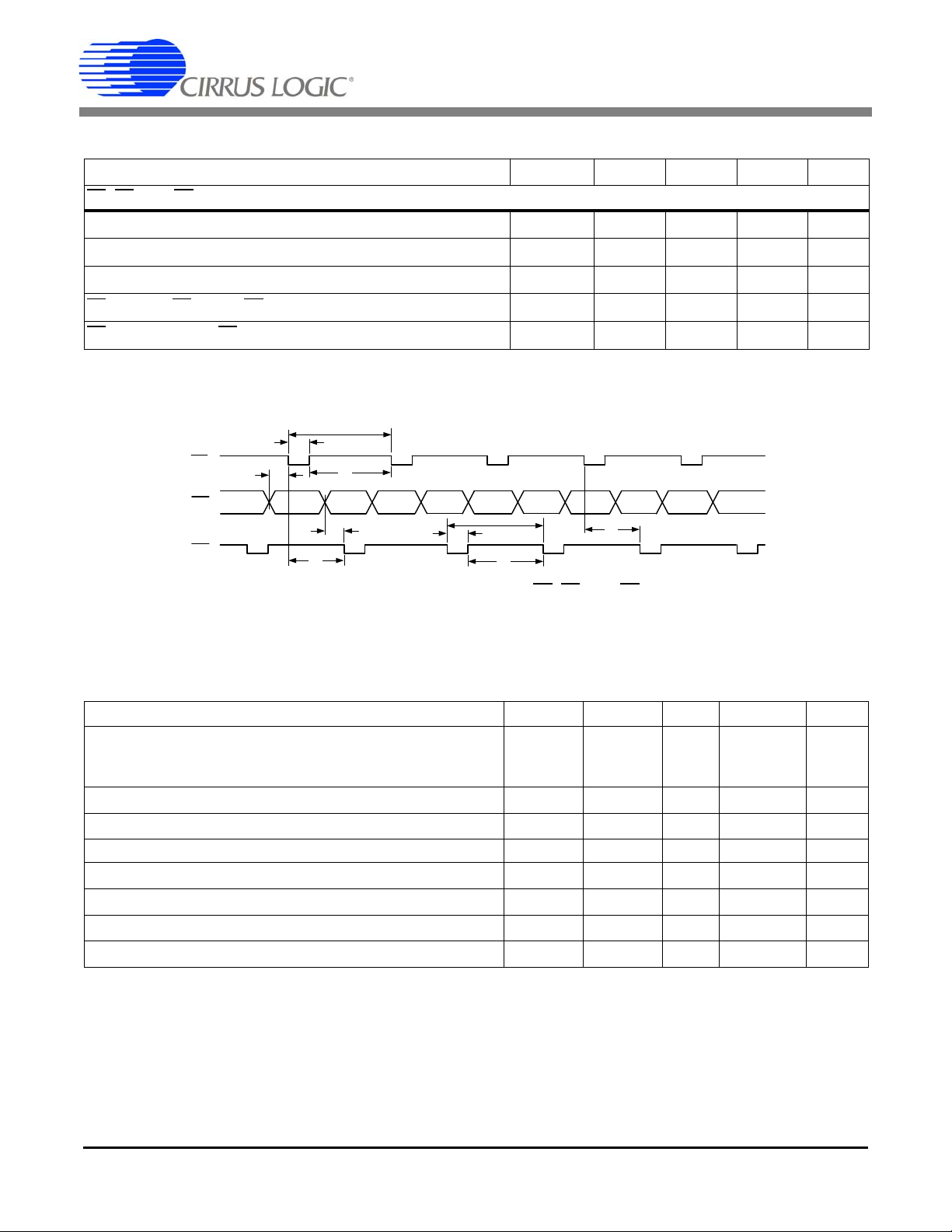

SWITCHING CHARACTERISTICS (Continued)

Parameter Symbol Min Typ Max Unit

E1

, E2, and E3 Timing (Note 19 and 20)

Period t

Pulse Width t

Rising Edge to Falling Edge t

Setup to E1 and/or E3 Falling Edge t

E2

Falling Edge to E3 Falling Edge t

E1

period

pw

3

4

5

Notes: 19. Pulse output timing is specified at DCLK = 4.096 MHz, E2MODE = 0, and E3MODE[1:0] = 0. Refer to

6.7 Energy Pulse Outputs on page 19 for more information on pulse output pins.

20. Timing is proportional to the frequency of DCLK.

500 - - s

244 - - s

6--s

1.5 - - s

248 - - s

ABSOLUTE MAXIMUM RATINGS

WARNING: Operation at or beyond these limits may result in permanent damage to the device.

Normal operation is not guaranteed at these extremes

Parameter Symbol Min Typ Max Unit

DC Power Supplies

Input Current, Any Pin Except Supplies

(Notes 21 and 22)

Positive Digital

Positive Analog

(Notes 23, 24, 25) I

Output Current, Any Pin Except VREFOUT I

Power Dissipation

Analog Input Voltage

Digital Input Voltage

(Note 26) PD --500mW

All Analog Pins V

All Digital Pins V

Ambient Operating Temperature T

Storage Temperature T

Notes: 21. VA+ and AGND must satisfy [(VA+) - (AGND)] + 6.0 V.

22. VD+ and AGND must satisfy [(VD+) - (AGND)] + 6.0 V.

23. Applies to all pins including continuous over-voltage conditions at the analog input pins.

24. Transient current of up to 100 mA will not cause SCR latch-up.

25. Maximum DC input current for a power supply pin is ±50 mA.

26. Total power dissipation, including all input currents and output currents.

.

VD+

VA+

IN

OUT

INA

IND

A

stg

-0.3

-0.3

--±10mA

--100mA

- 0.3 - (VA+) + 0.3 V

-0.3 - (VD+) + 0.3 V

-40 - 85 °C

-65 - 150 °C

-

-

+6.0

+6.0

V

V

DS682F3 13

Page 14

4. SIGNAL PATH DESCRIPTION

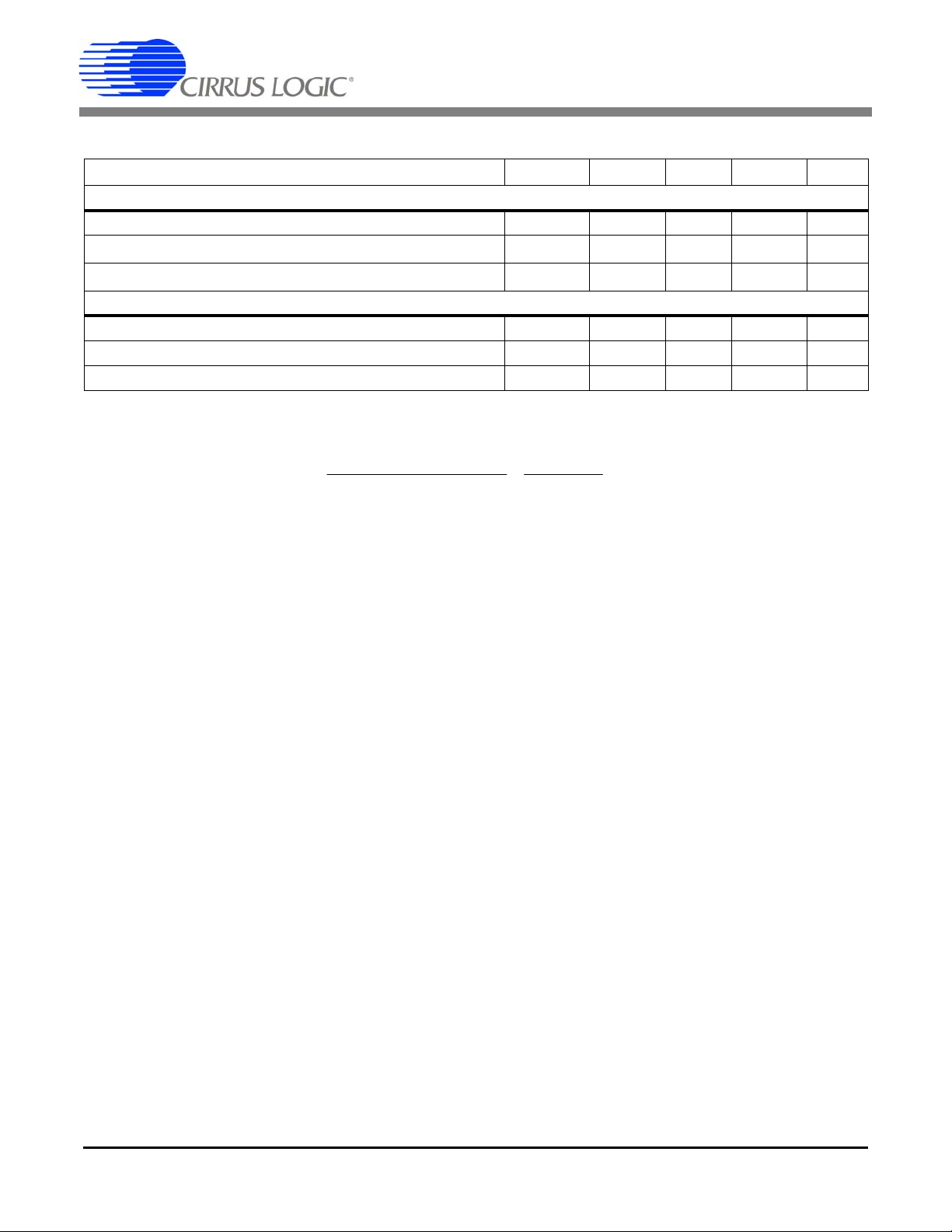

Figure 3. Signal Flow for V1, I1, P1, Q1 Measurements

FGA

V1

OFF

V1

GAIN

I1

OFF

I1

GAIN

Figure 4. Signal Flow for V2, I2, P2, Q2 Measurements

V2

OFF

V2

GAIN

I2

OFF

I2

GAIN

The data flow for voltage and current measurement and

the other calculations are shown in Figures 3, 4, and 5.

The data flow consists of two current

paths. Both voltage paths are derived from the

age

same differential input pins. Each curr ent path has its

own differential input pins.

4.1 Analog-to-Digital Converters

The voltage and temperature channels use second-order delta-sigma modulators and the two current channels use fourth-order delta-sigma modulators to convert

the analog inputs to single-bit digital data streams. The

converters sample at a rate of DCLK/8. This high sampling provides a wide dynamic range and simplifies anti-alias filter design.

4.2 Decimation Filters

The single-bit modulator output data is widened to

24 bits and down-sampled to DCLK/1024 with low-pass

paths and two vo lt-

CS5464

decimation filters. These decimation filters ar e third-order Sinc. Their outputs are passed through third-order

IIR “anti-sinc” filters, used to compensate for the amplitude roll-off of the decimation filters.

4.3 Phase Compensation

Phase compensation changes the ph ase of curren t relative to voltage by changing the sampling time in the

decimation filters. The amount of phase shift is set by

bits PC[7:0] in the Configuration register

channel 1 and bits PC[7:0] in the Control register (

for channel 2.

Phase compensation, PC[7:0] is a signed two’s complement binary value in the rang e of -1.0 to almost +1.0

output word rate (OWR) samples. Fo r a sample rate of

4000 Hz, the delay range is ±250

S, a phase shift of

±4.5° at 50 Hz and ±5.4° at 60 Hz. The step size would

be 0.0352° at 50 Hz and 0.0422° at 60 Hz at this sample

rate.

(Config) for

Ctrl)

14 DS682F3

Page 15

CS5464

I

RMS

I

n

n0=

N1–

N

-------------------- -

=

2

4.4 DC Offset and Gain Correction

The system and chip inherently have gain and offset errors which can be removed using t he gain and offset

registers. (See Section 9.

39). Each measurement channel has its own registers.

For every channel, the output of the IIR filter is added to

the offset register and multiplied by the gain register.

System Calibration on page

4.5 High-pass Filters

Optional high-pass filters (HPF in Figures 3 and 4) remove any DC from the selected signal paths. Subsequently, DC will also be removed from power, and all

low-rate results. (see Figures 5).

Each energy channel has a current and voltage path. If

an HPF is enabled in only one path, a phase-matching

filter (PMF) is applied to the other path which matches

the amplitude and phase delay of the HPF in the band

of interest, but passes DC. For more information, see

High-pass Filters on page 19. The HPF filter multi-

6.5

plexers drive the

I1, V1, I2, and V2 result registers.

4.6 Low-Rate Calculations

Low-rate results are derived from sample-rate results

integrated over

in the Cycle Count register. The low-rate interval is the

sample interval multiplied by

N samples, where N is the value stored

N.

4.7 RMS Results

The root mean square (RMS in Figure 5) calculations

are performed on

samples, using the formula:

N instantaneous voltage and current

DS682F3 15

Page 16

CS5464

V1

ACOFF

(V2

ACOFF

)

I1

ACOFF

(I2

ACOFF

)

P1

OFF

(P2

OFF

)

Figure 5. Low-rate Calculations

SV

RMSIRMS

=

PF

P

ACTIVE

S

----------------------

=

Q

WB

S2P

ACTIVE

2

–=

4.8 Power and Energy Results

The instantaneous voltage and current samples are

multiplied to obtain the instantaneous power (

(see Figure 3 and 4). The product is then average d over

N conversions to compute active power (P1

P2

).

AVG

Apparent power (

S1, S2) is the product of RMS voltage

and current as shown:

Power factor (

PF1, PF2) is active power divided by ap-

parent power as shown below. The sign of the power

factor is determined by the active power.

Q1

Wideband reactive power (

, Q2WB) is calculated

WB

by doing a vector subtraction of active power from apparent power.

Quadrature power (

Q1, Q2) are sample rate results ob-

tained by multiplying instantaneous current (

stantaneous quadrature voltage (

V1Q, V2Q) which are

created by phase shifting instantaneous voltage (

V2) 90 degrees using first-order integr ators. (see Figure

3 and 4). The gain of these integrators is inversely relat-

P1, P2)

AVG

I1, I2) by in-

V1,

ed to line frequency, so their gain is corrected by the

silon

register, which is based on line frequency.

Reactive power (

grating the instantaneous quadrature power over

,

samples.

Q1

AVG

, Q2

) is generated by inte-

AVG

4.9 Peak Voltage and Current

Peak current (I1

(

V1

PEAK

,

V2

PEAK

samples detected in the previous low-rate interval.

PEAK

, I2

) and peak voltage

PEAK

) are the largest current and voltage

4.10 Power Offset

The power offset registers, P1

to offset erroneous power sources resident in the system not originating from the power line. Residual power

offsets are usually caused by crosstalk into current

paths from voltage paths or from ripple on the meter or

chip’s power supply, or from inductance from a nearby

transformer.

These offsets can be either positive or negative, indicating crosstalk coupling either in phase or out of phase

with the applied voltage input. The power offset registers can compensate for either condition.

To use this feature, measure the average power at no

load using either Single or Continuous Conversion commands. Take the measured result (from the

(P2

) register), invert (negate) the value and write it

AVG

to the associated power offset register,

OFF

(P2

) can be used

OFF

P1

OFF

(P2

P1

Ep-

AVG

OFF

N

).

16 DS682F3

Page 17

5. PIN DESCRIPTIONS

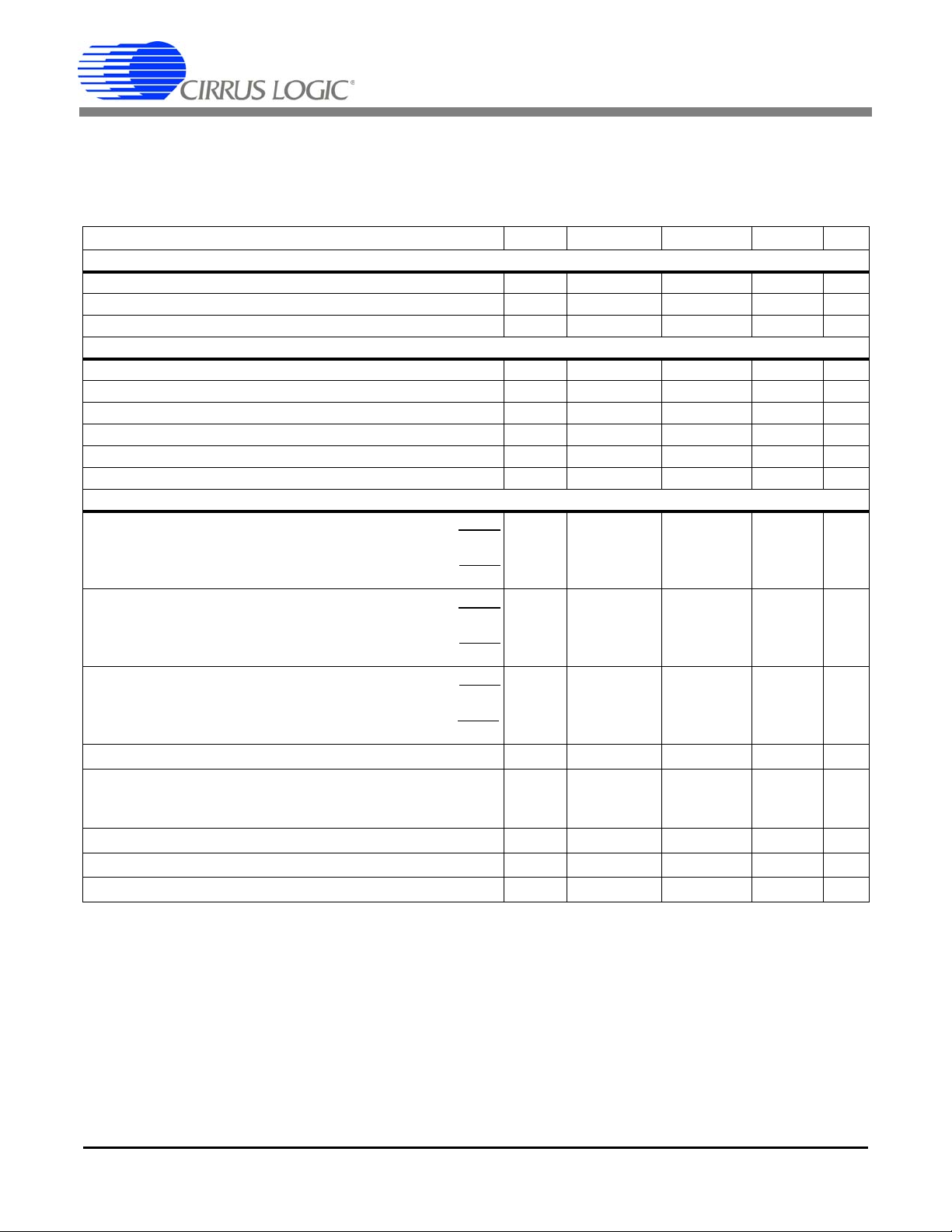

Figure 6. Oscillator Connections

Oscillator

Circuit

DGND

XIN

XOUT

C1

C1 =

22 pF

C2

C2 =

CS5464

5.1 Analog Pins

The CS5464 has three differential inputs: VINIIN1,

and IIN2

respectively. A single-ended power fail monitor input,

voltage reference input, and voltage reference output

are also available.

are the voltage, current1, and current2 inputs,

5.1.1 Voltage Inputs

The output of the line voltage resistive divider or transformer is connected to the VIN+ and VIN- input pins of

the CS5464. The voltage channel is equipped with a

10x, fixed-gain amplifier. The full-scale signal level that

can be applied to the voltage channel is ±250mV. If the

input signal is a sine wave, the maximum RMS voltage

is 250mVp /

mately 70.7% of maximum peak voltage.

2 176.78mVRMS which is approxi-

5.1.2 Current1 and Current2 Inputs

The output of the current-sensing resistor or transformer is connected to the IIN1+ (IIN2+) and IIN1- (IIN2-) input pins of the CS5464. To accommodate different

current-sensing elements, the cu rrent chan nel incorporates a programmable gain amplifier (PGA) with two selectable input gains. The full-scale signal level for the

current channels is ±50mV or ±250mV. If the input signal is a sine wave, the maximum RMS voltage is

35.35mVRMS or 176.78mVRMS which is approximately 70.7% of maximum peak voltage.

5.1.3 Power Fail Monitor Input

An analog input (PFMON) is provided to determine

when a power loss is imminent. By connecting a resistive divider from the unregulated meter power supply to

the PFMON input, an interrupt can be generated, or the

Low Supply Detected (LSD)

monitored to indicate low-supply conditions. The PFMON input has a comparator that trips around the level

of the voltage reference input (VREFIN).

Status register bit can be

5.1.4 Voltage Reference Input

The CS5464 requires a stable voltage reference of

2.5 V applied to the VREFIN pin. This reference can be

supplied from an external voltage reference or from the

VREFOUT output. A bypass capacitor of at least 0.1

is recommended at the VREFIN pin.

5.1.5 Voltage Reference Output

The CS5464 generates a 2.5 V reference (VREFOUT).

It is suitable for driving the VREFIN pin, but has very little fan-out and is not recommended for driving external

circuits.

5.1.6 Crystal Oscillator

An external quartz crystal can be connected to the XIN

and XOUT pins as shown in Figure 6. To reduce system

cost, each pin is supplied with an on-chip, phase-shifting capacitor to ground.

.

Alternatively, an external clock source can be connected to the XIN pin.

5.2 Digital Pins

5.2.1 Reset Input

The active-low RESET pin, when asserted, will halt all

CS5464 operations and reset internal hardware registers and states. When de-asserted, an initialization sequence begins, setting default register values.

5.2.2 CPU Clock Output

A logic-level clock output (CPUCLK) is provided at the

crystal frequency to drive an external CPU or microcontroller clock. Two phase choices are available.

5.2.3 Interrupt Output

The INT pin indicates an enabled Internal Stat us regis-

Status) bit is set. Status register bits indicate condi-

ter (

tions such as data ready, modulator oscillations, low

supply, voltage sag, current faults, numerical overflows,

and result updates.

F

5.2.4 Energy Pulse Outputs

The CS5464 provides three pins (E1, E2, E3) for pulse

energy outputs. These pins can also be used to output

other conditions, such as voltage sign, power fail monitor, or energy channel in use.

DS682F3 17

Page 18

CS5464

5.2.5 Serial Interface

The CS5464 provides 5 pins, SCLK, SDI, SDO, CS, and

MODE for communication between a host microcontroller or serial E

MODE is an input that, when high, indicates to the

CS5464 that a serial E

a host microcontroller. It has a weak pull-down allowing

it to be left unconnected if microcontroller mode is used.

SCLK is used to shift and qualify serial data. Serial data

changes as a result of the falling edge of SCLK and is

valid during the rising edge. It is a Schmitt-trigger input

2

PROM and the CS5464.

2

PROM is being used instead of

for host microcontrollers, and a driven output for serial

2

PROMs.

E

SDI is the serial data input to the CS5464.

SDO is the serial data output from the CS546 4. It’s out-

put drivers are disabled whenever CS

lowing other devices to drive the SDO line.

is the chip select input for the serial bus. A high logic

CS

level de-asserts it, tri-stating the SDO pin and clearing

the serial interface. A low logic level enables the serial

port. This pin may be tied low for systems not requiring

multiple SDO drivers. CS

facing to serial E

2

PROMs.

is a driven output when inter-

is de-asserted, al-

18 DS682F3

Page 19

6. SETTING UP THE CS5464

CS5464

6.1 Clock Divider

The internal clock to the CS5464 needs to operate

around 4 MHz. However, by using the internal clock divider, a higher crystal frequency can be used. This is important when driving an external microcontroller

requiring a faster clock and using the CPUCLK output.

K is the divide ratio from the crystal input to the internal

clock and is selected with Configuration

fig

) bits K[3:0]. It has a range of 1 to 16. A value of zero

results in a setting of 16.

register (Con-

6.2 CPU Clock Inversion

By default, CPUCLK is inverted from XIN. Setting Configuration

can be useful when one phase adds more noise to the

system than the other.

register bit iCPU removes this inversion. This

6.3 Interrupt Pin Behavior

The behavior of the INT pin is controlled by the IMODE

and IINV bits in the Configuration

IMODE IINV INT Pin

0 0 Active-low Level

0 1 Active-high Level

10 Low Pulse

11 High Pulse

Table 1. Interrupt Configuration

If IMODE = 1, the duration of the INT

DCLK cycles, where DCLK = MCLK/K.

register as shown.

pulse will be two

6.4 Current Input Gain Ranges

Control register bits I1gain (I2gain) select the input

range of the current inputs.

I1gain, I2gain Maximum Input

0±250mV10x

1 ±50 mV 50x

Table 2. Current Input Gain Ranges

Gain

6.5 High-pass Filters

Mode Control (Modes) register bi ts VHPF and IHPF activate the HPF in the voltage and current paths, respectively. Each energy channel has separate VHPF and

IHPF bits. When a high-pass filter is enabled in only one

path within a channel, a phase matching filter (PMF) is

applied to the other path within that channel. The PMF

filter matches the amplitude and phase response of the

HPF in the band of interest, but passes DC.

VHPF IHPF Filter Configuration

0 0 No filter on Voltage or Current

0 1 HPF on Current, PMF on Voltage

1 0 HPF on Voltage, PMF on Current

1 1 HPF on Current and V oltage

Table 3. High-pass Filter Configuration

6.6 Cycle Count

Low-rate calculations, such as average power and RMS

voltage and current integrate over several (

word rate (OWR) samples. The duration of this averaging window is set by the Cycle Count (

fault, Cycle Count is set to 4000 (1 second at output

word rate [OWR] of 4000 Hz). The minimum value for

Cycle Count is 10.

N) register. By de-

N) output

6.7 Energy Pulse Outputs

By default, E1 outputs active energy, E3, reactive energy, and E2

(See Figure 2.

page 13.)

Three pairs of bits in the Mode Control (

control the operation of these outputs. These bits are

named E1MODE[1:0], E2MODE[1:0], and

E3MODE[1:0]. Some combinations of these bits override others, so read the following paragraphs carefully.

The E2

energy channel in use (1 or 2). Table 4 lists the functions of E2

register.

Note: E2MODE[1:0]=3 is a special mode.

E2MODE1 E2MODE0 E2

The E3

itor status, voltage sign, or apparent energy. Table 5

, the sign of both active and reactive energy.

Timing Diagram for E1, E2, and E3 on

Modes) register

pin can output energy sign, apparent energy, or

as controlled by E2MODE[1:0] in the Modes

output

0 0 Energy Sign

0 1 Apparent Energy

1 0 Channel in Use

1 1 Enable E1MODE

Table 4. E2 Pin Configuration

pin can output reactive energy, power fail mon-

DS682F3 19

Page 20

CS5464

lists the functions of E3 as controlled by E3MODE[1:0]

Modes register when E1MODE is not enabled.

in the

E3MODE1 E3MODE0 E3 output

0 0 Reactive Energy

0 1 Power Fail Monitor

1 0 Voltage Sign

1 1 App arent Energy

Table 5. E3 Pin Configuration

When both E2MODE bits are high, the E1MODE bits

are enabled, allowing active, apparent, reactive, or

wideband reactive energy for

be output on E1

and E2. Table 6 lists the functions of E1

both energy channels to

and E2 with E1MODE enabled.

E1MODE1 E1MODE0 E1

/ E2 outputs

0 0 Active Energy

0 1 App arent Energy

1 0 Reactive Energy

1 1 Wideband Reactive

Ta bl e 6. E1 / E2 Modes

When E1MODE bits are enabled, the E3

pin outputs either the power fail monitor status, or the sign of the E1

and E2 outputs. Table 7 list the functions of the E3 pin

using E3MODE[1:0] in the

E1MODE is enabled

.

E3MODE1 E3MODE0 E3

Modes register when

output

0 0 Power Fail Monitor

0 1 Energy Sign

1 0 not used

1 1 not used

Ta bl e 7. E3 Pin with E1MODE enabled

6.8 No Load Threshold

The No Load Threshold register (Load

zero out the contents of

E

their magnitude is less than the

PULSE

and Q

Load

) is used to

MIN

registers if

PULSE

register value.

MIN

6.9 Energy Pulse Width

Note: Energy Pulse Width (PulseWidth) only applies to

, E2, or E3 pins that are configured to output pulses.

E1

When any are configured to output steady-state signals,

such as voltage sign, energy channel in use, power fail

monitor, or energy sign, pulse widths and output rates

do not apply.

The pulse width time (t

PulseWidth register which is an integer multiple of

in the

the sample or output word rate (OWR).

4000 Hz (a period of 250 uS) t

By default,

PulseWidth is set to 1.

) in Figure 2, is set by the value

pw

At OWR of

= PulseWidth x 250uS.

pw

6.10 Energy Pulse Rate

The full-scale pulse frequency of enabled E1, E2, E3

pins is the PulseRate x output word rate (OW R)/2. Th e

actual pulse frequency is the full-scale pulse frequency

multiplied by the pulse register’s (

Q

PULSE

) value.

E

PULSE

, S

PULSE

Example:

If the output word rate (OWR) is 4000 Hz, and the

PulseRate is set to 0.05, the full-rate pulse frequency is

0.05 x 4000 / 2 = 100 Hz. If the

, is 0.4567, the pulse output rate on E1 will be

E1

E

register, driving

PULSE

100 Hz x 0.4567 = 45.67 Hz.

6.11 Voltage Sag/Current Fault Detection

Voltage sag detection is used to determine when averaged voltage falls below a predetermined level for a

specified interval of time. Current fault detection determines when averaged current falls below a predetermined level for a specified interval of time.

The specified interval of time (duration) is set by the value in the

(I2Fault

V1Sag

) registers. Setting any of these to zero (de-

DUR

fault) disables the detect feature for the given channel.

The value is in output word rate (OWR) samples. The

predetermined level is set by the values in the

V1Sag

(I2Fault

LEVEL

LEVEL)

(V2Sag

registers.

Since the values of

put, only one voltage sag detector is necessary.

DUR

(V2Sag

) and I1Fault

LEVEL

) and I1Fault

DUR

DUR

LEVEL

V1 and V2 come from the same in-

,

20 DS682F3

Page 21

CS5464

Figure 7. Sag and Fault Detect

For each enabled input channel, the measured value is

rectified and compared to the associ at ed leve l re gis te r

Over the duration window, the number of samples

above and below the level are counted. If the number of

samples below the level exceeds the number of samples above, a

FAULT

(I2

FAULT

I1

Status register bit V1

) is set, indicating a sag or fault condi-

SAG

(V2

SAG

tion. (see Figure 7)..

6.12 Epsilon

The Epsilon reg ister is used to set the gain of the 90°

phase shift used in the quadrature power calculation.

The value in the

Epsilon register is the ratio of the line

frequency to the output word rate (OWR). It is, by default, 50/4000 (0.0125), for 50 Hz line and 4000 Hz

sample (OWR) frequencies.

For 60 Hz line frequency, it is 60/400 0 (0.015). Other

output word rates (OWR) can be used.

Epsilon can also be calculated automatically by the

CS5464 by setting the AFC bit in the Mode Control

Modes) register. The Frequency Update bit (FUP) in

(

Status register is set every time the Epsilon re gister

the

has been automatically updated.

6.13 Temperature Measurement

The on-chip temperature sensor is designed to measure temperature and optionally compensate for temperature drift of the voltage reference. It uses the V

a transistor to determine temperature.

Temperature measurements are stored in the Temperature register (

T) which, by default, is configured to a

range of ±128 degrees on the Celsius (°C) scale.

BE of

The application program can change both the scale and

.

range of Temperature (

T

Gain (

GAIN

) and Temperature Offset (T

T) by changing the T emperature

OFF

Two values must be known — the transistor’s

degree, and the transistor’s V

),

time of this publication, these values are:

BE at 0 degrees. At the

VBE (per degree) = 0.2769523 mV/°C or °K

V

0 = 79.2604368 mV at 0°C

BE

To determine the values to write to

the following formulae:

T

= ADFS / VBE / TFS x 2

GAIN

T

= -VBE0 / ADFS x 2

OFF

23

In the above equations, ADFS is the full-scale input

range of the temperature A/D conv er te r o r 83 3.333 mV

and T

is the desired full-scale range of the Tempera-

FS

ture register. The binary exponents are the bit positions

of the binary point of these registers.

To use the Celsius scale (°C) and cover the chip’s operating temperature range of -40°C to +85°C, the Temperature register range needs to be ±128 degrees. T

should be 128 degrees.

T

= 833.333 / 0.2769523 / 128 x 131072

GAIN

= 3081155 (0x2F03C3)

T

= -79.2604368 / 833.333 x 8388608

OFF

= -797862 (0xF3D35A)

These are the actual default values for these registers.

T

GAIN

and T

can also be used to calibrate the gain

OFF

and/or offset of the temperature sensor or A/D converter. (See Section 9.

System Calibration on page 39).

To use the Kelvin (°K) scale, simply add 273 times

VBE / AD

x 223 to T

FS

since 0°C = 273°K,. You will

OFF

also need more range. Since -40°C to +85°C is 233°K

to 358°K, a T

T

calculation.

GAIN

of 512 degrees should be used in the

FS

To use the Fahrenheit (°F) scale, mult iply

and add 32 times the new

VBE/ AD

since 0°C = 32°F. You will also want to use aTFS of 256

degrees to cover the -40°C to +85°C range.

The Temperature register (

T) updates every 2240 out-

put word rate (OWR) samples. The

TUP indicates when

T is updated.

T

GAIN

17

FS

Status register bit

and T

x 223 to T

) registers.

VBE per

, use

OFF

FS

VBE by 5/9

OFF

DS682F3 21

Page 22

7. USING THE CS5464

AVG

AVG

Figure 8. Energy Channel Selection

Figure 9. Fixed RMS Voltage Selection

CS5464

7.1 Initialization

The CS5464 uses a power-on-reset circuit (POR) to

provide an internal reset until the analog voltage reaches 4.0 V. The RESET

input pin can also be used by the

application circuit to reset the part.

After RESET

is removed and the oscillator is stable, an

initialization program is executed to set the default register values.

A Software Reset command is also provided to allow

the application to run the initialization prog ram without

removing power or asserting RESET

.

The application should avoid sending commands during

initialization. The DRDY bit in the

Status register indi-

cates when the initialization program has completed.

7.2 Power-down States

The CS5464 has two power-down states, stand-by and

sleep. In the stand-by state, all circuitry except the voltage reference and crystal oscillator is powered off. In

sleep state, all circuitry except the instruction decoder is

powered off.

To return the device to the active state, send a WakeUp/Halt command to the device. When returning from

stand-by mode, registers will retain their contents prior

to entering the stand-by state. When returning from

sleep mode, a complete initialization occurs.

7.3 Tamper Detection and Correction

The CS5464 provides compensation for at least two

forms of meter tampering. A second current input is provided in the event that the primary input is impaired by

tampering. (See Figure 14 on page 42). An internal

RMS voltage reference is also available in the even t that

the voltage input has been compromised by tampering.

Power and energy are calculated for BOTH current inputs (both energy channels). The CS5 464 can automatically choose the channel with the greater magnitude.

E

The register

, (also called Irms

MIN

level for automatic channel selection, and

sets a minimum difference that will allow a channel

) sets a minimum

MIN

Ichan

LEVEL

change.

Modes register bit Ichan selects the energy

channel, and is normally driven by the CS5464 program. This affects the pulse registers and pulse energy

outputs. (See figure 8).

The application program can also choose the more appropriate energy channel.

Modes register bit Ihold dis-

ables automatic selection and Ichan can be driven by

the application. Shown below is the channel selector.

If the application detects that the voltage input has been

impaired it may choose to use the fixed internal RMS

voltage reference by setting the VFIX bit in the

register. The value of this referenc e (VF

RMS

Modes

) is by default 0.707107 (full-scale RMS) but can be changed by

the application program. (See figure 9)

22 DS682F3

Page 23

CS5464

7.4 Command Interface

Commands and data are transferred most-significant bit

(MSB) first. Figure 1 on page 12, defines the serial port

timing. Commands are clocked in on SDI using SCLK.

They are a single byte (8 bits) long and fall into one of

four basic types:

1. Register Read

2. Register Write

3. Synchronizing

4. Instructions

Register reads will cause up to four bytes of register

data to be clocked out, MSB first on the SDO pin by

SCLK. During this time, other commands can be

clocked in on the SDI pin. Other commands will not interrupt read data, except another register read, which

will cause the new read data to appear on SDO.

Synchronizing can be sent while read data is being

clocked out if no other commands need to be sent.

Synchronizing commands are also used to synchronize

the serial port to a byte boundary. The CS

pins will also synchronize the serial port.

Register writes require three bytes of write data to follow, clocked in on the SDI pin, MSB first by SCLK.

Instructions are commands that will interrupt any instruction currently executing and begin the new instruction. These include conversions, calibrations, power

control, and soft reset.

(See Section 7.6

Commands on page 24).

and RESET

7.5 Register Paging

Read and Write commands access one of 32 registers

within a specified page. The Resgister Page Select register’s (

another page, write the desired page number to the

Page register. The Page register is always at address

31 and is accessible from within any page.

Page) default value is 0. To access registers in

DS682F3 23

Page 24

7.6 Commands

All commands are 1 byte (8 bits) long. Many comman d values are u nused and should NO T be written b y the

application program. All commands except register reads, register writes, or synchronizing commands will

abort any conversion, calibration, or any initialization sequence currently executing. This includes reset. No

commands other than reads or synchronizing should be executed until the reset sequence completes.

7.6.1 Conversion

B7 B6 B5 B4 B3 B2 B1 B0

1110CC000

Executes a conversion (measure m en t ) pro gr a m.

CC Continuous/Single Conversion

0 = Perform a Single Conversion (0xE0)

1 = Perform Continuous Conversion (0xE8)

7.6.2 Synchronization (SYNC0 and SYNC1)

B7 B6 B5 B4 B3 B2 B1 B0

1111111SYNC

CS5464

The serial interface is bidirectional. While reading data on the SDO output, the SDI input must be receiving

commands. If no command is needed during a read, SYNC0 or SYNC1 commands can be sent while read

data is received on SDO.

The serial port is normally initialized by de-asserting CS

more SYNC1 commands followed by a SYNC0. This is useful in systems where CS

. An alternative method of initialization is to send 3 or

is not used and tied low.

7.6.3 Power Control (Stand-by, Sleep, Wake-up/Halt and Software Reset)

B7 B6 B5 B4 B3 B2 B1 B0

10S1S00000

The CS5464 has two power-down states, stand-by and sleep. In stand-by, all circuitry except the voltage reference and clocks are turned off. In sleep, all circuitry except the command decoder is turned off. A

Wake-up/Halt command restores full-power operatio n after stand-by and issues a hardware reset afte r sleep.

The Software Reset command is a program that emulates a pin reset and is not a power co ntrol function.

S[1:0] 00 = Software Reset

01 = Sleep

10 = Wake-up/Halt

11 = Stand-by

24 DS682F3

Page 25

CS5464

7.6.4 Calibration

B7 B6 B5 B4 B3 B2 B1 B0

1 0 CAL5 CAL4 CAL3 CAL2 CAL1 CAL0

The CS5464 can perform gain and offset calibrations using either DC or AC sign als. Proper input levels must

be applied to the current inputs and voltage input before performing calibrations.

CAL[5:4]* 00 = DC Offset

01 = DC Gain

10 = AC Offset

11 = AC Gain

CAL[3:0] 0001 = Current for Channel 1

0010 = Voltage for Channel 1

0100 = Current for Channel 2

1000 = Voltage for Channel 2

Note: Anywhere from 1 to all 4 channels can be calibrate d simultaneously. Voltage cha nnels 1 and 2

use the same voltage input. Commands with CAL[5:0] = 0 are not calibrations.

DS682F3 25

Page 26

7.6.5 Register Read and Write

B7 B6 B5 B4 B3 B2 B1 B0

0W/R

Read and Write commands provide access to on-chip register s. After a Read command, th e addressed data

can be clocked out the SDO pin by SCLK. After a Write command, 24 bits of write data must fo llow. The data

is transferred to the addressed register after the 24

of 32 addresses each. To access a desired page, write its number to the

RA4 RA3 RA2 RA1 RA0 0

th

data bit is received. Registers are organized into pag es

Page register at address 31.

CS5464

W/R

Write/Read control

0 = Read

1 = Write

RA[4:0] Register address.

Page 0 Registers

Address

RA[4:0] Name Description

0 00000 Config Configuration

1 00001 I1 Instantaneous Current Channel 1

2 00010 V1 Instantaneous Voltage Channel 1

3 00011 P1 Instantaneous Power Channel 1

4 00100 P1

5 00101 I

6 00110 V1

AVG

1RMS

RMS

7 00111 I2 Instantaneous Current Channel 2

8 01000 V2 Instantaneous Voltage Channel 2

9 01001 P2 Instantaneous Power Channel 2

10 01010 P2

11 01011 I2

12 01100 V2

13 01101 Q1

AVG

RMS

RMS

AVG

14 01110 Q1 Instantaneous Quadrature Power Channel 1

15 01111 Status Internal Status

16 10000 Q2

AVG

17 10001 Q2 Instantaneous Quadrature Power Channel 2

18 10010 I1

19 10011 V1

PEAK

PEAK

20 10100 S1 Apparent Power Channel 1

21 10101 PF1 Power Factor Channel 1

22 10110 I2

23 10111 V2

PEAK

PEAK

24 11000 S2 Apparent Power Channel 2

25 11001 PF2 Power Factor Channel 2

26 11010 Mask Interrupt Mask

27 11011 T Temperature

28 11100 Ctrl Control

29 11101 E

30 11110 S

31 R 11111 Q

PULSE

PULSE

PULSE

31 W 11111 Page Register Page Select

Active Power Channel 1

RMS Current Channel 1

RMS Voltage Channel 1

Active Power Channel 2

RMS Current Channel 2

RMS Voltage Channel 2

Reactive Power Channel 1

Reactive Power Channel 2

Peak Current Channel 1

Peak Voltage Channel 1

Peak Current Channel 2

Peak Voltage Channel 2

Active Energy Pulse Output

Apparent Energy Pulse Output

Reactive Energy Pulse Output

Warning: Do not write to unpublished register locations.

26 DS682F3

Page 27

Page1 Registers

CS5464

Address

0 00000 I1

1 00001 I1

2 00010 V1

3 00011 V1

4 00100 P1

5 00101 I1

6 00110 V1

7 00111 I2

8 01000 I2

9 01001 V2

10 01010 V2

11 01011 P2

12 01100 I2

13 01101 V2

RA[4:0] Name Description

OFF

GAIN

OFF

GAIN

OFF

ACOFF

ACOFF

OFF

GAIN

OFF

GAIN

OFF

ACOFF

ACOFF

Current DC Offset Channel 1

Current Gain Channel 1

Voltage DC Offset Channel 1

Voltage Gain Channel 1

Power Offset Channel 1

Current AC (RMS) Offset Channel 1

Voltage AC (RMS) Offset Channel 1

Current DC Offset Channel 2

Current Gain Channel 2

Voltage DC Offset Channel 2

Voltage Gain Channel 2

Power Offset Channel 2

Current AC (RMS) Offset Channel 2

Voltage AC (RMS) Offset Channel 2

14 01110 PulseWidth Pulse Output Width

15 01111 PulseRate Pulse Output Rate (frequency)

16 10000 Modes Mode Control

17 10001 Epsilon Ratio of Line to Sample Frequency

18 10010 Ichan

LEVEL

Irms or E Channel Select Trip Level

19 10011 N Cycle Count (Number o f O W R Samples in One Low-rate Interval)

20 10100 Q1

21 10101 Q2

22 10110 T

23 10111 T

24 11000 E

25 11001 T

WB

WB

GAIN

OFF

MIN

SETTLE

26 11010 Load

27 11011 VF

RMS

(Irms

MIN

Wideband Reactive Power from Power Triangle Channel 1

Wideband Reactive Power from Power Triangle Channel 2

Temperature Sensor Gain

Temperature Sensor Offset

) Energy Channel Selector Minimum Operating Level

MIN

Filter Settling Time for Conversion Startup

No Load Threshold

Voltage RMS Fixed Reference

28 11100 G System Gain

29 11101 Time System Time (in samples)

31 W 11111 Page Register Page Select

Page2 Registers

Address

0 00000 V1Sag

1 00001 V1Sag

4 00100 I1Fault

5 00101 I1Fault

8 01000 V2Sag

9 01001 V2Sag

12 01100 I2Fault

13 01101 I2Fault

RA[4:0] Name Description

DUR

LEVEL

DUR

LEVEL

DUR

LEVEL

DUR

LEVEL

V Sag Duration Channel 1

V Sag Level Channel 1

I Fault Duration Channel 1

I Fault Level Channel 1

V Sag Duration Channel 2

V Sag Level Channel 2

I Fault Duration Channel 2

I Fault Level Channel 2

31 W 11111 Page Register Page Select

Warning: Do not write to unpublished register locations.

DS682F3 27

Page 28

CS5464

8. REGISTER DESCRIPTIONS

1. “Default” = bit states after power-on or reset

2. DO NOT write a “1” to any unpublished register bit.

3. DO NOT write to any unpublished register address.

8.1 Page Register

8.1.1 Page – Address: 31, Write-only, can be written from ANY page.

MSB LSB

6

2

5

2

4

2

3

2

2

2

1

2

0

2

Default = 0

Register Read and Write commands contain only 5 address bits. But the internal addre ss bus of the CS5464 is

12 bits wide. Therefore, registers are organized into “Pages”. There are 128 pages of 32 registers each. The

Page register provides the 7 high-order address bits and selects one of the 128 register pages. Not all pages

are used,

Page is a write-only integer containing 7 bits.

8.2 Page 0 Registers

8.2.1 Configuration (Config) – Address: 0

23 22 21 20 19 18 17 16

PC7 PC6 PC5 PC4 PC3 PC2 PC1 PC0

15 14 13 12 11 10 9 8

EWA - - IMODE IINV - - -

76543210

- - -iCPUK3K2K1K0

Default = 1 (K=1)

PC[7:0] Phase compensation for channel 1. Sets a delay in voltage, relative to current. Phase is signed

and in the range of -1.0

EWA Allows the E1

and E2 pins to be configured as open-drain outputs.

0 = Normal Outputs

1 = Open-drain Outputs

IMODE, IINV Interrupt configuration. Selects INT

00 = Low Logic Level When Asserted

01 = High Logic Level When Asserted

10 = Low-going Pulse on New Interrupt

11 = High-going Pulse on New Interrupt

value 1.0 sample (OWR) intervals.

pin behavior.

iCPU Inverts the CPUCLK output.

0=Default

1 = Invert CPUCLK.

K[3:0] Clock divider. Divides MCLK by K to generate internal clock DCLK. (DCLK = MCLK/K). K is

unsigned and in the range of 1 to 16. When zero, K = 16. At reset, K = 1.

28 DS682F3

Page 29

CS5464

8.2.2 Instantaneous Current (I1, I2), Voltage (V1, V2), and Power (P1, P2)

Address: 1 (I1), 2 (V1), 3 (P2), 7 (I2), 8 (V2), 9 (P2)

MSB LSB

-(20)2-12

-2

I1 (I2) and V1 (V2) contain instantaneous current and voltage, respectively, which are multiplied to yield in-

stantaneous power,

binary point to the right of the MSB.

-3

2

-4

2

-5

2

-6

2

-7

2

.....

-17

2

-18

2

-19

2

-20

2

-21

2

-22

2

P1 (P2). These are two's complement values in the range of -1.0 value 1.0, with the

-23

2

8.2.3 Active Power (P1

Address: 4 (P1

AVG

, P2

AVG

), 10 (P2

AVG

AVG

)

)

MSB LSB

0

-(2

)2-12