Page 1

CS5462

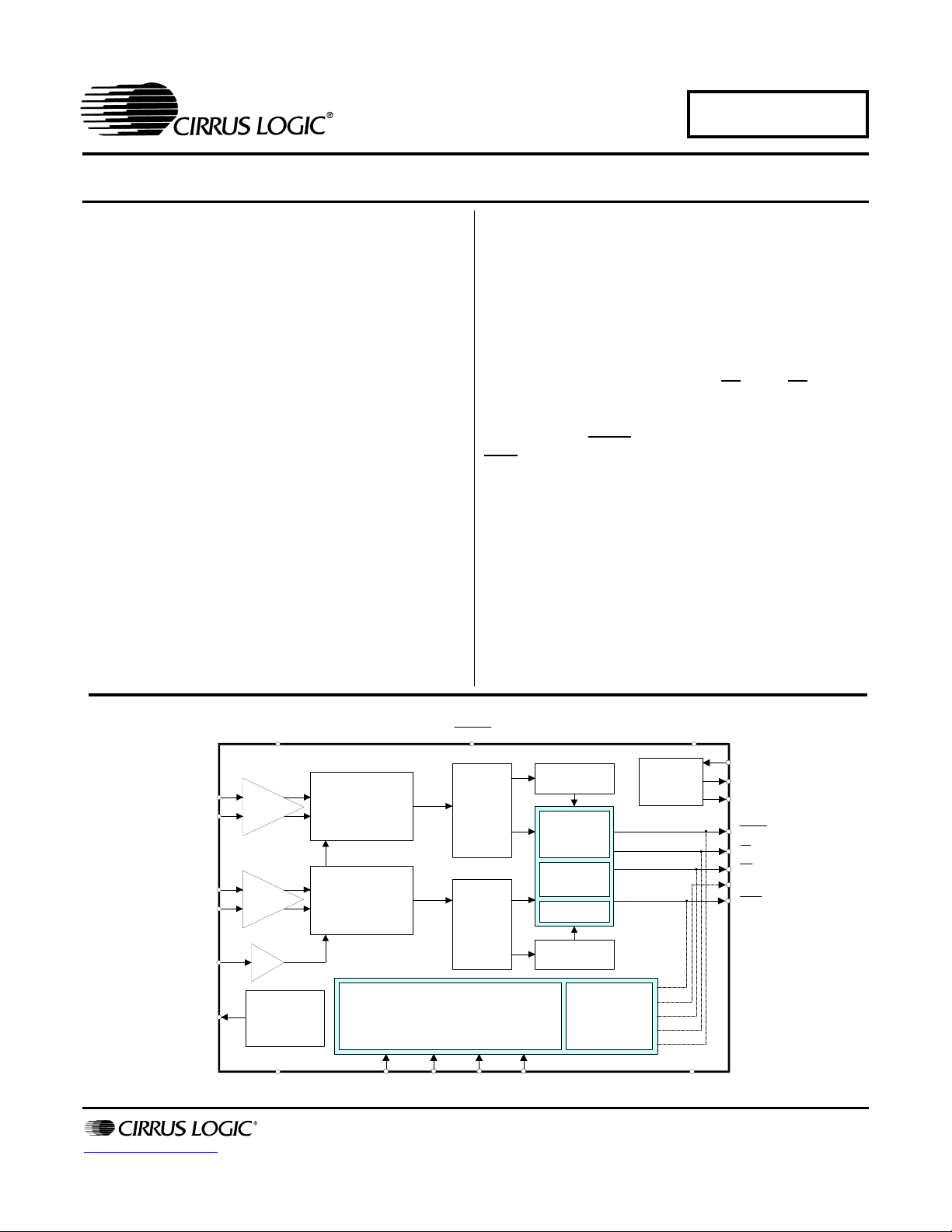

PGA

VA+

IIN+

IIN-

VIN+

VIN-

VREFIN

VREFOUT

High Pass

Filter

Voltage

Reference

x1

RESET

Digital

Filter

High Pass

Filter

x10

Energy to

Pulse Rate

Converter

4th Order

Modulator

2nd Order

Modulator

Digital

Filter

x10,x50

DGND / P1

Energy

Direction

Calibration

VD+ / P7

Configuration Inputs: On-Chip Calibration,

Pulse Output Mode / Output Frequency,

HPF Option, and

Current Channel Input Range

Clock

Generator

XOUT

CPUCLK

E2 / P4

E1 / P5

FOUT / P6

IGAIN CAL1FREQ CAL0

NEG/P2

P3

XIN

Program Select

Outputs

for

Configuration

AGND

Low-cost Power/Energy IC with Pulse Output

Features

Single-chip Power Measurement Solution

Energy Data Linearity: ±0.1% of Reading over

1000:1 Dynamic Range

On-chip functions: Measures Energy and

Performs Energy-to-Pulse Conversions

Meets Accuracy Spec for IEC 687/1036

On-chip System Calibration Option

High-pass Filter Option for Both I and V

2 Available Current Input Ranges

On-chip 2.5 V Reference (25 ppm/°C typ)

Pulse Outputs for Stepper Motor or Mechanical

Counter

On-chip Energy Direction Indicator

Ground Reference Input Signals with Single

Supply

High-frequency Output for Calibration

On-chip Power-on Reset

Power Supply Configurations:

VA+ = +5 V; AGND = 0 V; VD+ = +3.3 V to 5 V

I

Description

The CS5462 is a low-cost power meter solution

combining two analog-to-digital convertersADCs),

an energy-to-frequency converter, and energy pulse

outputs on a single chip. It is designed to accurately

measure and calculate energy for single-phase 2- or 3wire power metering applications with minimal external

components.

Low-frequency energy outputs, E1

average real power and can be used to drive a stepper

motor or a mechanical counter; the high-frequency

energy output FOUT

NEG

indicates negative power.

can be used for calibration; and

The CS5462 has configuration pins which allow for direct

configuration of pulse output format, pulse output

frequency, current channel input range, high-pass filter

option, and on-chip calibration.

The CS5462 also has a power-on reset function which

holds the part in reset until the supply reaches an

operable level.

ORDERING INFORMATION:

See page 16.

and E2, supply

http://www.cirrus.com

Copyright Cirrus Logic, Inc. 2011

(All Rights Reserved)

APR 11

DS547F1

Page 2

TABLE OF CONTENTS

1. GENERAL DESCRIPTION .......................................................................................................3

2. PIN DESCRIPTION ...................................................................................................................3

3. CHARACTERISTICS/SPECIFICATIONS ................................................................................. 5

ANALOG CHARACTERISTICS................................................................................................5

DIGITAL CHARACTERISTICS.................................................................................................7

SWITCHING CHARACTERISTICS ..........................................................................................7

ABSOLUTE MAXIMUM RATINGS ........................................................................................... 8

3.1 Theory of Operation ......................................................... .... ... ........................................... 9

3.1.1 Digital Filters ............. .... ... ... ... ....................................... ... ... .... ... ...........................9

3.1.2 Gain Calibration .................. ... ... .... ... ....................................... ... ... ... .... ... ... ... ........9

3.1.3 Energy-to-Frequency Conversion .......... .... ... ... ... .... ... ... ... ... .... ... ... ... .... .................9

4. FUNCTIONAL DESCRIPTION ...............................................................................................10

4.1 Programmable Gain Amplifier (PGA) ............................................................................... 10

4.2 Pulse-Rate Output ..................................... ... ...................................................................10

4.2.1 Stepper Motor Format. ........................................................................................10

4.2.2 Mechanical Counter Format ................................................................................ 11

4.3 Energy Direction Indicator ................................................................................................11

4.4 Internal Calibration Option ...............................................................................................11

4.5 Power-on Reset ............................ ... ... ....................................... ... ... .... ... ... ... .... ...............11

4.6 Oscillator Characteristics .................... ... .... ... ... ... .... ... ... .......................................... ... ... ...12

4.7 User Defined Settings .......................................................... ... ... ......................................12

4.8 Basic Application Circuit Configurations .......................................................................... 14

5. PACKAGE DIMENSIONS ....................................................................................................... 15

6. ORDERING INFORMATION .................................................................................................. 16

7. ENVIRONMENTAL, MANUFACTURING, & HANDLING INFORMATION ............................ 16

8. REVISIONS ............................................................................................................................. 16

CS5462

LIST OF FIGURES

Figure 1. Data Flow......................................................................................................................... 9

Figure 2. PGA Settings..................................................................................................................10

Figure 3. Pulse Output Settings ....................................................................................................10

Figure 6. Calibration Options......................................................................................................... 11

Figure 7. Power-on Reset .............................................................................................................12

Figure 8. Oscillator Connection.....................................................................................................12

Figure 9. Calibration, Frequency Select, and PGA Select ............................................................12

Figure 7. Power-on Reset .............................................................................................................13

Figure 8. Typical Connection Diagram..........................................................................................14

2 DS547F1

Page 3

CS5462

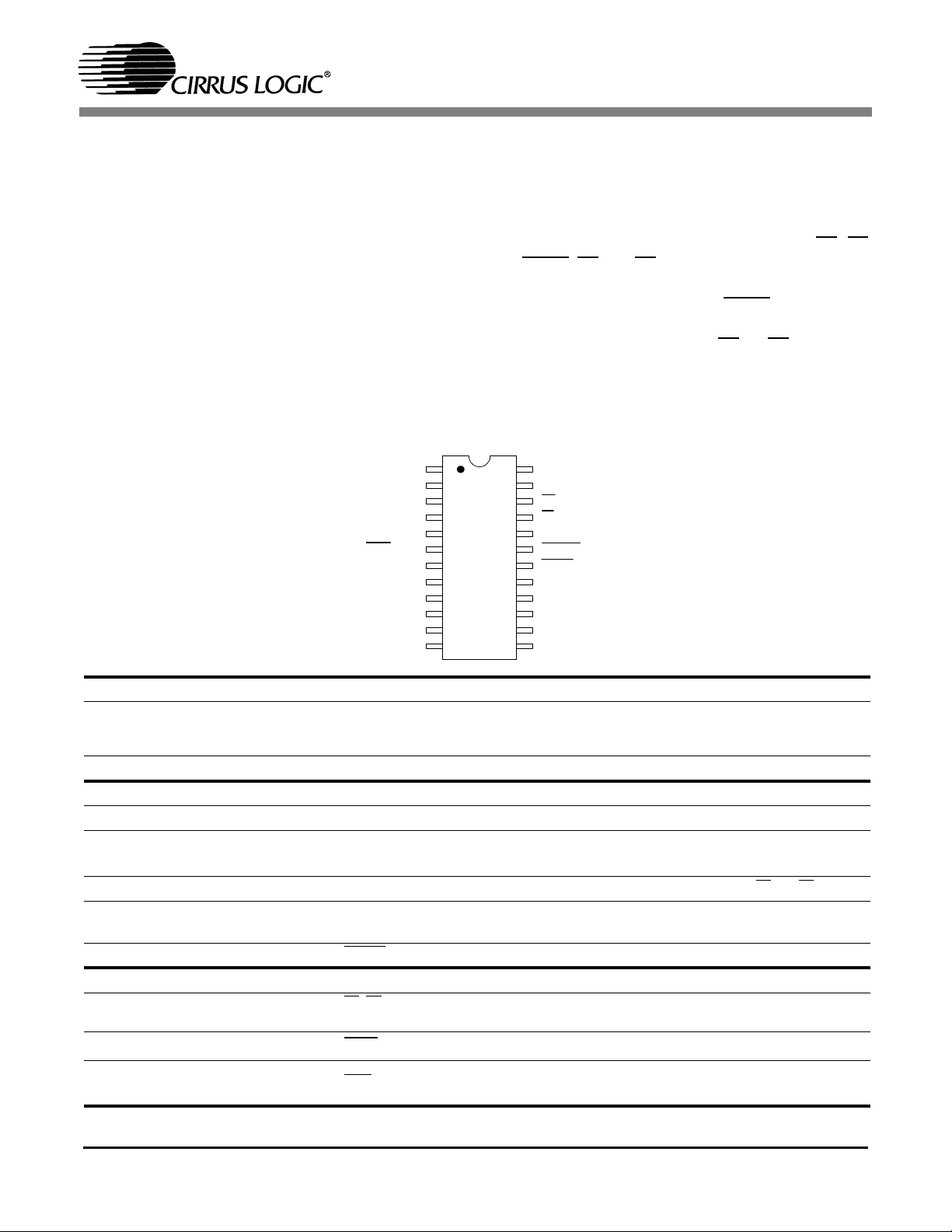

VREFIN 12Voltage Reference Input

VREFOUT 11Voltage Reference Output

VIN- 10Differenti al Voltage Input

VIN+ 9Differenti al Voltage Input

DGND 8Digital Ground

FREQ 7Frequency Select

NEG / P2 6Neg Energy Indi c ator / Prog Sel 2

CAL0 5Calibrat ion Pin 0

DGND / P1 4Digital Ground / Pr og S el 1

VD+ / P7 3Positive Power Supply / P r og Se l 7

CPUCLK 2CPU Clock Output

XOUT 1Crystal Out

AGND13 Analog Ground

VA+14 Positive Analog Supply

IIN-15 Different i al Current Input

IIN+16 Different i al Current Input

IGAIN17 Gain Select

FOUT / P618 High Frequency Output / Prog Sel 6

RESET19 Reset

P320 Program Select 3

E1 / P521 Energy Output 1 / Prog Sel 5

E2 / P422 Energy Output 2 / Prog Sel 4

CAL123 Calibr ation Pin 1

XIN24 Crystal In

1. GENERAL DESCRIPTION

The CS5462 is a CMOS monolithic power measurement device with an energy computation engine. The CS5462 combines a programmable gain

amplifier, two ADC’s, system calibration, and

energy-to-frequency conversion circuitry on a single chip.

The CS5462 is designed for energy measurement

applications and is optimized to interface to a shunt

or current transformer for current measurement,

and to a resistive divider or transformer for voltage

measurement. The current channel has a pro-

2. PIN DESCRIPTION

grammable gain amplifier (PGA) which provides

two full-scale input level options. With a single +5 V

supply on VA+/AGND, both of the CS5462’s input

channels accommodate common mode + signal

levels between (AGND - 0.25 V) and VA+.

The CS5462 has three pulse output pins: E1

, E2

and FOUT. E1 and E2 can be used to directly drive

a mechanical counter or stepper motor, or interface to a microcontroller. The FOUT

pin conveys

average real power at a pulse frequency many

times higher than that of the E1

or E2 pulse fre-

quency, allowing for high speed calibration.

Clock Generator

Crystal Out

Crystal In

CPU Clock Output 2

Control Pins

Calibration Pins 5, 23

Program

Selects

Frequency Select 7

Current Channel Gain

Select

Reset 19

Energy Pulse Outputs

Energy Output 1

High Freq Output

Negative Energy

Indicator

1,2,3,4,5,6

6

4

3

, 2

5

DS547F1 3

1,24

4,6,20,22,21,

18,3

17

21, 22

18

6

XOUT, XIN - A single stage amplifier inside the chip is connected to these pins and can be used

with a crystal to provide the system clock for the device. Alternatively, an external clock can be

supplied to the XIN pin to provide the system clock for the device.

CPUCLK - Output of on-chip oscillator which can drive one standard CMOS load.

CAL0, CAL1 - Must be tied to a program select pin for calibration.

P1, P2, P3, P4, P5, P6, P7 - Used in Calibration, Frequency Select, and Input Gain Select.

FREQ - Must be tied to a program select pin to determine the frequency of E1 and E2.

IGAIN - Must be tied to a program select pin to determine the Full-Scale Input Voltage Range of

the current channel.

RESET - Low activates Reset

E1, E2 - The energy output pin issues a fixed-width pulse train output with a rate proportional to

real energy.

FOUT - Outputs energy pulses at a maximum rate of 10 kHz. Used for calibration purposes.

NEG - Low indicates negative energy.

Page 4

Analog Inputs/Outputs

Differential

9,10

Voltage Inputs

Voltage

11

Reference Output

Voltage

12

Reference Input

Differential

16,15

Current Inputs

Power Supply Connections

Positive

Digital Supply

Digital Ground 4*

Analog Ground 13

Positive

14

Analog Supply

CS5462

VIN+, VIN- - Differential analog input pins for voltage channel.

VREFOUT - The on-chip voltage reference is output from this pin. The voltage reference has a

nominal magnitude of 2.5 V and is referenced to the AGND pin on the converter.

VREFIN - The voltage input to this pin establishes the voltage reference for the on-chip modula-

tor.

IIN+, IIN- - Differential analog input pins for current channel.

3

VD+ - The positive digital supply.

DGND - Digital Ground

AGND - Analog Ground

VA+ - The positive analog supply.

Notes: 1 Pin number 4 is described as Digital Ground (DGND) and also P1

2

Pin number 3 is described as Positive Power Supply (VD+) and also P7

3

Pin number 22 is described as Energy Output 2 (E2) and also P4

4

Pin number 21 is described as Energy Output 1 (E1) and also P5

5

Pin number 18 is described as High Frequency Output (FOUT) and also P6

6

Pin number 6 is described as Negative Energy Indicator (NEG) and also P2

4 DS547F1

Page 5

CS5462

3. CHARACTERISTICS/SPECIFICATIONS

• Min / Max characteristics and specifications are

guaranteed over all Operating Conditions.

• Typical characteristics and specificat ions are measured at nominal supply voltages and T

= 25 °C.

A

ANALOG CHARACTERISTICS

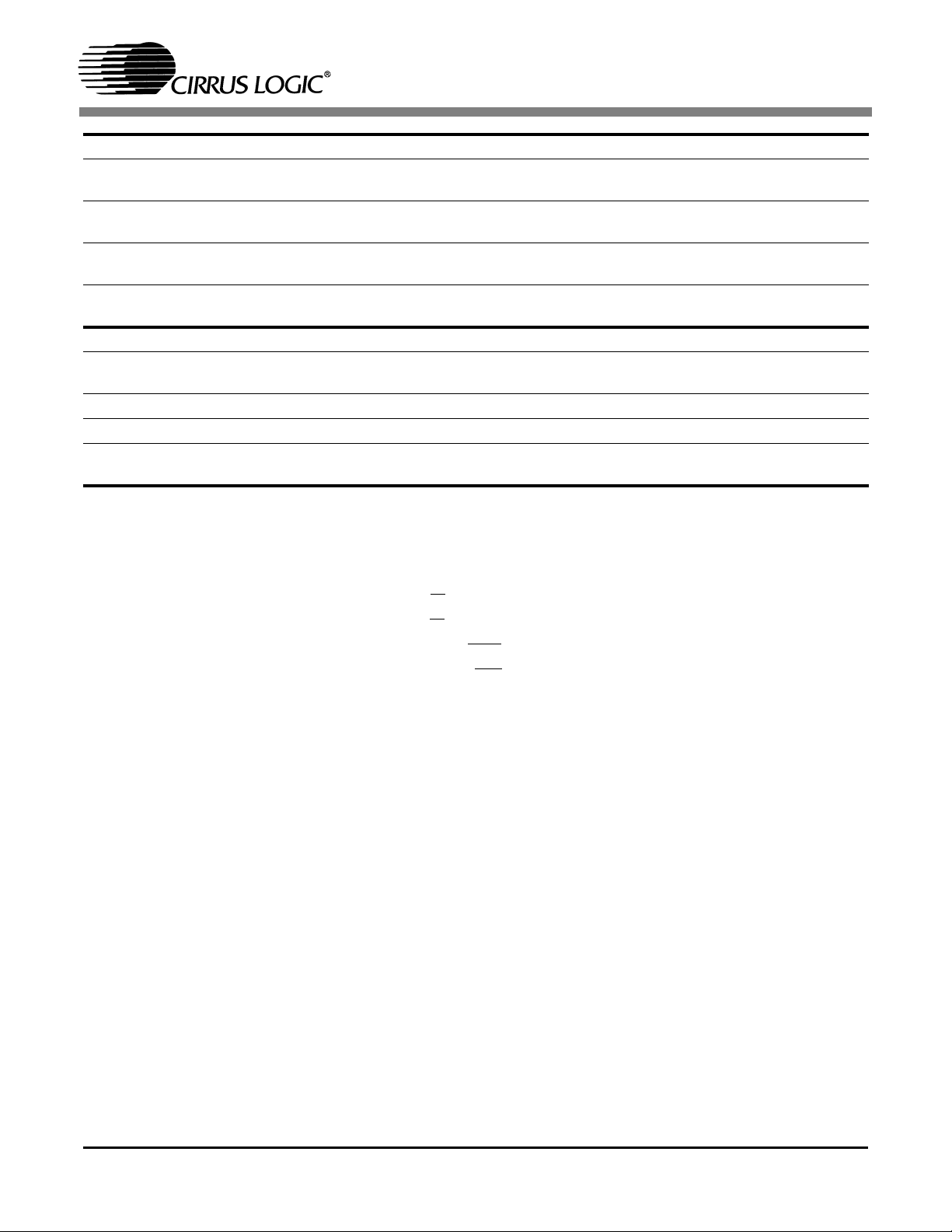

Parameter Symbol Min Typ Max Unit

Analog Inputs (Current Channel)

Maximum Differential Input Voltage Range (Gain = 10)

{(I

IN+)-(IIN-)} (Gain = 50)

Input Capacitance (All Gain Ranges) CinI -25-pF

Effective Input Impedance (All Gain Ranges)(Note 2) Z

Analog Inputs (Voltage Channel)

Maximum Differential Input Voltage Range {(V

Input Capacitance CinV -0.2-pF

Effective Input Impedance (Note 2) Z

Accuracy (Energy Outputs)

Offset Error VOS - .01 - %F.S.

Full-Scale Error (Note 1) FSE - .1 - %F.S.

IN+)-(VIN-)} VIN --500mV

• AGND = DGND = 0 V. All voltages with respect to

0V.

• CAL0 and CAL1 are connected to P4 unless otherwise noted.

IN -

I

-

inI 30 - - k

inV 5--M

-

-

500

100

mV

mV

P-P

P-P

P-P

Notes: 1. Applies After System Calibration

2. VA+ = VD+ = 5 V ±10 %; MCLK = 4.096 MHz

DS547F1 5

Page 6

CS5462

PSRR 20

0.150V

V

eq

----------------- -

log=

(VREFOUTMAX - VREFOUTMIN)

VREFOUT

AVG

(

(

1

T

A

MAX

- T

A

MIN

(

(

1.0 x 10

(

(

6

TC

VREF

=

ANALOG CHARACTERISTICS (Continued)

Parameter Symbol Min Typ Max Unit

Dynamic Characteristics

High Pass Filter Pole Frequency -3 dB - 0.5 - Hz

Power Supplies

Power Supply Currents I

I

(VD+ = 5 V)

D+

(VD+ = 3.3 V)

I

D+

Power Consumption (VD+ = 5 V)

(Note 3) (VD+ = 3.3 V)

Power Supply Rejection Ratio (50, 60 Hz)

(Note 4) Voltage Channel (Gain = 10)

Current Channel (Gain = 10)

(Gain = 50)

Notes: 3. All outputs unloaded. All inputs CMOS level.

Definition for PSRR: VREFIN tied to VREFOUT, VA+ = VD+ = 5 V, a 150 mV zero-to-peak sine wave (frequency

4.

= 60 Hz) is imposed onto the +5 V supply voltage at VA+ and VD+ pins. The “+” and “-” input pins of both input

channels are shorted to VA-. Then the CS5462 is put into an internal test mode and digital output data is collected

for the channel under test. The zero-peak value of the digital sinusoidal output signal is determined, and this value

is converted into the zero-peak value of the sinusoidal voltage that would need to be applied at the channel’s inputs,

in order to cause the same digital sinusoidal output. This voltage is then defined as Veq. PSRR is then (in dB):

A+

PSCA

PSCD

PSCD

PC -

PSRR

PSRR

PSRR

48

75

56

-

-

-

-

1.3

2.9

1.7

21

11.6

-

-

-

-

25

-

-

-

-

-

-

-

-

mA

mA

mA

mW

mW

dB

dB

dB

VREFOUT REFERENCE OUTPUT VOLTAGE

Parameter Symbol Min Typ Max Unit

Reference Output

Output Voltage REFOUT +2.4 +2.6 V

VREFOUT Temperature Coefficient TC

Load Regulation (Output Current 1 A Source or Sink) V

Reference Input

Input Voltage Range VREFIN +2.4 +2.5 +2.6 V

Input Capacitance - 4 - pF

Input CVF Current - 25 - nA

Notes: 5. The voltage at VREFOUT is measured across the temperature range. From these measurements the

following formula is used to calculate the VREFOUT Temperature Coefficient:.

VREF 25 60 ppm/°C

R

610mV

6 DS547F1

Page 7

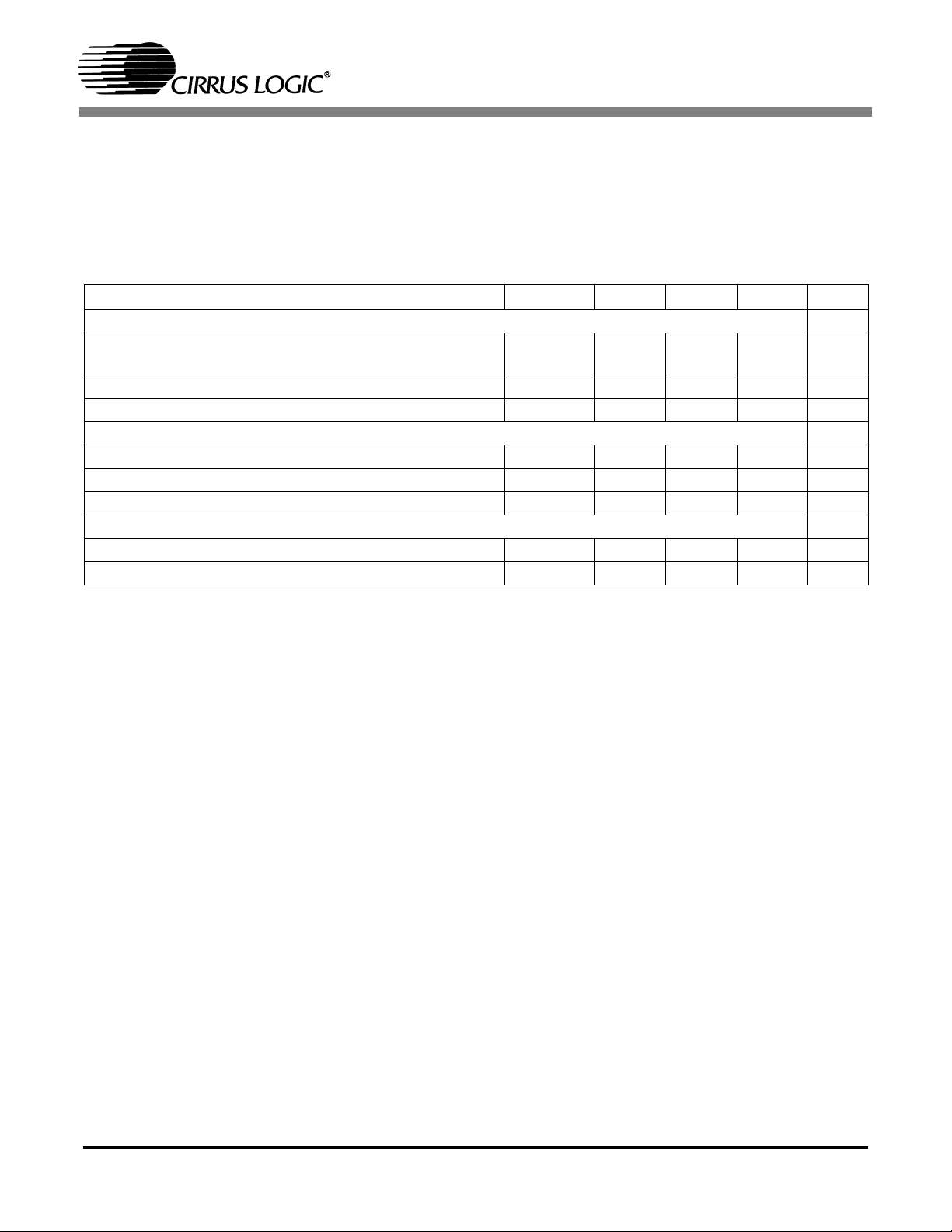

DIGITAL CHARACTERISTICS (Note 6)

Parameter Symbol Min Typ Max Unit

High-Level Input Voltage

XIN

RESET

Low-Level Input Voltage (VD = 5 V)

XIN

RESET

Low-Level Input Voltage (VD = 3.3 V)

XIN

RESET

High-Level Output Voltage (except XOUT) I

Low-Level Output Voltage (except XOUT) I

Input Leakage Current I

Digital Output Pin Capacitance C

Drive Current FOUT

, E1, E2, NEG, CPUCLK 90 mA

Notes: 6. All measurements performed under static conditions.

= +5 mA V

out

= -5 mA V

out

CS5462

V

IH

V

IL

V

IL

OH

OL

in

out

(VD+) - 0.5

0.8VD+

-

-

-

-

-

-

-

-

-

-

-

-

1.5

0.2VD+

0.3

0.2VD+

(VD+) - 1.0 - - V

--0.4V

-±1±10µA

-5-pF

V

V

V

V

V

V

SWITCHING CHARACTERISTICS

Parameter Symbol Min Typ Max Unit

Master Clock Frequency Internal Gate Oscillator MCLK 3 4.096 5 MHz

Master Clock Duty Cycle 40 - 60 %

CPUCLK Duty Cycle (Note 7) 40 60 %

Rise Times Any Digital Input

(Note 8) Any Digital Output

Fall Times Any Digital Input

(Note 8) Any Digital Output

Start-up

Oscillator Start-Up Time XTAL = 4.096 MHz (Note 9) t

7. If external MCLK is used, then the duty cycle must be between 45% and 55% to maintain this

specification.

8. Specified using 10% and 90% points on wave-form of interest. Output loaded with 50 pF.

9. Oscillator start-up time varies with crystal parameters. This specification does not apply when using an

external clock source.

t

t

rise

fall

ost

-

-

-

-

50

50

-

-

1.0

-

1.0

-

µs

ns

µs

ns

-60-ms

DS547F1 7

Page 8

ABSOLUTE MAXIMUM RATINGS

WARNING: Operation at or beyond these limits may result in permanent damage to the device.

Normal operation is not guaranteed at these extremes.

Parameter Symbol Min Typ Max Unit

DC Power Supplies (Notes 10, 10 and 12)

Positive Digital

Positive Analog

Input Current, Any Pin Except Supplies (Notes 13, 14, 15) I

Power Dissipation (Note 16) P

Analog Input Voltage All Analog Pins V

Digital Input Voltage All Digital Pins V

Ambient Operating Temperature T

Storage Temperature T

10. VA+ and AGND must satisfy {(VA+) - (AGND)} + 6.0 V.

11. VD+ and AGND must satisfy {(VD+) - (AGND)}

12. VA+ and VD+ can differ by as much as 200 mV, as long as VA+ > VD+.

13. Applies to all pins including continuous over-voltage conditions at the analog input pins.

14. Transient current of up to 100 mA will not cause SCR latch-up.

15. Maximum DC input current for a power supply pin is ±50 mA.

16. Total power dissipation, including all input currents and output currents.

VD+

VA+

IN

D --500mW

INA

IND

A

stg

+ 6.0 V.

-0.3

-0.3

-

-

--±10mA

- 0.3 - (VA+) + 0.3 V

-0.3 - (VD+) + 0.3 V

-40 - 85 °C

-65 - 150 °C

CS5462

+6.0

+6.0

V

V

8 DS547F1

Page 9

CS5462

x

VIN±

IIN±

PGA Gain Select

HPF Select

Freq Select

Energy to

Pulse Rate

Converter

E1

E2

FOUT

Calibration

Digital

Filters

Digital

Filters

4th Order

Modulator

2nd Order

Modulator

PGA

10x

x

On-Chip

Configuration

Output Mode Select

HPF

HPF

Figure 1. Data Flow

3.1 Theory of Operation

A computational flow diagram for the two data

paths is shown in Figure 1. The analog waveforms

at the voltage/current channel inputs are subject to

the gains of the input PGAs.

3.1.1 Digital Filters

The modulators convert the analog input voltages

on the I and V channels to a digital bitstream; which

is then filtered by the digital filter section. The digital filter is composed of low pass sinc

3

and IIR filters. The IIR filters are used to compensate for the

magnitude roll-off of the low pass filter section.

Both channels provide a high-pass filter option

which can be engaged into the signal path to remove the DC content from the current/voltage signal

before the energy calculations are made.

3.1.2 Gain Calibration

After being filtered, the instantaneous voltage and

current digital codes are used to calculate real av-

erage power. This power is then adjusted based on

the internal calibration setting defined at startup.

Calibrating the CS5462 is done by externally connecting the configuration input pins, CAL1 and

CAL0, to the program select output pins, P1 - P7,

in a particular sequence. These connections will internally compensate for small gain errors.

3.1.3 Energy-to-F requency Conversion

The calibrated energy value is then converted into

a pulse output stream with a average frequency

proportional to the measured energy. Pulse output

pins E1

directly drive a stepper motor or a mechanical

counter or interface a microcontroller or infrared

LED. The FOUT

quency of 10 kHz. With full scale inputs on both the

current and voltage channels FOUT

pulses with an average frequency of 10 kHz.

and E2 can be set to lower frequencies to

pulse output pin is set to max fre-

will output

DS547F1 9

Page 10

CS5462

IGAIN

500mV

P-P

10xP1

P2

P3

P4

P5

100mV

P-P

50x

500mV

P-P

10x

100mV

P-P

50x

P6

P7

500mV

P-P

10x

100mV

P-P

50x

500mV

P-P

10x

no hpf

no hpf

hpf both

hpf both

hpf Ich

hpf Ich

hpf Vch

Figure 2. PGA Settings

FREQ

0.25 Hz / StepP1

P2

P3

P4

P5

0.5 Hz / Step

1 Hz / Step

2 Hz / Step

4 Hz / Step

P6P72 Hz / mech cnt

16 Hz / mech cnt

Figure 3. Pulse Output Settings

0.25 Hz 0.5 Hz

250 ms 250 msPulse Width

Frequency

P1 P2

FREQ

connected to:

1 Hz 2 Hz

250 ms 250 ms

P3 P4

4 Hz

125 ms

P5

E1

pulse width

E2

4. FUNCTIONAL DESCRIPTION

4.1 Programmable Gain Amplifier (PGA)

The CS5462 is equipped with a PGA on the current

channel. While the voltage channel is always set to

a 10x differential input voltage range (500 mV

the current channel can be set to one of two different input ranges. The maximum differential voltage

range on the current channel can be set to 10x

(500 mV

The gain setting of the current channel’s PGA and

also the high pass filter option are selected by connecting the IGAIN pin to one of seven Program Select output pins. For all applications the IGAIN pin

must be tied to one and only one Program Select

pins. Figure 2 below shows the different options

that can be selected at startup. These seven differ-

ent options allow the CS5462’s PGA to be set up in

either 10x or 50x mode and enable or disable the

high pass filters in either of the voltage or the current channels.

During Startup the CS5462 will scan the IGAIN input pin and determine which Program Select output it is connected to and then set the PGA and

HPF’s accordingly.

4.2 Pulse-Rate Output

E1 and E2 pins provide a simple interface from

which signed energy can be accumulated. E1

E2

chanical counter mode. The connectivity of the

FREQ pin determines the pulse output mode and

10 DS547F1

P-P

) and 50x (100 mV

P-P

P-P

).

and

can be set to either stepper motor mode or me-

also the maximum frequency for E1

3 below describes the options for E1

and E2. Figure

and E2.

),

For all applications FREQ must be connected to

one and only one of the Program Selects outputs

(P1 - P7). The frequency setting chosen using the

above table is equal to the set pulse rate frequency

if and only if a full-scale signal is applied to each

channel. As the input signal decreases the pulse

rate and pulse width will decrease by a percentage

equal to the product of the percentages of fullscale inputs across each channel. For example, if

if FREQ is connected to P5, the maximum pulse

output rate is 4 Hz. Assuming 500 mV is selected

as full scale on each channel, 400 mV is measured

on current and voltage channels. 400 mV is 80% of

full scale. Since power is the product of current and

voltage the pulse outputs will be 80% * 80% = 64%

of full scale. Since 4 Hz is the set full scale output

rate, pulses should appear on E1

and E2 at a

64% * 4 Hz = 2.56 Hz rate.

4.2.1 Stepper Motor Format.

In stepper motor mode the CS5462 produces alternating pulses on E1

designed to directly drive a stepper motor. Each

pin produces active-low pulses with frequency dependent pulse widths. The figure below shows the

frequency and corresponding pulse width for each

option.

and E2. This pulse format is

Page 11

pulse width

E1

pulse width

Positive Energy Negative Energy

E2

2 Hz 16 Hz

125 ms 15 msPulse Width

Frequency

P6 P7

FREQ

connected to:

CAL1

+4.2%P1

P2

P4

P6

P7

+2.8%

0%

-2.8%

-4.2%

CAL0

+0.6%

+0.4%

0%

-0.4%

-0.6%

P3

P5

+1.4%

-1.4%

+0.2%

-0.2%

Figure 6. Calibration Options

CS5462

4.2.2 Mechanical Counter Format

In mechanical counter mode, the CS5462 produces pulses on E1

a bi-directional mechanical counter. Each pin produces active-low pulses which have pulse widths

of 125 ms or 15 ms, depending on the frequency

selected. In the figure below, the frequency and

corresponding pulse width is shown for each option available. In this mode when energy is positive, the pulses appear on E1

negative, pulses appear on E2

4.3 Energy Direction Indicator

For either pulse output mode, the NEG pin can be

used to indicate the direction of the energy calculated. The NEG

of the converter. If negative energy is detected the

NEG

pin will become active low and will remain ac-

tive low until positive energy is detected.

4.4 Internal Calibration Option

For most power meter applications the standard

accuracy requirements require the meter be calibrated to within a certain percentage. Calibrating a

CS5462 meter can be done a number of ways.

One calibration method is to externally adjust the

front-end input circuit by using a potentiometer or

resistor network. By adjusting the amount of gain in

the resistor divider on the front end the energy outputs can be adjusted to fit the accuracy required.

Although this method is available, it may be costly

to add the additional components and the accuracy

required is often difficult to achieve. As an alternative the CS5462 is designed to allow the user to

calibrate the part without the need for external potentiometers or resistor networks. The CS5462

provides a digital on-chip calibration solution. This

digital alternative can calibrate energy registration

error to within 0.1% without any analog adjustments.

DS547F1 11

and E2 which can be used to drive

; when energy is

.

pin is updated at the sample rate

This calibration is accomplished by connecting

each Configuration Input pin, CAL1 and CAL0, to

one of the Program Select Output pins, P1 - P7. At

startup the CS5462 will scan the CAL1 and CAL0

pins to discern what connections are made, and

then calibrate the gain accordingly.

CAL1 and CAL0 each have seven options which

allows for 49 different steps of 0.2% between

+4.8% and -4.8% of expected energy output. Before startup, CAL1 and CAL0 must each be connected to only one of the program select pins.

To Calibrate the CS5462:

1. Connect CAL1 and CAL0 to P4. This connection

will adjust the energy outputs by 0%.

2. Apply known current and voltage signals to the

inputs of the CS5462.

3. Measure the average pulse output frequency of

FOUT

, E1, or E2.

4. The average frequency will be within some percentage of the expected frequency. Depending on

the output of the uncalibrated chip, the CAL0 and

CAL1 pins can be adjusted using the above options

(see “User Defined Settings” on page 12 for more

on calibration).

4.5 Power-on Reset

The CS5462 is equipped with internal circuitry that

will put the chip into reset if power supply is lost.

This is particularly useful in black-out or brown-out

situations in which the power supply temporarily interrupted. The CS5462 will enter into reset if the

power drops below 2.5 V. The chip will remain in

reset until the supply rises to 4 V (See Figure 6) at

Page 12

CS5462

Reset Reset

Normal

Operation

5 V

4 V

2.5 V

1 V

0 V

Time

Supply

Voltage

Figure 7. Power-on Reset

Oscillator

Circuit

DGND

XIN

XOUT

C1

C1 = 22 pF

C2

C2 =

Figure 8. Oscillator Connection

P1

P2

P3

P4

P5

P6

P7

10x

50x

10x

50x

50x

10x

10x

CAL1 CAL0

0.25 Hz (stp)

FREQ

+4.2%

+2.8%

+1.4

0

-1.4%

-2.8%

-4.2%

IGAIN

+0.6%

+0.4%

+0.2%

0

-0.2%

-0.4%

-0.6%

0.5 Hz (stp)

1 Hz (stp)

2 Hz (stp)

4 Hz (stp)

4 Hz (mc)

16 Hz (mc)

500mV

100mV

500mV

100mV

100mV

500mV

500mV

no hpf

no hpf

hpf both

hpf both

hpf Ich

hpf Vch

hpf Ich

Figure 9. Calibration, Frequency Select, and

PGA Select

which time the CS5462 will configure itself and resume normal operation.

4.6 Oscillator Characteristics

XIN and XOUT are the input and output of an inverting amplifier which can provide oscillation and

can be configured as an on-chip oscillator, as

shown in Figure 8. The oscillator circuit is designed

to work with a quartz crystal or a ceramic resonator. To reduce circuit cost, two load capacitors C1

and C2 are integrated in the device, one between

XIN and DGND, one between XOUT and DGND.

Lead lengths should be minimized to reduce stray

capacitance. To drive the device from an external

clock source, XOUT should be left unconnected

while XIN is driven by the external circuitry. There

is an amplifier between XIN and the digital section

which provides CMOS level signals. This amplifier

works with sinusoidal inputs so there are no problems with slow edge times.

12 DS547F1

4.7 User Defined Settings EXAMPLE: Design a hybrid stepper motor meter

with an 2 Hz maximum pulse output frequency on

the E1

puts of the current and voltage channels and the

high pass filter enabled on the current channel only. Using the figure below these settings can be selected with two connections.

By directly connecting FREQ with P4 and IGAIN

with P5 the CS5462 is configured to drive a stepper motor with a maximum pulse output rate of

2 Hz, to support an input range of 500 mV

to remove all DC content on the current signals by

enabling the HPFs on the Ich. The CS5462 is now

ready for calibration.

Before applying power to the chip, connect the

CAL0 and CAL1 pins to P4. This will select

0% + 0% = 0% gain adjustment. After making this

connection the CS5462 is ready to be calibrated.

Once power is applied the CS5462 will begin a

startup sequence in which it will scan the FREQ,

IGAIN, CAL0, and CAL1 pins. After determining

which connections are made the FREQ, IGAIN,

CAL0, and CAL1 pins will become high impedance

inputs and the part will begin normal operation and

start converting. If on-chip calibration is required

place known voltages across the inputs on IIN±

and VIN±.

For example, 150 mV

used for both the current and voltage inputs.

424.26 mV

scale input of both the current and voltage channels. With this input on both channels the expected

pulse output frequency is

84.853% * 84.853% = 72% of full scale. This

, E2 pins with 500 mV

= ~424.26 mV

RMS

is ~84.853% of the maximum full

P-P

signal on the in-

P-P

P-P

P-P

, and

will be

Page 13

CS5462

P3

+4.4%

+3.0%

+1.6%

+0.2%

-4.0%

-2.6%

-1.2%

+4.8%

P1

P2

P3

P4

P5

P6

P7

P1 P2 P4 P5 P6 P7

+4.6%

+3.4% +3.2%

+2.0% +1.8%

+0.0%

+0.6% +0.4%

+4.2% +4.0% +3.8%

+2.8% +2.6% +2.4%

+1.4% +1.2% +1.0%

+3.6%

+2.2%

+0.8%

CA L0 connected to:

CAL1

connected

to:

-4.8%-4.6%-4.4 %

-3.4%-3.2%-3.0 %

-2.0%

-1.8%-1.6%

-0.6%

-0.4%

-0.2%

-4.2%-3.8%

-2.8%

-2.4%

-1.4%

-1.0%

-3.6%

-2.2%

-0.8%

Figure 7. Power-on Reset

means that E1 and E2 should have an average

pulse output frequency of 2 Hz * 72% = 1.44 Hz

and FOUT

should have an average pulse output

frequency of 10 kHz * 72% = 7.2 kHz. Assuming

that FOUT

error will be the same for E1

is used for calibration (although the gain

and E2), FOUT should

be measured to find the gain error. Suppose the

measured pulse output frequency is 6.966 kHz instead of 7.2 kHz. 6.996 kHz is 96.76% of 7.2 kHz.

This means that the gain error is 96.76% 100% = -3.24%. This error can be calibrated out by

connecting CAL1 to P2 and CAL0 to P2 (see Fig-

ure 7 for all connection options). This will adjust the

pulse rate frequency by 2.8% + 0.4% = 3.2%

(since the smallest calibration step size is 0.2%,

3.2% is the closest value that can offset the error

of -3.24). After these connections are made the average pulse output frequency of FOUT

, E1, and E2

will have a gain error less than or equal to -0.04%

of full scale.

DS547F1 13

Page 14

CS5462

Jumpers

for

Calibration,

Freq Select

and

Gain Select

Mechanical

Counter

DGND / P1

EDIR / P4

VD+ / P7

NEG / P2

P3

CAL0

CAL1

FREQ

IGAIN

EOUT

FOUT / P6

XOUT

XIN

CPUCLK

DGNDVA-

VREFOUT

VREFIN

IIN+

IIN-

VIN-

VIN+

AGND

3

15

14

9

10

16

12

11

13 8

2

24

1

18

21

22

17

7

5

23

20

6

4

120 VAC

nV

F F F

R

SHUNT

F

R

1

R

2

NL

AGND

VA+

E2 / P4

E1 / P5

R

I+

R

I-

R

V-

C

Idiff

C

Vdiff

C

V-

C

V+

C

I+

C

I-

Stepper

Motor

or

Figure 8. Typical Connection Diagram

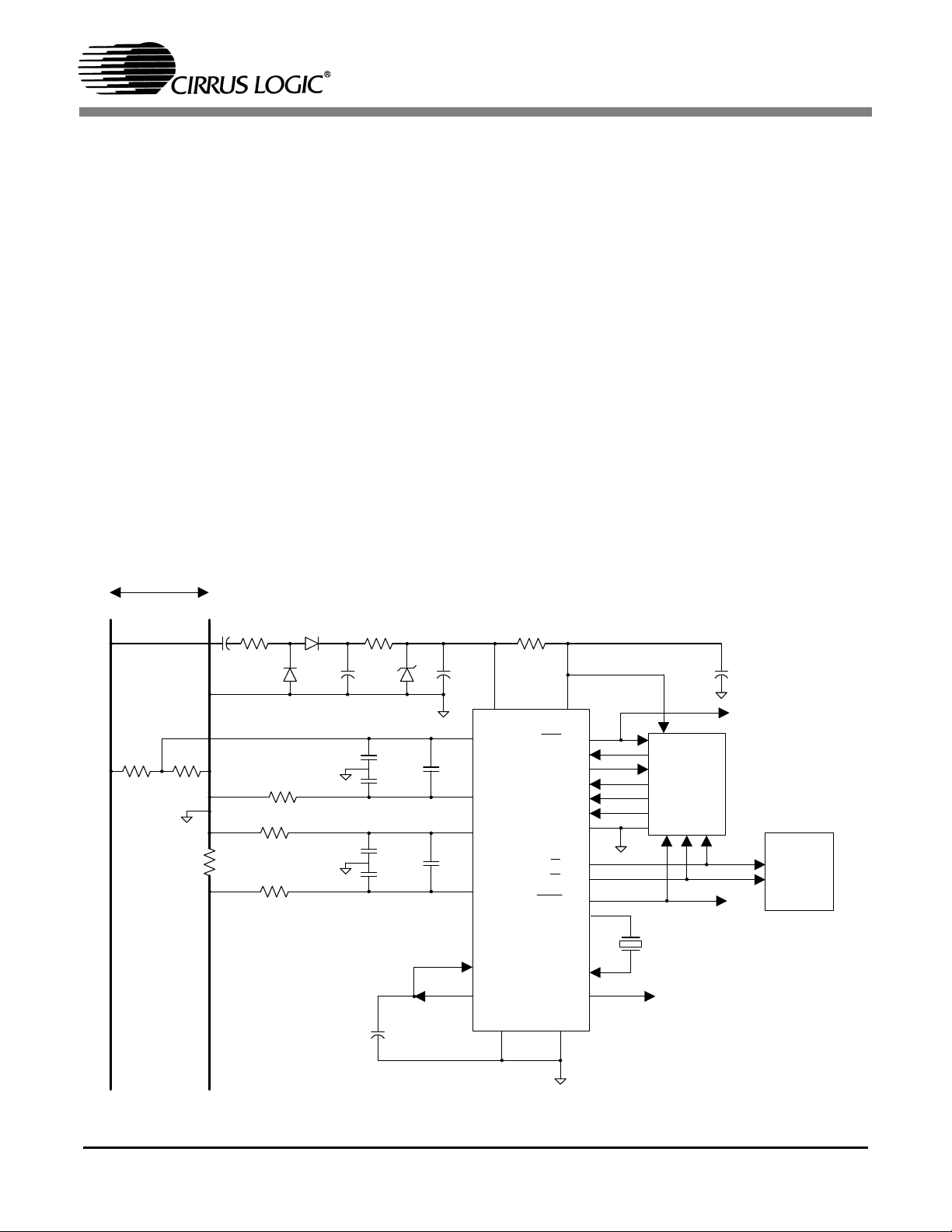

4.8 Basic Application Circuit Configurations

Figure 9 shows the CS5462 configured to measure

power in a single-phase 2-wire system while operating in a single supply configuration. In this diagram, the shunt resistor used to monitor the line

current is connected on the “Line” (hot) side of the

power mains. In most residential power metering

applications, the power meter’s current-sense

shunt resistor is intentionally placed on the hot side

of the power mains in order to detect a subscriber’s

attempt to steal power. In this type of shunt-resistor

configuration, the common-mode level of the

CS5462 must be referenced to the hot side of the

power line. This means that the common-mode potential of the CS5462 will typically oscillate to very

high voltage levels, as well as very low voltage levels, with respect to earth ground potential.

14 DS547F1

Page 15

5. PACKAGE DIMENSIONS

24L SSOP PACKAGE DRAWING

E

N

1

23

e

b

2

A1

A2

A

D

SEATING

PLANE

E1

1

L

SIDE VIEW

END VIEW

TOP VIEW

INCHES MILLIMETERS NOTE

DIM MIN NOM MAX MIN NOM MAX

A -- -- 0.084 -- -- 2.13

A1 0.002 0.006 0.010 0.05 0.13 0.25

A2 0.064 0.068 0.074 1.62 1.73 1.88

b 0.009 -- 0.015 0.22 -- 0.38 2,3

D 0.311 0.323 0.335 7.90 8.20 8.50 1

E 0.291 0.307 0.323 7.40 7.80 8.20

E1 0.197 0.209 0.220 5.00 5.30 5.60 1

e 0.022 0.026 0.030 0.55 0.65 0.75

L 0.025 0.03 0.041 0.63 0.75 1.03

0° 4° 8° 0° 4° 8°

CS5462

JEDEC #: MO-150

Controlling Dimension is Millimeters.

Notes: 1. “D” and “E1” are reference datums and do not included mold flash or protrusions, but do include mold

mismatch and are measured at the parting line, mold flash or protrusions shall not exceed 0.20 mm per

side.

2. Dimension “b” does not include dambar protrusion/intrusion. Allowable dambar protrusion shall be

0.13 mm total in excess of “b” dimension at maximum material condition. Dambar intrusion shall not

reduce dimension “b” by more than 0.07 mm at least material condition.

3. These dimensions apply to the flat section of the lead between 0.10 and 0.25 mm from lead tips.

DS547F1 15

Page 16

CS5462

Contacting Cirrus Logic Support

For all product questions and inquiries contact a Cirrus Logic Sales Representative.

To find the one nearest to you go to www.cirrus.com

IMPORTANT NOTICE

Cirrus Logic, Inc. and it s su bsi di ari e s ( “Ci rr us ”) bel i eve t hat the in for mat i on c ont ai ned i n t his doc ument i s acc ur at e and re l i abl e . Howe v er, th e in fo rmation is subject

to change without not ice and is provi ded “AS IS” wit hout warr anty of any kind (express or implied). Customers are advised to obtain the latest version of relevant

information to verify, before placing orde rs, that in forma tion bei ng rel ied on is curren t and com ple te. All prod ucts are so ld su bject to the terms and cond itions of sale

supplied at the time of order acknowledgment, including those pertaining to warranty, indemnification, and limitation of liability. No responsibility is assu med by Cirrus

for the use of this information, including use of this informa tion as the basis for m anufactur e or sale of any items, or for infringe ment of patents or oth er rights of third

parties. This document is the property of Cirrus and by furnishing this information, Cirru s gr an ts no license, express or implied under an y pa ten ts, m ask wor k r ights,

copyrights, trademarks, trade secrets or other intell ectual proper ty rights. Cirrus owns the cop yrights associated with the inform ation conta ined here in and g ives consent for copies to be made of the information only for use within your organization with respect to Cirrus integrated circuits or other products of Cirrus. This consent

does not extend to other copying such as copying for ge ne ral distribution, advertising or promotional purposes, or for creating any work for resale.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL APPLICATIONS”). CIRRUS PRODUCTS ARE NOT DESIGNED, AUTHORIZED OR WARR ANTED FOR USE

IN PRODUCTS SURGICALLY IMPLANTED INTO THE BODY, AUTOMOTIVE SAFETY OR SECURITY DEVICES, LIFE SUPPORT PRODUCTS OR OTHER CRITICAL APPLICATIONS. INCLUSION OF CIRRUS PRODUCTS IN SUCH APPLICATIONS IS UNDERSTOOD TO BE FULLY AT THE CUSTOMER'S RISK AND CIRRUS DISCLAIMS AND MAKES NO WARRANTY, EXPRESS, STATUTORY OR IMPLIED, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR PARTICULAR PURPOSE, WITH REGARD TO ANY CIRRUS PRODUCT THAT IS USED IN SUCH A MANNER. IF THE CUSTOMER OR CUSTOMER'S CUSTOMER USES OR PERMITS THE USE OF CIRRUS PRODUCTS IN CRITICAL APPLICATIONS, CUSTOMER AGREES, BY SUCH USE, TO FULLY

INDEMNIFY CIRRUS, ITS OFFICERS, DIRECTORS, EMPLOYEES, DISTRIBUTORS AND OTHER AGENTS FROM ANY AND ALL LI ABI LITY, INCLUDI NG ATTORNEYS' FEES AND COSTS, THAT MAY RESULT FROM OR ARISE IN CONNECTION WITH THESE USES.

Cirrus Logic, Cirrus, and the Cirrus Logic logo designs are trademarks of Cirrus Logic, Inc. All other br and and product names in this document may be trademarks

or service marks of their respective owners.

6. ORDERING INFORMATION

Model Temperature Package

CS5462-ISZ (lead free) -40 to +85 °C 24-pin SSOP

7. ENVIRONMENTAL, MANUFACTURING, & HANDLING INFORMATION

Model Number Peak Reflow Temp MSL Rating* Max Floor Life

CS5462-ISZ (lead free) 260 °C 3 7 Days

* MSL (Moisture Sensitivity Level) as specified by IPC/JEDEC J-STD-020.

8. REVISIONS

Revision Date Changes

A1 MAR 2003 Initial Release

PP1 OCT 2003 Initial release for Preliminary Product Information

F1 APR 2011 Removed lead-containing (Pb) device ordering information. Added MSL data.

16 DS547F1

Loading...

Loading...