Page 1

Features

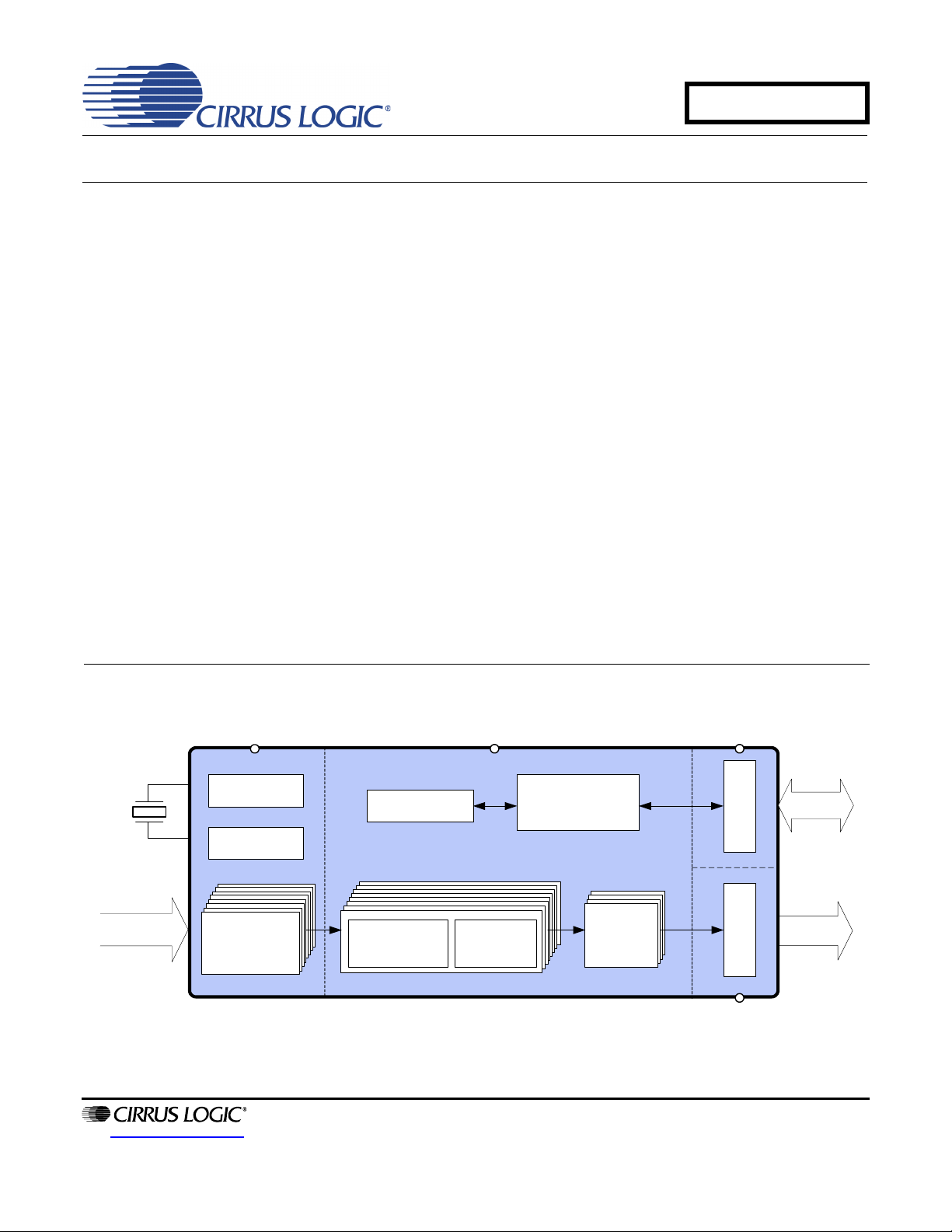

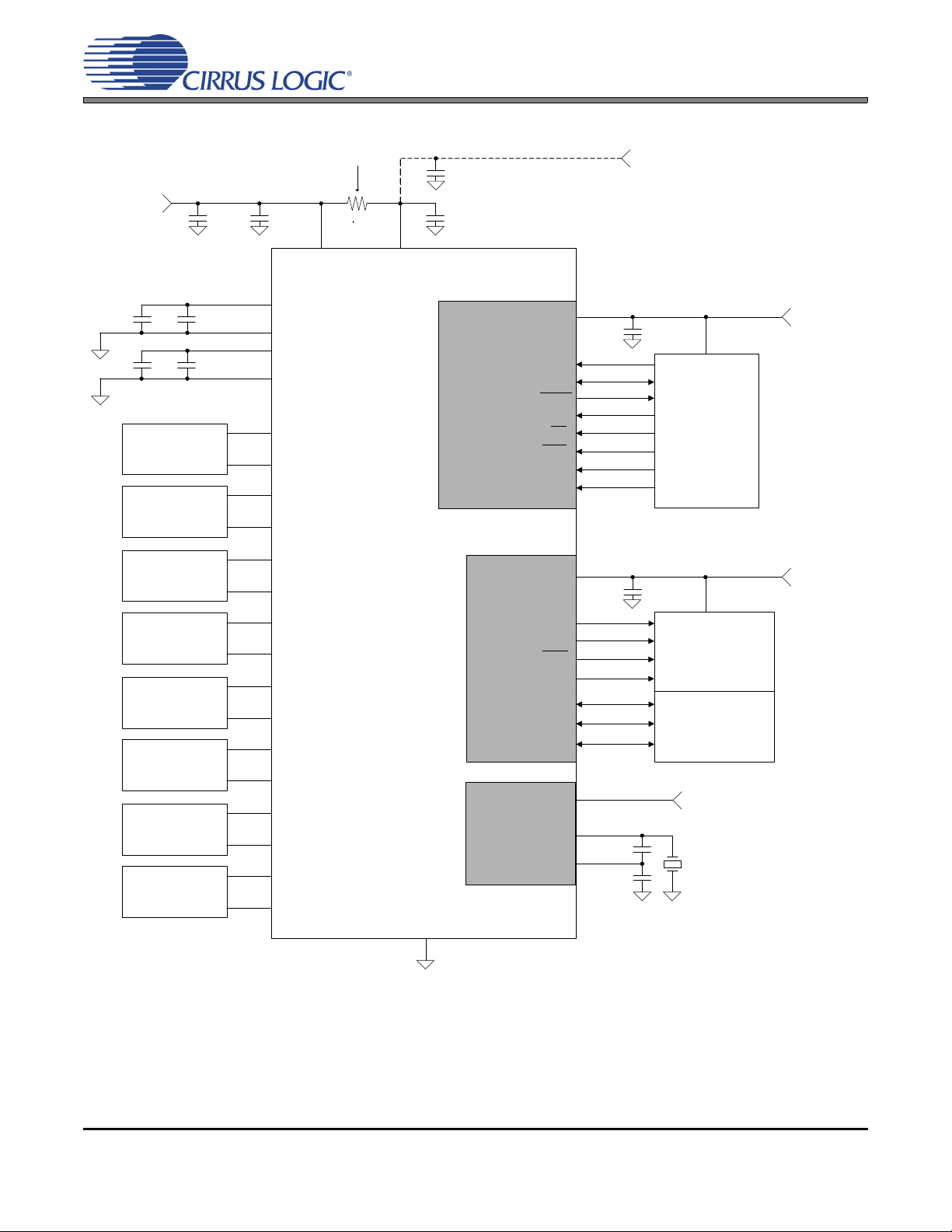

Digital

Audio

Voltage

Reference

Level

Translator

Level

Translator

Internal

Oscillator

VD

3.3 - 5V

Control Interface

I2C, SPI

or Pins

Configuration

Registers

VA

5V

VLC

1.8 - 5V

VLS

1.8 - 5V

8 Differential

Analog Inputs

Device

Control

Serial

Audio Out

PCM or

TDM

Decimation

Filter

High Pass

Filter

Multi-bit

ADC

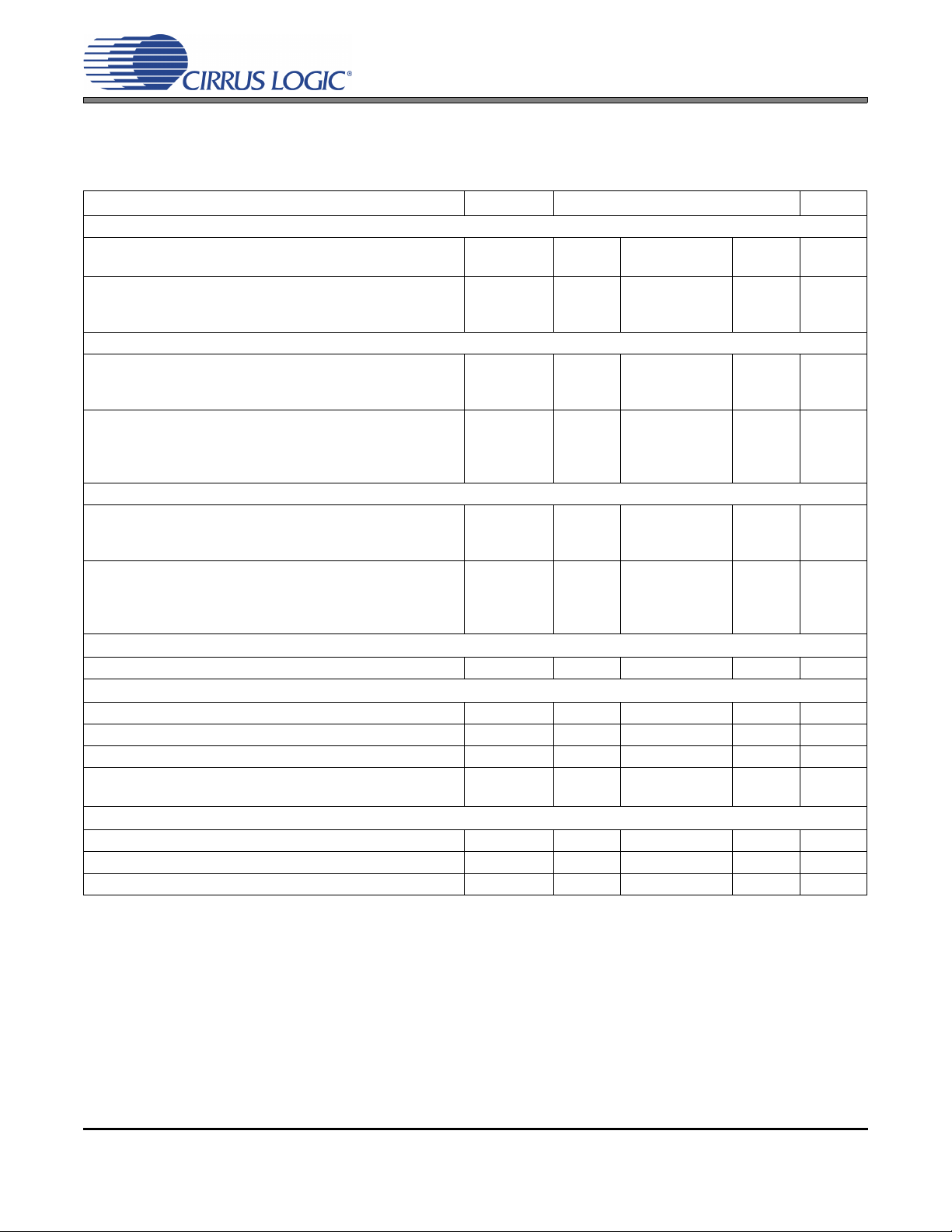

CS5368

114 dB, 192 kHz, 8-Channel A/D Converter

Advanced Multi-bit Delta-Sigma Architecture

24-Bit Conversion

114 dB Dynamic Range

-105 dB THD+N

Supports Audio Sample Rates up to 216 kHz

Selectable Audio Interface Formats

– Left-Justified, I²S, TDM

– 8-Channel TDM Interface Formats

Low Latency Digital Filter

Less than 680 mW Power Consumption

On-Chip Oscillator Driver

Operation as System Clock Master or Slave

Auto-Detect Speed in Slave Mode

Differential Analog Architecture

Separate 1.8 V to 5 V Logic Supplies for

Control and Serial Ports

High-Pass Filter for DC Offset Calibration

Overflow Detection

Footprint Compatible with the 4-Channel

CS5364 and 6-Channel CS5366

Additional Control Port Features

Supports I²C or SPI™ Control Interface per

specifications on page 17 and page 18

Individual Channel HPF Disable

Overflow Detection for Individual Channels

Mute Control for Individual Channels

Independent Power-Down Control per Channel

Pair

http://www.cirrus.com

Copyright Cirrus Logic, Inc. 2014

(All Rights Reserved)

JUL '14

DS624F5

Page 2

CS5368

Description

The CS5368 is a complete 8-channel analog-to-digital converter for digital audio systems. It performs sampling, analog-to-digital conversion, and anti-alias filtering, generating 24-bit values for all 8-channel inputs in serial form at

sample rates up to 216 kHz per channel.

The CS5368 uses a 5th-order, multi-bit delta sigma modulator followed by low latency digital filtering and decimation, which removes the need for an external anti-aliasing filter. The ADC uses a differential input architecture which

provides excellent noise rejection.

Dedicated level translators for the Serial Port and Control Port allow seamless interfacing between the CS5368 and

other devices operating over a wide range of logic levels. In addition, an on-chip oscillator driver provides clocking

flexibility and simplifies design.

The CS5368 is the industry’s first audio A/D to support a high-speed TDM interface which provides a serial output

of 8 channels of audio data with sample rates up to 216 kHz within a single data stream. It further reduces layout

complexity and relieves input/output constraints in digital signal processors.

The CS5368 is available in a 48-pin LQFP package in both Commercial (-40°C to 85°C) and Automotive grades

(-40°C to +105°C). The CDB5368 Customer Demonstration board is also available for device evaluation and

implementation suggestions. Please see “Ordering Information” on page 41 for complete ordering information.

The CS5368 is ideal for high-end and pro-audio systems requiring unrivaled sound quality, transparent conversion,

wide dynamic range and negligible distortion, such as A/V receivers, digital mixing consoles, multi-channel recorders, outboard converters, digital effect processors, and automotive audio systems.

2 DS624F5

Page 3

TABLE OF CONTENTS

1. PIN DESCRIPTION ................................................................................................................................. 6

2. TYPICAL CONNECTION DIAGRAM ................................................................................................... 9

3. CHARACTERISTICS AND SPECIFICATIONS .................................................................................... 10

RECOMMENDED OPERATING CONDITIONS ................................................................................. 10

ABSOLUTE RATINGS ....................................................................................................................... 10

SYSTEM CLOCKING ......................................................................................................................... 10

DC POWER ........................................................................................................................................ 11

LOGIC LEVELS ................................................................................................................................. 11

PSRR, VQ AND FILT+ CHARACTERISTICS .................................................................................... 11

ANALOG CHARACTERISTICS (COMMERCIAL) .............................................................................. 12

ANALOG CHARACTERISTICS (AUTOMOTIVE) ............................................................................... 13

DIGITAL FILTER CHARACTERISTICS ............................................................................................. 14

OVERFLOW TIMEOUT ...................................................................................................................... 14

SERIAL AUDIO INTERFACE - I²S/LJ TIMING ................................................................................... 15

SERIAL AUDIO INTERFACE - TDM TIMING ..................................................................................... 16

SWITCHING SPECIFICATIONS - CONTROL PORT - I²C TIMING ................................................... 17

SWITCHING SPECIFICATIONS - CONTROL PORT - SPI TIMING .................................................. 18

4. APPLICATIONS ................................................................................................................................... 19

4.1 Power ............................................................................................................................................. 19

4.2 Control Port Mode and Stand-Alone Operation .............................................................................. 19

4.2.1 Stand-Alone Mode ................................................................................................................. 19

4.2.2 Control Port Mode ................................................................................................................. 19

4.3 Master Clock Source ...................................................................................................................... 20

4.3.1 On-Chip Crystal Oscillator Driver .......................................................................................... 20

4.3.2 Externally Generated Master Clock ....................................................................................... 20

4.4 Master and Slave Operation ........................................................................................................... 21

4.4.1 Synchronization of Multiple Devices ......................................................................................21

4.5 Serial Audio Interface (SAI) Format ................................................................................................ 22

4.5.1 I²S and LJ Format .................................................................................................................. 22

4.5.2 TDM Format .......................................................................................................................... 23

4.5.3 Configuring Serial Audio Interface Format ............................................................................ 23

4.6 Speed Modes ................................................................................................................................. 23

4.6.1 Sample Rate Ranges ............................................................................................................ 23

4.6.2 Using M1 and M0 to Set Sampling Parameters .................................................................... 23

4.6.3 Master Mode Clock Dividers ................................................................................................. 24

4.6.4 Slave Mode Audio Clocking With Auto-Detect ...................................................................... 24

4.7 Master and Slave Clock Frequencies ............................................................................................. 25

4.8 Reset .............................................................................................................................................. 27

4.8.1 Power-Down Mode ................................................................................................................ 27

4.9 Overflow Detection ......................................................................................................................... 27

4.9.1 Overflow in Stand-Alone Mode .............................................................................................. 27

4.9.2 Overflow in Control Port Mode .............................................................................................. 27

4.10 Analog Connections ..................................................................................................................... 28

4.11 Optimizing Performance in TDM Mode ........................................................................................29

4.12 DC Offset Control ......................................................................................................................... 29

4.13 Control Port Operation .................................................................................................................. 30

4.13.1 SPI Mode ............................................................................................................................. 30

4.13.2 I²C Mode .............................................................................................................................. 31

5. REGISTER MAP ................................................................................................................................... 32

5.1 Register Quick Reference ............................................................................................................. 32

5.2 00h (REVI) Chip ID Code & Revision Register ............................................................................... 32

CS5368

DS624F5 3

Page 4

5.3 01h (GCTL) Global Mode Control Register ...................................................................................32

5.4 02h (OVFL) Overflow Status Register ........................................................................................... 33

5.5 03h (OVFM) Overflow Mask Register ............................................................................................ 33

5.6 04h (HPF) High-Pass Filter Register ............................................................................................. 34

5.7 05h Reserved ................................................................................................................................ 34

5.8 06h (PDN) Power Down Register .................................................................................................. 34

5.9 07h Reserved ................................................................................................................................ 34

5.10 08h (MUTE) Mute Control Register .............................................................................................. 34

5.11 09h Reserved .............................................................................................................................. 35

5.12 0Ah (SDEN) SDOUT Enable Control Register ............................................................................ 35

6. FILTER PLOTS ..................................................................................................................................... 36

7. PARAMETER DEFINITIONS ................................................................................................................ 39

8. PACKAGE DIMENSIONS ................................................................................................................... 40

THERMAL CHARACTERISTICS .......................................................................................................40

9. ORDERING INFORMATION ................................................................................................................ 41

10. REVISION HISTORY ......................................................................................................................... 41

LIST OF FIGURES

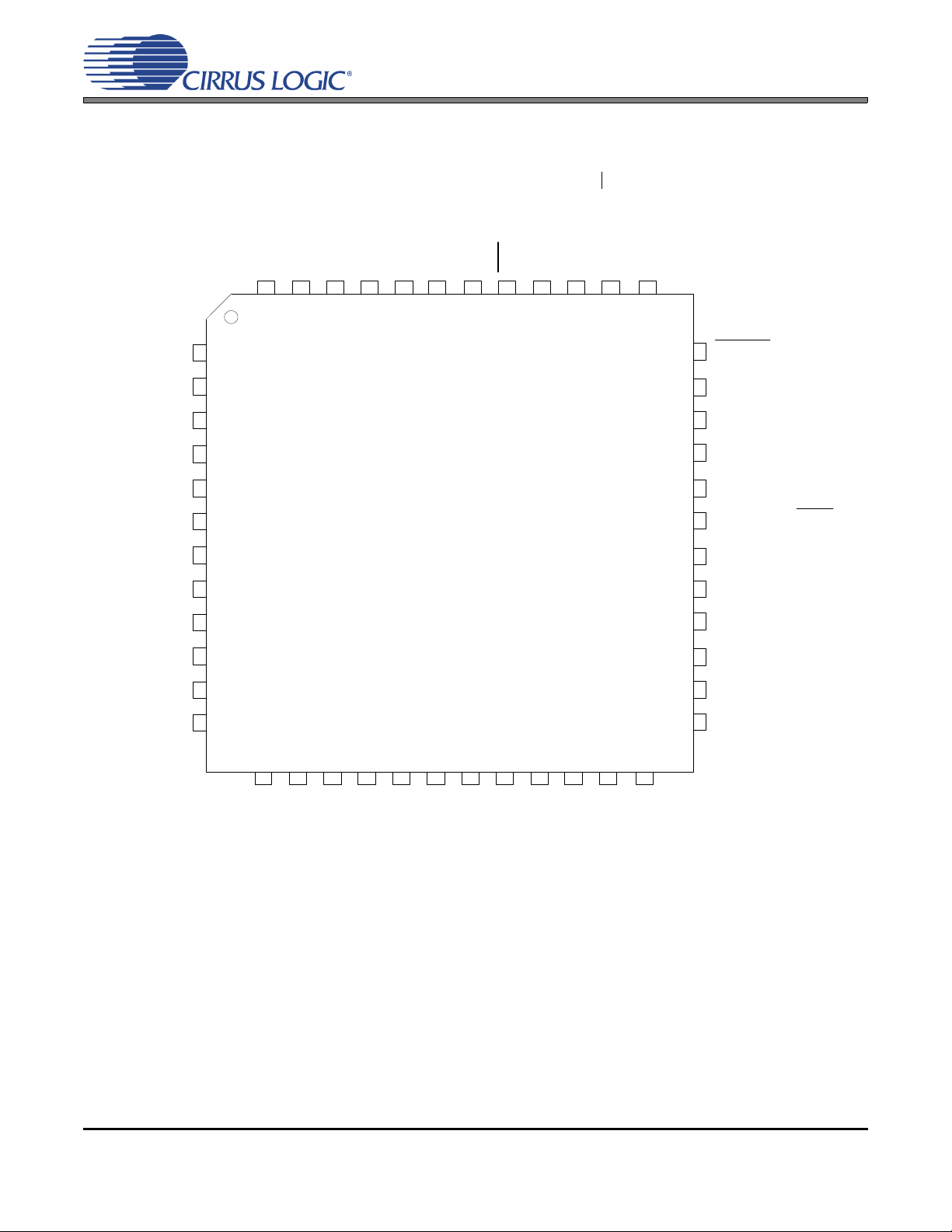

Figure 1. CS5368 Pinout ............................................................................................................................. 6

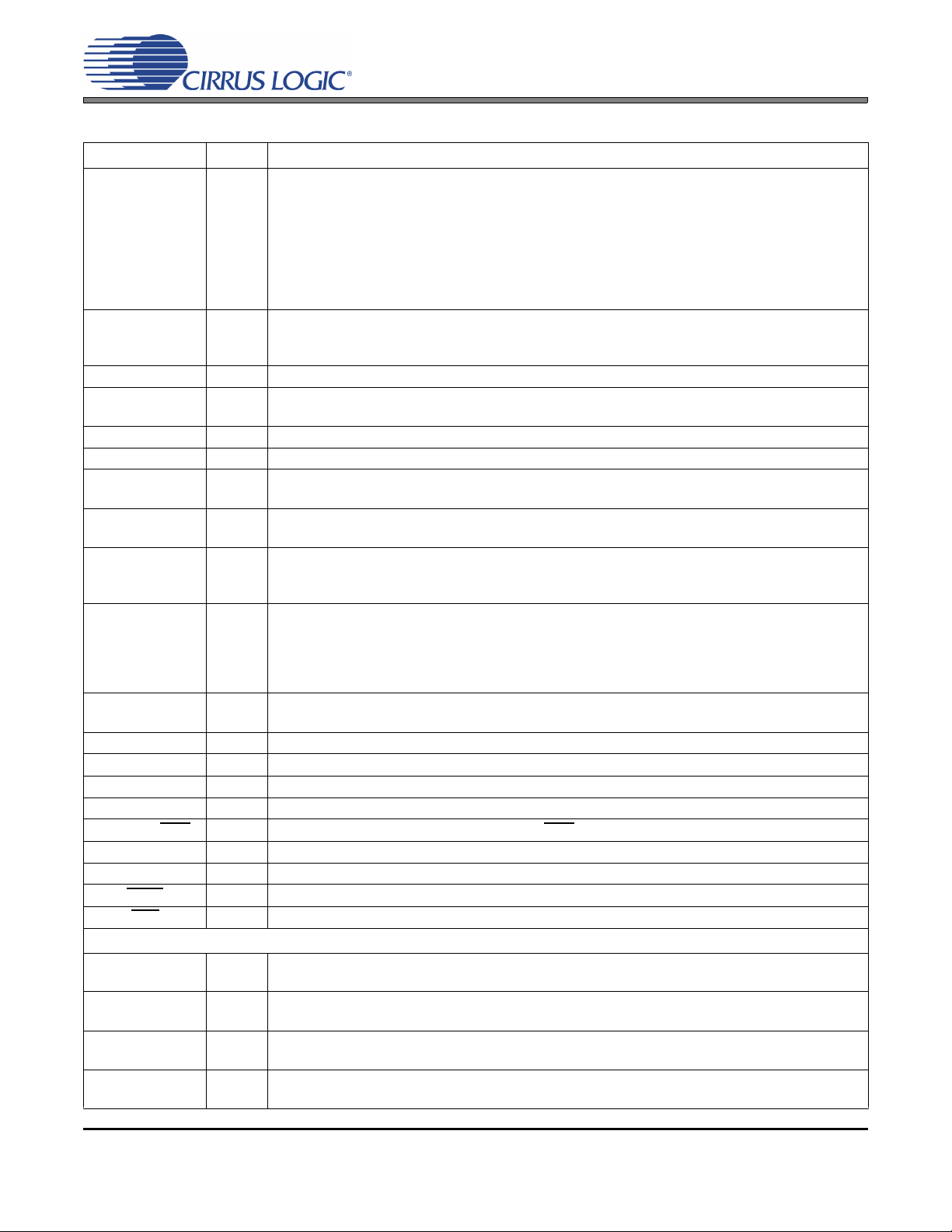

Figure 2. Typical Connection Diagram ........................................................................................................ 9

Figure 3. I²S/LJ Timing .............................................................................................................................. 15

Figure 4. TDM Timing ............................................................................................................................... 16

Figure 5. I²C Timing .................................................................................................................................. 17

Figure 6. SPI Timing ................................................................................................................................. 18

Figure 7. Crystal Oscillator Topology ........................................................................................................ 20

Figure 8. Master/Slave Clock Flow ........................................................................................................... 21

Figure 9. Master and Slave Clocking for a Multi-Channel Application ...................................................... 21

Figure 10. I²S Format ................................................................................................................................ 22

Figure 11. LJ Format ................................................................................................................................. 22

Figure 12. TDM Format ............................................................................................................................. 23

Figure 13. Master Mode Clock Dividers .................................................................................................... 24

Figure 14. Slave Mode Auto-Detect Speed ............................................................................................... 24

Figure 15. Recommended Analog Input Buffer ......................................................................................... 28

Figure 16. SPI Format ............................................................................................................................... 30

Figure 17. I²C Write Format ...................................................................................................................... 31

Figure 18. I²C Read Format ...................................................................................................................... 31

Figure 19. SSM Passband ........................................................................................................................ 36

Figure 20. DSM Passband ........................................................................................................................ 36

Figure 21. QSM Passband ........................................................................................................................ 36

Figure 22. SSM Stopband ......................................................................................................................... 37

Figure 23. DSM Stopband ......................................................................................................................... 37

Figure 24. QSM Stopband ........................................................................................................................ 37

Figure 25. SSM -1 dB Cutoff ..................................................................................................................... 38

Figure 26. DSM -1 dB Cutoff .................................................................................................................... 38

Figure 27. QSM -1 dB Cutoff ..................................................................................................................... 38

CS5368

4 DS624F5

Page 5

LIST OF TABLES

Table 1. Power Supply Pin Definitions ...................................................................................................... 19

Table 2. DIF1 and DIF0 Pin Settings ........................................................................................................ 23

Table 3. M1 and M0 Settings .................................................................................................................... 23

Table 4. Frequencies for 48 kHz Sample Rate using LJ/I²S ..................................................................... 25

Table 5. Frequencies for 96 kHz Sample Rate using LJ/I²S ..................................................................... 25

Table 6. Frequencies for 192 kHz Sample Rate using LJ/I²S ................................................................... 25

Table 7. Frequencies for 48 kHz Sample Rate using TDM ....................................................................... 25

Table 8. Frequencies for 48 kHz Sample Rate using TDM ....................................................................... 25

Table 9. Frequencies for 96 kHz Sample Rate using TDM ....................................................................... 26

Table 10. Frequencies for 96 kHz Sample Rate using TDM ..................................................................... 26

Table 11. Frequencies for 192 kHz Sample Rate using TDM ................................................................... 26

Table 12. Frequencies for 192 kHz Sample Rate using TDM ................................................................... 26

CS5368

DS624F5 5

Page 6

1. PIN DESCRIPTION

AIN3+

SDOUT1/TDM

VLS

SDOUT4

SDOUT3/TDM

GND

SDOUT2

M0/SDA/CDOUT

AIN5-

AIN1+

AIN5+

AIN6-

AIN6+

AIN3-

AIN7+

AIN7-

AIN8-

XTI

XTO

MCLK

AIN8+

VLC

DIF0/AD0/CS

DIF1/AD1/CDIN

AIN1-

M1/SCL/CCLK

VX

SCLK

LRCK/FS

OVFL

GND

MDIV

RST

6

2

4

8

10

1

3

5

7

9

11

12

13 14 15 16 17 18 19 20 21 22 23 24

31

35

33

29

27

36

34

32

30

28

26

25

48 47 46 45 44 43 42 41 40 39 38 37

CS5368

FILT+

AIN2-

VA

GND

GND

AIN2+

GND

REF_GND

VA

AIN4+

AIN4-

VQ

GND

VD

CLKMODE

CS5368

Figure 1. CS5368 Pinout

6 DS624F5

Page 7

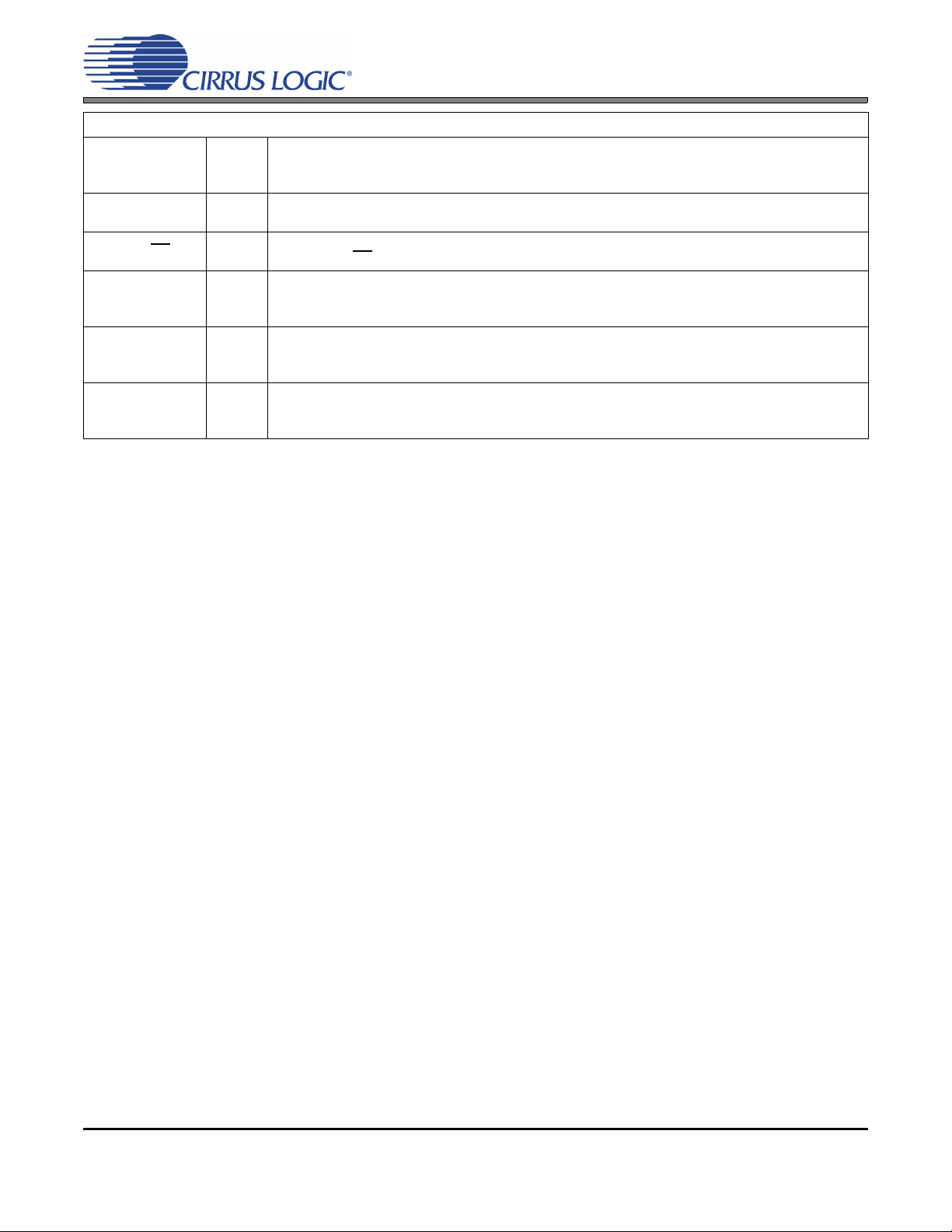

Pin Name Pin # Pin Description

AIN2+, AIN2AIN4+, AIN4AIN3+, AIN3AIN7+, AIN7AIN8+, AIN8AIN6+, AIN6AIN5+, AIN5AIN1+, AIN1-

GND

VA 4, 9 Analog Power (Input) - Positive power supply for the analog section

REF_GND 5

FILT+ 6 Positive Voltage Reference (Output) - Reference voltage for internal sampling circuits.

VQ 7 Quiescent Voltage (Output) - Filter connection for the internal quiescent reference voltage.

VX 20

XTI

XTO

MCLK 23

LRCK/FS 24

SCLK 25

SDOUT4 26 Serial Audio Data (Output) - Channels 7,8.

SDOUT2 27 Serial Audio Data (

VLS 28 Serial Audio Interface Power (Input) - Positive power for the serial audio interface.

SDOUT1/TDM 30 Serial Audio Data (Output) - Channels 1,2.

SDOUT3/TDM

VD 33 Digital Power (Input) - Positive power supply for the digital section.

VLC 35 Control Port Interface Power(Input) - Positive power for the control port interface.

OVFL

RST

1,2

11,12

13,14

15,16

17,18

43,44

45,46

47,48

10,19

29,32

Differential Analog (Inputs) - Audio signals are presented differently to the delta sigma modula-

tors via the AIN+/- pins.

3,8

Ground (Input) - Ground reference. Must be connected to analog ground.

Reference Ground (Input) - For the internal sampling circuits. Must be connected to analog

ground.

Crystal Oscillator Power (Input) - Also powers control logic to enable or disable oscillator cir-

cuits.

2122Crystal Oscillator Connections (Input/Output) - I/O pins for an external crystal which may be

used to generate MCLK.

System Master Clock (Input/Output) - When a crystal is used, this pin acts as a buffered MCLK

Source (Output). When the oscillator function is not used, this pin acts as an input for the system

master clock. In this case, the XTI and XTO pins must be tied low.

Serial Audio Channel Clock (Input/Output)

In I²S Mode, Serial Audio Channel Select. When low, the odd channels are selected.

In LJ Mode, Serial Audio Channel Select. When high, the odd channels are selected.

In TDM Mode, a frame sync signal. When high, it marks the beginning of a new frame of serial

audio samples. In Slave Mode, this pin acts as an input pin.

Main timing clock for the Serial Audio Interface (Input/Output) - During Master Mode, this pin

acts as an output, and during Slave Mode it acts as an input pin.

Output) - Channels 3,4.

31 Serial Audio Data (Output) - Channels 5,6. TDM is complementary TDM data.

36 Overflow (Output, open drain) - Detects an overflow condition on both left and right channels.

41 Reset (Input) - The device enters a low power mode when low.

Stand-Alone Mode

CLKMODE 34

DIF1

DIF0

M1

M0

MDIV 42

CLKMODE (Input) - Setting this pin HIGH places a divide-by-1.5 circuit in the MCLK path to the

core device circuitry.

37

DIF1, DIF0 (Input) - Inputs of the audio interface format.

38

39

Mode Selection (Input) - Determines the operational mode of the device.

40

MCLK Divider (Input) - Setting this pin HIGH places a divide-by-2 circuit in the MCLK path to the

core device circuitry.

CS5368

DS624F5 7

Page 8

Control Port Mode

CLKMODE 34

AD1/CDIN 37

AD0/CS

SCL/CCLK 39

SDA/CDOUT 40

MDIV 42

CLKMODE (Input) - This pin is ignored in Control Port Mode and the same functionality is

obtained from the corresponding bit in the Global Control Register. Note: Should be connected

to GND when using the part in Control Port Mode.

I²C Format, AD1 (Input) - Forms the device address input AD[1].

SPI Format, CDIN (Input) - Becomes the input data pin.

I²C Format, AD0 (Input) - Forms the device address input AD[0].

38

SPI Format, CS

I²C Format, SCL (Input) – Serial clock for the serial control port. An external pull-up resistor is

required for I²C control port operation.

SPI Format, CCLK (Input) – Serial clock for the serial control port.

I²C Format SDA (Input/Output) - Acts as an input/output data pin. An external pull-up resistor is

required for I²C control port operation.

SPI Format CDOUT (Output) - Acts as an output only data pin.

MCLK Divider (Input) - This pin is ignored in Control Port Mode and the same functionality is

obtained from the corresponding bit in the Global Control Register.

Note: Should be connected to GND when using the part in Control Port Mode.

(Input) - Acts as the active low chip select input.

CS5368

8 DS624F5

Page 9

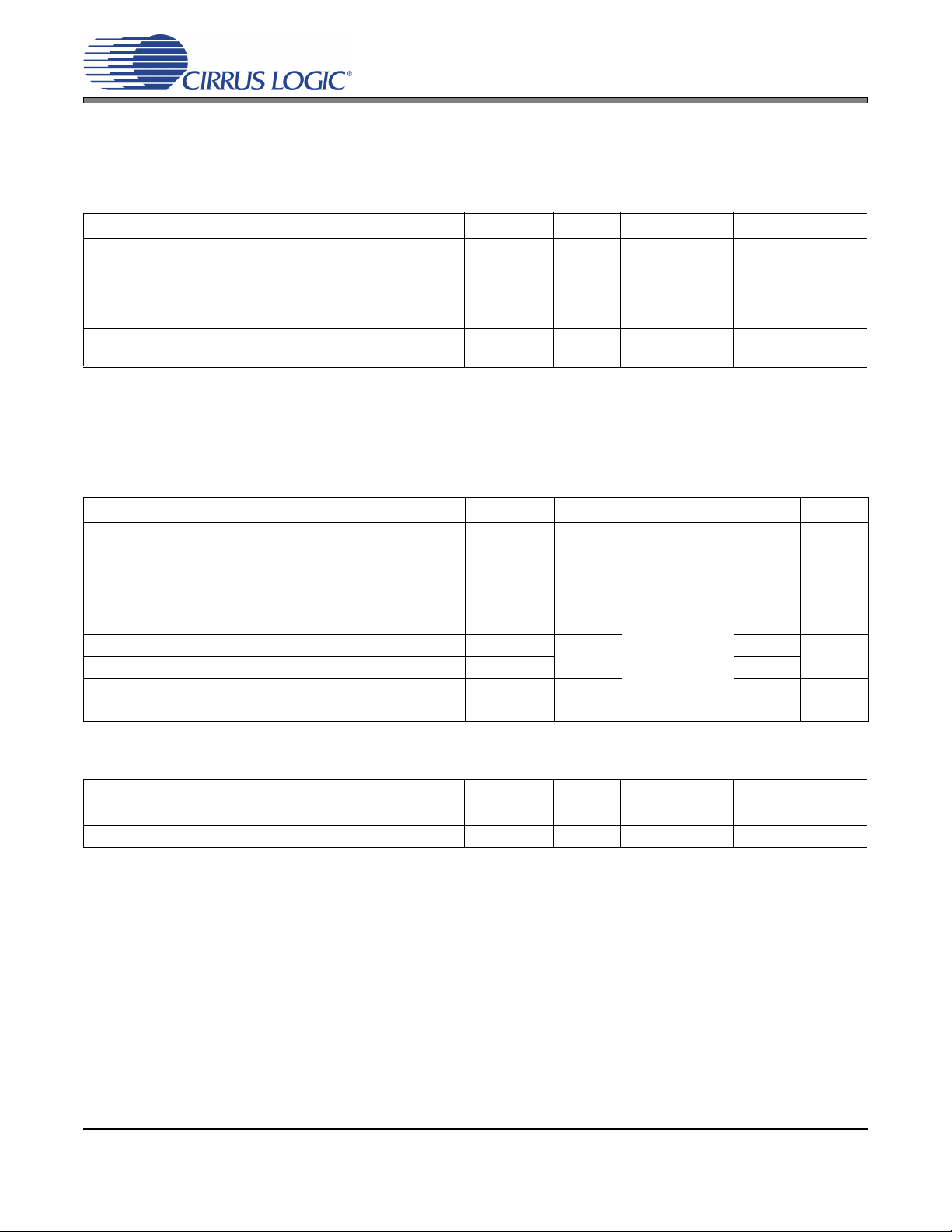

2. TYPICAL CONNECTION DIAGRAM

FILT+

D

+

VA V

+5V

5.1

1 F

+

SDOUT2

DIF0/AD0/CS

Power Down

and Mode

Settings

0.01

F

MODE0/SDA/CDOUT

MODE1/SCL/CCLK

REF_GND

VLC

F

AIN

+1

AIN

-

1

Channel 1 Analog

Input Buffer

AIN +2

AIN

-

2

Channel 2 Analog

Input Buffer

AIN +3

AIN

-

3

Channel 3 Analog

Input Buffer

AIN +4

AIN

-

4

Channel 4 Analog

Input Buffer

AIN

+5

AIN

-

5

Channel 5 Analog

Input Buffer

AIN

+6

AIN

-

6

Channel 6 Analog

Input Buffer

AIN

+7

AIN

-

7

Channel 7 Analog

Input Buffer

AIN

+8

AIN

-

8

Channel 8 Analog

Input Buffer

0.1 F

VQ

GND

220

F

0.1 F

+

1

F

GND

DIF1/AD1/CDIN

RST

OVFL

0.01

0.01F

+5V to 3.3V

1 F

+

A/D CONVERTER

CS5368

SDOUT1/ TDM

SDOUT4

SCLK

MCLK

Timing Logic

and Clock

Audio Data

Processor

MDIV

CLKMODE

39

40

36

37

38

41

42

34

27

31

30

26

24

25

23

LRCK/FS

+5V to 1.8V

6

5

7

8

47

48

1

2

13

14

11

12

45

46

43

44

15

16

17

18

3, 8, 10,

19, 29, 32

334, 9

35

VLS

F

0.01

28

XTI

XTO

21

22

+5V to 1.8V

+5V

VX

20

SDOUT3/ TDM

Resistor may only be used if

VD is derived from VA. If used,

do not drive any other logic

from VD.

CS5368

For analog buffer configurations, refer to Cirrus Application Note AN241. Also, a low-cost single-ended-to-differential solution is provided on the Customer Evaluation Board.

DS624F5 9

Figure 2. Typical Connection Diagram

Page 10

CS5368

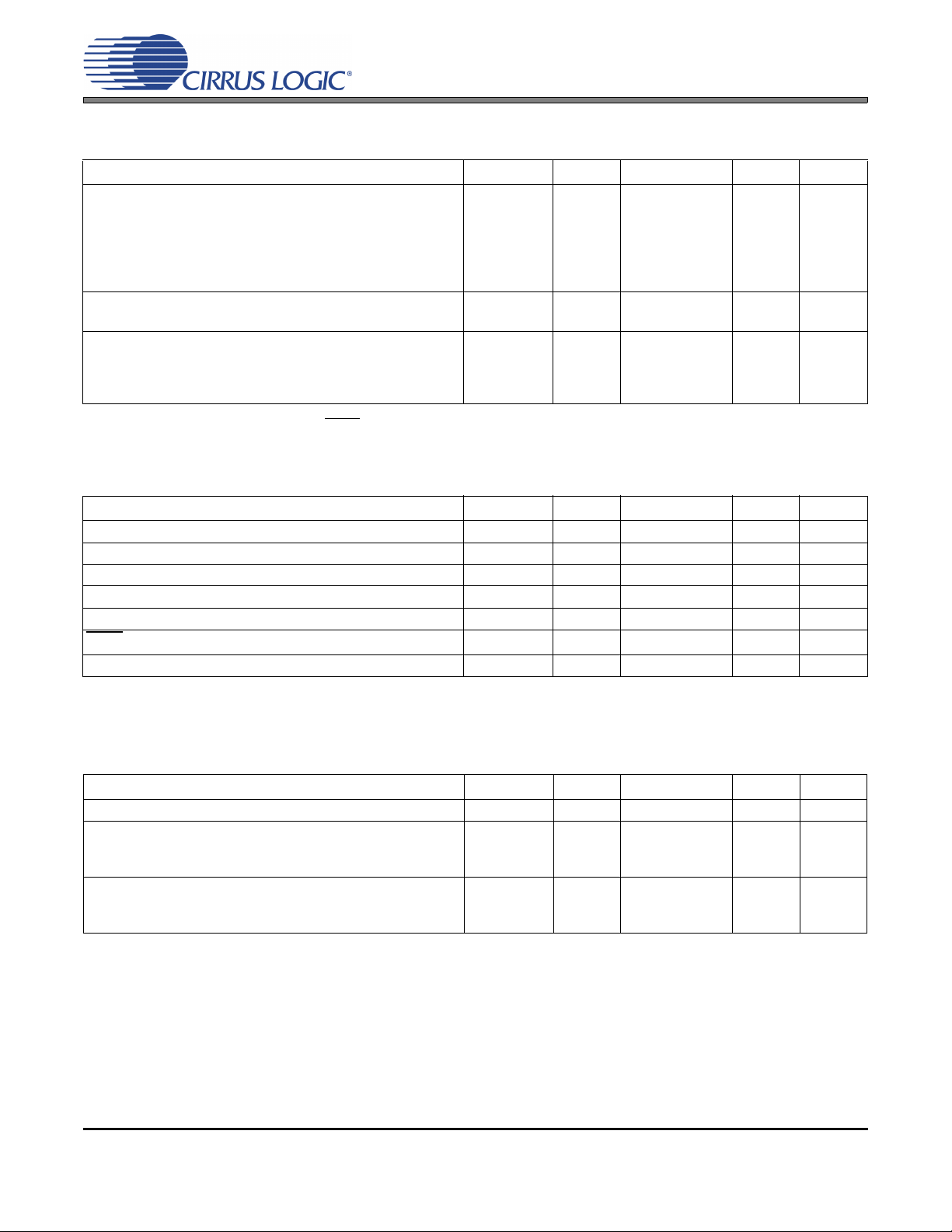

3. CHARACTERISTICS AND SPECIFICATIONS

RECOMMENDED OPERATING CONDITIONS

GND = 0 V, all voltages with respect to 0 V.

Parameter Symbol Min Typ Max Unit

DC Power Supplies: Positive Analog

Positive Crystal

Positive Digital

Positive Serial Logic

Positive Control Logic

Ambient Operating Temperature (-CQZ)

(-DQZ)

VA

VX

VD

VLS

VLC

T

AC

T

AA

4.75

4.75

3.14

1.71

1.71

-40

-40

1

5.0

5.0

3.3

3.3

3.3

5.25 V

-

-

85

105

°C

1. TDM Quad-Speed Mode specified to operate correctly at VLS 3.14 V.

ABSOLUTE RATINGS

Operation beyond these limits may result in permanent damage to the device. Normal operation is not guaranteed

at these extremes. Transient currents up to ±100 mA on the analog input pins will not cause SCR latch-up.

Parameter Symbol Min Typ Max Units

DC Power Supplies: Positive Analog

Positive Crystal

Positive Digital

Positive Serial Logic

Positive Control Logic

Input Current I

Analog Input Voltage V

Digital Input Voltage V

Ambient Operating Temperature (Power Applied) T

Storage Temperature T

VA

VX

VD

VLS

VLC

in

IN

IND

A

stg

-0.3 - +6.0 V

-10

-0.3

-50 +125

-65 +150

-

10 mA

VA+ 0.3

VL+0.3

C

V

SYSTEM CLOCKING

Parameter Symbol Min Typ Max Unit

Input Master Clock Frequency MCLK 0.512 55.05 MHz

Input Master Clock Duty Cycle t

clkhl

10 DS624F5

40 60 %

Page 11

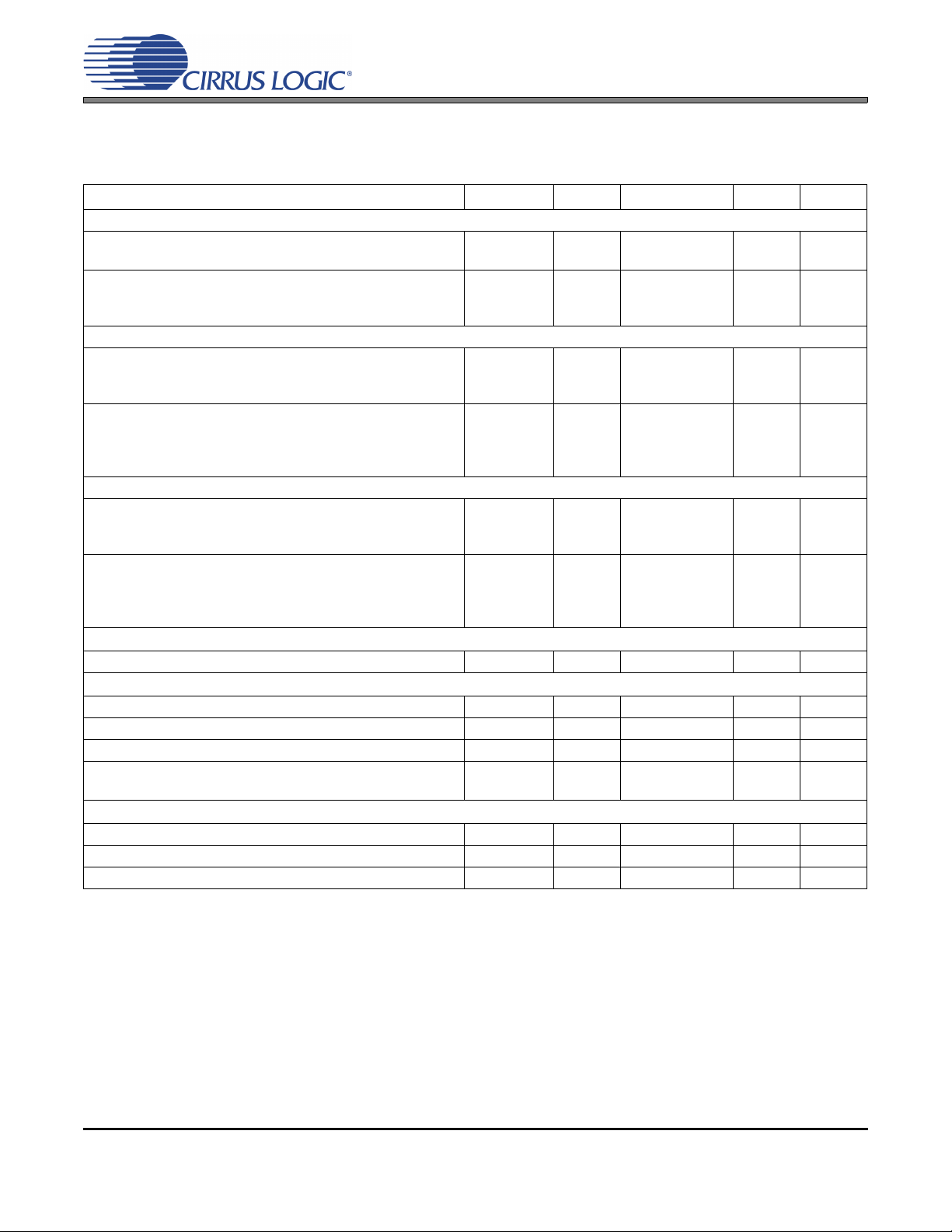

DC POWER

MCLK = 12.288 MHz; Master Mode; GND = 0 V.

Parameter Symbol Min Typ Max Unit

Power Supply Current VA = 5 V

(Normal Operation) VX = 5 V

VD = 5 V

VD = 3.3 V

VLS, VLC = 5 V

VLS, VLC = 3.3 V

Power Supply Current VA = VX = 5 V

(Power-Down) (Note 1) VLS, VLC, VD = 5 V

Power Consumption

Normal Operation All Supplies = 5 V

VA = VX = 5 V, VD = VLS = VLC = 3.3 V

(Power-Down) (Note 1)

I

A

I

X

I

D

I

D

I

L

I

L

I

A

I

D+L

--

-

-

100

4

70

42

12

5

50

500

930

675

2.75

CS5368

112

8

88

50

15

8

- A

1115

792

-

mA

mW

1. Power-Down is defined as RST

= LOW with all clocks and data lines held static at a valid logic level.

LOGIC LEVELS

Parameter Symbol Min Typ Max Units

High-Level Input Voltage %VLS/VLC V

Low-Level Input Voltage %VLS/VLC V

High-Level Output Voltage at 100 A load %VLS/VLC V

Low-Level Output Voltage at -100 A load %VLS/VLC V

SDA Low-Level Output Voltage at -2 mA load %VLC V

Current Sink

OVFL

Input Leakage Current logic pins only I

IH

IL

OH

OL

OL

in

70 - - %

--30%

85 - - %

--15%

--TBD%

-4 mA

-10 - 10 A

PSRR, VQ AND FILT+ CHARACTERISTICS

MCLK = 12.288 MHz; Master Mode. Valid with the recommended capacitor values on FILT+ and VQ as shown in

the “Typical Connection Diagram”.

Parameter Symbol Min Typ Max Unit

Power Supply Rejection Ratio at (1 kHz) PSRR - 65 - dB

V

Nominal Voltage

Q

Output Impedance

Maximum allowable DC current source/sink

Filt+ Nominal Voltage

Output Impedance

Maximum allowable DC current source/sink

-

-

VA/ 2

25

10

VA

4.4

10

V

-

-

k

A

V

k

A

DS624F5 11

Page 12

CS5368

ANALOG CHARACTERISTICS (COMMERCIAL)

Test Conditions (unless otherwise specified). VA = 5 V, VD = VLS = VLC 3.3 V, and TA = 25° C. Full-scale input

sine wave. Measurement Bandwidth is 10 Hz to 20 kHz.

Parameter Symbol Min Typ Max Unit

Single-Speed Mode Fs = 48 kHz

Dynamic Range A-weighted

unweighted

Total Harmonic Distortion + Noise -1 dB

referred to typical full scale -20 dB

-60 dB

Double-Speed Mode Fs = 96 kHz

Dynamic Range A-weighted

unweighted

40 kHz bandwidth unweighted

Total Harmonic Distortion + Noise -1 dB

referred to typical full scale -20 dB

-60 dB

40 kHz bandwidth -1dB

Quad-Speed Mode Fs = 192 kHz

Dynamic Range A-weighted

unweighted

40 kHz bandwidth unweighted

Total Harmonic Distortion + Noise -1 dB

referred to typical full scale -20 dB

-60 dB

40 kHz bandwidth -1dB

THD+N -

THD+N -

THD+N -

Dynamic Performance for All Modes

Interchannel Isolation - 110 - dB

DC Accuracy

Interchannel Gain Mismatch - 0.1 - dB

Gain Error -5 - 5 %

Gain Drift -

Offset Error HPF enabled

HPF disabled

Analog Input Characteristics

Full-scale Differential Input Voltage 1.07*VA 1.13*VA 1.19*VA Vpp

Input Impedance (Differential) - 250 - k

Common Mode Rejection Ratio CMRR - 82 - dB

108

105

108

105

-

108

105

-

0

-

114

111

-105

-91

-51

114

111

108

-105

-91

-51

-102

114

111

108

-105

-91

-51

-102

-

-

-99

-

-45

-dB

-99

-

-45

-

-dB

-99

-

-45

-

dB

dB

dB

dB

100 - ppm/°C

-

-

-

100

LSB

12 DS624F5

Page 13

CS5368

ANALOG CHARACTERISTICS (AUTOMOTIVE)

Test Conditions (unless otherwise specified). VA = 5.25 to 4.75 V, VD = 5.25 to 3.14 V, VLS = VLC = 5.25 to 1.71 V

and T

Single-Speed Mode Fs = 48 kHz

Dynamic Range A-weighted

Total Harmonic Distortion + Noise -1 dB

referred to typical full scale -20 dB

Double-Speed Mode Fs = 96 kHz

Dynamic Range A-weighted

Total Harmonic Distortion + Noise -1 dB

referred to typical full scale -20 dB

Quad-Speed Mode Fs = 192 kHz

Dynamic Range A-weighted

Total Harmonic Distortion + Noise -1 dB

referred to typical full scale -20 dB

Dynamic Performance for All Modes

Interchannel Isolation - 110 - dB

DC Accuracy

Interchannel Gain Mismatch - 0.1 - dB

Gain Error -7 - 7 %

Gain Drift -

Offset Error HPF enabled

Analog Input Characteristics

Full-scale Input Voltage 1.02*VA 1.13*VA 1.24*VA Vpp

Input Impedance (Differential) 250 - k

Common Mode Rejection Ratio CMRR - 82 - dB

= -40° to +85° C. Full-scale input sine wave. Measurement Bandwidth is 10 Hz to 20 kHz.

A

Parameter Symbol Min Typ Max Unit

unweighted

-60 dB

unweighted

40 kHz bandwidth unweighted

-60 dB

40 kHz bandwidth -1 dB

unweighted

40 kHz bandwidth unweighted

-60 dB

40 kHz bandwidth -1 dB

106

103

THD+N -

106

103

-

THD+N -

106

103

-

THD+N -

114

111

-105

-91

-51

114

111

108

-105

-91

-51

-102

114

111

108

-105

-91

-51

-102

100 - ppm/°C

HPF disabled

0

-

-

-

-dB

-97

-

-45

-dB

-97

-

-45

-

-dB

-97

-

-45

-

-

100

dB

dB

dB

LSB

DS624F5 13

Page 14

CS5368

DIGITAL FILTER CHARACTERISTICS

Parameter Symbol Min Typ Max Unit

Single-Speed Mode (2 kHz to 54 kHz sample rates)

Passband (Note 1) (-0.1 dB) 0

Passband Ripple -0.035 0.035 dB

Stopband (Note 1) 0.58

Stopband Attenuation -95 dB

Total Group Delay (Fs = Output Sample Rate) t

gd

-12/Fs s

-

Double-Speed Mode (54 kHz to 108 kHz sample rates)

Passband (Note 1) (-0.1 dB) 0

Passband Ripple -0.035 0.035 dB

Stopband (Note 1) 0.68

Stopband Attenuation -92 dB

Total Group Delay (Fs = Output Sample Rate) t

gd

-9/Fs s

-

Quad-Speed Mode (108 kHz to 216 kHz sample rates)

Passband (Note 1) (-0.1 dB) 0

Passband Ripple -0.035 0.035 dB

Stopband (Note 1) 0.78

Stopband Attenuation -92 dB

Total Group Delay (Fs = Output Sample Rate) t

gd

-5/Fs s

-

High-Pass Filter Characteristics

Frequency Response (Note 2) -3.0 dB

-0.13 dB

Phase Deviation

Passband Ripple -0dB

Filter Settling Time 10

(Note 2) @ 20 Hz

-

-

1

20

10 - Deg

5

/Fs - s

0.47 Fs

Fs

-

0.45 Fs

Fs

-

0.24 Fs

Fs

-

-Hz

Notes:

1. The filter frequency response scales precisely with Fs.

2. Response shown is for Fs equal to 48 kHz. Filter characteristics scale with Fs.

OVERFLOW TIMEOUT

Logic "0" = GND = 0 V; Logic "1" = VLS; CL = 30 pF, timing threshold is 50% of VLS.

Parameter Symbol Min Typ Max Unit

17

-1)/Fs

OVFL time-out on overrange condition

Fs = 44.1 kHz

Fs = 192 kHz

-

14 DS624F5

(2

2972

683

-ms

Page 15

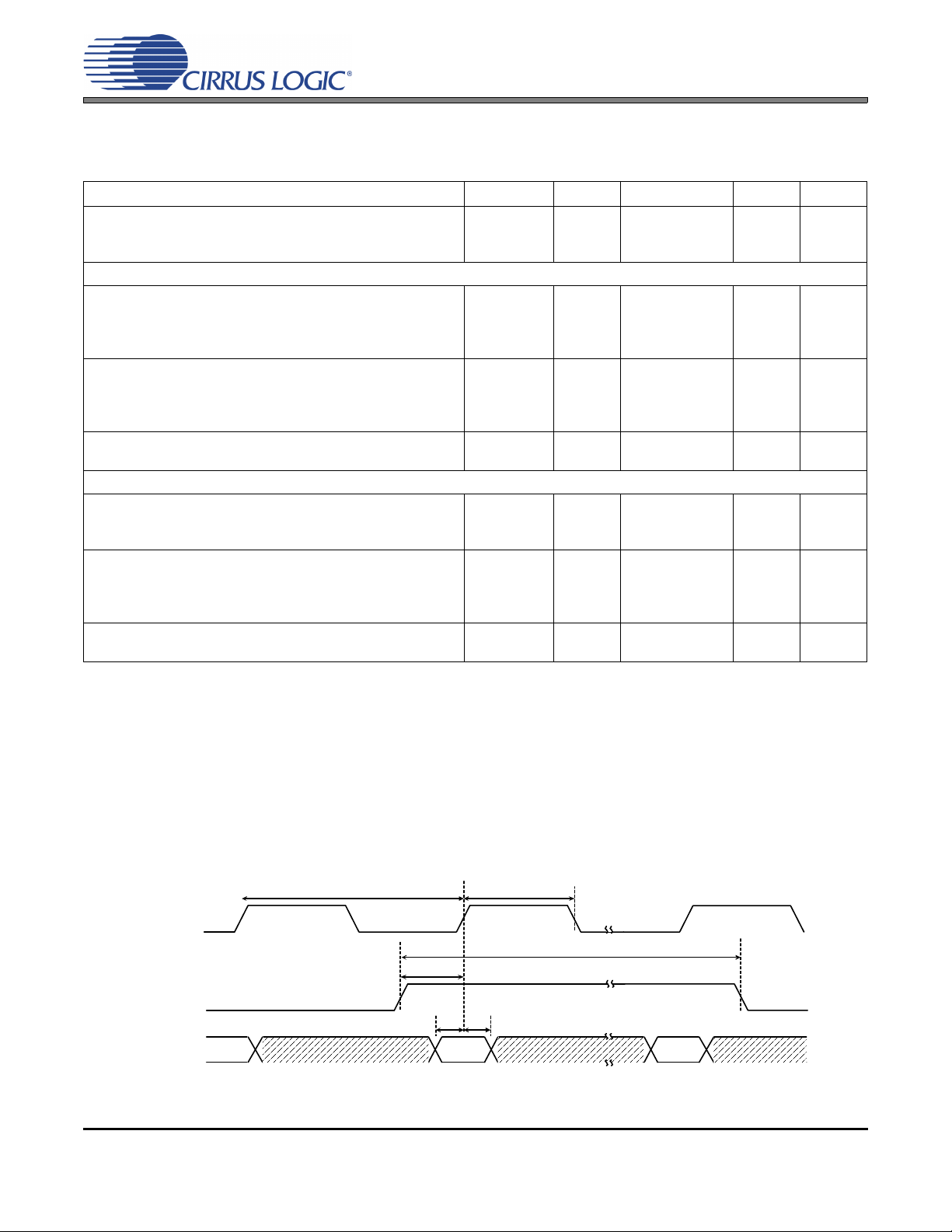

SERIAL AUDIO INTERFACE - I²S/LJ TIMING

LRCK

SDOUT

SCLK

data

channelchannel

data

t

HOLD2

t

SETUP2

t

HOLD1

t

SETUP1

t

PERIOD

t

HIGH

The serial audio port is a three-pin interface consisting of SCLK, LRCK and SDOUT.

Logic "0" = GND = 0 V; Logic "1" = VLS; C

Parameter Symbol Min Typ Max Unit

Sample Rates Single-Speed Mode

Double-Speed Mode

Master Mode

SCLK Frequency

SCLK Period 1/(64*216 kHz)

SCLK Duty Cycle (Note 1) (CLKMODE = 0)(Note 2)

(CLKMODE = 1)(Note 2)

LRCK setup before SCLK rising

LRCK hold after SCLK rising

SDOUT setup before SCLK rising

SDOUT hold after SCLK rising (VLS = 1.8 V)

after SCLK rising (VLS = 3.3 V)

after SCLK rising (VLS = 5 V)

Slave Mode

SCLK Frequency (Note 3)

SCLK Period 1/(64*216 kHz)

SCLK Duty Cycle

LRCK setup before SCLK rising

LRCK hold after SCLK rising

SDOUT setup before SCLK rising (VLS = 1.8 V)

before SCLK rising (VLS = 3.3 V)

before SCLK rising (VLS = 5 V)

SDOUT hold after SCLK rising (VLS = 1.8 V)

after SCLK rising (VLS = 3.3 V)

after SCLK rising (VLS = 5 V)

= 20 pF, timing threshold is 50% of VLS.

L

-

Quad-Speed Mode

-

t

PERIOD

t

HIGH

t

HIGH

t

SETUP1

t

HOLD1

t

SETUP2

t

HOLD2

t

HOLD2

t

HOLD2

64*Fs

72.3

-

t

PERIOD

t

HIGH

t

SETUP1

t

HOLD1

t

SETUP2

t

SETUP2

t

SETUP2

t

HOLD2

t

HOLD2

t

HOLD2

72.3

2

54

108

40

28

20

20

10

20

10

5

-

28

20

20

4

10

10

20

10

5

CS5368

54

-

-

50

33

--ns

--ns

64*Fs

-

-

--ns

--ns

108

216

64*Fs

60

38

-

65

kHz

Hz

ns

%

%

Hz

ns

%

Notes:

1. Duty cycle of generated SCLK depends on duty cycle of received MCLK as specified under “System

Clocking” on page 10.

2. CLKMODE functionality described in Section 4.6.3 "Master Mode Clock Dividers" on page 24.

3. In Slave Mode, the SCLK/LRCK ratio can be set according to preference. However, chip performance

is guaranteed only when using the ratios in Section 4.7 Master and Slave Clock Frequencies on page

25.

DS624F5 15

Figure 3. I²S/LJ Timing

Page 16

SERIAL AUDIO INTERFACE - TDM TIMING

FS

SDOUT

SCLK

data data

t

HOLD2

t

SETUP2

t

SETUP1

new frame

data

t

PERIOD

t

HIGH1

t

HIGH2

The serial audio port is a three-pin interface consisting of SCLK, LRCK and SDOUT.

Logic "0" = GND = 0 V; Logic "1" = VLS; C

Parameter Symbol Min Typ Max Unit

Sample Rates Single-Speed Mode

Double-Speed Mode

Master Mode

SCLK Frequency

SCLK Period 1/(256*216 kHz)

SCLK Duty Cycle (Note 2) (CLKMODE = 0)(Note 3)

(CLKMODE = 1)(Note 3)

FS setup before SCLK rising (Single-Speed Mode)

FS setup before SCLK rising (Double-Speed Mode)

FS setup before SCLK rising (Quad-Speed Mode)

FS width in SCLK cycles

SDOUT setup before SCLK rising

SDOUT hold after SCLK rising

Slave Mode

SCLK Frequency (Note 4)

SCLK Period 1/(256*216 kHz)

SCLK Duty Cycle

FS setup before SCLK rising (Single-Speed Mode)

FS setup before SCLK rising (Double-Speed Mode)

FS setup before SCLK rising (Quad-Speed Mode)

FS width in SCLK cycles

SDOUT setup before SCLK rising

SDOUT hold after SCLK rising

= 20 pF, timing threshold is 50% of VLS.

L

-

-

-

t

PERIOD

t

HIGH1

t

HIGH1

t

SETUP1

t

SETUP1

t

SETUP1

t

HIGH2

t

SETUP2

t

HOLD2

t

PERIOD

t

HIGH1

t

SETUP1

t

SETUP1

t

SETUP1

t

HIGH2

t

SETUP2

t

HOLD2

Quad-Speed Mode

1

2

54

108

256*Fs

18

40

28

20

18

5

128

5

5

18

28

20

20

10

1

5

5

-

-

-

-

50

33

-

-

-

-

-

-

256*Fs

-

-

-

-

-

-

-

-

54

108

216

256*Fs

60

38

-

-

-

128

-

-

-

65

-

-

-

244

-

-

CS5368

kHz

kHz

kHz

Hz

ns

%

%

ns

ns

ns

-

ns

ns

Hz

ns

%

ns

ns

ns

-

ns

ns

Notes:

1. TDM Quad-Speed Mode only specified to operate correctly at VLS 3.14 V.

2. Duty cycle of generated SCLK depends on duty cycle of received MCLK as specified under “System

Clocking” on page 10.

3. CLKMODE functionality described in Section 4.6.3 "Master Mode Clock Dividers" on page 24.

4. In Slave Mode, the SCLK/LRCK ratio can be set according to preference; chip performance is guaranteed only when using the ratios in Section 4.7 Master and Slave Clock Frequencies on page 25.

16 DS624F5

Figure 4. TDM Timing

Page 17

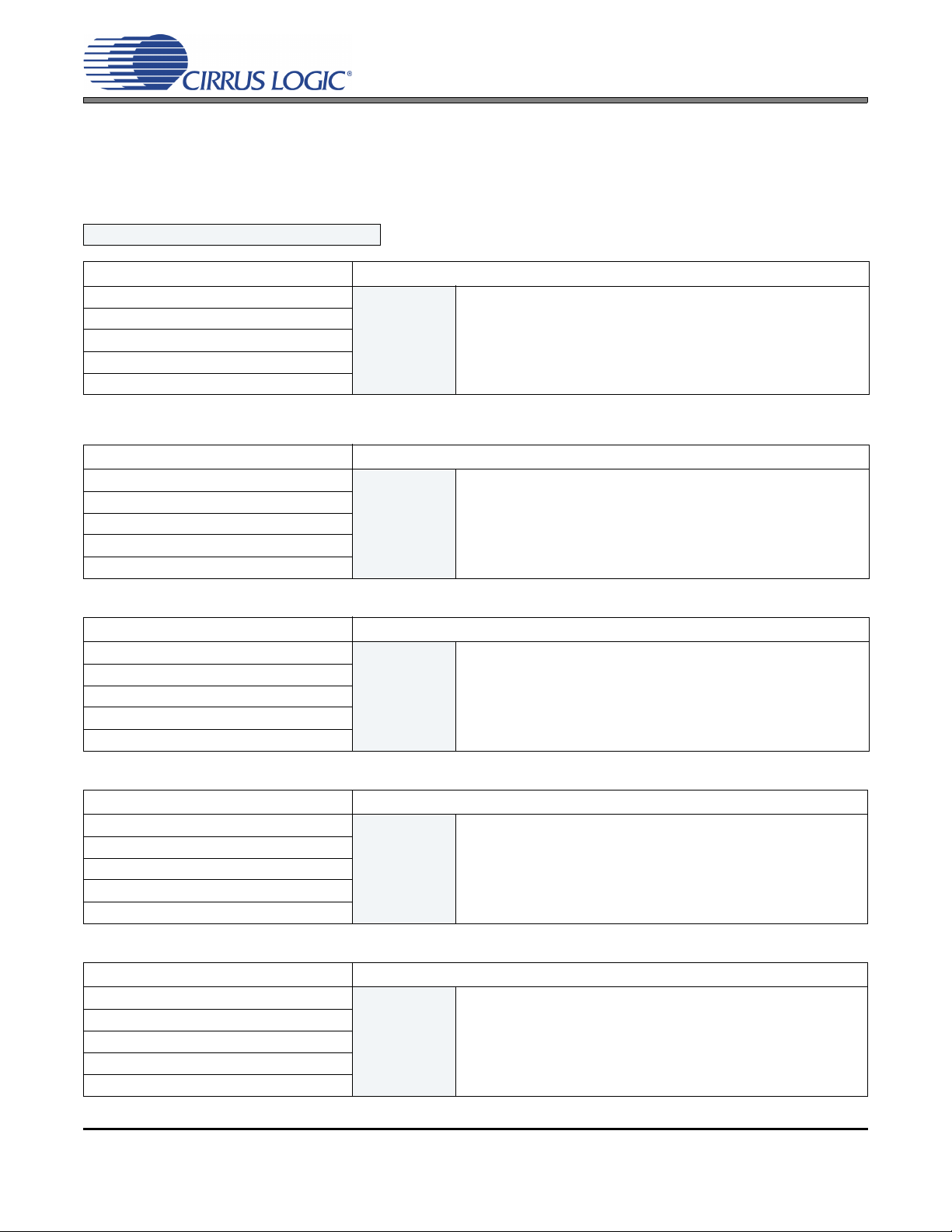

SWITCHING SPECIFICATIONS - CONTROL PORT - I²C TIMING

t

buf

t

hdst

t

lo wthdd

t

high

t

sud

Stop S ta rt

SDA

SCL

t

irs

RST

t

hdst

t

rc

t

fc

t

sust

t

susp

Start

Stop

Repe ated

t

rd

t

fd

t

ack

Inputs: Logic 0 = DGND, Logic 1 = VLC, SDA CL=30pF

Parameter Symbol Min Max Unit

SCL Clock Frequency f

Rising Edge to Start t

RST

Bus Free Time Between Transmissions t

Start Condition Hold Time (prior to first clock pulse) t

Clock Low time t

Clock High Time t

Setup Time for Repeated Start Condition t

SDA Hold Time from SCL Falling (Note 1)

SDA Setup time to SCL Rising (Note 2) t

Rise Time of SCL and SDA t

Fall Time SCL and SDA t

Setup Time for Stop Condition t

Acknowledge Delay from SCL Falling t

Notes:

scl

irs

buf

hdst

low

high

sust

t

hdd

sud

rc

fc

susp

ack

- 100 kHz

600

4.7 µs

4.0

4.7

4.0

4.7

0

600 ns

-1µs

-300ns

4.7 - µs

300 1000 ns

CS5368

ns

µs

1. Data must be held for sufficient time to bridge the transition time, t

, of SCL.

fc

Figure 5. I²C Timing

2. The operational timing specification deviates from the I2C-Bus Specification and User Manual of

250 ns.

DS624F5 17

Page 18

SWITCHING SPECIFICATIONS - CONTROL PORT - SPI TIMING

CS

CCLK

CDIN

CDOUT

RST

t

srs

t

scl

t

sch

t

css

t

r2

t

f2

t

csh

t

dsutdh

t

pd

Inputs: Logic 0 = DGND, Logic 1 = VLC, CDOUT CL=30pF

Parameter Symbol Min Max Units

CCLK Clock Frequency f

RST

Rising Edge to CS Falling t

CS

Falling to CCLK Edge t

CS High Time Between Transmissions t

CCLK Low Time t

CCLK High Time t

CDIN to CCLK Rising Setup Time t

CCLK Rising to DATA Hold Time (Note 1) t

CCLK Falling to CDOUT Stable t

Rise Time of CDOUT t

Fall Time of CDOUT t

Rise Time of CCLK and CDIN (Note 2) t

Fall Time of CCLK and CDIN (Note 2) t

sck

srs

css

csh

scl

sch

dsu

dh

pd

r1

f1

r2

f2

06.0MHz

20

20

1.0 s

66

66

40

15

-

100

50

25

CS5368

ns

-

ns

Notes:

1. Data must be held for sufficient time to bridge the transition time of CCLK.

2. For f

<1 MHz

sck

Figure 6. SPI Timing

18 DS624F5

Page 19

4. APPLICATIONS

4.1 Power

CS5368 features five independent power pins that power various functional blocks within the device and

allow for convenient interfacing to other devices. Table 1 shows what portion of the device is powered from

each supply pin. Please refer to “Recommended Operating Conditions” on page 10 for the valid range of

each power supply pin. The power supplied to each power pin can be independent of the power supplied to

any other pin.

To meet full performance specifications, the CS5368 requires normal low-noise board layout. The “Typical

Connection Diagram” on page 9 shows the recommended power arrangements, with the VA pins connected

to a clean supply. VD, which powers the digital filter, may be run from the system logic supply, or it may be

powered from the analog supply via a single-pole decoupling filter.

CS5368

Power Supply Pin

Pin Name Pin Number Functional Block

VA 4, 9 Analog Core

VX 20 Crystal Oscillator

VD 33 Digital Core

VLS 28 Serial Audio Interface

VLC 35 Control Logic

Table 1. Power Supply Pin Definitions

Decoupling capacitors should be placed as near to the ADC as possible, with the lower value high-frequency capacitors placed nearest to the device leads. Clocks should be kept away from the FILT+ and VQ pins

in order to avoid unwanted coupling of these signals into the device. The FILT+ and VQ decoupling capacitors must be positioned to minimize the electrical path to ground.

The CDB5368 evaluation board demonstrates optimum layout for the device.

4.2 Control Port Mode and Stand-Alone Operation

4.2.1 Stand-Alone Mode

In Stand-Alone Mode, the CS5368 is programmed exclusively with multi-use configuration pins. This mode

provides a set of commonly used features, which comprise a subset of the complete set of device features

offered in Control Port Mode.

To use the CS5368 in Stand-Alone Mode, the configuration pins must be held in a stable state, at valid logic

levels, and RST

tion on the reset function is available in Section 4.5 on page 22.

must be asserted until the power supplies and clocks are stable and valid. More informa-

4.2.2 Control Port Mode

In Control Port Mode, all features of the CS5368 are available. Four multi-use configuration pins become

software pins that support the I²C or SPI bus protocol. To initiate Control Port Mode, a controller that supports I²C or SPI must be used to enable the internal register functionality. This is done by setting the CPEN bit (Bit 7 of the Global Control Port Register). Once CP-EN is set, all of the device configuration pins

are ignored, and the internal register settings determine the operating modes of the part. Figure 4.13 on

page 30 provides detailed information about the I²C and SPI bus protocols.

DS624F5 19

Page 20

4.3 Master Clock Source

XTI

XTO

22

21

The CS5368 requires a Master Clock that can come from one of two sources: an on-chip crystal oscillator

driver or an externally generated clock.

4.3.1 On-Chip Crystal Oscillator Driver

When using the on-board crystal oscillator driver, the XTI pin (pin 21) is the input for the Master Clock (MCLK) to the device. The XTO pin (pin 22) must not be used to drive anything other than the oscillator tank

circuitry. When using the on-board crystal driver, the topology shown in Figure 7 must be used. The crystal

oscillator manufacturer supplies recommended capacitor values. A buffered copy of the XTI input is available as an output on the MCLK pin (pin 23), which is level-controlled by VLS and may be used to synchronize other parts to the device.

CS5368

Figure 7. Crystal Oscillator Topology

4.3.2 Externally Generated Master Clock

If an external clock is used, the XTI and XTO pins must be grounded, and the MCLK pin becomes an input

for the system master clock. The incoming MCLK should be at the logic level set by the user on the VLS

supply pin.

20 DS624F5

Page 21

4.4 Master and Slave Operation

ADC as

clock

master

Controller

LRCK/FS

SCLK

ADC as

clock

slave

Controller

LRCK/FS

SCLK

Master

ADC

Slave1

ADC

Slave2

ADC

Slave3

ADC

SCLK & LRCK/FS

CS5368 operation depends on two clocks that are synchronously derived from MCLK: SCLK and LRCK/FS.

See Section 4.5 on page 22 for a detailed description of SCLK and LRCK/FS.

The CS5368 can operate as either clock master or clock slave with respect to SCLK and LRCK/FS. In Master Mode, the CS5368 derives SCLK and LRCK/FS synchronously from MCLK and outputs the derived

clocks on the SCLK pin (pin 25) and the LRCK/FS pin (pin 24), respectively. In Slave Mode, the SCLK and

LRCK/FS are inputs, and the input signals must be synchronously derived from MCLK by a separate device

such as another CS5368 or a microcontroller. Figure 8 illustrates the clock flow of SCLK and LRCK/FS in

both Master and Slave Modes.

The Master/Slave operation is controlled through the settings of M1 and M0 pins in Stand-Alone Mode or

by the M[1] and M[0] bits in the Global Mode Control Register in Control Port Mode. See Section 4.6 on page

23 for more information regarding the configuration of M1 and M0 pins or M[1] and M[0] bits.

Figure 8. Master/Slave Clock Flow

CS5368

4.4.1 Synchronization of Multiple Devices

To ensure synchronous sampling in applications where multiple ADCs are used, the MCLK and LRCK must

be the same for all CS5368 devices in the system. If only one master clock source is needed, one solution

is to place one CS5368 in Master Mode, and slave all of the other devices to the one master, as illustrated

in Figure 9. If multiple master clock sources are needed, one solution is to supply all clocks from the same

external source and time the CS5368 reset de-assertion with the falling edge of MCLK. This will ensure that

all converters begin sampling on the same clock edge.

Figure 9. Master and Slave Clocking for a Multi-Channel Application

DS624F5 21

Page 22

4.5 Serial Audio Interface (SAI) Format

Odd Channels 1,3, ...

Even Channels 2,4, ...

LRCK

receiver latches data on rising edges of SCLK

SDOUT

SCLK

MSB

...

LSB MSB

...

LSB MSB

Odd Channels 1,3, ...

Even Channels 2,4, ...

LRCK

receiver latches data on rising edges of SCLK

MSB

...

LSB MSBMSB

...

LSBSDOUT

SCLK

The SAI port consists of two timing pins (SCLK, LRCK/FS) and four audio data output pins (SDOUT1/TDM,

SDOUT2, SDOUT3/TDM

and SDOUT4). The CS5368 output is serial data in I²S, Left-Justified (LJ), or Time

Division Multiplexed (TDM) digital audio interface formats. These formats are available to the user in both

Stand-Alone Mode and Control Port Mode.

4.5.1 I²S and LJ Format

The I²S and LJ formats are both two-channel protocols. During one LRCK period, two channels of data are

transmitted, odd channels first, then even. The MSB is always clocked out first.

In Slave Mode, the number of SCLK cycles per channel is fixed as described under “Serial Audio Interface

- I²S/LJ Timing” on page 15. In Slave Mode, if more than 32 SCLK cycles per channel are received from a

master controller, the CS5368 will fill the longer frame with trailing zeros. If fewer than 24 SCLK cycles per

channel are received from a master, the CS5368 will truncate the serial data output to the number of SCLK

cycles received. For a complete overview of serial audio interface formats, please refer to Cirrus Logic Application Note AN282.

CS5368

Figure 10. I²S Format

Figure 11. LJ Format

22 DS624F5

Page 23

4.5.2 TDM Format

Channel 6

SCLK

MSB LSBMSB LSBMSB LSBMSB LSBMSB LS BMSB

TDM O UT

Channel 1 Channel 4Channel 2 C hannel 5Channel 3

32 clks 32 clks 32 clks 32 clks 32 clks 32 clks

Channel 8

LSBMSB LS BMSB

Channel 7

32 clks 32 clks

FS

MSB

LSB

LSB

LSBMSB

Data

Zeroes

In TDM Mode, all eight channels of audio data are serially clocked out during a single Frame Sync (FS)

cycle, as shown in Figure 12. The rising edge of FS signifies the start of a new TDM frame cycle. Each

channel slot occupies 32 SCLK cycles, with the data left justified and with MSB first. TDM output data

should be latched on the rising edge of SCLK within time specified under ”Serial Audio Interface - TDM Tim-

ing” section on page 16. The TDM data output port resides on the SDOUT1 pin. The TDM

complimentary TDM data. All SDOUT pins will remain active during TDM Mode. Refer to Section 4.11 “Op-

timizing Performance in TDM Mode” on page 29 for critical system design information.

Figure 12. TDM Format

4.5.3 Configuring Serial Audio Interface Format

The serial audio interface format of the data is controlled by the configuration of the DIF1 and DIF0 pins in

Stand-Alone Mode or by the DIF[1] and DIF[0] bits in the Global Mode Control Register in Control Port

Mode, as shown in Table 2.

CS5368

output pin is

DIF1 DIF0 Mode

0 0 Left-Justified

01 I²S

10 TDM

11 Reserved

Table 2. DIF1 and DIF0 Pin Settings

4.6 Speed Modes

4.6.1 Sample Rate Ranges

CS5368 supports sampling rates from 2 kHz to 21 kHz, divided into three ranges: 2 kHz - 54 kHz, 54 kHz 108 kHz, and 108 kHz - 216 kHz. These sampling speed modes are called Single-Speed Mode (SSM),

Double-Speed Mode (DSM), and Quad-Speed Mode (QSM), respectively.

4.6.2 Using M1 and M0 to Set Sampling Parameters

The Master/Slave operation and the sample rate range are controlled through the settings of the M1 and

M0 pins in Stand-Alone Mode, or by the M[1] and M[0] bits in the Global Mode Control Register in Control

Port Mode, as shown in Table 3.

M1 M0 Mode Frequency Range

0 0 Single-Speed Master Mode (SSM) 2 kHz - 54 kHz

0 1 Double-Speed Master Mode (DSM) 54 kHz - 108 kHz

1 0 Quadruple-Speed Master Mode (QSM) 108 kHz - 216 kHz

1 1 Auto-Detected Speed Slave Mode 2 kHz - 216 kHz

Table 3. M1 and M0 Settings

DS624F5 23

Page 24

4.6.3 Master Mode Clock Dividers

÷ 128

÷ 64

M0M1

LRCK/ FS

Single

Speed

Quad

Speed

Double

Speed

00

01

10

÷ 2

÷ 4

÷ 1

SCLK

Single

Speed

Quad

Speed

Double

Speed

00

01

10

÷ 256

pin

CLKMODE

MDIV

n/a

MCLK

÷ 1

÷ 1.5 ÷ 2

÷ 1

÷ 2

÷ 1

bit MDIV1

MDIV0

0/1 0/1 0/1

MCLK DIVIDERS

SAMPLE RATE DIVIDERS

CLKMODE

128

64

Single-Speed

256

pin

CLKMODE

MDIV

n/a

External

MCLK

÷ 1

÷ 1.5 ÷ 2

÷ 1

÷ 2

÷ 1

bit MDIV1

MDIV0

0/1 0/1 0/1

MCLK DIVIDERS

CLKMODE

÷LRCK

LRCK

Double-Speed

Quad-Speed

SPEED MODE

Internal

MCLK

Figure 13 shows the configuration of the MCLK dividers and the sample rate dividers for Master Mode, in-

cluding the significance of each MCLK divider pin (in Stand-Alone Mode) or bit (in Control Port Mode).

CS5368

4.6.4 Slave Mode Audio Clocking With Auto-Detect

24 DS624F5

Figure 13. Master Mode Clock Dividers

In Slave Mode, CS5368 auto-detects speed mode, which eliminates the need to configure M1 and M0 when

changing among speed modes. The external MCLK is subject to clock dividers as set by the clock divider

pins in Stand-Alone Mode or the clock divider bits in Control Port Mode. The CS5368 compares the divideddown, internal MCLK to the incoming LRCK/FS and sets the speed mode based on the MCLK/LRCK ratio

as shown in Figure 14.

Figure 14. Slave Mode Auto-Detect Speed

Page 25

CS5368

4.7 Master and Slave Clock Frequencies

Tables 4 through 12 show the clock speeds for sample rates of 48 kHz, 96 kHz and 192 kHz. The MC-

LK/LRCK ratio should be kept at a constant value during each mode. In Master Mode, the device outputs

the frequencies shown. In Slave Mode, the SCLK/LRCK ratio can be set according to design preference.

However, device performance is guaranteed only when using the ratios shown in the tables.

Control Port Mode only

LJ/I²S MASTER OR SLAVE SSM Fs = 48 kHz

MCLK Divider 4 3 2 1.5 1

MCLK (MHz)

SCLK (MHz)

MCLK/LRCK Ratio 1024 768 512 384 256

SCLK/LRCK Ratio

Table 4. Frequencies for 48 kHz Sample Rate using LJ/I²S

LJ/I²S MASTER OR SLAVE DSM Fs = 96 kHz

MCLK Divider 4 3 2 1.5 1

MCLK (MHz) 49.152 36.864 24.567 18.384 12.288

SCLK (MHz)

MCLK/LRCK Ratio

SCLK/LRCK Ratio 64 64 64 64 64

Table 5. Frequencies for 96 kHz Sample Rate using LJ/I²S

49.152 36.864 24.576 18.384 12.288

3.072 3.072 3.072 3.072 3.072

64 64 64 64 64

6.144 6.144 6.144 6.144 6.144

512 384 256 192 128

LJ/I²S MASTER OR SLAVE QSM Fs = 192 kHz

MCLK Divider 4 3 2 1.5 1

MCLK (MHz) 49.152 36.864 24 18.384 12.288

SCLK (MHz)

MCLK/LRCK Ratio

SCLK/LRCK Ratio 64 64 64 64 64

Table 6. Frequencies for 192 kHz Sample Rate using LJ/I²S

12.288 12.288 12.288 12.288 12.288

256 192 128 96 64

TDM MASTER SSM Fs = 48 kHz

MCLK Divider 4 3 2 1.5 1

MCLK (MHz) 49.152 36.864 24.567 18.384 12.288

SCLK (MHz)

MCLK/FS Ratio

SCLK/FS Ratio 256 256 256 256 256

Table 7. Frequencies for 48 kHz Sample Rate using TDM

12.288 12.288 12.288 12.288 12.288

1024 768 512 384 256

TDM SLAVE SSM Fs = 48 kHz

MCLK Divider 4 3 2 1.5 1

MCLK (MHz)

SCLK (MHz)

MCLK/FS Ratio 1024 768 512 384 256

SCLK/FS Ratio

Table 8. Frequencies for 48 kHz Sample Rate using TDM

49.152 36.864 24.567 18.384 12.288

12.288 12.288 12.288 12.288 12.288

256 256 256 256 256

DS624F5 25

Page 26

CS5368

TDM MASTER DSM Fs = 96 kHz

MCLK Divider 4 3 2- -

MCLK (MHz)

SCLK (MHz)

MCLK/FS Ratio

SCLK/FS Ratio

Table 9. Frequencies for 96 kHz Sample Rate using TDM

TDM SLAVE DSM Fs = 96 kHz

MCLK Divider 4 3 2 1.5 1

MCLK (MHz)

SCLK (MHz) 24.576 24.576 24.576 24.576 24.576

MCLK/FS Ratio

SCLK/FS Ratio

Table 10. Frequencies for 96 kHz Sample Rate using TDM

TDM MASTER QSM Fs = 192 kHz

MCLK Divider 4 ----

MCLK (MHz)

SCLK (MHz) 49.152 - - - -

MCLK/FS Ratio

SCLK/FS Ratio

Table 11. Frequencies for 192 kHz Sample Rate using TDM

49.152 36.864 24.567 - -

24.576 24.576 24.576 - -

512 384 256 - -

256 256 256 - -

49.152 36.864 24.567 18.384 12.288

512 384 256 192 128

256 256 256 256 256

49.152 - - - -

256 - - - -

256 - - - -

TDM SLAVE QSM Fs = 192 kHz

MCLK Divider 4 3 2 1.5 1

MCLK (MHz)

SCLK (MHz) 49.152 49.152 49.152 49.152 49.152

MCLK/FS Ratio

SCLK/FS Ratio

Table 12. Frequencies for 192 kHz Sample Rate using TDM

49.152 36.864 24.567 18.384 12.288

256 192 128 96 64

256 256 256 256 256

26 DS624F5

Page 27

4.8 Reset

The device should be held in reset until power is applied and all incoming clocks are stable and valid. Upon

de-assertion of RST

starts sending audio output data a maximum of 524288 MCLK cycles after the release of RST

ing between mode configurations in Stand-Alone Mode, including clock dividers, serial audio interface format, master/slave, or speed modes, it is recommended to reset the device following the change by holding

the RST

pin low for a minimum of one MCLK cycle and then restoring the pin to a logic-high condition.

, the state of the configuration pins is latched, the state machine begins, and the device

4.8.1 Power-Down Mode

The CS5368 features a Power-Down Mode in which power is temporarily withheld from the modulators, the

crystal oscillator driver, the digital core, and the serial port. The user can access Power-Down Mode by

holding the device in reset and holding all clock lines at a static, valid logic level (either logic-high or logiclow). “DC Power” on page 11 shows the power-saving associated with Power-Down Mode.

4.9 Overflow Detection

4.9.1 Overflow in Stand-Alone Mode

The CS5368 includes overflow detection on all input channels. In Stand-Alone Mode, this information is

presented as open drain, active low on the OVFL

range condition in any channel is detected. The data will remain low, then time-out as specified in Section

"Overflow Timeout" on page 14. After the time-out, the OVFL

been any other over-range condition detected. Note that an over-range condition on any channel will restart

the time-out period.

CS5368

. When chang-

pin. The pin will go to a logical low as soon as an over-

pin will return to a logical high if there has not

4.9.2 Overflow in Control Port Mode

In Control Port Mode, the Overflow Status Register interacts with the Overflow Mask Register to provide

interrupt capability for each individual channel. See Section 5.4 "02h (OVFL) Overflow Status Register" on

page 33 for details on these two registers.

DS624F5 27

Page 28

4.10 Analog Connections

VQ

+

634

634

91

91

+

-

-

2700 pF

470 pF

470 pF

COG

COG

10 uF

10 uF

ADC AIN+

ADC AIN-

AIN+

AIN-

COG

100

k

10 k

10

k

100

k

The analog modulator samples the input at half of the internal Master Clock frequency, or 6.144 MHz nominally. The digital filter will reject signals within the stopband of the filter. However, there is no rejection of

input signals that are at (N X 6.144 MHz) the digital passband frequency, where n=0,1,2.... Refer to

Figure 15, which shows the suggested filter that will attenuate any noise energy at 6.144 MHz in addition to

providing the optimum source impedance for the modulators. The use of capacitors that have a large voltage coefficient (such as general-purpose ceramics) must be avoided since these can degrade signal linearity. COG capacitors are recommended for this application. For additional configurations, refer to Cirrus

Application Note AN241.

CS5368

Figure 15. Recommended Analog Input Buffer

28 DS624F5

Page 29

4.11 Optimizing Performance in TDM Mode

Noise Management is a design technique that is utilized in the majority of audio A/D converters. Noise management is relatively simple conceptually. The goal of noise management is to interleave the on-chip digital

activity with the analog sampling processes to ensure that the noise generated by the digital activity is minimized (ideally non-existant) when the analog sampling occurs. Noise management, when implemented

properly, minimizes the on-chip interference between the analog and digital sections of the device. This

technique has proven to be very effective and has simplified the process of implementing an A/D converter

into a systems design. The dominate source of interference (and most difficult to control) is the activity on

the serial audio interface (SAI). However, noise management becomes more difficult to implement as audio

sample rates increase simply due to the fact that there is less time between transitions on the SAI.

The CS5368 A/D converter supports a multi-channel Time-Division-Multiplexed interface for Single, Double

and Quad-Speed sampling modes. In Single-Speed Mode, sample rates below 50 kHz, the required frequencies of the audio serial ports are sufficiently low that it is possible to implement noise-management. In

this mode, the performance of the devices are relatively immune to activity on the audio ports.

However, in Double-Speed and Quad-Speed modes there is insufficient time to implement noise management due to the required frequencies of the audio ports. Therefore, analog performance, both dynamic

range and THD+N, can be degraded if the serial port transitions occurr concurrently with the analog sampling. The magnitude of the interference is not only related to the timing of the transition but also the di/dt or

transient currents associated with the activity on the serial ports. Even though there is insufficient time to

properly implement noise management, the interference effects can be minimized by controlling the transient currents required of the serial ports in Double- and Quad-Speed TDM Modes.

CS5368

In addition to standard mixed-signal design techniques, system performance can be maximized by following

several guidelines during design.

– Operate the serial audio port at 3.3 V and not 5 V. The lower serial port voltage lowers transent

currents.

– Operate the A/D converter as a system clock Slave. The serial clock and Left/Right clock become high-

impedence inputs in this mode and do not generate significant transient currents.

– Place a buffer on the serial data output very near the A/D converter. Minimizing the stray capacitance

of the printed circuit board trace and the loading presented by other devices on the serial data line will

minimize the transient current.

– Place a resistor, near the converter, beween the A/D serial data output and the buffer. This resistor will

reduce the instantaneous switching currents into the capacitive loads on the nets, resulting in a slower

edge rate. The value of the resistor should be as high as possible without causing timing problems

elsewhere in the system.

4.12 DC Offset Control

The CS5368 includes a dedicated high-pass filter for each channel to remove input DC offset at the system

level. A DC level may result in audible “clicks” when switching between devices in a multi-channel system.

In Stand-Alone Mode, all of the high-pass filters remain enabled. In Control Port Mode, the high-pass filters

default to enabled, but may be controlled by writing to the HPF

spective high-pass filter is enabled, and it continuously subtracts a measure of the DC offset from the output

of the decimation filter. If any HPF

ister is frozen, and this DC offset will continue to be subtracted from the conversion result.

register. If any HPF bit is taken low, the re-

bit is taken high during device operation, the value of the DC offset reg-

DS624F5 29

Page 30

4.13 Control Port Operation

MAP

MSB

LSB

DATA

byte 1

byte n

R/W

R/W

ADDRESS

CHIP

ADDRESS

CHIP

CDIN

CCLK

CS

CDOUT

MSB

LSB

MSB

LSB

1001111

1001111

MAP = Memory Address Pointer, 8 bits, MSB first

High Impedance

The Control Port is used to read and write the internal device registers. It supports two industry standard

formats, I²C and SPI. The part is in I²C format by default. SPI Mode is selected if there is ever a high-to-low

transition on the AD0/CS

pin after the RST pin has been restored high.

In Control Port Mode, all features of the CS5368 are available. Four multi-use configuration pins become

software pins that support the I²C or SPI bus protocol. To initiate Control Port Mode, a controller that supports I²C or SPI must be used to enable the internal register functionality. This is done by setting the

CP-EN bit (Bit 7 of the Global Control Port Register). Once CP-EN is set, all of the device configuration pins

are ignored, and the internal register settings determine the operating modes of the part.

4.13.1 SPI Mode

In SPI Mode, CS is the CS5368 chip select signal; CCLK is the control port bit clock (input into the CS5368

from a controller); CDIN is the input data line from a controller; CDOUT is the output data line to a controller.

Data is clocked in on the rising edge of CCLK and is supplied on the falling edge of CCLK.

To write to a register, bring CS low. The first seven bits on CDIN form the chip address and must be

1001111. The eighth bit is a read/write indicator (R/W), which should be low to write. The next eight bits

form the Memory Address Pointer (MAP), which is set to the address of the register that is to be updated.

The next eight bits are the data that will be placed into the register designated by the MAP. During writes,

the CDOUT output stays in the Hi-Z state. It may be externally pulled high or low with a 47 k resistor, if

desired.

CS5368

There is a MAP auto-increment capability, which is enabled by the INCR bit in the MAP register. If INCR is

a zero, the MAP will stay constant for successive read or writes. If INCR is set to a 1, the MAP will autoincrement after each byte is read or written, allowing block reads or writes of successive registers.

To read a register, the MAP has to be set to the correct address by executing a partial write cycle that finishes (CS

desired. To begin a read, bring CS

high) immediately after the MAP byte. The MAP auto-increment bit (INCR) may be set or not, as

low, send out the chip address and set the read/write bit (R/W) high.

The next falling edge of CCLK will clock out the MSB of the addressed register (CDOUT will leave the high

impedance state). If the MAP auto-increment bit is set to 1, the data for successive registers will appear

consecutively

.

Figure 16. SPI Format

30 DS624F5

Page 31

4.13.2 I²C Mode

4 5 6 7 24 25

SCL

CHIP ADDRESS (WRITE) MAP BYTE DATA

DATA +1

START

ACK

STOP

ACKACKACK

1 0 0 1 1 AD1 AD0 0

SDA

INCR 6 5 4 3 2 1 0 7 6 1 0 7 6 1 0 7 6 1 0

0 1 2 3 8 9 12 16 17 18 1910 11 13 14 15 27 28

26

DATA +n

SCL

CHIP ADDRESS ( WRITE)

MAP BYTE

DATA

DATA +1

START

ACK

STOP

ACK

ACK

ACK

1 0 0 1 1 AD1 AD0 0

SDA

1 0 0 1 1 AD1 AD0 1

CHIP ADDRESS ( READ)

START

INCR 6 5 4 3 2 1 0

7 0 7 0 7 0

NO

168 9 12 13 14 154 5 6 7 0 1 20 21 22 23 24

26 27 28

2 3 10 11 17 18 19 25

ACK

DATA + n

STOP

In I²C Mode, SDA is a bidirectional data line. Data is clocked into and out of the part by the clock, SCL.

There is no CS pin. Pins AD0 and AD1 form the two least-significant bits of the chip address and should

be connected through a resistor to VLC or DGND, as desired. The state of the pins is latched when the

CS5368 is being released from RST.

A Start condition is defined as a falling transition of SDA while SCL is high. A Stop condition is a rising transition of SDA while SCL is high. All other transitions of SDA occur while SCL is low. The first byte sent to

the CS5368 after a Start condition consists of a 7-bit chip address field and a R/W bit (high for a read, low

for a write). The upper five bits of the 7-bit address field are fixed at 10011. To communicate with a CS5368,

the chip address field, which is the first byte sent to the CS5368, should match 10011 and be followed by

the settings of the AD1 and AD0. The eighth bit of the address is the R/W bit. If the operation is a write, the

next byte is the Memory Address Pointer (MAP), which selects the register to be read or written. If the operation is a read, the contents of the register pointed to by the MAP will be output. Setting the auto-increment bit in MAP allows successive reads or writes of consecutive registers. Each byte is separated by an

acknowledge bit. The ACK bit is output from the CS5368 after each input byte is read and is input to the

CS5368 from the microcontroller after each transmitted byte.

Since the read operation cannot set the MAP, an aborted write operation is used as a preamble. The write

operation is aborted after the acknowledge for the MAP byte by sending a Stop condition. The following

pseudocode illustrates an aborted write operation followed by a read operation.

Send start condition.

Send 10011xx0 (chip address & write operation).

Receive acknowledge bit.

Send MAP byte, auto increment off.

Receive acknowledge bit.

Send stop condition, aborting write.

Send start condition.

Send 10011xx1 (chip address & read operation).

Receive acknowledge bit.

Receive byte, contents of selected register.

Send acknowledge bit.

Send stop condition.

CS5368

Figure 17. I²C Write Format

DS624F5 31

Figure 18. I²C Read Format

Page 32

CS5368

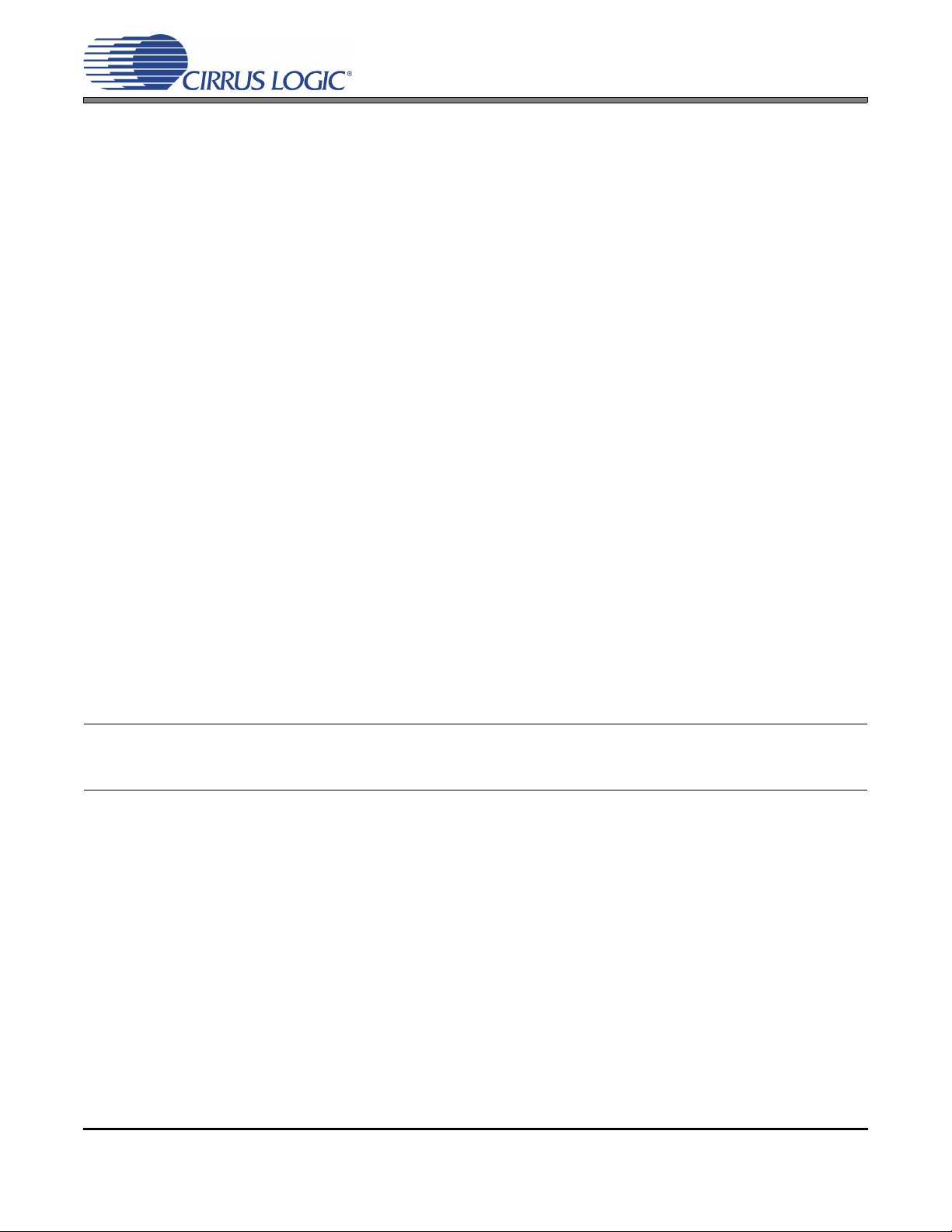

5. REGISTER MAP

In Control Port Mode, the bits in these registers are used to control all of the programmable features of the ADC. All

registers above 0Ah are RESERVED.

5.1 Register Quick Reference

Adr Name7654 3210

00 REVI CHIP-ID[3:0] REVISION[3:0]

01 GCTL CP-EN CLKMODE MDIV[1:0] DIF[1:0] MODE[1:0]

02 OVFL OVFL8 OVFL7 OVFL6 OVFL5 OVFL4 OVFL3 OVFL2 OVFL1

03 OVFM OVFM8 OVFM7 OVFM6 OVFM5 OVFM4 OVFM3 OVFM2 OVFM1

04 HPF HPF8 HPF7 HPF6 HPF5 HPF4 HPF3 HPF2 HPF1

05 RESERVED - - - - - - - -

06 PDNE RESERVED PDN-BG PDN-OSC PDN87 PDN65 PDN43 PDN21

07 RESERVED - - - - - - - -

08 MUTE MUTE8 MUTE7 MUTE6 MUTE5 MUTE4 MUTE3 MUTE2 MUTE1

09 RESERVED - - - - - - - -

0A SDEN RESERVED SDEN4

SDEN3 SDEN2 SDEN1

5.2 00h (REVI) Chip ID Code & Revision Register

R/W76543210

R CHIP-ID[3:0] REVISION[3:0]

Default: See description

The Chip ID Code & Revision Register is used to store the ID and revision of the chip.

Bits[7:4] contain the chip ID, where the CS5368 is represented with a value of 0x8.

Bits[3:0] contain the revision of the chip, where revision A is represented as 0x0, revision B is represented

as 0x1, etc.

5.3 01h (GCTL) Global Mode Control Register

R/W76543210

R/W CP-EN CLKMODE MDIV[1:0] DIF[1:0] MODE[1:0]

Default: 0x00

The Global Mode Control Register is used to control the Master/Slave Speed modes, the serial audio data

format and the Master clock dividers for all channels. It also contains a Control Port enable bit.

Bit[7] CP-EN manages the Control Port Mode. Until this bit is asserted, all pins behave as if in Stand-Alone

Mode. When this bit is asserted, all pins used in Stand-Alone Mode are ignored, and the corresponding register values become functional.

Bit[6] CLKMODE Setting this bit puts the part in 384X mode (divides XTI by 1.5), and clearing the bit invokes 256X mode (divide XTI by 1.0 - pass through).

32 DS624F5

Page 33

CS5368

Bits[5:4] MDIV[1:0] Each bit selects an XTI divider. When either bit is low, an XTI divide-by-1 function is

selected. When either bit is HIGH, an XTI divide-by-2 function is selected. With both bits HIGH, XTI is divided by 4.

The table below shows the composite XTI division using both CLKMODE and MDIV[1:0].

CLKMODE,MDIV[1],MDIV[0] DESCRIPTION

000 Divide-by-1

100 Divide-by-1.5

001 or 010 Divide-by-2

101 or 110 Divide-by-3

011 Divide-by-4

111 Reser ved

Bits[3:2] DIF[1:0] Determine which data format the serial audio interface is using to clock-out data.

DIF[1:0]

0x00 Left-Justified format

0x01 I²S format

0x02 TDM

0x03 Reserved

Bits[1:0] MODE[1:0] This bit field determines the device sample rate range and whether it is operating as

an audio clocking Master or Slave.

MODE[1:0]

0x00 Single-Speed Mode Master

0x01 Double-Speed Mode Master

0x02 Quad-Speed Mode Master

0x03 Slave Mode all speeds

5.4 02h (OVFL) Overflow Status Register

R/W76543210