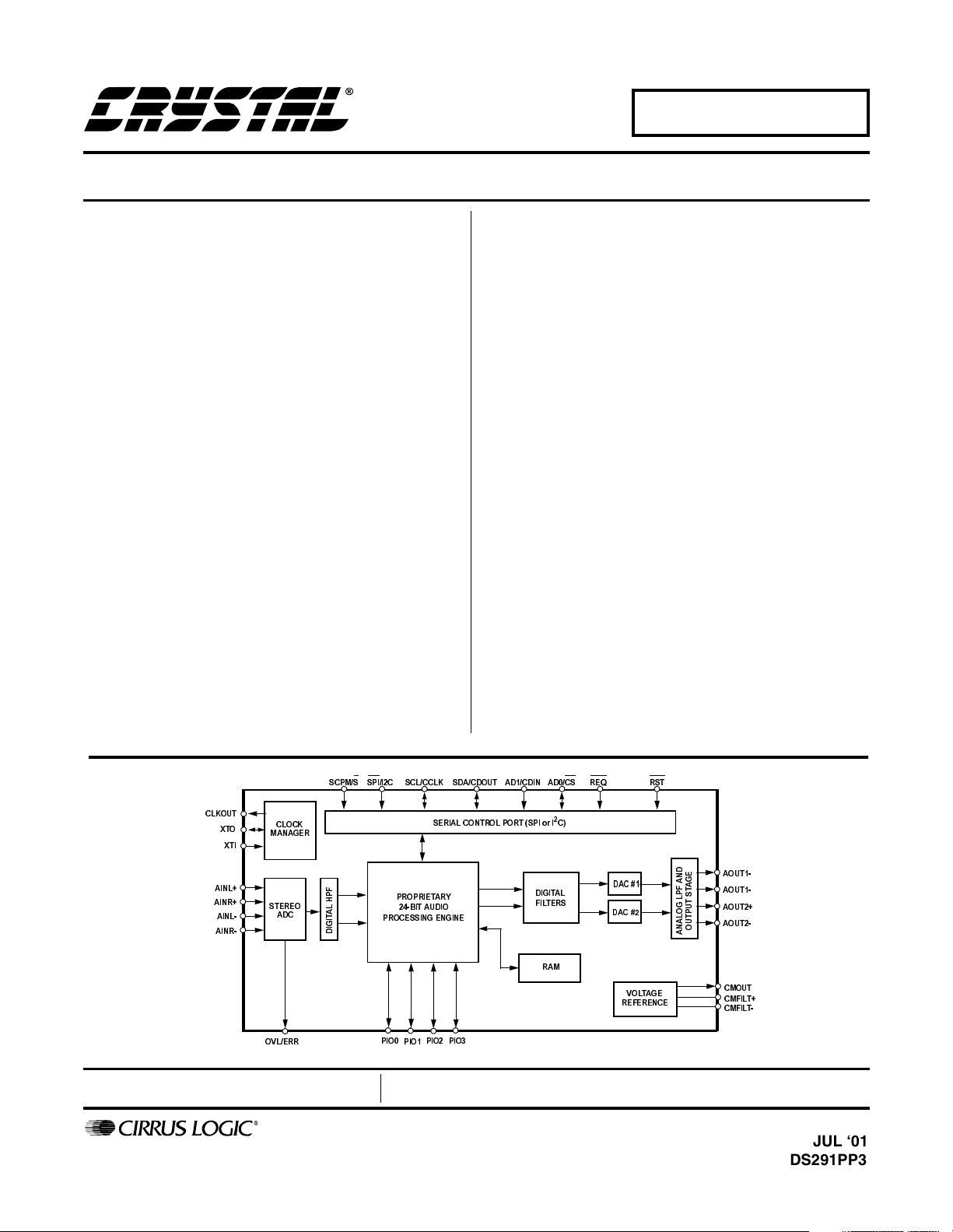

CS4812

Fixed Function Multi-Effects Audio Processor

Features

l DSP for embedded reverb/effects

applications

– 24-bit Audio Processing Engine

– No External RAM required

– Two 24-bit ∆Σ ADCs with 100 dB Dyn. Range

– Two 24-bit ∆Σ DACs with 100 dB Dyn. Range

l Mono Guitar or Mixer Effects firmware

included

l Real time parameter control via messaging

protocol

l Serial Control Port for microcontroller

interface

l Single +5V supply operation

l 100-pin Metric Quad Flat Package (MQFP)

ORDERING INFO

CS4812-KM -10 to +70°C 100-pin MQFP

CDB4812 Electric Guitar Effects w/

Parameter Controls.

Description

The CS4812 is a complete audio effects processing

system on a chip. This device includes a proprietary 24bit audio processing engine with considerable on-chip

RAM, two ADCs and two DACs. A full-featured serial

control port allows interfacing to an external host

microcontroller. Other features such as single +5V

operation simplify system design.

The CS4812, combined with Crystal effects firmware, is

the ideal solution for a variety of effects processing

applications where user parameter control is desired.

The Crystal effects firmware provides a messaging

protocol for the serial control port that allows an external

microcontroller to have real-time parameter control over

the audio effects. The complete processor and effects

solution may be evaluated with the CDB4812

demonstration board. The CDB4812 demonstrates a

host of mono electric guitar effects including a digital

spring reverb, delay, chorus, flange and tremolo with

parameter adjustment capability. Please refer to AN195

for more information on application firmware for the

CS4812.

I

6&306 63,,& 6&/&&/. 6'$&'287 $'&',1 $'&6 5(4 567

&/.287

;72

;7,

$,1/

$,15

$,1/

$,15

&/2&.

0$1$*(5

67(5(2

$'&

29/(55

Advance Product Information

P.O. Box 17847, Austin, Texas 78760

(512) 445 7222 FAX: (512) 445 7581

http://www.cirrus.com

6(5,$/&21752/325763,RU,&

'

$287

(

)

3

+

/

$

7

,

*

,

'

35235,(7$5<

%,7$8',2

352&(66,1*(1*,1(

3,2

3,2

3,23,2

',*,7$/

),/7(56

5$0

'$&

'$&

92/7$*(

5()(5(1&(

1

*

$

$

)

7

$287

3

6

/

7

*

8

$287

2

3

/

7

$

8

$287

1

2

$

&0287

&0),/7

&0),/7

This document contains information for a new product.

Cirrus Logic reserves the right to modify this product without notice.

Copyright Cirrus Logic, Inc. 2001

(All Rights Reserved)

DS291PP3

JUL ‘01

1

TABLE OF CONTENTS

1. CHARACTERISTICS AND SPECIFICATIONS ........................................................................ 4

2. TYPICAL CONNECTION DIAGRAMS ................................................................................... 14

3. FUNCTIONAL DESCRIPTION ............................................................................................... 17

3.1 Overview .......................................................................................................................... 17

3.2 Analog Inputs ................................................................................................................... 17

3.2.1 Line Level Inputs ................................................................................................. 17

3.2.2 Digital High Pass Filter ........................................................................................ 18

3.3 Analog Outputs ................................................................................................................ 18

3.3.1 Line Level Outputs .............................................................................................. 18

3.4 Clock Generation ............................................................................................................. 19

3.4.1 Clock Source ....................................................................................................... 19

3.5 Serial Control Port ............................................................................................................ 19

3.5.1 SPI Bus ............................................................................................................... 19

3.5.1.1 SPI Master Mode ................................................................................ 20

3.5.1.2 SPI Slave Mode .................................................................................. 20

2

3.5.2 I

3.6 Boot Modes ...................................................................................................................... 26

3.6.1 AutoBoot ............................................................................................................. 26

3.6.2 HostBoot ............................................................................................................. 26

3.7 Resets ............................................................................................................................. 27

4. POWER SUPPLY AND GROUNDING ................................................................................... 28

5. PIN DESCRIPTIONS .............................................................................................................. 29

6. PARAMETER DEFINITIONS .................................................................................................. 33

7. PACKAGE DIMENSIONS ...................................................................................................... 34

C Bus ................................................................................................................ 23

3.5.2.1 I

3.5.2.2 I

CS4812

2

C Master Mode ................................................................................. 23

2

C Slave Mode ................................................................................... 24

LIST OF FIGURES

Figure 1. SPI Control Port Slave Mode Timing .......................................................... 8

Figure 2. SPI Control Port Master Mode (AutoBoot) Timing ..................................... 9

Figure 3. I

Figure 4. I

Figure 5. Typical Connection Diagram, Control Port Slave Mode ........................... 14

Figure 6. Typical Connection Diagram, Control Port I

Figure 7. Typical Connection Diagram, Control Port SPI Master Mode .................. 15

Figure 8. Typical Connection Diagram, Control Port I

Figure 9. Typical Connection Diagram, Control Port SPI Slave Mode .................... 16

Figure 10.Recommended Line Input Buffer .............................................................. 17

Contacting Cirrus Logic Support

For a complete listing of Direct Sales, Distributor, and Sales Representative contacts, visit the Cirrus Logic web site at:

http://www.cirrus.com/corporate/contacts/

Preliminary product information describes products which are in production, but for which full characterization data is not yet available. Advance product information describes products which are in development and subject to development changes. Cirrus Logic, Inc. has made best efforts to ensure that the information

contained in this document is accurate and reliable. However, the information is subject to change without notice and is provided “AS IS” without warranty of any

kind (express or implied). No responsibility is assumed by Cirrus Logic, Inc. for the use of this information, nor for infringements of patents or other rights of third

parties. This document is the property of Cirrus Logic, Inc. and implies no license under patents, copyrights, trademarks, or trade secrets. No part of this publication may be copied, reproduced, stored in a retrieval system, or transmitted, in any form or by any means (electronic, mechanical, photographic, or otherwise)

without the prior written consent of Cirrus Logic, Inc. Items from any Cirrus Logic website or disk may be printed for use by the user. However, no part of the

printout or electronic files may be copied, reproduced, stored in a retrieval system, or transmitted, in any form or by any means (electronic, mechanical, photographic, or otherwise) without the prior written consent of Cirrus Logic, Inc.Furthermore, no part of this publication may be used as a basis for manufacture or

sale of any items without the prior written consent of Cirrus Logic, Inc. The names of products of Cirrus Logic, Inc. or other vendors and suppliers appearing in

this document may be trademarks or service marks of their respective owners which may be registered in some jurisdictions. A list of Cirrus Logic, Inc. trademarks and service marks can be found at http://www.cirrus.com.

2C®

Control Port Slave Mode Timing ...................................................... 11

2C®

Control Port Master Mode (AutoBoot) Timing .................................. 12

2

C Master Mode ................... 15

2

C Slave Mode ..................... 16

2 DS291PP3

Figure 11.Single Ended Input ................................................................................... 18

Figure 12.Butterworth Output Filters ........................................................................ 18

Figure 13.Output Mute Circuit .................................................................................. 19

Figure 14.Control Port Timing, SPI Master Mode AutoBoot ..................................... 20

Figure 15.Control Port Timing, SPI Slave Mode Write ............................................. 20

Figure 16.SPI Slave Write Flow Diagram ................................................................. 21

Figure 17.Control Port Timing, SPI Slave Mode Read ............................................. 21

Figure 18.SPI Slave Mode Read Flow Diagram........................................................ 22

Figure 19.SPI Slave Mode Read Flow Diagram with DSP REQ .............................. 22

Figure 20.Control Port Timing, I

Figure 21.I

2

C Slave Mode Write Flow Diagram ........................................................ 24

Figure 22.Control Port Timing, I

Figure 23.Control Port Timing, I

2

Figure 24.I

Figure 25.I

C Slave Mode Read Flow Diagram ....................................................... 25

2

C Slave Mode Read Flow Diagram with DSP REQ ............................... 26

2

C Master Mode AutoBoot ..................................... 23

2

C Slave Mode Write .............................................. 24

2

C Slave Mode Write .............................................. 24

Figure 26.HostBoot Flow Diagram ........................................................................... 27

Figure 27.CS4812 Suggested Layout ...................................................................... 28

Figure 28.Pin Assignments ...................................................................................... 29

CS4812

DS291PP3 3

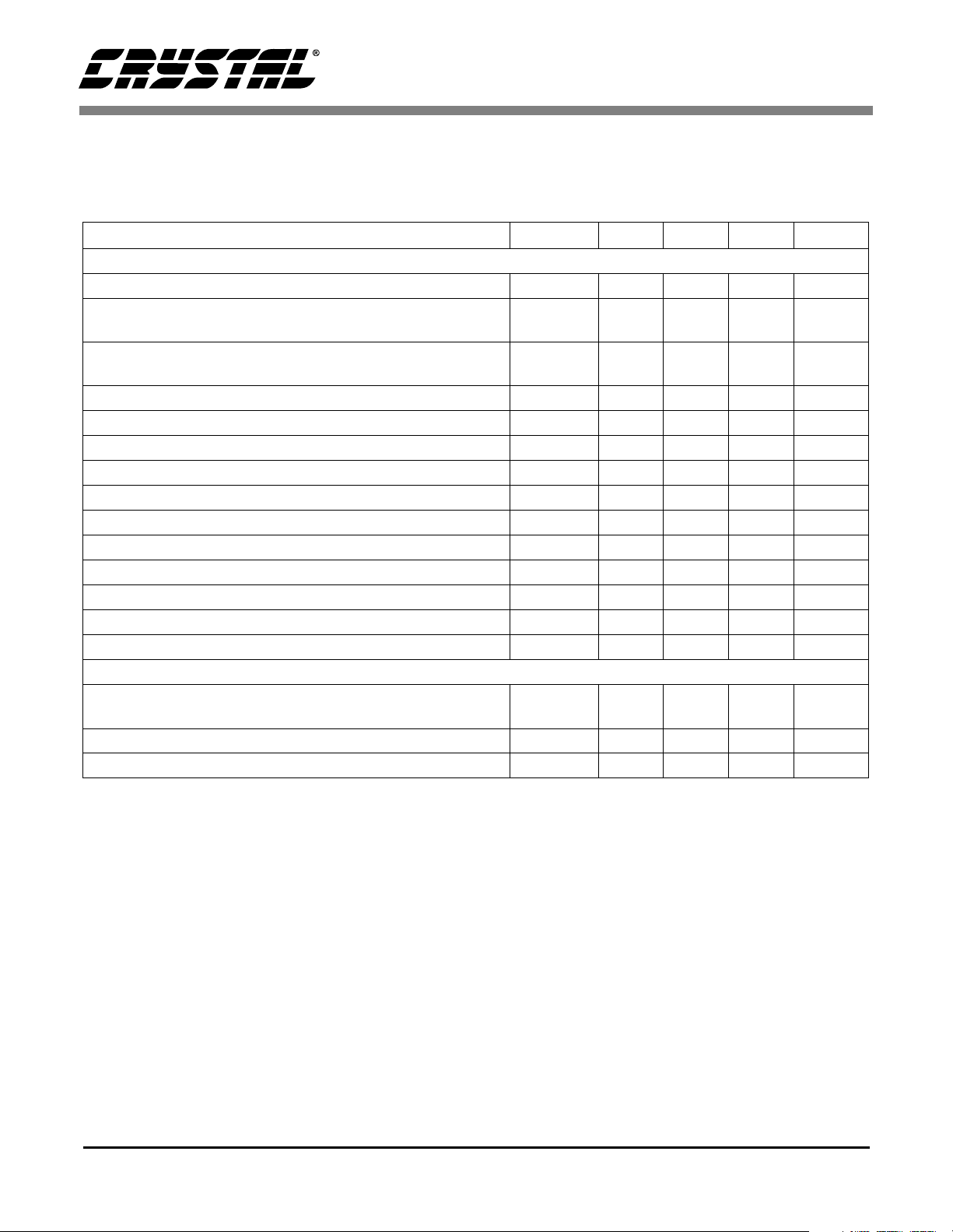

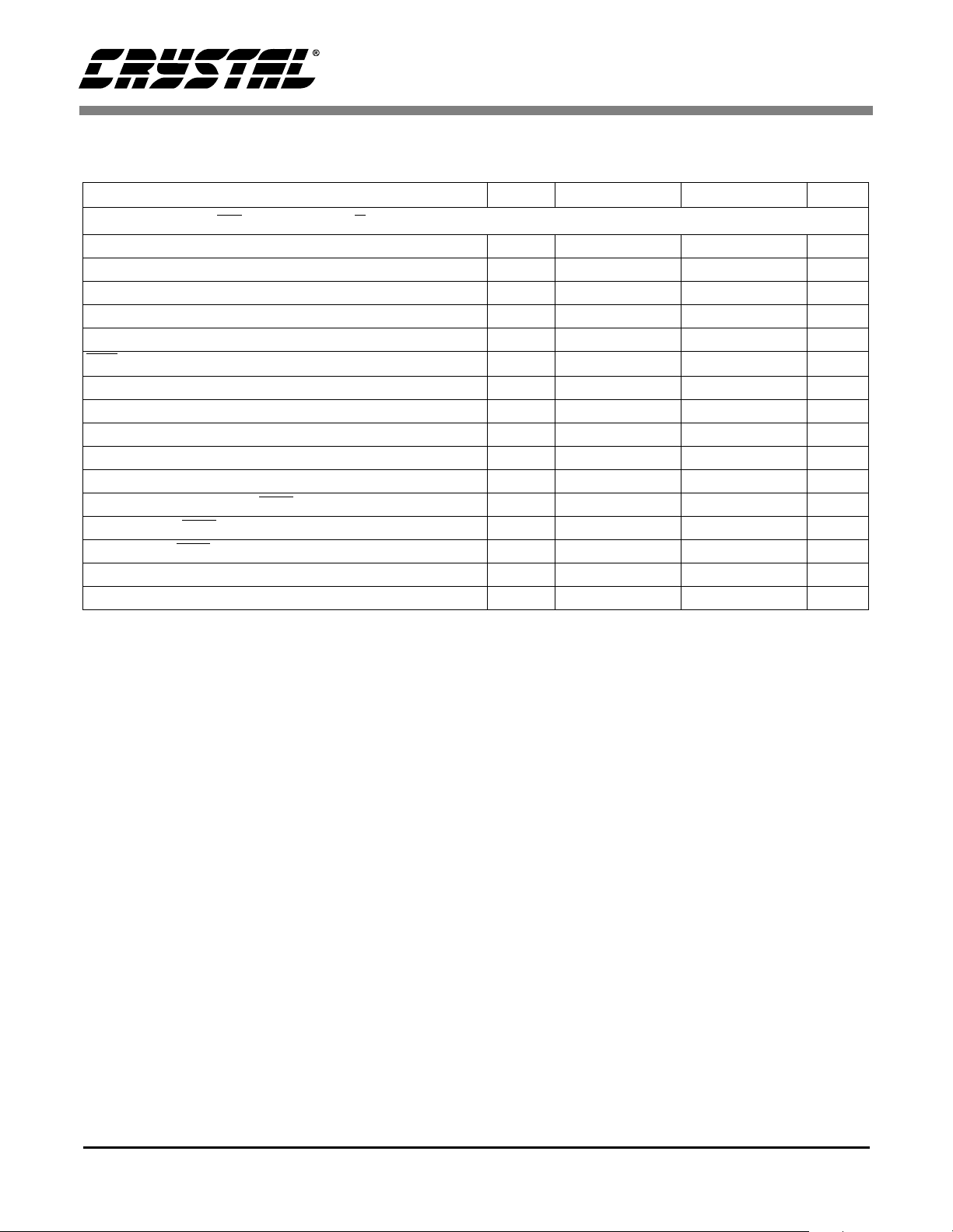

1. CHARACTERISTICS AND SPECIFICATIONS

CS4812

ADC CHARACTERISTICS (T

997 Hz; Fs = 48 kHz; XTI = 12.288 MHz (PLL disabled). Measurement Bandwidth is 20 Hz to 20 kHz.)

Parameters Symbol Min Typ Max Units

Analog Input Characteristics

ADC Conversion Stereo Audio channels 16 - 24 Bits

Dynamic Range (A weighted, Note 5)

(unweighted, Note 5)

Total Harmonic Distortion + Noise (Note 1,5)

(PLL enabled) (Note 1,2,5)

Interchannel Isolation - 90 - dB

Interchannel Gain Mismatch - 0.1 - dB

Offset Error (with high pass filter enabled) (Note 6) - - 0 LSB

Full Scale Input Voltage (Differential) 1.9 2.0 2.1 V

Gain Drift (Note 2) - 100 - ppm/°C

Input Resistance 10 - - kΩ

Input Capacitance - - 15 pF

CMOUT Output Voltage - 2.3 - V

Common Mode Rejection Ratio (Note 2) CMRR 60 dB

Group Delay (Fs = Output Sample Rate) (Note 4) t

Group Delay Variation vs. Frequency ∆t

High Pass Filter Characteristics

Frequency Response -3dB (Note 3)

Phase Deviation @ 20 Hz (Note 3) - 10 - Degree

Passband Ripple - - 0 dB

= 25°C; VA, VD = + 5V; -1 dB Full Scale Input Sine wave,

A

-0.14dB (Note 3)

THD+N -

gd

gd

93

90

-

-15/Fs- s

--0µs

-

-

100

97

-92

-92

3.7

20

-

-

-87

-

-

-

dB

dB

dB

rms

Hz

Hz

Notes: 1. Referenced to typical full-scale differential input voltage (2 V

2. Bench tested only.

3. Filter characteristics scale with output sample rate.

4. Group delay for Fs = 48 kHz, t

5. Measured using differential analog input circuit, see Figure 10.

6. Filter Response is not tested but guaranteed by design.

4 DS291PP3

= 15/48 kHz = 313 µs.

gd

rms

).

CS4812

DAC CHARACTERISTICS (T

997 Hz; Fs = 48 kHz; XTI = 12.288 MHz (PLL disabled). Measurement Bandwidth is 20 Hz to 20 kHz.)

Parameters Symbol Min Typ Max Units

Analog Output Characteristics - Minimum Attenuation, 10 kΩ, 100 pF load; unless otherwise specified.

DAC Resolution 16 - 24 Bits

Dynamic Range (DAC not muted, A weighted) 95 100 - dB

Total Harmonic Distortion + Noise THD+N - -90 -85 dB

Interchannel Isolation - 90 - dB

Interchannel Gain Mismatch - 0.1 - dB

Offset Voltage (differential) (Note 7) - -20 ± 5 - mV

Offset Voltage (V+/V- relative to CMOUT) (Note 7) - -45/-25 - mV

Full Scale Output Voltage (Differential) 1.9 2.0 2.1 V

Gain Drift (Note 2) - 100 - ppm/°C

Out of Band Energy (Fs/2 to 2Fs, Note 2) - -60 - dBFS

Analog Output Load Resistance

Capacitance

Group Delay (Fs = Input Sample Rate) t

Analog Loopback Performance

Signal-to-Noise Ratio (CCIR-2K weighted, -20 dB input) CCIR-2K - 74 - dB

Power Supply

Power Supply Current Operating

Power Down (Note 8)

Power Supply Rejection (1 kHz, 10 mV

= 25°C; VA, VD = + 5V; -1 dB Full Scale Output Sine wave,

A

10

-

gd

, Note 2) - 50 - dB

rms

-16/Fs- s

-

-

-

-

200

1

100

rms

-

-

-

kΩ

pF

mA

mA

Notes: 7. Measured with DAC calibration disabled.

8. Measured with XTI clock disabled.

DS291PP3 5

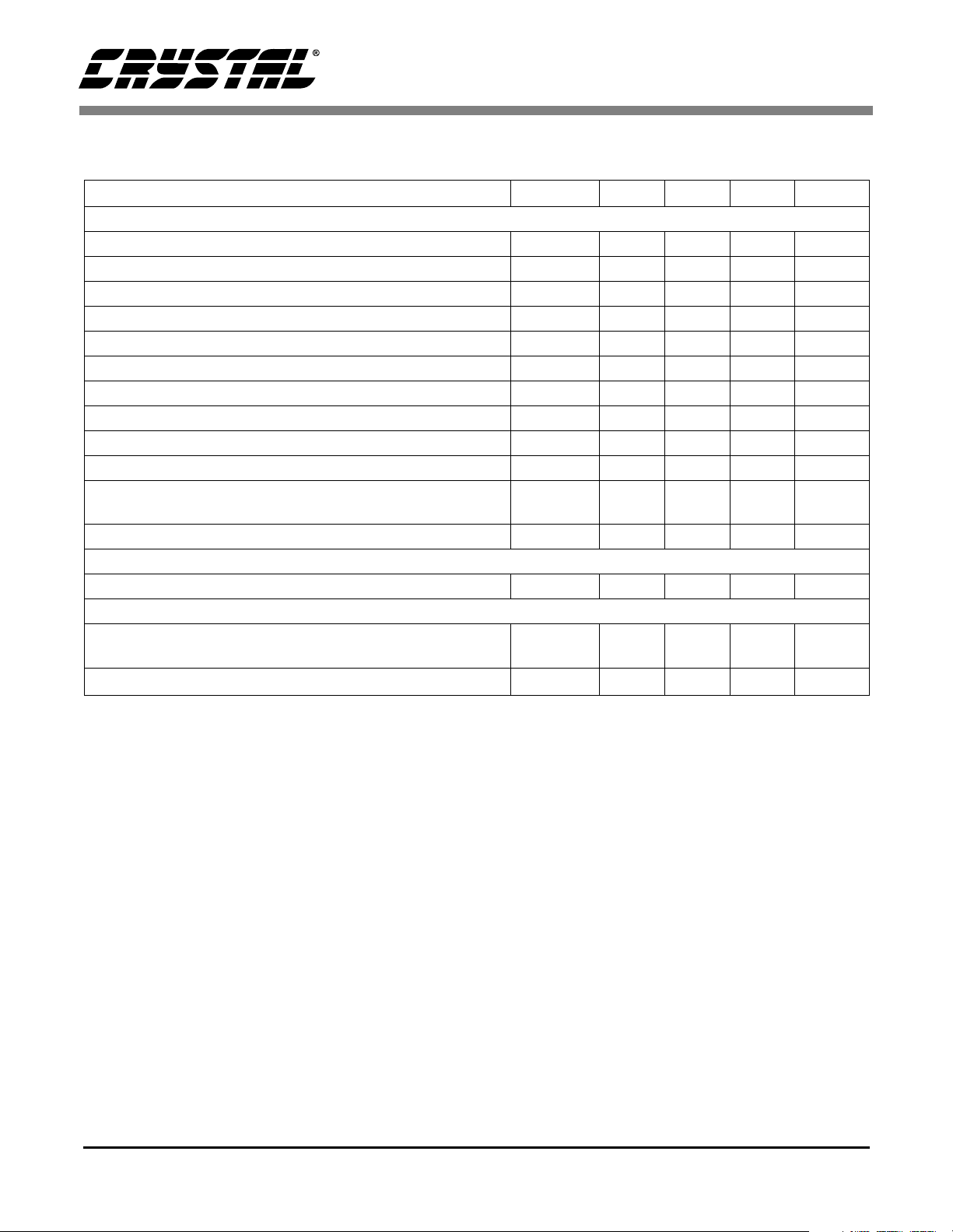

CS4812

SWITCHING CHARACTERISTICS (T

Parameters Symbol Min Typ Max Units

Audio ADC’s & DAC’s Sample Rate Fs 30 - 50 kHz

XTI Frequency XTI = 128Fs, 256Fs, 512Fs 3.84 - 25.6 MHz

XTI Duty Cycle XTI = 128Fs, 256Fs, 512Fs (Note 9) 40 - 60 %

XTI Jitter Tolerance - 500 - ps

Low Time (Note 10) 500 - - ns

RST

Notes: 9. Guaranteed by characterization but not tested.

10. On power-up, the CS4812 RST

state.

pin should be asserted until the power supplies have reached steady

= 25 °C; VA, VD = +5V, CL = 30 pF)

A

6 DS291PP3

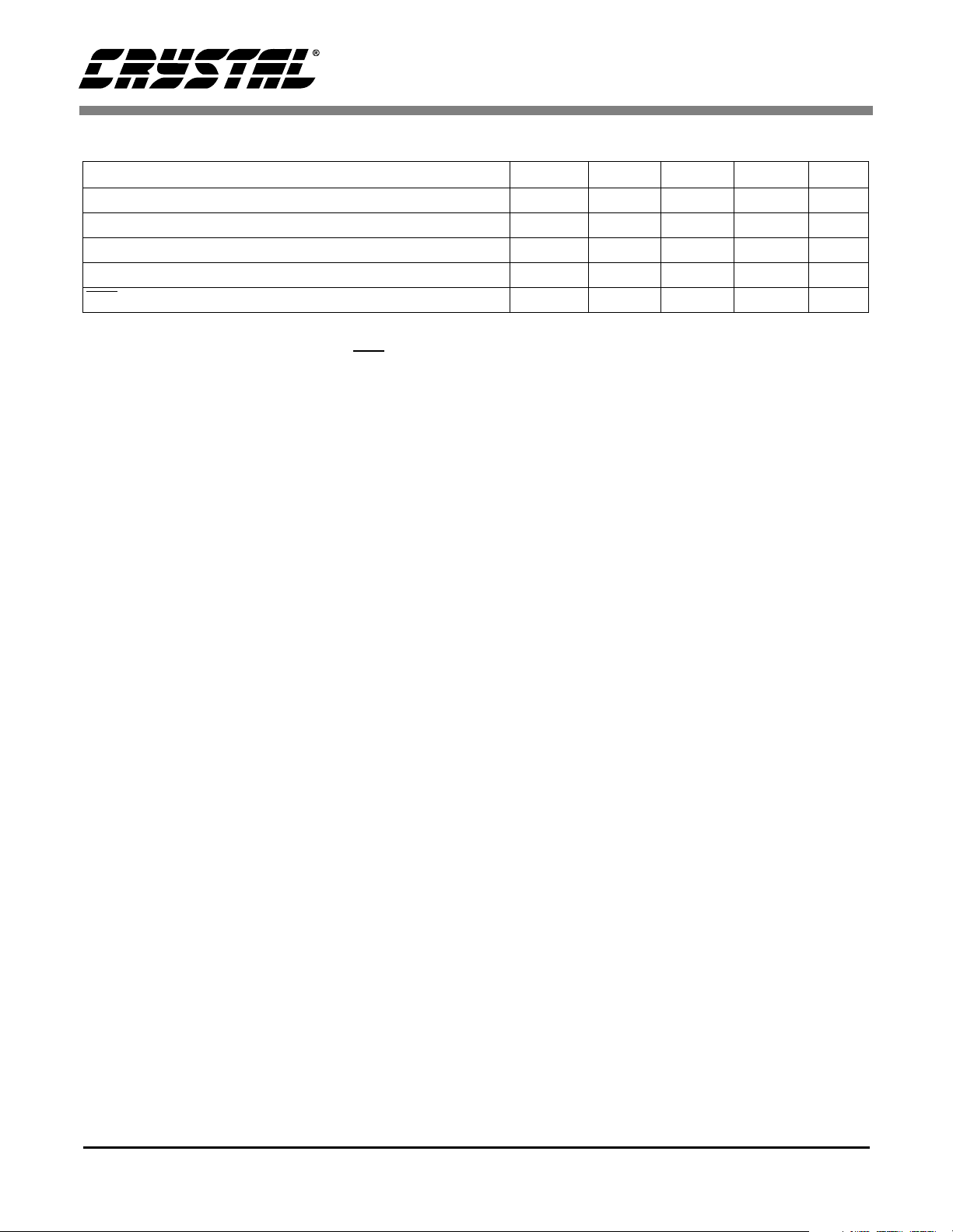

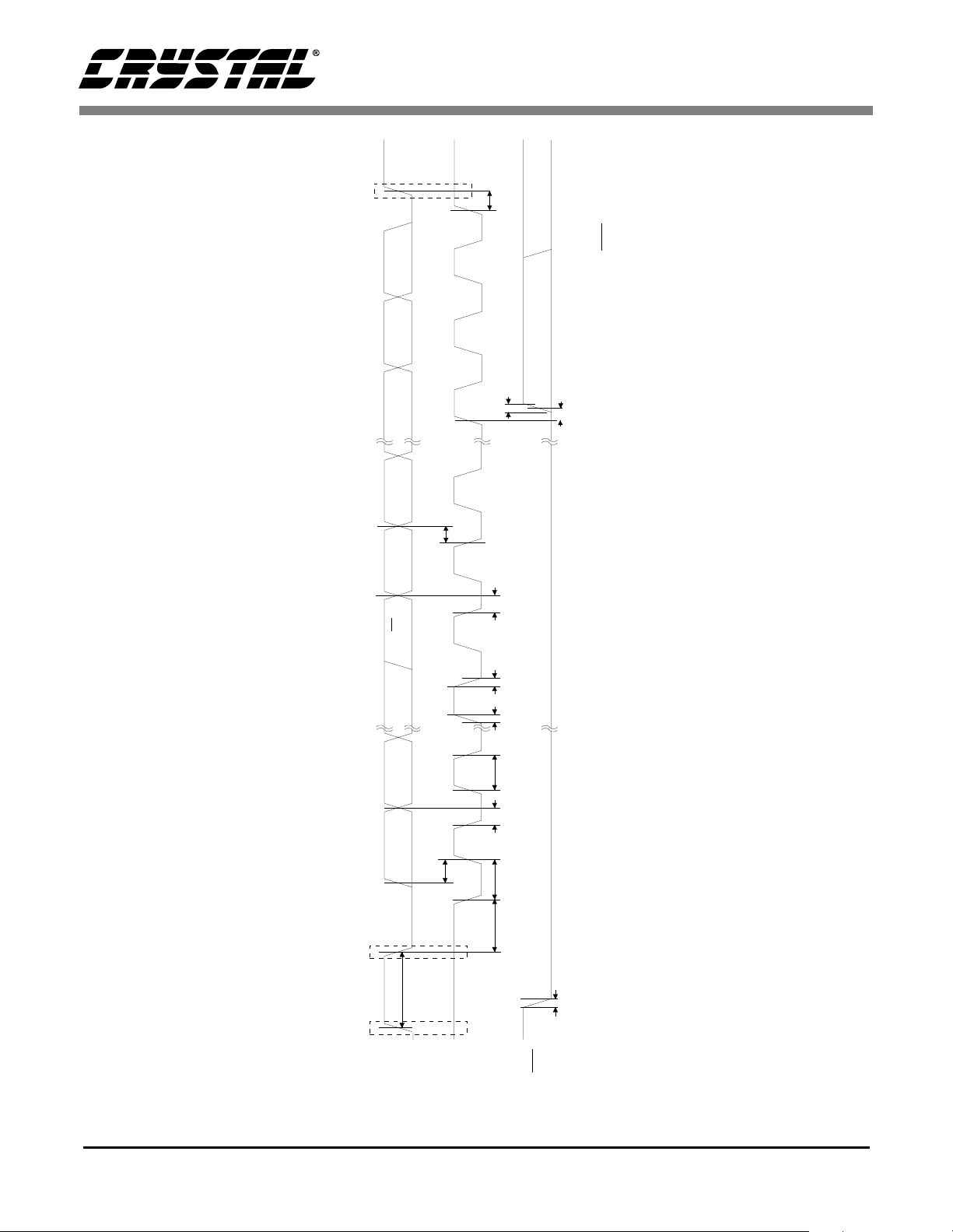

SWITCHING CHARACTERISTICS - CONTROL PORT - SPI SLAVE

(TA = 25 °C; VA, VD = 5 V; Inputs: Logic 0 = DGND, Logic 1 = VD, CL = 30 pF)

Parameter Symbol Min Max Unit

CS4812

SPI Slave Mode (SPI

CCLK Clock Frequency

CCLK Low Time

CCLK High Time

Rise Time of Both CDIN and CCLK Lines

Fall Time of Both CDIN and CCLK Lines

Setup Time CDIN to CCLK Rising

Hold Time CCLK Rising to CDIN (Note 11)

Time from CCLK edge to CDOUT Valid (Note 12)

Rise Time for CDOUT

Fall Time for CDOUT

CS

Falling to CCLK Rising

Time from CCLK Falling to CS

High Time Between Active CS

Time from CCLK Rising to REQ

Rise Time for REQ

Fall Time for REQ

/I2C = 0, SCPM/S = 0, Note 14)

Rising

Rising (Note 13)

f

sck

t

scl

t

sch

t

t

t

cdisu

t

cdih

t

scdov

t

cdor

t

cdof

t

css

t

sccsh

t

csht

t

scrh

t

t

-6MHz

66 - ns

66 - ns

r

f

-100ns

-100ns

40 - ns

15 - ns

-45ns

-25ns

-25ns

20 - ns

0-ns

1-µs

-2*DSPCLK+10ns

rr

rf

-100ns

-100ns

Notes: 11. Data must be held for sufficient time to bridge 100 ns transition time of CCLK.

12. CDOUT should NOT be sampled during this time period.

13. DSPCLK frequency is twice the DSP instruction rate.

14. Timing is guaranteed by characterization. Production test guarantees functionality.

DS291PP3 7

CS4812

A6

csht

t

sccsh

t

7

6

5

LSB

MSB

R/W

A0A6 A5

tri-state

LSB

MSB

cscdo

t

*

rh

t

scdov

t

scdov

t

scrh

t

* See section 3.5.1.2 for a detailed explanation of REQ behavior

Figure 1. SPI Control Port Slave Mode Timing

cdih

t

cdisu

t

rf

t

CDIN

CDOUT

REQ

(output)

CS

sch

t

scl

t

css

t

(input)

f

t

r

t

(input)

SCL/CCLK

8 DS291PP3

SWITCHING CHARACTERISTICS - CONTROL PORT - SPI MASTER

(TA = 25°C, VA, VD = 5V; Inputs: logic 0 = DGND, logic 1 = VD, CL = 30 pF)

Parameter Symbol Min Typ Max Units

SPI Master (AutoBoot) Mode (SPI

CCLK Clock Frequency (Note 15)

CCLK Low Time

CCLK High Time

CCLK Rise Time (Note 16)

CCLK Fall Time (Note 16)

RST

rising to CS falling

High Time Between Transmissions

CS

CS

Falling to CCLK Edge

CS

Falling to CDOUT valid

CCLK Falling to CDOUT valid

CDIN to CCLK Rising Setup Time

CCLK Rising to DATA Hold Time

CCLK Falling to CS

rising

/I2C = 0, SCPM/S = 1, Note 14)

f

sck

t

scl

t

sch

t

r2

t

f2

t

srs

t

csh

t

css

t

dv

t

pd

t

dsu

t

dh

t

clcs

-Fs-kHz

-1/(2*Fs)-ns

-1/(2*Fs)-ns

-12-ns

-12-ns

-42-µs

37 - - µs

5--µs

- - 50 ns

--100ns

80 - - ns

80 - - ns

40 - - ns

CS4812

Notes: 15. Depending on the input clock configuration, CCLK may be up to 2*Fs temporarily during AutoBoot after

RST

is de-asserted and before the control port registers have been initialized.

16. Measured with a 2.2 kΩ pull-up resistor to VD.

RST

CS

CCLK

CDIN

CDOUT

t

srs

t

css

t

t

t

sch

scl

t

t

f2

dsu

t

dh

t

r2

clcs

t

csh

t

dv

t

pd

Figure 2. SPI Control Port Master Mode (AutoBoot) Timing

DS291PP3 9

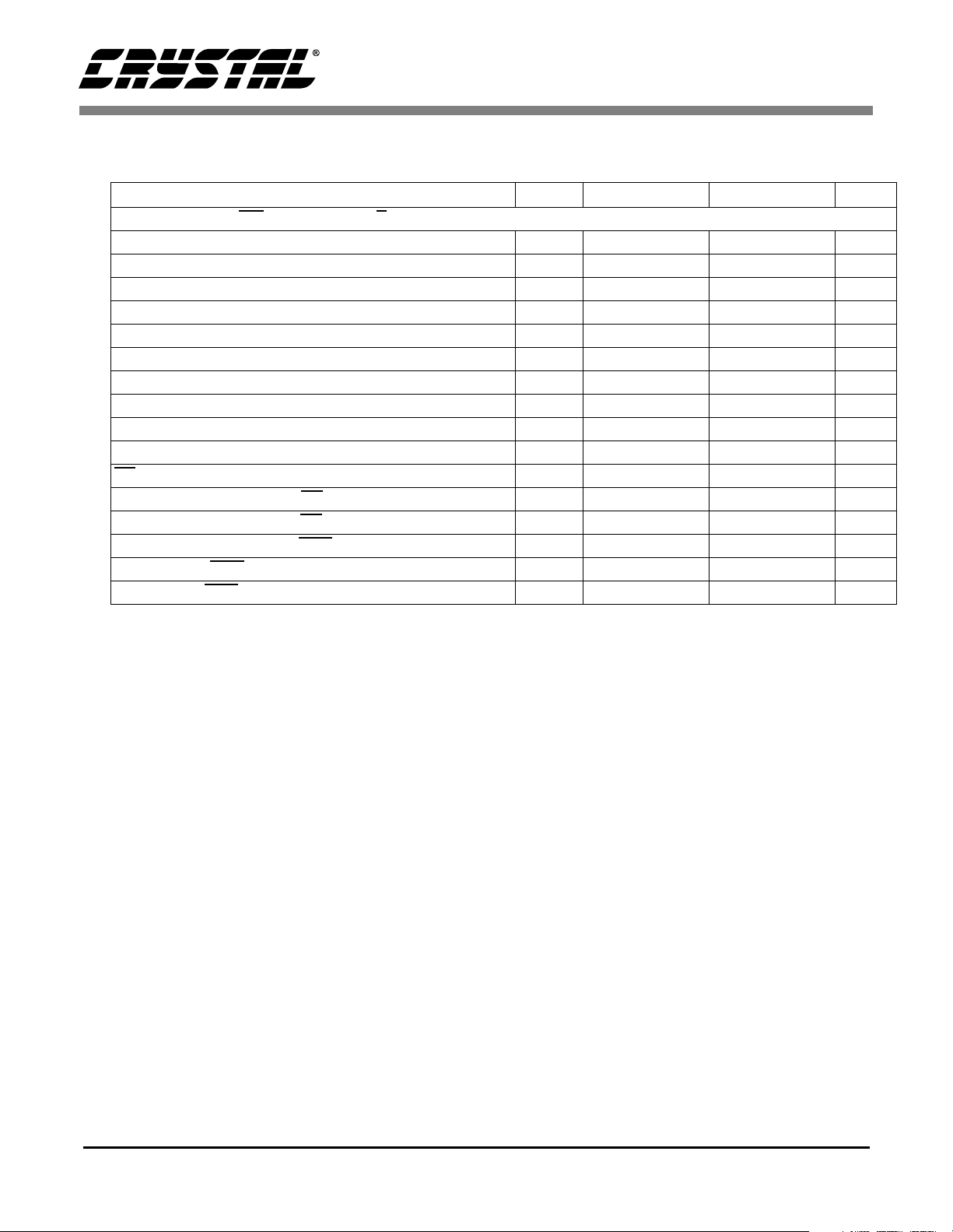

SWITCHING CHARACTERISTICS - CONTROL PORT - I2C® SLAVE

(TA = 25 °C; VA, VD = 5 V; Inputs: Logic 0 = DGND, Logic 1 = VD, CL = 30 pF)

Parameter Symbol Min Max Units

2C®

Slave Mode (SPI/I2C = 1, SCPM/S = 0) (Note 17)

I

SCL Clock Frequency

Bus Free Time Between Transmissions

Start Condition Hold Time (prior to first clock pulse)

SCL Low Time

SCL High Time

rising to start condition (Note18)

RST

SDA Hold Time from SCL Falling (Note 19)

Rise Time of Both SDA and SCL

Fall Time of Both SDA and SCL

SCL Falling to CS4812 ACK

SCL Falling to SDA Valid During READ

Time from SCL Rising to REQ

Rising (Note 20)

Rise Time for REQ

Fall Time for REQ

Setup Time for Stop Condition

Setup Time for Repeated Start

f

scl

t

buf

t

hdst

t

low

t

high

t

srs

t

hdd

t

sca

t

scsdv

t

scrh

t

t

t

susp

t

sust

t

r

t

f

rr

rf

-100kHz

4.7 - µs

4.0 - µs

4.7 - µs

4.0 - µs

1-ms

0-µs

-1µs

-300ns

-1.3µs

-1.5µs

-2*DSPCLK+10ns

-100ns

-100ns

4.7 - µs

4.7 µs

CS4812

Notes: 17. Use of the I

Semiconductors.

18. Not tested.

19. Data must be held for sufficient time to bridge the 300 ns transition time of SCL.

20. DSPCLK frequency is twice the DSP instruction rate.

2

C bus interface requires a license from Philips. I2C is a registered trademark of Philips

10 DS291PP3

CS4812

stop

ACK

LSB

MSBA0A6 A5

ACK

R/W

susp

t

8

7

rr

6

scsdv

t

t

80

sca

t

7

*

scrh

t

* See section 3.5.2.2 for a detailed explanation of REQ behavior

f

t

r

(input)

SCL/CCLK

t

high

t

hdd

t

low

t

hdst

t

rf

t

REQ

6

01

sud

t

start

buf

t

stop

SDA

Control Port Slave Mode Timing

®

C

2

Figure 3. I

DS291PP3 11

CS4812

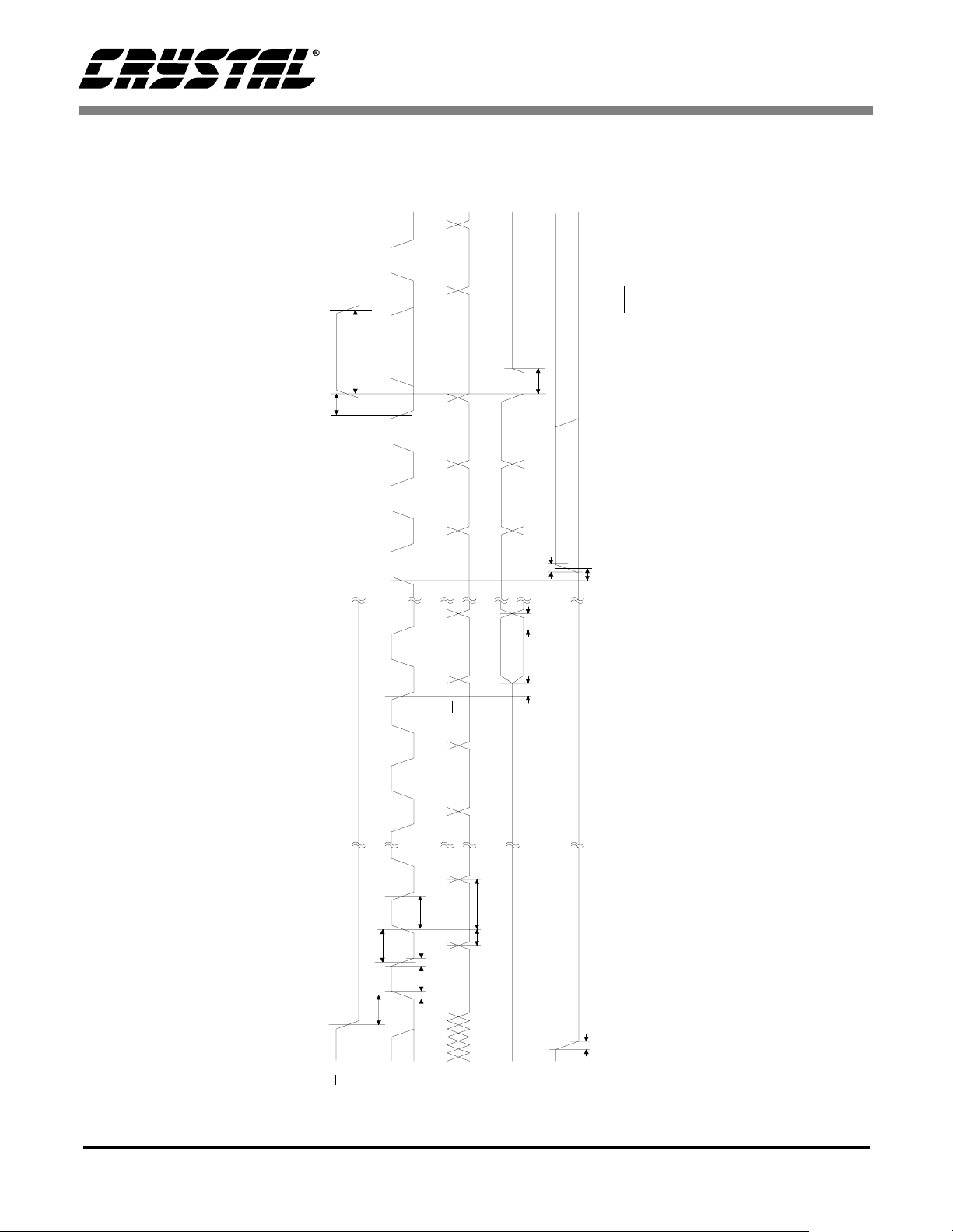

SWITCHING CHARACTERISTICS - CONTROL PORT - I2C® MASTER (T

VA, VD = 5V; Inputs: logic 0 = DGND, logic 1 = VD, C

Parameter Symbol Min Typ Max Units

2C®

I

Master (AutoBoot) Mode (SPI/I2C = 1, SCPM/S = 1) (Note 21)

SCL Clock Frequency (Note 22)

Clock Low Time

Clock High Time

Bus Free Time Between Transmissions

RST

rising to start condition

Start Condition Hold Time

Setup Time for Repeated Start Condition

SDA Setup Time to SCL Rising

SDA Hold Time from SCL Falling (Note 23)

SCL falling to SDA Output Valid

SCL and SDA Rise Time (Note 24)

SCL and SDA Fall Time (Note 24)

Setup Time for Stop Condition

Notes: 21. Use of the I

2

C bus interface requires a license from Philips. I2C is a registered trademark of Philips

Semiconductors.

22. Depending on the input clock configuration, CCLK may be up to 2*Fs temporarily during AutoBoot after

has been de-asserted and before the control port registers have been initialized.

RST

23. Data must be held for sufficient time to bridge the worst case fall time of 300 ns for CCLK/SCL.

24. For both SDA transmitting and receiving.

= 30 pF)

L

f

scl

t

low

t

high

t

buf

t

irs

t

hdst

t

sust

t

sud

t

hdd

t

cldv

t

t

t

susp

-Fs-kHz

-1/(2*Fs)-µs

-1/(2*Fs)-µs

4.7 - - µs

-22-µs

4.0 - - µs

13.5 - - µs

250 - - ns

0--µs

--1.5µs

r

f

--1µs

--300ns

4.7 - - µs

= 25°C;

A

RST

t

SDA

SCL

(output)

irs

Stop Start

t

buf

t

hdst

t

low

t

cldv

t

hdd

t

high

t

sud

Repeated

Start

t

sust

t

hdst

Stop

t

f

t

r

t

susp

Figure 4. I2C® Control Port Master Mode (AutoBoot) Timing

12 DS291PP3

CS4812

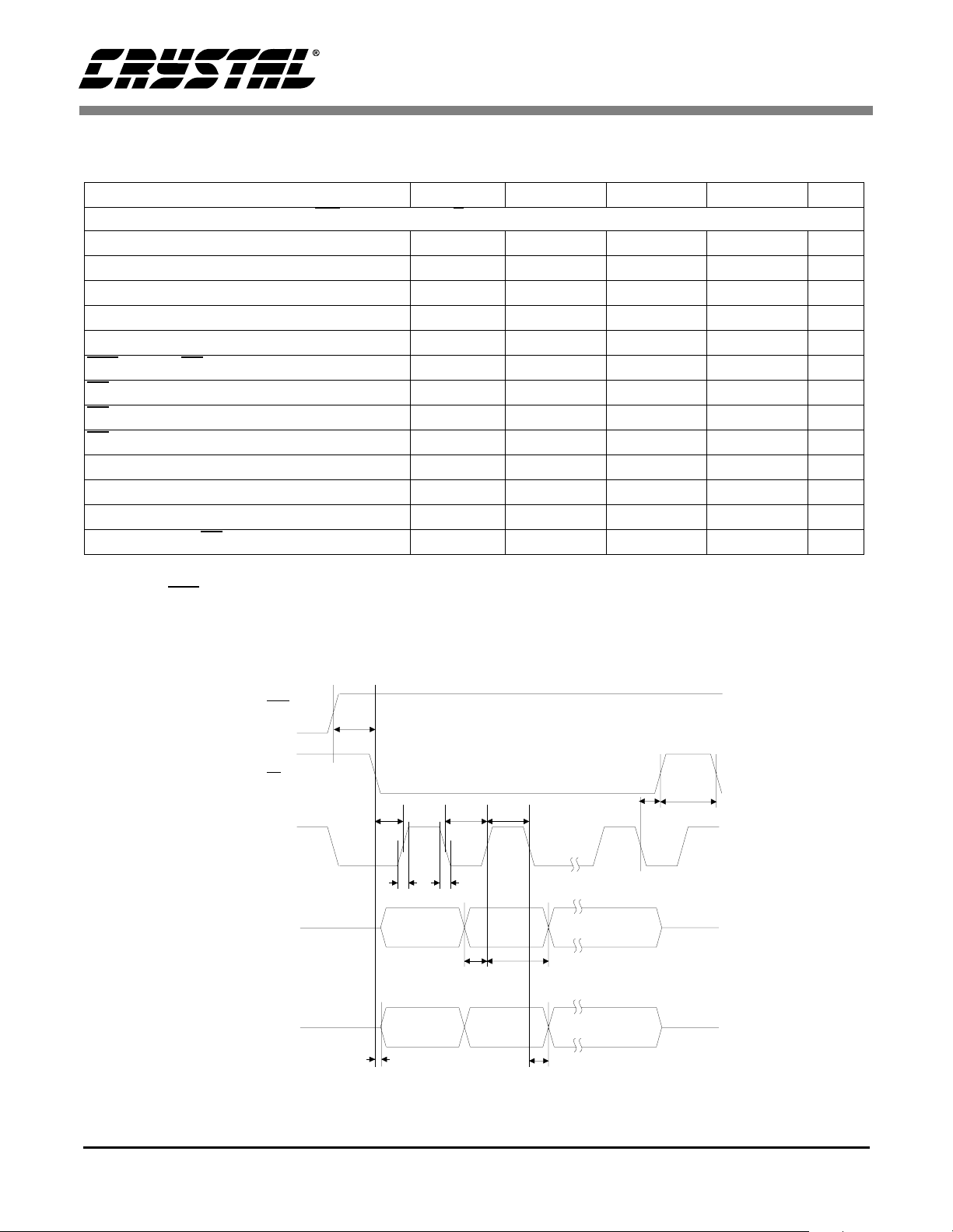

ABSOLUTE MAXIMUM RATINGS (All voltages with respect to AGND = DGND = 0V.)

Parameters Symbol Min Typ Max Units

Power Supplies Digital

AnalogVDVA

Input Current (Note 25) - - ±10.0 mA

Analog Input Voltage (Note 26) -0.7 - (VA)+0.7 V

Digital Input Voltage (Note 26) -0.7 - (VD)+0.7 V

Ambient Temperature (Power Applied) -55 - +125 °C

Storage Temperature -65 - +150 °C

Notes: 25. Any pin except supplies. Transient currents of up to ±100 mA on the analog input pins will not cause

SCR latch-up.

26. The maximum over or under voltage is limited by the input current.

Warning: Operation at or beyond these limits may result in permanent damage to the device.

Normal operation is not guaranteed at these extremes.

RECOMMENDED OPERATING CONDITIONS

(All voltages with respect to AGND = DGND = 0V.)

-0.3

-0.3

-

-

6.0

6.0

V

V

Parameters Symbol Min Typ Max Units

Power Supplies Digital

|VA - VD| < 0.4V AnalogVDVA

Operating Ambient Temperature T

DIGITAL CHARACTERISTICS (T

= 25 °C; VA, VD = 5V)

A

A

4.75

4.75

5.0

5.0

5.25

5.25

-10 25 70 °C

Parameters Symbol Min Typ Max Units

High-level Input Voltage (except XTI) V

Low-level Input Voltage (except XTI) V

High-level Output Voltage at I

Low-level Output Voltage at I

= -2.0 mA (except XTO) V

0

= 2.0 mA (except XTO) V

0

High-level Input Voltage (XTI) V

Low-level Input Voltage (XTI) V

IH

IL

OH

OL

IH

IL

2.8 - (VD)+0.3 V

-0.3 - 0.8 V

(VD)-1.0 - - V

--0.4V

2.8 - - V

--2.3V

Input Leakage Current (Digital Inputs) - - 10 µA

Output Leakage Current (High-Z Digital Outputs) - - 10 µA

SWITCHING CHARACTERISTICS - PROGRAMMABLE I/O

(TA = 25 °C; VA, VD = 5V ±5%; Inputs: logic 0 = DGND, logic 1 = VD, CL = 30 pF)

Parameters Symbol Min Typ Max Units

Output Rise Time t

Output Fall Time t

rpo

fpo

-200 -ns

-200 -ns

V

V

DS291PP3 13

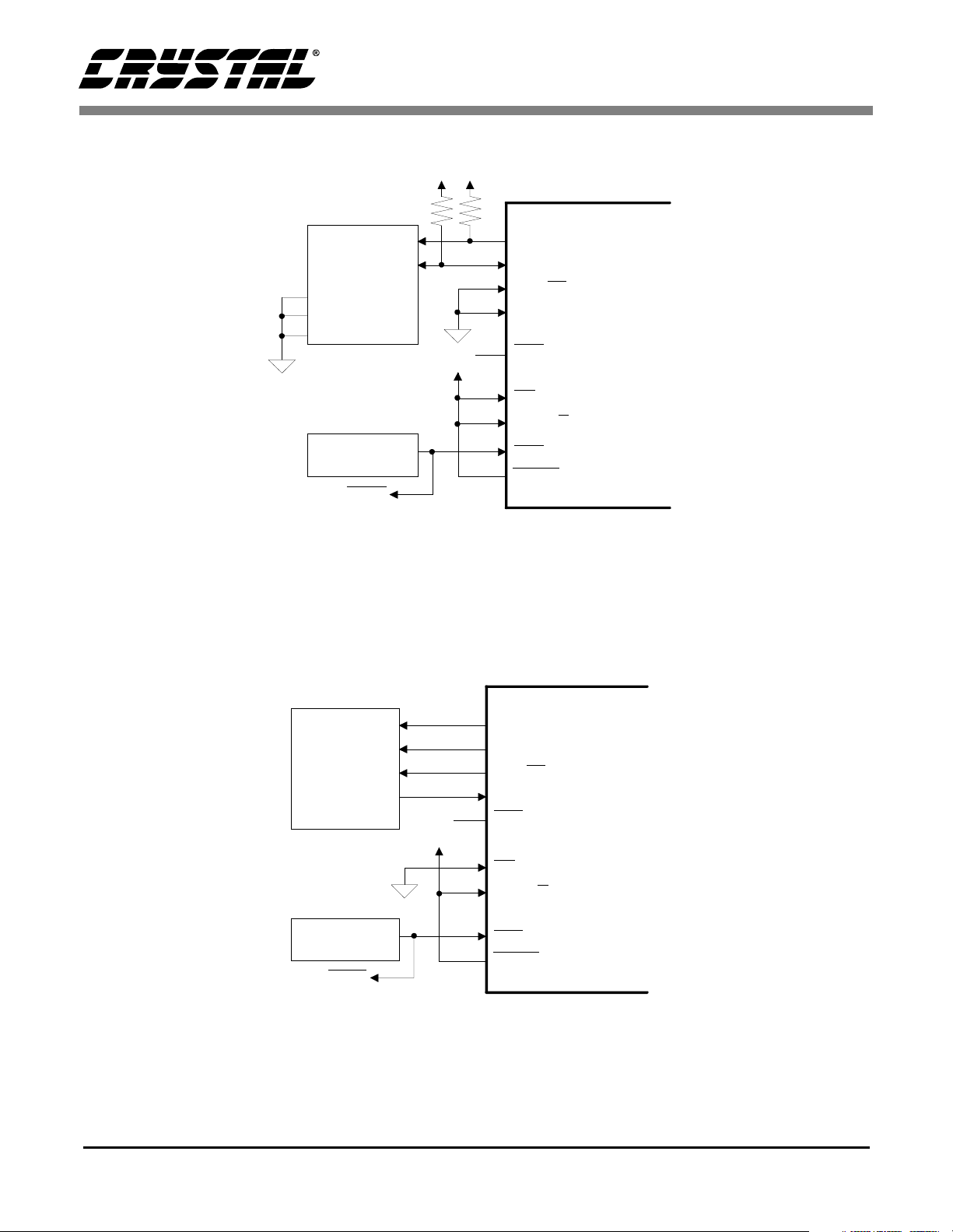

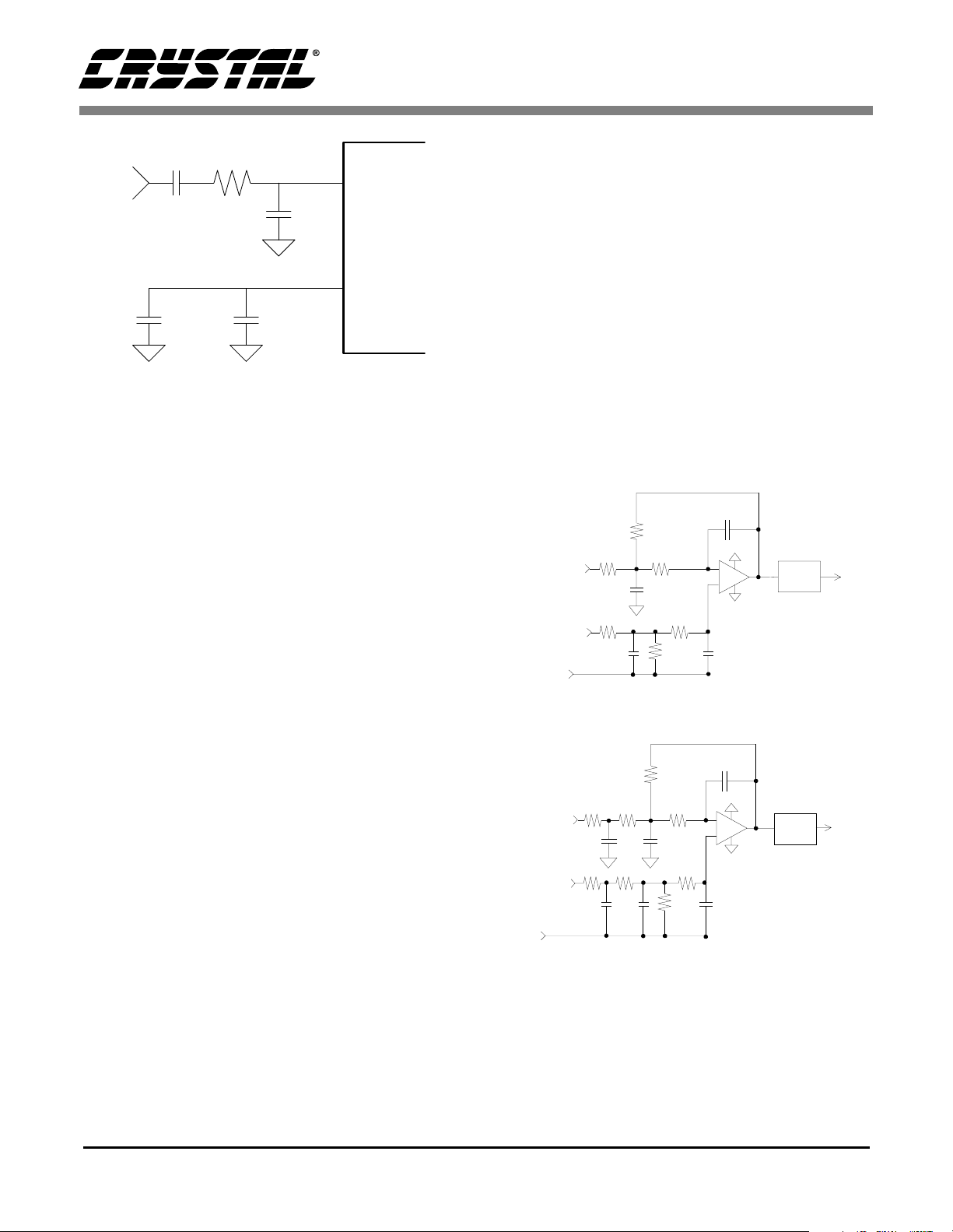

2. TYPICAL CONNECTION DIAGRAMS

12

VA1..3

AIN1L+

AIN1L-

AIN1R+

AIN1R-

ANALOG

FILTER

ANALOG

FILTER

86

87

90

91

1µF

+

AA

8818

0.1µF

Ferr ite Bead

43

VD1..2

+

65

µ

F 0.1µF

1

D

AOUT1+

AOUT1-

AOUT2+

AOUT2-

CS4812

+5 V

D

7

ANALOG

8

FILTER

9

ANALOG

10

FILTER

Program ROM

or

Serial EEPROM

To Optional

Input and

Output Buff ers

Microcontroller

1µF

+

1µF

A

DQ

74HC74

R

S

Mode/Reset

Cir cui t

RESET

Control /

Monit or

Cir cui tr y

R=33

S

All unuse d inputs

should be t ied to gro und.

2.2

K

0.1 µF

VD

D

Ω

0.1 µF

AA

VD

92

39

93

94

2.2

K

63

62

68

67

71

47

69

70

72

41

40

37

35

CMOUT

OVL

CMFILT+

CMFILT-

SCL/CCLK

SDA/CDOUT

AD0/CS

AD1/C DIN

REQ

CLKOUT

SPI/I 2C

SCPM/S

RST

PIO0

PIO1

PIO2

PIO3

AGND1..4

11

13 8919

A

CS4812

DGND1.. 4

42

44

64

D

RES-NC

RES-NC

RES-NC

RES-NC

RES-NC

RES-NC

RES-NC

XTI

45

1 M

39 pF

D

14

15

16

17

20

21

22

23

57

58

59

60

61

95

97

73

32

34

36

38

48

82

83

96

Ω

Optional External

Clock I nput instea d

of Crystal

VD

D

RES-NC

RES-NC

RES-NC

RES-NC

RES-NC

RES-NC

RES-NC

RES-NC

RES-VD

RES-DGND

RES-DGND

RES-DGND

RES-DGND

RES-DGND

RES-DGND

RES-DGND

RES-DGND

XTO

66

46

39 pF

D

Figure 5. Typical Connection Diagram, Control Port Slave Mode

14 DS291PP3

D

EEPROM

A0

A1

A2

Reset

Circuit

2

IC

RESET

2.2 K

VD

D

VD

VD

2.2 K

63

62

68

67

71

69

70

72

73

CS4812

CS4812

SCL/CCLK

SDA/CDOUT

AD0/CS

AD1/CDIN

REQ

SPI/I2C

SCPM/S

RST

PLLEN

Figure 6. Typical Connection Diagram, Control Port

2

I

C Master Mode

CS4812

63

SCL/CCLK

62

SPI

EEPROM

VD

D

Res et

Cir cuit

RESET

68

67

71

69

70

72

73

SDA/CDOUT

AD0/CS

AD1/CDIN

REQ

SPI/I2C

SCPM/S

RST

PLLEN

Figure 7. Typical Connection Diagram, Control Port

SPI Master Mode

DS291PP3 15

CS4812

VD

2.2 K

SDA

SCL

MICRO

CONTROLLER

GPIO

RESET

CIRCUIT

Figure 8. Typical Connection Diagram, Control Port

2

I

C Slave Mode

VD

D

74HC74

R

S

2.2 K

VD

SDA/CDOUT

SCL/CCLK

CLKOUT

AD0/CS

AD1/CDIN

REQ

SPI/I2C

SCPM/S

D

RST

PLLEN

CS4812

CS4812

SDA/CDOUT

SCL/CCLK

CLKOUT

AD0/CS

AD1/CDIN

REQ

SPI/I2C

SCPM/S

RST

PLLEN

CCLK

MICRO

CONTROLLER

RESET

CIRCUIT

MISO

CS

MOSI

GPIO

D

74HC74

R

S

D

VD

Figure 9. Typical Connection Diagram, Control Port

SPI Slave Mode

16 DS291PP3

CS4812

3. FUNCTIONAL DESCRIPTION

3.1 Overview

The CS4812 is a complete audio subsystem on a

chip, integrating an DSP with on-chip RAM, two

24-bit ADCs, two 24-bit DACs, and a serial control

port.

The sigma-delta ADCs include linear phase digital

anti-aliasing filters and only require a single-pole

external passive filter.

The sigma-delta DACs include analog switchedcapacitor anti-image filters and require an external

second or third order active filter that can be easily

integrated into an output differential-to-single-ended converter circuit.

The serial control port is designed to accommodate

I2C® or SPI interfaces and can operate in master or

slave mode. It allows interfacing to external nonvolatile memory for stand-alone operation or to a

host-controller for real-time control. All communications between the DSP and an external EEPROM

or host-controller are handled through the serial

control port.

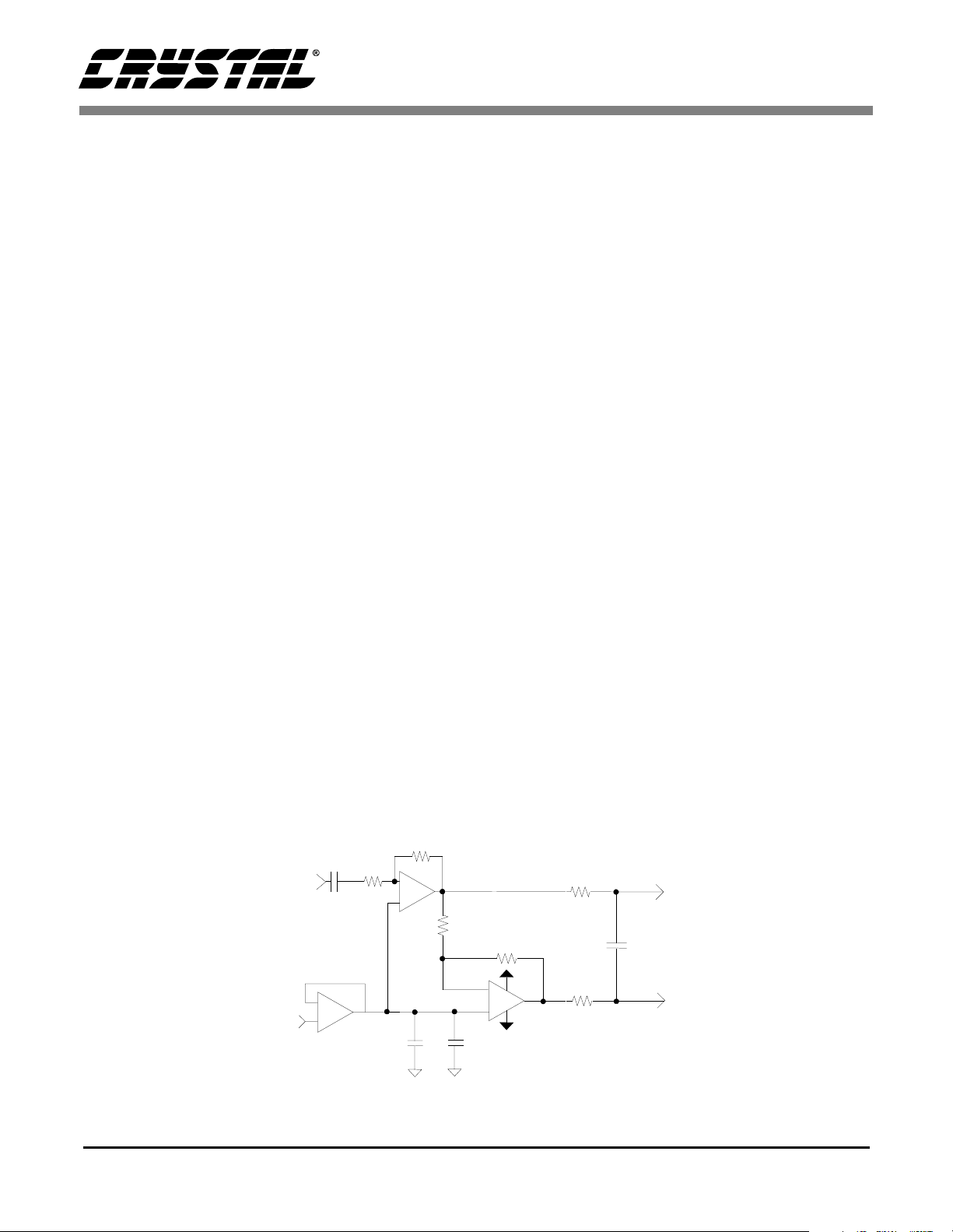

3.2 Analog Inputs

3.2.1 Line Level Inputs

AINR+, AINR-, AINL+, and AINL- are the line

level analog inputs (See Figure 5). These pins are

internally biased to the CMOUT voltage of 2.3 V.

A DC blocking capacitor placed in series with the

input pins allows signals centered around 0 V to be

input to the CS4812. Figure 5 shows operation with

a single-ended input source. This source may be

supplied to either the positive or negative input as

long as the unused input is connected to ground

through capacitors as shown. When operated with

single-ended inputs, distortion will increase at input levels higher than -1 dBFS. If better performance is required, a single-ended-to-differential

converter, shown in Figure 10, may be used. It provides unity gain, DC blocking and anti-alias filtering.

Inputs may be externally AC or DC coupled. This

permits use of the ADCs for input of audio signals

or for measurement of DC control voltages. By default, an internal high pass filter removes any DC

offsets from both of the ADC inputs. If measurement of DC is required on either of the ADC inputs,

then the on-chip high pass filter must be disabled.

Analog audio input signals that are DC coupled

must be biased at 2.3 V to maintain proper input

4.7 k

10µF

10 k

input signal

(2 Vrms max)

CMOUT

DS291PP3 17

+

-

+

Figure 10. Recommended Line Input Buffer

-

+

10 k

10 k

+5 V

-

+

+

GND

0.1µF10µf

150

AIN -

2.2 nf

150

AIN +

CS4812

CS4812

AIN

AIN

150

22 µF

2.2 nF

100 µF 0.1 µF

+

Ω

Figure 11. Single Ended Input

signal swing. DC control input voltages may range

from ground to Vcc.

ADC output data is in twos-complement binary

format. For inputs above full scale, the ADC digital

output saturates. The OVL output pin asserts when

the analog input is out-of-range.

3.2.2 Digital High Pass Filter

In DC coupled systems, a small DC offset may exist between the input circuitry and the A/D converters. The CS4812 includes a defeatable high pass

filter after the decimator to remove these DC components. The high pass filter response is given in

“High Pass Filter Characteristics” on page 4 and

scales linearly with sample rate. In applications

where DC level measurement is required, as would

occur when one of the ADC inputs is used for measurement of DC control voltages, the high pass filter may be disabled via a control port register.

Note: The high pass filter defeat operates on both

ADC inputs simultaneously therefore external DC

blocking must be provided in the design of the analog audio input circuit.

of driving 10 k

Ω loads to full scale. These amplifi-

ers internally biased to the CMOUT voltage of 2.3

V.

The recommended off-chip analog filter is a second

order Butterworth with a 3 dB corner at Fs. A third

order Butterworth filter with a -3 dB corner at 0.75

Fs can be used if greater out of band noise filtering

is desired. These filters can be easily integrated into

a differential-to-single-ended converter circuit as

shown in the 2-pole and 3-pole Butterworth filters

of Figure 12. The hardware mute circuit referenced

in Figure 12 is shown in Figure 13. Hardware muting is recommended on power-up and powerdown.

220 pF

Ω

14.0 k

+5 V

_

+

GND

Ω

Ω

220

pF

220

pF

Ω

+5 V

Ω

_

+

pF

GND

Ω

220

pF

Ω

Output

Mute Ckt

Output

Mute Ckt

Line

Out

Line

Out

BUFFERED

BUFFERED

CMOUT

CMOUT

A

OU T-

A

OUT+

A

A

OU

OUT+

2200

2200

Ω

T-

2.8k

2.8k

14.0 k

14.0 k

1000

pF

pF

3.24 k

1000

Ω

pF

2-Pole Butterworth Filter

Ω

Ω

11.0k

Ω

Ω

11.0k

pF

2200

Ω

pF

3.24 k

14.0 k

14.0k

2.8k

2200

2.8k

14.0k

3.3 Analog Outputs

3-Pole Butterworth Filter

3.3.1 Line Level Outputs

The CS4812 contains on-chip differential buffer

amplifiers that produce line level outputs capable

18 DS291PP3

Figure 12. Butterworth Output Filters

3.4 Clock Generation

Line Out

VA

From

CS4812

PIO

MMBT3906

MMBT3904

MMBT3906

10 k

Ω

10 k

Ω

10 k

Ω

GND

3.3 k

Ω

10 µF

1 kΩ10 µF

+

From Op-Amp

Figure 13. Output Mute Circuit

The CS4812 master clock may be generated by using the on-chip oscillator with an external crystal or

may be derived from an external clock source.

CS4812

tializes the hardware configuration registers and

downloads the application code to the DSP via 2

dedicated control port registers. Application messaging between the host and the DSP is also done

via these control port registers. The operation of the

control port may be completely asynchronous to

the audio sample rate. However, it is recommended

that the control port pins remain static when not in

use.

The required control port register settings are contained in the Crystal effects firmware application

code EEPROM image.

The control port supports the SPI bus and the I2C

bus in both master and slave modes. The bus interface is selected via the SPI/I2C pin and the master/slave mode is selected via the SCPM/S pin.

These pins are sampled during de-assertion of the

RST pin.

®

3.4.1 Clock Source

The CS4812 requires a 256 Fs master clock to run

the internal logic. The two possible clock sources

are the on-chip crystal oscillator or an external clock

input to the XTI pin.

When using the on-chip crystal oscillator, external

loading capacitors are required. (see Figure 5) High

frequency crystals (>8 MHz) should be parallel

resonant, fundamental mode and designed for

20 pF loading. (equivalent to 40 pF to ground on

each leg)

3.5 Serial Control Port

The serial control port contains all of the main control logic for the chip. It controls power-on sequencing, hardware configuration and DSP

operation. In AutoBoot mode, the serial control

port manages the entire boot process including initialization of its own hardware configuration registers from EEPROM, code download from the

EEPROM to the DSP and initialization of the CODEC. In host-controlled mode, the host-device ini-

Master mode is selected for stand-alone operation

when AutoBooting from an external serial EEPROM. Slave mode is selected when the CS4812 is

connected to an external host controller.

3.5.1 SPI Bus

The SPI bus interface consists of 5 digital signals,

CCLK, CDIN, CDOUT, CS and REQ. CCLK, the

control port bit clock, is used to clock individual data

bits. CDIN, the control data input, is the serial data

input line to the CS4812. CDOUT, the control data

output, is the output data line from the CS4812. It is

Ω

open-drain and requires a 2.2 k

CS, the chip select signal, is asserted low to enable

the SPI port. REQ, the request pin, is used by the

DSP to request a read by a host controller when operating in control port slave mode. Data is clocked

into the chip on the rising edge of CCLK and out on

the falling edge. When in slave mode, the CLK signal must be synchronous with the internal DSP

clock. An external D flip flop off of CLKOUT as

shown in Figure 9 can be used to retime the CLK signal. There is limited drive capability on CLKOUT so

pull-up resistor.

DS291PP3 19

CS4812

a buffer may be required to minimize the capacitive

loading on CLKOUT.

CCLK and CS may be inputs or outputs with respect

to the CS4812. If the serial control port of the

CS4812 is defined as the master, then CCLK and CS

are outputs and CCLK requires a 2.2 kΩ pull-up resistor. If the CS4812 is defined as the slave, then

CCLK and CS are inputs and no pull-up resistor is required on CCLK.

3.5.1.1 SPI Master Mode

The SPI master mode is designed for read-only operation during AutoBooting from a serial EEPROM.

X25650 serial EEPROM, or equivalent, is shown in

Figure 14. On exit from reset, the CS4812 asserts CS.

A typical AutoBoot sequence with a Xicor

CS

0 1 2 21 22 23 24

7 8 9 10 113 4 5 6 30 3125 26 27 28 29

The 8-bit read instruction (00000011) is sent to the

EEPROM followed by a pre-defined 16-bit start address.

The CS4812 then automatically clocks out sequential bytes from the EEPROM until the last byte

has been received.

After the last byte is received, the

CS4812 deasserts CS and begins program execution.

At this point, the serial control port becomes inactive

until the next reset.

3.5.1.2 SPI Slave Mode

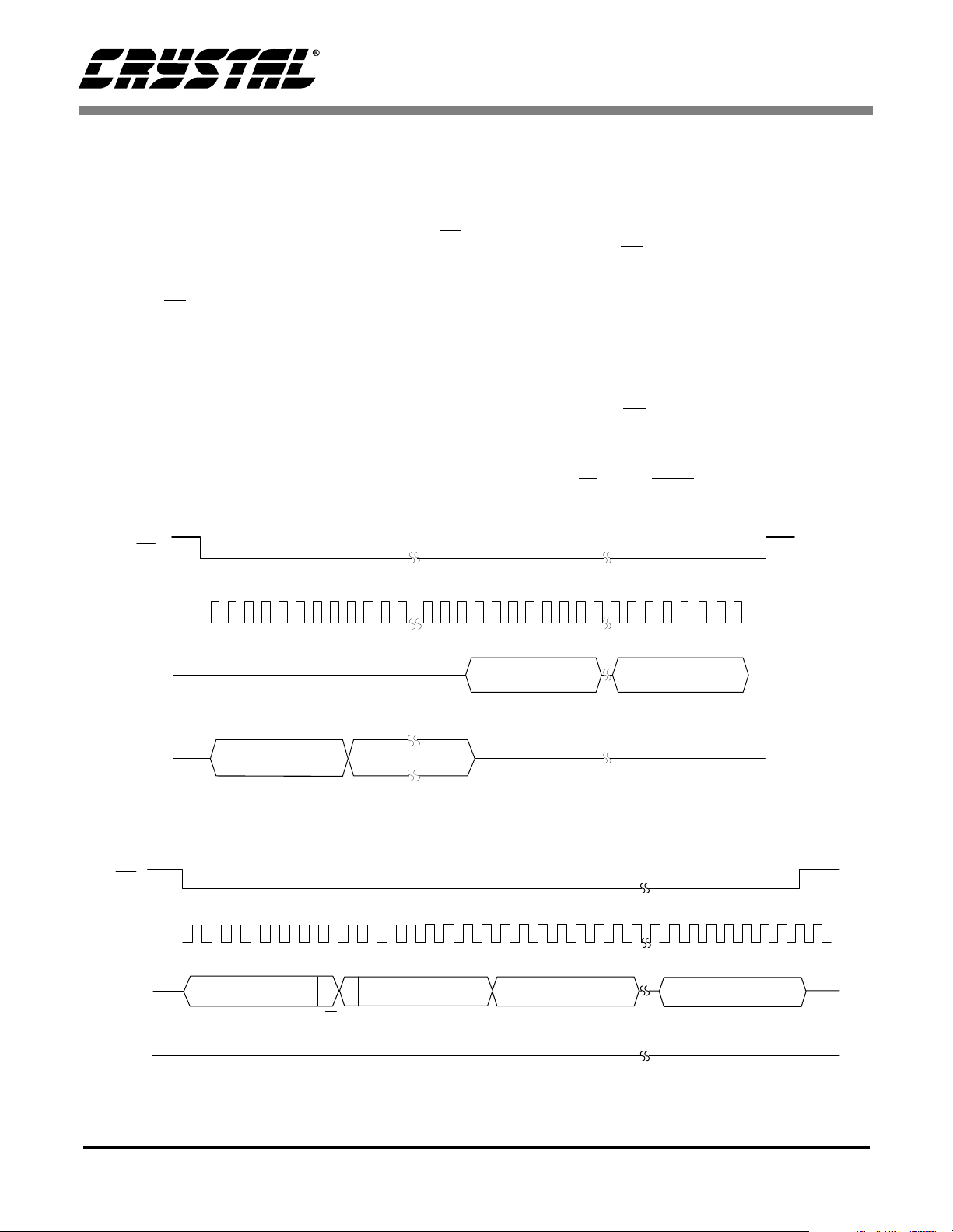

In SPI slave mode, a write sequence from an external host controller is shown in Figure 15. The host

controller asserts CS and sends a 16-bit write preamble to the CS4812. This preamble consists of a

7-bit chip address (must be 0010000) followed by

a one-bit R/W (Read/Write) bit (set to 0 for write)

CDOUT

CS

(input)

CLK

(input)

CDIN

(input)

CDOUT

(output)

CLK

CDIN

READ

COMMAND

MSB

ADDRESS = 0X0000

0 0 0 0 0 0 00 0 0 0 0 0 1 1

Figure 14. Control Port Timing, SPI Master Mode AutoBoot

8 9 10 114 5 6 7 0 1 2 3 16 17 18 19 20 21 22

CHIP ADDRESS (WRITE) MAP BYTE

INCR

0 0 1 0 0 0 0 0

MSB

6 5 4 3 2 1 0

R/W

Figure 15. Control Port Timing, SPI Slave Mode Write

16-BIT

7 6 5 4 3 2 1 0

12 13 14 15

DATA

DATA DATA +n

7 6 5 4 3 2 1 0

DATA + n

7 6 5 4 3 2 1 0

23

7 6 5 4 3 2 1 0

20 DS291PP3

CS4812

SET CS LOW

WRITE DATA BYTE

MORE DATA?

SET CS HIGH

Y

WRITE MAP BYTE

N

WRITE ADDRESS BYTE

WITH R/W BIT = 0

Figure 16. SPI Slave Write Flow Diagram

and a memory address pointer (MAP) byte. The

MAP byte contains the address of the control port

register to be accessed. Following the preamble,

the host controller sends the actual data byte to be

written to the register designated by the MAP. The

host controller then de-asserts CS. Figure 16 shows

the SPI slave mode write flow diagram.

In SPI slave mode, a read sequence from an external controller is shown in Figure 17. The host controller executes a partial write-cycle by sending a

16-bit write preamble to the CS4812 with the MAP

byte set to the address of the control port byte register to be read. The host controller then de-asserts

CS, re-asserts CS, and sends the 7-bit chip address

followed by the R/W bit set to 1. The host controller then clocks out the control port register designated by the MAP byte. The host controller then

de-asserts CS. Figure 18 shows the SPI mode slave

read flow diagram initiated by the host microcontroller. Figure 19 shows the SPI slave mode read

flow diagram incorporating the DSP REQ

signal.

REQ is used to notify the host controller that a data

byte from the DSP is waiting to be read.

The behavior of the REQ

signal is dependent on

when data is written to the serial control port output

register in relation to CCLK and bit 2 of the current

byte being transferred. There are three cases of

REQ behavior:

CS

(input)

CLK

(input)

CDIN

(input)

CDOUT

(output)

REQ

(output)

0 0 1 0 0 0 0 0

MSB

0 1 2 3 4 5 6 7 8 9 13 14 15

CHIP ADDRESS (W RITE)

R/W

Figure 17. Control Port Timing, SPI Slave Mode Read

10 11 12

MAP BYTE

INCR

6 5 4 3 2 1 0 0 0 1 0 0 0 0 1

1. The REQ

line will be de-asserted immediately

following the rising edge of CCLK on the D2 bit of

the current byte being transferred if there is no data

in the serial control port output register. The REQ

line remains de-asserted and a stop condition

CHIP ADD RESS (RE AD)

R/W

DATA

7 6 5 4 3 2 1 0

DATA

7 6 5 4 3 2 1 0

DS291PP3 21

SET CS LOW

WRITE ADDRESS BYTE

READ DATA BYTE

MORE BYTES

SET CS HIGH

Y

WRITE ADDRESS BYTE

WRITE MAP BYTE

N

TOGGLE CS

WITH R/W BIT = 0

WITH R/W

BIT = 1

Figure 18. SPI Slave Mode Read Flow Diagram

TO READ?

REQ LOW?

Y

SET CS LOW

WRITE ADDRESS BYTE

WITH R/W BIT = 0

WRITE MAP BYTE FOR

DSP OUTPUT REGISTER

(MAP = 0

X

27)

TOGGLE CS

WRITE ADDRESS BYTE

WITH R/W

BIT = 1

CS4812

N

should be issued by the bus master, thus completing the transfer.

2. If data is written to the serial control port output

register prior to the rising edge of CCLK for the D2

data bit, REQ will remain asserted. The bus master

should continue to shift out this new byte.

3. If data is placed in the SCP output register by the

DSP after the rising edge of CCLK for the D2 bit,

REQ will be immediately re-asserted, thus creating

a pulse on REQ. The byte in the SCP out register

may be read by the bus master as part of the current

transaction or may be read later as part of a new

read transaction.

READ DATA BYTE

FROM DSP OUTPUT REGISTER

REQ STILL LOW?

N

SET CS HIGH

Y

Figure 19. SPI Slave Mode Read from DSP Core

Flow Diagram using DSP REQ

The CS4812 has a MAP auto increment capability

which allows block reads or writes of successive

control port registers.This feature is enabled by setting the INCR bit in the MAP byte.

During a write sequence, multiple bytes may be

written by continuing to send data bytes to the

CS4812 after the first data byte and before de-asserting CS. If auto increment is disabled, the last

data byte sent will appear in the register designated

by the MAP. If auto increment is enabled, data

bytes sent following the first data byte will be written to successive registers following that designated in the MAP.

22 DS291PP3

CS4812

During a read sequence, multiple bytes may be read

by continuing to clock out data bytes to the CS4812

after the first data byte and before de-asserting CS.

If auto increment is disabled, the last data byte read

will be the register designated by the MAP. If auto

increment is enabled, data bytes read following the

first data byte will be read from successive registers

following that designated in the MAP.

3.5.2 I2C Bus

The I2C bus interface implemented on the CS4812

consists of 3 digital signals, SCL, SDA and REQ.

SCL, or serial clock, is used to clock individual

data bits. SDA, or serial data, is a bidirectional data

line. REQ, the request pin, is used by the DSP to request a host read when operating in control port

slave mode. Two additional pins, AD1 and AD0,

are inputs which determine the 2 lowest order bits

of the 7-bit I2C device address.

SCL may be defined as an input or an output with

respect to the CS4812. If the serial control port of

the CS4812 is defined as the master, then SCL is an

open-drain output and requires a pull-up resistor as

shown in Figure 5. Conversely, if the serial control

port of the CS4812 is defined as the slave, then

SCL is an input.

SDA carries time-multiplexed bidirectional serial

data. It is open-drain and requires a pull-up resistor

as shown in Figure 5.

AD1 and AD0, the inputs which determine the 2

lowest order bits of the 8-bit I2C device address, are

meaningful only when the CS4812 is operating as

a slave device and may be tied to ground when the

CS4812 is configured for master mode.

When operating in control port slave mode, the

REQ

output pin is used by the CS4812 DSP to re-

quest communication with the master.

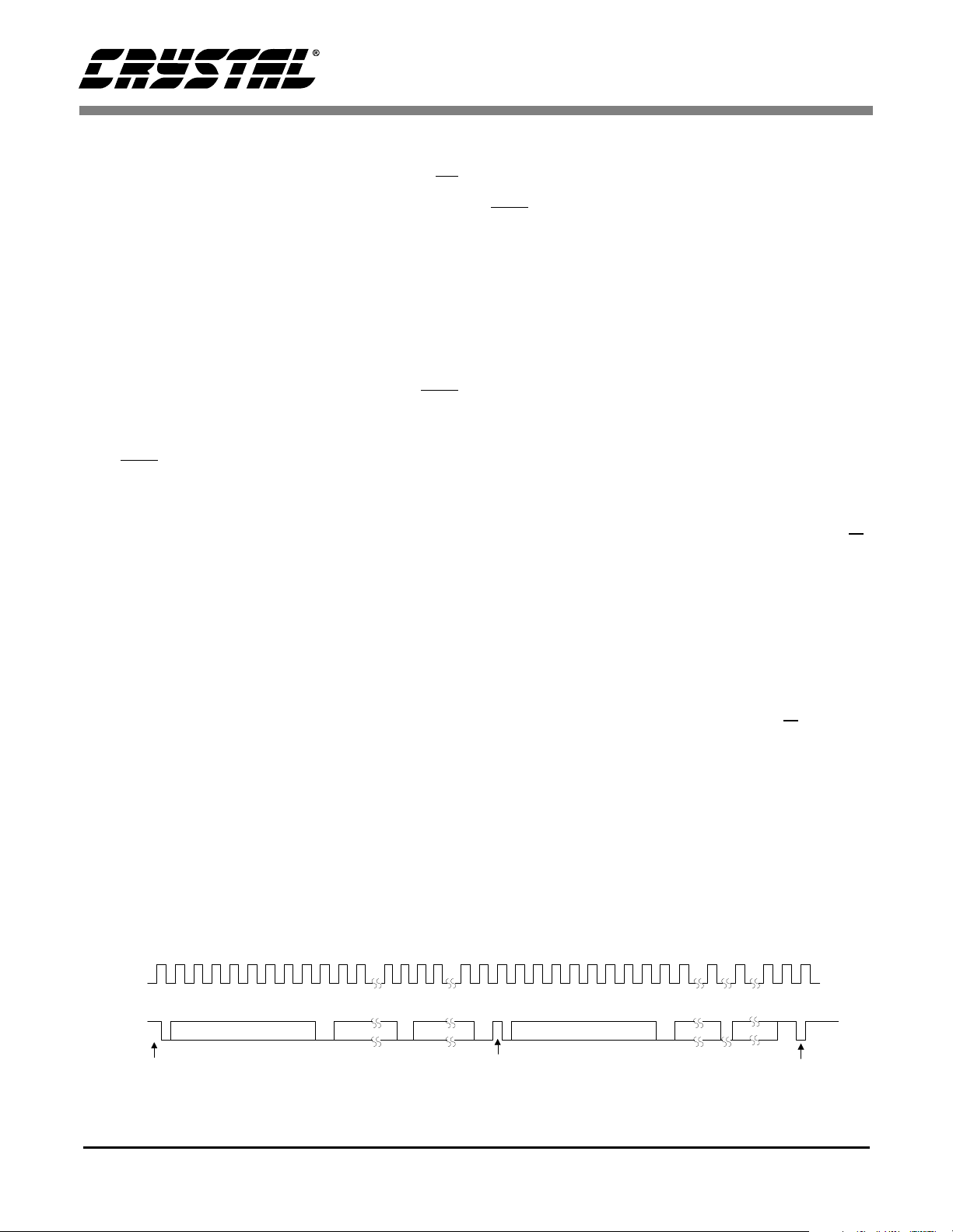

3.5.2.1 I2C Master Mode

The I2C master mode is designed for read-only operation during AutoBooting from a serial EEPROM. A typical AutoBoot sequence with a

Microchip X24256 serial EEPROM, or equivalent,

is shown in Figure 20. On exit from reset, the

CS4812 sends an initial write preamble to the EEPROM which consists of a I2C start condition and

the slave address byte. The slave address consists

of the 4 most significant bits set to 1010, the following 3 bits corresponding to the device select

bits, A2, A1 and A0 set to 000 and the last bit (R/W)

set to 0. Following this, a 2-byte EEPROM starting

address of 0x0000 is sent to the EEPROM. The 2byte EEPROM starting address uses only the lowest 13 bits and sets the highest 3 bits to zero. To begin reading from the EEPROM, the CS4812 sends

another start condition followed by a read preamble. The read preamble is identical to the write preamble except for the state of the R/W bit. The

CS4812 then automatically clocks out sequential

bytes from the EEPROM until the last byte has

been received. These bytes include initial values

for all control port registers as well as the DSP application code. After the last byte, the CS4812 initiates a stop condition and begins program

execution. At this point, the serial control port becomes inactive until the next reset. Actual EE-

0 1 2 3

SCL

CHIP ADDRESS (WRITE) CHIP ADDRESS (READ)MEMORY ADDRESS DATA DATA +n

SDA

DS291PP3 23

1 0 1 0 A2 A1 A0 0 0 0 0 0 0 0 1 0 1 0 A2 A1 A0 1

START

4 5 6 7

ACK NO

Figure 20. Control Port Timing, I2C Master Mode AutoBoot

16 17 18 19 25 26 27 28 29

ACK

START STOP

34 35 36 3730 31 32 338 9 10

7 0

ACKACK

7 0

ACK

PROM memory mapping is handled automatically

by the development tools and is transparent to the

designer.

3.5.2.2 I2C Slave Mode

In I2C slave mode, a write sequence from an external host controller is shown in Figure 22.. The host

controller sends a write preamble consisting of a

start condition followed by the slave address for the

CS4812. The slave address byte consists of a 7-bit

address field (00100|AD1|AD0) followed by a

Read/Write bit (set to 0). AD1 and AD0 correspond

to the logic levels applied to the these pins on the

CS4812. The host controller then sends a MAP

byte which contains the address of the control register to be accessed followed by the actual data byte

to be written to the register designated by the MAP.

Upon completion of this, the host controller then

sends a stop condition to complete the transaction.

Figure 21 shows the I2C slave mode write flow diagram

2

C slave mode, a read sequence by an external

In I

host controller is shown in Figure 23. The host controller sends a write preamble to the CS4812 which

CS4812

SEND I2C START

WRITE ADDRESS BYTE

WITH R/W

SEND MAP BYTE

SEND DATABYTE

SEND I2C STOP

Figure 21. I2C Slave Mode Write Flow Diagram

BIT = 0

GET ACK

GET ACK

GET ACK

MORE DATA?

N

Y

0 1 2 3 8 9 12 16 17 18 1910 11 13 14 15 27 28

4 5 6 7 24 25

26

SCL

SDA

CHIP ADDRESS (WRIT E) MAP BYTE DATA

0 0 1 0 0 AD1 AD0 0

START

DATA +1

INCR

6 5 4 3 2 1 0 7 6 1 0 7 6 1 0 7 6 1 0

ACK

DATA +n

ACKACKACK

STOP

Figure 22. Control Port Timing, I2C Slave Mode Write

168 9 12 13 14 154 5 6 7 0 1 20 21 22 23 24

CHIP ADDRESS (READ)

0 0 1 0 0 AD1 AD0 1

ACK

START

26 27 28

DATA +1

7 0 7 0 7 0

ACK

ACK

DATA + n

NO

STOPACK

SCL

SDA

REQ

CHIP ADDRESS (WRITE)

0 0 1 0 0 AD1 AD0 0

START

2 3 10 11 17 18 19 25

MAP BYTE DATA

INCR

6 5 4 3 2 1 0

ACK

Figure 23. Control Port Timing, I2C Slave Mode Read

24 DS291PP3

consists of a start condition followed by its slave

address byte with the Read/Write bit set to 0. The

host controller then initiates a read preamble. The

read preamble is identical to the write preamble except for the state of the Read/Write bit. The host

controller then sends a MAP byte which contains

the address of the control register to be accessed.

After receiving the MAP byte, the CS4812 returns

the contents of this register to the host controller.

The host controller may continue reading registers

by sending additional MAP bytes or complete the

transaction by initiating a stop condition. Figure 24

shows the SPI mode slave read flow diagram initiated by the host microcontroller. Figure 25 shows

2

C slave mode read flow diagram incorporat-

the I

ing the DSP REQ signal. REQ is used to notify the

host controller that a data byte from the DSP is

waiting to be read.

The behavior of the REQ

signal is dependent on

when data is written to the SCP output register in

relation to SCL and bit 1 of the current byte being

transferred. There are three cases of REQ behavior:

SEND I2C START

WRITE ADDRESS BYTE

WITH R/W BIT = 0

GET ACK

SEND MAP BYTE

GET ACK

SEND I2C START

WRITE ADDRESS BYTE

WITH R/W

BIT = 1

GET ACK

CS4812

1. The REQ

line will be de-asserted immediately

following the rising edge of SCL on the D1 bit of

the current byte being transferred if there is no data

in the SCP output register. The REQ line remains

de-asserted and a stop condition should be issued

by the bus master, thus completing the transfer.

2. If data is written to the SCP output register prior

to the rising edge of SCL for the D1 bit, REQ will

remain asserted. The bus master should continue to

shift out this new byte.

3. If data is placed in the SCP output register by the

DSP after the rising edge of SCL for the D1 bit,

REQ will be immediately re-asserted, thus creating

a pulse on REQ. The byte in the SCP out register

may be read by the bus master as part of the current

transaction or may be read later as part of a new

read transaction.

The CS4812 has a MAP auto increment capability

which allows block reads or writes of successive

READ DATABYTE

MORE BYTES

TO READ?

N

SEND NACK

SEND I2C STOP

Figure 24. I2C Slave Mode Read Flow Diagram

Y

SEND ACK

control port registers.This feature is enabled by setting the INCR bit in the MAP byte.

During a write sequence, multiple bytes may be

written by continuing to send data bytes to the

CS4812 after the first data byte and before initiating a stop condition. If auto increment is disabled,

the last data byte sent will appear in the register

designated by the MAP. If auto increment is en-

DS291PP3 25

Figure 25. I2C Slave Mode Read from DSP Core

Flow Diagram with DSP REQ

N

REQ LOW?

Y

SEND I2C START

WRITE ADDRESS BYTE

WITH R/ W

BIT = 0

GET ACK

READ DATABYTE

REQ STILL LOW?

N

Y

SEND ACK

SEND NACK

SEND I2C STOP

GET ACK

WRITE ADDRESS BYTE

WITH R/W

BIT = 1

GET ACK

SEND I2C START

SEND MAP BYTE

CS4812

abled, data bytes sent following the first data byte

will be written to successive registers following

that designated in the MAP.

During a read sequence, multiple bytes may be read

by continuing to clock in data bytes to the CS4812

after the first data byte and before initiating a stop

condition. If auto increment is disabled, the last

data byte read will be the register designated by the

MAP. If auto increment is enabled, data bytes read

following the first data byte will be read from successive registers following that designated in the

MAP.

3.6 Boot Modes

There are two different techniques that allow the

system to load the application code into the

CS4812. The first technique is called, “AutoBoot”

and allows the application code to be loaded from

an external serial EEPROM with an I2C or SPI interface. This technique is used in system applications that due not have a host. The second

technique is called, “Host Boot” and allows the application code to be loaded directly from the host

microcontroller via I2C or SPI communication interface. This method may eliminate the need for an

external EEPROM.

3.6.1 AutoBoot

The AutoBoot method simply requires an external

EEPROM with an I2C or SPI serial bus interface.

The DSP, automatically loads and runs the application code resident in the EEPROM upon deassertion of the RESET line. It should be noted that this

technique is used for systems that do not have a microcontroller and do not require real-time adjustment of the application code parameters. Please

refer to Table 10 on page 6 for the timing requirements of the RESET line.

3.6.2 HostBoot

By using the HostBoot technique, an external microcontroller is required to download the applica-

26 DS291PP3

tion code. This technique allows for real-time

control of all parameters specific to the application

code. Please refer to Figure 26 for the HostBoot

procedure flow chart and to Section 1.2.1 of

AN195 for an example of a host boot sequence.

3.7 Resets

SEND APPLICATION

SPECIFIC CONTROL PORT

CONFIG BYTES

WRITE BYTE 0XA4

TO CONTROL PORT

REGISTER 4 (MAP = 4)

CS4812

There are several reset mechanisms in the CS4812

which affect different parts of the chip. Full chip reset can only be achieved by asserting the external

RST pin. With RST asserted, the chip enters low

power mode during which the control port, CODEC and DSP are reset, all registers are returned to

their default values and the DAC outputs are muted. The RST pin should be asserted during powerup until the power supplies have reached steady

state.

If the supply voltage drops below 4 Volts, the CODEC is reset, the DAC outputs are muted and the

DSP automatically executes a soft reset.

Upon exit from a CODEC reset, the DSP restarts

the application code and the CODEC performs the

following procedure:

– The CODEC resynchronizes.

– The DAC outputs unmute.

WRITE BYTE 0XA5

TO CONTROL PORT

REGISTER 4

WRITE BYTE 0XA7

TO CONTROL PORT

REGISTER 4

SEND 3 BYTE MESSAGE TO

THE DSP INPUT REGISTER

(MAP = 3) :0X000004

WAIT FOR REPLY FROM DSP

(REQ LINE GOES LOW)

READ REPLY BYTE FROM DSP

OUTPUT REGISTER (MAP = 27)

REPLY BYTE

= 0

X

01?

Y

WRITE .LDT FILE INTO

DSP INPUT REGISTER (MAP = 16)

(LOAD APPLICATION CODE)

N

REQ

LOW?

Y

READ REPLY BYTE FROM DSP

OUTPUT REGISTER (MAP = 27)

REPLY BYTE

= 0X02?

Y

SEND 3 BYTE MESSAGE TO

THE DSP INPUT REGISTER

(MAP = 16):0X000005

WRITE BYTE 0XA6

TO CONTROL PORT

REGISTER 4

N

N

Figure 26. HostBoot Flow Diagram

DS291PP3 27

CS4812

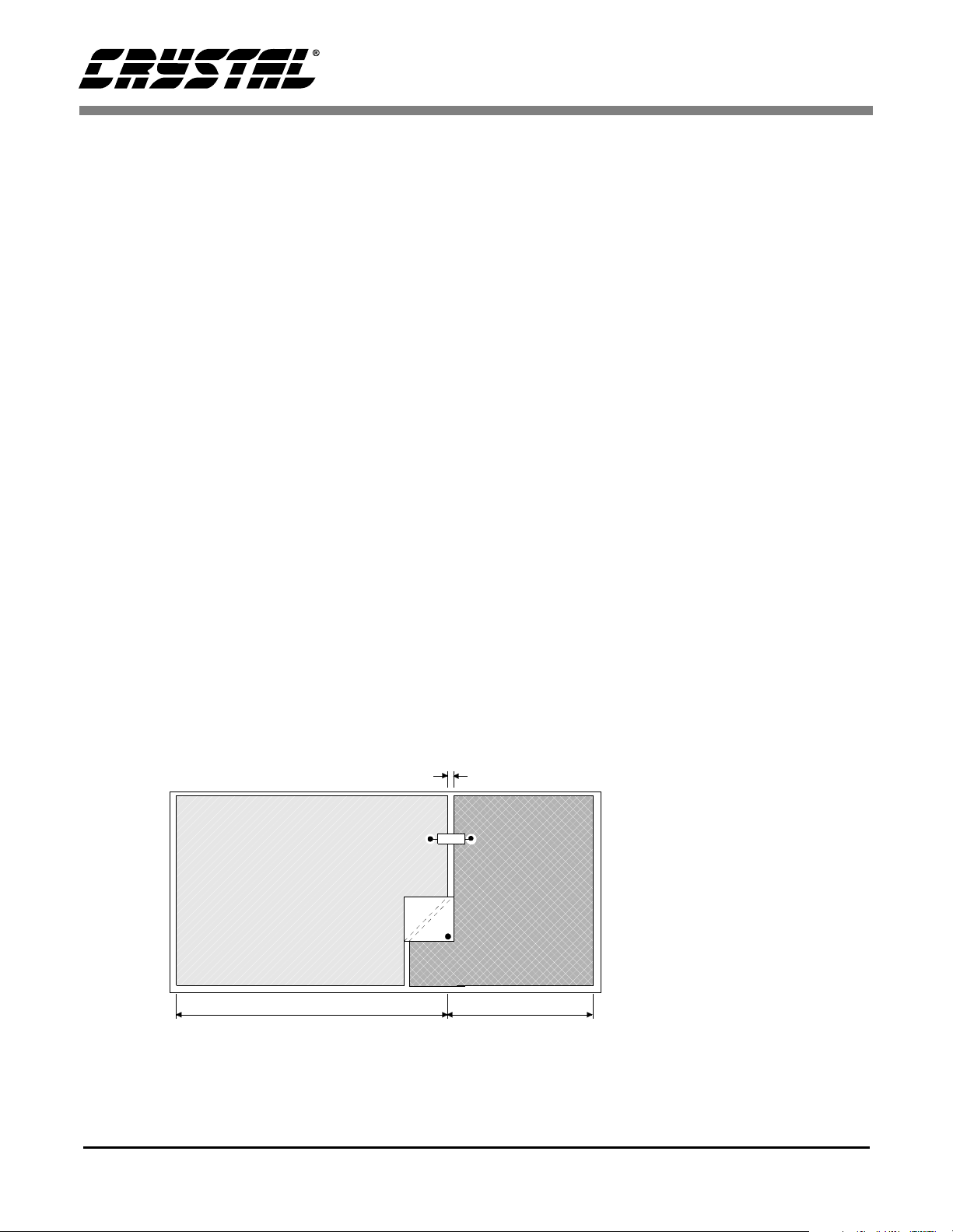

4. POWER SUPPLY AND GROUNDING

Proper layout and grounding is critical to obtaining

optimal audio performance in your system. The

most important rule to remember is to not allow

currents from digital circuitry to couple into sensitive analog circuitry. This is generally done by using a separate or filtered power supply for the

analog circuitry, physically separating the analog

and digital components and traces in the pcb layout

and using wide traces or planes for ground and

power. One misplaced component or trace can severely degrade overall system performance.

When using separate supplies, the analog and digital power should be connected to the CS4812 via a

ferrite bead, positioned closer than 1" to the device

(see Figure 21). The CS4812 VA pin should be derived from the quietest power source available. If

only one supply is available, use the suggested arrangement in Figure 5.

A single solid ground plane is the simplest grounding scheme that works well in many cases. All analog and digital grounds shown in Figure 5 should

be tied to the one plane.

Decoupling capacitors should be placed as close as

possible to the device with the lowest value capacitor closest to the chip. Any power and ground connection vias should be placed near their respective

component pins and should be attached directly to

the appropriate plane. If traces are used for the

power supplies to the CS4812, they should be as

wide as possible to maintain low impedance.

It is recommended to solder the CS4812 directly to

the printed circuit board. Soldering improves performance and enhances reliability

>

1/8"

Digital

Power

Plane

Digital Interface

Figure 27. CS4812 Suggested Layout

28 DS291PP3

Ferrite

Bead

CS4812

Analog Signals &

Components

Analog

Power

Plane

Note that the CS4812

is oriented with its

digital pins towards the

digital end of the board.

5. PIN DESCRIPTIONS

CS4812

DGND

AD1/CDIN

AD0/CS

SPI/I2C

SCPM/S

REQ

RST

RES-VD

NC

NC

NC

NC

NC

NC

NC

NC

RES-DGND

RES-DGND

NC

NC

AINL+

AINL-

VA

AGND

AINR+

AINR-

CMOUT

CMFILT+

CMFILT-

RES-NC

RES-DGND

RES-NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

AOUT1+

AOUT1-

AOUT2+

AOUT2-

AGND

VA

AGND

RES-NC

RES-NC

80 79 7 8 77 76 75 74 73 72 71 70 69 68 67 66 65 64 6 362 61 60 59 58 57 56 55 54 53 52 5 1

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

CS4812

100-PIN MQFP

VD

DGND

SCL/CCLK

SDA/CDOUT

RES-NC

RES-NC

RES-NC

RES-NC

RES-NC

NC

NC

NC

NC

NC

NC

NC

NC

RES-DGND

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

CLKOUT

XTO

XTI

DGND

VD

DGND

PIO0

PIO1

OVL

RES-DGND

PIO2

RES-DGND

PIO3

RES-DGND

NC

RES-DGND

NC

NC

NC

NC

NC

NC

NC

NC

RES-NC

RES-NC

RES-NC

RES-NC

AGND

VA

RES-NC

RES-NC

Figure 28. Pin Assignments

DS291PP3 29

Power Supply

VA - Analog Power

Power: analog supply, +5V.

AGND - Analog Ground

Ground: analog ground.

VD - Digital Power

Power: digital supply, +5V.

DGND - Digital Ground

Ground: digital ground.

Analog Inputs

AINL+/-,AINR+/- - Differential Analog Inputs

Inputs: These pins accept differential analog input signals and are internally biased to the reference

voltage of 2.3 V. The + and - input signals should be 180° out of phase. A single-ended signal may also

be directly applied to either the + or - input with the other input AC coupled to ground through a

capacitor. In general, differential input signals provide better performance. For best audio performance,

a passive anti-aliasing filter is required. The typical connection diagram in Figure 5. shows the

recommended single-ended input circuit. Figure 10 shows the recommended differential input circuit.

Inputs may be externally AC or DC coupled. This permits use of the ADCs for input of audio signals or

for measurement of DC control voltages. By default, an internal high pass filter removes any DC offsets

from both of the ADC inputs. If measurement of DC is required on either of the ADC inputs, then the

internal high pass filter must be disabled. Analog audio input signals that are DC coupled must be

biased at 2.3 V to maintain proper input signal swing. DC control input voltages may range from ground

to Vcc and should be applied to only the + or - input with the other input coupled to ground through a

capacitor.

CS4812

OVL - ADC Overload Indicator

Output: This pin is asserted if either ADC is clipping. The pin does not latch and de-asserts when

clipping stops.

Analog Outputs

AOUT1+/-, AOUT2+/- - Differential Audio Outputs

Outputs: These pins output differential analog signals which are biased to the internal reference voltage

of approximately 2.3V. The + and - output signals are 180° out of phase resulting in a nominal

differential output voltage of twice the output pin voltage. For best performance, an anti-imaging filter is

required. Figure 12 shows the recommended second and third order Butterworth differential-to-singleended output buffer circuits.

Voltage Reference

CMOUT - Common Mode Output

Output: This pin provides an internally generated reference of 2.3V to be used for biasing external

analog circuitry. The load on CMOUT must be DC only, with an impedance of not less than 50 kΩ.

CMFILT+,CMFILT- - Common Mode Filter Connections

Inputs: These pins are connections for external filter components required by the internal common mode

reference circuit. See the typical connection diagram in Figure 5. for details.

30 DS291PP3

Serial Control Port

SCPM/S - Serial Control Port Master/Slave Select

Input: This pin configures the serial control port as a master if tied to VD or a slave if tied to DGND.

/I2C - Serial Control Port Format Select

SPI

Input: This pin configures the control port for I

SCL/CCLK - Serial Control Port Clock

Bidirectional: This pin clocks serial control port data into and out of SDA in I

clocks control port data into CDIN and out of CDOUT. When the serial control port is configured as a

master, SCL/CCLK is an output and is generated internally. When the serial control port is configured as

a slave, SCL/CCLK is an input and may operate asynchronously to the master clock.

CS4812

2

C format if tied to VD or SPI format if tied to DGND.

2

C mode. In SPI mode, it

AD0/CS

- I2C Address Bit 0 / SPI Chip Select

2C®

Bidirectional: In I

mode, AD0 is an input and defines bit 0 of the partial chip address. The upper 5

bits of the 7-bit address must be 00100. In SPI mode, CS

port is defined as a master in SPI mode, CS

slave in SPI mode, CS

AD1/CDIN - I

Input: In I

is an input.

2

C Address Bit 1 / SPI Data Input

2C®

mode, AD1 is an input and defines bit 1 of the partial chip address. The upper 5 bits of

is an output. When the serial control port is defined as a

the 7-bit address must be 00100. In SPI mode, CDIN is the serial control port data input and is clocked

in on the rising edge of CCLK.

SDA/CDOUT - I

Bidirectional: In I

2

C Data / SPI Data Output

2C®

mode, SDA is the bidirectional data I/O line. In SPI mode, CDOUT is the serial

control port data output and is clocked out on the falling edge of CCLK.

REQ

- DSP Output Request

Output: This pin is used when the serial control port is configured for slave mode operation. This pin is

asserted when the DSP has written a byte to a register in the control port. When this register is read by

the master device, REQ

is de-asserted.

Clock and Crystal

XTI, XTO - Crystal Oscillator Connections (Master Clock)

Input, Output: These pins provide connections for an external parallel resonant quartz crystal.

Alternately, an external clock source may be applied to XTI. The clock frequency must be 256xFs.

CLKOUT - Clock Output

Output: This pin provides a clock output which can be used to synchronize external components.

Available output frequencies 1xFs, 128xFs and 256xFs are selectable via a control port register. The

default frequency is 256xFs. It is recommended to externally buffer this signal with a CMOS gate as

shown in Figure 5.

is the chip select pin. When the serial control

Miscellaneous

PIO0:3 - General Purpose Inputs/Outputs

Bidirectional: These pins are general-purpose digital I/O pins. The Default state is input. The

functionality of these pins after boot-up is determined by the application firmware code loaded into the

device during the boot-up process.

RST

- Reset

Input: This pin causes the device to enter a low power mode and forces all control port and i/o registers

to be reset to their default values. The control port can not be accessed when reset is low.

DS291PP3 31

NC - No Connect

Input: These pins are not internally connected and should be tied to ground for optimal performance.

RES-NC - Reserved, No Connect

These pins are reserved and must be left unconnected for normal operation.

RES-VD - Reserved, Connect to VD

These pins are reserved and must be tied to VD for normal operation.

RES-DGND - Reserved, Connect to DGND

These pins are reserved and must be tied to digital ground for normal operation.

RES-AGND - Reserved, Connect to AGND

These pins are reserved and must be tied to analog ground for normal operation.

CS4812

32 DS291PP3

6. PARAMETER DEFINITIONS

Dynamic Range

The ratio of the full scale RMS value of the signal to the RMS sum of all other spectral components

over the specified bandwidth. Dynamic range is a signal-to-noise measurement over the specified

bandwidth made with a -60 dbFs signal. 60 dB is then added to the resulting measurement to refer the

measurement to full scale. This technique ensures that the distortion components are below the noise

level and do not effect the measurement. This measurement technique has been accepted by the Audio

Engineering Society, AES17-1991, and the Electronic Industries Association of Japan, EIAJ CP-307.

Total Harmonic Distortion + Noise

The ratio of the RMS value of the signal to the RMS sum of all other spectral components over the

specified bandwidth (typically 20 Hz to 20 kHz), including distortion components. Expressed in decibels.

ADCs are measured at -1dBFs as suggested in AES 17-1991 Annex A.

Idle Channel Noise / Signal-to-Noise-Ratio

The ratio of the RMS analog output level with 1kHz full scale digital input to the RMS analog output

level with all zeros into the digital input. Measured A-weighted over a 10 Hz to 20 kHz bandwidth. Units

in decibels. This specification has been standardized by the Audio Engineering Society, AES17-1991,

and referred to as Idle Channel Noise. This specification has also been standardized by the Electronic

Industries Association of Japan, EIAJ CP-307, and referred to as Signal-to-Noise-Ratio.

Total Harmonic Distortion (THD)

THD is the ratio of the test signal amplitude to the RMS sum of all the in-band harmonics of the test

signal. Units in decibels.

Interchannel Isolation

A measure of crosstalk between channels. Measured for each channel at the converter’s output with no

signal to the input under test and a full-scale signal applied to the other channel. Units in decibels.

CS4812

Frequency Response

A measure of the amplitude response variation from 20Hz to 20kHz relative to the amplitude response

at 1kHz. Units in decibels.

Interchannel Gain Mismatch

For the ADCs, the difference in input voltage that generates the full scale code for each channel. For

the DACs, the difference in output voltages for each channel with a full scale digital input. Units are in

decibels.

Gain Error

The deviation from the nominal full scale output for a full scale input.

Gain Drift

The change in gain value with temperature. Units in ppm/°C.

Offset Error

For the ADCs, the deviation in LSBs of the output from mid-scale with the selected input grounded. For

the DACs, the deviation of the output from zero (relative to CMOUT) with mid-scale input code. Units

are in volts.

DS291PP3 33

7. PACKAGE DIMENSIONS

100L MQFP PACKAGE DRAWING

D1

D

CS4812

E

E1

1

e

B

∝

L

INCHES MILLIMETERS

DIM MIN MAX MIN MAX

A --- 0.134 --- 3.400

A1 0.010 0.014 0.250 0.350

B 0.009 0.015 0.220 0.380

D 0.667 0.687 16.950 17.450

D1 0.547 0.555 13.900 14.100

E 0.904 0.923 22.950 23.450

E1 0.783 0.791 19.900 20.100

e* 0.022 0.030 0.550 0.750

∝

L 0.018 0.030 0.450 0.750

* Nominal pin pitch is 0.65 mm

Controlling dimension is mm.

JEDEC Designation: MS022

0.000° 7.000° 0.00° 7.00°

A

A1

34 DS291PP3

• Notes •

Loading...

Loading...