Chromalox TTUH-10A, TTUH-15A, TTUH-20A, TTUH-25A, TTUH-30A Installation, Operation and MAINTENANCE

...

Chromalox® |

|

|

|

|

|

Installation, Operation |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DIVISION 4 |

|

|

|

SECTION TTUH |

|

and |

|

|

|

||

SALES |

(Supersedes PD400-14) PD400-15 |

||||

RENEWAL PARTS IDENTIFICATION |

REFERENCE |

||||

|

161-048415-001 |

||||

|

DATE OCTOBER, 2000 |

||||

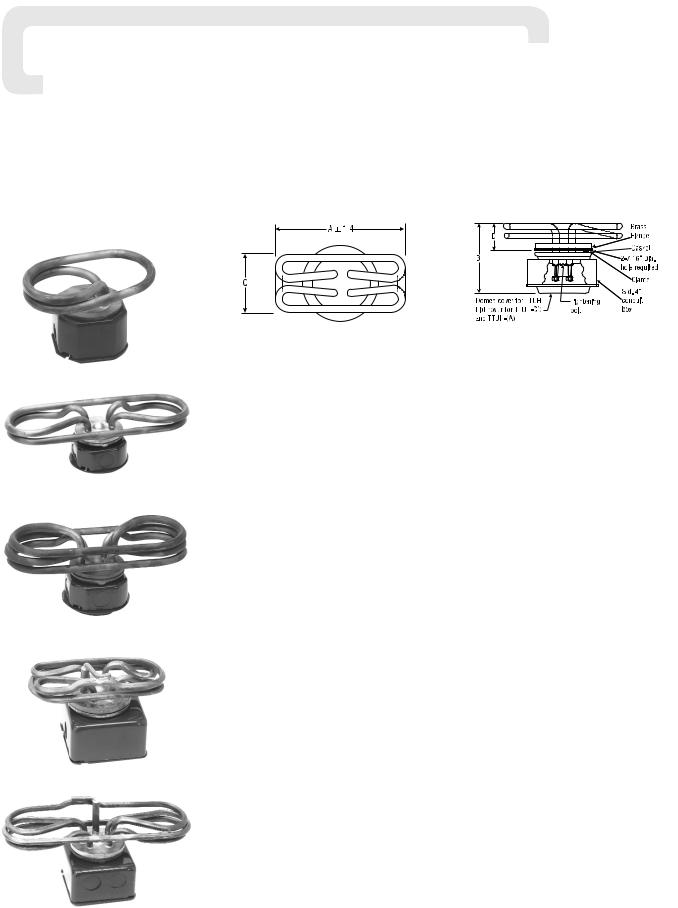

Type TTUH and TTUH-CO URN Heaters

TTUH-20A

TTUH-50

TTUH-703WSS

TTUH-CO-30

TTUH-CO-503

Specifications — TTUH

|

|

|

|

Dimensions (In.) |

|

||

|

|

|

|

|

|

|

Extends |

|

|

|

|

Overall |

|

|

Into |

Model |

Volts |

kW |

W/In2 |

Length |

|

|

Tank |

A |

B |

C |

D‡ |

||||

TTUH — 1 Phase — 3” min. liquid depth |

|

|

|

|

|||

TTUH-10A |

120 |

1 |

42 |

6-3/4 |

4-9/16 |

4-1/4 |

2-5/16 |

TTUH-15A |

120 |

1.5 |

57 |

6-3/4 |

4-9/16 |

4-1/4 |

2-5/16 |

TTUH-15A |

208 |

1.5 |

57 |

6-3/4 |

4-9/16 |

4-1/4 |

2-5/16 |

TTUH-15A |

240 |

1.5 |

57 |

6-3/4 |

4-9/16 |

4-1/4 |

2-5/16 |

|

|

|

|

|

|

|

|

TTUH-20A |

120 |

2 |

57 |

6-3/4 |

4-9/16 |

4-1/4 |

2-5/16 |

TTUH-20A |

208 |

2 |

57 |

6-3/4 |

4-9/16 |

4-1/4 |

2-5/16 |

TTUH-20A |

240 |

2 |

57 |

6-3/4 |

4-9/16 |

4-1/4 |

2-5/16 |

|

|

|

|

|

|

|

|

TTUH-25A |

120 |

2.5 |

58 |

6-3/4 |

4-9/16 |

4-1/4 |

2-5/16 |

TTUH-25A |

208 |

2.5 |

58 |

6-3/4 |

4-9/16 |

4-1/4 |

2-5/16 |

TTUH-25A |

240 |

2.5 |

58 |

6-3/4 |

4-9/16 |

4-1/4 |

2-5/16 |

|

|

|

|

|

|

|

|

TTUH-30A |

120 |

3 |

55 |

6-3/4 |

4-9/16 |

4-1/4 |

2-5/16 |

TTUH-30A |

208 |

3 |

55 |

6-3/4 |

4-9/16 |

4-1/4 |

2-5/16 |

TTUH-30A |

240 |

3 |

55 |

6-3/4 |

4-9/16 |

4-1/4 |

2-5/16 |

|

|

|

|

|

|

|

|

TTUH-40A |

120 |

4 |

53 |

9-1/2 |

4-9/16 |

4 |

1-3/8 |

TTUH-40A |

208 |

4 |

53 |

9-1/2 |

4-9/16 |

4 |

1-3/8 |

TTUH-40A |

240 |

4 |

53 |

9-1/2 |

4-9/16 |

4 |

1-3/8 |

|

|

|

|

|

|

|

|

TTUH-50 |

208 |

5† |

39 |

12-3/4 |

4-9/16 |

4 |

1-11/16 |

TTUH-50 |

240 |

5† |

39 |

12-3/4 |

4-9/16 |

4 |

1-11/16 |

|

|

|

|

|

|

|

|

TTUH-60 |

208 |

6† |

42 |

14-1/2 |

4-9/16 |

4 |

1-11/16 |

TTUH-60 |

240 |

6† |

42 |

14-1/2 |

4-9/16 |

4 |

1-11/16 |

TTUH-70 |

208 |

7† |

49 |

14-1/2 |

4-9/16 |

4 |

1-11/16 |

TTUH-70 |

240 |

7† |

49 |

14-1/2 |

4-9/16 |

4 |

1-11/16 |

|

|

|

|

|

|

|

|

TTUH — 3 Phase — 3” min. liquid depth |

|

|

|

|

|||

TTUH-303 |

208 |

3† |

55 |

8-3/4 |

4-5/8 |

3-1/8 |

1-15/16 |

TTUH-303 |

240 |

3† |

55 |

8-3/4 |

4-5/8 |

3-1/8 |

1-15/16 |

TTUH-403 |

208 |

4† |

74 |

8-3/4 |

4-5/8 |

3-1/8 |

1-15/16 |

TTUH-403 |

240 |

4† |

74 |

8-3/4 |

4-5/8 |

3-1/8 |

1-15/16 |

TTUH-408 |

480 |

4† |

74 |

8-3/4 |

4-5/8 |

3-1/8 |

1-15/16 |

TTUH-503 |

208 |

5† |

73 |

11 |

4-5/8 |

3-1/8 |

1-15/16 |

TTUH-503 |

240 |

5† |

73 |

11 |

4-5/8 |

3-1/8 |

1-15/16 |

|

|

|

|

|

|

|

|

TTUH-603 |

208 |

6† |

67 |

11-1/16 |

5 |

4-1/16 |

2-3/8 |

TTUH-603 |

240 |

6† |

67 |

11-1/16 |

5 |

4-1/16 |

2-3/8 |

TTUH-603 |

480 |

6† |

67 |

11-1/16 |

5 |

4-1/16 |

2-3/8 |

TTUH-703 |

208 |

7† |

78 |

11-1/16 |

5 |

4-1/16 |

2-3/8 |

TTUH-703 |

240 |

7† |

78 |

11-1/16 |

5 |

4-1/16 |

2-3/8 |

|

|

|

|

|

|

|

|

TTUH-803 |

208 |

8† |

69 |

11-1/8 |

5 |

4-1/16 |

2-3/8 |

TTUH-803 |

240 |

8† |

69 |

11-1/8 |

5 |

4-1/16 |

2-3/8 |

|

|

|

|

|

|

|

|

TTUH-1203 |

240 |

12† |

98 |

17-3/4 |

5 |

4-1/16 |

2-3/8 |

|

|

|

|

|

|

|

|

‡ Minimum liquid level should be maintained at 1/2” above D dimension.

† Brazed terminal construction; cannot be wired for 3 heats.

Specifications — TTUH-CO

|

|

|

|

Dimensions (In.) |

|

||

|

|

|

|

|

|

|

Extends |

|

|

|

|

Overall |

|

|

Into |

Model |

Volts |

kW |

W/In2 |

Length |

|

|

Tank |

A |

B |

C |

D‡ |

||||

TTUH-CO — 1 Phase with cutout — 3-1/4” min. liquid depth |

|

||||||

TTUH-CO-10 |

120 |

1 |

42 |

7-7/16 |

4-8/16 |

3-1/16 |

1-3/8 |

|

|

|

|

|

|

|

|

TTUH-CO-15 |

120 |

1.5 |

62 |

7-7/16 |

4-13/16 |

3-1/16 |

2-3/8 |

|

|

|

|

|

|

|

|

TTUH-CO-15 |

208 |

1.5† |

62 |

7-7/16 |

4-13/16 |

3-1/16 |

2-3/8 |

TTUH-CO-15 |

240 |

1.5† |

62 |

7-7/16 |

4-13/16 |

3-1/16 |

2-3/8 |

|

|

|

|

|

|

|

|

TTUH-CO-20 |

208 |

2 |

60 |

9-7/16 |

4-13/16 |

3-1/16 |

2-1/8 |

TTUH-CO-20 |

240 |

2 |

60 |

9-7/16 |

4-13/16 |

3-1/16 |

2-1/8 |

TTUH-CO-25 |

208 |

2.5 |

40 |

6-3/4 |

4-13/16 |

3-1/16 |

2-1/8 |

TTUH-CO-25 |

240 |

2.5 |

40 |

6-3/4 |

4-13/16 |

3-1/16 |

2-1/8 |

|

|

|

|

|

|

|

|

TTUH-CO-30 |

208 |

3 |

55 |

6-3/4 |

4-13/16 |

3-1/16 |

2-1/8 |

TTUH-CO-30 |

240 |

3 |

55 |

6-3/4 |

4-13/16 |

3-1/16 |

2-1/8 |

|

|

|

|

|

|

|

|

TTUH-CO-40 |

208 |

4† |

64 |

9-1/2 |

4-13/16 |

3-1/16 |

2-1/8 |

TTUH-CO-40 |

240 |

4† |

64 |

9-1/2 |

4-13/16 |

3-1/16 |

2-1/8 |

TTUH-CO-50 |

208 |

5† |

70 |

12-3/4 |

5-3/8 |

4 |

2-11/16 |

TTUH-CO-50 |

240 |

5† |

70 |

12-3/4 |

5-3/8 |

4 |

2-11/16 |

|

|

|

|

|

|

|

|

TTUH-CO-60 |

208 |

6† |

73 |

14-1/2 |

5-3/8 |

4 |

2-11/16 |

TTUH-CO-60 |

240 |

6† |

73 |

14-1/2 |

5-3/8 |

4 |

2-11/16 |

TTUH-CO-70 |

240 |

7† |

85 |

14-1/2 |

5-3/8 |

4 |

2-11/16 |

TTUH-CO — 3 Phase with cutout — 3-1/2” min. liquid depth |

|

||||||

TTUH-CO-303 |

208 |

3 |

55 |

8-3/4 |

5-13/16 |

3-1/8 |

2-23/32 |

TTUH-CO-303 |

240 |

3 |

55 |

8-3/4 |

5-13/16 |

3-1/8 |

2-23/32 |

TTUH-CO-403 |

208 |

4 |

74 |

8-3/4 |

5-13/16 |

3-1/8 |

2-23/32 |

TTUH-CO-403 |

240 |

4 |

74 |

8-3/4 |

5-13/16 |

3-1/8 |

2-23/32 |

TTUH-CO-503 |

208 |

5 |

73 |

11 |

5-13/32 |

3-1/8 |

2-23/32 |

TTUH-CO-503 |

240 |

5 |

73 |

11 |

5-13/32 |

3-1/8 |

2-23/32 |

TTUH-CO-503 |

480 |

5 |

73 |

11 |

5-13/32 |

3-1/8 |

2-23/32 |

TTUH-CO-603 |

208 |

6 |

72 |

11-1/16 |

5-3/4 |

4-1/16 |

3 |

TTUH-CO-603 |

240 |

6 |

72 |

11-1/16 |

5-3/4 |

4-1/16 |

3 |

TTUH-CO-703 |

208 |

7 |

78 |

11-1/16 |

5-3/4 |

4-1/16 |

3 |

TTUH-CO-703 |

240 |

7 |

78 |

11-1/16 |

5-3/4 |

4-1/16 |

3 |

TTUH-CO-703 |

480 |

7 |

78 |

11-1/16 |

5-3/4 |

4-1/16 |

3 |

TTUH-CO-803 |

208 |

8 |

69 |

14-1/2 |

5-3/4 |

4-1/16 |

3 |

TTUH-CO-803 |

240 |

8 |

69 |

14-1/2 |

5-3/4 |

4-1/16 |

3 |

TTUH-CO-803 |

480 |

8 |

69 |

14-1/2 |

5-3/4 |

4-1/16 |

3 |

TTUH-CO-903 |

208 |

9 |

78 |

14-1/2 |

5-3/4 |

4-1/16 |

3 |

TTUH-CO-903 |

240 |

9 |

78 |

14-1/2 |

5-3/4 |

4-1/16 |

3 |

TTUH-CO-903 |

480 |

9 |

78 |

14-1/2 |

5-3/4 |

4-1/16 |

3 |

TTUH-CO-1003 |

208 |

10 |

82 |

17-11/16 |

5-3/4 |

4-1/16 |

3 |

TTUH-CO-1003 |

240 |

10 |

82 |

17-11/16 |

5-3/4 |

4-1/16 |

3 |

TTUH-CO-1003 |

480 |

10 |

82 |

17-11/16 |

5-3/4 |

4-1/16 |

3 |

TTUH-CO-1203 |

240 |

12 |

98 |

17-11/16 |

5-3/4 |

4-1/16 |

3 |

TTUH-CO-1203 |

480 |

12 |

98 |

17-11/16 |

5-3/4 |

4-1/16 |

3 |

‡ Minimum liquid level should be maintained at 1/2” above D dimension.

† Brazed terminal construction; cannot be wired for 3 heats.

© 2010 Chromalox, Inc.

GENERAL

FIRE/EXPLOSION HAZARD. This heater is not intended for use in hazardous atmospheres where flammable vapors, gases, liquids or other combustible atmospheres are present as defined in the National Electrical Code. Failure to comply can result in personal injury or property damage.

Chromalox TTUH and TTUH-CO food equipment heaters are ideal for coffee urns, steam tables, kettles, humidifiers and other commercial uses.

Heater Construction Characteristics

A.An opening of 2-7/16” in diameter in the bottom of the tank is required to insert the heater.

B.High watt density.

C.4” conduit box is mounted to the tank by a tightening bolt.

The system designer is responsible for the safety of this equipment and should install adequate back-up controls and safety devices with their electric heating equipment. Where the consequences of failure could result in personal injury or property damage, back-up controls are essential.

INSTALLATION

ELECTRIC SHOCK HAZARD. Disconnect all power before installing or servicing heater. Failure to do so could result in personal injury or property damage. Heater must be installed by a qualified person in accordance with the National Electrical Code, NFPA 70.

FIRE HAZARD. Since heaters are capable of developing high temperatures, extreme care should be taken to:

A.Avoid mounting heaters in an atmosphere containing combustible gases and vapors.

B.Avoid contact between heaters and combustible materials.

C.Keep combustible materials far enough away to be free of the effects of high temperature.

D.Keep heater immersed at all times.

2

Loading...

Loading...