Champion 66 WSPW User Manual

Project

Item No.

Quantity

(1M) 4/06 Printed in U.S.A.

CH098

Gas Heated Water Saver

High Temperature Rack Conveyor

Single-tank Dishwashing Machine with Prewash

66 WSPW 66"

66WSPW GAS RACK CONVEYOR

Champion Industries, Inc.

P. O. Box 4149, Winston-Salem, NC 27115

Tel: 336/661-1556 Fax: 336/661-1979

www.championindustries.com

Gas

Gas Heating

Systems

SPECIFIER STATEMENT

Specified unit will be Champion model 66WSPW gas

heated water saver high temperature rack conveyor

single-tank dishwashing machine with prewash.

Features top mounted control cabinet; upper and lower

one-piece stainless steel spray arm assemblies, removable

internal scrap basket with two-piece scrap screen. Large

15-1/2" prewash and 26" wash and door with front access and

double-hook safety latch. Anti-jam conveyor drive system.

1 year parts and labor warranty.

Single

Source

STANDARD FEATURES

• Dual-pawl cradle drive system

• One-piece cast stainless steel upper

& lower spray arm assemblies

• Internal removable scrap baskets with

two-piece scrap screens

• Standard vertical opening accommodates

18" x 26" sheet pans

• Wide 15-1/2" and 26" leakproof doors,

internally-fitted

• Anti-jam conveyor drive system

• Energy Sentinel (Idle pump shut-off)

• Convenient top-mounted controls

• Automatic tank fill

• Common utility connections

• Door safety switch

• Door activated drain closures

• Enclosure panels (front and sides)

• Splash shields

• Low-water tank heat protection

• Rinse-saver device

• Stainless steel heavy-gauge construction,

including base and feet

• Prewash pump 1 Hp motor

• External prewash scrap basket

• Wash pump 2 Hp motor

• Stainless steel pumps and impellers

• Single-point electrical connection

Gas Heated Water Saver

High Temperature Rack Conveyor

Single-tank Dishwashing Machine

66WSPW GAS RACK CONVEYOR

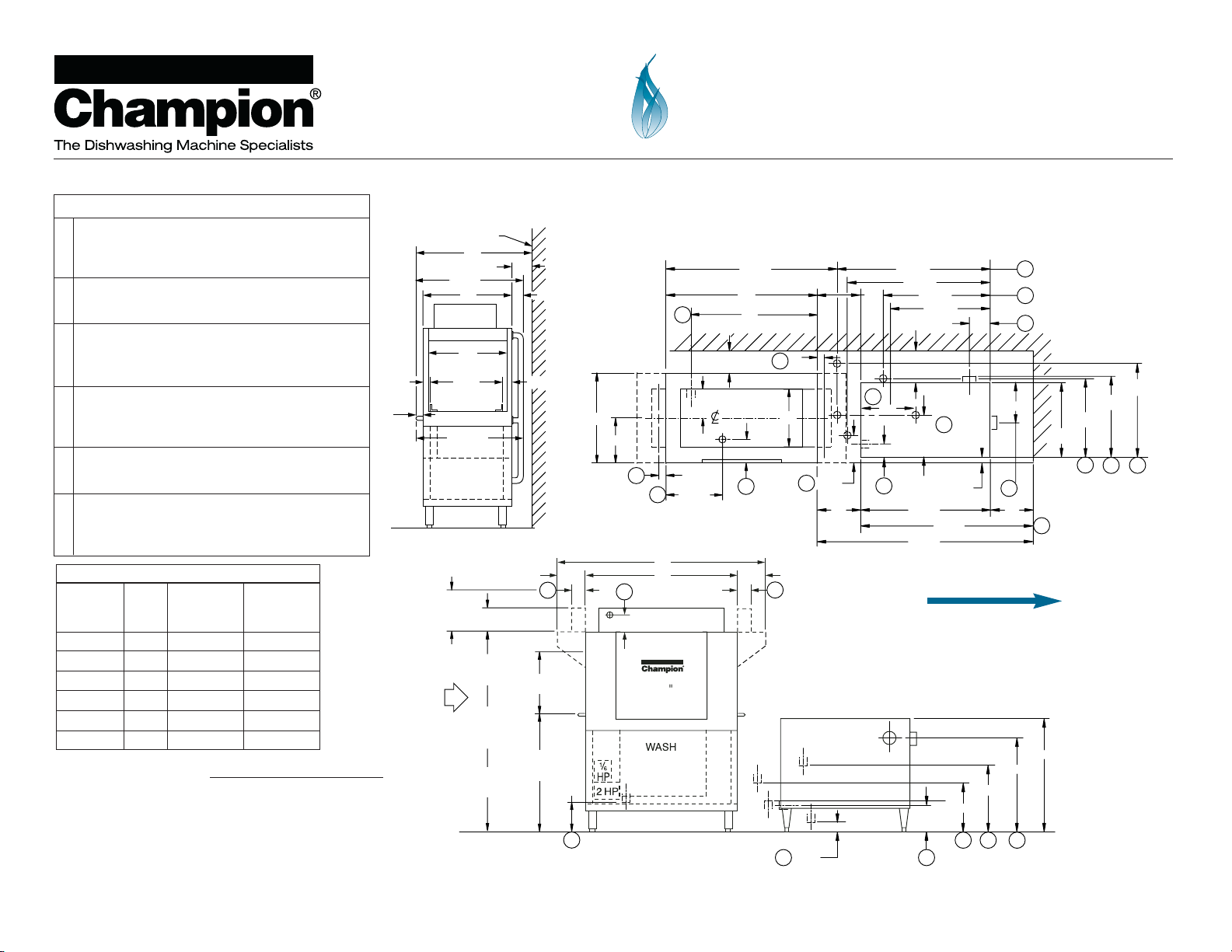

Dimensions shown in inches

Warning: Gas burner intake and exhaust venting required in

accordance with local codes. Exhaust must be vented outside.

Warning: Plumbing, gas and electrical connections should be made

by qualified personnel who will observe all the applicable plumbing,

sanitary, safety codes and the National Electrical Code.

Note: Water Hammer Arrestor (meeting ASSE-1010 standard or

equivalent) to be supplied (by others) in common water supply line at

service connection.

Gas

12"

49-1/2"

6"

25"

28-1/2"

36"

44"

6"

8"

12-1/2"

16"

2"

2"

1A

4B

5

5

4A

3A

3A

42-1/2"

39-5/8"

29-3/4"

27-3/4"

8-3/4"

5-3/4"

7-3/4"

12" 12"35-7/8"

47-7/8"

59-7/8"

6-1/4"

11-7/8"

20-3/4"

1-1/2"

24-1/8"

3-3/4"

13"

27-3/8"

23-3/8"

2

6B

3B

2

1B

6B

3B

4

1B

6C

6" Nom.

Wall

2

"

CONTROL

CABINET

22"

25"

30-5/8"

30-5/8"

2-3/8"

3-5/8"

20-1/8"

2-1/2"

33"

OPENING

INS. TRACK

Left-to-Right Operation

5"

26

Door

20-3/4"

Clear

34"

Load

Height

89"

Door

Removal

82"

Door

Open

Height

58-1/2"

Machine

Height

12"

Plumbing

Clearance

Cowl

Cowl

7"

5"

2-3/4"

3C

3A

1B

23B

4B

60"

44"8" 8"

4"4"

1A

4A

6

7-1/4"

13-3/4"

19-5/8"

25-3/4"

31-1/8"

HATCO

GAS BOOSTER

MOD. # PMG-200

Front View

Plan View

Left-to-Right Operation

Volume crated: 252 cu. ft.

Shipping weight crated: 1550 lbs.

Details, Dimensions & Connections

Utilities

1 Electrical

A. Machine connection (see box)

B. Booster connection requires 15 amps

@ 120/60/1

2 Hot Water

3/4" NPT 140°F hot water connection.

Flow pressure 25 psi.

3 Drain

A. 1-1/2 NPT machine connection.

B. T/P relief valve to open drain

C. 1/2" NPT vent to open drain

4 Vents

(Dishwasher) (4" x 16" outside)

A. Load end: 200 CFM @ 1/4" S.P.

B. Unload end: 400 CFM @ 1/4" S.P.

5 Gas

3/4" NPT requires: LP Gas – 52 CFH for 130,000

BTU/hr. Natural Gas – 130 CFH for 130,000 BTU/hr.

6 Gas Flue

4" OD exhaust

A. Left end of booster (specify when ordering)

B. Rear of booster (specify when ordering)

Machine Load Amps

Minimum Maximum

Supply Ckt. Overcurrent

Elec. Rated Conductor Protective

Specs. Amps Ampacity Device

208/60/1 16 20 20

240/60/1 15 20 20

208/60/3 8 15 15

240/60/3 8 15 15

480/60/3 4 15 15

575/60/3 3 15 15

Loading...

Loading...