Page 1

IMPORTANT SAFETY RULES - SAVE THESE INSTRUCTIONS

These safety alert symbols mean Caution - a personal safety or property damage instruction. This

tubular motor is designed and tested to offer reasonable safe service provided it is installed and

operated in strict accordance with the following safety rules.

Failure to comply with the following instructions may result in serious personal injury

or property damage.

WARNING: IT IS IMPORTANT FOR THE SAFETY

OF PERSONS TO FOLLOW THESE

INSTRUCTIONS. SAVE THESE INSTRUCTIONS.

To avoid injury, completely lower the shutter before

loosening the screws in the tube end of the shutter.

Installation and wiring must be in compliance with

your local building and electrical codes.

Disconnect the power supply to the shutter motor

before commencing any repairs

A suitable power phase jumper (full-pole disconnect

with 3 mm contact opening gap) must be fitted in the

power supply..

GB-1

Before You Begin:

1. Carefully read all the information contained in this Owner’s Manual before beginning installation procedures.

2. Check the shutter to be sure it is not broken or damaged, and that it opens and closes smoothly.

3. Determine whether the motor needs to be installed on the left side,

4. Ensure that the motor can be pushed in as far as the stop. The limit switch is controlled by the plastic ring which must be

pushed fully on.

Carton Contents

(1) TM10, TM20, TM30 or TM50 Tubular Motor

(2) Screw M5x15 with washer (1 each)

TM20, TM30, TM50

Screw 4.8x22 with washer (1 each) – TM10

(3) Tube Adapter Set, 60mm octagonal

TM20, TM30, TM50

(4) Tube Adapter Set, 40mm octagonal TM10

(5) Square tube bracket (1) or alternatively

(5.1) square tube pin (1) and 2 screws

(6) Mounting bracket (1)

(7) Cotter pin (1)

(8) Screw 3,9 x 6,5 (3) TM20, TM30, TM50 to

armoured bracket

(9) Motor bracket TM10 (2 parts)

(10) Mounting screws (2) TM10 for Motor bracket

(11) adjuster pin

(1) or the right side, (2) of the shutter.

F

Warranty for Tubular Motor

Chamberlain GmbH warrants to the first retail purchaser of this product that the product shall be free from any defect in materials

and/or workmanship for a period of 24 full months (2 years) from the date of purchase for TM10, TM20, TM30 or TM50 Series

Models. Upon receipt of the product, the first retail purchaser is under obligation to check the product for any visible defects.

Conditions: The warranty is strictly limited to the reparation or replacement of the parts of this product which are found to be

defective and does not cover the costs or risks of transportation of the defective parts or products.

This warranty does not cover non-defect damage caused by unreasonable use (including use not in complete accordance with

Chamberlain’s instructions for installation, operation and care; failure to provide necessary maintenance and adjustment; or any

adaptations of or alterations to the products), labor charges for dismantling or reinstalling of a repaired or replaced unit or

replacement batteries.

A product under warranty which is determined to be defective in materials and/or workmanship will be repaired or replaced

(at Chamberlain’s option) at no cost to the owner for the repair and/or replacement parts and/or product. Defective parts will be

repaired or replaced with new or factory rebuilt parts at Chamberlain’s option.

If, during the warranty period, the product appears as though it may be defective, contact your original place of purchase.

This warranty does not affect the purchaser’s statutory rights under applicable national legislation in force nor the purchaser’s rights

against the retailer arising from their sales purchase contract. In the absence of applicable national or EC legislation, this warranty

will be the purchaser’s sole and exclusive remedy, and neither Chamberlain GmbH nor its affilliates or distributors shall be liable for

any incidental or consequential dmages for any express or implied warranty relating to this product.

No representative or person is authorized to assume for Chamberlain GmbH any other liability in connection wit the sale of

this product.

A

Any damaged power supply wiring must be replaced

by the manufacturer or the manufacturer’s customer

service agent.

Do not allow children to play with fixed controls.

Keep remote controls away from children.

Frequently examine the installation for imbalance or

signs of wear. Do not use if repair or adjustment is

necessary.

Watch the moving shutter or awning and keep

away until the shutter has completely stopped.

Ensure that the motor is accessible at all times

following installation.

Install it on the side where the manual pull is located. Close the shutter.

Page 2

INSTALLATION

Rough- in or install conduit pipe to the connector box for the

electrical connecting line according to local building and

electrical codes.

Push the tube adapter (3/4) onto the motor (1), and

secure the drive adapter with the fixing parts (2)

supplied. Insert the square tube bracket (5) into the

recess in the motor head, and apply gentle pressure

until it engages. If a square tube pin (5.1) has been

supplied, secure this with the screws. On model TM10,

the motor bracket (9) is secured by means of 2 motor

bracket mounting screws (10).

Fully unroll the shutter (a). Remove the shutter material

from the tube (b). Remove the manual control (c).

Remove the tube.

Push the motor (1) completely into the tube. The limit

switch operates only if the drive unit is fully inserted.

Ensure that the adapter ring is pushed fully home. Do

not force it or strike it. Do not damage the tubular

motor by drilling!

Proceed according to the specific requirements for leftsided (a) or right-sided (b) operation:

Secure the mounting bracket (6) to the wall (10) (use

suitable screws and plugs).

Insert the square tube bracket on the motor (1) into the

mounting bracket (6) and secure with the cotter pin (7).

Make sure the set screws for the limit adjustments

(beneath the mounting bracket) are accessible.

Don’t return the shutter material to the tube yet!

ELECTRICAL CONNECTION

Never connect more than one motor to a timer or

wall switch without using a central module – (h)

(available as an accessory), i.e. one central

module is required for each connected motor.

The illustration also shows the wall bracket on the drive side

(b), the motor drive (a); the steel tube (c); the end cap (d);

and the opposite wall bearing (e).

For a left-side motor installation, follow the wiring diagram

exactly as shown in the control accessory package.

For the correct direction of rotation in a right-side motor

installation, electrical wires (brown & black) must be reversed

between the control accessory and the motor. (See

instructions packed with the accessory you have chosen).

Have the electrical hook-up done by a qualified

electrician in compliance with your local electrical code.

TCS1ED Rocker switch (f)

TCT2ED Programmable Timer (g)

TCTX2ED Remote Control Wall Switch (w/o fig.)

TCTRX2ED Programmable Timer with Integrated

Receiver (w/o fig.)

TCRX3ED Rolling Shutter Receiver (w/o fig.)

WTMTZ Central Module (h)

Additional accessories can be found in section M on

page 3.

E

F

I

GB-2

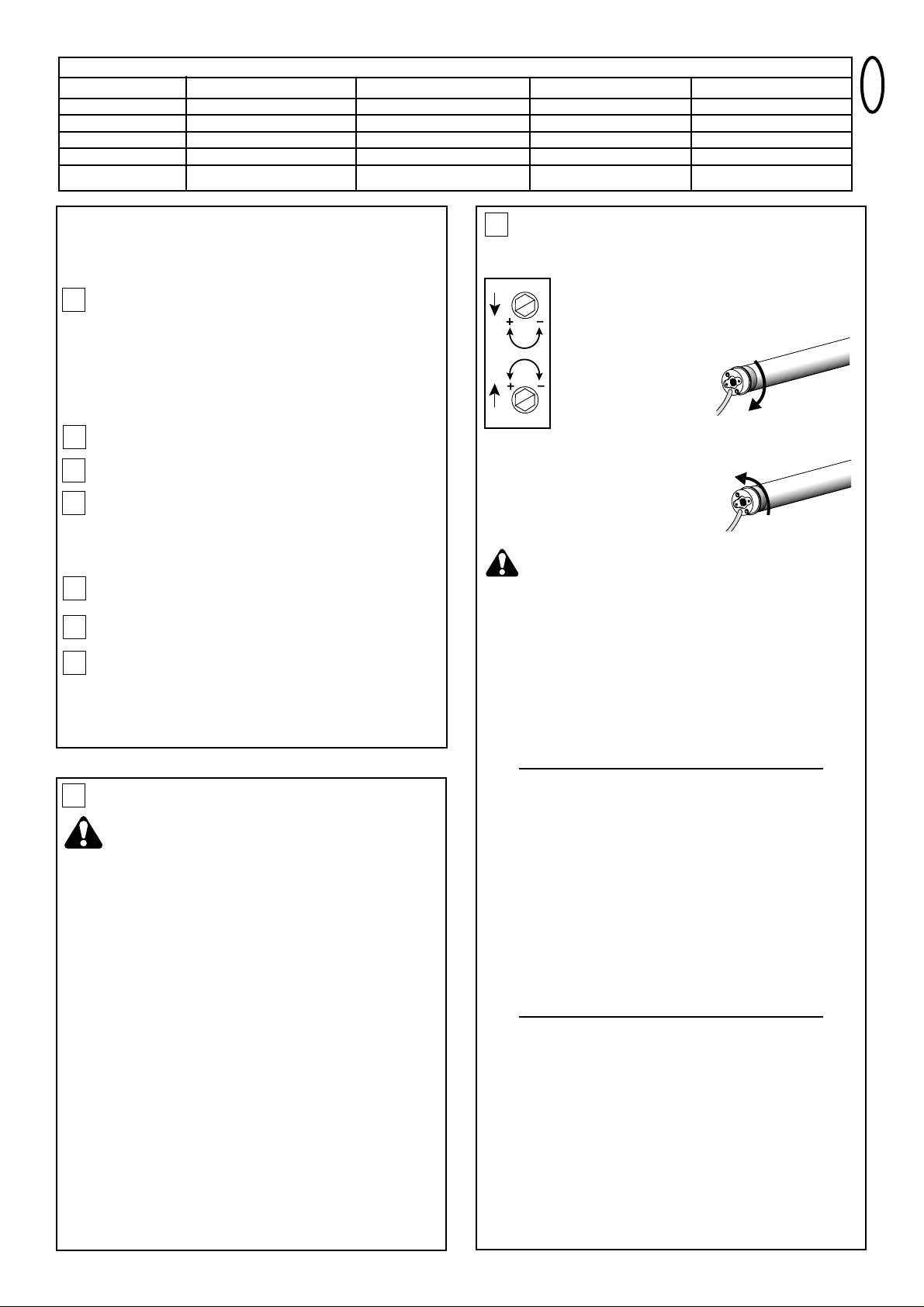

SETTING THE LIMITS

Procedure for Adjusting

“Open” and “Cose” Positions

(refer to figure I for lefthanded installation)

#1 Limit Setting for “Shutter Open”

+ = increase closing travel

– = decrease closing travel

#2 Limit Setting for “Shutter Close”

+ = increase opening travel

– = decrease opening travel

Please observe that the limitis of the motor only

operate in a complete installation.

Read the following instructions carefully before making

any open or close limit adjustments.

To attach the shutter material on the tube, use ONLY

the 3.9 x 6.5 mounting screws included (TM20, TM30,

TM50). Otherwise, the drive might be damaged by screws

which are too long.

This instruction applies particularly to model TM10 (no

screws included). Use the appropriate fixing parts to

secure the shutter material to the tube. The drive may

be damaged by using screws which are too long.

IF ADJUSTMENTS ARE NEEDED, PROCEED AS

FOLLOWS:

LIMIT ADJUSTMENT SCREW #1 - OPEN

Run the motor through an open cycle.

♦ If motor stops before shutter is fully opened:

Turn set screw #1 toward + and open the shutter until

desired position is reached.

♦

If motor stops after shutter is fully opened:

Close shutter below desired position. Turn set screw #1

toward – and open shutter again. Repeat this step as often

as necessary to reach the desired position

LIMIT ADJUSMENT SCREW #2 - CLOSE

Run the motor through a close cycle. Attach the shutter

material to the tube.

♦ If motor stops too soon (before shutter is fully

closed):

Turn set screw #2 toward + and close shutter again, until

desired position is reached.

♦

If motor stops after shutter is fully closed:

Retract shutter above desired position. Turn set screw #2

toward – and close shutter again. Repeat this step as often

as necessary to reach the desired position.

D

C

G

H

J

B

Technical Data

Typ

Power

Power Supply

Torque

Pulling Force

R.P.M.

TM50

235 Watts

230V / 50Hz, cable 2m

40Nm

72kg (60mm Tube)

18 U/Min.

TM10

125 Watts

230V / 50Hz, cable 2m

10Nm

18kg (40mm Tube)

14 U/Min.

TM30

185 Watts

230V / 50Hz, cable 2m

20Nm

35kg (60mm Tube)

18 U/Min.

TM20

155 Watts

230V / 50Hz, cable 2m

15Nm

25kg (60mm Tube)

18 U/Min.

Page 3

No. Part Description

(a) 704636 Motor TM10

120785ASA Motor TM20

120758ASA Motor TM30

120756ASA Motor TM50

(b) TAO70ASA Tube adapter octagonal 70mm

(Not for TM10)

(c) WT860-1 Octagonal tube 60mm with endcap - 1m

WT860-2 Octagonal tube 60mm with endcap - 2m

WT860-3 Octagonal tube 60mm with endcap - 3m

(d) 120995 Endcap for octagonal tube 60mm

(e) 121084 Universal wall bearing for WT860

(f) TCS1ED Wall Switch (Rocker switch)

(g) TCT2ED Programmable Timer

TCTRX2ED Programmable Timer with integrated

Receiver

TCTTX2ED Programmable Timer with integrated

Transmitter

(h) WTMZ1 Central Module

(i) TCRX3ED Rolling Shutter Remote Control Receiver

(j) TCTX2ED Remote Control Wall Switch

TCRX2ED Rolling Shutter Control with integrated

Receiver

(k) WTMLS1 Light Sensor

(l) TAP65ASA Tube adapter profile shaft 65mm

(Not for TM10)

(m) TCLS1ED Remote Control Light and

Glass Breakage Sensor

(n) 703280 Switch - flush mount

708218 Accessory pack TM10 - Motor bracket

(w/o figure)

708223 Accessory pack TM10 - Adapter

(w/o figure)

041TM707008 Accessory pack TM20, TM30, TM50

(w/o figure)

TAM120155 Tube adapter awning 78mm, TM50 only

(w/o figure)

TAM120162 Tube adapter awning 85mm, TM50 only

(w/o figure)

GB-3

TROUBLE SHOOTING

Motor does not run

• Public electricity supply failure. Check with a neighbor.

• Circuit breaker has tripped or fuse is blown. Check house

overload protector. If necessary, have an authorized

electrician redistribute the load.

• The switch is defective. Have it checked by an authorized

electrician and replaced if necessary.

• Repeated operation may have tripped the motor

overload protector switch. Wait 15 minutes and try

again.

Motor runs intermittently

• Have the wiring connection between switch and motor

checked by an authorized electrician. Replace if

necessary.

Motor does not shut off

• Check to be sure tube adapter is positioned all the way

up to the stop on the tube.

• Check to be sure the motor has been inserted all the

way into the tube.

709164-GB

M

a

b

d

f

i

j

c

h

g

k

e

K

Main

230 V/50 Hz

Color Scale for Drive Table

1 yellow-green

2 blue

3 black

4 brown

Model 703280 switch

L

Main

230 V/50 Hz

Color Scale for Drive Table

1 yellow-green

2 blue

3 black

4 brown

Connection of the

2I 1IPI

N

E

L1.2 (brown)

N (blue)

PE (yellow-green)

Equipment Grounding Conductor PE

Neutral MP

Phase Direction of Rotation 1

Phase Direction of Rotation 2

L1.1 (black)

Control Cable

4 x 0,75

Connection of the

Model TCS1ED switch

L

L1.2 (brown)

N (blue)

PE (yellow-green)

Equipment Grounding Conductor PE

Neutral MP

Phase Direction of Rotation 1

Phase Direction of Rotation 2

L1.1 (black)

Control Cable

4 x 0,75

M

TM

M

TM

TM

TM

m

l

n

M

M

Loading...

Loading...