Page 1

CONTROLLER

BOARD

GL

MODEL SW470

MEDIUM DUTY SWING GATE OPERATOR

Serial # _______________________

(located on electrical box cover)

Installation Date _________________

2 YEAR WARRANTY

MODEL SW490

HEAVY DUTY SWING GATE OPERATOR

INTENDED FOR PROFESSIONAL INSTALLATION ONLY.

VISIT WWW.LIFTMASTER.COM TO LOCATE A PROFESSIONAL

INSTALLING DEALER IN YOUR AREA.

THIS MANUAL IS TO BE LEFT WITH THE PROPERTY OWNER.

MODELS SW470 AND SW490 ARE FOR VEHICULAR PASSAGE GATES

ONLY AND NOT INTENDED FOR PEDESTRIAN PASSAGE GATE USE.

Page 2

TABLE OF CONTENTS

WARNING WARNING

WARNING

WARNING WARNING

WARNING

CAUTION CAUTION

WARNING

WARNING

OPERATOR SPECIFICATIONS

Carton Inventory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Operator Dimensions and Specifications . . . . . . . . . . . . . . . . . . .3

UL325 Model Classifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

OPERATOR WARNINGS

Suggested Safety Protection Device Locations. . . . . . . . . . . . . . .5

Safety Installation Information . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Gate Construction Information . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Safety for Swing and Ornamental Grill Type Gates . . . . . . . . . . . . 8

Warranty Sign Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

INSTALLATION

Post Mounting (SW470) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Pad Mounting (SW470) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Pad Mounting (SW490) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Control Arm and Gate Bracket Installation (SW470). . . . . . . . . .12

Control Arm Assembly (SW490) . . . . . . . . . . . . . . . . . . . . . 13-14

Manual Disconnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

WIRING

Power Wiring Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

On/Off Switch Power Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Stop/Reset Button Control Wiring . . . . . . . . . . . . . . . . . . . . . . . 16

ADJUSTMENT

Programming the Radio Receiver. . . . . . . . . . . . . . . . . . . . . . . . 17

Limit Switch Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

RPM Sensor (Hall Effect) Adjustment. . . . . . . . . . . . . . . . . . . . .19

SAMS (Sequenced Access Management System) . . . . . . . . . . . 20

Accessory Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21-22

Control Board Illustration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Controller Programming and Features . . . . . . . . . . . . . . . . . 24-25

Program Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-27

TROUBLESHOOTING

MAINTENANCE

Operator Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Single Phase Wiring Diagram (SW470) . . . . . . . . . . . . . . . . . . . 31

Single Phase Wiring Diagram (SW490) . . . . . . . . . . . . . . . . . . . 32

Three Phase Wiring Diagram (SW490). . . . . . . . . . . . . . . . . . . .33

Control Connection Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Repair Parts and Illustrated Parts - SW470 . . . . . . . . . . . . . 35-36

Repair Parts and Illustrated Parts - SW490 . . . . . . . . . . . . . 37-38

Variable Parts - SW490 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Safety Accessories for Secondary Entrapment Protection . . . . .39

WARRANTY POLICY AND SERVICE

IMPORTANT NOTE

• BEFORE attempting to install, operate or maintain the operator,

you MUST read and fully understand this manual and follow all

safety instructions.

• These instructions are intended to highlight certain safety related

issues. These instructions are not intended to be comprehensive.

Because each application is unique, it is the responsibility of the

purchaser, designer, installer and end user to ensure that the

total gate system is safe for its intended use.

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .40

28-29

Mechanical

Electrical

When you see these Safety Symbols and Signal Words on the

following pages, they will alert you to the possibility of serious

injury or death if you do not comply with the warnings that

accompany them. The hazard may come from something

mechanical or from electric shock. Read the warnings carefully.

When you see this Signal Word on the following pages, it will alert

you to the possibility of damage to your gate and/or the gate

operator if you do not comply with the cautionary statements that

accompany it. Read them carefully.

CARTON INVENTORY

Before beginning your installation check that all components were

supplied and received undamaged. Refer to list below for factory

supplied parts.

HARDWARE KITS SW470 (K77-SW470) & SW490 (K77-SW490)

PART NO. DESCRIPTION QTY.

SW470

02-401-SP Stop Button 1

10-2108-T Arm Channel 1

10-2109 Extension Arm 1

10-2111 Gate Bracket 1

40-3505 Warning Sign 2

80-2103 Black Plastic Knob 2

82-HN38-18 3/8 x 1-1/2 Hex Head Bolt 2

82-SB50-08 1/2-13 x 1/2 Shoulder Bolt 2

84-FN-38 3/8-16 Serrated Flanged Nut 4

85-FW-38 3/8" Flat Washer 2

SW490

02-401-SP Stop Button 1

06-2025-T Arm Channel 1

08-2001 Extension Arm 2

10-2011 Gate Bracket 1

70-18618 Warning Sign 1

10-3900 39" Galvanized Steel Pipe 1

11-18619 Pivot Pin 1

12-10172 3/4 Bushing 2

40-18627 Label, Disconnect 1

40-3505 Warning Sign 2

80-207-20 3/8 x 3/8 x 1-1/2 Key 1

80-575 3/4 Flat Washer 4

82-HN38-16 3/8-16 x 1 Hex Head Bolt 2

82-HN75-28 3/4-10 x 3 Hex Head Bolt 1

82-NH38-06CP 3/8-16 x 3/8 Cone Point Set 6

84-RH-75 3/4-10 Hex Nut 1

85-LS-38 3/8 Lockwasher 2

86-CP05-300 Cotter Pin 2

2

2

Page 3

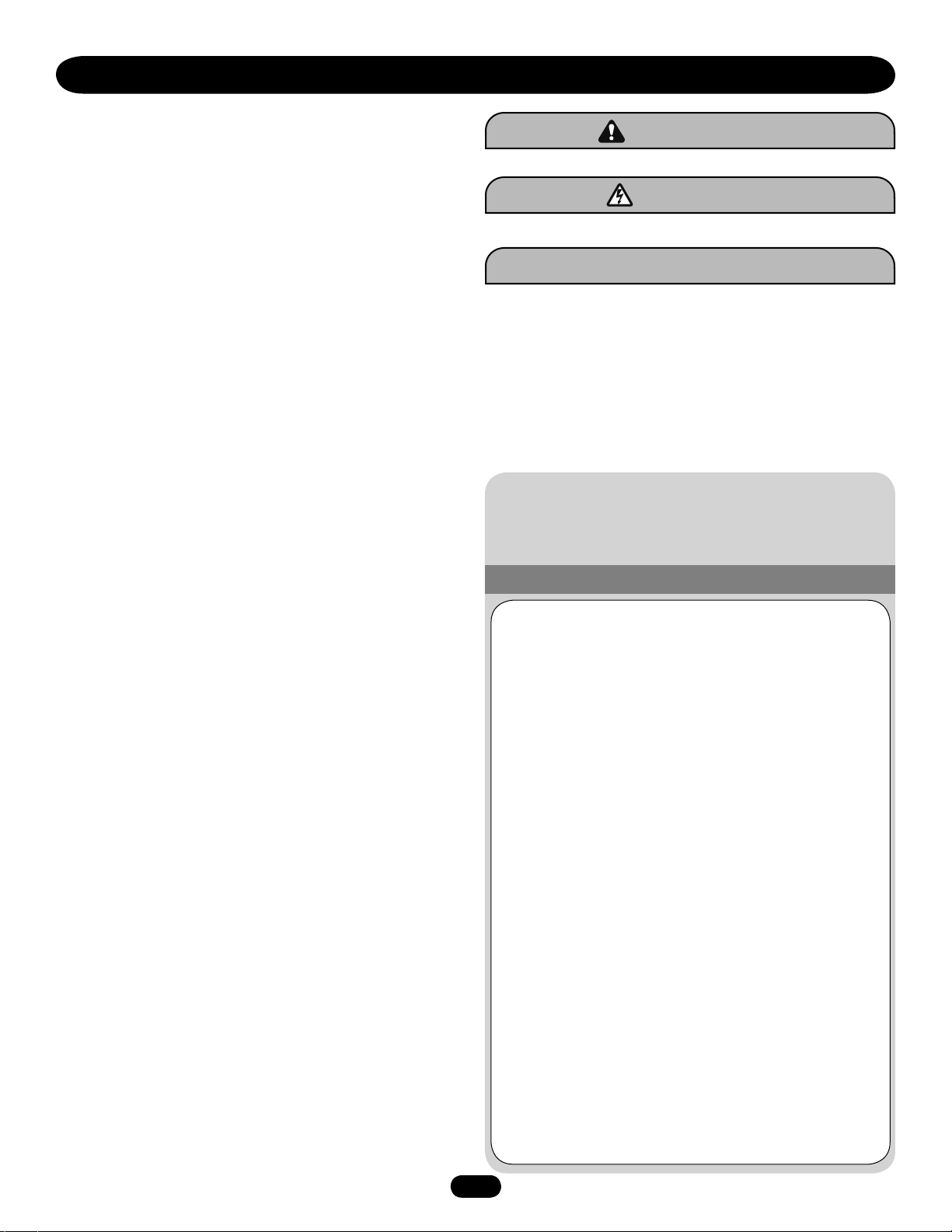

OPERATOR DIMENSIONS AND SPECIFICATIONS

MODEL SW470

• 1/2 HP Motor

Maximum Gate Weight – 500 lbs. (226.8 kg)

Maximum Gate Width – 12 ft. (3.7 m)

MODEL SW490

• 1/2 HP Motor

Maximum Gate Weight – 750 lbs. (340.2 kg)

Maximum Gate Width – 16 ft. (4.9 m)

• 3/4 HP Motor

Maximum Gate Weight – 900 lbs. (408.2 kg)

Maximum Gate Width – 19 ft. (5.8 m)

6.81"

(17.3 cm)

14.25"

(36.2 cm)

7.03"

(17.9 cm)

13.38"

(34 cm)

7.12"

(18.1 cm)

(61.6 cm)

10"

(25.4 cm)

(76.8 cm)

24.25"

20"

(50.8 cm)

30.24"

26.24"

(66.7 cm)

13" (33 cm)

13.63"

(34.6 cm)

• 1 HP Motor

Maximum Gate Weight – 1000 lbs. (453.6 kg)

Maximum Gate Width – 22 ft. (6.7 m)

22"

(55.9 cm)

18.5"

(47 cm)

17.63"

(44.8 cm)

13.75"

(35 cm)

3

3

Page 4

Moving Gate Can Cause

Injury or Death

KEEP CLEAR! Gate may move at any

time without prior warning.

Do not let children operate the gate or

play in the gate area.

This entrance is for vehicles only.

Pedestrians must use separate entrance

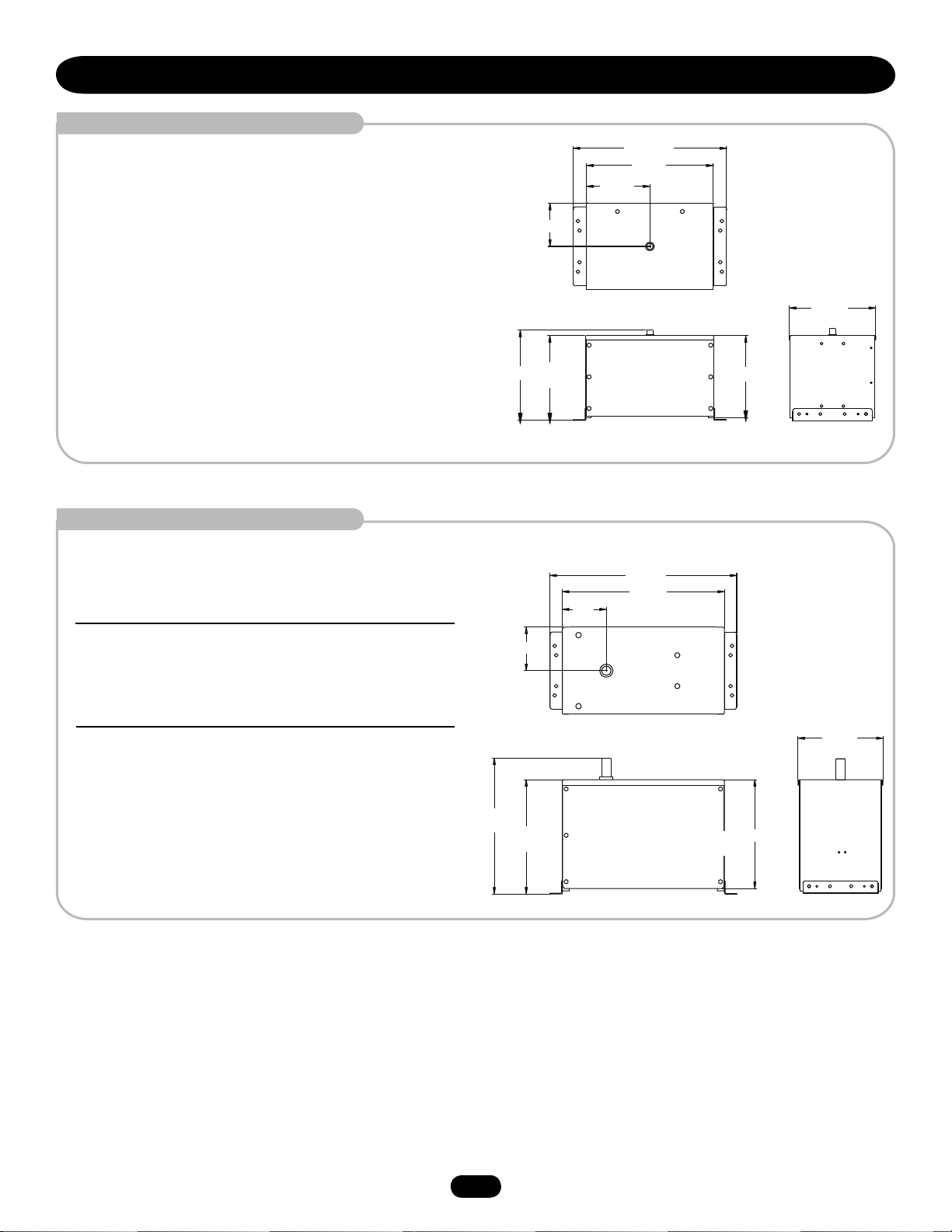

UL325 MODEL CLASSIFICATIONS

The SW470 and SW490 are intended for use with vehicular swing gates. The opener can be used in

Class I, Class II, Class III and Class IV applications.

CLASS I – RESIDENTIAL VEHICULAR GATE OPERATOR

A vehicular gate operator (or system) intended for use in a home of one-to four single family dwellings,

or a garage or parking area associated therewith.

CLASS II – COMMERCIAL/GENERAL ACCESS VEHICULAR GATE OPERATOR

A vehicular gate operator (or system) intended for use in a commercial location or building such as a

multi-family housing unit (five or more single family units) hotel, garage, retail store or other building

servicing the general public.

CLASS III – INDUSTRIAL/LIMITED ACCESS VEHICULAR GATE OPERATOR

A vehicular gate operator (or system) intended for use in a industrial location or building such as a

factory or loading dock area or other location not intended to service the general public.

CLASS IV – RESTRICTED ACCESS VEHICULAR GATE OPERATOR

A vehicular gate operator (or system) intended for use in a guarded industrial location or building such

as an airport security area or other restricted access locations not servicing the general public, in which

unauthorized access is prevented via supervision by security personnel.

SAFETY ACCESSORY SELECTION

All UL325 compliant LiftMaster gate operators will accept external

entrapment protection devices to protect people from motorized

gate systems. UL325 requires that the type of entrapment

protection correctly matches each gate application. Below are the

six types of entrapment protection systems recognized by UL325

for use on this operator.

ENTRAPMENT PROTECTION TYPES

Type A: Inherent obstruction sensing system, self-contained

within the operator. This system must sense and initiate

the reverse of the gate within two seconds of contact

with a solid object.

Type B1: Connections provided for a non-contact device, such as a

photoelectric eye can be used as a secondary protection.

Type B2: Connections provided for a contact sensor. A contact

device such as a gate edge can be used for secondary

protection.

Type C: Inherent adjustable clutch or pressure relief valve.

Type D: Connections provided for a control requiring continuous

pressure to operate the operator

open and close.

Type E: Built-in audio alarm. Examples

include sirens, horns or buzzers.

NOTE: UL requires that all installations must

have warning signs placed in plain view on

both sides of the gate to warn pedestrians of

the dangers of motorized gate systems.

UL325 ENTRAPMENT PROTECTION REQUIREMENTS

GATE OPERATOR ENTRAPMENT PROTECTION

UL325 Slide Gate Operator Swing & Gate Barrier

Installation (Arm) Operator

Class

Class

I & II

Class III

Class IV

Primary

Type

A

A, B1 or B2A, B1, D or

A, B1, B2

or D

Secondary

Type

B1, B2

or D

E

A, B1, B2,

D or E

Primary

Type

A or C

A, B1, B2,

A, B1,

or C

A, B1, C or DA, B1, C, D

The chart above illustrates the entrapment protection

requirements for each of the four UL325 classes.

In order to complete a proper installation you must satisfy the

entrapment protection chart shown above. That means that

the installation must have one primary means of entrapment

protection and one independent secondary means of

entrapment protection. Both primary and secondary

entrapment protection methods must be designed, arranged

or configured to protect against entrapments in both the open

and close directions of gate travel.

For Example: For a slide gate system that is installed on a

single-family residence (UL325 Class I) you must provide the

following: As your primary type of entrapment protection you

must provide Type A- inherent (built into the operator)

entrapment sensing and at least one of the following as your

secondary entrapment protection: Type B1- Non-contact

sensors such as photoelectric eyes, Type B2- Contact sensors

such as gate edges or Type D- Constant pressure control.

4

4

Secondary

Type

C or D

D or E

or E

Page 5

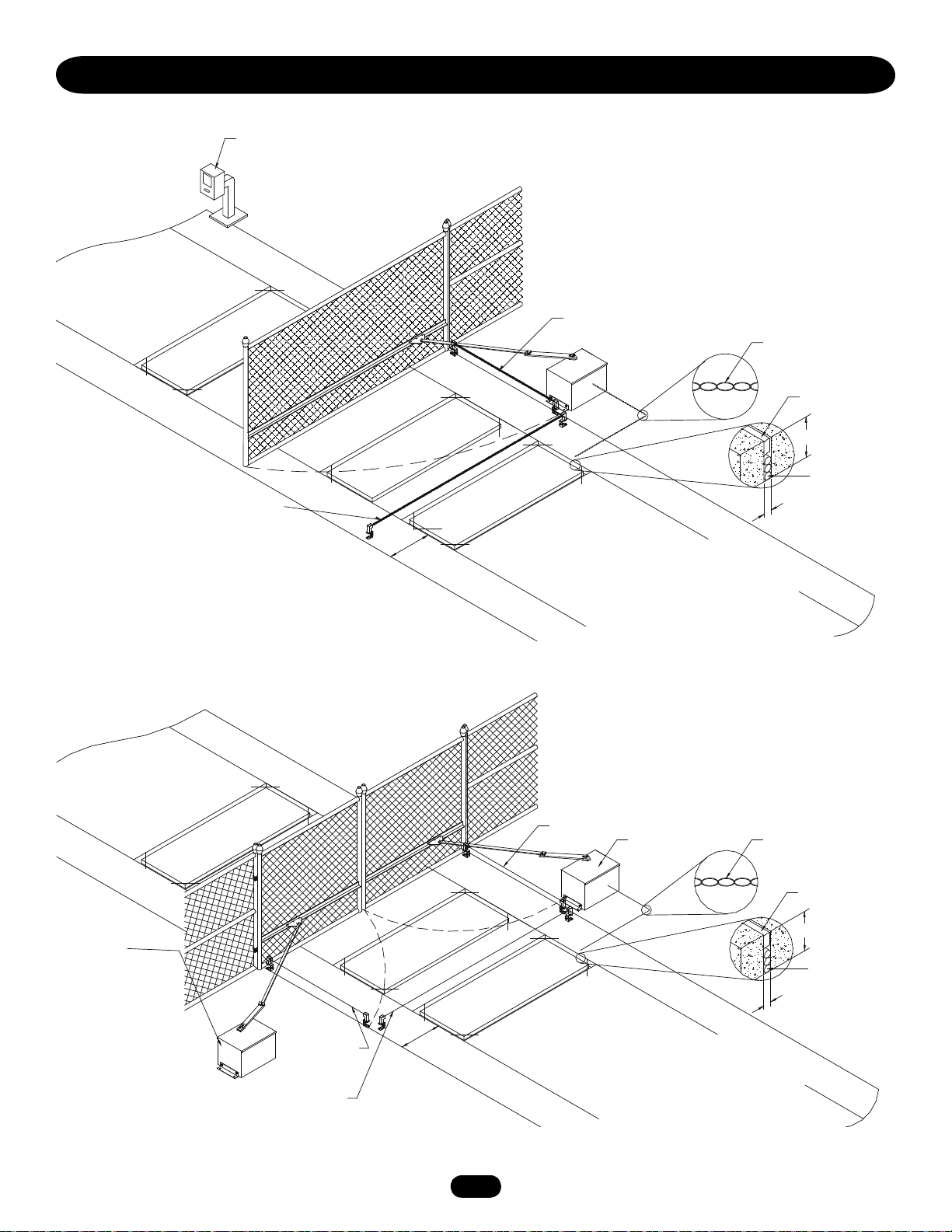

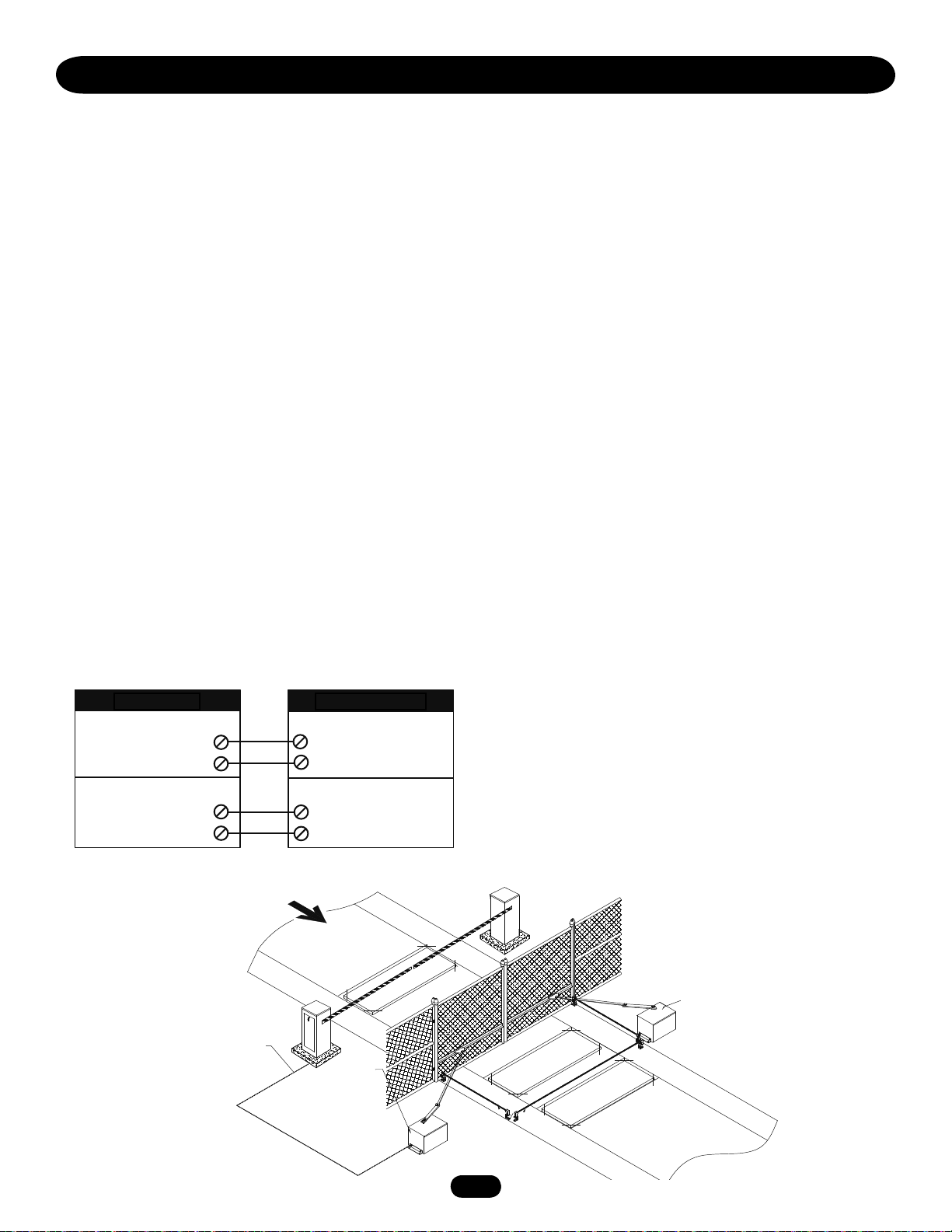

SUGGESTED SAFETY PROTECTION DEVICE LOCATIONS

SWING GATE SYSTEM

STREET

Interrupt (Safety) Loop

Telephone

Entry System

Photo eye for

close cycle

Shadow

Loop

4' (1.2 m)

Typical

Interrupt (Safety) Loop

Photo eye for

open cycle

Run twisted wire*

from loop to

operator

Seal Loops*

1-1/2" (37 mm)

Loop Wire* Layer

1/4" (6 mm) or larger

depending on loop wire

size

COMPLEX

OR

PARKING LOT

DUAL SWING GATE SYSTEM

STREET

Interrupt (Safety)

Loop

Gate 1

Photo eye for

open cycle

Photo eye for

close cycle

Shadow

Loop

4' (1.2 m)

Typical

Interrupt (Safety)

Loop

Photo eye for

open cycle

Gate 2

PARKING LOT

Run twisted wire*

from loop to

operator

Seal Loops*

1-1/2" (37 mm)

Loop Wire* Layer

1/4" (6 mm) or larger

depending on loop wire

size

COMPLEX

OR

* REFER TO LOOP MANUFACTURER’S INSTRUCTIONS FOR DETAILED INSTALLATION & LOOP WIRING INSTRUCTIONS.

55

Page 6

SAFETY INSTALLATION INFORMATION

1. Vehicular gate systems provide convenience and security. Gate systems are comprised of many component parts. The gate

operator is only one component. Each gate system is specifically designed for an individual application.

2. Gate operating system designers, installers and users must take into account the possible hazards associated with each individual

application. Improperly designed, installed or maintained systems can create risks for the user as well as the bystander. Gate

systems design and installation must reduce public exposure to potential hazards.

3. A gate operator can create high levels of force in its function as a component part of a gate system. Therefore, safety features must

be incorporated into every design. Specific safety features include:

• Gate Edges • Guards for Exposed Rollers • Photoelectric Sensors

• Screen Mesh • Vertical Posts • Instructional and Precautionary Signage

4. Install the gate operator only when:

a. The operator is appropriate for the construction and the usage class of the gate.

b. All openings of a horizontal slide gate are guarded or screened from the bottom of the gate to a minimum of 4' (1.2 m) above

the ground to prevent a 2 1/4" (6 cm) diameter sphere from passing through the openings anywhere in the gate, and in that

portion of the adjacent fence that the gate covers in the open position.

c. All exposed pinch points are eliminated or guarded, and guarding is supplied for exposed rollers.

5. The operator is intended for installation only on gates used for vehicles. Pedestrians must be supplied with a separate access

opening. The pedestrian access opening shall be designed to promote pedestrian usage. Locate the gate such that persons will not

come in contact with the vehicular gate during the entire path of travel of the vehicular gate.

6. The gate must be installed in a location so that enough clearance is supplied between the gate and adjacent structures when

opening and closing to reduce the risk of entrapment. Swinging gates shall not open into public access areas.

7. The gate must be properly installed and work freely in both directions prior to the installation of the gate operator.

8 Controls intended for user activation must be located at least six feet (6') away from any moving part of the gate and where the

user is prevented from reaching over, under, around or through the gate to operate the controls. Outdoor or easily accessible

controls shall have a security feature to prevent unauthorized use.

9. The Stop and/or Reset (if provided separately) must be located in the line-of-sight of the gate. Activation of the reset control shall

not cause the operator to start.

10. A minimum of two (2) WARNING SIGNS shall be installed, one on each side of the gate where easily visible.

11. For a gate operator utilizing a non-contact sensor:

a. Reference owner’s manual regarding placement of non-contact sensor for each type of application.

b. Care shall be exercised to reduce the risk of nuisance tripping, such as when a vehicle trips the sensor while the gate is

still moving.

c. One or more non-contact sensors shall be located where the risk of entrapment or obstruction exists, such as the perimeter

reachable by a moving gate or barrier.

12. For a gate operator utilizing a contact sensor such as an edge sensor:

a. One or more contact sensors shall be located where the risk of entrapment or obstruction exists, such as at the leading edge,

trailing edge and post mounted both inside and outside of a vehicular horizontal slide gate.

b. One or more contact sensors shall be located at the bottom edge of a vehicular vertical lift gate.

c. A hard wired contact sensor shall be located and its wiring arranged so the communication between the sensor and the gate

operator is not subject to mechanical damage.

d. A wireless contact sensor such as the one that transmits radio frequency (RF) signals to the gate operator for entrapment

protection functions shall be located where the transmission of the signals are not obstructed or impeded by building structures,

natural landscaping or similar obstruction. A wireless contact sensor shall function under the intended end-use conditions.

e. One or more contact sensors shall be located on the inside and outside leading edge of a swing gate. Additionally, if the bottom

edge of a swing gate is greater than 6" (152 mm) above the ground at any point in its arc of travel, one or more contact sensors

shall be located on the bottom edge.

f. One or more contact sensors shall be located at the bottom edge of a vertical barrier (arm).

6

6

Page 7

GATE CONSTRUCTION INFORMATION

Vehicular gates should be installed in accordance with ASTM F2200: Standard Specification for Automated Vehicular Gate Construction.

For a copy, contact ASTM directly at 610-832-9585 or www.astm.org.

1. GENERAL REQUIREMENTS

1.1 Gates shall be constructed in accordance with the provisions

given for the appropriate gate type listed, refer to ASTM

F2200 for additional gate types.

1.2 Gates shall be designed, constructed and installed to not fall

over more than 45 degrees from the vertical plane, when a

gate is detached from the supporting hardware.

1.3 Gates shall have smooth bottom edges, with vertical bottom

edged protrusions not exceeding 0.50 inches (12.7 mm)

when other than the exceptions listed in ASTM F2200.

1.4 The minimum height for barbed tape shall not be less than 8

feet (2.44 m) above grade and for barbed wire shall not be

less than 6 feet (1.83 m) above grade.

1.5

An existing gate latch shall be disabled when a manually

operated gate is retrofitted with a powered gate operator.

1.6 A gate latch shall not be installed on an automatically

operated gate.

1.7 Protrusions shall not be permitted on any gate, refer to ASTM

F2200 for Exceptions.

1.8 Gates shall be designed, constructed and installed such that

their movement shall not be initiated by gravity when an

automatic operator is disconnected.

1.9 A pedestrian gate shall not be incorporated into a vehicular

gate panel or that portion of the adjacent fence that the gate

covers in the open position.

3.1.4 Positive stops shall be required to limit travel to the

designed fully open and fully closed positions. These stops

shall be installed at either the top of the gate, or at the

bottom of the gate where such stops shall horizontally or

vertically project no more than is required to perform their

intended function.

3.1.5 All gates shall be designed with sufficient lateral stability to

assure that the gate will enter a receiver guide, refer to

ASTM F2200 for panel types.

3.2 The following provisions shall apply to Class IV vehicular

horizontal slide gates:

3.2.1 All weight bearing exposed rollers 8 feet (2.44 m), or less,

above grade shall be guarded or covered.

3.2.2 Positive stops shall be required to limit travel to the

designed fully open and fully closed positions. These stops

shall be installed at either the top of the gate, or at the

bottom of the gate where such stops shall horizontally or

vertically project no more than is required to perform their

intended function.

2. SPECIFIC APPLICATIONS

2.1 Any non-automated gate that is to be automated shall be

upgraded to conform to the provisions of this specification.

2.2 This specification shall not apply to gates generally used for

pedestrian access and to vehicular gates not to be

automated.

2.3 Any existing automated gate, when the operator requires

replacement, shall be upgraded to conform to the provisions

of this specification in effect at that time.

3. VEHICULAR HORIZONTAL SLIDE GATES

3.1 The following provisions shall apply to Class I, Class II and

Class III vehicular horizontal slide gates:

3.1.1 All weight bearing exposed rollers 8 feet (2.44 m), or less,

above grade shall be guarded or covered.

3.1.2 All openings located between 48 inches (1.22 m) and 72

inches (1.83 m) above grade shall be designed, guarded or

screened to prevent a 4 inch

(102 mm) diameter sphere from passing through the

openings anywhere in the gate, and in that portion of the

adjacent fence that covers in the open position.

3.1.3 A gap, measured in the horizontal plane parallel to the

roadway, between a fixed stationary object nearest the

roadway, (such as a gate support post) and the gate frame

when the gate is in either the fully open position or the

fully closed position, shall not exceed 2-1/4 inches

(57 mm), refer to ASTM F2200 for Exception.

4. VEHICULAR HORIZONTAL SWING GATES

4.1 The following provisions shall apply to Class 1, Class II

and Class III vehicular horizontal swing gates:

4.1.1 Gates shall be designed, constructed and installed so as

not to create an entrapment area between the gate and

the supporting structure or other fixed object when the

gate moves toward the fully open position, subject to the

provisions in the 4.1.1.1 and 4.1.1.2.

4.1.1.1 The width of an object (such as a wall, pillar or column)

covered by a swing gate when in the open position shall

not exceed 4 inches (102 mm), measured from the

centerline of the pivot point of the gate, refer to ASTM

F2200 for exception.

4.1.1.2 Except for the zone specified in Section 4.1.1.1, the

distance between a fixed object such as a wall, pillar or

column, and a swing gate when in the open position shall

not be less than 16 inches (406 mm), refer to ASTM

F2200 for exception.

4.2 Class IV vehicular horizontal swing gates shall be

designed, constructed and installed in accordance with

security related parameters specific to the application in

question.

7

Page 8

Moving Gate Can Cause

Injury or Death

KEEP CLEAR! Gate may move at any

time without prior warning.

Do not let children operate the gate or

play in the gate area.

This entrance is for vehicles only

Pedestrians must use separate entrance

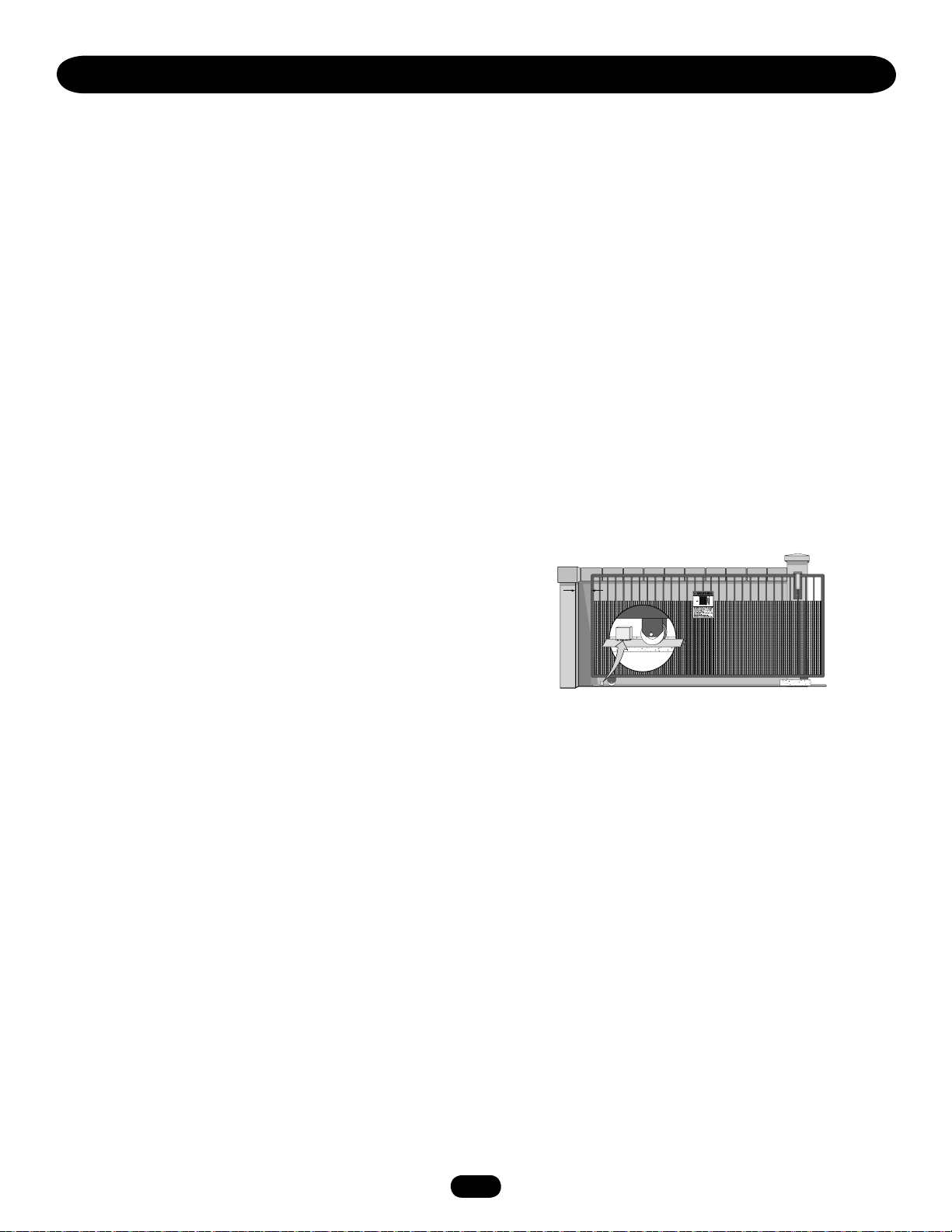

SAFETY PRECAUTIONS FOR SWING AND

WARNING WARNING

WARNING

WARNING WARNING

WARNING

ORNAMENTAL "GRILL TYPE GATES"

To prevent SERIOUS INJURY or DEATH from a moving gate:

• Entrapment protection devices MUST be installed to protect

anyone who may come near a moving gate.

• Locate entrapment protection devices to protect in BOTH the

open and close gate cycles.

• Locate entrapment protection devices to protect between

moving gate and RIGID objects, such as posts.

• A swinging gate shall NOT open into public access ways.

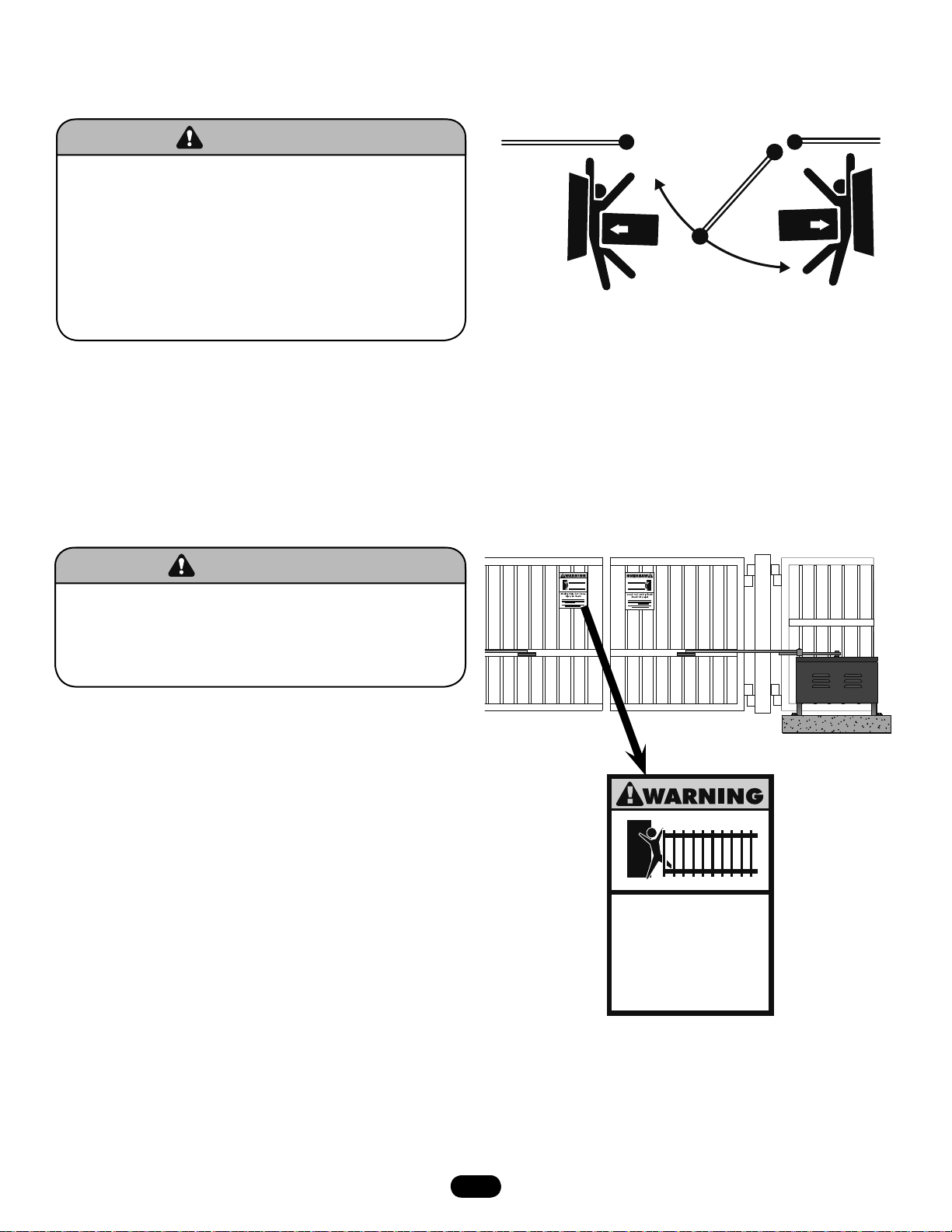

WARNING SIGN PLACEMENT

To prevent SERIOUS INJURY or DEATH from a moving gate:

• Install warning signs on EACH side of gate in PLAIN VIEW.

• Permanently secure each warning sign in a suitable manner

using fastening holes.

8

8

Page 9

INSTALLATION

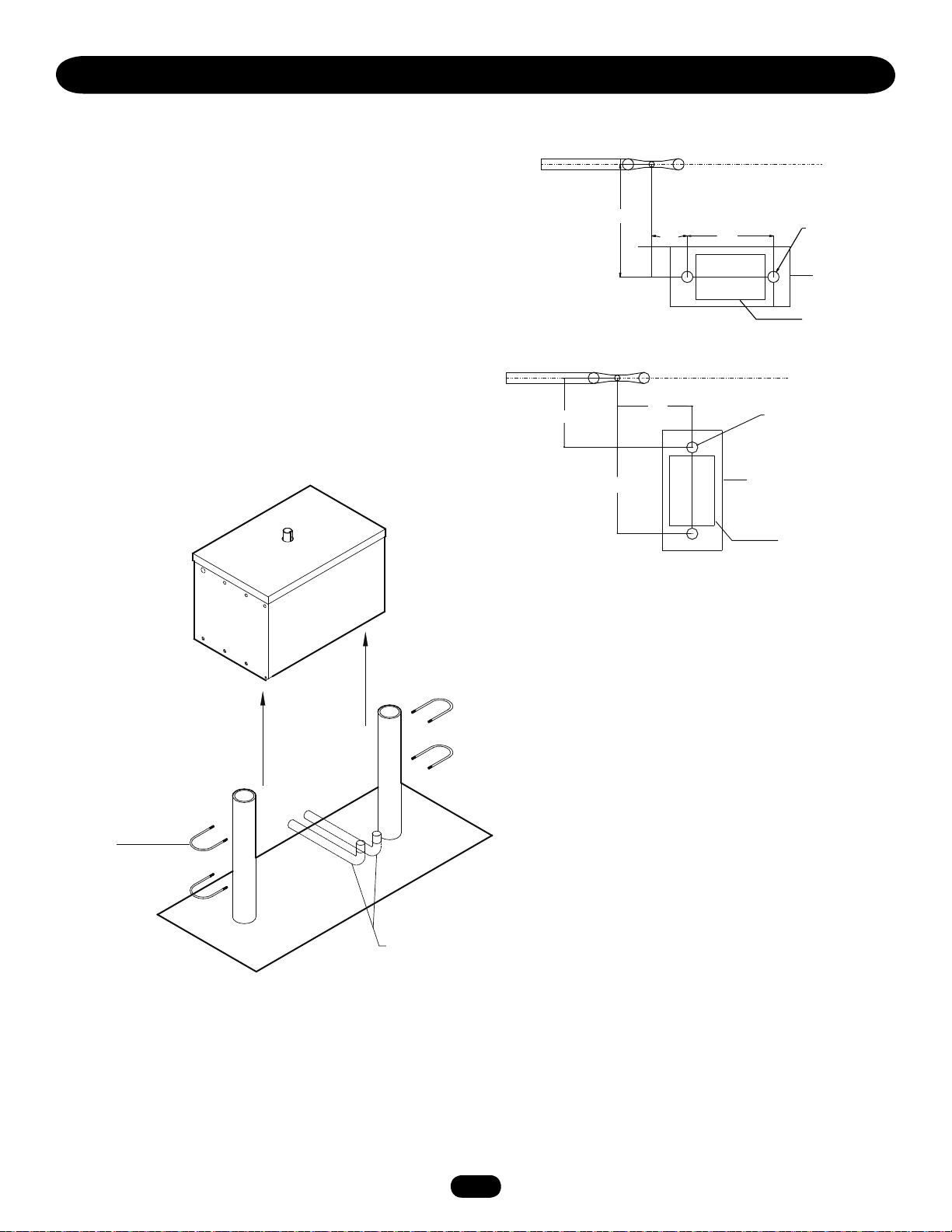

POST MOUNTING (SW470)

1. Locate and anchor two posts made of 3" (7.6 cm) outer

diameter heavy walled pipe. Posts should be parallel and

square to the gate.

IMPORTANT NOTE: The distance between mounting posts and

the relative location of the operator to the gate and fence is

critical.

2. Locate electrical conduit, as required, prior to pouring concrete.

3. Set mounting post and electrical conduit in place (Figure 2).

Knockouts for 3" pipe clamps (not supplied) are provided in the

operator.

Figure 2

Figure 1

18.5"

30"

9.5"

Parallel Mount

20"

23"

Fence

Fence

23"

Concrete pad

16 x 32 minimum

3" O.D. pipe

(2 req’d.)

Concrete pad

16 x 32 minimum

Operator

3" O.D. pipe

(2 req’d.)

Operator

3" U-bolt

(4 required)

Perpendicular Mount

Power and control wiring should

be run in separate conduit

9

Page 10

c

INSTALLATION

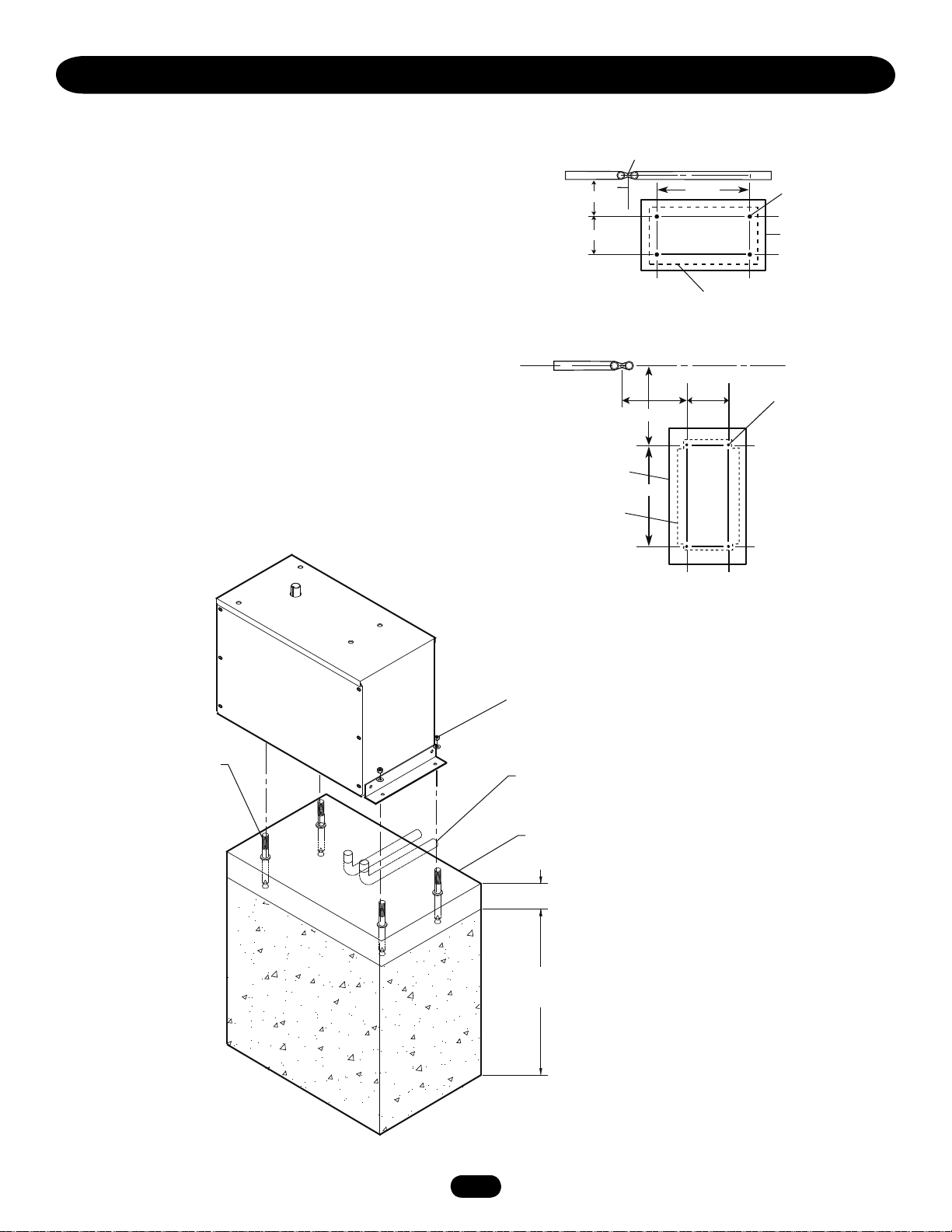

PAD MOUNTING (SW470)

1. Layout the concrete pad (Figure 1).

IMPORTANT NOTE: The relative location of the operator to the

fence and the gate is critical. Be sure that the measurements for

operator mounting are taken from the centerline of the fence and

of the gate hinge.

2. Locate electrical conduit, as required, prior to pouring concrete.

3. Pour concrete pad.

4. Bolt the (2) pad mount brackets to the bottom of the operator

with the hardware provided.

5. Secure the operator to the concrete pad. It is very important

that the operator be level and square to the gate.

Figure 2

Figure 1

24"

8"

Gate

Concrete pad

18"x34" min.

Profile of

Operator

SW470

Perpendicular

Hinge Pin

9-3/4"

Parallel Mount

18-3/4"

22-1/2"

22-1/2"

Operator

Centerline

8"6"

Fence

1/2" Redhead

(4 required.)

Concrete pad 18"x34" min.

8"16"1/2" Redhead

(4 required)

1/2" red head bolts or

anchors (4 required)

Perpendicular Mount

Using suitable hardware secure

operator to L-bolts

Power and control wiring should be

run in separate conduit

Concrete Pad

2" to 4" above grade

Depth required by

local codes or below

frost line

10

10

Page 11

INSTALLATION

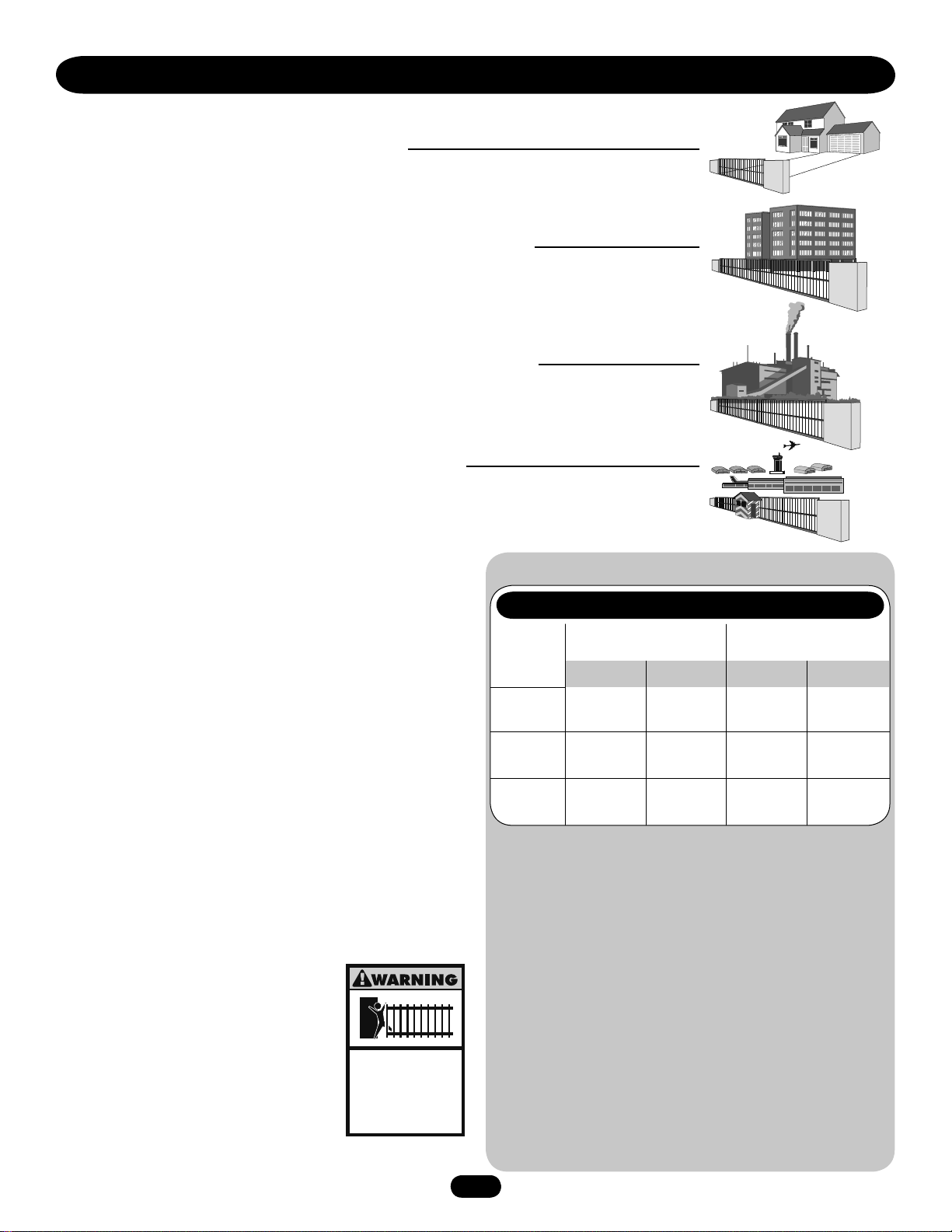

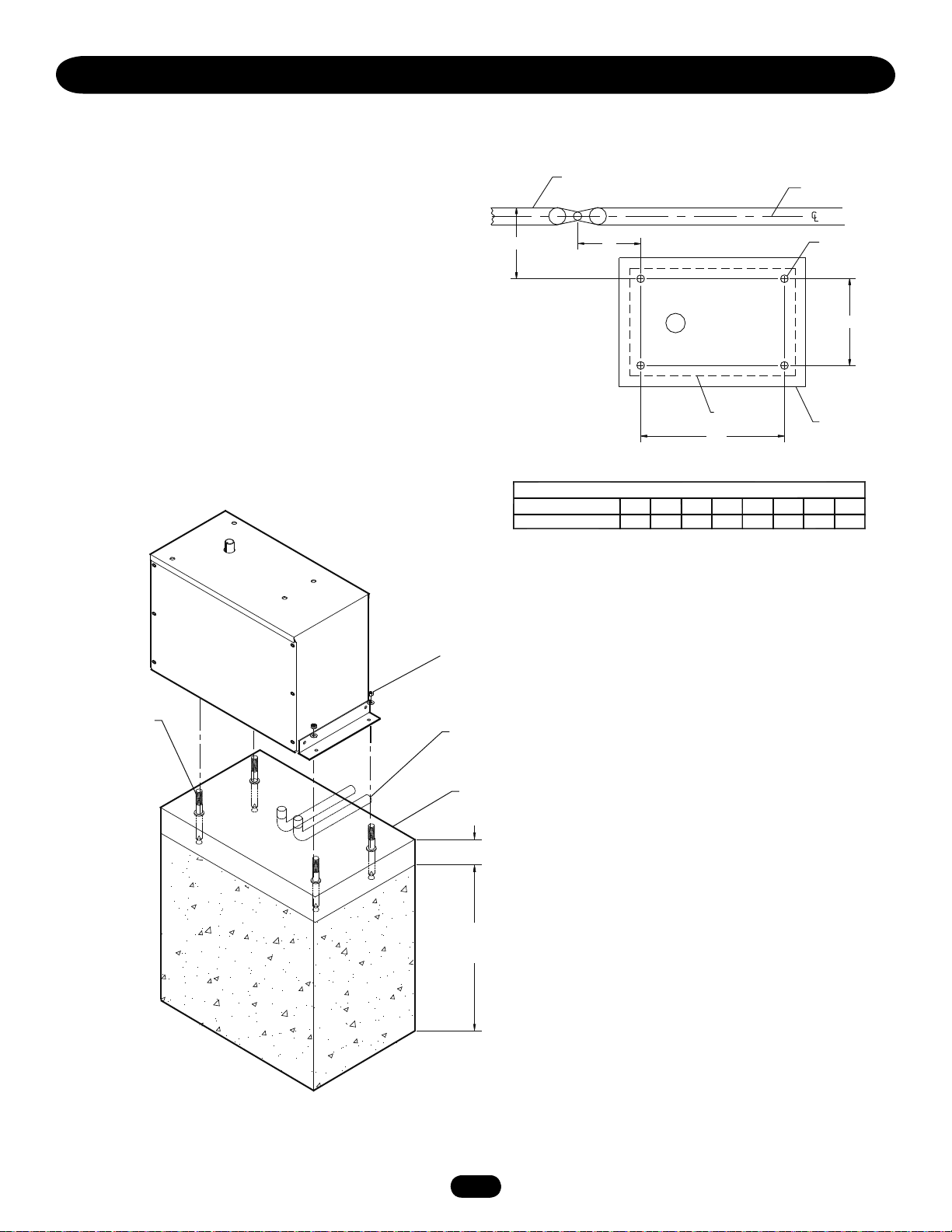

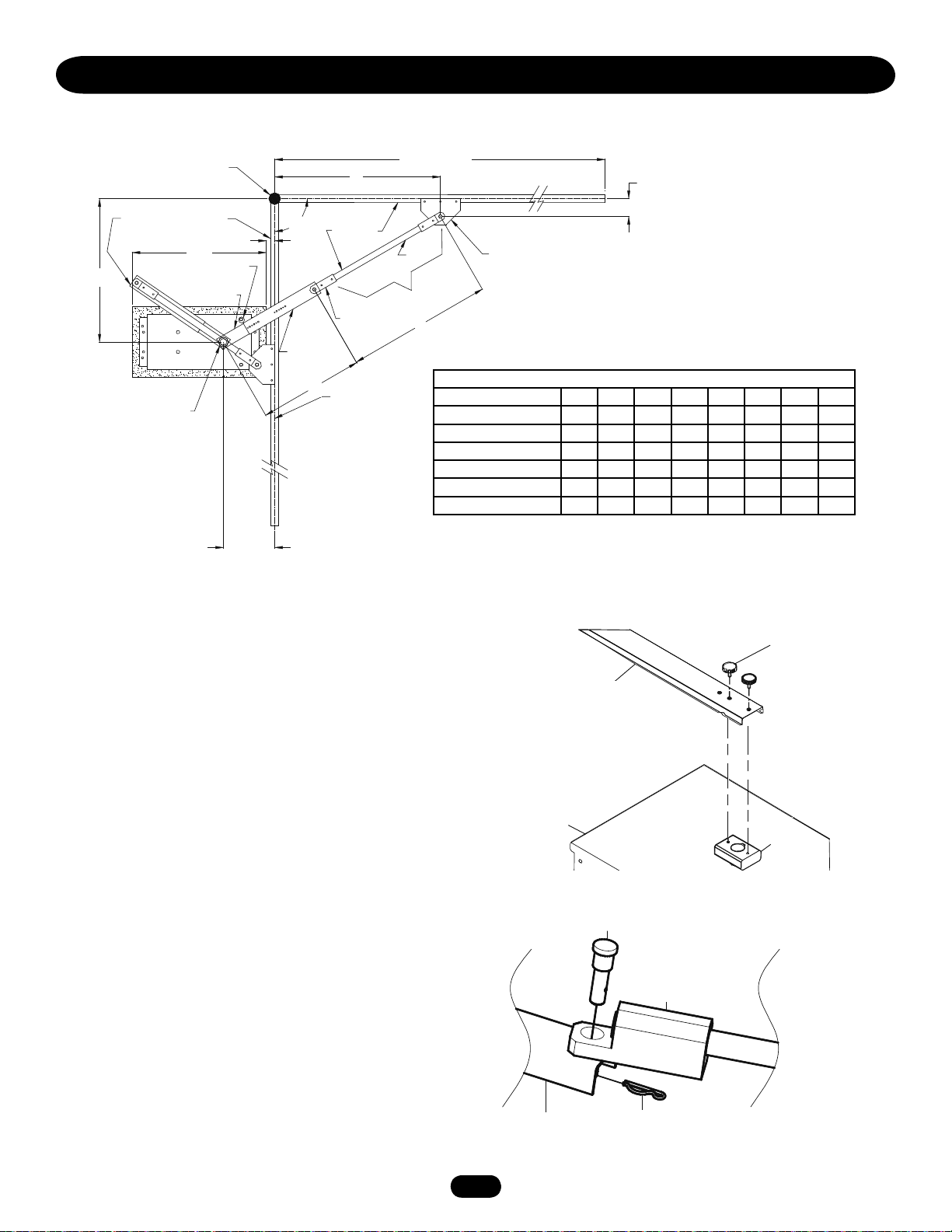

PAD MOUNTING (SW490)

1. Measure the gate length and select appropriate “P” dimension

from the gate installation table.

2. Layout the concrete pad as detailed in Figure 1.

IMPORTANT NOTE: The relative location of the operator to the

fence and the gate is critical. Be sure that the measurements for

operator mounting are taken from the centerline of the fence and

of the gate hinge.

3. Locate electrical conduit, as required, prior to pouring concrete.

4. Pour concrete pad.

5. Bolt the (2) pad mount brackets to the bottom of the operator

with the hardware provided (Install the operator so that the

output shaft is on the side closest to the gate).

6. Secure the operator to the pad. It is very important that the

operator be level and square to the gate.

Figure 2

Figure 1

P

GATE LENGTH (FEET)

P DIMENSION IN INCHES

Gate

5"

Output

Shaft

Operator

28"

SW490 GATE OPERATOR INSTALLATION TABLE

8-9 10-11 12-13 14-15 16-17 18-19 20-21 22

21.9 25.3 28.8 32.3 35.7 39.2 42.7 46.1

Fence

1/2" Redhead

(4 Required)

8"

Concrete Pad

18" x 34" min.

1/2" red head bolts or

anchors (4 required)

Using suitable hardware secure

operator to L-bolts

Power and control wiring should be

run in separate conduit

Concrete Pad

2" to 4" above grade

Depth required by

local codes or below

frost line

11

11

Page 12

INSTALLATION

WARNING

CAUTION CAUTION

WARNING

WARNING

Model SW470

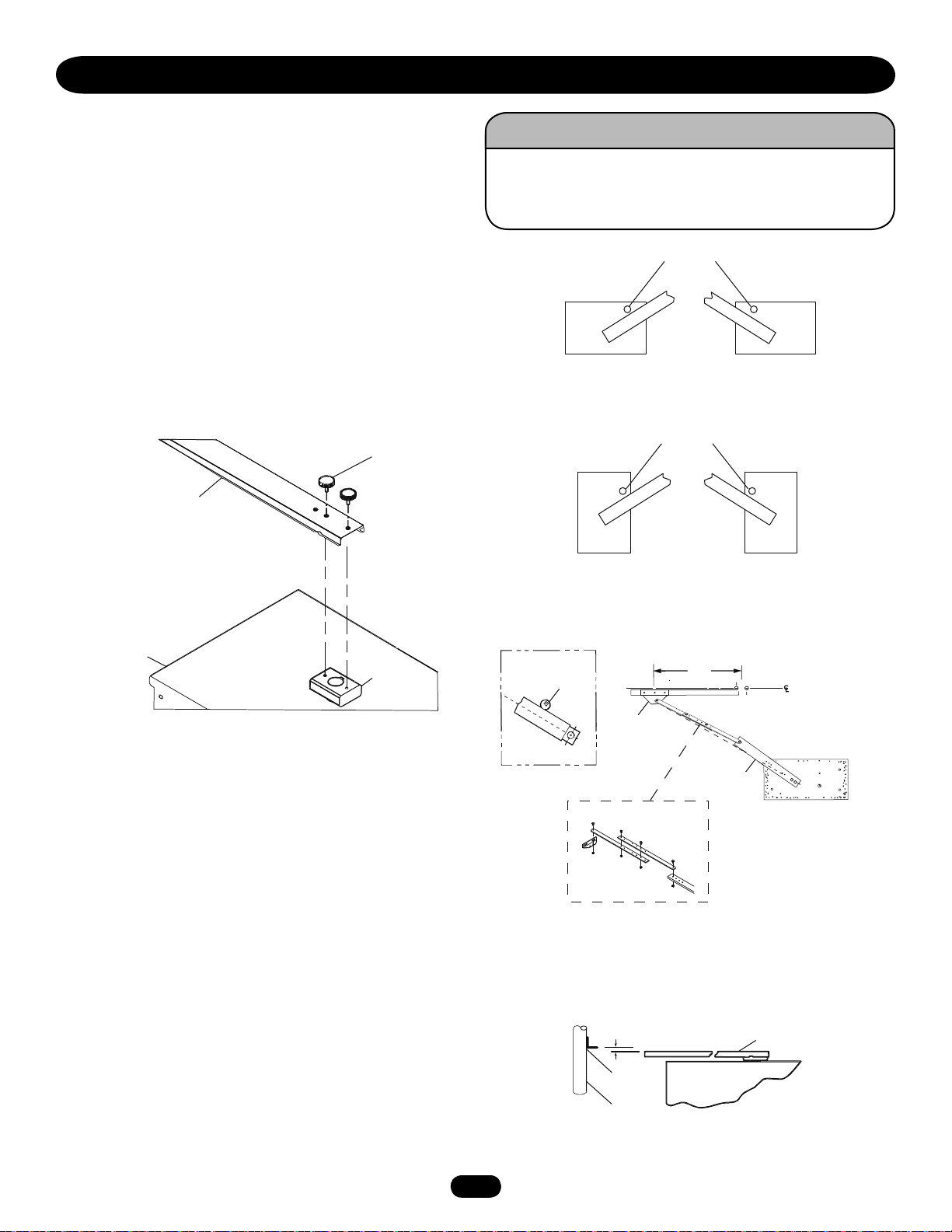

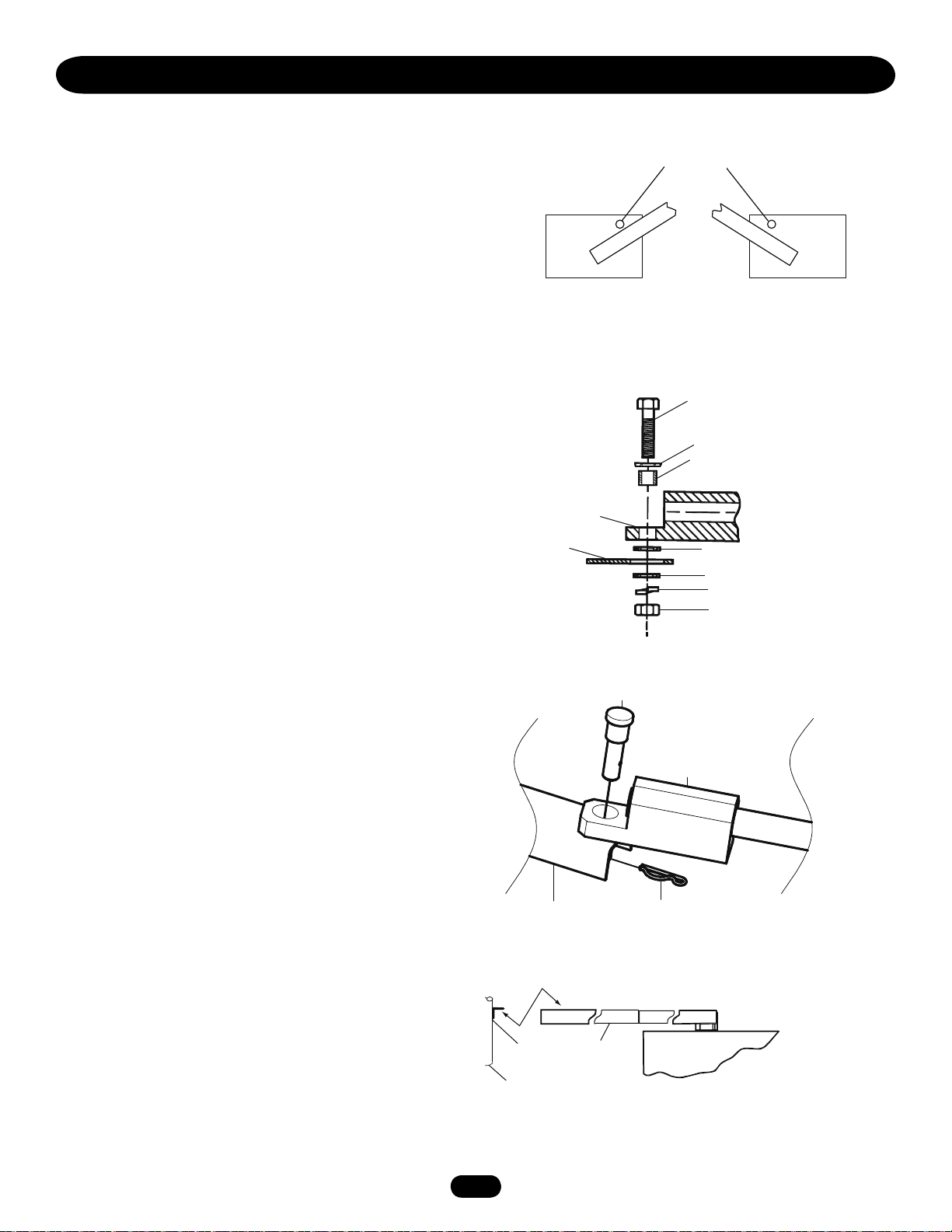

CONTROL ARM ASSEMBLY (SW470)

1. Set the control arm stop on the operator in the positions

appropriate for the installation (Figure 1).

2. Install the arm channel to the hub assembly to the operator

output shaft.

3. Secure the arm channel to arm hub with 1/4-20 black plastic

knobs provided (Hub is factory installed - Figure 2).

4. Assemble extension arm to control arm. Be sure to keep the

extension arm with spot-faced side up. Use the holes that are

appropriate for desired degree of gate opening. The extension

arm should swivel easily on pivot screws when the nuts are

tightened. Attach the other end of the actuator arm to the gate

brackets (Figure 3).

If the arm stop is installed incorrectly, the gate will be

prevented from opening and damage to the operator may

result!

Figure 1

Left hand

installation

Close Stops

Right hand

installation

SW470 Parallel to Fence

Figure 2

Housing

Arm Channel

Black Plastic

Knob

Hub

Assembly

Figure 3

Eccentric stop during

installation of gate

plate

Installation Detail

Close Stops

“L.H.”

“R.H.”

SW470 Perpendicular to Fence

36"

Gate

Plate

Crank Extension

Extension arm

installation detail

Hinge Pin

Eccentric stop (operating position

after adjustment). Arm must

swing approximately 2 degrees

past straight position (See detail)

NOTE: Dotted line indicates

straight arm position

GATE BRACKET INSTALLATION (SW470)

1. Install gate bracket (supplied) or install an angle (2" x 2" x 1/4"

by others) horizontally on gate, at the same height as the top

surface of the control arm extension (see figure to the right).

2. Adjust the eccentric stop as shown so that the wide area of the

eccentric stop is against the arm. Be sure that the control arm

and actuator are in a straight line. Install the gate bracket and if

required install an angle (for SW490 2" x 2" x 1/4" by others) at

the appropriate point on the gate in reference to gate hinge pin.

NOTE: As an alternative, (2) 3/8-16 bolts and a nut plate are

provided. Adjust arm length and then rotate the eccentric stop

180 degrees so that the small thickness is against the arm. This

will provide the necessary deflection in the arm assembly to lock

the gate.

12

12

Top of gate bracket should be mounted 1/2"

higher than top of arm channel

Arm Channel

Gate

Bracket

Gate

Page 13

INSTALLATION

MODEL SW490

2"x2"x1/4"

angle

(by others)

gate

Control arm

extension

CONTROL ARM ASSEMBLY (SW490)

1. Set the control arm’s close stop on the operator so that its

position corresponds with the handling of the installation

(Figure 1).

2. Remove the open stop, as it is not to be used in this

application. Use any existing hardware necessary to seal the

open stop’s hole in the operator’s cover.

3. Measure the length of the gate panel and select the appropriate

extension arm (x) and control arm (Y) dimensions from the

gate installation table.

4. Install the control arm hub assembly to the operator’s output

shaft. Make sure that the key is properly inserted into the hub

assemblies keyway. Lock the key in place with using the set

screw provided in the hub.

5. Attach control arm extension to control arm hub assembly by

bolting or welding the two pieces together to achieve the

proper control arm dimension (Y).

6. Determine the proper location of the gate bracket by measuring

the gate panel’s length and referring to the gate installation

table (Dimension B) on the next page. Install the supplied gate

bracket or install your own gate bracket (recommended

2" x 2" x 1/4" angle) horizontally on the gate and at the same

height as the top surface of the control arm extension. Secure

the gate bracket to the gate by either welding or bolting the

bracket to the gate.

7. Assemble one extension arm holder to the gate bracket using

supplied hardware (Figure 2).

8. Assemble the other extension arm holder to the control arm

extension using the supplied pivot pin assembly and cotter pin

(Figure 3).

9. Measure and cut pipe (not provided) and position the pipe into

the extension arm holders to achieve the proper extension arm

dimension (X). Insert the hex head set screws in each

extension arm holder in order to hold pipe firmly. Do not

tighten until testing and all final adjustment have been

completed (Figure 4).

Figure 1

Left hand

installation

Figure 2

Extension Arm Holder 3/4"

Gate bracket or

extension arm

Figure 3

Close Stops

Right hand

installation

SW490 Parallel to Fence

3/4"-10 x 3 Hex Head Bolt

3/4" Flat Washer

3/4" Bushing

3/4" Flat Washer

3/4" Flat Washer

Split Lock Washer 3/4"

3/4"-10 Hex Nut

Pivot pin assembly

Extension arm holder

Figure 4

1313

Extension arm

Cotter Pin

Bottom of angle and top of control

arm extension should be level

Control arm

extension

Page 14

INSTALLATION

CONTROL ARM ASSEMBLY (SW490) continued

D

Gate Hinge

Open gate position

34"

Closed gate stop

Control arm hub

assembly

Output Shaft

Gate Length

B

90º

2"

Control arm

extension

C

13"

Closed

gate

position

Extension

Arm Holder

Y

Gate Center Line

Pipe

Extension

Arm

X

Gate Length (Feet) 8-9 10-11 12-13 14-15 16-17 18-19 20-21 22

A Dimension (Inches) 4.5 4.5 4.5 4.5 4.5 4.5 4.5 4.5

B Dimension (Inches) 24 30 36 42 48 54 60 66

C Dimension (Inches) 13 13 13 13 13 13 13 13

D Dimension (Inches) 25.9 29.3 32.8 36.3 39.7 43.2 46.7 50.1

X Dimension (Inches) *25.7 *29 *32.8 *36.9 *41.2 *45.6 *50 *54.6

Y Dimension (Inches) **17 **20.6 **23.8 26.6 29.3 31.8 34.2 36.6

All table dimensions are measured from pivot to pivot.

* Cut/add excess pipe for desired extension arm pivot to pivot dimension.

** Cut excess control arm extension and/or control arm hub assembly for desired pivot to

pivot dimension. Weld or bolt extension arm to arm assembly.

Gate Bracket

SW490 Gate Installation Table

A

4.5"

MANUAL DISCONNECT

MODEL SW470

1. Remove the (2) black knobs securing the control arm to the

operator (Figure 1).

2. Swing arm assembly off to the side. Gate should swing freely.

MODEL SW490

1. Remove hitch pin and pivot pin securing control arm to arm

assembly (Figure 2).

2. Swing arm assembly off to the side. Gate should swing freely.

Figure 1

Figure 2

Black Plastic

Knob

Arm Channel

Housing

Hub

Assembly

Pivot Pin Assembly

Extension Arm Holder

1414

Extension Arm

Cotter Pin

Page 15

WIRING

WARNING

WARNING WARNING

To reduce the risk of SEVERE INJURY or DEATH:

• ANY maintenance to the operator or in the area near the

operator MUST not be performed until disconnecting the

electrical power and locking-out the power via the operator

power switch. Upon completion of maintenance the area

MUST be cleared and secured, at that time the unit may be

returned to service.

• Disconnecting power at the fuse box BEFORE proceeding.

Operator MUST be properly grounded and connected in

accordance with local electrical codes. NOTE: The operator

should be on a separate fused line of adequate capacity.

• ALL electrical connections MUST be made by a qualified

individual.

• DO NOT install any wiring or attempt to run the operator

without consulting the wiring diagram. We recommend that

you Install an optional reversing edge BEFORE proceeding

with the control station installation.

• ALL power wiring should be on a dedicated circuit and well

protected. The location of the power disconnect should be

visible and clearly labeled.

• ALL power and control wiring MUST be run in separate

conduit.

• BEFORE installing power wiring or control stations be sure to

follow all specifications and warnings described below. Failure

to do so may result in SEVERE INJURY to persons and/or

damage to operator.

POWER WIRING INSTALLATION

Wiring Specifications (STRANDED COPPER WIRE)

On a Dual Gate System, each unit must be installed on ITS OWN separate circuit.

WIRE GAUGE 6

• 1/2 HP Motor ------- 425 ft. (129.5 m) 1845 ft. (562.4 m) 2557 ft. (779.4 m) 12789 ft. (3898.1 m) 15987 ft. (4872.8 m)

• 3/4 HP Motor ------- 291 ft. (88.7 m) 1107 ft. (337.4 m) 1827 ft. (556.9 m) 6394 ft. (1948.9 m) 10657 ft. (3248.3 m)

• 1 HP Motor --------- 213 ft. (64.9 m) 852 ft. (259.7 m) 1278 ft. (389.5 m) 5115 ft. (1559.1 m) 7993 ft. (2436.3 m)

115 Vac 230 Vac

SINGLE PHASE

230 Vac 460 Vac 575 Vac

THREE PHASE

WIRE GAUGE 8

• 1/2 HP Motor ------- 269 ft. (82 m) 1165 ft. (355.1 m) 1614 ft. (492 m) 8072 ft. (2460.4 m) 10089 ft. (3075.1 m)

• 3/4 HP Motor ------- 183 ft. (55.8 m) 699 ft. (213.1 m) 1152 ft. (351.1 m) 4035 ft. (1229.9 m) 6726 ft. (2050.1 m)

• 1 HP Motor --------- 134 ft. (40.8 m) 537 ft. (163.7 m) 807 ft. (246 m) 3228 ft. (983.9 m) 5044 ft. (1537.4 m)

WIRE GAUGE 10

• 1/2 HP Motor ------- 168 ft. (51.2 m) 730 ft. (222.5 m) 1012 ft. (308.5 m) 5064 ft. (1543.5 m) 6330 ft. (1929.4 m)

• 3/4 HP Motor ------- 115 ft. (35.1 m) 438 ft. (133.5 m) 723 ft. (220.4 m) 2532 ft. (771.8 m) 4220 ft. (1286.3 m)

• 1 HP Motor --------- 84 ft. (25.6 m) 337 ft. (102.7 m) 506 ft. (154.2 m) 2025 ft. (617.2 m) 3165 ft. (964.7 m)

WIRE GAUGE 12

• 1/2 HP Motor ------- 105 ft. (32 m) 458 ft. (139.6 m) 634 ft. (193.2 m) 3171 ft. (966.5 m) 3964 ft. (1208.2 m)

• 3/4 HP Motor ------- 72 ft. (22 m) 274 ft. (83.5 m) 503 ft. (153.3 m) 1585 ft. (483.1 m) 2643 ft. (805.6 m)

• 1 HP Motor --------- 53 ft. (16.2 m) 211 ft. (64.3 m) 316 ft. (96.3 m) 1269 ft. (386.8 m) 1982 ft. (604.1 m)

NOTE: Calculated using NEC guidelines. Local codes and conditions must be reviewed for suitability of wire installation. All power

wiring should be dedicated and protected. Location of primary power disconnect should be labeled.

1515

Page 16

STOP/RESET BUTTON WIRING

STOP/RESET

1 2 3 4 5 6 7 8 9 10

WIRING

ON/OFF SWITCH POWER WIRING

NOTE: Before running power wiring refer to wiring specifications

on page 15 for correct wire gauges.

Secure all electrical power connections inside the disconnect

switch electrical box. Refer to electrical wiring diagrams on pages

31-33.

IMPORTANT: On three phase operators, power connections must

be properly phased. If phased incorrectly, the gate operator will

run reversed. To correct this situation, shut off power at main

power source and at the operator’s electrical disconnect switch.

Then reverse any two of the three power leads.

SINGLE PHASE

All single phase operators will have the following:

115V 208/230V

• L1 (NEUTRAL), WHITE • L1 (HOT), BLACK

• L2 (HOT), BLACK • L2 (HOT), BLACK

• GROUND, GREEN • GROUND, GREEN

ON/OFF Switch

Cover

Wire Nut Connections

(See Instructions)

THREE PHASE

All three phase operators will have the following:

• L1 BLACK • L2 BLACK

• L3 BLACK • GROUND, GREEN

STOP/RESET BUTTON CONTROL WIRING (REQUIRED)

1. This control will function as a Stop/Reset command and is to

be wired within line of sight of the gate. The operator will not

function unless this circuit is completed.

2. Wire control station to terminals 3 and 5 in the control box on

the operator.

J1 CONNECTOR

Power Wiring Conduit

Control Conduit

STOP/RESET

Button

NOTE: For additional control station options refer to pages

21 and 22.

1616

Page 17

M

M

24V

12V

HIGH

NORM

C

P2

M

ADJUSTMENT

WARNING

WARNING WARNING

WARNING WARNING

WARNING

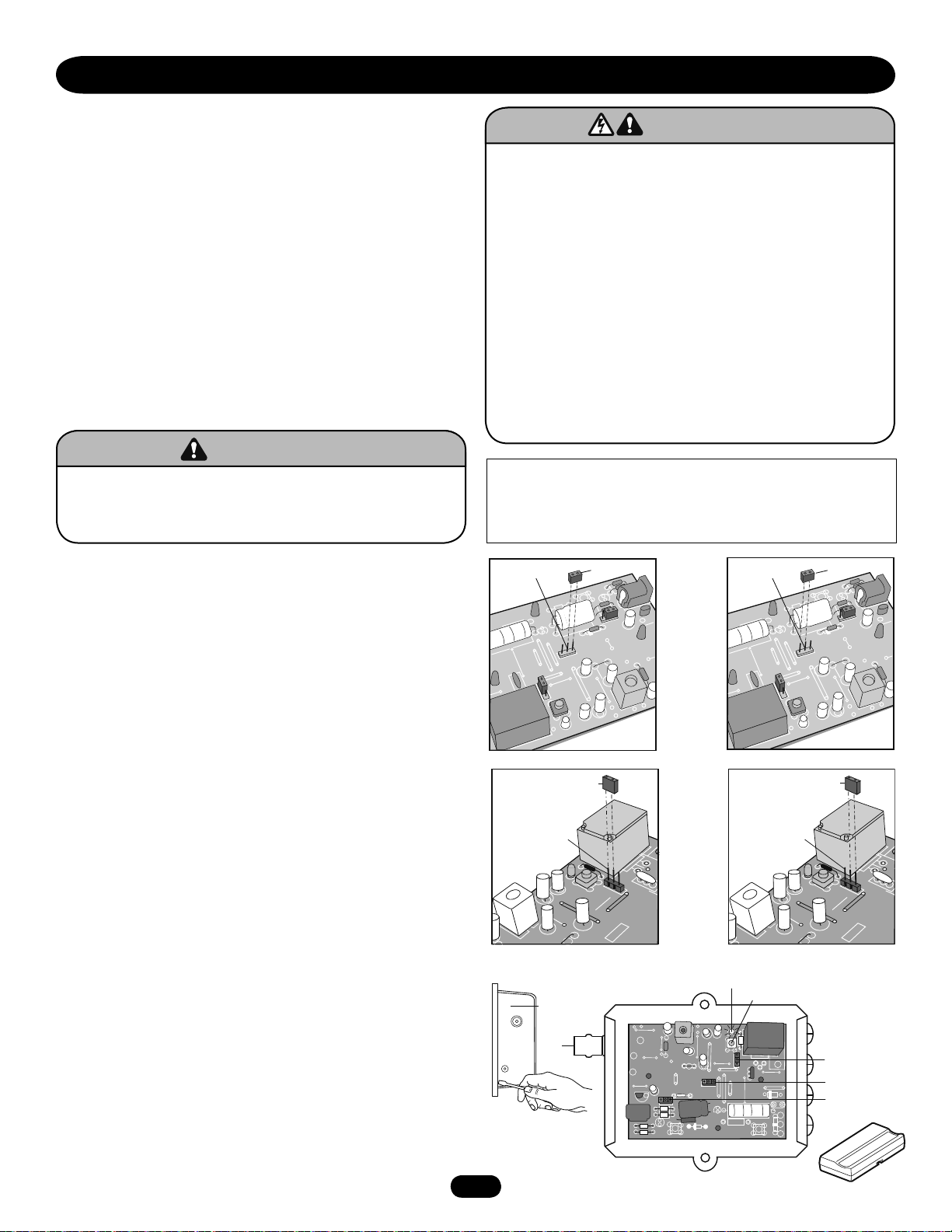

PROGRAMMING THE RADIO RECEIVER

SET SECURITY MODE

The Universal Receiver can be used with up to 15 315 MHz rolling

code remote controls or PINs in HIGH security mode. Alternately,

it can be used with up to 31 of any type 315 MHz remote control

in NORMAL security mode, including any combination of rolling

code, billion code, or dip switch remotes.

The jumper must be set at the HIGH position for the receiver to

operate in HIGH security mode. It must be set at NORMAL

position to operate at the NORMAL mode (Figure 1).

When changing from NORMAL to HIGH security mode, any

previous remote control codes must be erased. Repeat Steps 2

and 3 in the Programming Section below to reprogram the

receiver for each remote control in use.

The receiver is factory set at HIGH.

To prevent possible SERIOUS INJURY or DEATH, the use of

CONSTANT OPERATION on residential openers is

PROHIBITED.

To prevent possible SERIOUS INJURY or DEATH from

electrocution:

• Be sure power is not connected BEFORE installing the

receiver.

To prevent possible SERIOUS INJURY or DEATH from a

moving gate or garage door:

• ALWAYS keep remote controls out of reach of children.

NEVER permit children to operate, or play with remote

control transmitters.

• Activate gate or door ONLY when it can be seen clearly, is

properly adjusted, and there are no obstructions to door

travel.

• ALWAYS keep gate or garage door in sight until completely

closed. NEVER permit anyone to cross path of moving gate

or door.

NOTICE: To comply with FCC and or Industry Canada (IC) rules, adjustment or modifications of

this receiver and/or transmitter are prohibited, except for changing the code setting or replacing

the battery. THERE ARE NO OTHER USER SERVICEABLE PARTS.

Tested to Comply with FCC Standards FOR HOME OR OFFICE USE. Operation is subject to the

following two conditions: (1) this device may not cause harmful interference, and (2) this device

must accept any interference received, including interference that may cause undesired operation.

SET OUTPUT DURATION

For commercial applications, the receiver can be set for either

constant or momentary closure on the output contacts. Use of

constant closure is prohibited on residential garage door openers

because it overrides the safety reversal devices.

With the jumper in the “M” (Momentary) position, the contacts

will close for 1/4 second regardless of the length of radio

transmission. With the jumper in “C” (Constant) position, the

contacts will stay closed as long as the radio continues

transmitting (Figure 2).

The receiver is factory set at M.

PROGRAMMING THE REMOTE TO THE RECEIVER

1. Pry open the front panel of receiver case with a coin or a

screwdriver. Re-connect power to opener (Figure 3).

2. Press and release the “learn” button on the receiver. The learn

indicator light will glow steadily for 30 seconds.

3. Within 30 seconds, press and hold the button on the hand-held

remote that you wish to operate your garage door.

The opener will now operate when the push button on either the

receiver or the remote control is pressed.

Repeat Steps 2 and 3 for each remote control that will be used to

operate the garage door opener.

To erase all remote control codes:

Press and hold the “learn” button on the receiver panel until the

indicator light turns off (about 6 seconds). All remote control

codes are now erased. Then follow the steps above to reprogram

each remote control.

Security Mode

Terminals

CONSTANT

OPERATION

OPENING RECEIVER

17

17

Output

Duration

Terminals

Connect

Antenna

Jumper

SECURITY MODE

Jumper

OPEN RECEIVER

HIGH

Figure 1

Figure 2

Figure 3

Indicator Light

Security Mode

Terminals

MOMENTARY

OPERATION

Output

Duration

Terminals

Learn Button

Jumper

NORMAL

SECURITY MODE

Jumper

Output Duration

Terminals

Security Mode

Power Supply Jumper

Page 18

ADJUSTMENT

WARNING

CAUTION CAUTION

WARNING

WARNING

LIMIT SWITCH ADJUSTMENT

NOTE: For limit location and configuration refer to Figure 1.

1. Before turning on power, disconnect extension arm from

gate bracket so gate is no longer connected to operator.

Push manual release pin(s) up through the control arm, slide

clevis pin in place and secure with a cotter pin.

2. The (3) collars are held to shaft by set screws. The collars

should now be loose on the shaft. If not, loosen all set

screws until collars are moving freely on shaft.

When following limit switch adjustment procedure, the motor

belt will turn and the control arm will move during some

steps. Keep hands and tools out of operator and away from

arm and drive shaft unless power is off or SERIOUS INJURY

may occur.

TO ADJUST CLOSE LIMIT SWITCH

3. Turn on electrical power.

4. Press CLOSE button (if installed) or connect terminals

4 & 5 on J1 terminal strip to cause the gate to close. The

control arm should move in the close direction.

5. When control arm is pointed in approximate direction of gate

bracket (on fully closed gate) press STOP button or release

terminals to stop control arm.

NOTE: If control arm does not move far enough to point in proper

direction, the close limit switch has been prematurely actuated.

Turn off power, loosen set screw on close limit cam and rotate

nut away from close limit switch. Repeat steps 3 and 4 until

control arm is pointed in correct direction.

6. Turn off power. Be sure close limit cam is freely turning.

Rotate cam in close direction. Stop when cam just clicks

close limit switch. Tighten set screw.

7. Reconnect gate bracket to extension arm. If arm has moved

too far in close direction to allow connection of gate bracket

turn off power, connect terminals 5 & 7 to rotate arm in

opposite direction, and press STOP button when arm is in

desired position.

TO ADJUST OPEN LIMIT SWITCH

8. Turn on power. Press OPEN button (if installed) or connect

terminals 5 & 7 on J1 terminal strip. Gate should open. If

gate does not open the open limit cam may be already

actuating open limit switch or an improper electrical

connection may have been made. Turn off power, inspect,

correct and repeat this step.

9. When gate reaches desired fully open position press STOP

button or release terminals. Turn off power. Limit cam

should turn freely. Rotate cam in open direction. Stop when

cam just clicks the open limit switch. Tighten set screw.

10. Fine tune both switch settings by using J1 terminals 4 & 5

(to CLOSE) of 5 & 7 (to OPEN) and the factory supplied

STOP button to move gate and rotating limit collars slightly

to alter gate travel. Rotate cam away from limit switch to

increase travel, toward switch to decrease travel.

Drive Shaft

Set Screw

Aux switch (optional)

Limit Switch “A”

Limit Switch “B”

LIMIT DIRECTION

DIRECTION OF

GATE TO OPEN

RIGHT

(Factory Default)

LEFT

OPEN

LIMIT

A

B

Limit Switch

Limit Cam

CLOSE

LIMIT

B

A

18

18

Page 19

ADJUSTMENT

WARNING WARNING

WARNING

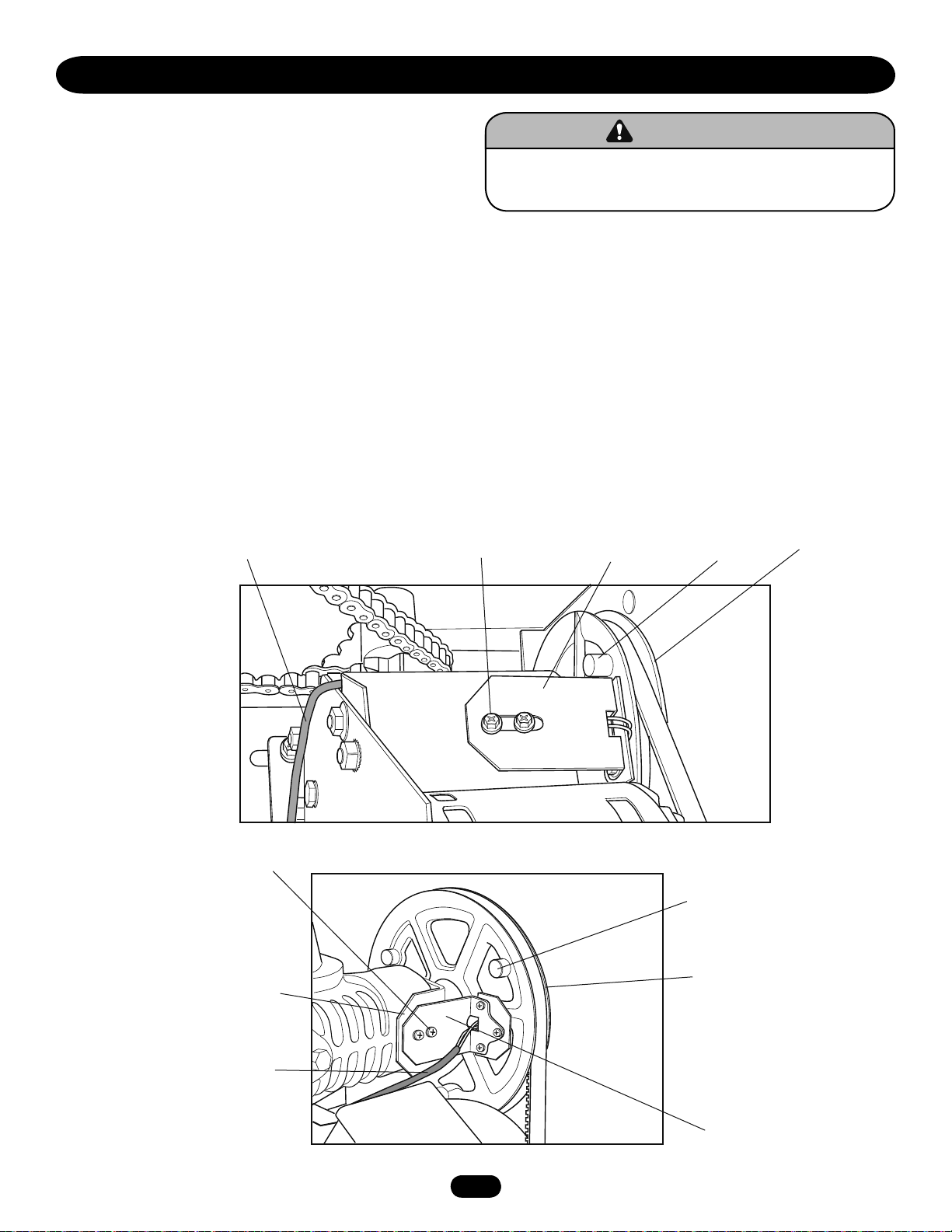

RPM SENSOR (HALL EFFECT) ADJUSTMENT

NOTE: Normally the RPM sensor (hall effect) does not need

adjustment, but may go out of alignment due to shipping

vibration or rough handling.

These operators use an internal entrapment protector system.

This system consists of the control board, magnet, and RPM

sensor. It may become necessary to adjust the sensor for correct

alignment. To do so, please perform the following steps:

1. Loosen the two screws holding the hall bracket to the frame.

2. Adjust the bracket so that the sensor is:

a. Parallel with the pulley.

b. .020" (.051 cm) away from the pulley's magnet. Use a

feeler gauge to measure the distance.

3. Tighten screws to secure assembly.

4. Manually rotate pulley to ensure that each magnet clears the

sensor board.

If a magnet does not clear the board, re-adjust the RPM

(hall effect) assembly accordingly.

To reduce the risk of SEVERE INJURY or DEATH:

• Disconnect power BEFORE performing ANY adjustments.

MODEL SW470

MODEL SW490

Hall Effect Cable

Mounting

Screw (2)

Mounting

Bracket

Mounting

Screw (2)

Hall Effect

Bracket

Pulley

Magnet

Pulley

Magnet

Pulley

Pulley

Hall Effect Cable

Hall Effect

Magnet

1919

Page 20

ADJUSTMENT

SEQUENCED ACCESS MANAGEMENT SYSTEM (SAMS)

The Sequenced Access Management System or SAMS allows the

customer more control when managing vehicular entrances to

areas such as apartment complexes, businesses and gated

communities. The basic concept of the system is that traffic is

controlled by two gates installed in tandem, a fast moving gate

such as a barrier gate operator and a slower moving more secure

or ornamental gate such as a single or pair of slide/swing gate

operator. The design of this gate system balances the demands of

speed during high traffic periods with security during low traffic

periods. Barrier gates typically have the fastest open times of the

many gate operator types and the slide or swing gates allow you

to effectively seal off the perimeter of the complex you are

planning to secure.

NOTE: Connect all entry devices to the slide or swing gate. If

using a device, such as a 7-day timer, to latch the slide or swing

gate open during high traffic times, connect the device’s N/O relay

output to the control board’s Interrupt Loop input. Once the

device activates the Interrupt Loop input, the next vehicle to

access the SAMS system will lock the gate in the open position

until the device deactivates. When the device deactivates, the

timer to close will automatically close and secure the gate.

SAMS OPERATION

1. When an authorized vehicle accesses the gate system, the SAM

system responds by first opening the gate farthest from the

vehicle, the swing or slide gate.

2. Once the swing or slide gate is open, the barrier gate begins its

open cycle.

TERMINAL BLOCK

INTERRUPT LOOP INPUT AUXILIARY LIMIT SWITCH

TB5

TB8

SAMS RELAY AT J5 TERMINAL STRIP

N/0

COM

BG770 BARRIER GATE

N/0

COM

1 (OPEN)

3 (COMMON)

3. Once the barrier is open the vehicle may pass through the SAM

system. At this point you have two options in how you would

like to initiate the SAM systems closure. You may chose to:

a. Use a timer to close system to automatically close the

barrier gate after a preset amount of time or

b. Use a loop system to close the barrier gate after the vehicle

has passed through the SAM system.

4. Once the barrier gate is closed the slide or swing gate will

activate its internal timer to close and begin closing.

5. If another authorized vehicle accesses the SAM system before

the slide or swing begins to close the barrier will open and

allow the vehicle to pass through the SAM system.

6. If another authorized vehicle accesses the SAM system during

the slide or swing gates closing cycle the SAM system will

reopen the slide or swing gate. Once the slide or swing gate

reaches the open position the barrier will then open to allow

the vehicle to pass through the SAM system.

7. If no other authorized vehicles access the SAM system the

swing or slide gate will close followed by the barrier.

SAMS WIRING

1. Install conduit between the BG770 and the SW420 for SAMS

control wiring.

2. Run a 4-conductor cable in the conduit between the BG770

SW420.

3. Locate the SAMS relay terminals (J5) on the control board in

the SW420 and locate the auxiliary limit switch in the BG770.

4. Attach a wire from the SAMS relay terminal (J5) on the control

board to terminal 1 on the BG770 terminal strip.

5. Attach a wire from the SAMS relay terminal (J5) on the control

board to terminal 3 on the BG770 barrier gates terminal strip.

6. Attach a wire from terminal J1-5 on the control board to the

common (COM) on the auxiliary limit switch in the barrier gate.

7. Attach a wire from terminal J1-8 on the control board to the

normally open (NO) on the auxiliary limit switch.

8. Test for correct functionality of the SAM system.

SAMS Conduit

TRAFFIC

STREET

Second

Hold Open Loop

2020

Shadow Loop

Safety Loop

Master

COMPLEX

OR

PARKING LOT

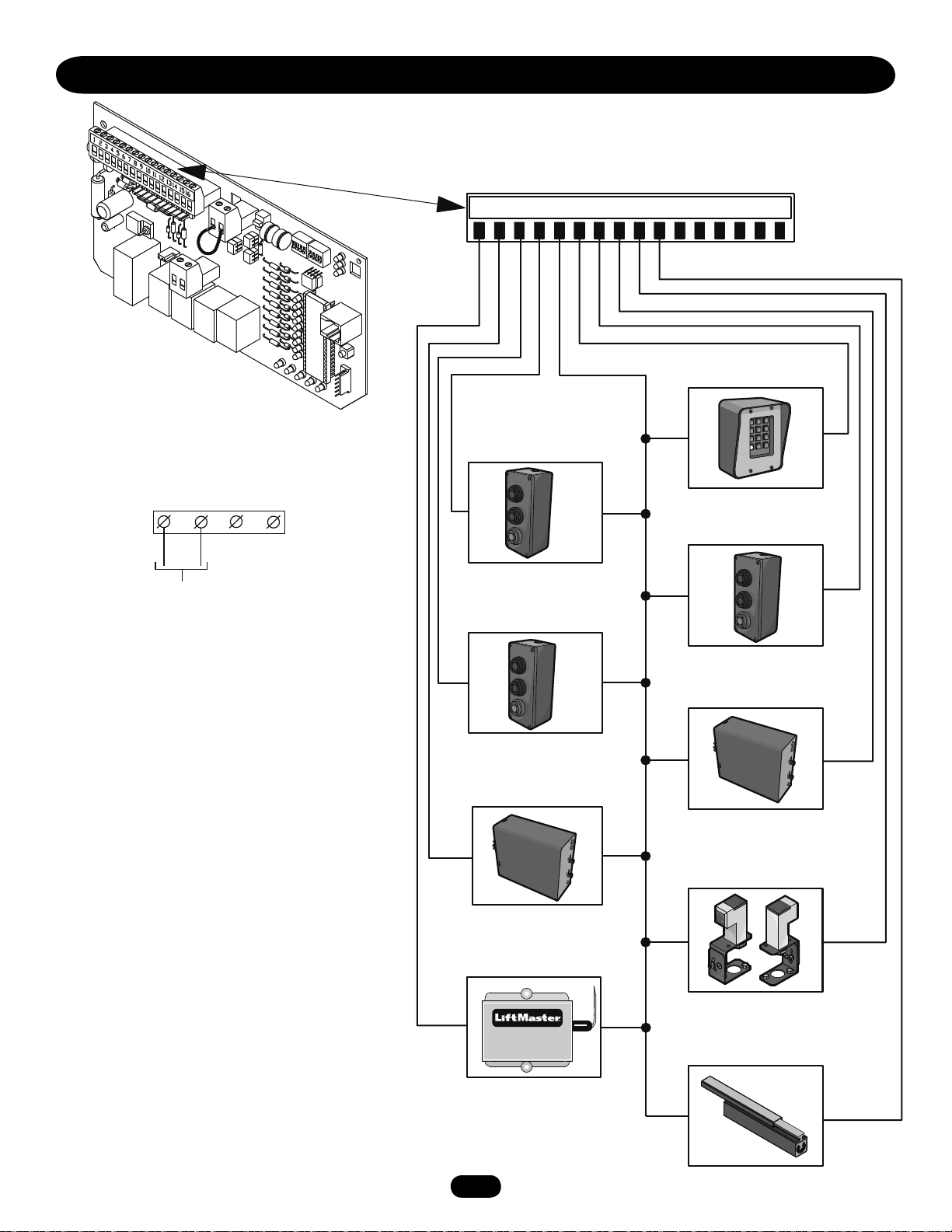

Page 21

SOFT OPEN

1 2 3 4 5 6 7 8 9 10

INTERRUPT (SAFETY) LOOP INPUT

5 8 9 10 11 12

12345678910111213141516

R2

R1

R4

R3

24 Vac

FREQ

FREQ

FREQ

3

6

9

#

2

5

8

0

1

7

ADJUSTMENT

ONE BUTTON WIRING

1 2 3 4 5 6 7 8 9 10

SHADOW LOOP INPUT

1 2 3 4 5 6 7 8 9 10

ACCESSORY WIRING

All inputs are normally open and momentary, except the stop

(N.C.). The following instructions are based upon UL325, and

include recommendations for significant increase in safety.

We strongly recommend that you follow the UL guidelines

presented throughout the manual. Refer to instructions shipped

with optional control devices for mounting, wiring, programming

and adjustment.

24 Vac Accessory Power

Can be found at terminals R1 and R2 located on radio terminal

block.

J1 Terminal Block

Control Board

J1 Terminals 1 & 5 - Residential Radio (single button) Input

These terminals are intended for use with a radio receiver in a

residential application or as a single button control. This allows

the user to open the gate by activating the remote control when

the gate is closed or between limits. This input also gives the user

the ability to close the gate by activating the remote control when

the gate is on the open limit.

J1 Terminals 2 & 5 - Shadow Loop Input

These terminals are intended for use with a loop detector and is

primarily used on swing gate operators. This input protects cars

by preventing the gate from moving off of the open or close limit

when the shadow loop input is active.

J1 Terminals 6 & 5 - Soft Open

These terminals are intended for use as a general open control.

Accessories that may be wired to this input include: Telephone

Entry Systems, Radio Receiver (Commercial Applications), Exit

Loop Detector, Keypads, 7-Day Timer.

NOTE: Will not override a double entrapment (signalled by the

gate stopped and entrapment alarm on).

Field Wiring Terminals 8 & 5 - Interrupt (Safety) Loop Input

These terminals are intended for use with a loop detector. This

input functions to reverse a closing gate to the open limit.

Latching this input will reset the timer to close.

21

21

Page 22

OP

E

N

CL

O

SE

ST

O

P

OP

E

N

CL

O

SE

ST

O

P

O

P

E

N

CL

O

SE

ST

O

P

ADJUSTMENT

OBSTRUCTION OPEN (EDGE/PHOTO EYE INPUT)

5 8 9 10 11 12

OBSTRUCTION CLOSE (EDGE/PHOTO EYE INPUT)

5 8 9 10 11 12

STOP/RESET BUTTON WIRING

R1 R2 R3 R4 3 5

HARD CLOSE CONTROL INPUT

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

HARD OPEN CONTROL INPUT

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

ACCESSORY WIRING

Field Wiring Terminals 9 & 5 - Obstruction Open

(Edge/Photo Eye Input)

Edge Input: See Programming Section

This input will reverse an opening gate to the close limit.

Activating this input when the gate is closing will have no effect.

NOTE: If upon reversal a second separate obstruction is detected

(gate edge or RPM sensor), gate will stop and alarm.

Photo Eye Input: See Programming Section

This input will pause an opening gate. Once the input (photo eye)

is cleared, the gate continues to open. Activating this input when

the gate is closing will have no effect.

Field Wiring Terminals 10 & 5 - Obstruction Close

(Edge/Photo Eye Input)

Edge Input: See Programming Section

This input will reverse a closing gate to the open limit. When

reaching the open limit the Timer to-Close, if enabled, will be

disabled until another command is given. Activating this input

when the gate is closing will have no effect. NOTE: If upon

reversal a second separate obstruction is detected (gate edge or

RPM sensor), gate will stop and alarm.

Photo Eye Input: See Programming Section

This input will reverse a closing gate to the open limit. This input

will not affect the Timer-to-Close. Activating this input when the

gate is closing will have no effect.

Field Wiring Terminals 3 & 5 - Stop/Reset Control Input

These terminals are intended for use with a single stop/reset

button or the stop control of a three-button station that is

installed within line of site of the gate. This input functions to

stop the gate or to reset the gate after an entrapment fault.

NOTE: This input uses a normally closed circuit and the operator

will not run until a stop control is installed.

J1 Terminals 4 & 5 - Hard Close Control Input

These terminals are intended for use only with the close control

of a three-button station that is installed within line of sight of the

gate. A momentary activation of this input will cause the gate to

close. Activation of this input for longer than three seconds will

enable the control to be used as a constant pressure override

device. This will allow the user, in emergencies, to override a

failed accessory such as a loop detector or photo-eye.

J1 Terminals 7 & 5 - Hard Open Control Input

These terminals are intended for use only with the open control of

a three-button station that is installed within line of sight of the

gate. A momentary activation of this input will cause the gate to

open. Activation of this input for longer than three seconds will

enable the control to be used as a constant pressure override

device. This will allow the user, in emergencies, to override a

failed accessory such as a loop detector or photo eye.

STOP

CLOSE

OPEN

22

Page 23

CONTROL BOARD ILLUSTRATION

J4 Connector

Master/Second

Main Terminal

Wiring

J2 Connector

Dip Switch #4

Master/Second

Potentiometer Timer-to-Close

Potentiometer Force

Adjustment

Dip Switch #2

Dip Switch #1

Diagnostic LED

Limit LEDs

J5 Connector

SAMS

Relay Drive

Troubleshooting LEDs

J1 Terminal

Troubleshooting LEDs

Programming Port

(factory use only)

Motor Learn

Button

J3 Connector

Aux. Relay Drive

(not used)

23

Page 24

ADJUSTMENT

CONTROL BOARD PROGRAMMING AND FEATURES

MOTOR LEARN FUNCTION (FORCE PROFILE)

This function is preprogrammed at factory. If either board or

motor is replaced, the controller will need to be programmed to

“LEARN” the specific motor RPM profile of your operator. Switch

“S3” is provided for this. This is important for accurate force

control. Failure to do so may result in improper and unsafe

operation.

To learn the motor:

NOTE: Motor Learn must be performed in stand alone mode.

1. The operator must remain attached to the gate throughout the

entire process.

2. Press the motor learn button. The yellow LED should start to

flash rapidly.

3. Install a jumper on either the hard open or the hard close input

terminals. The motor will run for a few seconds and then stop.

If the LED goes out the motor is learned. If the unit activates a

limit before completing the learn or some other error occurs,

the LED will go back to on continuously. If this happens, try

learning while running in the opposite direction.

NOTE: It is important that the jumper is in constant contact

while the gate is moving in learn mode.

FORCE CONTROL

Set the force control pot such that the unit will complete a full

cycle of gate travel but can be reversed off an obstruction without

applying an unreasonable amount of force. On most operators

this will be around the middle of the range.

MOTOR LEARN BUTTON

Motor

Learn

Button (S3)

FORCE CONTROL

Force Control

Min

Max

NOTE: For LED location refer to illustration on previous page.

DIAGNOSTICS (LEDS AND CODES)

There are three diagnostic LEDs. Two red LEDs (OLS, CLS) are

indicators for the open and close limits. The LEDs are illuminated

when the limit switch contacts are closed.

The third amber LED (DIAG) is used to blink out diagnostic

codes. The number is the count of the number of times the LED

is on in an 8 second period. The LED is on for approximately 1/2

second and repeats every second until the number is reached.

There will be a pause following each pulse cycle (1-6 pulses) to

differentiate between the different diagnostic codes.

LED Code Diagnostic Meaning Cleared By

Flashed

OFF Normal operation N/A

1 Single entrapment sensed Control Input

2 Double entrapment Hard Input*

3 Failed or no hall Removal of

effect sensor problem

4 Exceed maximum motor Hard Input*

run time

5 Limit fault Control Input

6 Loss of communications Removal of

between master and problem

second during run mode

On No Motor not learned Completion

Flash of Motor Learn

Routine

* Hard inputs include open override, close override

and stop inputs.

24

Page 25

ADJUSTMENT

CONTROL BOARD PROGRAMMING AND FEATURES (CONTINUED)

RELAY DRIVE TROUBLESHOOTING LEDS

There are 5 troubleshooting LEDs on relay drives K1 through K5. These LEDs will be illuminated when the microcontroller relay drive is

activated.

LED LED NAME DESCRIPTION

D6 Contactor A On when Contactor A is activated

D5 Contactor B On when Contactor B is activated

D4 SAM On when SAM relay is activated

D3 Lock On when Mag Lock relay is activated

D2 Alarm On when Alarm Relay is activated

TROUBLESHOOTING LEDS

There are 9 troubleshooting LEDs.

LED LED NAME DESCRIPTION

D11 Radio On when Radio switch is activated

D13 Shadow On when Shadow Loop is activated

D15 Hard Close On when Close switch is activated

D17 (Green) Stop On when Stop switch is not activated

D19 Soft Open On when Open switch is activated

D21 Hard Open On when Open switch is activated

D24 Interrupt (Safety) Loop On when Interrupt/Safety Loop activated

D29 Obstruction Open On when Edge is activated or when Photo Eye

Beam is broken

D31 Obstruction Close On when Edge is activated or when Photo Eye

Beam is broken

25

Page 26

RT LT

SW SL

1 2 3 4

ON

SAVE

TTC

ON

S1

1 2 3 4

ON

SAVE

TTC

ON

S1

RT LT

SW SL

APEMs

ON

CLED PH

OPED PH

1 2 3 4

WARN

MAG

ON

S2

ON

CLED PH

OPED PH

1 2 3 4

WARN

MAG

ON

S2

ON

CLED PH

OPED PH

1 2 3 4

WARN

MAG

ON

S2

ON

CLED PH

OPED PH

1 2 3 4

WARN

MAG

ON

S2

1 2 3 4

ON

SAVE

TTC

ON

S1

1 2 3 4

ON

SAVE

TTC

ON

S1

RT LT

SW SL

RT LT

SW SL

PROGRAM SETTINGS (DIP SWITCH S1)

1 2 3 4

ON

SAVE

TTC

ON

S1

1 2 3 4

ON

SAVE

TTC

ON

S1

RT LT

SW SL

RT LT

SW SL

1 2 3 4

ON

SAVE

TTC

ON

S1

1 2 3 4

ON

SAVE

TTC

ON

S1

RT LT

SW SL

RT LT

SW SL

NOTE: For all S1, S2 and S4 switch settings to take effect, the Save Mode switch must be set to the off position.

TIMER-TO-CLOSE ENABLE

This switch enables the auto close timer. The timer to close

feature works in conjunction with the potentiometer located on

the board.

TIMER-TO-CLOSE

ENABLED

TIMER-TO-CLOSE

DISABLED

(Factory Default)

SLIDE/SWING

This switch selects slide or swing gate operation, in order to

optimize gate behavior for specific application.

SL = Slide • SW = Swing

RIGHT/LEFT OPERATION

This switch selects the gate opening direction, to the left or to

the right. Right/Left operation is determined from the inside of

fence looking out.

TIMER-TO-CLOSE

SWING GATE

LEFT HAND RIGHT HAND

Max = 180 sec

Min = 0 sec

SLIDE GATE

(Factory Default)

“SAVE” SWITCH

This switch stores all settings into memory and locks out changes.

NOTE: For any programming changes to take effect this switch

must be in OFF position. When switch is ON, no settings can be

changed.

PROGRAM SETTINGS (DIP SWITCH S2)

MAGLOCK ENABLE

This switch enables the Maglock feature. On an open command

there will be a half second delay after the maglock relay is

released before the motor starts.

WARNING ENABLE

This switch enables the gate “in motion” alarm feature. The

alarm will beep 3 seconds prior to movement and throughout

movement.

(Factory Default)

LOCKED UNLOCKED

(Factory Default)

MAGLOCK ENABLED MAGLOCK DISABLED

(Factory Default)

WARNING ENABLED WARNING DISABLED

(Factory Default)

26

Page 27

PROGRAM SETTINGS (DIP SWITCH S2)

ON

CLED PH

OPED PH

1 2 3 4

WARN

MAG

ON

S2

ON

CLED PH

OPED PH

1 2 3 4

WARN

MAG

ON

S2

ON

CLED PH

OPED PH

1 2 3 4

WARN

MAG

ON

S2

ON

CLED PH

OPED PH

1 2 3 4

WARN

MAG

ON

S2

EDGE/PHOTO OPEN

This switch (S2-3) selects edge or photo sensor for the gate

opening protection input.

Open Photo Eye (Pause): When the controller is configured

for photo eyes, the input functions to pause the gate during

the opening cycle. Once the input is cleared the gate

continues to open.

Open Edge: When the controller is configured for safety

edges, the input functions to reverse the gate to the close

limit when the edge is activated during the opening cycle.

EDGE OPEN PHOTO OPEN

(Factory Default)

MASTER/SECOND SYSTEMS

Dual Gate Communications

The control board is capable of running the operator in a master

or second mode depending on (S4) switch setting.

Before initiating any command the master unit queries for the

presence of a “second unit” for a time period of one second. If

the master gets no response the operator will operate in a stand

alone mode. NOTE: For single unit applications, a jumper must be

placed between pins 1 and 2 of the J4 connector. In this mode no

further communications will take place during travel. If the master

detects the presence of a second unit the master will continue to

query the second unit during travel. The second unit will send a

response to the master for every query. The second operator will

stop if there is a period of one second or more of no

communications.

EDGE/PHOTO CLOSE

This switch (S2-4) selects edge or photo sensor for the gate

closing protection input.

Close Photo Eye (Reverse): When the controller is

configured for photo eyes, the input functions to reverse the

gate to the open limit when activated during the close cycle.

NOTE: Timer-to-Close will reset if enabled.

Close Edge: When the controller is configured for safety

edges, the input functions to reverse the gate to the open

limit when activated during the close cycle. The entrapment

is not cleared at the limit and the timer to close will be

disabled. The Timer-to-Close may be enabled by activating

the interrupt loop, soft open or hard open input.

EDGE CLOSE PHOTO CLOSE

(Factory Default)

When two operators are connected in dual gate configuration

accessories may be connected to either the master or second.

NOTE: Do not run Master/Second communication wiring in the

same conduit as the power and control wiring. The Second unit

will require a normally close stop circuit for proper system

operation. After Master/Second wiring has been completed and

the S4 switch programmed, both units must have their power

cycled to initiate proper Master/Second communication. The

motor learn function must be completed in stand alone mode

prior to Master/Second wiring.

Master or Standalone

Gate Setting

Master

Unit

ON

S4

Second Gate

Setting

Master

Unit

ON

S4

TRAFFIC

SAMS

Conduit

STREET

Hold Open

Second

Shadow Loop

Safety Loop

27

Second

Unit

COMPLEX

OR

PARKING LOT

Terminal

Block

(Twisted Pair)

Shielded

Cable

Conduit

Second

Unit

Terminal

Block

Earthground Rod

(One Side Only)

Page 28

TROUBLESHOOTING

SYMPTOM POSSIBLE CAUSES SOLUTION

Operator fails to

run.

No Stop Control. Check the green LED (D17) on control board. If the green LED is off,

check to make sure a stop control has been installed across terminals

J1-3 & J1-5 of the control board.

Fault in the operator. Check the yellow

diagnostic LED at the top right of the

control board next to the programming

dip switches.

An accessory is active or

malfunctioning. Check the red input

status LEDs, D11-D31.

Improper J4 Connector Wiring

(Master/Second).

Low or no high voltage power. Measure the incoming voltage at the unit’s on/off switch. It should be

If the yellow LED blinks six times there is a master/second unit

communication failure. If operator is a single unit make sure there is a

jumper across J4 pins 1 & 2. If operator is in a dual gate configuration

make sure that the communication wiring between the two units is

undamaged and complete.

If the yellow light is solid the board needs to learn the motor. Follow

the directions on page 24.

If any red LEDs are on, check the corresponding input. An installed

accessory may be wired incorrectly or malfunctioning. Remove the

accessory and test the operator.

Stand-alone Operators: make sure there is a jumper installed across

the J4 connector.

Master/Second Operation: Make sure that the master/second wiring is

installed correctly and is intact (not damaged).

within 5% of the operator’s rating when running. Make sure that the

proper wire gauge was used for the distance between breaker and

operator by consulting the wiring specifications section on page 14 of

this manual.

The relays chatter

when the operator

begins to move.

The operator runs

slow and/or trips

the internal

overload.

Motor runs but gate

does not move.

Low or no low voltage power. Measure the voltage at terminals R1 & R2 in the operator. This

voltage should be within 5% of 24 Vac. If the high voltage power is

good and the low voltage power is bad, check transformer wiring and

replace transformer.

No LEDs illuminated on the control

board.

Low secondary (low voltage) power. Measure the voltage at terminals R1 & R2 in the operator. This

Low primary (high voltage) power. Measure the incoming line voltage at the unit’s on/off switch as well

Problem in the motor. Perform a visual inspection of the motor. Examine the motor’s labels

Damaged or improperly tensioned

belt/drive chain.

If both primary and secondary power is good, check to make sure that

the J2 connector is making good contact with the pins on the board. If

all is good, replace the control board.

voltage should be within 5% of 24 Vac. If the high voltage power is

good and the low voltage power is bad, check to make sure the circuit

breaker is not tripped and that the correct primary tap is used on the

transformer. If breaker and tap are correct replace the transformer.

as the meter base or sub panel. Make sure there is not a major

change in voltage. The voltage at the operator should be within 5% of

the operator’s rating when running.

Check the number of amps currently being drawn from the panel,

make sure that the total power being drawn does not exceed the

panel’s rating.

Make sure that the proper wire gauge was used for the distance

between breaker and operator by consulting the wiring specifications

section on page 15 of this manual.

for any distortion or signs of over heating. Replace the motor if it is

humming, grinding or making excessive noise. NOTE: Repeated motor

problems indicate poor primary power.

Make sure that the operator’s belt/drive chain is intact and tensioned

correctly.

28

Page 29

TROUBLESHOOTING continued

SYMPTOM POSSIBLE CAUSES SOLUTION

Master or Second

operator is not

functioning

properly.

Operator runs but

then stops and

reverses direction.

The operator opens

immediately upon

power up and does

not close.

Programming

changes do not

effect the gate.

Open photo eye

reverses gate

closed when

activated during

opening.

Failure to cycle power after setup. The power to each unit must be cycled in order to initiate proper

master/second communication if the operators were previously in

stand-alone mode.

The communication wiring may be

damaged or improperly wired for dual

gate operation.

The master or second unit is not

programmed correctly.

Entrapment (Force Pot) incorrectly set. This pot must be set so that the gate will run smoothly normally and

Gate is binding or not running

smoothly.

Observe red LEDs D29 and D31. Both LEDs will indicate the activation of entrapment protection devices

The Hall Effect Sensor is not aligned/

adjusted correctly.

Check the red input status LEDs,

D11-D31, for indication of an active or

malfunctioning accessory.

Check the save switch on switch S1-1. If the switch S1-1 is in the on position any subsequent programming

Open obstruction input is programmed

incorrectly.