Chamberlain SLY2500 User Manual

SLIDING GATE OPERATOR

Installation SLY2500

For gates up to 2.500kg

www.liftmaster.de

Email: info@chamberlain.de

Chamberlain GmbH

Alfred Nobel Strasse 4

D-66793 Saarwellingen

Germany 11/2008-b

BEFORE YOU BEGIN

Make sure to leave sufficient space.

Windload: Even light wind may cause the motor to reverse (safety-reverse) as the forces effecting the gate are very

high. This applies especially to solid panel gates.

Gate Size: Gate size is an important factor. Wind can slow down gate or distort it, leading to higher amount of

required force.

Gate weight: Specification of gate weight represents only a rough parameter, which can vary according to actual

demand. Operation is important.

Influence of temperature: Low outdoor temperatures can impede or even prevent starting torque (gro und

deformation etc.). High outdoor temperatures can lead to premature initiation of temperature protection switch.

Notice: Motors are not designed to run permanent run (continuous operation). O utside temperature and gate

represent important parameters for actual operating duration.

Attention: This product may only be installed from professional installers. Only qualified and trained electricians may

connect, programme and service the controls. Qualified and trained electricians meet the following requirements:

- have knowledge of the general and specific safety and accident prevention regulations,

- have knowledge of the relevant electrical regulations,

- are trained in the use and care of appropriate safety equipment,

- are capable of recognising the dangers associated with electricity.

Model Number: SLY2500 SLY2500E2

Controller none CB400

Max. Gate weight (kg) 2500kg 2500kg

Motor Protection Switch yes yes

Hold to run function no yes

Automatic function no yes

IR-Sensor no yes

Automatic close no yes*

Flashing Light no yes*

Safety edges no yes*

Emergency Stop no yes*

Radio no external

External Light switching function no yes*

Traffic light with Red-Light no yes*

Technical Data

Voltage 230V

Phases 1

Frequency 50Hz

Capacitor 2 x 16µF

Current (nominal) 3,85A

Power 0,55 kW

Torque (max.) 120Nm

Gear Reduction 1:40

Duty Cycle Rating 50%

Temperature Range -25/+55°C

Thermal Protection: 140°C

IP-Rating IP55

Gate Speed 10m/min

Sprocket 90mm / Module 4

Weight 41kg

* requires optional ZM-SKS-B plug in card

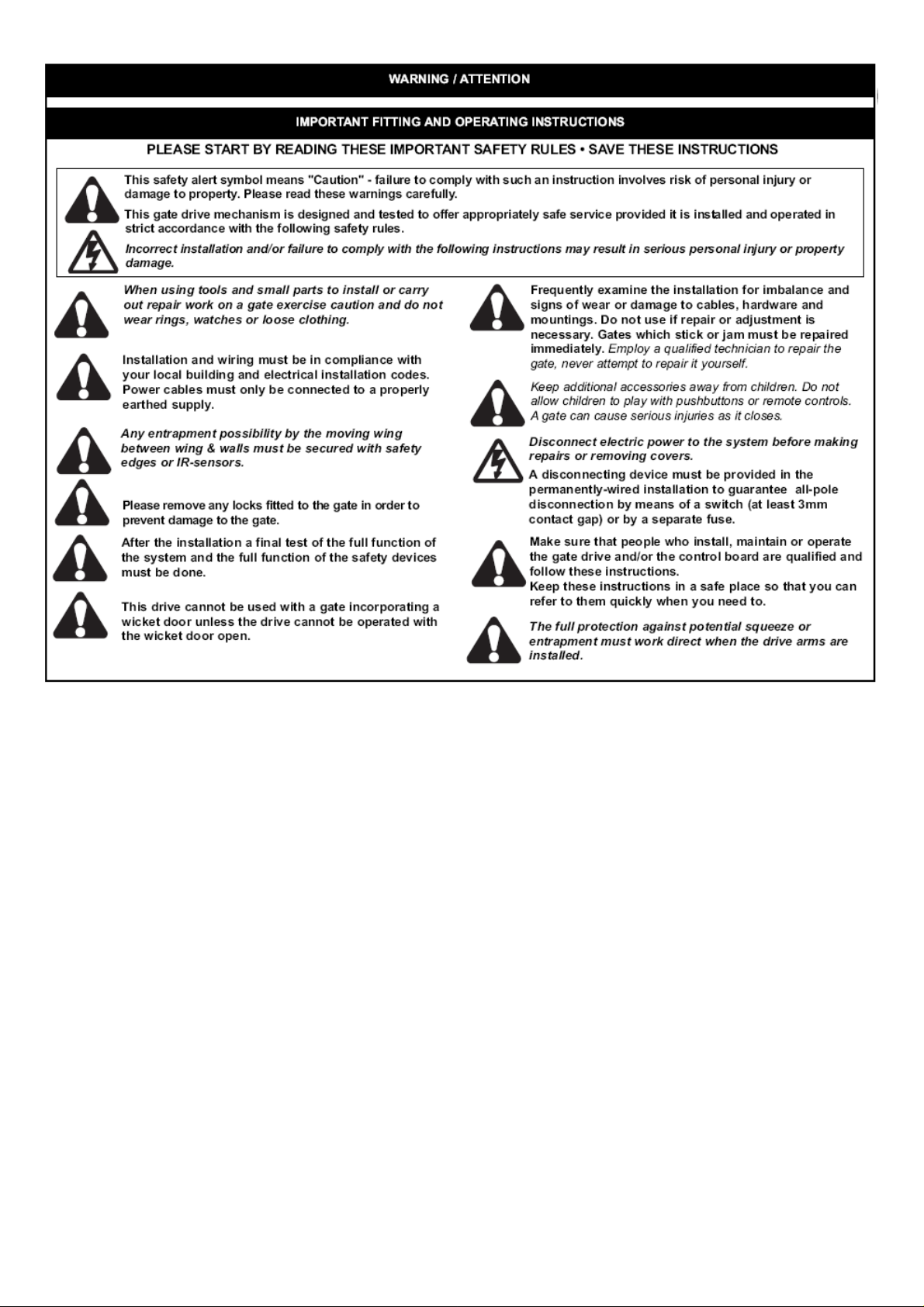

INSTALLATION OF DRIVE

The base for the drive can either be concreted or, if

appropriate, made of steel.

The concrete plinth needs to be of an appropriate size

(approx. 80cm long x 80cm wide x 100cm deep).

Notice: Precisely determine the height of the plinth

(motor mounting socket) and the distance from the gate

prior to installation. You are advised to work as

precisely as possible.

MOUNTING MOTOR AND GEAR UNIT

The weight of the gate should not be borne by the cog

wheel! Position the drive via the adjustment holes such

that its location vis-à-vis the rack bar complies with the

installation dimensions.

MOUNTING RACK BAR

The easiest way to fit the rack bar is to first place it on

the motor's drive cog, disengage the motor and, by

pushing the gate further with the rack bar, screwing the

bar bit by bit firmly in position. In this way, you ensure

that the rail bar engages with the cog wheel in an

optimum manner. While doing this, do not forget to

mark each fixing point.

Notice:

For gates with weights above 3.000kg it is recommended to

use two steel racks.

The tooth racks should be fitted as shown with an overlap

from rack to rack. For two rack mounting the M8 screw must

be replaced with a longer type to suit the application.

Steel racks are recommended (320001 = 1m)

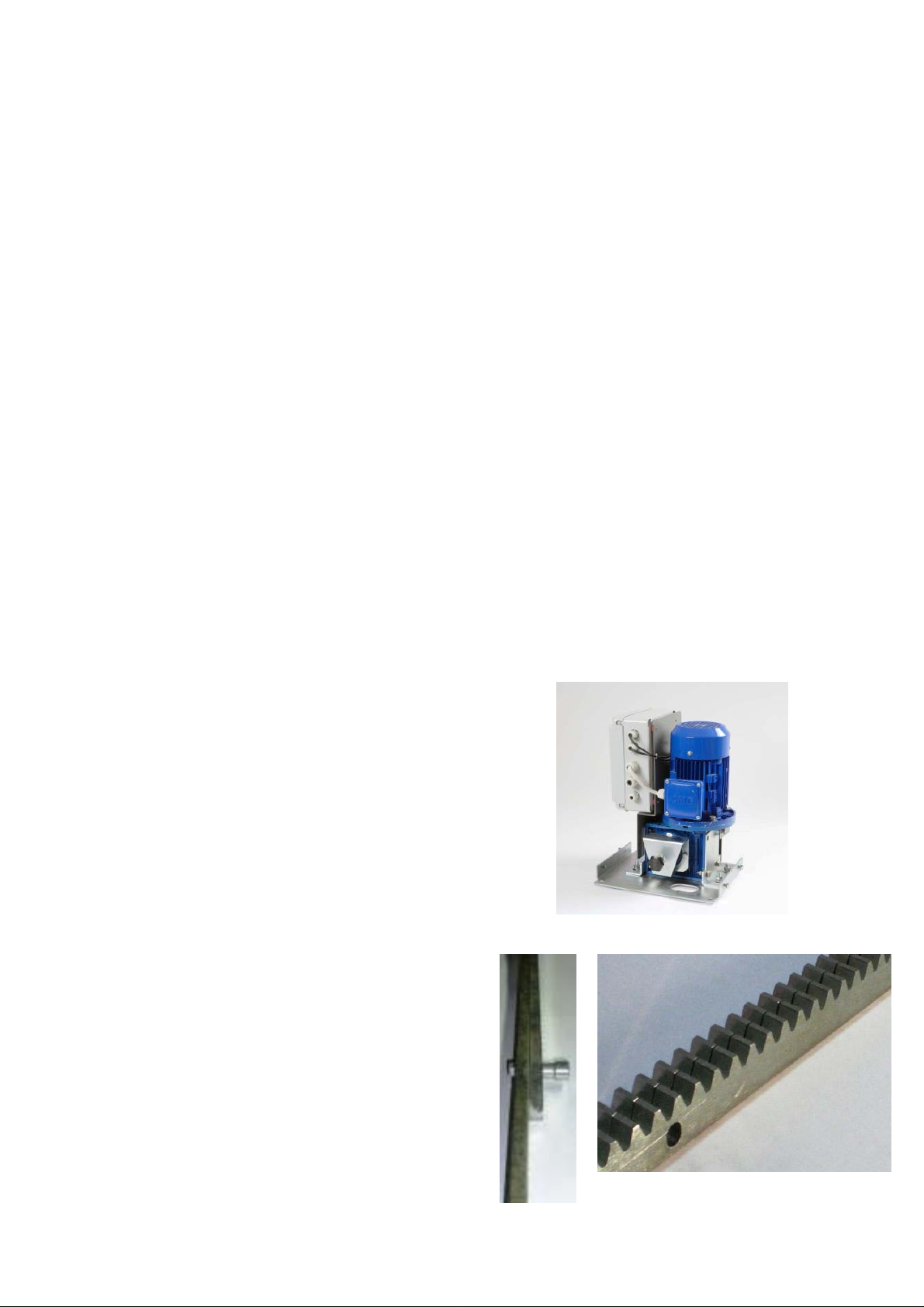

DRIVE RELEASE MECHANISM

(MANUAL OPERATION)

The drive is equipped with a lockable release

mechanism to enable the gate to be operated

manually during a power out.

Open Door

1. Open lock with key

2. Push on lock to open

3. Turn opening lever into position

Disengage gear:

Turn knob fully inside (clockwise).

Engage gear:

Turn knob outside (anti-clockwise).

Notice: For full engagement of gear it is important to

turn the knob completely outside (anti-clockwise).

FITTING LIMIT SWITCHES (TO GATE)

• The drive should be disengaged before this part of

the assembly work is carried out.

• Slide the gate into the closed position.

• Mount the limit switch bracket such that the roller of

the first switch is situated approximately in the

middle of the bracket. Repeat this process for the

open position. The bracket must be mounted with

screws immediately.

INITIAL OPERATION

Check gate functionality manually when the drive has

been disengaged. Electrical operation is possible

only if a controller (CB400) is connected.

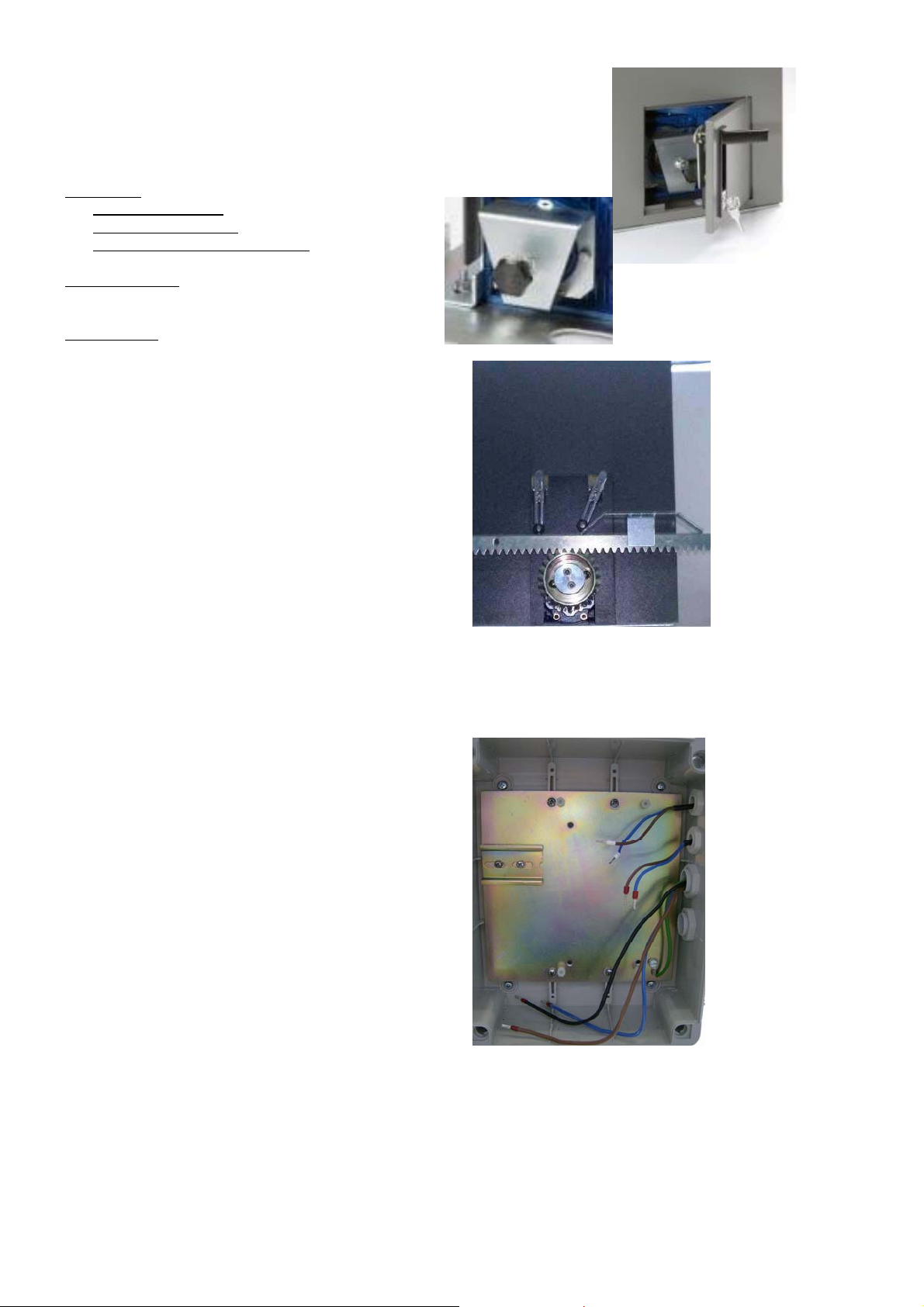

ELECTRICAL CONNECTION:

See electrical wiring diagram with control board

CB400

• Control board pre-installed

• Limit switch pre-wired to NC contacts

• Motor pre-wired to control board box

• Control board box pre-installed

Always ensure that the mechanical and electrical

safety requirements relevant to the given system are

complied with. A sliding gate can also be secured by

implementing on-site measures (fence, wall, etc.).

MAINTENANCE WORK (monthly)

The drive mechanics are generally maintenance-free.

Check at regular intervals that the gate hardware and

the drive are all firmly in place.

• Disengage the drive and check gate functionality.

Only an easy-running gate will work well with a

drive. A drive is no substitute for a poorly

functioning gate.

• Inspect for oil leakage on gear box.

• Inspect for damage to electrical wiring

Declaration of Conformity

Automatic Gate Opener Models……… SLY2500

are in conformity to the applicable sections of Standards:

EN55014 • EN61000-3 • EN60555, EN60335-1 • ETS300 683 • EN60335-1: 2002 • EN60335-2-103:

2003 • EN55014-1: 2000 + A1 + A2 • EN55014-2: 2001 • EN61000-3-2: 2000 • EN61000-3-3: 1995 +

A1 • EN 301 489-3, V1.3.1 • EN13241-1

per the provisions & all amendments

of the EU Directives .................................2006/95/EC, 2004/108/EC, 1999/5/EG

Automatic Gate Opener Models , when installed and maintained according to all the Manufacturer’s

instructions in combination with a Gate, which has also been installed and maintained according to all

the Manufacturer’s instructions, meets the provisions of EU Directive 89/392/EEC and all

amendments.

Harry Naumann

Manager, Regulatory Affairs

Chamberlain GmbH

D-66793 Saarwellingen

Germany

October, 2008

Declaration of Incorporation

I, the undersigned, hereby declare that the equipment

specified above and any accessory listed in the manual

conforms to the above Directives and Standards.

Loading...

Loading...