CAT1320, CAT1321

T

T

T

T

Supervisory Circuits with I2C Serial 32K CMOS EEPROM

FEATURES

N

E

G

F

O

R

L

E

A

E

H

L

E

E

E

A

TM

R

D

F

■ Precision power supply voltage monitor

— 5V, 3.3V and 3V systems

- +5.0V (+/- 5%, +/- 10%)

- +3.3V (+/- 5%, +/- 10%)

- +3.0V (+/- 10%)

■ Active low reset, CAT1320

■ Active high reset, CAT1321

■ Valid reset guaranteed at V

■ 400kHz I

2

C bus

CC

=1V

DESCRIPTION

The CAT1320 and CAT1321 are complete memory and

supervisory solutions for microcontroller-based systems.

A 32kbit serial EEPROM memory and a system power

supervisor with brown-out protection are integrated

together in low power CMOS technology. Memory

interface is via a 400kHz I2C bus.

The CAT1320 provides a precision VCC sense circuit

and drives an open drain output, RESET low whenever

VCC falls below the reset threshold voltage.

The CAT1321 provides a precision VCC sense circuit

that drives an open drain output, RESET high whenever

VCC falls below the reset threshold voltage.

The power supply monitor and reset circuit protect

memory and system controllers during power up/down

and against brownout conditions. Five reset threshold

voltages support 5V, 3.3V and 3V systems. If power

supply voltages are out of tolerance reset signals become

■ 3.0V to 5.5V operation

■ Low power CMOS technology

■ 64-Byte page write buffer

■ 1,000,000 Program/Erase cycles

■ 100 year data retention

■ 8-pin DIP, SOIC, TSSOP and TDFN packages

■ Industrial temperature range

active, preventing the system microcontroller, ASIC or

peripherals from operating. Reset signals become inactive

typically 200 ms after the supply voltage exceeds the reset

threshold level. With both active high and low reset options,

interface to microcontrollers and other ICs is simple. In

addition, the RESET (CAT1320) pin can be used as an

input for push-button manual reset capability.

The CAT1320/21 memory features a 64-byte page. In

addition, hardware data protection is provided by a V

sense circuit that prevents writes to memory whenever V

CC

CC

falls below the reset threshold or until VCC reaches the reset

threshold during power up.

Available packages include an 8-pin DIP, SOIC, TSSOP

and 4.9 x 3mm TDFN.

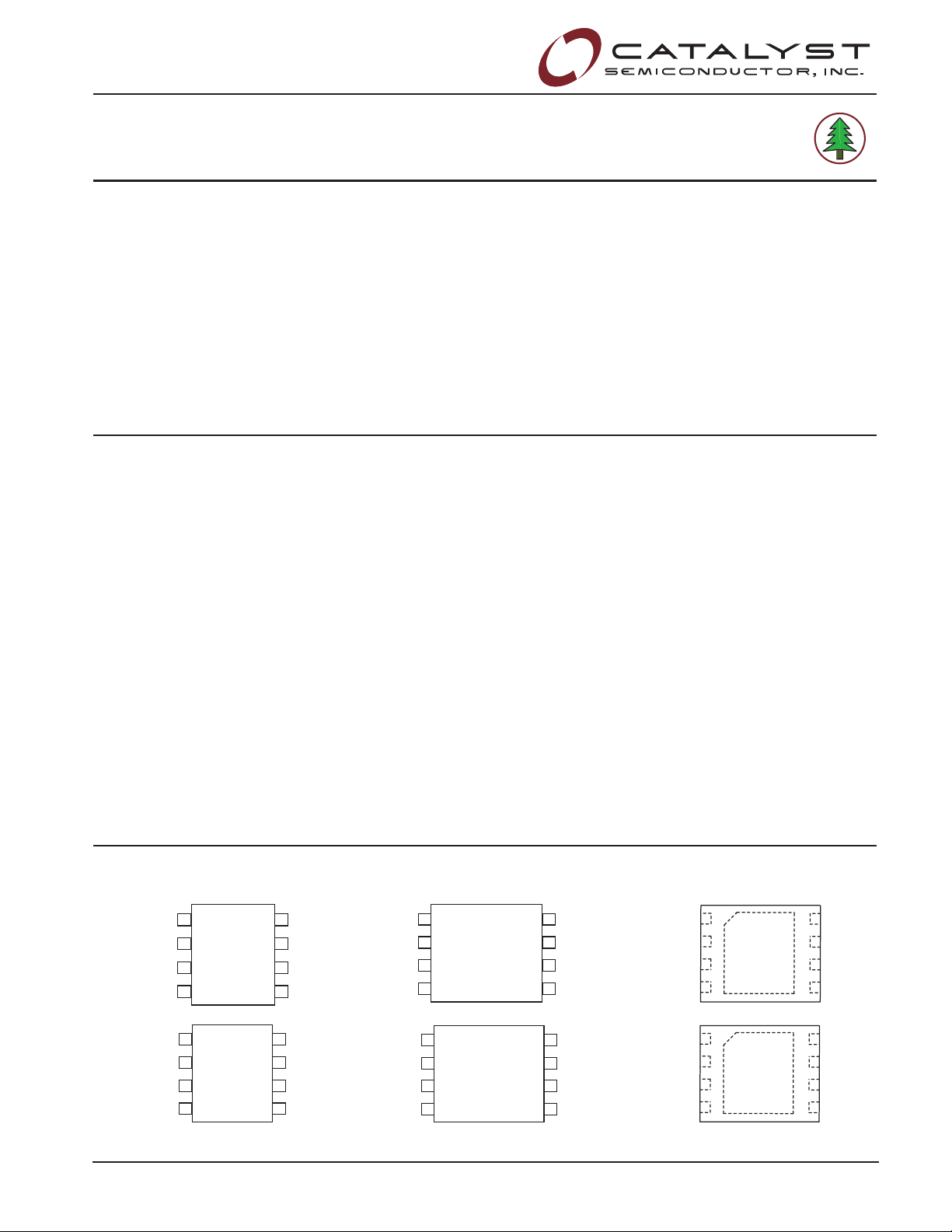

PIN CONFIGURATION

PDIP (P, L) SOIC (J, W)

1

A0 V

A1

2

CAT1320

A2

3

V

4

SS

1

A0

A1

2

CAT1321

A2

3

V

4

SS

© 2005 by Catalyst Semiconductor, Inc.

Characteristics subject to change without notice

8

7

6

5

8

7

6

5

CC

RESE

SCL

SDA

V

CC

RESET

SCL

SDA

TSSOP (U, Y)

1

A0 V

A1

2

CAT1320

A2

3

V

4

SS

1

A0

A1

2

CAT1321

A2

3

V

4

SS

1

8

7

6

5

8

V

RESET

7

SCL

6

SDA

5

CC

RESE

SCL

SDA

CC

TDFN PACKAGE: 4.9MM X 3MM

(RD2, ZD2)

1

A0

2

A1

A2

V

SS

A0

A1

A2

V

SS

3

4

1

2

3

4

CAT1320

CAT1321

8

V

CC

7

RESE

6

SCL

5

SDA

8

V

CC

7

RESE

6

SCL

5

SDA

Doc. No. 20585, Rev. 00

CAT1320, CAT1321 Advance Information

L

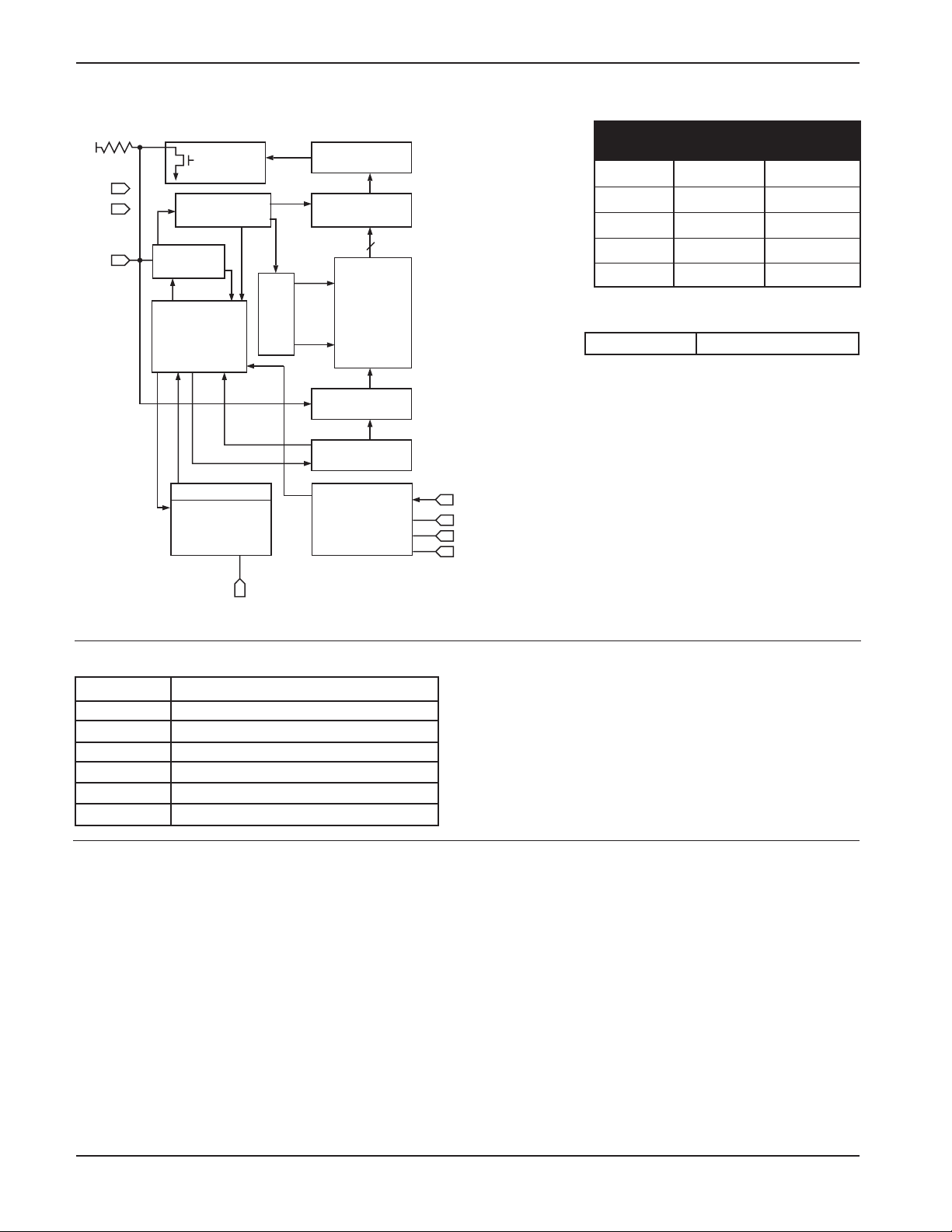

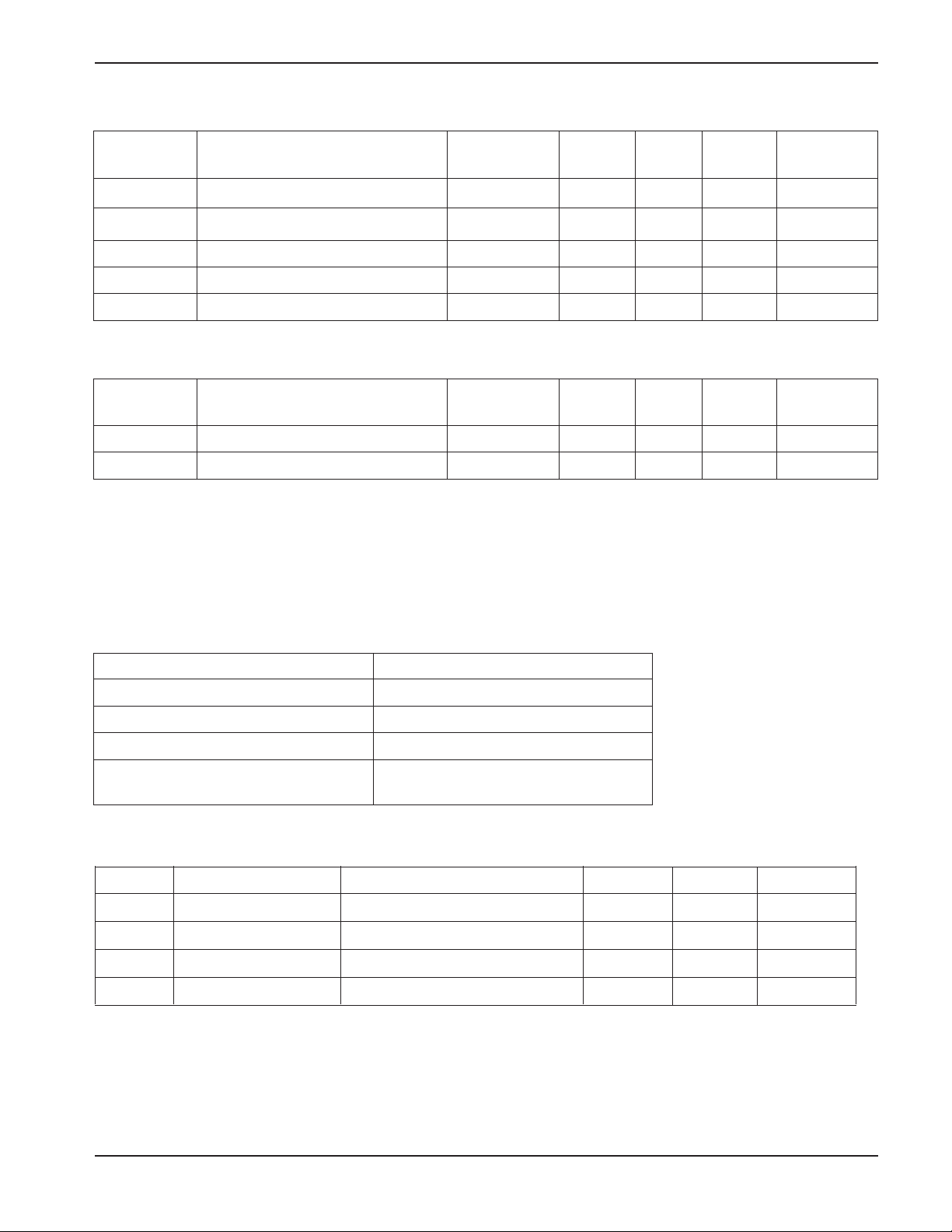

BLOCK DIAGRAM — CAT1320, CAT1321

EXTERNAL LOAD

SENSE AMPS

SHIFT REGISTERS

COLUMN

DECODERS

32kbit

EEPROM

DATA IN STORAGE

HIGH VOLTAGE/

TIMING CONTROL

STATE COUNTERS

SLAVE

ADDRESS

COMPARATORS

V

CC

V

SS

SDA

D

ACK

WORD ADDRESS

BUFFERS

START/STOP

LOGIC

CONTROL

LOGIC

RESET Controller

Precision

Vcc Monitor

OUT

XDEC

Threshold Voltage Options

Part Dash Minimum Maximum

Number Threshold Threshold

-45 4.50 4.75

-42 4.25 4.50

-30 3.00 3.15

-28 2.85 3.00

-25 2.55 2.70

OPERATING TEMPERATURE RANGE

Industrial -40˚C to 85˚C

SC

A0

A1

A2

RESET (CAT1320)

RESET (CAT1321)

PIN FUNCTIONS

Pin Name Function

RESET Active Low Reset Input/Output (CAT1320)

V

SS

SDA Serial Data/Address

SCL Clock Input

RESET Active High Reset Output (CAT1321)

V

CC

Ground

Power Supply

PIN DESCRIPTION

RESET/

These are open-drain pins and RESET can also be used

as a manual reset trigger input. By forcing a reset condition

on the pin the device will initiate and maintain a reset

condition. The RESET pin must be connected through a

pull-down resistor and the RESET pin must be connected

through a pull-up resistor.

SDA: SERIAL DATA ADDRESS

The bidirectional serial data/address pin is used to transfer all data into and out of the device. The SDA pin is an

open drain output and can be wire-ORed with other open

drain or open collector outputs.

RESETRESET

RESET: RESET OUTPUTS

RESETRESET

SCL: SERIAL CLOCK

Serial clock input.

A0, A1, A2: DEVICE ADDRESS INPUTS

When hardwired, up to eight CAT1320/21 devices may

be addressed on a single bus system (refer to Device

Addressing). When the pins are left unconnected, the

default values are zeros.

Doc. No. 25085, Rev. 00

2

Advance Information CAT1320, CAT1321

ABSOLUTE MAXIMUM RATINGS

Temperature Under Bias .................... -40°C to +85°C

Storage Temperature ........................ -65°C to +105°C

Voltage on any Pin with

Respect to Ground

with Respect to Ground ................ -0.5V to +7.0V

V

CC

(1)

............. -0.5V to +VCC +2.0V

Stresses above those listed under “Absolute Maximum Ratings” may

cause permanent damage to the device. These are stress ratings only,

and functional operation of the device at these or any other conditions

outside of those listed in the operational sections of this specification

is not implied. Exposure to any absolute maximum rating for extended

periods may affect device performance and reliability.

Note:

(1) Output shorted for no more than one second. No more than

one output shorted at a time.

Package Power Dissipation

Capability (T

= 25°C) ................................... 1.0W

A

Lead Soldering Temperature (10 secs) ............ 300°C

Output Short Circuit Current

(1)

........................ 100 mA

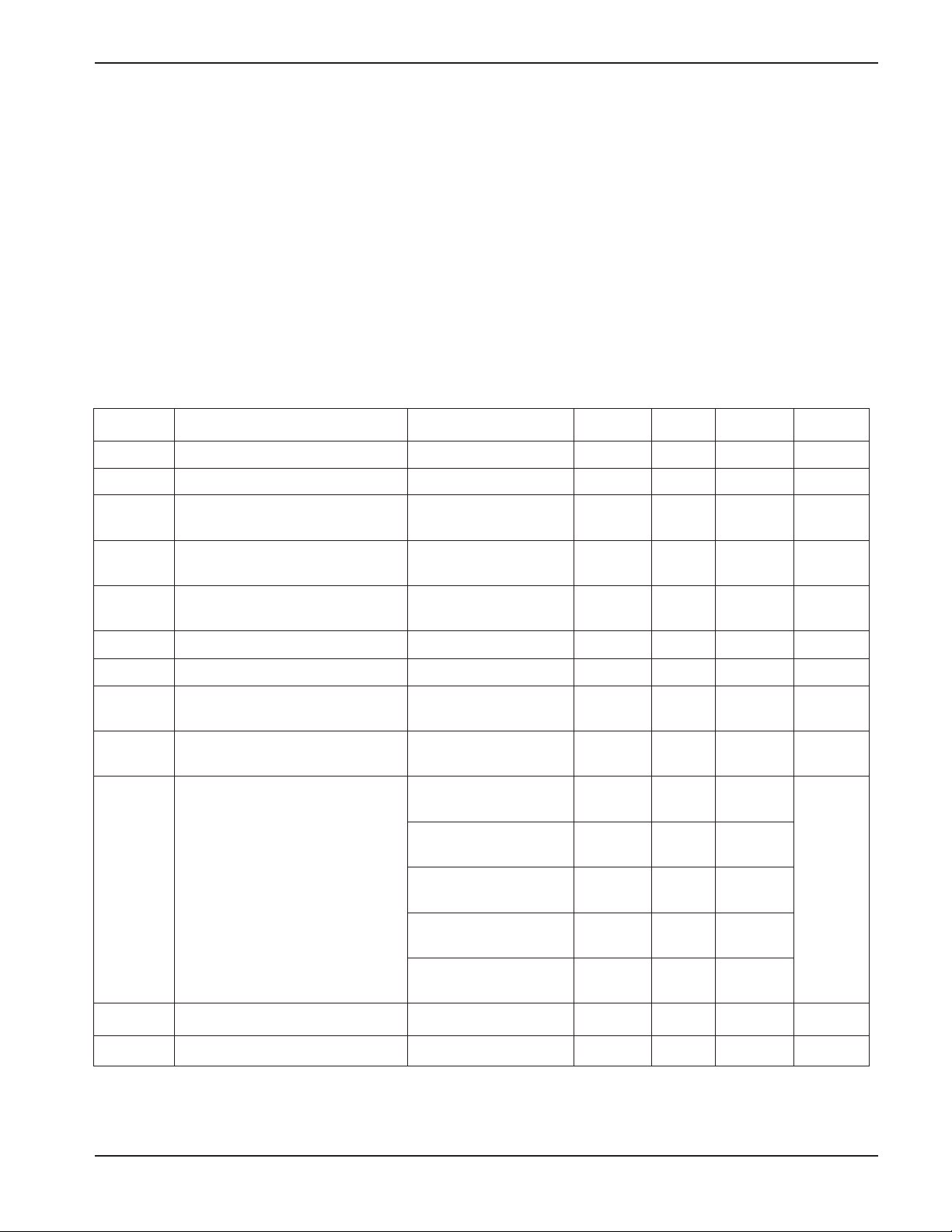

D.C. OPERATING CHARACTERISTICS

VCC = +3.0V to +5.5V and over the recommended temperature conditions unless otherwise specified.

lobmySretemaraPsnoitidnoCtseTniMpyTxaMstinU

I

IL

I

OL

I

1CC

I

2CC

I

BS

2

V

LI

2

V

HI

V

LO

V

HO

V

HT

1

V

DILAVR

1

V

TR

Notes:

1. This parameter is tested initially and after a design or process change that affects the parameter. Not 100% tested.

2. VIL min and VIH max are reference values only and are not tested.

,ADS( TESER )

)TESER(

tnerruCegakaeLtupnIV

tnerruCegakaeLtuptuOV

)etirW(tnerruCylppuSrewoP

)daeR(tnerruCylppuSrewoP

tnerruCybdnatS

NI

NI

f

LCS

V

CC

f

LCS

V

CC

V

NI

ccVotDNG=2-01Aµ

ccVotDNG=01-01Aµ

zHk004=

V5.5=

zHk004=

V5.5=

,V5.5=ccV

ccVroDNG=

3Am

1Am

04Aµ

egatloVwoLtupnI5.0-ccVx3.0V

egatloVhgiHtupnIccVx7.05.0+ccVV

egatloVwoLtuptuO

egatloVhgiHtuptuO

dlohserhTteseR

VdilaVtuptuOteseR

CC

egatloV00.1V

I

V

I

HO

V

V(

V(

V(

V(

V(

Am3=

LO

V0.3=

CC

Am4.0-=

V0.3=

CC

54-x231TAC

)V5=

CC

24-x231TAC

)V5=

CC

03-x231TAC

CC

)V3.3=

82-x231TAC

CC

)V3.3=

52-x231TAC

)V3=

CC

-ccV

57.0

05.457.4

52.405.4

00.351.3

58.200.3

55.207.2

4.0V

siseretsyHdlohserhTteseR51Vm

V

V

3

Doc No. 25085, Rev. 00

CAT1320, CAT1321 Advance Information

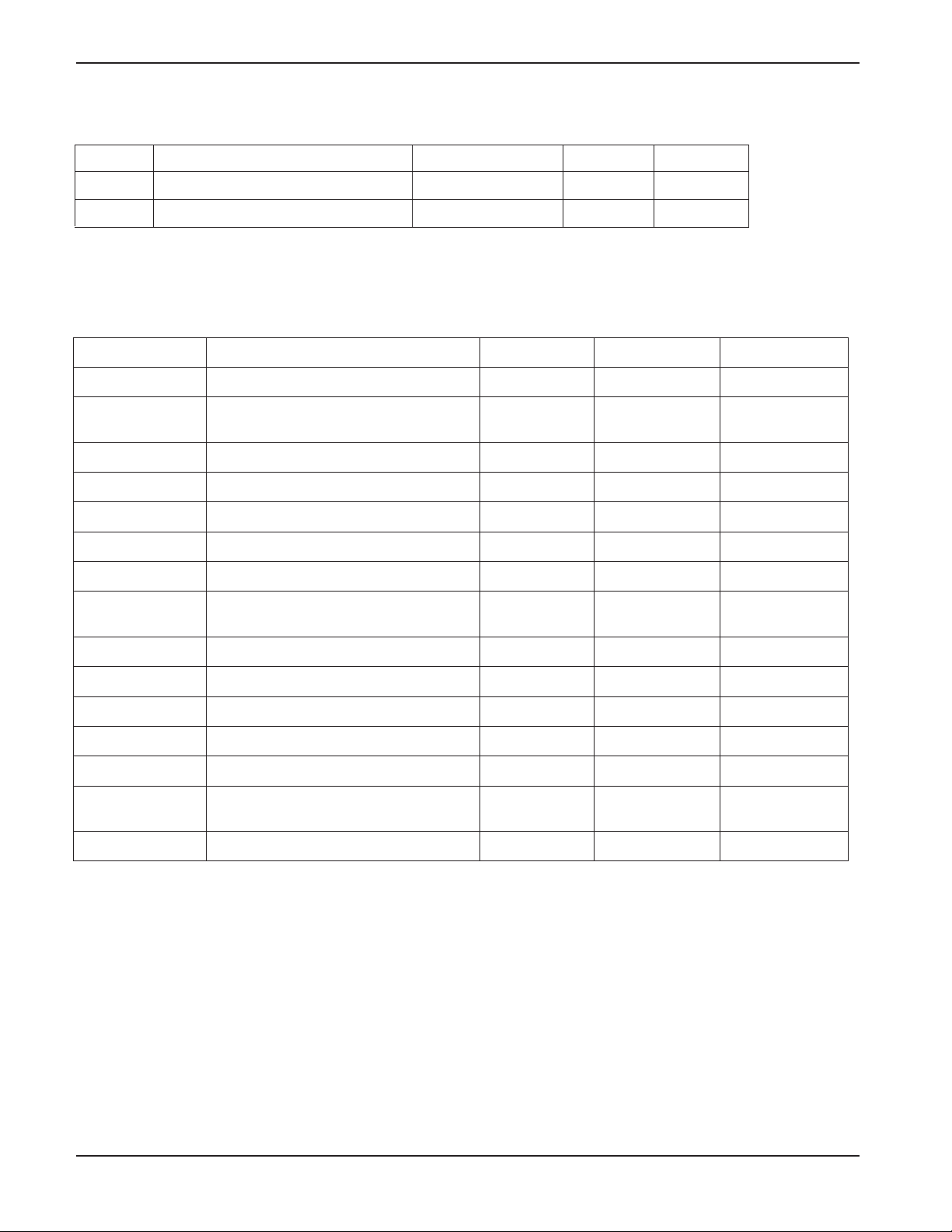

CAPACITANCE

TA = 25°C, f = 1.0 MHz, VCC = 5V

Symbol Test Test Conditions Max Units

(1)

C

C

OUT

(1)

IN

Output Capacitance V

= 0V 8 pF

OUT

Input Capacitance VIN = 0V 6 pF

A.C. CHARACTERISTICS

V

= 3.0V to 5.5V and over the recommended temperature conditions, unless otherwise specified.

CC

2

elcyCetirW&daeRyromeM

lobmySretemaraPniMxaMstinU

f

LCS

1

t

PS

t

WOL

t

HGIH

1

t

R

1

t

F

t

ATS;DH

t

ATS;US

t

TAD;DH

t

TAD;US

t

OTS;US

t

AA

t

HD

1

t

FUB

3

t

CW

ycneuqerFkcolC004zHk

ekipSretliFtupnI

)LCS,ADS(noisserppuS

001sn

doirePwoLkcolC3.1sµ

doirePhgiHkcolC6.0sµ

emiTesiRLCSdnaADS003sn

emiTllaFLCSdnaADS003sn

emiTdloHnoitidnoCtratS6.0sµ

emiTputeSnoitidnoCtratS

)tratSdetaepeRarof(

6.0sµ

emiTdloHtupnIataD0sn

emiTputeStupnIataD001sn

emiTputeSnoitidnoCpotS6.0sµ

dilaVtuOataDotwoLLCS009sn

emiTdloHtuOataD05sn

aerofeBeerFebtsumsuBehtemiT

tratSnaCnoissimsnarTweN

3.1sµ

)egaProetyB(emiTelcyCetirW5sm

Notes:

1. This parameter is characterized initially and after a design or process change that affects

the parameter. Not 100% tested.

2. Test Conditions according to “AC Test Conditions” table.

3. The write cycle time is the time from a valid stop condition of a write sequence to the end of

the internal program/erase cycle. During the write cycle, the bus interface circuits are disabled,

SDA is allowed to remain high and the device does not respond to its slave address.

Doc. No. 25085, Rev. 00

4

Advance Information CAT1320, CAT1321

RESET CIRCUIT A.C. CHARACTERISTICS

lobmySretemaraP

t

TSRUP

t

DPR

t

HCTILG

tuoemiTteseR2etoN031002072sm

V

HT

V

CC

yaleDtuptuoTESERot3etoN5sµ

htdiWesluPtcejeRhctilG5,4etoN03sn

tseT

snoitidnoC

niMpyTxaMstinU

hctilGRMytinummIhctilGteseRlaunaM5etoN001sn

t

WRM

6,5

GNIMITPU-REWOP

lobmySretemaraP

t

RUP

t

WUP

Notes:

1. Test Conditions according to “AC Test Conditions” table.

2. Power-up, Input Reference Voltage VCC = VTH, Reset Output Reference Voltage and Load according to “AC Test Conditions” Table

3. Power-Down, Input Reference Voltage VCC = VTH, Reset Output Reference Voltage and Load according to “AC Test Conditions” Table

4. VCC Glitch Reference Voltage = V

5. This parameter is characterized initially and after a design or process change that affects the parameter. Not 100% tested.

6. t

PUR

and t

are the delays required from the time VCC is stable until the specified memory operation can be initiated.

PUW

THmin

htdiWesluPRM5etoN5 sµ

tseT

snoitidnoC

niMpyTxaMstinU

noitarepOdaeRotpU-rewoP 072sm

noitarepOetirWotpU-rewoP 072sm

; Based on characterization data

AC TEST CONDITIONS

segatlovesluptupnIV2.0

CC

V8.0ot

CC

semitllafdnaesirtupnIsn01

segatlovecnerefertupnIV3.0

segatlovecnerefertuptuOV5.0

daoLtuptuO

C

L

V7.0,

CC

CC

CC

I:ecruoStnerruC

LO

;Am3=

Fp001=

RELIABILITY CHARACTERISTICS

Symbol Parameter Reference Test Method Min Max Units

(1)

N

END

(1)

T

DR

(1)

V

ZAP

(1)(2)

I

LTH

Notes:

1. This parameter is tested initially and after a design or process change that affects the parameter. Not 100% tested.

2. Latch-up protection is provided for stresses up to 100mA on input and output pins from -1V to VCC + 1V.

Endurance MIL-STD-883, Test Method 1033 1,000,000 Cycles/Byte

Data Retention MIL-STD-883, Test Method 1008 100 Years

ESD Susceptibility MIL-STD-883, Test Method 3015 2000 Volts

Latch-Up JEDEC Standard 17 100 mA

5

Doc No. 25085, Rev. 00

CAT1320, CAT1321 Advance Information

DEVICE OPERATION

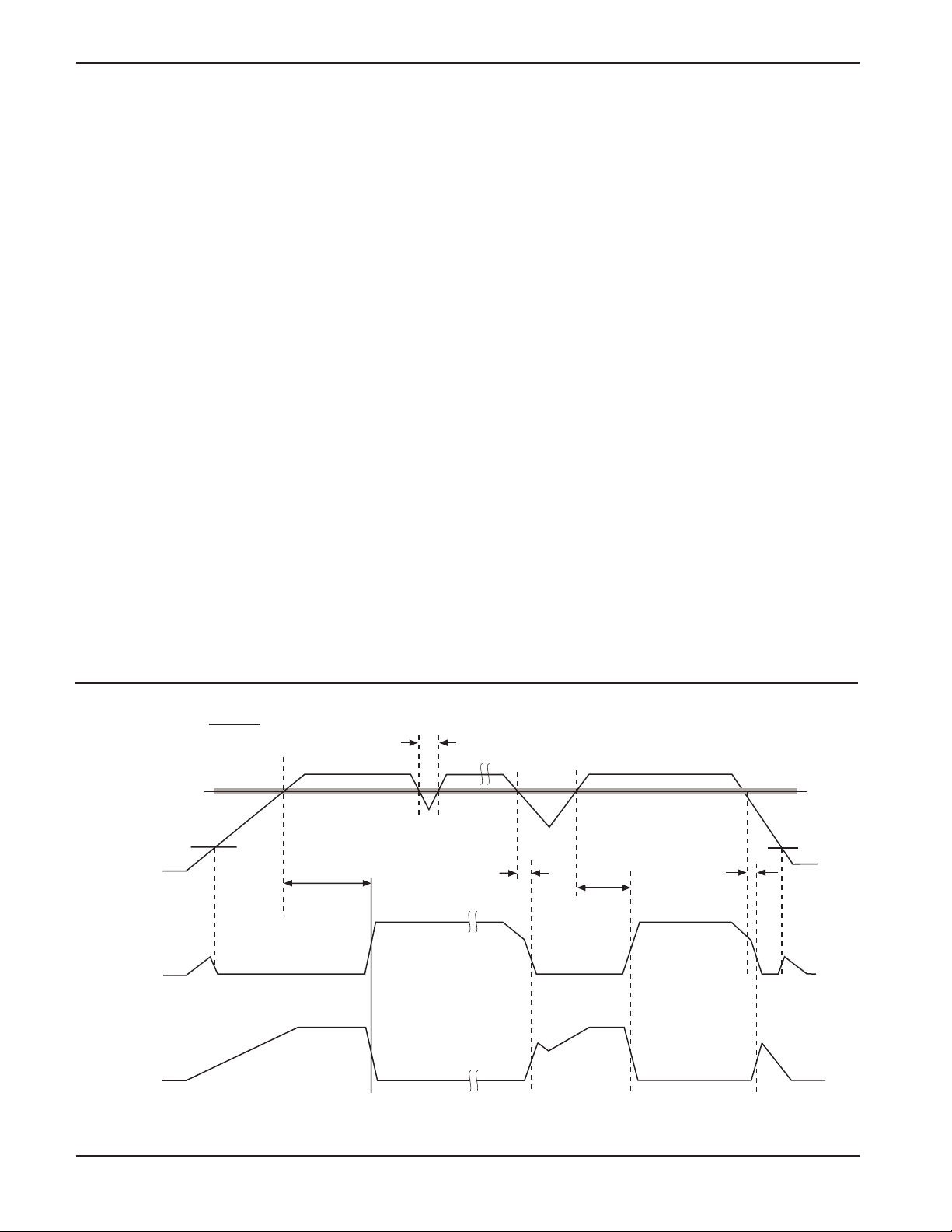

Reset Controller Description

The CAT1320/21 precision Reset controllers ensure

correct system operation during brownout and power

up/down conditions. They are configured with opendrain RESET/RESET outputs.

During power-up, the RESET/RESET output remains

active until VCC reaches the VTH threshold and will

continue driving the outputs for approximately 200ms

(t

) after reaching VTH. After the t

PURST

PURST

timeout

interval, the device will cease to drive the reset output.

At this point the reset output will be pulled up or down by

their respective pull up/down resistors.

During power-down, the RESET/RESET output will be

active when V

output will be valid so long as VCC is >1.0V (V

falls below VTH. The RESET/RESET

CC

RVALID

The device is designed to ignore the fast negative going

VCC transient pulses (glitches).

Reset output timing is shown in Figure 1.

Manual Reset Operation

The RESET pin can operate as reset output and manual

reset input. The input is edge triggered; that is, the

RESET input will initiate a reset timeout after detecting

a high to low transition.

When RESET I/O is driven to the active state, the 200

msec timer will begin to time the reset interval. If external

reset is shorter than 200 ms, Reset outputs will remain

active at least 200 ms.

Glitches shorter than 100 ns on RESET input will not

generate a reset pulse.

Hardware Data Protection

The CAT1320/21 family has been designed to solve

many of the data corruption issues that have long been

associated with serial EEPROMs. Data corruption occurs

when incorrect data is stored in a memory location which

is assumed to hold correct data.

).

Whenever the device is in a Reset condition, the embedded

EEPROM is disabled for all operations, including write

operations. If the Reset output is active, in progress

communications to the EEPROM are aborted and no new

communications are allowed. In this condition an internal

write cycle to the memory can not be started, but an in

progress internal non-volatile memory write cycle can not

be aborted. An internal write cycle initiated before the

Reset condition can be successfully finished if there is

enough time (5ms) before VCC reaches the minimum

value of 2V.

Figure 1. RESET/RESET Output Timing

V

TH

V

RVALID

V

CC

RESET

RESET

Doc. No. 25085, Rev. 00

t

PURST

t

GLITCH

t

6

RPD

t

PURST

t

RPD

Advance Information CAT1320, CAT1321

Figure 2.

RESETRESET

RESET as Manual Reset Input Operation and Timing

RESETRESET

RESET

(Input)

(Output)

Figure 3. Bus Timing

SCL

t

SDA IN

SDA OUT

RESET

SU:STA

t

MRW

t

PURST

t

F

t

LOW

t

HD:STA

t

AA

t

HIGH

t

HD:DAT

t

LOW

t

DH

t

R

t

SU:DAT

t

SU:STO

t

BUF

7

Doc No. 25085, Rev. 00

CAT1320, CAT1321 Advance Information

EMBEDDED EEPROM OPERATION

SDA when SCL is HIGH. The CAT1320/21 monitors the

The CAT1320 and CAT1321 feature a 32kbit

embedded serial EEPROM that supports the I2C Bus

data transmission protocol. This Inter-Integrated

Circuit Bus protocol defines any device that sends

data to the bus to be a transmitter and any device

receiving data to be a receiver. The transfer is

controlled by the Master device which generates the

serial clock and all START and STOP conditions for

bus access. Both the Master device and Slave device

can operate as either transmitter or receiver, but the

Master device controls which mode is activated.

I2C Bus Protocol

The features of the I2C bus protocol are defined as

follows:

(1) Data transfer may be initiated only when the bus is

not busy.

(2) During a data transfer, the data line must remain

stable whenever the clock line is high. Any changes in

the data line while the clock line is high will be interpreted

as a START or STOP condition.

START Condition

The START Condition precedes all commands to the

device, and is defined as a HIGH to LOW transition of

SDA and SCL lines and will not respond until this

condition is met.

STOP Condition

A LOW to HIGH transition of SDA when SCL is HIGH

determines the STOP condition. All operations must end

with a STOP condition.

DEVICE ADDRESSING

The Master begins a transmission by sending a START

condition. The Master sends the address of the particular

slave device it is requesting. The four most significant

bits of the 8-bit slave address are programmable in metal

and the default is 1010.

The last bit of the slave address specifies whether a

Read or Write operation is to be performed. When this bit

is set to 1, a Read operation is selected, and when set

to 0, a Write operation is selected.

After the Master sends a START condition and the slave

address byte, the CAT1320/21 monitors the bus and

responds with an acknowledge (on the SDA line) when

its address matches the transmitted slave address. The

CAT1320/21 then performs a Read or Write operation

depending on the R/W bit.

Figure 4. Write Cycle Timing

SCL

SDA

BYTE n

ACK8TH BIT

t

WR

STOP

CONDITION

START

CONDITION

ADDRESS

Doc. No. 25085, Rev. 00

8

Advance Information CAT1320, CAT1321

ACKNOWLEDGE

After a successful data transfer, each receiving device

is required to generate an acknowledge. The

acknowledging device pulls down the SDA line during

the ninth clock cycle, signaling that it received the 8 bits

of data.

The CAT1320/21 responds with an acknowledge after

receiving a START condition and its slave address. If the

device has been selected along with a write operation,

it responds with an acknowledge after receiving each 8bit byte.

When the CAT1320/21 begins a READ mode it transmits

8 bits of data, releases the SDA line and monitors the

line for an acknowledge. Once it receives this

acknowledge, the CAT1320/21 will continue to transmit

data. If no acknowledge is sent by the Master, the device

terminates data transmission and waits for a STOP

condition.

Figure 5. Start/Stop Timing

WRITE OPERATIONS

Byte Write

In the Byte Write mode, the Master device sends the

START condition and the slave address information (with

the R/W bit set to zero) to the Slave device. After the Slave

generates an acknowledge, the Master sends two 8-bit

address bytes that are to be written into the address

pointers of the device. After receiving another acknowledge

from the Slave, the Master device transmits the data to be

written into the addressed memory location. The CAT1320/

21 acknowledges once more and the Master generates

the STOP condition. At this time, the device begins an

internal programming cycle to non-volatile memory. While

the cycle is in progress, the device will not respond to any

request from the Master device.

SDA

SCL

Figure 6. Acknowledge Timing

SCL FROM

MASTER

DATA OUTPUT

FROM TRANSMITTER

DATA OUTPUT

FROM RECEIVER

Figure 7. Slave Address Bits

START BIT

START

STOP BIT

1

89

ACKNOWLEDGE

Default Configuration

CAT

1010A2A1A0R/W

9

Doc No. 25085, Rev. 00

CAT1320, CAT1321 Advance Information

Page Write

The CAT1320/21 writes up to 64 bytes of data in a single

write cycle, using the Page Write operation. The page

write operation is initiated in the same manner as the byte

write operation, however instead of terminating after the

initial byte is transmitted, the Master is allowed to send up

to additional 63 bytes. After each byte has been

transmitted, the CAT1320/21 will respond with an

acknowledge and internally increment the lower order

address bits by one. The high order bits remain

unchanged.

Figure 8. Byte Write Timing

S

T

A

BUS ACTIVITY:

MASTER

SDA LINE

R

T

S

SLAVE

ADDRESS

BYTE ADDRESS

A15–A

*

*

*

*

A

C

K

If the Master transmits more than 64 bytes before sending

the STOP condition, the address counter ‘wraps around,’

and previously transmitted data will be overwritten.

When all 64 bytes are received, and the STOP condition

has been sent by the Master, the internal programming

cycle begins. At this point, all received data is written to

the CAT1320/21 in a single write cycle.

S

T

8

A7–A

0

A

C

K

DATA

A

C

K

O

P

P

A

C

K

*=Don’t Care Bit

Figure 9. Page Write Timing

S

T

A

BUS ACTIVITY:

MASTER

SDA LINE

*=Don’t Care Bit

R

T

S

SLAVE

ADDRESS

S

BYTE ADDRESS

A15–A

8

**

*

*

A

C

K

A7–A

0

A

C

K

A

C

K

DATA n

A

C

K

A

C

K

DATA n+63DATA

A

C

K

T

O

P

P

A

C

K

Doc. No. 25085, Rev. 00

10

Advance Information CAT1320, CAT1321

Acknowledge Polling

Disabling of the inputs can be used to take advantage of

the typical write cycle time. Once the stop condition is

issued to indicate the end of the host’s write opration, the

CAT1320/21 initiates the internal write cycle. ACK polling

can be initiated immediately. This involves issuing the

start condition followed by the slave address for a write

operation. If the device is still busy with the write operation,

no ACK will be returned. If a write operation has

completed, an ACK will be returned and the host can

then proceed with the next read or write operation.

Figure 10. Immediate Address Read Timing

S

T

BUS ACTIVITY:

MASTER

A

R

T

SLAVE

ADDRESS

Read Operations

The READ operation for the CAT1320/21 is initiated in

the same manner as the write operation with one

exception, that R/W bit is set to one. Three different

READ operations are possible: Immediate/Current

Address READ, Selective/Random READ and

Sequential READ.

S

T

O

P

SDA LINE

SCL

SDA 8TH BIT

S

89

P

A

C

K

DATA

N

O

A

C

K

STOPNO ACKDATA OUT

11

Doc No. 25085, Rev. 00

CAT1320, CAT1321 Advance Information

Immediate/Current Address Read

The CAT1320 and CAT1321 address counter contains

the address of the last byte accessed, incremented by

one. In other words, if the last READ or WRITE access

was to address N, the READ immediately following

would access data from address N+1. For all devices,

N=E=4,095. The counter will wrap around to Zero and

continue to clock out valid data. After the CAT1320 and

CAT1321 receives its slave address information (with

the R/W bit set to one), it issues an acknowledge, then

transmits the 8-bit byte requested. The master device

does not send an acknowledge, but will generate a

STOP condition.

Selective/Random Read

Selective/Random READ operations allow the Master

device to select at random any memory location for a

READ operation. The Master device first performs a

‘dummy’ write operation by sending the START condition,

slave address and byte addresses of the location it

wishes to read. After the CAT1320 and CAT1321

acknowledges, the Master device sends the START

condition and the slave address again, this time with the

R/W bit set to one. The CAT1320 and CAT1321 then

responds with its acknowledge and sends the 8-bit byte

requested. The master device does not send an

acknowledge but will generate a STOP condition.

Sequential Read

The Sequential READ operation can be initiated by

either the Immediate Address READ or Selective READ

operations. After the CAT1320 and CAT1321 sends the

inital 8-bit byte requested, the Master will responds with

an acknowledge which tells the device it requires more

data. The CAT1320 and CAT1321 will continue to output

an 8-bit byte for each acknowledge, thus sending the

STOP condition.

The data being transmitted from the CAT1320 and

CAT1321 is sent sequentially with the data from address

N followed by data from address N+1. The READ

operation address counter increments all of the CAT1320

and CAT1321 address bits so that the entire memory

array can be read during one operation.

Figure 11. Selective Read Timing

S

T

A

BUS ACTIVITY:

MASTER

SDA LINE

*=Don’t Care Bit

R

T

S

SLAVE

ADDRESS

Figure 12. Sequential Read Timing

BUS ACTIVITY:

MASTER

SDA LINE

SLAVE

ADDRESS

A

C

K

S

T

A

C

K

A

R

T

S

A

C

K

DATA n+2

ADDRESS

A

C

K

DATA

A

C

K

DATA n+xDATA n

BYTE ADDRESS SLAVE

A15–A

8

*

*

*

*

A

C

K

A

C

K

A7–A

A

C

K

DATA n+1

0

S

T

O

P

P

N

O

A

C

K

S

T

O

P

P

N

O

A

C

K

Doc. No. 25085, Rev. 00

12

Advance Information CAT1320, CAT1321

PACKAGE OUTLINES

8-LEAD PDIP (P, L)

0.245 (6.17)

0.295 (7.49)

0.300 (7.62)

D

0.120 (3.05)

0.150 (3.81)

0.180 (4.57) MAX

0.325 (8.26)

0.100 (2.54)

BSC

0.045 (1.14)

0.060 (1.52)

0.014 (0.36)

0.022 (0.56)

0.015 (0.38)

—

0.110 (2.79)

0.150 (3.81)

Dimension D

Pkg Min Max

8L 0.355 (9.02) 0.400 (10.16)

0.310 (7.87)

0.380 (9.65)

Notes:

1. Complies with JEDEC Publication 95 MS001 dimensions; however, some of the dimensions may be more stringent.

2. All linear dimensions are in inches and parenthetically in millimeters.

13

Doc No. 25085, Rev. 00

CAT1320, CAT1321 Advance Information

PACKAGE OUTLINES

8-LEAD SOIC (J, W)

0.050 (1.27) BSC

0.1890 (4.80)

0.1968 (5.00)

0.013 (0.33)

0.020 (0.51)

0.0099 (0.25)

0.0196 (0.50)

0.1497 (3.80)

0.1574 (4.00)

0.0532 (1.35)

0.0688 (1.75)

0.0040 (0.10)

0.0098 (0.25)

x 46

°

0.0075 (0.19)

0.0098 (0.25)

0.2284 (5.80)

0.2440 (6.20)

0° - 8

°

0.016 (0.40)

0.050 (1.27)

Dimension D

Pkg Min Max

8L 0.1890(4.80) 0.1968(5.00)

Notes:

1. Complies with JEDEC publication 95 MS-012 dimensions; however, some dimensions may be more stringent.

2. All linear dimensions are in inches and parenthetically in millimeters.

3. Lead coplanarity is 0.004" (0.102mm) maximum.

Doc. No. 25085, Rev. 00

14

Advance Information CAT1320, CAT1321

PACKAGE OUTLINES

8-LEAD TSSOP (U, Y)

15

Doc No. 25085, Rev. 00

CAT1320, CAT1321 Advance Information

PACKAGE OUTLINES

8-PAD TDFN 4.9X3MM PACKAGE (RD2, ZD2)

8

(5)

4.90 + 0.10

1

PIN 1 INDEX AREA

3.00 + 0.10

(S)

5

A

B

5

3.00 + 0.15

8

2.00 + 0.15

0.15

0.10

0.20

0.25

0.60 + 0.10 (8X)

2x

0.15 c

d

4

2x

0.15

c

d

0.30 + 0.05 (8X)

8x

j

0.10m C A B

4

1.95 REF. (2x)

PIN 1 ID

1

0.65 TYP. (6x)

f 0.10 c

8x

0.20 REF.

d 0.08 c

C

NOTE:

1. ALL DIMENSION ARE IN mm. ANGLES IN DEGREES.

2. COPLANARITY APPLIES TO THE EXPOSED PAD AS WELL AS THE TERMINALS.

COPLANARITY SHALL NOT EXCEED 0.08mm.

3. WARPAGE SHALL NOT EXCEED 0.10mm.

4. PACKAGE LENGTH / PACKAGE WIDTH ARE CONSIDERED AS SPECIAL

CHARACTERISTIC(S).

5. REFER TO JEDEC MO-229, FOOTPRINTS ARE COMPATIBLE TO 8 MSOP.

0.75 + 0.05

0.0-0.05

Doc. No. 25085, Rev. 00

16

Advance Information CAT1320, CAT1321

Ordering Information

Prefix Device # Suffix

CAT

Optional

Company ID

1320

Product

Number

1320: 32K

1321: 32K

J

I TE13

Temperature Range

I = Industrial (-40˚C to 85˚C)

-30

Tape & Reel

TE13: 2000/Reel

SOIC: 2000/Reel

TSSOP: 2000/Reel

TDFN: 2000/Reel

Package

P: PDIP

J: SOIC

U: TSSOP

RD2: 8-pad TDFN (4.9mmx3mm)

L: PDIP (Lead free, Halogen free)

W: SOIC, JEDEC (Lead free, Halogen free)

Reset Threshold

Voltage

45: 4.5-4.75V

42: 4.25-4.5V

30: 3.0-3.15V

28: 2.85-3.0V

25: 2.55-2.7V

Y: TSSOP (Lead free, Halogen free)

ZD2: TDFN 4.9x3mm (Lead free, Halogen free)

Note:

(1) The device used in the above example is a CAT1320JI-30TE13 (Supervisory circuit with I2C serial 32k CMOS EEPROM, SOIC, Industrial

Temperature, 3.0-3.15V Reset Threshold Voltage, Tape and Reel).

17

Doc No. 25085, Rev. 00

REVISION HISTORY

Date Rev. Reason

1/25/2005 00 Initial issue

Copyrights, Trademarks and Patents

Trademarks and registered trademarks of Catalyst Semiconductor include each of the following:

DPP ™ AE2 ™

Catalyst Semiconductor has been issued U.S. and foreign patents and has patent applications pending that protect its products. For a complete list of patents

issued to Catalyst Semiconductor contact the Company’s corporate office at 408.542.1000.

CATALYST SEMICONDUCTOR MAKES NO WARRANTY, REPRESENTATION OR GUARANTEE, EXPRESS OR IMPLIED, REGARDING THE SUITABILITY OF ITS

PRODUCTS FOR ANY PARTICULAR PURPOSE, NOR THAT THE USE OF ITS PRODUCTS WILL NOT INFRINGE ITS INTELLECTUAL PROPERTY RIGHTS OR THE

RIGHTS OF THIRD PARTIES WITH RESPECT TO ANY PARTICULAR USE OR APPLICATION and SPECIFICALLY DISCLAIMS ANY and ALL LIABILITY ARISING

OUT OF ANY SUCH USE OR APPLICATION, INCLUDING BUT NOT LIMITED TO, CONSEQUENTIAL OR INCIDENTAL DAMAGES.

Catalyst Semiconductor products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or

other applications intended to support or sustain life, or for any other application in which the failure of the Catalyst Semiconductor product could create a

situation where personal injury or death may occur.

Catalyst Semiconductor reserves the right to make changes to or discontinue any product or service described herein without notice. Products with data sheets

labeled "Advance Information" or "Preliminary" and other products described herein may not be in production or offered for sale.

Catalyst Semiconductor advises customers to obtain the current version of the relevant product information before placing orders. Circuit diagrams illustrate

typical semiconductor applications and may not be complete.

Catalyst Semiconductor, Inc.

Corporate Headquarters

1250 Borregas Avenue

Sunnyvale, CA 94089

Phone: 408.542.1000

Fax: 408.542.1200

www.catalyst-semiconductor.com

Publication #: 25085

Revison: 00

Issue date: 1/25/05

Loading...

Loading...