Page 1

Engine

Engine Model Cat®C15 ACERT™

Gross Power – SAE J1995 324 kW 435 hp

Net Power – SAE J1349 313 kW 419 hp

Weights

Rated Payload 32.7 tonnes 36 tons

Body Capacities

Heaped SAE 2:1 19.7 m

3

25.8 yd

3

735

Articulated Truck

®

®

Page 2

2

735 Articulated Truck

The 735 Caterpillar®Articulated Truck is a world-leading earthmoving solution.

The 735 offers proven reliability and

durability, high performance, low fuel

consumption, operator comfort and low

operating costs.

Complete Customer Support

Your Cat dealer offers a wide range

of services that can be set up under a

customer support agreement when you

purchase your equipment. The dealer will

help you choose a plan that can cover

everything from machine configuration

to eventual replacement. pg. 11

Serviceability

Long service intervals and easy

maintenance provide better machine

availability, resulting in lower owning

and operating costs. pg. 10

Performance and Productivity –

Suspension and Traction Control

Three-point front suspension provides

a smooth ride, allowing the operator

to travel at speed over rough terrain.

Cross-axle differential locking system

provides full driveline locking for

maximum performance in adverse

conditions. pg. 6

Performance and Productivity –

Power Train

The Cat C15 ACERT engine, matched

with the seven-speed forward and

two speed reverse electronic controlled

transmission, provides a wide operating

range for smooth shifting. pg. 5

✔

Cat®C15 Engine with ACERT Technology

The core concept behind ACERT

technology is advanced combustion.

ACERT engine technology carefully

controls the combustion process to reduce

pollutant levels while maintaining

performance and efficiency. pg. 4

✔

Page 3

✔ New Feature

3

Durability and Reliability

The 735 has built-in durability and

reliability. Cat purpose-built articulated

truck drivetrain components, front frame

and hitch ensure maximum performance

in the toughest applications. pg. 9

Ease of Operation

Ergonomically designed wrap-around

dash, tilt and telescopic steering wheel,

easy-to-reach controls and outstanding

all-around viewing promote fast,

confident machine operation. pg. 8

✔

Operator Comfort

Large center-mounted cab, oscillating

front axle, air suspension seat, full-size

trainer seat and large storage space

provide exceptional operator comfort.

pg. 7

✔

Page 4

ACERT Technology. The Cat C15 ACERT

engine introduces a series of evolutionary,

incremental improvements that provide

breakthrough engine technology built

on systems and components developed

by Caterpillar®with proven reliability.

The technology capitalizes on Cat

expertise in four core engine systems:

fuel, air, electronics and after treatment.

ACERT technology is a unique and

revolutionary systems solution that

enables Cat engines to meet today’s

clean air regulations, thus establishing

the building blocks for attaining

tomorrow’s more stringent standards.

C15 Block. The one-piece, gray iron

block features generous ribbing for

stiffness and heavy bearing bulkheads

for rigidity and strength as the crankshaft

turns. Straight O-ring connection points

reduce the loss of engine oil and fluids.

Cylinder Head and Piston Technology.

The C15 has a cross-flow cylinder head

with refined port geometry, which

improves breathing and provides better

combustion. The Monotherm/steel

pistons have a forged steel design, which

offers high strength, light weight and

tighter tolerances. The result is better

oil control, minimal blow-by and long

liner life.

Advanced Diesel Engine Management

(ADEM) A4 Engine Controller.

The ADEM A4 electronic control

module manages fuel delivery to get

the best performance per liter or gallon

of fuel used. The engine management

system provides flexible fuel mapping,

allowing the engine to respond quickly

to varying application needs. It tracks

engine and machine conditions while

keeping the engine operating at peak

efficiency.

Fuel Delivery. Multiple injection

fuel delivery involves a high degree

of precision. Precisely shaping the

combustion cycle lowers combustion

chamber temperatures, generating

fewer emissions and optimizing fuel

combustion. This translates into more

work output for your fuel cost.

Noise Reduction Technologies.

Noise reduction has been achieved

through design changes to the isolated

top cover, oil pan, multiple injection

strategy, insulated timing case cover,

sculpted crankcase and gear train

refinements.

4

Cat C15 Engine with ACERT Technology

A combination of proven systems and innovative new technologies, ACERT engines optimize

performance while meeting EPA Tier 3 and EU Stage 3a engine exhaust emission regulations.

Page 5

Mechanically Actuated Electronic

Unit Injection (MEUI). A highly evolved

fuel system with a proven record of

reliability in the field. It combines the

technical advancement of an electronic

control system with the simplicity

of direct mechanically controlled unit

fuel injection. It excels in its ability

to control injection pressure over the

entire engine operating speed range.

These features allow the C15 to have

complete control over injection timing,

duration and pressure.

Air-to-Air Aftercooling (ATAAC).

ATAAC keeps air intake temperatures

down and, in concert with the tight

tolerance combustion chamber

components, maximizes fuel efficiency

and minimizes emissions. Significant

improvements in airflow are generated

by a turbocharger, unique cross-flow

head and a single overhead camshaft.

Wastegate Turbocharging. Single

wastegate turbocharger provides higher

boost over a wide range, outstanding

low-end performance with improved

peak torque and engine response.

Electronic Transmission. The Caterpillar

seven-speed electronically controlled

transmission is designed specifically for

the articulated truck and its applications.

It features anti-hunt shift strategy for

speed continuity. It also incorporates

Individual Clutch Modulation (ICM)

to ensure constant shift times even

when the oil is cold.

Two Reverse Gears. The transmission

arrangement provides a second reverse

gear for improved performance when

operating in longer rear hauling

applications. First gear reverse is now

of a lower ratio for increased rimpull

on wet or steep grades.

Controlled Throttle Shifting (CTS).

Significantly reduces power train stress

and clutch wear by controlling engine

speed, torque converter lock-up and

transmission clutch engagements.

Engine Overspeed Inhibitor. Electronic

Transmission Control (ETC) protects

against engine overspeeding by shifting

the transmission up one gear at specified

rpm settings. If the transmission is in its

highest gear, torque converter lockup

disengages.

Directional Shift Management.

Regulates engine speed during directional

shifts to prevent damage caused by

high-speed directional changes.

Caterpillar Engine Compression Brake.

Provides extra braking effort on downhill

grades. It is an excellent match for the

Cat C15 ACERT engine, turning it into

a power absorbing air compressor. It has

very fast response time and produces

no additional heat, so it can be used

continuously.

Usable Rimpull. Power train components

work together to offer more usable

rimpull at higher speeds on effective

grades. In first gear, the torque converter

overcomes grade resistance by sending

more torque to the wheels and preventing

engine lugging. On downhill grades, the

engine compression brake works like

a brake by slowing the machine.

Hydraulic Fan. The remote-mounted

hydraulic fan is temperature sensitive

providing variable speeds when needed,

which minimizes power requirements.

The result is more power to the ground

and faster cycle times.

5

Performance and Productivity – Power Train

Integrated power train with more power, greater performance and lower fuel consumption –

the power to do more work.

Page 6

Front Suspension. The three-point front

suspension oscillates ±6° to provide a

smooth ride, allowing the operator to

travel at speed over rough terrain and

softening impact loads on structures

and components.

A-Frame Construction. The front

suspension uses an oscillating A-frame

with a lateral tie rod to control axle

sideways movement. The independent

low-pressure, oil-nitrogen suspension

cylinders provide an excellent ride

in rough conditions. Low pressure

ensures consistent damping and

increased seal life.

Front Suspension Cylinders. Large bore,

low pressure cylinders are purpose

designed for tough applications and

offer a soft, smooth ride.

Mounting Points. Suspension mounting

points are integrated into the axle housing,

increasing reliability.

Rear Suspension. Features a walking

beam geometry with Caterpillar designed

rear suspension mounts which provide

a reliable and stable ride for excellent

load retention.

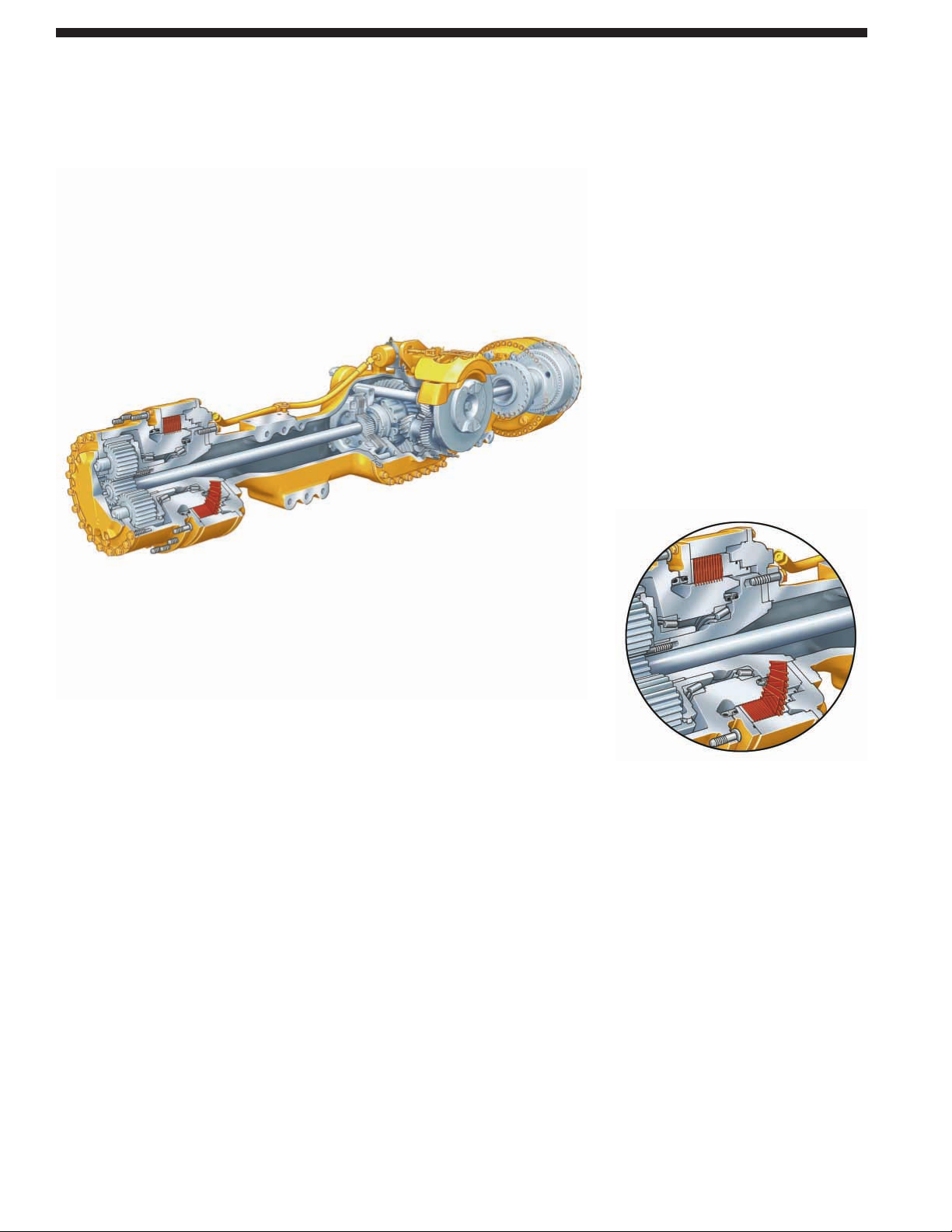

Traction Control. The traction control

system is comprised of a wet clutched

inter-axle differential and wet clutched

cross-axle differentials. All differentials

can be engaged and disengaged on-thego for maximum versatility. When used

together, the differentials provide

100 percent driveline locking.

Inter-Axle Differential Lock. Locks all

three axles in unison and modifies

torque distribution for excellent traction

in poor underfoot conditions and on

grades. It is operated by a switch

located at the footrest.

Cross-Axle Differential Locks.

Provides full driveline locking –

all three axles and all six wheels –

for maximum performance in the most

adverse conditions. Acts in unison with

the inter-axle differential lock when

the footswitch is actuated and the

dash-mounted switch is selected.

Fast Hoist Cycle Times. Fast body raise

and lower times mean less time spent

in the dump area.

Service brake detail

Enclosed, Oil-Cooled Brakes.

Multi-plate oil-immersed brakes are

fitted to both front and center axles.

These brakes provide outstanding

stopping capability, while maintaining

maximum durability and low wear

characteristics.

Exhaust Heat System. The body comes

exhaust heat ready.

Load-Carrying Capacity. The 735 has a

large target area to provide consistently

high load-carrying capacity. Its diverging

flow design gives clean load ejection,

which maximizes production and avoids

the waste of material carry-back.

6

Performance and Productivity – Suspension and Traction Control

Suspension systems and traction control – delivering power to the ground in all conditions.

Page 7

Ride Comfort. The three-point front

suspension with its oscillating axle and

low-pressure ride struts, combined with

the center-mounted cab, offers unrivaled

levels of ride comfort for the operator

in all driving conditions. The operator

remains comfortable and productive

throughout the day.

Spacious Two-Person Cab. The 735

features a large two-person cab, offering

comfortable working space for both the

operator and trainer or trainee. All 700

Family articulated trucks use the same

spacious cab design.

Air Suspension Seat. The air suspension

seat enhances operator comfort with a

cushioned upper high back, adjustable

damping with three settings, ride zone

indicator and adjustable lumbar settings.

It is fully adjustable to provide the

optimal driving position.

Storage Space. Plenty of storage space

to create a safe, secure and uncluttered

working environment.

Trainer Seat. Full-size trainer seat features

a fully padded seat with a backrest and

a wide, retractable seatbelt for a secure

and comfortable ride. The trainer seat

is positioned next to the operator seat,

giving both the operator and trainer a

clear view of the instrument panel,

controls and the road.

Heating/Ventilation/Air Conditioning.

Twelve vents provide air distribution

to keep the operator comfortable and to

provide rapid defrosting of all windows.

Heating, air conditioning and defrosting

are standard. The recirculation filter is

positioned for easy servicing.

Radiator Mounting. The radiator is

mounted at an angle to prevent heat

transfer to the cab.

Dual-Sliding Window. The right-hand

window is a dual-sliding window.

Opening this window with the left

rear hinged window provides crossflow ventilation and enhanced

operator comfort.

Sound Levels. Cab mounts are designed

to reduce noise and vibration in the cab.

All connections to the cab are resiliently

mounted. The operator’s station makes

extensive use of sound-absorbing and

barrier materials to keep sound levels low.

Steering Column. A comfortable driving

position is provided by a telescopic and

tilt steering column.

7

Operator Comfort

The operator’s office – high productivity from a comfortable, motivated operator.

Page 8

Ergonomic Layout. The controls and

layout of the cab are designed to make

it as easy to operate as your car. Quick,

easy to read and simple to operate, the

controls and gauges on the 735 allow

the operator to concentrate on production.

Dash. The Generation II wrap-around

dash puts all controls within easy reach of

the operator. Featuring LED illuminated

rocker switches, large LCD display and a

rear wash wipe rocker switch. It provides

an automotive feel with the industrial

strength you would expect from

Caterpillar.

Viewing Area. The low sloping hood

and placement of the cooling package

behind the cab give the operator excellent

all-around visibility. The large glass

area and central operator position also

provide excellent visibility.

Wipers. The wet arm wiper system

cleans more glass area and is bottommounted to keep it out of the operator’s

line of sight. Windows are tinted to

reduce glare.

Differential Lock Controls. The inter-axle

differential lock is engaged/disengaged

by using a raised switch incorporated into

the drivers foot rest, for ease of operation.

For 100% lock up, all three cross-axle

differential locks act in unison with the

inter-axle differential lock when the foot

switch is activated and a dash mounted

switch is selected. Disengaging the foot

switch opens all differential locks

immediately.

Transmission and Hoist Levers.

The hoist lever provides easy, comfortable

operation. The transmission lever offers

excellent comfort, along with the control

for top gear limit, transmission hold

and neutral lock.

Suspended Pedals. Easy to operate and

reach with plenty of leg and foot room.

Suspended pedals also make it easier

to clean the cab floor by keeping the

pedals out of the dirt.

Cat 2S Machine Monitoring System.

Provides an improved method of

monitoring critical machine functions

and alerts the operator to an immediate

or impending problem. The system

provides four levels of warning.

8

Ease of Operation

Designed for simple, easy operation, the 735 allows the operator to focus on production.

Page 9

Front Frame. The front frame design

features a large box section and wide,

stiff frame beams to handle torque loads.

The divergent frame design decreases

stress in the hitch area and optimizes

suspension geometry. The frame design

makes maximum use of robotic welding

for increased durability.

Rear Frame. Twin-box construction

minimizes stress concentrations and

provides low weight with long

service life.

Castings. Both front and rear frames make

extensive use of heavy-duty steel castings.

Suspension. Three-point oscillating axle

front suspension provides unparalleled

ride quality. It also protects the truck

from the most adverse road conditions

by absorbing shock loads that would

otherwise reach the frame.

Articulating/Oscillating Hitch.

The articulating hitch provides the

truck with steering articulation, and

the oscillation ensures all-wheel ground

contact in rough terrain.

Hitch Construction. Two-piece bolted

hitch features a strong, durable cast steel

head bolted to a hard-wearing forged

steel tube. The hitch tube has hardened

bearing areas and a hardened thrust face

for reduced maintenance and longer life.

Steer Cylinders In-Line with Hitch.

Steer cylinders are in-line with the hitch,

minimizing steer loads and stress in the

hitch area.

Service Brakes. Oil-cooled, multiple

disc brakes are continuously cooled

for exceptional, non-fading braking.

They are designed and built for reliable,

adjustment-free operation.

Parking Brake. Located on the center

axle in an elevated position out of the

dirt and designed to deliver high heat

capacity and abuse resistance.

Cat Power Train Components. All major

components have been purpose-designed

for earthmoving applications. In fact,

many of the major components have

been designed specifically for

articulated trucks.

Radiator Protection. The radiator is

located behind the cab for improved

visibility. This design incorporates

three levels of protection:

1) Body Spill Guard.

2) Cab Steel Spill Guard.

3) High-Strength Surround.

9

Durability and Reliability

High availability leads to high productivity. Excellent durability keeps ownership costs low.

Page 10

Long Service Intervals. Long engine oil

change and hydraulic oil change intervals

lower maintenance costs and downtime.

Wheel-bearing adjustment is completely

eliminated.

Lube Points. Lube points are grouped at

the rear of the front frame and the front

of the rear frame. Universal joints are

lubed for life, eliminating servicing.

Autolube is optional.

Service Points. Engine dipstick and

fuel cap, air and fuel filters and the fuel

priming pump are all mounted on the

left side of the engine under the hood,

with the transmission dipstick and filler

on the right side. Coolant level indicator

and fill cap are outside the cab.

Radiator. The radiator package is located

behind the cab, which provides easy

access to the inlet and outlet sides of

the radiator. The ATAAC radiator is

located at the front of the truck.

Extended Life Coolant. Extends the

change interval and improves component

life by reducing aluminum corrosion.

Hood. The hood is raised and lowered

electrically, minimizing operator effort

when servicing the machine.

Electrical Service Center. Located inside

the cab, this service center provides a

power port, diagnostic connector and

Cat Data Link connector.

Cat Data Link Connector. The Cat Data

Link connector provides a plug-in using

a laptop computer with Electronic

Technician (ET) software. The Cat Data

Link port performs programming

functions on all electronic controls.

Service Access. The cab tilts to the side

to provide easy access underneath, which

simplifies servicing of the transmission,

drive shafts and hydraulic pumps.

Machine electrical and hydraulic

interfaces are located on the right side

of the cab, behind a removable cab

body panel for easy access.

Integrated Transmission Package.

The transmission integrates the

transmission pump and torque converter

into a single package. Because the

transmission is an integral design, it

eliminates many of the external hoses,

resulting in less servicing and higher

reliability.

Engine and Transmission Removal.

The front frame design allows the

engine and transmission to be removed

and installed in one piece.

Truck Transport. The suspension

system eliminates the need to lower the

suspension when transporting the truck,

reducing maintenance and downtime.

Output Transfer Gear. Provides lubrication

of all bearings and clutches using a

distributed-pressure lubricated and

filtered system. Better lubrication and

filtration reduce service and repair.

10

Serviceability

More time on production, less time and money spent on servicing.

Page 11

Selection. Make detailed comparisons

of the machines you are considering

before you buy. What are the job

requirements, machine attachments

and operating hours? What is your need

for machine availability and do you

have the proper loading tool match?

Your Cat dealer can help.

Custom Products. The 735 is compatible

with a wide range of Caterpillar and

auxiliary equipment manufacturers’

specialized products. For more

information, contact your local

Cat dealer.

Purchase. Look past the initial price,

look at the value the 735 offers.

Consider the resale value, compare

productivity and day-to-day operating

costs and fuel consumption. Consult your

local Cat dealer for financing options.

Operation. For the best operating

techniques to increase productivity

and your profit, turn to your Cat dealer

for the latest training literature and

trained staff.

Maintenance. Repair option programs

guarantee the cost of repairs up front.

Diagnostic programs such as S•O•S

SM

and Technical Analysis help you avoid

unscheduled repairs.

Replacement. Repair or rebuild?

Cat articulated trucks are designed for

longer life with rebuildable components.

Your Cat dealer can help you evaluate

the cost involved so you can make the

right choice.

Product Support. The 735 offers easy

maintenance with combined service

points and extended service intervals

to keep the machine running longer.

Your local Cat dealership will be

with you every step of the way with its

unsurpassed worldwide parts support,

trained technicians and customer

support agreements.

Warranty. Your local Cat dealer is there

to support and protect you. Extended

warranty options are also available.

www.cat.com. For more complete

information on Cat products, dealer

services and industry solutions, visit

us on the Web at www.cat.com.

11

Complete Customer Support

Cat dealer services help you operate longer with lower costs.

Page 12

12

735 Articulated Truck specifications

Sound Levels

Interior Cab 79 dB(A)

• Operator sound exposure Leq (equivalent sound pressure

level) measured according to work cycle procedures

specified in ANSI/SAE J1166 OCT 98 is 79 dB(A), for the

cab offered by Caterpillar, when properly installed and

maintained and tested with doors and windows closed.

• Hearing protection may be needed when operating with an

open operator station and cab (when not properly maintained

or doors/windows open) for extended periods or in noisy

environments.

Operating Weights

Front Axle – Empty 18 997 kg 41,881 Ib

Center Axle – Empty 6534 kg 14,406 Ib

Rear Axle – Empty 5860 kg 12,919 Ib

Total – Empty 31 391 kg 69,206 Ib

Front Axle – Rated Load 3364 kg 7,417 Ib

Center Axle – Rated Load 14 668 kg 32,337 Ib

Rear Axle – Rated Load 14 668 kg 32,337 Ib

Total – Rated Load 32 700 kg 72,091 Ib

Front Axle – Loaded 22 361 kg 49,298 Ib

Center Axle – Loaded 21 202 kg 46,743 Ib

Rear Axle – Loaded 20 528 kg 45,256 Ib

Total – Loaded 64 091 kg 141,297 Ib

Body Plate Thickness

Front 8 mm 0.31 in

Scow 14 mm 0.55 in

Side 12 mm 0.47 in

Base 14 mm 0.55 in

Service Refill Capacities

Fuel Tank 560 L 148 gal

Cooling System 95 L 25.1 gal

Hydraulic System 328 L 86.6 gal

Engine Crankcase 40 L 10.6 gal

Transmission 85 L 22.5 gal

Final Drives/Differential 80 L 21.1 gal

Output Transfer Gear Box 24 L 6.3 gal

Engine

Engine Model Cat®C15 ACERT™

Gross Power – SAE J1995 324 kW 435 hp

Net Power – SAE J1349 313 kW 419 hp

Net Power – ISO 9249 319 kW 424 hp

Net Power – EEC 80/1269 319 kW 424 hp

Bore 137 mm 5.4 in

Stroke 171.5 mm 6.75 in

Displacement 15.2 L 926 in

3

• The power ratings apply at rated speed of 1,700 rpm when

tested under the conditions for the specified standard.

• The net power advertised is the power available at the

flywheel when the engine is equipped with alternator, air

cleaner, muffler and fan at minimum speed.

• Net power when the fan is at maximum speed is 304 kW

(407 hp) per the SAE reference conditions.

• The 735 meets EPA Tier 3/EU Stage 3a emission

specifications for the U.S. and Europe through 2010.

• No engine derating required below 2438 m (8,000 ft).

Weights

Rated Payload 32.7 tonnes 36 tons

Body Capacities

Heaped SAE 2:1 19.7 m

3

25.8 yd

3

Struck 14.5 m

3

19.0 yd

3

Heaped SAE 1:1 24.5 m

3

32.0 yd

3

Transmission

Forward 1 8.29 km/h 5.15 mph

Forward 2 11.33 km/h 7.04 mph

Forward 3 15.37 km/h 9.55 mph

Forward 4 20.66 km/h 12.84 mph

Forward 5 28.01 km/h 17.41 mph

Forward 6 37.78 km/h 23.48 mph

Forward 7 51.25 km/h 31.85 mph

Reverse 1 8.00 km/h 4.97 mph

Reverse 2 10.84 km/h 6.74 mph

Page 13

13

735 Articulated Truck specifications

Standards

Brakes SAE J/ISO 3450-1998

Cab/FOPS SAE J231 JAN81 and

ISO 3449-1992 Level II

Cab/ROPS SAE J1040 May 1994 and

ISO 3471-1994

Steering ISO 5010 1992E

Body Hoist

Raise time 11 Seconds

Lower time 7 Seconds

Page 14

14

735 Articulated Truck specifications

Turning Circle

Dimensions are for machines equipped

with 26.5R25 tires.

Turning dimensions

Dimensions

Steer angle — left/right 45°

SAE turning radius 8138 mm 320.4 in

Clearance radius 8595 mm 338.4 in

Inside radius 4182 mm 164.7 in

Aisle width 5637 mm 221.9 in

Steering

Lock to Lock 4.6 seconds @ 60 rpm

6809 mm

22.3'

2982 mm

635 mm

9.8'

2'

°70

1458 mm

4.7'

6088 mm

5467 mm

1966 mm

6.4'

20.0'

17.9'

Inside

of Body

534 mm

1.7'

4244 mm

13.9'

10 889 mm

35.7'

3221 mm

10.5'

3690 mm*

12.1'

3328 mm

10.9'

3703 mm

12.1'

2687 mm

8.8'

3353 mm

* If equipped with a scissor tailgate.

11.00'

Optimal Loader/Truck Pass Matching

Hydraulic Excavators 385C 365C 345C

Loader Capacity (Tonnes) – 50 min hr 954-1193 750-1100 665-805

Loader Capacity (Tons) – 50 min hr 1049-1314 825-1210 735-885

Passes 3 4 5

Wheel Loaders 988H 980H 972H 966H 962H

Loader Capacity (Tonnes) – 50 min hr 565-790 590-650 490-565 400-535 325-400

Loader Capacity (Tons) – 50 min hr 625-870 650-715 540-625 440-590 360-440

Passes 3 3-4 4-5 5 6

An optimum system match gives you a major productivity advantage. The 735 is an excellent match for the Cat 385C, 365C and

345C Hydraulic Excavators; and Cat 966H, 972H, 980H and 988H Wheel Loaders. This results in increased production and lower

system costs per unit of volume moved.

Page 15

15

735 Articulated Truck specifications

Gradeability/Speed/Rimpull

To determine performance, read from

Gross Weight down to % Total Resistance.

Total Resistance equals actual % grade plus

1% for each 10 kg/metric ton (20 lb/ton) of

Rolling Resistance. From this point, read

horizontally to the curve with the highest

attainable speed range. Then, go down to

Maximum Speed. Usable Rimpull depends

on traction available.

kg x 1000

110

50

100

45

90

40

80

35

70

30

60

25

50

20

RIMPULL

1A — 1st Gear

1B — 1st Gear

2 — 2nd Gear

40

15

30

10

20

5

10

0

0

(Converter Drive)

(Direct Drive)

STANDARD*

GROSS WEIGHT

0

5 10 15 20 25 30 35 40 45 50 55 60 65 70

20 40 60 80 100 120 140

0

lb x 1000

E

L

1A

1B

2

3

4

5

6

0 5 10 15 20 25 30 35

0102030

7

40

50 60

SPEED

3 — 3rd Gear E — Empty 31 391 kg (69,206 Ib)

4 — 4th Gear

5 — 5th Gear

6 — 6th Gear

7 — 7th Gear

L — Loaded 64 090 kg (141,297 Ib)

* at sea level

kg x 1000

lb x 1000

40%

35%

30%

25%

20%

15%

10%

5%

mph

km/h

TOTAL RESISTANCE %

(GRADE PLUS ROLLING RESISTANCE)

Retarding Performance

To determine performance, read from

Gross Weight down to % Effective Grade.

Effective Grade equals actual % favorable

grade plus 1% for each 10 kg/metric ton

(20 lb/ton) of Rolling Resistance. From this

point, read horizontally to the curve with

the highest attainable speed range. Then, go

down to Maximum Speed. Retarding effect

on these curves represents full application of

the retarder.

GROSS WEIGHT

010203040 7050 60

0 20 40 60 80 100 120 140 160

1

EL

2

3

4

5

6

0 5 10 15 20 25 30 35 40

0102030405060

SPEED

1 — 1st Gear

2 — 2nd Gear

3 — 3rd Gear

4 — 4th Gear

5 — 5th Gear

6 — 6th Gear

7 — 7th Gear

E — Empty 31 391 kg (69,206 Ib)

L — Loaded 64 090 kg (141,297 Ib)

kg x 1000

lb x 1000

35%

30%

25%

20%

15%

10%

7

5%

% EFFECTIVE GRADE (FAVORABLE)

mph

km/h

Page 16

16

735 Articulated Truck specifications

Standard Equipment

Standard equipment may vary. Consult your Caterpillar dealer for details.

Seat, fully adjustable, air suspension

Seat, padded companion/trainer

Seatbelts, two retractable

Secondary steering – electronic

S•O•SSMsampling valves

Spill guard, front, integral part of fabricated body

Starting receptacle, electric, remote

Storage – two cup holders, flask receptacle, under seat storage,

door pocket, behind seat storage, coat hook

Sun visor

Three-axle, six wheel drive

Tilt and telescopic steering wheel

Tires, 26.5R25, radial

Tow pins, front and rear

Vandalism protection: lockable caps for fuel tank and

hydraulic oil tank

Windows, opening side, tinted

Windshield wiper and washer, two speed, intermittent (front)

Windshield wiper and washer, two speed (rear)

Air conditioning with R134A refrigerant

Air vents, adjustable

Auto shift seven-speed forward and two speed reverse

transmission

Back up alarm

Body, adapted for exhaust heat

Cat C15 engine with ACERT Technology

CD/Radio ready

Differentials, standard with clutched cross-axle differential

locks for all axles

Electrical system: 24 volt, 5A 24- to 12-volt converter

Electro hydraulic hoist control

Engine compression brake

Ether starting aid

Glass windows, laminated and tinted, front

Glass windows, toughened and tinted, sides and rear

Guards: rear window radiator, crankcase and axle

Headlights, four

Heater and defroster with four-speed fan

Horn, electric

Lights: cab interior, front, side rear, two reversing/working

lights, two stop/tail lights, front and rear direction indicators

Mirrors, main and auxiliary, left and right

Mud flaps, wheel arch and body mounted, with transportation

tie backs

Oil-cooled brakes, enclosed

ROPS/FOPS cab, with full instrumentation, including:

– Instrument cluster display module.

– Indicator lamps: left turn, secondary steering, primary

steering loss, front and rear brake temp (735/740 and

740 Ejector only), brake oil pressure, action lamp,

transmission fault, park brake, charging system status,

differential lock, body not in float, right turn, high beam,

transmission hold, machine filter warning, retarder,

retarder up shift warning

– Gauges: engine oil pressure, engine coolant temperature,

torque converter oil temperature, fuel level, and fuel tank

level gauge

– Meters: service hour meter, speedometer, tachometer

Page 17

17

735 Articulated Truck specifications

Optional Equipment

Optional equipment may vary. Consult your Caterpillar dealer for details.

Exhaust heated body

Fast fuel fill

Flashing Xenon Beacon

Heated rear-view mirrors

Product Link, Radio and Worldwide

Tailgate:

– Scissor-type

Autolube installation for automatic greasing of bearings

Bath oil, pre-cleaner

Body liners

Caterpillar Work Area Vision System (WAVS)

rear-view camera

CD/Radio, heavy duty

Cold weather start attachment

Cycle counter/operator monitoring kit

Page 18

735 Articulated Truck specifications

18

Notes

Page 19

735 Articulated Truck specifications

19

Notes

Page 20

For more complete information on Cat products, dealer services,

and industry solutions, visit us on the web at www.cat.com

© 2007 Caterpillar

All Rights Reserved

Printed in U.S.A.

Materials and specifications are subject to change without notice.

Featured machines in photos may include additional equipment.

See your Caterpillar dealer for available options.

CAT, CATERPILLAR, their respective logos, “Caterpillar Yellow” and the

POWER EDGE trade dress, as well as corporate and product identity used herein,

are trademarks of Caterpillar and may not be used without permission.

AEHQ5648-03 (4-07)

Replaces AEHQ5648-02

735 Articulated Truck

R

Loading...

Loading...