Page 1

(with price)

INDEX

LCD VIDEO MONITOR

VM-570B

JUNE 1994

Page

Specifications.............................................................................................1

Block Diagram ...........................................................................................2

Power Supply.............................................................................................3

Adjustment

Linear PCB..........................................................................................4

A/D PCB..............................................................................................6

Printed Circuit Boards................................................................................7

Wiring Diagram........................................................................................10

Electrical Parts List ..................................................................................11

Mechanical Parts List...............................................................................16

Exploded View / Disassembly..................................................................17

Waveforms...............................................................................................18

Schematic Diagrams................................................................................19

R

Page 2

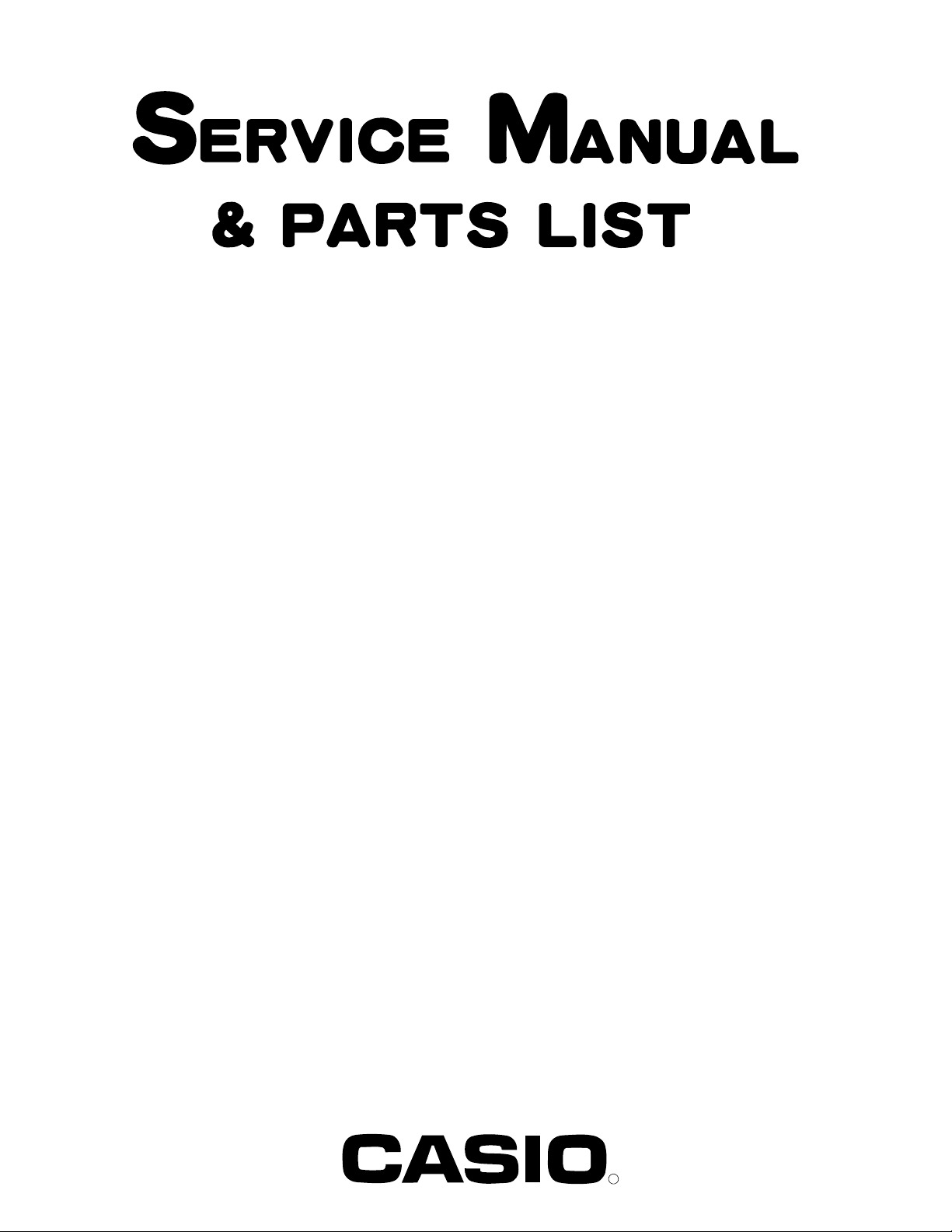

POWER SUPPLY

VCC2

VEE1

VCC7

VCC6

GND

DC 6V

from IC400

Vref

GND

C151

Q100

R101

R103

C152

Q101

Q102

R104

C153

T100

LC12U-21

2

1

9

8

D115

3

4

D116

5

D117

6

7

D118

L101

C115

C116

C117

C118

Fig. 3

The power supply consists of DC-DC converter, and causes the voltages to be output as shown in Table - 2.

Name Voltage Function

VCC2 4.0 ± 0.02V Main voltage

VCC6 48.0 ~ 72.0V Tuning voltage

VCC7 28.0 ~ 40.0V Display voltage

VEE1 -8.4 ~ -5.6V Display voltage

Table - 2

— 3 —

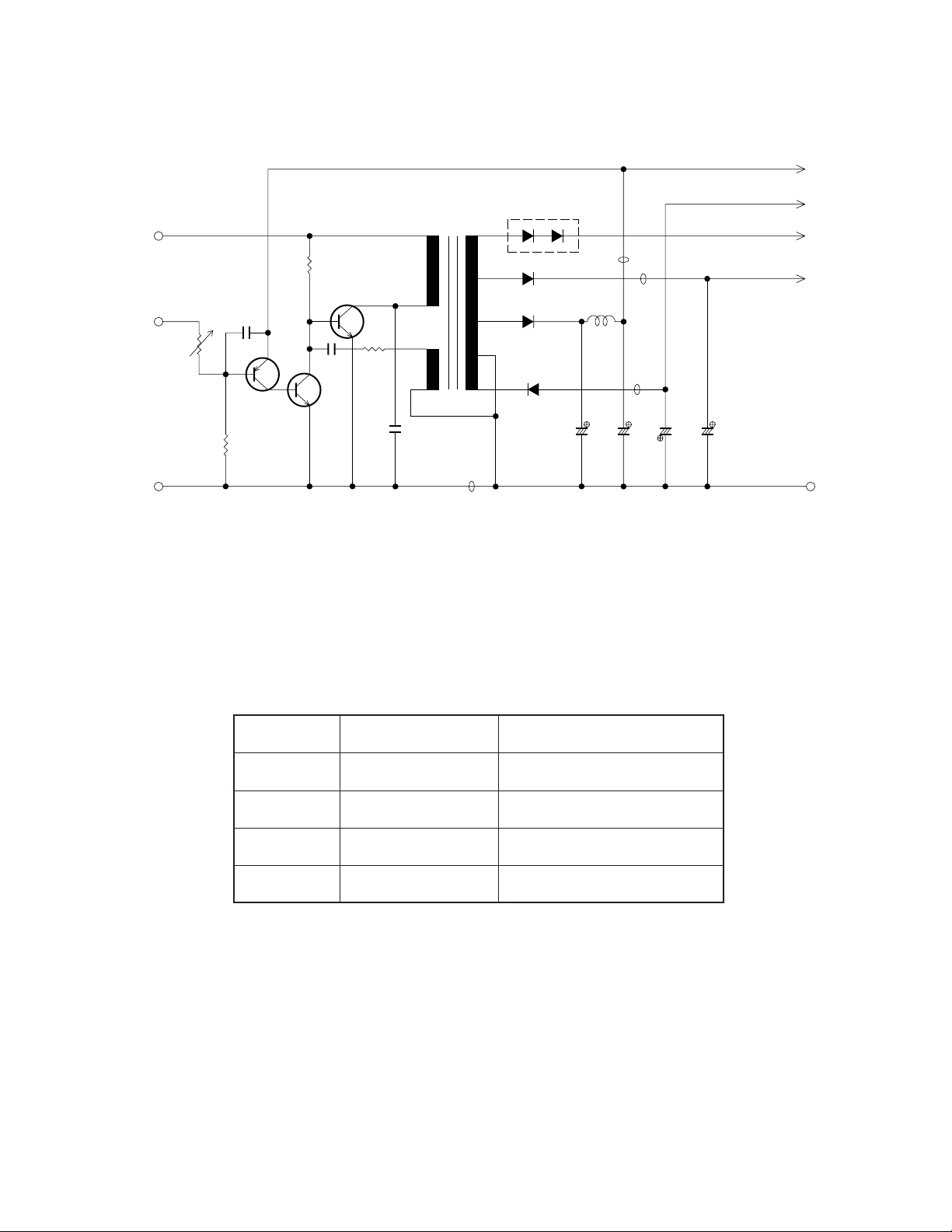

Page 3

ADJUSTMENT

Linear PCB

1) Items to Be Adjusted:

Item Measuring Instrument

VCC2 voltage setting Voltmeter

Contrast adjustment TV signal generator, Pattern generator, Oscilloscope

AGC adjustment TV signal generator, Pattern generator, IF levelmeter

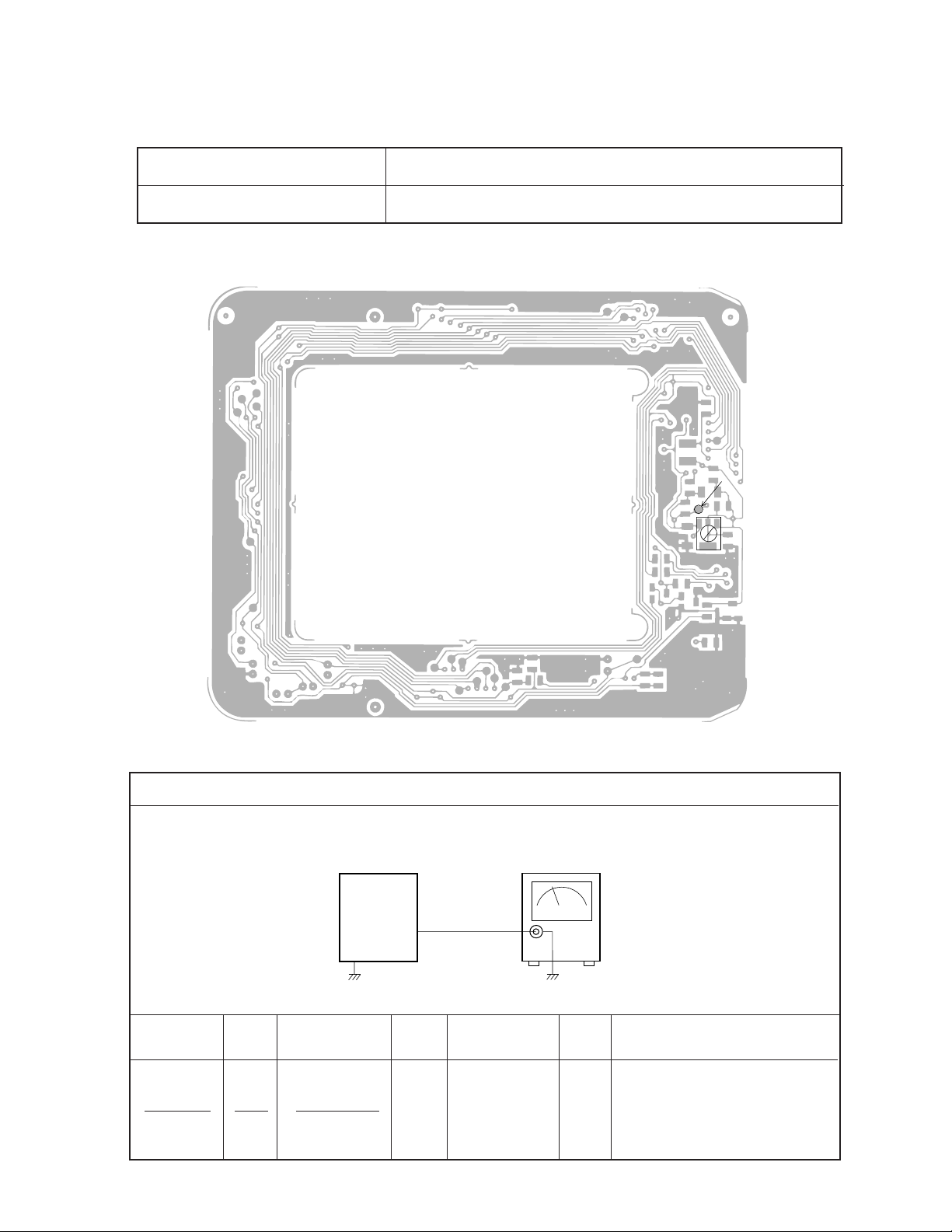

2) Adjustment and Test Point Locations:

TOP VIEW

TP1

VR100

— 4 —

Page 4

TP5

BOTTOM VIEW

TP3

R200

TP2

Pad IF

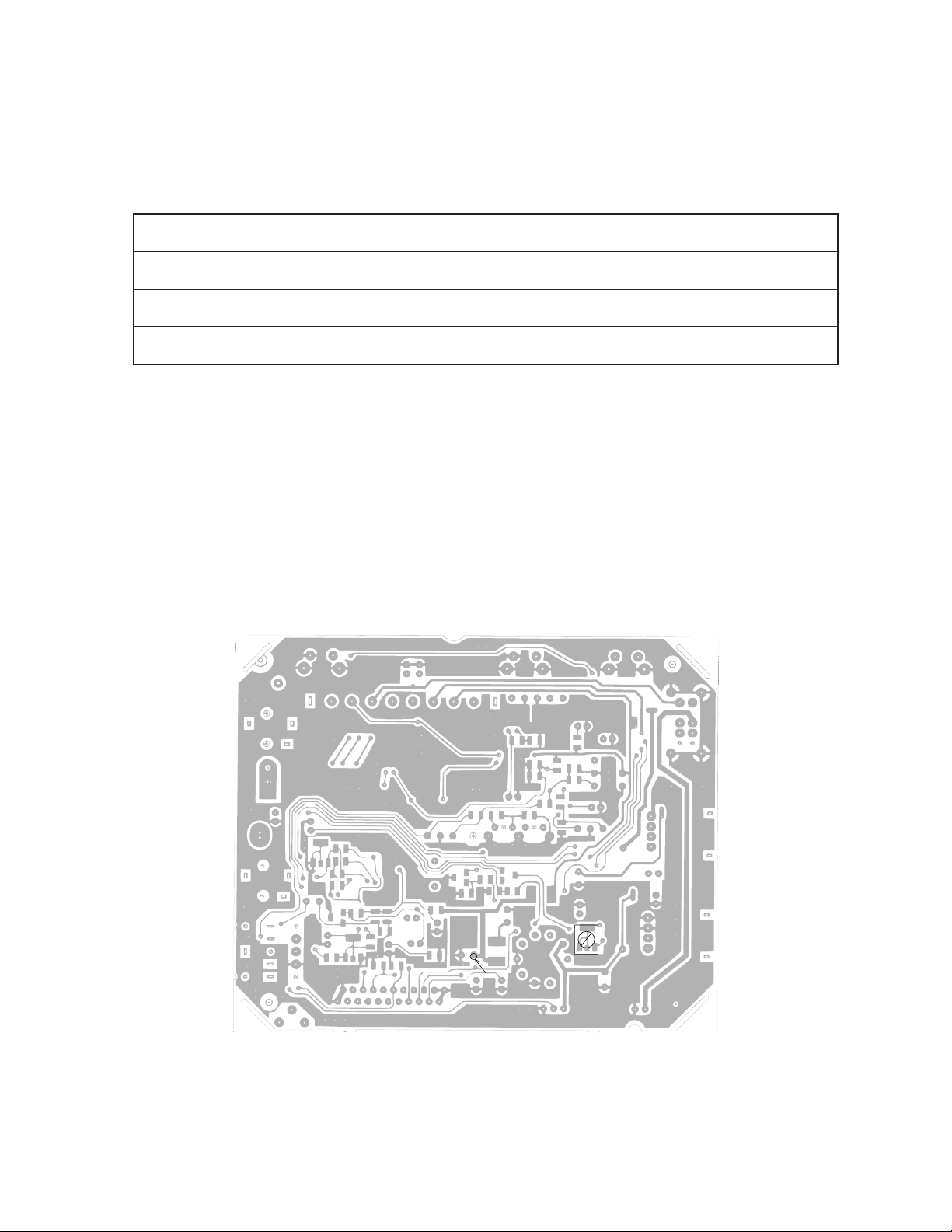

3) Equipment Connection / Procedure

Vcc2 Voltage Setting

Set

Voltmeter

Output

TP1

Input Input Input Output Output

Connection Point Signal Connection Point

Adjust Adjust for

VR100 TP1

Voltmeter

Adjust for 4.00 ± 0.02V

reading on voltmeter.

* Open soldering pad IF.

VHS

HQ

AV

Jack

Color bar

Contrast Adjustment

PLAY

Input Output

AV-C1

cord

OscilloscopeVCR VR300 TP5

— 5 —

Set Oscilloscope

TP5

Adjust step form wave to read

0.8 ± 0.05 Vp-p.

Page 5

A/D PCB

1) Item to Be Adjusted:

Item Measuring Instrument

Clock adjustment Voltmeter

2) Adjustment and Test Point Locations:

TOP VIEW

TP6

3) Equipment Connection / Procedure

Set

VR700

Clock Adjustment

Voltmeter

Output

TP6

Input Input Input Output Output

Connection Point Signal Connection Point

Adjust Adjust for

VR700

Voltmeter

— 6 —

TP6

Adjust for 2.00 ± 0.05V

reading on voltmeter.

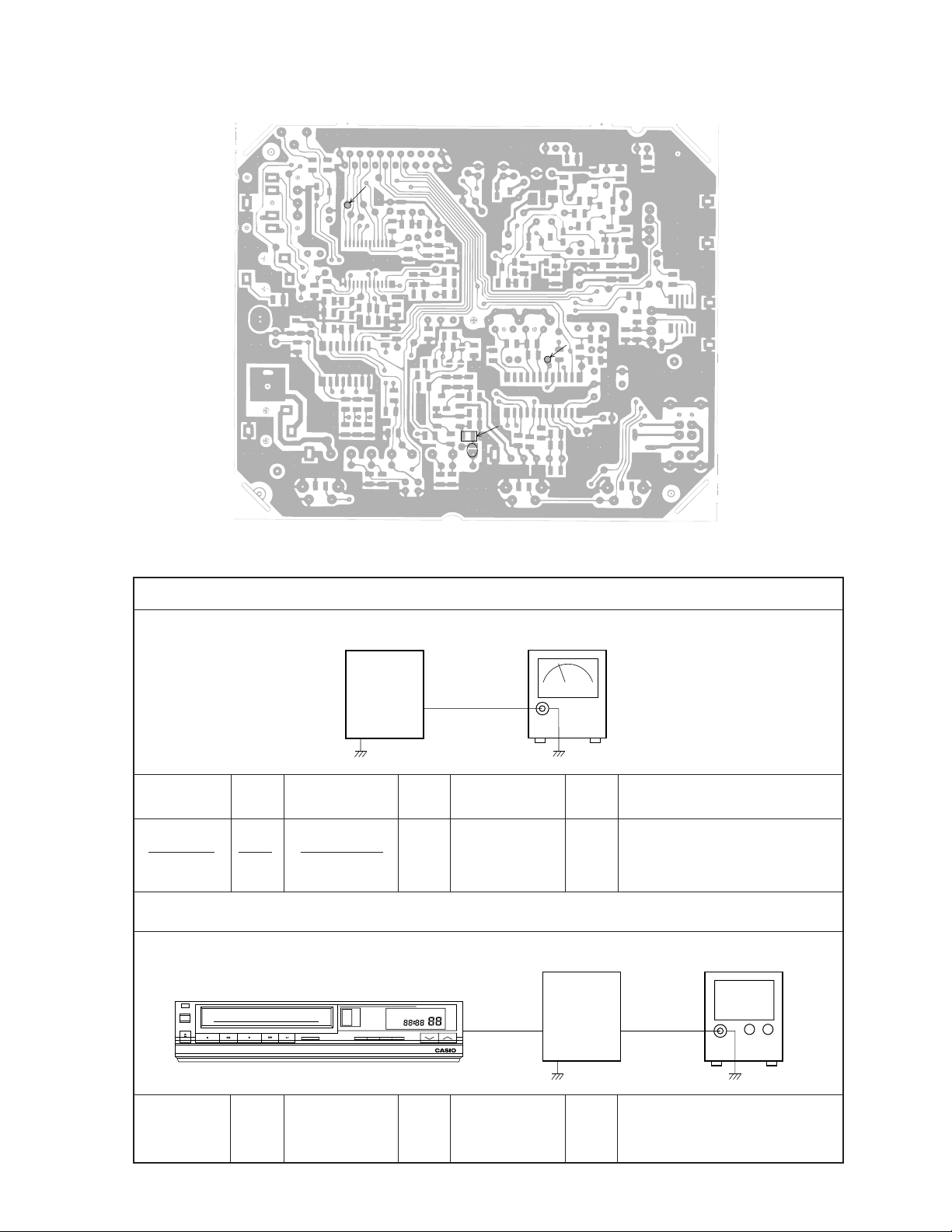

Page 6

PRINTED CIRCUIT BOARDS

Linear PCB (Top View)

C410

SW100

R321

VR301

JK600

JK250

C317

C313

R325

Q300

R329

VR

300

R308

Linear PCB (Bottom View)

R323 R322

R312

R310

R320

C356

R603

C355

C450

C357 @

IC400

R326

R327

R328

R307

R302

IC300

R314

R313

H300

C310

C312

CN700

C351

C352

R318

R317

C311

R340

R305

R304

R315

R120

R306

C350

R301

C315

C116

C119

R303

C358

R316

C359

D110

R435

C115

C117

D118

R114

L101

T100

R104

D117

D116

CN600

C190

R103

D115

C610

C118

VR

100

CN100

C110

Q102

C153

C152

Q101

Q100

R100

C151

R606 R605

R101

C653

R602

C652

C611

C612

FU100

C160

R601

VR600

VR800

R600

IC600

— 7 —

Page 7

A/D PCB (Top View)

C762

D710

C782

D730

R720

C700

C761

C781

L701

C780

VR700

R709

R721

C783

D700

C811

C813

C812

BL PCB (Top View)

C810

C815

CN300

Q900

L900

R900

Q901

C952

C850

C770

R800

T900

C710

D711

R722

R804

C953

DC PCB (Top View)

JK100

D150

— 8 —

Page 8

A/D PCB (Bottom View)

R716

R717

C776

C763

C777

IC700

C775

R704

R702 R701

R708

R707

R715

R703

R710

L700

R712

(C.D)

R711

(A.B)

R700

C771

R820

R806

C855

C772

D800

R815

R801

C860

R818

R819 R816

Q802 D810 D811

Q801

R807

R802

R803

Q806

Q805

C856

C861

R817

R808

Q800

— 9 —

Page 9

A/D PCB

WIRING DIAGRAM

Linear PCB

1

22

122

— 10 —

Page 10

EXPLODED VIEW / DISASSEMBLY

1

2

34

4

5-1

2-2

2-2

2-1

2-2

2-4

2-3

2-5

37

29

12

5

13

14

7

31

9

32

33

32

10

8

30

6

35

21

22

36

20

19

26

22

16-1

25

23-3

23-4

15

16-2

16

17

23-1

23-5

23

28

11 @@

— 17 —

Page 11

WAVEFORMS

1.0V

1 IC300 Pin 1

4 IC300 Pin 4

64µsec

64µsec

600mV

2.4V

2.5V

0.22µsec

2 IC300 Pin 23

5 IC300 Pin 5

64µsec

2.6V

2.3V

2.1V

64µsec

3 IC300 Pin 10, 11, 12

14V

3.9µsec

6 Q102 Collector

2.2V

7 Q102 Base

0 Q800 Base

4.0µsec

132µsec

420mV

8 IC700 Pin 17

A IC700 Pin 12

152nsec 547nsec

9 IC700 Pin 14

2.5V

63.5µsec

— 18 —

Page 12

Linear PCB

SCHEMATIC DIAGRAMS

2

3

1

TP5

7

6

TP1

5

4

— 19 —

Page 13

A/D PCB

10

8

11

TP6

9

— 20 —

Page 14

BL PCB

VCC1-1

To Linear PCB

GND

SP

1

EYP-1BF102L

C952

ECQ-V1H184JZ

Q900

2SD965-R

Q901

2SD965-R

L900

RCH-875-101K

T900

NT-01

5

4

3

2

112

10

C953

DE0905

SL181J2K

EYP-1BF102L

LAMP

3

2

SP

— 21 —

Loading...

Loading...