Page 1

SERVICE MANUAL

INDEX

VAN MECHELEN

www.vanmechelen.be

(without price)

UP-360

JAN. 2004

Page 2

CONTENTS

UP-360 PAGE

1. SPECIFICATIONS

1-1. PRINTING SPECIFICATION .............................................................................1

1-2. PAPER SPECIFICATION..................................................................................1

1-3. INTERFACE SPECIFICATION..........................................................................2

2. DISASSEMBLY............................................................................................ 4

3. CIRCUITRY

3-1. SYSTEM BLOCK DIAGRAM ............................................................................8

3-2. POWER SUPPLY CIRCUIT ..............................................................................9

3-3. POWER SUPPLY SPECIFICATION ...............................................................11

3-4. HD64F7045F MICROCOMPUTER..................................................................12

3-5. RESET CIRCUIT .............................................................................................20

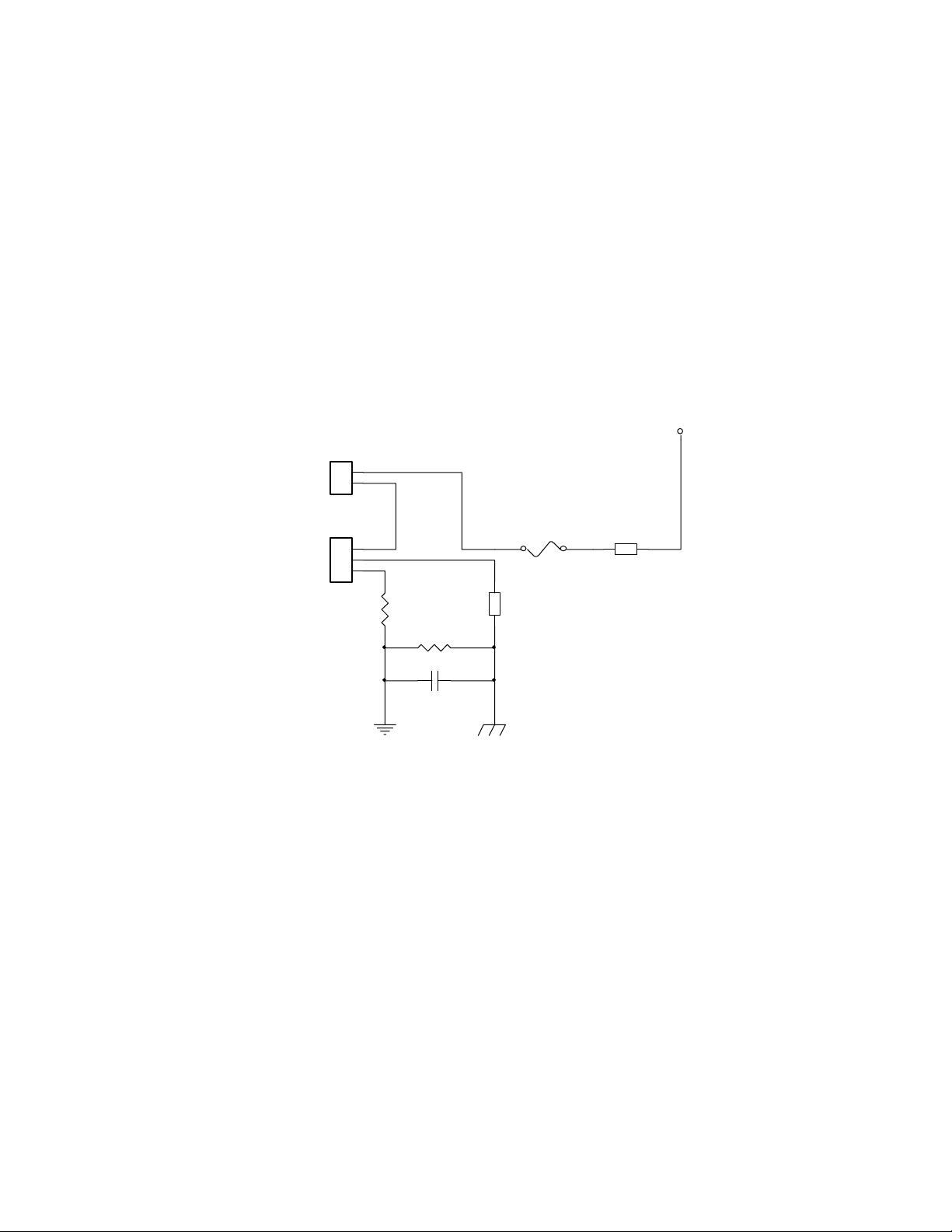

3-6. DRAWER CIRCUIT .........................................................................................20

3-7. BUZZER CIRCUIT...........................................................................................21

3-8. FLASH MEMORY CIRCUIT ............................................................................21

3-9. EXTERNAL MEMORY CIRCUIT.....................................................................22

3-10. CHARACTER GENERATOR CIRCUIT...........................................................23

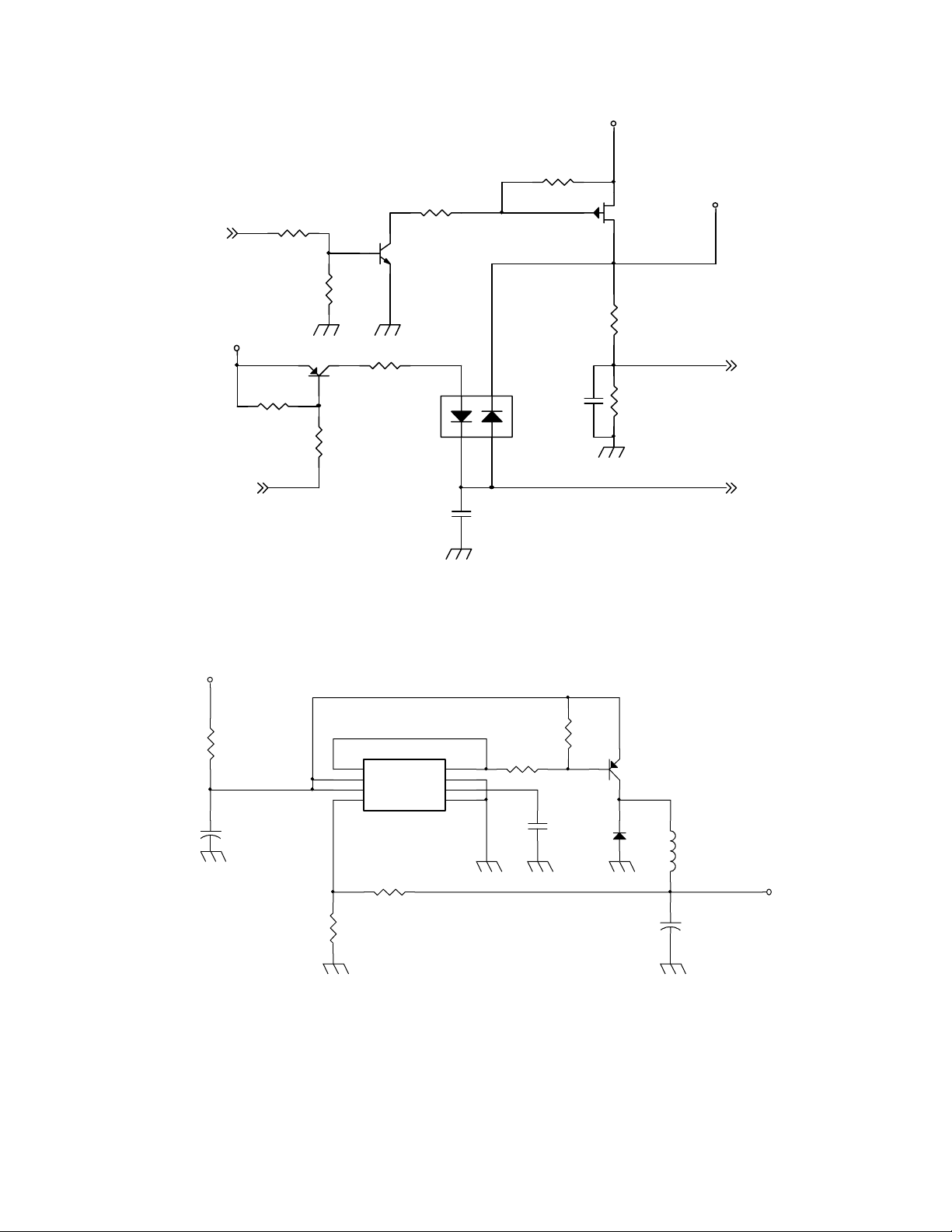

3-11. PRINTER CIRCUIT..........................................................................................23

3-12. SERIAL INTERFACE CIRCUIT.......................................................................25

4. MAINTERNANCE & TROUBLESHOOTING

4-1. INSTALLING OR REPLACING PAPER ROLL...............................................26

4-2. ADJUSTING THE PAPER NEAR END SENSOR (TH200s ONLY) ...............26

4-3. PAPER JAM....................................................................................................27

4-4. TROUBLESHOOTING ....................................................................................27

4-5. SELF TEST......................................................................................................29

5. SETTING & CHECKING THE DIP SWITCHES ........................................ 30

6. CIRCUIT DIAGRAMS................................................................................. 31

7. PARTS LIST............................................................................................... 34

Page 3

1. SPECIFICATIONS

1-1. PRINTING SPECIFICATION

Model NO. of Printer Mechanism: LTPF347A-C576 *1

Printing Method: Direct Line Thermal

Dot pitch: 8 dot / mm

Printing Speed: 210 mm per second (Max.)

Printing width: 72mm / 576 dots

Character structure: 8 x 16 (font B) 12 x 24 (font A)

Printing Columns: 69 columns / line 46 columns / line

Character Size: 1.00 x 2.00 1.50 x 3.00

Feed Speed: 220 mm per second

Interface: RS232C (serial)

Input buffer: 8k bytes

Command: ESC / POS compliant

Paper Width & Diameter: 80 mm (W) x 80 mm Dia. Max.

Thermal head life: 100 Million Pulses / 100 km or more

Cutting method: *2 ACUF324A

Partial cut(one point left uncut) *2

Auto cutter life: 500,000 cuts

Operating time of auto cutter: 600 msec max/cycle

Operating temperature: 0 °C ~ 40 °C

Storage temperature: -20 °C ~ 50 °C

Humidity: 80 %

Dimension: 145 mm (W) x 193.2 mm (L) x 120.1 mm (H)

Transfer speed: Max 38.4 kBps

Supply voltage in standby: 24V DC / 100mA

Mean voltage: Approx. 1.3 A *3

Power Consumption: Approx. 4 W *3

Weight: 1.1kg

*1 Manufactured by SIIP&S Inc. (Former name: Seiko Instruments Inc.)

*2 CAUTION: Paper must be fed 3 mm after cutting to prevent paper jam.

*3 These values vary according to environmental temperature when printed font A(12 x 24) with a rolling pattern.

1-2. PAPER SPECIFICATION

Paper Width: 79.5 ± 0.5mm (3.13 ± 0.02”)

Paper roll size: Roll diameter: Maximum 80 mm (3.15”)

Take-up paper roll width: 80 + 0.5/-1.0mm (3.15 + 0.02/-0.04”)

Specified paper: Specified thermal roll paper: NTP080-80

[Original paper:TF50KS-E2C Nippon Paper Industries Co., Ltd.]

Packaged roll paper:

[Original paper:PD160R-N (Oji Paper Mfg. Co., Ltd.)]

In Japan: Nakagawa Manufacturing Co., Ltd.

In U.S.A: Nakagawa Mfg. (U.S.A.) Inc.

In Europe: Nakagawa Mfg. (Europe) GmbH

In Southeast Asia: N.A.K. Mfg. (Malaysia) SDN BHD

*The following paper can be used instead of the paper above:

Original paper: HP220AB1 (Mitsubishi Paper Mills Ltd.)

Paper roll spool diameter: Inside 12 mm (0.47”)

Outside 18 mm (0.71”)

NOTE:The end of the paper roll must be free to come off the spool when finished. It must not be adhesively

attached or attached in another semi-permanent manner.

— 1 —

Page 4

1-3. INTERFACE SPECIFICATION

1-3-1. RS-232 SERIAL INTERFACE SPECIFICATION

Data transmission: Serial. EIA RS232C compliant

Synchronization: Asynchronous

Handshaking: DTR/DSR or XON/XOFF control (*)

Signal levels: MARK = -3 to -15V: Logic “1”/OFF

SPACE = +3 to +15V: Logic “0”/ON

Baud rate: 9600, 19200, 38400bps (*)

Data word length: 8 bits

Parity Settings: None, even, odd (*)

Stop bits: 1 or more

Connector (printer side): Female DSUB-25 pin connector

Notes: *The data word length, baud length, and parity depend on the DIP switch settings. (Refer to

5.SETTING & CHECKING THE DIP SWITCHES.)

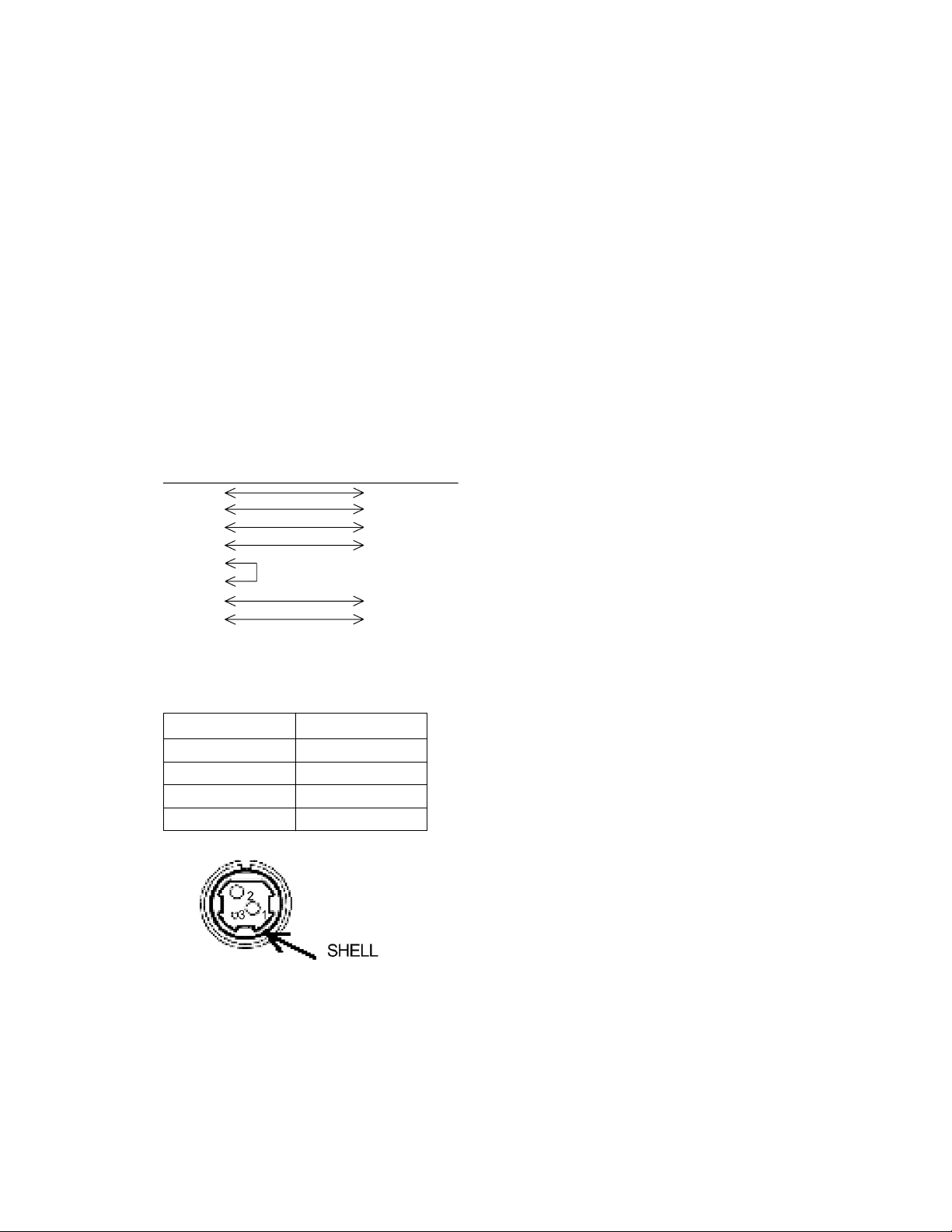

1-3-2. SERIAL INTERFACE CONNECTION EXAMPLE

HOST SIDE PRINTER SIDE

(DTE ex.8251) (Pin No.)

TxD RxD (3)

RxD TxD (2)

DTR DSR (6)

DSR DTR (20)

RTS

CTS

GND GND (7)

FG FG (1)

1-3-3. POWER SUPPLY CONNECTOR

The connector is connected the printer to an external power source.

CONNECTOR MODEL:

PIN SIGNAL

1 +24V

2 GND

3NC

SHELL F. G

Printer side: Hosiden TCS7960-532010 or equivalent

User side: Hosiden TCP8927-631100 or equivalent

Hosiden TCP8927-531100 or equivalent

— 2 —

Page 5

1-3-4. DRAWER KICK-OUT CONNECTOR

The pulse specified by ESC p or DLE DC4 is output to this connector. The HOST can confirm the status

of the input signal by using the DLE EOT, GS a, or GS r commands.

PIN I/O DESCIPTION

1 - Frame ground

2 Output Drawer kick-out drive signal 1

3 Input Drawer open/close signal

4 Output +24 V

5 Output Drawer kick-out signal 2 *

6 - Signal ground

* Two drawers can be used with a Y-cable that meets the following specifications.

Pin 1: Frame ground ............................................................ Pin1

Pin 2: Drawer kick-out drive signal 1 ................................... Pin2

Pin 3: Drawer open/close signal .......................................... Pin3 Connector of Drawer No.1

Pin 4: +24V .......................................................................... Pin4

Pin 5: Drawer kick-out signal 2 .................... ......... Pin6

Pin 6: Signal ground Pin6 ............. ............................. Pin1

........................ Pin2

................... Pin3 Connector of Drawer No.2

.............. Pin4

....................................... Pin6

CONNECTIOR MODEL:

Printer side: MOLEX52065-6615 or equivalent

Used side: 6-position 6-contact (RJ12 telephone jack)

— 3 —

Page 6

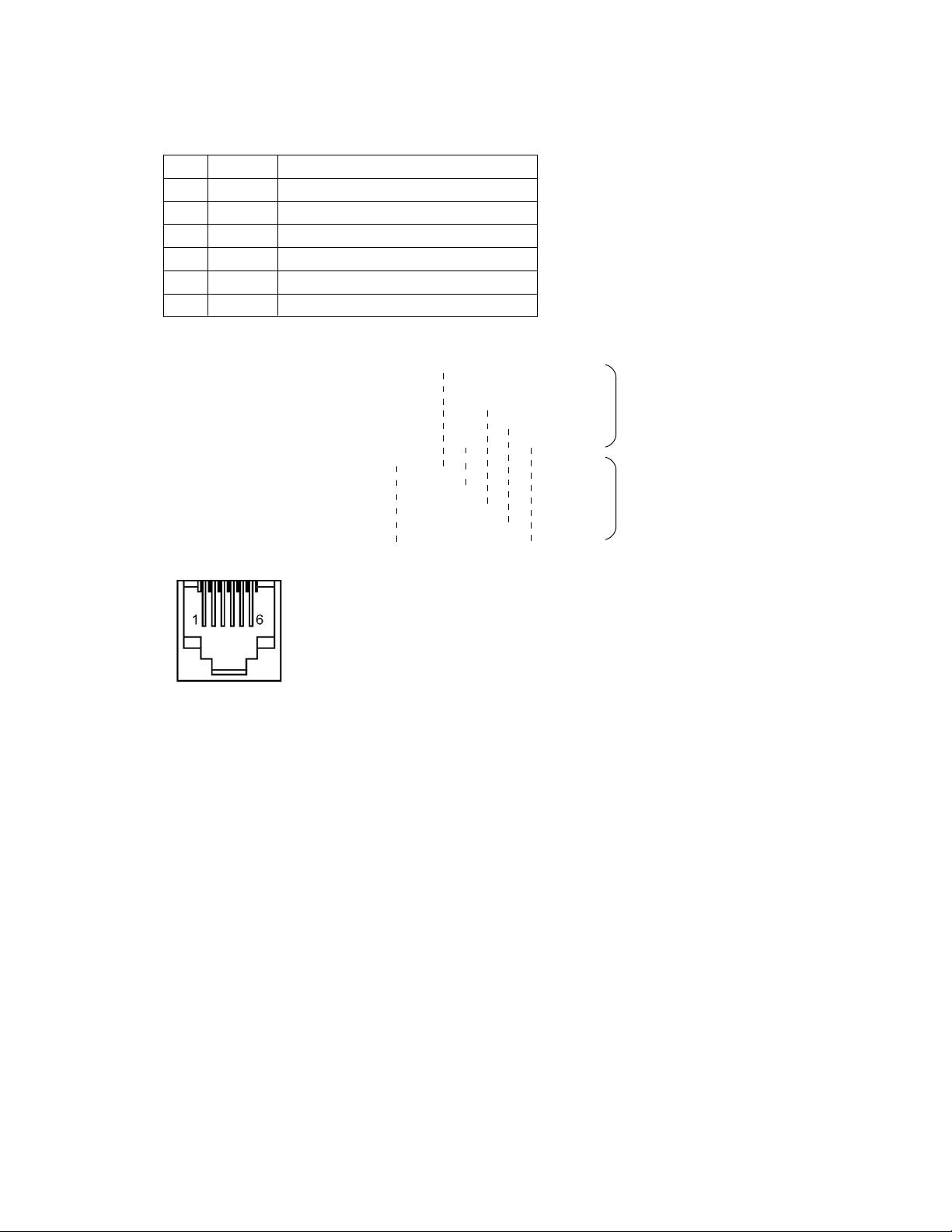

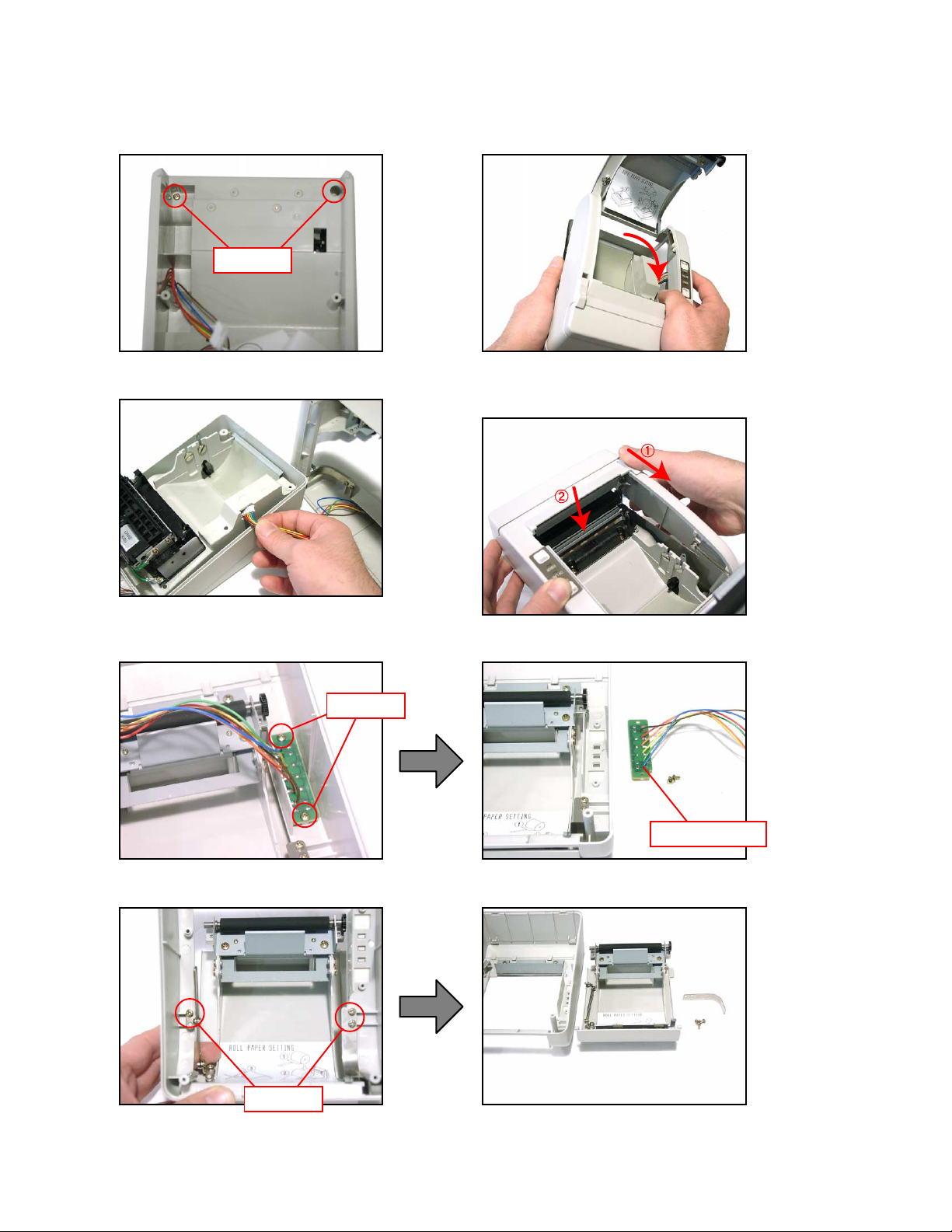

2. DISASSEMBLY

1. Remove the four screws at the bottom of the printer unit.

2. Remove the cable tie.

Screws

3. Remove the two connectors and two screws (CN5, CN6).

Cable tie

CN6

(To Power Switch)

CN5

(To Contorl Panel)

(Earth wires for the printer and the auto cutter)

(An earth wire for the NE sensor)

Precaution when assembling:

Bend the rug terminal in L shape and put it inside the PCB.

NG example

The rug terminal faces outward.

Screw

Screw

4.Remove the three connectors (CN, CN2, CN3) and the FPC (J1), and then remove the main PCB.

CN3

(To NE Sensor)

CN2

(To Auto Cutter)

CN

(To Printer Motor)

— 4 —

FFC (J1)

Page 7

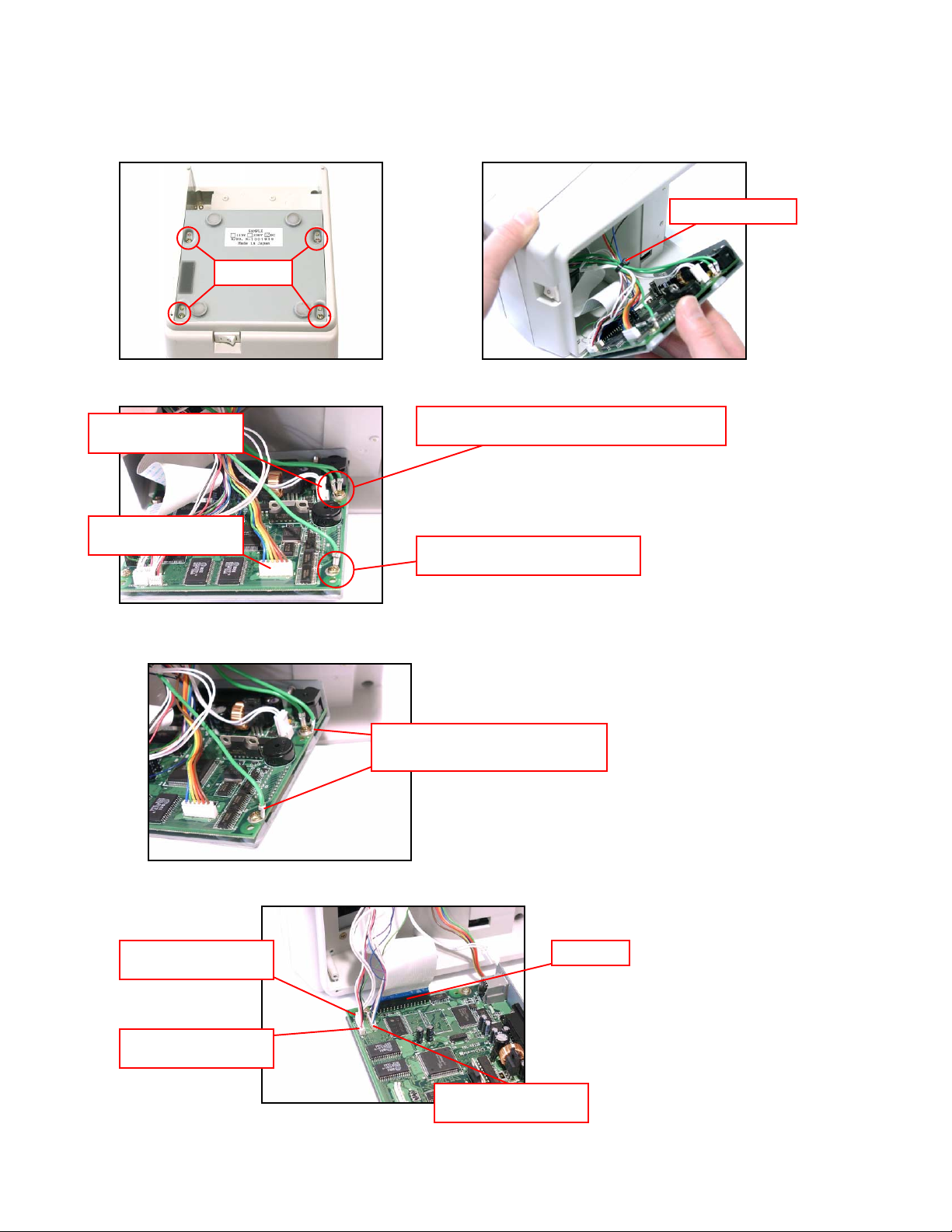

5. Remove the two screws.

6. Remove the upper cover while the printer cover is open.

Screws

Precaution when assembling:

Let the connector through the hole.

7. Remove the two screws and then the control panel.

Screws

Precaution when assembling:

Slide the lever of the cover to “close” and then fit the

upper cover into the printer.

8. Remove the three screws and then the printer cover.

Screws

— 5 —

Control Panel

Page 8

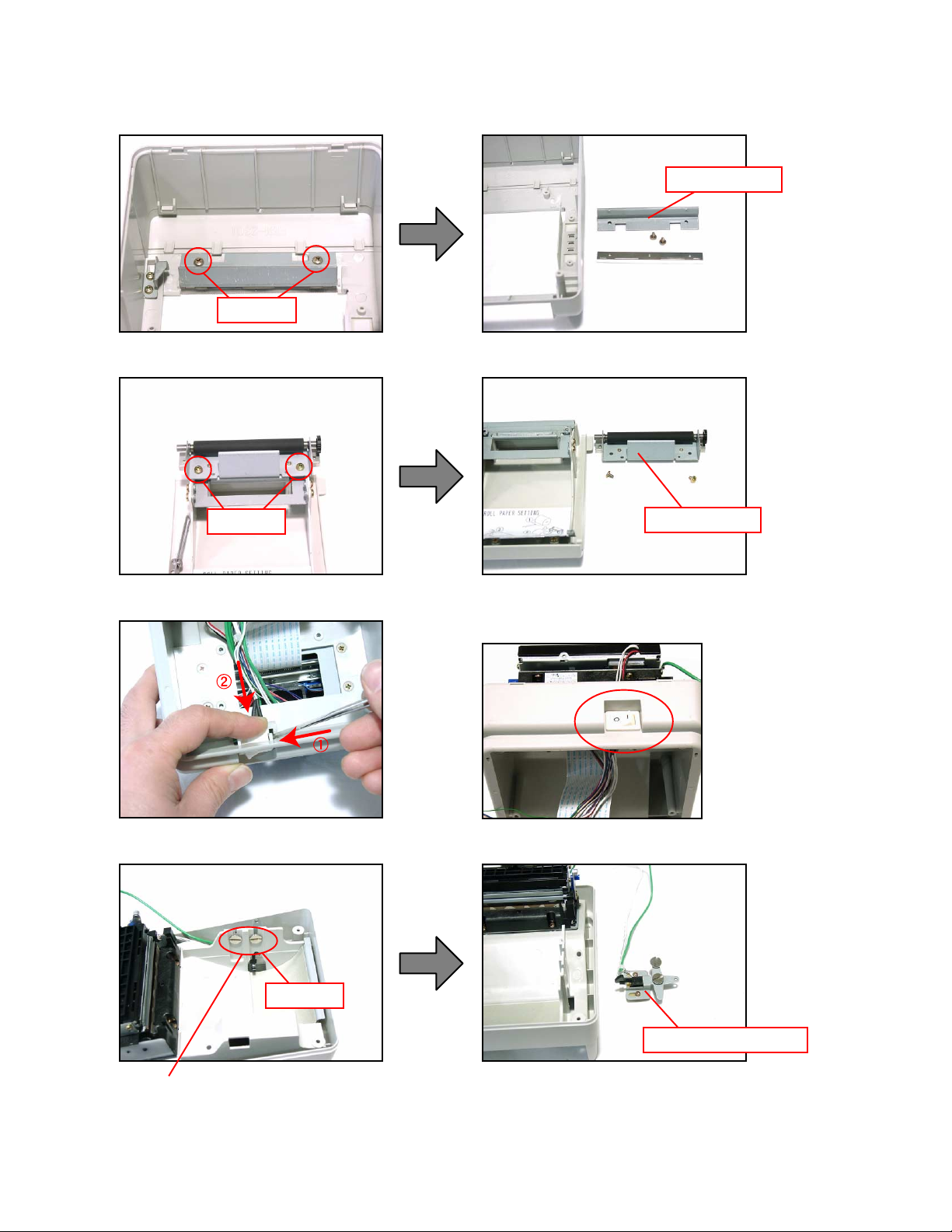

9. Remove the two screws and then the paper guide and the cutter.

Screws

10. Remove the two screws and then the platen unit.

Paper guide

Screws

11. Remove the power switch.

Direction of the power switch when assembling

12. Loosen the two screws and then remove the end sensor unit.

Platen unit

Loosen

Precaution when assembling

Fix the end sensor unit at the lowest of the groove.

— 6 —

End sensor unit

Page 9

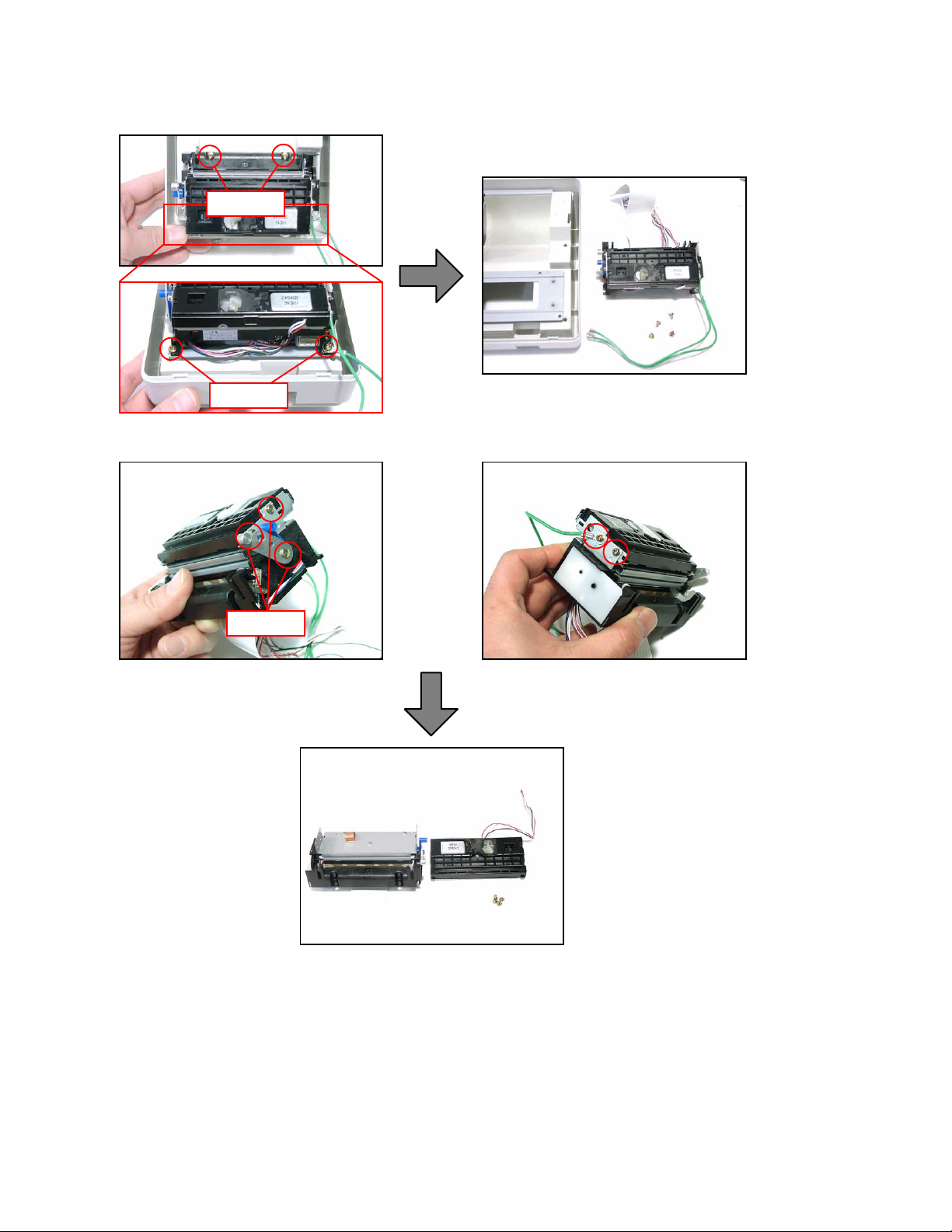

13. Remove the four screws and then the printer unit.

Screws

Screws

14. Remove the five screws and then the printer.

Screws

— 7 —

Page 10

3. CIRCUITRY

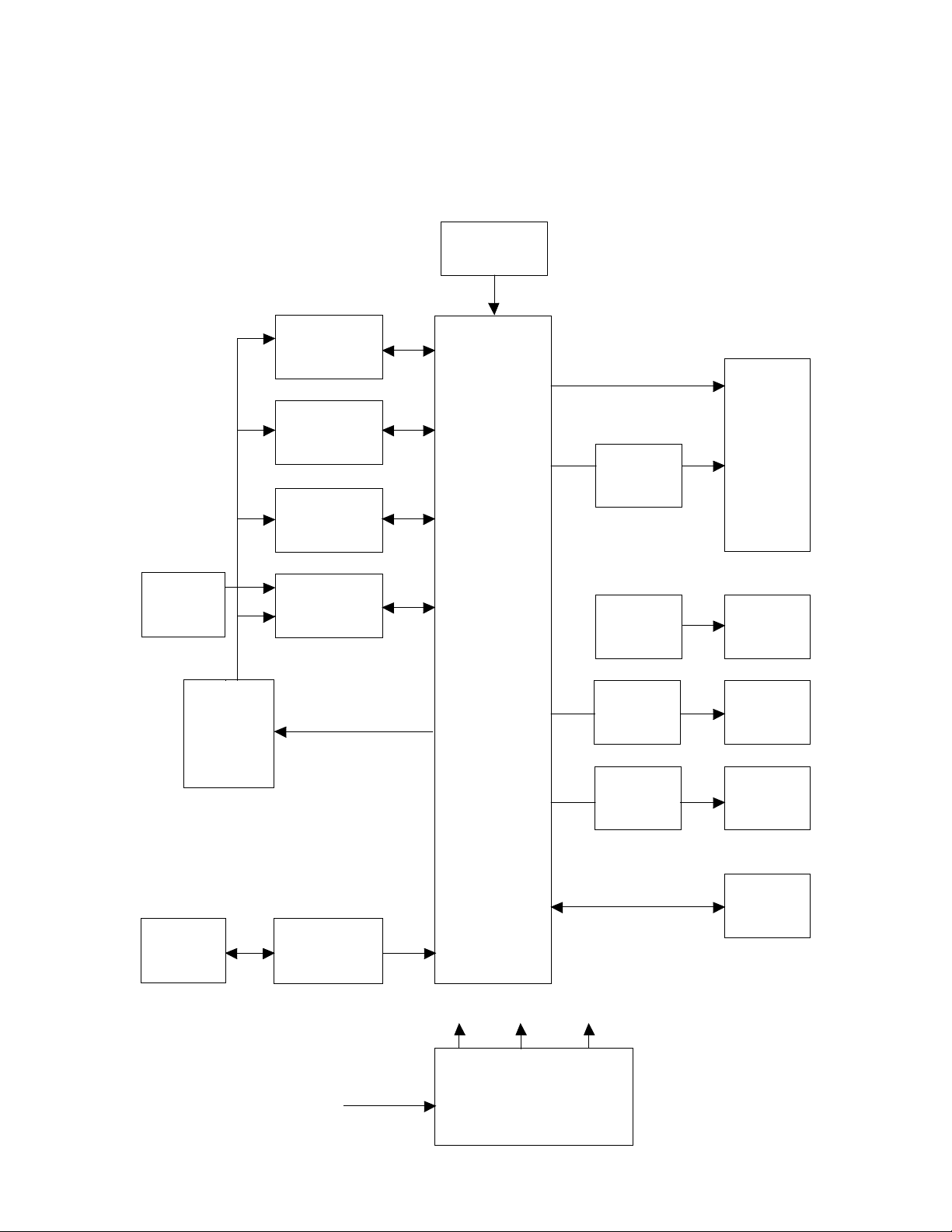

3-1. SYATEM BLOCK DIAGRAM

The terminal that wses 16 bits single chip microcomputer. The CPU has 256K Flash ROM and 4K bytes of internal

RAM.

External memory are 128K bytes SRAM 2 pcs, Flash memory (NV bit-image) and Character generator.

Clock

6.754MHz

SRAM

128K x 2 bytes

Printer

Head

FLASH ROM

512K bytes

Character

Generator

Motor

Drive

L6219

Motor

DIP SW

74LV139

Serial

Interface

RS232C

Decode

74LV541

HIN232CB

CPU

HD64F7045

VP VCC RESET

Driver

MB3853

Driver

Driver

TD62308

Auto

Cutter

LED

Panel SW

Drawer

Unit

Near

End sens.

+24V

Power Supply

— 8 —

Page 11

3-2. POWER SUPPLY CIRCUIT

The power supply source is a DC 24V.

+24V(VP)

Power supply voltage.

+24V(HVP)

The printer motor and head voltages are the +24V same as source voltage.

+5V (VCC)

The circuit generating the +5V uses the 24V.It apply the switting-circut of a M5291 , 2SB1455 and Coil (SFT8-40S).

POWER SUPPLY CIRCUIT continued

VP

VP

CN6

POWER

SW

1

2

B2P-SHF-1AA

CN7

1

2

3

TCS796053-2010

R185

0

R182

F2

125V/3A

FB3

MPZ3216S500A

FB2

MPZ3216S500A

C81

1M

1000pF

— 9 —

Page 12

HVP for VP

HVPSW

VCC

R147

10K

R141

3.3K

Q3

2SA1037

R143

10K

R148

3.3K

R145

R140

Q2

2SC2412

680 1%

10K

VP

10K

R137

Q1

2SJ553S

R144

56.2K 1%

3

1

DA1

1SS319

4

2

C55

0.1uF

R146

10K 1%

HVP

SHVP

HVCCSW#

POWER SUPPLY CIRCUIT continued

VCC for VP

VP

R181

+

27 1W DIP

C79

100uF/50V

U21

8

Qo

7

Ipek

6

Vin

5

Vref

M5291F

R184

1.1K 1%

R183

3.6K 1%

C56

100pF

SC

SE

Co

GND

SHR

R179

100

1

2

3

4

R180

300 1/2W

C80

330pF

Q7

2SB1455

D7

EC20QS6

+

L5

SF-T8-40S

VCC

C82

1000uF/10V

— 10 —

Page 13

3-3. POWER SUPPLY SPECIFICATION

Input-Power Consumption

Input: DC24V ±10%

Standing

by : Maximum 10 watts

Printing : Maximum 48 watts

Output-Rated Voltage

Voltage : 24±2.0V Standing by

VP to GND Ripple : Less than 0.3V p-p Printing

Stability : Line regulation-less than 0.5V Viac –10% to +10%

Temp. regulation-less than 0.5V Temp. 0°C to 40°C

Voltage : 5.0V±0.25V Standing by

VCC to GND Ripple : Less than 0.2V p-p Printing

Stability : Line regulation-less than 0.2V Viac –10% to +10%

Temp. regulation-less than 0.2V Temp. 0°C to 40°C

— 11 —

Page 14

3-4. HD64F7045F MICROCOMPUTER

Description

The M3612SAFP is a single-chip microcomputer designed with CMOS silicon gate technology.

It is housed in a 100-pin QFP.

In addition to its simple instruction sets, the ROM, RAM and I/O addresses are placed on the

same memory map to enable easy programming.

PIN Configuration (Top view)

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

1

2

3

4

5

6

7

8

9

U5

PA23

PE14

PA22

PA21

PE15

VSS

PC0/A0

PC1/A1

PC2/A2

PC3/A3

PC4/A4

VCC

PC5/A5

VSS

PC6/A6

PC7/A7

PC8/A8

PC9/A9

PC10/A10

PC11/A11

PC12/A12

PC13/A13

PC14/A14

PC15/A15

PB0/A16

VCC

PB1/A17

VSS

PA20

PA19

PB2

PB3

PA18

PB4

VSS

PB5

144

143

PE13

142

PE12

141

PE11

140

VSS

139

PE10

138

PE9

137

PE8

135

136

PE7

PA5/SCK1

134

VCC

PA4/TXD1

131

133

132

PA3/RXD1

PA2/SCK0

128

129

130

VSS

PA1/TXD0

PA0/RXD0

127

AVref

AVCC

126

125

PF7/AN7

123

124

AVSS

PF6/AN6

PF5/AN5

122

121

PF4/AN4

120

119

PF3/AN3

PF2/AN2

PF1/AN1

118

117

PF0/AN0

116

VSS

PE6

115

PE5

114

PE4

113

PE3

112

111

VCC

110

109

PE2

PE1

PA17/WAIT

PE0

PA15/CK

PLLVss

PLLCAP

PLLVcc

PA16/AH

EXTAL

RES

MD0

MD1

VCC

NMI

MD2

MD3

XTAL

VSS

VSS

VCC

D10

VSS

D11

VCC

D12

D13

D14

D15

108

107

106

105

104

103

102

101

100

99

98

97

96

95

94

93

92

D0

91

D1

90

D2

89

D3

88

D4

87

86

D5

85

84

D6

83

D7

82

D8

81

D9

80

79

78

77

76

75

74

73

HD64F7045F

A1938A2039VCC40A2141VSS42PA1443WDTOVF

A18

37

44

PD3145PD3046WRH

47

48

WRL

49

CS1

50

CS0

PA951PA8

CS3

52

53

54

— 12 —

VSS

CS2

PD2956PD2857PD2758PD2659PD25

55

VSS

VCC

PD24

PD2364PD2265PD2166PD2067PD1968PD1869PD17

60

61

62

63

VSS

PD16

70

71

72

Page 15

Function of HD64F7045

SH7040 Product Overview [HD6437040], [HD6417040]

SH7041 Product Overview [HD6437041], [HD6417041]

SH7042 Product Overview [HD6437042], [HD6477042]

SH7043 Product Overview [HD6437043], [HD6477043]

SH7044 Product Overview [HD64F7044], [HD6437044]

SH7045 Product Overview [HD64F7045], [HD6437045]

CPU:

Original Renesas architecture

32-bit internal data bus

General-register machine

• Sixteen 32-bit general registers

• Three 32-bit control registers

• Four 32-bit system registers

RISC-type instruction set

• Instruction length: 16-bit fixed length for improved code efficiency

• Load-store architecture (basic operations are executed between registers)

• Delayed branch instructions reduce pipeline disruption during branch

• Instruction set based on C language

Instruction execution time: one instruction/cycle (35 ns/instruction at 28.7-MHz operation)

Address space: Architecture supports 4 G bytes

On-chip multiplier: multiplication operations (32 bits x 32 bits 64 bits) and multiplication/accumulation operations

(32 bits x 32 bits + 64 bits 64 bits) executed in two to four cycles

Five-stage pipeline

Cache Memory:

1-kbyte instruction cache

Caching of instruction codes and PC relative read data

4-byte line length (1 longword: 2 instruction lengths)

256 entry cache tags

Direct map method

On-chip ROM/RAM, and on-chip I/O areas not objects of cache

Used in common with on-chip RAM; 2 k bytes of on-chip RAM used as address array/data array

when cache is enabled

Interrupt Controller (INTC):

Nine external interrupt pins (NMI, IRQ0-IRQ7)

Forty-three internal interrupt sources (forty-four for A mask)

Sixteen programmable priority levels

User Break Controller (UBC):

Generates an interrupt when the CPU or DMAC generates a bus cycle with specified conditions

Simplifies configuration of an on-chip debugger

— 13 —

Page 16

Bus State Controller (BSC):

Supports external extended memory access

• 16-bit (QFP-112, TQFP-120), or 32-bit (QFP-144) external data bus

Memory address space divided into five areas (four areas of SRAM space, one area of DRAM space) with the

following settable features:

• Bus size (8, 16, or 32 bits)

• Number of wait cycles

• Outputs chip-select signals for each area

• During DRAM space access:

Outputs RAS and CAS signals for DRAM

Can generate a RAS precharge time assurance Tp cycle

DRAM burst access function

• Supports high-speed access mode for DRAM

DRAM refresh function

• Programmable refresh interval

• Supports CAS-before-RAS refresh and self-refresh modes

Wait cycles can be inserted using an external WAIT signal

Address data multiplex I/O devices can be accessed

Direct Memory Access Controller (DMAC) (4 Channels):

Supports cycle-steal transfers

Supports dual address transfer mode

Can be switched between direct and indirect transfer modes (channel 3 only)

• Direct transfer mode: transfers the data at the transfer source address to the transfer destination address

• Indirect transfer mode: regards the data at the transfer source address as an address and transfers the data

at that address to the transfer destination address

Data Transfer Controller (DTC):

Data transfer independent of the CPU possible through peripheral I/O interrupt requests

Transfer mode can be set for each interrupt factor (transfer mode set in memory)

Multiple data transfers possible for one activating factor

Abundant transfer modes

• Normal mode/repeat mode/block transfer mode selectable

Transfer unit can be set to byte/word/longword

Interrupts activating the DTC requested of the CPU

• Interrupts can be generated to the CPU after completion of one data transfer

• Interrupts can be generated to the CPU after completing all designated data transfers

Transfer can be activated by software

— 14 —

Page 17

Multifunction Timer/Pulse Unit (MTU):

Maximum 16 types of waveform output or maximum 16 types of pulse I/O processing possible based on 16-bit

timer, 5 channels

16 dual-use output compare/input capture registers

16 independent comparators

8 types of counter input clock

Input capture function

Pulse output mode

• One shot, toggle, PWM, phase-compensated PWM, reset-synchronized PWM

Multiple counter synchronization function

Phase-compensated PWM output mode

• Non-overlapping waveform output for 6-phase inverter control

• Automatic setting for dead time

• PWM duty cycle can be set from 0 to 100%

• Output off function

Reset-synchronized PWM mode

• 3-phase output of any duty cycle positive phase/reverse phase PWM waveforms

Phase calculation mode

• 2-phase encoder calculation processing

Compare Match Timer (CMT) (Two Channels):

16-bit free-running counter

One compare register

Generates an interrupt request upon compare match

Watchdog Timer (WDT) (One Channel):

Watchdog timer or interval timer

Count overflow can generate an internal reset, external signal, or interrupt

Serial Communication Interface (SCI) (Two Channels):

(Per Channel):

Asynchronous or clock-synchronous mode is selectable

Can transmit and receive simultaneously (full duplex)

On-chip dedicated baud rate generator

Multiprocessor communication function

I/O Ports:

QFP 112 (SH7040, SH7042, SH7044), TQFP-120 (SH7040, SH7042)

• Input/output: 74

• Input: 8

• Total: 82

QFP 144 (SH7041, SH7043, SH7045)

• Input/output: 98

• Input: 8

• Total: 106

— 15 —

Page 18

A/D Converter:

10 bits x 8 channels

Conversion upon external trigger possible

Sample and hold function: two on-chip units (two channels can be sampled simultaneously)

Depending on the product, there is a high speed, mid-accuracy A/D on-chip type and a midspeed, high accuracy

A/D on-chip type. For details, see the product lineup.

Large Capacity On-Chip Memory:

ROM (128 kbytes PROM, 256 kbytes/128 kbytes/64 kbytes mask ROM, 256 kbytes flash ROM)

• SH7044, SH7045: 256 kbytes (flash ROM, mask ROM)

• SH7042, SH7043: 128 kbytes (ZTAT, mask ROM)

• SH7040, SH7041: 64 kbytes (mask ROM)

RAM: 4 kbytes (2 kbytes when cache is used)

Operating Modes:

Operating modes

• Expanded mode with ROM disabled

• Expanded mode with ROM enabled

• Single-chip mode

Processing states

• Program execution state

• Exception processing state

• Bus-released state

Power-down modes

• Sleep mode

• Software standby mode

Clock Pulse Generator (CPG):

On-chip clock pulse generator

• On-chip clock-doubling PLL circuit

— 16 —

Page 19

Port assigns (HD64F7045F)

port in/out active function

PA0 out L HLAT#

PA1 out HDATA

PA2 out HCLK

PA3 out LRXD

PA4 out LTXD

PA5 — NC

PA6 out L CS2#

PA7 out L CS3#

PA8 — NC

PA9 — NC

PA10 out L CS0#

PA11 out L CS1#

PA12 out L WRL#

PA13 out L WRH#

PA14 out L RD#

PA15 — NC

PA16 in H CUTS

PA17 — NC

PA18 out L LDSR#

PA19 — NC

PA20 out L LDTR#

PA21 out H ST0

PA22 out H ST1

PA23 — NC

PB0 out A16

PB1 out A17

PB2 — NC

PB3 — NC

PB4 in L THE#

PB5 — NC

PB6 out A18

PB7 out A19

PB8 out A20

PB9 out A21

PC0 — NC

PC1 out A1

PC2 out A2

PC3 out A3

PC4 out A4

PC5 out A5

PC6 out A6

PC7 out A7

PC8 out A8

PC9 out A9

— 17 —

Page 20

Port assign continued

port in/out active function

PC10 out A10

PC11 out A11

PC12 out A12

PC13 out A13

PC14 out A14

PC15 out A15

PD0 in/out L D0

PD1 in/out H D1

PD2 in/out H D2

PD3 in/out H D3

PD4 in/out H D4

PD5 in/out H D5

PD6 in/out D6

PD7 in/out D7

PD8 in/out H D8

PD9 in/out H D9

PD10 in/out H D10

PD11 in/out H D11

PD12 in/out H D12

PD13 in/out H D13

PD14 in/out H D14

PD15 in/out H D15

PD16 out H RMT0

PD17 out H RMTO1

PD18 out H RMTO2

PD19 out H RMTO3

PD20 out H RMTO4

PD21 out H RMTO5

PD22 — NC

PD23 — NC

PD24 — NC

PD25 — NC

PD26 — NC

PD27 — NC

PD28 — NC

PD29 — NC

PD30 — NC

PD31 — NC

PE0 out H CUTE

PE1 out H CUT0

PE2 out H CUT1

PE3 — NC

PE4 — NC

PE5 — NC

— 18 —

Page 21

Port assign continued

port in/out active function

PE6 — NC

PE7 — NC

PE8 out L DRW1#

PE9 out L HVCCSW#

PE10 out L DRW2#

PE11 out H HVPSW

PE12 out H RHSTB0

PE13 out H RHSTB1

PE14 out H BUZZER

PE15 — NC

PF0 in H SVCC

PF1 in H SHVP

PF2 in H RTH

PF3 — NC

PF4 in H SVP

PF5 in H SHR

PF6 in L RPEND#

PF7 — NC

— 19 —

Page 22

3-5. RESET CIRCUIT

R

The reset circuit is connected in order to do all the systems Initialization before the action

start of the CPU.

It is possible and is reset from the outside with the setting of DIPSW No.1.

The DSRRST# is signal of the DIP SW No.1point.

The LDSR# is signal from of RS232C port.

VCC

VCC

R172

1K

C74

0.1uF

U20D

8

12

13

11

74HC00

C73

0.1uF

U20A

1

3

2

74HC00

VCC

C76

0.1uF

U20B

4

5

74HC00

R173

6

330

DSRRST#

LDSR#

R175

4.7K

0.1uF

VP

R171

10K

U19

1

NC

2

IN

3

NC

4

R174

1K

C77

1000pF

GND

M51957BFP

R177

1K

C72

C71

0.1uF

8

NC

7

VCC

6

OUT

5

C

U20C

9

10

74HC00

C78

100pF

VCC

3-6. DRAWER CIRCUIT

The solenoid for a DRW1 is activated using the signal PE8 from the CPU.

The solenoid for a DRW2 is activated using the signal PE10 from the CPU.

This signal is normally High, and goes Low to cause the drawer to run.

VCC

C75

1000pF

RES#

DRW1#

DRW2#

DRWSENS

R154 10K

R153 10K

R152 10K

R158

470

R155 10K

R159

C68

0.1uF

U17

3

I1

6

I2

11

I3

14

I4

4

GND

5

GND

12

GND

13

GND

TD62308AF

R157

3.3K

470

C58

VCC

COM1

COM2

VCC1

VCC2

0.1uF

2

O1

7

O2

10

O3

15

O4

9

16

1

8

D5

1SS355

D6

1SS355

VCC

VP

F1

125V/1A

DRAWE

CN4

1

2

3

4

5

6

R156

0

TM5RE2-66

— 20 —

Page 23

3-7. BUZZER CIRCUIT

The buzzer circuit uses as its input signal PE14 from the CPU.

The PE14 signal is Low for normally.

These signals are Low signal and goes High on 2 conditions, the Buzzer is ON.

VP

BUZZER

3-8. FLASH MEMORYCIRCUIT

Flash memory is used for the NV bit-image.

U2

10K

25

24

23

22

21

20

19

18

8

7

6

5

4

3

2

1

48

17

16

9

10

11

12

13

14

15

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

NC

WE

RESET

NC

NC

RY/BY

MBM29F400TA

R56

A1

A2

A3

A4

A5

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A20

WRL#

RES#

D15/A-1

VCC

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

D11

D12

D13

D14

CE

VSS

OE

VCC

VSS

BYTE

R178

4.7K

BZ1

PS1740P02

Q6

DTC143EKA

29

31

33

35

38

40

42

44

30

32

34

36

39

41

43

45

26

27

28

37

46

47

CS3#

RD#

D0

D1

D2

D3

D4

D5A6

D6

D7

D8

D9

D10

D11

D12

D13

D14

D15

VCC

R5310K

C11

0.1uF

— 21 —

Page 24

3-9. EXTERNAL MEMORY CIRCUIT

The two S-RAM (128K bytes BS62LV1024SC-70) used as an external memory.

Memory are used at high and low data.

CS2# is chip select.

RD# is used for Output Enable .

WRL# and WRH#2 are used for Write Enable control.

EXTERNAL MEMORY CIRCUIT

U4

VCC

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

CS2#

WRL#

RD#

12

A0

11

A1

10

A2

9

A3

8

A4

7

A5

6

A6

5

A7

27

A8

26

A9

23

A10

25

A11

4

A12

28

A13

3

A14

31

A15

2

A16

22

S1

30

S2

29

W

24

OE

uPD431000AGW

VCC

13

D0

D0

14

D1

D1

15

D2

D2

17

D3

D3

18

D4

D4

19

D5

D5

20

D6

D6

21

D7

D7

1

NC

VCC

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

CS2#

WRH#

RD#

U8

12

A0

11

A1

10

A2

9

A3

8

A4

7

A5

6

A6

5

A7

27

A8

26

A9

23

A10

25

A11

4

A12

28

A13

3

A14

31

A15

2

A16

22

S1

30

S2

29

W

24

OE

uPD431000AGW

VCC

C9

0.1uF

C14

0.1uF

D8

13

D0

D9

14

D1

D10

15

D2

D11

17

D3

D12

18

D4

D13

19

D5

D14

20

D6

D15

21

D7

1

NC

— 22 —

Page 25

3-10. CHARACTER GENERATOR CIRCUIT

The character generator is a PTJCG2(Japanese).

Chip select is the CS10#, deta read select is the RD#.

PIN connection.

3-11. PRINTER CIRCUIT

U7

A1 D15

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11 D5

A12

A13

A14

A15

A16

A17

A18

A19

A20

CS10#

RD#

11

A0

10

A1

9

A2

8

A3

7

A4

6

A5

5

A6

4

A7

42

A8

41

A9

40

A10

39

A11

38

A12

37

A13

36

A14

35

34

3

2

43

12

14

33

A15

A16

A17

A18

A19

CE

OE

BYTE

D15/A-1

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

D11

D12

D13

D14

NC

NC

VDD

GND

GND

15

17

D14

19

D13

21

D12

24

D11

26

D10

28

D9

30

D8

16

D7

18

D6

20

22

D4

25

D3

27

D2

29

D1

31

D0

1

44

23

13

32

PTJCG2

VCC

R6610K

Printer is thermal printer.

Printing data is clocked serial from the CPU. Control signal are HDAT,HCLK and HLAT#.

Printings on signal are the RHSTB0 and RHSTB1, two-division control.

Temperature sensor of Printer Head is connected to the RTH and THE#.

R111

0

R115

22K 1%R1223K 1%

U15

2

A1

3

A2

4

A3

5

A4

6

A5

7

A6

8

A7

9

A8

1

G1

19

G2

SN74LV541ANSR

VCCVCC

R11616K 1%

C45

0.1uF

18

Y1

17

Y2

16

Y3

15

Y4

14

Y5

13

Y6

12

Y7

11

Y8

R112

0

R113

0

R114

0

R118

0

R119

0

RHSTB0

RHSTB1

HLAT#

HCLK

HDATA

RTH

HTE#

VCCVCC

VCC

D1

R11710K

1SS355

3

1

2

D2

1SS355

4 8

R131

10K

R13210K

U14A

uPC393G2

C43

0.1uF

C44

0.1uF

HVP

VCC

J1

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

HLEM28S-1

Head

— 23 —

Page 26

Printer circuit continues

r

Motor Control

Motor control IC is as U13 (L6219DSA). U13 are control from CPU.

Signals are RMT0, RMT1, RMT2, RMT3, RMT4 and RMT5.

Control reference voltage is U12.Name is the SVCC.

Paper Sensor signal is RPEND#.

Head up sensor signal is RHEDUP#.

VCC

SVCC

RMT0

RMT1

RMT2

RMT3

RMT4

RMT5

R104

10K

VCC

R10510K

R107

R108

R106

R109

10K

10K

10K

10K

uPC1093J

U12

R123

1.0 1% 1/2W

R103

200

1

R120

R121

C41

C46

R124

330pF

330pF

470pF

C40

U13

15

VREF1

11

VREF2

16

PH1

10

PH2

20

I01

17

I11

8

I02

9

I12

56K

14

56K

RC1

12

RC2

23

SENSE1

1K

22

COMP1

C47

L6219DSA

1000pF

VCC

OUT1A

OUT1B

OUT2A

OUT2B

GND0

GND1

GND2

GND3

SENSE2

COMP2

1

21

2

5

24

VS

13

VSS

6

7

18

19

3

4

3

K

REF

A

2

R125

C48

1000pF

VCC

1K

C42

0.1uF

1.0 1% 1/2W

VP

R126

VCC

R110

200

CN1

1

2

3

4

5

6

7

8

9

53047-0910

R Moto

RPEND#

RHEADUP#

R129

R130

D3

470

470

1SS355

D4

1SS355

VCC

47K

R127

10K

R128

C49

470pF

C50

0.1uF

— 24 —

Page 27

3-12. SERIAL INTERFACE CIRCUIT

PC I/F (RC232C)

U18 is latch IC. U18 (HIM232CB) is RS232C transceiver.

TXD, RXD, RTS and CTS are UART communication ports.

LTXD

LDTR#

LRXD

LDSR#

C59

1uF/25V

U18

11

T1IN

10

T2IN

12

R1OUT

9

R2OUT

1

C1+

3

C1-

4

+

1uF/25V

C2+

5

C2-

HIN232

+

C66

T1OUT

T2OUT

R1IN

R2IN

VCC

GND

V+

V-

14

7

13

8

16

2

6

15

1uF/25V

C67

+

1uF/25V

L1

L2

L3

L4

VCC

C60

C61

+

0.1uF

MPZ2012S300A

MPZ2012S300A

MPZ2012S300A

MPZ2012S300A

C62 C63 C64 C65

1000pF X 4

FB1

MPZ3216S500A

P1

1

14

2

15

3

16

4

17

5

18

6

19

7

20

8

21

9

22

10

23

11

24

12

25

13

CDS3125-0126

— 25 —

Page 28

4. MAINTERNANCE & TROUBLESHOOTING

4-1. INSTALLING OR REPLACING PAPER ROLL

CAUTION: make sure that paper rolls meets printer’s specification. Do not use paper rolls that have one end

glued to the core. This causes excessive load on the paper feed.

1: Make sure that the printer is not printing or receiving data, and open the printer cover by pressing the cover

open knob. Unroll several inches of the paper as shown.

2: Insert the paper roll as shown.

3: Pull out several inches of paper and close the printer cover as shown.

Tear off the excess paper on the cutter edge.

4-2. ADJUSTING THE PAPER NEAR END SENSOR

A sensor detects when the paper roll is running out. Due to variation in the width of paper roll cores, it is

difficult to measure the exact length of the paper left on the roll when the detector is triggered. The factory

setting is based on a paper roll core with an outside diameter of 18mm and an inside diameter of 12mm. If you

use a paper roll with different widths, adjust the setting as described below.

1: Open the printer cover and remove the paper roll.

2: Loosen the adjusting screw and move the tab to fit the core of the paper roll.

3: Tighten the adjusting screw.

4: Replace the paper roll and close the printer cover.

— 26 —

Page 29

4-3. PAPER JAM

CAUTION : Do not touch the printer head because they are very hot after continuous printing. Do not attempt

to clear a paper jam until the printer cools down.

1: Turn the printer off and press the cover open button.

2: Remove the jammed paper and replace the paper roll.

If the printer cover can’t be opened after a paper jam, check the Automatic Paper Cutter.

1: Remove the Automatic Paper Cutter Cover.

2: Pull up the clear film, and slowly turn the screw inside clockwise until the cutter edge reaches home position,

see below.

3: Now, the printer cover should open easily. Remove the paper jam and replace the paper roll.

4-4. TROUBLESHOOTING

Error Contents

Can’t turn the printer ON

ON LINE Indicator doesn’t

light up

ERROR Indicator is ON

ERROR Indicator is ON

Causes / Points to check

Is the Power Switch turned ON?

Is the connector on the power adapter

properly connected?

Does the Printer reset when you turn the

Power Switch ON?

Does the LED on the Adapter light up

when connected to the wall?

Other

Is the ERROR Indicator ON?

Press the ON LINE Button

Check if the printer is out of paper

The Cover doesn’t open even if you

press the Cover Open Button

The Printer Cover doesn’t close com-

pletely

Solutions

Turn the Power Switch ON

Connect the Connector firmly

If it does, something is wrong with the

Operation Panel.

If it doesn’t, check the connection of the

Power Supply Cord. If the connection is OK,

something is wrong with the Adapter.

Something may be wrong with the Power

Switch Parts or with the Main Board.

If it is, see “ERROR Indicator is ON

If ON LINE Indicator turns on, it’s normal

If paper is out, replace with a new roll

The Automatic Paper Cutter may be locked.

Open the Cover by pressing the Cover Open

Button, and Close it again by pushing at

centerofthecover.

— 27 —

Page 30

Error Contents

ERROR Indicator doesn’t

light up while paper is

exhausted

(The Printer Cover is close)

ERROR Indicator doesn’t

light up while the Printer

Cover is open

Can’t print the self test

Printing cannot be done by

the commands from the

HOST or printing garbled

Drawer Kick doesn’t work

Causes / Points to check

ON LINE Indicator lights up by using the

ON LINE Button

Other

ON LINE Indicator lights up and off after

pushing the ON LINE button.

Other

ON LINE Indicator is not ON

Printing causes the paper to feed

Check print capability by running the

Self-Test

Is the Connector of Interface firmly

connected with screws?

Check the setting of DIP Switch

Is the drawer kick connected properly?

Is Y-cable connected in reverse order?

Other

Solutions

Something is wrong with Paper Sensor on

the MAIN Board inside the Printer

Something is wrong with the Operating

Panel.

Something is wrong with Paper Sensor of

the MAIN Board inside the Printer

Something is wrong with the Operating

Panel

See “ON LINE Indicator doesn’t light up

Something is wrong internally or with the

Printer Head.

If printing fails, see “Can’t Print”

Seat the Connector firmly and tighten the

screws

Refer APPENDIX A and set the switches

correctly, then power cycle the printer

Re-plug in the cable. You should hear or

feela click if the proper connection is made.

Check the Y-cable and verify it is connected

in the correct order.

Something may be wrong with the MAIN

Board inside the Printer.

ERROR Indication and ON

LINE Indication flash on and

off alternately

Check the setting of DIP Switch

Turn the printer off, make any necessary

changes, then turn theprinteron.

— 28 —

Page 31

4-5. SELF TEST

Use the self test to check that your printer is operating properly. It checks the control circuits, printer

mechanisms, print quality, and displays the firmware version and DIP switch settings.

1: Make sure that the printer cover is closed properly and turn the power off.

2: While holding down the FEED button, turn the printer on and continue holding down the FEED button until

the self test starts.

3: The self test will end automatically and detach the self test print out.

Self Print (Japanese CG)

The number changes according to the version.

Confirm that the font is JAPANESE.

DIPSW setting appears differently if the setting

at the factory default is different.

Board defect if "not found" appears.

Write defect if "OK" does not appear.

Printing quality is confirmed.

24 dot font ANK (one byte) characters

Page 1 <20> h ~ <FF>h

24 dot font Chinese characters

<30>h <21>h ~ 90 characters total

16 dot font ANK (one byte) characters

Page 1 <20>h ~ <FF>h

16 dot font Chinese characters

<30>h<7B>h ~ 176 characters total

— 29 —

Cut

Page 32

5. SETTING & CHECKING THE DIP SWITCHES

No.

1

2

3

4

5

6

7

8

9

10

Reset By Dtr Signals Off Invalid On Valid

Reserved Off Fixed to Off

Protocol Off XON/XOFF On DTR/DSR(*)

Baud Rate Refer to the table “a” below

Parity Refer to the table “b” below

Undefined Off / On /

Low power consumption mode* Off Off On On

Undefined Off / On /

CONTENTS STATUS STATUS

* Printing speed is fixed to 150mm/sec. max and power consumption to approx. 8A max (instantaneous value).

Table "a" Baud rate

NO. 4800bps 9600bps 19200bps 38400bps

4 off off on on

5 off on off on

Table "b" Parity

NO. NON EVEN ODD NON

6 off off on on

7 off on off on

Before changing DIP switch setting

1: Make sure that Power of the printer is turned off.

2: Remove the rubber cap at the bottom of the printer.

3: Change the status of DIP switch by using something with a point.

4: Cover the DIP switch with the rubber cap.

CAUTION: The new status becomes effective when the printer power is turned on.

DIP SWITCH POSITION

DIP SWITCH

ON

OFF

Rubber Cap

— 30 —

Page 33

6. CIRCUIT DIAGRAMS

8

RES#

CUTS

CUTE

CUT0

CUT1

E

D

C

R61

R62

R63

R64

R65

B

RHEADUP#

ONLINE_SW#

A

DRWSENS

DSRRST#

RFEED#

RNEND#

HVCCSW#

BUZZER

47k

47k

47k

47k

47k

RPEND#

HDATA

DRW1#

DRW2#

HVPSW

RHSTB0

RHSTB1

LDSR#

SVCC

SHVP

RTH

SVP

SHR

HLAT#

HCLK

LRXD

LTXD

LDTR#

HTE#

RMT0

RMT1

RMT2

RMT3

RMT4

RMT5

R92 47K

ST1

ST0

R93

R94 47K

47K

8

7

R38

47k

47k

R39

R40

47k

47k

R41

R42

47k

47K

R45

47K

R49

R51

R57

R58

R59

R60

U11

A1

Y1

A2

Y2

A3

Y3

A4

Y4

A5

Y5

A6

Y6

A7

Y7

A8

Y8

G1

G2

SN74LV541ANSR

47k

47k

47k

47k

47k

47k

R69

47k

R70

R79

47k

R80

47k

R81

47k

47k

R82

47k

R83

18

D0

17

D1

16

D2

15

D3

14

D4

13

D5

12

D6

11

D7

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

VCC

R96

R99

R95

R97

R98

47K

47K

47K

47K

47K

2

3

4

5

6

7

8

9

1

19

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

SH7041

U5

PA23

PE14

PA22

PA21

PE15

VSS

PC0/A0

PC1/A1

PC2/A2

PC3/A3

PC4/A4

VCC

PC5/A5

VSS

PC6/A6

PC7/A7

PC8/A8

PC9/A9

PC10/A10

PC11/A11

PC12/A12

PC13/A13

PC14/A14

PC15/A15

PB0/A16

VCC

PB1/A17

VSS

PA20

PA19

PB2

PB3

PA18

PB4

VSS

PB5

144

143

142

141

140

139

VSS

PE9

PE13

PE12

PE11

PE10

A1938A2039VCC40A2141VSS42PA1443WDTOVF

A18

37

A19

A18

A21

A20

138

137

136

135

134

133

132

131

130

129

128

127

126

125

124

PE8

PE7

44

VCC

PA5/SCK1

PD3145PD30

46

PA4/TXD1

PA3/RXD1

WRH47WRL

48

PA1/TXD0

PA2/SCK0

CS149CS0

50

VSS

PA0/RXD0

PA951PA8

52

AVCC

CS353CS2

54

AVref

PF7/AN7

PF6/AN6

VSS

PD2956PD2857PD2758PD2659PD25

55

R84

10K

7

123

AVSS

R85

10K

122

PF5/AN5

PF4/AN4

R86

10K

121

PF3/AN3

60

R87

10K

120

61

R8810K

119

PF2/AN2

PF1/AN1

VSS

PD24

62

VCC

R89

10K

118

63

R90

10K

117

PF0/AN0

VCC

6

116

115

114

113

112

111

VSS

PE6

PE5

PE4

PE3

VCC

PD2364PD2265PD2166PD2067PD1968PD1869PD17

70

CS0#

CS1#

CS2#

CS3#

WRL#

WRH#

RD#

6

110

109

PE2

PE1

PE0

PA15/CK

PA17/WAIT

PA16/AH

VSS

PD16

71

72

1

2

3

4

5

6

7

8

9

10 11

C2

PLLVss

PLLCAP

PLLVcc

VCC

EXTAL

XTAL

VCC

VCC

S1

SW DIP-10

10uF/10V

+

RES

MD0

MD1

NMI

MD2

MD3

VSS

D0

D1

D2

D3

D4

VSS

D5

D6

D7

D8

D9

D10

VSS

D11

D12

D13

D14

D15

R360

C4 0.01uF

108

107

106

105

104

103

102

101

100

99

98

97

96

95

94

93

92

91

90

89

88

87

86

85

84

83

82

81

80

79

78

77

76

75

74

73

5

VCC

RES#

8

7

6

5

C7

2

3

4

5

6

7

8

9

1

19

U1

VCC

WP

SCL

SDA

BR24C16F

VCC

470pF

6.754MHz

200

U10

A1

A2

A3

A4

A5

A6

A7

A8

G1

G2

SN74LV541ANSR

C1

0.1uF

A0

A1

A2

GND

R44

200

C6

0.1uF

C8

10pF

Y1

C10

18

Y1

17

Y2

16

Y3

15

Y4

14

Y5

13

Y6

12

Y7

11

Y8

R18

R17

R16

10K

10K

10K

VCC

R37

0

10uF/10V

+

C3

C5 0.01uF

VCC

R431k

47k

R47 47k

R46

3K 1%

R50

VCC

DA0

DA1

DA2

DA3

DA4

DA5

DA6

DA7

DA8

DA9

DA10

DA11

DA12

DA13

DA14

DA15

VCC

C13

0.1uF

VCC

R73 47K

R72 47K

R71 47K

R74

R76

R75

47K

47K

47K

20

19

18

17

16

15

14

13

12

R54

1M

R55

R77

R78

47K

47K

5

4

VCC

VCC

R68

U9A

2

A

3

B

1

G

SN74LV139ANSR

U9B

14

A

13

B

15

G

SN74LV139ANSR

C39

0.1uF

R101

R2

R4

R6

R8

R10

R12

R14

R19 100K

R21 100K

R23

R25

R27

R29

R31

R33

R35

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

D11

D12

D13

D14

D15/A-1

CE

VSS

OE

VCC

VSS

BYTE

C11

0.1uF

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

D11

D12

D13

D14

D15/A-1

CE

VSS

OE

VCC

VSS

BYTE

VCC

R91

100

100

R102

100

C15

0.1uF

29

31

33

35

38

40

42

44

30

32

34

36

39

41

43

45

26

27

28

37

46

47

Y0

Y1

Y2

Y3

Y0

Y1

Y2

Y3

DA0

DA1

DA2

DA3

DA4

DA5

DA6

DA7

1

2

3

4

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A20 A20

WRL#

RES#

10pF

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

WRL#

RES#

D0

D1

D2

D3

D4

D5

D6

D7

R100

DA8

DA9

DA10

DA11

DA12

DA13

DA14

DA15

U2

25

A0

24

A1

23

A2

22

A3

21

A4

20

A5

19

A6

18

A7

8

A8

7

A9

6

A10

5

A11

4

A12

3

A13

2

A14

1

A15

48

A16

17

A17

16

A18

9

A19

10

NC

11

WE

12

RESET

13

NC

14

NC

15

RY/BY

MBM29F400TA

R56

10K

U6

NOT USE

25

A0

24

A1

23

A2

22

A3

21

A4

20

A5

19

A6

18

A7

8

A8

7

A9

6

A10

5

A11

4

A12

3

A13

2

A14

1

A15

48

A16

17

A17

16

NC

9

NC

10

NC

11

WE

12

RESET

13

NC

14

NC

15

RY/BY

10K

A20

A21

A1

A2

100

4

3

33

CS10#

RD#

R1

33

R3

33

R5

33

R7

33

R9

R11

33

R13

33

R15

33

33

R20

R22

33

R24

33

R26

33

R28

33

33

R30

33

R32

R34

33

NOT USE

U3

11

10

9

8

7

6

5

4

42

41

40

39

38

37

36

35

34

3

2

43

12

14

33

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

CE

OE

BYTE

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

D11

D12

D13

D14

D15/A-1

NC

NC

VDD

GND

GND

VCC

U7

11

A0

10

A1

9

A2

8

A3

7

A4

6

A5

5

A6

4

A7

42

A8

41

A9

40

A10

39

A11

38

A12

37

A13

36

A14

35

A15

34

A16

3

A17

2

A18

43

A19

12

CE

14

OE

33

BYTE

PTJCG2

VCC

CS11#

DA0

DA1

DA2

DA3

DA4

DA5

DA6

DA7

DA8

DA9

DA10

DA11

DA12

DA13

DA14

DA15

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

RD#

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A20

100K

VCC

100K

100K

100K

100K

100K

100K

100K

100K

100K

100K

100K

100K

100K

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

D11

D12

VCC

D13

D14

D15

CS3#

RD#

R5310K

29

D0

31

D1

33

D2

35

D3

38

D4

40

D5

42

D6

44

D7

30

D8

32

D9

34

D10

36

D11

39

D12

4

5

6

7

12

11

10

9

CS13#

CS0#

RD#

D13

D14

D15

VCC

R6710K

CS10#

CS11#

CS_CENTRO#

CS_CENTR1#

41

43

45

26

27

28

37

46

47

15

17

19

21

24

26

28

30

16

18

20

22

25

27

29

31

1

44

23

13

32

C12

0.1uF

D15/A-1

C16

0.1uF

2

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

D11

D12

D13

D14

D15

15

D0

17

D1

19

D2

21

D3

24

D4

26

D5

28

D6

30

D7

16

D8

18

D9

20

D10

22

D11

25

D12

27

D13

29

D14

31

1

NC

44

NC

23

VDD

13

GND

32

GND

Address Map

CS0 (0x00000000-0x003FFFFF) Program MBM29F400/MBM29F800 (70nS)

CS1 (0x00400000-0x004FFFFF) Char-Gen PTJCG2-01 (100ns)

(0x00500000-0x005FFFFF) Char-Gen PTJCG3-01 (100ns)

(0x00500000-0x005FFFFF) Char-Gen PTCCG1-01 (120ns)

(0x00700000-0x007FFFFF) Memory Mapped I/O

CS2 (0x00800000-0x00BFFFFF) RAM Area uPD431000AGW (70ns)

CS3 (0x00C00000-0x00FFFFFF) NVRAM Area MBM29F400 (70ns)

U4

D15

D14

D13

D12

D11

D10

D9

D8

D7

D6

D5

D4

D3

D2

D1

D0

VCC

VCC

R5210K

D15

D14

D13

D12

D11

D10

D9

D8

D7

D6

D5

D4

D3

D2

D1

D0

VCC

VCC

R66

10K

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

CS2#

WRL#

RD#

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

CS2#

WRH#

RD#

12

A0

11

A1

10

A2

9

A3

8

A4

7

A5

6

A6

5

A7

27

A8

26

A9

23

A10

25

A11

4

A12

28

A13

3

A14

31

A15

2

A16

22

S1

30

S2

29

W

24

OE

uPD431000AGW

U8

12

A0

11

A1

10

A2

9

A3

8

A4

7

A5

6

A6

5

A7

27

A8

26

A9

23

A10

25

A11

4

A12

28

A13

3

A14

31

A15

2

A16

22

S1

30

S2

29

W

24

OE

uPD431000AGW

1

E

13

D0

D0

14

D1

D1

15

D2

D2

17

D3

D3

18

D4

D4

19

D5

D5

20

D6

D6

21

D7

D7

1

NC

VCC

C9

0.1uF

13

D8

D0

14

D9

D1

15

D10

D2

17

D11

D3

18

D12

D4

19

D13

D5

20

D14

D6

21

D15

D7

1

NC

VCC

C14

0.1uF

D

C

B

C18

A1

100pF

C19

A2

C20

100pF

A3

100pF

C21

A4

C22

100pF

A5

100pF

C23

A6

100pF

C24

A7

C25

100pF

A8

C26

100pF

A9

C27 100pF

A10

C28

100pF

A11

100pF

C29

A12

C30

100pF

A13

100pF

C31

A14

100pF

C32

A15

C33

100pF

A16

100pF

C34

A17

C35

100pF

A18

100pF

C36

A19

100pF

C37

A20

100pF

C38

A21

A

Model

CASIO COMPUTER CO.,LTD.

3

2

UP-360

1

— 31 —

Page 34

8

VCC

E

SVCC

RMT0

RMT1

RMT2

RMT3

RMT4

RMT5

R104

10K

R107

R108

R106

R109

R10510K

10K

10K

10K

10K

D

RPEND#

RHEADUP#

C

uPC1093J

7

VCC

R103

200

U12

R123

1.0 1% 1/2W

3

K

REF

A

2

470pF

C40

1

U13

15

VREF1

11

VREF2

16

PH1

10

PH2

20

I01

17

I11

8

I02

9

I12

14

RC1

12

RC2

23

SENSE1

22

1K

COMP1

C47

L6219DSA

1000pF

VCC

470

R129

470

R130

R120

R121

330pF

C41

56K

56K

330pF

C46

R124

D3

1SS355

D4

1SS355

OUT1A

OUT1B

OUT2A

OUT2B

GND0

GND1

GND2

GND3

SENSE2

COMP2

VCC

6

1

21

2

5

24

VS

13

VSS

6

7

18

19

3

4

R125

C48

1000pF

47K

10K

VP

VCC

C42

0.1uF

R126

1K

1.0 1% 1/2W

R127

R128

C49

470pF

C50

0.1uF

5

VCC

R110

200

CN1

1

2

3

4

5

6

7

8

9

53047-0910

R Motor

RHSTB0

RHSTB1

HLAT#

HCLK

HDATA

HTE#

4

3

2

HVP

VCC

1

E

J1

28

27

26

25

0

R111

U15

2

A1

3

A2

4

A3

5

A4

6

A5

7

A6

8

A7

9

A8

1

G1

19

G2

SN74LV541ANSR

R115

22K 1%R1223K 1%

VCCVCC

R116

16K 1%

C45

0.1uF

18

Y1

17

Y2

16

Y3

15

Y4

14

Y5

13

Y6

12

Y7

11

Y8

R112 0

R113

R114

R118

R119

0

0

0

0

C44

0.1uF

VCCVCC

VCC

D1

R11710K

1SS355

RTH

D2

1SS355

3

1

2

C43

U14A

4 8

R131

10K

R13210K

uPC393G2

0.1uF

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

HLEM28S-1

Head

D

C

VCC

VCC

5

7

R145

U14B

uPC393G2

Q2

2SC2412

680 1%

6

VP

10K

R140

C56

100pF

R137

10K

3

1

DA1

1SS319

4

2

C55

0.1uF

Q1

2SJ553S

R144

56.2K 1%

R146

10K 1%

HVP

C54

0.1uF

R138

56.2K 1%

R142

10K 1%

SVP

SHVP

SHR

Head

Resistance

B

A

R133

10K

U16

2

C52

0.1uF

3

7

1

9

IN1

IN2

INH

VCC1

MON

MB3853PS-G

OUT1

OUT2

VCC2

GND

CUT0

CUT1

CUTE

R134

B

CUTS

A

RNEND#

VPVCC

6

4

R150

VCC

R135

10K

R136

C53

0.1uF

VCC

R149

10K

470

C57

0.1uF

8

5

R139

+

C51

100uF/50V

470

CUTTER

CN2

1

2

3

4

53047-0410

Receipt Near End Sensor

CN3

1

2

R151

B2B-EH

HVPSW

HVCCSW#

R141

3.3K

10K

R143

VCC

R147

10K

Q3

2SA1037

R148

3.3K

CASIO COMPUTER CO.,LTD.

8

7

6

5

4

3

2

UP-360

1

— 32 —

Model

Page 35

8

E

DRW1#

DRW2#

D

DRWSENS

C

R171

10K

1

2

3

R174

1K

C77

1000pF

4

C72

0.1uF

R175

4.7K

DSRRST#

B

LDSR#

U19

NC

IN

NC

GND

M51957BFP

9

10

R177

1K

R153 10K

R152

10K

R158

470

U20C

74HC00

7

VCC

R154 10K

R155 10K

U17

3

I1

6

I2

11

I3

14

I4

4

GND

5

GND

12

GND

13

GND

TD62308AF

R157

3.3K

R159

470

C68

0.1uF

C71

VCC

0.1uF

8

NC

7

VCC

6

OUT

5

C

C74

0.1uF

8

C78

100pF

2

O1

7

O2

10

O3

15

O4

9

COM1

16

COM2

1

VCC1

8

VCC2

0.1uF

C58

VCC

D5

1SS355

D6

1SS355

VCCVCC VP

R172

1K

U20D

12

13

11

74HC00

C73

0.1uF

6

VP

F1

125V/1A

VCC

DRAWER

R156

0

1

2

3

4

5

6

CN4

TM5RE2-66

5

LDTR#

LRXD

LDSR#

LTXD

4

U18

11

T1IN

10

T2IN

12

R1OUT

9

R2OUT

1

C1+

3

C1-

4

1uF/25V

C2+

5

C2-

HIN232

C59

1uF/25V

+

+

C66

T1OUT

T2OUT

3

14

7

13

R1IN

8

R2IN

16

VCC

2

V+

6

V-

15

GND

C67

+

1uF/25V

1uF/25V

L1

L2

L3

L4

VCC

C60

C61

+

0.1uF

MPZ2012S300A

MPZ2012S300A

MPZ2012S300A

MPZ2012S300A

2

C62 C63 C64 C65

1000pF X 4

MPZ3216S500A

1

P1

1

14

2

15

3

16

4

17

5

18

6

19

7

20

8

21

9

22

10

23

11

24

12

25

FB1

13

CDS3125-0126

E

D

R160

4.7K

R161

R169

VCC

C69

0.1uF

VCC

0.1uF

R1621K

R1644.7K

VCC

R166

4.7K

4.7K

R167

1K

R170

C70

Q5

2SA1037

BUZZER

Q4

2SA1037

R165

470

R178

4.7K

R168

470

VCCVCC

R163

470

CN5

1

2

3

4

5

6

B6B-EH

OP Pannel

C

VP

BZ1

PS1740P02

Q6

DTC143EKA

B

ONLINE_SW#

ST0

ST1

RFEED#

U20A

1

2

VCC

74HC00

C76

0.1uF

3

U20B

4

5

74HC00

R173

6

330

C75

1000pF

RES#

1K

ONLINE#

ERRER#

1K

VP

CN6

B2P-SHF-1AA

TCS796053-2010

1

2

CN7

1

2

3

R185

0

R182

1M

C81

1000pF

F2

125V/5A

FB3

MPZ3216S500A

FB2

MPZ3216S500A

R181

27 1W DIP

C79

+

100uF/50V

8

7

6

5

R184

1.1K 1%

U21

Qo

Ipek

Vin

Vref

M5291F

R183

3.6K 1%

R180

1

SC

2

SE

Co

GND

300 1/2W

3

4

POWER

SW

A

C80

330pF

R179

100

Q7

2SB1455

D7

EC20QS6

+

L5

SF-T8-40S

C82

1000uF/10V

A

VCC

Model

CASIO COMPUTER CO.,LTD.

8

7

6

5

4

3

2

UP-360

1

— 33 —

Page 36

7. PARTS LIST

PARTS LIST

MODEL : UP-360

CONTENTS

Explode view.................................................................................................................................. 35

1. MAIN BOARD UNIT................................................................................................................. 36

2. CONTROL PANEL .................................................................................................................. 37

3. POWER SW ASSY.................................................................................................................. 37

4. NEAR END SENSOR UNIT..................................................................................................... 37

5. CASE UNIT.............................................................................................................................. 38

NOTES :

1. Price and specifications are subject to change withput prior notice.

2. As for spare parts order and supply, refer to the “GUIDEBOOK for Spare Parts Supply”, published

separately.

3. The numbers in item column corespond to the same numbers in drawing.

4. CASIO does not supply the spare parts without parts code.

5. Remarks

Q'ty : Quantity used per unit

RANK: A = Essential

B = Stock recommended

C = Less recommended

X = No stock recommended

— 34 —

Page 37

25

16

20

17

28

23

22

7

15-1

8

6

12

14

Including

Auto cuter

5

26

27

12-1

11

2

Including

Printer

19

4

18

9

15

24

13

3

1

10

21

— 35 —

Page 38

Price

N Item Code No. Specification

1. MAIN BOARD UNIT

N 1 94870892 MAIN BOARD UNIT 010663-03 20-010666-01 1 DV A

N U5 94870893 CPU HD64F7045F-28 00-00503760 1 DL A

N U2 94870894 FLASH MEMORY MBM29F400TC-70PFTN 00-00501653 1 BX A

U4,8 69324034 S-RAM BS62LV1024SC-70 2 AY A

U18 19048920 RS232 T/R HIN232CB-T 00-00501390 1 BA A

N U9 94870895 IC SN74LV139ANSR 00-00603762 1 AF B

U10,11,15 94870070 IC SN74LV541ANSR 00-00603801 3 AN B

U20 94870600 IC SN74HC00NSR 00-00611100 1 AD B

U12 21207391 IC UPC1093J 1 AE B

N U13 94870896 IC L-6219 00-00606015 1 BL B

N U14 94870897 IC UPC393G2 00-00604136 1 AG B

N U16 94870898 IC MB3853PS-G 00-00608000 1 BM B

N U17 94870899 IC TD62308AF 00-00606288 1 AU B

U19 94870063 IC M51957BFP-C61J 00-00600281 1 AI B

N U21 94870900 IC M5291FP-600C 00-00600125 1 AL B

N U7 94870901 IC PTJ CG2 00-00609260 1 CF B

N Y1 94870902 CRYSTAL Q22MA4060105200 00-02300825 1 AS B

N Q1 94870903 FET 2SJ553STR 00-00702135 1 BC B

N Q2 94870904 TRANSISTOR 2SC2412KT146 00-00700850 1 AA B

Q3-5 23903076 TRANSISTOR 2SA1037AKT146 3 AA B

N Q7 94870905 TRANSISTOR 2SB1455 00-00700055 1 AQ B

Q6 94870083 TRANSISTOR DTC143EKAT146 00-00700890 1 AB B

DA1 23902513 DIODE 1SS319(TE85L) 1 AB C

D1-6 23901820 DIODE 1SS355TE-17 6 AA C

N D7 94870906 DIODE/SWITCHING EC31QS06TE12L 00-00800325 1 AF C

R2,4,6,8,10,12,14,19, RESISTOR/CHIP MCR10EZHJ104 16 X

21,23,25,27,29,31,33,

35

R44,55,103,110 RESISTOR/CHIP MCR10EZHJ201 4 X

R16-18,52,53,56,66-68, RESISTOR/CHIP MCR10EZHJ103 38 X

84-90,104-109,117,

128,131-133,135,137,

140,143,147,149,

152-155,171

R54,105 RESISTOR/CHIP MCR10EZHJ105 2 X

R38-42,45-49,51, RESISTOR/CHIP MCR10EZHJ473 43 X

57-65,69-83,92-99,127

R120,121 RESISTOR/CHIP MCR10EZHJ563 2 X

R43,124,125,161,162, RESISTOR/CHIP MCR10EZHJ102 10 X

169,170,172,174,177

R129,130,139,150, RESISTOR/CHIP MCR10EZHJ471 9 X

158,159,163,165,168

R141,148,157 RESISTOR/CHIP MCR10EZHJ332 3 X

R173 RESISTOR/CHIP MCR10EZHJ331 1 X

R160,164,166,167, RESISTOR/CHIP MCR10EZHJ472 8 X

175,178

R91,100,101,102,179 RESISTOR/CHIP MCR10EZHJ101 5 X

R1,3,5,7,9,11,13,15,20, RESISTOR/CHIP MCR10EZHJ330 16 X

22,24,26,28,30,32,34

R36,37,111-114,118, RESISTOR/CHIP MCR10EZHJ000 10 X

119,156,185

R115 RESISTOR/CHIP MCR10EZHF2202 1 X

R116 RESISTOR/CHIP MCR10EZHF1602 1 X

R50,122 RESISTOR/CHIP MCR10EZHF3001 2 X

R138,144 RESISTOR/CHIP MCR10EZHF5622 2 X

R142,146 RESISTOR/CHIP MCR10EZHF1002 2 X

Parts Name

Code

RankQ'ty

- 36 -

Page 39

Price

N Item Code No. Specification

R145 RESISTOR/CHIP MCR10EZHF6800 1 X

R184 RESISTOR/CHIP MCR10EZHF1101 1 X

R183 RESISTOR/CHIP MCR10EZHF3601 1 X

R123,126 RESISTOR/CHIP MCR50JZHFL1R00 2 X

R180 RESISTOR/CHIP MCR100JZHJ301 1 X

R181 RESISTOR RSF1BS 27 OHM 1 X

C4,5 CC-CHIP MCH185CN 103KK 2 X

C1,6,9,11-16,39,42-45, CC-CHIP MCH182FN 104ZK 30 X

50,52-55,57,58,61,

68-74,76

C7,40,49 CC-CHIP MCH185A 471JK 3 X

C8,10 CC-CHIP MCH185A 100DK 2 X

C41,46,80 CC-CHIP MCH185A 331JK 3 X

C47,48,62-65,75,77,81, CC-CHIP MCH185C 102KK 13 X

83,84

C18-38,56,78 CC-CHIP MCH185A 101JK 23 X

N C51,79 94870907 E-CAP 100MF50V 00-01200910 2 AB C

N C82 94870908 E-CAP 1000MF10V 00-01200930 1 AC C

N F2 94870909 FUSE 0473005.YRT1 00-02502170 1 AJ A

N F1 94870910 FUSE CCV 1 00-02500615 1 AG A

N L5 94870911 INDUCTOR SF-T8-40S-PF 00-01800065 1 AL C

N CN4 94870912 CONNECTOR TM5RE2-66(50) 00-04003210 1 AW C

N L1-4 94870913 INDUCTOR/CHIP MPZ2012S300A 00-01800210 4 AC C

N FB1-3 94870914 INDUCTOR BLM31PG500SN1L 00-02300096 3 AB C

N BZ1 94870915 BUZZER PS1740P02 00-02400410 1 AF C

N J1 94870916 CONNECTOR HLEM28S-1 00-03200541 1 AG C

N CN1 94870917 CONNECTOR 53047-0910 00-03200583 1 AF C

P1 94870517 CONNECTOR/D-SUB DB25-SK-2-4-4#40/1006 00-03204000 1 AP C

CN6 19060819 CONNECTOR B2P-SHF-1AA 00-04000010 1 AA C