Page 1

EXTERNAL PRINTER

FEB. 2000

MODEL UP-250

(without price)

TECHNICAL MANUAL

Page 2

1. This document contains confidential, proprietary information of CASIO or its affiliates.

You must keep such information confidential. If the user is a business entity or organization,

you must limit disclosure to those of your employees, agents and contractors who have

a need to know and who are also bound by obligations of confidentiality.

2. On the earlier of (a) termination of your relationship with CASIO, or (b) CASIO’s request,

you must stop using the confidential information. You must then return or destroy the

information, as directed by CASIO.

3. If a court, arbitrator, government agency or the like orders you to disclose any confidential

information, you must immediately notify CASIO. You agree to give CASIO reasonable

cooperation and assistance in resisting disclosure.

4. You may use confidential information only for the purpose of operating or servicing the

products to which the document relates, unless you obtain the prior written consent of CASIO

for some other use.

5. CASIO warrants that it has the right to disclose the confidential information.

CASIO MAKES NO OTHER WARRANTIES CONCERNING THE CONFIDENTIAL

INFORMATION OR ANY OTHER INFORMATION IN THE DOCUMENT, INCLUDING

(WITHOUT LIMITATION) ANY WARRANTY OF TITLE OR NON-INFRINGEMENT.

CASIO has no liability for loss or damage arising from or relating to your use of or

reliance on the information on the document.

6. You may not reproduce, store or transmit the confidential information in any form or by any

means (electronic, mechanical, photocopying, recording, or otherwise) without the prior

written permission of CASIO.

7. Your obligations under this Agreement are in addition to any other legal obligations.

CASIO does not waive any right under this Agreement by failing to exercise it. The laws of

Japan apply to this Agreement.

CONFIDENTIALITY AGREEMENT

BY USING THIS DOCUMENT, YOU AGREE TO ABIDE BY THE TERMS OF THIS

AGREEMENT. PLEASE RETURN THIS DOCUMENT IMMEDIATELY IF YOU DO NOT AGREE

TO THESE TERMS.

Page 3

FCC CLASS A

FCC Compliance Statement

For American Users

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment

is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference, in which case the user will be required to correct the interference

at his or her own expense.

WARNING

The connection of a non-shielded printer interface cable to this printer will invalidate the FCC Verification of this device

and may cause interference levels which exceed the limits established by the FCC for this equipment.

You are cautioned that changes or modifications not expressly approved by the party responsible for compliance could void

your authority to operate the equipment.

FOR CANADIAN USERS

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel brouilleur du Canada.

GEREÄUSCHPEGEL

Gemäß der Dritten Verordrung zum Gerätesicherheitsgecsetz (Maschinenlärminformations- Verordnung-3. GSGV) ist der

arbeitsplatzbezogene Geräusch-Emissionswert kleiner als 70 dB(A) (basierend auf ISO 7779).

Page 4

Introduction

PU-250 Series (Type B) printers are one-station printers for ECR and POS use that can print the results of weighing or

measuring. The main features of the PU-250 Series (Type B) printers are the following:

o High-speed printing through logic-seeking control

o Excellent reliability and long life resulting from the use of two stepping motors, one for moving the carriage and one

for paper feeding

o Flexible paper feed setting permits printing in accordance with any user-defined format

o Command protocol based on ESC/POS, a widely used standard

o Built-in drawer kick-out interface provides capability to drive two drawers

o Selectable character fonts (7 x 9, 9 x 9)

o Semi-automatic paper loading capability

o AC adapter (included) provides compact power supply

o Compact and light in weight

o Automatic Status Back (ASB) function to automatically send printer status changes

o Auto-cutter euipped

o Two-color printing: black and red are selectable.

Notes and Cautions

Note:

Notes have important information and useful tips on the operation of your printer.

CAUTION:

Cautions must be observed to avoid damage to your equipment.

Page 5

CONTENTS

Chapter 1 Features and General Specifications ......................................................1

Features .......................................................................................................................... 2

Printing Specifications ........................................................................................................ 2

Character Specifications..................................................................................................... 3

Paper .................................................................................................................................. 4

Auto-cutter .......................................................................................................................... 5

Paper Roll Supply Device................................................................................................... 5

Receive Buffer .................................................................................................................... 5

Electrical Specifications...................................................................................................... 5

Ribbon Cassette .................................................................................................................5

External Dimensions and Weight........................................................................................ 6

Environmental Specifications ............................................................................................. 6

Reliability ............................................................................................................................ 7

Safety Standards ................................................................................................................7

Printer Installation Position ................................................................................................. 7

Hardware Configuration ................................................................................................ 8

Main Unit Specifications ............................................................................................... 9

Paper Feed Motor............................................................................................................... 9

Carriage Motor.................................................................................................................... 9

Print Head Unit ................................................................................................................... 9

Home Position Sensor........................................................................................................ 9

Paper End Detector .......................................................................................................... 10

Paper Roll Near-end Detector (Optional) ......................................................................... 10

Connectors ................................................................................................................... 10

Interface Connector .......................................................................................................... 10

Power Supply Connector...................................................................................................11

Drawer Kick-Out Connector............................................................................................... 11

Interface ........................................................................................................................ 13

RS-232 Serial Interface .................................................................................................... 13

RS-485 Serial Interface (option) ....................................................................................... 16

IEEE 1284 Parallel Interface ............................................................................................ 16

Buttons and Switches ................................................................................................. 19

Power Switch....................................................................................................................19

Panel Button ..................................................................................................................... 19

DIP Switches ....................................................................................................................20

Panel LEDs ................................................................................................................... 22

Self-test......................................................................................................................... 22

Error Processing.......................................................................................................... 23

Printer Operation When an Error Occurs........................................................................... 23

Data Receive Error ............................................................................................................ 23

Buffer Full Printing ...................................................................................................... 23

Detectors and Printing ................................................................................................ 23

Hexadecimal Dump...................................................................................................... 24

Performing a Hexadecimal Dump..................................................................................... 24

Options .........................................................................................................................24

External Power Supply PS-170 ........................................................................................ 25

Page 6

Chapter 2 Mechanism Configuration and Operating Principles...........................26

Printer Mechanism Operating Principles................................................................... 26

Print mechanism unit ........................................................................................................ 27

Print head unit movement................................................................................................. 28

Wire movement when a single dot is printed.................................................................... 28

Printing a character (9x9 font) ......................................................................................... 29

Paper Feed Mechanism Unit ............................................................................................ 30

Paper loading (semi-automatic loading) ........................................................................... 31

Paper feeding ...................................................................................................................31

Ribbon Feed Mechanism Unit .......................................................................................... 32

Ribbon feeding ................................................................................................................. 33

Detection Mechanism Unit................................................................................................ 34

Home position detection mechanism................................................................................ 34

Paper detection mechanism ............................................................................................. 35

Paper roll near-end detection mechanism (optional)........................................................ 35

Auto-cutter mechanism..................................................................................................... 35

Ribbon Switch Mechanism Unit ................................................................................. 36

Switching from Black to Red............................................................................................. 36

Releasing from Red to Black ............................................................................................ 36

Electrical Circuitry Operating Principles ................................................................... 37

Hardware Configuration.................................................................................................... 37

Principles of Operation ............................................................................................... 41

Power Supply Circuitry ..................................................................................................... 41

Control Circuitry................................................................................................................ 42

CPU .................................................................................................................................. 43

Various detector circuits.................................................................................................... 46

Host interface circuit ......................................................................................................... 47

Drawer kick-out drive circuit ............................................................................................. 47

DIP switch read circuit ...................................................................................................... 48

Printer Mechanism Driver Circuits ............................................................................. 50

Print head driver circuit..................................................................................................... 50

Paper feed motor driver circuit ......................................................................................... 51

Carriage motor driver circuit ............................................................................................. 51

Auto-cutter driver circuit.................................................................................................... 52

Chapter 3 Handling and Maintenance .....................................................................53

Handling Precautions .................................................................................................. 53

Storage Precautions ......................................................................................................... 53

Use Precautions ............................................................................................................... 53

Paper Handling Precautions ............................................................................................. 53

Ribbon Cassette Handling Precautions ............................................................................ 54

Replacing the Paper Roll............................................................................................. 54

Replacing the Ribbon Cassette .................................................................................. 57

Removing Jammed Paper ........................................................................................... 60

Using the Power Switch Cover ................................................................................... 64

Inspection and Maintenance....................................................................................... 65

Cleaning........................................................................................................................66

Page 7

Lubricants..................................................................................................................... 66

Standard Lubrication ........................................................................................................ 66

Lubricants ......................................................................................................................... 66

Lubrication Points ............................................................................................................. 67

Tool List ........................................................................................................................ 67

Chapter 4 Troubleshooting ......................................................................................68

Self-test......................................................................................................................... 68

Initiating the Self-test ........................................................................................................68

Self-test Standby .............................................................................................................. 68

Ending the Self-test .......................................................................................................... 68

Troubleshooting Flowchart......................................................................................... 69

Troubleshooting Tables ............................................................................................... 76

Error Types and Countermeasures ............................................................................ 82

Chapter 5 Disassembly, Assembly, and Adjustment .............................................87

Small Part Specifications ............................................................................................ 87

Disassembly ................................................................................................................. 88

Removing the fuse............................................................................................................ 88

Removing the print head unit............................................................................................ 89

Removing the auto-cutter ................................................................................................. 91

Removing the main circuit board assembly ...................................................................... 92

Sub-assembly A ........................................................................................................... 94

Paper feed frame unit assembly ....................................................................................... 94

Main Assembly 1 .......................................................................................................... 98

Ribbon switch lever, ribbon release spring, ribbon release lever,

ribbon intermediate gear, ribbon transmission gear, ribbon take-up assembly,

and ribbon drive plate assembly ....................................................................................... 98

Main Assembly 2 ........................................................................................................ 100

Tension plate assembly .................................................................................................. 100

Main Assembly 3 ........................................................................................................ 100

Paper feed frame assembly ............................................................................................ 100

Main Assembly 4 ........................................................................................................ 101

Carriage motor assembly................................................................................................ 101

Main Assembly 5 ........................................................................................................ 102

Carriage sub assembly................................................................................................... 102

Main Assembly 6 ........................................................................................................ 103

Carriage shaft assembly................................................................................................. 103

Main Assembly 7 ........................................................................................................ 104

Adjustment roller shaft holder assembly......................................................................... 104

Main Assembly 8 ........................................................................................................ 105

Carriage guide shaft assembly ....................................................................................... 105

Main Assembly 9 ........................................................................................................ 105

Belt tension spring assembly.......................................................................................... 105

Page 8

Main Assembly 10 ...................................................................................................... 106

Sensor assembly ............................................................................................................ 106

Main Assembly 11 ...................................................................................................... 108

Carriage motor heat sink assembly ................................................................................ 108

Main Assembly 12 ...................................................................................................... 108

Print head FPC assembly ............................................................................................... 108

Main Assembly 13 ...................................................................................................... 110

Print head unit ................................................................................................................ 110

Main assembly 14....................................................................................................... 111

Left cover fixing plate and right cover fixing plate........................................................... 111

Main Assembly 15 ...................................................................................................... 112

Ribbon frame earth plate ................................................................................................ 112

Main Assembly 16 ...................................................................................................... 113

Ribbon frame assembly , ribbon frame spring, and ribbon frame fixing plate.................. 113

Main Assembly 17 ...................................................................................................... 114

Thumb-screw and head cover ........................................................................................ 114

Main Assembly 1 (Case Unit).................................................................................... 115

Lower cutter plate assembly ........................................................................................... 115

Main Assembly 2 (Case Unit).................................................................................... 116

Upper plate assembly ..................................................................................................... 116

Main Assembly 3 (Case Unit).................................................................................... 118

Main circuit board assembly ........................................................................................... 118

Main Assembly 4 (Case Unit).................................................................................... 119

Inserting the cables ........................................................................................................ 119

Main Assembly 5 (Case Unit).................................................................................... 120

Lower case assembly ..................................................................................................... 120

Main Assembly 6 (Case Unit).................................................................................... 121

Manual cutter assembly and auto-cutter fixing plate ...................................................... 121

Main Assembly 7 (Case Unit).................................................................................... 123

Auto-cutter assembly ...................................................................................................... 123

Main Assembly 8 (Case Unit).................................................................................... 126

Paper roll receive rollers, upper case, guide roller, and switch panel assemblies .......... 126

Main Assembly 9 (Case Unit).................................................................................... 128

Interface circuit board assembly and connector plate .................................................... 128

Main Assembly 10 (Case Unit).................................................................................. 130

Lower plate, ROM cover, and rubber foot assembly....................................................... 130

Main Assembly 11 (Case Unit) .................................................................................. 131

Main cover assembly ...................................................................................................... 131

Main Assembly 12 (Case Unit).................................................................................. 132

Near-end detector assembly (optional)........................................................................... 132

Adjustment ................................................................................................................. 134

Platen gap adjustment.................................................................................................... 134

Page 9

Appendix....................................................................................................................135

RS-485 Serial Interface .............................................................................................. 135

Main Circuit Board Parts Layout .............................................................................. 140

RS-232 Serial Interface Circuit Board Parts Layout ............................................... 141

IEEE 1284 Parallel Interface Circuit Board Parts Layout ....................................... 142

RS-485 Serial Interface Circuit Board Parts Layout ............................................... 143

Main Circuit Board Diagram...................................................................................... 144

RS-232 Serial Interface Circuit Board Diagram....................................................... 145

IEEE 1284 Parallel Interface Circuit Board Diagram............................................... 146

RS-485 Serial Interface Circuit Board Diagram....................................................... 147

Printer Mechanism Unit Overall Exploded Diagram ............................................... 148

Case Unit Overall Exploded Diagram....................................................................... 149

Printer Mechanism Unit Lubrication Points Diagram............................................. 150

Case Unit Lubrication Points Diagram .................................................................... 151

Parts List....................................................................................................................152

EXPLODED DIAGRAM FOR TM-U200B/U210B NO.1 .............................................154

EXPLODED DIAGRAM FOR TM-U200B/U200PB/U210B/U210PB NO.2 ................155

Page 10

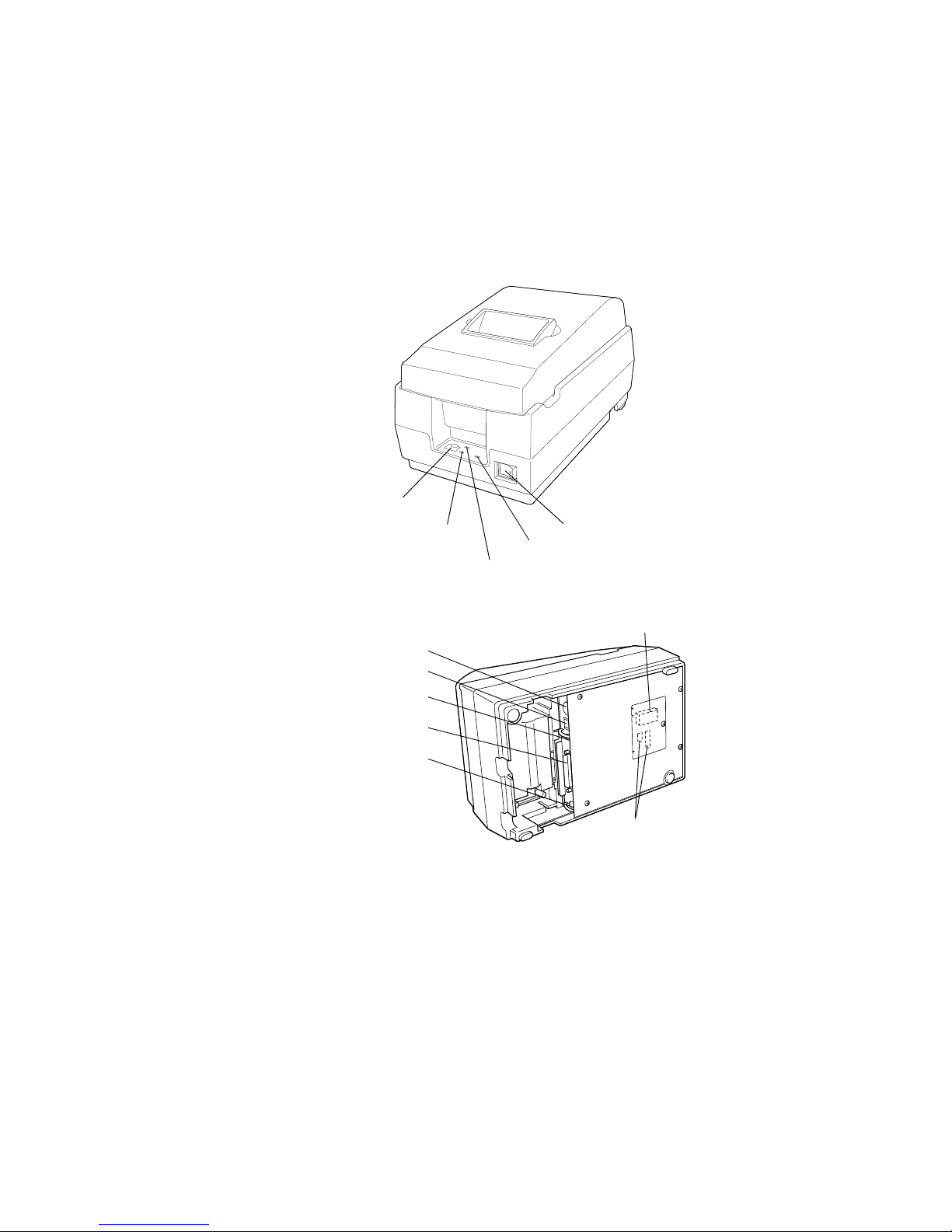

Figure 1-1 PU-250 appearance

POWER LED

Power switch

PAPER OUT LED

ERROR LED

FEED button

(PAPER OUT/PRESS FEED)

PROM

DIP switches

Power supply connector

Drawer kick-out connector

Frame ground screw

Interface connector

Frame ground screw

— 1 —

Chapter 1

Features and General Specifications

Page 11

Features

Printing Specifications

NOTE:

If the print duty ratio is too high, the operation of the print head is stopped by the duty limit. In

such circumstances, the print speeds shown above cannot be guaranteed.

cpi = characters per inch.

Printing method: Serial impact dot-matrix

Head wire configuration: 9-pin serial type

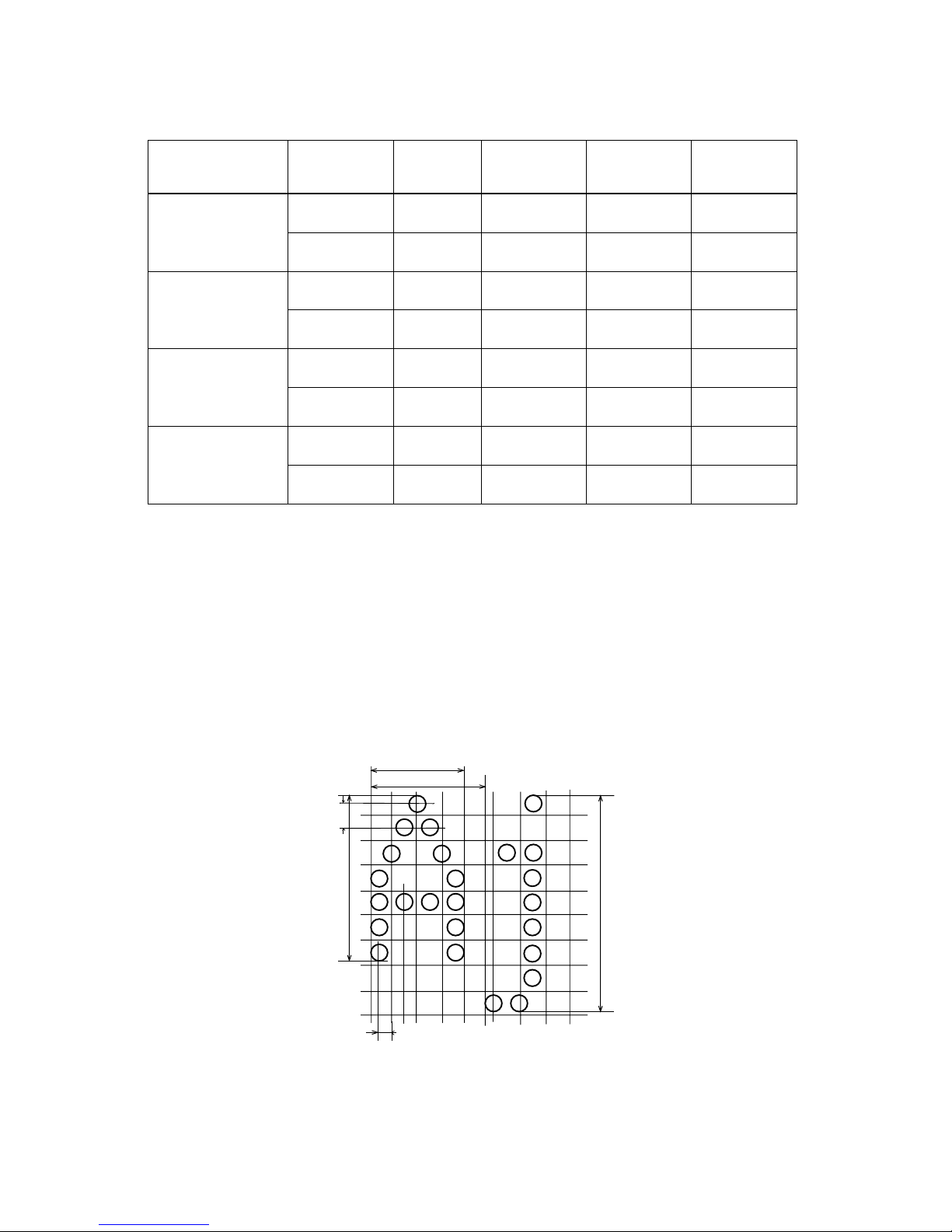

Figure 1-2 Dot configuration

Dot pitch: 0.353 mm (1/72")

Dot wire diameter 0.29 mm (0.01")

Printing direction: Bidirectional with logic seeking

Printing width: 63.34 mm (2.49")

Line feed: 4.233 mm (1/6"): default setting

Programmable in units of 1/144 inch by using commands.

Paper feed method Friction feed

Paper feed speed: Approximately 4.17 inches/second (25 lines/second) during

continuous paper feeding

Characters per line: See the table on the next page.

Characters per inch: See the table on the next page.

Total dot count (horizontal

direction)

7 x 9 font: 400 half-dot positions per line

9 x 9 font: 400 half-dot positions per line

Print speed Approximately 3.5 lines/second (40 columns, 16 cpi)

Approximately 6.4 lines/second (16 columns, 16 cpi)

0.29 mm (0.01")

(wire diameter)

0.317 mm (0.012")

0.353 mm

(0.014")

— 2 —

Page 12

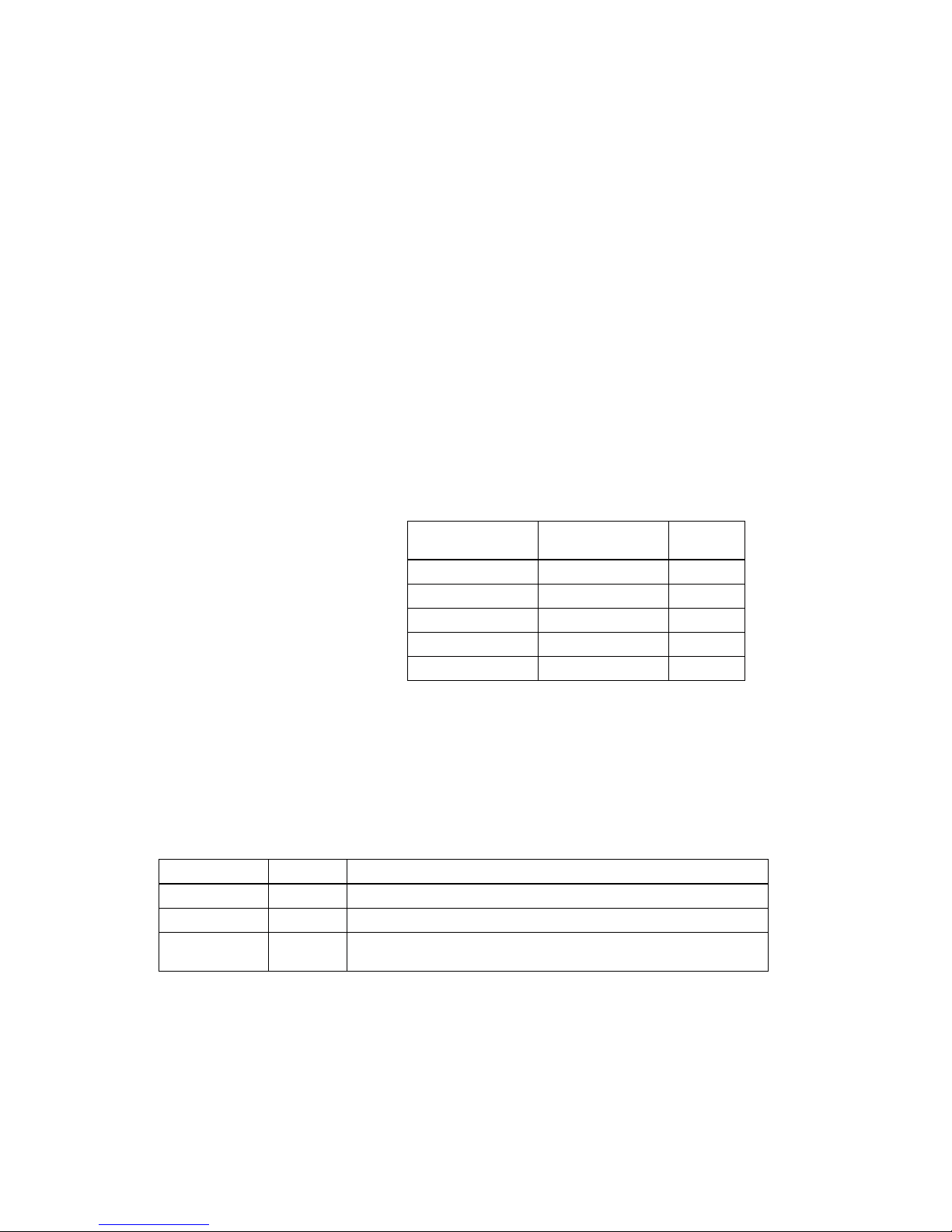

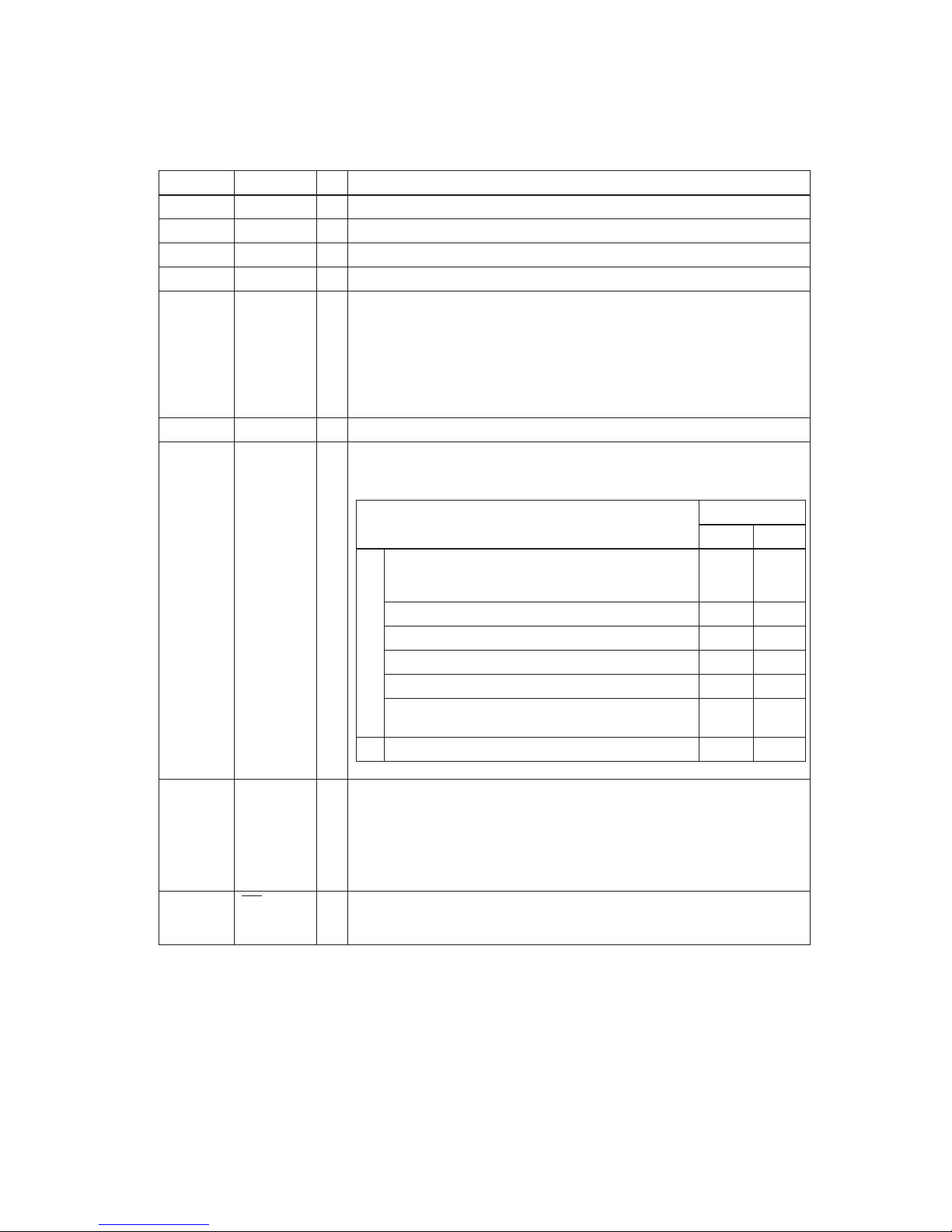

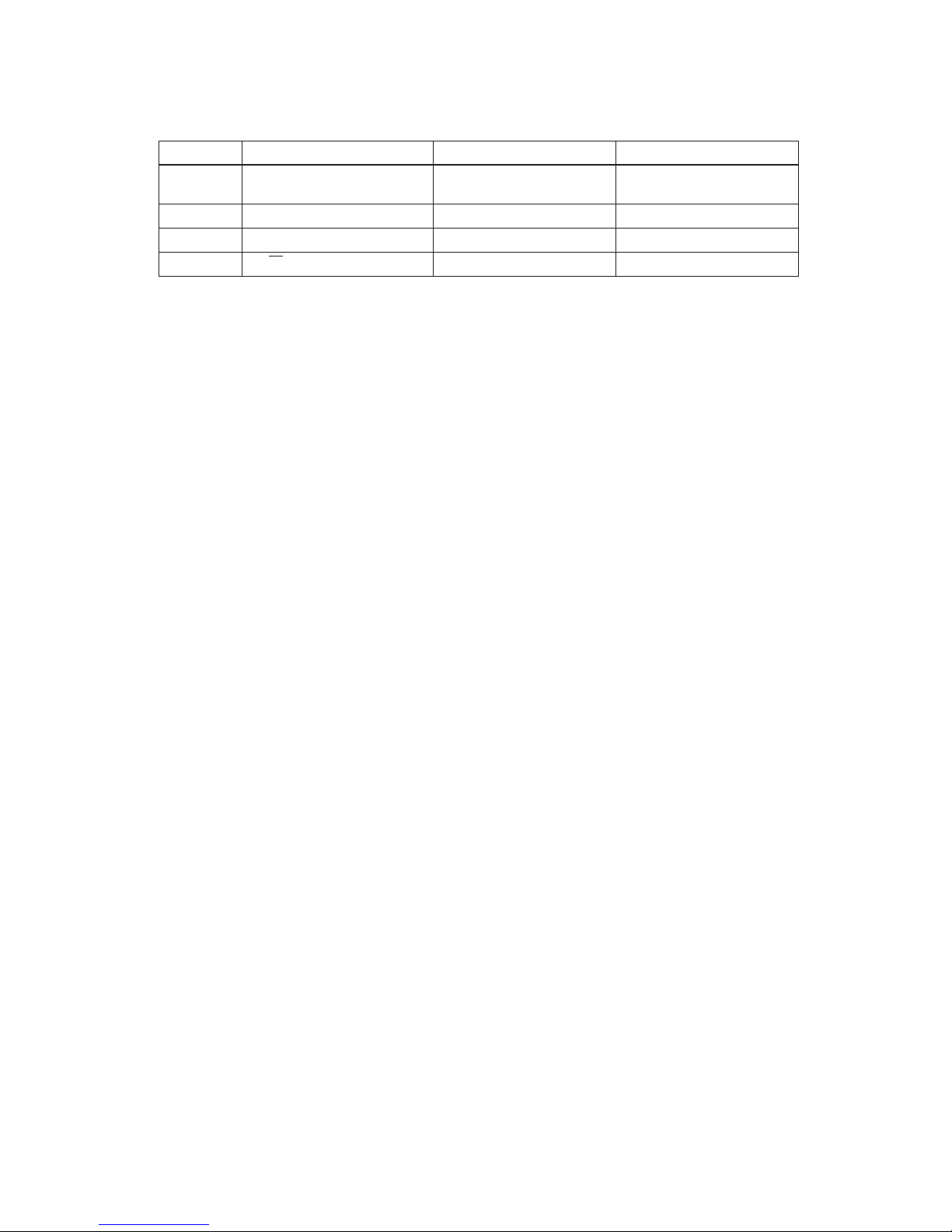

Character dimensions, characters per inch, characters per line

NOTE:

The default font is 7 x 9; the dot spacing between characters is either 3 half dots or 2 half dots,

depending on the setting of DIP switch 2-1.

Character Specifications

Character Structure

Horizontal x Vertical

Character

Structure

Character Set

Character

Dimensions

WxH

Dot Spacing

Between

Characters

Characters Per

Line (cpl)

Characters Per

Inch (cpi)

7 x 9

ANK

1.2 x 3.1 mm

(.047 x .122")

3 half dots 40 16

Graphics

1.7 x 3.1 mm

(.070 x .122")

0 40 16

9 x 9

ANK

1.6 x 3.1 mm

(.063 x .122")

3 half dots 33 13.3

Graphics

2.0 x 3.1 mm

(.079 x .122")

0 33 13.3

7 x 9

ANK

1.2 x 3.1 mm

(.047 x .122")

2 half dots 42 17.8

Graphics

1.6 x 3.1 mm

(.063 x .122")

0 42 17.8

9 x 9

ANK

1.6 x 3.1 mm

(.063 x .122")

2 half dots 35 14.5

Graphics

1.9 x 3.1 mm

(.075 x .122")

0 35 14.5

Character sets: Alphanumeric: 95

International: 32

Graphics: 128 x 8 pages

Character structure: 7 x 9 with 400 half-dot positions per line

9 x 9 with 400 half-dot positions per line

Figure 1-3 Character size (7 x 9 font example)

3.1 mm

(0.122")

2.4 mm

(0.094")

1. 24 m m (0 .049" )

1.59 m m (0.0 63")

0.159 mm (0.006")

0.353 mm

(0.014")

— 3 —

Page 13

Paper

(*1)

This dimension shows the distance from the manual cutter to the print position.

(*2)

Values fo r the p rin ting are a are calcul ated (between dot cen ters) wit h the wi re diameter (0.29 m m [.011 "]).

Paper types: Paper roll: Plain paper or pressure-sensitive paper

Paper roll width: 76 ± 0.5 mm (2.99 ± .020")

Paper roll maximum

diameter:

83 mm (3.27")

Paper roll core: Unless there is an optional near-end detector, you cannot use a paper

roll with the core and paper glued together.

Normal paper: Thickness: 1 sheet: 0.06 to 0.085 mm (.0024 to .0034")

Weight: 52.3 to 64 g/m

2

(13.9 to 17 lb)

(45 to 55 kg/1000 sheets/1091 x 788)

Pressure-sensitive paper Original sheet + up to 1 copy sheet

Thickness: 1 sheet: 0.05 to 0.08 mm (.0020 to .0031")

Total thickness: 0.2 mm (.0079") or less

Recommended paper: Mitsubishi - carbonless paper (blue)

Top and middle sheets: N40Hi

paper thickness: 0.06 mm (.0024")

weight: 47.2 g/m

2

(12.6 lb)

Bottom sheet: N60

paper thickness: 0.08 mm (.0031")

weight: 68.0 g/m

2

(18.1 lb)

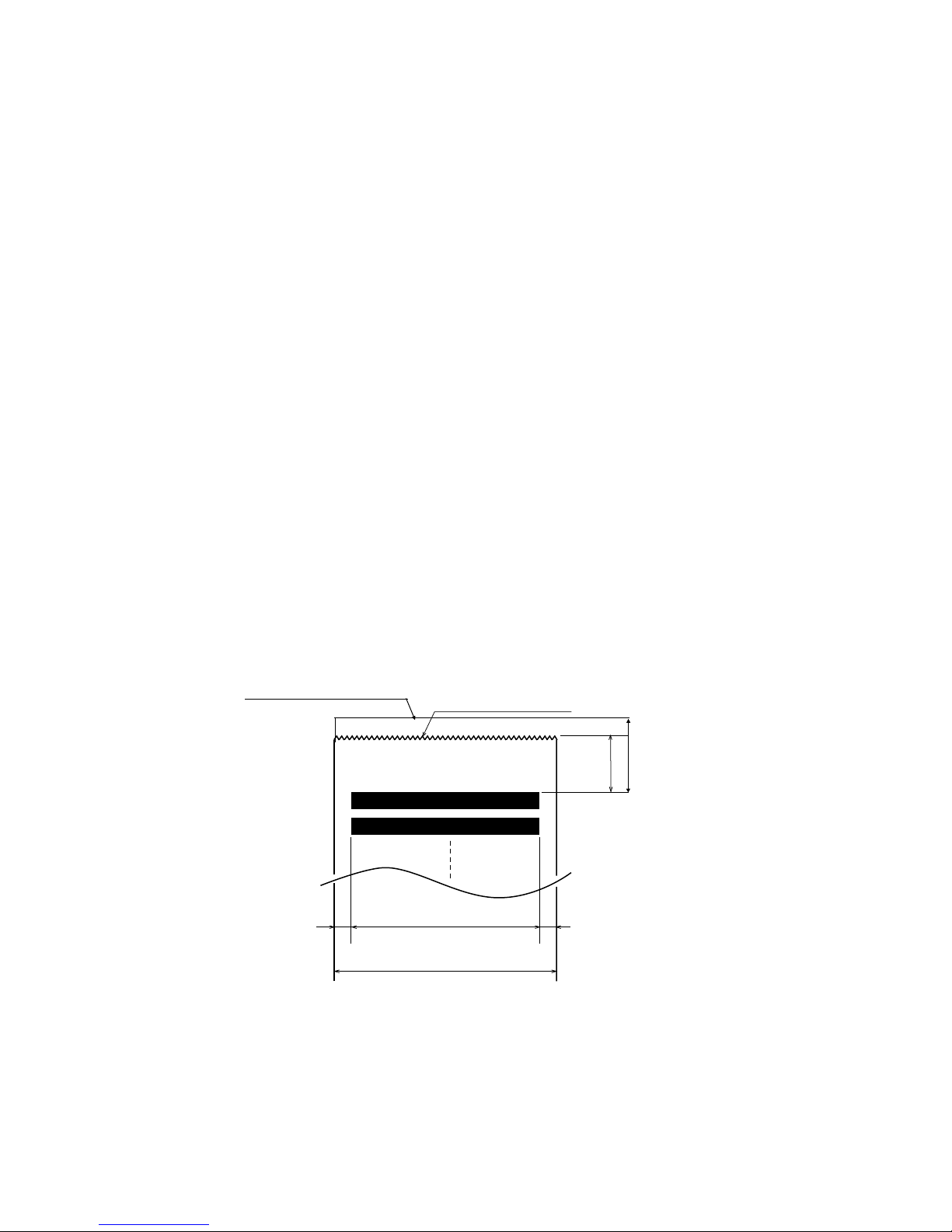

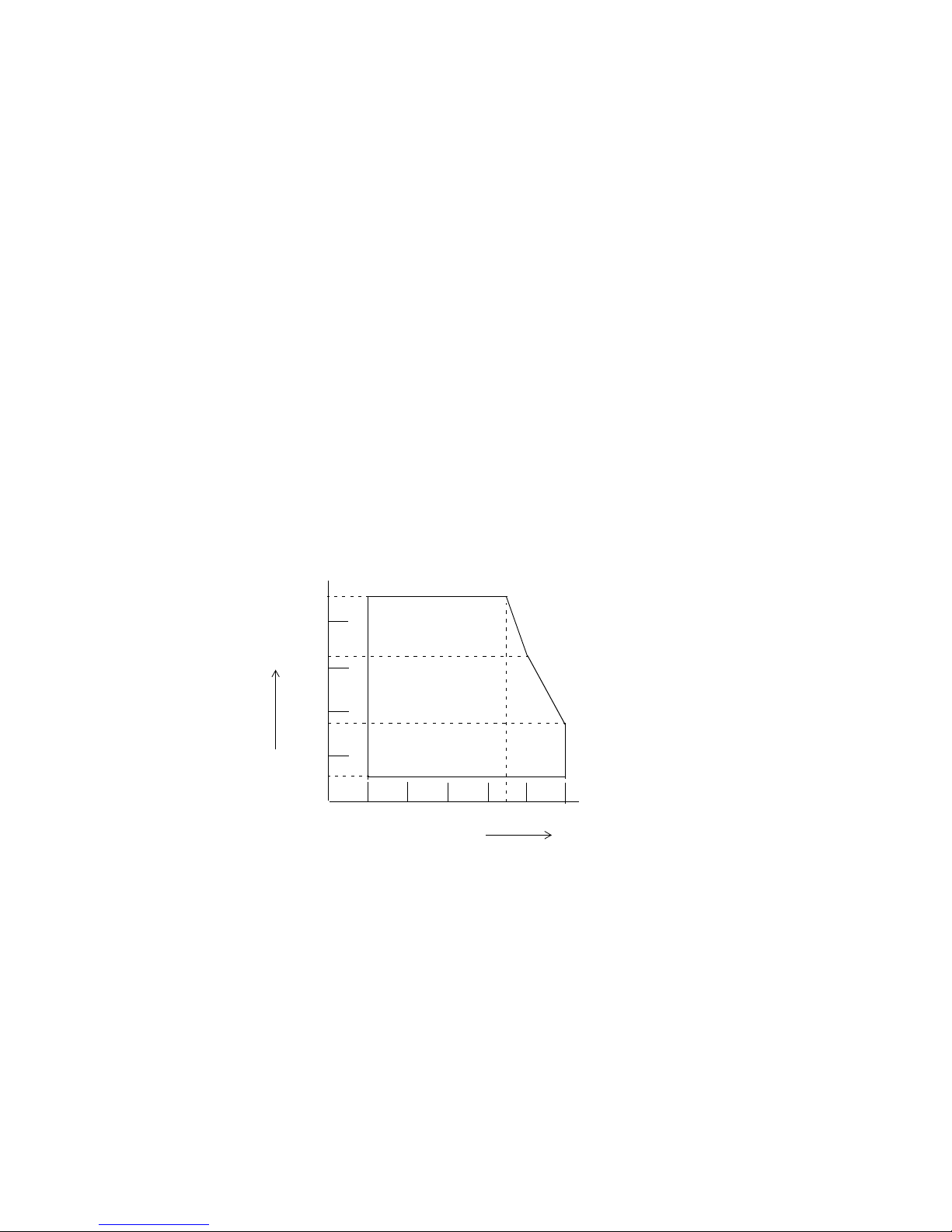

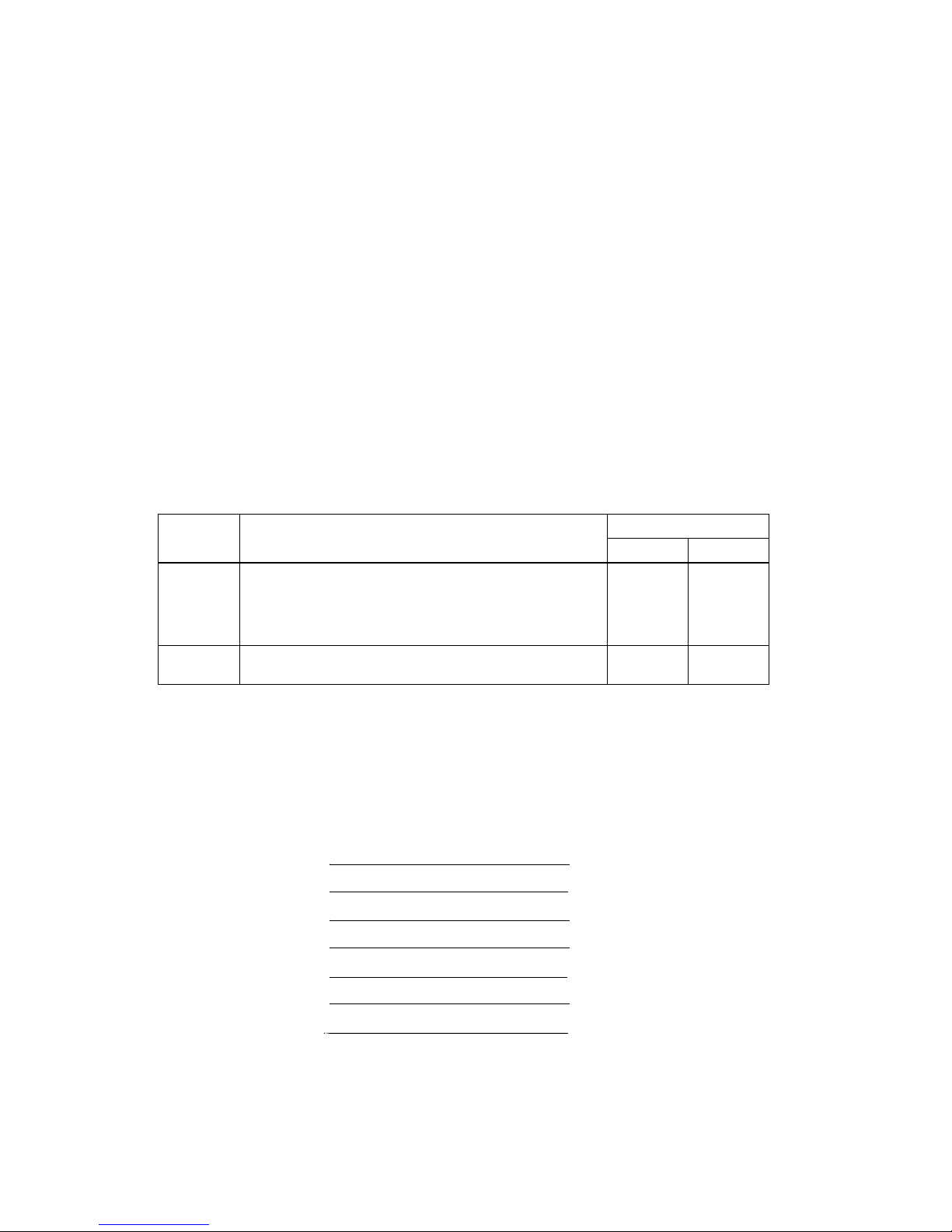

Figure 1-4 Printing area

Maximum of 200 dots, 400 positions

76 mm (2.99")

20.2 mm (0.79") (*1)

Cutting position (manual cutter)

(*2)

63.34 mm (2.49")

[5.9 mm (0.23")] [6.76 mm (0.27")]

Cutting position (auto-cutter)

27 mm (1.063")

— 4 —

Page 14

Auto Cutter

Partial cut is executed by a command. (A partial cut leaves one point uncut.)

Paper Roll Supply Device

Receive Buffer

Either 1KB or 40 bytes, selectable by DIP switches.

Electrical Specifications

Ribbon Cassette

Ribbon cassette specifications

(*1)

Ribbon life is based on the following conditions:

Character font: 7 x 9 font (with descenders)

Print pattern: ASCII 96-character rolling pattern. See the specification published by EPSON for the print

pattern example.

NOTE:

Malfunctions and other problems may occur if a ribbon cassette other than the specified one is used.

Supply device: Drop-in loading

Power supply One of the following five AC adapters is included, depending on

the specifications:

AC adapter specifications

Power consumption

(except when driving

drawer kick-out):

Operating: Mean average 43 W

Standby: Average 6 W

Model number Color Ribbon life (*1)

ERC-38 (P) Purple 4 million characters (with continuous printing at 25° C [77° F])

ERC-38 (B) Black 3 million characters (with continuous printing at 25° C [77° F])

ERC-38 (B/R)

Black and

Red

Black: 1.5 million characters (with continuous printing at 25° C [77° F])

Red: 750,000 characters (with continuous printing at 25° C [77° F])

Settings and

shipment

Input voltage range

Model

name

Japan 100 V ± 10%, 50/60 Hz PA-6508

North America 120 V ± 10%, 60 Hz PB-6509

Europe (Germany) 230 V ± 10%, 50 Hz PB-6510

Europe (U.K.) 230 V ± 10%, 50 Hz PA-6511

Australia 240 V ± 10%, 50 Hz PA-6513

— 5 —

Page 15

External Dimensions and Weight

Environmental Specifications

Height: 150 mm (5.91")

Width: 160 mm (6.30")

Depth: 248 mm (9.76")

Weight: Approximately 2.5 kg (5.5 lb)

Color: EPSON standard gray

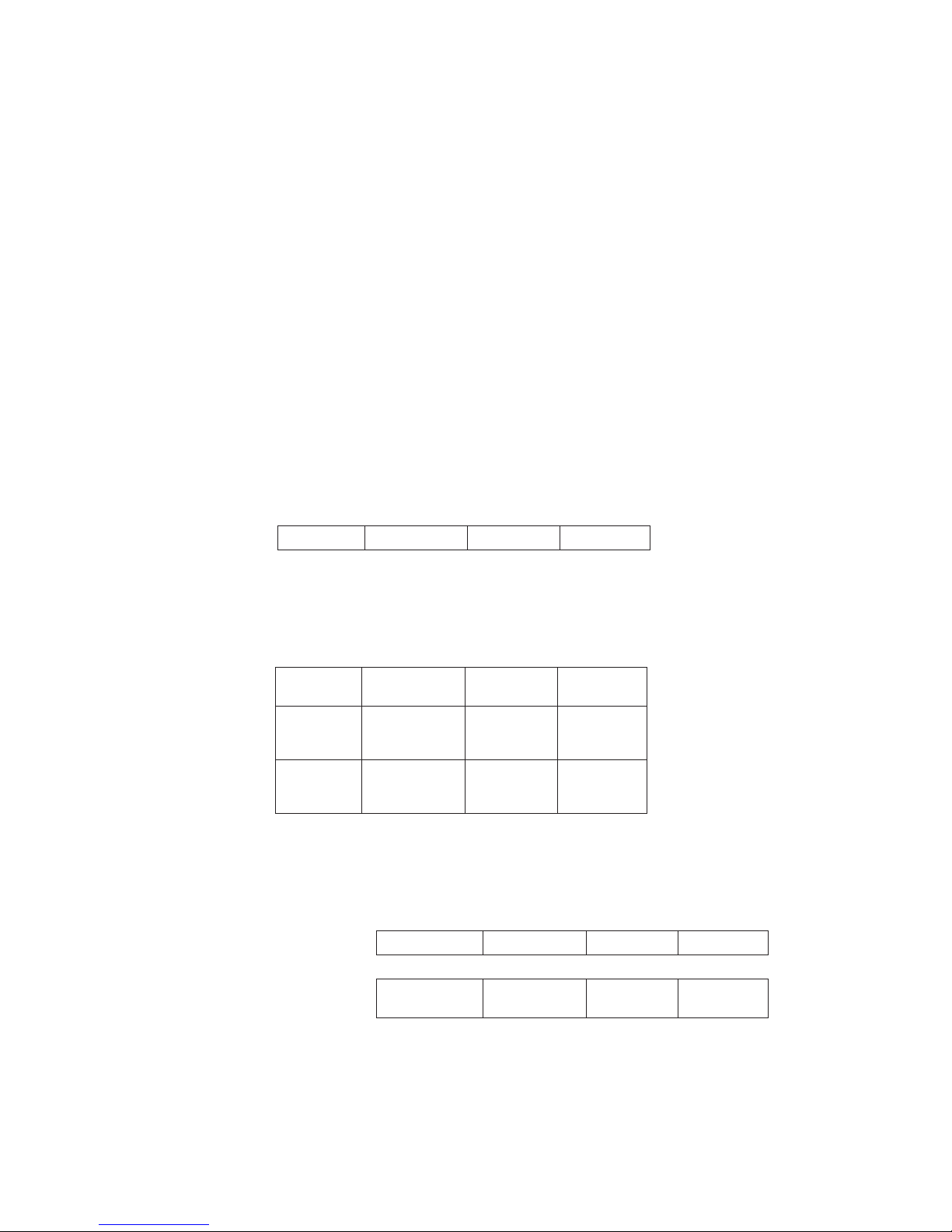

Temperature: Operating: 0° to 50° C (32° to 122° F)

At 34° C (93° F) or higher, there are humidity restrictions;

see the figure below.

Storage: –10° to 50° C (14° to 122° F), except paper and ribbon

Humidity: Operating: 10% to 90% RH (non-condensing)

Storage: 10% to 90% RH (non-condensing), except paper and ribbon

Figure 1-5 Operating temperature and humidity range

Vibration resistance: When packed:

Frequency: 5 to 55 Hz

Acceleration: 2 G

Sweep: 10 minutes (half cycle)

Duration: 1 hour

Directions: x, y, and z

Operating Temperature Range

40° C (104° F), 65%

34° C (93° F), 90%

50° C (122° F), 35%

80

60

40

20

0

0 10 40

Environmental Temperature

Relative Humidity [% RH]

50

90

10

3020

— 6 —

Page 16

Reliability

Safety Standards

The following standards are applied only to the printers that are so labeled.

Printer Installation Position

Install the printer horizontally. Make sure it does not tilt more than 15°. The printer must also be installed

so that it does not move or vibrate during paper cutting or the drawer kick-out operation. Fastening tape

is available as an option.

Impact resistance: When packed:

Package: EPSON standard package

Height: 60 cm (23.62")

Directions: 1 corner, 3 edges, and 6 surfaces

When unpacked:

Height: 5 cm (1.97")

Directions: Lift one edge and release it (for all 4 edges)

Life

Mechanism: 7,500,000 lines (See the UP-250) Specification for the print color

switching number.

Print head: 150 million characters (using an average of 2 dots/wire per character.)

(The print pattern is shown in the UP-250 Specification in Figure A-1.)

Auto cutter: 800,000 cuts

End of life is defined as the point at which the printer reaches the

beginning of the wear out period.

MTBF 180,000 hours

Failure is defined as a random failure occurring within the time of the

random failure period.

MCBF 18,000,000 lines

This is an average failure interval based on failures relating to wear out

and random failures up to the life of 7,500,000 lines.

For Europe: CE Marking: EN55022, EN50082-1, EN45501

Safety standards: TÜV

EMI: FCC class A

For USA:

Safety standards: UL1950-2TH-D3

c-UL

— 7 —

Page 17

Hardware Configuration

Figure 1-6 UP-250 main unit configuration

Carriage motor

Paper feed motor

Paper end detector

Print head unit

Home position sensor

Paper roll near-end detector (optional)

Main circuit board

Interface circuit board

— 8 —

Page 18

Type: 4-phase, 48-polarity, PM-type stepping motor

Drive voltage: 24 VDC ± 10%

Winding resistance: 58 Ω ± 2.9 Ω at 25°C (77°F), per phase

Current consumption: Peak: 1.1 A in worst case

Average: 200 mA at 24 VDC, 25°C (77°F), 600 pps

350 mA maximum

Type: 4-phase, 48-polarity, PM-type stepping motor

Drive voltage: 24 VDC ± 10%

Winding resistance: 39.5 Ω ± 1.9 Ω at 25°C (77°F), per phase

Current consumption: Peak: 1.5 A maximum

Average: 400 mA at 24 VDC, 25°C (77°F), 952 pps

600 mA maximum

Number of solenoids: 9

Winding resistance: 19.2 Ω ± 5% at 25°C (77°F), per phase

Drive voltage: 24 VDC ± 10%

Type: Photo sensor

Voltage: 5 VDC ± 5%

Output level: LOW when the carriage home position is detected

— 9 —

Main Unit Specifications

Paper Feed Motor

Carriage Motor

Print Head Unit

Home Position Sensor

Page 19

Paper End Detector

Paper Roll Near-end Detector (Optional)

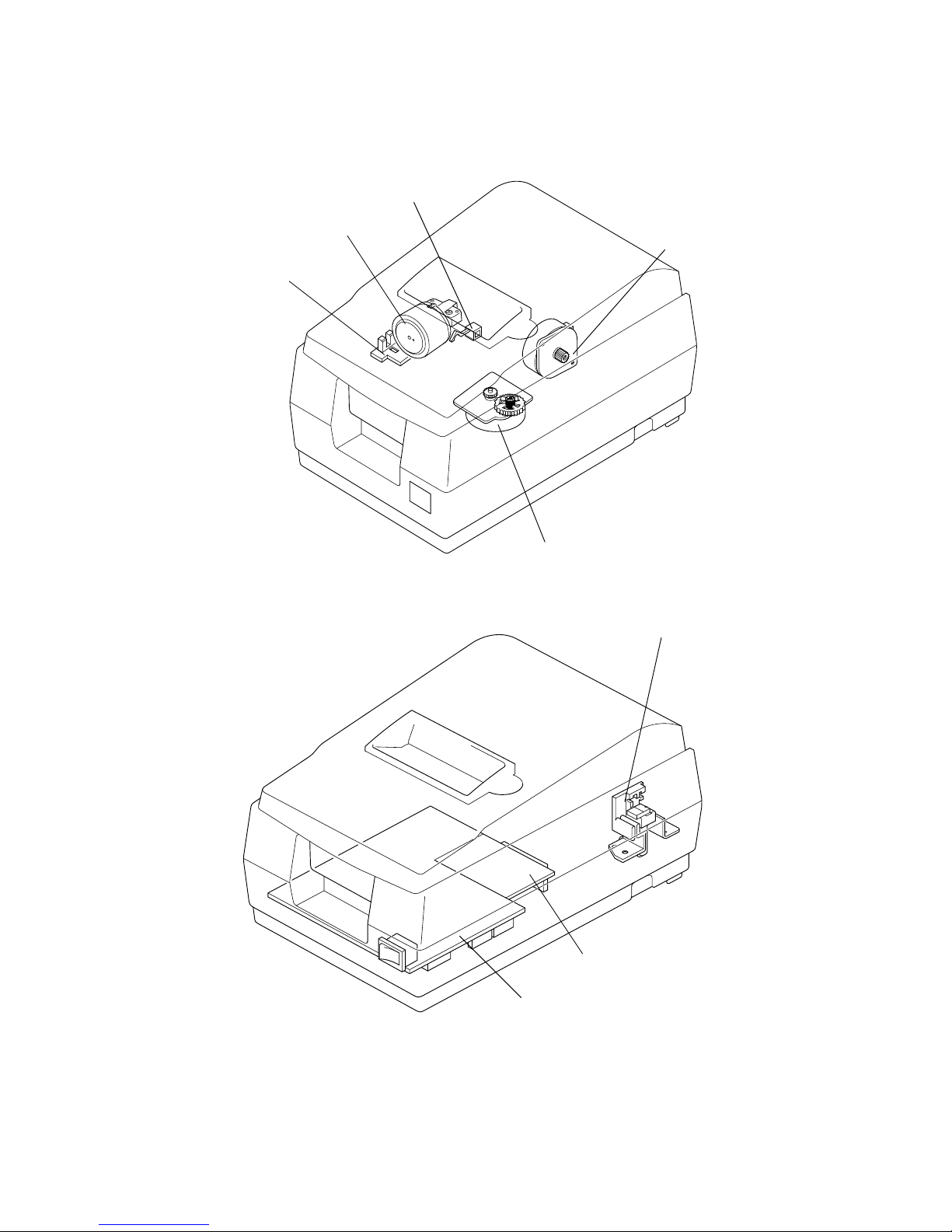

Connectors

Figure 1-7 Connector panel (serial interface)

Figure 1-8 Connector panel (parallel interface)

Interface Connector

See the interface section.

Type: Microswitch

Voltage: 5 VDC ± 5%

Output level: High when paper end is detected

Type: Microswitch

Voltage: 5 VDC ± 5%

Output level: Low when a paper near-end is detected

Frame ground

screw connector

Power supplyDrawer kick-out

connector

Interface

connector

Frame ground

screw

Power supply

connector

Drawer kick-out

connector

Frame ground

screw

Interface

connector

Frame ground

screw

— 10 —

Page 20

— 11 —

This connector is used to connect the printer to an external power source.

NOTE:

Be sure to ground the frame ground (FG) screw on the board at the bottom of the unit. Ground

wire terminal hole diameter: 3.2 mm (.13"). Ground wire thickness: AWG 18 or equivalent.

A pulse specified by the

ESC p

command is output to the drawer kick-out connector. The host

can confirm the status of the input signal by using the

GS a

,

GS r

, or

DLE EOT

commands.

The host computer can check the drawer open/closed status with the

DLE EOT, GS a

, and

GS r

commands.

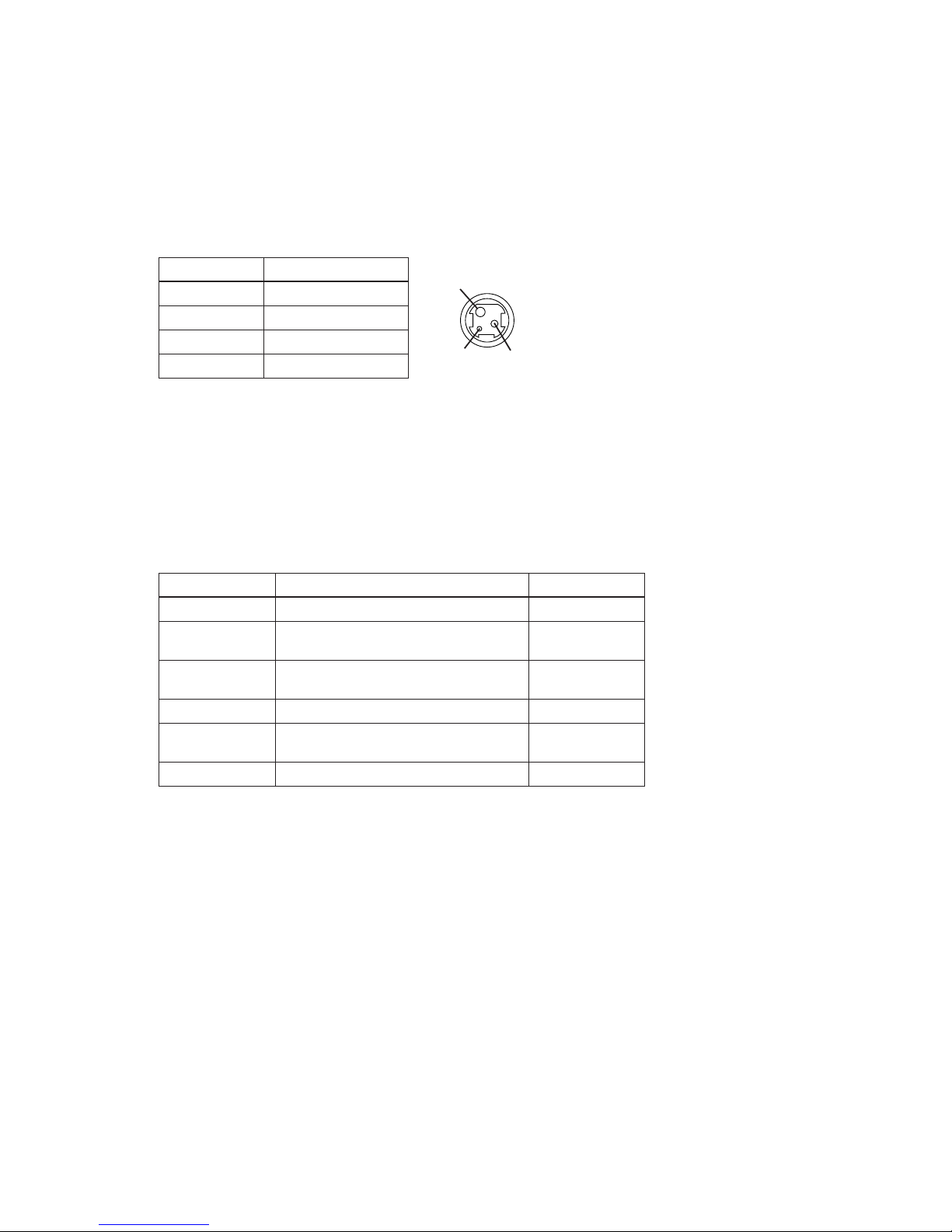

Pin assignments: See the table below.

Pin Number

1 + power supply

2 GND

3NC

Shell Frame GND

Pin Number Signal name Direction

1 Frame GND

2

Drawer kick-out drive signal 1

(See "Drawer kick-out drive signal," below.)

Output

3

Drawer open/close signal

(See "Drawer open/closed signal," below.)

Input

4 +24

—

—VDC

5

Drawer kick-out drive signal 2

(See "Drawer kick-out drive signal," below.)

Output

6 Signal GND —

Input signal level: LOW = 0 V

HIGH = 2 to 5 V (at connector pin 3)

2

3 1

Signal Name

Power Supply Connector

Drawer Kick-Out Connector

Power supply connector pin assignments

Drawer kick-out connector pin assignments

Drawer open/closed signal

Page 21

NOTES:

❏

Two driver transistors cannot be energized simultaneously.

❏

The drawer drive duty must be as shown below:

❏

Be sure to use the printer power supply (connector pin 4) for the drawer power source.

Output signal: Voltage = Approximately 24 VDC

Current = 1 A or less

Output waveform: Outputs the waveforms in Figure 1-8 to pins

2 and 5 of the connector.

t

1 (ON time) and t2

(OFF time) are specified by

ESC p

.

t

1 x 2 ms

t

2 x 2 ms

ON time

(ON time + OFF time)

≤ 0.2

— 12 —

Drawer kick-out drive signal

CAUTION:

To avoid overcurrent, resistance of the drawer kick-out solenoid must be 24 Ω or more.

Figure 1-9 Drawer kick-out drive signal output waveform

CAUTION:

Do not connect a telephone line to the drawer kick-out connector; otherwise the printer and the telephone

line may be damaged.

Page 22

Interface

RS-232 Serial Interface

NOTES:

❏

Handshaking, data word length, baud rate, and parity depend on DIP switch settings.

❏

Data transmitted from the printer has 1 stop bit (fixed).

Data transmission: Serial (compatible with RS-232)

Synchronization: Asynchronous

Handshaking: DTR/DSR or XON/XOFF control

Signal levels: MARK = -3 to -15 V: Logic 1/OFF

SPACE = +3 to +15 V: Logic 0/ON

Baud rates: 4800, 9600 bps

Data word length: 7 or 8 bits

Parity settings: None, even, odd

Stop bits: 1 or more

Connector: Female D-SUB 25-pin connector or equivalent

— 13 —

Page 23

NOTES:

❏

When the remaining space in the receive buffer is 16 bytes, the printer buffer becomes full.

This status continues until the space in the receive buffer increases to 32 bytes.

❏

The printer ignores data received when the remaining space in the receive buffer is 0 bytes.

❏

XON is not transmitted when the receive buffer is full.

Pin number Signal name I/O Function

1 FG — Frame ground

2 TXD O Transmit data

3 RXD I Receive data

4 RTS O Same as the DTR signal

6 DSR I This signal indicates whether the host computer can receive data. SPACE

indicates the host computer can receive data, and MARK indicates the host

computer cannot receive data. When DTR/DSR control is selected, the printer

transmits data after confirming this signal (except when transmitting data by

DLE

EOT

and

GS a

). When XON/XOFF control is selected, the printer does not check

this signal. Changing the DIP switch setting lets this signal be used as a reset

signal for the printer. The printer is reset when the signal remains MARK for

1 ms or more.

7 SG — Signal ground

20 DTR O 1) When DTR/DSR control is selected, this signal indicates whether the printer is

busy. SPACE indicates the printer is ready to receive data, and MARK indicates

the printer is busy. A busy condition can be changed using DIP SW 1-8 as follows:

2) When XON/XOFF control is selected:

This signal indicates whether the printer is correctly connected and ready to

receive data. SPACE indicates the printer is ready to receive data. The signal is

always SPACE except in the following cases:

❏

During the period after power on until the printer is ready to receive data.

❏

During self test.

25 INIT

I Changing DIP switch setting enables this signal to be used as a reset signal for

the printer (see the DIP switch settings in the “Buttons and Switches” section of

this chapter). The printer is reset when the signal remains SPACE for 1 ms or more.

Printer

DIP SW 1-8 status

ON OFF

1. During the period from when power is turned on

(including reset using the interface) to when the

printer is ready to receive data.

BUSY BUSY

2. During self-test BUSY BUSY

3. During paper feeding using the paper FEED button — BUSY

4. When the printer stops printing for a paper-end. — BUSY

5. When an error has occurred. — BUSY

6. When a temporary abnormality occurs in the

power supply voltage

— BUSY

7. When the receive buffer becomes full. (See Notes.) BUSY BUSY

Off line

20 DTR

RS-232 interface connector pin assignments and functions

Interface Connector Pin Assignments

— 14 —

Page 24

Switching between on line and off line

The printer does not have an on-line/off-line button. It goes off line under the following

conditions:

❏

Between the time when power is turned on (including reset using the interface) and when

the printer is ready to receive data.

❏

During the self-test.

❏

During paper feeding using the paper

FEED

button.

❏

Between the time when the printer stops printing for a paper-end and when the on-line

recovery wait time finishes after loading paper (if an empty paper supply is detected by

either the paper roll end detector or the paper roll near-end detector with a printing halt

feature enabled for low paper by

ESC c 4

).

❏

When an error has occurred.

XON/XOFF transmission timing

When XON/XOFF control is selected, the printer transmits XON or XOFF signals as follows.

(

*1) XON is not transmitted when the receive buffer is full.

(*2) XOFF is not transmitted when the receive buffer is full.

NOTE:

The XON code is 11H and the XOFF code is 13H.

Printer status

DIP SW 1-8 status

ON OFF

XON

transmission

• When the printer goes on line after turning power on or after

reset using the interface.

• When the receive buffer is released from the buffer full state.

• When the printer switches from off line to on line (*1).

• When the printer recovers from an error through a command.

Transmission

Transmission

----

----

Transmission

Transmission

Transmission

Transmission

Transmission

Transmission

XOFF

transmission

• During an error condition.

• When the receive buffer becomes full (*2).

Transmission

----

Transmission

Transmission

Serial interface connection example

NOTES:

❏

Set handshaking so that transmitted data can be received.

❏

Transmit data to the printer after turning on the power and initializing the printer.

Host

Printer

TXD

DSR

CTS

RXD

DTR

FG

SG

RXD

DTR

RTS

TXD

DSR

FG

SG

— 15 —

Page 25

RS-485 Serial Interface (option)

Refer to the Appendix for details.

IEEE 1284 Parallel Interface

Complies with the standard described in t he IEEE 12 84 specificat ion by the I nstitute o f Electr ical

and Electronic Engineers, Inc.

Specification

Data transmission: 8-bit parallel

Synchronization: Externally supplied STRO BE

signals

Handshaking:

and BUSY signals

Signal levels: TTL-compatible

Connector: 57RE-40360-830B (DDK) or equivalent (IEEE 1284 Type B)

Reverse communication

(Printer to host): Nibble or byte mode

Reverse Mode (Data Transmission from Printer to Host)

Status data transmission from the printer to the host occurs in nibbl e or byte mode. These modes

allow data transmission from the asynchronous printer under control of the host. Data

transmissions in nibble mode are made via the existing control lines in u nits of four bits (a

nibble). In byte mode, data transmissions proceed by making the eight-bit data lines

bidirectional. Both modes fail to proceed concurrently in compatibility mode, causing half

duplex transmission. The IEEE 1284 nibble/byte modes are under development in draft form

and may be subject to change.

ACK

— 16 —

Page 26

Interface Connector Pin Assignments

IEEE 1284 interface connector pin assignments and functions

NOTES:

❏

❏

❏

❏

❏

❏

Overscored signal names are LOW active signals.

If a host does not provide for the signal lines listed above, two-way communication fails.

For interfacing, signal lines must use twisted pair cables with the return sides connected to signal

ground level.

Interfacing conditions must all be based on the TTL level to meet the characteristics described below.

In addition, both the rise and fall time of each signal must be 0.5 µs or less.

Data transmission must not ignore the ACK or BUSY signal. An attempt to transmit data with either

the ACK or BUSY signal ignored can cause lost data. (Data transmissions to the printer must be made

after verifying the ACK signal or while the BUSY signal is at a LOW level.)

Interface cables should be as short in length as possible.

NC: Not Connected

ND: Not Defined

— 17 —

Pin number Source Compatibility Mode Nibble Mode Byte Mode

1 Host Strobe

Host Clk Host Clk

2 Host/Ptr Data0 (LSB) Data0 (LSB) Data0 (LSB)

3 Host/Ptr Data1 Data1 Data1

4 Host/Ptr Data2 Data2 Data2

5 Host/Ptr Data3 Data3 Data3

6 Host/Ptr Data4 Data4 Data4

7 Host/Ptr Data5 Data5 Data5

8 Host/Ptr Data6 Data6 Data6

9 Host/Ptr Data7 (MSB) Data7 (MSB) Data7 (MSB)

10 Printer Ack

PtrClk PtrClk

11 Printer Busy PtrBusy/Data3,7 PtrBusy

12 Printer PError

AckDataReq/

Data2,6

AckDataReq

13 Printer Select Xflag/Data1,5 Xflag

14 Hostr AutoFd

HostBusy HostBusy

15 NC ND ND

16 GND GND GND

17 FG FG FG

18 Printer Logic-H Logic-H Logic-H

19-30 GND GND GND

31 Host Init

Init Init

32 Printer Fault DataAvail /Data0, 4 DataAvail

33 GND ND ND

34 Printer DK_STATUS ND ND

35 Printer +5V ND ND

36 Host SelectIn

1284-Active 1284-Active

Page 27

Reception of status from the printer through the bidirectional parallel interface

In bidirectional parallel interface operation, printer status transmission is available using the

two-way communication facility of the IEEE 1284-compatible nibble/byte modes. In this case,

unlike in RS-232 serial interface operation, real-time interruptions from the printer to the host

are disabled, and so you must pay attention to the following.

❏

The maximum capacity of the printer’s internal buffer is 100 bytes (except ASB status).

Status signals exceeding this capacity are discarded. To prevent possible loss of status, the

host must be ready for data reception (Reverse Mode).

❏

When ASB is used, the host is preferably in the wait state for data reception (Reverse Idle

Mode). When this state is not available, the host enters Reverse Mode to continually monitor

data presence.

❏

When ASB is used, preference is given to ASB status for transmission over other status

signals. Any accumulated ASB status signals left for transmission from the last to the newest

ASB status transmissions are transmitted together at one time as one ASB status showing the

presence of change, followed by the latest ASB status.

Example: In the normal (wait) state, the ASB status is configured as follows:

In a sequence of operations including near end detection and the paper FEED button being pressed

and released, the following pieces of data are accumulated.

When ASB status is received following this, a total of eight (8) bytes of ASB will be transmitted as follows:

Accumulated ASB (

➀+➁+➂).

First Status Second Status Third Status Fourth Status

0001 0000 0000 0000 0000 0000 0000 0000

First Status Second Status Third Status Fourth Status

➀

0001 0000 0000 0000 0000 0011 0000 0000

Near end

detection.

➁

0101 1000 0000 0000 0000 0011 0000 0000

Paper FEED

button is

pressed.

➂

0001 0000 0000 0000 0000 0011 0000 0000

Paper FEED

button is

released.

First Status Second Status Third Status Fourth Status

Accumulated ASB (

➀+ ➁+ ➂

) 0101 1000 0000 0000 0000 0011 0000 0000

+ First Status Second Status Third Status Fourth Status

The latest ASB (➂)

Fourth Status

0001 0000 0000 0000 0000 0011 0000 0000

— 18 —

Page 28

Notes on setting DIP switch 1-8 to ON

The printer mechanism stops but does not become busy when an error occurs, printing stops for

a paper end, or paper is fed using the FEED button.

When setting DIP switch 1-8 to ON to enable handshaking with the printer, be sure to check the

printer status with

GS a

and ASB function. In this setting, the default value of

n

for

GS a

is 2.

The printer automatically transmits the printer status, depending on on-line/off-line changes.

When using

DLE EOT

and

DLE ENQ

, be sure that the receive buffer does not become full.

❏

If the host cannot transmit data when the printer is busy or if an error occurs,

DLE EOT

and

DLE ENQ

cannot be used when printer is busy because the receive buffer has become full.

❏

With a host that can transmit data when the printer is busy, if the printer’s receive buffer

becomes full while the host is sending bit-image data, a

DLE EOT

or

DLE ENQ

command

transmitted during sending of bit-image data is processed as bit-image data, not as a

command. Secondly, any data transmitted when the receive buffer is full may be lost.

Example: Check printer status using

GS r

after transmitting each line of data and use the 1KB

receive buffer. Transmit one line of data so that the receive buffer does not become full.

Buttons and Switches

Power Switch

Note:

Turn on the power only after connecting the power supply.

Panel Button

The panel button is enabled or disabled by the

ESC c 5

command. This button is inactive if it is

disabled.

Note:

The

ESC c 5

command enables or disables the panel button. When disabled, the button does not

function. However, when loading a paper roll, you can feed paper with the

FEED

button during the

paper loading waiting time if the paper loading waiting time is set by

GS z 0

. Press the

FEED

button

again after the

PAPER OUT LED

starts blinking to return the printer to the on-line state.

Type: Rocker switch

Function: The power switch turns the power on or off.

Feed

(FEED

) button: Type: Non-locking push button

Function: Feeds paper based on the line feed amount set by

ESC 2

and

ESC 3

.

— 19 —

Page 29

DIP Switches

Serial interface (RS-232 and RS-485 (option))

The DIP switches are located at the bottom of the case.

NOTES:

❏

Do not change the setting of DIP switch 2-2 (fixed to ON).

❏

Changes in DIP switch settings (excluding switches 2-3 and 2-4, which are I/F reset signals) are

recognized only when printer power is turned on or reset using the interface. If the DIP switch setting

is changed after printer power is turned on, the change does not take effect until the printer is turned

on again or reset.

Parallel interface (IEEE 1284)

The DIP switches are located at the bottom of the case.

DIP switch 1

DIP Switch Function ON OFF

1 Data receive error Ignored Prints “?”

2 Receive buffer capacity Data buffer 40 bytes Data buffer 1KB

3 Handshaking XON/XOFF DTR/DSR

4 Data word length 7 bits 8 bits

5 Parity check Yes No

6 Parity selection Even Odd

7 Baud rate selection 4800 bps 9600 bps

8 Busy condition When the receive buffer is full

When the receive buffer is full

in off-line status

DIP switch 2

DIP Switch Function ON OFF

1

Print column selection

7 ✕ 9 font/9 ✕ 9 font

42CPL/35CPL 40CPL/33CPL

2

For internal use only

Setting must not be changed. (Fixed to ON.)

3 I/F pin 6 reset signal Enabled Disabled

4 I/F pin 25 reset signal Enabled Disabled

DIP switch 1

DIP Switch Function ON OFF

1 Auto line feed Enabled Disabled

2 Receive buffer 40 bytes Approximately 1KB

3-7 Undefined

8 Busy condition

Receive buffer full

Scanning data

Off-line

Receive buffer full

Scanning data

— 20 —

Page 30

NOTES:

❏

Do not change the setting of DIP switches 2-2 and 2-4 (fixed to ON).

❏

Changes in DIP switch settings (excluding switch 2-4, which is the I/F reset signal) are recognized

only when printer power is turned on or reset using the interface. If the DIP switch settings are changed

after printer power is turned on, the change does not take effect until the printer is turned on again or

reset.

DIP switch 2

DIP Switch Function ON OFF

1

Print column selection

I/F Init reset signal

7 ✕ 9 font/9 ✕ 9 font

42CPL/35CPL 40CPL/33CPL

2 Internal use (See Notes.)

3 Undefined

4

Fixed to ON Fixed to ON

— 21 —

Page 31

Panel LEDs

Self-test

The printer has a self-test function that checks the following:

❏

Control circuit functions

❏

Printer mechanisms

❏

Print quality

❏

Control ROM version

❏

DIP switch settings.

See Chapter 4 for instructions on running a self-test.

Power (

POWER

) LED: Green

On: 24 V power supply is stable.

Off: 24 V power supply is not stable.

Paper roll near-end

(

PAPER OUT

) LED:

Red

On: Paper roll near-end is detected. (*1)

Off: Adequate paper remains on the paper roll (normal

condition).

Blinking: Waiting for restart test print on paper roll or for

return to on-line status after automatic paper

feeding.

(*1)

The near-end detector is an option.

Error (

ERROR

) LED: Red

On: Off-line (except during paper feeding using the

FEED

button and during the self-test).

Off: Normal operation.

Blinking Error state. (Refer to “Error types and

countermeasures” in Chapter 4.)

— 22 —

Page 32

Error Processing

Printer Operation When an Error Occurs

The printer executes the following operations upon detecting an error:

Serial interface

❏

All mechanical operations stop.

❏

DTR signal is set to MARK (only when DTR/DSR is selected and DIP switch 1-8 is off).

❏

The

ERROR

LED blinks.

❏

XOFF is transmitted when XON/XOFF control is selected (only when DIP switch 1-8 is off).

Parallel interface

❏

All mechanical operations stop.

❏

The BUSY signal is set to HIGH (only when DIP switch 1-8 is off).

❏

The

ERROR

LED blinks.

❏

Fault

signal is set to LOW.

Data Receive Error

If one of the following errors occurs, the printer prints “?” or ignores the data, depending on the

setting of DIP switch 1-1:

❏

Parity error

❏

Framing error

❏

Overrun error.

Buffer Full Printing

When subsequent data is received after the printer processes one line of data in the print buffer,

the printer automatically prints the processed data and feeds the paper one line.

Detectors and Printing

When the printer detects a paper near-end, it stops or continues printing, depending on the

ESC

c 4

command setting. The roll paper detector always halts printing when there is no paper.

— 23 —

Page 33

Hexadecimal Dump

This function prints data transmitted from the host computer in hexadecimal numbers and in

their corresponding ASCII characters.

Performing a Hexadecimal Dump

1. Turn the printer power off.

2. Set DIP switch 1-2 to on to select 40 bytes for the receive buffer capacity.

3. Turn the power on while pressing the

FEED

button.

4. Before finishing the initialization of the printer, release the

FEED

button, then press the

FEED

button again. The printer first prints “Hexadecimal Dump” on the paper roll, and prints the

data received thereafter in hexadecimal numbers and their corresponding characters until

the printer is turned off.

NOTES:

❏

“.” is printed if no printable ASCII character corresponds to the data received.

❏

Control commands are printed in bold for emphasis.

❏

During the hexadecimal dump, all commands except DLE EOT and DLE ENQ are disabled.

❏

Insufficient print data to fill the last line can be printed by taking the printer off line.

(See “Switching between on line and off line“ earlier in this chapter.)

Sample hexadecimal dump

Hexadecimal Dump

1B 21 00 1B 26 02 40 40 1B 69 : . ! . . & . @ @.i

1B 25 01 1B 63 34 00 1B 30 31 : . % . c4 . .. 01

41 42 43 44 45 46 47 48 49 4A : ABCDEFGHIJ

Options

❏

Paper roll near end detector (dealer option)

❏

External power supply PS-170

❏

Printer fastening tape (DF-10)

❏

RS-485 serial interface

❏

IEEE 1284 compatible interface board (Bidirectional parallel: factory-installed)

❏

RS-232 compatible interface board (factory-installed)

— 24 —

Page 34

External Power Supply PS-170

Specifications

Input Conditions

Output specifications

Compliance to safety regulation

The following standards are applied only to the equipment with marks and statements

NOTE:

Use o n l y t he EP SON PS-1 7 0 power supply to avoid da mage t o the printer and the power supply.

100 V, 120 V, or 230 V (specified at time of purchase)

Input voltage (rating) 90 to 264 V

(100 VAC-10% to 230 VAC + 15%)

108 VAC to 132 V (120 V type)

Frequency (rating) 50 to 60 Hz ± 3 Hz

Input current (rating) Less than 100 VA

AC switch None

Energizing LED None

Output voltage (rating) 24 VDC ± 5%

Output voltage (rati ng) 2.0 A

Output electric power

(rating)

48 W

Output peak current 4.5 A (within 300 msec)

UL/C-UL/TÜV

— 25 —

Page 35

Chapter 2 Mechanism Configuration and Operating Principles

Printer Mechanism Operating Principles

The M-U200 printer mechanism mounted in the UP-250 is composed of six mechanisms: print, paper

feed, ribbon feed, detector, auto-cutter, and ribbon switch.

Figure 2-1 M-U200

— 26 —

Page 36

Print mechanism unit

The print mechanism unit consists of the parts shown in the figure below.

Figure 2-2 Print mechanism unit

Paper feed

frame assembly

Belt

Print head unit

Belt tension

pulley

Carriage

guide shaft

Carriage shaft

Carriage motor

assembly

Print head FPC

Print head ground

plate assembly

Carriage sub

assembly

— 27 —

Page 37

Print head unit movement

When the carriage motor is driven and the carriage motor gear moves in the direction of arrow B

(forward rotation), the rotational power is conveyed to the belt drive pulley, then the belt. Next,

the carriage sub assembly, which is fixed to the belt, moves in the direction of arrow B.

When the carriage motor gear rotates in the direction of arrow A (reverse rotation), the carriage

sub assembly moves in the direction of arrow A.

Wire movement when a single dot is printed

When the specified print head drive pulse is input to the drive coil, the iron core is magnetized,

and the actuating plate is pulled in the direction of arrow A. This action pushes the wire toward

the platen. When the wire strikes the ink ribbon and paper against the platen, a single dot is

printed. (The “platen” is the portion of the paper feed frame being struck by the wires during

printing.)

When energizing of the drive coil is completed, the wire and actuating plate are returned to the

standby position by the wire return spring and actuating plate spring.

Figure 2-3 Print head unit movement

Figure 2-4 Printing

Belt

Carriage motor gear

Belt drive pulley

Carriage sub assembly

B

A

Actuating

Paper roll

Ink ribbon

Wire return

Drive coil

plate

spring

Wire

Wire guide

Iron core

Platen

— 28 —

Page 38

Printing a character (9x9 font)

A character is printed by energizing the print solenoids with respect to the carriage sub

assembly portion. (The reference timing for the print solenoids is the carriage motor phase

switching signals.) The print head unit moves 0.31 7 mm (0.012”) (in approximately 1.05 ms) each

time the carria ge motor rotates on e step (7.5°).

To print the character “2,” print solenoids 2 and 9 are energized first using the same timing as

the carriage motor phase switching signal. Then, print solenoid 8 is energized at TnH (being

delayed a half dot). The remaining print solenoids are energized correspondingly, and the

character “2” is finally printed.

Figure 2-5 Print timing chart

1

2

3

5

4

6

7

8

9

Tn

TnH

Tn+2Tn+1

TnH(4)

Tn+5Tn+4

Carriage motor phase

switch timing

Print solenoid

Tn+3

— 29 —

Page 39

Paper Feed Mechanism Unit

The paper feed mechanism unit consists of the parts shown in the figure below. Paper feeding is

performed by driving the paper feed motor (stepping motor).

Figure 2-6 Paper feed mechanism unit

Paper hold

spring

Paper hold roller

Paper hold

roller shaft

Paper feed

roller assembly

Upper paper guide

Paper feed

frame assembly

Paper feed

reduction gear

Paper feed motor

— 30 —

Page 40

Paper loading (semi-automatic loading)

When the paper roll is manually inserted into the paper feed roller, the paper detection switch in the paper

path detects the paper, and semi-automatic loading is executed. (Semi-automatic loading is the function

that automatically feeds paper to the top of the paper feed frame assembly when a paper roll is inserted

in the paper path after the detector detects no paper.)

Paper feeding

Paper feeding is performed by conveying the paper feed motor’s rotational power from the paper feed

motor gear through the paper feed reduction gear, paper feed gear, and paper feed roller.

Since the paper feed roller and paper hold roller are pressed together, paper advances to the top of the

paper feed frame assembly because of the friction between the rubber of the paper feed roller and the

paper hold roller.

Figure 2-7 Paper loading

Paper

Paper feed

Upper paper guide

Guide roller

Upper case

Paper feed roller

Base frame assembly

Paper hold roller

Paper hold

plate spring

frame

— 31 —

Page 41

During printing, the paper feed motor is driven after each line is printed, causing the paper to be

fed a specified amount. While the

FEED

button on the control panel is pressed, the paper feed

motor is driven and the paper roll is fed.

Ribbon Feed Mechanism Unit

The ribbon feed mechanism unit consists of the parts shown in the figure below. The printer

feeds the ribbon automatically as the carriage motor rotates.

Figure 2-8 Paper feeding

Figure 2-9 Ribbon feed mechanism unit

Paper roll

Paper feed roller

Paper feed

Paper feed

Paper feed gear

Paper hold roller

reduction gear

motor gear

Ribbon intermediate gear

Ribbon cassette

Ribbon take-up

assembly

Ribbon drive

plate assembly

Ribbon transmission

gear

Ribbon frame

assembly

— 32 —

Page 42

Ribbon feeding

When the carriage motor rotates forward and the carriage motor gear rotates in the direction of arrow A,

the ribbon intermediate gear and ribbon drive gear rotate in the directions of arrows B and C, respectively.

This causes the ribbon drive plate to move in the direction of arrow D, with the ribbon intermediate gear

shaft in the center, until the ribbon drive gear engages the ribbon transmission gear.

Since the ribbon transmission gear and the ribbon take-up gear are always engaged, the ribbon take-up

gear rotates in the direction of arrow E.

When the carriage motor rotates in the reverse direction and the carriage motor gear rotates in the

direction of arrow F, the ribbon drive plate moves in the direction of arrow G, disengaging the ribbon

drive gear from the ribbon transmission gear.

Therefore, the ribbon take-up assembly rotates in the direction of arrow E only when the carriage motor

rotates forward. Then the ribbon feed and ribbon hold rollers in the ribbon cassette, which are engaged

with the ribbon take-up assembly, rotate and the ribbon is fed.

Figure 2-10 Ribbon feeding

Carriage motor gear

Ribbon intermediate gear

Ribbon take-up

Ribbon take-up

Ribbon transmission gear

gear

assembly

Ribbon drive

gear

F

A

C

B

G

D

E

Ribbon feed roller

Ribbon drive

plate

— 33 —

Page 43

Detection Mechanism Unit

The detection mechanism unit consists of the home position detection, paper detection, and

near-end detection (optional) mechanisms.

Home position detection mechanism

The home position detection mechanism consists of the detection protrusion at the left side of the

carriage sub assembly and the sensor sub assembly at the left side of the base frame. It determines the

home position, identifies the carriage position, and detects carriage sub assembly operation errors.

The sensor sub assembly consists of an LED and photo transistor. When the carriage sub assembly

moves, the detection protrusion passes between the LED and photo transistor and blocks the optical

axis of the photo transistor, changing the output level of the photo transistor.

The change in the output level is used as a signal to detect the movement of the carriage sub assembly.

Figure 2-11 Detection mechanism unit

Figure 2-12 Home position detection diagram

Paper detector

Home position sensor

Printer side

The light is blocked

The light is

not blocked

Carriage sub assembly detection protrusion

Signal level at A

High

Low

+5V

GND

A

— 34 —

Page 44

Paper detection mechanism

The paper detection mechanism is located in the paper path. The mechanism provides paper end

detection for the paper roll and semi-automatic loading by detecting presence or absence of the paper

roll when it is inserted. Since the paper detector switch sub assembly is a micro switch, it is always ON

when the paper roll is loaded.

Paper roll near-end detection mechanism (optional)

The near-end detector assembly consists of the near-end detector lever and a microswitch sensor and

is located on the right side of the lower case. This detector senses the amount of paper left on the paper

roll.

The tip of the near-end detection lever is always pressed against the edge of the paper roll by a spring

inside the microswitch. Therefore, when there is a large amount of paper remaining on the roll, the nearend detection lever is pressed against the side of the paper roll as depicted by the solid lines in the figure

below. This keeps the microswitch turned on. When the amount of paper left on the roll decreases below

a predetermined amount, the tip of the near-end detection lever no longer presses against the side of the

roll and moves in the direction indicated by the arrow into the hole in the center of the roll core.

This turns the microswitch off and generates a signal indicating that the paper roll is near its end.

Auto-cutter mechanism

The printer executes a partial cut (one point left uncut) by driving the cutter motor.

When the motor is energized from the standby state, the wormwheel rotates in the direction indicated

by arrow A through the gears from the motor. The resulting motion of the wheel pin through arm slot C

causes the arm to move in direction B. This, in turn, causes slot D to move the

Figure 2-13 Paper roll near-end detection mechanism

Paper roll center

Lower case

Microswitch

Near-end

detection lever

Paper roll

— 35 —

Page 45

movable blade drive pin in direction E to make the blade execute a cut. If the motor continues

rotating, the wormwheel makes one rotation and it makes the movable blade return to the

standby position and the cutting is finished.

Figure 2-14 Auto-cutter mechanism

Ribbon Switch Mechanism Unit

The ribbon switch mechanism unit consists of the carriage motor assembly, carriage sub assembly,

tension plate assembly, tension belt pulley, home position detector assembly, ribbon frame assembly,

ribbon frame spring, ribbon switch lever, ribbon release lever, and ribbon release spring.

The mechanism unit is placed at the left and right of the carriage sub assembly, whose position is

controlled by the number of carriage motor steps, using the home position as the reference position.

It switches between the black and red ribbon in the ribbon switch and ribbon release areas outside the

printing area.

Switching from Black to Red

When the carriage, sub assembly (print head unit) moves in direction E and reaches the ribbon switch

area, the ribbon switch lever is pushed by the ribbon switch section and moved to position A (shown by

the dotted lines). The ribbon assembly frame is pushed upward by the push face for the ribbon frame.

The detent face for the ribbon switch falls into the ribbon switch lever hole in the ribbon frame assembly

and the ribbon frame assembly is set to the red position.

Releasing from Red to Black

When the carriage sub assembly moves in the D direction and reaches the ribbon release area, the

ribbon release lever is pushed by the ribbon release section. Then portion C pushes theribbon frame

assembly upward. At this time, the detent face for the ribbon switch is released from the ribbon switch

lever hole in the ribbon frame assembly and the ribbon switch lever is returned to ribbon switch lever

position B (shown by the solid lines) by the spring power of the

Wormwheel

Movable blade drive pin

Slot D

Arm

Wheel pin

Movable blade

— 36 —

Page 46

ribbon release spring. When the carriage sub assembly moves in the E direction, the ribbon

frame assembly and ribbon release lever return to their original positions because of the spring