Page 1

T

L

Y

Carson Manufacturing Co., Inc.

5451 North Rural Street

Indianapolis, IN 46220

Phone: (888) 577-6877 Fax: (317) 254-2667

www.carsonsirens.com

TECHNICAL BULLETIN

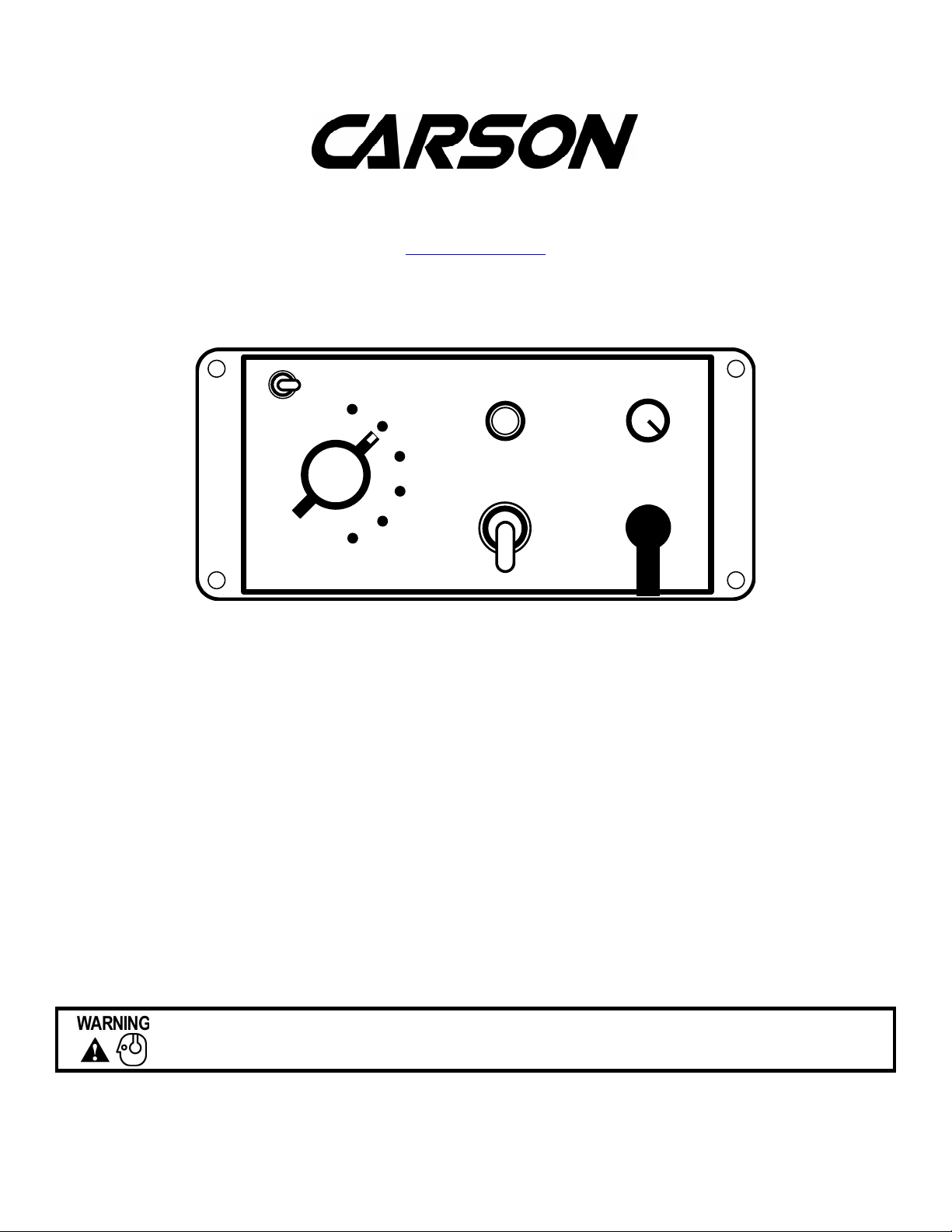

OFF/ON

RADIO

HRN/T

MAN

WAI

YELP

PHASR/W-

ON

SIREN

POWER

PA

VOL

SA 441

INSTALLATION AND

OPERATING MANUAL

SA-441-83F (FLUSH MOUNT CONTROL HEAD)

SA-441-83FX (FLUSH MOUNT WITH EXTENDED MIC)

Carson is a trademark of Carson Manufacturing Company, Inc.

Sound Hazard - Sound level from siren speaker (>120dBA @ 10 feet) may cause hearing damage.

Do not operate siren without adequate hearing protection for you and anyone in immediate vicinity.

(Ref. OSHA 1910.95 for occupational noise exposure guidelines)

TB0335B Page 1 of 10 10/18/03

Page 2

SA-441-83 SPECIFICATIONS

INPUT POWER: 11-16 Volts DC, 8 Amps DC per 100W Speaker

Power off current to amplifier is 1mA Max.

SIREN MODE

OUTPUT POWER: 15 VDC input, 100W speakers

Two outputs - 105 Watts RMS per output

AUDIO MODE

OUTPUT POWER: 14 VDC input, 100W speakers

Two outputs - 40 Watts RMS per output

SIREN

FREQUENCY: 700Hz - 1450Hz Nominal

CYCLE RATES: WAIL - 15 cycles/min

YELP - 210 cycles/min

PHASER - 10 cycle/sec

AUDIO

RESPONSE: 200Hz - 10KHz +/-3db

Harmonic Distortion Less than 3% @ 1KHz

RADIO INPUT

SENSITIVITY: 0.75VAC Input Min. for 40 Watts RMS Output (1 spkr)

OPERATING

TEMPERATURE: -15° F to +140° F

SIZE: Amplifier 9" Wide X 2-1/2" High X 6-3/4" Deep

Control Head 6-1/4" Wide X 2-7/8" High X 1" Deep

WEIGHT: Amplifier 4.25 pounds

Control Head 1 pound

NIGHT VISIBILITY: Control Head panel is backlit with independent lead tied to vehicle dash lights.

AMPLIFIER PROTECTION: High Voltage – Siren output stops with input voltage above highest rating

Stops high output power from blowing speaker

Reverse Polarity – Fuse(s) blows when power is wired backwards

Shorted Output – Fuse(s) blows if speaker shorts (a common problem)

CONTROL HEAD PROTECTION: No fuse but has reverse polarity protection.

NOTICE

Due to continuous product improvements, we must reserve the right to change any specifications and information,

contained in this manual at any time without notice.

Carson Manufacturing Co., Inc. makes no warranty of any kind with regard to this manual, including, but not limited to,

the implied warranties of merchantability and fitness for a particular purpose.

Carson Manufacturing Co., Inc. shall not be liable for errors contained herein or for incidental or consequential

damages in connection with the furnishing, performance, or use of this manual.

TB0335B Page 2 of 10 10/18/03

Page 3

INSTALLATION

Proper installation of the unit is essential for years of safe, reliable operation. Please read all instruction before

installing the unit. Failure to follow these instructions can cause serious damage to the unit or vehicle and may void

warranties.

SAFETY PRECAUTIONS

For the safety of the installer, vehicle operator, passengers and the community please observe the following safety

precautions. Failure to follow all safety precautions and instructions may result in property damage, injury or

death.

Qualifications - The installer must have a firm knowledge of basic electricity, vehicle electrical systems and

emergency equipment.

Sound Hazard - Sound level from siren speaker (>120dBA @ 10 feet) may cause hearing damage.

Do not operate siren without adequate hearing protection for you and anyone in immediate vicinity.

(Ref. OSHA 1910.95 for occupational noise exposure guidelines)

Mounting - Mount the control head for easy access by the vehicle operator. DO NOT mount in air bag deployment

area. Assure clearances before drilling in vehicle.

Wiring - Use wiring capable of handling the current required. Make sure all connections are tight. Route wiring to

prevent wear, overheating and interference with air bag deployment. Install and check all wiring before connection to

vehicle battery.

Testing - Test all siren functions after installation to assure proper operation. Test vehicle operation to assure no

damage to vehicle.

Keep These Instructions - Keep these instructions in the vehicle or other safe place for future reference. Advise the

vehicle operator of the location.

AMPLIFIER MOUNTING

Choose a mounting location in an area such as the driver compartment firewall, under a seat, etc. Mounting the

amplifier in the engine compartment or in an area directly exposed to weather is not

ventilation to prevent overheating. Consider wire routing and access to connector. Install amplifier to vehicle using

1/4" hardware (not supplied).

May need to set RADIO VOLUME ADJUST on side of amplifier before final mounting and installation.

May also need to set POWER OUTPUT ADJUSTMENT on inside of amplifier.

CONTROL HEAD MOUNTING

Select a mounting location in an area such as the dash or overhead console. Choose a mounting location convenient

to the operator and away from any air bag deployment areas. Consider wire routing and access to connections, as

well as microphone bracket placement.

A microphone clip along with mounting screws (CP3633) holds the microphone in place.

FLUSH MOUNT

The flush mount control head requires a hole in the dash. Use the mounting template on the last page. Note that the

template may not print actual size and may need sizing on a copier. Use #6 screws to fasten to dash.

FLUSH MOUNT WITH EXTENDED MICROPHONE

The flush mount control head with extended microphone is mounted the same as the flush mount except that the

microphone cable extension will also go behind the dash. Allow room for this cable as well.

recommended. Assure adequate

Control Head – Rear View

Microphone

Extension

Cable

TB0335B Page 3 of 10 10/18/03

Page 4

A

A

CONTROL HEAD ELECTRICAL CONNECTIONS

All control head leads may be extended with #22 AWG or larger lead wire.

Negative Connection (Black) - Connect to same ground or negative supply as amplifier.

Positive Connection (Red) - Connect to positive DC supply. It is recommended that the lead be connected to the

accessory output of the fuse block. This provides additional protection of a fused input to the control head.

Lights (Yellow) - This lead may be connected to the dash lights or to the red power lead. Connecting to the dash

lights will turn on the panel lights whenever the dash lights are on.

When connected to the red lead, make sure that the ignition switch controls the power to that connection. This

prevents the panel lights from being continuously on.

Control (White) - Connect to white lead from amplifier. Route this lead away from radio transmitter antenna lead to

prevent RF interference being fed to the siren amplifier.

Auxiliary Input (Green) - Used for Siren control. Performs same function as Siren button. Connect to a normally

open switch or to horn ring circuit. Circuit may connect to either positive or negative. When connected to horn ring

circuit, use a SPDT switch to connect horn ring to either vehicle horn or to manual control circuit.

NOTE: Permanent disconnection of the vehicle horn is NOT recommended.

NOTE: Be sure to cut lead short if not used to prevent R.F. interference and insulate with electrical tape.

dded

SPDT

Switch

HORN

RING

SWITCH

HORN RING

CONNECTION

HORN

UX

TB0335B Page 4 of 10 10/18/03

Page 5

A

A

AMPLIFIER ELECTRICAL CONNECTIONS

Disconnect vehicle battery before making the following electrical connections.

Electrical connections to the amplifier are made using the wiring harness supplied. If the amplifier needs service the

connector can be easily removed without unwiring the harness. The power supply for the amplifier must be capable of

delivering peak currents up to 50 amps for adequate short circuit protection and reliable operation. The preferred

source is directly at the vehicle battery. A fuse on the unit protects from overload.

Wire Size and Termination - The diagram shows the minimum wire size used for each connection. If the wire is

longer than 10 ft. use the next larger wire size. Use only high quality crimp connectors for installation on the vehicle.

Negative Connection (Black) - Both leads must be used. Connect to negative battery connector or high current

buss.

Positive Connection (Red) - Both leads must be used. Connect to positive battery connector or high current buss. A

power relay may be used.

Speaker A Connection (Brown) - Both leads must be used. Connect 1 lead to each terminal or lead of the speaker.

Connect in same polarity (phasing) as Speaker B to assure loudest siren sound.

Speaker B Connection (Orange) - Both leads must be used. Connect 1 lead to each terminal or lead of the speaker.

Connect in same polarity (phasing) as Speaker A to assure loudest siren sound.

Control Connection (White) - Connect to white lead from control head. Route this lead away from radio transmitter

antenna lead to prevent RF interference being fed to the siren amplifier.

Optional Radio Input Connection (Blue) - Connect 1 lead to each terminal of the radio speaker or output connector.

The input is isolated and polarity is not important. May need to set RADIO VOLUME ADJUST on side of unit.

#14 AWG BLK

Use both leads

Extend with #12

-

BAT

+

#14 AWG RED

Use both leads

Extend with #12

+

SPKR

A

Extend spkr leads with #16

SPKR

B

For loudest siren sound

be sure speak ers are wired

in same polarity.

#18 AWG BRN

#18 AWG BRN/BLK

+

#18 AWG ORG

-

#18 AWG ORG/BLK

AMPLIFIER POWER

HARNESS CONNECTIONS

CP3877

CABLE

CONTROL HEAD

OFF/ON

RADIO

HRN/TT

MAN

WAIL

YELP

PHASR/W-Y

PA

SIREN

VOL

ON

POWER

(CP3040 CABLE)

GRN (AUX)

YEL (DASH LIGHTS)

BLK (-VDC)

RED (+VDC)

WHT

CONTROL

AMPLIFIER

RADIO VOLUME

DJUST

(CP3889

CABLE)

BLU TO TWO WAY

RADIO SPEAKER

15AMP FUSE

UTOMOTIVE TYPE

FUSE A (SPKR A)

FUSE B (SPKR B)

(CP3877 CABLE)

- ORG/BLK TO SPKR B + ORG TO SPKR B +

BLK TO -VDC

RED TO +VDC

- BRN/BLK TO SPKR A + BRN TO SPKR A +

TB0335B Page 5 of 10 10/18/03

Page 6

Y

NORMAL OPERATION (Dual Mode Switch Off)

Sound Hazard - Sound level from siren speaker (>120dBA @ 10 feet) may cause hearing damage.

Do not operate siren without adequate hearing protection for you and anyone in immediate vicinity.

(Ref. OSHA 1910.95 for occupational noise exposure guidelines)

DUAL MODE

SWITCH

OFF/ON

RADIO

HRN/TT

MAN

WAIL

YELP

PHASR/W-

ON

SIREN

POWER

PA

VOL

SA 441

The Toggle Power Switch controls the siren power. The siren may be left on any time the vehicle is in

operation. The power should be turned off when vehicle is not being used to conserve battery power.

The Rotary Function Switch selects various operating modes. These modes are as follows:

RADIO - This mode reproduces, or repeats, the output of a radio. The radio must be connected and

HORN - Also considered a standby mode. Horn and PA Override available in this mode.

MAN - The siren tone is controlled Manually with SIREN button. PA Override available in this mode.

RADIO VOLUME ADJUSTed for this mode to function. PA override available in this mode.

WAIL - The siren produces a normal rise-fall tone pattern. This mode should be used on highways or

areas with constant traffic flow. Yelp and PA Override available in this mode.

YELP - The siren produces a moderate warble tone. This mode should be used in lightly congested

areas. Horn and PA Override available in this mode.

PHASER - The siren produces a very fast warble tone. This mode should be used at intersections or in

highly congested areas. Horn and PA Override available in this mode.

OVERRIDE FUNCTIONS (Normal Mode)

PUBLIC ADDRESS

(PA) OVERRIDE - Pressing the microphone button in any operating mode allows the operator to use the siren as

a public address amplifier. The operating mode resumes when the button is released. (Hold

the microphone close to your lips for proper operation and adjust the PA VOLume Control)

HORN OVERRIDE - By pressing the SIREN button the siren tone output is replaced by the horn tone. The siren

tone resumes when the button is released. (This feature is not available in WAIL mode.)

YELP OVERRIDE - Available only in WAIL mode. By momentarily pressing the SIREN button the tone output is

switched to the Yelp tone. Pressing the button again switches the tone output back to Wail.

RADIO VOLUME ADJUST

The RADIO VOLUME ADJUST is a one time setting which depends on the radio connected and its normal volume.

Access the RADIO VOLUME ADJUST through a hole on the side of the amplifier.

Switch siren to RADIO mode and turn on the power. With the volume on the radio itself set to normal level, set the

RADIO VOLUME ADJUST to the desired level.

TB0335B Page 6 of 10 10/18/03

Page 7

DUAL MODE OPERATION (Dual Mode Switch On)

Sound Hazard - Sound level from siren speaker (>120dBA @ 10 feet) may cause hearing damage.

Do not operate siren without adequate hearing protection for you and anyone in immediate vicinity.

(Ref. OSHA 1910.95 for occupational noise exposure guidelines)

The Toggle Dual Mode Switch gives the amplifier the ability to produce two different siren tones to each

speaker simultaneously. This changes some of the Rotary Function Switch modes and provides different Override

Functions. The Dual Mode Switch may be left on and use the Rotary Manual position as standby mode.

The Rotary Function Switch selects the following modes:

RADIO - Same as normal mode. PA override available in this mode.

TWO-TONE - Or HI-LO, a common European tone. Both speakers produce same sound. Horn and PA

Override available in this mode.

MAN - In dual mode this is also considered standby mode. The siren tone is controlled manually with

SIREN button. Both speakers produce manual tone slightly out of phase to give stereo effect.

PA Override available in this mode.

WAIL - The siren produces dual Wail. Each speaker produces independent Wail tone. Dual Yelp and

PA Override available in this mode.

YELP - The siren produces dual Yelp. Each speaker produces independent Yelp tone. Phaser and

PA Override available in this mode.

WAIL/YELP - The siren produces Wail to one speaker and Yelp to the other speaker. Phaser and PA

Override available in this mode.

OVERRIDE FUNCTIONS (Dual Mode)

PUBLIC ADDRESS

(PA) OVERRIDE - Same as normal mode.

HORN OVERRIDE - Same as normal mode, both speakers produce same Horn tone.

DUAL YELP

OVERRIDE - Available only in Dual Wail mode. By momentarily pressing the SIREN button the tone output

is switched to the Dual Yelp tone. Pressing the button again switches the tone output back to

Dual Wail.

PHASER OVERRIDE - By pressing the SIREN button the siren tone output is replaced by the Phaser tone. Both

speakers produce same Phaser tone. The siren tone resumes when the button is released.

TB0335B Page 7 of 10 10/18/03

Page 8

SERVICE

This unit is designed to provide years of reliable service under even the worst conditions. Many times there may

appear to be a problem with the unit when the true problem is in the speaker(s) or improper installation. The following

chart shows typical symptoms and possible causes.

A blown panel fuse(s) doesn't necessarily mean that the unit is bad. If a speaker or speaker lead is shorted this fuse

will blow before the unit is damaged. Disconnect the SPKR leads and replace the fuse. If the siren emits a sound

when in the Yelp position it is OK. Check the speaker(s) or leads for possible shorting.

Note: Older versions of this amplifier unit used one 20AMP fuse to supply both internal amplifiers. This means that if

one internal amplifier output is shorted and blows the fuse, the other internal amplifier will also lose power even though

it may be fine. Be sure to check both amplifier unit outputs for shorted wiring or speaker.

PROBLEMS

Symptom Possible Cause Check

No Power or siren output Power switch not turned on

Bad Speaker

Connector or connections loose

Panel fuse(s) blown

Loose connection at power source

No siren tone –

PA works

No PA PA volume not set properly Try turning the PA volume control.

Distorted siren sound Speaker assembly loose

Intermittent siren tone High Voltage Protection

Horn or manual stuck on Siren switch stuck

No Radio Unit not connected to a radio

Wrong siren tone Ground system noise Are control head and amplifier connected to good

Dual mode switch does

not work

High Voltage Protection

Mic Button stuck

Intermittent Aux Input connection

Low Vehicle voltage

Connector loose

Loose connection at power source

Mic Button activation

Circuit breaker in supply

connection

Aux Input improperly connected

Radio volume too low

Only one internal amplifier works

One speaker damaged

Does backlighting come on?

Do you hear a “pop” when turned on?

With siren on, yelp selected, listen for tone in

amplifier.

Is an external fuse or circuit breaker used?

Are the power leads connected to a good buss?

The input voltage must be less than highest rating.

Does Mic Button release properly?

Is the speaker bell or tip loose?

Is the Aux Input used and wired properly?

The input voltage must be greater than lowest rating.

Is the vehicle voltage regulator working properly?

Is the connector tight on the back of the unit?

Check for loose leads back to power source.

Is something lying on the microphone?

Is a circuit breaker used with at least 50A rating?

Does the Siren pushbutton switch return fully when

released?

Is the Aux Input used and wired properly?

Is the radio connected properly to the unit?

Can you hear the radio in the vehicle?

Try adjusting the internal radio volume control.

ground?

Is one fuse on the amplifier blown?

Try replacing the speaker.

RETURN

If you have any questions concerning this or any other Carson product, please contact our Technical Service

Department at (888) 577-6877. Many issues can be handled over the phone. We can also be reached via e-mail at

service@carsonsirens.com

If a product must be returned for any reason, please contact our Technical Service Department to obtain a Returned

Merchandise Authorization number (RMA#) before you ship the product to Carson. Please write the RMA# clearly on

the package near the mailing label. Be sure to provide a return address, contact and phone number, along with a brief

description of the problem.

TB0335B Page 8 of 10 10/18/03

Page 9

T

Y

p

6

3

9

Control Head

10

OFF/ON

5

(one pair each end)

(output for

s

eaker B shown)

12 11

13

RADIO

HRN/T

MAN

WAIL

YELP

PHASR/W-

PARTS

1

7

2

4

SIREN

ON

POWER

PA

VOL

8

SA 441

Item Part # Description

1 8025 DRS/CAP

Button, red w/ dress nut (C&K #801803000 Cap, #702501201 Nut) (for pushbutton switch)

CP3040 Cable, control head power

ES00003-09 Cable, microphone extension 8FT (CP3850 is 18FT) (for SA-441-83FX version)

2 CP3046

CP4000

Control, PA volume (1K ohm) (for all other PCB's)

Control, PA volume no face mount (1K ohm) (for PCB CP3873 Rev. E and higher)

CP3880 Cover, control head back push on

3 CP4852 Knob, rotary function switch

4 CP4853 Knob, PA volume control

5 CP3881 Label, control head front panel

JKL#7001PSBL Lamp, T-1-3/4 14V Bi-pin (JKL #7001)

CP3570

ES00028-10

Microphone (for SA-441-83F version)

Microphone with locking connector (for SA-441-83FX version)

CP3633 Microphone clip with mounting screws

6 CP3035-1 Panel, control head front

7 8121D2V40 Switch, pushbutton siren (C&K #8121SD2V4GE)

8 7101-T-C-Q Switch, toggle power (C&K #7101TCQ)

9 CP3599 Switch, rotary function

10 SS2846 Switch, toggle dual mode (C&K #7101MYW3BE)

Amplifier

Item Part # Description

CP3877 Cable, amplifier power

CP3889 Cable, radio and control line

11 640584-1 Connector, power (AMP #640584-1)

12 CP3876 Cover, amplifier (does not include CP3875 chassis)

CP3408 Fuse holder

13 CP4119 Transistor, output (pairs required) (Industry standard TIP36C, Not Texas Instruments)

TB0335B Page 9 of 10 10/18/03

Page 10

CONTROL HEAD INSTALLATION TEMPLATE

1/2”

5-7/8”

6-1/4”

5-1/4”

2-5/8”

This inner area

to be removed.

1/8”

CAUTION: Please note that top and bottom edges only

provide 1/8” overlap. Cut carefully.

2-1/2”

2-7/8”

TB0335B Page 10 of 10 10/18/03

Loading...

Loading...