Carrier 48EJ, EY024-048 User Manual

Installation, Start-Up and

Service Instructions

CONTENTS

Page

SAFETY CONSIDERATIONS ...................1

INSTALLATION .............................1-31

Step 1 — Provide Unit Support ...............1

• ROOF CURB

• ALTERNATE UNIT SUPPORT

Step 2 — Rig and Place Unit ..................2

• POSITIONING

• ROOF MOUNT

Step 3 — Field Fabricate Ductwork ............2

Step 4 — Install Flue Hood ..................12

Step5—TrapCondensate Drain ............13

Step 6 — Install Gas Piping ..................13

Step 7 — Controls Options ..................13

• CONSTANT VOLUME APPLICATIONS

• VARIABLE AIR VOLUME (VAV) APPLICATIONS

Step 8 — Make Electrical Connections .......16

• POWER WIRING

• FIELD POWER SUPPLY

• FIELD CONTROL WIRING

Step 9 — Make Outdoor-Air Inlet

Adjustments ...............................24

• ECONOMIZER

• ECONOMIZER SETTINGS

Step 10 — Position Power Exhaust/Barometric

Relief Hood ...............................29

Step 11 — Install All Accessories ............30

START-UP ................................31-44

SERVICE ..................................44-55

TROUBLESHOOTING ......................56-61

START-UP CHECKLIST ................CL-1,CL-2

48EJ,EK,EW,EY024-048

Single Package Rooftop Units

Electric Cooling/Gas Heating

1. Improper installation, adjustment, alteration, service, or maintenance can cause property damage, personal injury, or loss of life. Refer to the User’s

Information Manual provided with this unit for more

details.

2. Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other

appliance.

What to do if you smell gas:

1. DO NOT try to light any appliance.

2. DO NOT touch any electrical switch, or use any phone

in your building.

3. IMMEDIATELY call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

4. If you cannot reach your gas supplier, call the fire

department.

Disconnect gas piping from unit when pressure testing

at pressure greater than 0.5 psig. Pressures greater than

0.5 psig will cause gas valve damage resulting in haz-

ardous condition. If gas valve is subjected to pressure

greater than 0.5 psig, it must be replaced before use. When

pressure testing field-supplied gas piping at pressures of

0.5 psig or less, a unit connected to such piping must be

isolated by closing the manual gas valve(s).

INSTALLATION

Step 1 — Provide Unit Support

SAFETY CONSIDERATIONS

Installation and servicing of air-conditioning equipment

can be hazardous due to system pressure and electrical components. Only trained andqualifiedservice personnel should

install, repair, or service air-conditioning equipment.

Untrained personnel can perform the basic maintenance

functions of cleaning coils and filters and replacing filters.

All other operations should be performed by trained service

personnel. When working on air-conditioning equipment, observe precautions in the literature, tags and labels attached

to the unit, and other safety precautions that may apply.

Follow all safety codes. Wearsafety glasses and work gloves.

Use quenching cloth for unbrazing operations. Have fire extinguishers available for all brazing operations.

Before performing service or maintenance operations on

unit, turn off main power switch to unit. Electrical shock

could cause personal injury.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1

Tab 1a

PC 111 Catalog No. 564-962 Printed in U.S.A. Form 48E-5SI Pg 1 8-97 Replaces: 48E-3SI

1. All panels must be in place when rigging.

2. Unit is not designed for handling by fork truck.

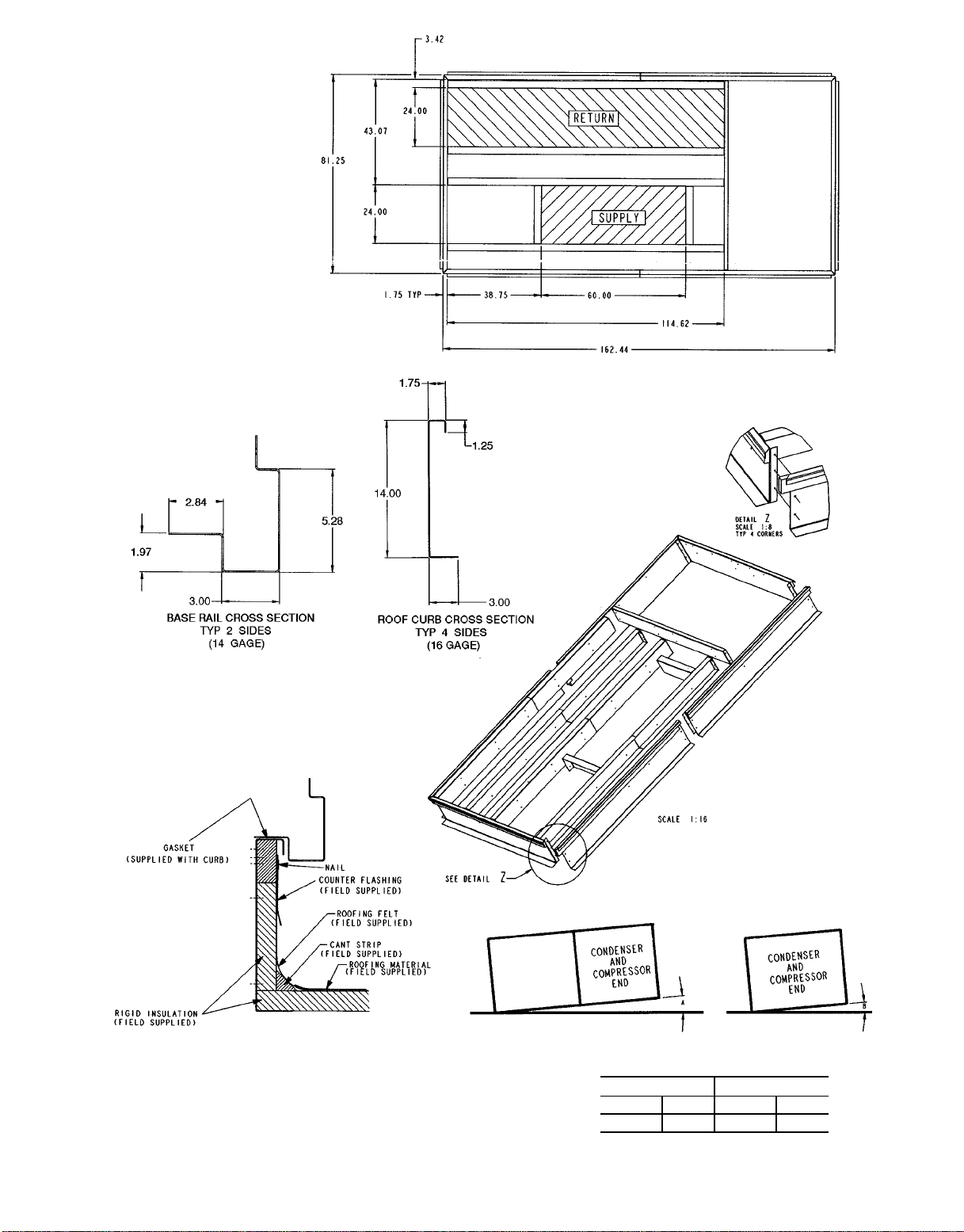

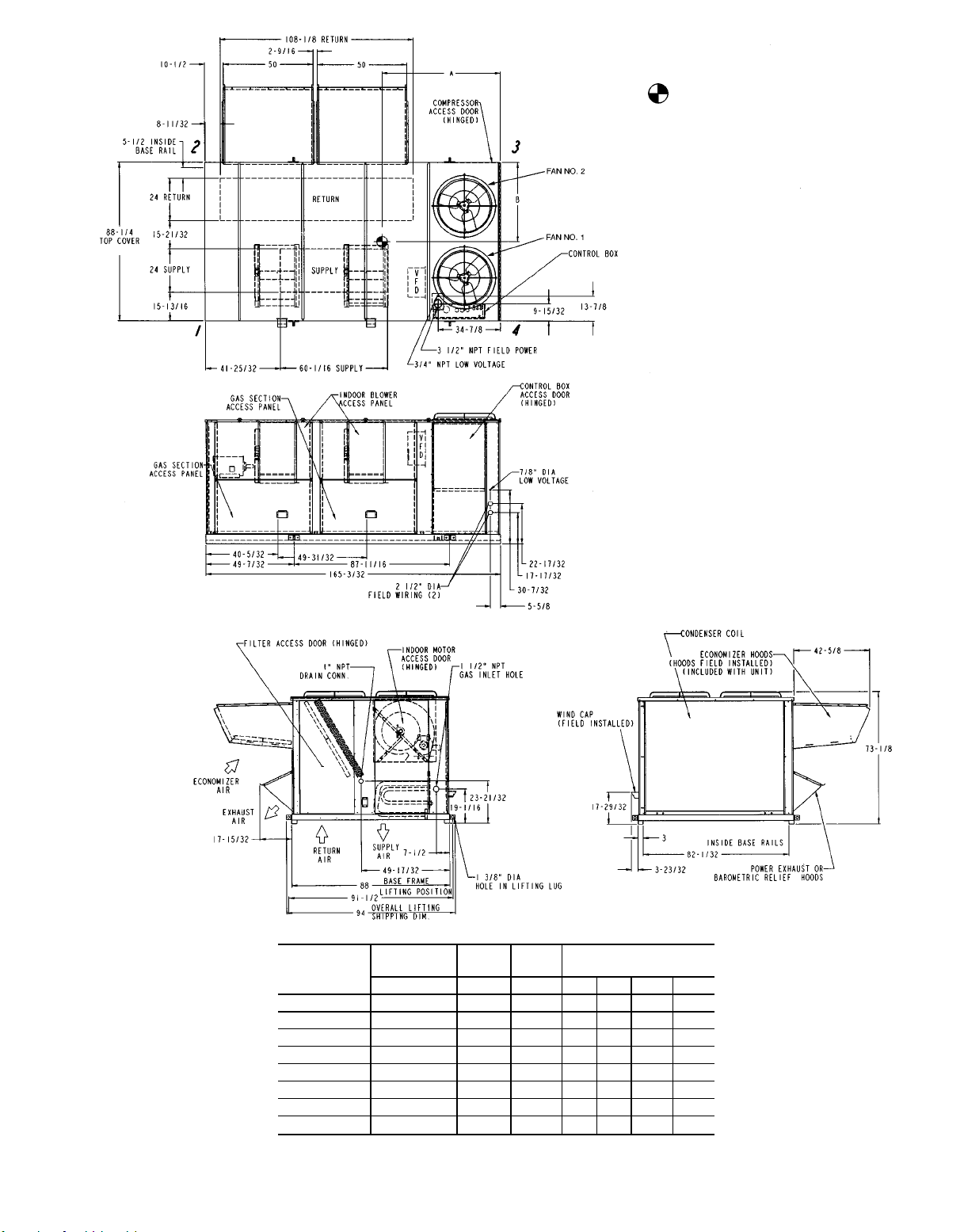

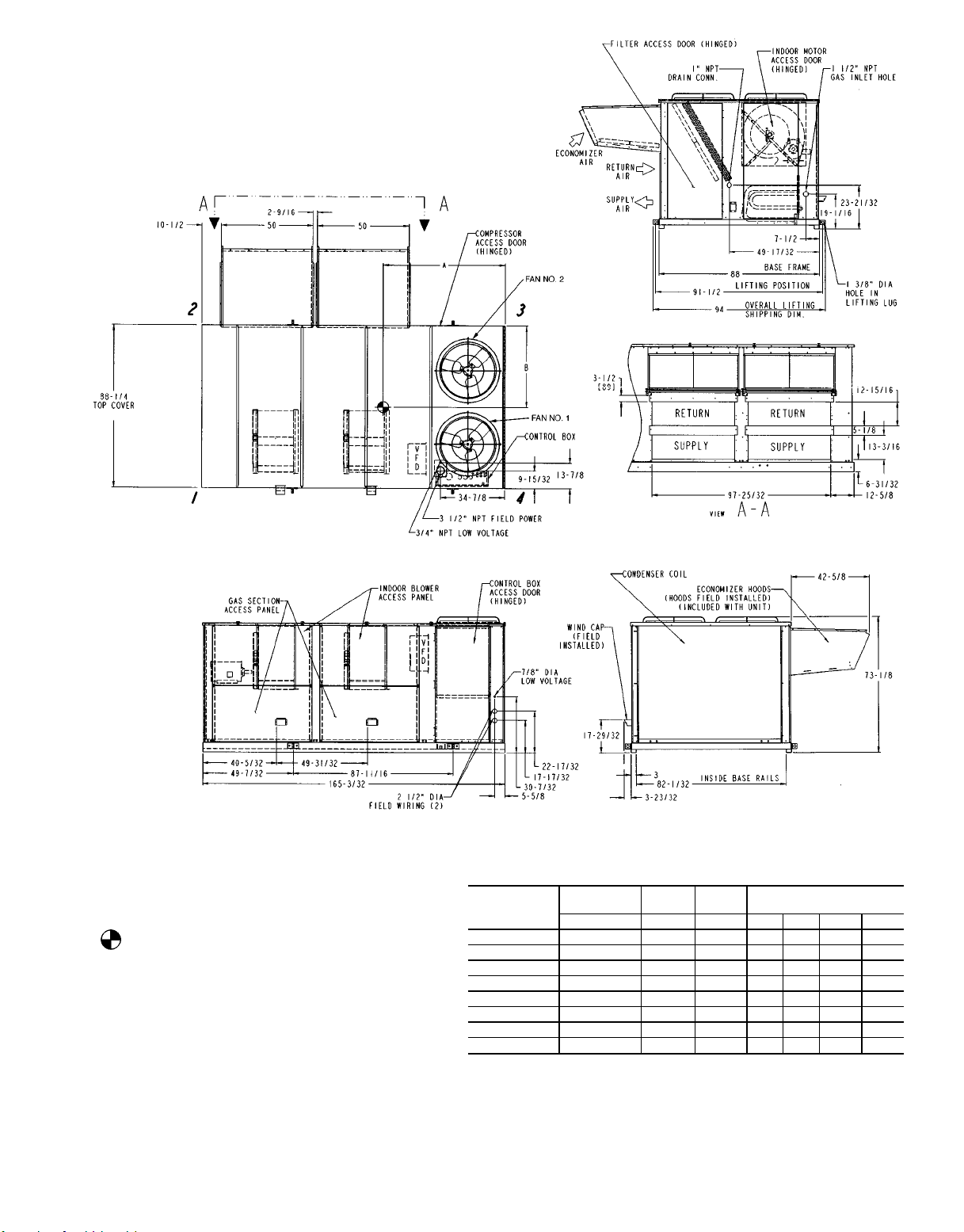

ROOF CURB — Assemble or install accessory roof curb in

accordance with instructions shipped with this accessory.See

Fig. 1 and 2. Install insulation, cant strips, roofing, and counter

flashing as shown. Ductwork can be installed to roof curb

before unit is set in place. Curb should be level. This is necessary to permit unit drain to function properly. Unit leveling tolerance is shown in Fig. 1 and 2. Refer to Accessory

Roof Curb Installation Instructions for additional information as required. When accessory roof curb is used, unit may

be installed on class A, B, or C roof covering material.

IMPORTANT: The gasketing of the unit to the roof

curb is critical for a watertight seal. Install gasket with

the roof curb as shown in Fig. 1 and 2. Improperly

applied gasket can also result in air leaks and poor unit

performance.

ALTERNATE UNIT SUPPORT— When the preferred curb

or slab mount cannot be used, support unit with sleepers on

perimeter, using unit curb support area. If sleepers cannot be

used, support long sides of unit (refer to Fig. 3-6) with a

minimum number of 4-in. x 4-in. pads spaced as follows:

48EJ,EK,EW,EY024-034 units require 3 pads on each side;

48EJ,EK,EW,EY038-048 units require 4 pads on each side.

Unit may sag if supported by corners only.

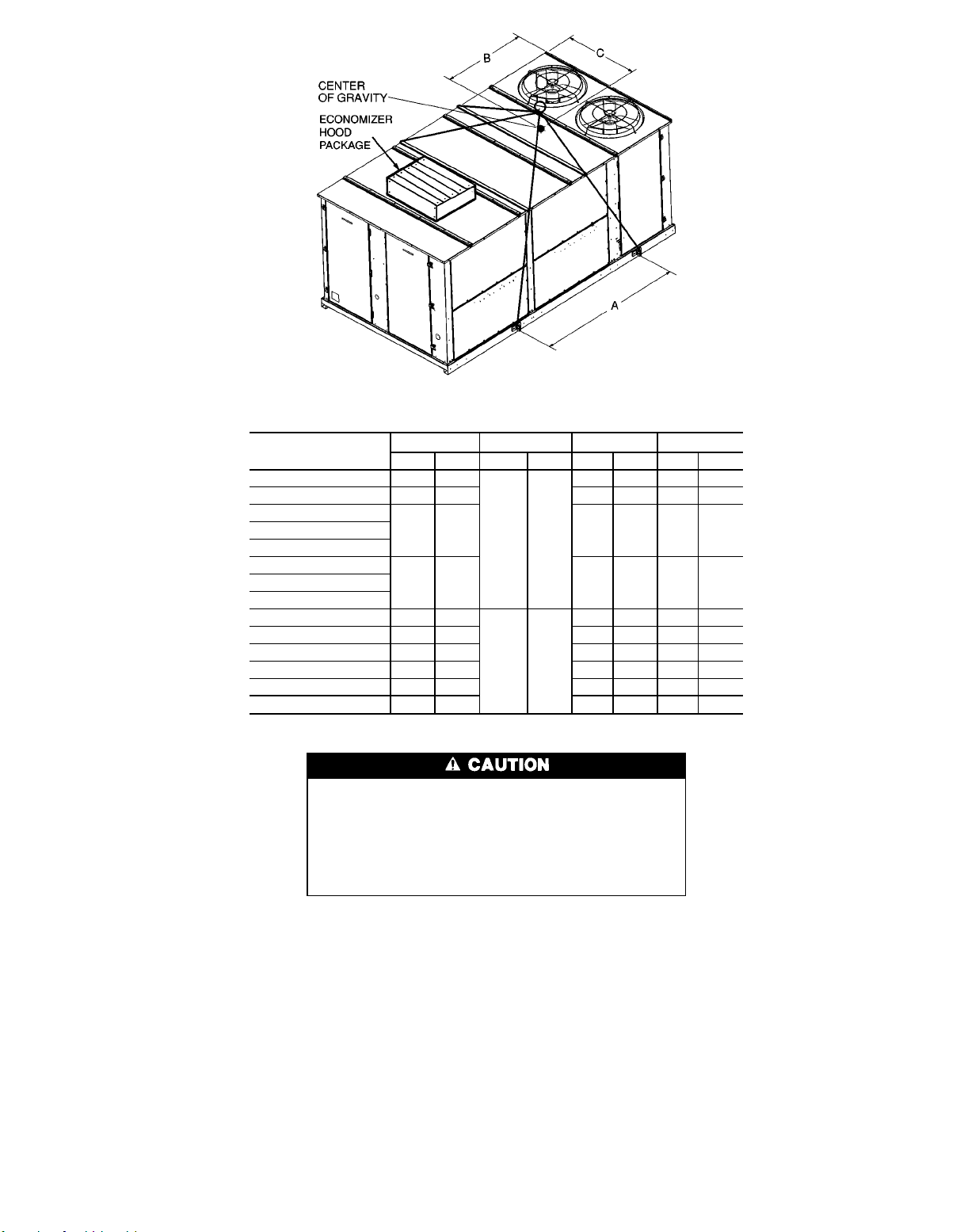

Step 2 — Rig and Place Unit — Inspect unit for trans-

portation damage. File any claim with transportation agency.

Do not drop unit; keep upright. Use spreader bars over

unit to prevent sling or cable damage. Level by using unit

frame as a reference; leveling tolerance is shown in Fig. 1

and 2. See Fig. 7 for additional information. Unit operating

weight is shown in Table 1.

NOTE: On retrofit jobs, ductwork may be attached to old

unit instead of roof curb. Be careful not to damage ductwork

when removing old unit. Attach existing ductwork to roof

curb instead of unit.

Four lifting lugs are provided on the unit base rails as shown

in Fig. 7. Refer to rigging instructions on unit.

POSITIONING — Maintain clearance, per Fig. 3-6, around

and above unit to provide minimum distance from combustible materials, proper airflow, and service access.

Do not install unit in an indoor location. Do not locate

unit air inlets near exhaust vents or other sources of contaminated air. For proper unit operation, adequate combustion and ventilation air must be provided in accordance with

Section 5.3 (Air for Combustion and Ventilation) of the

National Fuel Gas Code, ANSI Z223.1 (American National

Standards Institute).

Although unit is weatherproof, guard against water from

higher level runoff and overhangs.

Locate mechanical draft system flue assembly at least

4 ft from any opening through which combustion products

could enter the building, and at least 4 ft from any adjacent

building. When unit is located adjacent to public walkways,

flue assembly must be at least 7 ft above grade.

ROOF MOUNT — Check building codes for weight distribution requirements. Unit weight is shown in Table 1.

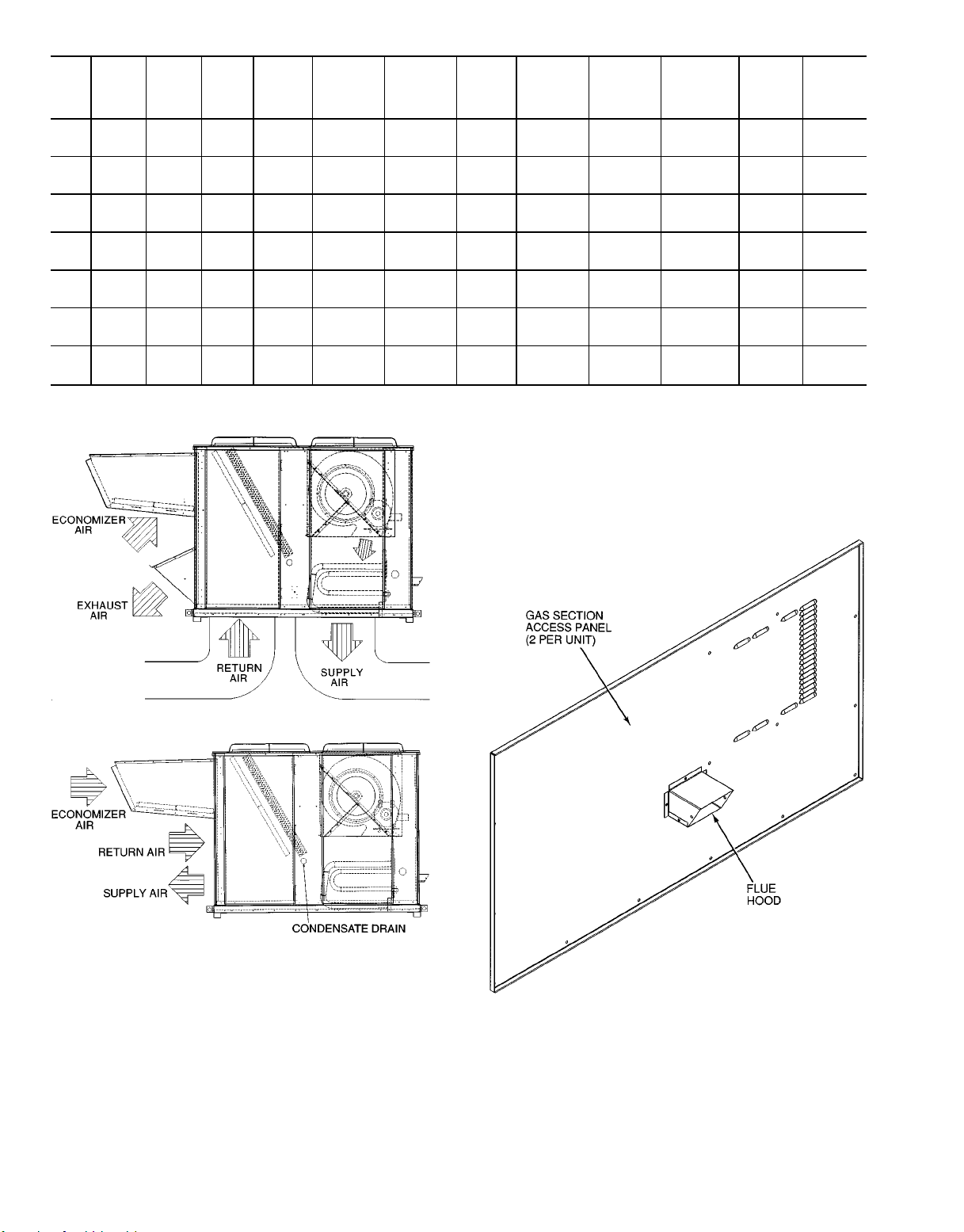

Step 3 — Field Fabricate Ductwork

48EJ,EK UNITS — Field-fabricated ductwork should be attached to the roof curb. Supply and return duct dimensions

are shown in Fig. 3 and 4. Air distribution is shown in

Fig. 8.

To attach ductwork to roof curb, insert duct approximately 10 to 11 in. up into roof curb. Connect ductwork to

14-gage roof curb material with sheet metal screws driven

from inside the duct.

Secure all ducts to the building structure, using flexible

duct connectors between roof curb and ducts as required. Ducts

passing through an unoccupied space must be insulated and

covered with a vapor barrier. Outlet grilles must not lie

directly below unit discharge. The return duct must have a

90-degree elbow before opening into the building space if

the unit is equipped with power exhaust.

For vertical supply and return units, tools or parts could

drop into ductwork and cause an injury. Install 90 degree elbow turns in the supply and return ductwork between the unit and the conditioned space. If a 90 degree

elbow cannot be installed, then grilles of sufficientstrength

and density should be installed to prevent objects from

falling into the conditioned space.

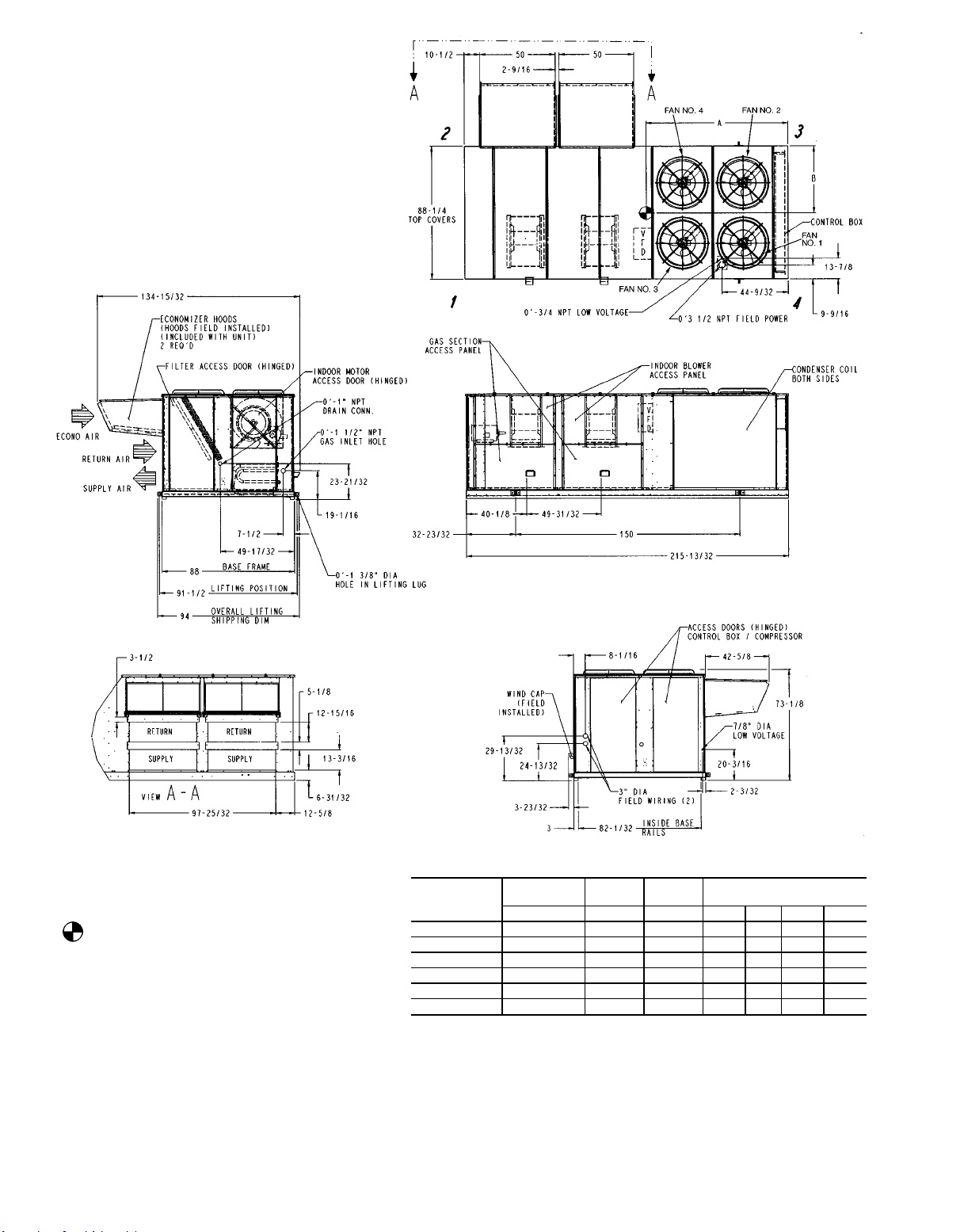

48EW,EY UNITS — Remove shipping covers from supply

and return air openings. Attach field-supplied ductwork to

unit. Use a single duct over both return openings and a single

duct over both supply openings. See Fig. 5 and 6 for duct

opening dimensions. Secure all ducts to the building structure. See Fig. 9. Use flexible duct connectors between unit

and ducts as required. Insulate and weatherproof all external

ductwork, joints, and building openings with counter flashing and mastic in accordance with applicable codes.

Ducts passing through an unconditioned space must be

insulated and covered with a vapor barrier.

Install accesssory barometric relief or power exhaust in

the field-fabricated return ductwork. Refer to Position Power

Exhaust/Barometric Relief Damper Hood section on

page 26 for more information.

Instructions continued on page 12.

2

NOTES:

1. All roof curb parts are to be 16 ga galvanized steel.

2. Dimensions are in inches.

3. Toprevent standing water in the drain pan of the indoor

sectionandtheheatexchangers,unit can only be pitched

as shown.

Fig. 1 — Roof Curb (Sizes 024-034)

UNIT LEVELING TOLERANCES DIMENSIONS*

*From edge of unit to horizontal.

(Degrees and Inches)

AB

Deg. in. Deg. in.

1.0 2.9 .50 .75

3

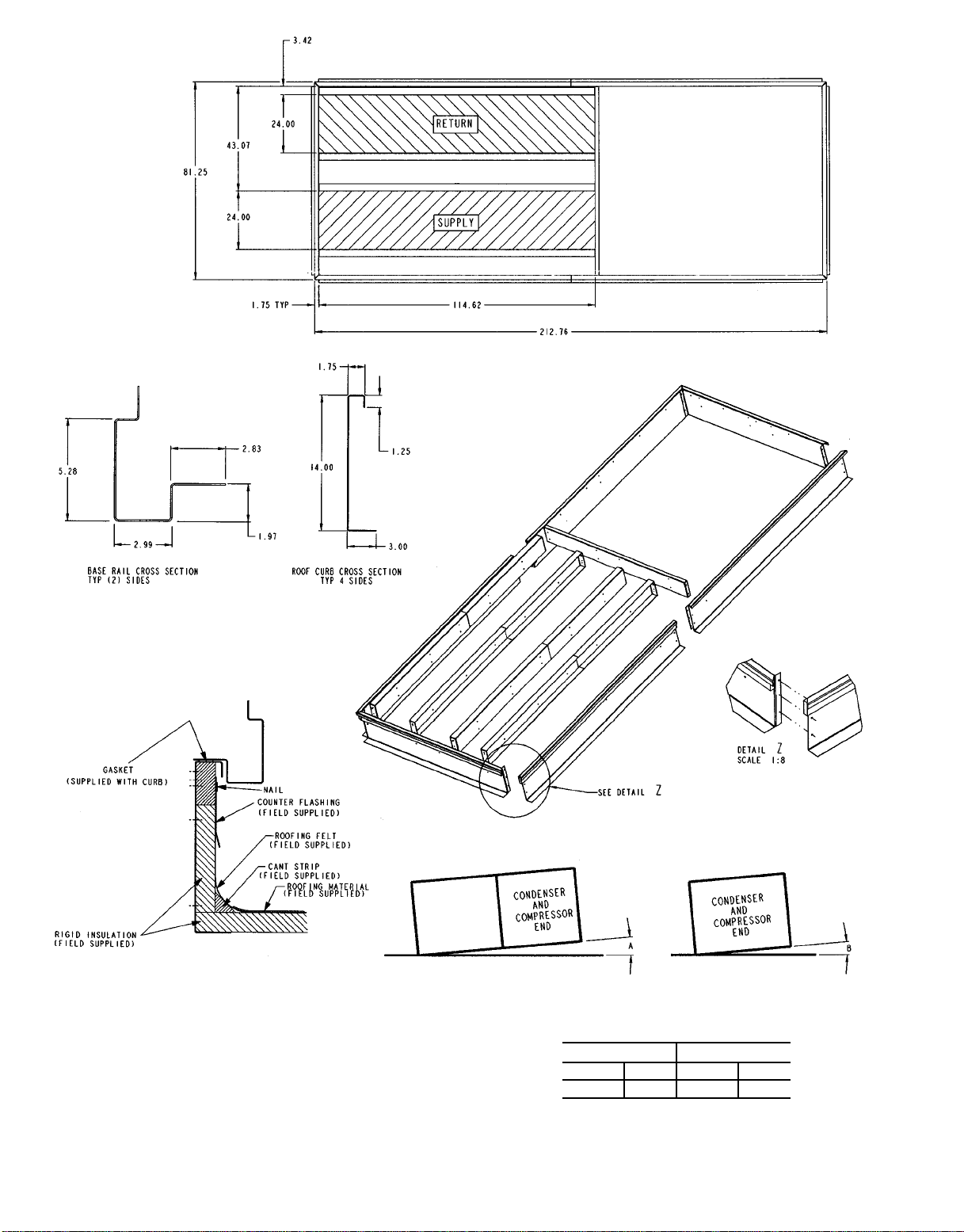

NOTES:

1. All roof curb parts are to be 16 ga galvanized steel.

2. Dimensions are in inches.

3. Toprevent standing water in the drain pan of the indoor

sectionandtheheatexchangers,unit can only be pitched

as shown.

Fig. 2 — Roof Curb (Sizes 038-048)

UNIT LEVELING TOLERANCES DIMENSIONS*

*From edge of unit to horizontal.

(Degrees and Inches)

AB

Deg. in. Deg. in.

1.0 2.9 .50 .75

4

VFD — Variable Frequency Drive

NOTES:

1. Weights include economizer (STD).

2. Center of gravity.

3. Do not locate adjacent units with flue dischargefacingeconomizerinlet.Minimum clearances to be:

Adjacent Units: 158-09

Top of Units: No overhang

Condenser Coil: 48-09

Economizer Side: 68-09

Gas Heat Side: 48-09

Filter Access Side: 108-09 (For Removal of

Evaporator Coil)

4. For smaller service and operational clearances, contact Carrier Application Engineering department.

5. Bottom ducts designed to be attached to accessory roof curb. If unit is mounted on dunnage, it is recommended the ducts be

supported by cross braces as done on accessory roof curb.

6. Dimensions are in inches.

UNIT

SIZE

OPERATING

WEIGHT

lb ft-in. ft-in. 1 2 3 4

48EJ,EKD024 4176 6- 0

48EJE024 4256 6- 1

48EJ,EKD028 4262 5- 9

48EJE028 4342 5-10

48EJ,EKD030 4262 5- 9

48EJE030 4342 5-10

48EJ,EKD034 4262 5- 9

48EJE034 4342 5-10

A B CORNER WEIGHT (lb)

3

⁄83-63⁄8879 954 1220 1124

5

⁄163-611⁄16917 973 1218 1148

5

⁄83-8 899 899 1232 1232

1

⁄83-85⁄16929 916 1240 1257

5

⁄83-8 899 899 1232 1232

1

⁄83-85⁄16929 916 1240 1257

5

⁄83-8 899 899 1232 1232

1

⁄83-85⁄16929 916 1240 1257

Fig. 3 — Base Unit Dimensions, 48EJ,EK024-034

5

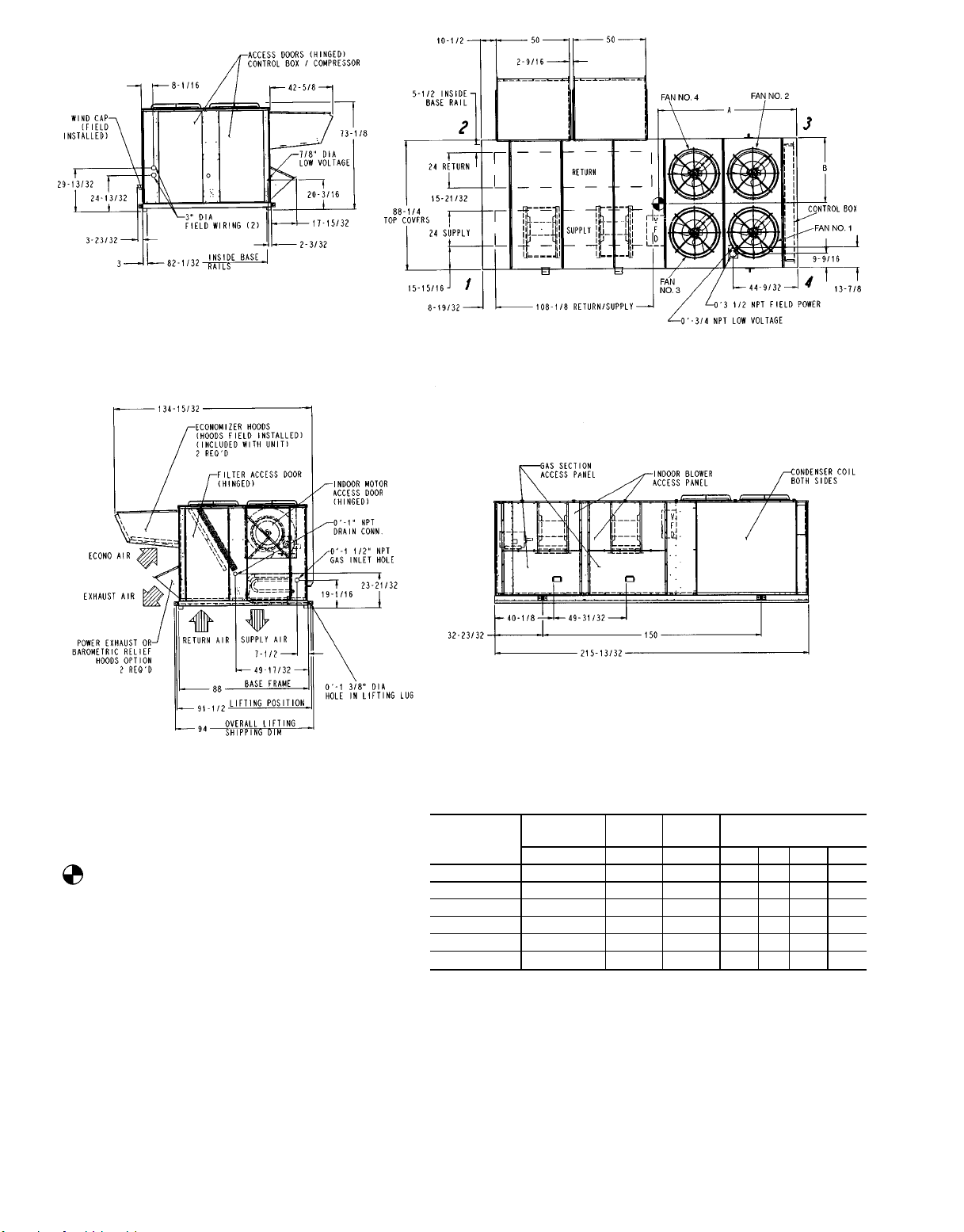

VFD — Variable Frequency Drive

NOTES:

1. Weights include economizer (STD).

2. Center of gravity.

3. Do not locate adjacent units with flue discharge facing economizer inlet. Minimum clearances to be:

Adjacent Units: 158-09

Top of Units: No overhang

Condenser Coil: 48-09

Economizer Side: 68-09

Gas Heat Side: 48-09

Filter Access Side: 108-09 (For Removal of Evaporator Coil)

4. For smaller service and operational clearances, contact

Carrier Application Engineering department.

5. Bottom ducts designed to be attached to accessory roof curb.

If unit is mounted on dunnage, it is recommended the ducts be

supported by cross braces as done on accessory roof curb.

6. Dimensions are in inches.

Fig. 4 — Base Unit Dimensions, 48EJ,EK038-048

UNIT

SIZE

OPERATING

WEIGHT

lb ft-in. ft-in. 1 2 3 4

48EJ,EKD038 4442 7- 8

48EJE038 4602 7-10

48EJ,EKD044 4668 7- 5

48EJE044 4828 7- 6

48EJ,EKD048 4955 7- 3

48EJE048 5115 7- 5

6

A B CORNER WEIGHT (lb)

11

⁄163-107⁄81021 894 1180 1347

1

⁄83-113⁄161080 934 1200 1388

5

⁄163-107⁄81033 906 1275 1455

13

⁄163-113⁄161094 945 1293 1496

11

⁄163-101⁄21068 953 1384 1550

3

⁄163-1013⁄161129 994 1401 1592

VFD — Variable Frequency Drive

NOTES:

1. Weights include economizer (STD).

2. Center of gravity.

3. Do not locate adjacent units with flue discharge facing economizer inlet.

Minimum clearances to be:

Adjacent Units: 158-09

Top of Units: No overhang

Condenser Coil: 48-09

Economizer Side: 68-09

Gas Heat Side: 48-09

Filter Access Side: 108-09 (For Removal of Evaporator Coil)

4. For smaller service and operational clearances, contact Carrier

Application Engineering department.

5. Dimensions are in inches.

6. For side-supply/return applications, a single return and supply ductwork

connection is recommended for covering both return and both supply

openings.

Fig. 5 — Base Unit Dimensions, 48EW,EY024-034

UNIT

SIZE

OPERATING

WEIGHT

lb ft-in. ft-in. 1 2 3 4

48EW,EYD024 4176 6- 0

48EWE024 4256 6- 1

48EW,EYD028 4262 5- 9

48EWE028 4342 5-10

48EW,EYD030 4262 5- 9

48EWE030 4342 5-10

48EW,EYD034 4262 5- 9

48EWE034 4342 5-10

7

A B CORNER WEIGHT (lb)

3

⁄83-63⁄8879 954 1220 1124

5

⁄163-611⁄16917 973 1218 1148

5

⁄83-8 899 899 1232 1232

1

⁄83-85⁄16929 916 1240 1257

5

⁄83-8 899 899 1232 1232

1

⁄83-85⁄16929 916 1240 1257

5

⁄83-8 899 899 1232 1232

1

⁄83-85⁄16929 916 1240 1257

VFD — Variable Frequency Drive

NOTES:

1. Weights include economizer (STD).

2. Center of gravity.

3. Do not locate adjacent units with flue discharge facing economizer

inlet. Minimum clearances to be:

Adjacent Units: 158-09

Top of Units: No overhang

Condenser Coil: 48-09

Economizer Side: 68-09

Gas Heat Side: 48-09

Filter Access Side: 108-09 (For Removal of Evaporator Coil)

4. For smaller service and operational clearances, contact Carrier

Application Engineering department.

5. Dimensions are in inches.

6. For side-supply/return applications, a single return and supply ductwork connection is recommended for covering both return and both

supply openings.

Fig. 6 — Base Unit Dimensions, 48EW,EY038-048

UNIT

SIZE

OPERATING

WEIGHT

lb ft-in. ft-in. 1 2 3 4

48EW,EYD038 4442 7- 8

48EWE038 4602 7-10

48EW,EYD044 4668 7- 5

48EWE044 4828 7- 6

48EW,EYD048 4955 7- 3

48EWE048 5115 7- 5

8

A B CORNER WEIGHT (lb)

11

⁄163-107⁄81021 894 1180 1347

1

⁄83-113⁄

5

⁄163-107⁄81033 906 1275 1455

13

⁄163-113⁄

11

⁄163-101⁄21068 953 1384 1550

3

⁄163-1013⁄161129 994 1401 1592

16

1080 934 1200 1388

16

1094 945 1293 1496

UNIT

48EJ,EK,EW,EYD024 4176 1894

48EJ,EWE024 4256 1930 73.3 1862 42.7 1085

48EJ,EK,EW,EYD028

48EJ,EK,EW,EYD034

48EJ,EWE028

48EJ,EWE034

48EJ,EK,EW,EYD038 4442 2015

48EJ,EWE038 4602 2087 94.1 2390 47.2 1199

48EJ,EK,EW,EYD044 4668 2117 89.3 2268 46.9 1191

48EJ,EWE044 4828 2190 90.8 2306 47.2 1199

48EJ,EK,EW,EYD048 4955 2248 87.7 2228 46.5 1181

48EJ,EWE048 5115 2320 89.2 2266 46.8 1189

WEIGHT A B C

lb kg in. mm in. mm in. mm

72.4 1839 42.4 1072

4262 1933 69.6 1768 44.0 111848EJ,EK,EW,EYD030

4342 1969 70.1 1781 44.3 112548EJ,EWE030

87.68 2227

92.7 2355 46.9 1191

150 3810

NOTICE TO RIGGERS:

ALL PANELS MUST BE IN PLACE

WHEN RIGGING.

NOTE: Rig with four cables and spread with two

92 in. (2337 mm) spreader bars. Maintain a distance of 74 in. (1880 mm) from top of unit to

eyehook.

NOTE:

Add 32 lb (14.5 kg) for domestic crating.

Add 312 lb (142 kg) for export crating (024-034 units).

Add 346 lb (157 kg) for export crating (038-048 units).

Add 250 lb (113 kg) for power exhaust.

Add 220 lb (100 kg) for copper condenser coil (024-034 units).

Add 285 lb (129 kg) for copper condenser coil (038,044 units).

Add 380 lb (172 kg) for copper condenser coil (048 unit).

Fig. 7 — Rigging Label

9

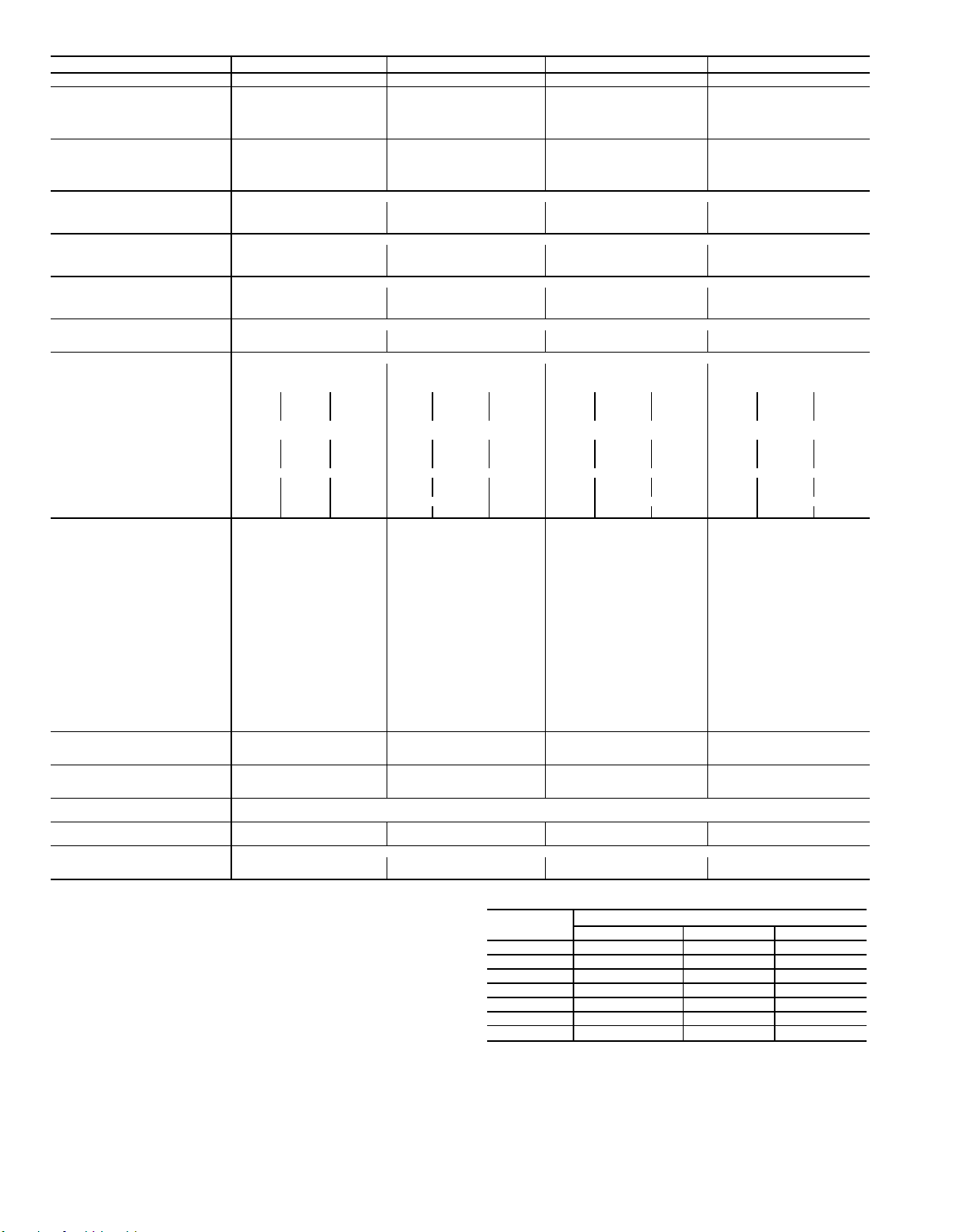

Table 1 — Physical Data

UNIT 48EJ,EK,EW,EY 024D/E 028D/E 030D/E 034D/E

NOMINAL CAPACITY (tons) 20 25 27 30

OPERATING WEIGHT (lb)*

Unit

Al/Al† (Lo Heat/Hi Heat) 4176/4256 4262/4342 4262/4342 4262/4342

Al/Cu† (Lo Heat/Hi Heat) 4396/4476 4482/4562 4482/4562 4482/4562

Roof Curb (14-in. curb) 365 365 365 365

COMPRESSOR

Type Ckt 1 06D328 06D328 06D537 06D537

Ckt 2 06D818 06D328 06D328 06D537

Number of Refrigerant Circuits 22 2 2

Oil (oz) (Ckt 1, Ckt 2) 115, 88 115 ea. 115 ea. 115 ea.

REFRIGERANT TYPE R-22

Operating Charge (lb-oz)

Circuit 1** 25-0 25-0 25-0 25-0

Circuit 2 31-0 25-0 25-0 25-0

CONDENSER COIL Cross-Hatched

Quantity 11 1 1

Rows...Fins/in. 4...15 4...15 4...15 4...15

Total Face Area (sq ft) 33.3 33.3 33.3 33.3

CONDENSER FAN Propeller Type

Nominal Cfm 13,420 13,420 13,420 13,420

Quantity...Diameter (in.) 2...30 2...30 2...30 2...30

Motor Hp (1075 Rpm) 11 1 1

EVAPORATOR COIL Cross-Hatched

Rows...Fins/in. 4...15 4...15 4...15 4...15

Total Face Area (sq ft) 31.7 31.7 31.7 31.7

EVAPORATOR FAN Centrifugal Type

Quantity...Size (in.) 2...20x15 2...20x15 2...20x15 2...20x15

Type Drive Belt Belt Belt Belt

Nominal Cfm 8,000 10,000 11,000 12,000

Motor Hp 5 10†† 15 7.5 10†† 15 10 15†† 20 10 15†† 20

Motor Frame Size (Standard) S184T S215T D254T S213T S215T D254T S215T D254T S256T S215T D254T S256T

Motor Bearing Type Ball Ball Ball Ball

Maximum Allowable Rpm 1200 1200 1200 1200

Motor Pulley Pitch Diameter 4.8 4.4 5.7 5.4 6.1 5.5 4.4 4.9 5.9 4.4 5.7 5.9

Nominal Motor Shaft Diameter (in.) 1

Fan Pulley Pitch Diameter (in.) 12.4 8.6 9.1 12.4 11.1 8.7 9.4 8.1 8.7 9.0 9.1 8.7

Nominal Fan Shaft Diameter (in.) 1

Belt, Quantity...Type

Belt, Length (in.)

Pulley Center Line Distance (in.) 16.0-18.7 15.6-18.4 15.0-17.9 15.6-18.4 15.0-17.9 15.6-18.4 15.0-17.9 15.6-18.4 15.0-17.9

Factory Speed Setting (rpm) 717 924 1096 773 962 1106 848 1059 1187 884 1096 1187

FURNACE SECTION

Rollout Switch Cutout Temp (F)| 225 225 225 225

Burner Orifice Diameter

(in. ...drill size)

Thermostat Heat Anticipator

Setting (amps)

Gas Input (Btuh) Stage 1 Low 262,500 262,500 262,500 262,500

Efficiency (Steady State) (%) 82 82 82 82

Temperature Rise Range 15-45/35-65 15-45/35-65 15-45/35-65 15-45/35-65

Manifold Pressure (in. wg)

Gas Valve Quantity 22 2 2

Field Gas Connection Size

HIGH-PRESSURE SWITCH (psig)

Cutout 426 426 426 426

Reset (Auto.) 320 320 320 320

LOW-PRESSURE SWITCH (psig)

Cutout 77 7 7

Reset (Auto.) 22 22 22 22

OUTDOOR-AIR FILTERS 8...16 × 25

Quantity...Size (in.) 4...20 × 25

RETURN-AIR FILTERS

Quantity...Size (in.) 10...20x24x2 10...20x24x2 10...20x24x2 10...20x24x2

POWER EXHAUST Direct Drive, 3-Speed, Single-Phase Motor (Factory-Wired for High Speed) and Forward-Curved Fan

Motor, Quantity...Hp 4...1 4...1 4...1 4...1

Fan, Diameter... Width (in.) 11...10 11...10 11...10 11...10

(High Efficiency) S184T S215T S254T S213T S215T S254T S215T S254T S256T S215T S254T S256T

1

⁄

8

13⁄

8

15⁄

15

⁄

1...BX59622...BX51542...5VX530531...BX59621...5VX590592...5VX530532...BX52552...5VX500502...5VX530532...BX51542...5VX530532...5VX530

Natural Gas Std .111...34 .111...34 .111...34 .111...34

Liquid Propane Alt .089...43 .089...43 .089...43 .089...43

Stage 1 0.1 0.1 0.1 0.1

Stage 2 0.1 0.1 0.1 0.1

High 394,000 394,000 394,000 394,000

Stage 2 Low 350,000 350,000 350,000 350,000

High 525,000 525,000 525,000 525,000

Natural Gas Std 3.5 3.5 3.5 3.5

Liquid Propane Alt 3.5 3.5 3.5 3.5

(in.-FPT)

16

1.5 1.5 1.5 1.5

LEGEND

Al — Aluminum

Cu — Copper

*Weightof unit does not include variable frequency drive(VFD) barometric relief, or power

exhaust. If a VFD is installed, add the VFD weight in the table at right.

†Evaporator coil fin material/condenser coil fin material.

**Sizes 024-034: Circuit 1 uses the lowerportion of condensercoil, Circuit 2uses the upper

portion. Sizes 038-048: Circuit 1 uses the left condenser coil, Circuit 2 the right. All units

have intertwined evaporator coils.

††Motor and drive shown will deliver approximately 2.5 in. wg net external static. See

Table 2 for more information.

\Rollout switch is manual reset.

3

⁄89 Copper Tubes, Aluminum Lanced, Aluminum Pre-Coated, or Copper Plate Fins

3

⁄89 Copper Tubes, Aluminum Plate Fins, Intertwined Circuits

8

13⁄

8

13⁄

8

15⁄

8

13⁄

8

15⁄

8

15⁄

8

13⁄

8

15⁄

8

15⁄

8

115⁄

16

115⁄

16

115⁄

16

53

NOTE: High heat is for 48EJ,EW only.

VFD

(Hp)

208/230 v 460 v 575 v

VFD WEIGHTS (lb)

5 20 22 60

7.5 51 37 64

10 51 61 64

15 61 63 109

20 63 111 109

25 105 112 174

30 172 118 180

10

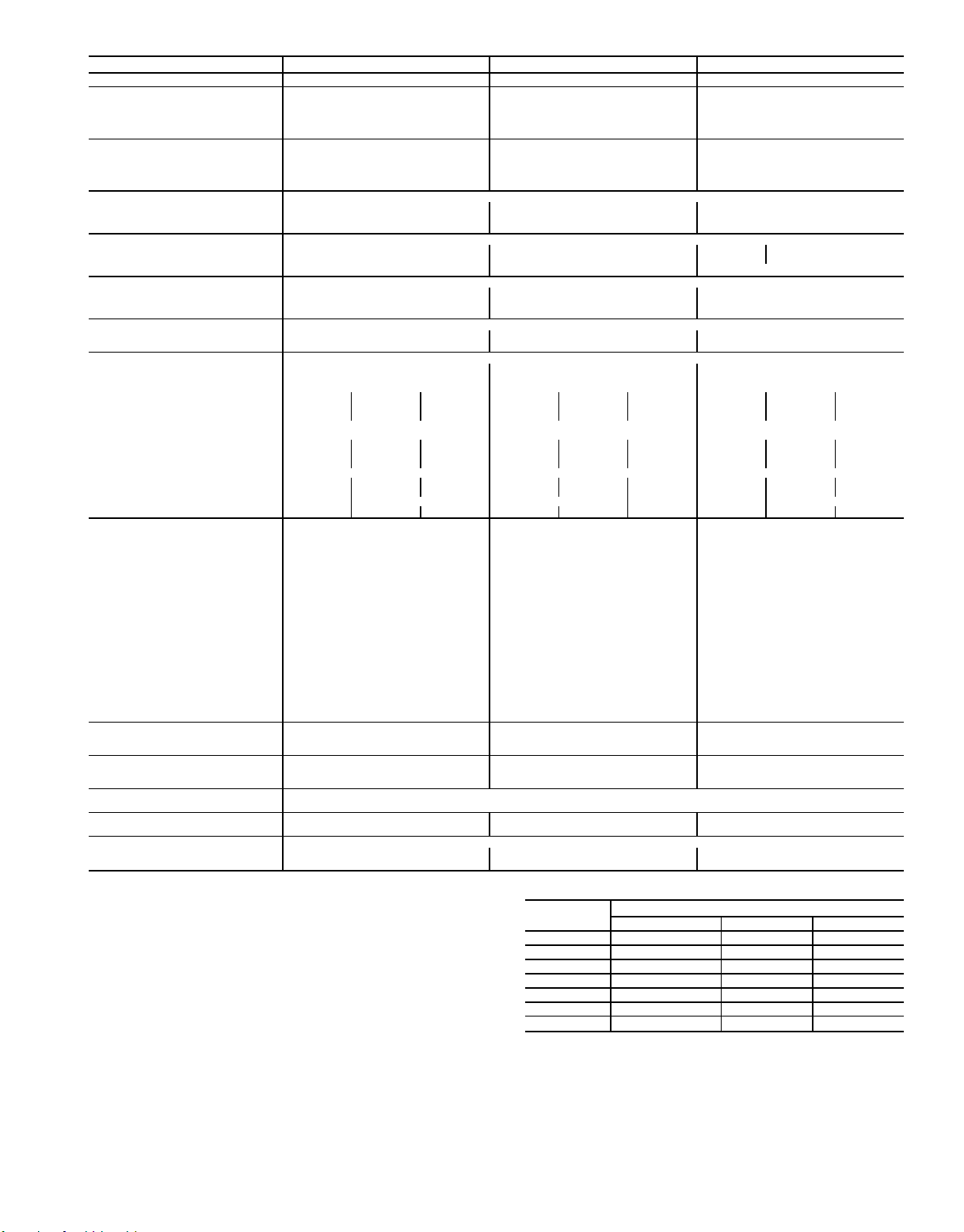

Table 1 — Physical Data (cont)

UNIT 48EJ,EK,EW,EY 038D/E 044D/E 048D/E

NOMINAL CAPACITY (tons) 35 40 45

OPERATING WEIGHT (lb)*

Unit

Al/Al† (Lo Heat/Hi Heat) 4442/4602 4668/4828 4955/5115

Al/Cu† (Lo Heat/Hi Heat) 4727/4887 4953/5113 5335/5495

Roof Curb (14-in. curb) 410 410 410

COMPRESSOR

Type Ckt 1 06D537 06EA250 06EA265

Ckt 2 06D537 06EA250 06EA250

Number of Refrigerant Circuits 222

Oil (oz) (Ckt 1, Ckt 2) 115 ea. 224 ea. 304, 224

REFRIGERANT TYPE R-22

Operating Charge (lb-oz)

Circuit 1** 34-0 35-0 41-0

Circuit 2 34-0 35-0 41-0

CONDENSER COIL Cross-Hatched

Quantity 2211

Rows...Fins/in. 3...15 3...15 4...15 3...15

Total Face Area (sq ft) 58.3 58.3 66.7

CONDENSER FAN Propeller Type

Nominal Cfm 27,064 27,064 27,064

Quantity...Diameter (in.) 4...30 4...30 4...30

Motor Hp (1075 Rpm) 111

EVAPORATOR COIL Cross-Hatched

Rows...Fins/in. 3...15 3...15 4...15

Total Face Area (sq ft) 34.7 34.7 34.7

EVAPORATOR FAN Centrifugal Type

Quantity...Size (in.) 2...20x15 2...20x15 2...20x15

Type Drive Belt Belt Belt

Nominal Cfm 14,000 16,000 18,000

Motor Hp 10 15†† 20 15 20†† 25 20 25†† 30

Motor Frame Size (Standard) S215T D254T S256T D254T S256T S284T S256T S284T S286T

Motor Bearing Type Ball Ball Ball

Maximum Allowable Rpm 1200 1200 1200

Motor Pulley Pitch Diameter 6.1 5.3 5.7 5.3 5.7 7.5 6.3 5.9 7.5

Nominal Motor Shaft Diameter (in.) 1

Fan Pulley Pitch Diameter (in.) 13.7 9.5 9.5 9.5 9.5 11.1 11.1 12.5 11.1

Nominal Fan Shaft Diameter (in.) 1

Belt, Quantity...Type

Belt, Length (in.)

Pulley Center Line Distance (in.) 15.6-18.4 15.0-17.9 15.0-17.9 14.6-17.6 15.0-17.9 14.6-17.6

Factory Speed Setting (rpm) 779 976 1050 976 1050 1182 993 1134 1182

FURNACE SECTION

Rollout Switch Cutout Temp (F)| 225 225 225

Burner Orifice Diameter

(in. ...drill size)

Thermostat Heat Anticipator

Setting (amps)

Gas Input (Btuh) Stage 1 Low 300,000 300,000 300,000

Efficiency (Steady State) (%) 82 82 82

Temperature Rise Range 10-40/30-60 10-40/30-60 10-40/30-60

Manifold Pressure (in. wg)

Gas Valve Quantity 222

Field Gas Connection Size (in.-FPT) 1.5 1.5 1.5

HIGH-PRESSURE SWITCH (psig)

Cutout 426 426 426

Reset (Auto.) 320 320 320

LOW-PRESSURE SWITCH (psig)

Cutout 777

Reset (Auto.) 22 22 22

OUTDOOR-AIR FILTERS 8...16 × 25

Quantity...Size (in.) 4...20 × 25

RETURN-AIR FILTERS

Quantity...Size (in.) 10...20x24x2 10...20x24x2 10...20x24x2

POWER EXHAUST Direct Drive, 3-Speed, Single-Phase motor (Factory-Wired for High Speed) and Forward Curved Fan

Motor, Quantity...Hp 4...1 4...1 4...1

Fan, Diameter... Width (in.) 11...10 11...10 11...10

(High Efficiency) S215T S254T S256T S254T S256T S284T S256T S284T S286T

3

⁄

8

1...5VX650652...5VX530532...5VX550552...5VX530532...5VX550552...5VX590592...5VX570572...5VX630632...5VX610

Natural Gas Std .120...31 .120...31 .120...31

Liquid Propane Alt .096...41 .096...41 .096...41

Stage 1 0.1 0.1 0.1

Stage 2 0.1 0.1 0.1

High 600,000 600,000 600,000

Stage 2 Low 400,000 400,000 400,000

High 800,000 800,000 800,000

Natural Gas Std 3.5 3.5 3.5

Liquid Propane Alt 3.5 3.5 3.5

15⁄

8

15

⁄

16

LEGEND

Al — Aluminum

Cu — Copper

*Weightof unit does not include variable frequency drive(VFD) barometric relief, or power

exhaust. If a VFD is installed, add the VFD weight in the table at right.

†Evaporator coil fin material/condenser coil fin material.

**Sizes 024-034: Circuit 1 uses the lowerportion of condensercoil, Circuit 2uses the upper

portion. Sizes 038-048: Circuit 1 uses the left condenser coil, Circuit 2 the right. All units

have intertwined evaporator coils.

††Motor and drive shown will deliver approximately 2.5 in. wg net external static. See

Table 2 for more information.

\Rollout switch is manual reset.

3

⁄89 Copper Tubes, Aluminum Lanced, Aluminum Pre-Coated, or Copper Plate Fins

3

⁄89 Copper Tubes, Aluminum Plate Fins, Intertwined Circuits

15⁄

8

15⁄

8

115⁄

15⁄

8

16

17⁄

8

15⁄

8

NOTE: High heat is for 48EJ,EW only.

VFD

(Hp)

208/230 v 460 v 575 v

VFD WEIGHTS (lb)

5 20 22 60

7.5 51 37 64

10 51 61 64

15 61 63 109

20 63 111 109

25 105 112 174

30 172 118 180

115⁄

17⁄

8

16

17⁄

8

59

11

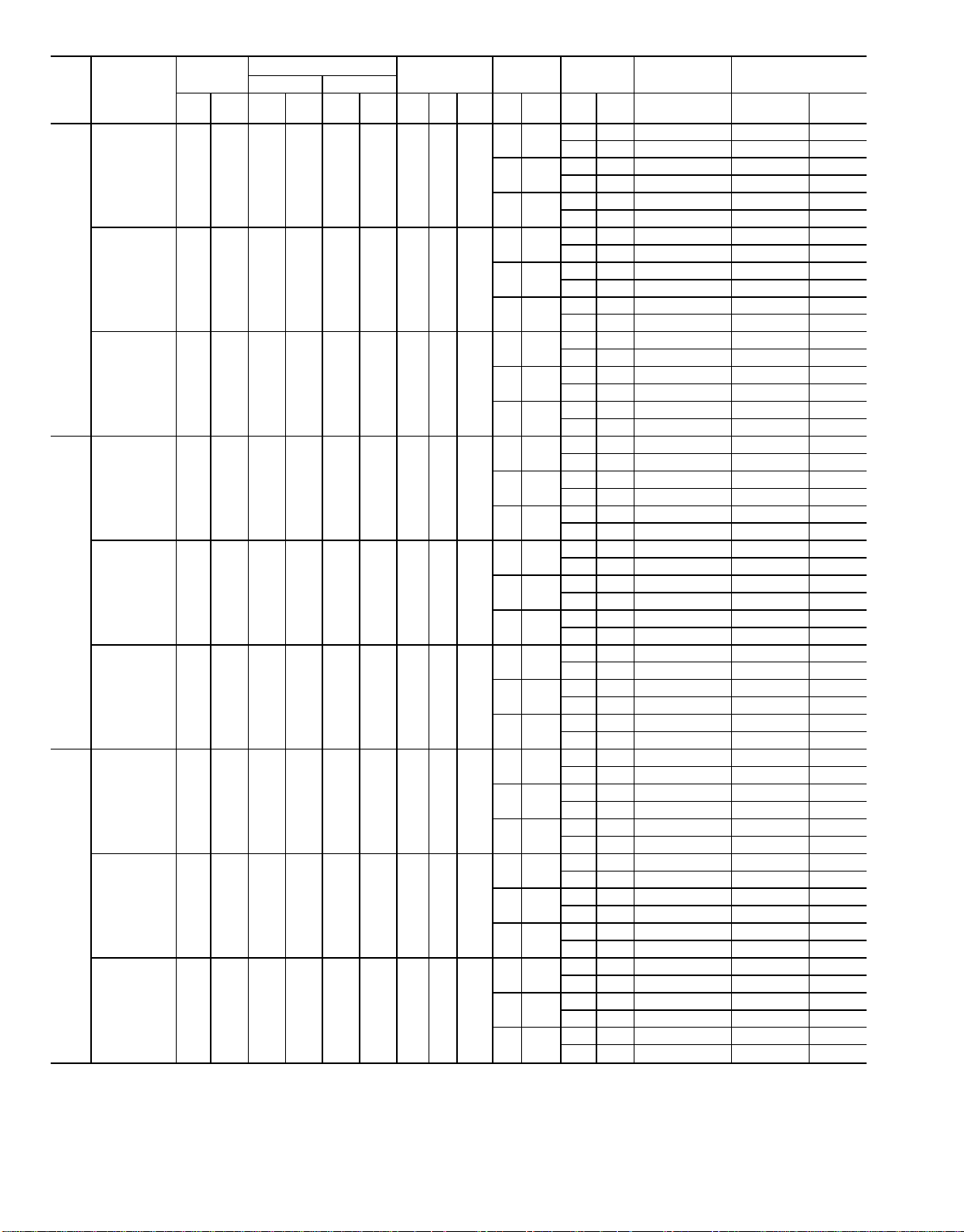

Table 2 — Evaporator Fan Motor Data (Units with Starting Serial Numbers 4197 and Later)

UNIT

MOTOR

SIZE

48E

024

028

030

034

038

044

048

NOTE: Motor shaft speed is 1750 rpm. The fan shaft diameter is 1

MOTOR

SHAFT

HP

10 1.38 924 2BK50 4.4 None-1.375 2B5V86 8.6 B-1.9375 (2) BX51 54 5.21

15 1.62 1096 2B5V56 5.7 B-1.625 2B5V90 9.1 B-1.9375 (2) 5VX530 53 6.00

7.5 1.38 773 BK60H 5.4 H-1.375 1B5V124 12.4 B-1.9375 BX59 62 6.48

10 1.38 962 1B5V60 6.1 H-1.375 1B5V110 11.1 B-1.9375 5VX590 59 7.37

15 1.62 1106 2B5V54 5.5 B-1.625 2B5V86 8.7 B-1.9375 (2) 5VX530 53 6.12

10 1.38 848 2BK50 4.4 None-1.375 2B5V94 9.4 B-1.9375 (2) BX52 55 5.27

15 1.62 1059 2B5V48 4.9 B-1.625 2B5V80 8.1 B-1.9375 (2) 5VX500 50 6.63

20 1.62 1187 2B5V58 5.9 B-1.625 2B5V86 8.7 B-1.9375 (2) 5VX530 53 7.31

10 1.38 884 2BK50 4.4 H-1.375 2B5V90 9.0 B-1.9375 (2) BX51 54 5.24

15 1.62 1096 2B5V56 5.7 B-1.625 2B5V90 9.1 B-1.9375 (2) 5VX530 53 6.00

20 1.62 1187 2B5V58 5.9 B-1.625 2B5V86 8.7 B-1.9375 (2) 5VX530 53 7.31

10 1.38 779 1B5V60 6.1 None-1.375 1B5V136 13.7 B-1.9375 5VX650 65 7.62

15 1.62 976 2B5V52 5.3 B-1.625 2B5V94 9.5 B-1.9375 (2) 5VX530 53 6.37

20 1.62 1050 2B5V56 5.7 B-1.625 2B5V94 9.5 B-1.9375 (2) 5VX550 55 7.60

15 1.62 976 2B5V52 5.3 B-1.625 2B5V94 9.5 B-1.9375 (2) 5VX530 53 6.37

20 1.62 1050 2B5V56 5.7 B-1.625 2B5V94 9.5 B-1.9375 (2) 5VX550 55 7.60

25 1.88 1182 2B5V74 7.5 B-1.875 2B5V110 11.1 B-1.9375 (2) 5VX590 59 7.60

20 1.62 993 2B5V62 6.3 B-1.625 2B5V110 11.1 B-1.9375 (2) 5VX570 57 7.22

25 1.88 1134 2B5V80 5.9 B-1.875 2B5V124 12.5 B-1.9375 (2) 5VX630 63 7.36

30 1.88 1182 2B5V74 7.5 B-1.875 2B5V110 11.1 B-1.9375 (2) 5VX590 59 9.07

DIA.

(in.)

5 1.12 717 BK55 4.8 None-1.125 1B5V124 12.4 B-1.9375 BX59 62 5.10

FAN

SHAFT

SPEED

(rpm)

MOTOR

SHEAVE

MOTOR

SHEAVE

PITCH

DIAMETER

(in.)

BUSHING

DIAMETER

(in.)

15

⁄16inches.

FAN

FAN

SHEAVE

SHEAVE

PITCH

DIAMETER

(in.)

BUSHING

DIAMETER

(in.)

BELT

(QUANTITY)

OUTSIDE

BELT

LENGTH

TENSION

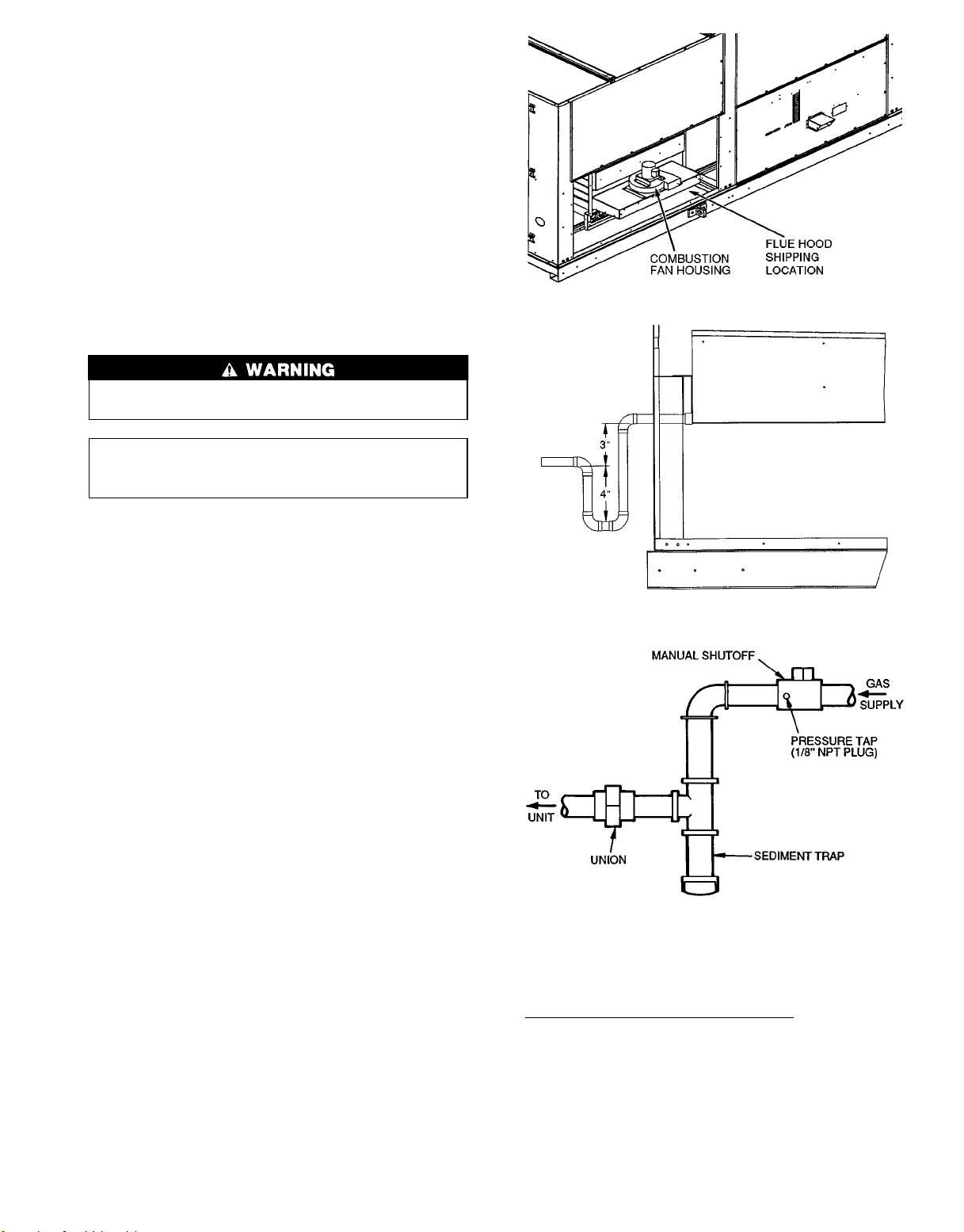

Step 4 — Install Flue Hood — Flue hood is shipped

inside gas section of unit. To install, secure flue hood to access panel. See Fig. 10.

NOTE: When properly installed, flue hood will line up with

combustion fan housing. See Fig. 11.

BELT

(Lb at

.24 in.)

Fig. 8 — Air Distribution — Thru-the-Bottom

Fig. 9 — Air Distribution — Thru-the-Side

Fig. 10 — Flue Hood Location

12

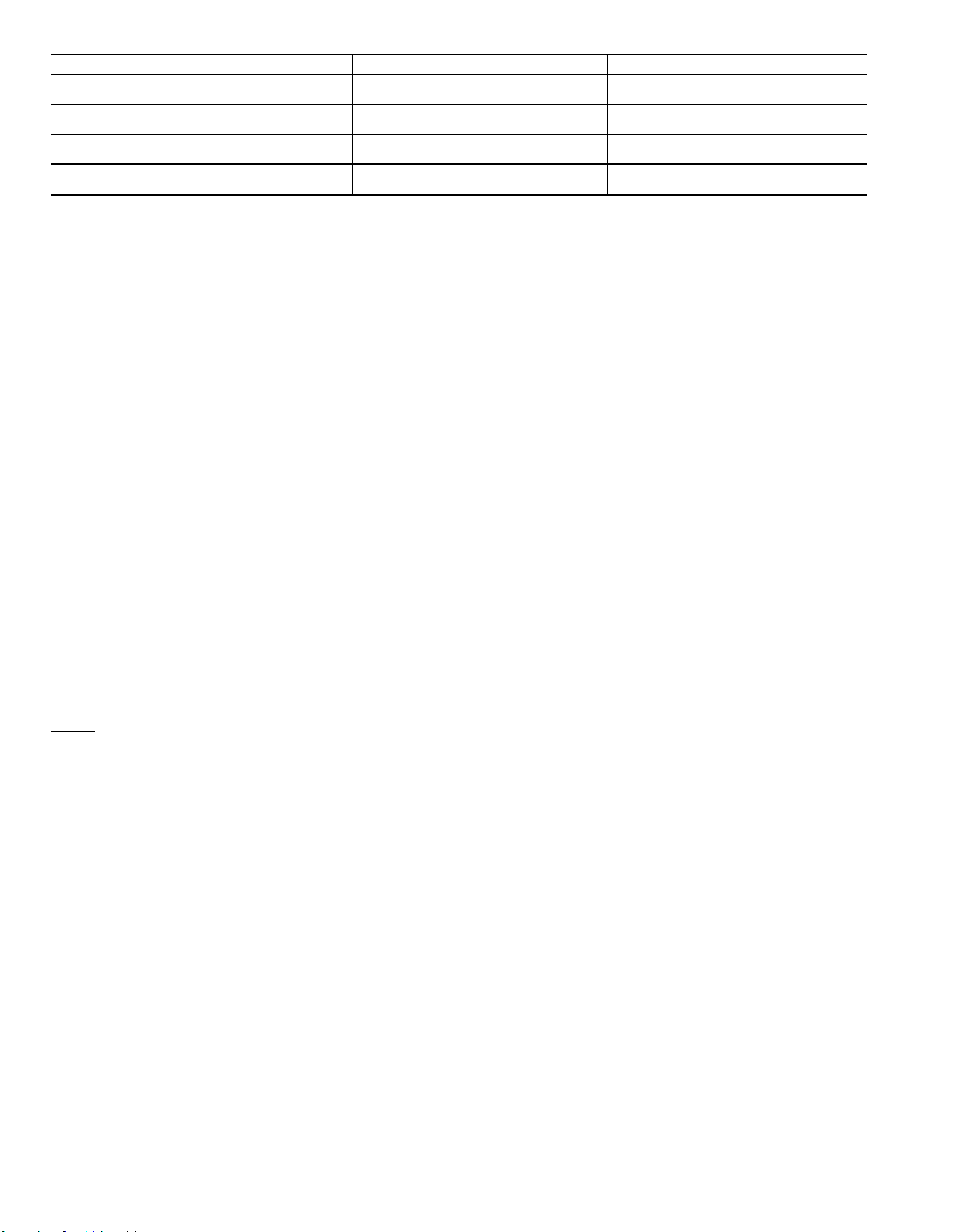

Step5—TrapCondensate Drain — See Fig. 3-6

for drain location. Condensate drain is open to atmosphere

and must be trapped. Install a trapped drain at the drain location. A trap at least 4-in. deep must be used. See Fig. 12.

Trap must be installed to prevent freeze-up.

Condensate pans are sloped so that water will completely

drain from the condensate pan to comply with indoor air quality guidelines. The condensate drain pan is fitted with a 1-in.

FPT coupling.

Step 6 — Install Gas Piping — Unit is equipped for

use with natural gas. Installation must conform with local

building codes or, in the absence of local codes, with the

National Fuel Gas Code, ANSI Z223.1.

Install manual gas shutoff valve with a

sure tap for test gage connection at unit. Field gas piping

must include sediment trap and union. See Fig. 13. An

1

⁄8-in. NPT is also located on the gas manifold adjacent to

the gas valve.

Do not pressure test gas supply while connected to unit.

Always disconnect union before servicing.

IMPORTANT: Natural gas pressure at unit gas connection must not be less than 5 in. wg or greater than

13.5 in. wg.

1

⁄8-in. NPT pres-

Fig. 11 — Combustion Fan Housing Location

Size gas-supply piping for 0.5-in. wg maximum pressure

drop. Do not use supply pipe smaller than unit gas

connection.

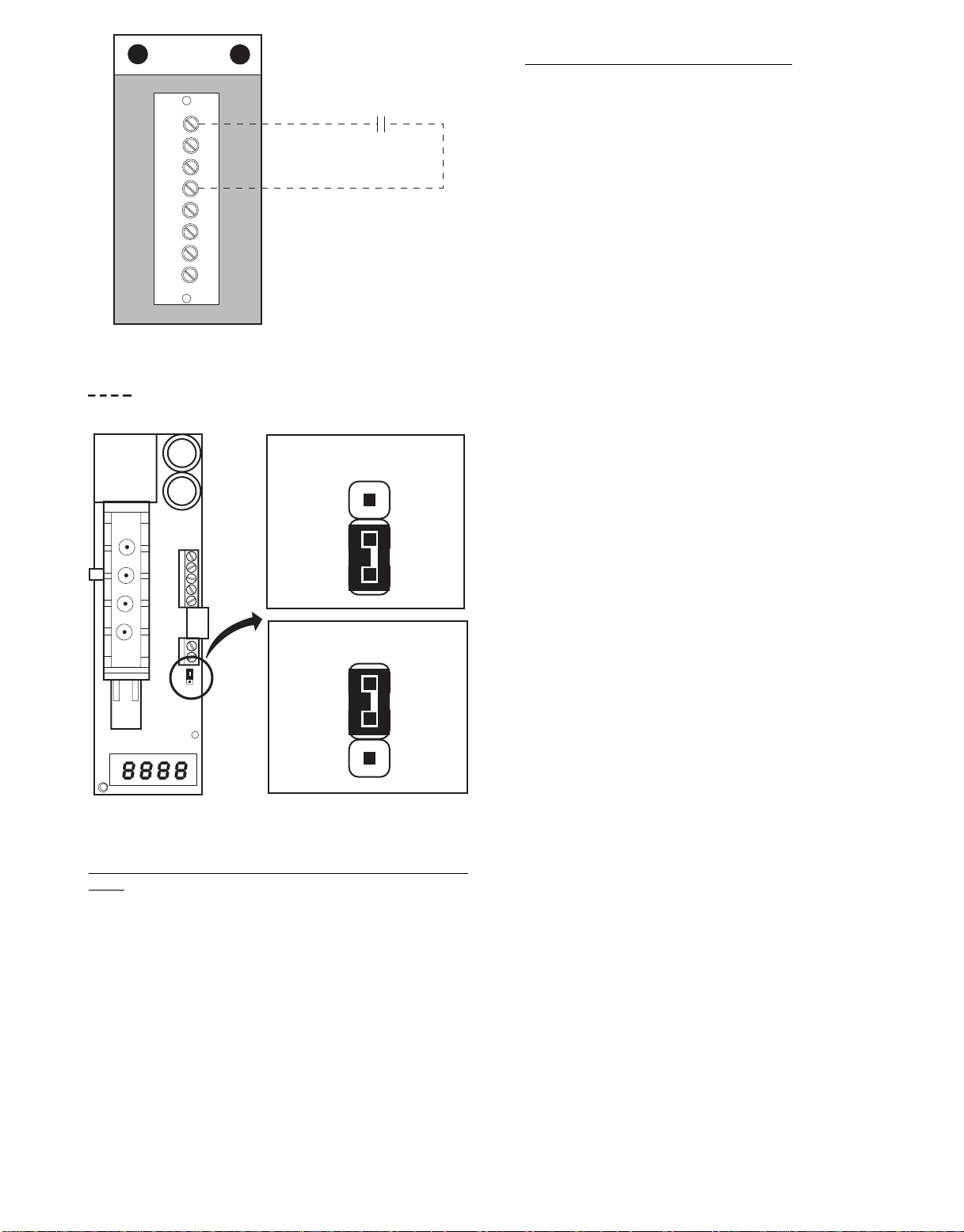

Step 7 — Controls Options — The control options

that the units can provide are based on the following parameters: CV (constant volume) or VAV (variable air volume)

operation; stand-alone unit with field-supplied sensors installed (CV or VAV); as a system via Carrier Comfort System (TEMP or VVTt); optional electronic expansion board

installed (CV or VAV); linked to the Carrier Comfort

Network; and availability of a computer and software

(ComfortWorks™ Building Supervisor, and Service Tool) or

LID-2B accessory installed to access the base control board.

See Table 3.

NOTE: Access to the base control board allows unit occupancy schedules, unit timeclock, and various set points to be

changed from their factory-defined default settings.

All units are equipped with a supply air thermistor (SAT)

located in the supply fan discharge and an outdoor air thermistor (OAT) located in the outdoor air hood. Variable air

volume units are supplied with a return air thermistor (RAT)

located on the return air damper support.

CONSTANT VOLUME APPLICATIONS — The units, as

shipped, are operable as stand-alone units, using either a standard (mechanical or electronic) 2-stage heat, 2-stage cool thermostat, or with an electronic room sensor and a timeclock to

establish unit start and stop times.

With a standard thermostat (programmable is optional),

heating and cooling operation is set by space temperature.

With a space sensor and timeclock, the machine will operate at default values unless they are changed using appropriate input devices. The space sensor senses space temperature and may be equipped with a timed override feature, which

allows unit operation during unoccupied periods.

Fig. 12 — Condensate Drain Trap Piping Details

(Typical Roof Curb or Slab Mount Shown)

Fig. 13 — Field Gas Piping

The space sensors may be used in multiples of 4 or 9 to

achieve space temperature averaging. The use of a space sensor also allows the unit to be turned on and off from a remote signal.

Features with Thermostat Control of Unit

• two-stage heating

• two-stage cooling

• control of unit using Y1, Y2, W1, W2, and G thermostat

inputs

• control of the indoor fan

• outdoor-air temperature/supply-air temperature

monitoring

• control of an outdoor air condenser fan based on outdoor-

air temperature

13

Table 3 — Controls Options and Configurations (Non-Thermostat Applications)

UNIT CONFIGURATION DEFAULT COOLING DEFAULT HEATING

CV or VAV Unit with SPT Sensor

CV Unit with SPT Sensor and Remote

Start/Stop Switch

VAV Unit Remote Start/Stop Switch Only

VAV Unit with SPT Sensor and Remote

Start/Stop Switch

LEGEND

CV — Constant Volume

NA — Not Available

RAT — Return-Air Temperature

SAT — Supply-Air Temperature

SPT — Space Temperature

VAV — VariableAir Volume

Unoccupied Cooling — 90 F (SPT)

Occupied Cooling — NA

Unoccupied Cooling — 90 F (SPT)

Occupied Cooling — 78 F (SPT)

Unoccupied Cooling — 90 F (RAT)

Occupied Cooling — 55 F (SAT)

Unoccupied Cooling — 90 F (SPT)

Occupied Cooling — 55 F (SAT)

*With DIP Switch No. 5 configured to OPEN (Occupied Heat

Enabled).

NOTE: Space temperature sensor and remote start/stop switch are

field-supplied.

Unoccupied Heating — 55 F (SPT)

Occupied Heating — NA

Unoccupied Heating — 55 F (SPT)

Occupied Heating — 68 F (SPT)

Unoccupied Heating — 55 F (RAT)

Occupied Heating — 68 F (RAT)*

Unoccupied Heating — 55 F (SPT)

Occupied Heating — 68 F (RAT)*

• control of modulating economizer damper to provide free

cooling when outdoor conditions are suitable, using

supply-air temperature as a control point

• control of the economizer damper and indoor fan to obtain

unoccupied free cooling

• provide power exhaust output to an external power exhaust controller

• support a field test for field checkout

• control of 2 stages of CV power exhaust

• compressor Time Guardt (power up, minimum off and on

times)

• compressor lockout during low supply-air temperature

Additional features are provided by accessing the standard unit control board via software with a computer. These

features are:

• electronic expansion board features (if installed)

• control board diagnostics

• ability to change supply air set point (economizer control)

• ability to change high outdoor temperature lockout set point

(economizer control)

• ability to change power exhaust set points

NOTE: A CV unit without a thermostat requires a field-

supplied sensor for operation.

Features with Sensor Control of Unit (Stand-Alone Appli-

cations — Unit control is limited to CV unoccupied default

set points, 90 F for cooling, 55 F for heating. There are

2 sensor options available:

• T-55 sensor will monitor room temperature and provide

unoccupied override capability (1 hour)

• T-56 sensor will monitor room temperature, provide un-

occupied override capability (1 hour), and provide a temperature offset of 5° F.

Standard features are:

• support of remote occupied/unoccupied input to start and

stop the unit

• cooling capacity control of 3 stages using economizer and

2 compressors to maintain space temperature to an occupied or unoccupied set point

• enable heating or cooling during unoccupied periods as

required to maintain space temperature within the unoccupied set points

• adjustment of space temperature set points of ±5° F when

using a T-56 sensor

Additional features with sensor control of unit (with computer access) are:

• 365 day timeclock with backup (supports minute, hour,day

of week, date, month, and year)

• daylight savings time function

• occupancy control with 8 periods for unit operation

• holiday table containing up to 18 holiday schedules

• ability to initiate timed override from T-55or T-56 sensors

for a timed period of 1 to 4 hours

• ability to use multiple space temperature sensors to average the space temperature

• temperature compensated start to calculate early start times

before occupancy

• access to the Display, Maintenance, Configuration,

Service, and Set Point data tables through network

software

When the unit is equipped with a field-supplied space

temperature sensor and a remote contact closure (remote start/

stop) on the base control board, the occupied default set points

will monitor unit operation. The occupied default set points

are 78 F cooling and 68 F heating. See Fig. 14 for remote

start/stop wiring.

NOTE: For units with a field-supplied space temperature sesor which have not had the base unit control board accessed

via software to set an occupancy schedule, the remote start/

stop closure will allow the unit to operate in the preconfigured occupied default set points (based on return-air

temperature) of 78 F cooling and 68 F heating. Without this

feature, the unit will control to the unoccupied default set

points of 90 F cooling and 55 F heating.

An electronic expansion board may be field-installed to

provide the following features:

• control of modulating economizer damper to maintain in-

door air quality (IAQ) when outdoor conditions are

suitable

NOTE: The IAQ sensor must be set for current output

(4 to 20 mA), not voltage output. Ensure the jumper on

the sensor is in the upper position. See Fig. 15.

• provide discrete inputs for fan status, filter status, field-

applied status, and demand limit

• provide an output for the external alarm light indicator

• provide power exhaust fire outputs for direct control of

modulated power exhaust stages during fire or smoke modes

• control of smoke control modes including evacuation, smoke

purge, pressurization, and fire shutdown (modulating power

exhaust required)

When the unit is connected to the CCN (Carrier Comfort

Network), the following expansion board features can be

utilized:

• perform Demand Limit functions based on CCN loadshed

commands or the state of the discrete input

• alarm monitoring of all key parameters

• CCN protocol

• provides CCN IAQ participation

See Carrier TEMP or VVTt (Variable Volume and Temperature) literature for complete TEMP (single zone) or VVT

(multi-zone) application information.

14

REMOTE

START/STOP

SWITCH

(FIELD-SUPPLIED)

R

Y1

Y2

W1

W2

G

C

X

CONTROL

BOX

LEGEND

Field Supplied Wiring

Fig. 14 — Field Control Remote Start/Stop

JUMPER CONNECTION

FOR VOLTAGE OUTPUT

JUMPER CONNECTION

FOR CURRENT OUTPUT

Fig. 15 — Indoor Air Quality Sensor Configuration

Features with Sensor Control of Unit (Network Applications) — The base control board provides, as standard, a connection for use with a Carrier VVT system and can also be

integrated into a Carrier Comfort Network.

When the unit is accessed via a PC equipped with ComfortWorks™, Building Supervisor, or Service Tool software,

or accessory LID-2B, the following features can be

accessed:

• on-board timeclock can be programmed

• occupancy schedules can be programmed

• unit set points can be changed

• alarms can be monitored

This access is available on the base control board via a

RJ-11 phone jack or a 3-wire connection to the communication bus. See Fig. 16. The timeclock has a 10-hour minimum back-up time to provide for unit power off for servicing unit or during unexpected power outages. For complete

Carrier Comfort System (CCS) or Carrier Comfort Network

(CCN) features and benefits, refer to the product literature.

VARIABLE AIR VOLUME (VAV) APPLICATIONS

Features with Stand-Alone Applications — The units, as

shipped, are operable as stand-alone units with the addition

of a timeclock to establish unit start and stop times.

Heating and cooling in both on and off modes is controlled to default values by the base unit control. Set points

may be changed with appropriate input devices.

The control has an on-board occupancy schedule which

can be set using an input device and eliminates the need for

an external timeclock.

During both the on and off periods, cooling operation is

controlled to the supply air setting and heating is controlled

to the return air setting (or to the optional space temperature

sensor). During the on period, the supply fan runs continuously.During the off period, the supply fan will be activated

if the return air sensor is outside of the set points and will

run log enough to accurately sample the space temperature.

The supply fan will then continue to run until any heating or

cooling load is satisfied, at which point it will turn off.

The use of a space sensor will allow for supply air reset

to conserve energy and maintain comfort. If equipped with

an override feature, the sensor will allow operation during

the off period for a fixed length of time.

Base unit control supports a Heat Interlock Relay (field

supplied) to fully open the VAV terminal devices during heating operation.

Standard features of a VAV unit with a remote start/stop

switch are:

• control board diagnostics

• control of an outdoor condenser fan based upon outdoor

air temperature

• control of modulating economizer to provide free cooling

when outdoor conditions are suitable, using supply-air temperature as a set point

• support of remote occupied/unoccupied input to start or

stop the unit

• provide power exhaust output to an external power ex-

haust controller

• support supply-air temperature reset to offset supply air

set point

• support a field test for field check out

• support linkage to DAV systems

• cooling capacity control of up to 6 stages plus economizer

with compressors and unloaders to maintain supply air temperature set point during occupied periods

• control of one stage of heat to maintain return-air tem-

perature at heating set point during occupied periods

• provide a variable frequency drive high voltage relay out-

put to enable VFD

• control of heat interlock relay

• compressor Time Guard override (power up, minimum off

and on times)

With the addition of a remote start/stop switch heating or

cooling is enabled during unoccupied periods as required to

maintain space temperature to within unoccupied set points.

Additional features may be provided with Electronic

Access to Unit Control Board. These features are:

• additional control board diagnostics

• electronic expansion board features (if installed)

• control of the economizer damper and indoor fan to obtain

unoccupied free cooling

• 365-day timeclock with backup (supports minute, hour, day,

month, and year)

• holiday table containing up to 18 holiday schedules

• occupancy control with 8 periods for unit operation

• support a set of display, maintenance, configuration, serv-

ice, and set point data tables for interface with Building

Supervisor, ComfortWorks, or Service Tool software software or accessory LID-2B

15

When a VAV unit with a space temperature sensor is accessed via a computer, the following additional features are

available:

• ability to initiate timed override from T-55 sensors

• temperature compensated start to calculate early start time

before occupancy

• provide space temperature reset to reset the supply air set

point upward when the temperature falls below the occupied cooling set point

An electronic expansion board may be field-installed to

provide the following features:

• fan status

• filter status

• field-applied status

• demand limiting

• IAQ Sensor

• OAQ Sensor

• alarm light

• fire unit shutdown

• fire pressurization

• fire evacuation

• fire smoke purge

When the unit is connected to the CCN (Carrier Comfort

Network), the following expansion board features can be

utilized:

• CCN IAQ (indoor air quality) participation

• CCN OAQ (outdoor air quality) participation

• CCN demand limit participation

• modulated power exhaust override

• ability to use multiple space temperature sensors (mul-

tiples of 4 and 9 only) to average space temperature (DAV

only)

Afield-supplied T -55space temperature sensor can be added

to monitor room temperature and provide unoccupied override capability (1 hour).

When the unit is equipped with a field-supplied space temperature sensor and a remote contact closure (remote start/

stop) the occupied default set points will monitor unit operation. The occupied default set points are 55 F (supply air)

cooling and 68 F (return air temperature) heating. See

Fig. 14 for remote start/stop wiring.

NOTE: For units without a space temperature sensor and which

have not had the base unit control board accessed via software to set an occupancy schedule, the remote start/stop closure will allow the unit to operate in the pre-configured occupied default set points of 55 F (supply-air temperature)

cooling and 68 F (return-air temperature) heating. Without

an occupancy schedule, the unit will control to the unoccupied default set points of 90 F (return air) cooling and 55 F

(return air) heating.

Features with NetworkApplications —The base control board

provides, as standard, a connection for use with a Carrier

Comfort System and can also be integrated into a Carrier

Comfort Network. When the unit is accessed via a PC equipped

with ComfortWorks™, Building Supervisor, or Service Tool

software or LID-2B accessory,the following features can be

accessed:

• on-board timeclock can be programmed

• occupancy schedules can be programmed

• unit set points can be changed

• alarms can be monitored

This access is available on the base control board via a

RJ-11 phone jack or a 3-wire connection to the communication bus. See Fig. 16. The internal timeclock has a 10-hour

minimum back-up time to provide for unit power off for servicing unit or during unexpected power outages. For complete Carrier Comfort System (CCS) or Carrier Comfort

Network (CCN) features and benefits, refer to the product

literature.

Step 8 — Make Electrical Connections

POWER WIRING — Units are factory wired for the voltage

shown on the unit nameplate.

When installing units, provide a disconnect per NEC

(National Electrical Code) of adequate size (MOCP [maximum overcurrent protection] of unit is on the informative

plate). All field wiring must comply with NEC and all local

codes. Size wire based on MCA (minimum circuit amps) on

the unit informative plate. See Fig. 17 for power wiring connections to the unit power terminal block andequipment ground.

The main power terminal block is suitable for use with

aluminum or copper wire. See Fig. 17. Units have circuit

breakers for compressors, fan motors, and control circuit. If

required by local codes, provide an additional disconnectswitch.

Whenever external electrical sources are used, unit must be

electrically grounded in accordance with local codes, or in

absence of local codes, with NEC, ANSI C1-latest year.

All field wiring must comply with NEC and local code

requirements.

FIELD POWER SUPPLY — Unit is factory wired for voltage shown on unit nameplate. See Table 4 for electrical data.

Field wiring can be brought into the unit from bottom

(through basepan and roof curb) or through side of unit (corner post next to control box).

1

⁄2-in. NPT coupling for field power wiring and a

A3

3

⁄4-in. NPT coupling for 24-v control wiring are provided in

basepan. In the side post, there are two 21⁄2-in. (024-034) or

3-in. (038-048) knockouts for the field power wiring. See

Fig. 3-6. If control wiring is to be brought in through the

side of unit, a7⁄8-in. diameter hole is provided in the condenser side post next to the control box.

If disconnect box is mounted to corner post, be careful

not to drill any screws into the condenser coil.

Routing Through Bottom of Unit — If wiring is brought in

through bottom of unit, use field-supplied watertight conduit

to run power wiring from basepan out through bottom

31⁄2-in. hole to the disconnect box and back into unit to the

main control box.

Use strain relief going into control box through 2

diameter hole provided. After wires are in unit control box,

connect to power terminal block (see Power Wiring section

above).

Low-voltage wiring must be run in watertight conduit from

the basepan to control box and through

7

⁄8-in. diameter hole

provided in bottom of unit control box. Field-supplied strain

relief must be used going into the box. After wiring is in

control box, make connections to proper terminals on terminal blocks (see Field Control Wiring section on page 21).

Install conduit connector in unit basepan as shown in

Fig. 3-6. Route power and ground lines through connector to

terminal connections in unit control box as shown on unit

wiring diagram and Fig. 17.

Routing Through Side of Unit — Route power wiring in fieldsupplied watertight conduit into unit through 21⁄2-in. hole.

See Fig. 17.

Use field-supplied strain relief going into control box through

1

⁄2-in. diameter hole provided. After wires are in unit con-

2

trol box, connect to power terminal block (see Power Wiring

section on this page).

Bring low-voltage control wiring through factory-drilled

7

⁄8-in. diameter hole in condenser side post. Use strain relief

going into7⁄8-in. diameter hole in bottom of unit control box.

After wiring is in control box, make connection to proper

terminals on terminal blocks (see Field Control Wiring section on page 21).

1

⁄2-in.

16

17

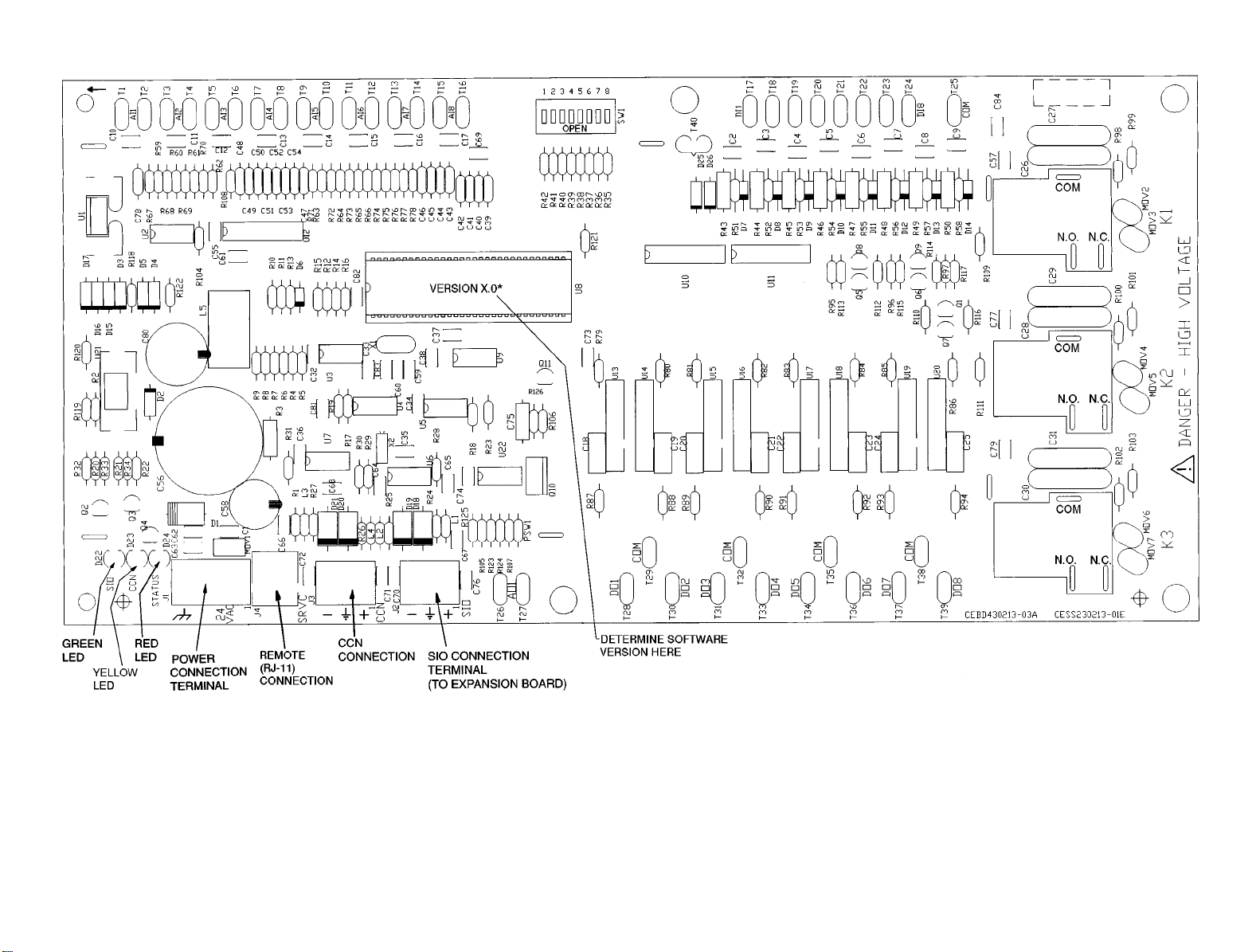

LEGEND

CCN — Carrier Comfort Network

COM — Common

D—Diode

LED — Light-Emitting Diode

N.C. — Normally Closed

N.O. — Normally Open

R—Relay

SIO — Serial Input/Output

SW — Switch

T—Terminal

Fig. 16 — Control Board Diagram

*Where X is the unit control software version number.

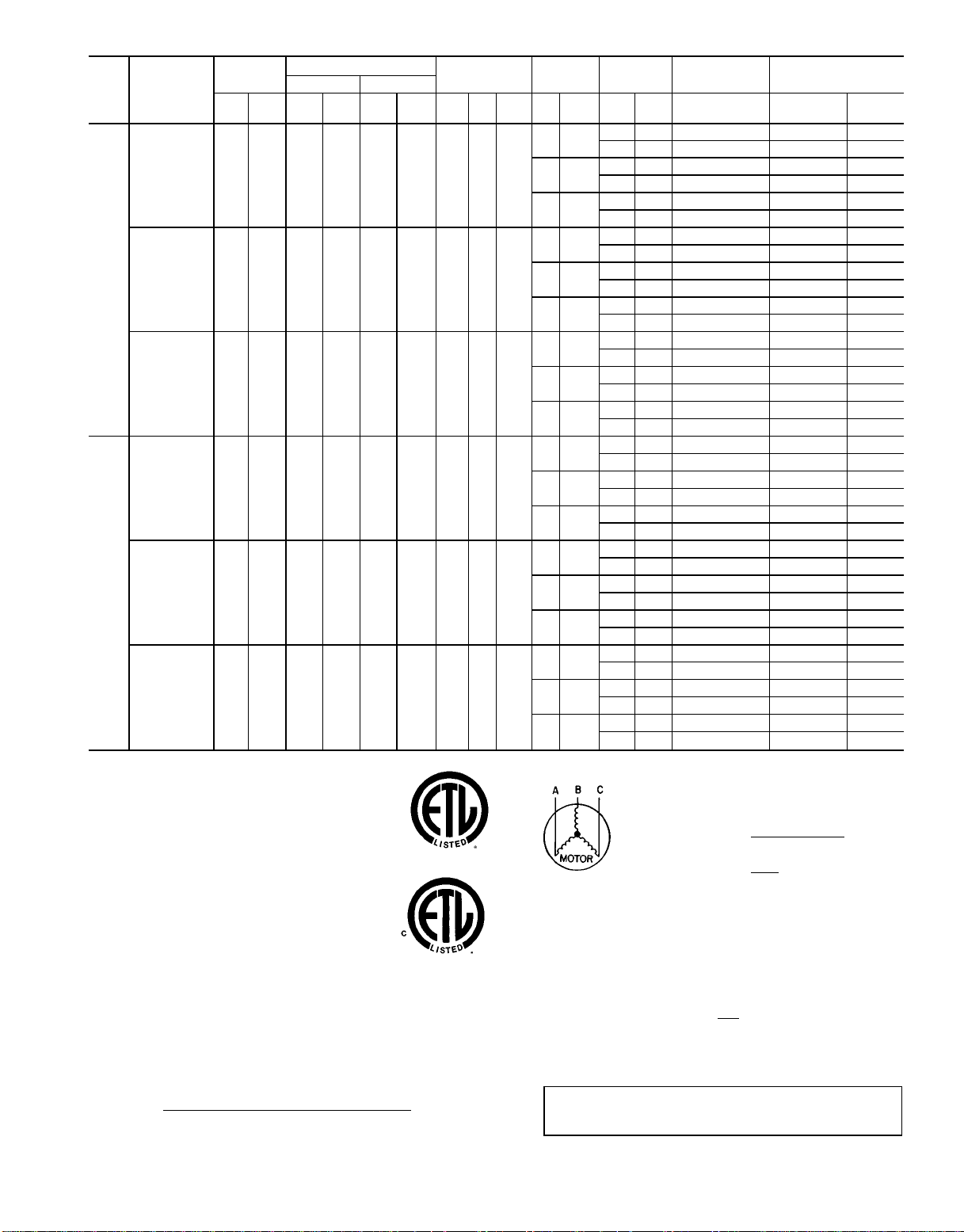

Table 4 — Electrical Data

UNIT

SIZE

48E

024

028

030

NOMNAL

VOLTAGE

(3 Ph 60 Hz)

208/230 187 254 39.1 228 25.6 160 2 1 5.3

460 414 508 19.9 114 11.5 80 2 1 2.7

575 518 632 16.0 91 9.6 64 2 1 2.4

208/230 187 254 39.1 228 39.1 228 2 1 5.3

460 414 508 19.9 114 19.9 114 2 1 2.7

575 518 632 16.0 91 16.0 91 2 1 2.4

208/230 187 254 57.1 266 39.1 228 2 1 5.3

460 414 508 25.6 120 19.9 114 2 1 2.7

575 518 632 20.5 96 16.0 91 2 1 2.4

VOLTAGE

RANGE

Min Max RLA LRA RLA LRA Qty Hp

COMPRESSOR

No. 1 No. 2

OFM IFM

POWER

EXHAUST

FLA

Hp FLA FLA LRA FLA MCA MOCP*

(ea)

— — 0.96 101.8/100.3 125/125

16.7/

5

15.2

23.6 41.6 0.96 125.4/123.9 150/150

— — 0.96 115.9/113.1 150/150

30.8/

10

28.0

23.6 41.6 0.96 139.5/136.7 175/175

— — 0.96 131.3/127.1 150/150

46.2/

15

42.0

23.6 41.6 0.96 154.9/150.7 175/175

5 7.6

10 14.0

15 21.0

5 6.1

10 11.0

15 17.0

7.5

10

15

7.5 11.0

10 14.0

15 21.0

7.5 9.0

10 11.0

15 17.0

10

15

20

10 14.0

15 21.0

20 27.0

10 11.0

15 17.0

20 22.0

— — 0.50 49.4 60

12.6 23.6 0.50 62.0 80

— — 0.50 55.8 70

12.6 23.6 0.50 68.4 80

— — 0.50 62.8 80

12.6 23.6 0.50 75.4 90

— — 0.50 40.5 50

12.6 23.6 0.50 53.1 60

— — 0.50 45.4 60

12.6 23.6 0.50 58.0 70

— — 0.50 51.4 60

12.6 23.6 0.50 64.0 80

— — 0.96 122.8/120.6 150/150

24.2/

22.0

23.6 41.6 0.96 146.4/144.2 175/175

— — 0.96 129.4/126.6 150/150

30.8/

28.0

23.6 41.6 0.96 153.0/150.2 175/175

— — 0.96 144.8/140.6 175/175

46.2/

42.0

23.6 41.6 0.96 168.4/164.2 200/200

— — 0.50 61.2 80

12.6 23.6 0.50 73.8 90

— — 0.50 64.2 80

12.6 23.6 0.50 76.8 90

— — 0.50 71.2 90

12.6 23.6 0.50 83.8 100

— — 0.50 49.8 60

12.6 23.6 0.50 62.4 70

— — 0.50 51.8 60

12.6 23.6 0.50 64.4 80

— — 0.50 57.8 70

12.6 23.6 0.50 70.4 80

— — 0.96 151.9/149.1 200/200

30.8/

28.0

23.6 41.6 0.96 175.5/172.7 225/225

— — 0.96 167.3/163.1 225/225

46.2/

42.0

23.6 41.6 0.96 190.9/186.7 225/225

— — 0.96 180.5/175.1 225/225

59.4/

54.0

23.6 41.6 0.96 204.1/198.7 250/250

— — 0.50 71.3 90

12.6 23.6 0.50 83.9 100

— — 0.50 78.3 100

12.6 23.6 0.50 90.9 110

— — 0.50 84.3 100

12.6 23.6 0.50 96.9 110

— — 0.50 57.4 70

12.6 23.6 0.50 70.0 90

— — 0.50 63.4 80

12.6 23.6 0.50 76.0 90

— — 0.50 68.4 80

12.6 23.6 0.50 81.0 100

COMBUSTION

FAN MOTOR

See Legend and Notes on page 19.

POWER SUPPLY

18

Table 4 — Electrical Data (cont)

UNIT

FLA — Full Load Amps

HACR — Heating, Air Conditioning and

IFM — Indoor (Evaporator) Fan Motor

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps

MOCP — Maximum Overcurrent Protection

NEC — National Electrical Code

OFM — Outdoor (Condenser) Fan Motor

RLA — Rated Load Amps

*Fuse or HACR circuit breaker.

NOTES:

1. In compliance with NEC requirements for multimotor and combi-

2. Unbalanced 3-Phase Supply Voltage

NOMINAL

SIZE

VOLTAGE

48E

(3 Ph 60 Hz)

208/230 187 254 57.1 266 57.1 266 2 1 5.3

034

038

nation load equipment (refer to NEC Articles 430 and 440), the

overcurrent protective device for the unit shall be fuse or HACR

breaker. Canadian units may be fuse or circuit breaker.

Never operate a motor where a phase imbalance in supply voltage is greater than 2%.

the percent voltage imbalance.

% Voltage Imbalance

= 100 x

460 414 508 25.6 120 25.6 120 2 1 2.7

575 518 632 20.5 96 20.5 96 2 1 2.4

208/230 187 254 57.1 266 57.1 266 4 1 5.3

460 414 508 25.6 120 25.6 120 4 1 2.7

575 518 632 20.5 96 20.5 96 4 1 2.4

Refrigeration

max voltage deviation from average voltage

VOLTAGE

RANGE

Min Max RLA LRA RLA LRA Qty Hp

LEGEND

Use the following formula to determine

average voltage

COMPRESSOR

No. 1 No. 2

or

OFM IFM

FLA

Hp FLA FLA LRA FLA MCA MOCP*

(ea)

10

15

20

10 14.0

15 21.0

20 27.0

10 11.0

15 17.0

20 22.0

10

15

20

10 14.0

15 21.0

20 27.0

10 11.0

15 17.0

20 22.0

EXAMPLE: Supply voltage is 460-3-60.

Determine maximum deviation from average voltage.

(AB) 457 − 452=5v

(BC) 464 − 457=7v

(AC) 457 − 455=2v

Maximum deviation is 7 v.

Determine percent voltage imbalance.

% Voltage Imbalance = 100 x

This amount of phase imbalance is satisfactory as it is below the

maximum allowable 2%.

IMPORTANT: If the supply voltage phase imbalance is more

than 2%, contact your local electric utility company

immediately.

POWER

EXHAUST

— — 0.96 169.9/167.1 225/200

30.8/

28.0

23.6 41.6 0.96 193.5/190.7 250/225

— — 0.96 185.3/181.1 225/225

46.2/

42.0

23.6 41.6 0.96 208.9/204.7 250/250

— — 0.96 198.5/193.1 250/250

59.4/

54.0

23.6 41.6 0.96 222.1/216.7 275/250

— — 0.50 77.0 100

12.6 23.6 0.50 89.6 110

— — 0.50 84.0 100

12.6 23.6 0.50 96.6 110

— — 0.50 90.0 110

12.6 23.6 0.50 102.6 125

— — 0.50 61.9 80

12.6 23.6 0.50 74.5 90

— — 0.50 67.9 80

12.6 23.6 0.50 80.5 100

— — 0.50 72.9 90

12.6 23.6 0.50 85.5 100

— — 0.96 180.5/177.7 225/225

30.8/

28.0

23.6 41.6 0.96 204.1/201.3 250/250

— — 0.96 195.9/191.7 250/225

46.2/

42.0

23.6 41.6 0.96 219.5/215.3 275/250

— — 0.96 209.1/203.7 250/250

59.4/

54.0

23.6 41.6 0.96 232.7/227.3 275/275

— — 0.50 82.4 100

12.6 23.6 0.50 95.0 110

— — 0.50 89.4 110

12.6 23.6 0.50 102.0 125

— — 0.50 95.4 110

12.6 23.6 0.50 108.0 125

— — 0.50 66.7 80

12.6 23.6 0.50 79.3 90

— — 0.50 72.7 90

12.6 23.6 0.50 85.3 100

— — 0.50 77.7 90

12.6 23.6 0.50 90.3 110

COMBUSTION

FAN MOTOR

AB = 452 v

BC = 464 v

AC = 455 v

Average Voltage =

7

457

= 1.53%

POWER SUPPLY

452 + 464 + 455

3

1371

=

3

= 457

19

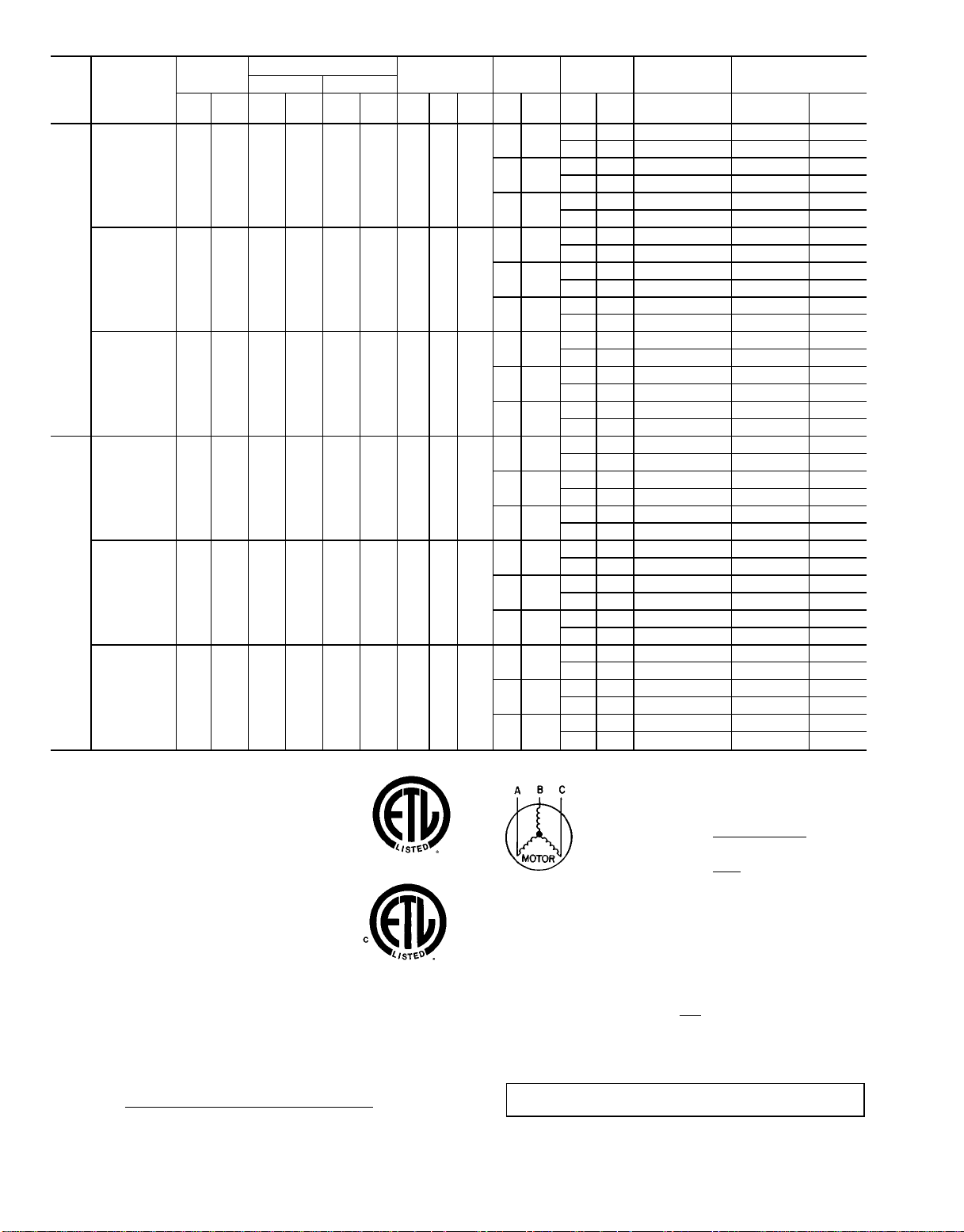

Table 4 — Electrical Data (cont)

UNIT

FLA — Full Load Amps

HACR — Heating, Air Conditioning and

IFM — Indoor (Evaporator) Fan Motor

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps

MOCP — Maximum Overcurrent Protection

NEC — National Electrical Code

OFM — Outdoor (Condenser) Fan Motor

RLA — Rated Load Amps

*Fuse or HACR circuit breaker.

NOTES:

1. In compliance with NEC requirements for multimotor and combi-

2. Unbalanced 3-Phase Supply Voltage

NOMINAL

SIZE

VOLTAGE

48E

(3 Ph 60 Hz)

208/230 187 254 69.2 345 69.2 345 4 1 5.3

044

048

nation load equipment (refer to NEC Articles 430 and 440), the

overcurrent protective device for the unit shall be fuse or HACR

breaker. Canadian units may be fuse or circuit breaker.

Never operate a motor where a phase imbalance in supply voltage is greater than 2%.

the percent voltage imbalance.

% Voltage Imbalance

= 100 x

460 414 508 28.8 173 28.8 173 4 1 2.7

575 518 632 26.7 120 26.7 120 4 1 2.4

208/230 187 254 82.1 446 69.2 345 4 1 5.3

460 414 508 42.3 223 28.8 173 4 1 2.7

575 518 632 34.6 164 26.7 120 4 1 2.4

Refrigeration

max voltage deviation from average voltage

VOLTAGE

RANGE

Min Max RLA LRA RLA LRA Qty Hp

LEGEND

Use the following formula to determine

average voltage

COMPRESSOR

No. 1 No. 2

or

OFM IFM

FLA

Hp FLA FLA LRA FLA MCA MOCP*

(ea)

15

20

25

15 21.0

20 27.0

25 34.0

15 17.0

20 22.0

25 27.0

20

25

30

20 27.0

25 34.0

30 40.0

20 22.0

25 27.0

30 32.0

EXAMPLE: Supply voltage is 460-3-60.

Determine maximum deviation from average voltage.

(AB) 457 − 452=5v

(BC) 464 − 457=7v

(AC) 457 − 455=2v

Maximum deviation is 7 v.

Determine percent voltage imbalance.

% Voltage Imbalance = 100 x

This amount of phase imbalance is satisfactory as it is below the

maximum allowable 2%.

IMPORTANT:Ifthesupply voltage phase imbalance is more than

2%, contact your local electric utility company immediately.

POWER

EXHAUST

— — 0.96 223.1/218.9 275/275

46.2/

42.0

23.6 41.6 0.96 246.7/242.5 300/300

— — 0.96 236.3/230.9 300/300

59.4/

54.0

23.6 41.6 0.96 259.9/254.5 300/300

— — 0.96 251.7/244.9 300/300

74.8/

68.0

23.6 41.6 0.96 275.3/268.5 300/300

— — 0.50 96.6 125

12.6 23.6 0.50 109.2 125

— — 0.50 102.6 125

12.6 23.6 0.50 115.2 125

— — 0.50 109.6 125

12.6 23.6 0.50 122.2 150

— — 0.50 86.7 110

12.6 23.6 0.50 99.3 125

— — 0.50 91.7 110

12.6 23.6 0.50 104.3 125

— — 0.50 96.7 110

12.6 23.6 0.50 109.3 125

— — 0.96 252.4/247.0 300/300

59.4/

54.0

23.6 41.6 0.96 276.0/270.6 300/300

— — 0.96 267.8/261.0 300/300

74.8/

68.0

23.6 41.6 0.96 291.4/284.6 300/300

— — 0.96 281.0/273.0 300/300

88.0/

80.0

23.6 41.6 0.96 304.6/296.6 350/300

— — 0.50 119.5 150

12.6 23.6 0.50 132.1 150

— — 0.50 126.5 150

12.6 23.6 0.50 139.1 175

— — 0.50 132.5 150

12.6 23.6 0.50 145.1 175

— — 0.50 101.6 125

12.6 23.6 0.50 114.2 125

— — 0.50 106.6 125

12.6 23.6 0.50 119.2 150

— — 0.50 111.6 125

12.6 23.6 0.50 124.2 150

COMBUSTION

FAN MOTOR

AB = 452 v

BC = 464 v

AC = 455 v

Average Voltage =

7

457

= 1.53%

POWER SUPPLY

452 + 464 + 455

3

1371

=

3

= 457

20

Loading...

Loading...